Heavy machinery remote controlling system

A remote control system, heavy machinery technology, applied in electrical program control, program control in sequence/logic controllers, etc., can solve problems such as a large shortage of operators, hinder local economic development, and highlight the contradiction between market supply and demand, and achieve high The effect of construction efficiency, increasing operator's income, and solving recruitment difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

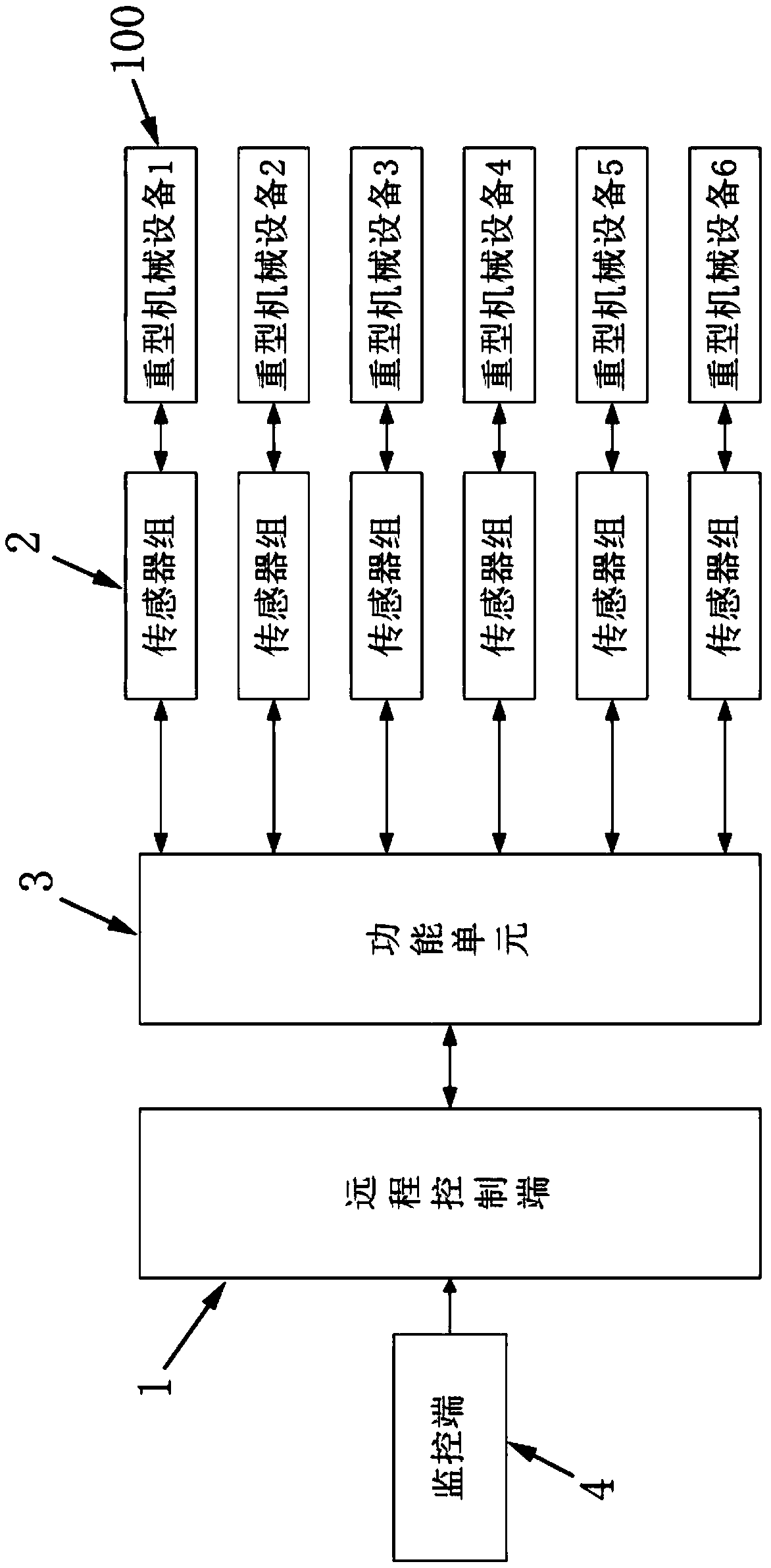

[0030] Please refer to figure 1 , a heavy machinery remote control system provided in Embodiment 1 of the present invention, comprising:

[0031] A remote control terminal 1, the remote control terminal 1 establishes a communication connection with each heavy machinery equipment 100, and the operator can remotely control at least one of the heavy machinery equipment 100 to work through the remote control terminal 1; the remote control terminal 1 This includes computers, phones, and tablets, among others.

[0032] The sensor group 2, the sensor group 2 includes several different types of sensors, each of which is distributed on each of the heavy machinery equipment 100, and each of the sensors is used for real-time monitoring of the The working conditions of the heavy machinery equipment 100, its own running conditions and working environment information; the sensor group 2 includes various sensors such as angle sensors, distance sensors, gyroscope sensors, temperature sensors...

Embodiment 2

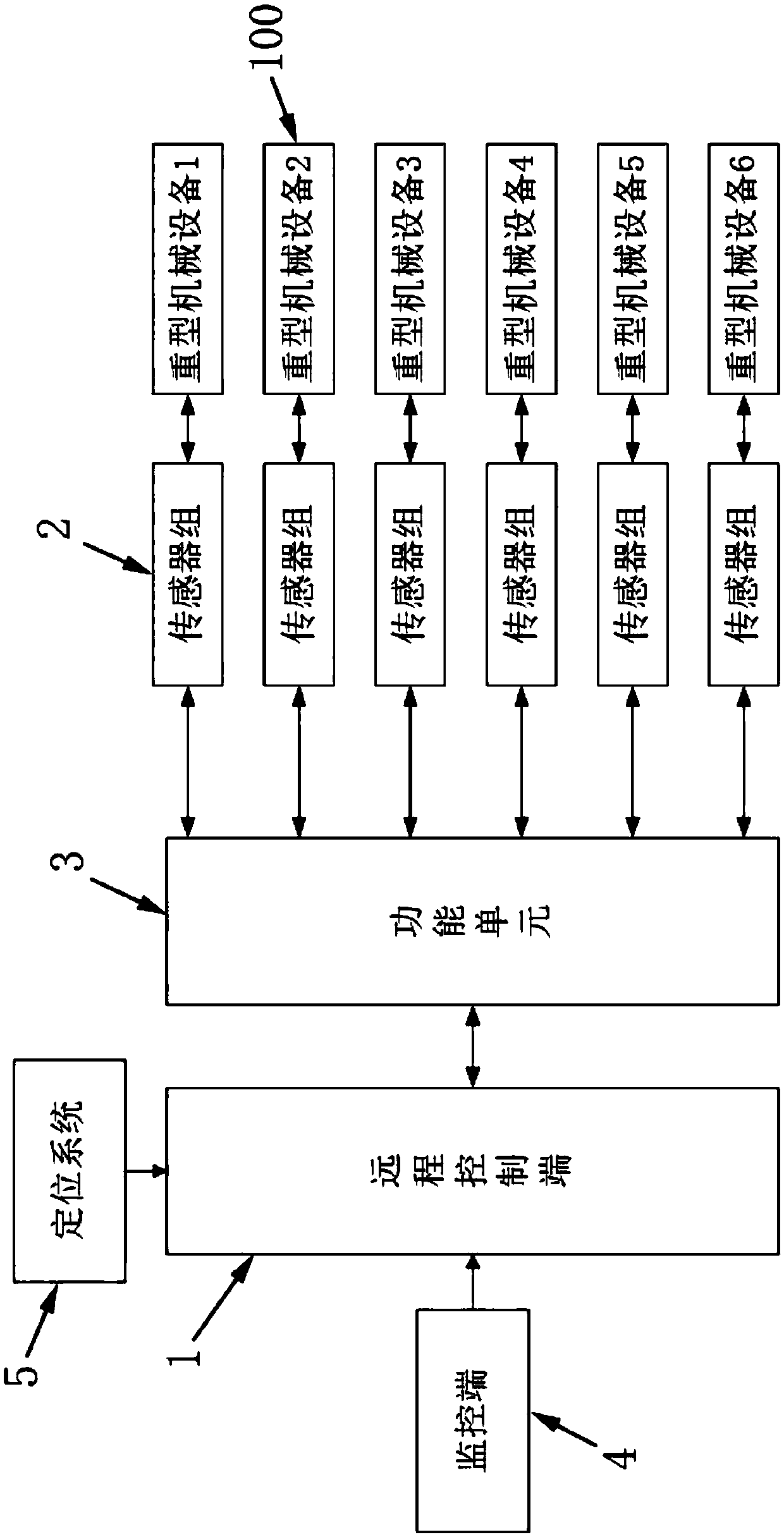

[0043] Please refer to figure 2The difference between the second embodiment and the first embodiment is that the heavy machinery remote control system provided by the second embodiment also includes a positioning system 5, the positioning system 5 can be a positioning device such as a positioner, and the positioning system 5 is preferably installed in Each of the heavy machinery equipment 100 is used to locate the heavy machinery equipment 100 in real time and send the positioning information to the functional unit 3 and / or the remote control terminal 1 in real time.

[0044] The heavy machinery remote control system provided in Embodiment 2 also includes an alarm system (not shown in the figure), and the alarm system can be set on the functional unit 3 or the remote control terminal 1, or both on the functional unit 3 and the remote control terminal 1 . The construction activity range of each of the heavy machinery equipment 100 is preset on the functional unit 3 and / or the...

Embodiment 3

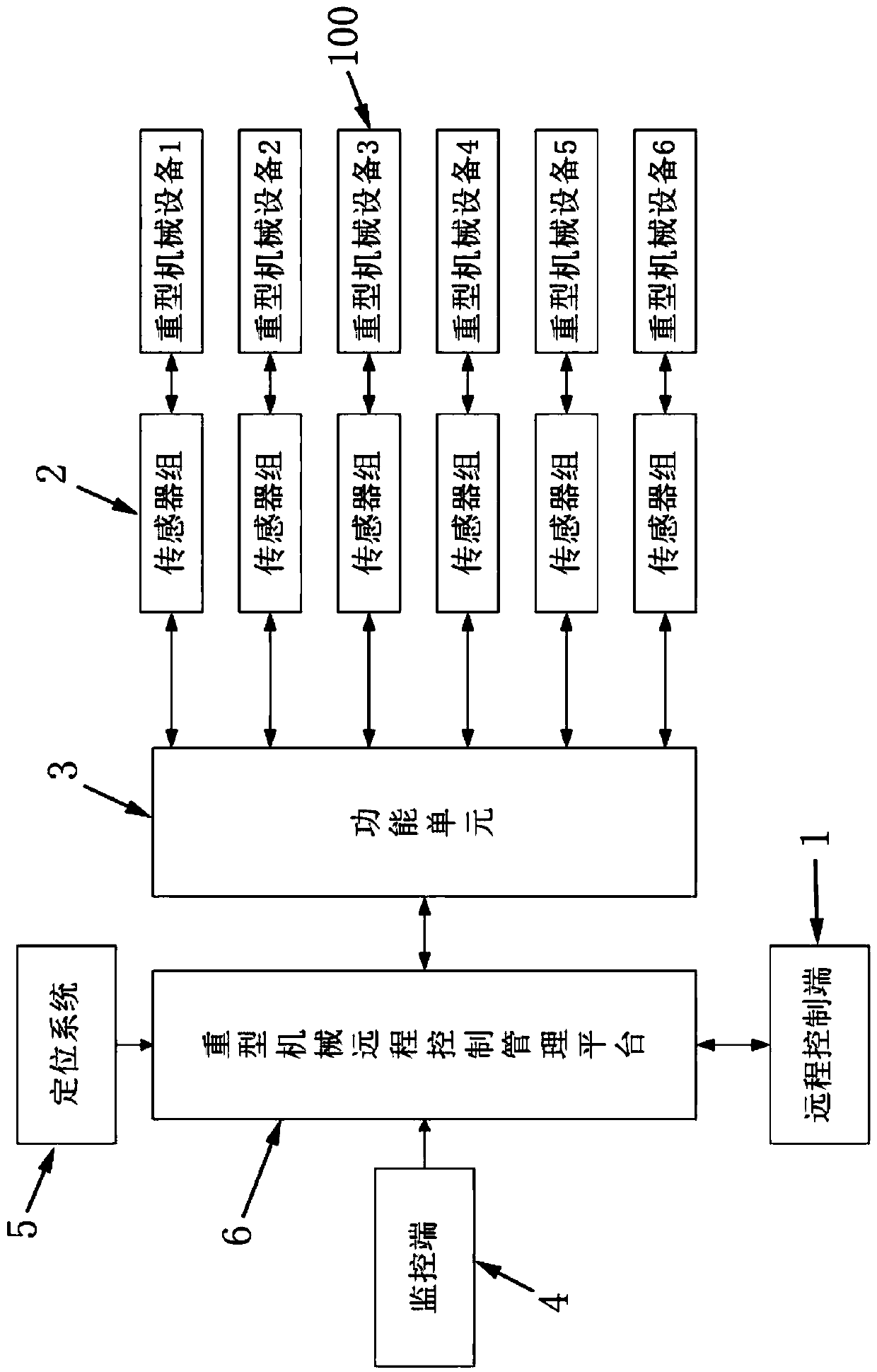

[0046] Please refer to image 3 The difference between the third embodiment and the second embodiment is that the heavy machinery remote control system provided by the third embodiment also includes a heavy machinery remote control management platform 6, and the heavy machinery remote control management platform 6 is an application software, which can be Installed on control terminals such as computers and mobile phones, the heavy machinery remote control management platform 6 is used to process and analyze each of the sensors, the functional units 3, the remote control terminal 1, the monitoring terminal 4 and all According to the various data information returned by the positioning system 5, the construction party can conduct real-time interactive communication with the operator at the remote end through the heavy machinery remote management platform 6, and can issue work to each heavy machinery equipment 100 at the same time. instruction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com