An electric tricycle stator winding machine

An electric tricycle and stator winding technology, which is applied in the manufacture of motor generators, electric components, electrical components, etc., can solve the problems of production efficiency impact and high dependence on operators, and achieve the requirements of reducing the professionalism of operation. Recruitment is difficult and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described below in conjunction with accompanying drawing.

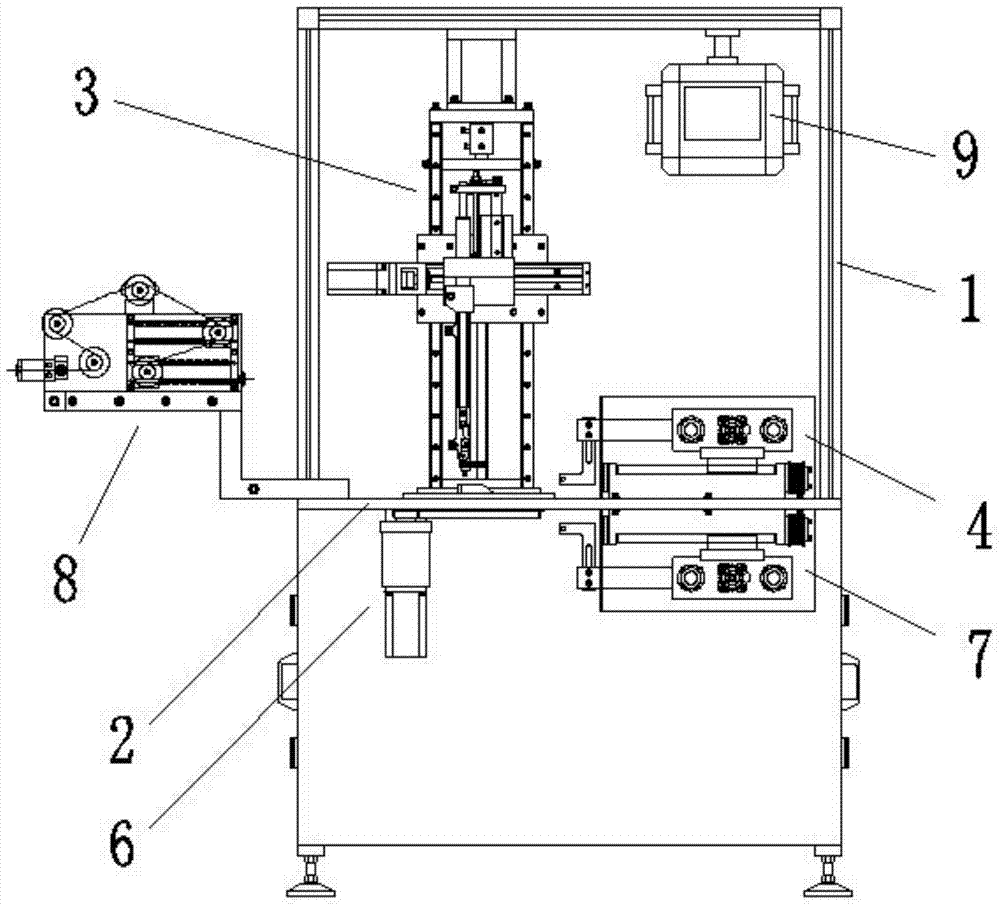

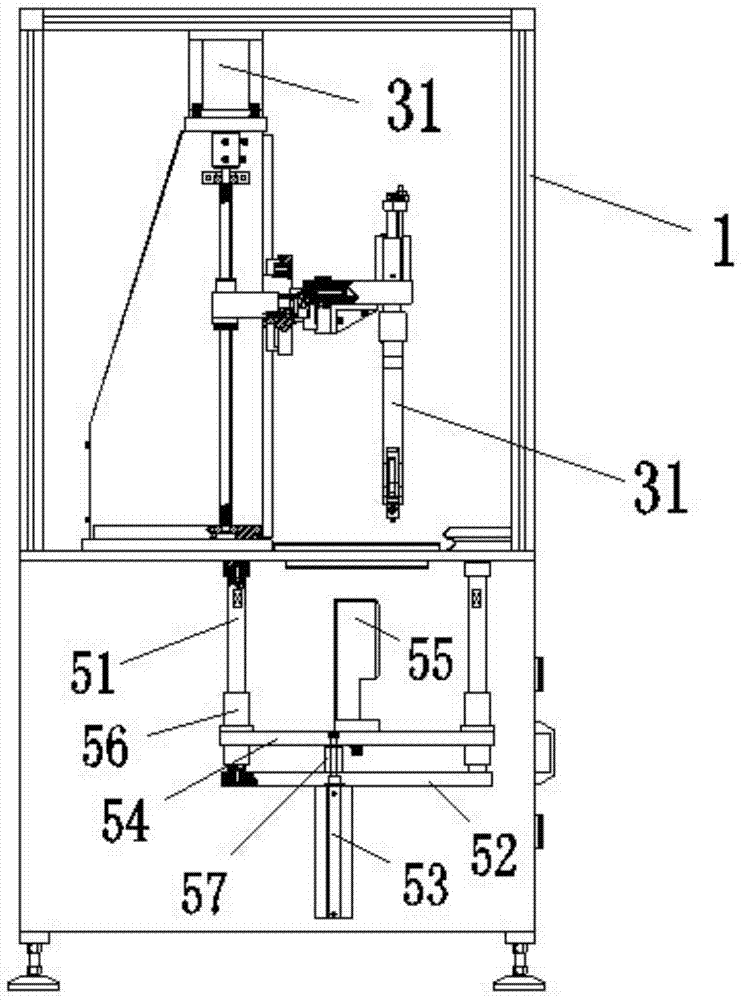

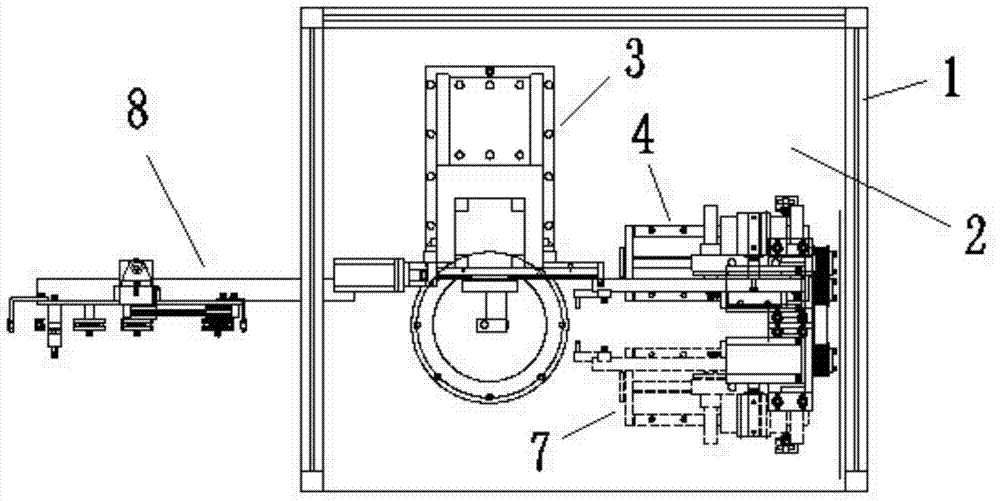

[0028] as attached Figure 1-3 As shown, a kind of electric tricycle stator winding machine described in the present invention comprises frame 1, and the middle part of frame 1 is provided with horizontal working surface 2, and the side of frame 1 is provided with tensioning mechanism 8, and frame 1 is provided with an operation panel 9; the upper part of the work surface 2 is equipped with a winding moving mechanism 3 and an upper hook mechanism 4, and the lower part of the work surface 2 is equipped with a mold installation mechanism, an indexing mechanism 6 and a lower hook mechanism 7.

[0029] like Figure 4-6 As shown, the winding moving mechanism 3 includes an up and down moving frame 32, a left and right moving frame 35 and a winding rod adjustment assembly; the up and down moving frame 32 is provided with an up and down servo motor 33 and an up and down moving screw mandrel 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com