Integrated coaxial recycling serial connection type high-efficiency cyclone separator

A technology of cyclone separator and recirculation, which is applied in the direction of cyclone devices and devices in which the axial direction of the cyclone can be reversed, etc., can solve the problems of long gas flow path, small split diameter, and reduced separation efficiency, and achieve gas flow The effect of short path, stable gas flow field and less space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

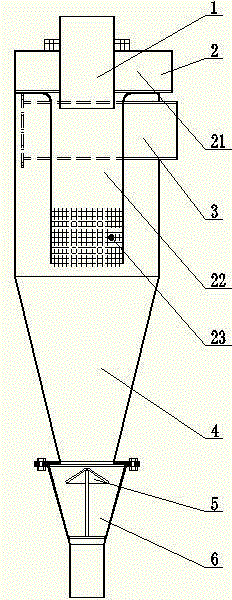

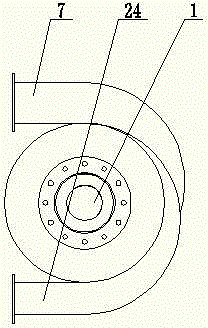

[0016] The present invention comprises a main casing 4, an air inlet pipe 7, an exhaust pipe 1 and a discharge bin 6, and a backflow device 2 is also provided on the top of the main casing 4, and the backflow device 2 includes a backflow pipe 24, a backflow volute 21 and a backflow pipe 21 connected to the backflow The inner cylinder 22 at the lower end of the volute 21, the inner cylinder 22 is coaxially arranged with the main casing 4 and the exhaust pipe 1; Body 4 is connected to form intake volute 3 . A vortex stabilizer 5 is arranged in the discharge bin 6; the lower wall of the inner cylinder 22 is a mesh 23-like structure.

[0017] During work, the dust-containing gas is positively input by the intake pipe 7 of the present invention, and is accelerated through the intake volute 3 and introduced into the straight barrel section of the main housing 4 for rapid rotation and downward movement. When the dust-containing gas enters the lower part of the main housing 4 The int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com