Crude oil separation system

A technology of separation system and oil-gas separator, which is applied in the field of crude oil separation, which can solve the problems of insufficient oil-gas separator delivery, unstable oil pressure, blocked pipelines, etc., and achieve the effects of reducing the carrying rate, increasing the residence time, and preventing pipeline clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

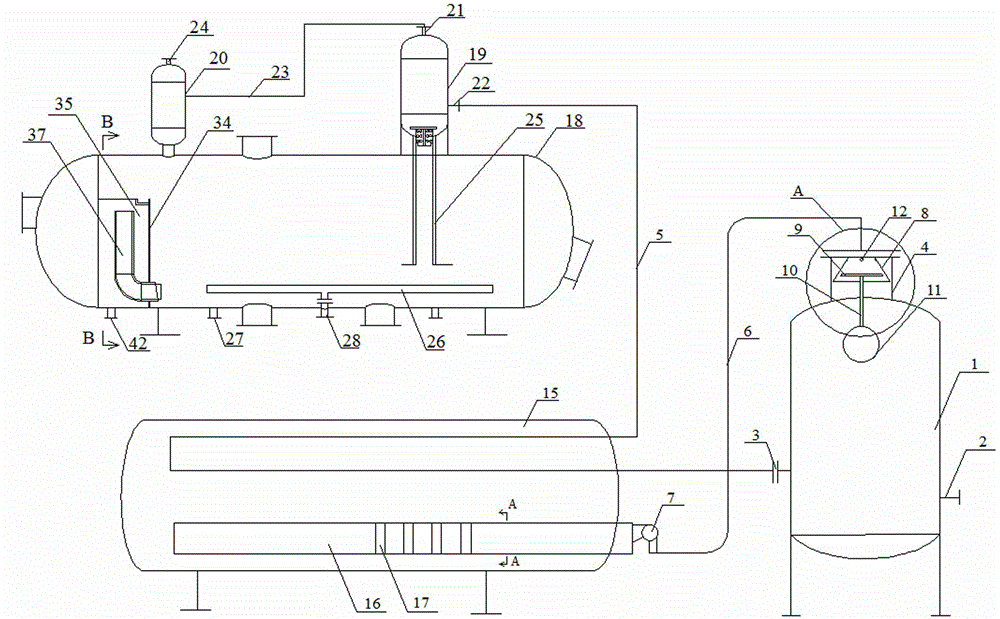

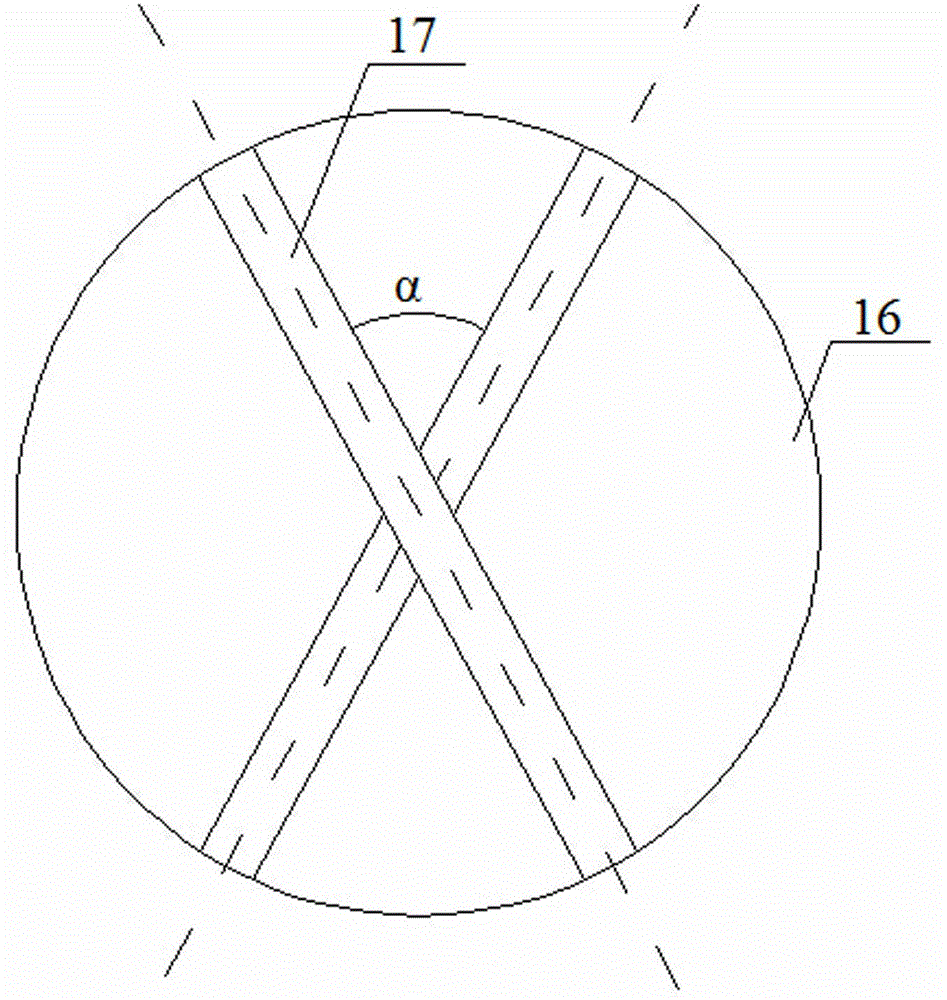

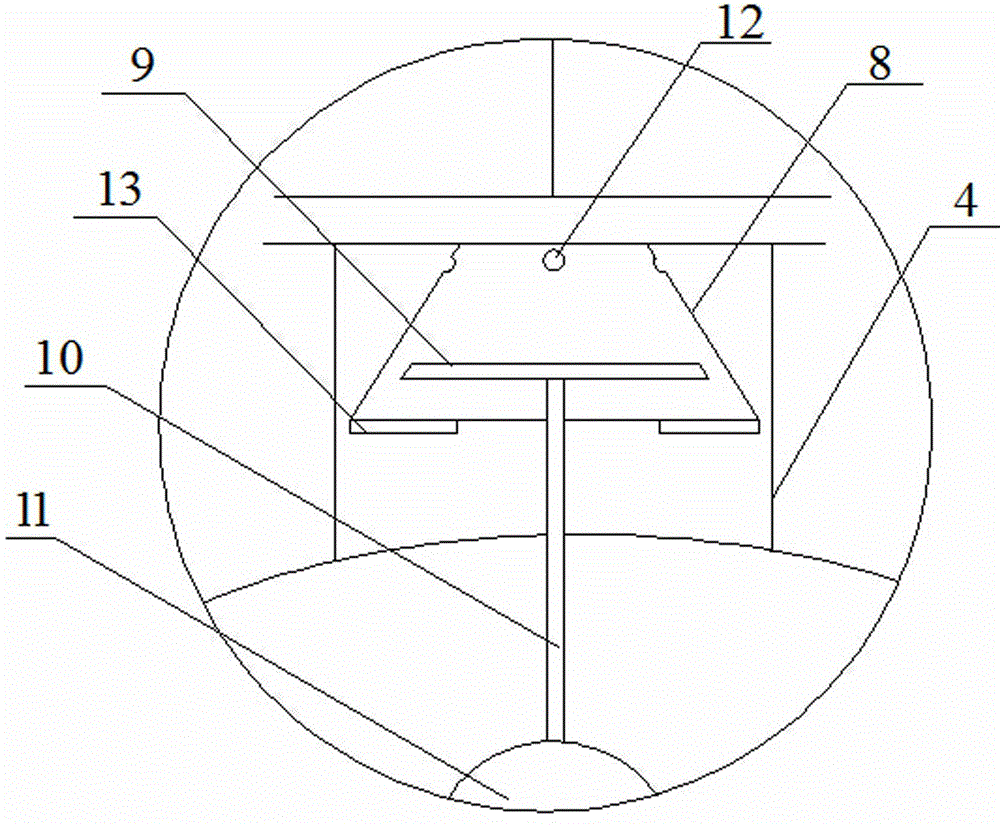

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 As shown, the crude oil separation system of this embodiment includes a primary separation system and a secondary separation system, and a crude oil heating system is arranged between the primary separation system and the secondary separation system; the primary separation system includes an oil-gas separation system A device 1 is provided with a crude oil inlet 2 and an oil outlet 3 at the bottom of the oil-gas separator, and an anti-overflow non-extinguishing device is provided in the gas outlet 4 at the top of the oil-gas separator, and the oil outlet is connected with an oil pipeline 5, The gas outlet is connected to the natural gas pipeline 6, the oil pipeline is connected to the secondary separation system after being heated by the crude oil heating system, and the natural gas pipeline is connected to the burner 7 arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com