Cleaning and disinfection part of automatic production line for fillet processing

A production line, cleaning and disinfection technology, applied in fish cleaning/descaling, food preparation, food science and other directions, can solve the problems of simple function, difficult recruitment, low efficiency, etc., to solve the problem of difficult recruitment, good effect and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

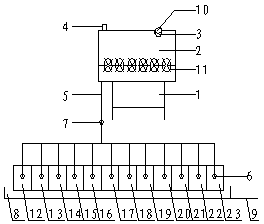

[0016] in the attached figure 1 Among them, a cleaning and disinfection part of an automatic production line for processing fish fillets, which includes a bracket 1, is characterized in that: the bracket 1 is provided with a water tank 2, and the water tank 2 is provided with a drug discharge port 3, a water inlet pipe 4 and a water outlet pipe 5. The water inlet pipe 4 is connected to the water source. Each branch of the automated production line is provided with a high-pressure water nozzle 6. The high-pressure water nozzle 6 is connected to the water outlet pipe 5. The outlet pipe 5 is provided with a switch 7. Each subdivision of the assembly line is provided with a water receiving tank 8 below, and the water receiving tank 8 is provided with a sewer pipe 9 to communicate with the sewer. A sealing cover 10 is provided on the medicine dispensing port 3 of the water tank 2 , and an electric stirring device 11 is provided in the water tank 2 . A rotatable high-pressure water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com