Patents

Literature

215results about How to "Guaranteed separation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

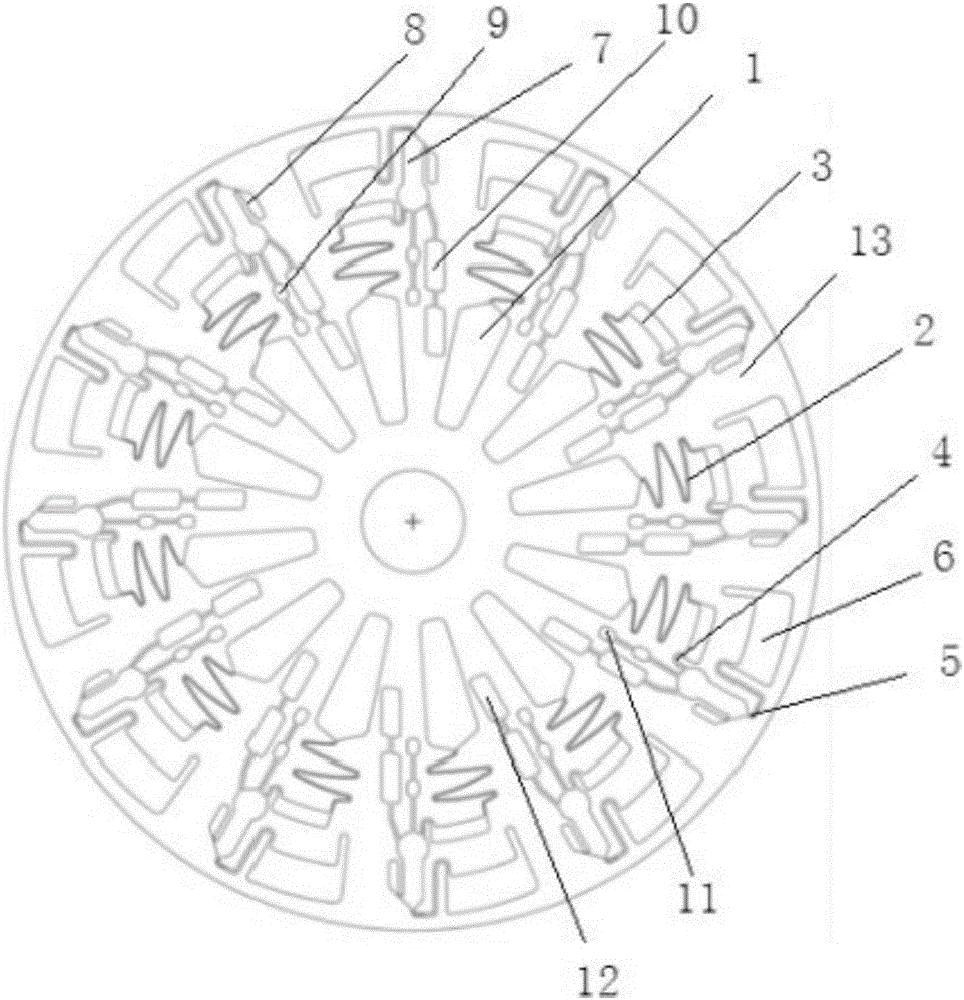

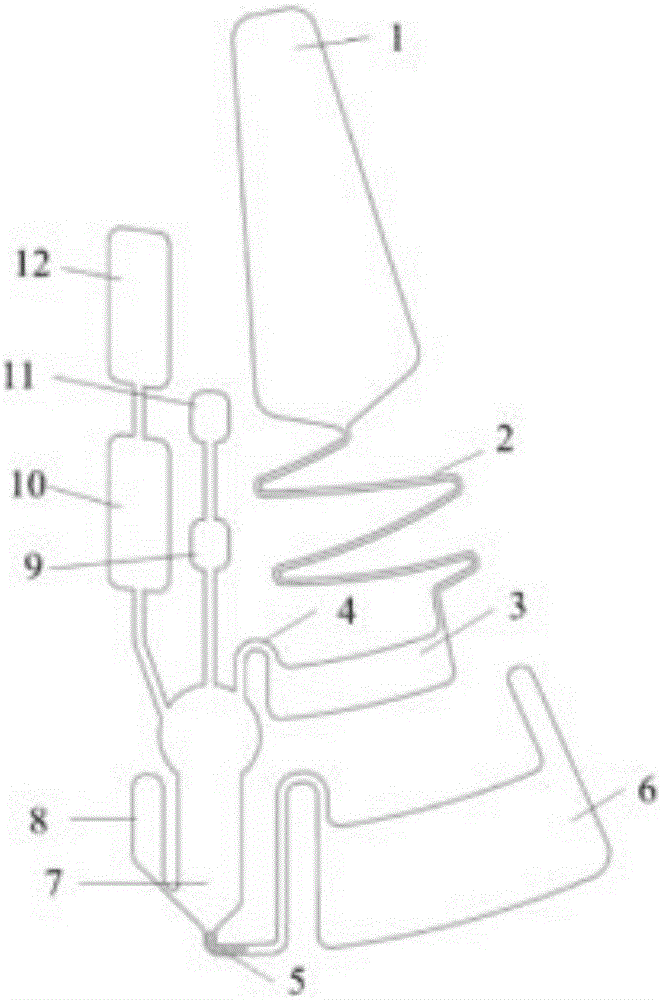

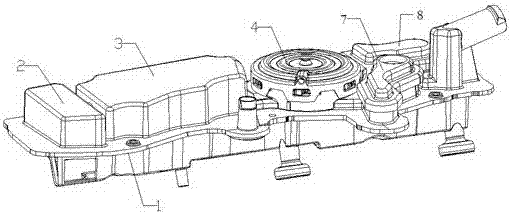

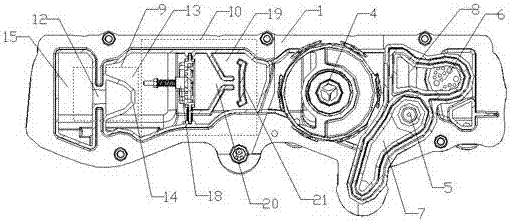

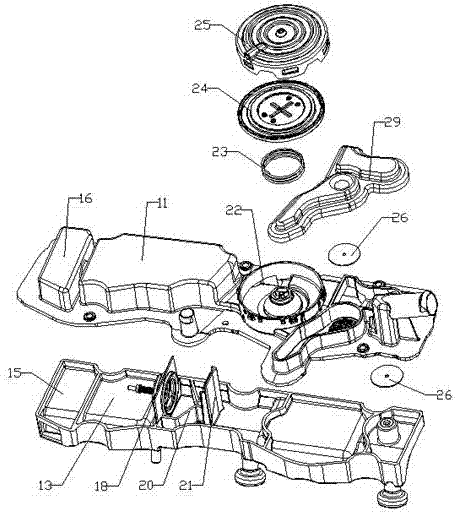

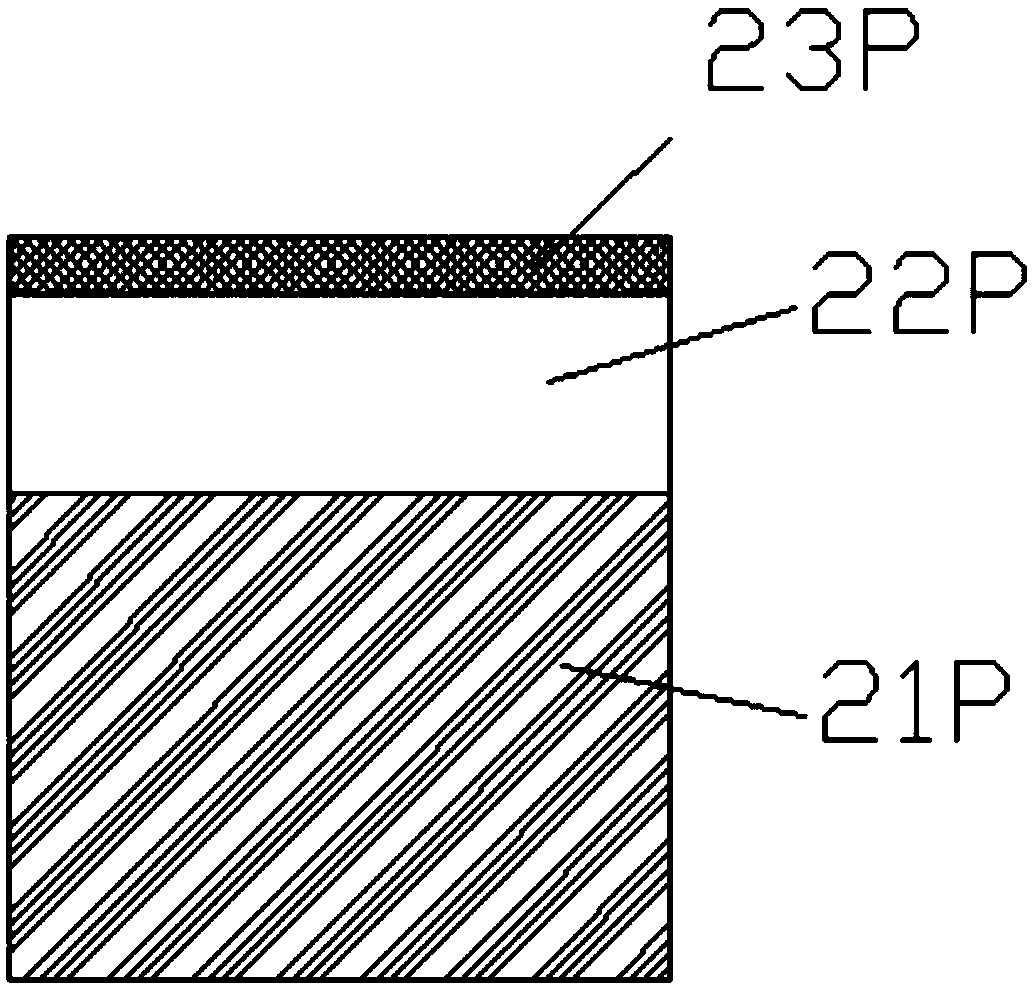

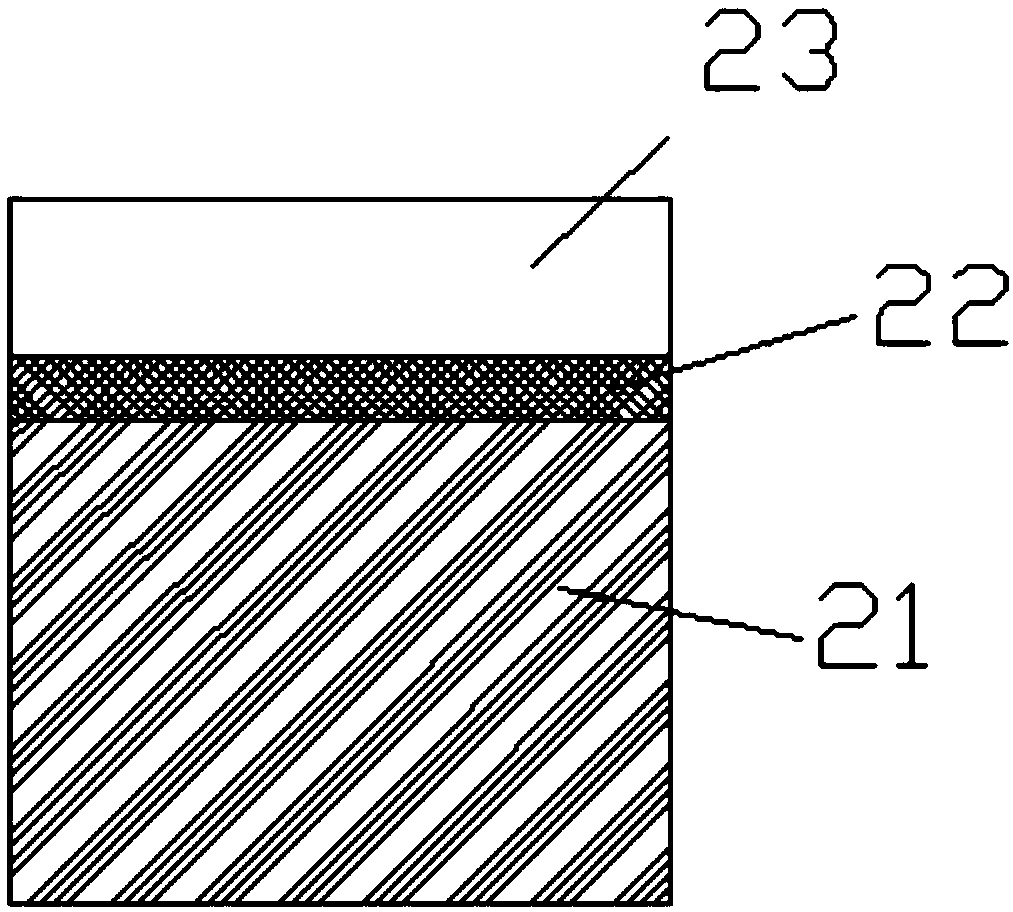

Microfluidic chemiluminescence immune detection device and use method thereof

ActiveCN105842468AEnsure Quantitative EffectGuaranteed separation efficiencyMaterial analysisEngineeringBlood plasma

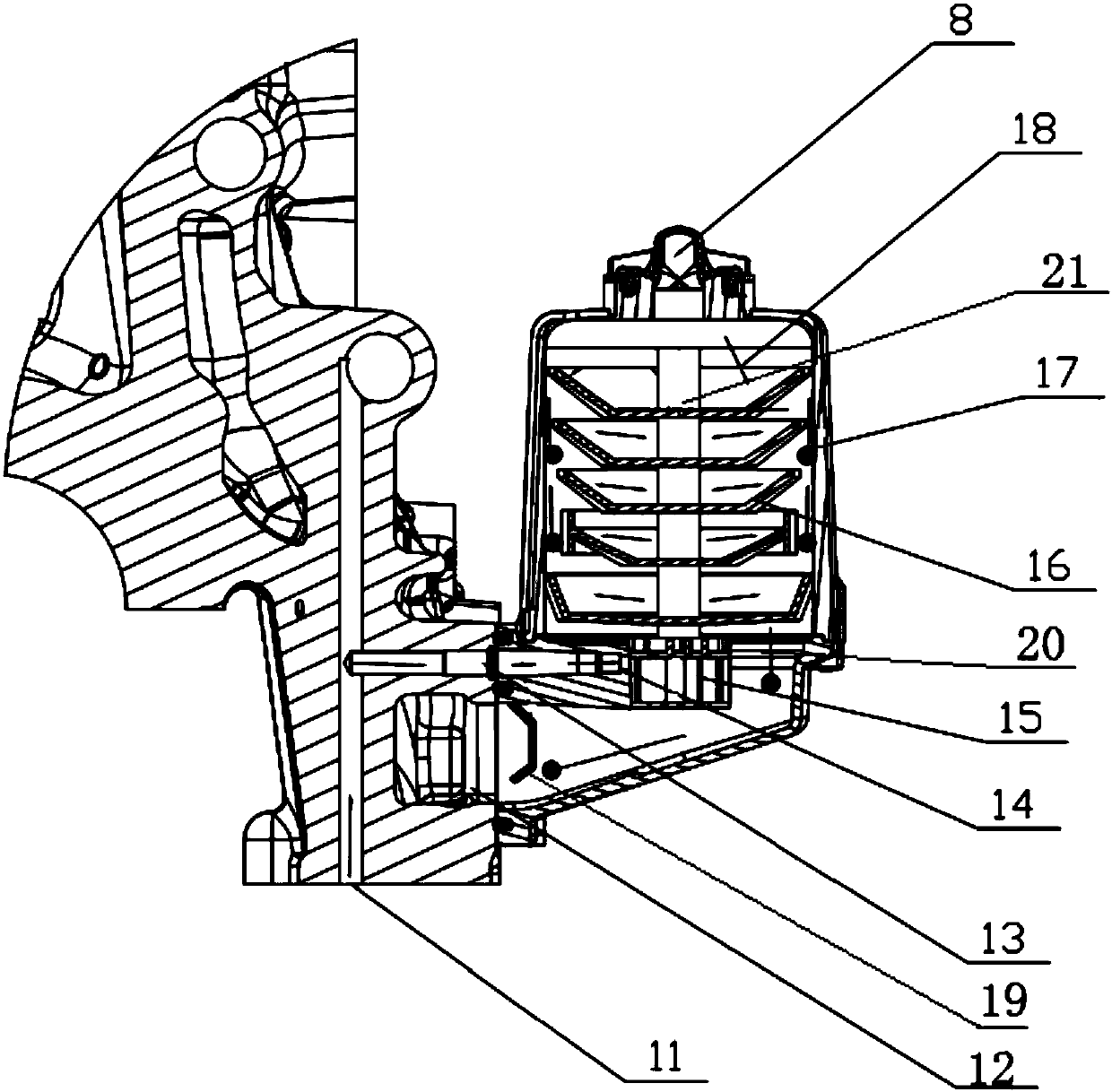

The invention discloses a microfluidic chemiluminescence immune detection device and a use method thereof. The microfluidic chemiluminescence immune detection device comprises a microfluidic disc which is provided with a microflow detecting unit, the microflow detecting unit comprises a whole blood injection tank, a whole blood separation channel, a blood cell storage tank, a plasma conveying runner, a mixing / detecting tank, a first reagent storage tank, a cleaning liquid injection tank, a gas compressing and releasing tank, a waste liquid tank, a second reagent storage tank and a fourth reagent storage tank. Micro fluid in the microfluidic disc can be intelligently controlled through a simple method, meanwhile, reaction liquid can be fully mixed, it is guaranteed that a reaction system is carried out efficiently, and quantitative detection of hCG concentration in a sample is fast achieved. The advantages of being easy to operate, high in detecting sensitivity, accurate and reliable in result, good in repeatability and low in cost are achieved.

Owner:ZHEJIANG PUSHKANG BIOTECHNOLOGY CO LTD

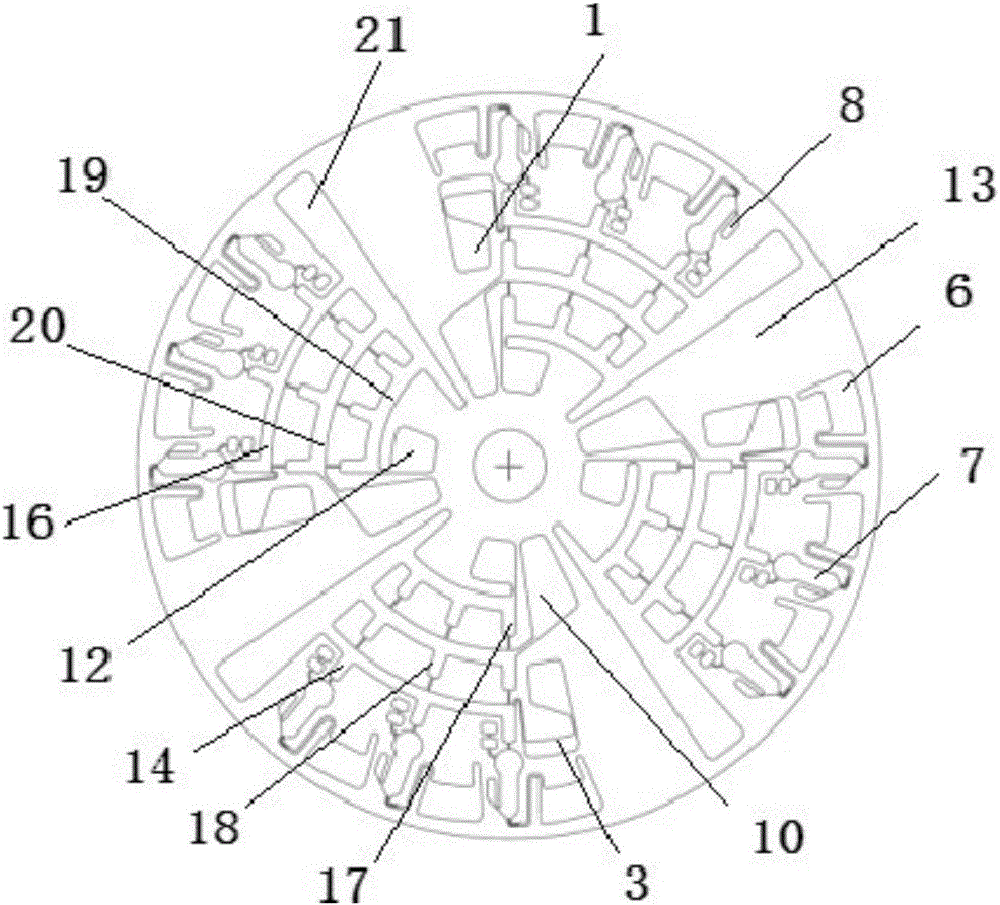

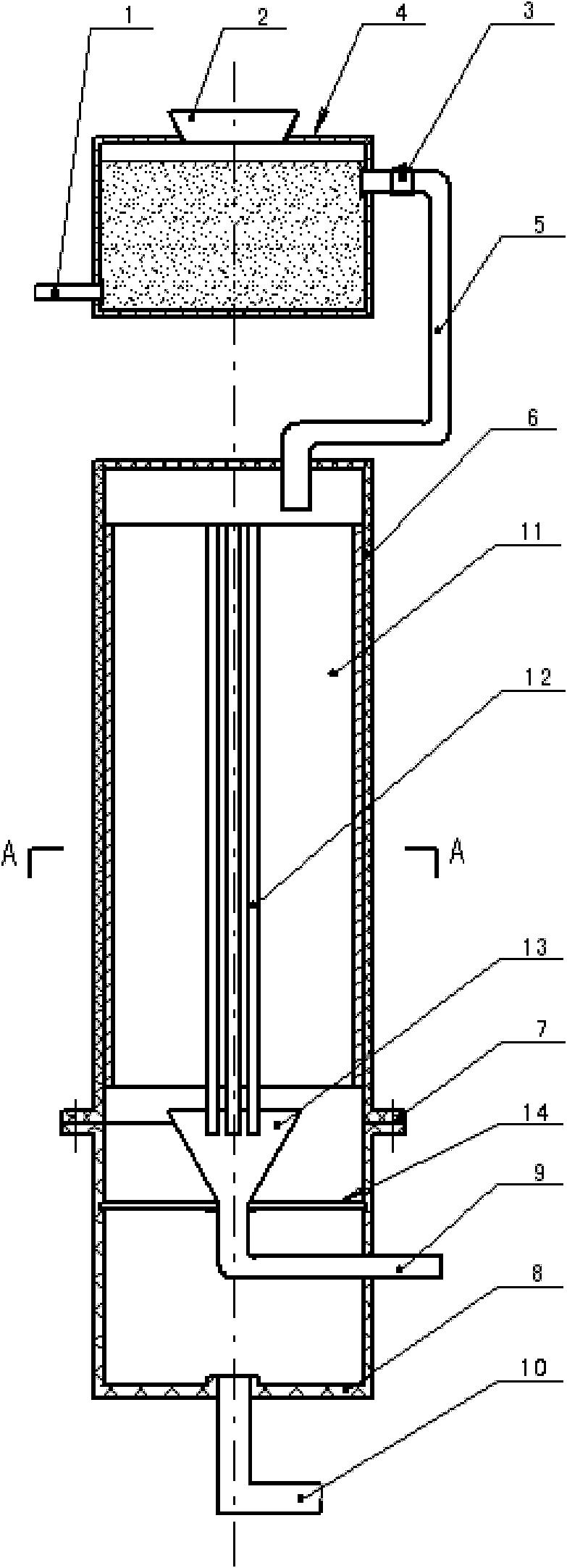

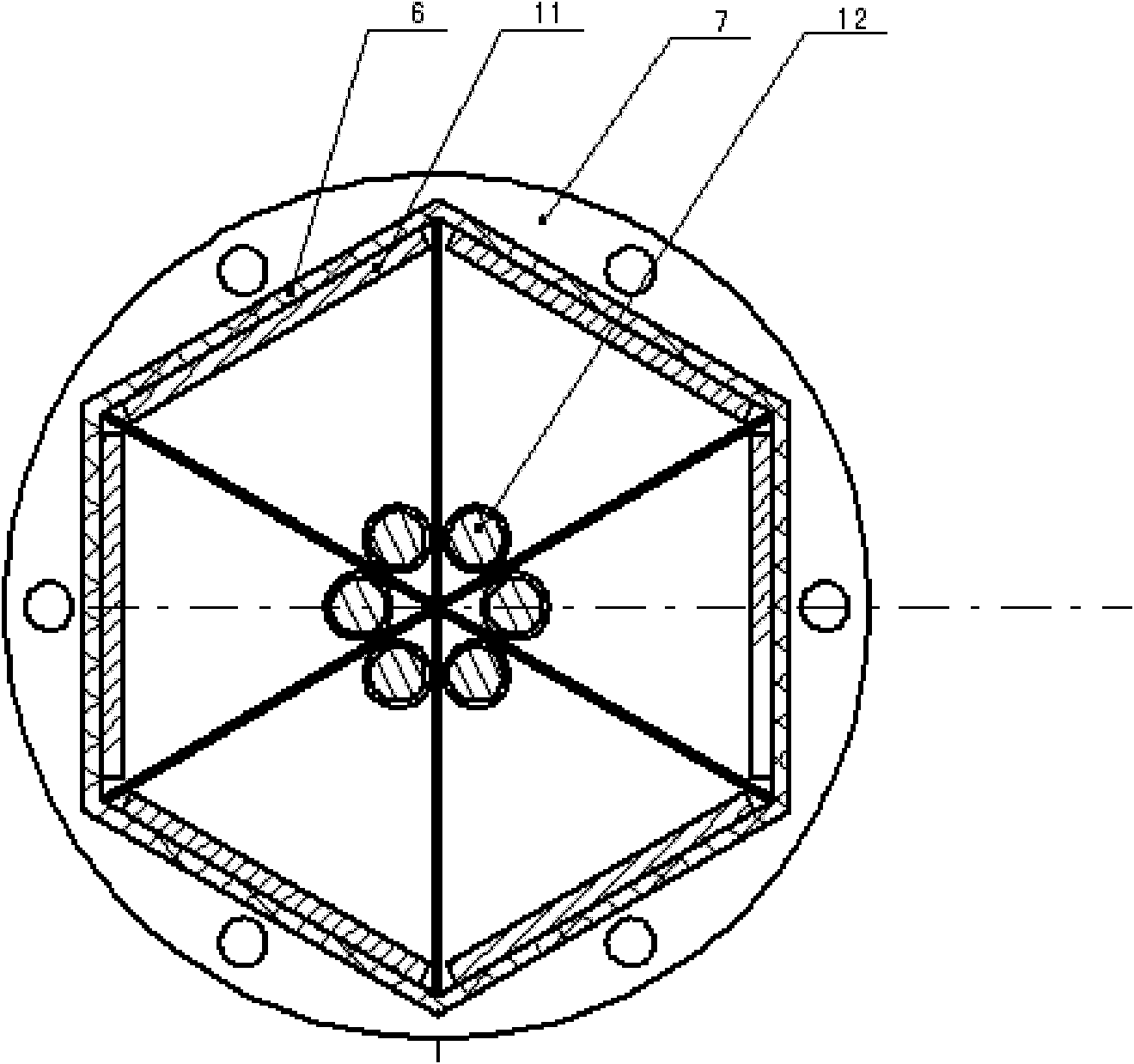

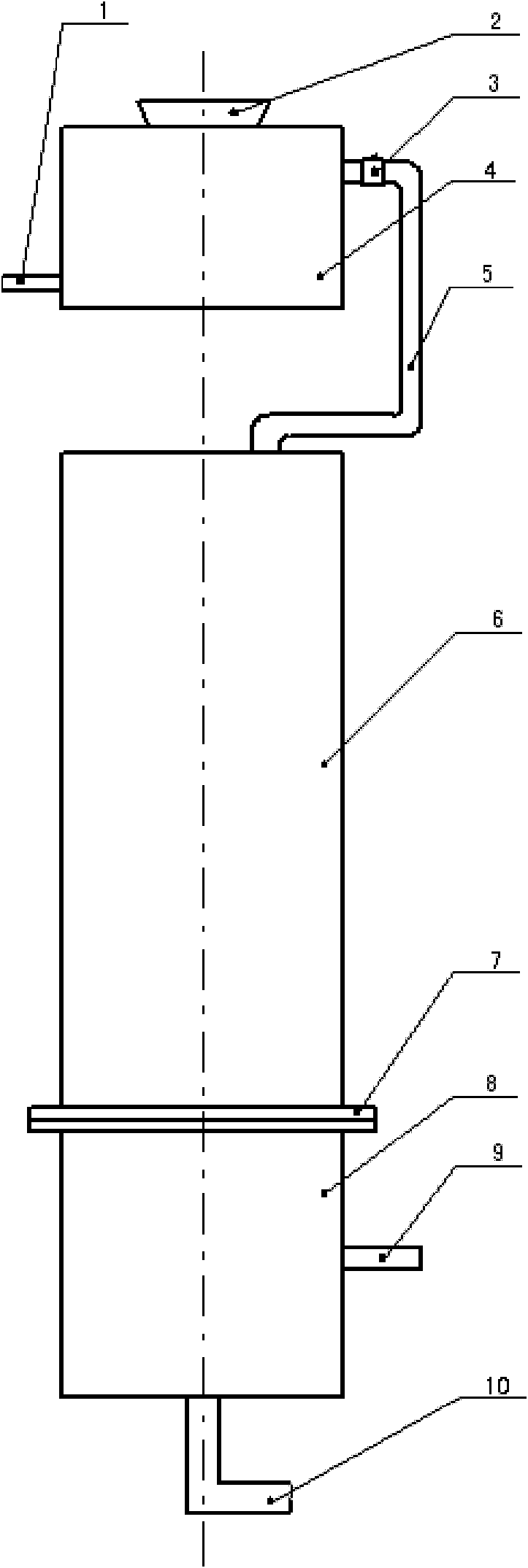

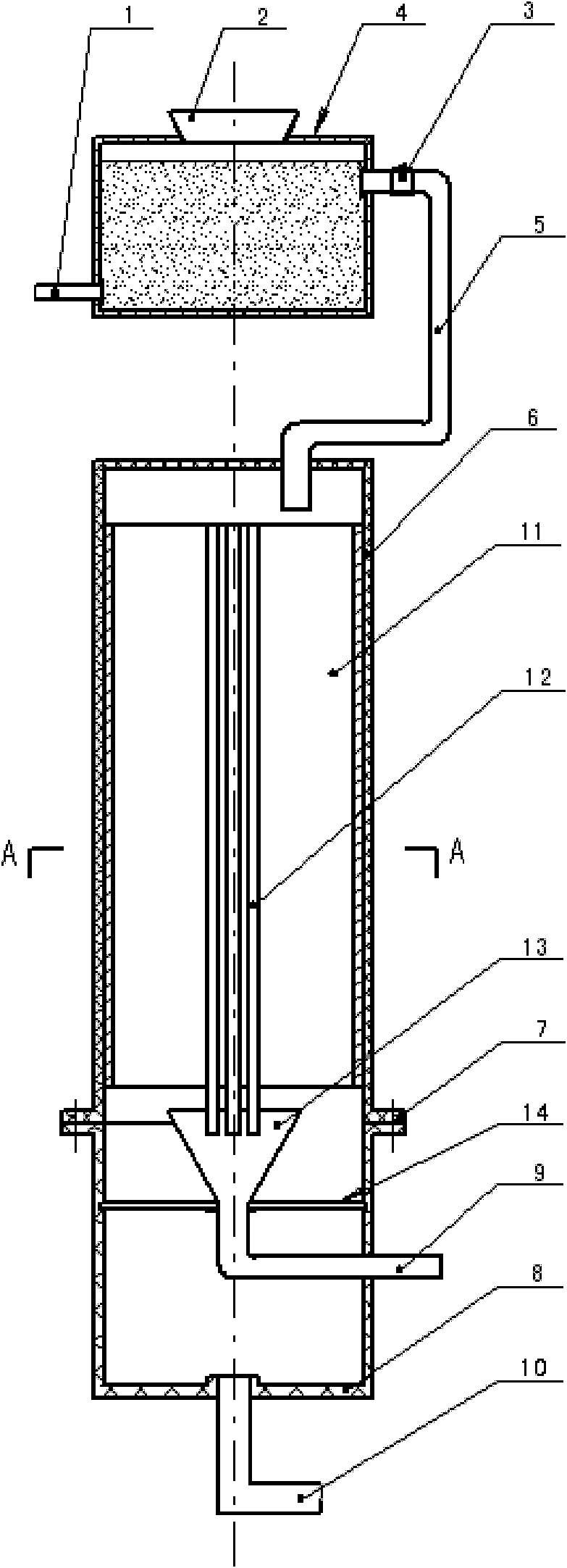

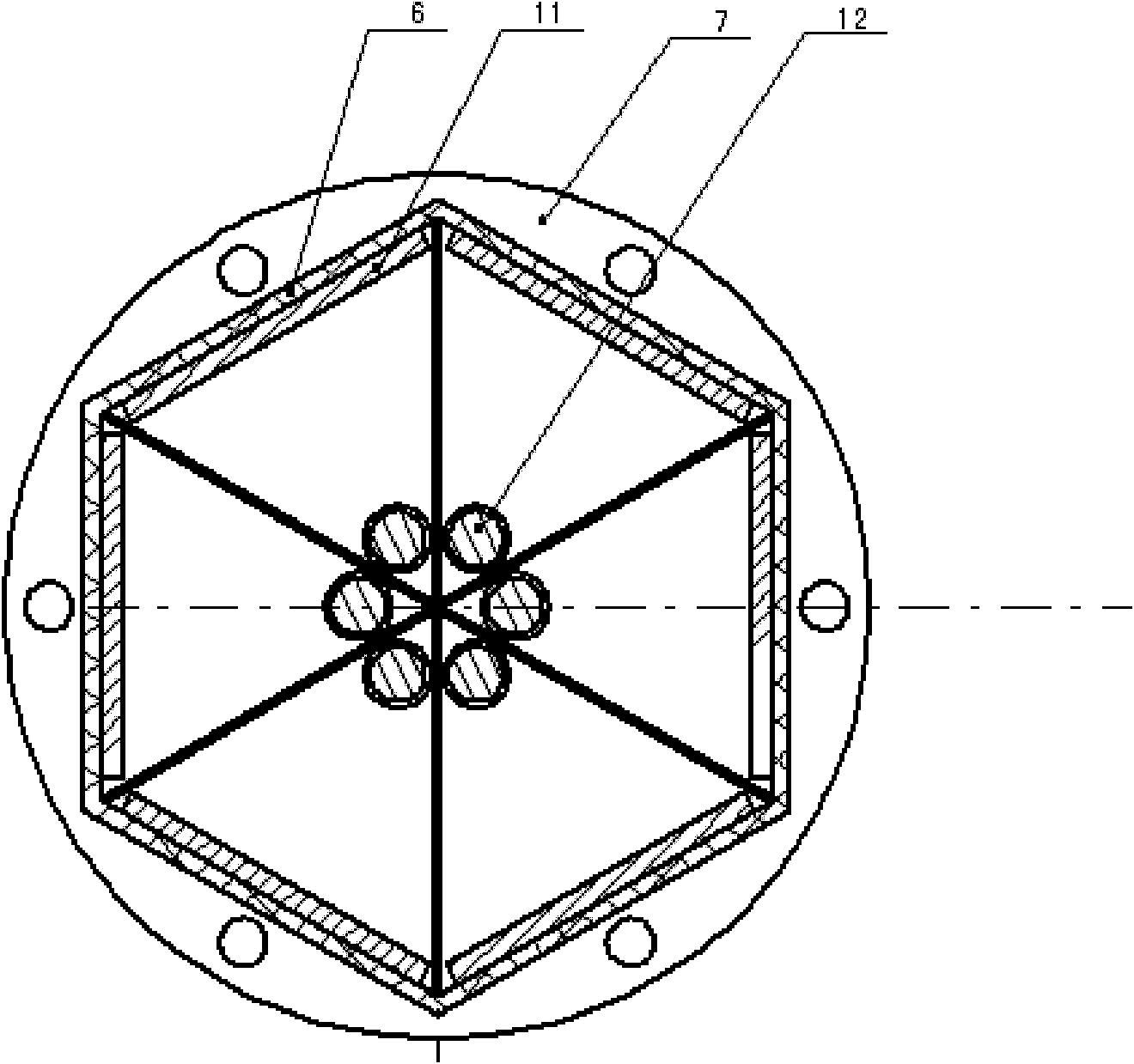

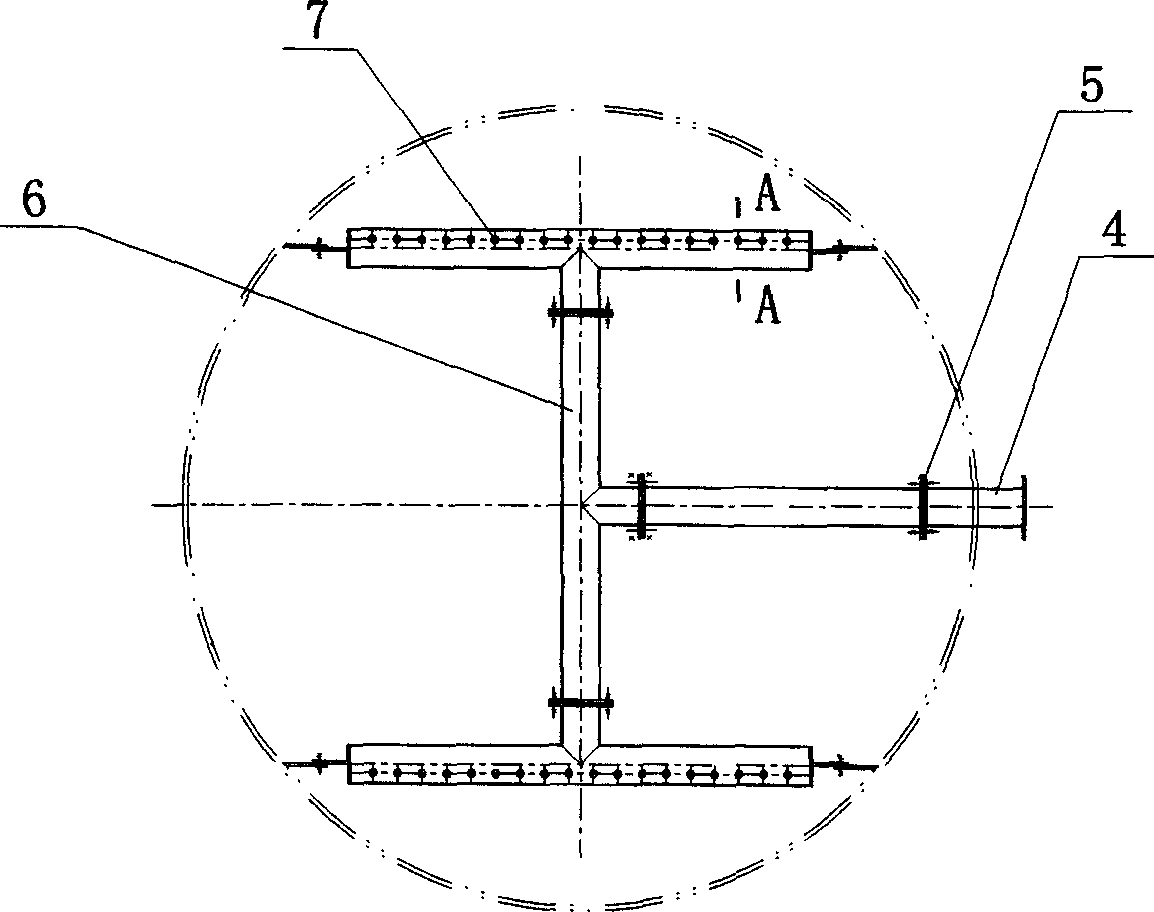

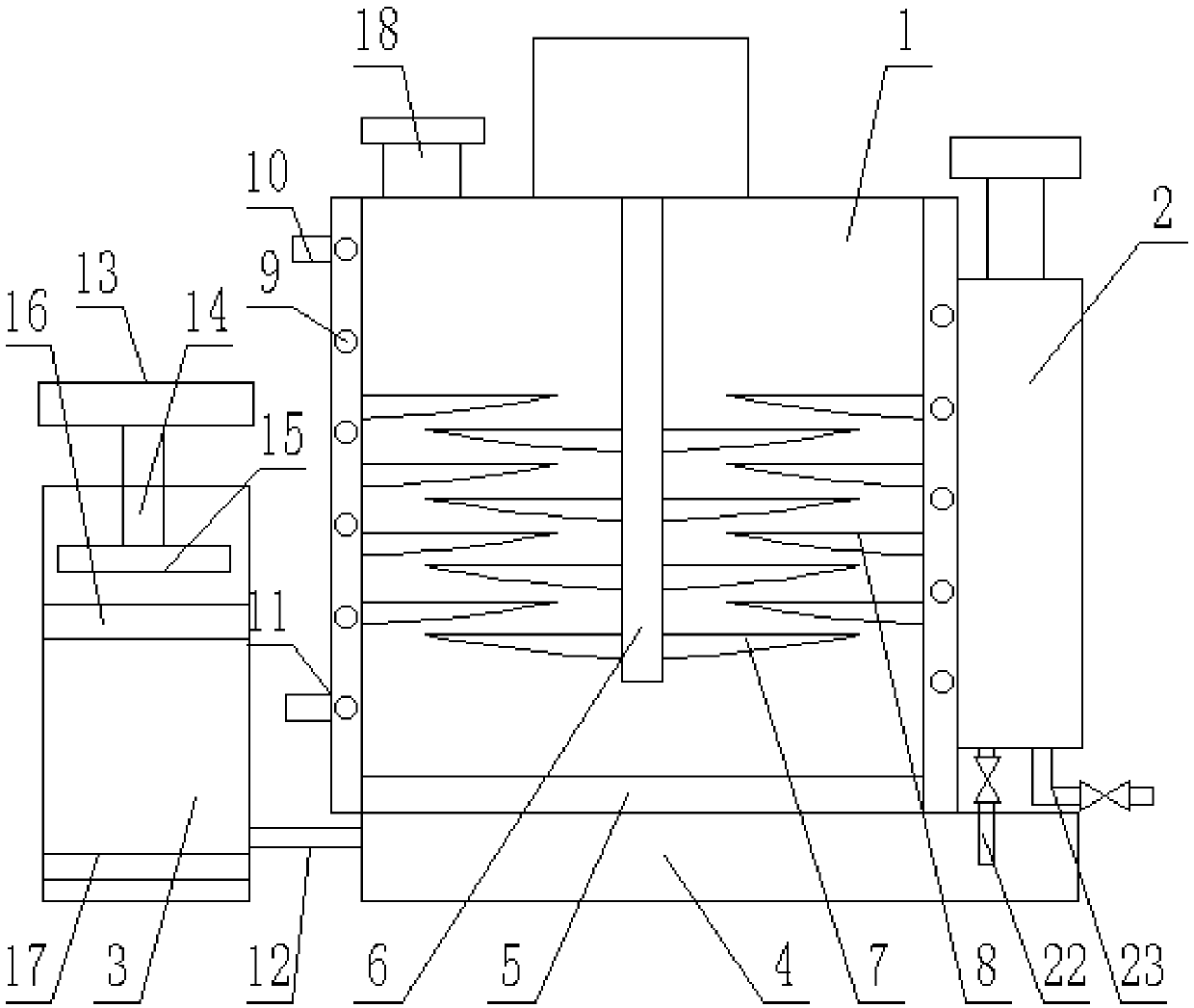

Dielectrophoresis separation system for recycling precious metals

InactiveCN101890296AGuaranteed separation efficiencyContinuous controllability of separation processDispersed particle separationSeparation technologyEngineering

The invention relates to a dielectrophoresis separation system for recycling precious metals, which comprises a mixer, a separation chamber and a collector, wherein the dielectrophoresis separation chamber is in a vertical hexagonal barrel shape; the six edges in the hexagonal barrel are respectively provided with a stainless steel sheet electrode; the center shaft in the hexagonal barrel corresponding to each stainless steel sheet electrode is evenly equipped with an insulated wire electrode; the collector is installed below the insulated wire electrodes; the lower end of the dielectrophoresis separation chamber is coaxially provided with the collector; a funnel organ is installed in the collector corresponding to the lower end of the insulated wire electrode; the funnel organ is communicated with an output pipe; and the lower bottom of the collector is provided with a cyclic outlet. The invention acquires unseparated precious metal granules in precious metal waste by utilizing the unique high selectivity and high controllability in the dielectrophoresis principle in physical chemistry to maximally recycle precious metals and minimize the possible environmental pollution caused by precious metals. The invention provides a brand new environment-friendly high-efficiency continuous separation technology for separating and recycling precious metals in tailings and waste. The invention has the advantages of environmental protection and energy saving, and is beneficial to further separation of precious metals in precious metal lean ores and tailings in China.

Owner:王冰

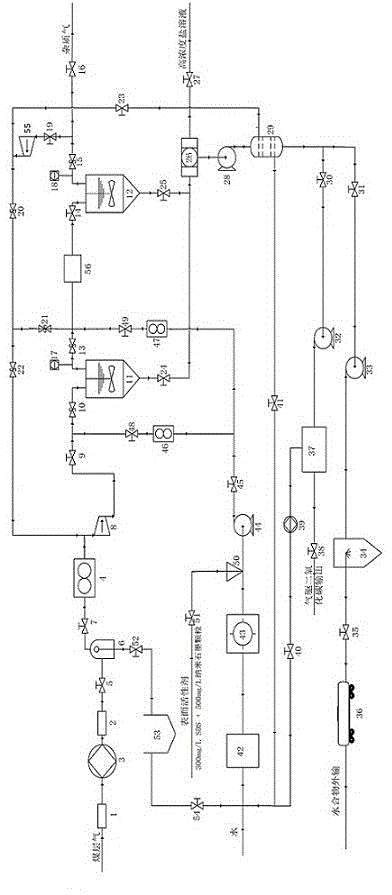

Device and method for purifying and concentrating coal bed gas and treating produced water

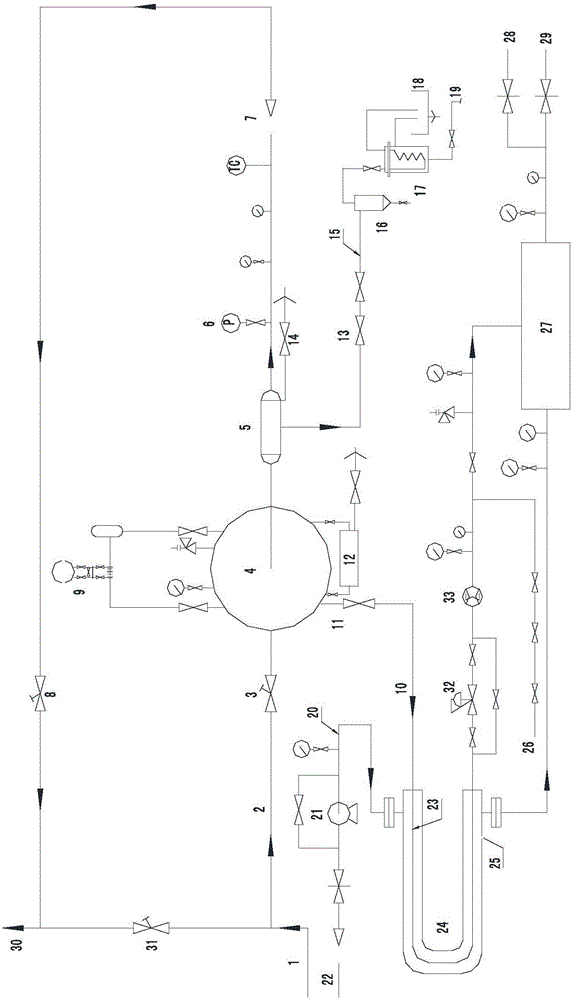

ActiveCN104479780AIncrease concentrationEasy to transportGaseous fuelsMultistage water/sewage treatmentHigh concentrationFlame arrester

The invention relates to the technical field of exploitation and utilization of coal bed gases, and in particular relates to a device and a method for purifying and concentrating a coal bed gas and treating produced water. The device comprises a wet flame arrester, a water ring vacuum pump, a gas flow meter, a one-way gas valve, a separator, a fireproof and explosion-proof compressor, a safety valve, a hydrate generating unit, a gas-liquid two-phase valve, a gas concentration monitor, a stop valve, a filter, a one-way liquid valve, a slurry pump, a three-phase separator, a granulating machine, a stop valve, an outer transportation vehicle, a hydrate decomposing unit, a water pump, an ice making device, a grinding device, a liquid flow meter, a Laval spray valve and a clarifier. Two hydrate reactors are adopted to fix CO2 and methane in the coal bed gas respectively, and the CO2 released after regeneration is used as a gas-driving raw gas for improving the recovery ratio of the coal bed gas, so that the release of CO2 of a gas field is reduced, and high-concentration methane hydrate is granulated and transported outwards for application; and a salt draining effect during formation of the hydrate is used to ensure that a lot of salt-containing produced water during exploitation of the coal bed gas can be treated to meet requirements for reinjection to a stratum layer, so that resources are saved, and the environment is protected.

Owner:江苏智芯今创科技有限公司

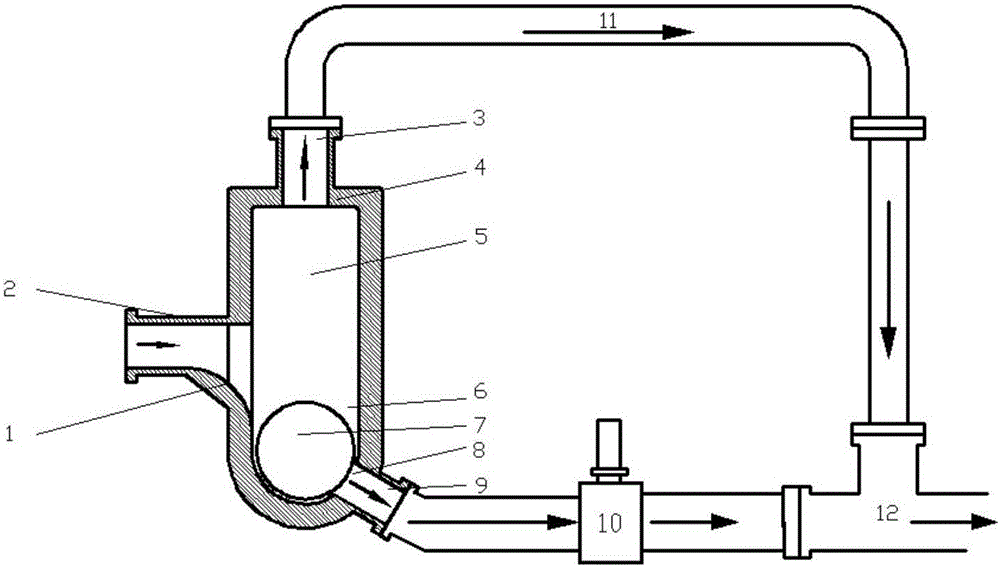

Online detection device for wellhead water content of high-water-containing oil well

ActiveCN105974098AImprove separation efficiencyReduce shockLiquid degasificationPreparing sample for investigationGas phaseEngineering

The invention provides an online detection device for wellhead water content of a high-water-containing oil well. The online detection device comprises a separation cavity, wherein a mixed liquid inlet is arranged at the lower part of the separation cavity, a gas-phase flow outlet is formed in the top of the separation cavity, and a separation liquid outlet is formed in the bottom of the separation cavity; separation liquid flows out through gravity and pipeline pressure; the separation cavity is internally provided with a floating ball; the gas-phase flow outlet and the separation liquid outlet are connected with an oil conveying pipeline; a water content detection sensor is arranged on a connection pipeline of the separation liquid outlet and the oil conveying pipeline; three-phase flow mixed liquid enters the separation cavity from a mixed liquid inlet through a flow line slide slope; gas-phase flow moves upwards to enter a gas cabin and is finally returned back to the oil conveying pipeline; separation liquid flows down and is slowly separated; the gas-phase flow continually moves upward to be more completely separated through movement of the liquid in the distance from the separation cavity to the separation liquid outlet; after being detected, the separation liquid flowing out from the separation liquid outlet finally enters the oil conveying pipeline; and whole equipment does not generate environment pollution in a utilization process, and the measurement precision of the high water content detection sensor is extremely improved.

Owner:齐齐哈尔盛欣机械制造有限公司

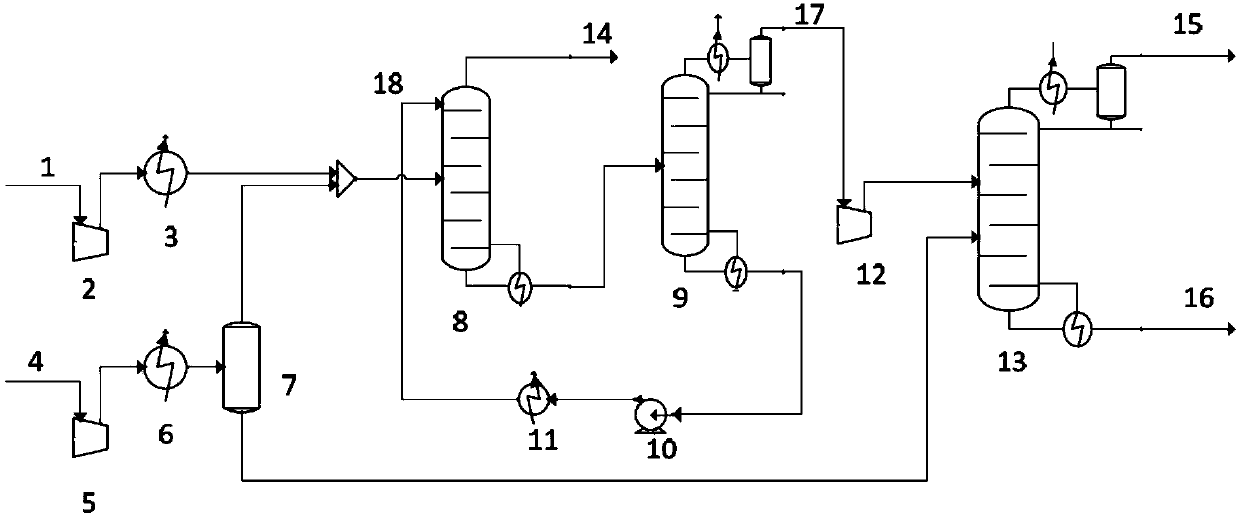

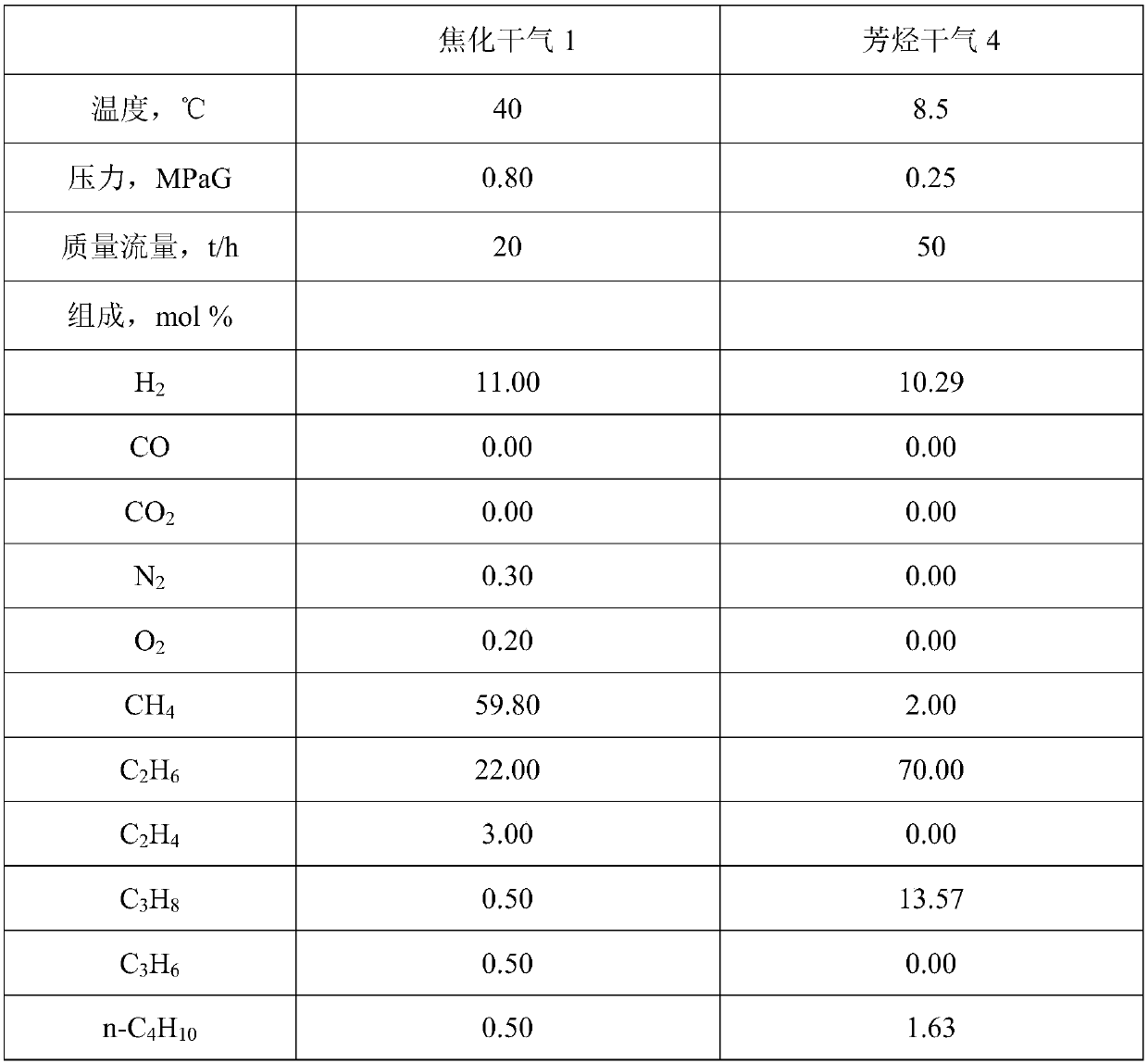

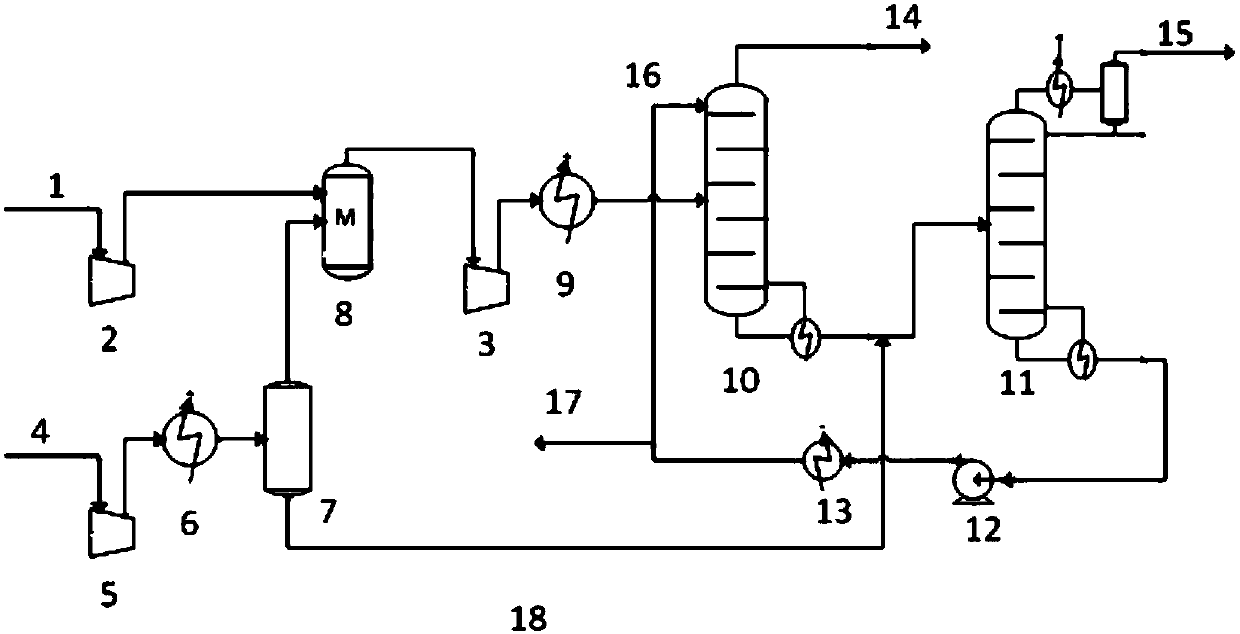

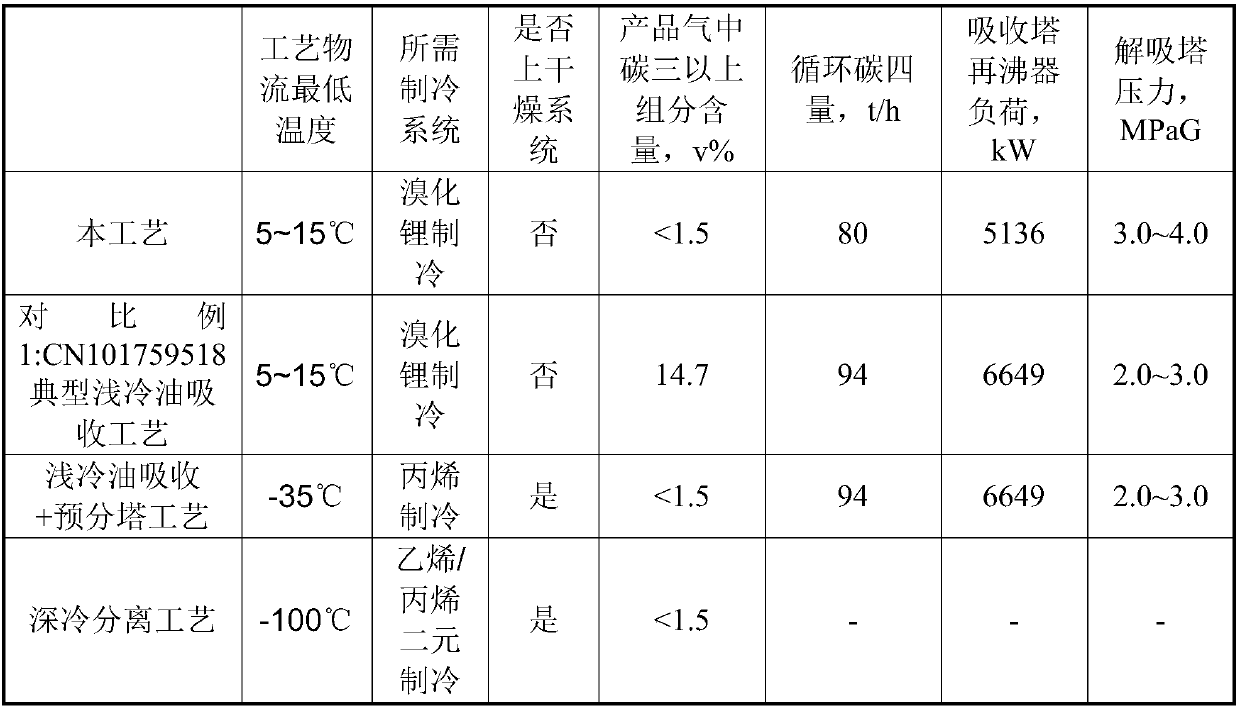

Device and method for recycling carbon 2 in refinery dry gas by aid of oil absorption and compression condensation processes

ActiveCN109749780AImprove separation efficiencyGuaranteed separation efficiencyGaseous mixture working upDry gasRefinery

The invention belongs to the technical field of refinery dry gas separation and recycling, and relates to a device and a method for recycling carbon 2 in refinery dry gas by the aid of oil absorptionand compression condensation processes. The device comprises an absorption tower, a desorption tower and an ethane tower. Inlet pipelines of the absorption tower include a coking dry gas inlet pipeline and an aromatic hydrocarbon dry gas inlet pipeline, a compressor, a cooler and a liquid separation tank are arranged on the aromatic hydrocarbon dry gas inlet pipeline, and a gas-phase discharge pipeline of the liquid separation tank is connected to the absorption tower; a tower kettle of the absorption tower is connected with the desorption tower; a tower top of the desorption tower is connected with the ethane tower, and a tower kettle of the desorption tower is connected with the upper portion of the absorption tower; an ethane-rich gas discharge pipeline is connected with a tower top ofthe ethane tower, a light hydrocarbon discharge pipeline is connected with a tower kettle of the ethane tower, and a liquid-phase discharge pipeline of the liquid separation tank is connected with theethane tower. The device and the method have the advantages that the contents of hydrogen, methane and components at the levels higher than carbon 3 in ethane-rich gas in products can be controlled by the aid of the method, dryers and propylene refrigeration compressors can be omitted, and accordingly the investment and energy consumption of the device can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

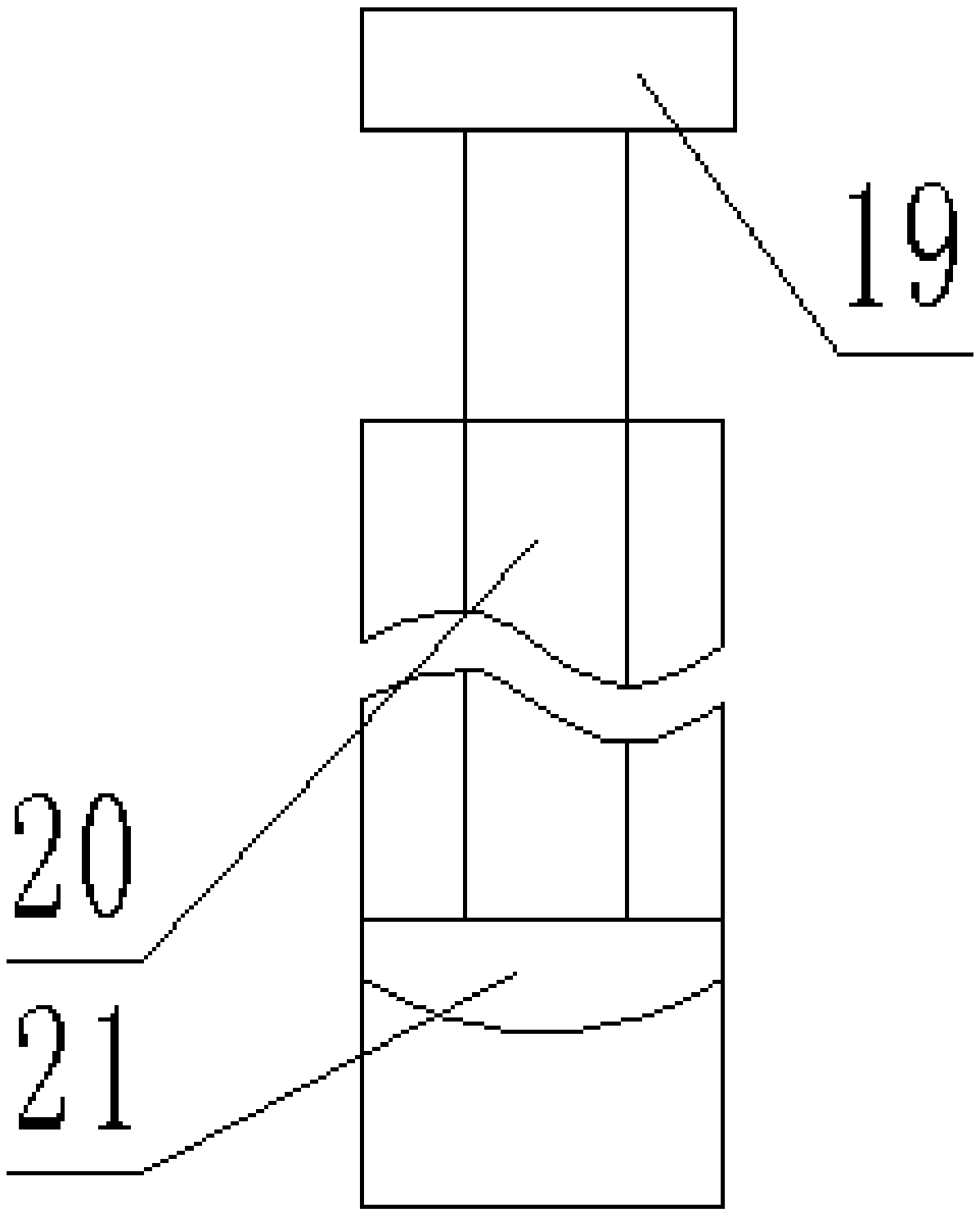

Efficient continuous process for pollution-free recovery of precious metals by a dielectrophoresis method

InactiveCN101912732AGuaranteed separation efficiencyContinuous controllability of separation processDispersed particle separationProcess efficiency improvementHeavy metalsPrecious metal

This invention relates to an efficient continuous process for pollution-free recovery of precious metals by a dielectrophoresis method, which comprises the following steps of: (1) mixing materials in a mixing box; (2) separating in a dielectrophoresis separation chamber; (3) collecting in a collector, wherein the lower end of the dielectrophoresis separation chamber is coaxially provided with the collector; a funnel is arranged corresponding to the lower end of insulated wire electrode in the collector; the funnel outputs precious metals through an output pipe; the bottom of the collector is provided with a loop exit which allows separated suspension to enter the next dielectrophoresis separation chamber for circulating re-separation. Based on the special high selectivity and high controllability of the dielectrophoresis principle in physical chemistry, unseparated precious metal particles in precious metal wastes are captured so as to realize maximum recovery and minimize the degree of contamination that may be caused by precious metals; therefore, the efficient continuous process of the invention is a new environmentally-friendly efficient continuous process for separating and recovering precious metals from tailings and waste, is energy-saving and contributes to the further separation of precious metal lean ores and tailings in China.

Owner:王冰

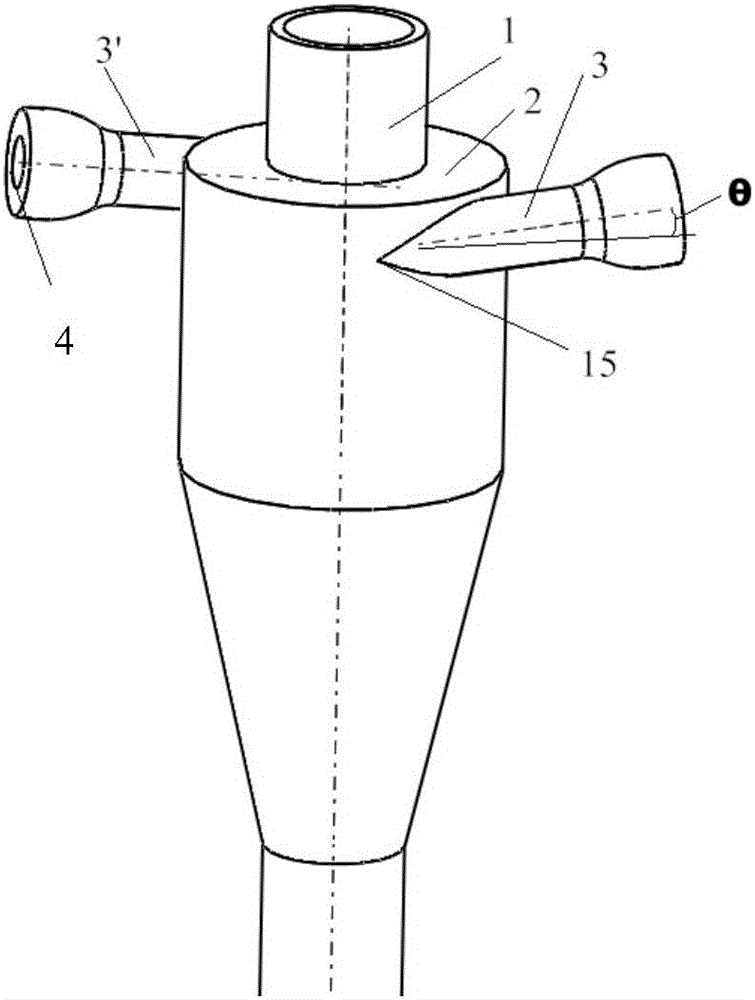

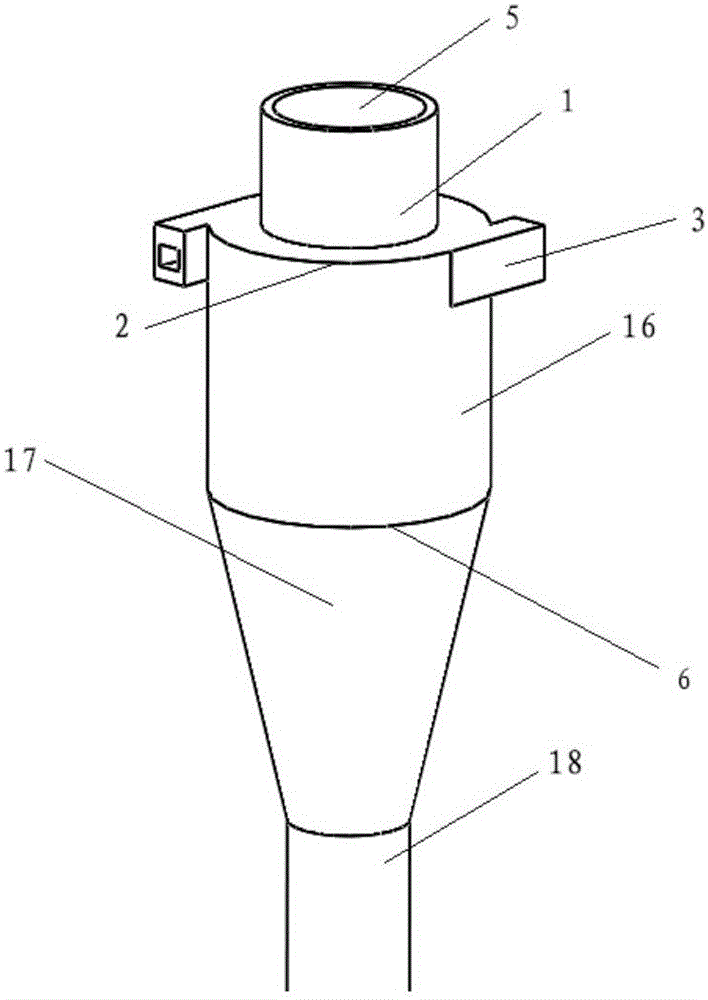

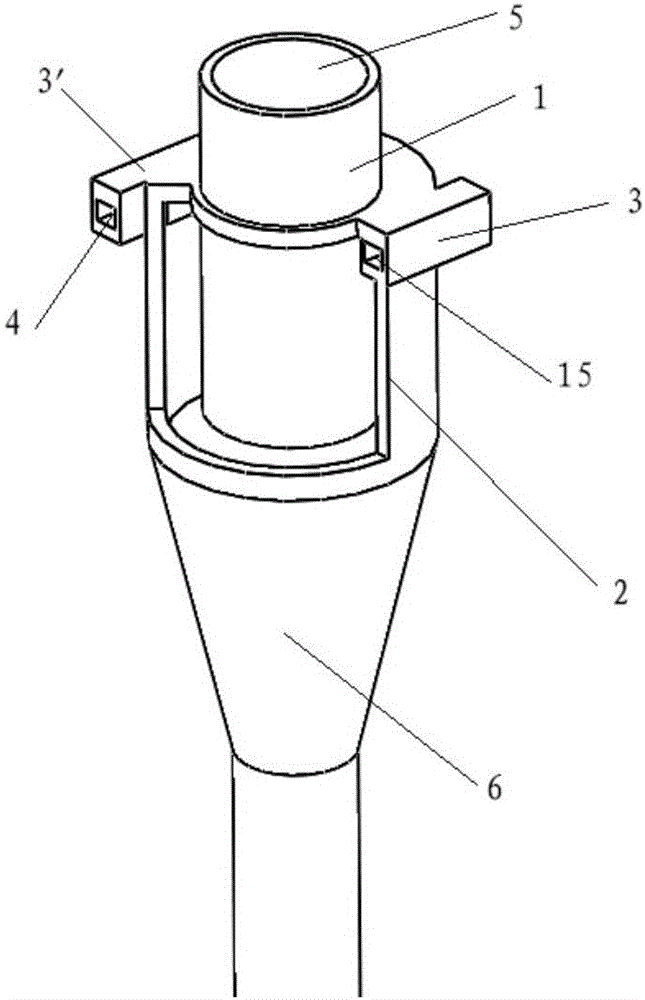

Micro cyclone separator with double-side air inlet function and high-pressure separation device adopting separator

InactiveCN105903580AIncrease media handling capacityHigh speedReversed direction vortexCycloneEngineering

The invention provides a micro cyclone separator with a double-side air inlet function and a high-pressure separation device adopting the separator. The micro cyclone separator with the double-side air inlet function comprises an inner pipe and an outer pipe. An air outlet of the cyclone separator is formed in the top of the inner pipe. Part of the lower portion of the inner pipe enters the upper portion of the outer pipe. The top of the outer pipe is connected with the outer wall of the inner pipe in a sealing mode. The micro cyclone separator is characterized in that two air inlets communicating with the interior of the outer pipe are formed in the top of the outer wall of the outer pipe, and the two air inlets extend in the tangential direction of the outer wall of the outer pipe correspondingly and are distributed in a central symmetry mode. By means of the double-side air inlets which are distributed in the tangential direction in the central symmetry mode, the air inlet area is effectively increased, the air inlet efficiency is improved, the medium treating capacity is improved, the pressure drop is reduced, and the separation efficiency is improved.

Owner:BEIJING YUANCHENG IND SAFETY TECH CO LTD

Mussel processing method

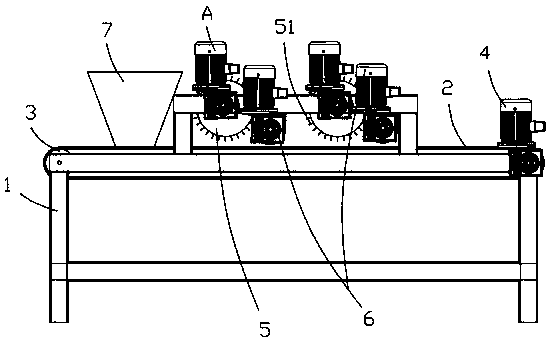

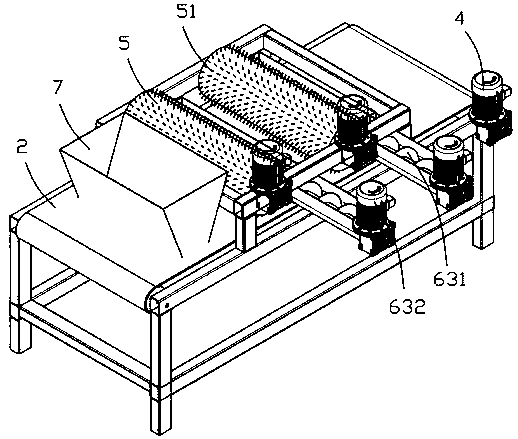

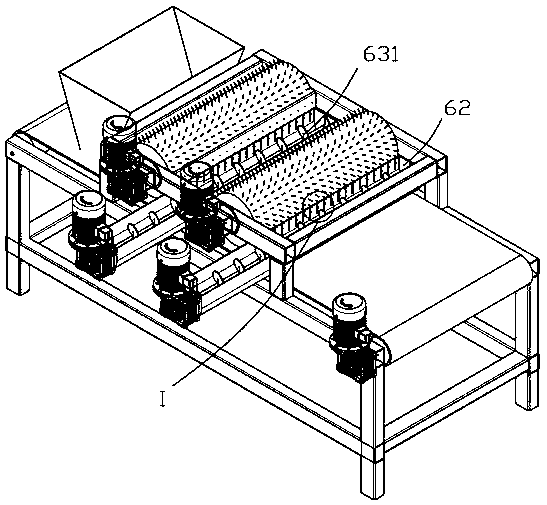

ActiveCN109042822AGuaranteed separation efficiencyIntegrity guaranteedShellfish/bivalves grading/classificationBivalves processingEngineeringMussel

The invention relates to a mussel processing method. The mussel processing method comprises the following steps: rubbing fresh harvested mussels, unhairing the mussels, cleaning the mussels, sorting the mussels, cooking the mussels, vibrating and discharging the mussels, further opening the opened mussels, separating shells and flesh of the mussels, draining the mussel flesh, laying the mussel flesh on a drying device, drying the mussel flesh by utilizing the drying device to prepare the mussel flesh into dry mussels which are easy to store, and packaging the dry mussels. By adopting the mussel processing method, the efficiency for separating the mussel flesh and the mussel shells can be ensured, and the completeness of the mussel flesh can be ensured.

Owner:泾县集知佳工业设计有限公司

Oil-gas separator

ActiveCN107152324ASimple structureEfficient and thorough separationMachines/enginesCrankcase ventillationEngineeringPressure difference

The invention relates to an oil-gas separator, and belongs to the technical field of automobile engines. The oil-gas separator comprises a separator body, a moving gas gathering chamber, an oil-gas separating part, a pressure adjusting valve, a small load one-way valve, a large load one-way valve, a small load channel and a large load channel; the moving gas gathering chamber is arranged on the left portion of the separator body, and is connected with the oil-gas separating part, the pressure adjusting valve is arranged on the rear side of the oil-gas separating part, the small load channel and the large load channel are formed in the rear side of the pressure adjusting valve, the small load channel is provided with the small load one-way valve, and the large load channel is provided with the large load one-way valve. The one-way valves are directly integrated in the separator body, the oil-gas separating part of the special structure is arranged, oil and gas can be efficiently and thoroughly separated, the separating efficiency is improved, meanwhile,, the structure of the oil-gas separator is simplified, the manufacturing cost of the separator is reduced, the oil-gas separating efficiency is ensured, meanwhile, it is ensured that the pressure difference of the whole oil-gas separator is within the reasonable range, and the engine oil consumption is reduced.

Owner:HENGST FILTER SYST (KUNSHAN) CO LTD

Soil organic restoration device and soil restoration method for smart agriculture

The invention discloses a soil organic restoration device for smart agriculture. A thermal stripping box is clamped to one side of the top end of a supporting frame, a movable roller is placed on the inner side of the thermal stripping box, a discharging hopper is installed on the inner side of the thermal stripping box, a separation limiting plate is connected to the inner side of the thermal stripping box, a concentration sleeve is welded to one end of the thermal stripping box, and a gas conveying pipe penetrates through one end of the concentration sleeve. A gas inlet end of the gas conveying pipe is installed at the top end of a concentration box in a penetrating mode, a gas outlet pipe penetrates through one end of the movable roller, and a gas outlet end of the gas inlet pipe is installed at the bottom end of a separation box in a penetrating mode. Through a conveying belt, the movable roller and the gas conveying pipe, generated steam is exhausted while soil is subjected to thermal stripping, the moisture content in the thermal stripping box is reduced, and meanwhile, heat is recycled for the second time, so that the movable roller is heated, the temperature of the movable roller is guaranteed, soil is heated while the conveying belt is dried, the soil is prevented from being attached to the surface of the conveying belt, and the treatment effect of the soil is guaranteed.

Owner:芷兰生态环境建设有限公司

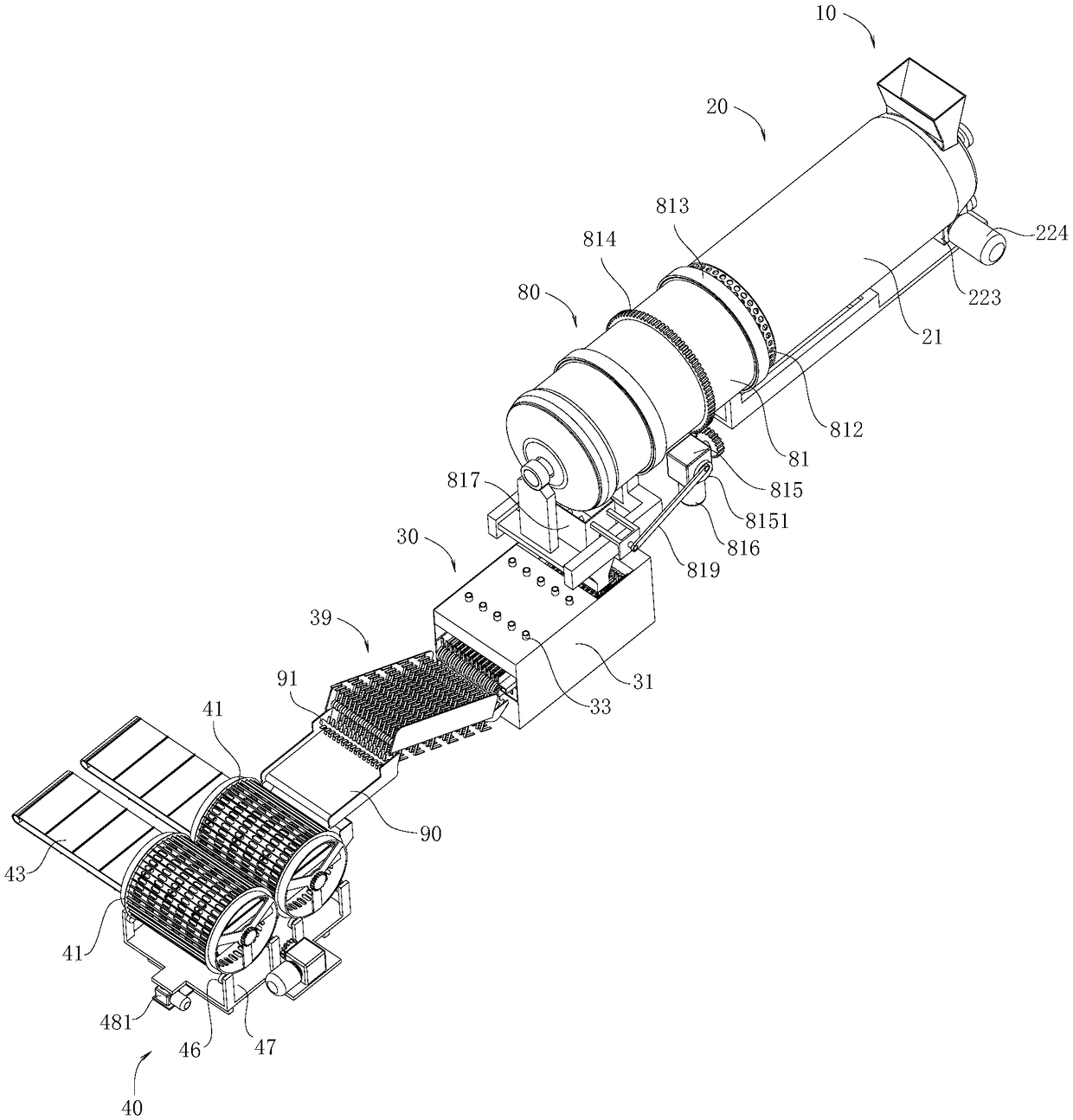

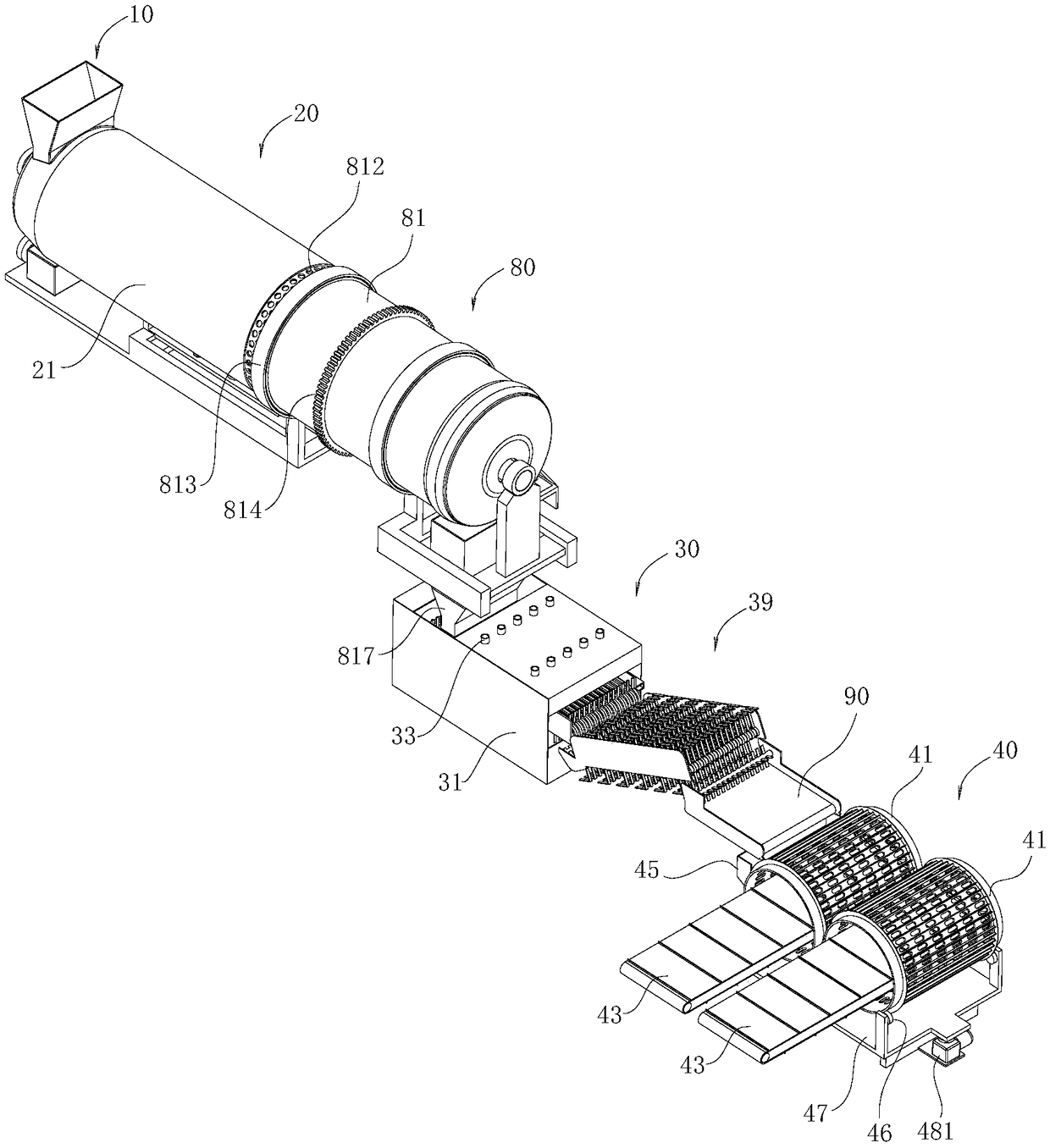

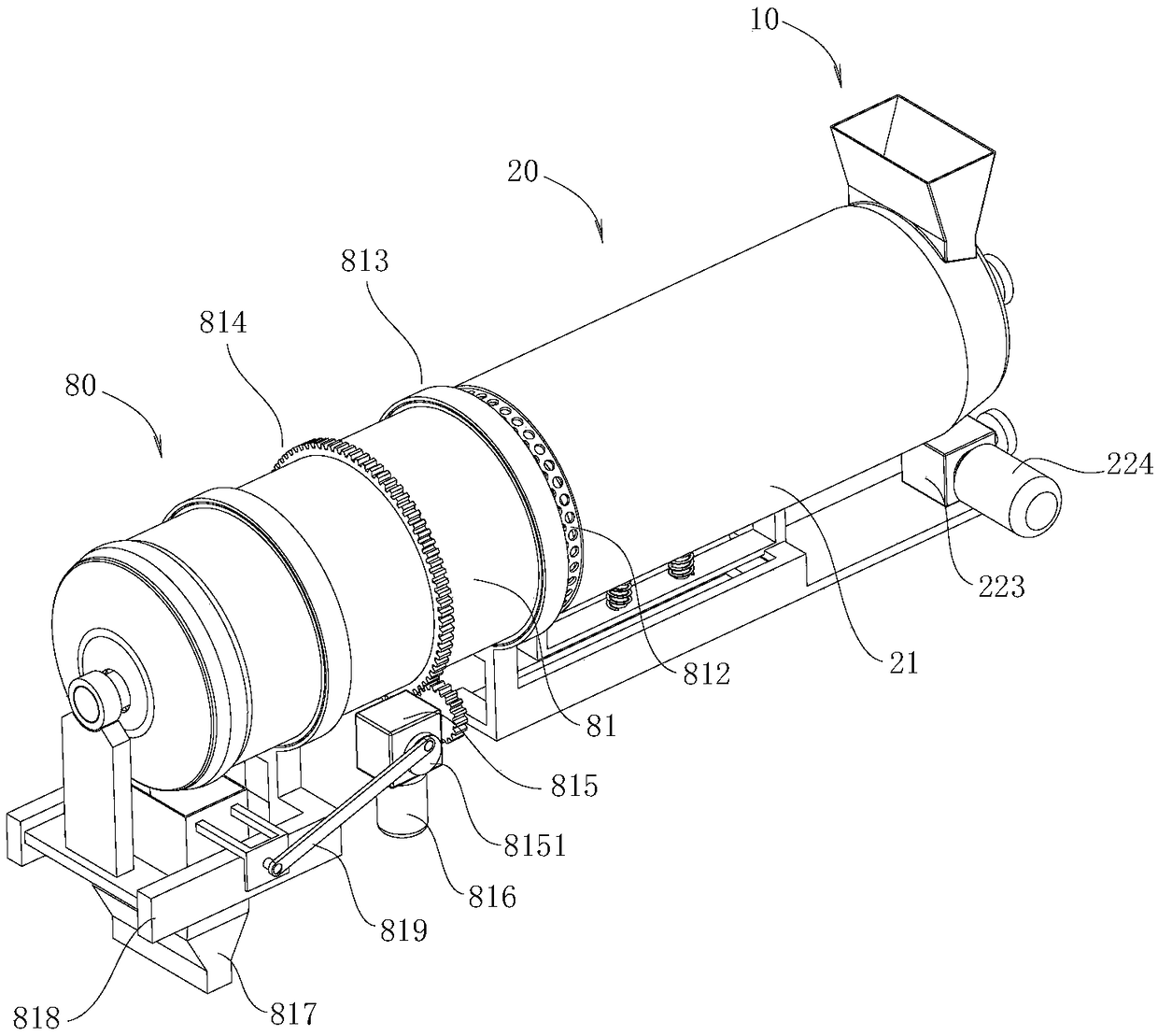

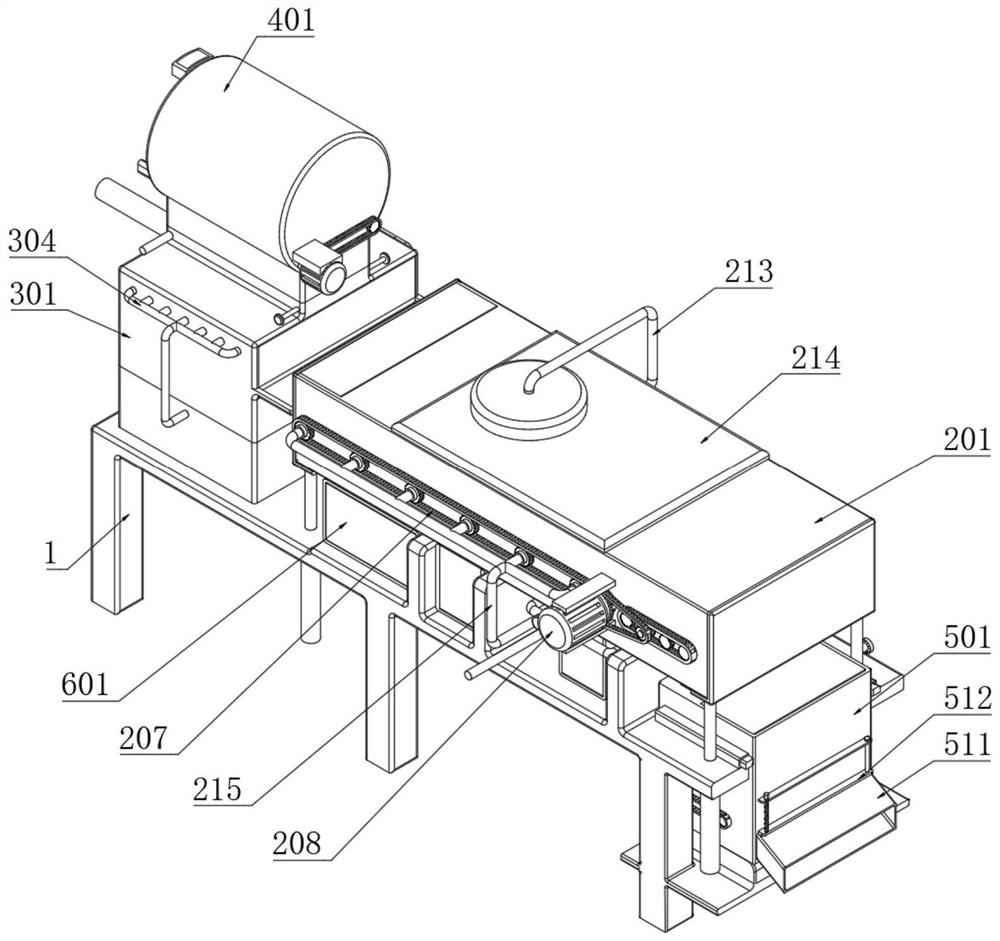

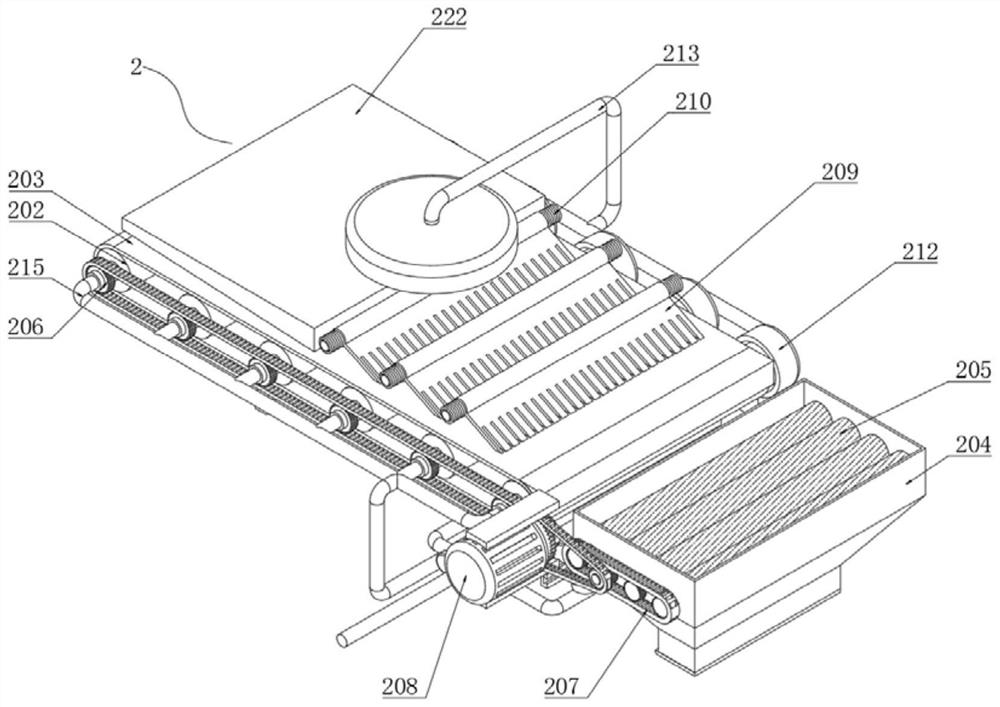

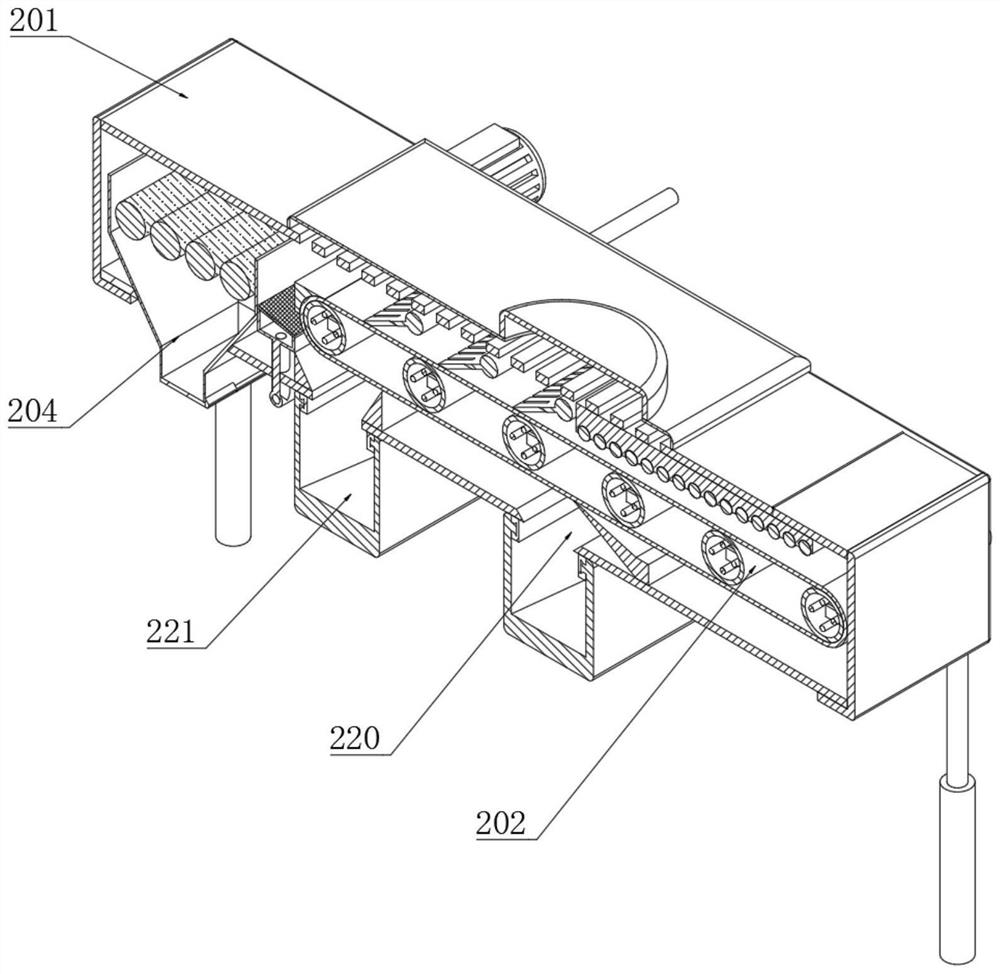

Mussel processing system

ActiveCN109042825AGuaranteed separation efficiencyIntegrity guaranteedShellfish/bivalves grading/classificationBivalves processingSurface cleaningEngineering

The invention relates to a mussel processing system. The mussel processing system comprises a feeding mechanism, a kneading apparatus, a cleaning apparatus, a grading apparatus, a cooking apparatus, avibrating and discharging apparatus, a shell-flesh separating apparatus, an unhairing apparatus and a mussel mouth opening apparatus, wherein byssus, sand and bur on the surface of the mussels are separated from the mussel shell by utilizing the kneading apparatus, the kneaded mussels are guided into the cleaning apparatus to be cleaned, so that separated mussels with clean surface can be obtained, the separated mussels having clean surfaces are guided into the grading apparatus to be graded according to the size, the graded mussels are separately guided into the cooking apparatus to be cooked to make the mussels open, and the opened mussels are guided into the vibrating and discharging apparatus, so that the opened mussels are separately guided into the shell-flesh separation apparatus,the flesh in the opened mussels is separated from the mussel shell, so as to obtain the mussel flesh, and the mussel flesh is dried to obtain dry mussel flesh; and by adopting the mussel processing system, the efficiency of separating the flesh and shell can be improved, and the completeness of the mussel flesh can be ensured at the same time.

Owner:王根节

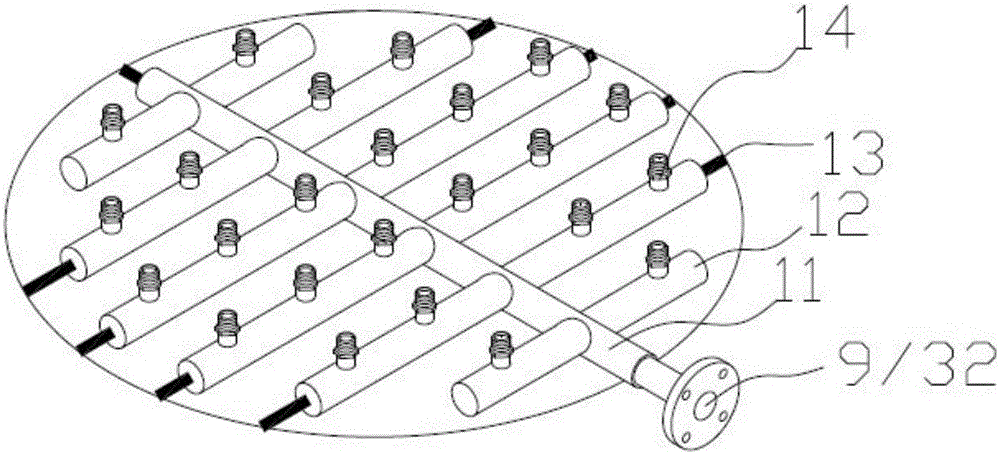

Pipe groove type liquid distributor applied to flue gas desulfurization tower

ActiveCN103143238AImprove the uniformity of liquid distributionGuaranteed separation efficiencyDispersed particle separationEngineeringDistillation

The invention relates to a pipe groove type liquid distributor applied to a flue gas desulfurization tower. The pipe groove type liquid distributor is composed of a liquid inlet tube, a liquid distributing pipe, a first-stage groove and a second-stage groove which are engaged with each other, wherein the liquid distributing pipe is divided into two stages which are engaged up and down through a middle partition board with variable interval equant liquid distributing holes; a second-stage bottom surface is provided with equal interval equant liquid distributing holes and liquid sealing pipes; the outlet end of each liquid sealing pipe is provided with a buffer; the bottom of the first-stage groove is provided with the second-stage groove vertical to the first-stage groove in a long axis direction at the middle position between corresponding adjacent liquid sealing pipes; uniform section rectangular liquid distribution liquid sealing pipes respectively inserted in each second-stage groove are arranged at the bottom of the first-stage groove; upper and lower liquid discharge holes at equal intervals are formed in both side groove boards of the second-stage groove; an anti-blocking baffle board is arranged inside each upper liquid discharge hole, and a flow guide groove board correspondingly engaged with a wire distributing board is arranged outside each upper liquid discharge hole; and a liquid distributing board is arranged at the lower part of each lower liquid discharge hole of the second-stage groove. The pipe groove type liquid distributor has the characteristics of liquid distribution uniformity, impact foam generation prevention, entrainment prevention and blockage prevention, and can be widely applied to large, middle and small containers for absorption and distillation such as flue gas desulfurization.

Owner:TIANJIN TIANDA TIANJIU TECH CO LTD

Crude oil separation system

ActiveCN104804763APrevent overflowAvoid pollutionGaseous fuelsTreatment with plural serial refining stagesThermodynamicsCombustor

Owner:PUYANG XINGTAI METAL STRUCTURE PROD

Method for recycling C-2 in dry gas of refinery

ActiveCN109748771AImprove separation efficiencyHigh recovery rateHydrocarbonsAbsorption purification/separationRecovery methodPhase splitting

The invention relates to the field of dry gas treatment, and particularly discloses a method for recycling C-2 in dry gas of a refinery. The method includes: 1), subjecting aromatic hydrocarbon dry gas to compression treatment and cooling phase-splitting treatment sequentially; 2), feeding coked dry gas into a coked dry gas compressor for compression treatment, and a gaseous phase obtained throughcooling phase-splitting treatment into a segment or an outlet of a coked gas dry gas compressor; 3), cooling mixed dry gas gathering at the outlet of the coked dry gas compressor, and using C-4 fraction as an absorbing agent for absorbing treatment in an absorbing tower; 4), feeding a liquid phase obtained by cooling phase-splitting treatment in the step 1) and tower kettle material flow of the absorbing tower into a desorbing tower for desorbing treatment. The method is high in C-2 recycling rate, a propylene refrigerating system and a drying system are not needed, components above C-3 in product gas are low in content, and the method has the advantages of low energy consumption and little investment.

Owner:CHINA PETROLEUM & CHEM CORP +1

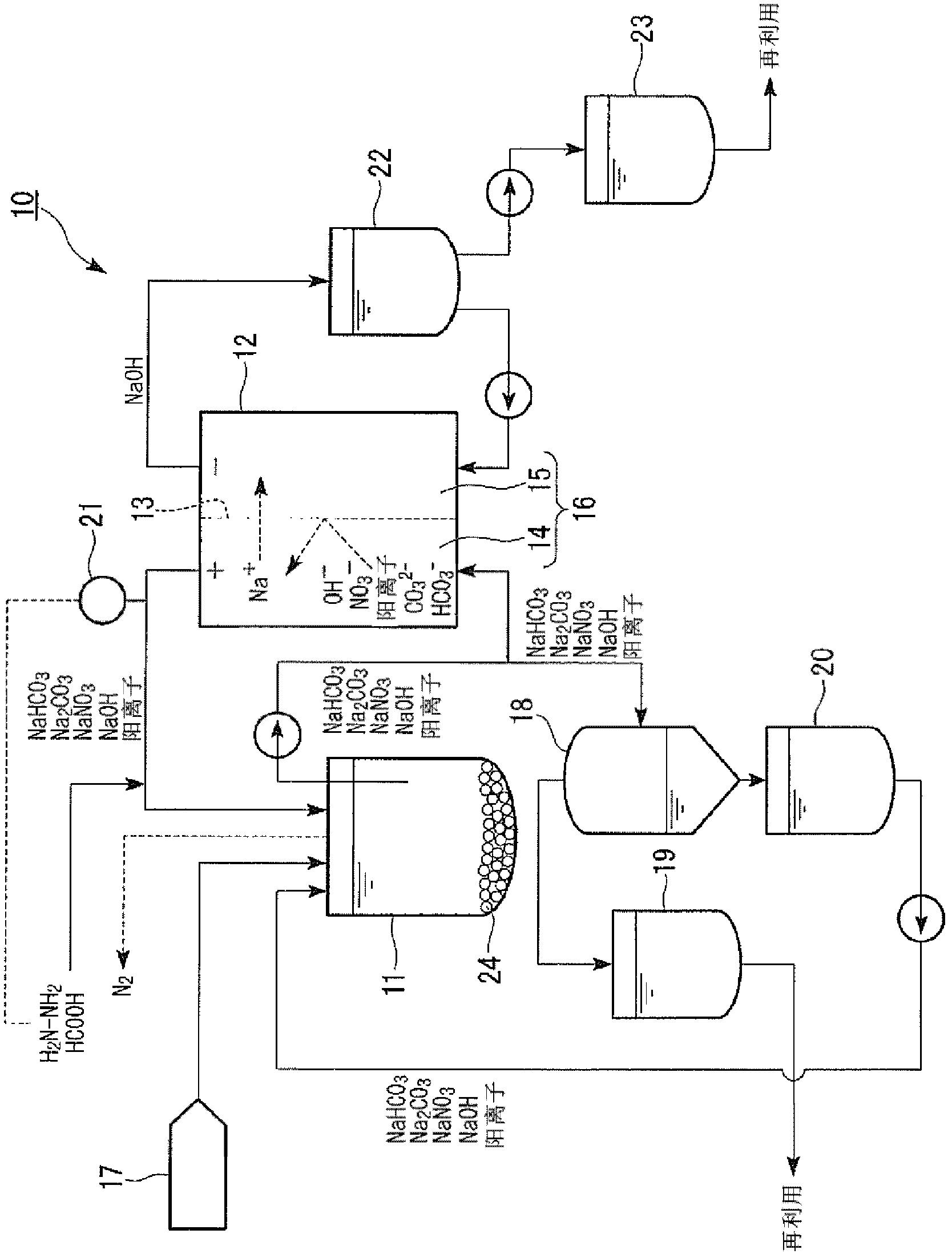

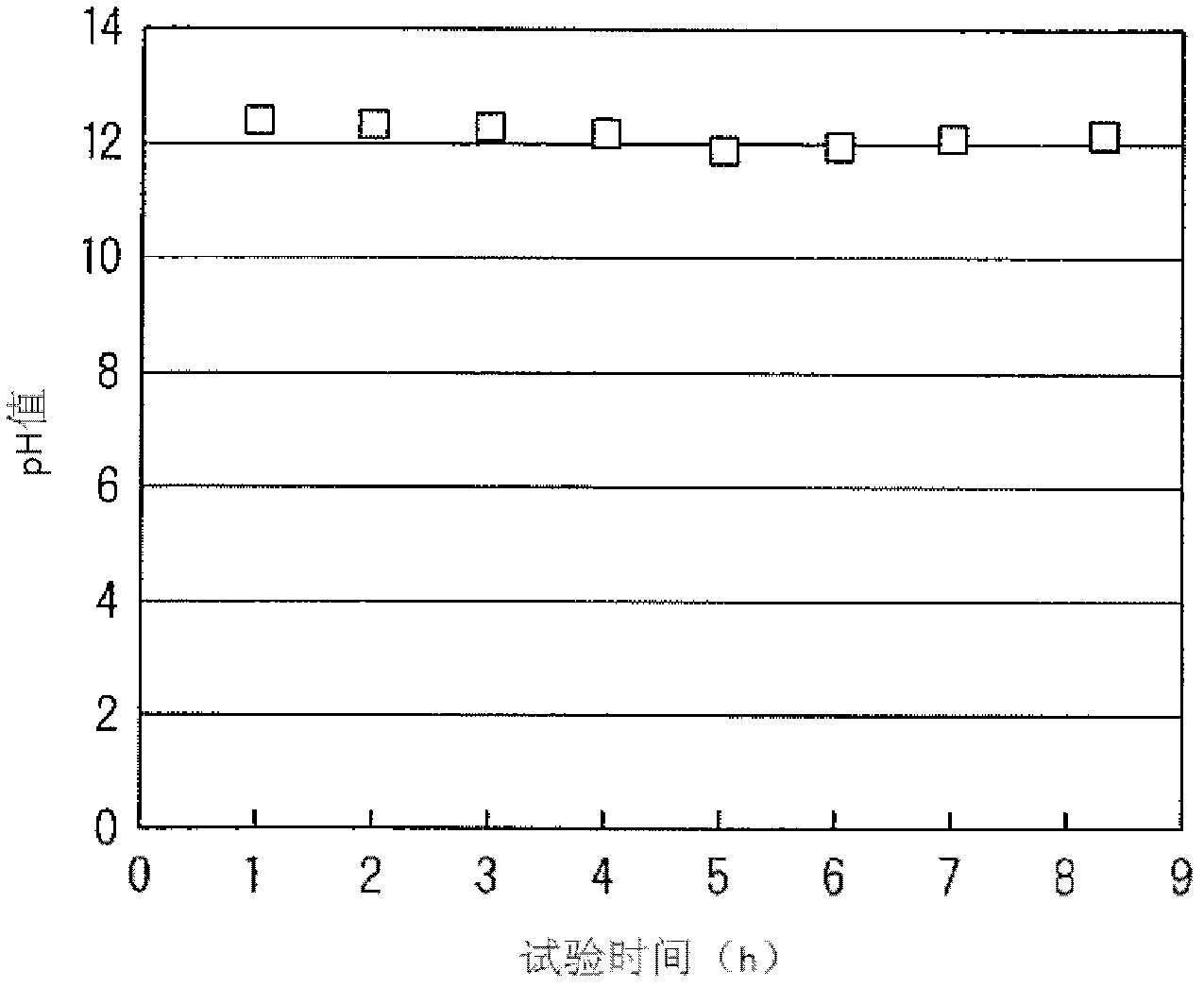

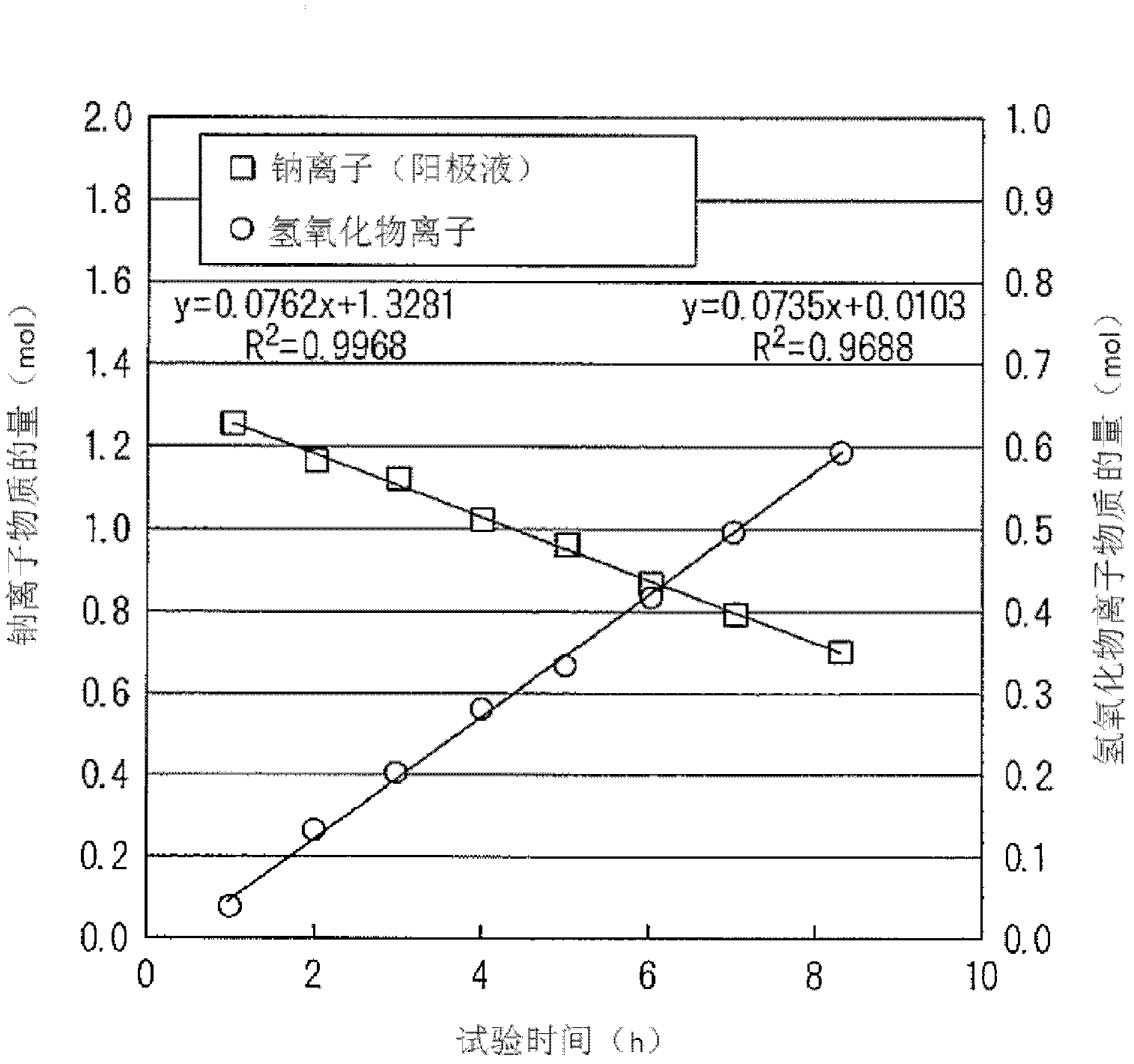

Method for treating radioactive waste solution and device for treating same

InactiveCN102396034AIncreased volume reduction rateGuaranteed separation efficiencyMembranesWater treatment parameter controlIonSodium salt

Disclosed is a method for treating a radioactive waste solution containing a sodium salt which comprises: a waste solution-reducing step for partially reducing sodium nitrate contained in the radioactive waste solution to thereby convert the radioactive waste solution into a reduced solution containing at least one compound selected from sodium hydroxide, sodium hydrogen carbonate and sodium carbonate; and an electrodialysis step for supplying the reduced solution to an anode chamber in an electrolytic tank, in which an anode and a cathode are provided on either side of a permeable membrane that selectively allows the passage of sodium ion, and electrodialyzing the reduced solution. The method for treating a radioactive waste solution is characterized in that: in the electrodialysis step, sodium ion having passed through the permeable membrane is separated and recovered as sodium hydroxide in the cathode chamber; a radioactive substance remaining in the anode chamber is separated as a concentrated radioactive substance solution; the thus separated sodium hydroxide and concentrated radioactive substance solution are each recovered; and the formation speed of at least one compound selected from sodium hydroxide, sodium hydrogen carbonate and sodium carbonate in the waste solution-reducing step is equalized to the recovery speed of sodium ion in the electrodialysis step. Also disclosed is a device for treating a radioactive waste solution.

Owner:JGC CORP

Black soldier fly larva screening device for treating kitchen garbage

ActiveCN112189629AProtectAvoid Black Soldier Fly Larval DeathsAnimal husbandryHermetia illucensRefuse Disposals

The invention relates to the technical field of garbage treatment, in particular to a black soldier fly larva screening device for treating kitchen garbage. According to the technical scheme, the black soldier fly larva screening device for treating the kitchen garbage comprises a hollow shell, and a separation part is arranged in the shell; the shell is divided into a feeding cavity and a transition cavity by the separation part, and the separation part is provided with a plurality of channels for black soldier fly larvae to pass through; the feeding cavity is provided with a feeding port capable of being opened and closed; the transition cavity is provided with an air inlet and an air outlet, and the air outlet is used for being connected with a negative pressure fan; and the transitioncavity is further connected with an insect storage cavity, the upper end of the insect storage cavity is communicated with the lower end of the transition cavity, the air outlet is located above the insect storage cavity, and an insect taking door is arranged at the bottom of the insect storage cavity. According to the black soldier fly larva screening device, hatched larvae and hatched bases canbe rapidly separated, it is guaranteed that when the black soldier fly larvae are thrown into the kitchen garbage, accurate metering is achieved, the larva screening efficiency is improved, and then the treatment efficiency of the kitchen garbage is guaranteed.

Owner:SICHUAN HUIDATONG MACHINERY EQUIP MFG

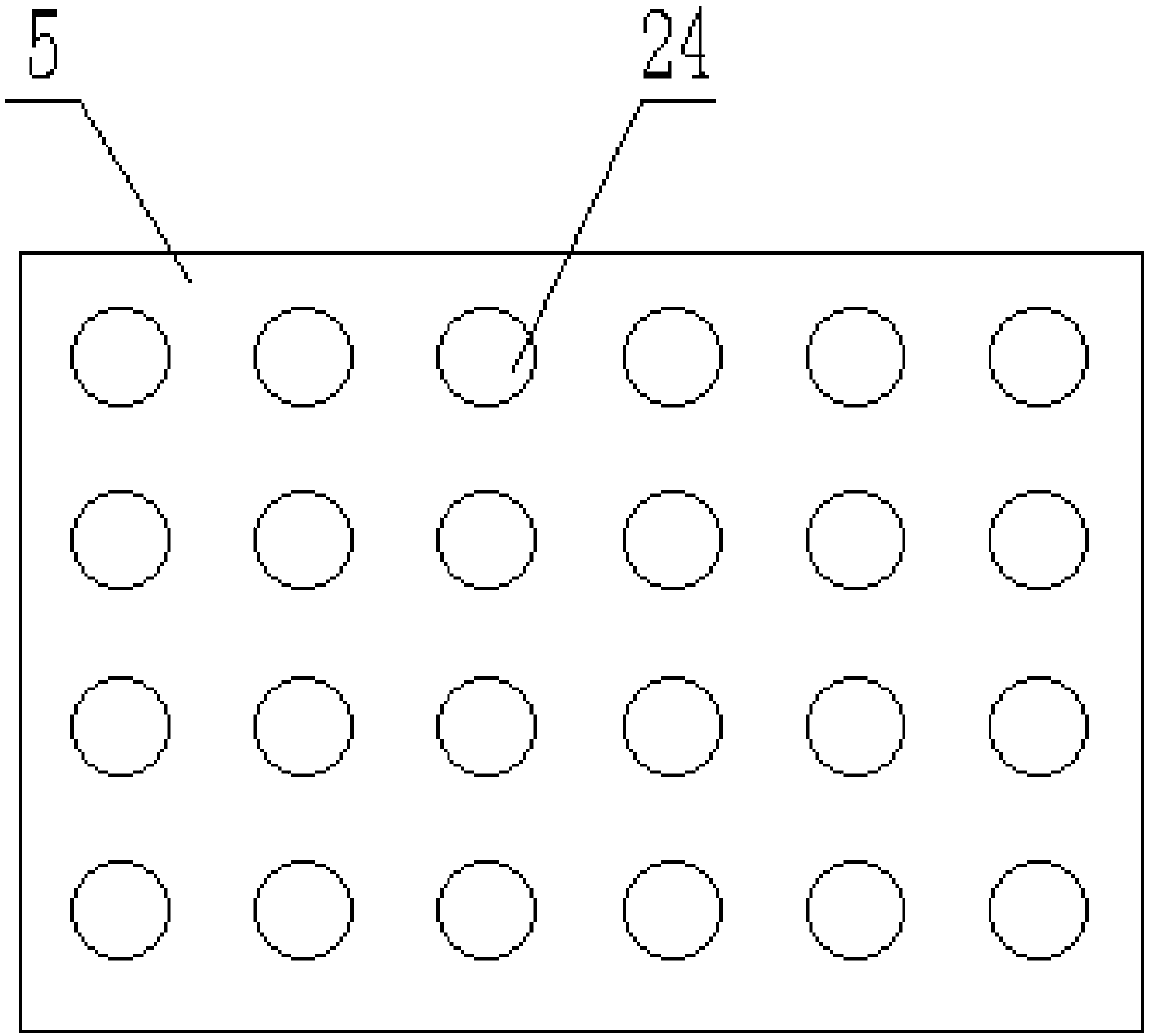

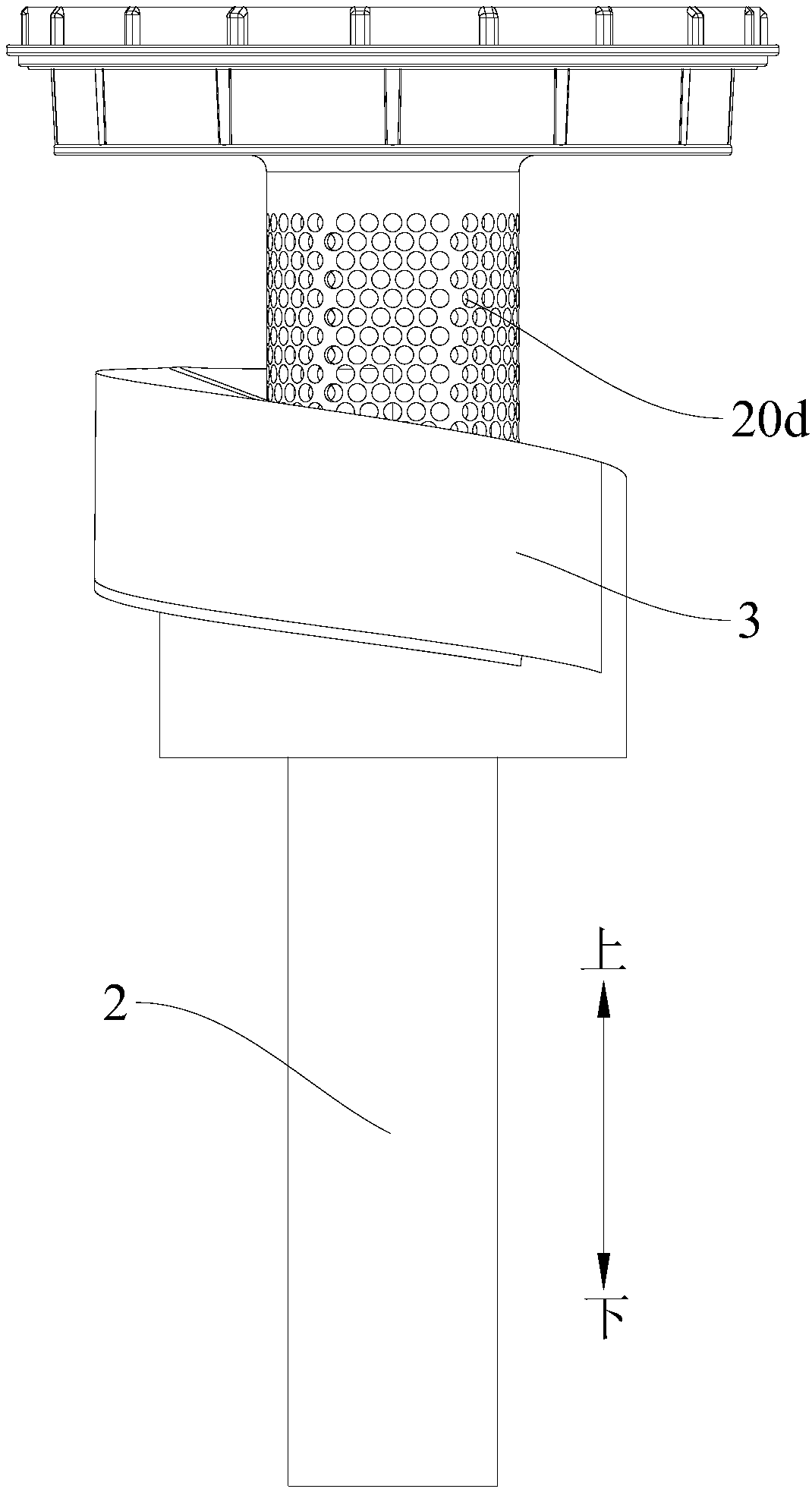

Decompression tower bottom coke inhibiting device and its uses

The invention provides a bottom burnt-against device of pressure-relief tower, which comprises a porous baffle plate, a liquid baffle cap and a support bar plate. Wherein, the baffle plate is a cylinder whose diameter is not less than the inner diameter of extract kettle; the porous rate of said cylinder is higher than 90%; the diameter of external edge of liquid baffle cap is lager than the porous baffle plate; and the support bar plate is arranged between the liquid baffle cap and the porous baffle plate. The invention has better effect when used in quench oil distributing tubes; the burnt-against device is mounted under the stripping section and above the extract kettle, while the quench oil distributing tubes are arranged on the burnt-against device. The invention can improve the flow-ability of liquid, strengthen the turbulence, avoid the generation and accumulation of coke, and confirm the normal operation and separation effect of tower.

Owner:TIANJIN UNIV

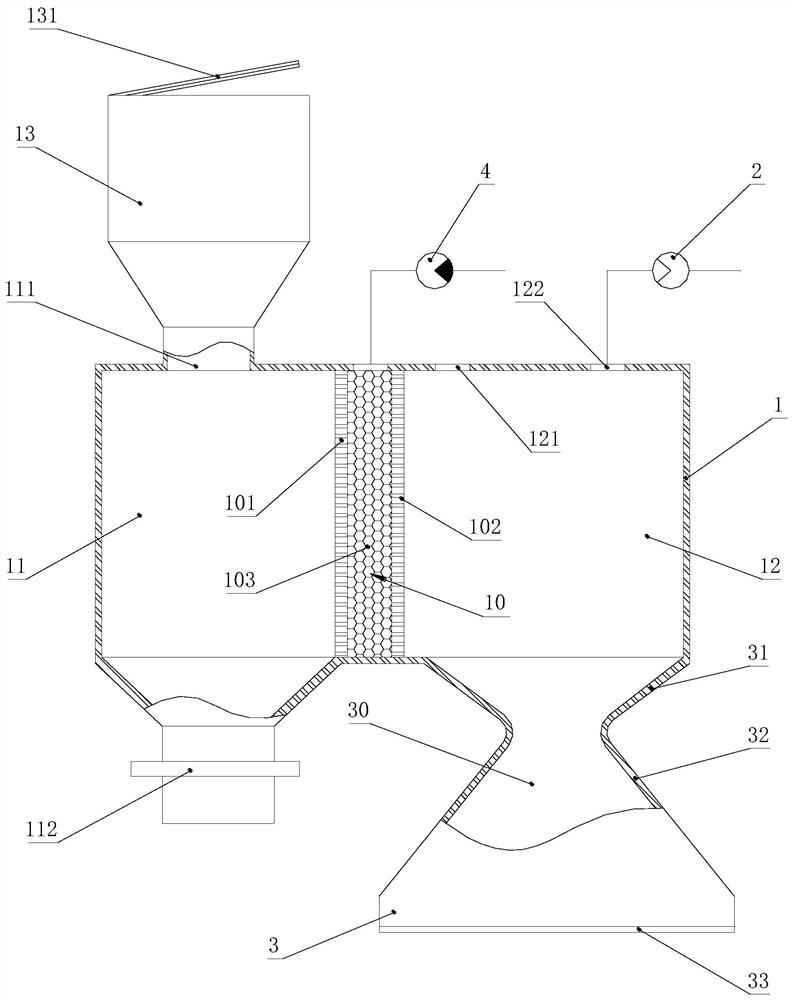

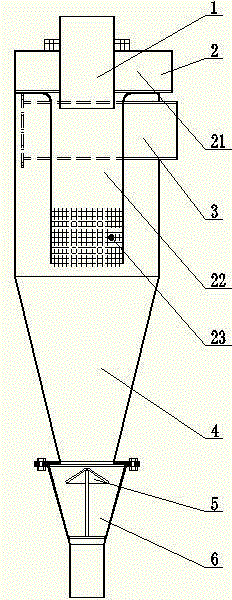

Combined type mobile grain dust remover

InactiveCN106215590AImprove adsorption capacityGuaranteed separation efficiencyCombination devicesCyclonic separationEngineering

The invention belongs to the technical field of environment-friendly equipment and especially relates to a combined type mobile grain dust remover. The combined type mobile grain dust remover comprises a cyclone body, a grain filtering bed and a dust collecting hopper and is characterized in that the dust collecting hopper is arranged under the cyclone body; the grain filtering bed is arranged on the inner side of the cyclone body; an inner filter screen and an outer filter screen are respectively arranged on the two sides of the grain filtering bed; the outer filter screen is located between the cyclone body and the grain filtering bed; an air inlet is arranged above the cyclone body; an air outlet is arranged above the grain filtering bed; a separating screen is arranged above the dust collecting hopper; one side of the separating screen is higher than the other side; the lower side of the separating screen extends out of the dust collecting hopper and is communicated with a storage box; the storage box is communicated with the top of the grain filtering bed through a filter material conveying pipeline. The combined type mobile grain dust remover has the beneficial effects that the two principles of cyclone separation dust removal and grain filtering dust removal are combined with each other, a secondary separating function is realized in one device, the problem of low dust removing efficiency of the grain dust remover is solved and the occupied area is small.

Owner:TIANJIN MAOBIN MACHINERY EQUIP

Method for utilizing NaCl solution to separate nematode

InactiveCN102607928AAvoid damageReduce power consumptionPreparing sample for investigationSucroseSaccharum

The invention relates to a method for utilizing NaCl solution to separate nematode, which relates to a method for separating the nematode, and aims to solve the problems that: the used time is longer, the working amount is large, the nematode is easy to damage and the electric energy is consumed when an existing sucrose centrifugal flotation method is used for separating the nematode. The method for utilizing the NaCl solution to separate the nematode comprises the flowing steps of: I, adding a nematode carrier sample into the NaCl solution, and stirring to obtain mixed liquor; II, stewing the mixed liquor to obtain liquid supernatant and precipitates; III, replacing the nematode carrier sample with the precipitates, repeating the steps, removing the precipitates, and obtaining liquid supernatant; and IV, merging the liquid supernatant, injecting the liquid supernatant into a sample sieve group, and carrying out back flushing on a high-mesh sample sieve by utilizing water to obtain the nematode. The method can be applied to fields of biology, geography, environmental sciences and the like.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

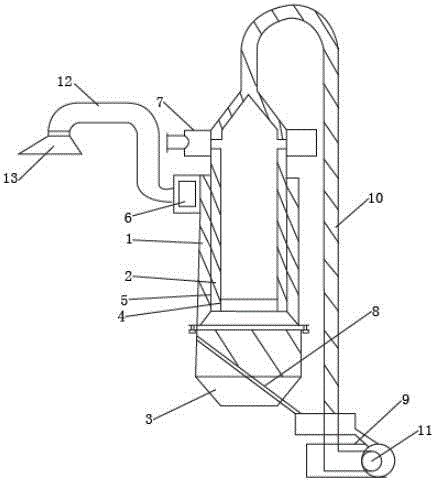

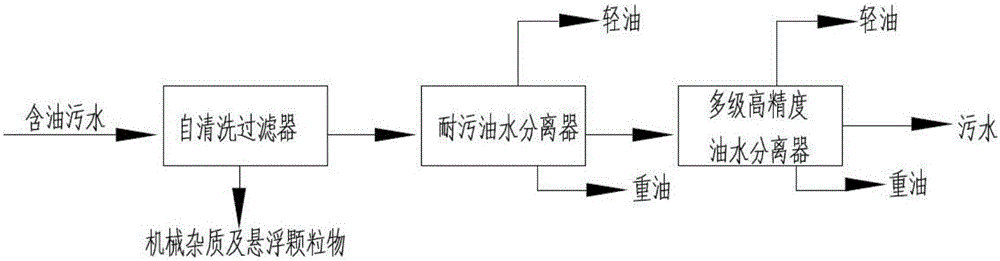

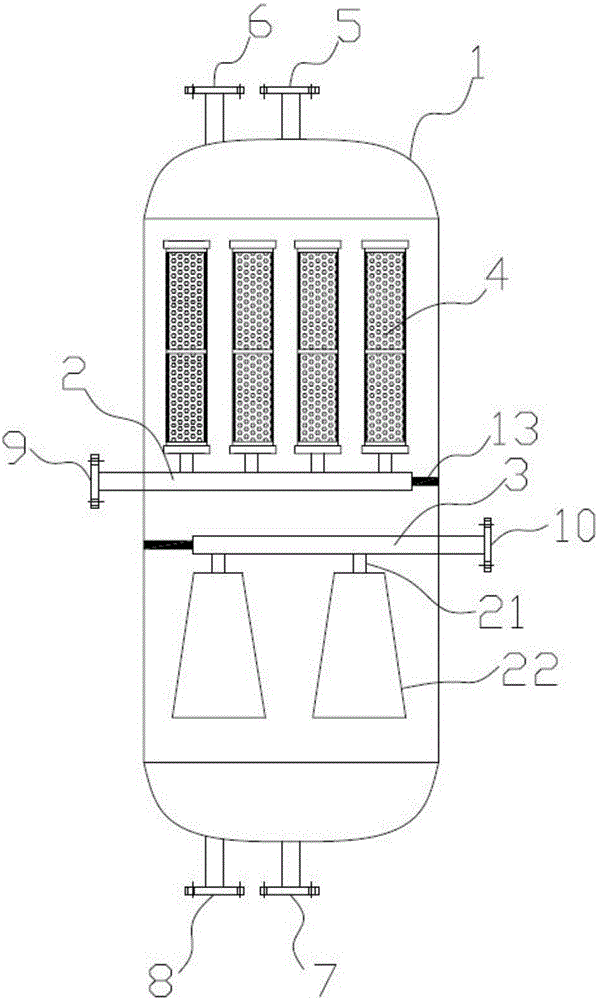

United multistage oil-water separation process

ActiveCN106045088AEasy to separateNo secondary pollutantsFatty/oily/floating substances removal devicesTreatment involving filtrationEconomic benefitsSewage

The invention discloses a united multistage oil-water separation process. The united multistage oil-water separation process comprises the specific steps of 1 pretreatment, 2 primary separation and 3 secondary separation, wherein united multistage treatment is conducted on oily sewage by serially connecting a self-cleaning filter, a stain-resisting oil-water separator and a multistage high-precision oil-water separator, oil in oily sewage, especially dispersed oil, emulsified oil and the like, are rapidly separated in a pure physical mode, and oil recycling is achieved. The united multistage oil-water separation process comprises simple steps, is low in operating cost, good in operability and good in separation accuracy, can greatly improve the oil-water separation efficiency and effect and achieve recycling of various types of oil, can also produce remarkable economic benefits while achieving the environmental protection purpose and is suitable for industrialized application.

Owner:湖州深净环境科技有限公司

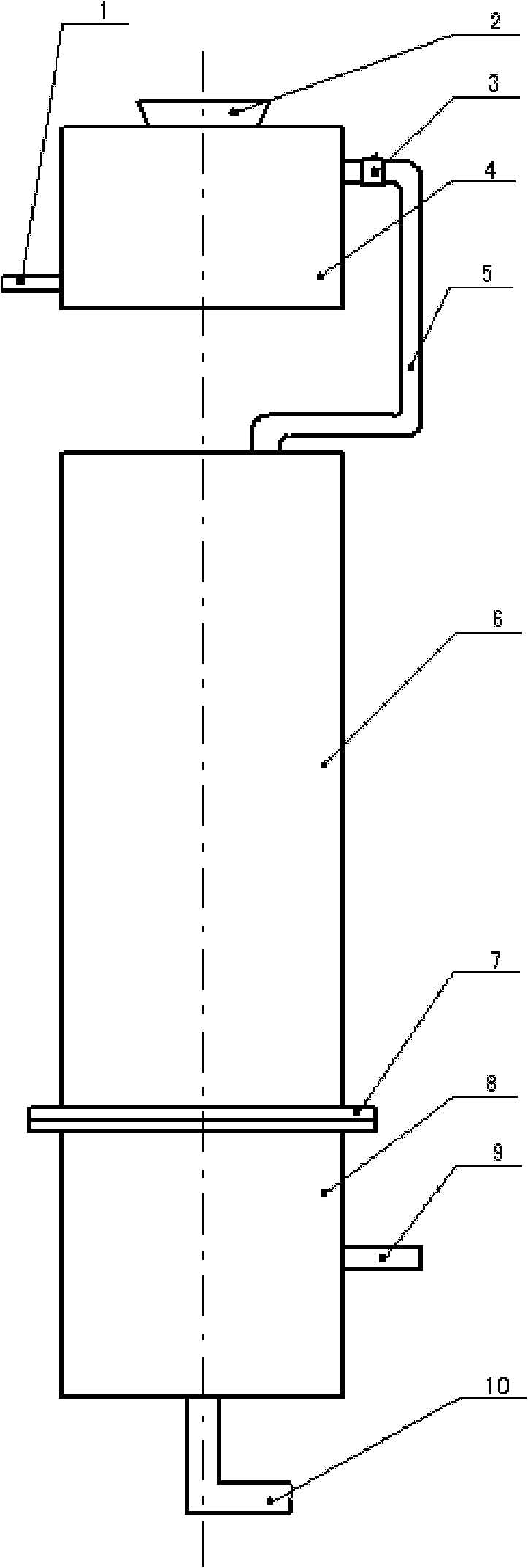

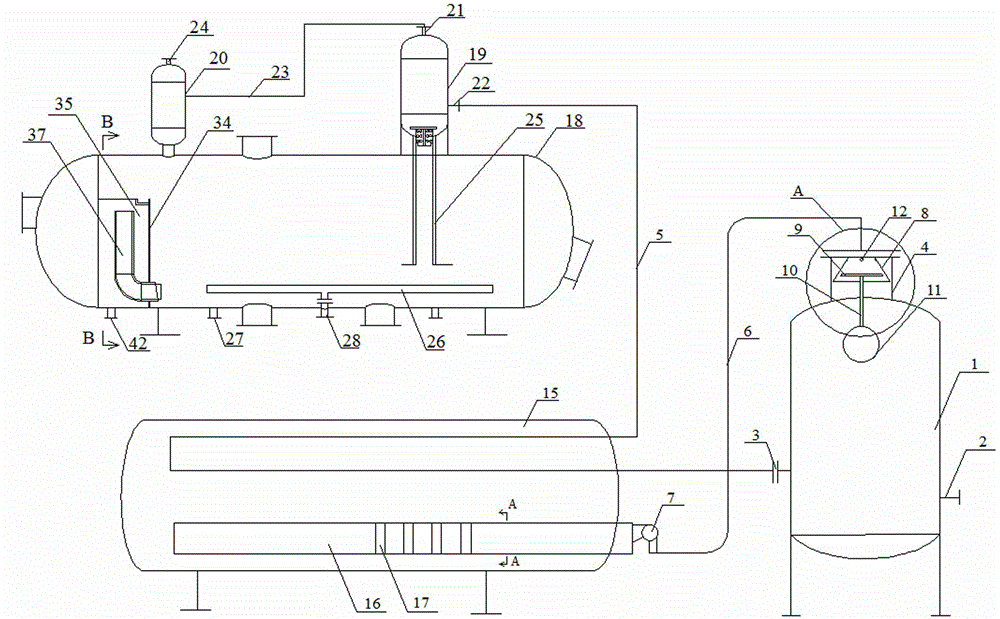

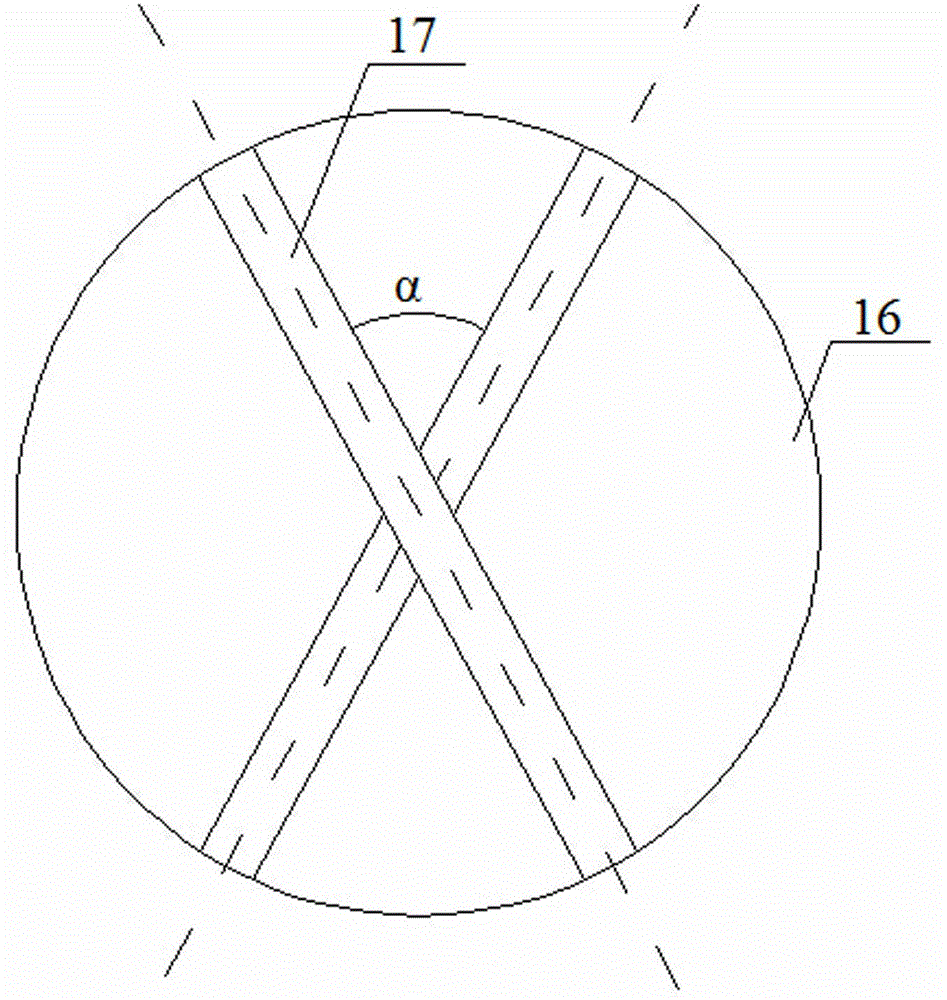

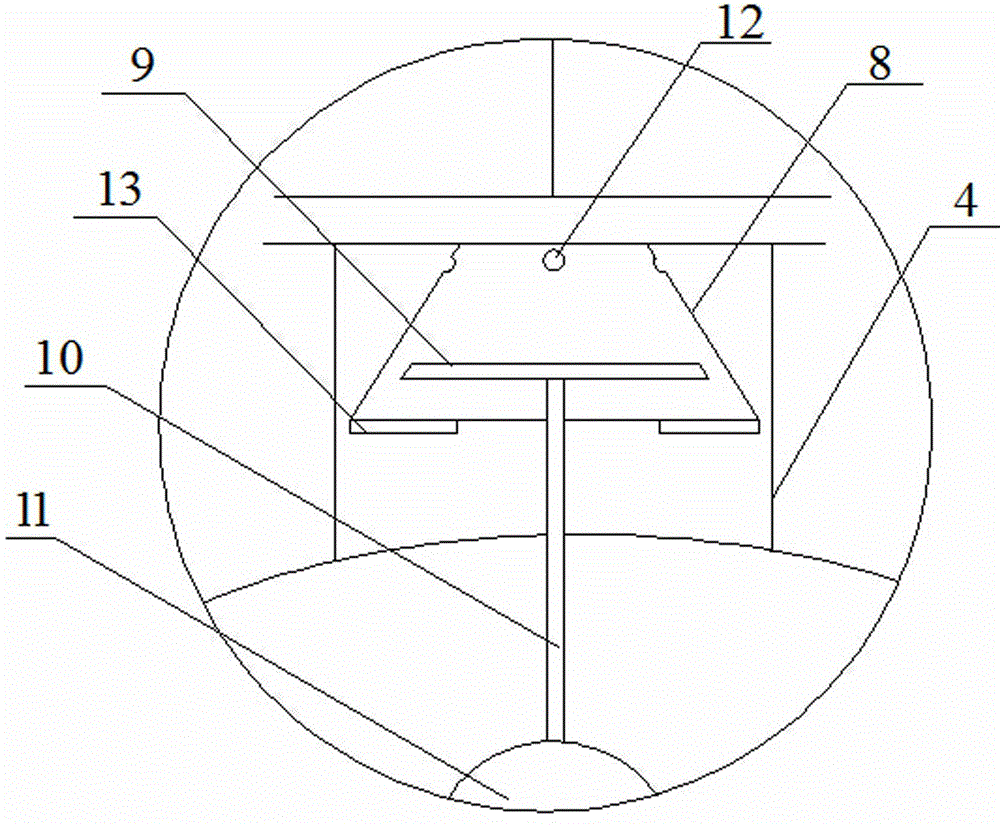

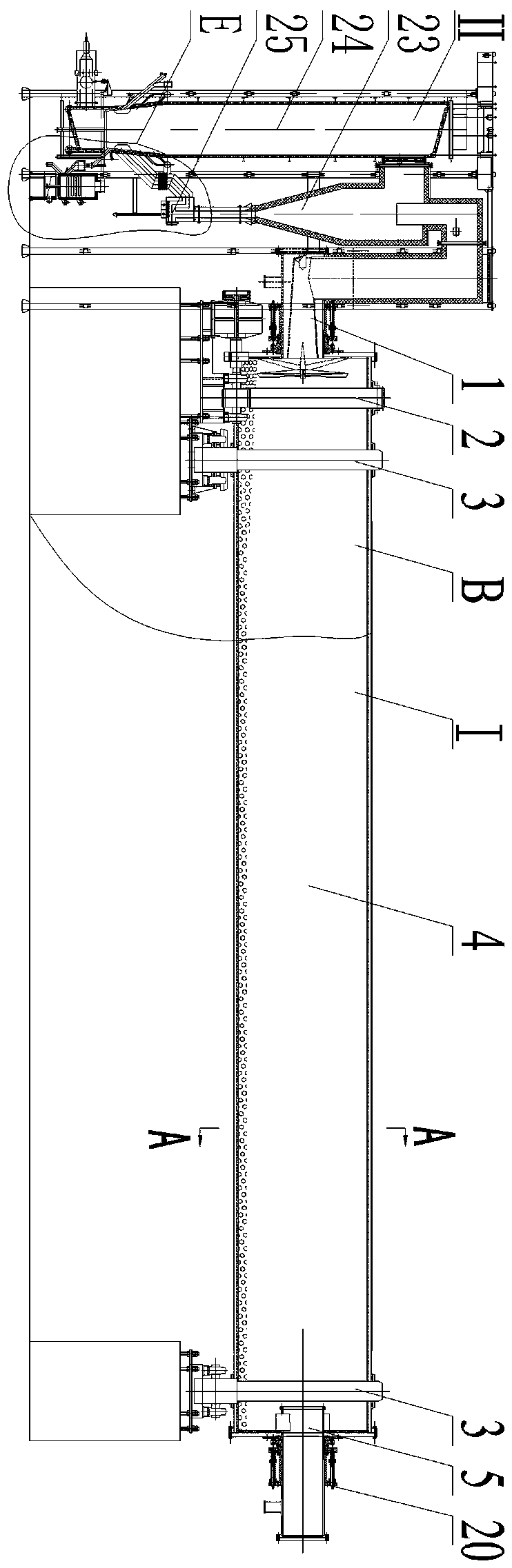

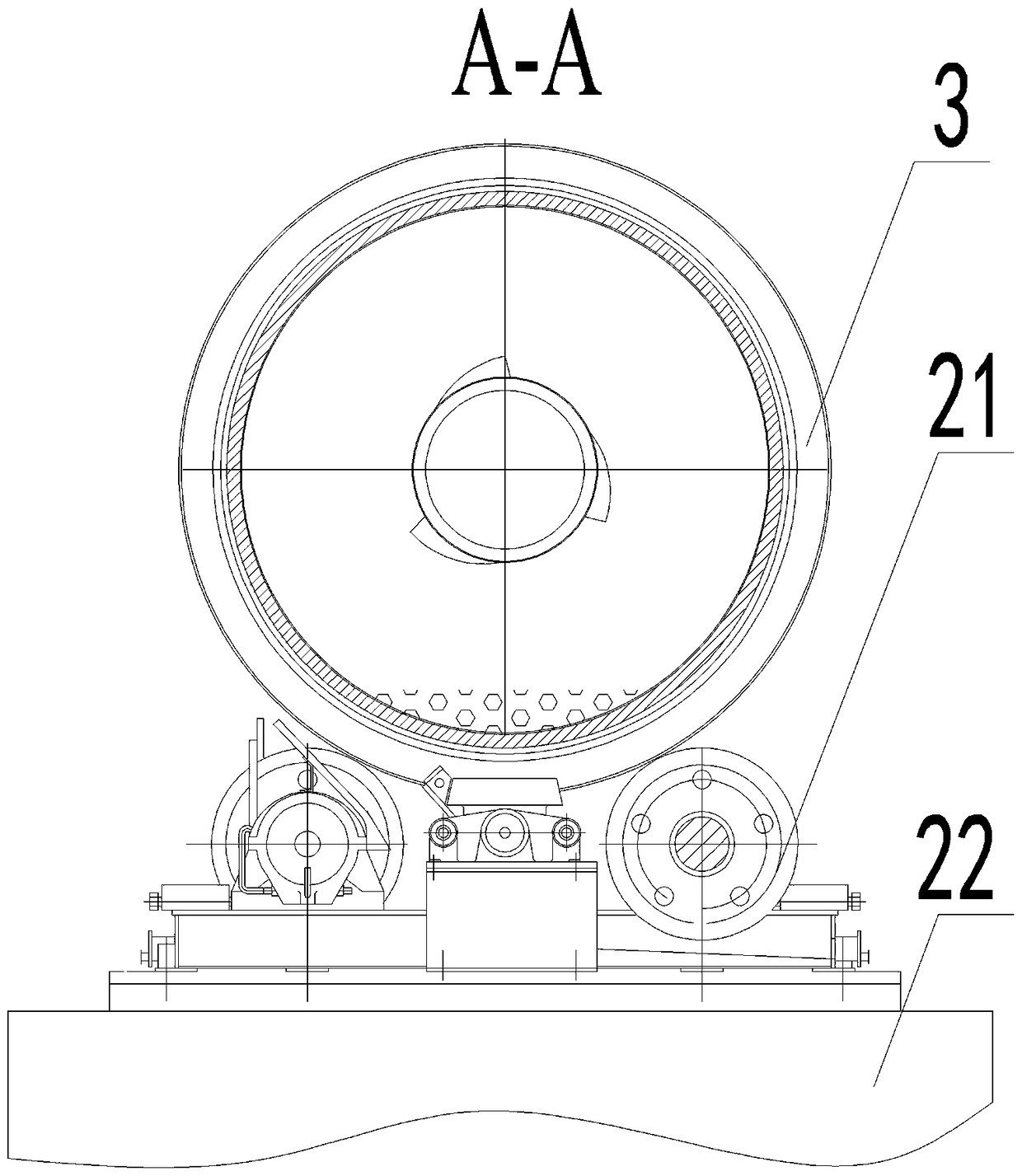

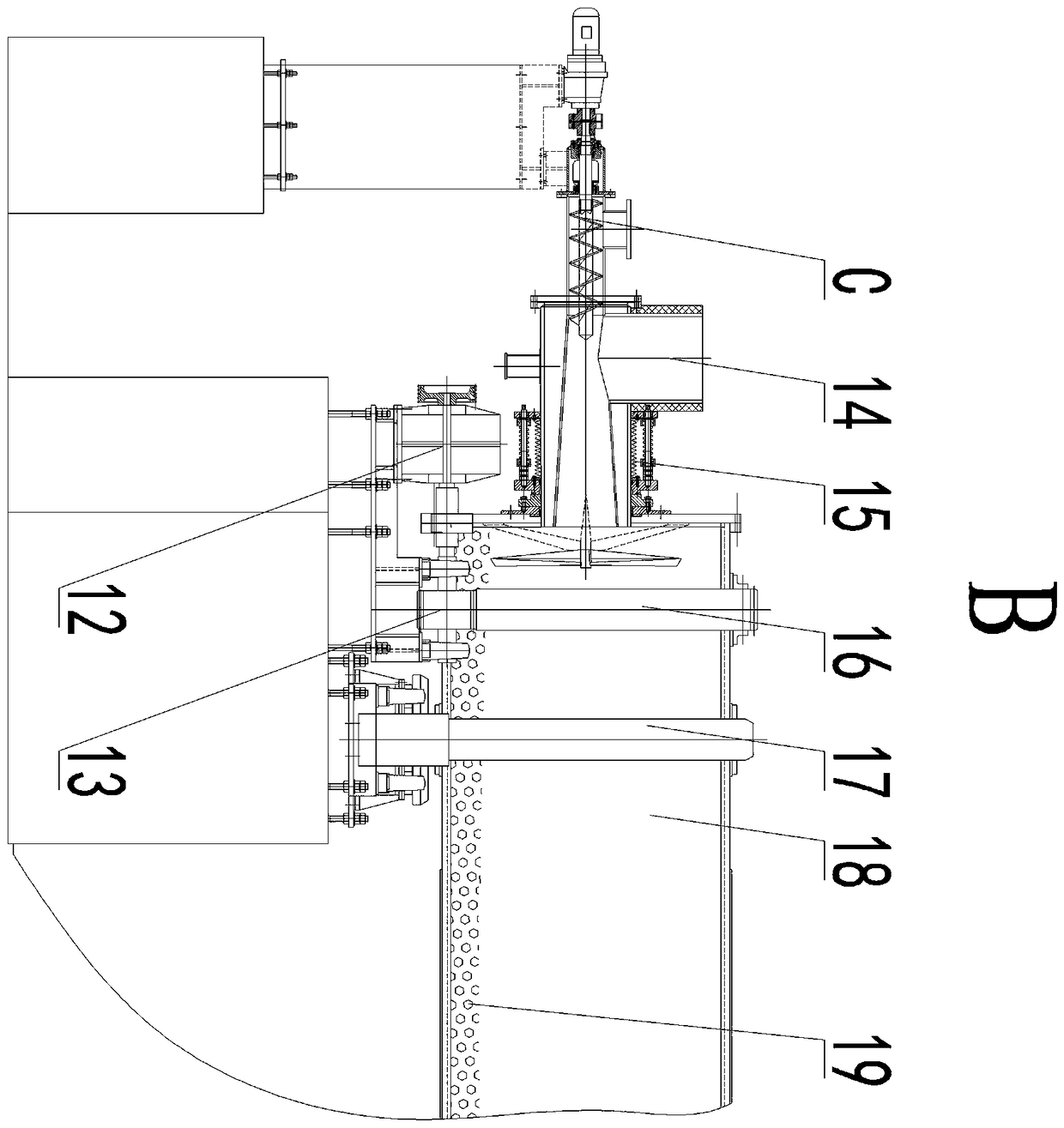

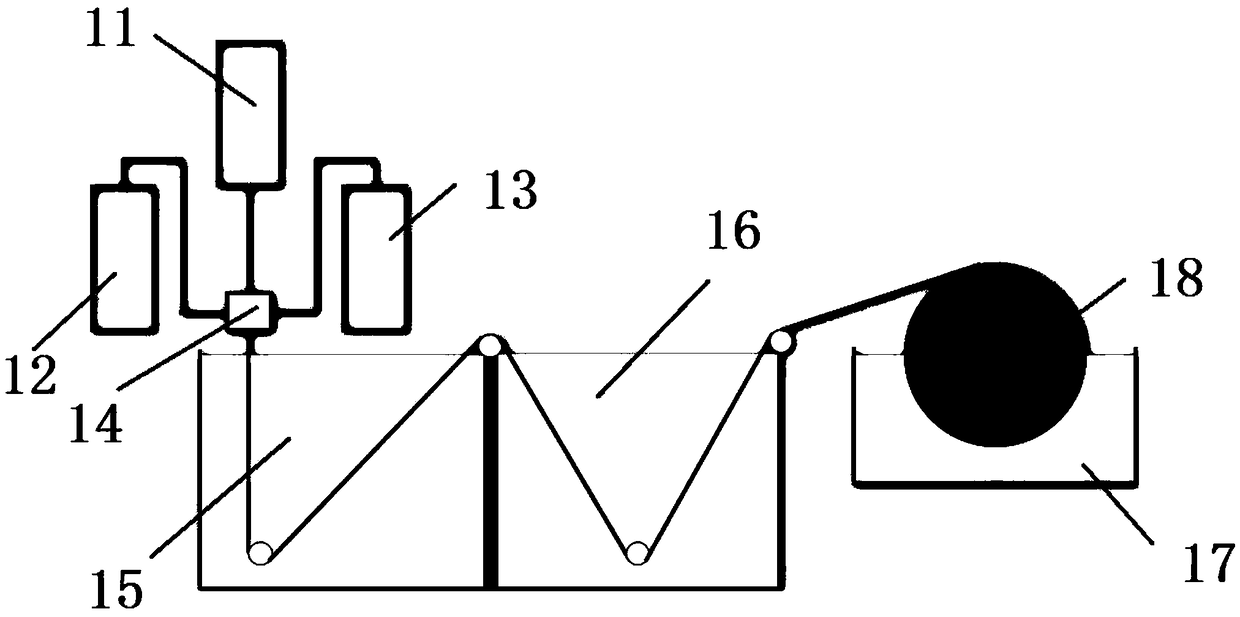

Oil field steam injection boiler steam dryness increasing device

ActiveCN105910088ALess investmentSolve the problem of low drynessFluid removalSteam separation arrangementsOil productionEngineering

The invention discloses an oil field steam injection boiler steam dryness increasing device, and mainly solves the defect of low thickened oil production efficiency due to insufficient dryness of steam provided by a traditional oil field steam injection boiler. The oil field steam injection boiler steam dryness increasing device is characterized in that a steam dryness increasing pipeline (2) includes a boiler steam outlet (1), a high-pressure steam and water separator (4) and a sampling separator (5); boiler steam passes through a high-pressure stop valve A (3) by the boiler steam outlet (1) to enter the high-pressure steam and water separator (4); and high-dryness steam separated by the high-pressure steam and water separator (4) enters the sampling separator (5), and passes through a pressure transducer A (6), a one-way valve (7) and a high-pressure stop valve B (8) in sequence to enter a steam injection pipe network through a steam injection pipe network joint (30). The oil field steam injection boiler steam dryness increasing device can increase the steam dryness by above 95% so as to improve the thickened oil production efficiency.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

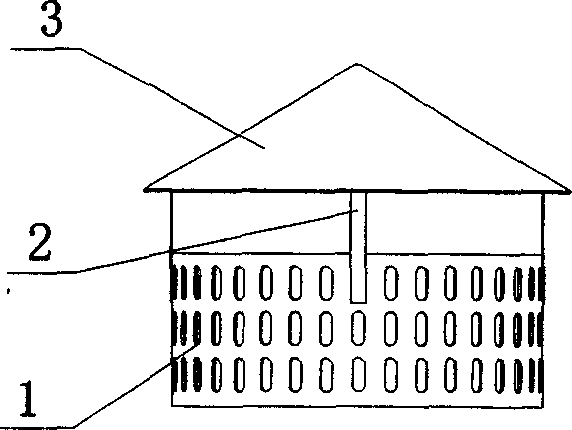

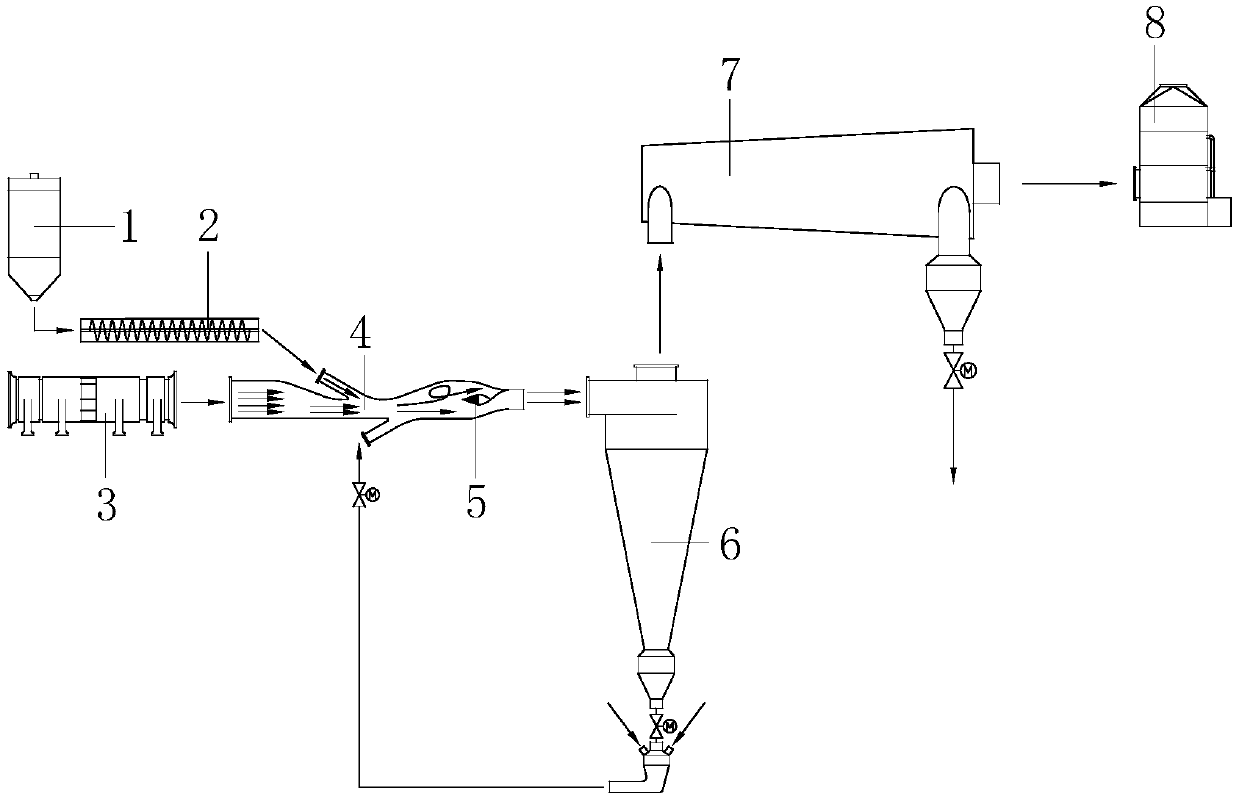

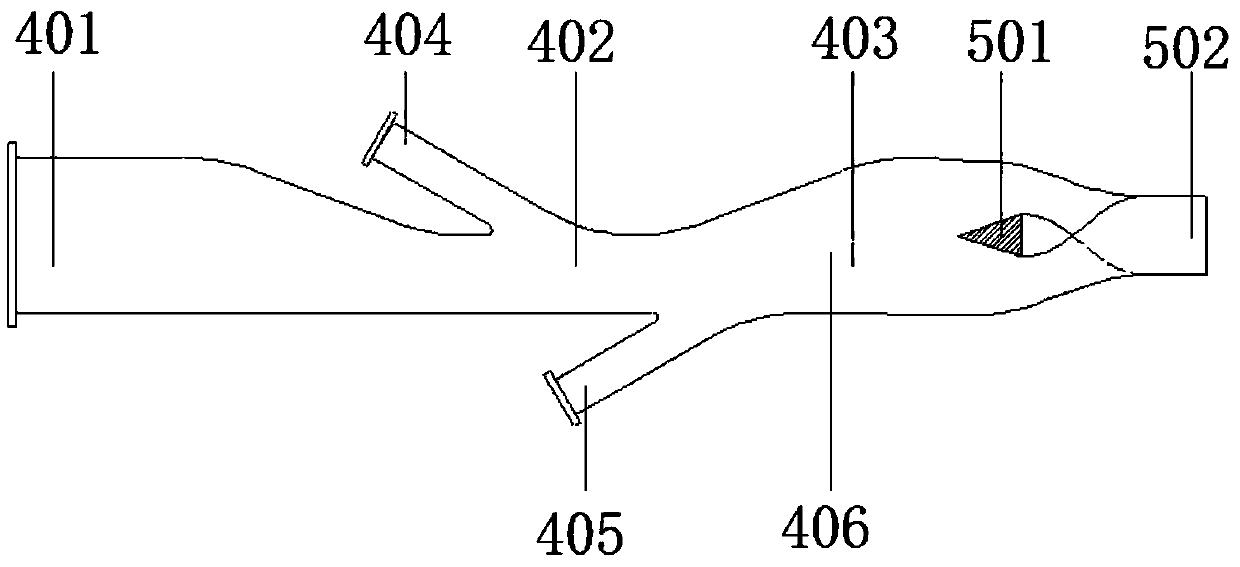

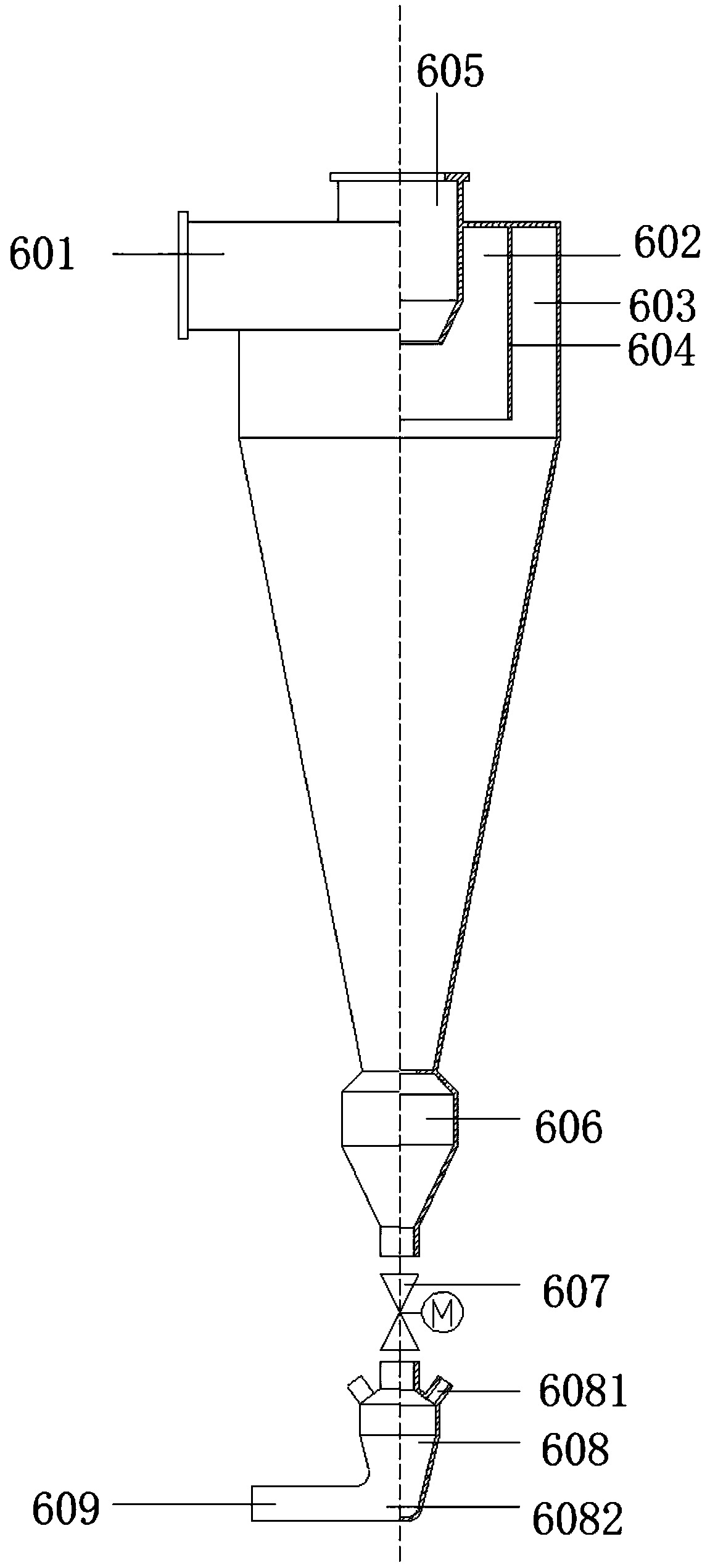

Cyclone system for sludge drying

The invention provides a cyclone system for sludge drying. The cyclone system comprises a material bin, a spiral conveying pipe, a high-speed cyclone cluster, an eccentric venturi pipe, a wedge-shapedtorque pipe splitter, a semi double duct cyclone separator, a tortuous centrifugal speed reduction settler and a spraying tower. Gas turbulent flow is utilized to preliminarily smash materials through the eccentric venturi pipe, the smashed materials are divided and sent into the semi double duct cyclone separator to be subjected to preliminary drying and separation, sludge containing large solidparticles can be directly discharged out or enters the eccentric venturi pipe again to be subjected to solid-liquid drying and separation, meanwhile, gas containing small particles enters the detourcentrifugal speed reduction settler to be subjected to secondary deep solid-liquid drying and separation, and finally the separated gas is input into the spraying tower to be treated so as to reduce pollution. The device is an unpowered part, and is designed in a modularized mode, the structure is compact, and the reliability is high.

Owner:HUNAN UNIV +1

Sampling device for biotechnological separation

InactiveCN110514488AAvoid pollutionGuaranteed separation efficiencyPreparing sample for investigationChemical engineering

The invention discloses a sampling device for biotechnology separation. The device comprises a separation box, a sampling cylinder and a dosing box; the separation box is positioned between the sampling cylinder and the dosing box; a rotating motor is arranged at the center of the top of the separation box; the output end of a rotary motor is connected with a stirring shaft extending into the separation box; the stirring shaft is provided with a plurality of rotary crushing cutters; fixed crushing cutters staggered relative to the rotary crushing cutters in a vertical direction are arranged onthe inner wall of the separation box; and a sample inlet communicated with the interior of the separation box is formed in the top of the separation box. According to the sampling device, the rotarycrushing cutters and the fixed crushing cutters which are arranged in a staggered manner are arranged in the separation box to crush a sample; a solution is conveyed into a sample layer through the dosing box, so that the sample can be crushed and stripped off sequentially, and therefore, separation efficiency can be ensured, and sampling accuracy is improved; and the sampling cylinder is adopted,and therefore, a sampling process is convenient, the possibility of misoperation is reduced, and a condition that the sample is polluted is avoided.

Owner:佛山市嘉懿行农业科技有限公司

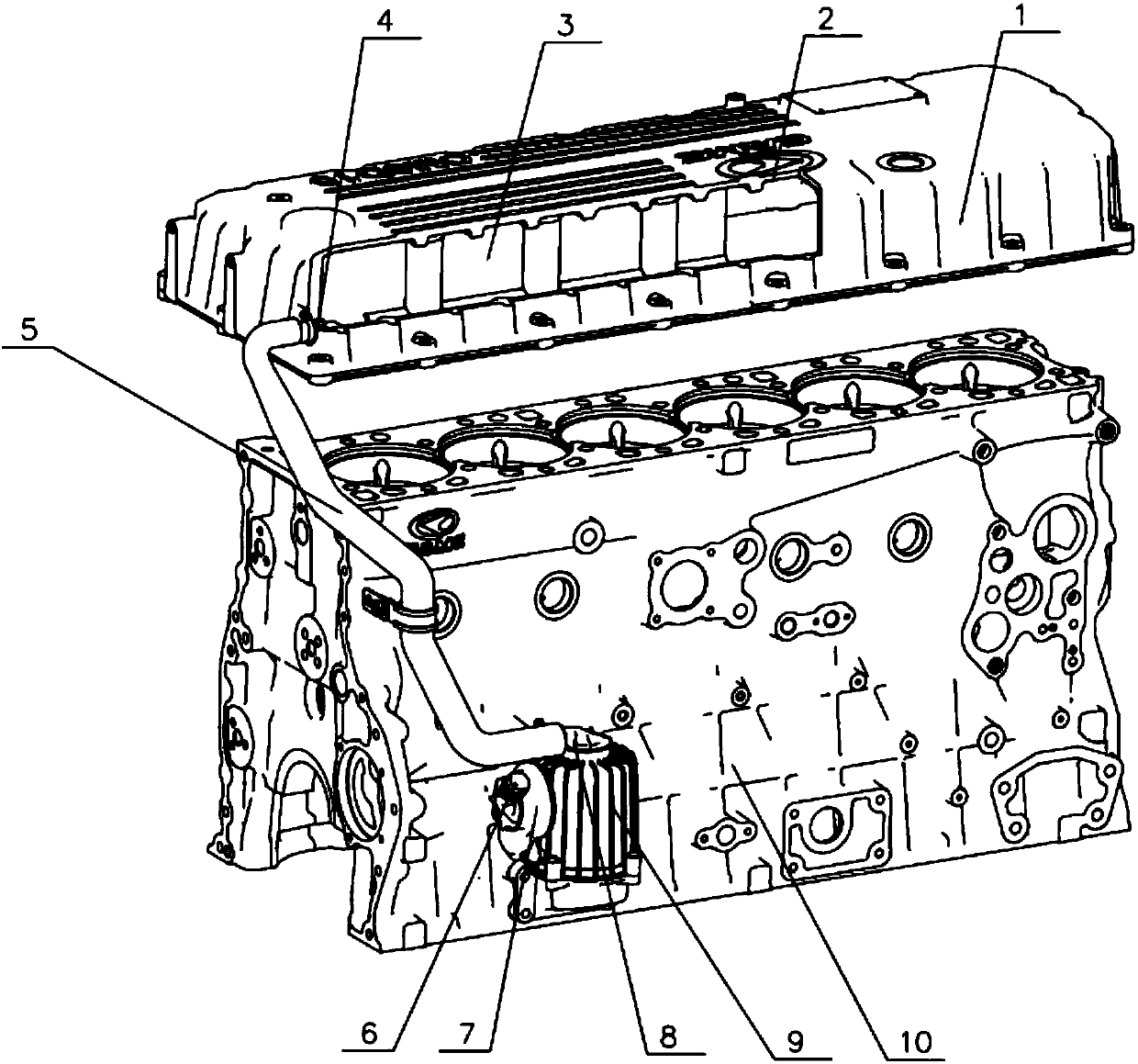

Engine and engine oil-gas separator thereof

PendingCN107842411AReduce use costExtended service lifeMachines/enginesCrankcase ventillationInlet channelCylinder block

The invention discloses an engine oil-gas separator. The engine oil-gas separator comprises a separator body, a cylinder block oil inlet channel and an engine oil pump, wherein the separator body comprises a cover shell fixedly connected to a cylinder block, a rotary shaft arranged in the cover shell, blades arranged on the rotary shaft and a driving rotor connected to the rotary shaft; the rotaryshaft is vertically arranged; the top of the cover shell is provided with a separator inlet, and the bottom of the cover shell is provided with a separator oil outlet; the side portion of the cover shell is provided with a separator gas outlet; the cylinder block oil inlet channel is formed in the cylinder block, and an outlet of the cylinder block oil inlet channel is aligned with the driving rotor; the engine oil pump is used for delivery engine oil and can deliver engine oil in the cylinder block oil inlet channel, so that the engine oil is sprayed to the driving rotor to drive the drivingrotor. In the engine oil-gas separator, the engine oil is sprayed to the driving rotor to make the blades rotate; oil and gas are separated through the centrifugal separation principle, the separation efficiency can be guaranteed, and the usage cost of users can be reduced. The invention further discloses an engine comprising the engine oil-gas separator. The separation efficiency can be improved. The usage cost can be reduced.

Owner:ANHUI HUALING AUTOMOBILE

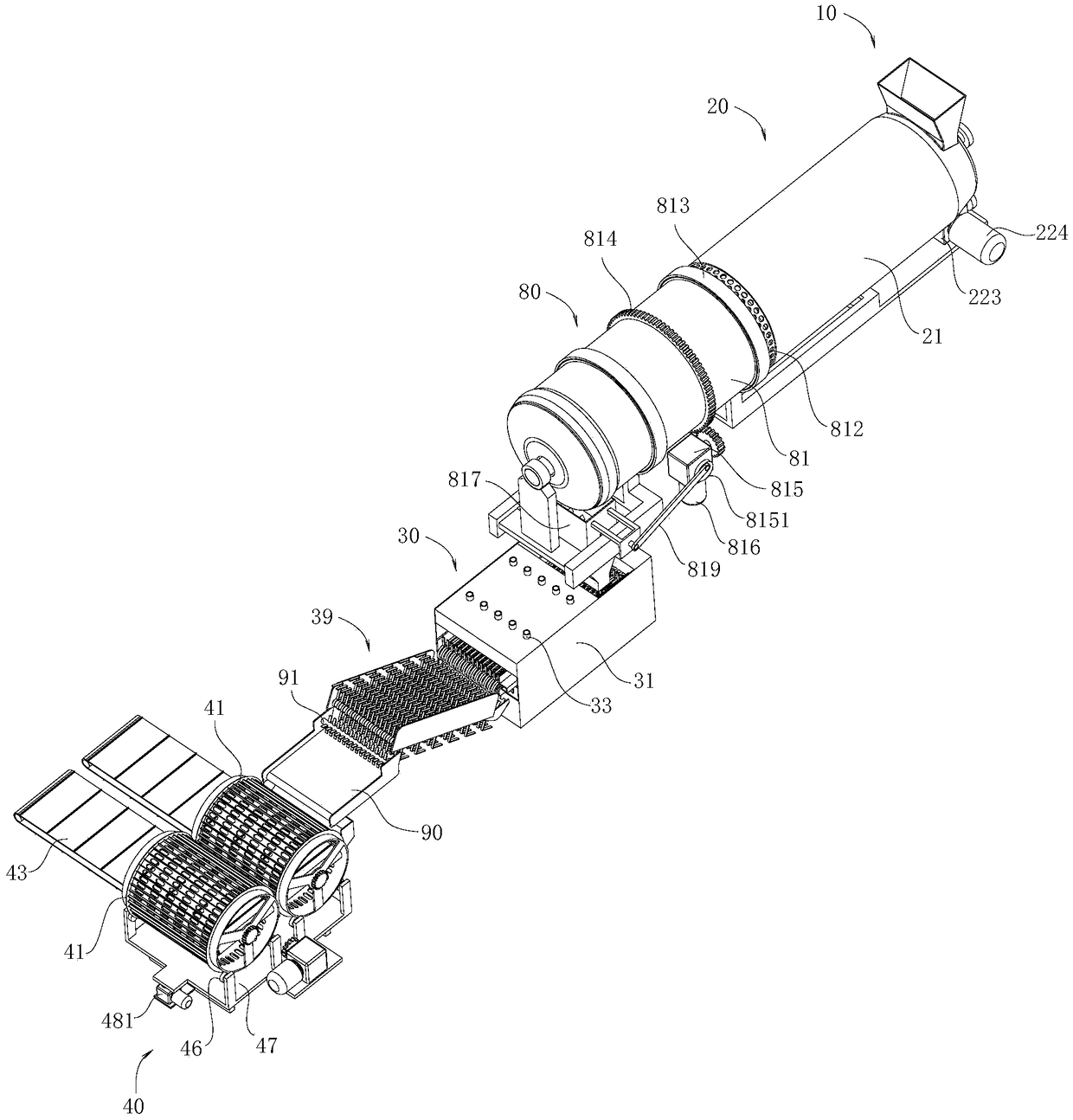

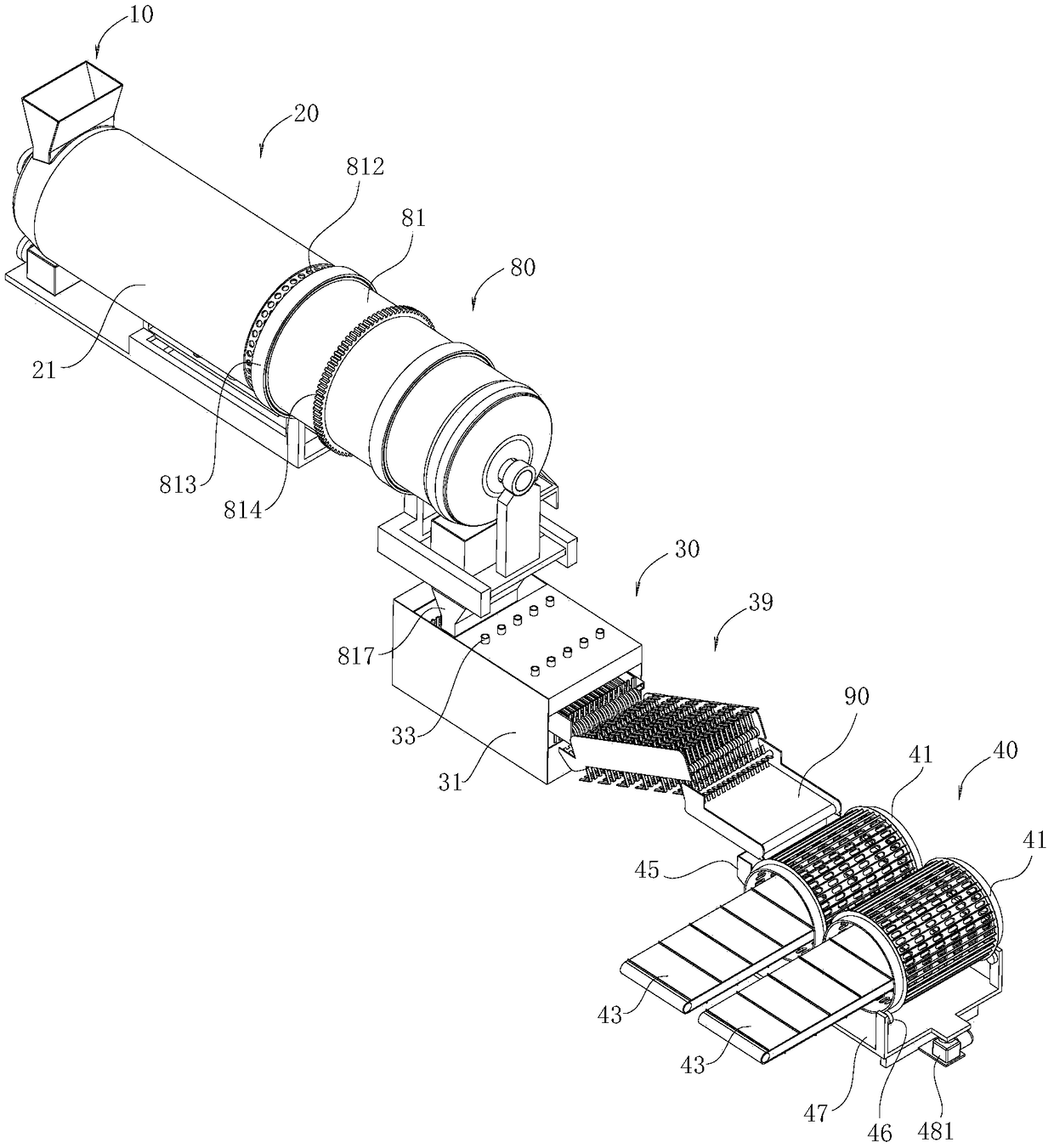

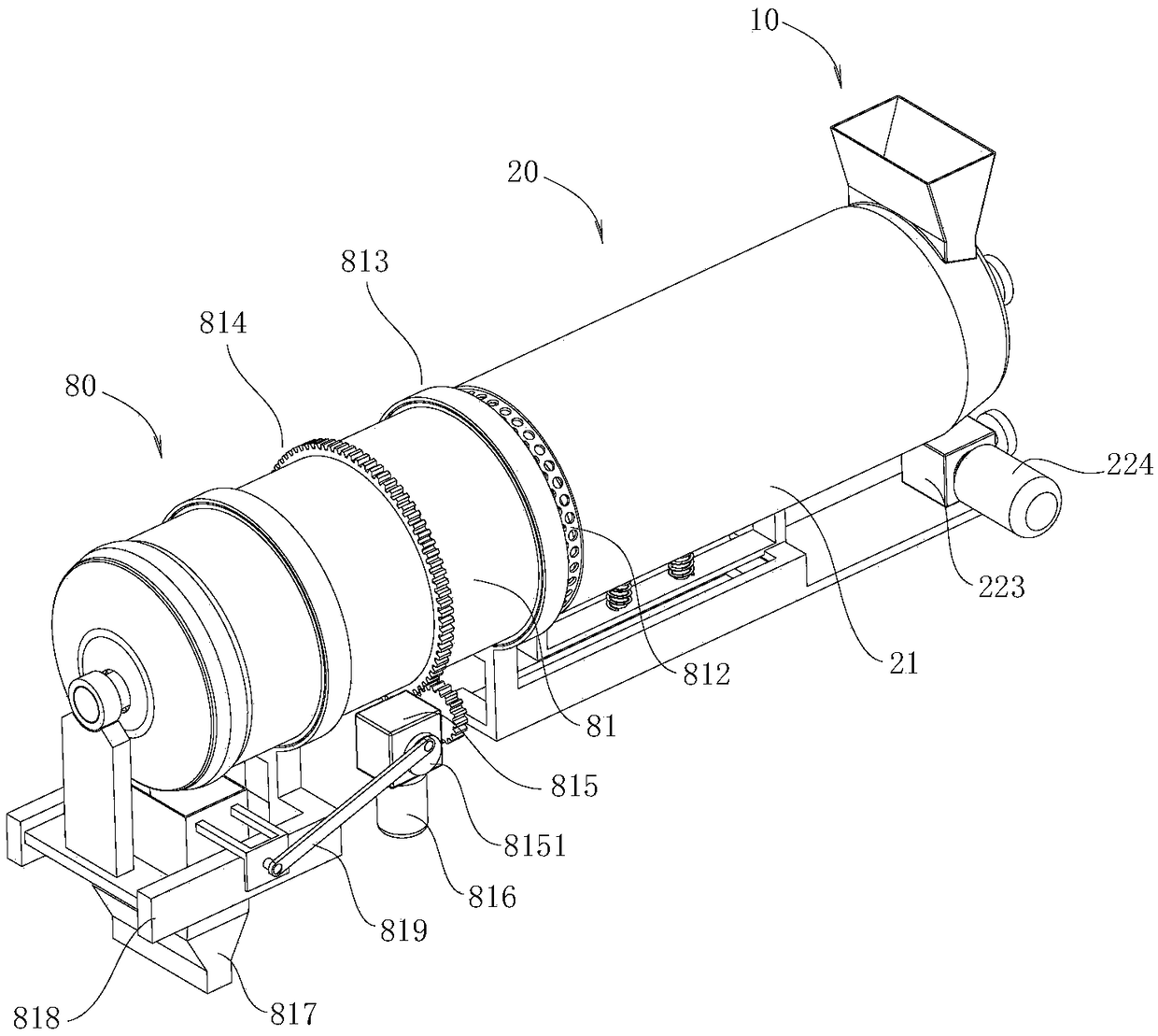

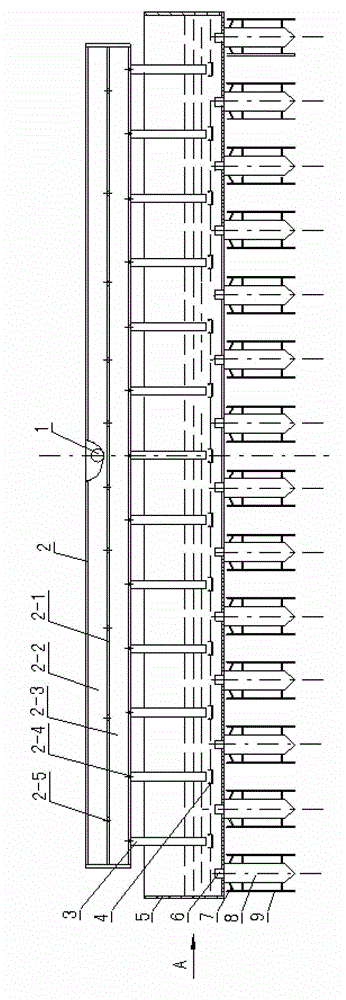

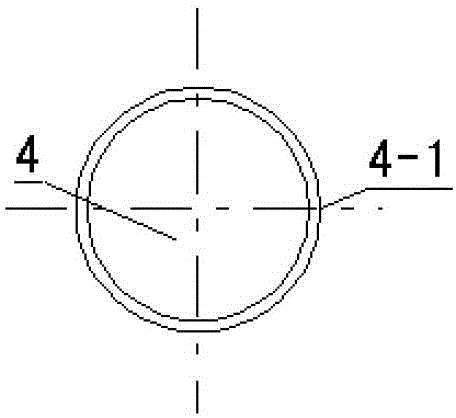

Roller type fruit shell separating machine

The invention relates to the field of fruit shell separation equipment, and discloses a roller type fruit shell separating machine. The roller type fruit shell separating machine comprises a machine frame and a material conveying belt, and further comprises at least one roller which is arranged above the material conveying belt and stretches across the width direction of the material conveying belt, needle thorns are arranged on the peripheries of the rollers so as to pierce fruit shells on the material conveying belt and perform subsequent separation when the rollers rotate, the rotating direction of the rollers is the same as the running direction of the material conveying belt, and a distance is formed between the free end of each needle thorn on the rollers and the surface of the material conveying belt; and the roller type fruit shell separating machine further comprises slag discharging mechanisms which are arranged corresponding to the rollers, and the slag discharging mechanisms can strip the fruit shells on the needle thorns of the rollers. According to the fruit shell separating machine, the concept that a traditional fruit shell separating machine needle thorn plate is used for sorting shells through up-and-down periodic movement is subverted, then the mode by which the needle thorns are fully distributed on the surfaces of the rollers which do rotating motion, so that sorting of the fruit shells is always carried out through the needle thorns on the mixed fruit shell materials on the material conveying belt in the rotating process of the rollers, the material conveying belt can be used for continuous conveying, the needle thorns are orderly and densely arranged on the rollers, so that the separation efficiency and the separation rate of the fruit shells areensured.

Owner:HUNAN DASANXIANG TEA OIL CO LTD

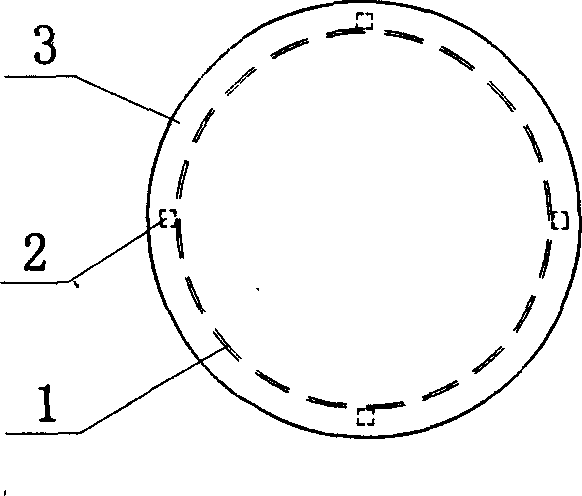

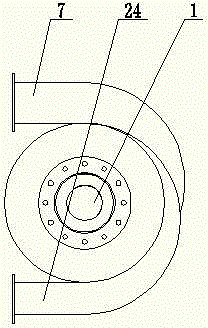

Integrated coaxial recycling serial connection type high-efficiency cyclone separator

The invention relates to an integrated coaxial recycling serial connection type high-efficiency cyclone separator which is small in size, short in air flow route, small in pressure drop, stable in air flow field, stable in property and high in separation efficiency. The integrated coaxial recycling serial connection type high-efficiency cyclone separator comprises a main shell, an air inlet tube, an exhaust tube and a discharge cabin. The integrated coaxial recycling serial connection type high-efficiency cyclone separator is structurally characterized in that a backflow device is further arranged on the top of the main shell; the backflow device comprises a backflow tube, a backflow volute and an inner cylinder which is connected with the lower end of the backflow volute; the inner cylinder is coaxially arranged with the main shell and the exhaust tube; the air inlet tube is arranged on the main shell below the backflow device; and the air inlet tube is connected with the main shell so as to form an air inlet volute.

Owner:魏昊元

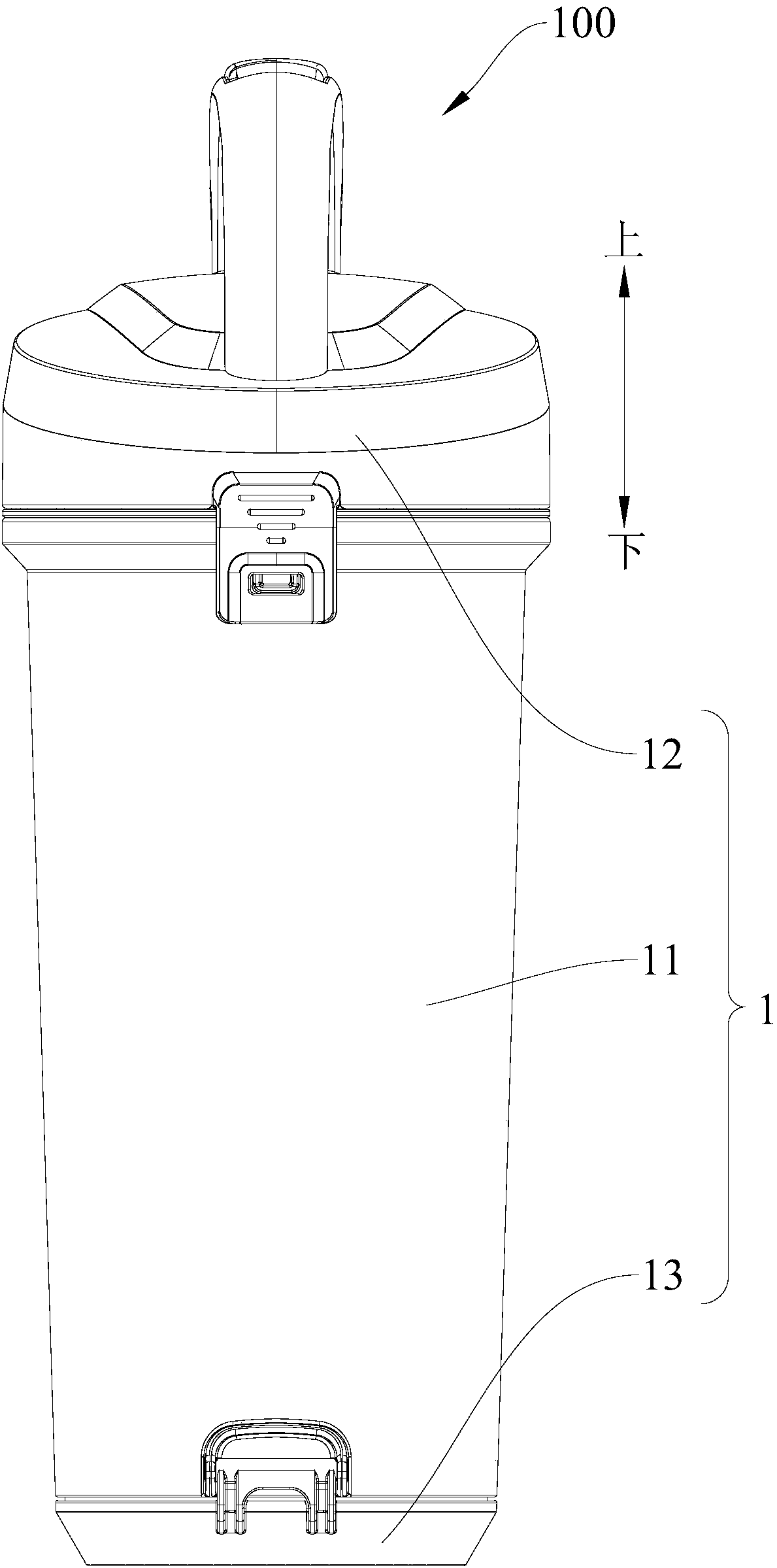

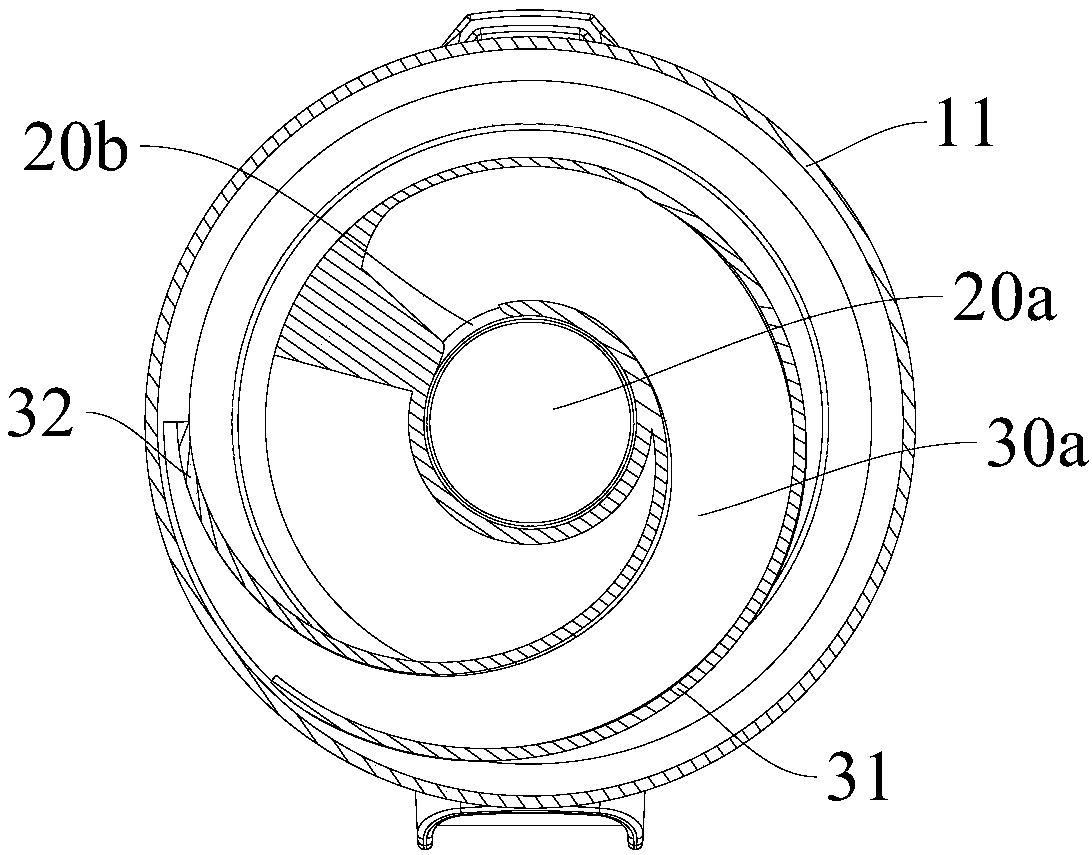

Dust cup and dust collector provided with dust cup

The invention discloses a dust cup and a dust collector provided with the dust cup. The dust cup comprises a dust cup main body, a passage piece and a spiral passage piece, wherein an air inlet is formed in the bottom of the dust cup main body and an air outlet is formed in the top of the dust cup main body; the passage piece is arranged in the dust cup main body; the lower end of the passage piece is connected to the air inlet, and the upper end of the passage piece is connected to the air outlet; a dividing piece is arranged in the passage piece, so that the interior of the passage piece isdivided into an air outlet passage and an air inlet passage which is arranged under the air outlet passage; a plurality of through holes are formed in the sidewall, corresponding to the air outlet passage, of the passage piece, and a communicating port is formed in the sidewall, corresponding to the air inlet passage, of the passage piece; one end of the spiral passage piece is connected to the communicating port and the other end of the spiral passage piece extends upwards in a spiral form along the axial direction of the passage piece until to the sidewall of the dust cup main body; and theother end of the spiral passage piece communicates with the interior of the dust cup main body. The dust cup provided by the invention is simple in structure and convenient for cleaning; and the dust-gas separating efficiency of a dust collection device can be improved, and pressure loss can be reduced.

Owner:JIANGSU MIDEA CLEANING APPLIANCES +1

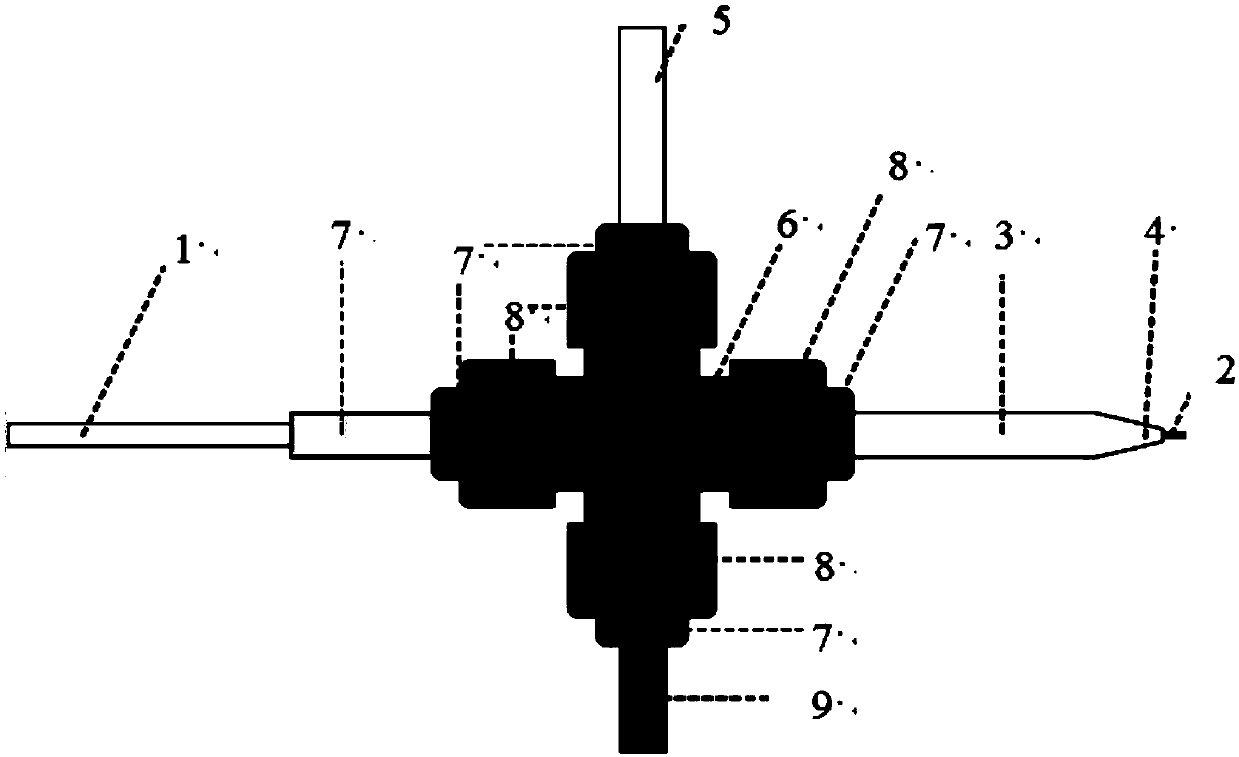

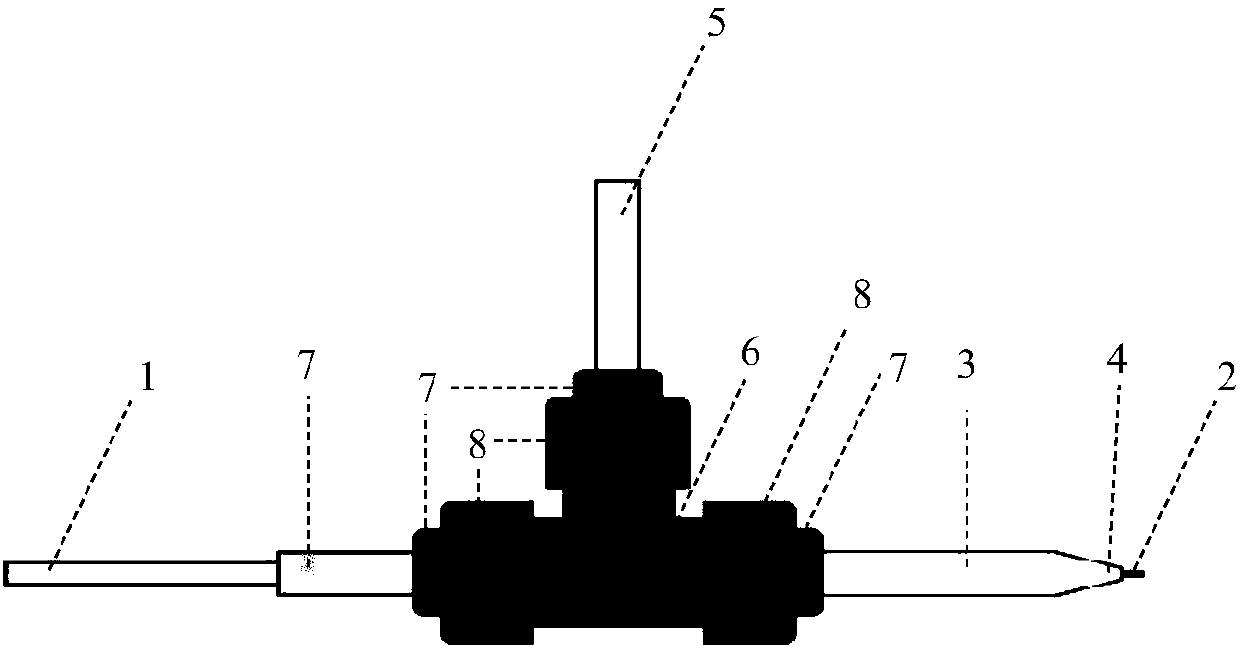

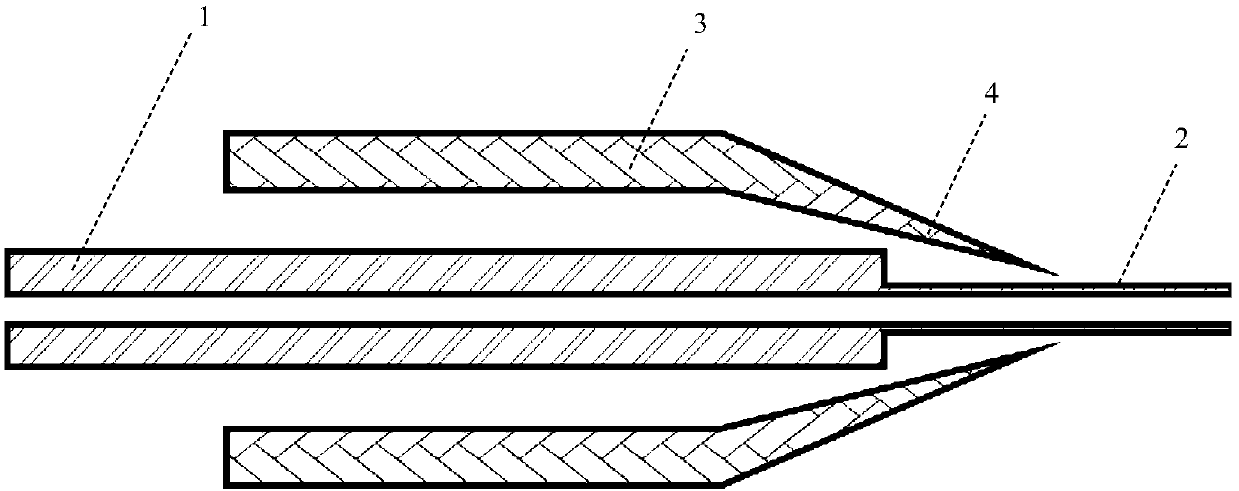

Electrospray ionization mass spectrometry interface device with tiny dead volume and utilization method thereof

ActiveCN107796903ASmall dead volumeExtended service lifeComponent separationESI mass spectrometryDead volume

The invention discloses an electrospray ionization mass spectrometry interface device with tiny dead volume and a utilization method thereof. The interface device comprises an analysis capillary tube,a sheath flow capillary tube, a sheath flow connection tube, a connection component and an electrode. A sheath flow solution storage container and the sheath flow capillary tube are connected throughthe sheath flow connection tube, the connection component is used for assembling the analysis capillary tube and the sheath flow capillary tube into a sleeve structure, and the electrode is used forproviding power for electrospray. The interface device has advantages that by design of processing the thin-wall analysis capillary tube, the small-outlet sheath flow capillary tube, laminar sheath fluid surface flow and the like, the interface dead volume can be sharply decreased, sample separation efficiency is guaranteed, and the service life of the interface device is prolonged.

Owner:ZHEJIANG UNIV

Application method of circulating fluidized bed roasting rotary integrated furnace

ActiveCN108131665AReduce environmental pollutionReduce manufacturing costFluidized bed combustionGas current separationFlue gasRotary furnace

The invention relates to the technical fields of environmental protection and resource cyclic and comprehensive utilization, in particular to an application method of a circulating fluidized bed roasting rotary integrated furnace. The application method is characterized in that a roasting excitation rotary furnace and a circulating fluidized bed coal-fired furnace are included; by means of a guiding pipe designed to be arranged beside an outlet of a material return pipe, the local bore pressure of the outlet of the material return pipe is reduced, and thus the material column height of a vertical pipe is reduced; and the purposes that materials are balanced, and separation efficiency is guaranteed are achieved, and the circulating fluidized bed coal-fired furnace and the roasting excitation rotary furnace can be effectively combined and operate normally. High-temperature flue gas carries fly ash of the circulating fluidized bed coal-fired furnace to enter an ejector through a hot air channel, is mixed with materials such as a guiding agent and then is guided by a flow dividing cone to pounce at spiral blades of a distributor and tossed to the inner wall of a rotating excitation rotary barrel body in the rotation tangential direction of the spiral blades under the effect of centrifugal force; and a high-aluminum ball stacking layer suspends in the rotating excitation rotary barrel body, and mutual rubbing and grinding are conducted, so that kaolin finished product particles are obtained.

Owner:山东信开源科技创新发展有限责任公司

Hollow fiber permeating and vaporizing film and preparation method

ActiveCN109499373AThe production process steps are simpleShorten the production cycleMembranesDistillationFiberMaterials science

The invention discloses a double-layer hollow fiber permeating and vaporizing film and a preparation method. The double-layer hollow fiber permeating and vaporizing film is characterized in that by controlling the formulas of a film casting liquid of an outer layer and a film casting liquid of an inner layer, the prepared double-layer hollow fiber permeating and vaporizing film is of a particularskin layer structure; a selective separating layer for hollow fiber permeating and vaporizing is arranged between an outer protecting layer and an inner support layer. The double-layer hollow fiber permeating and vaporizing film has the advantages that the outer protecting layer is used for protecting the selective separating layer, so that the separating efficiency and stability of the hollow fiber permeating and vaporizing film are improved; the hollow fiber permeating and vaporizing film is prepared by a one-step double-layer extruding technology, and the preparation technology is simple.

Owner:NANJING WEIXIN ENVIRONMENTAL PROTECTION EQUIP TECH RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com