Patents

Literature

291 results about "Shell separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

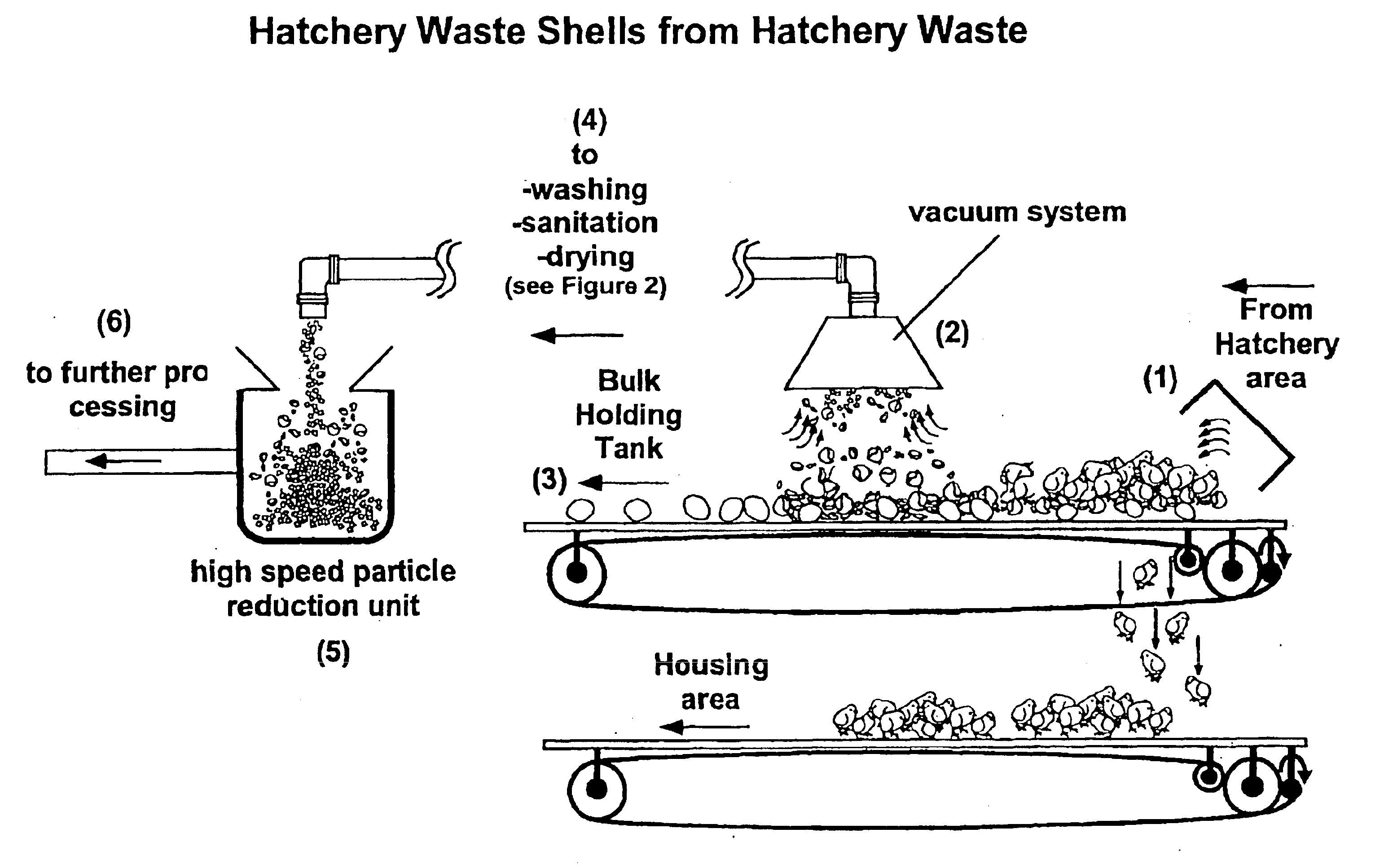

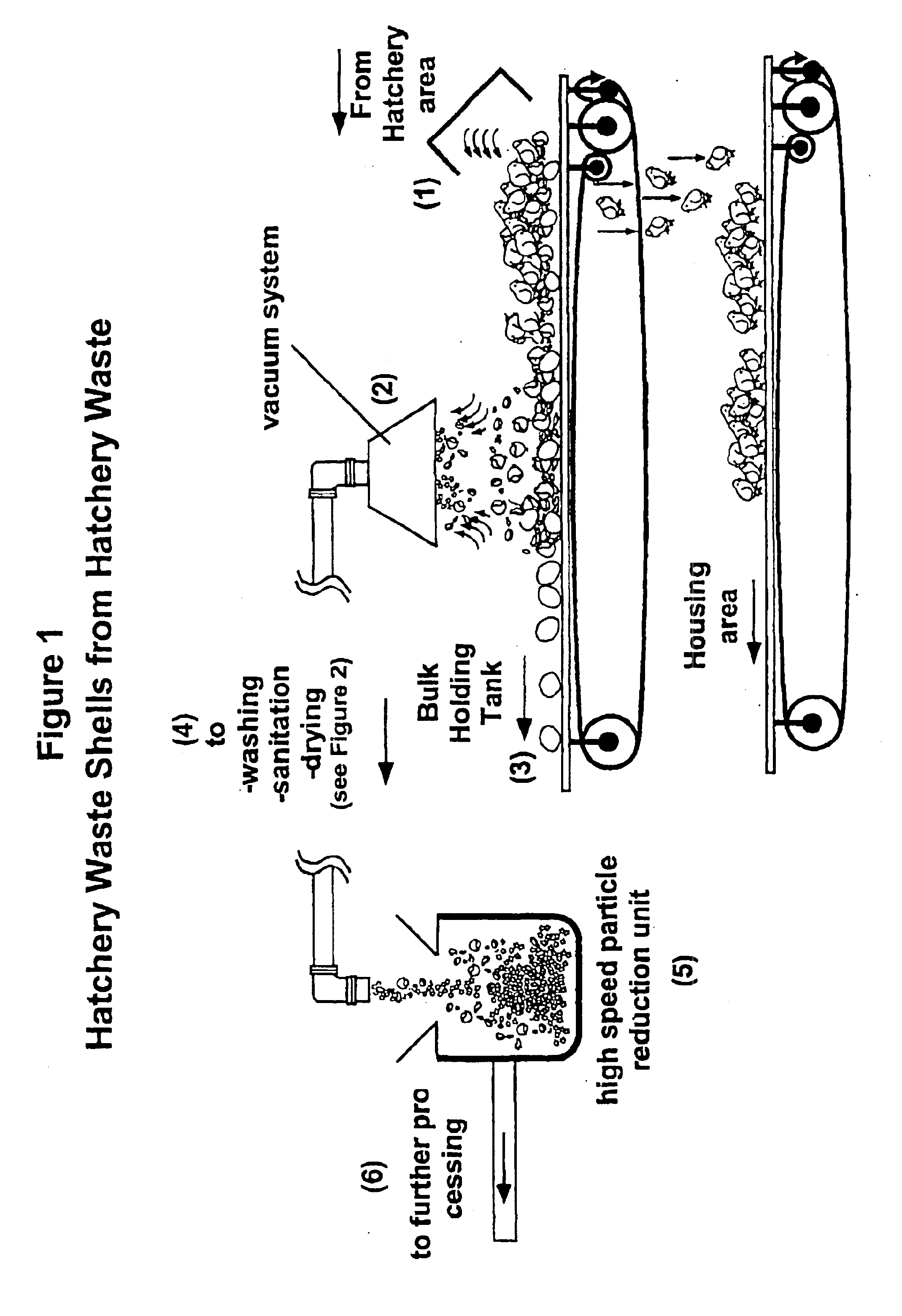

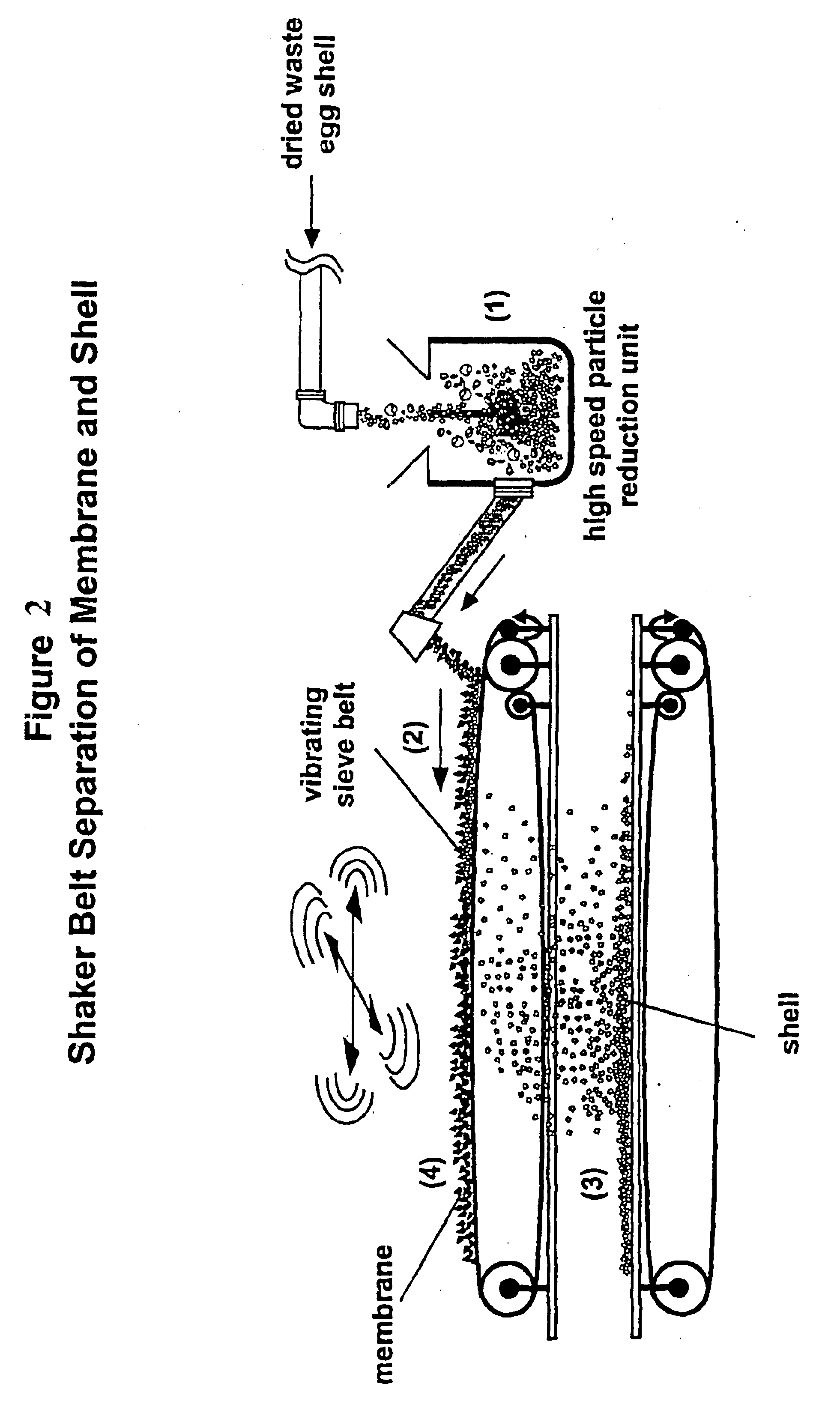

Hatchery eggshell waste processing method and device

InactiveUS6899294B2Reduce environmental impactEconomic benefitVitamin food ingredientsPeptide/protein ingredientsWaste processingEggshell

A method and apparatus for separating the organic membrane portion of waste egg shells from the hard inorganic mineral portion thereof, so that each can be used or further processed as desired, thereby addressing the environmental and economic issues associated with disposing of waste egg shells. The membrane and shell are separated by first processing waste eggshells so as to yield small waste eggshell particles. During this processing, the waste eggshell particles are at least slightly abraded, whereby the linking structure between the membrane and shell is at least partially disrupted. Thereafter, the waste eggshell particles are conveyed to a device, which isolates the two components based on their size and weight differences. The methods listed above can provide products from the eggshell waste including precipitated calcium carbonate, membrane, protein, amino acids, collagen and other important components.

Owner:PENN STATE RES FOUND

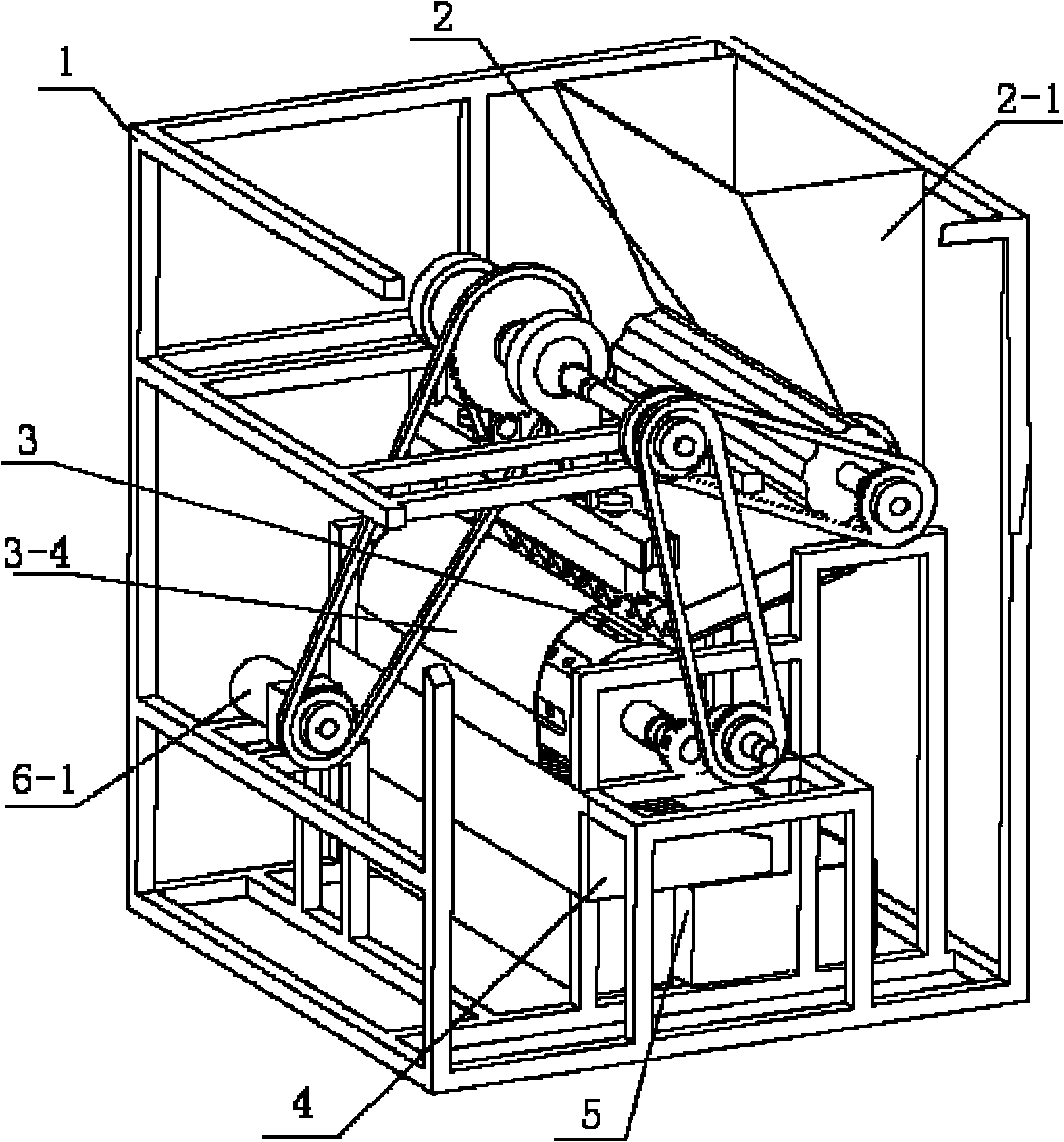

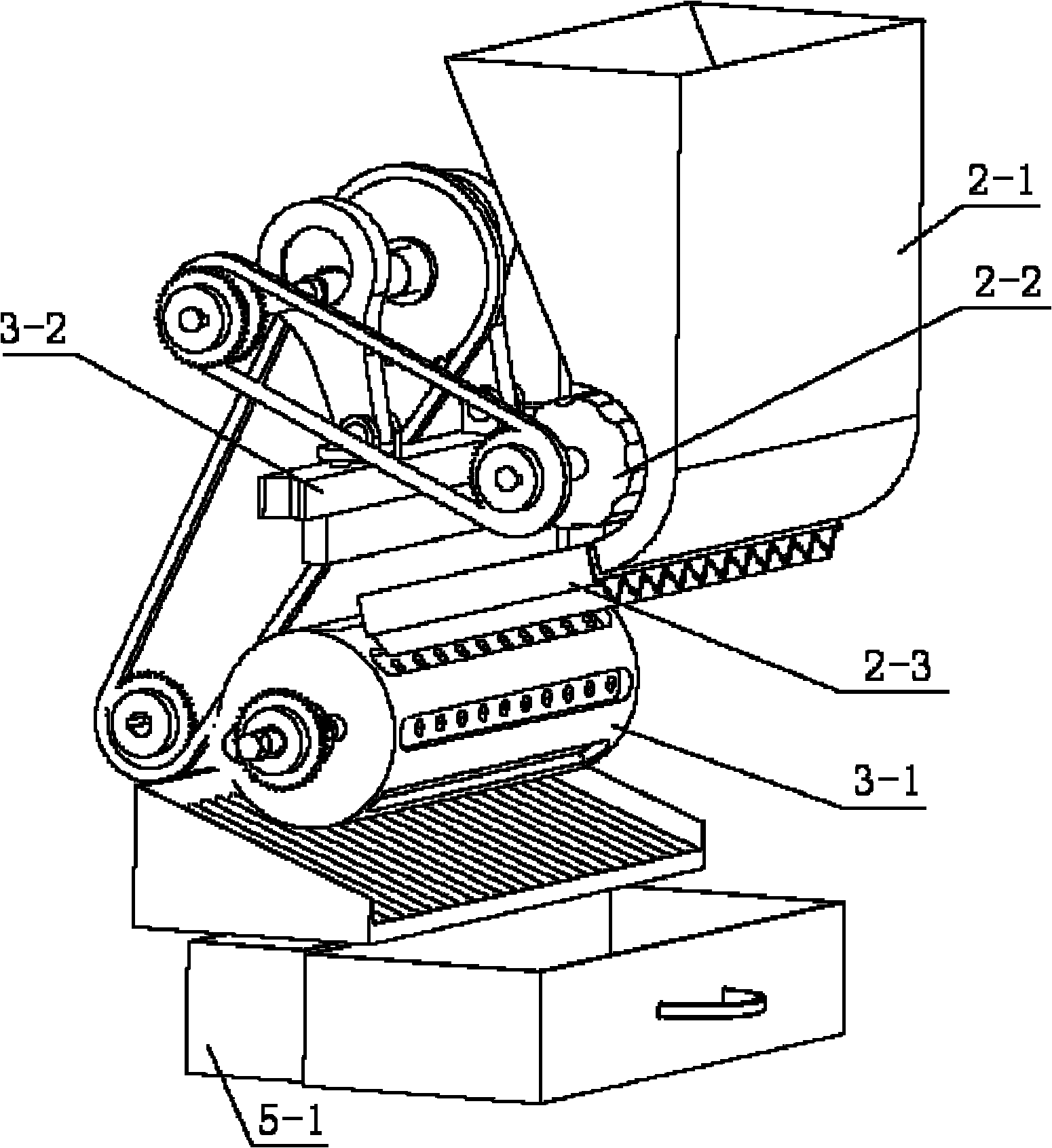

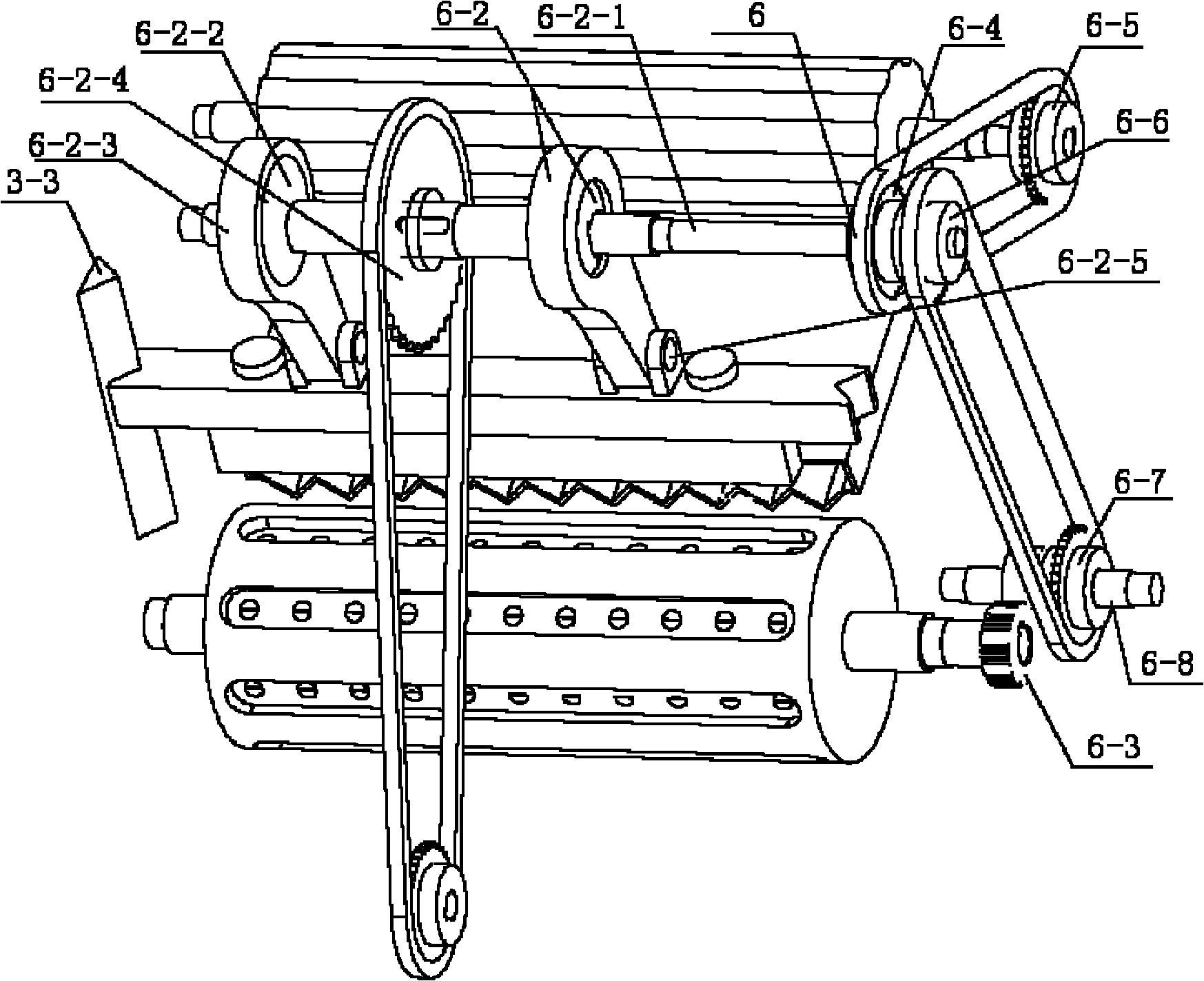

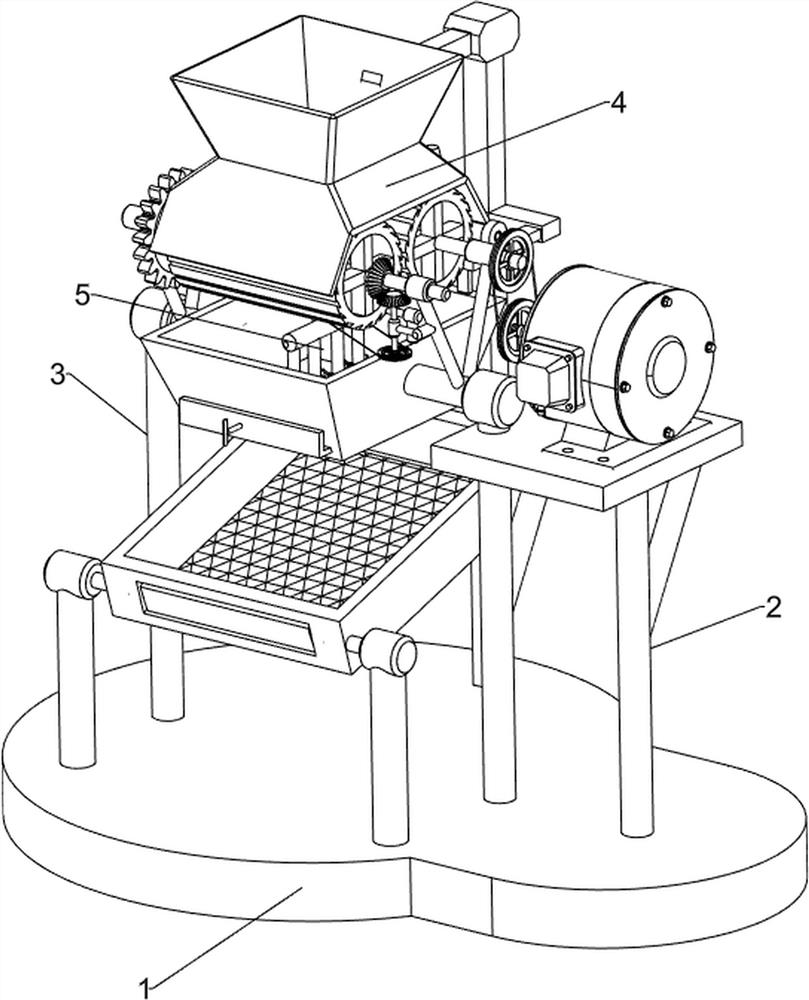

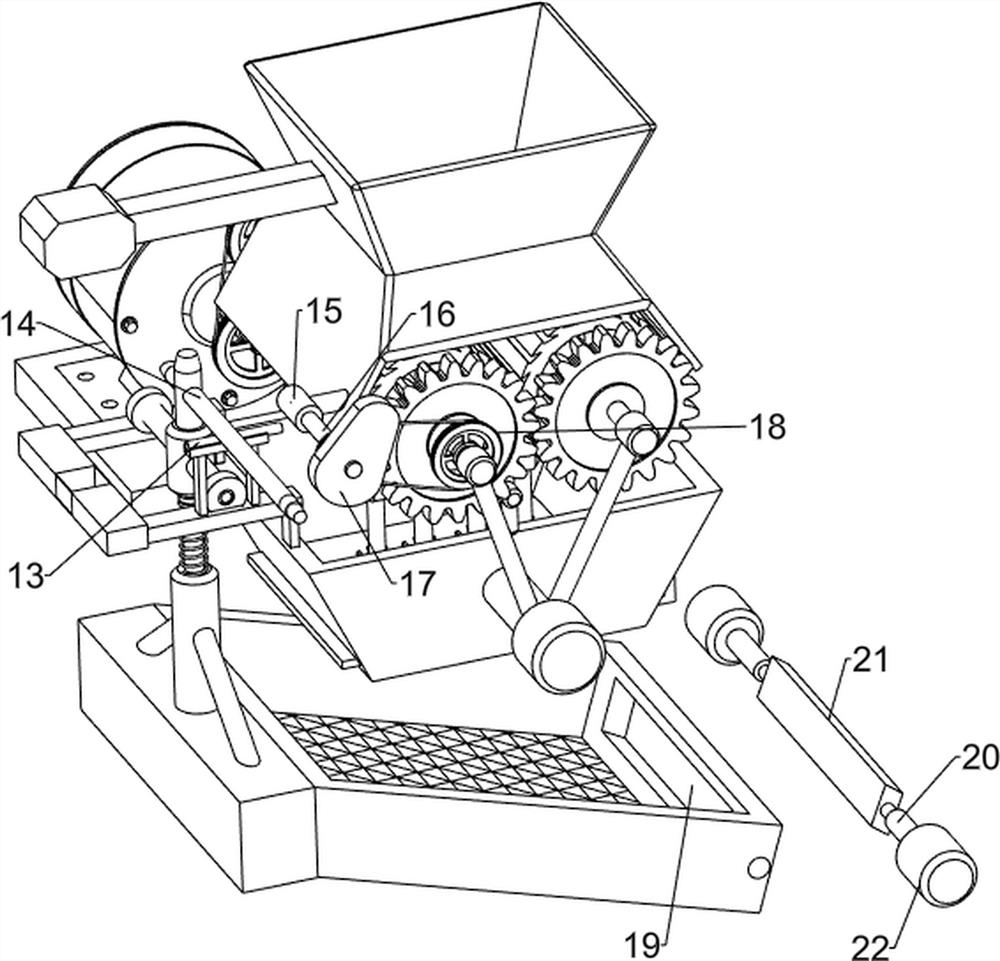

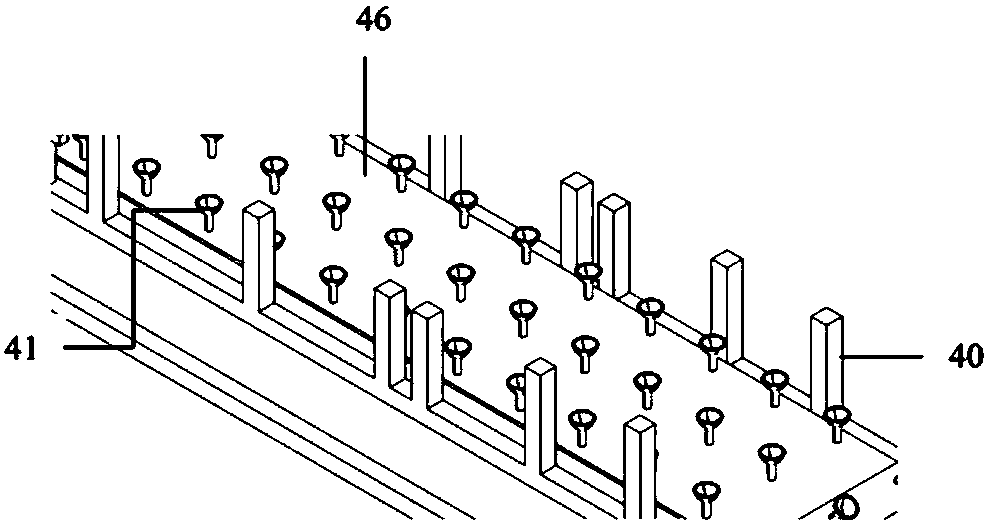

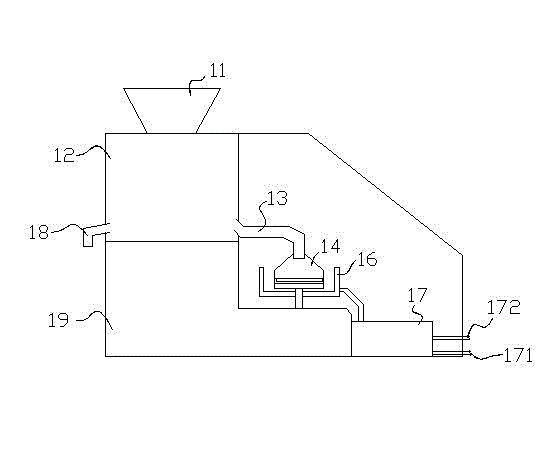

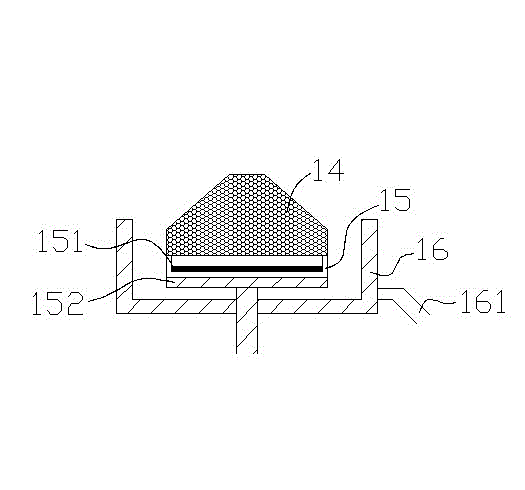

Hickory nut shell-crushing and sorting machine

The invention relates to a hickory nut shell-crushing and sorting machine. The hickory nut shell-crushing and sorting machine comprises a machine frame, a feeding module, an extruding module, a crushed shell separation sieve and a discharging module, wherein the feeding module comprises a feed hopper, a poking roller and a feeding guide slot; the extruding module comprises an extruding roller, an extruding heavy hammer, a lifting sliding rail and a cover board; the extruding roller is arranged on the machine frame through a bearing and a bearing pedestal; transverse slots are formed in the circumferential direction of the extruding roller uniformly; small round holes for accommodating the hickory nuts are formed in the transverse slot uniformly; an extruding blade is arranged in each small round hole; the lifting sliding rail is arranged on the machine frame; the cover board is arranged on the machine frame; the cover board is covered on the two sides and the top part of the extruding roller; a square hole of which the area is bigger than that of the lower end of the extruding heavy hammer is formed over the cover board; the crushed shell separation sieve is arranged under the extruding roller; and the discharging device is positioned under the crushed shell separation sieve. The hickory nut shell-crushing and sorting machine has the advantages of mechanized work, high production efficiency and stable work.

Owner:日照瑞达建设集团有限公司

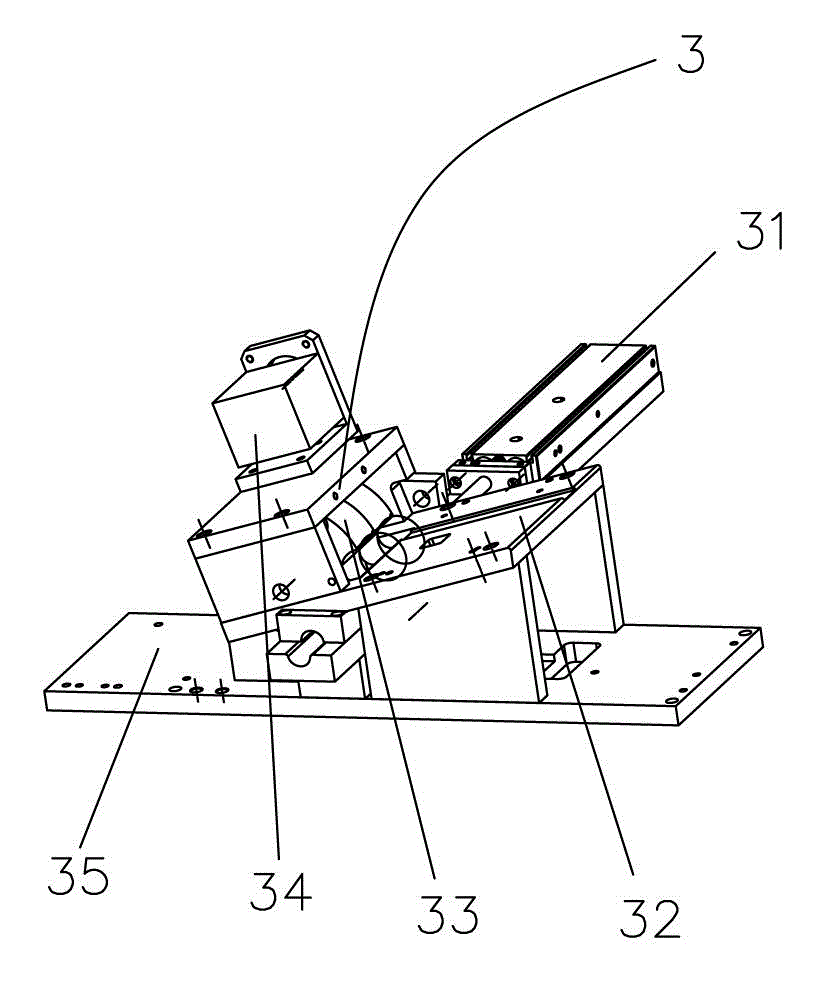

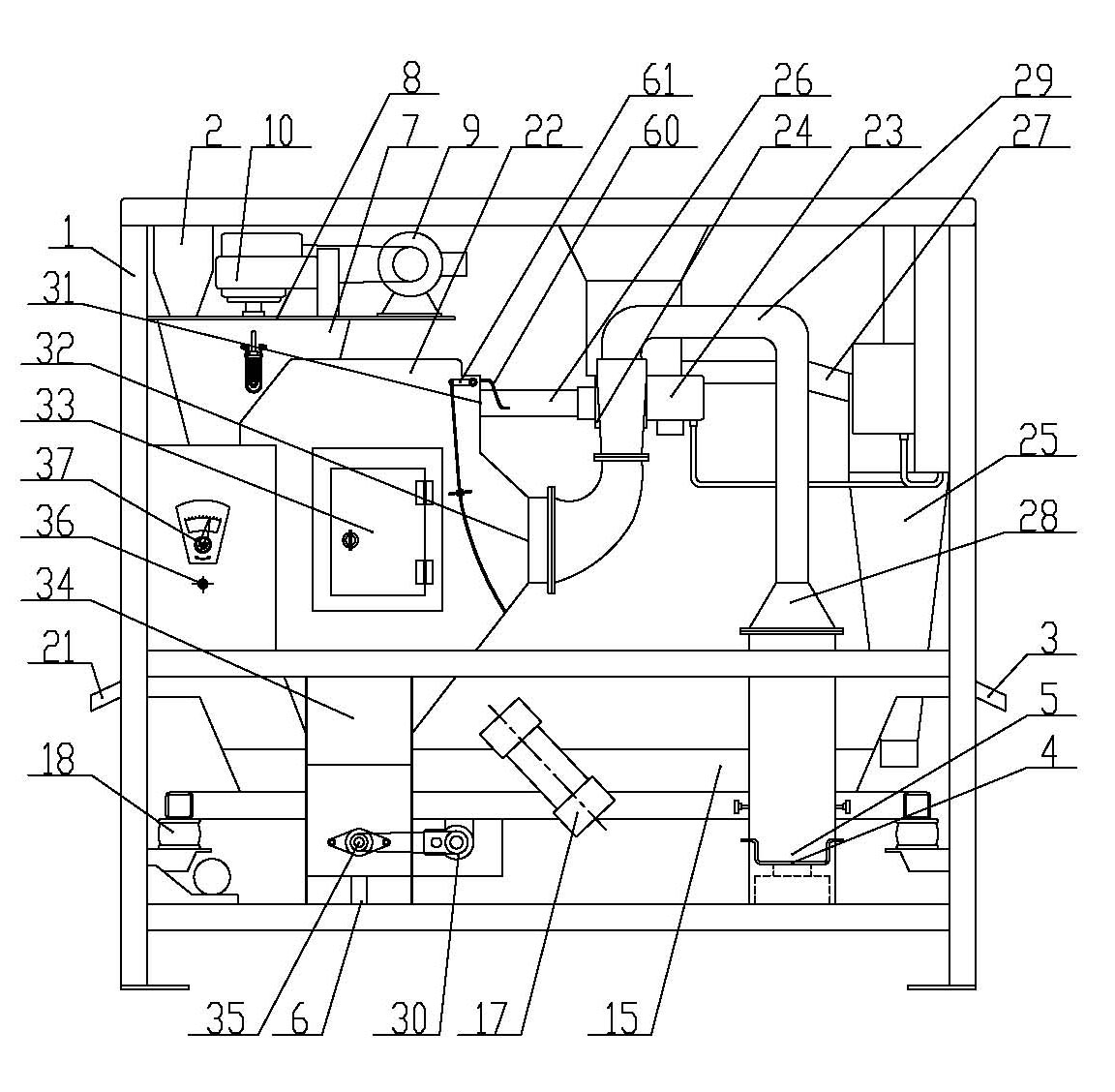

Automatic assembling equipment for lithium battery

ActiveCN104810560AAssembly precisionLow costAssembling battery machinesFinal product manufactureEngineeringSpot welding

The invention discloses automatic assembling equipment for a lithium battery. The automatic assembling equipment is characterized by comprising a battery core feeding bin, a steel shell feeding bin, a battery core position-searching mechanism, a shell entering mechanism, a spot welding mechanism, and a lug arranging and testing mechanism, wherein the battery core feeding bin comprises a defective battery core separation mechanism; the steel shell feeding bin comprises a defective steel shell separation mechanism; the battery core position-searching mechanism comprises a material conveying rail, a discharging cylinder, an indexing position-searching wheel and a stepping motor; a battery core enters into the indexing position-searching wheel through a material rail. Compared with the common labor forces, the automatic assembling equipment for the lithium battery has the advantages that the cost is lower, the assembly is more accurate, and the manufacture cost is effectively reduced.

Owner:张飞武

Combine-harvester for rapes, rice and wheats

The invention discloses a combine-harvester for rapes, rice and wheats. The combine-harvester for the rapes, the rice and wheats is capable of combining the functions of harvesting, threshing and grading of the rices and wheats and the rapes into a whole. The combine-harvester for the rapes, the rice and wheats comprises a rack, an actuating mechanism, a panicle-inlet mechanism, a threshing mechanism and a grain-shell separating mechanism, wherein the panicle-inlet mechanism is installed on the rack, the threshing mechanism is located at the back of the threshing mechanism, and the grain-shell separating mechanism is connected with a grain outlet of the threshing mechanism. The grain-shell separating mechanism comprises a vibrating grading sieve, a shell-blowing fan and a shell outlet, the vibrating grading sieve is composed of a vibrating grading sieve basket, an upper-layer sieve-piece angle-adjustable sieve and a lower-layer net-shaped sieve, wherein the upper-layer sieve-piece angle-adjustable sieve and the lower-layer net-shaped sieve are installed on the vibrating grading sieve basket. According to the combine-harvester for the rapes, the rice and wheats, due to the fact that the sieve-piece angle-adjustable sieve is added on the vibrating grading sieve basket, on one hand, impurities can be further graded, on the other hand, the sizes of sieve openings can be controlled by adjusting angles of sieve pieces, and the combine-harvester for the rapes, the rice and wheats is capable of achieving the grading of the rice and wheats and the rapes.

Owner:四川天顺祥农机有限公司

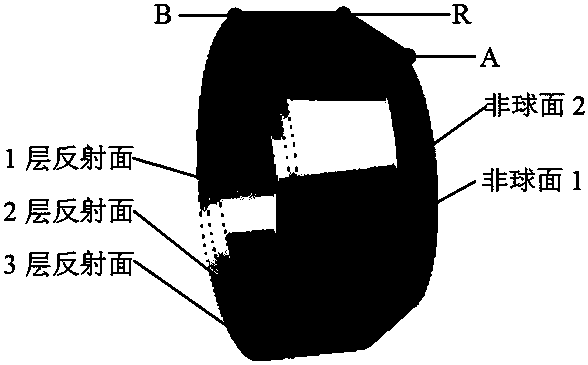

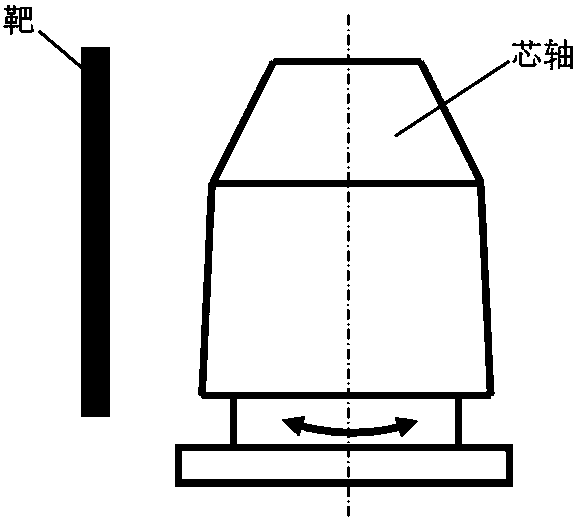

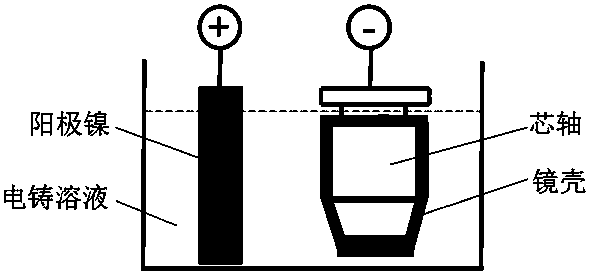

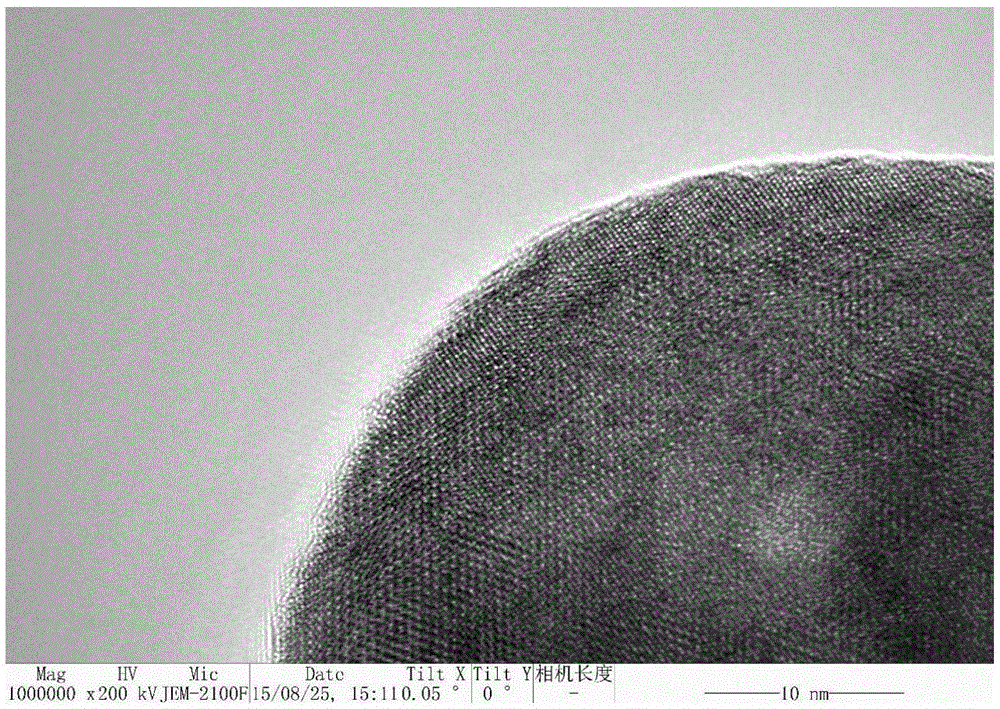

Process for manufacturing Wolter-I reflector by means of copying

ActiveCN107561609AReduce manufacturing costTake off smoothlyMirrorsElectroforming processesReflective layerRefrigeration

The invention discloses a process for manufacturing a Wolter-I reflector by means of copying. The process includes the following steps that: a precision mandrel used for copying is manufactured; a DLCfilm is applied by means of the PVD (Physical Vapor Deposition) process; a gold film reflective layer is applied by means of the PVD process; a reflector shell is obtained through electroforming; thesurface of the reflector shell is trimmed; a reflector is released from the mandrel in a low-temperature refrigeration room by using a mold release device; and the surface of the reflector is washed.According to the process of the invention, DLC is applied between the copying gold film and the surface of the mandrel so as to be adopted as a release layer, and therefore, the gold film can be effectively prevented being damaged, and the smooth release of the gold film from the mandrel can be facilitated; the gold film is plated at the rotation surface and two end surfaces of the mandrel simultaneously, and therefore, electroforming nickel can be prevented from infiltrating between the gold film at the end surfaces of the mandrel and the surface of the mandrel during an electroforming process; electroforming time can be prolonged, the strength of the reflector shell is increased, the deformation of the reflector shell is prevented, and the reflector shell is easy to shell, transport andinstall; and the mandrel is made to be separated from the reflector shell through an auxiliary shelling device in the low-temperature room, and therefore, the manufacturing cost increase of the reflector and health hazards can be avoided.

Owner:HARBIN INST OF TECH

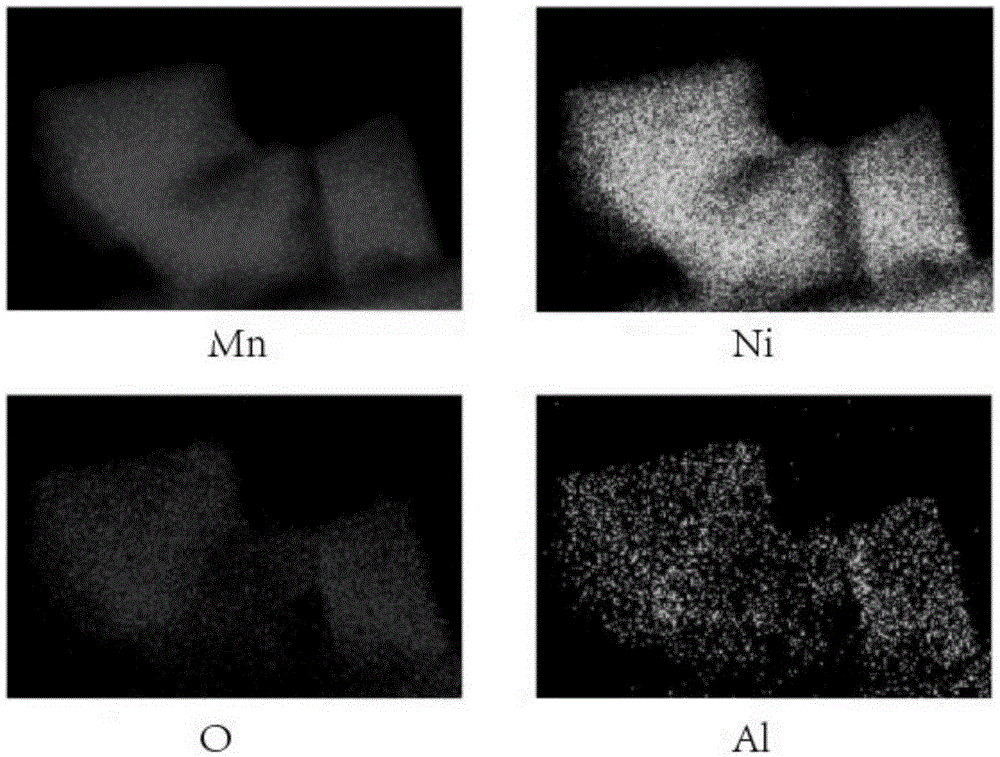

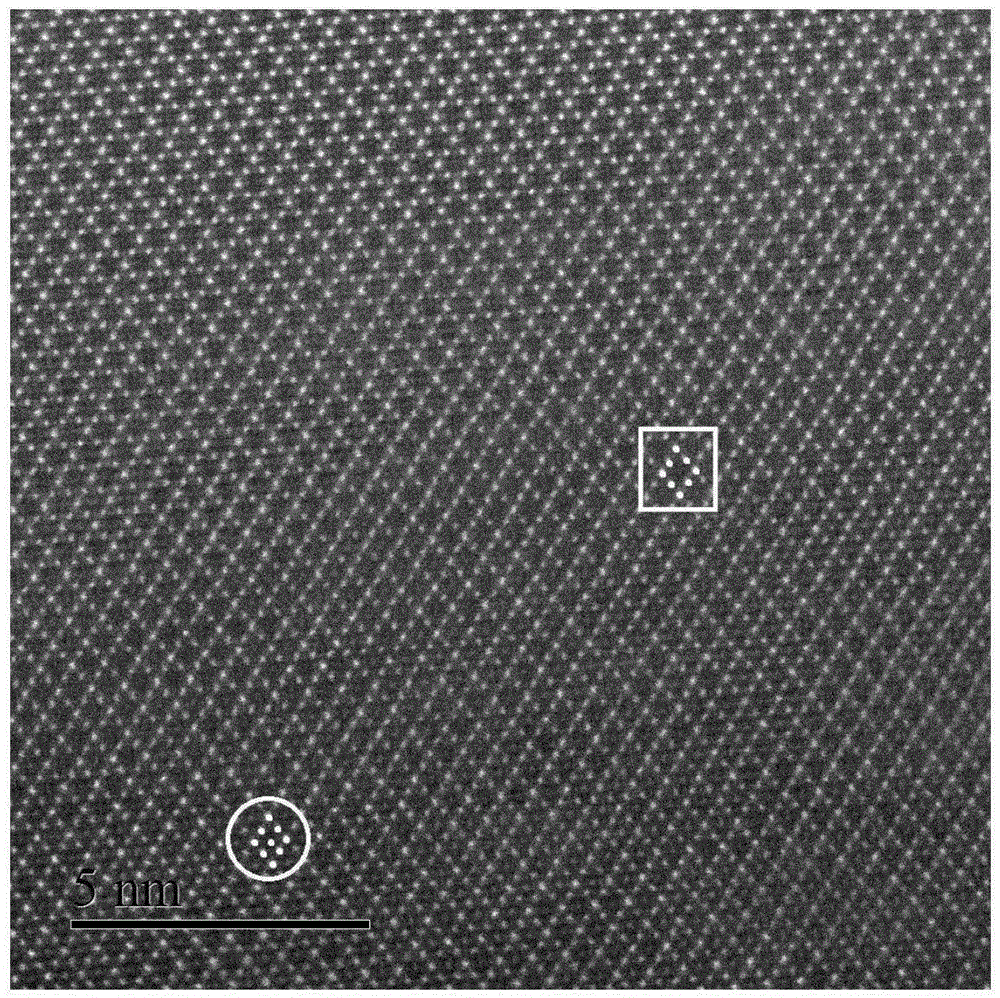

Cathode material and preparation method and applications thereof

ActiveCN106887583AImprove thermal stabilityImprove cycle stabilityCell electrodesSecondary cellsSpinelManganese oxide

The invention discloses a cathode material and a preparation method and applications thereof. The cathode material is spinel type lithium nickel manganese oxide LiNi<0.5>Mn<1.5>O<4-[delta]> 0=<[delta]<0.1. The cathode material has metal elements, the concentration of the metal elements gradually decreases from the surface to the inner, thus a shell layer, which has a structure similar with the nucleus structure, is formed, moreover, the tight connection thickness is greater than 0; and the metal elements account for not more than 10 wt% of the weight of the spinel type lithium nickel manganese oxide (X<=10wt%). A precipitate controllable method is adopted to quantitatively precipitate metal elements on the surface of lithium nickel manganese oxide; then a thermal treatment is carried out to make the metal elements penetrate from the surface to the interior so as to in-situ form a shell layer on the surface of nucleus of lithium nickel manganese oxide; the similarity of the structures of the shell layer and the nucleus is high, the compatibility is good, and the problem of nucleus-shell separation is well solved. Due to the shell layer, the thermal stability, circulation stability, and structure stability of the cathode material during the charge-discharge process are prominently improved, and the cathode material has a wide application prospect in the field of energy storage.

Owner:INST OF CHEM CHINESE ACAD OF SCI

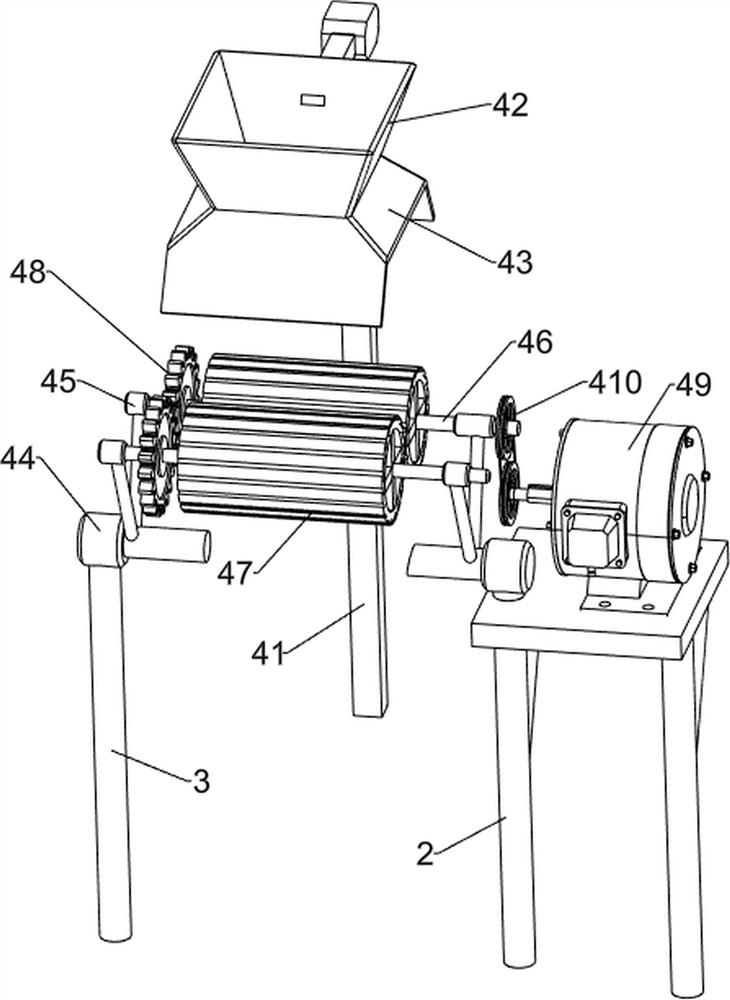

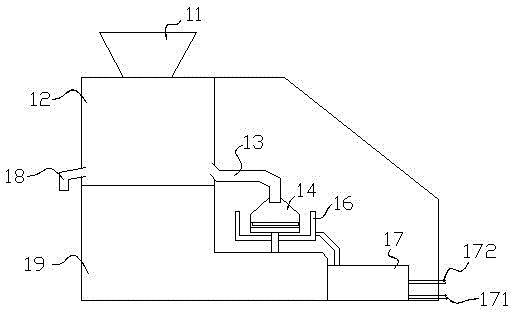

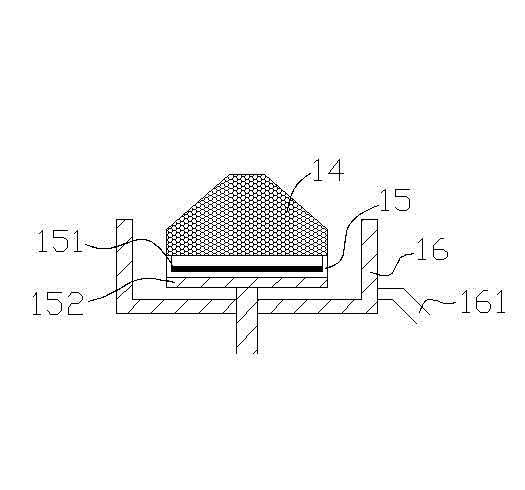

Nut shell breaking separator

The invention relates to a shell breaking device of nut type foods, in particular to a shell breaking separation device of nuts such as walnuts, apricots, pistachio nuts, almonds and the like. The shell breaking separation device is a nut shell breaking separator which comprises a stand, a grind type shell breaking device, a screening device and a suction separation device, wherein the stand below the grind type shell breaking device is provided with the screening device; the stand in front of the grind type shell breaking device is provided with the suction separation device, a suction port is positioned above a fruit nut guide groove and can adsorb fruit shells mixed in the fruit nuts; and a fruit shell separation outlet is positioned at the lower end of the suction separation device. The separator has a rational and compact structure and is convenient to use, the fruit shells are crushed by kneading the nuts through the rotation of an inner shell breaking mill in an outer shell breaking mill; the bigger fruit shells are separated from the fruit nuts through the screening device; the small fruit shells are separated from the fruit nuts through the suction separation device; and the device has the characteristics of suitability for machining various nuts, high production efficiency, good separation effect, low fruit nut breaking rate and loss rate and high reliability.

Owner:喀什光华现代农业有限公司

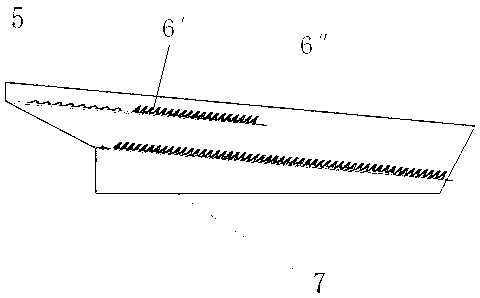

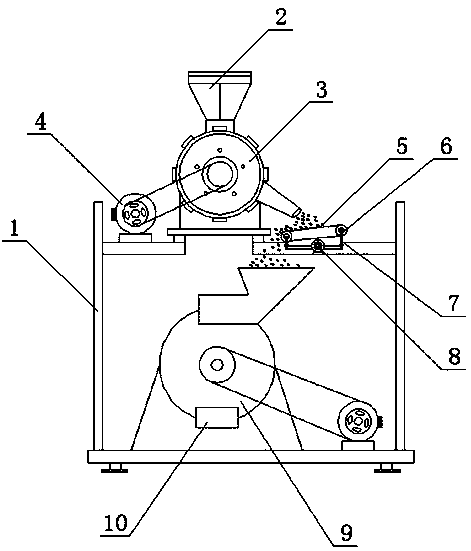

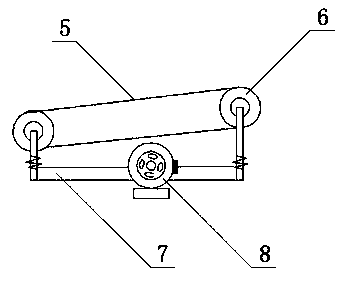

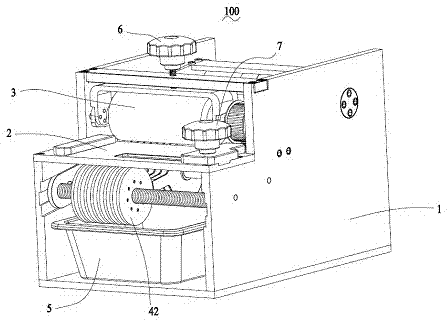

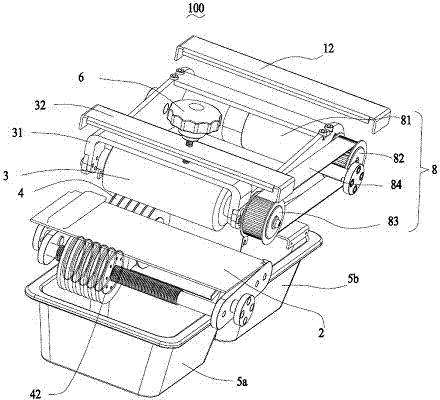

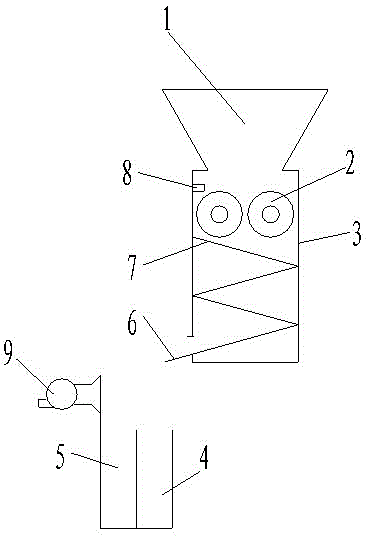

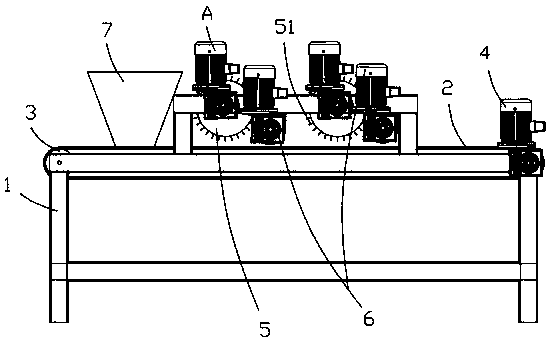

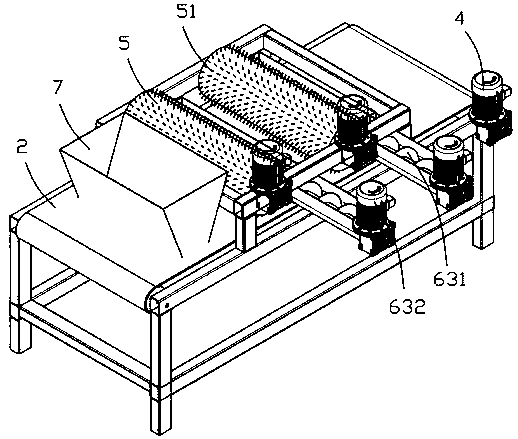

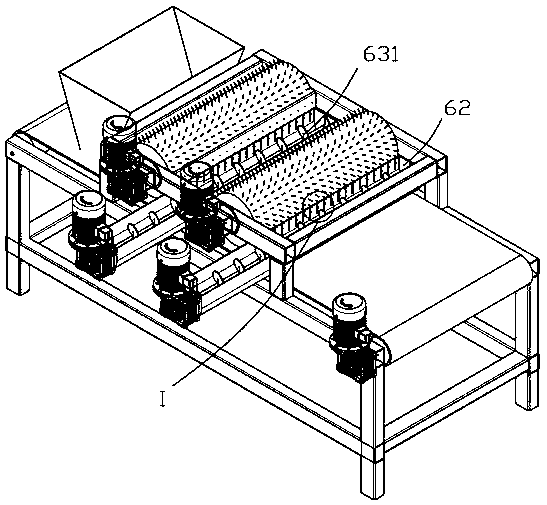

Shelling pulverizer of bean fodder

InactiveCN103623908AEfficient separationQuality improvementSievingScreeningAgricultural engineeringLegume crops

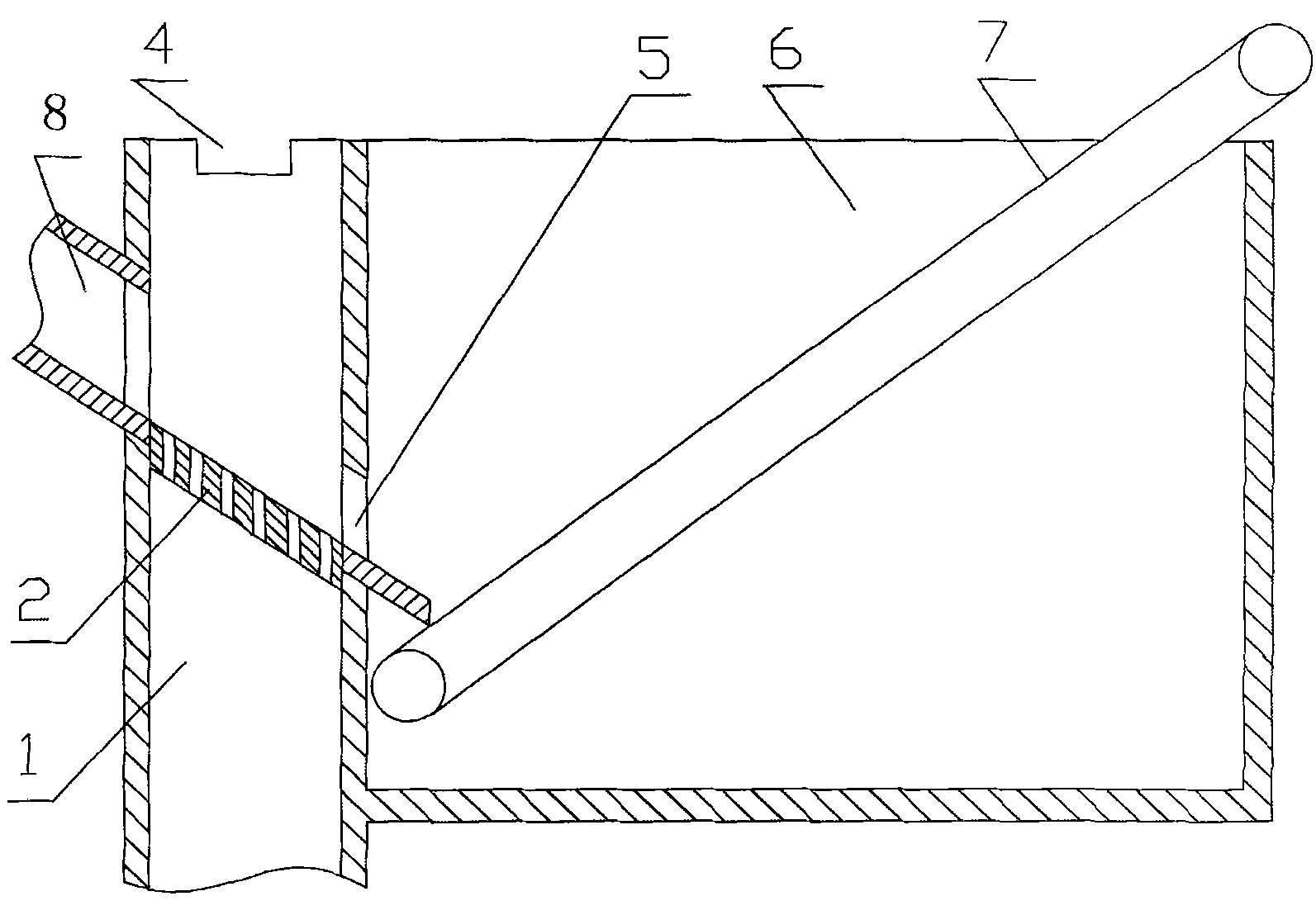

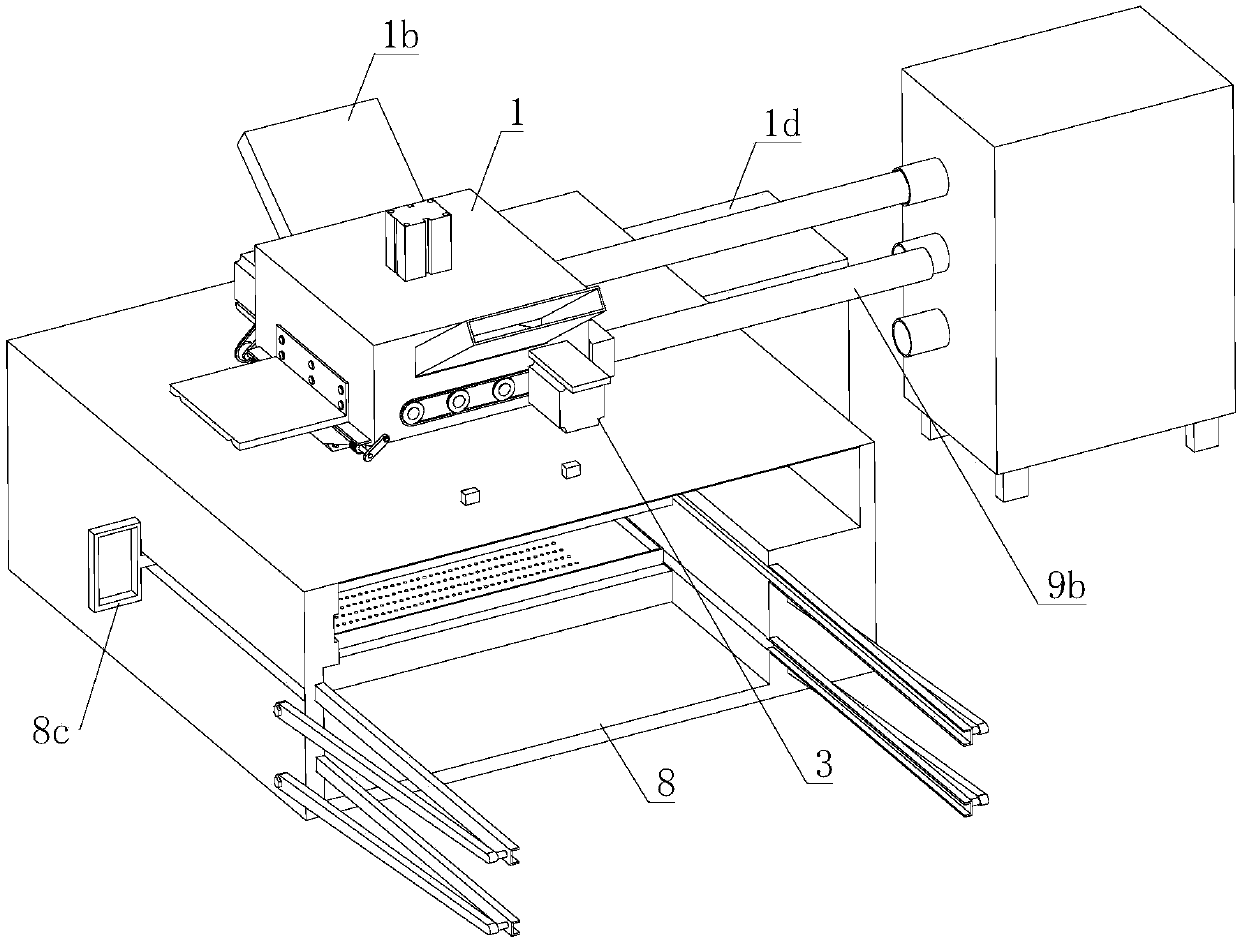

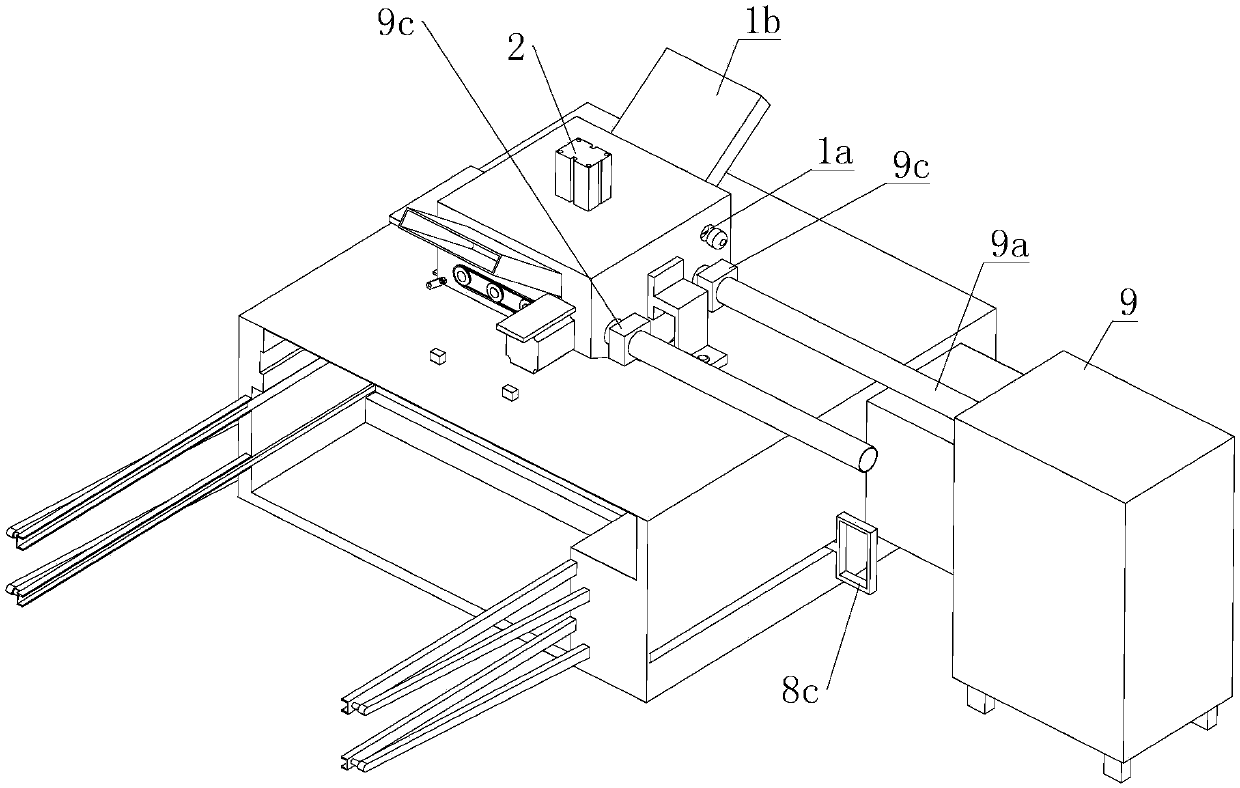

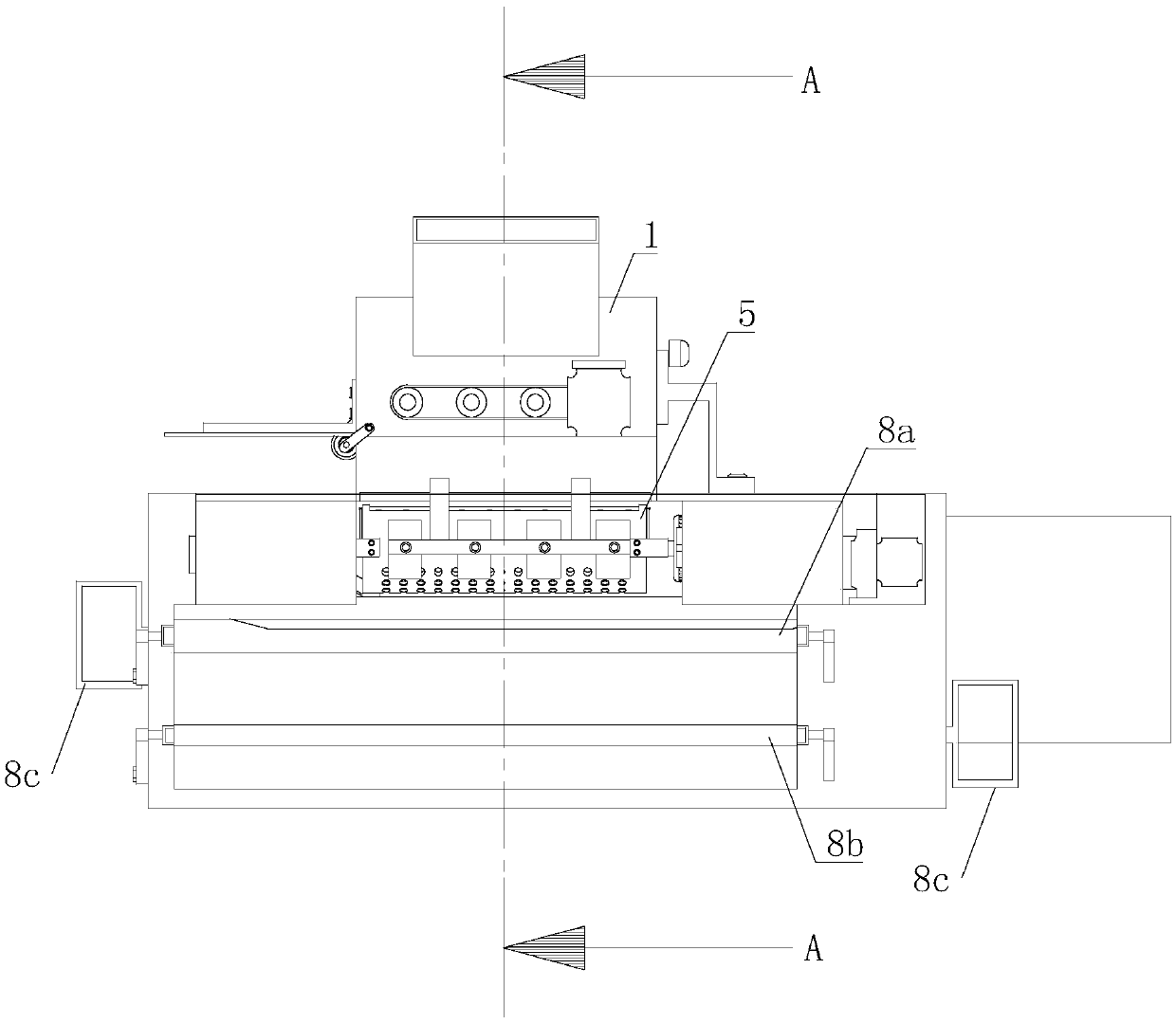

The invention discloses a shelling pulverizer of a bean fodder. The shelling pulverizer comprises a rack (1), wherein the rack (1) is provided with a feed hopper (2); a shell smashing device (3) is arranged below the feed hopper (2) and is connected with a belt pulley of a shell smashing motor (4) through a driving belt, and a belt screen sieve (5) is arranged below a discharge opening of the shell smashing device (3) and is arranged on a belt shaft (6); the belt shaft (6) is arranged on a vibrating frame (7), the vibrating frame (7) is movably connected with the rack (1), and a feeding opening of a pulverizing device (9) is arranged right below a discharging end of the belt screen sieve (5). The shelling pulverizer provided by the invention has the advantages that the smashed shell, dust and the like can be effectively separated under the action of the belt screen sieve, beans separated out are pulverized under the action of the smashing device, the shelling, separation and pulverizing of legume crops are finished at one time, the shelling and separating effects are good, the quality of the processed powder is good, and the purity is improved.

Owner:HUBEI HUICHUANG HEAVY ENG

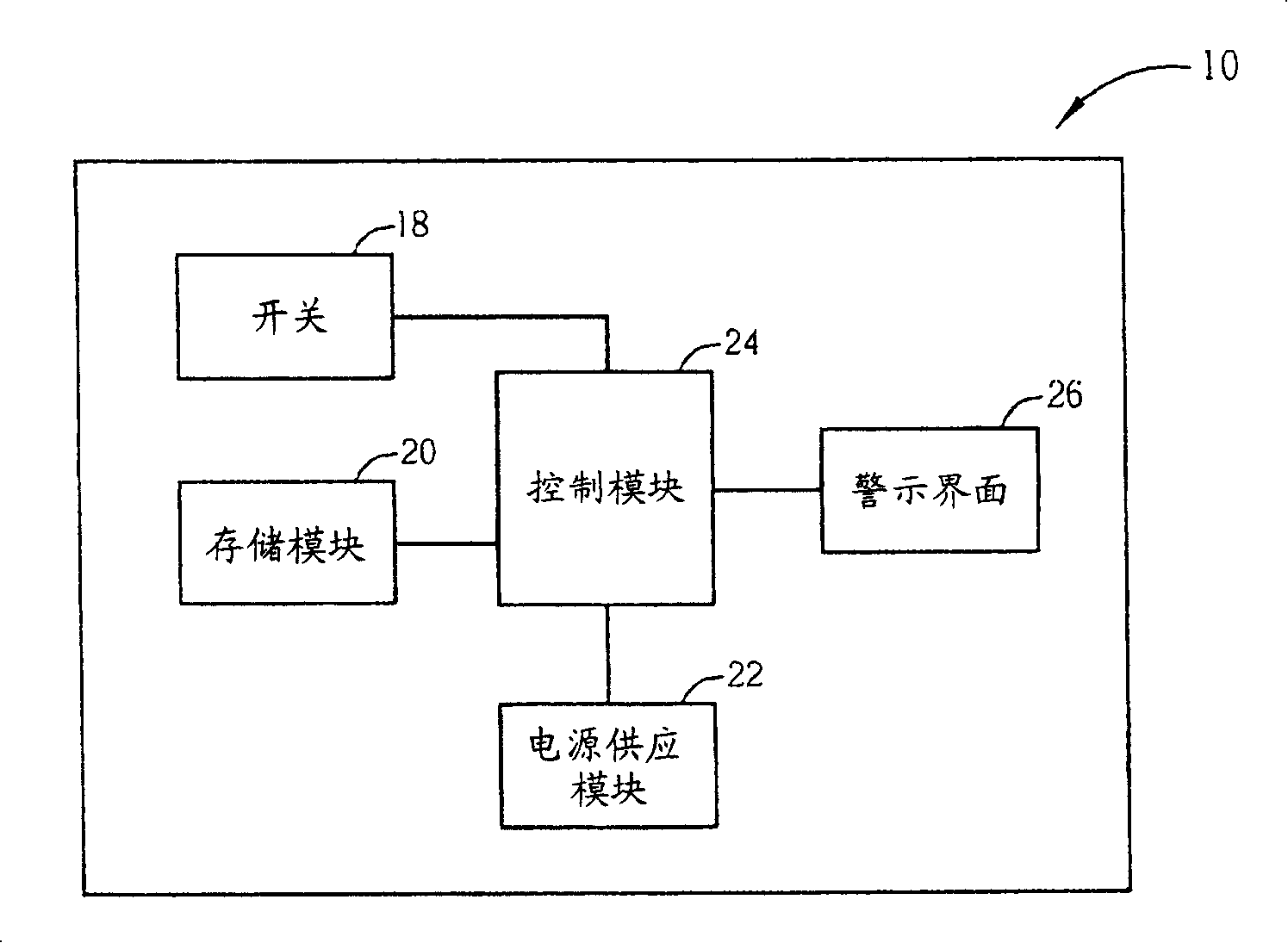

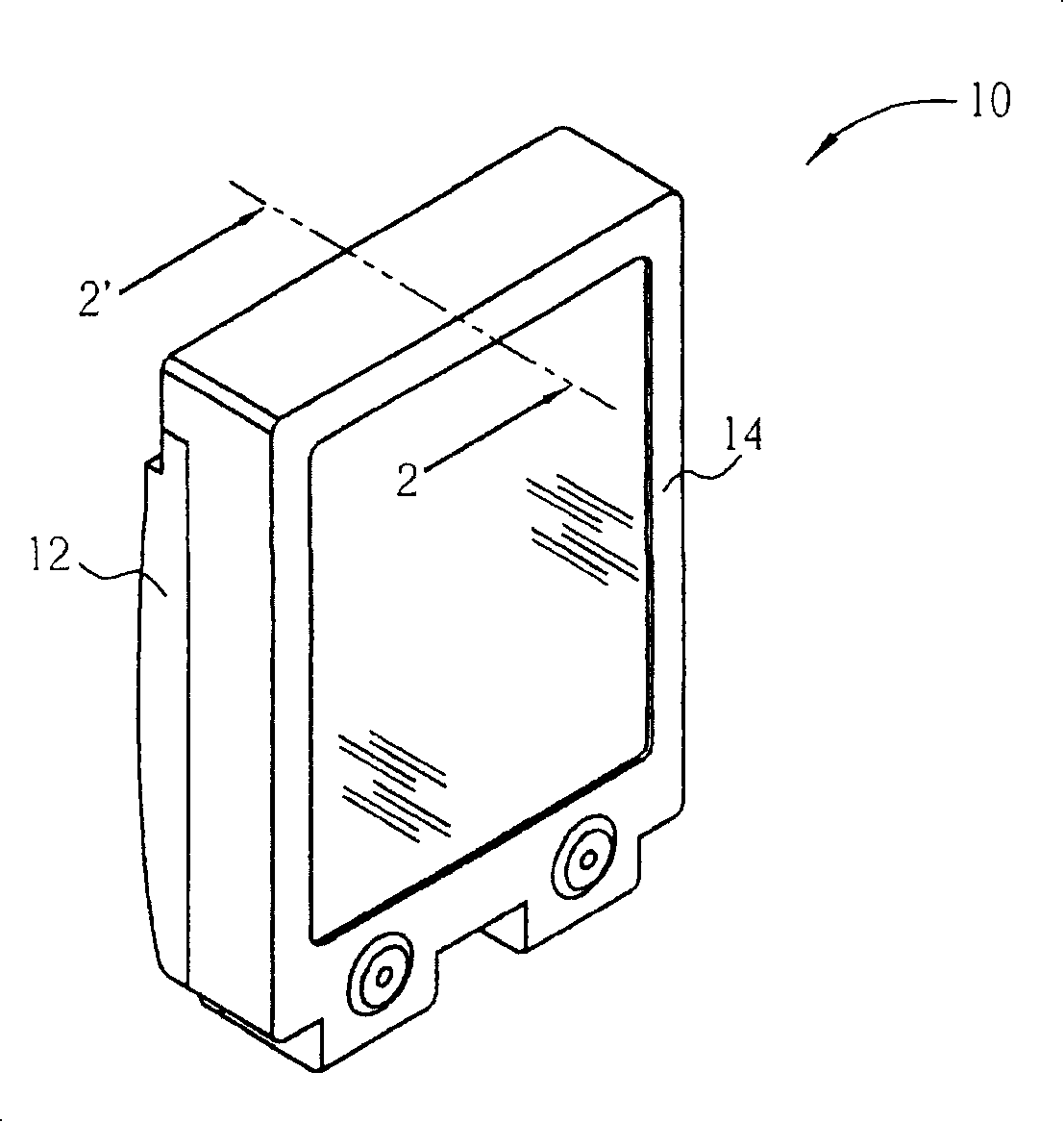

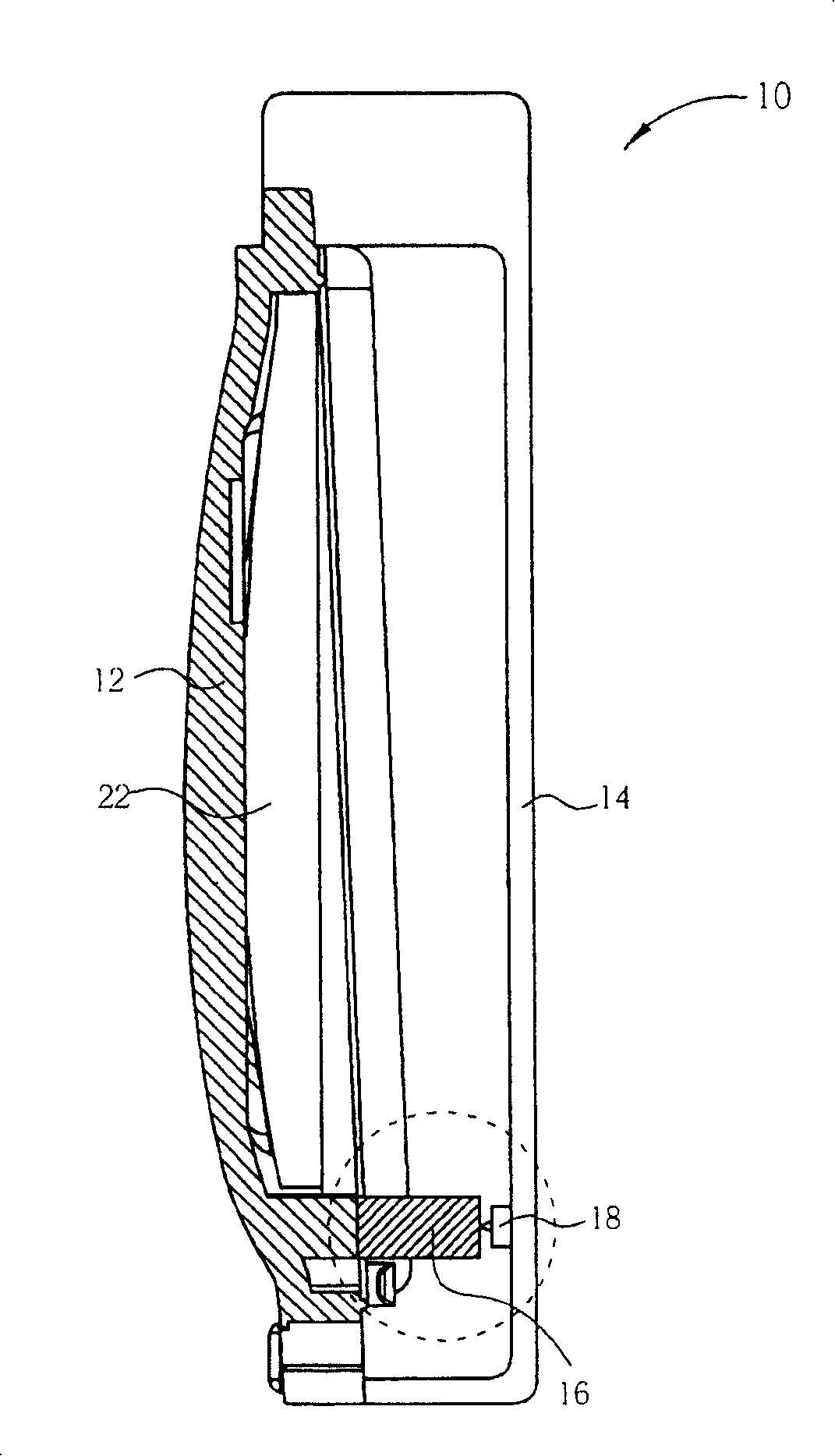

Portable electronic device with shell separation detection function

InactiveCN101242715ACasings/cabinets/drawers detailsElectrical testingComputer moduleConductive materials

A portable electronic device with housing separation detection function, which includes a first housing, a elastic structure connected to the first housing, a conductive material layer disposed at one side of the elastic structure, a second housing, which the first housing is removably connected to, a circuit board disposed at one side of the second housing, a metal membrane disposed onto the circuit board, which is arranged at the corresponding position of conductive material layer, a detection module assembled in the second housing for detecting whether the conductive material layer contacts the metal membrane, wherein when the first housing contacts the second housing, the conductive material layer contacts the metal membrane, and when first housing is separated from the second housing, the conductive material layer separates the metal membrane.

Owner:ASKEY COMP

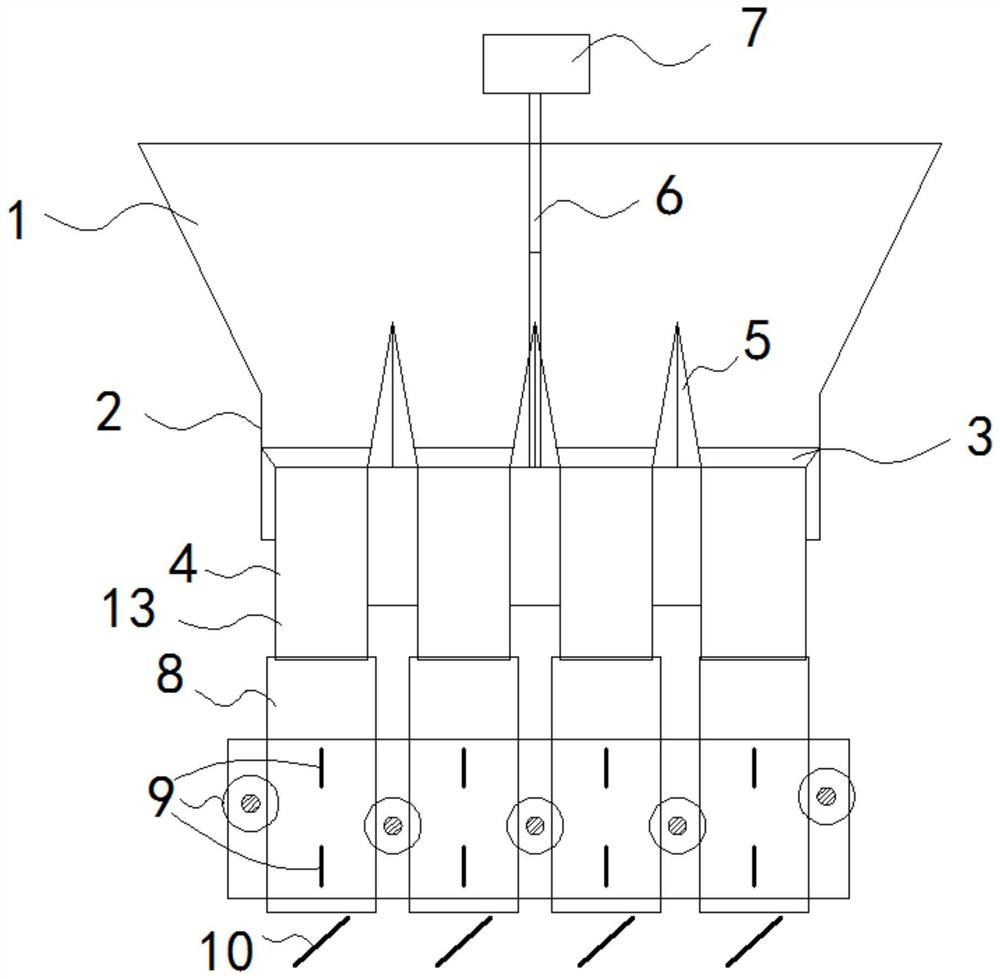

Agricultural peanut shelling and separating device

InactiveCN112167650AQuick shellingEasy to collectSievingScreeningAgricultural engineeringStructural engineering

The invention relates to a separating device, in particular to an agricultural peanut shelling and separating device. The invention provides the agricultural peanut shelling and separating device which can realize automatic discharging, screening and separating, and shelling. The agricultural peanut shelling and separating device provided by the invention comprises a base, a first fixing frame, ashell breaking device, and a scattering device, wherein a first support is arranged on one side of the top of the base; the first fixing frame is arranged on the other side of the top of the base; theshell breaking device is arranged at the top of the base, and is located between the first support and the first fixing frame; and the scattering device is arranged on the lower side of the shell breaking device. The shell breaking device and the scattering device are controlled by a servo motor to operate, so that the shell breaking device quickly breaks the shells of peanuts, the working time is saved, peanut kernels and peanut shells are thoroughly separated in cooperation with the scattering device, and workers can conveniently collect the peanut kernels and the peanut shells.

Owner:林妹

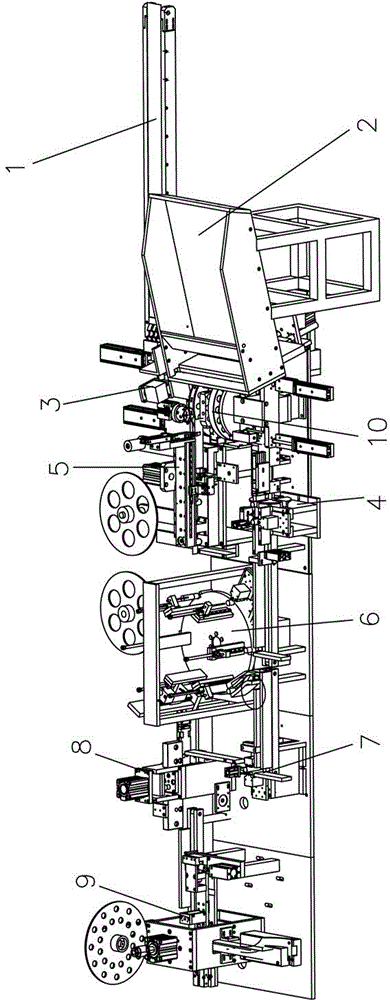

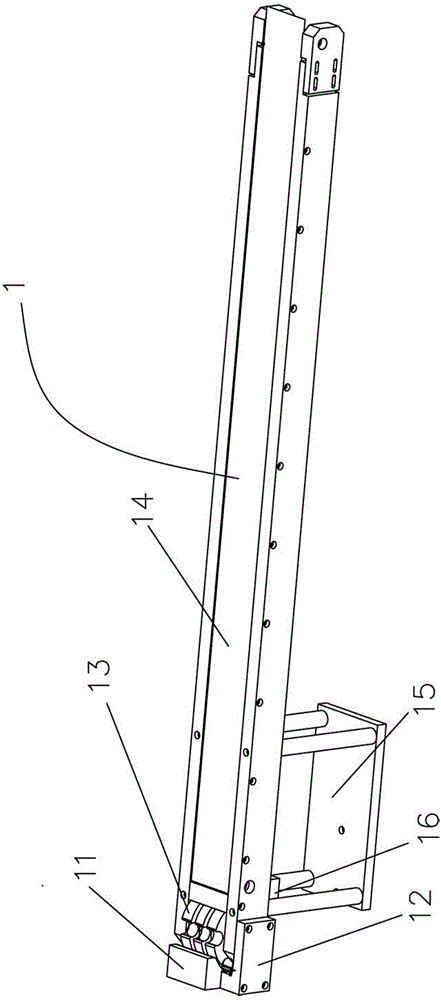

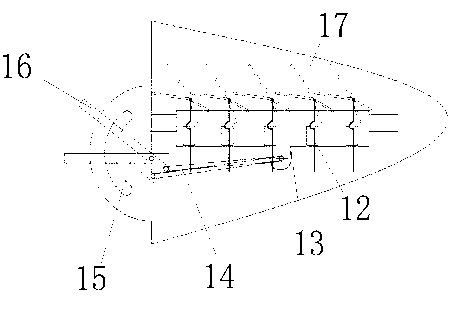

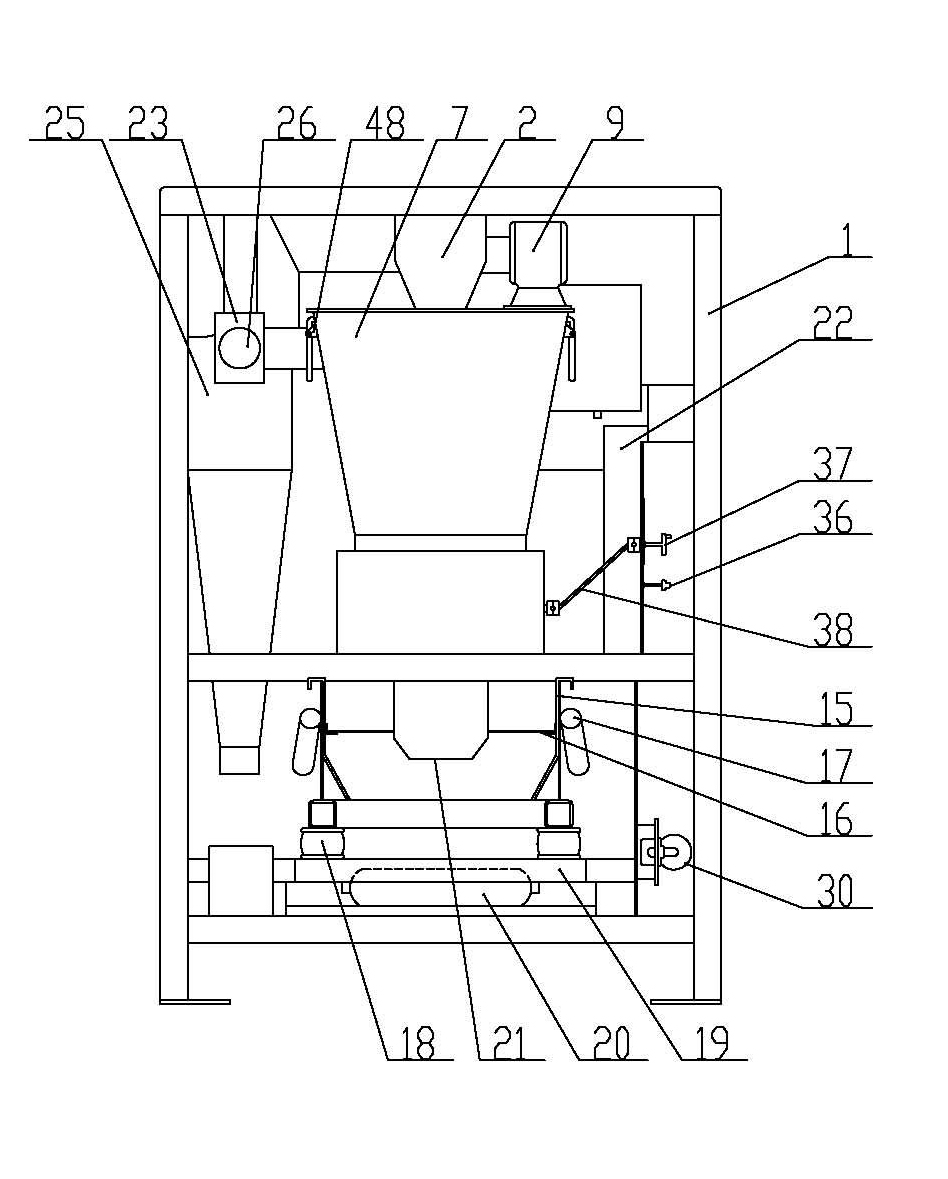

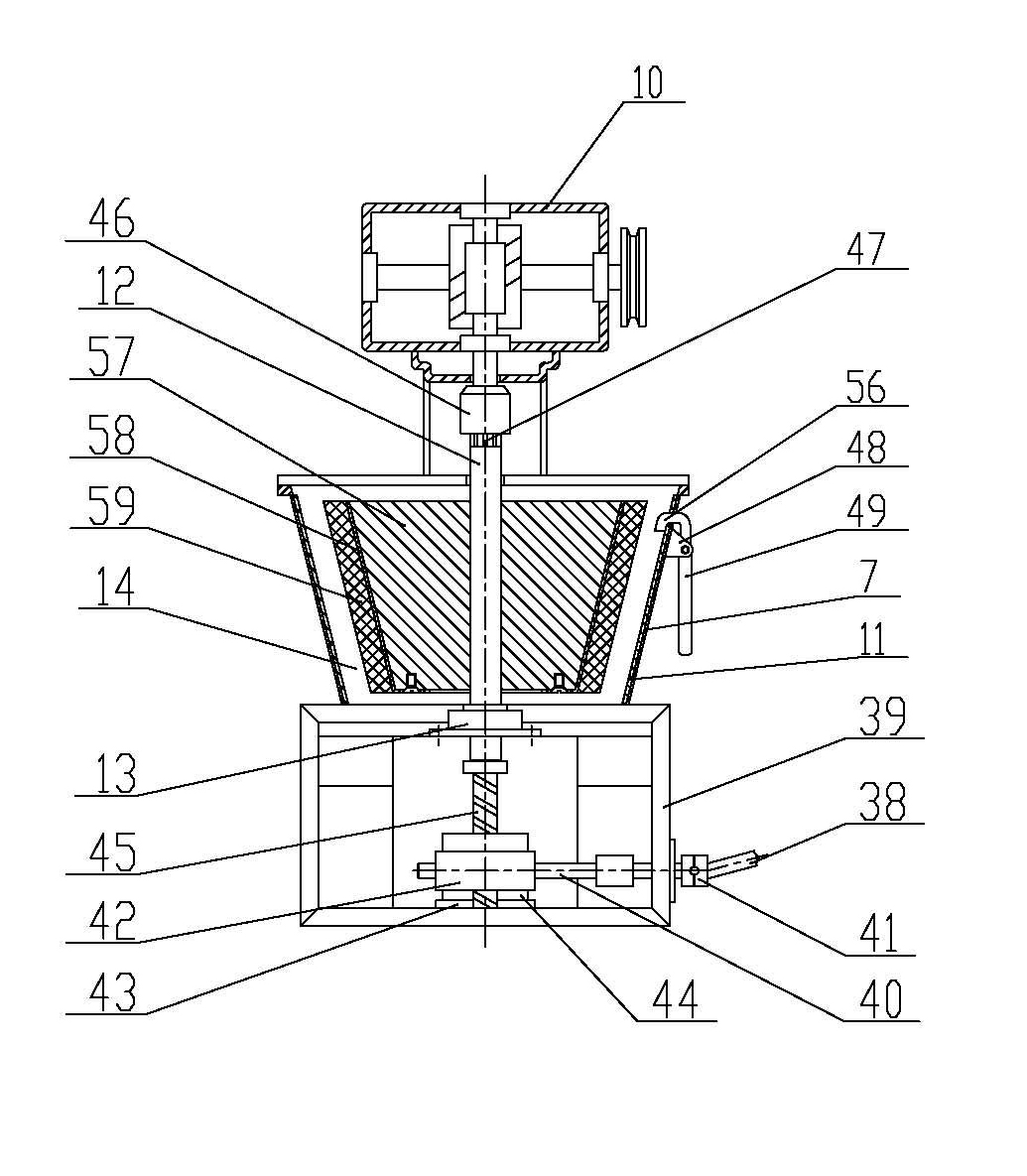

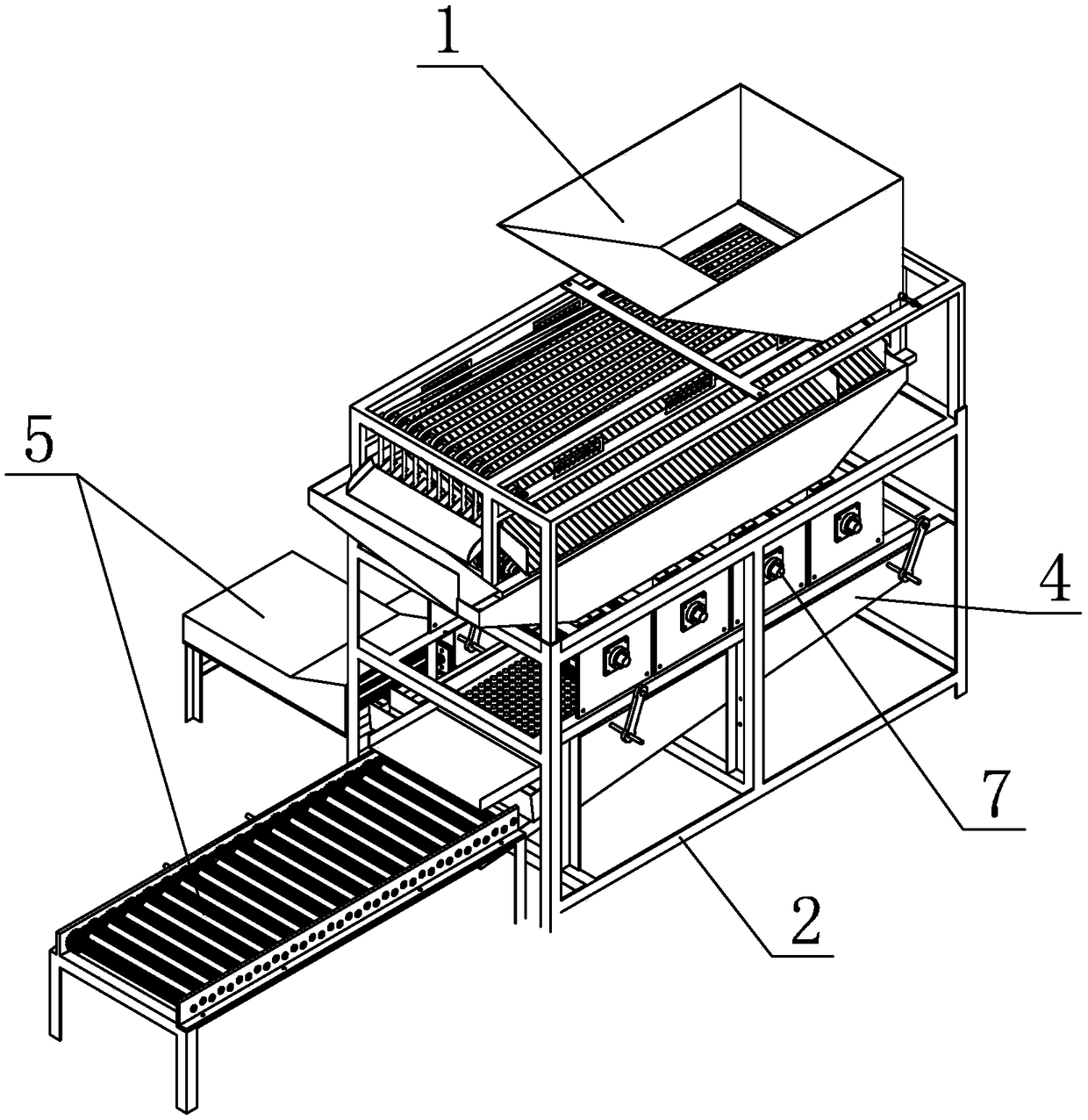

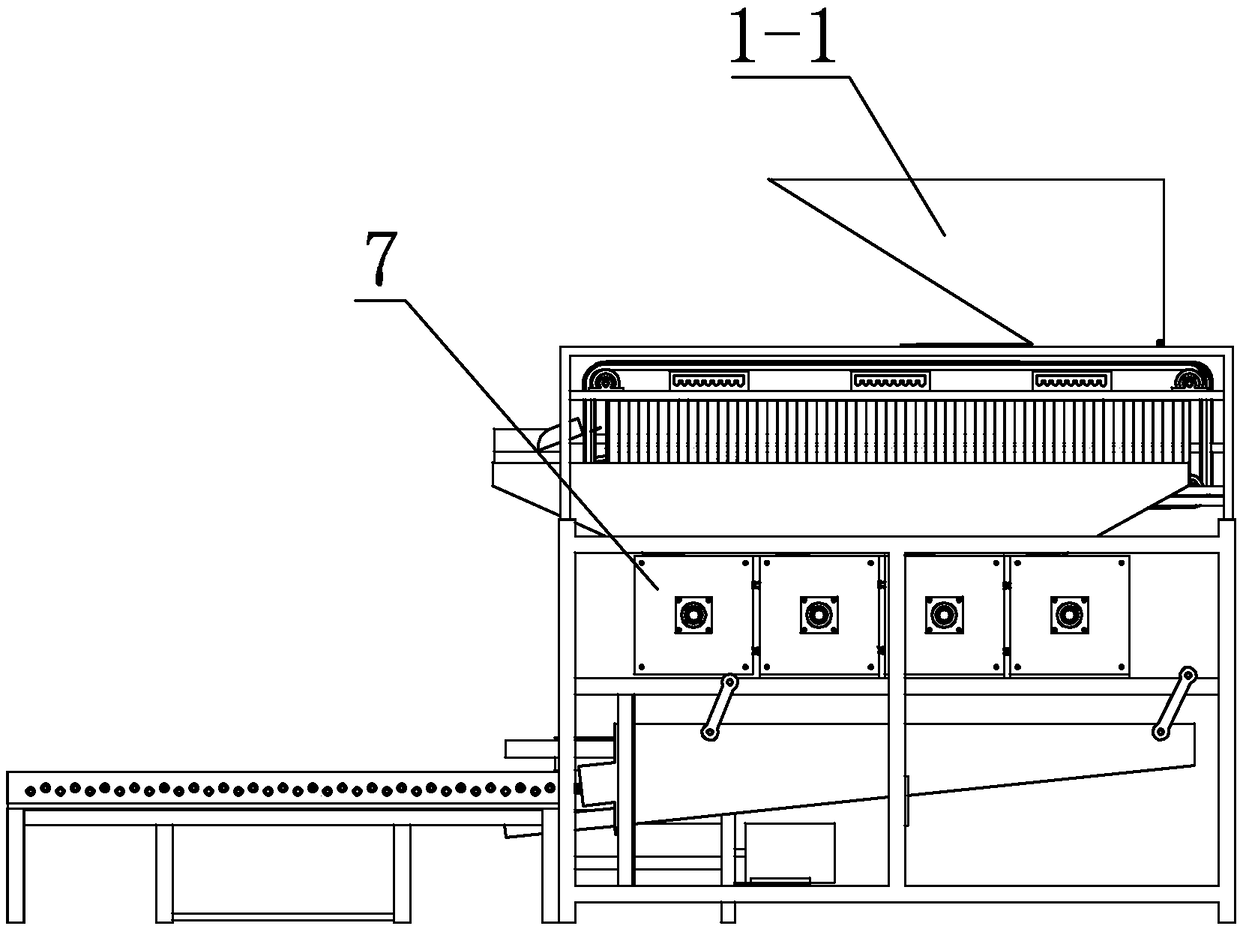

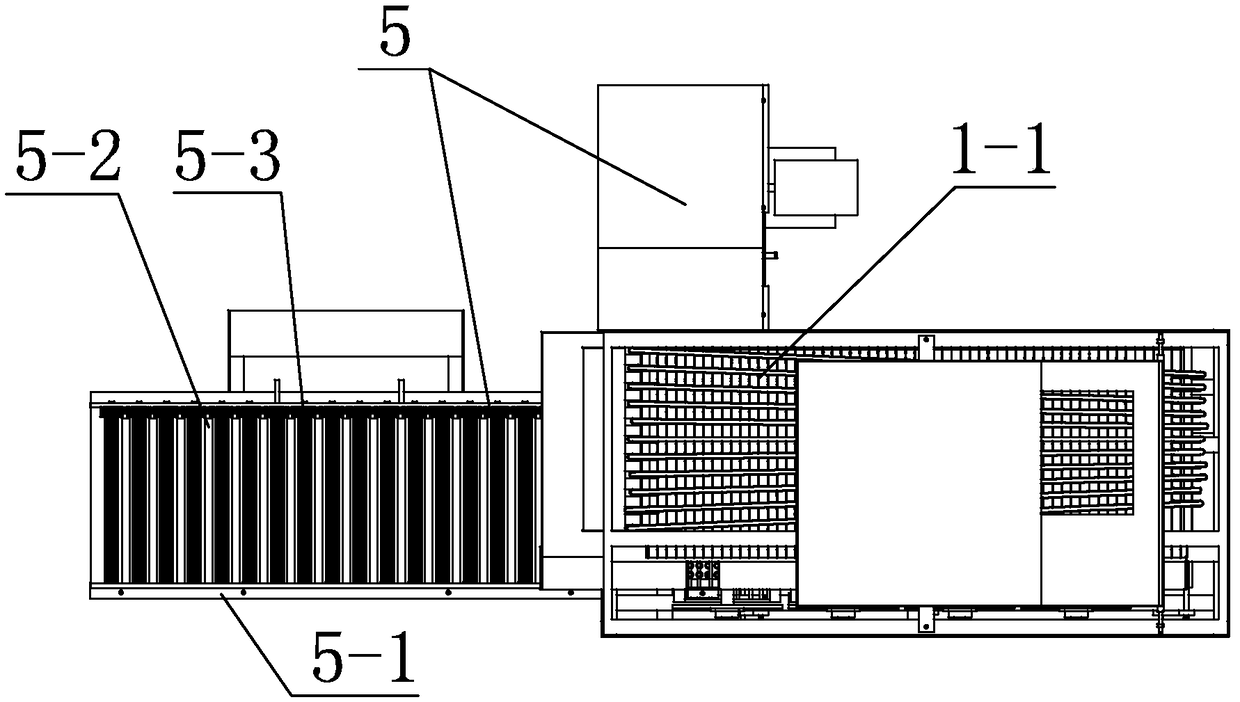

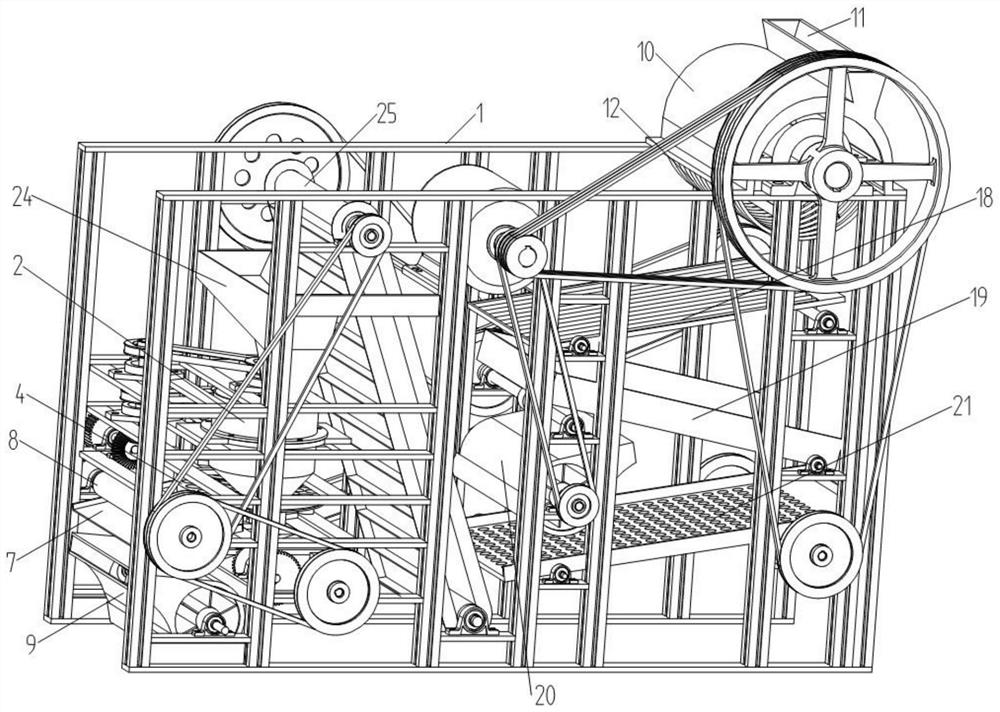

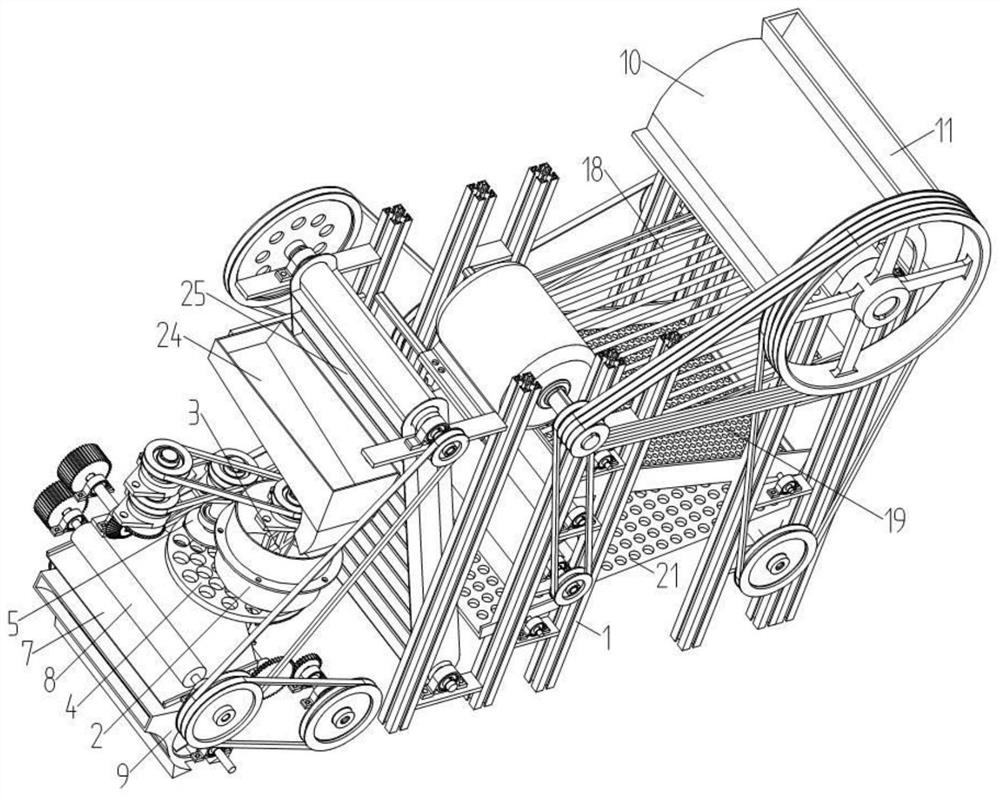

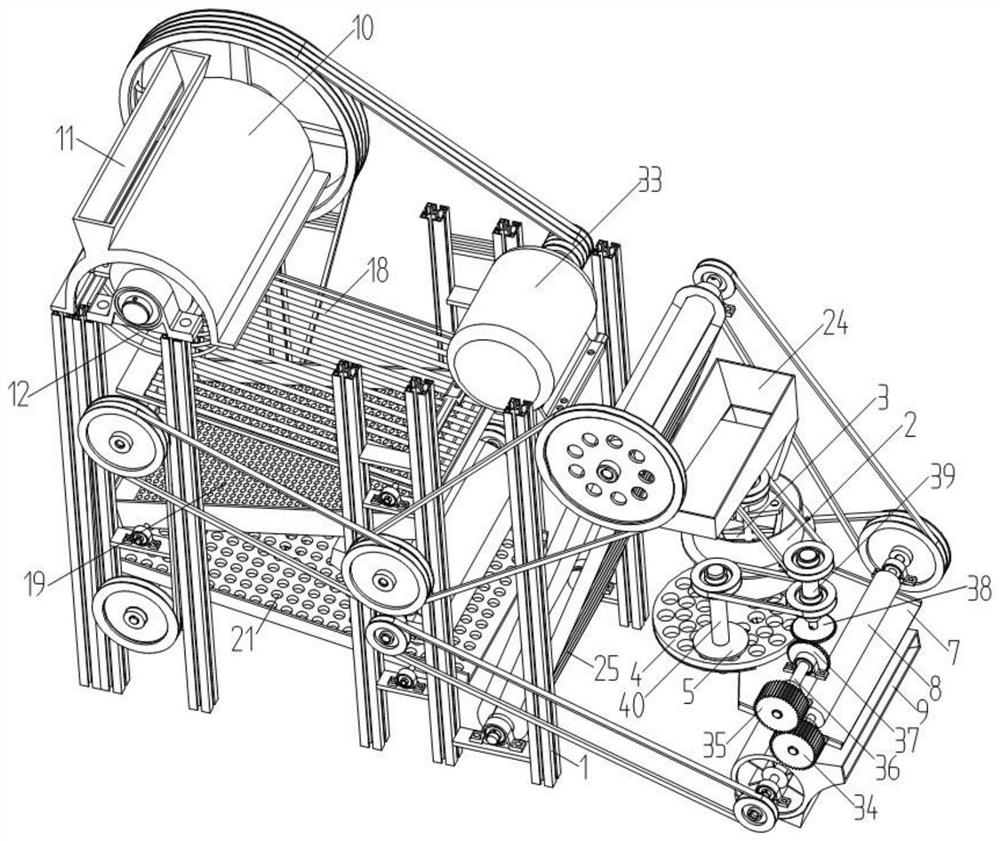

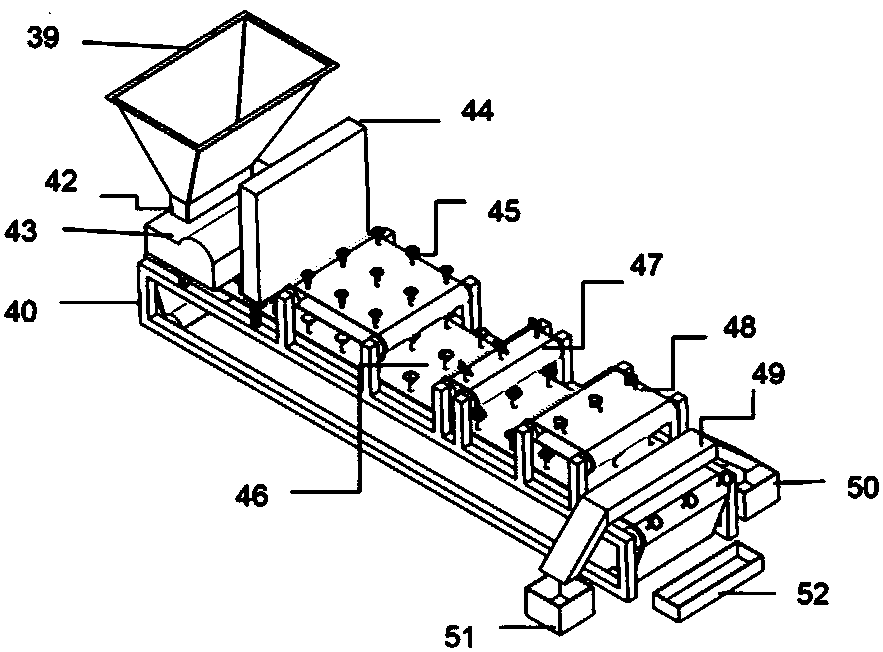

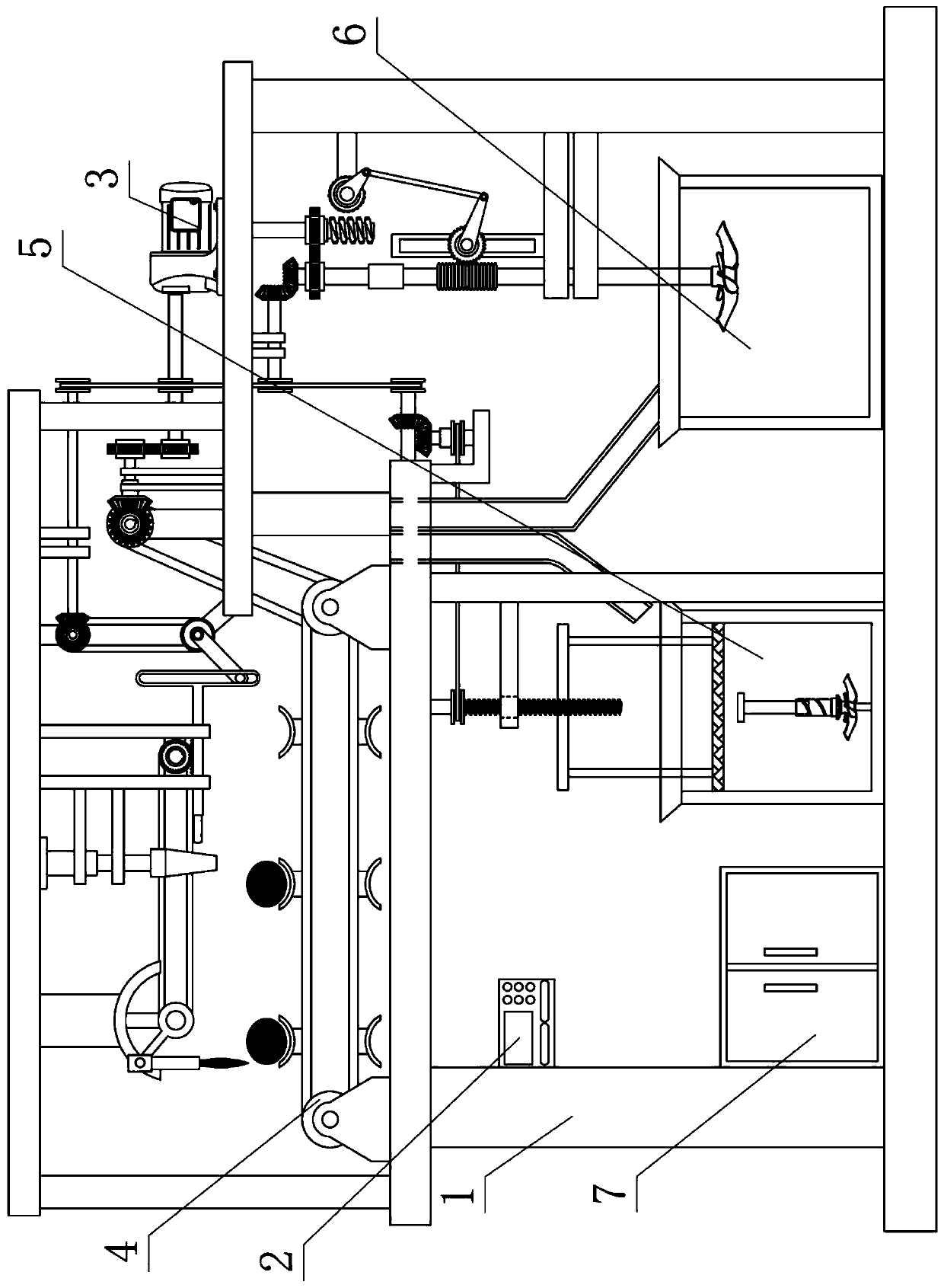

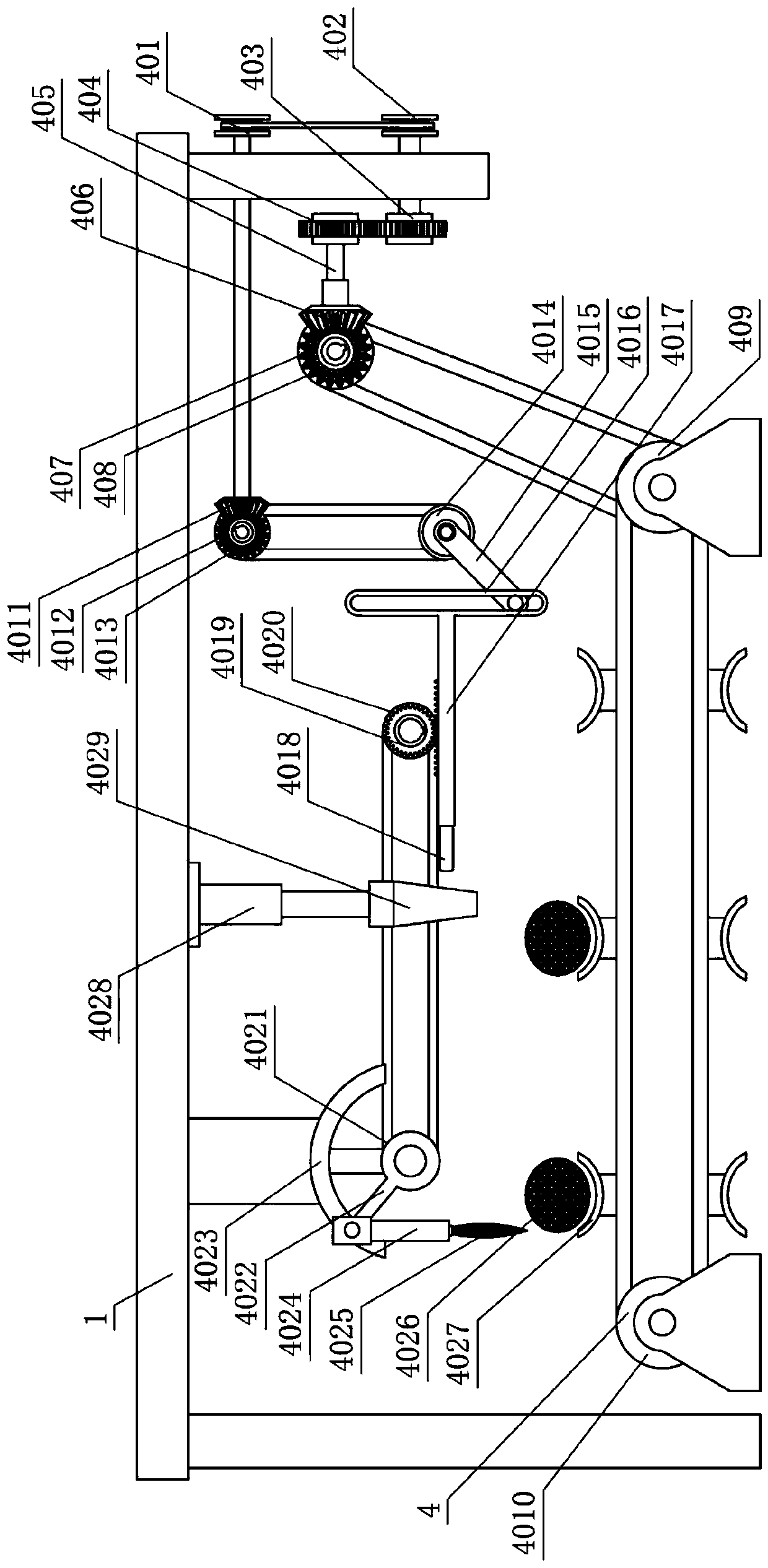

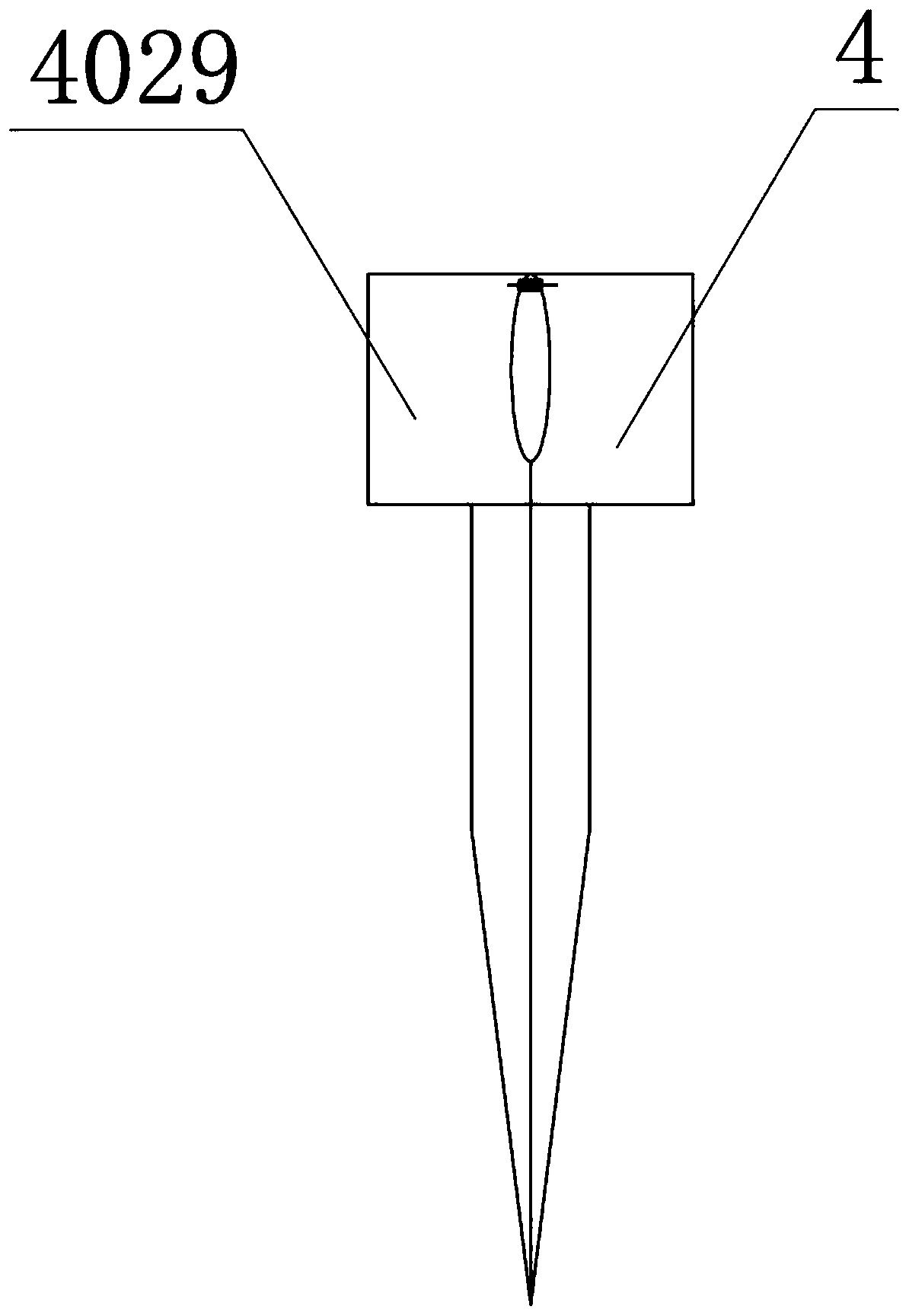

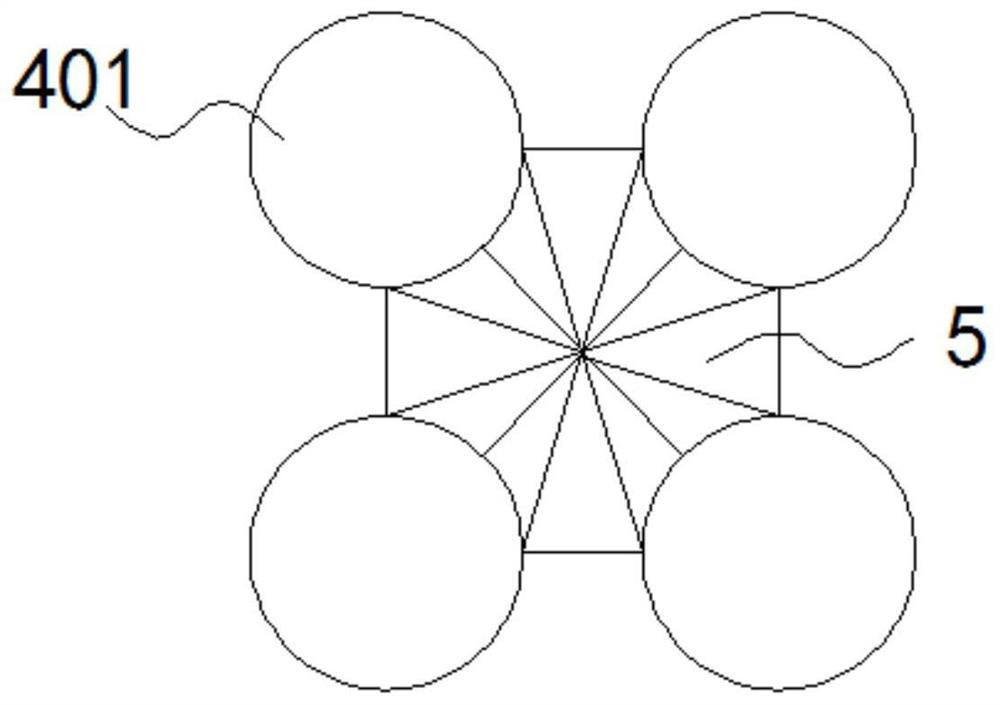

Grading type shelling and separating integrated machine for camellia oleifera fresh fruits based on multiple channels

PendingCN109007873AAvoid the problems of low cleaning rate and high damage rateImprove cleanlinessHuskingHullingCamellia oleiferaBiology

The invention discloses a grading type shelling and separating integrated machine for camellia oleifera fresh fruits based on multiple channels, and relates to shelling and separating equipment for the camellia oleifera fresh fruits as economic forest woody oil plant crops. The aim is to solve the problems that since the camellia oleifera fresh fruits are prone to being smashed during direct shelling, camellia seeds are high in loss, and since the sizes of the camellia oleifera fruits are different, the threshing rate of the camellia oleifera fruits is low, and camellia oleifera fruit shells and the camellia oleifera seeds are not ideal in separation effect during separation of fruit shell and the camellia seed mixtures. The grading type shelling and separating integrated machine comprisesa multi-channel sorting mechanism, a machine frame, a drive mechanism, a vibration sieving mechanism, two sets of seed and shell separation mechanisms, multiple hoppers and multiple shelling devices;the hoppers are fixed to the machine frame, each shelling device fixed to the machine frame is arranged below the corresponding hopper, the upper portion of each hopper corresponds to a sorting discharging port of the multi-channel sorting mechanism, each shelling device is driven by the drive mechanism, and a first discharging port is formed in the lower portion of each shelling device. The grading type shelling and separating integrated machine is suitable for shelling and shell and seed separating of the camellia oleifera fresh fruits.

Owner:HARBIN RES INST OF FORESTRY MACHINERY CHINA MIN OF FORESTRY

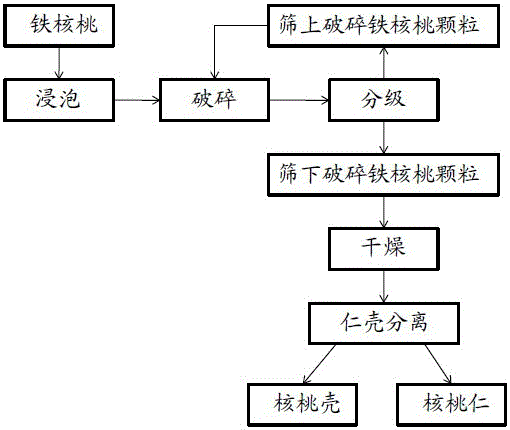

Method for crushing purely natural wild juglans sigillata and separating kernels from shells

The invention discloses a method for crushing purely natural wild juglans sigillata and separating kernels from shells. The method comprises the following steps of performing soaking: placing the juglans sigillata in clean water for soaking so as to obtain soaked juglans sigillata; performing crushing: placing the soaked juglans sigillata into a crushing machine for crushing so as to obtain crushed juglans sigillata granules of which kernels and shells are mixed; performing classifying: placing the crushed juglans sigillata granules of which the kernels and the shells are mixed into a sorting machine for sorting so as to obtain large crushed juglans sigillata granules on a sieve and small crushed juglans sigillata granules under the sieve; performing drying: performing drying treatment on the small crushed juglans sigillata granules under the sieve so as to obtain dried juglans sigillata granules of which the kernels and the shells are mixed; and performing kernel-shell separation: placing the dried juglans sigillata granules of which the kernels and the shells are mixed in a color selector for color selection separation so as to obtain separated juglans sigillata shells and juglans sigillata kernels. The method for crushing purely natural wild juglans sigillata and separating kernels the shells is simple in technology, safe, environmentally-friendly, convenient and high-efficient.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Flaxseed paste and its processing method

The invention discloses a flaxseed paste and a processing method. The processing method comprises the following steps: selecting fully ripe flaxseeds as raw materials; cleaning and frying the flaxseeds; then hulling the flaxseeds into a flaxseed and hull mixture by using a rubbing-type flaxseed huller; then separating the flaxseeds from hulls by using flaxseed and shell separation equipment; finally, further separating the hulls in the flaxseeds by using a color selector so as to make the hull content of the flaxseeds be controlled within 1 percent; frying the flaxseeds; then milling the flaxseeds into a paste body by using a stone mill; and packaging and sterilizing the paste body to form the flaxseed paste. The content of alpha-linolenic acid in the flaxseed paste processed by the invention reaches about 40 percent, and the content of protein reaches about 20 percent, and moreover, cyanogenic glycoside does not exist.

Owner:深圳市诚致生物开发有限公司

Preparation method and preparation device of peony seed blending oil with lipid-lowering health-care effect

InactiveCN104017641AImprove oil yieldLow priceFatty substance preservation using additivesFatty-oils/fats refiningDistilled waterOil water

The invention relates to a preparation method and a preparation device of edible blending oil and in particular relates to a preparation method of peony seed blending oil with a lipid-lowering health-care effect as well as a cold oil press for preparing the peony seed blending oil. The preparation method comprises the following steps: performing pretreatment comprising shelling and kernel-shell separation, on peony seeds, pressing the peony seeds obtained through the kernel-shell separation, performing one-step pressing during pressing, adding distilled water into the obtained oil residues, heating, performing ultrasonic shaking centrifugal treatment, sequentially adding water, heating and performing ultrasonic shaking centrifugal treatment, obtaining coarse oil, purifying the coarse oil, and finishing the pressing process. In the process flow, the used cold oil press comprises a feeding hole, a pressing chamber, a residue discharge channel, an oil outlet and a power device, and also comprises a centrifugal pan, an oil filter cover, a heating device, an ultrasonic source, an oil groove and an oil-water separation chamber. The peony seed blending oil prepared by the method is low in price, has effective lipid-lowering health-care effects during long-term eating and accords with the diet concept of modern people.

Owner:LUOYANG CHUNKUI AGRI DEV

Relief goods carrier based on gun launching

ActiveCN106005414AAchieve precise deliveryAchieve separationLaunching/towing gearLaunching weaponsTerrainComing out

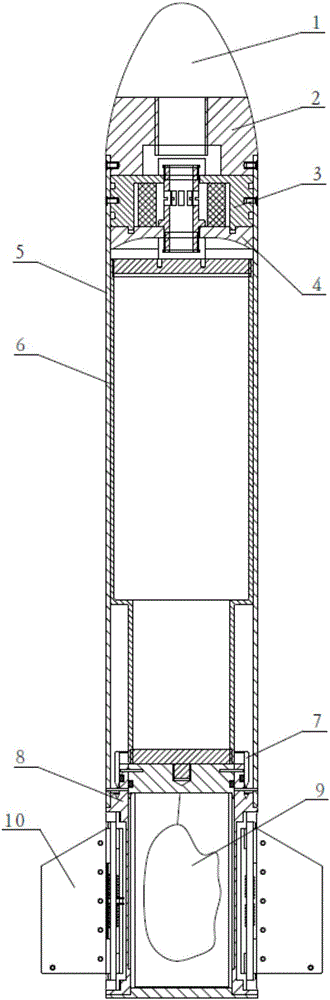

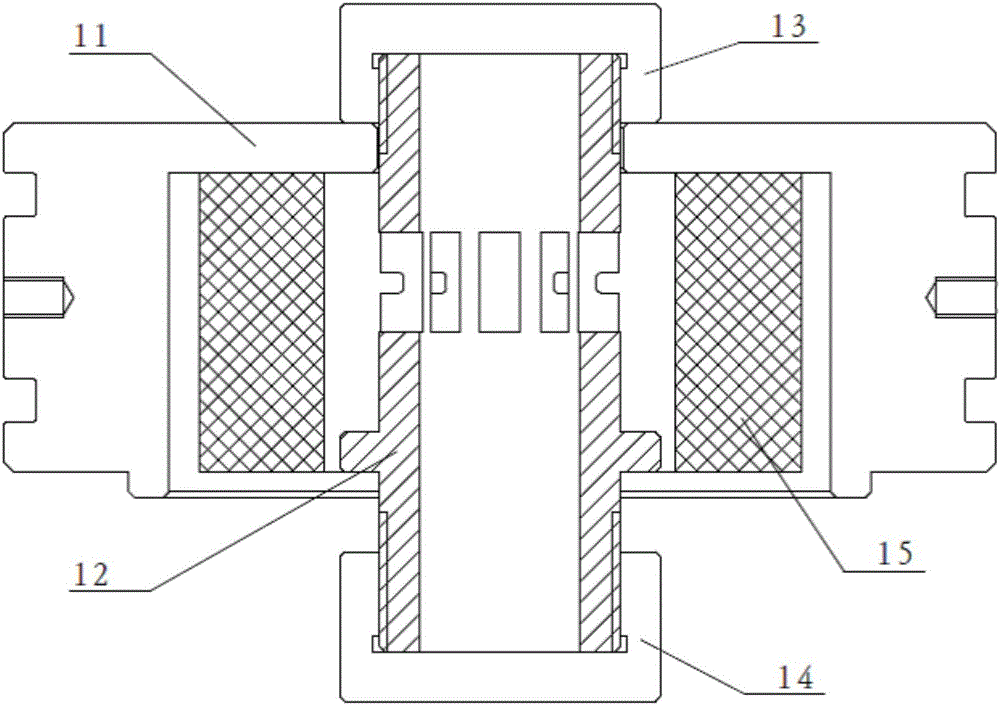

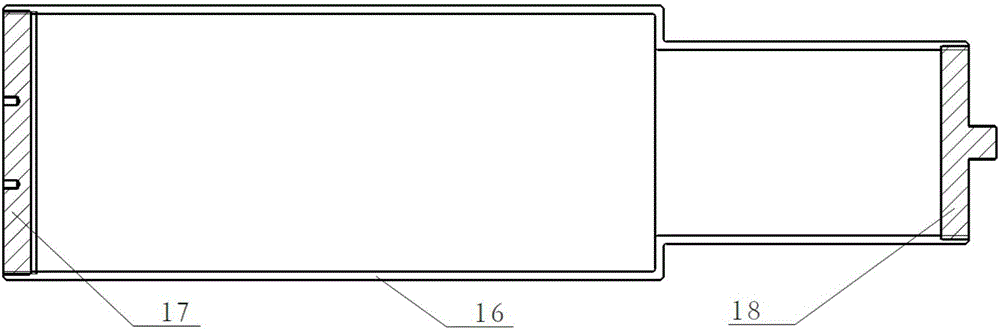

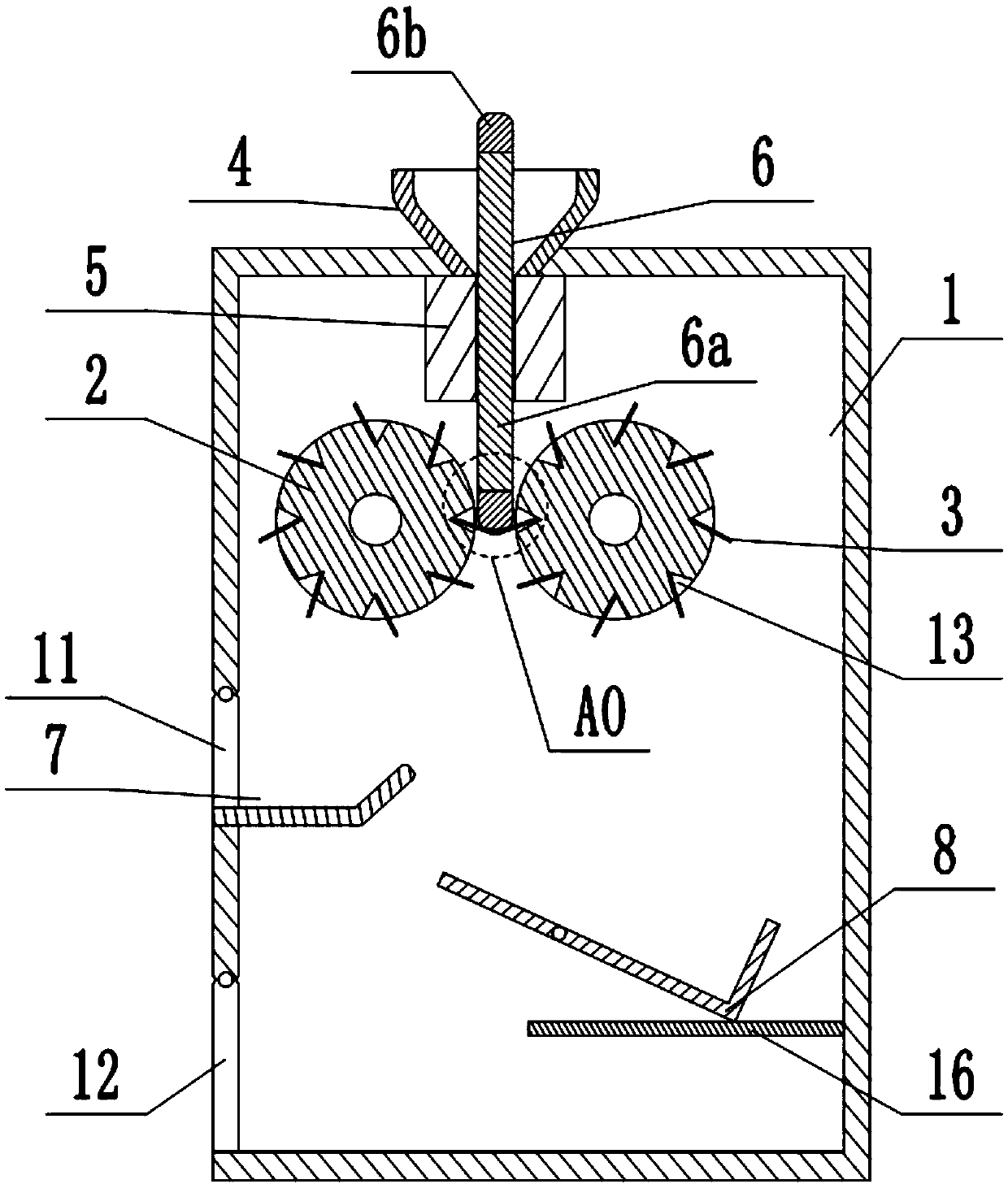

The invention relates to a relief goods carrier based on gun launching. The carrier comprises a hood (1), an electric initiating controller (2), a combustor component (3), a piston (4), a shell (5), an inner cylinder component (6), a shear ring (7), a chute compartment component (8), a brake parachute (9) and a stabilizer fin (10), wherein the inner cylinder component (6) contains and protects relief goods, the chute compartment component (8) contains the brake parachute (9), and the combustor component (3) is used for generating high pressure and enables the inner cylinder component (6) and the shell (5) to be separated while the brake parachute (9) comes out of the chute compartment component (8) smoothly. By the adoption of the carrier, long-distance and high-fall accurate delivery can be achieved under the condition of complex terrain and severe weather. The carrier is simple in structural design, brake parachute extraction and inner cylinder and shell separation can be achieved through one time of acting, and injuries to personnel and surroundings are avoided through reasonable utilization of initiating explosive devices.

Owner:BEIJING MECHANICAL EQUIP INST

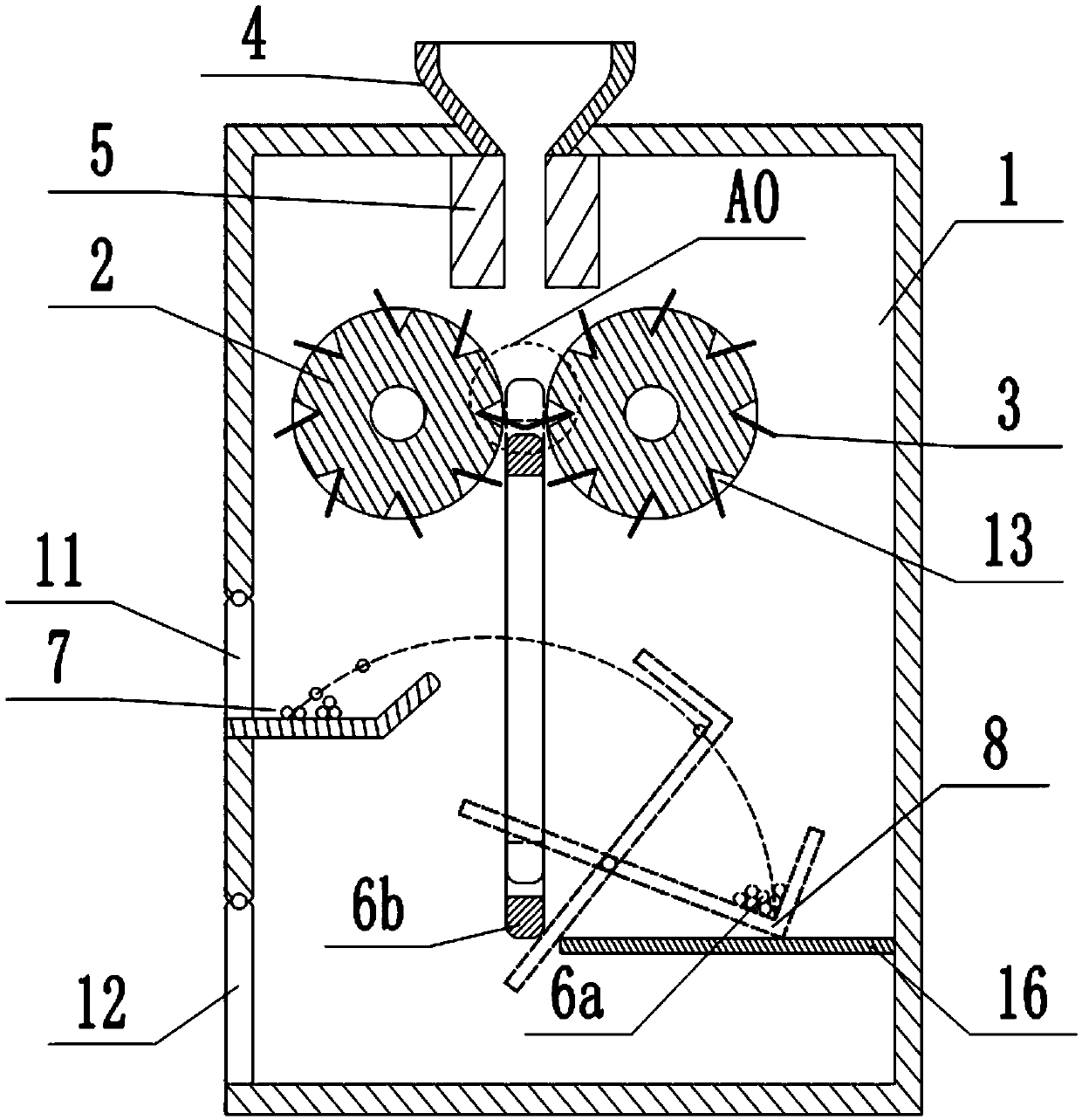

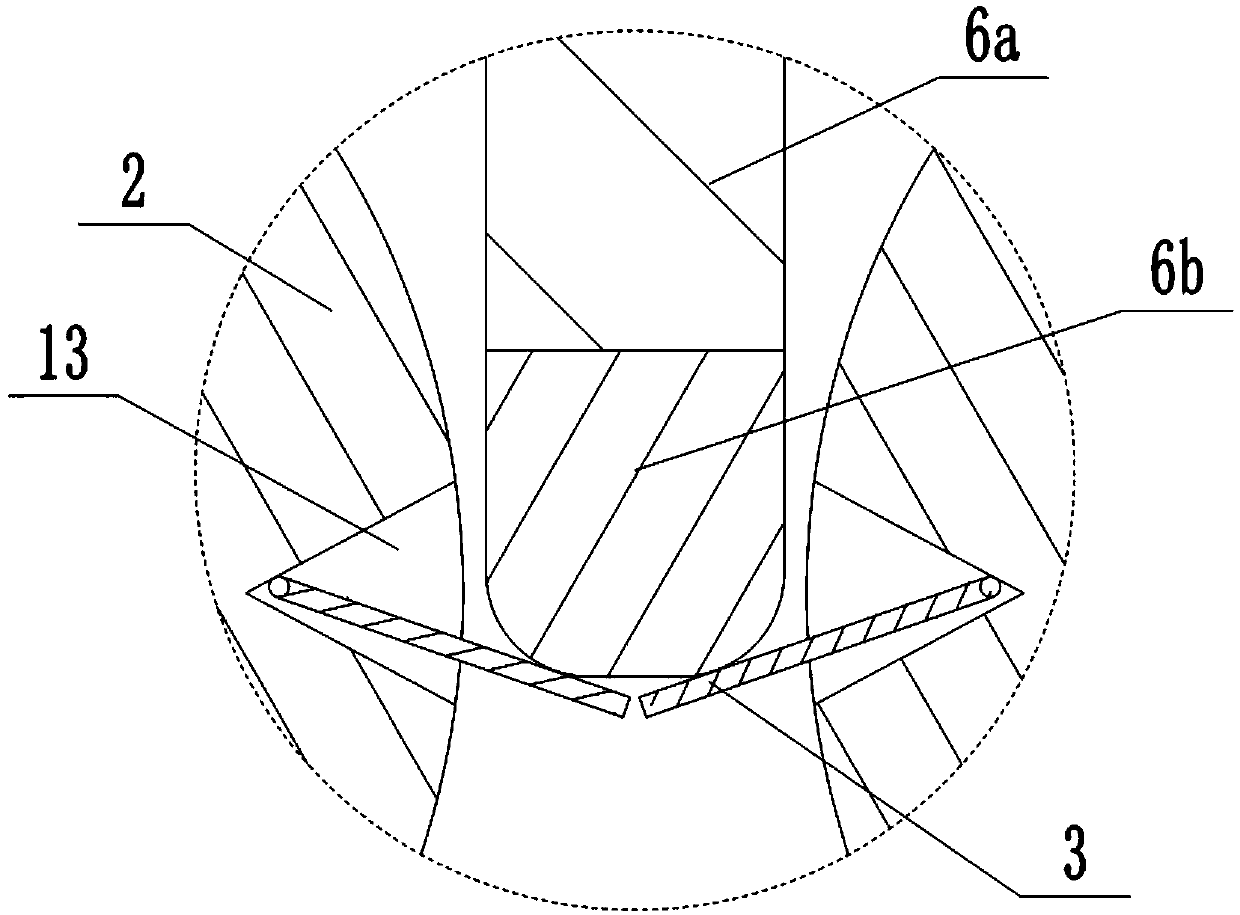

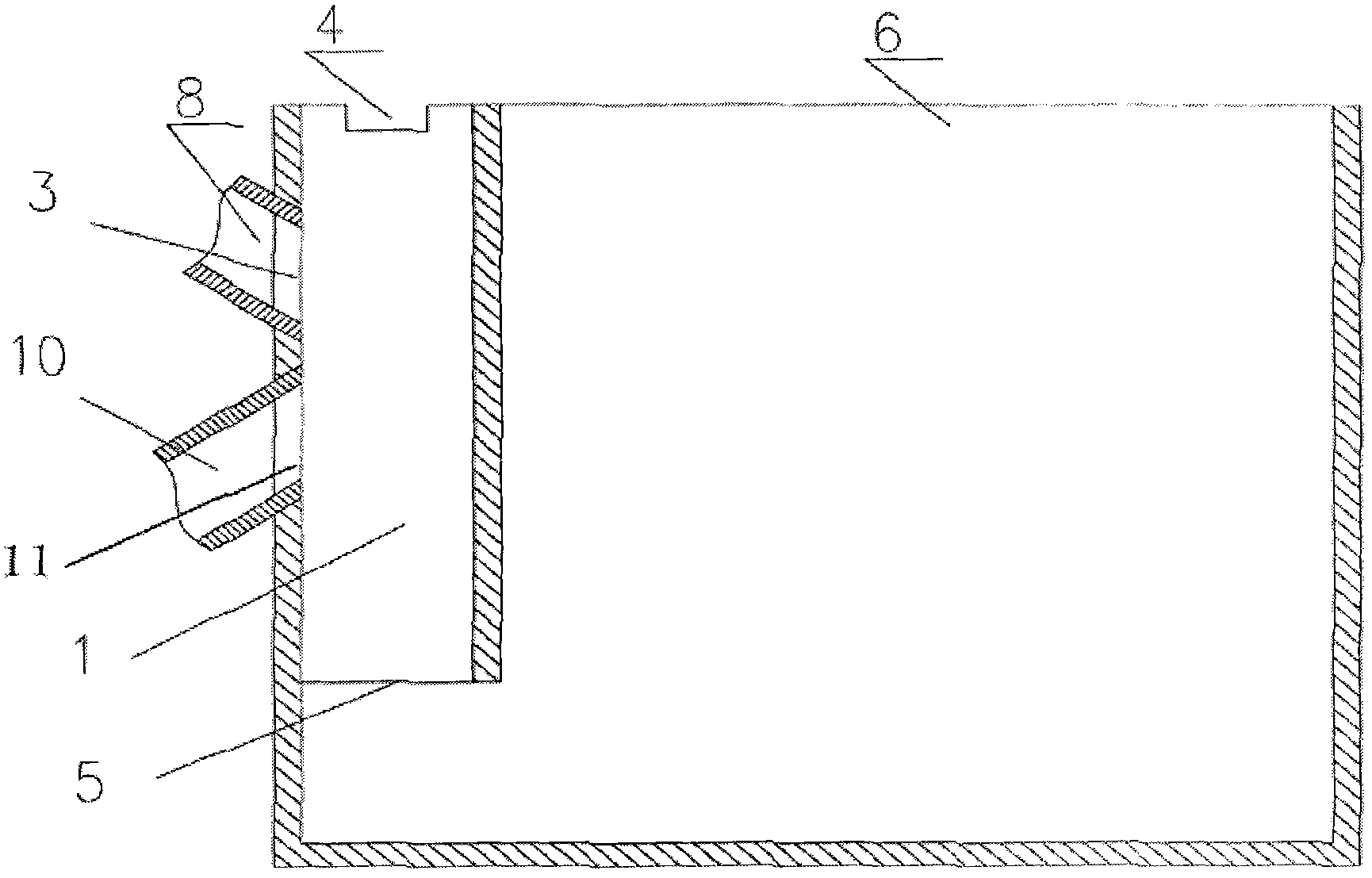

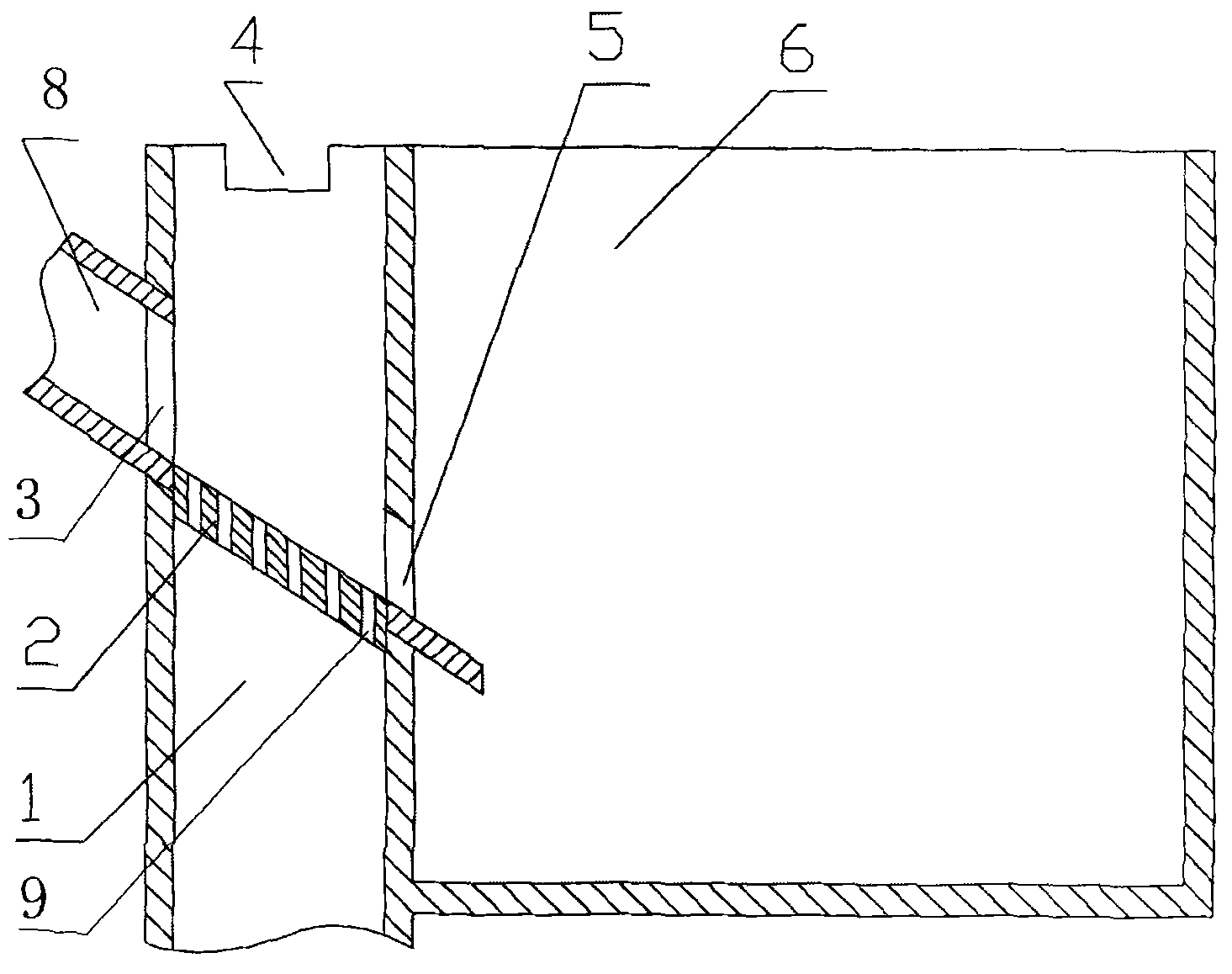

Waste electric appliance shell separation and recovery device

The invention relates to the technical field of metal recovery, in particular to a waste electric appliance shell separation and recovery device. The waste electric appliance shell separation and recovery device comprises a box body, a material inlet and a material outlet, and further comprises a collecting mechanism and two crushing rollers rotationally arranged in the box body; the two crushingrollers are parallel to each other and are located in the same plane; a first conical groove is uniformly distributed in the periphery of the crushing rollers, crushing nails are arranged in the firstconical groove, the crushing nails are hinged in the first conical groove, and the crushing nails on the two crushing rolls are correspondingly arranged; the collecting mechanism comprises a collecting frame and a swingable collecting plate; and the collecting frame and the collecting plate are both located below the crushing rollers. According to the technical scheme, when a metal frame of the waste electric appliance shell and non-metal materials are separated and crushed, the integrity of the metal frame is kept so that subsequent reutilization can be facilitated.

Owner:宁波隆锐机械制造有限公司

Method for removing shells from sea sand and a separation device using same

The invention provides a method for removing shells from sea sand and a separation device using the same. The invention combines the screening method and the hydraulic classification method and artificially makes a Newtonian fluid field, so that a dispersed phase (shells) and a continuous phase (sea sand) make relative movement in an artificial fluid field, and the shells are enabled to float upwards, thereby separating the shells from the sea sand. The separation device of the invention has the advantages of simple structure, low investment, low operating cost, favorable separating effect and long service life. By combining machinery and hydraulic power, the method has the advantages of low cost, no environment pollution; and by combining hydraulic classification and screening, the method can separate the shells from the sea sand, and has the advantages of low operating cost and favorable separating effect.

Owner:陈惠玲 +2

Automatic clam cleaning and meat-shell separation equipment and application method thereof

PendingCN109566709ASpeed up sand spitAdd block sand spit efficiencyBivalves processingClimate change adaptationSteam cookingElectric machine

The invention relates to the field of preparation of clams, in particular to automatic clam cleaning and meat-shell separation equipment. The equipment comprises a cleaning bin, a transition bin, a steam cooking device and a separation device, wherein the cleaning bin is arranged on the top of the transition bin and is communicated with the transition bin; the separation device comprises a separation barrel, a servo motor, a shedding mechanism and a translation mechanism which are arranged in the transition bin; the separation barrel is horizontally hinged with the upper part of the interior of the transition bin; the shedding mechanism and the servo motor are respectively arranged at the two ends of the separation barrel; the translation mechanism is arranged by the side of the servo motor; the cleaning bin is internally provided with a cover device; the steam cooking device comprises a steam generator, a steam inlet pipeline and a sewage discharge pipeline; the sewage discharge pipeline is communicated with the interior of the cleaning bin; and a steam outlet end of the steam generator is communicated with the interior of the cleaning bin through the steam inlet pipeline. According to the invention, the clams are effectively cleaned and then rapidly cooked for shell opening, and then the clams with shells opened in batches are subjected to meat-shell separation, so that product processing automation is realized, and product processing efficiency is further increased.

Owner:HALAODA FUJIAN FOOD

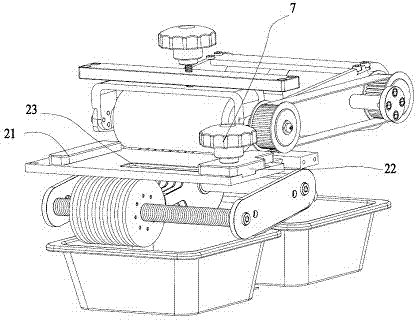

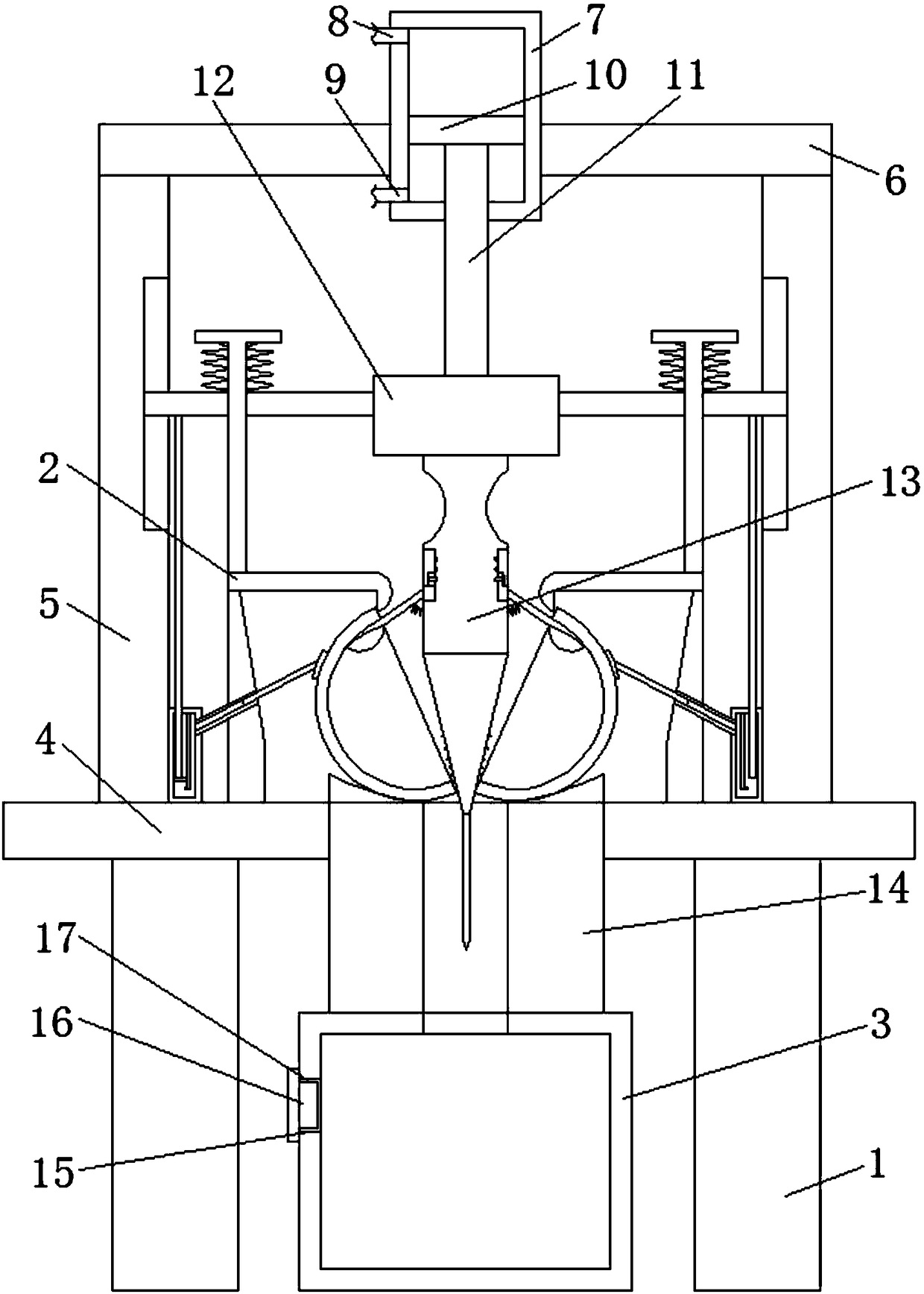

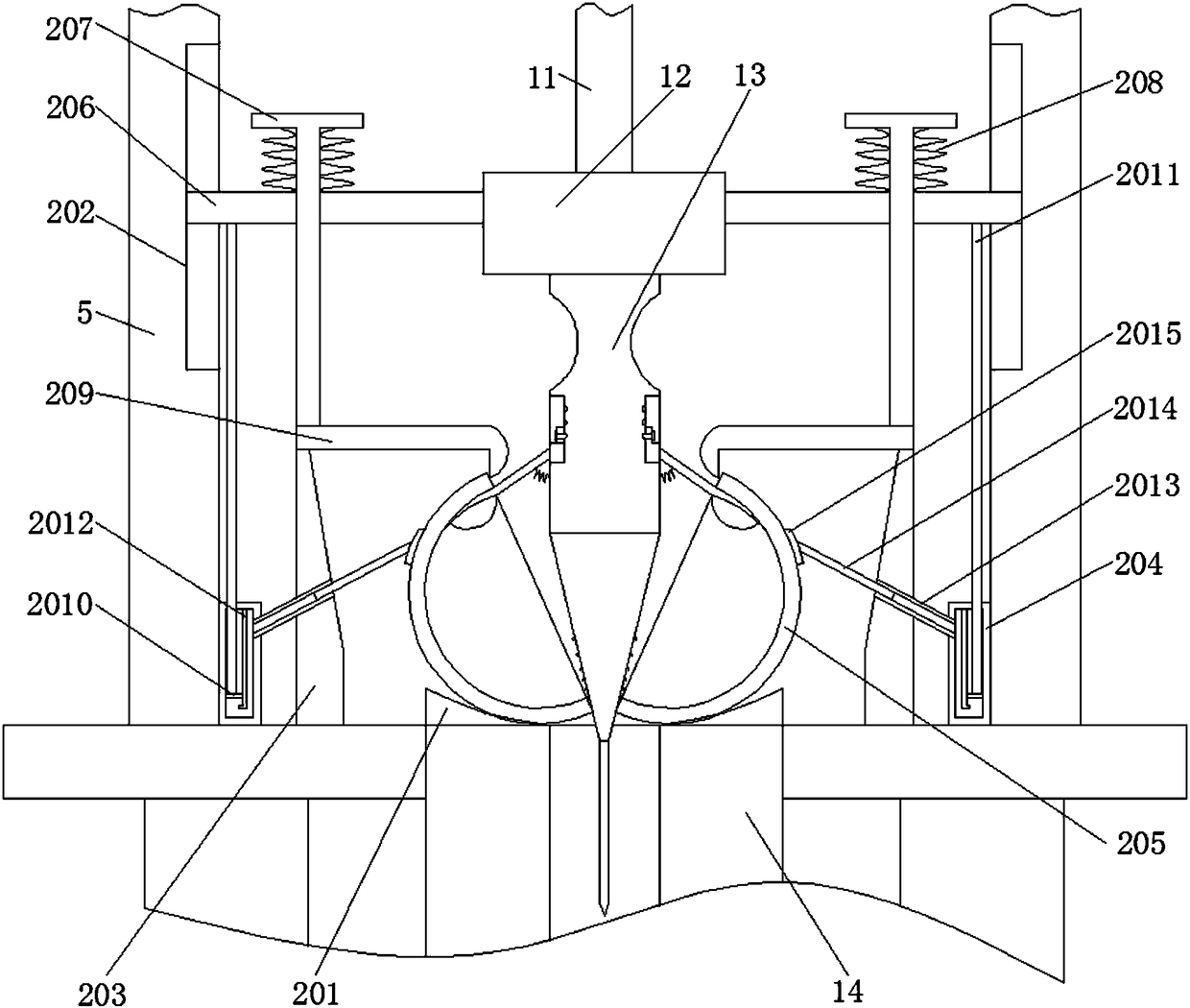

Mechanical Chinese chestnut sheller

InactiveCN113142604AImprove stabilityImprove environmental adaptabilityGas current separationHuskingEngineeringShell separation

The invention provides a mechanical Chinese chestnut sheller. The mechanical Chinese chestnut sheller comprises a rack, wherein a Chinese chestnut pretreatment device is fixed to the rack andused for separating Chinese chestnuts from Chinese chestnut packages and screening the separated Chinese chestnuts; a heating device used for heating the screened Chinese chestnuts to separate Chinese chestnut pulp from Chinese chestnut shells is further fixed to the rack; a scratch rubbing device is further arranged below the heating device, and comprises a disc with holes, a disc-shaped cutter and a first driving mechanism, and the first driving mechanism is used for driving the disc-shaped cutter to rotate in the circumferential direction to conduct scratch rubbing on the Chinese chestnuts; and the first driving mechanism is further used for driving the perforated disc to rotate in the circumferential direction, so that the Chinese chestnuts are gradually rotated below the disc-shaped cutter to be scratched and rubbed, and Chinese chestnut shells are broken after scratching and rubbing. According to the mechanical Chinese chestnut sheller provided by the invention, a mechanical method is adopted for shelling and is combined with a heating and vibrating method, so that the production efficiency is improved and the shelling rate of shelling is increased on the premise of not damaging the taste and integrity of kernels.

Owner:SHAANXI SCI TECH UNIV

An improved system for de-shelling cashew nut and a process thereof

InactiveCN107613792APrecise tearPrecise throwCharacter and pattern recognitionKitchen equipmentThermodynamicsSteam cooking

The present invention discloses an improved system with customized steam cooking, popping, tearing and shell separator mechanisms for de-shelling cashew nut and an improved process with customized steam cooking, popping, tearing and shell separator mechanisms for de-shelling cashew nut. The improved system comprises of: a main frame, a hopper, a feeding unit, a singulator unit, a main conveyor (horizontal or rotary), an optics unit, a customized steaming system, a customized popping system, a customized tearing system, a shell separator unit, and multiple collection units. The disclosed improved system provides accurate amount of pressurized steam to individual cashew nut according to their steam requirement, thereby enabling such customized steamed cashew nuts for accurate popping and accurate tearing each cashew nuts, thereby ultimately avoiding high cashew kernel breakage and providing high percentage of substantially whole kernel as a final product, moreover this kind of customizedsteaming adapted for steaming cashew nuts provide good quality of kernels which has high market value.

Owner:NANOPIX INTEGRATED SOFTWARE SOLUTIONS

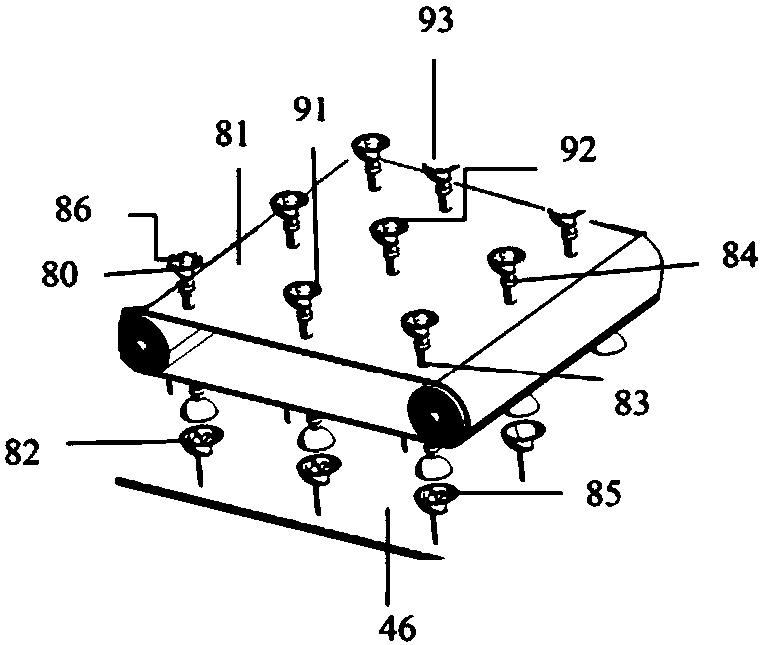

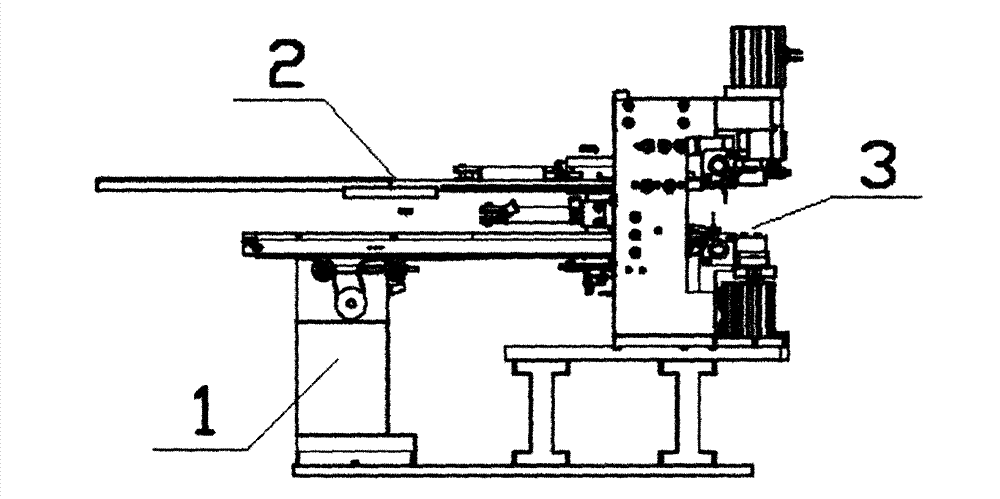

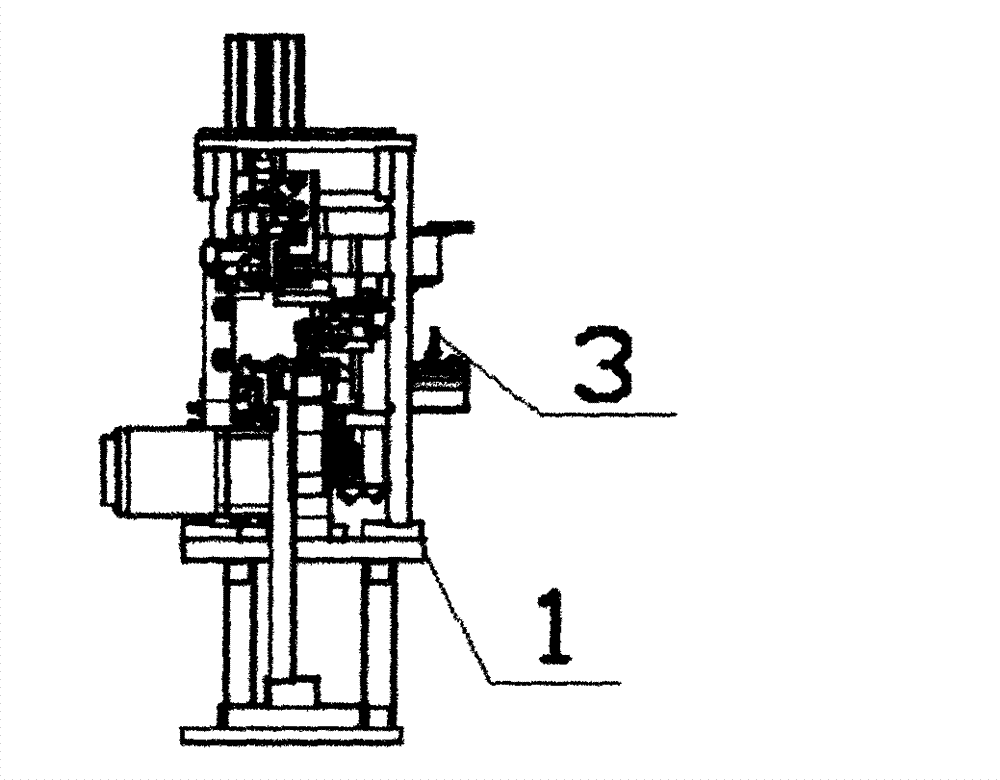

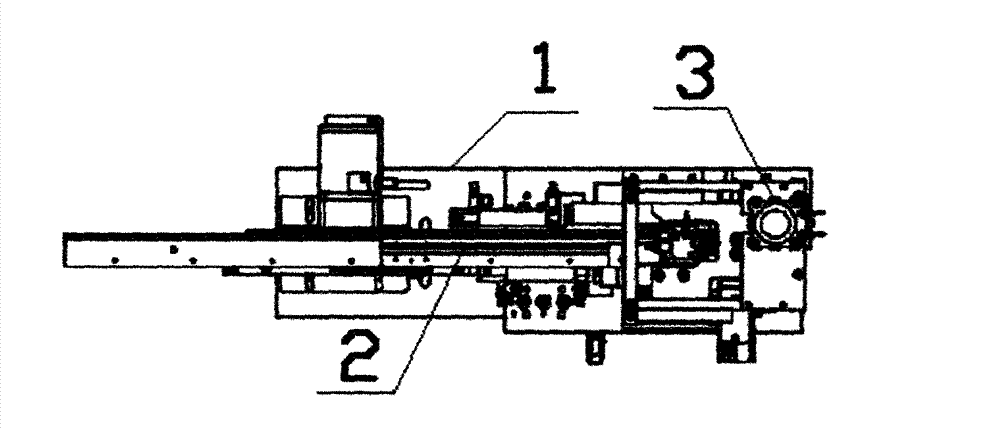

Medicine stripping machine

ActiveCN103158910AImprove efficiencyHigh speedArticle unpackingBiomedical engineeringShell separation

The invention provides a medicine stripping machine which comprises a medicine placing platform, a driving mechanism, a medicine pressing mechanism and a medicine shell separation mechanism. The medicine pressing mechanism is driven by the driving mechanism and arranged on one side of the medicine placing platform, and the medicine shell separation mechanism is arranged on the other side of the medicine placing platform. The medicine stripping machine automatically completes separation of drug packing, is high in efficiency and is rapid in speed.

Owner:SUZHOU IRON TECH

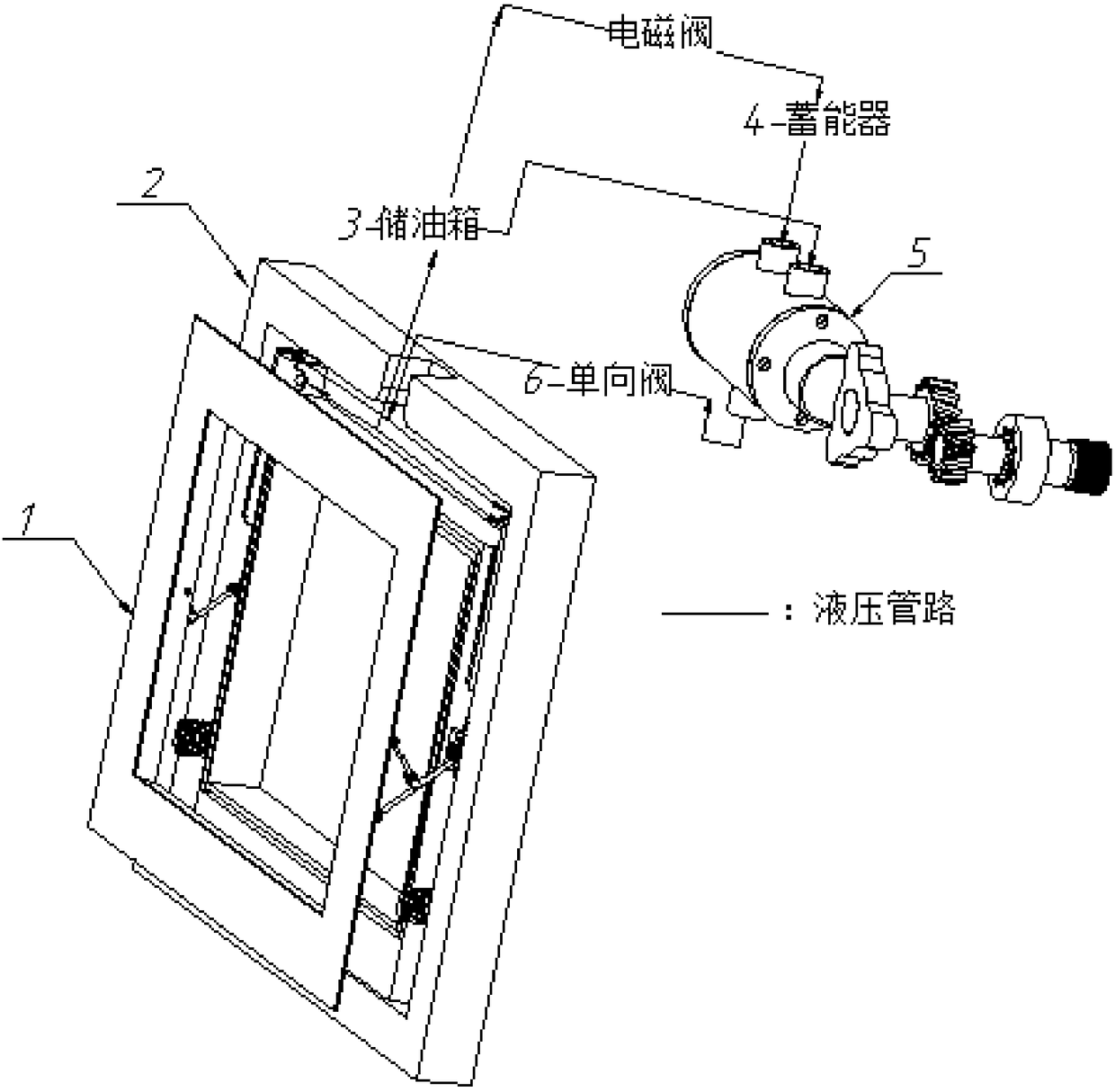

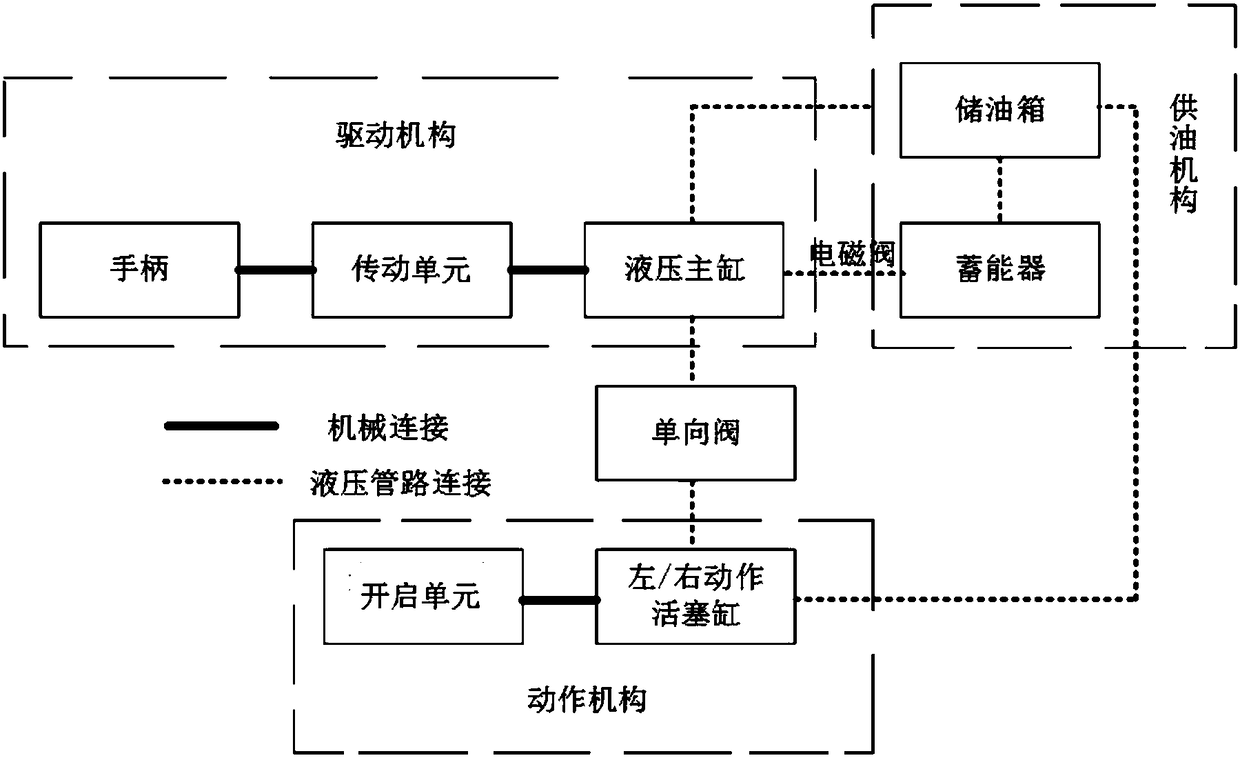

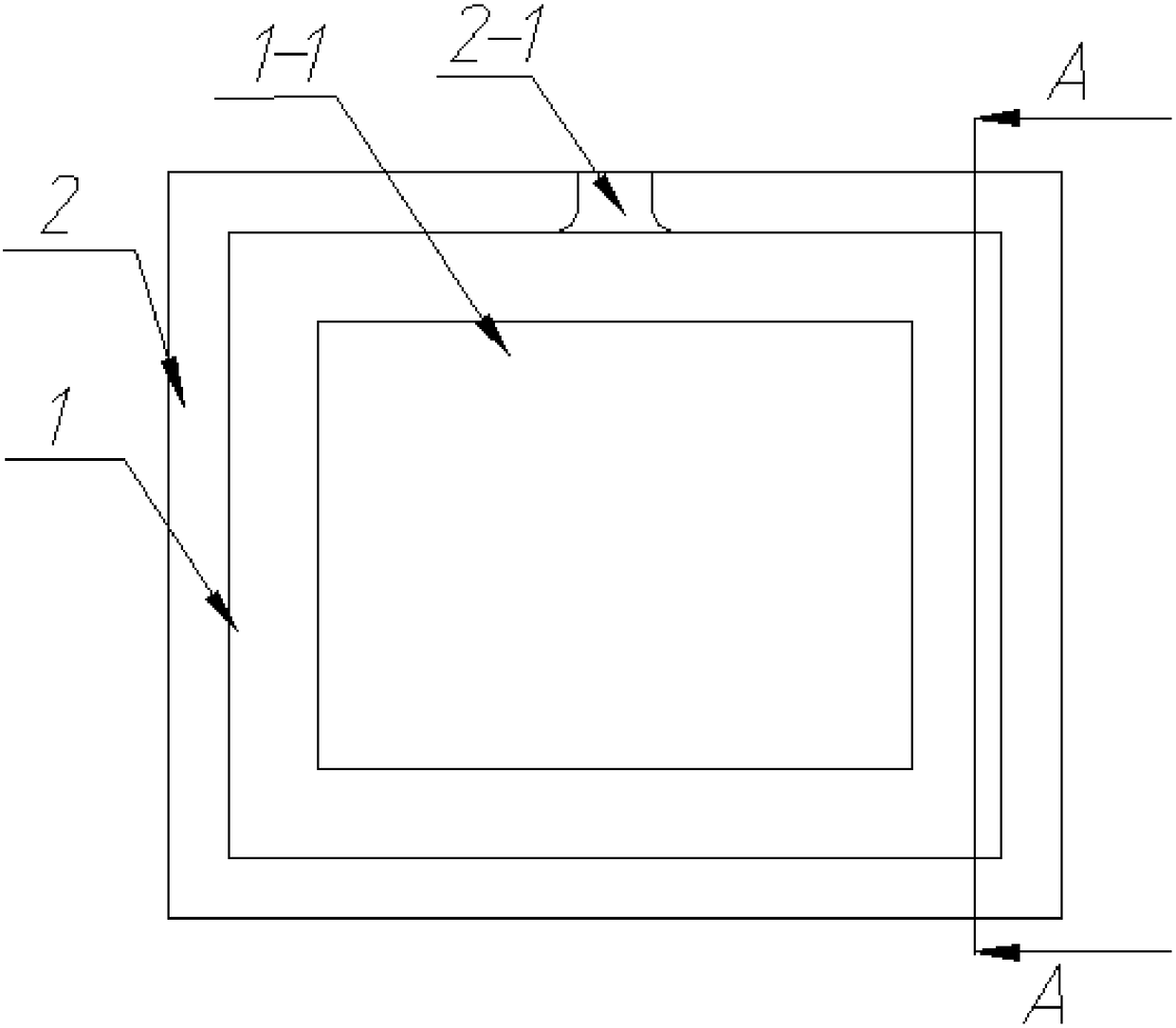

Hydraulic-driven type passenger car safety escape window

InactiveCN108590415AGuaranteed breakageGuaranteed SqueezePedestrian/occupant safety arrangementPower-operated mechanismMaster cylinderReciprocating motion

The invention relates to a hydraulic-driven type passenger car safety escape window. The hydraulic-driven type passenger car safety escape window is used for escape of passengers in emergency situations, and comprises a safety window shell, an action mechanism, a driving mechanism and an oil supply mechanism; the safety window shell is used for being separated in an emergency state so as to obtaina passenger safety escape channel; the action mechanism is used for separating the safety window shell, and providing the support for the safety window shell when the safety window shell is separated; the driving mechanism is used for providing continuous oil pressure, driving a hydraulic main cylinder to move in a reciprocating mode, and providing the safety window shell separation power; and the oil supply mechanism is used for storing the pipeline hydraulic oil and allowing the pipeline hydraulic oil to pass through so as to provide the initial power for separation of the safety window shell. Compared with an escape window in the prior art, the hydraulic-driven type passenger car safety escape window has the advantages that the degree of easiness in opening of a passenger car safety escape window in the emergency state is improved, meanwhile, the opening speed is increased, and then the escape possibility and the escape efficiency of passengers in a passenger car when the emergencysituation occurs are improved.

Owner:CHANGAN UNIV

Production method and preparation method for peony seed blending oil with liver protection effect

The invention relates to a production method and a preparation method for edible blending oil and provides a production method for peony seed blending oil with a liver protection effect and a cold oil press for preparing the peony seed blending oil. The production method comprises the following steps: carrying out pre-treatment of husking, kernel-shell separation and the like on peony seeds; pressing peony seed kernels obtained by the kernel-shell separation; adding distilled water into oil dreg obtained by first time of pressing in a pressing process and heating; carrying out ultrasonic concussion centrifugal treatment; then adding water, heating and carrying out the ultrasonic concussion centrifugal treatment to obtain crude oil; and carrying out purification to finish a pressing process. In the process, the used cold oil press comprises a feeding opening, a pressing chamber, a dreg discharging channel, an oil outlet and a power device, and is further provided with a centrifugal disc, an oil filtering cover, a heating device, an ultrasonic wave source, an oil groove, an oil-water separation chamber and the like; according to the peony seed blending oil prepared by the invention, the cost of the peony seed blending oil is low; the peony seed blending oil has the effect of effectively protecting liver when being eaten for a long time and meets the diet idea of modern people.

Owner:LUOYANG CHUNKUI AGRI DEV

Processing device of momordica grosvenori sweetening agent for toothpaste

ActiveCN111248454AAffect qualityAvoid irritationBioreactor/fermenter combinationsBiological substance pretreatmentsToothpasteTraditional medicine

The invention relates to toothpaste, in particular to a processing device of a momordica grosvenori sweetening agent for toothpastes. The technical problem to be solved by the invention is to providethe processing device of the momordica grosvenori sweetening agent for toothpastes. The processing device of the momordica grosvenori sweetening agent for toothpastes comprises a support frame, a control screen, a motor, a fruit shell separation mechanism, an impurity removal mechanism, an enzymolysis mechanism and a storage cabin; the control screen is arranged at the middle bottom of the left end in the support frame; the motor is arranged on the right of the top of the support frame; and the fruit shell separation mechanism is arranged at the left top in the support frame, and the middle ofthe right end of the fruit shell separation mechanism is connected to the motor. The device achieves the effects that momordica grosvenori shells and pulp are separated, and prevents acidic substances in the shells from influencing the quality of the sweetening agent. meanwhile, the separated shells can be used as medicine after impurities carried by fluff on the outer surfaces are removed, enzymes with a tongue numbing effect in the pulp are removed, and the stimulation effect on the oral cavity is avoided.

Owner:江苏罗来雅实业股份有限公司

Peanut shell separator

InactiveCN104799401AAvoid it happening againGood for healthHuskingHullingBiotechnologyStructural engineering

The invention discloses a peanut shell separator, which comprise a barrel, wherein one side of the top end of the barrel is provided with a feeding inlet, two shell crushing rollers arranged side by side are arranged below the feeding inlet, sprinkler heads are arranged between the shell crushing rollers and the feeding inlet, a discharging plate inclined downwards is arranged below the shell crushing rollers, a shell collecting barrel and a peanut collecting barrel are arranged below the end, extending out of the barrel, of the discharging plate, the shell collecting barrel close to the end, extending out of the barrel, of the discharging plate, a fan is arranged on the top end of the peanut collecting barrel and is located at one side opposite to the position where the shell collecting barrel located, and the air outlet of the fan faces the shell collecting barrel. The peanut shell separator provided by the invention has the advantages that the dust is prevented from generating during the peanut production process, so as to protect environment and beneficial to the health of workers, moreover, the structure is simple, the production and maintenance are facilitated, the fault is less likely to occur; through the design of the fan, the separating efficiency of peanuts and shells is improved.

Owner:LIUZHOU SANNONG TECH

Flesh-shell separator for industrial processing of yellow passion fruits in passion fruits

The invention provides a flesh-shell separator for industrial processing of yellow passion fruits in passion fruits, and relates to the field of fruit processing. The flesh-shell separator comprises supporting legs, a flesh-shell separation supporting mechanism and a flesh juice storage tank, wherein a flesh-juice separation supporting plate is soldered on surfaces of the supporting legs; a side plate is soldered on the surface of the flesh-juice separation supporting plate; a supporting top plate is soldered on the surface of the side plate; and a hydraulic cylinder is arranged on the surfaceof the supporting top plate in a penetrating manner. According to the flesh-shell separator for industrial processing of yellow passion fruits in passion fruits, a flesh-shell separation supporting body has a hollow-square shaped surface, a round passion fruit can be positioned conveniently due to the square opening, and flesh can conveniently slide from the inside of the flesh-shell separation supporting body to the inside of the flesh-juice storage tank, so that the problems that plenty of manpower is required for removing flesh from passion fruits, the processing speed is relatively low, and labor cost is high can be effectively solved.

Owner:付明贵

Domestic full-automatic poached egg frying machine

The invention discloses a domestic full-automatic poached egg frying machine. By means of the domestic full-automatic poached egg frying machine, material supply, oil adding, egg-shell separation, shell throwing and frying are finished though one button. The complicated procedures of starting cooking fire, and frying and baking in smoky oil in a daily domestic egg frying process are removed, and what is only needed is to put multiple raw eggs on the machine and start the button, and according to the taste selection which is set in advance, frying is automatically completed within 3-7 min. Evenkids can make breakfast by themselves, the traditional egg frying process is thoroughly replaced, the operation of frying eggs becomes very simple, smoke is avoided, the taste of different personnelcan be met, and the operation strength of a person is lowered; meanwhile, in the frying process, the person can do other things, and the domestic full-automatic poached egg frying machine is high in automated degree and can meet the requirements of different people.

Owner:张宥

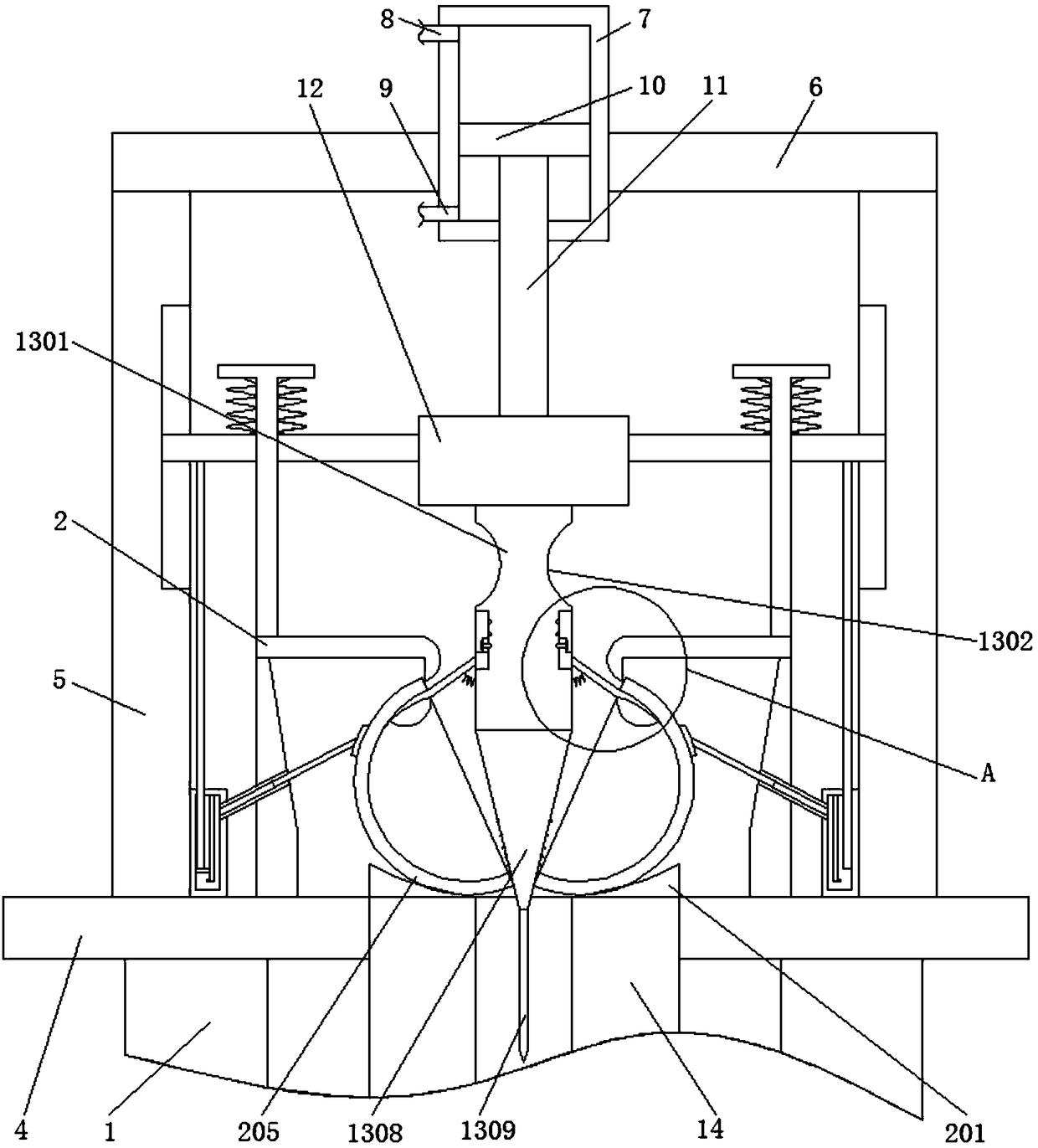

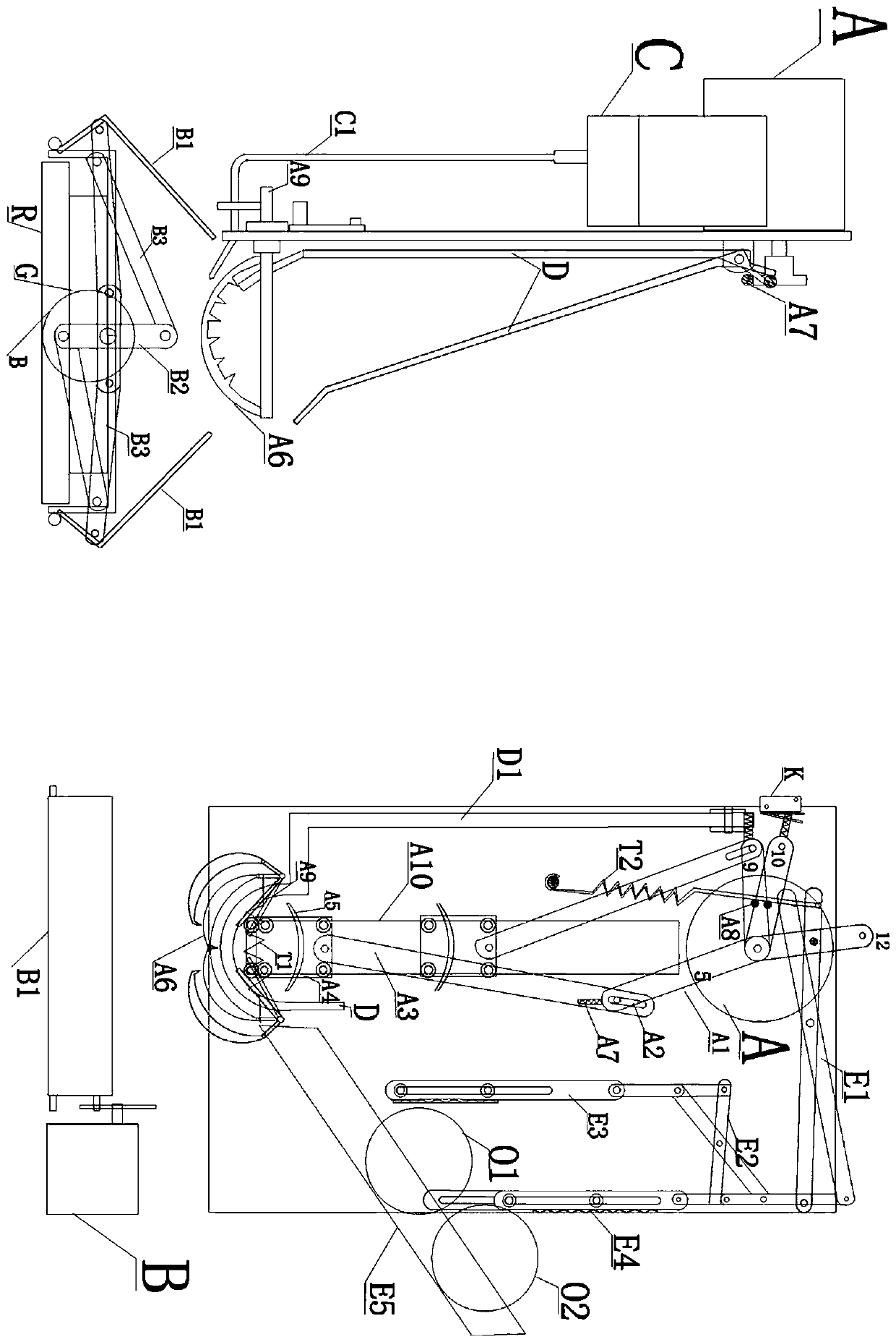

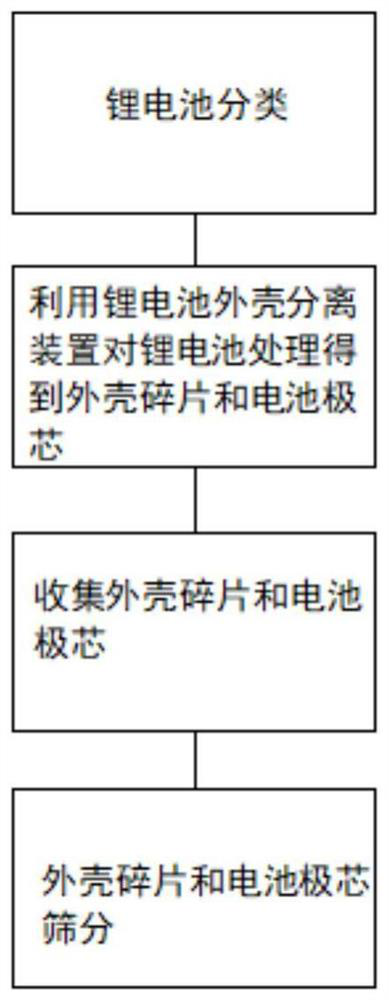

Efficient separation and recovery process for lithium battery

ActiveCN111653845AHigh efficiency of separation and recoveryReduce difficultyWaste accumulators reclaimingBattery recyclingPhysical chemistryBattery cell

The invention discloses an efficient separation and recovery process for lithium batteries. The efficient separation and recovery process comprises the following steps: 1, classifying the shapes of collected waste lithium batteries; 2, removing the shell of the lithium battery by using a lithium battery shell separation device; 3, collecting shell fragments and battery pole cores falling from thelithium battery shell separation device by using a collector; and 4, filtering the shell fragments and the battery pole core by using a vibrating screen device to finish separation and recovery of theshell material and the battery pole core. According to the method, firstly, collected waste lithium batteries are subjected to shape classification to classify cylindrical lithium batteries, and thecylindrical lithium batteries are subjected to special separation, so that the separation and recovery efficiency is improved. And secondly, the lithium battery shell is vertically cut and beveled byutilizing the lithium battery shell separation device, so that the lithium battery shell is in a sheet shape, the lithium battery shell is conveniently separated from the battery pole core, the laterrecovery difficulty is reduced, and the separation and recovery efficiency is improved.

Owner:广西华政新能源科技有限公司

Automatic assembly and automatic ultrasonic machine for data line plastic shell

InactiveCN103199405AImprove product qualityEasy to operateContact member assembly/disassemblyProduction rateManufacturing data

The invention discloses an automatic assembly and automatic ultrasonic machine for a data line plastic shell. The automatic assembly and automatic ultrasonic machine for the data line plastic shell comprises a base station and automatic machining devices arranged on the base station. Each automatic machining device comprises a plastic shell separation mechanism, a plastic shell assembly mechanism and an automatic ultrasonic device. Before the plastic shell is separated, vibrating disks are installed to carry out material separation on an upper plastic shell body and a lower plastic shell body, and the vibrating disk, the plastic shell separation mechanism, the plastic assembly mechanism and the automatic ultrasonic device are integrated into a set of the automatic machining device. The automatic machining devices are installed on the base station as two sets, the AM automatic machining device is arranged on the upper-left side of the base station, and the BM automatic machining device is arranged on the right side of the base station. By utilization of mechanical automatic machining, required assembly and die assembly operations of the data line plastic shell are finished, the trouble that in the prior whole process, manual operation is carried out is saved, the operation is simple, a data line only needs to be inserted into a corresponding position, normal and stable production can be achieved, compared with the manual operation, the automatic assembly and automatic ultrasonic machine for the data line plastic shell reduces a large amount of labor and improves working efficiency, and the manufactured product is stable in quality.

Owner:NINGBO BROAD TELECOMM

Roller type fruit shell separating machine

The invention relates to the field of fruit shell separation equipment, and discloses a roller type fruit shell separating machine. The roller type fruit shell separating machine comprises a machine frame and a material conveying belt, and further comprises at least one roller which is arranged above the material conveying belt and stretches across the width direction of the material conveying belt, needle thorns are arranged on the peripheries of the rollers so as to pierce fruit shells on the material conveying belt and perform subsequent separation when the rollers rotate, the rotating direction of the rollers is the same as the running direction of the material conveying belt, and a distance is formed between the free end of each needle thorn on the rollers and the surface of the material conveying belt; and the roller type fruit shell separating machine further comprises slag discharging mechanisms which are arranged corresponding to the rollers, and the slag discharging mechanisms can strip the fruit shells on the needle thorns of the rollers. According to the fruit shell separating machine, the concept that a traditional fruit shell separating machine needle thorn plate is used for sorting shells through up-and-down periodic movement is subverted, then the mode by which the needle thorns are fully distributed on the surfaces of the rollers which do rotating motion, so that sorting of the fruit shells is always carried out through the needle thorns on the mixed fruit shell materials on the material conveying belt in the rotating process of the rollers, the material conveying belt can be used for continuous conveying, the needle thorns are orderly and densely arranged on the rollers, so that the separation efficiency and the separation rate of the fruit shells areensured.

Owner:HUNAN DASANXIANG TEA OIL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com