Roller type fruit shell separating machine

A separator and drum-type technology, applied in the direction of solid separation, classification, chemical instruments and methods, etc., can solve the problems of easy failure, high manufacturing cost, complex structure of the separator, etc., and achieve high efficiency and good shelling effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

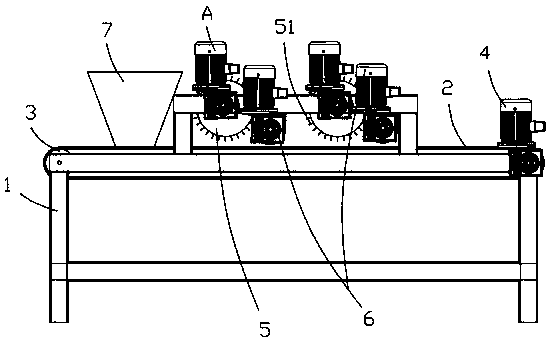

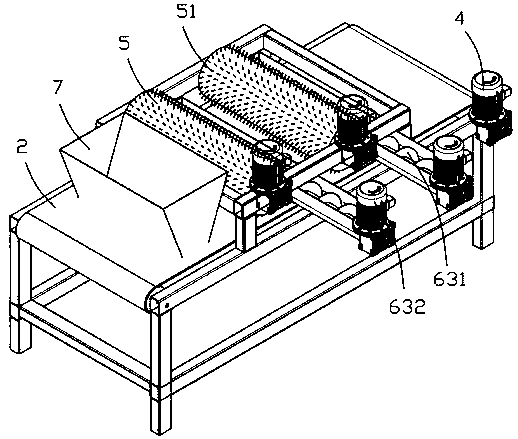

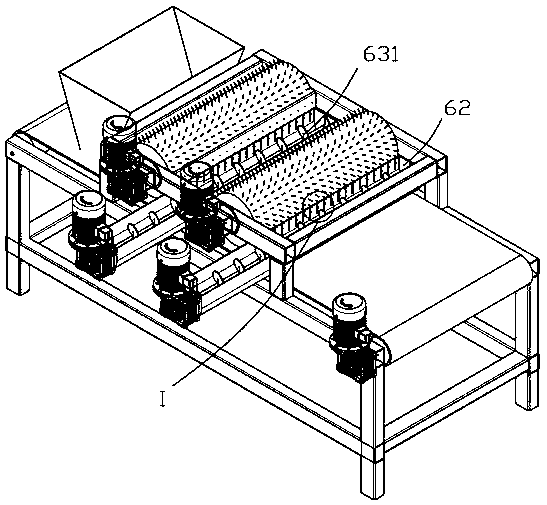

[0027] Provide a drum type husk separator, such as Figure 1 to Figure 3 Shown, it comprises frame 1, and frame 1 is provided with the conveying belt 2 that is used to transport the mixed fruit shell material, and the conveying process of conveying belt 2 is identical with the belt conveying in the prior art, is formed by two rollers Driven by 3, the rollers are driven by motor 4, one is a driving roller and the other is a passive roller. There are two rollers 5 side by side above the conveyor belt 2 across the width direction of the conveyor belt. There is a certain distance between the two rollers 5. Each roller is driven by a motor A to rotate. Hard needles are arranged on the outer periphery of the rollers 5. Thorn 51 is carried out follow-up separation in the fruit shell thorn on the conveying belt so that cylinder rotates, and the direction of rotation of cylinder 5 is identical with the running direction of conveying belt 2 (that is, when conveying belt is conveyed cloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com