Device and method for recycling carbon 2 in refinery dry gas by aid of oil absorption and compression condensation processes

A refinery dry gas and condensation technology, which is used in the processing of gas mixtures, petroleum industry, and hydrocarbon oil processing, can solve the problems of high energy consumption and large investment, and achieve high separation efficiency, low cost, and easy availability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

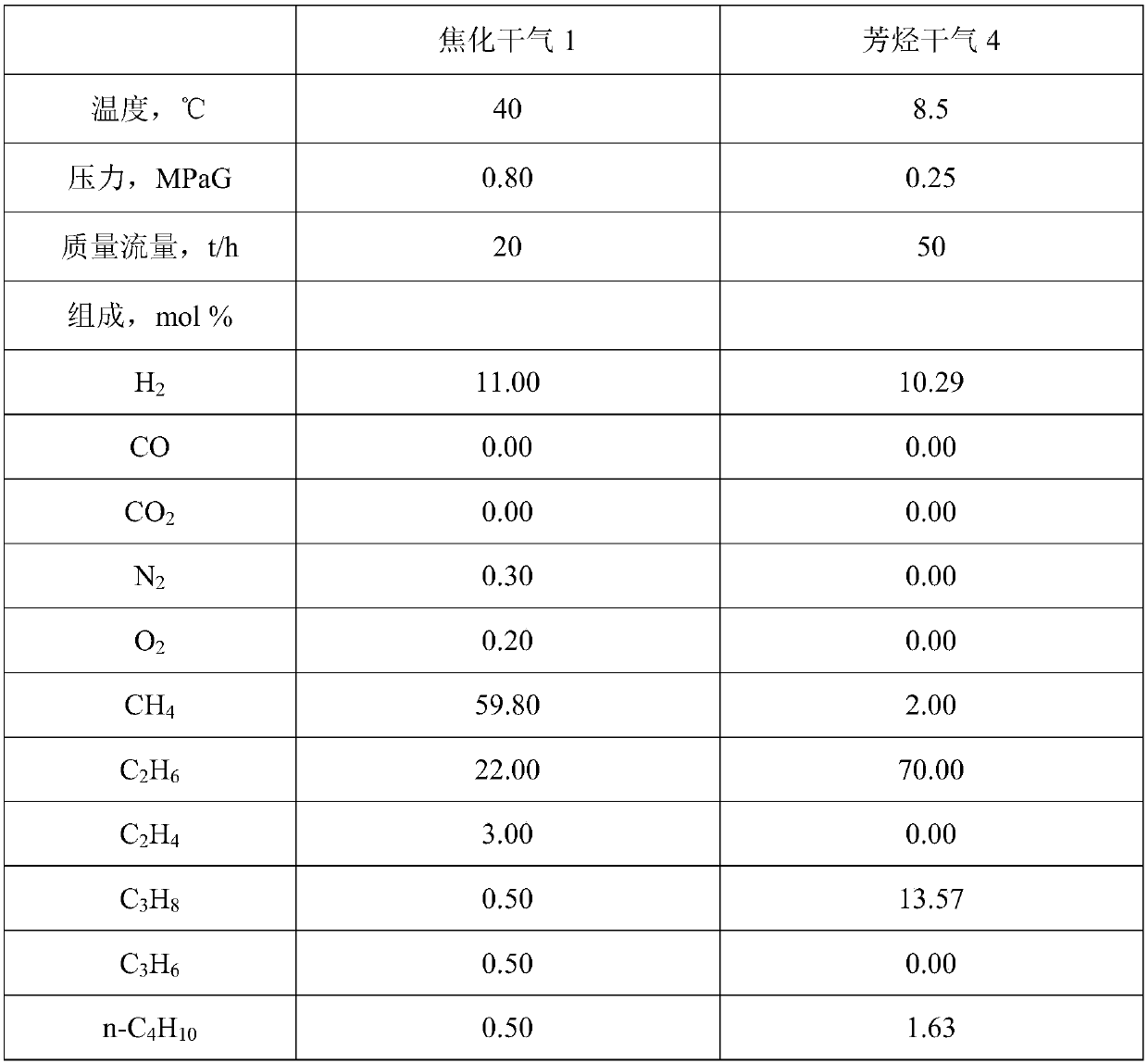

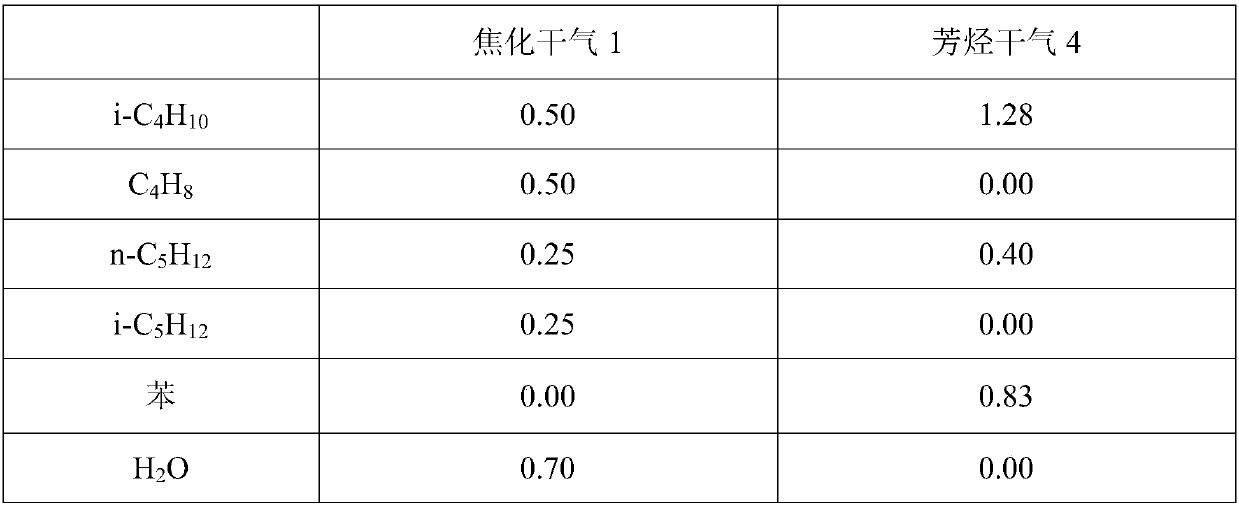

[0051] The composition of coking dry gas and aromatics dry gas in a refinery is shown in Table 1.

[0052] Table 1 Refinery dry gas flow composition

[0053]

[0054]

[0055] The oil absorption and compression condensation method of the present invention is used to recover the carbon dioxide in the refinery dry gas and the method to separate the refinery dry gas.

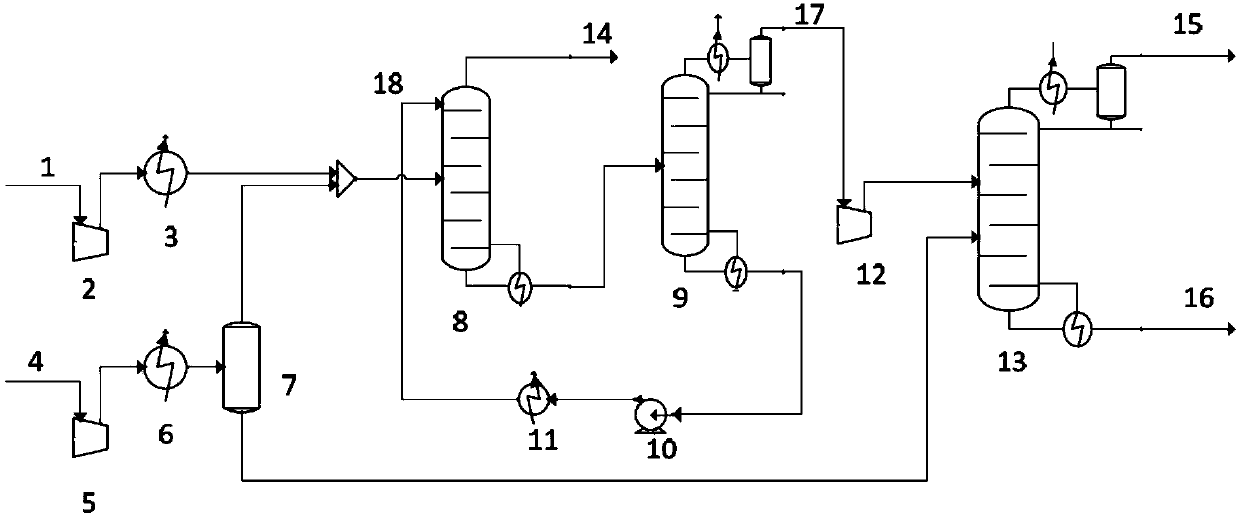

[0056] Described device comprises absorption tower 8, desorption tower 9 and ethane tower 13,

[0057] The inlet pipeline of the absorption tower 8 includes two branches, which are respectively a coking dry gas inlet pipeline and an aromatics dry gas inlet pipeline. After the two pipelines are combined, they are connected to the middle of the absorption tower 8. According to the material flow direction, the coking dry gas inlet pipeline A coking dry gas compressor 2 and a coking dry gas cooler 3 are arranged in sequence on the top, and an aromatic hydrocarbon dry gas compressor 5, an aromatic hydrocarbon dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com