Coloring machine for manually coloring artware

A technology for handicrafts and shaders, which is applied to the device, coating, special surface and other directions of coating liquid on the surface, can solve the problems of inconvenient production, low solvent ignition point, hidden safety hazards of production enterprises, etc., and achieves easy use and low cost. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

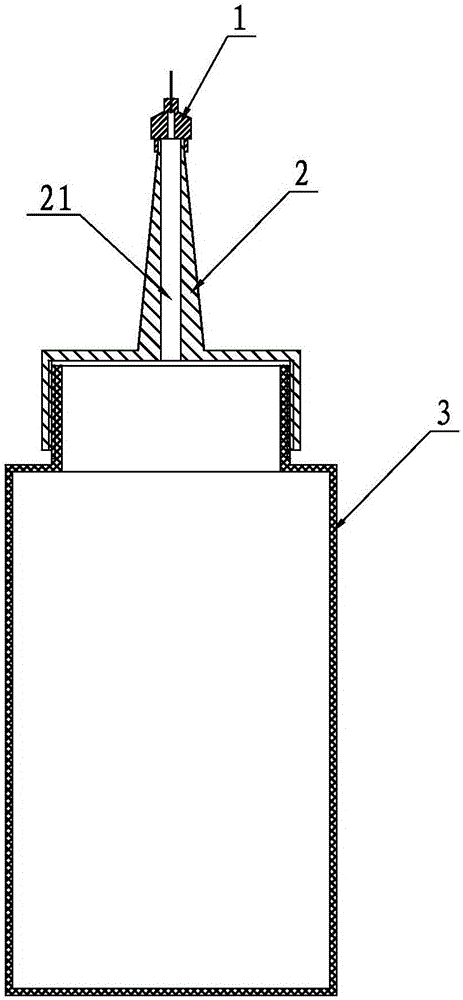

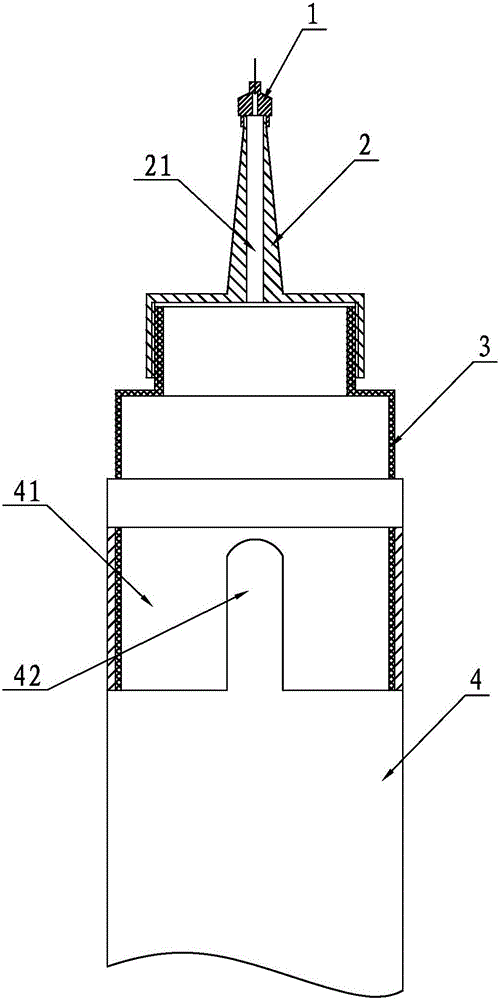

[0024] Example 1: A shader for hand-colored crafts, such as Figure 1~2 As shown, it includes a coloring needle 1, a feeding cap 2, a soft liquid storage bottle 3 and a hard pressurizer 4. The coloring needle 1 is sealed and installed on the upper end of the feeding cap 2, and the lower end of the feeding cap 2 is sealed and screwed. On the opening of the soft liquid storage bottle 3, a liquid outlet through hole 21 is provided in the center of the feeding cap 2, and the inner cavity of the colored needle 1 and the soft liquid storage bottle 3 passes through the liquid outlet through hole 21 of the feeding cap 2 Connected, the hard pressurizer 4 is set on the outside of the soft liquid storage bottle 3, the inner diameter of the hard pressurizer 4 is in transition with the outer circle of the soft liquid storage bottle 3, and the hard pressurizer 4 is in contact with the soft liquid storage bottle 3. The contact section of the liquid storage bottle 3 has a gap 41, the angle of...

Embodiment 2

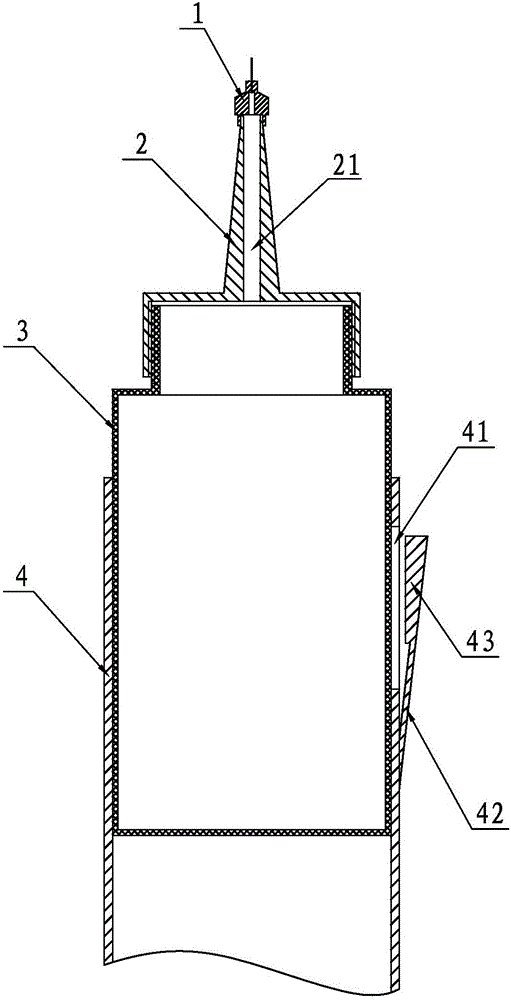

[0025] Embodiment 2: The difference with Embodiment 1 is that, as image 3 As shown, the fixed end of the elastic pressing piece 42 is fixedly connected to the outer surface of the hard presser 4, and a protrusion 43 is provided on the inner surface of the free end of the elastic pressing piece 42, and the elastic pressing piece 42 is pressed inwardly. The paint in the soft liquid storage bottle 3 can be pressed out.

Embodiment 3

[0026] Embodiment 3: The difference with Embodiment 1 is that, as Figure 4 ~ Figure 5 As shown, a mounting hole 44 is formed on the opening end surface of the notch 41 of the hard presser 4 , and one end of the elastic pressing piece 42 is fixedly inserted into the mounting hole 44 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com