Patents

Literature

54results about How to "Save hydrogen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

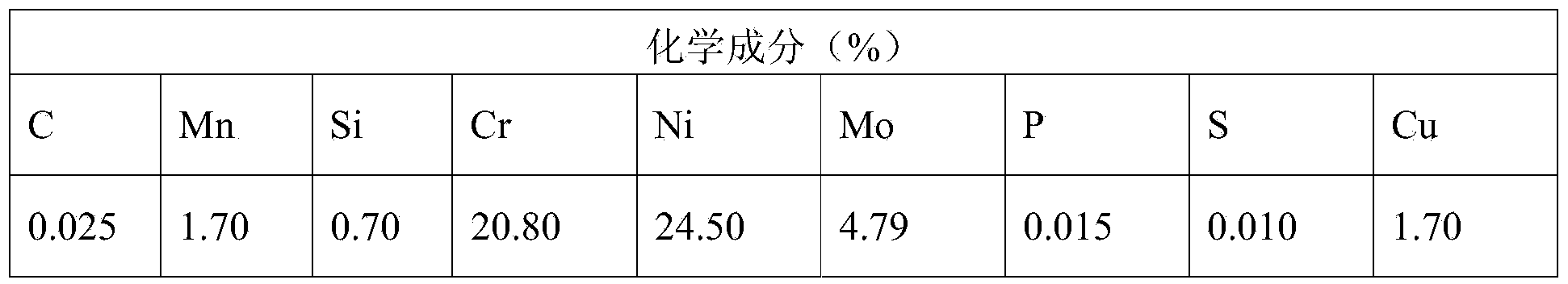

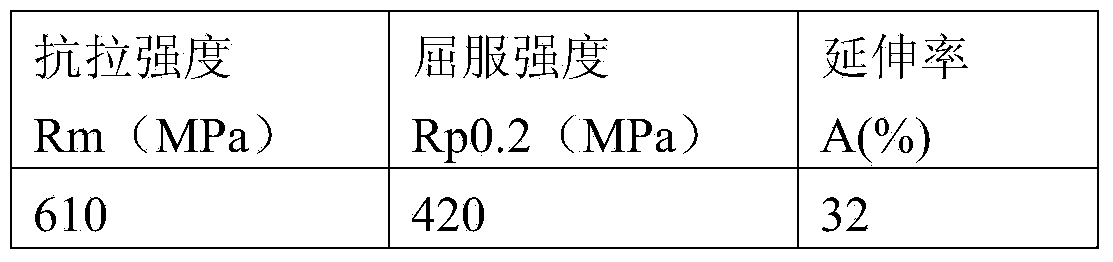

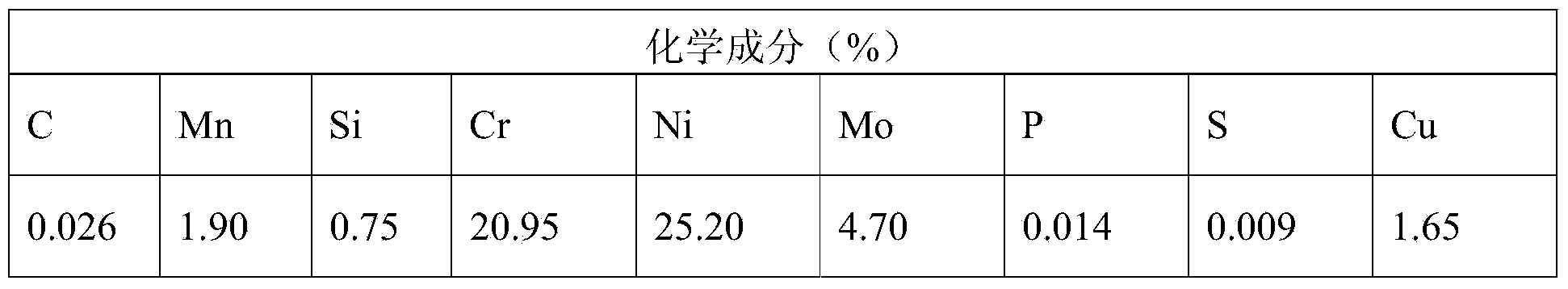

Superaustenitic stainless steel electrode

ActiveCN103921018AThe amount of addition is adaptableReduce lossWelding/cutting media/materialsSoldering mediaElectrolysisPhosphoric acid

The invention provides a superaustenitic stainless steel electrode. A coating of the superaustenitic stainless steel electrode at least comprises the following components, by mass, 35 to 45 percent of rutile, 2 to 5 percent of titanium dioxide, 6 to 12 percent of marble, 6 to 12 percent of dolomite, 1 to 3 percent of quartz, 3.5 to 6.5 percent of cryolite, 4 to 8 percent of dehydrated feldspar, 3 to 5 percent of dehydrated phlogopite, 6 to 8 percent of chromium metal, 6 to 8 percent of electrolytic manganese, 3 to 6 percent of ferrotitanium, 1 to 2 percent of chromium oxide green, 2 to 4 percent of nickel powder, 0.5 to 1.5 percent of ferromolybdenum and 0.5 to 1.5 percent of sodium alginate. The coating of the superaustenitic stainless steel electrode is formed by mixing all the components according to the proportions, potassium and sodium are added to be mixed with sodium silicate, and the coating coats a core wire H02Cr20Ni25Mo4Cu to form the electrode. Carbon content is extremely low, comprehensive corrosion of sulfuric acid and phosphoric acid can be resisted, the corrosion of acetic acid at any temperature and in any concentration under ordinary pressure can be resisted, and an ideal welding material is provided for steel for manufacturing various strong acid storing and transporting containers.

Owner:HUBEI CHUANWANG SPECIAL WELDING MATERIALS

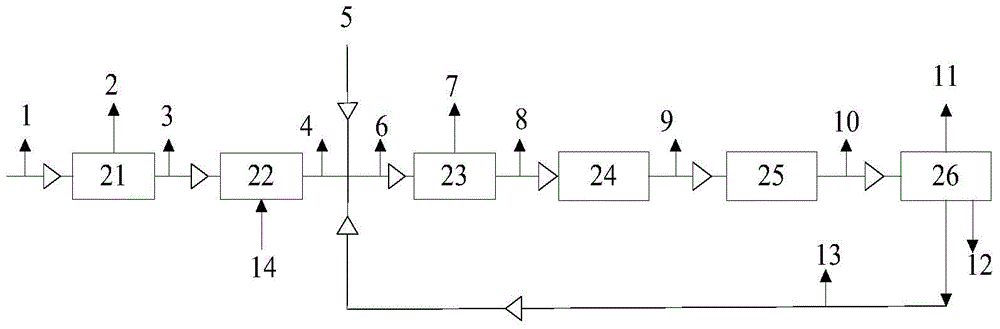

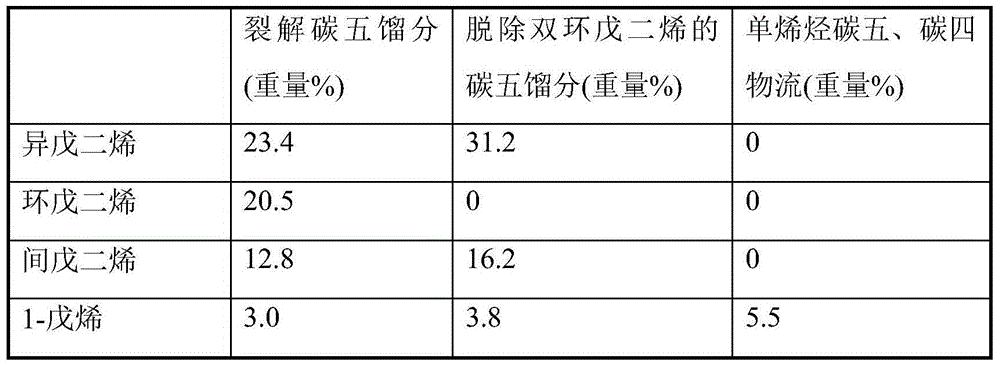

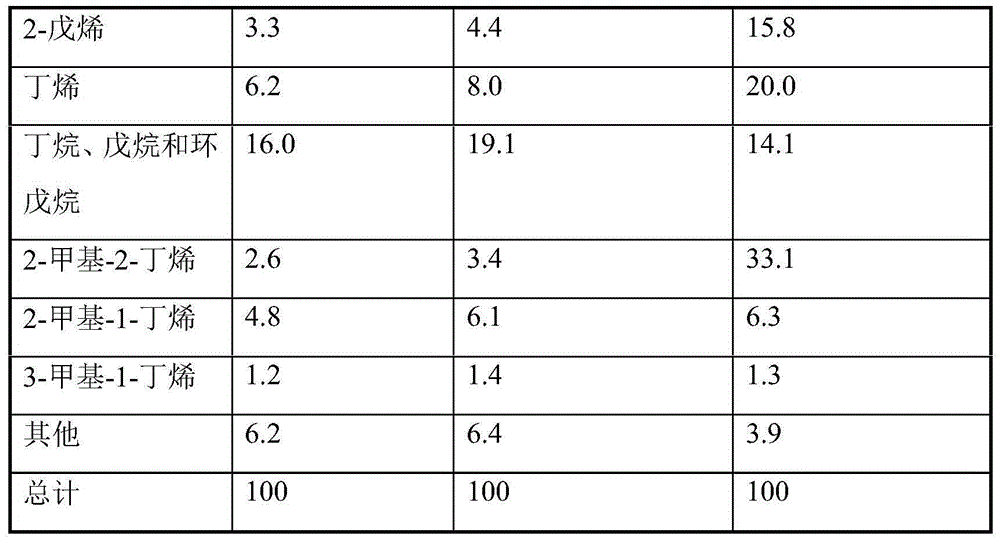

Method of utilizing cracked, C5 fraction

ActiveCN1810743AHigh purityOptimize the marketHydrocarbon by hydrogenationHydrocarbon by hydrocarbon cracking2-methylbutaneHydrogenation process

The method of utilizing cracked C5 fraction includes the first dimerizing cyclopentadiene in the cracked C5 fraction into dicyclopentadiene, separating dicyclopentadiene, selectively hydrogenating diene in the residual material into monoene and directly converting olefine to produce ethylene and propylene. The method may have etherification reaction before or after olefine conversion to produce methyl tert-amyl ether product and high purity isoamylene product further. The method may include a full hydrogenation process to produce pentane, which may be used as cracked material in a main cracking furnace or separated into n-pentane produce and isopentane product. The method is flexible and practical.

Owner:CHINA PETROLEUM & CHEM CORP

Method for preparing colloidal sol containing chloride and aluminium

ActiveCN1743267ALow costIncrease Al/Cl mass ratioAluminium compoundsColloidal chemistry detailsHydrogenAluminium chlorohydrate

The invention discloses a method for preparing chlorine-contained Aluminum Sol. The method is as follow: make polymerized aluminum chloride water solution whose formula is Al2(OH)1-3Cl3-5 fully contact and react with metal aluminum to prepare a aluminum sol in which the content of aluminum is 5-13 mass% and the mass ratio of AL / CL is 0.6-2.0. In the invention polymerized aluminum chloride is used to replace partial metal aluminum to produce aluminum sol, hydrochloric acid isn't used, so the corrosion to equipment is less, hydrogen exhaust amount is low, operation is more safety and cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

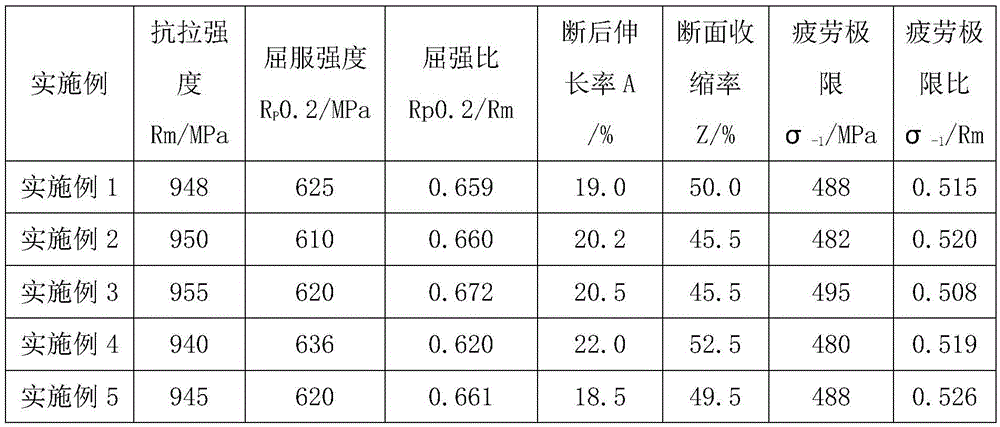

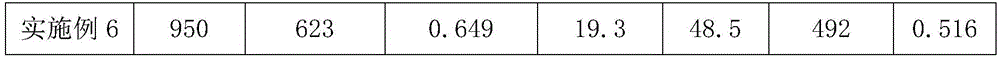

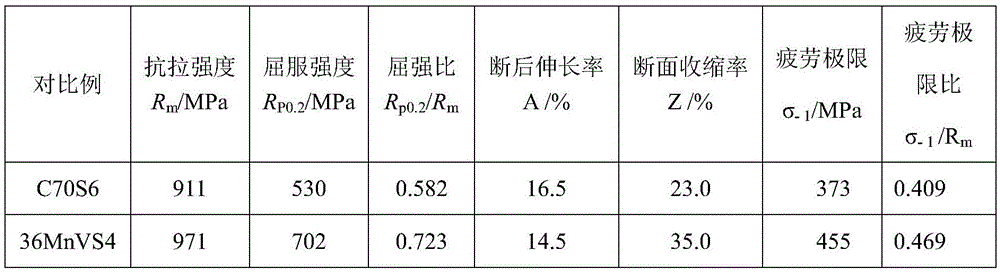

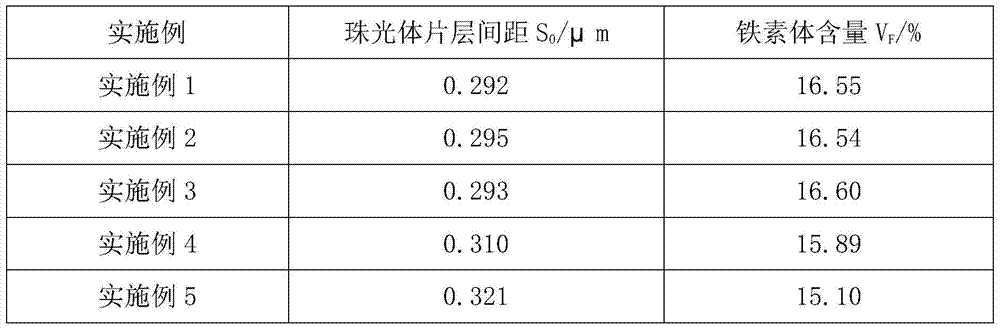

Non-quenched and non-tempered steel, production method of non-quenched and non-tempered steel and cracking connecting rod manufactured through non-quenched and non-tempered steel

ActiveCN105463318AImprove fatigue toughnessHigh fatigue toughnessConnecting rodsProcess efficiency improvementChemical compositionToughness

The invention provides non-quenched and non-tempered steel, a production method of the non-quenched and non-tempered steel and a cracking connecting rod manufactured through the non-quenched and non-tempered steel. The non-quenched and non-tempered steel is prepared from, by mass percent, 0.46%-0.52% of C, 0.70%-0.80% of Si, 1.53%-1.60% of Mn, 0.008%-0.015% of P, 0.02%-0.035% of S, 0.15%-0.25% of Cr, 0.20%-0.25% of Ni, 0.04%-0.07% of Mo, 0.02%-0.04% of Al, 0.14%-0.16% of V, 0.025%-0.035% of Nb, 0.001%-0.002% of B, 0.14%-0.25% of N and the balance Fe and inevitable impurity elements. The fatigue toughness of the steel can be improved through the element Nb. The element B can be segregated in a grain boundary and fused in ferrite separated out of the grain boundary, the separated-out ferrite is strengthened, and the cracking performance is improved.

Owner:SUZHOU SUXIN SPECIAL STEEL +2

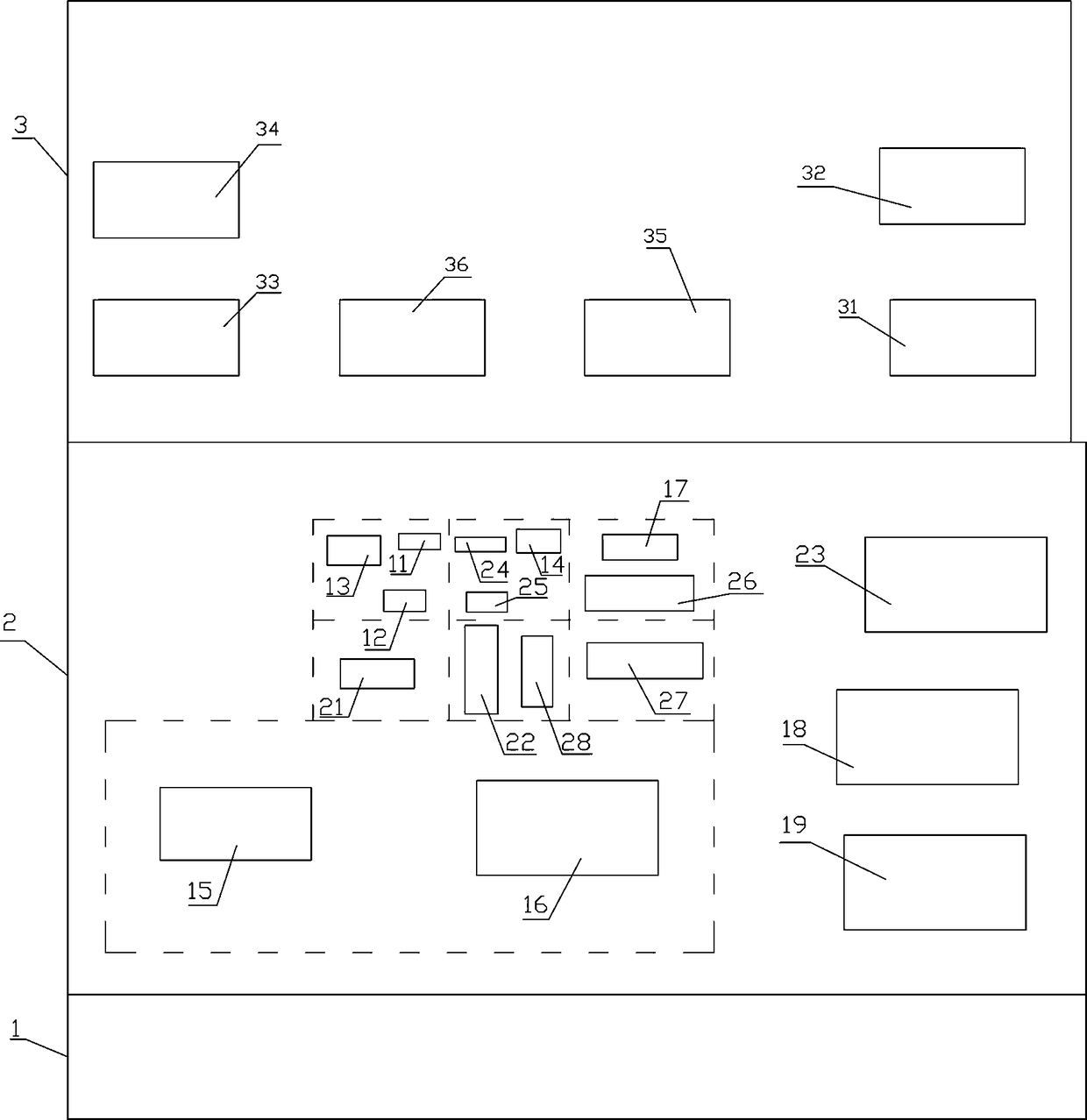

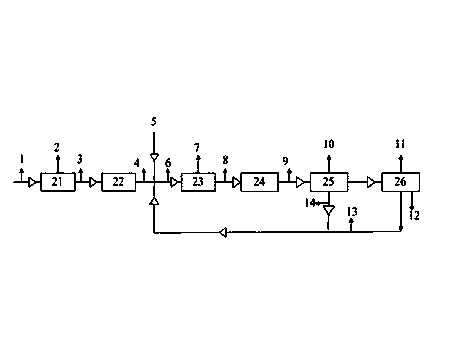

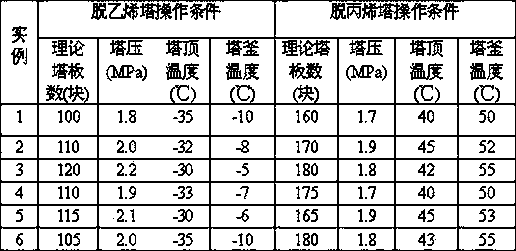

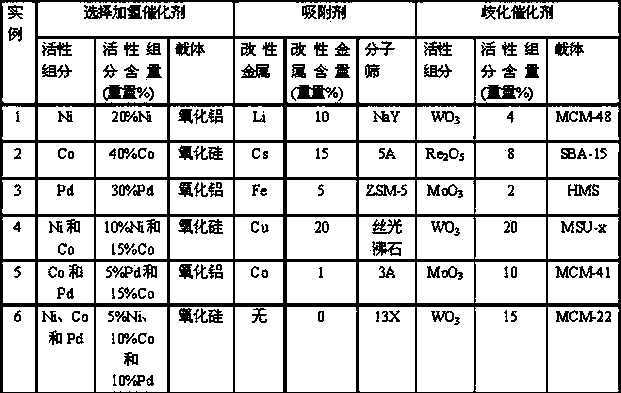

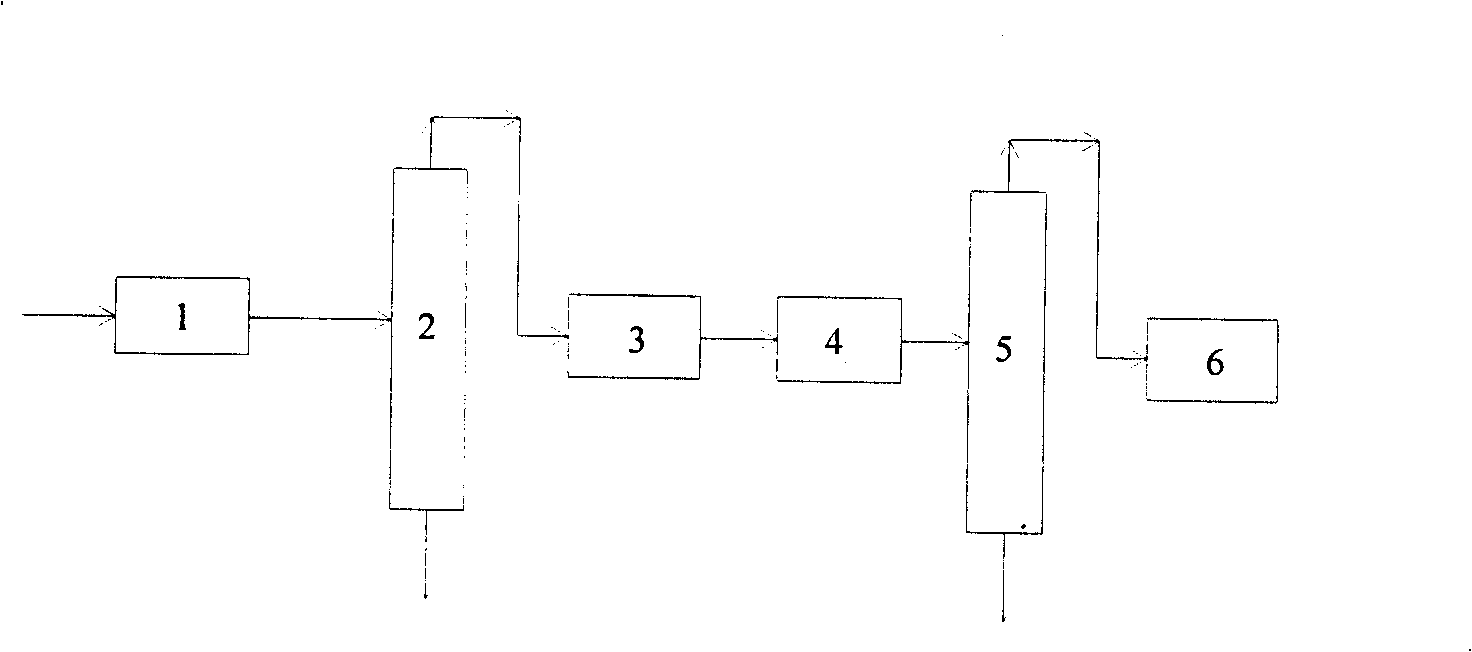

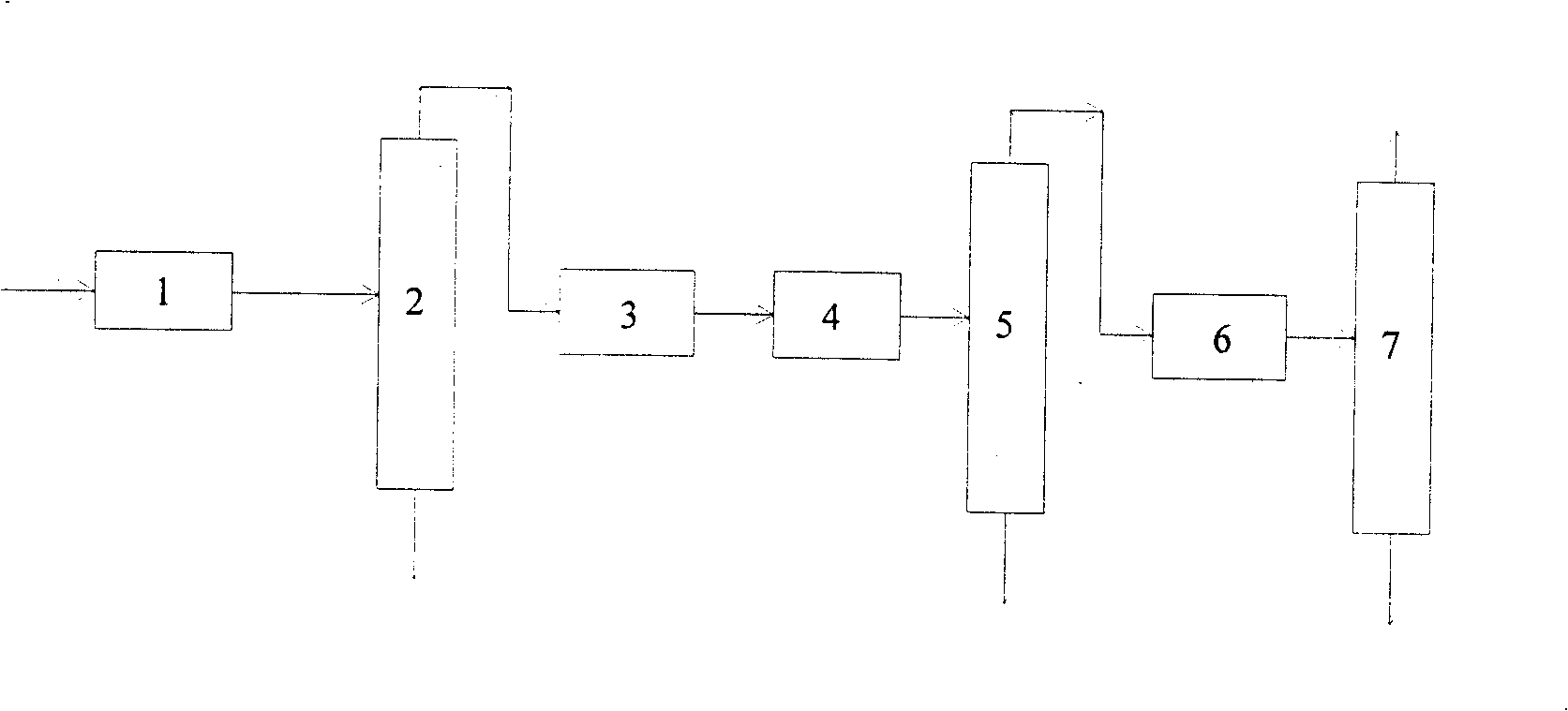

Method for producing propylene

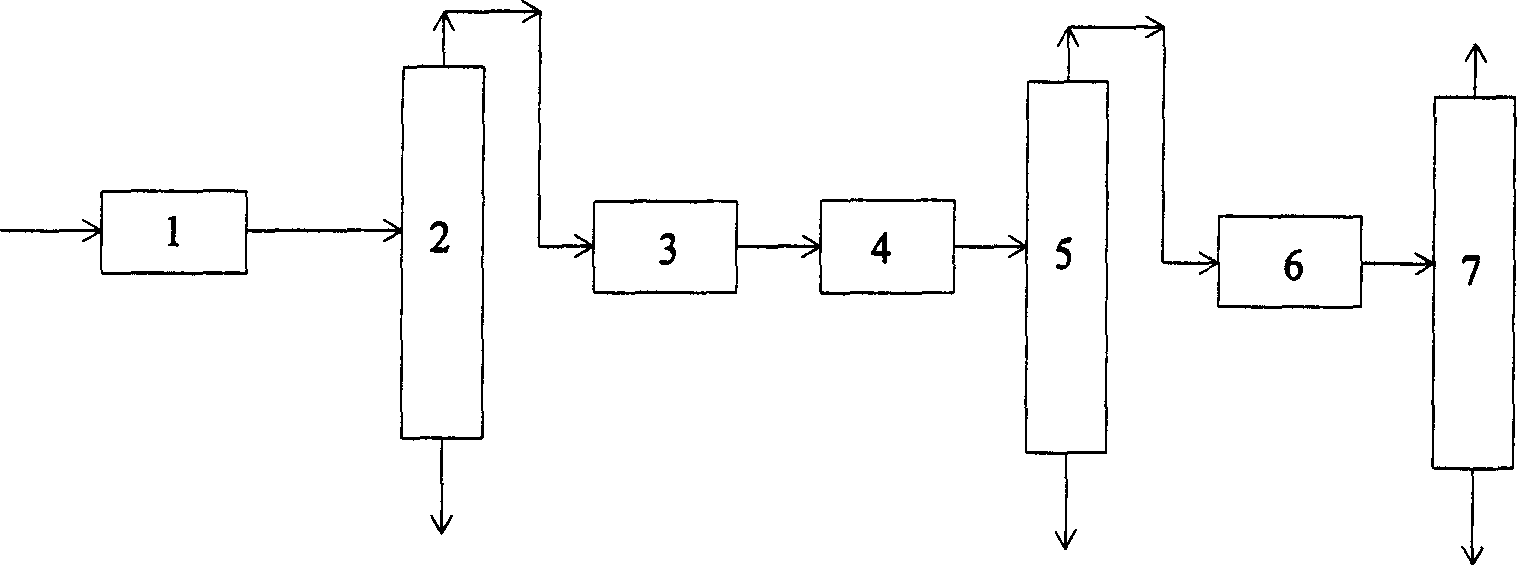

InactiveCN105585401ASave hydrogenImprove economic efficiencyHydrocarbon purification/separationHydrocarbon by metathesis reactionSorbentContact reaction

The invention relates to a method for producing propylene. The invention mainly aims at solving a problem of low propylene weight yield in prior arts. According to the propylene production method, cracked C5, C4 and ethylene are adopted as raw materials. The method comprises the following steps: a cracked C5 fraction is delivered into a de-cyclopentadiene unit; after reaction separation, a C5 material flow with cyclopentadiene removed is delivered into a selective hydrogenation reactor; under the existences of a hydrogenation catalyst and hydrogen, diolefin is selectively hydrogenated into monoolefine; the obtained monoolefine C5, C4 material and ethylene are mixed; the mixture is treated with an adsorbent; a material flow obtained after adsorption is subjected to a contact reaction with an isomerization catalyst and a disproportionation catalyst, such that a material flow containing a product propylene and unreacted ethylene, C5 and C4 is obtained; and propylene is obtained after separation. With the method, the problem is well solved. The method can be used in industrial production of propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

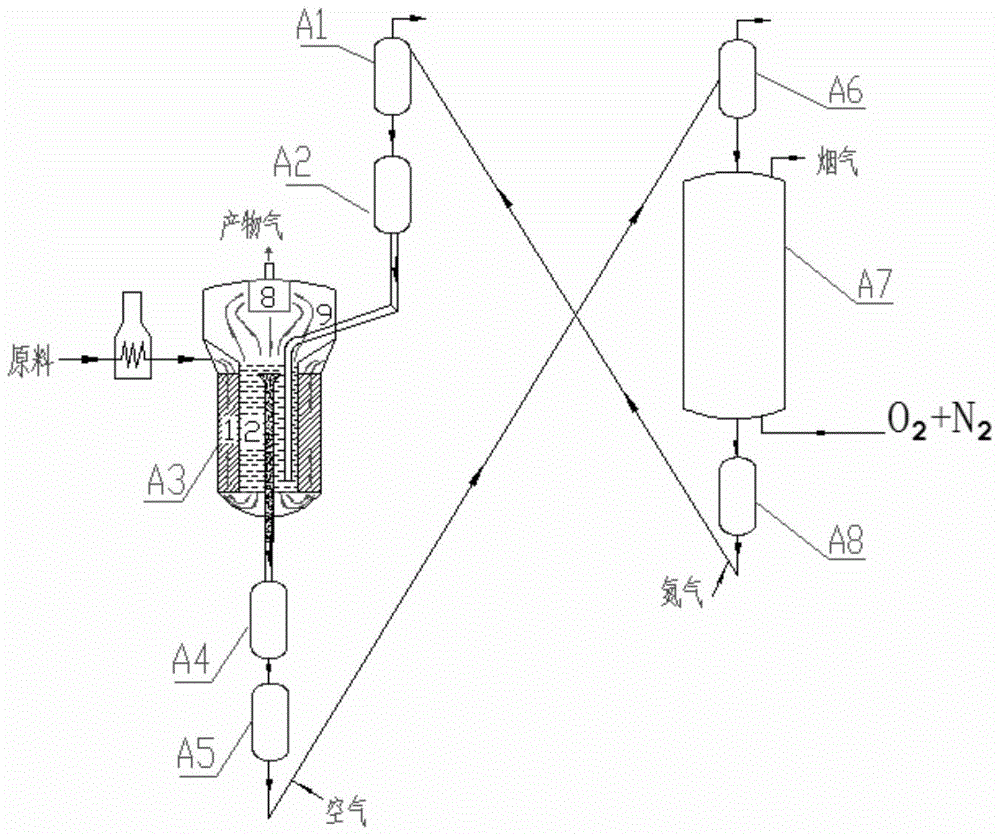

Method for producing methionine

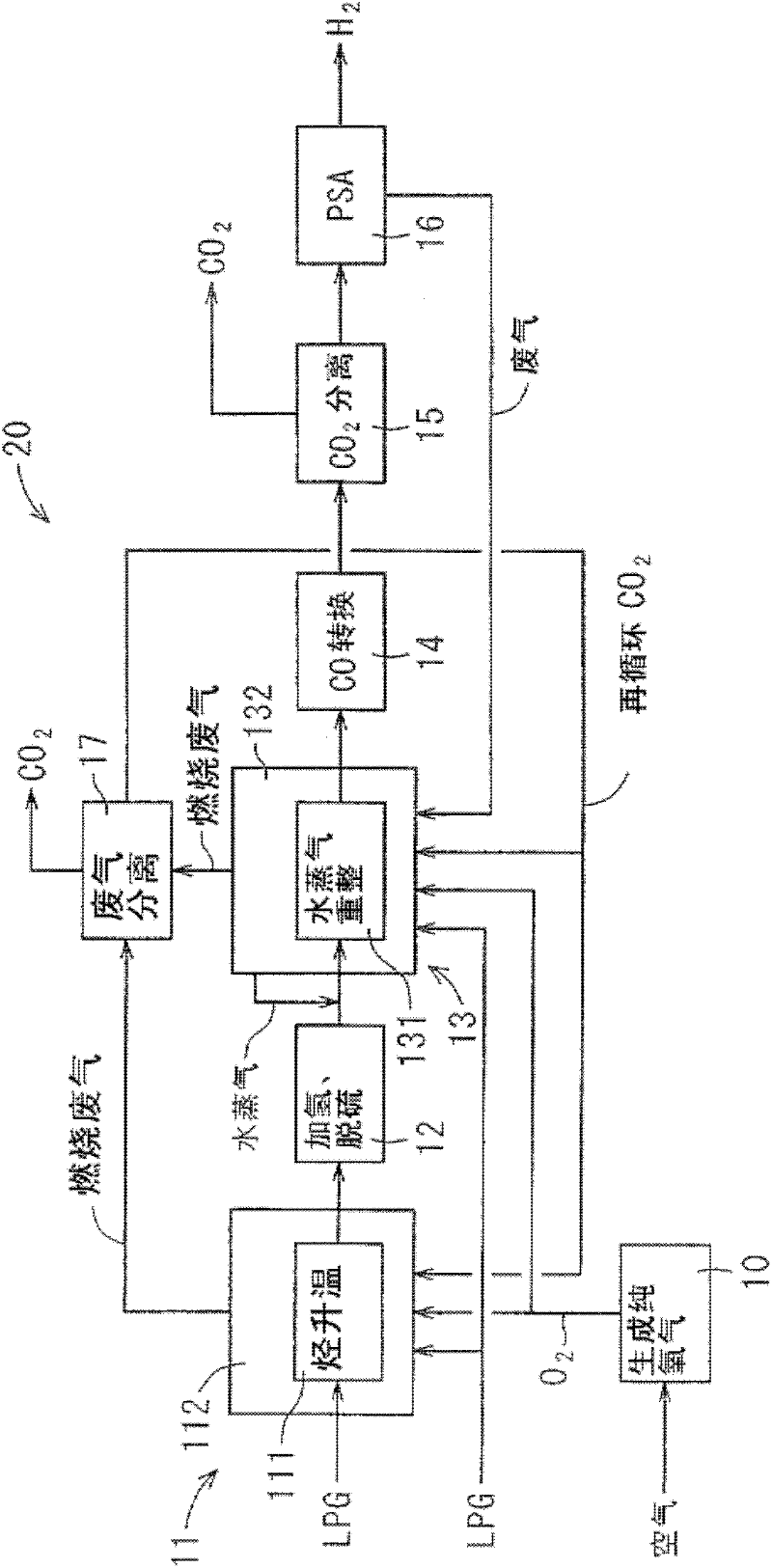

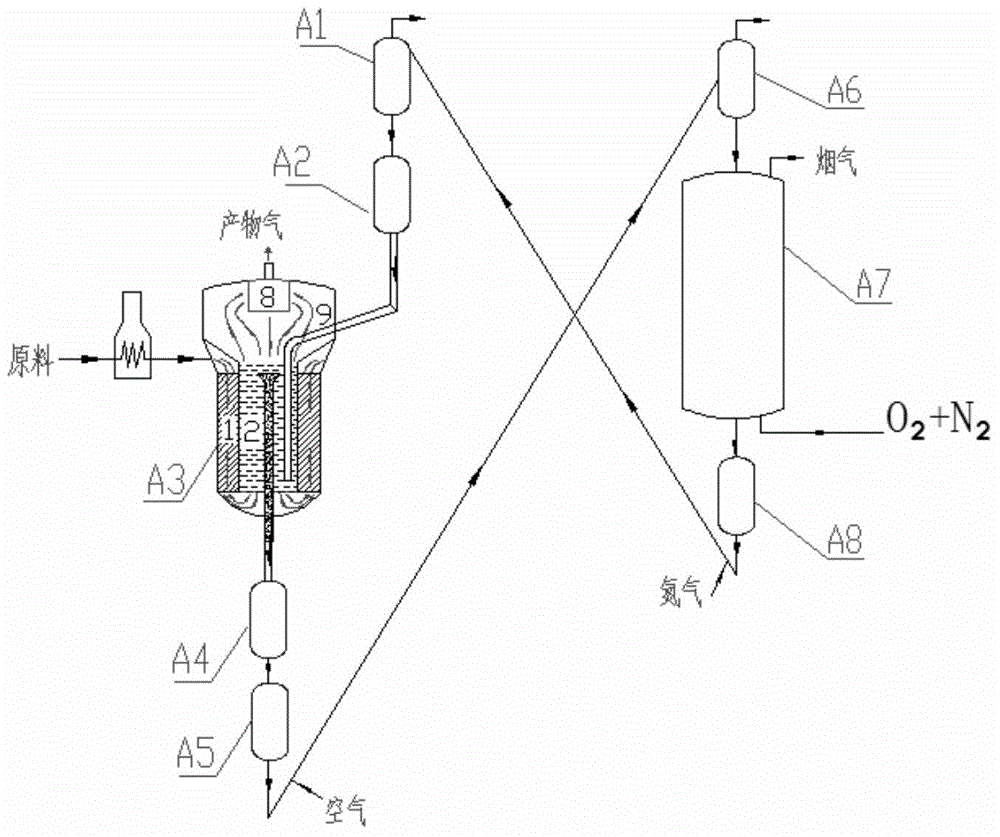

A method for producing methionine includes a hydrolyzing step of hydrolyzing 5-([beta]-methylmercaptoethyl)hydantoin, and a crystallizing step of crystallizing with carbon dioxide introduced into a reaction solution after hydrolysis, to obtain methionine. In the crystallizing step, as carbon dioxide introduced into the hydrolysis reaction solution, carbon dioxide that is separated in a carbon dioxide separation section (15) from a reformed gas formed by steam reforming reaction in a steam reformation section (13) and carbon dioxide that is separated in an exhaust gas separation section (17) from a combustion exhaust gas generated by pure oxygen combustion in a hydrocarbon heating furnace (12) and a reformation reaction heating furnace (132) are used.

Owner:SUMITOMO CHEM CO LTD

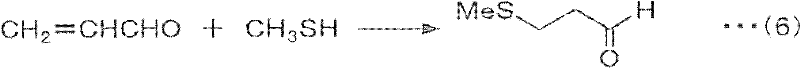

Liquid hydrogen production line

PendingCN108534462AIncrease productivityReduce consumptionSolidificationLiquefactionAir preheaterProduction line

The invention discloses a liquid hydrogen production line comprising a hydrogen intensively-containing grid charging workshop, a hydrogen processing workshop and a liquid hydrogen storing workshop. Ahydrogen purifier, a hydrogen filter, a first heat exchanger group, a second heat exchanger group, a circulating hydrogen low-pressure compressor, a circulating hydrogen high-pressure compressor, a circulating hydrogen purifier, a circulating hydrogen filter, a first circulating hydrogen expansion unit, a second circulating hydrogen expansion unit, a nitrogen compressor, a liquid nitrogen air preheater, a liquid hydrogen storage tank, an ice maker system, a cold box vacuum system, a diffusing device and an electric heater are arranged in the hydrogen processing workshop. A liquid hydrogen pump, a liquid hydrogen storage tank, a liquid hydrogen truck-loading arm, a liquid hydrogen tank box, a BOGC compressor and a BOG air pre-heater are arranged in the liquid hydrogen storage workshop. Theliquid hydrogen production line is high in production efficiency and low in production cost.

Owner:ZHANGJIAGANG RES INST OF HYDROGEN ENERGY CO LTD

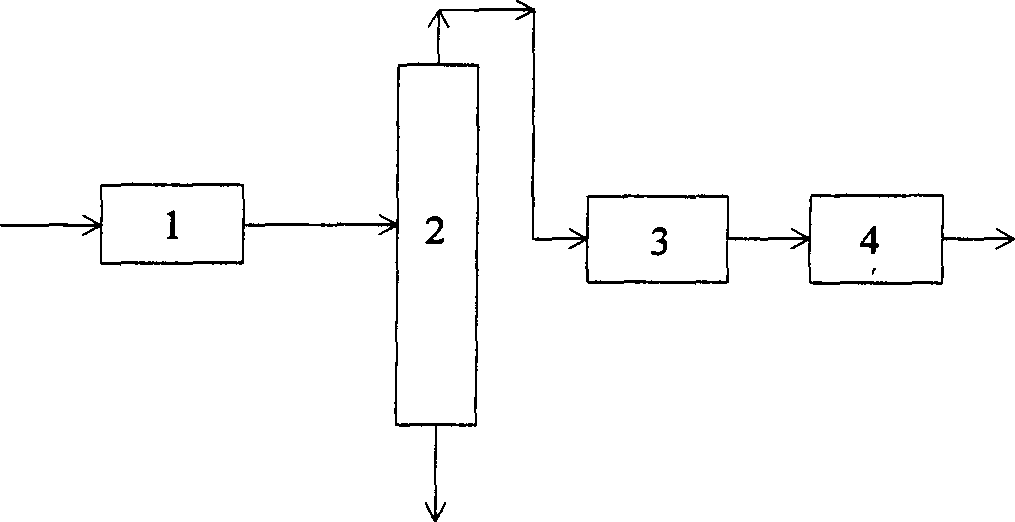

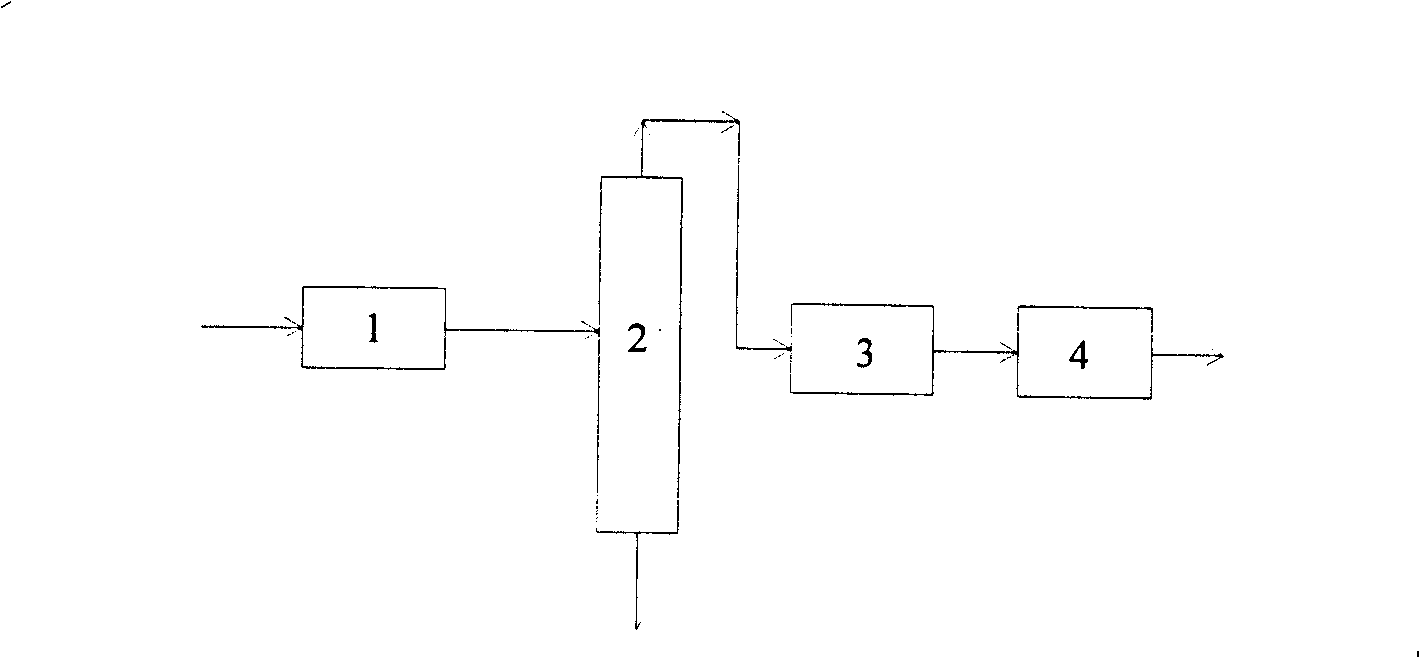

Method for preparing propylene by using cracking C5 fraction

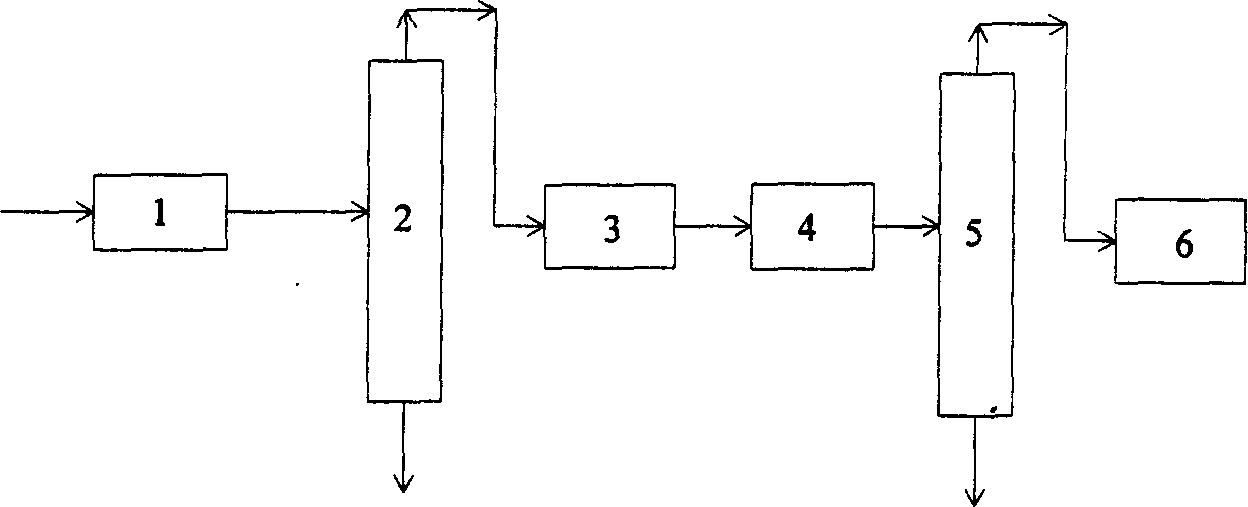

ActiveCN104109071AOptimize the marketSave hydrogenHydrocarbon by metathesis reactionHydrocarbonsDisproportionationEthylene

The invention relates to a method for preparing propylene by using a cracking C5 fraction. The problem of low mass yield of propylene in the prior art is mainly solved. The method for preparing propylene by using cracking C5 fraction, adopting the cracking C5 fraction and ethylene as raw materials, comprises the following steps: sending the cracking C5 fraction to a cyclopentadiene removal unit, reacting, separating to obtain a cyclopentadiene removed C5 flow, sending the cyclopentadiene removed C5 flow to a selective hydrogenation reactor, selectively hydrogenating diolefin in the presence of a hydrogenation catalyst and hydrogen to obtain monoolefin, mixing the obtained monoolefin C5 material with ethylene, processing by an adsorbent, allowing the obtained adsorption flow to contact and react with a disproportionation catalyst to obtain a flow containing a product propylene, unreacted ethylene and C5, and separating to obtain propylene. The method well solves the problem, and can be used in the industrial production for preparing propylene by using the cracking C5 fraction.

Owner:CHINA PETROLEUM & CHEM CORP +1

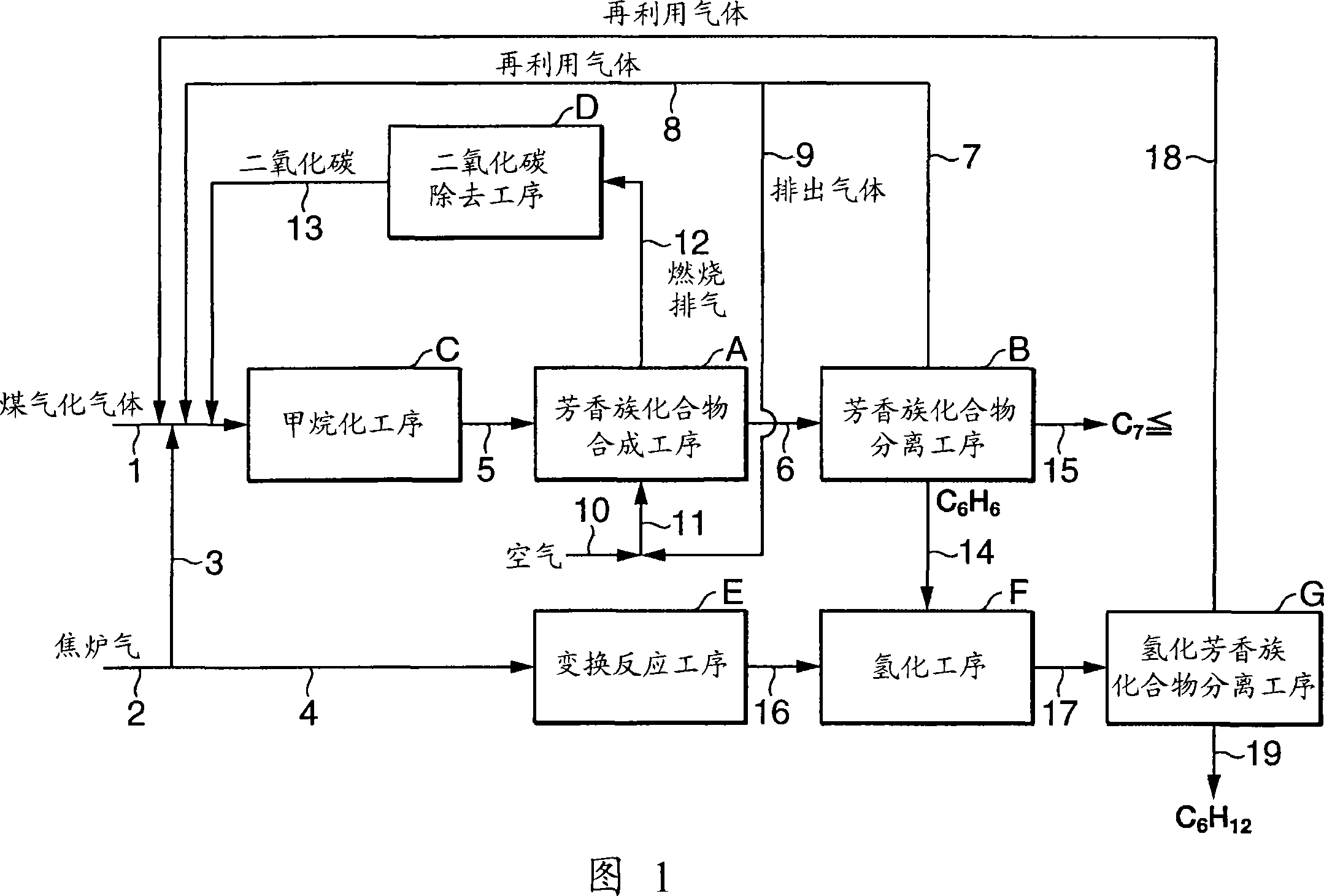

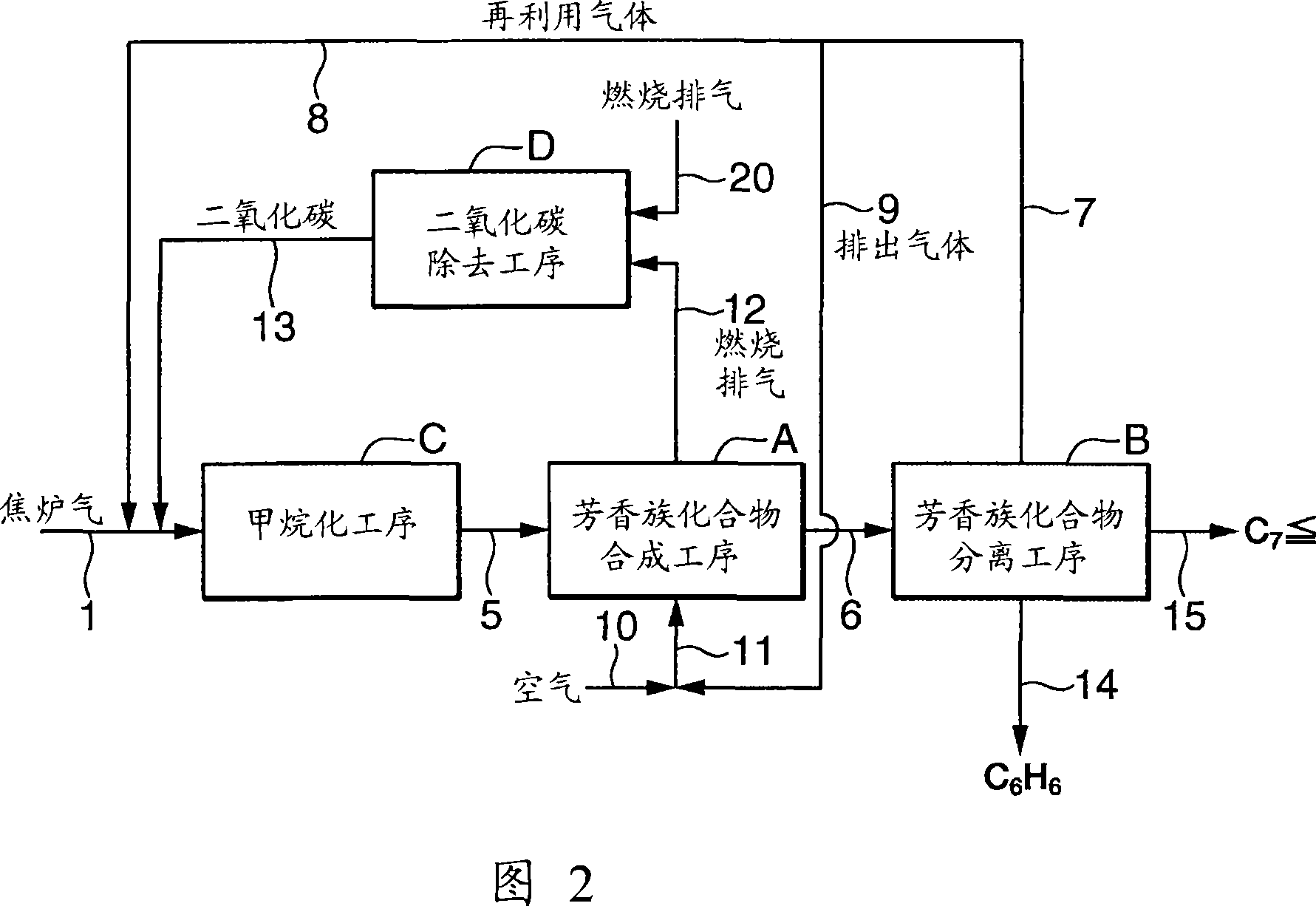

Process for production of aromatic compound and process for production of hydrogenated aromatic compound

ActiveCN101115700AEasy to manufactureSave hydrogenHydrocarbon from carbon oxidesOrganic chemistry methodsCarbon dioxideHydrocarbon

The present invention provides a method for producing aromatic compounds using a catalytic reaction of lower hydrocarbons that is advantageous for industrial production. The method for producing aromatic compounds includes a methanation step and an aromatic compound synthesis step. The methanation step is to contact hydrogen-containing gas with carbon monoxide and / or carbon dioxide in the presence of a catalyst, so that the hydrogen in the gas reacts with carbon monoxide. and / or react with carbon dioxide to convert into methane and water; the aromatic compound synthesis process is to react lower hydrocarbons with the methane obtained in the methanation process in the presence of a catalyst to obtain a product containing aromatic compounds and hydrogen gas.

Owner:MITSUBISHI RAYON CO LTD

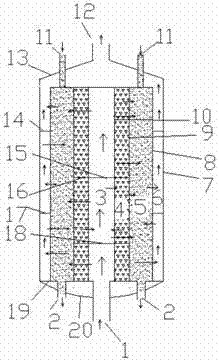

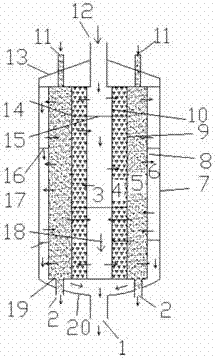

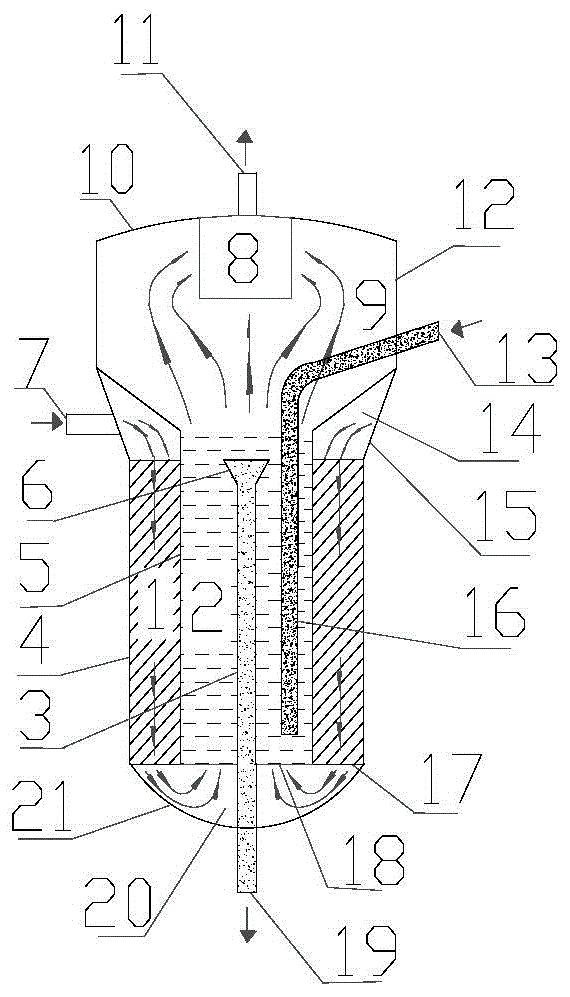

A method for adsorption and desulfurization of petroleum hydrocarbons

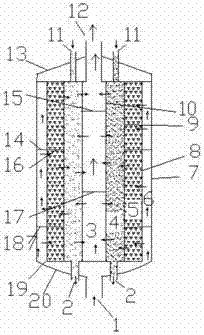

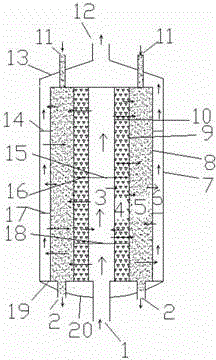

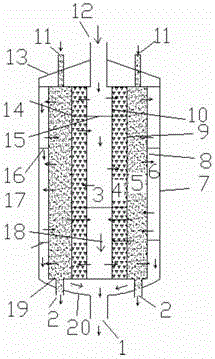

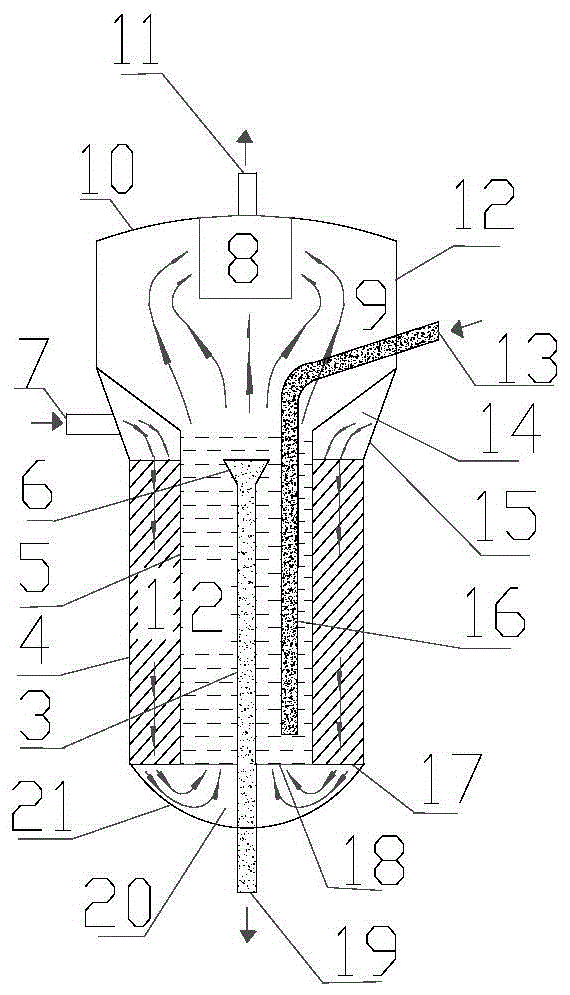

ActiveCN105623732BReduce wearSimple structureTreatment with hydrotreatment processesHydrogenHydrodesulfurization

A petroleum hydrocarbon adsorption desulfurization method adopts a moving bed radial flow reactor. The reactor is divided into a fluid feed channel, a catalyst fixed bed layer, a catalyst moving bed layer and a fluid discharge channel in the radial direction from outside to inside or from inside to outside; the top and the bottom of the reactor are respectively provided with a fluid feed inlet and a fluid discharge outlet; the top of the catalyst moving bed layer is provided with a moving bed catalyst inlet, and the bottom of the catalyst moving bed layer is provided with a moving bed catalyst outlet; the fluid feed channel, the catalyst fixed bed layer, the catalyst moving bed layer and the fluid discharge channel are separated by materials with pores. The wear of a catalyst can be reduced, a lot of hydrogen for reducing a hydrogenation desulfurization catalyst can be saved, device construction and operation process are simplified, energy consumption is saved, and the production continuous reaction and regeneration are facilitated. The method can be used for a deep desulfurization process of sulfur-containing C4 fractions and catalytically cracked gasoline. In addition, the reaction device provided by the invention has the advantages of simple structure and high production efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

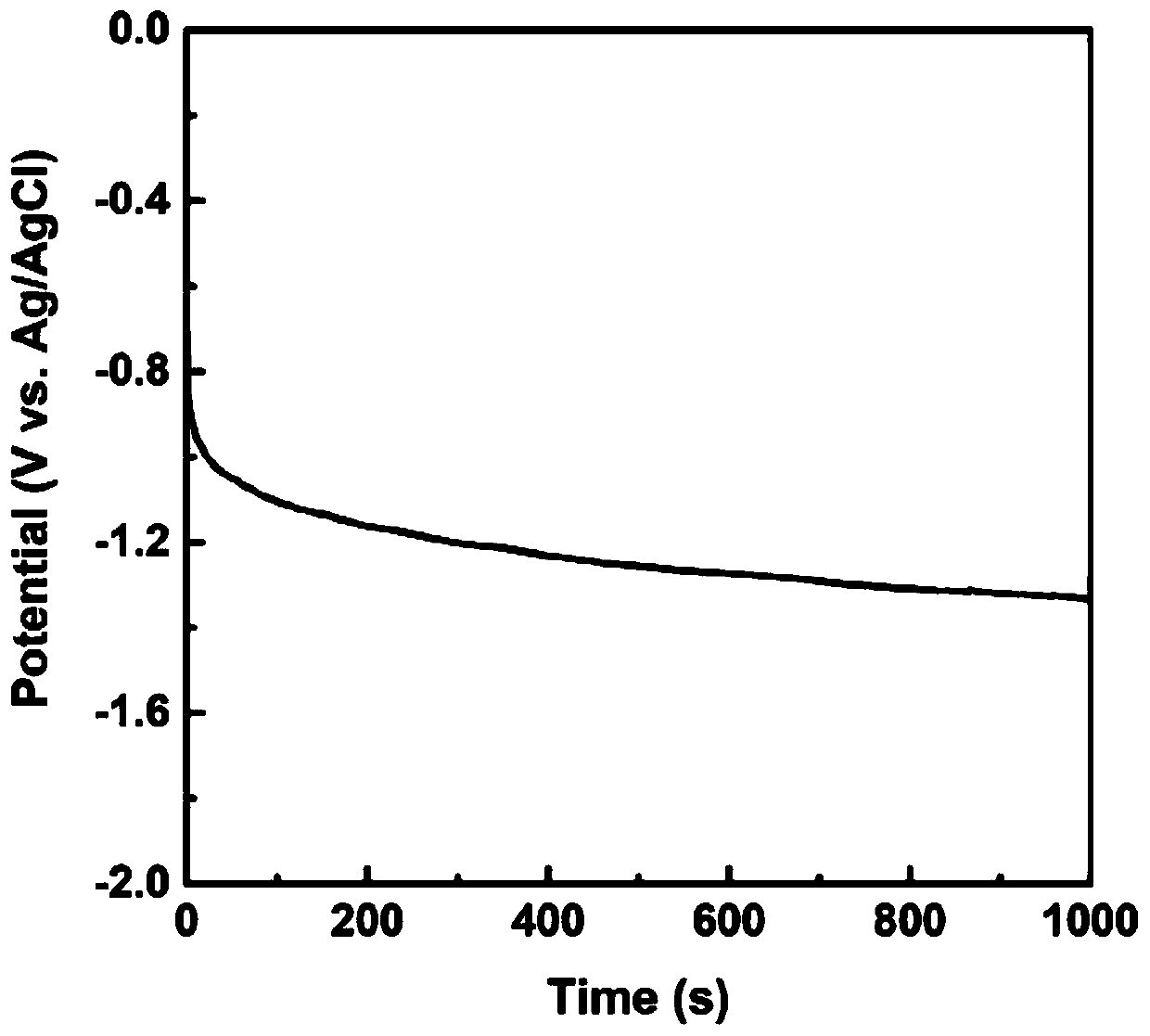

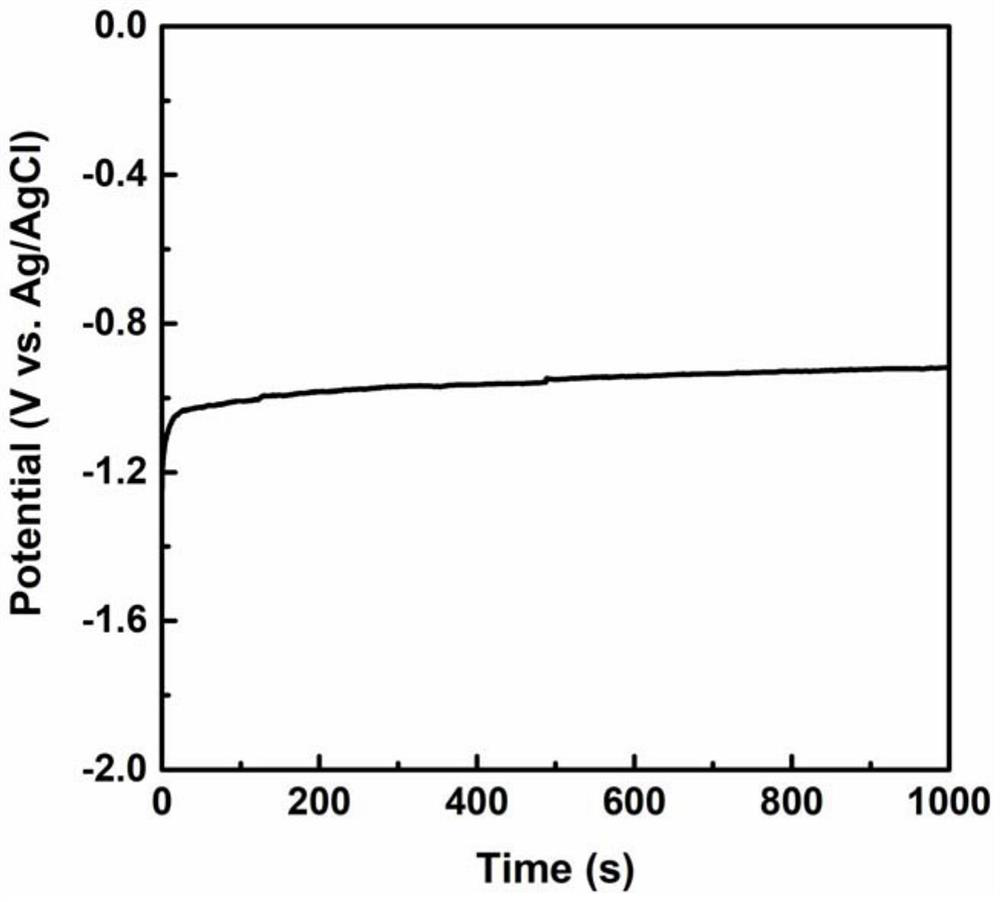

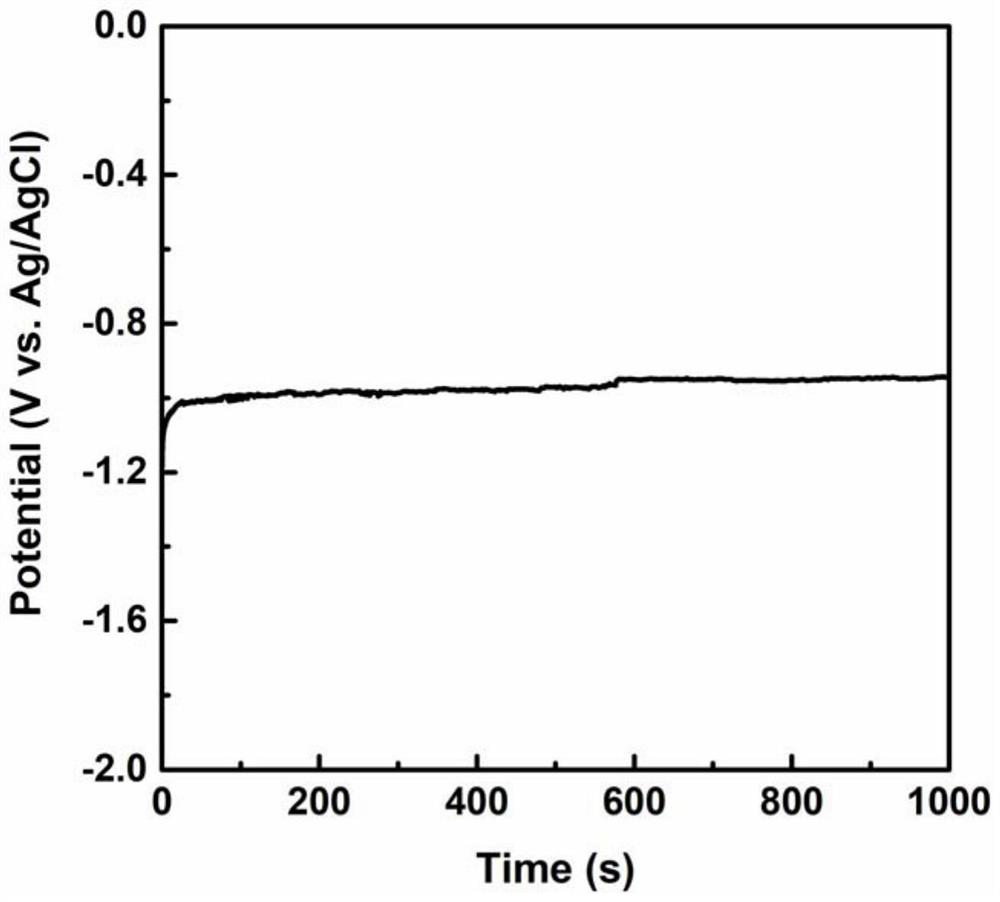

Preparing method of Si/Ni-Fe-V photo-anode

The invention discloses a preparing method of a Si / Ni-Fe-V photo-anode. Nickel sulfate, ferrous sulfate and vanadyl sulfate are dissolved in de-ionized water under the atmosphere of inert gas to obtain an electro-deposition solution. Ferrous ions in the solution can be prevented from being oxidized into ferric ions. A sealed silicon photo-anode is immersed into the prepared electro-deposition solution, and the Si / Ni-Fe-V photo-anode is prepared through an electro-deposition method. Ni2+, Fe2+ and V4+ in the electro-deposition solution are reduced into a NiFeV alloy film on the surface of a silicon electrode, and the surface of the silicon anode is wrapped by the NiFeV alloy film, so that a target Si / Ni-Fe-V photo-anode product is obtained. By adopting current density which is 0.8-1.2 mA.cm<-2>, voltage during deposition is far smaller than the redox standard potential of nickel, iron and vanadium, and under-potential co-deposition is realized; and when deposition is carried out at the deposition current density, little hydrogen is produced in the deposition process, the deposited NiFeV alloy film is denser due to the fact that air pores are not prone to forming, and the surface of the silicon anode is better protected. The method is simple and can realize large-scale production.

Owner:XI AN JIAOTONG UNIV

Petroleum hydrocarbon adsorption desulfurization method

ActiveCN105623732AReduce wearSimple structureTreatment with hydrotreatment processesHydrogenHydrodesulfurization

A petroleum hydrocarbon adsorption desulfurization method adopts a moving bed radial flow reactor. The reactor is divided into a fluid feed channel, a catalyst fixed bed layer, a catalyst moving bed layer and a fluid discharge channel in the radial direction from outside to inside or from inside to outside; the top and the bottom of the reactor are respectively provided with a fluid feed inlet and a fluid discharge outlet; the top of the catalyst moving bed layer is provided with a moving bed catalyst inlet, and the bottom of the catalyst moving bed layer is provided with a moving bed catalyst outlet; the fluid feed channel, the catalyst fixed bed layer, the catalyst moving bed layer and the fluid discharge channel are separated by materials with pores. The wear of a catalyst can be reduced, a lot of hydrogen for reducing a hydrogenation desulfurization catalyst can be saved, device construction and operation process are simplified, energy consumption is saved, and the production continuous reaction and regeneration are facilitated. The method can be used for a deep desulfurization process of sulfur-containing C4 fractions and catalytically cracked gasoline. In addition, the reaction device provided by the invention has the advantages of simple structure and high production efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

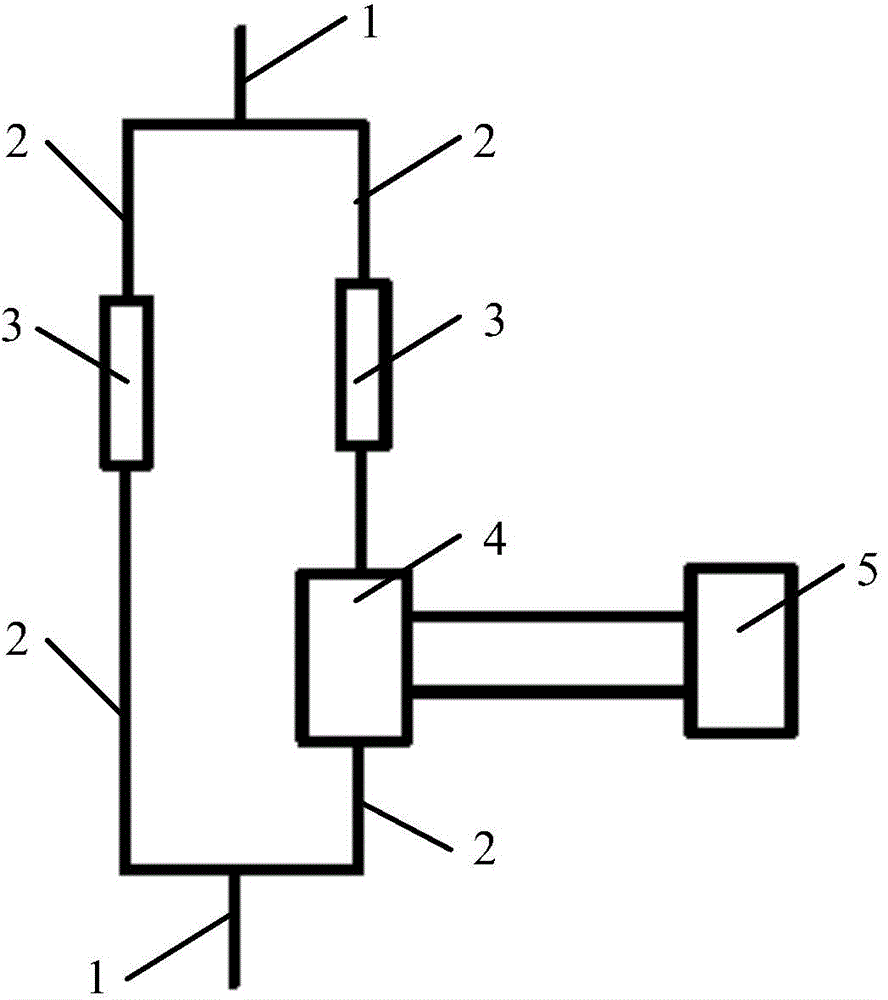

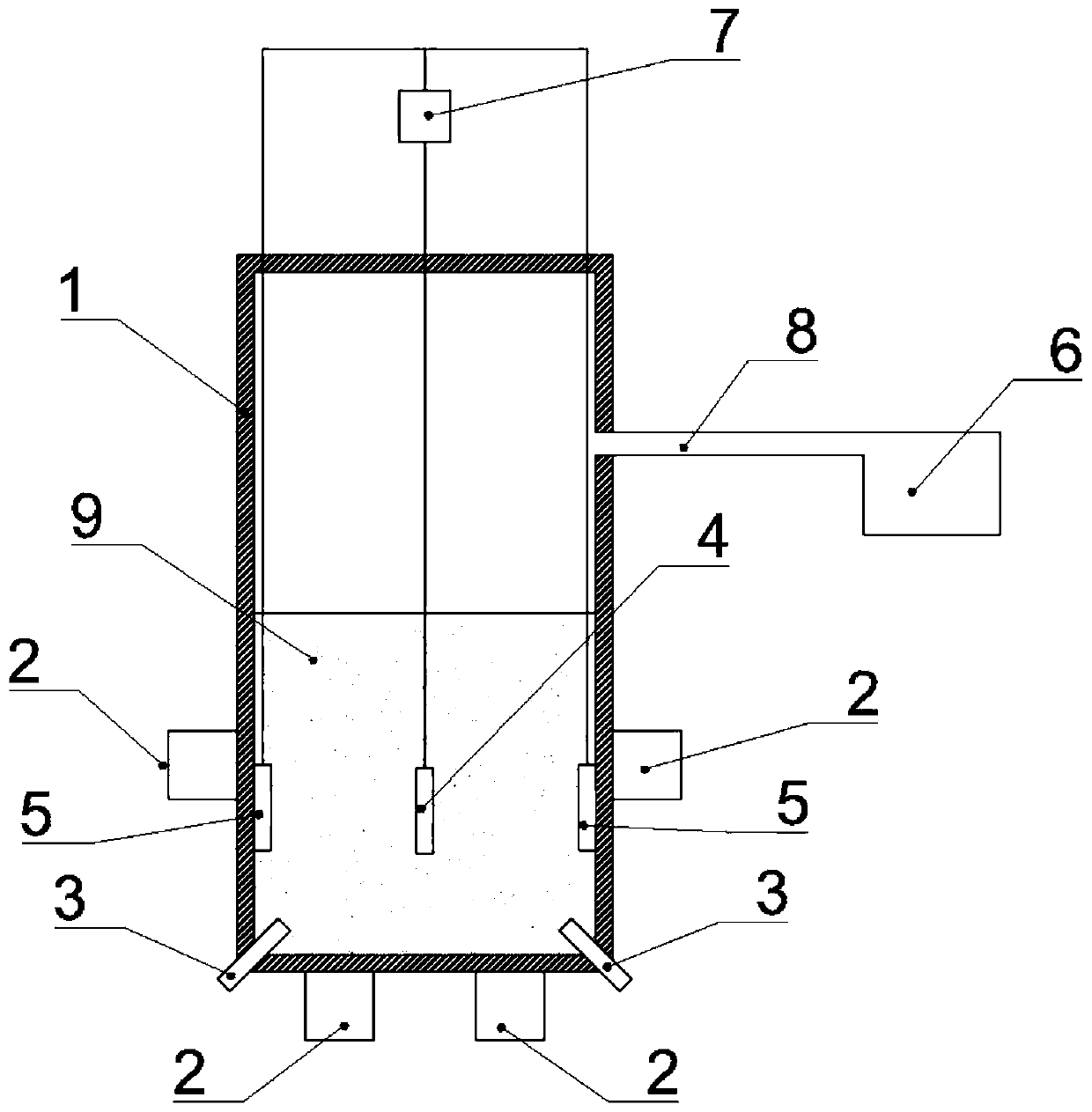

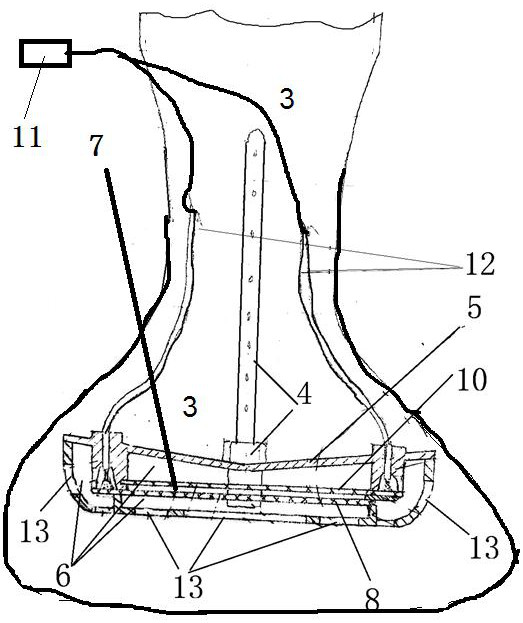

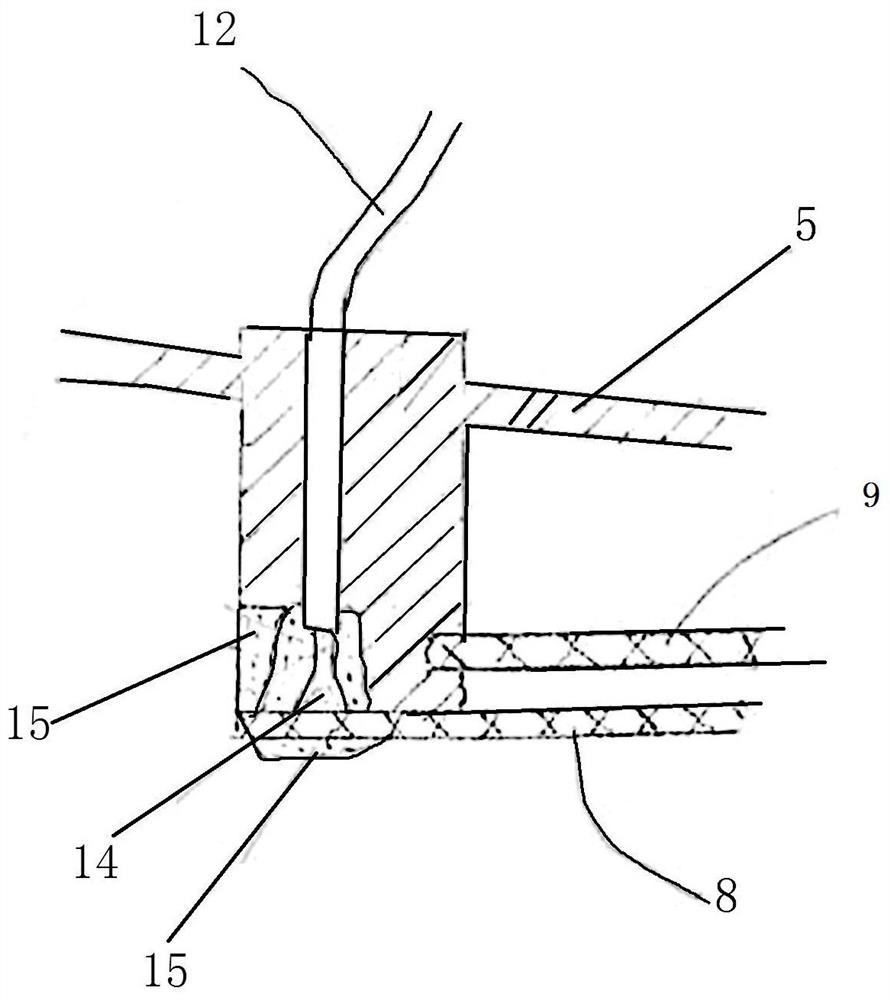

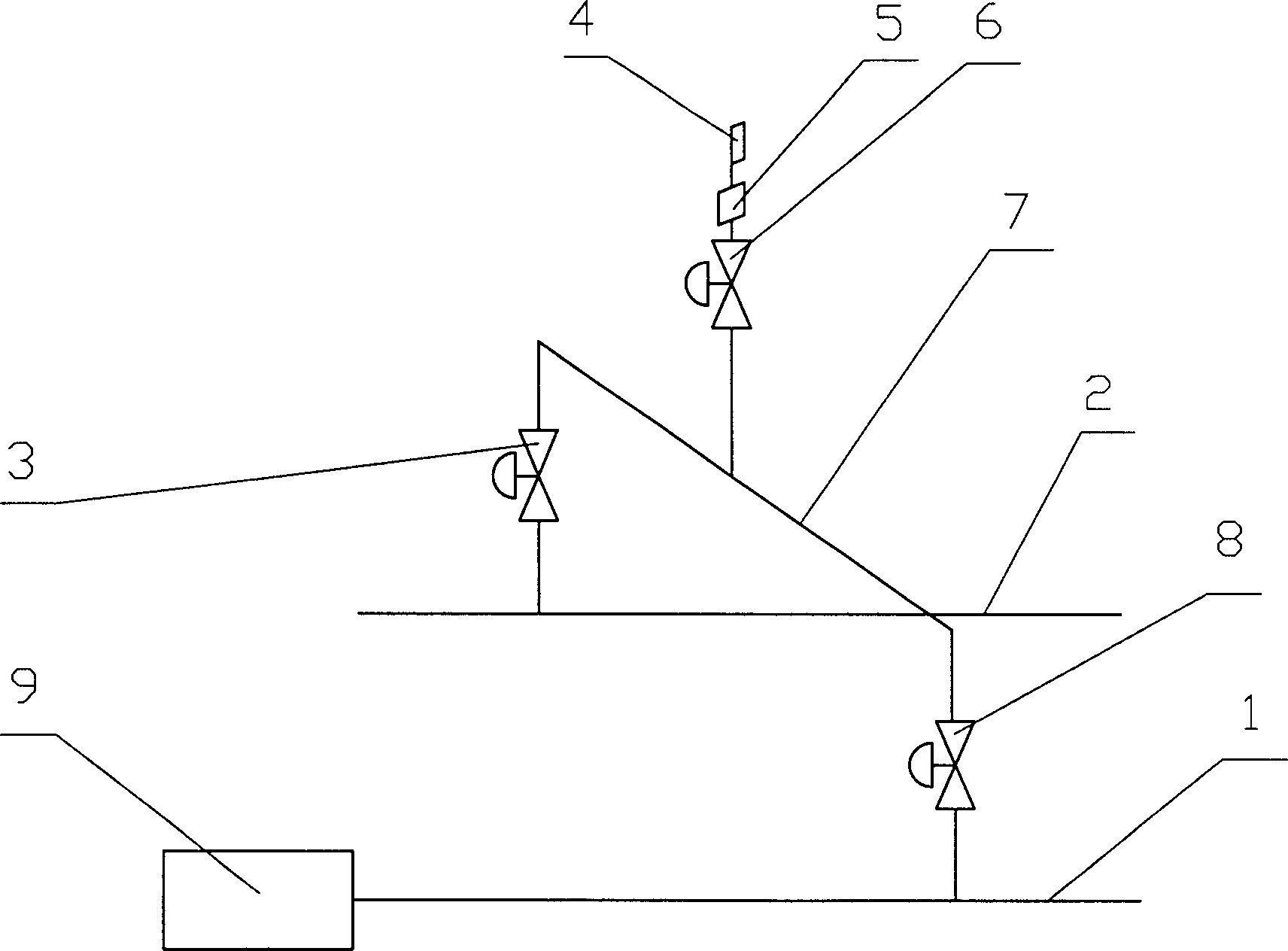

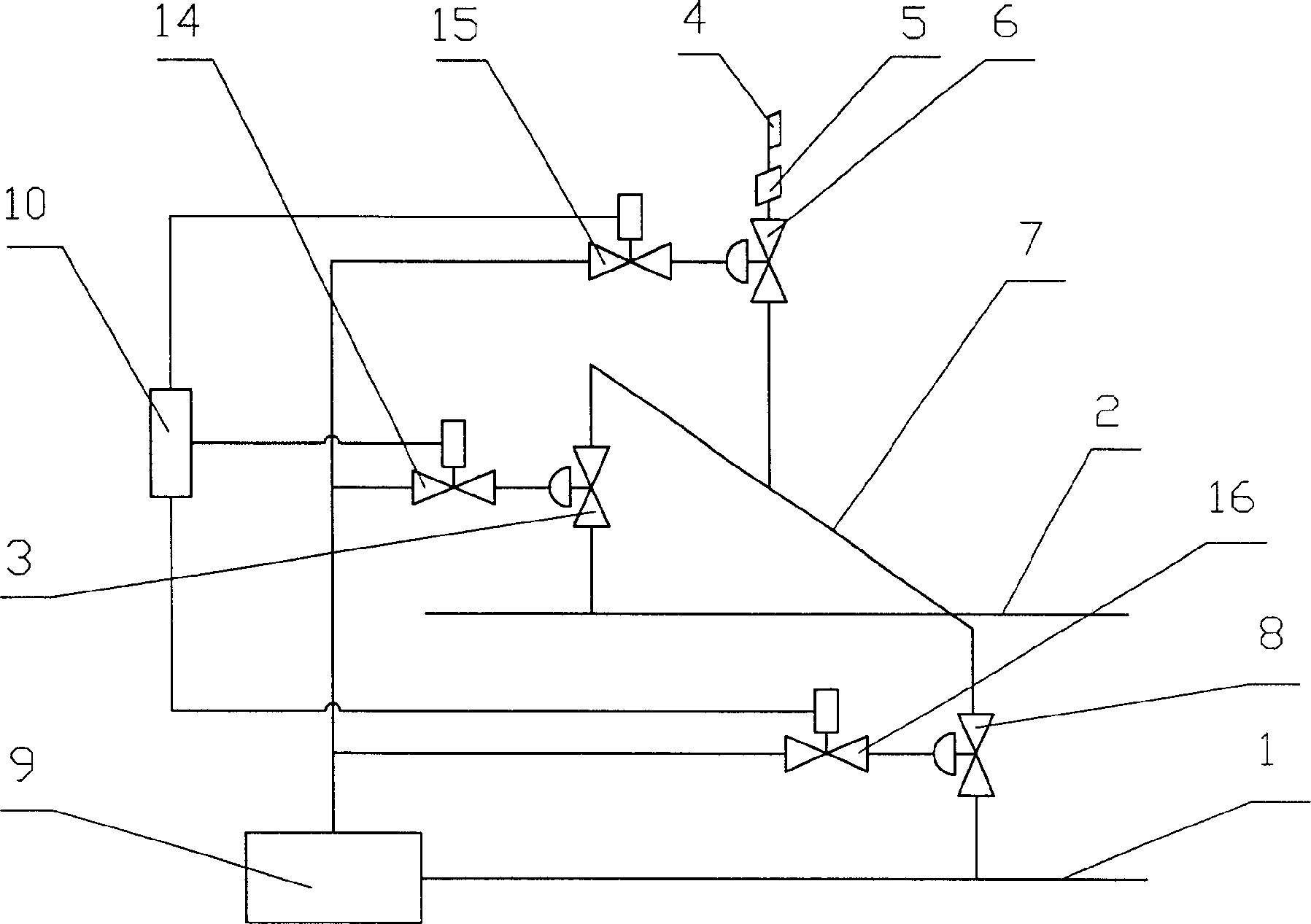

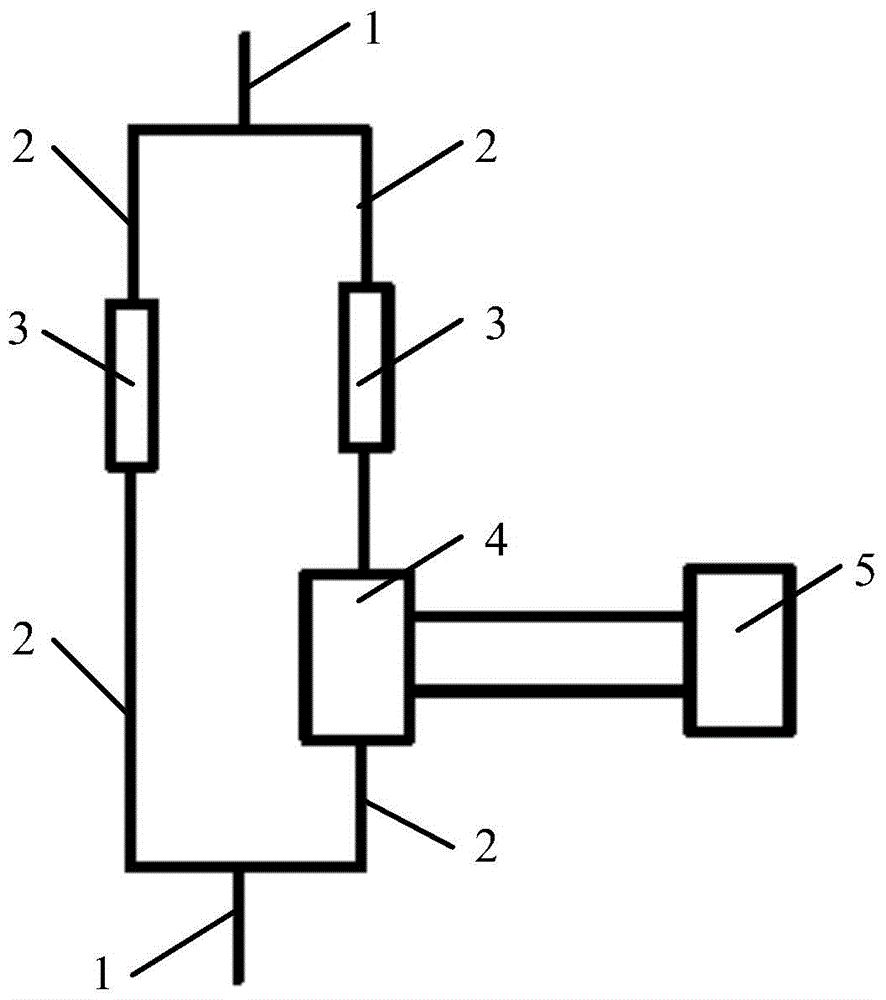

Hydrogen gas flow regulating device for tungsten alloy material incipient fusion sintering

The invention discloses a hydrogen gas flow regulating device for tungsten alloy material incipient fusion sintering. The device is arranged on a hydrogen supplying pipe (1) of an incipient fusion hood and is electrically connected with an incipient fusion sintering control system (5). One segment of the hydrogen supplying pipe (1) is composed of two hydrogen supplying branches (2) connected in parallel. One of the hydrogen supplying branches (2) is a small-flow hydrogen supplying branch, and the other hydrogen supplying branch (2) is a large-flow hydrogen supplying branch. The two hydrogen supplying branches (2) are provided with hydrogen gas flow meters (3) respectively. The large-flow hydrogen supplying branch is provided with an electromagnetic valve (4) for controlling on-off of the large-flow hydrogen supplying branch, and the electromagnetic valve (4) is electrically connected with the incipient fusion sintering control system (5). By means of the hydrogen gas flow regulating device for tungsten alloy material incipient fusion sintering, the flow of hydrogen gas entering the incipient fusion hood can be regulated, the proper hydrogen gas flow can be provided for incipient fusion sintering in the heating, heat preservation and cooling periods, and the purposes of saving the hydrogen gas and the cost are achieved.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

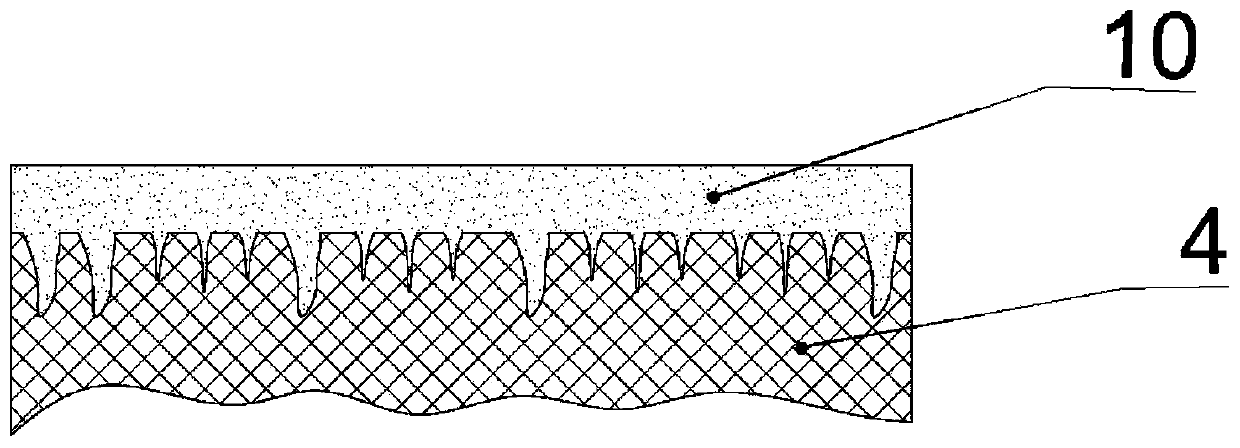

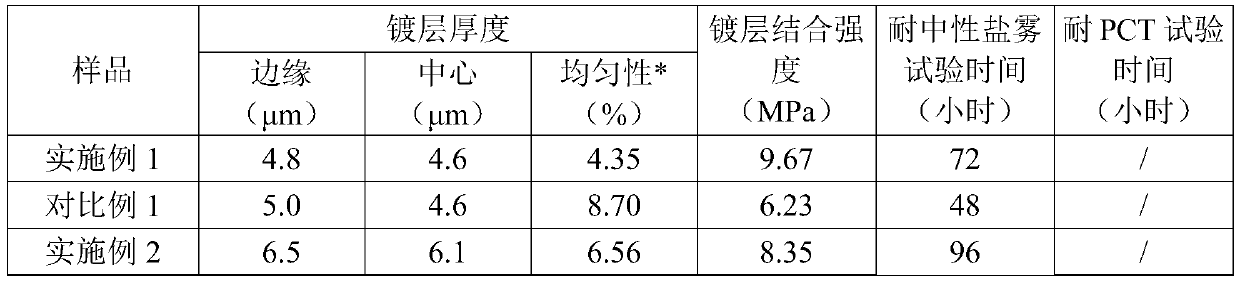

Electroplating technology

The invention discloses an electroplating technology. The electroplating technology includes a pretreatment process, a vacuum sucking process and an electroplating process. In the pretreatment process, pretreatment is conducted on the surface of a magnet. In the vacuum sucking process, vacuum sucking is conducted on the pretreated magnet, and the vacuum sucking state is maintained. In the electroplating process, the magnet obtained after vacuum sucking is immersed into electroplating liquid, under the condition of negative pressure, ultrasonic waves and water flow impacts, a metal protection layer is electroplated on the surface of the magnet. By means of the electroplating technology, the bonding strength of the manufactured metal protection layer and the magnet is high, in addition, corrosion resistance is good, disengagement is not likely to happen, and in addition, the electroplating efficiency is high.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

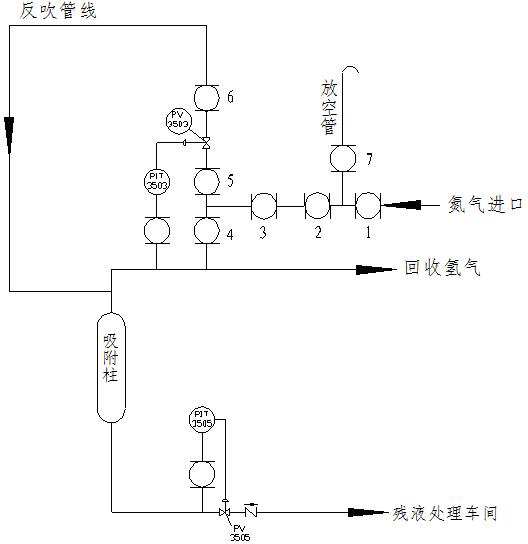

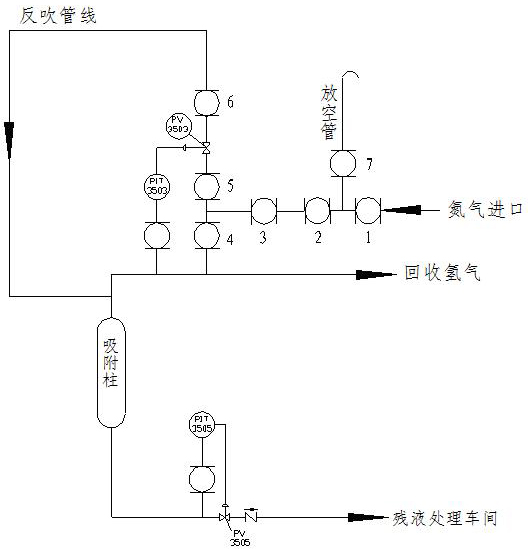

Analytical method of adsorption column for polysilicon tail gas dry separation system

InactiveCN102284225AOvercoming serious deficitsAvoid safety hazardsDispersed particle separationEnvironmental engineeringNitrogen gas

The invention discloses a method for analyzing an adsorbing column of a polycrystalline silicon tail gas dry method separation system. The method comprises the following steps of: a) performing back flushing and analysis on the adsorbing column by using nitrogen; b) replacing the adsorbing column by using hydrogen; and c) cooling the nitrogen or hydrogen which carries a large amount of chlorosilane by circulating water and a refrigerating fluid after back flushing and cooling, and after the chlorosilane in the nitrogen or the hydrogen is separated, conveying nitrogen or hydrogen to a raffinate treatment workshop and leaching and emptying. The method overcomes the conditions that hydrogen used for back flushing is not effectively utilized, and hydrogen is seriously insufficient in the production of polycrystalline silicon and avoids the potential safety hazard brought by leaching and emptying; and after the adsorbing column is subjected to back flushing and analysis by using the nitrogen with relatively low cost instead of hydrogen, the adsorbing column is replaced by the hydrogen, so that the hydrogen can be effectively saved, and the production cost and potential safety hazard brought by leaching and emptying are reduced.

Owner:SICHUAN RENESOLA SILICON MATERIAL

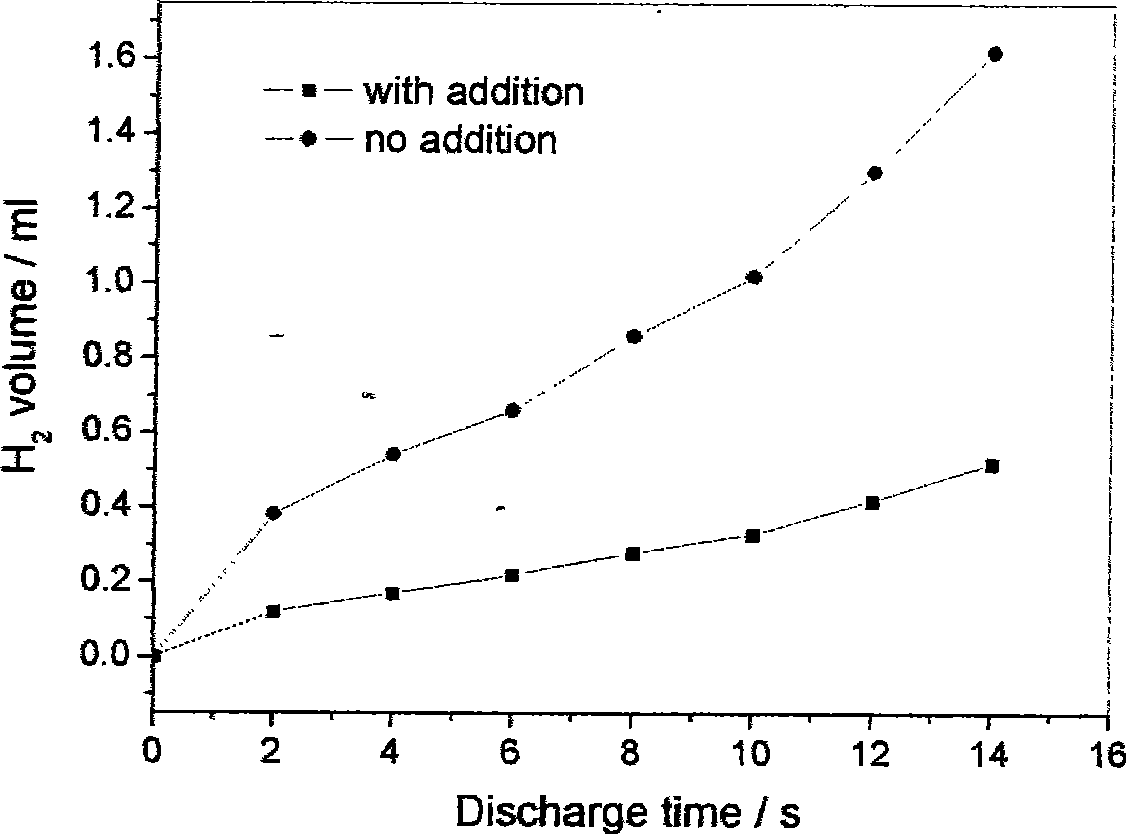

Water system lithium cell electrolyte solution

InactiveCN101483255AInhibit corrosion reactionImprove discharge efficiencySecondary cellsAqueous electrolyte cellsDischarge efficiencyCorrosion reaction

The invention relates to a water system lithium battery electrolyte comprising water, an alkalis and an additive agent characterized in that the additive agent is a RSiX3, wherein the R in the RSiX3 is selected from an amino group, a sulfhydryl, a vinyl, an epoxy radical, a cyano and a methacryloyloxyl or the like, the X is an alkoxyl group. The alkoxyl group in the additive agent is hydrolyzed in water solution and an alcohol is formed adsorbing on a lithium electrode surface; the part containing RSi- is adsorbed on the lithium electrode surface, which improves the discharging efficiency when the metal lithium is used as a battery cathode, inhibits a corrosion reaction between the metal lithium and the electrolyte, thereby reducing the generation of the hydrogen on the lithium electrode, improving the electrode utilization efficiency and the battery safety. The electrolyte containing the additive agent for the water lithium battery, any proper anode and the metal lithium cathode can be combined into the water system lithium battery.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

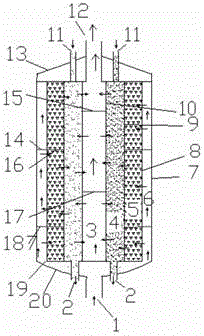

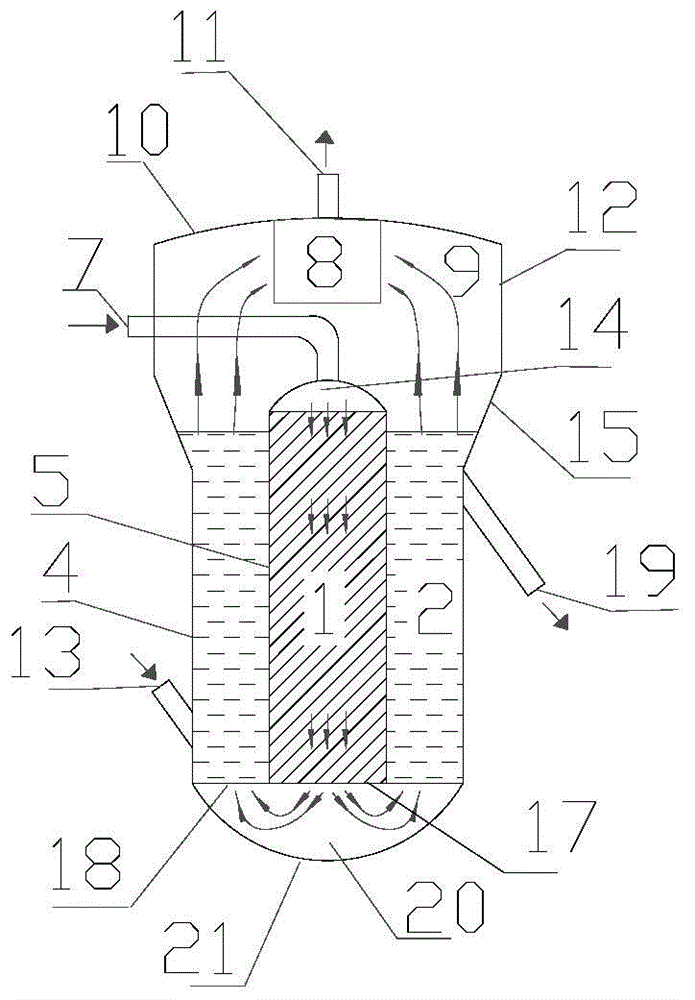

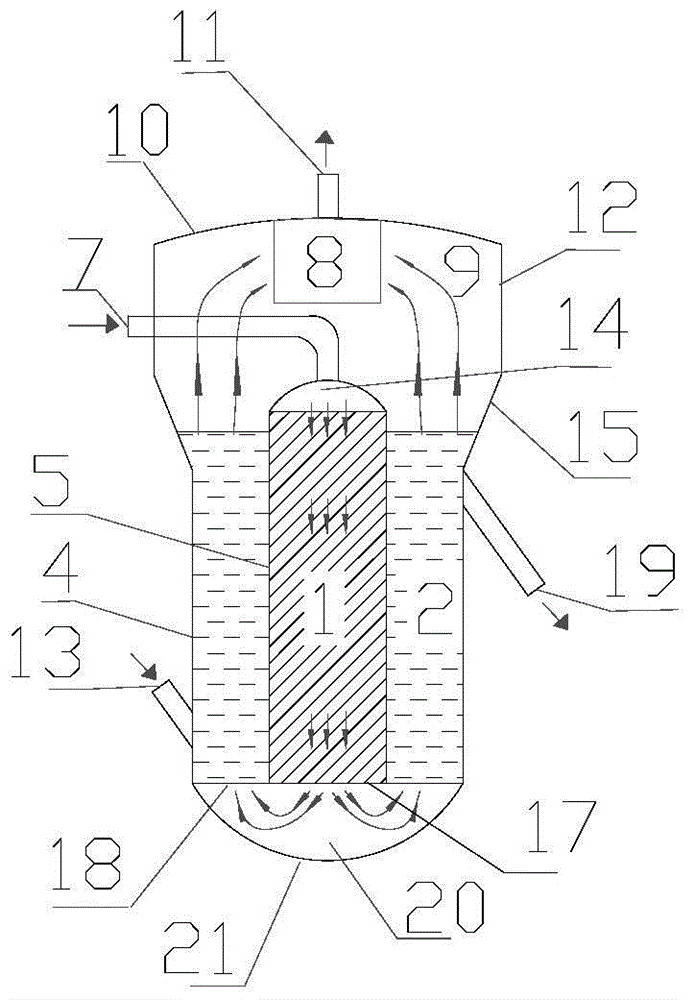

Petroleum hydrocarbon adsorption desulfurization method

ActiveCN105623733AReduce wearSimple structureTreatment with hydrotreatment processesFluidized bedGas phase

A petroleum hydrocarbon adsorption desulfurization method adopts a fixed bed-fluidized bed reactor which is divided into a particle settling zone, a reaction zone and a gas buffer zone from top to bottom; the reaction zone is divided into a fixed bed layer and a fluidized bed layer in the radial direction from outside to inside or from inside to outside; a separation plate which enables gas to pass through and enables catalyst particles not to pass through is arranged between the lower part of the fixed bed layer as well as the fluidized bed layer and the gas buffer zone; a space between the upper part of the fixed bed layer and the particle settling zone is closed; the upper part of the fluidized bed layer communicates with the particle settling zone; the upper part of the fixed bed layer is provided with a fluid feed inlet; the particle settling zone is internally provided with a gas-solid separator; a gas phase outlet of the gas-solid separator is a fluid discharge outlet of the reactor; the fluidized bed layer is also provided with a fluidized catalyst inlet and outlet. The petroleum hydrocarbon adsorption desulfurization method provided by the invention simplifies device construction and operation process, saves the energy consumption, and is beneficial for realizing continuous reaction and regeneration of production.

Owner:CHINA PETROLEUM & CHEM CORP +1

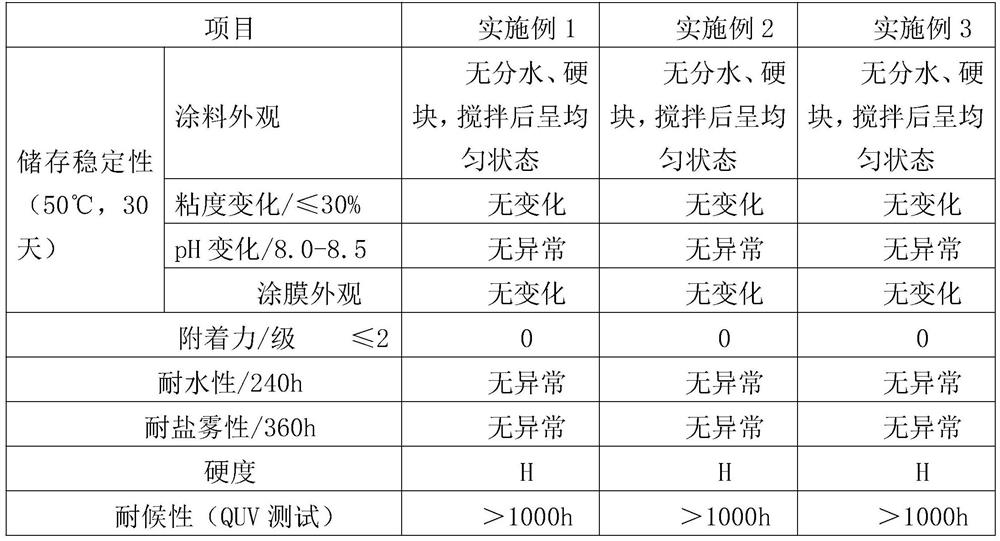

Acrylate emulsion and application thereof in aluminum powder paint

ActiveCN112898494AImprove dispersion stabilityEasy alignmentAnti-corrosive paintsPhosphoric Acid EstersEmulsion

The invention relates to an acrylate emulsion and application thereof in aluminum powder paint. The preparation method of the acrylate emulsion comprises the following steps: adding 20-40 parts of deionized water, 0.2-0.4 part of a nonionic emulsifier and 0.5-0.9 part of an anionic emulsifier into a four-neck flask, and then adding two thirds of a core monomer mixed solution and an initial initiator aqueous solution; then, dropwise adding the remaining core monomer mixed solution and the initiator aqueous solution at the same time, and then dropwise adding N-N dimethylethanolamine until the pH is equal to 6; adding a shell monomer mixed solution and a shell initiator aqueous solution; sequentially adding an aqueous solution of tert-butyl hydroperoxide and an aqueous solution of sodium sulfite, and finally adding 0.3-0.8 part of N-N dimethylethanolamine to adjust the pH value to 7.5-8, thereby obtaining the product. The phosphate ester resin is used for wrapping the oily aluminum powder, the process is simple and convenient, the cost is low, the wrapping property is good, the prepared coating is good in stability, hydrogen is not generated or little hydrogen is generated after long-term storage, tank expansion is avoided, the metallic feeling is excellent after spraying, and good corrosion resistance is provided for the aluminum powder coating.

Owner:三棵树(上海)新材料研究有限公司

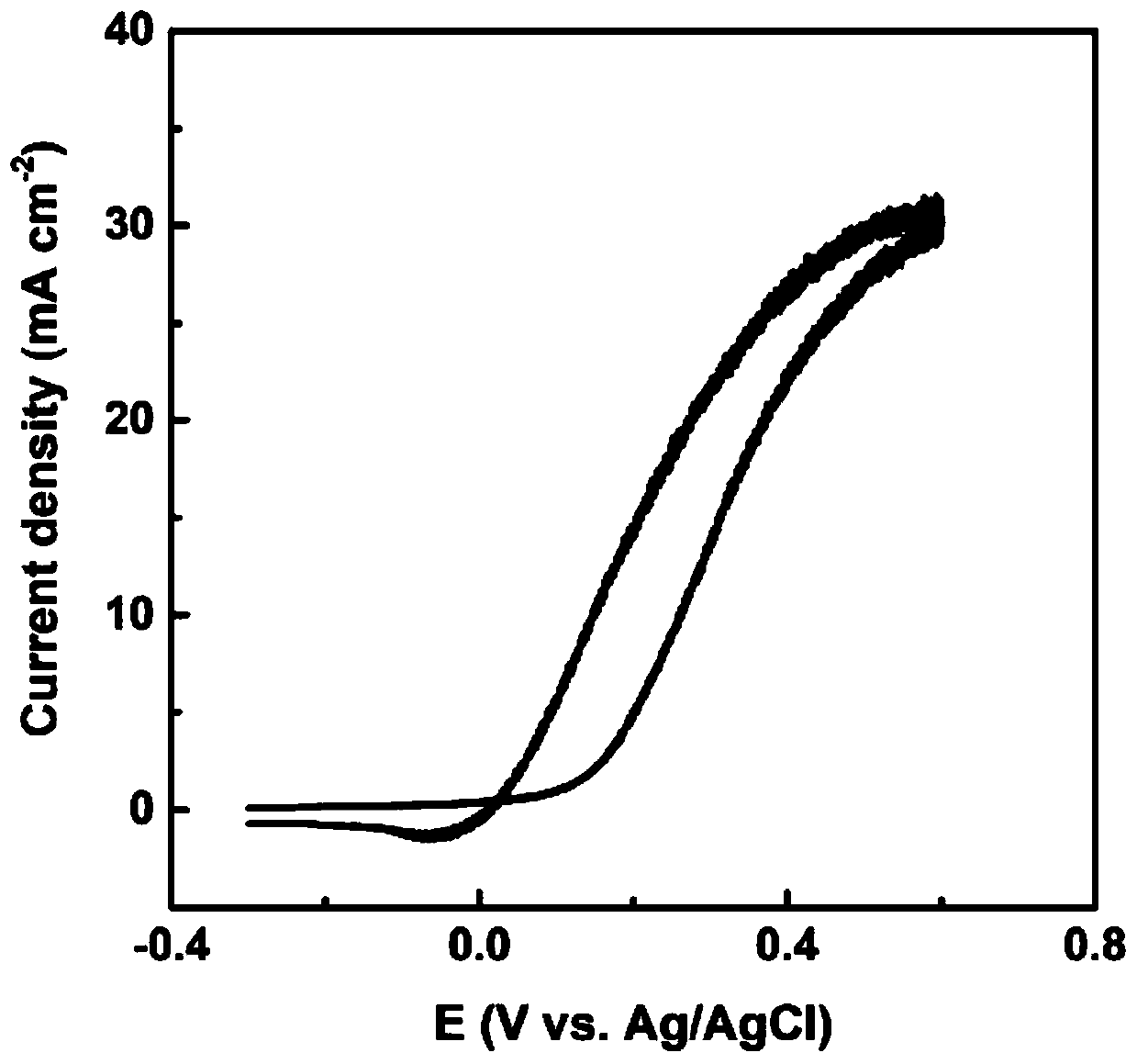

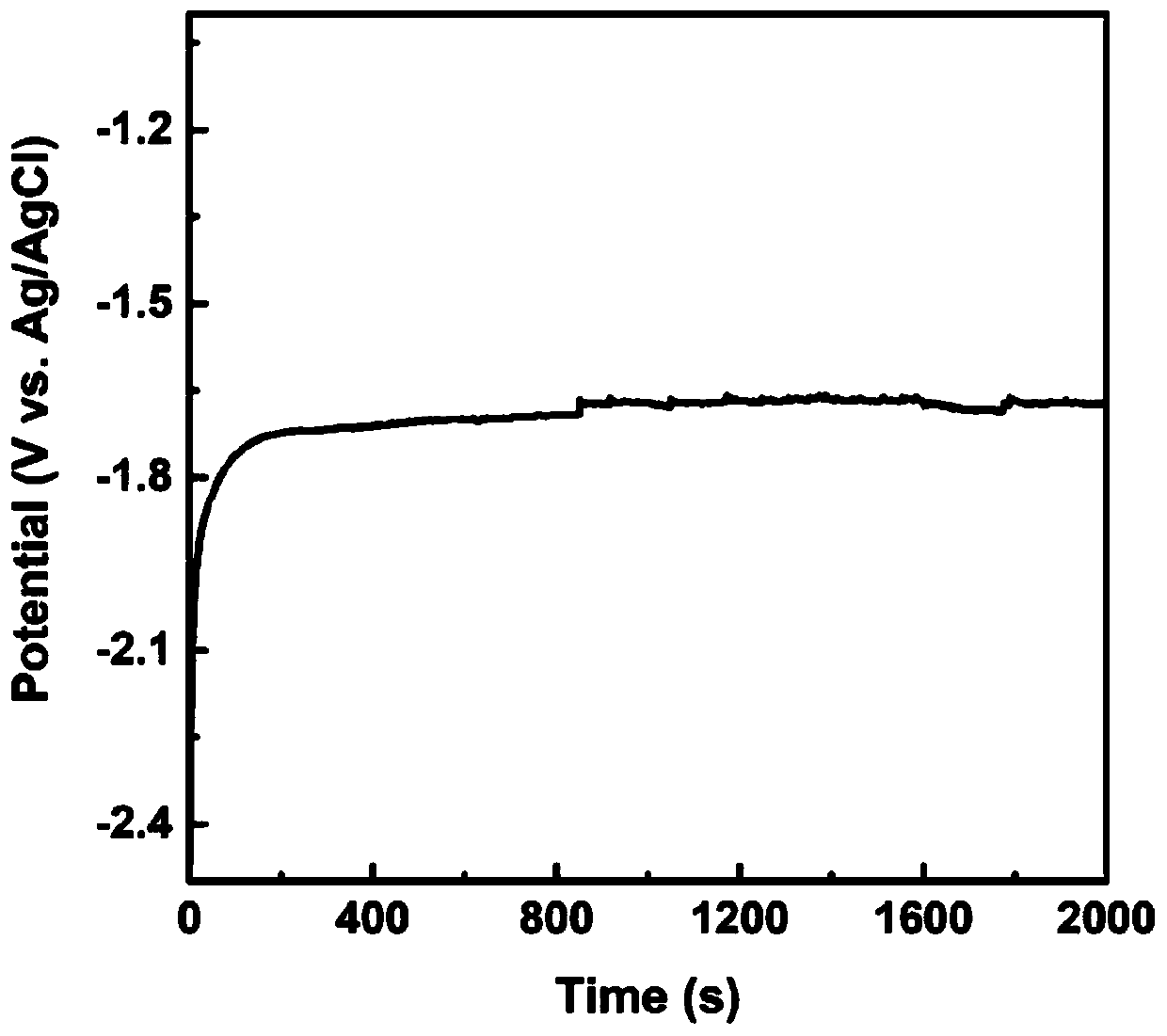

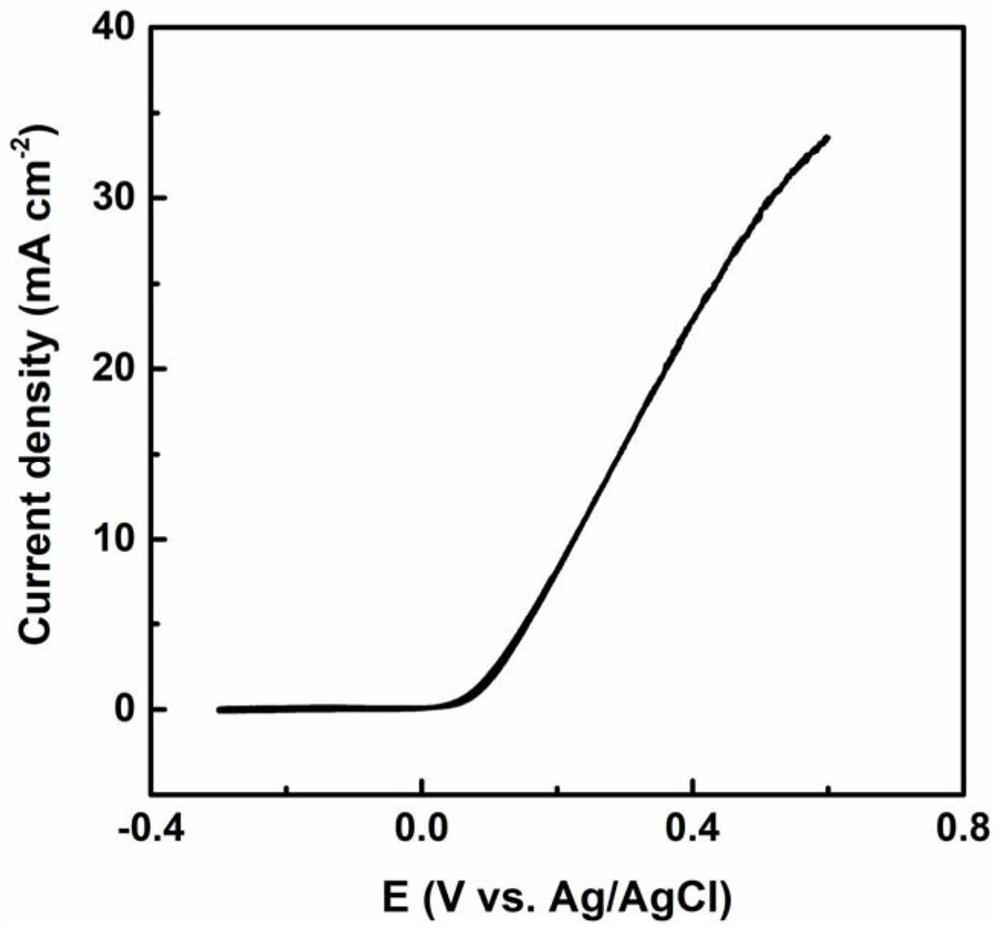

Preparation method of silicon/nickel-cobalt-iron photo-anode

PendingCN114262910AEffective protectionAvoid Corrosion PassivationEnergy inputElectrodesDecompositionElectrochemical decomposition

The invention discloses a silicon / nickel-cobalt-iron photo-anode preparation method, nickel sulfate, cobalt sulfate and ferrous sulfate are dissolved in deionized water to form a uniformly mixed electro-deposition solution, inert gas is used for maintaining the existence of iron elements in the solution in the form of ferrous ions, and in the under-potential deposition process, the content of the ferrous ions in the solution is reduced; divalent nickel-cobalt-iron elements form a compact nickel-cobalt-iron alloy film on the surface of a silicon electrode, a silicon anode is effectively protected to avoid corrosion and passivation, the outermost layer of the nickel-cobalt-iron alloy film is oxidized to generate a complex nickel-cobalt-iron (hydrogen) oxide at the initial stage of photoelectric water decomposition, and the photoelectric water decomposition efficiency is improved. More surface active sites are provided for photoelectrochemical water decomposition to accelerate the photoelectrochemical water decomposition process so as to accelerate the generation of hydrogen, the silicon / nickel-cobalt-iron photo-anode synthesized by the method can be prepared on a large scale in a controllable, repeatable and rapid manner by using the existing electro-deposition equipment in a factory, and the method is suitable for industrial production. And no toxic chemical reagent is added in the whole synthesis process, the conditions are mild, and no pollution is caused.

Owner:XI AN JIAOTONG UNIV +1

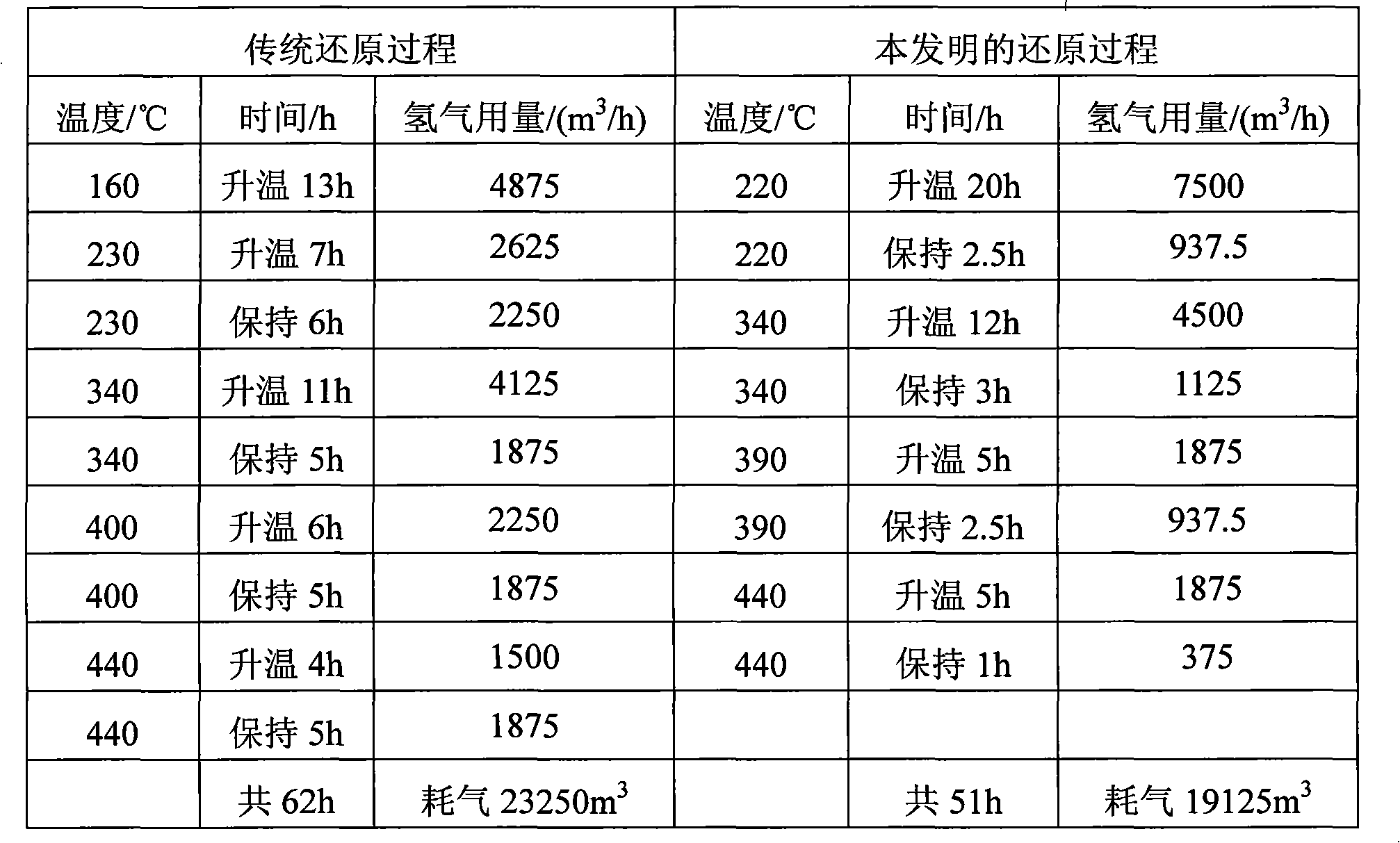

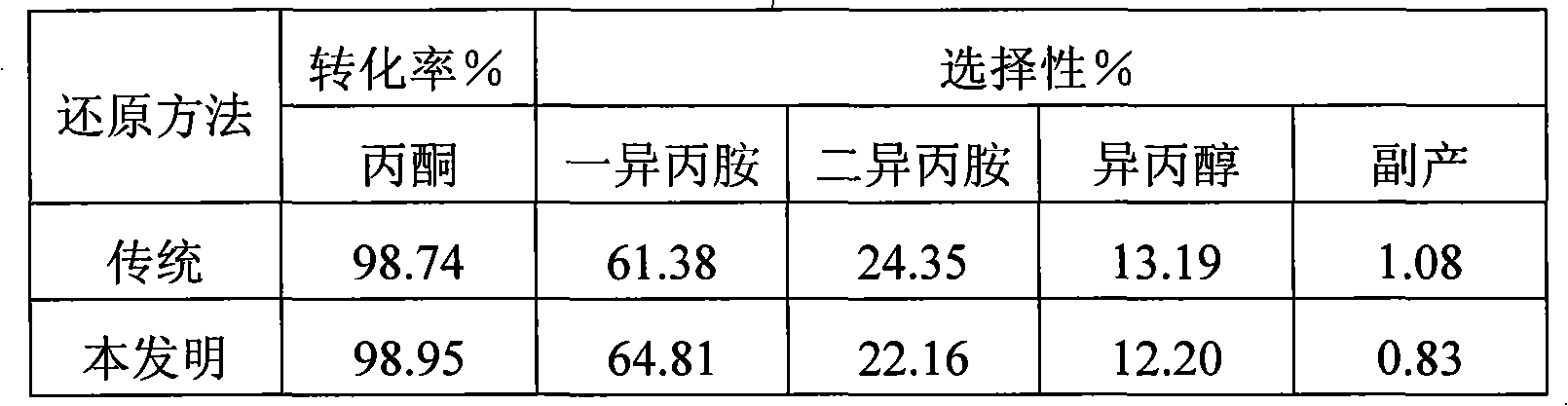

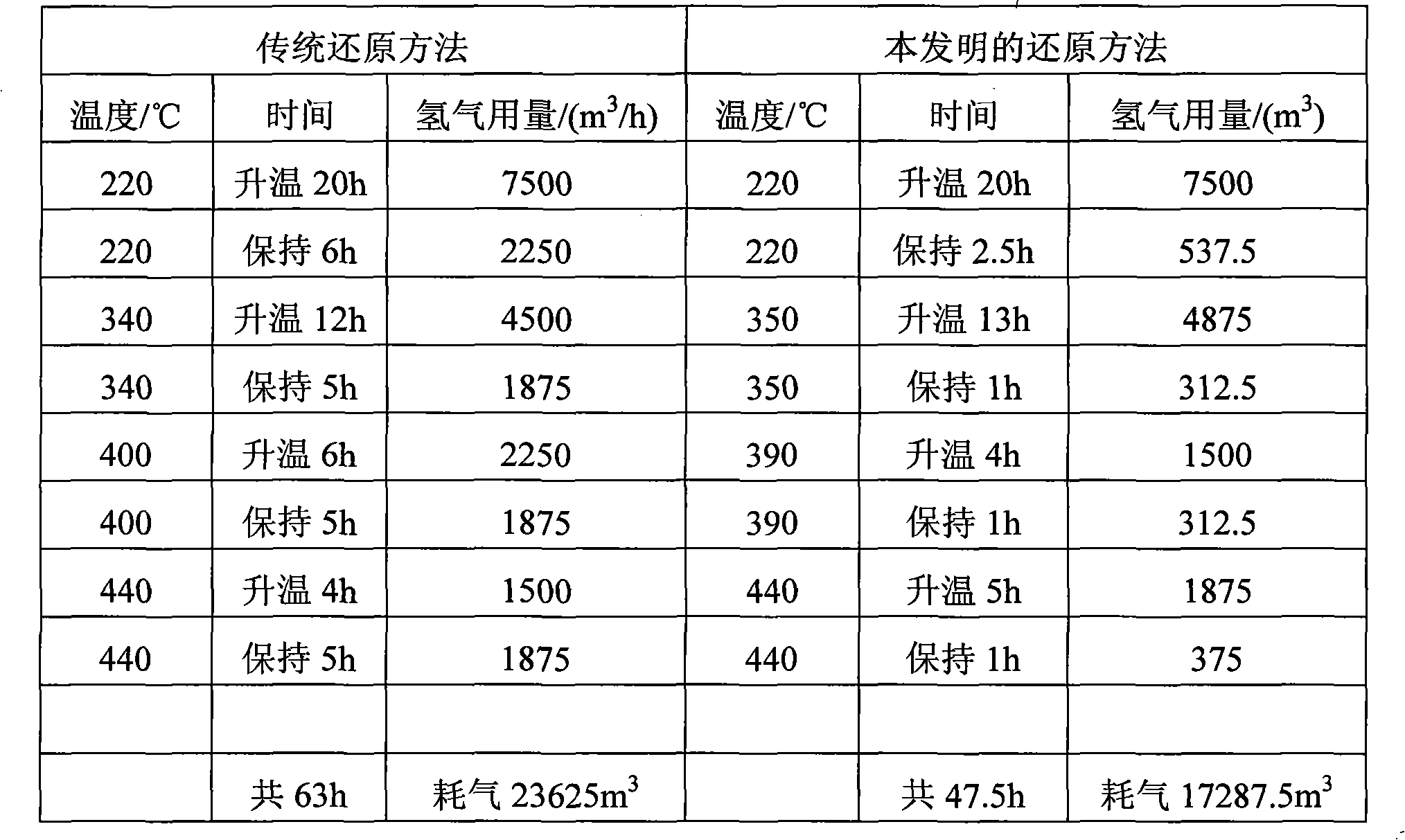

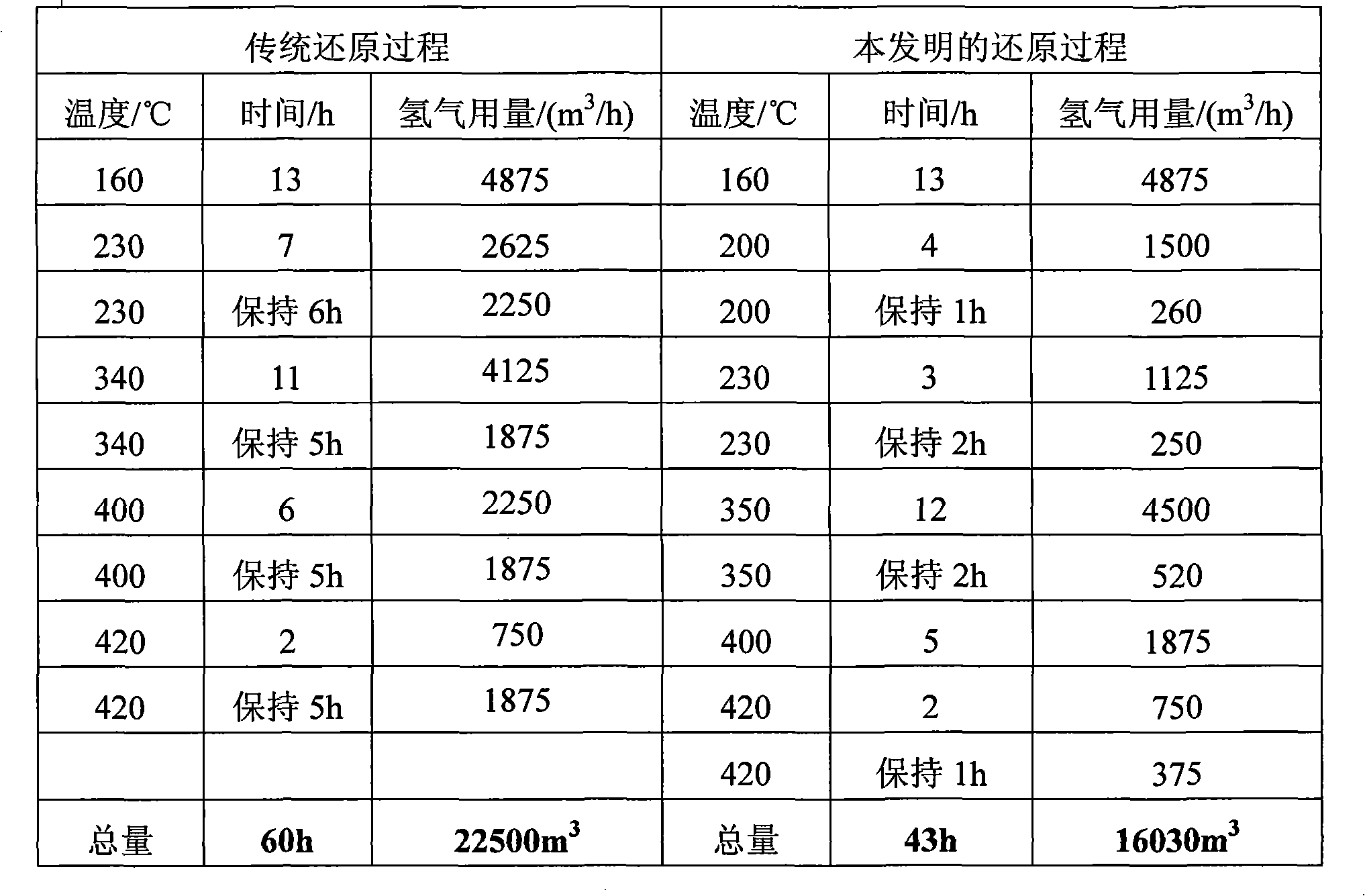

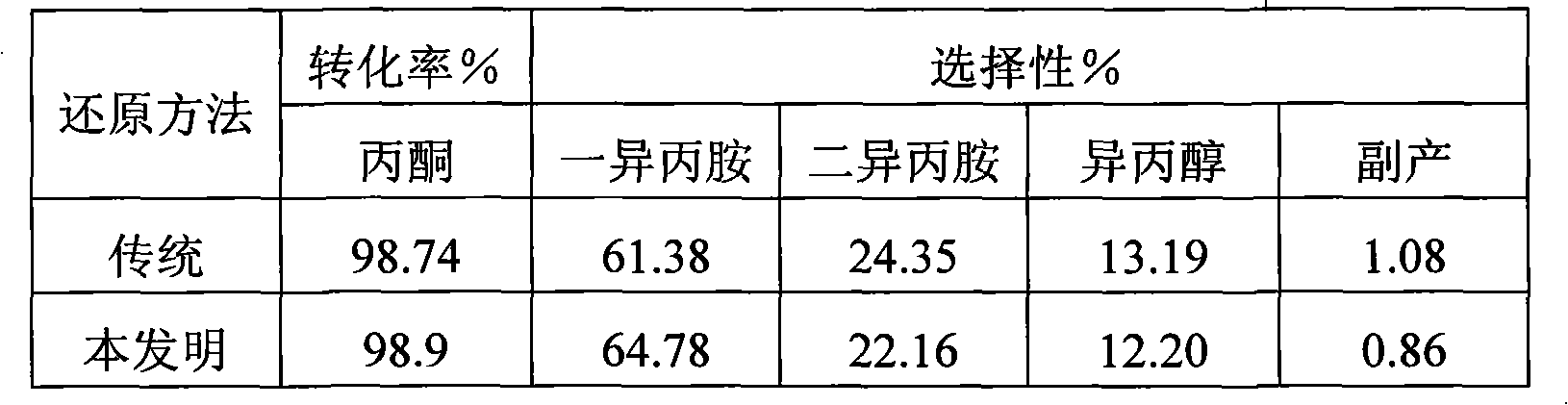

Rapid reducing method of catalyst

ActiveCN102335633AShorten the timeSave hydrogenCatalyst activation/preparationTemperature control using electric meansControl systemReduction ratio

The invention relates to a rapid reducing method of a catalyst. In order to solve the problems of long catalyst reduction time and large hydrogen consumption quantity in the industrial production at present, the inventor provides the method comprising the steps of: in a reduction process of the catalyst, online-analyzing concentrations of hydrogen in gas at an inlet of a reduction furnace and gasin an outlet of the reduction furnace in real time, loading an online analysis result to a catalyst reduction control system, and regulating the reduction temperature of the reduction furnace by the reduction control system according to the change of the online-analyzed concentrations of the hydrogen. By using the method, the automatic reduction control of the catalyst reduction furnace can be realized, the whole reduction process can be monitored, the whole reduction time of the catalyst is reduced, the consumption of the hydrogen is reduced, thus the processing period of the catalyst is greatly shortened and the processing cost of the catalyst is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-speed temperature programmed reduction method for catalyst

ActiveCN102335635ANo pulverizationShorten the timeCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHydrogen concentrationSpace velocity

The invention relates to a high-speed temperature programmed reduction method for a catalyst. In order to solve the universal problems of long catalyst reduction time and great hydrogen consumption in present catalyst reduction equipment, the inventor puts forward the method of: during a catalyst reduction process, conducting on-line analysis for hydrogen concentrations in the inlet gas and outlet gas of a reduction furnace, and under a constant catalyst reduction space velocity, analyzing the difference of hydrogen concentrations at the inlet and outlet by a reduction control program, and adjusting the reduction temperature in the reduction furnace as well as the hydrogen concentration in the reduction gas. The method of the invention can guarantee the reduction of overall catalyst reduction time and the saving of hydrogen consumption based on fully reducing the catalyst, so that the overall processing period of the catalyst is substantially shortened and the catalyst production costis reduced, thus boasting extensive practical application value.

Owner:CHINA PETROLEUM & CHEM CORP +1

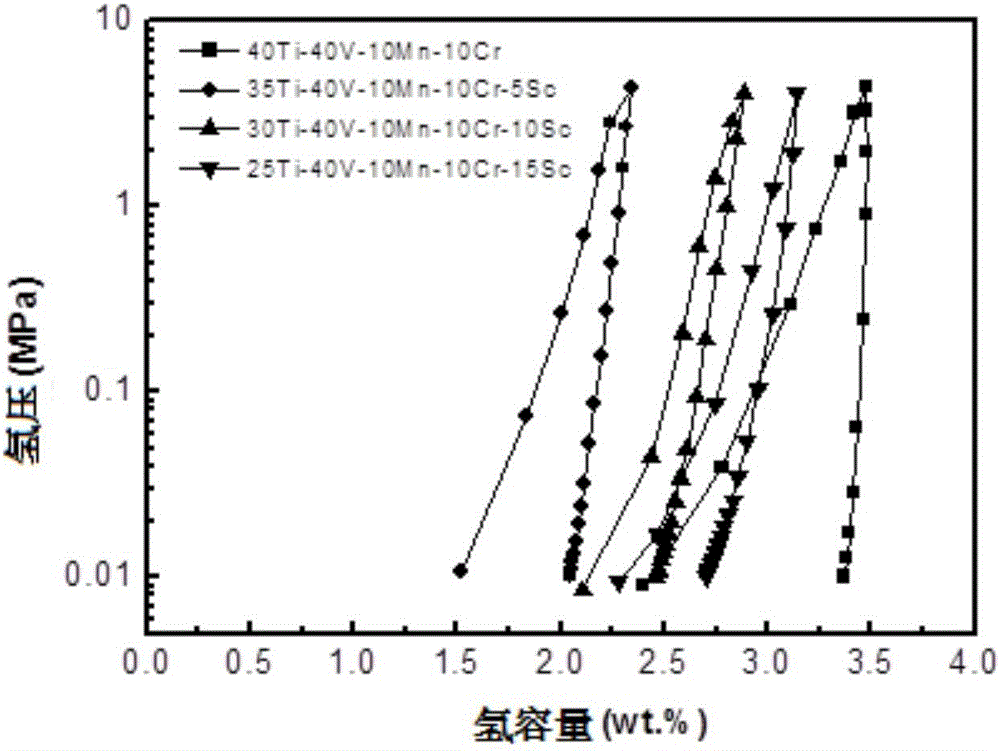

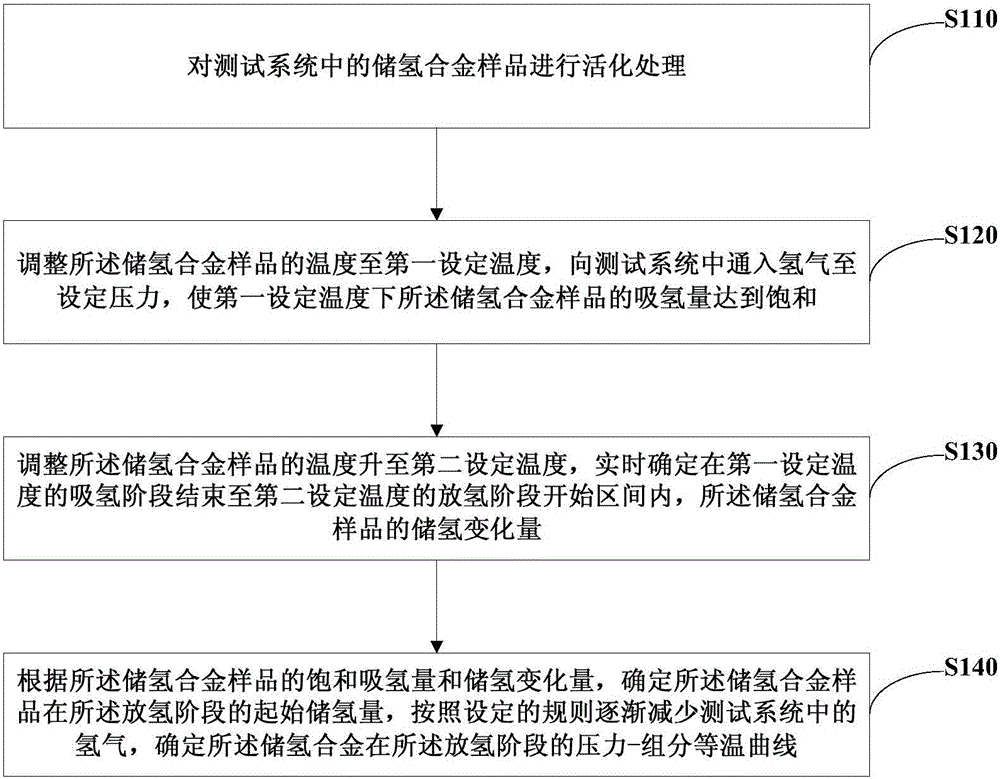

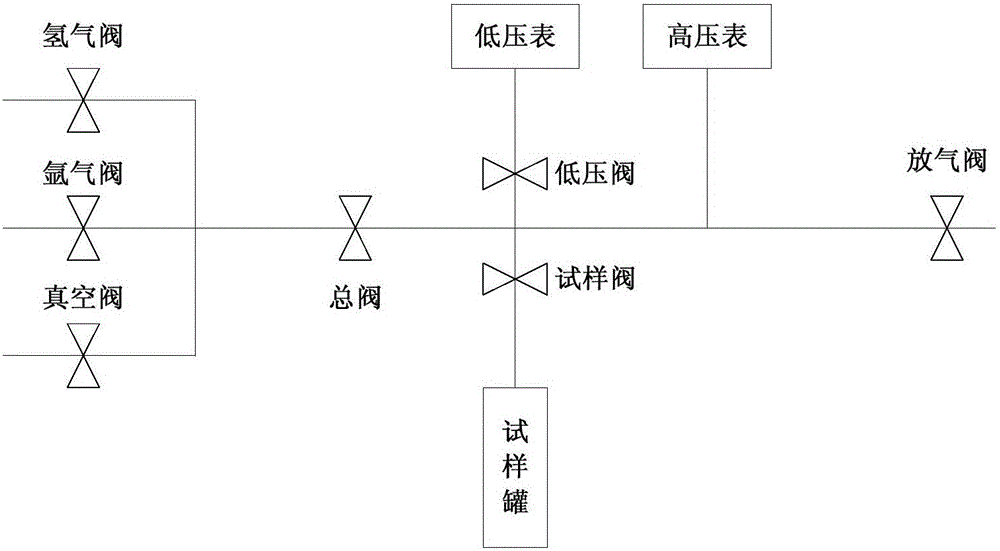

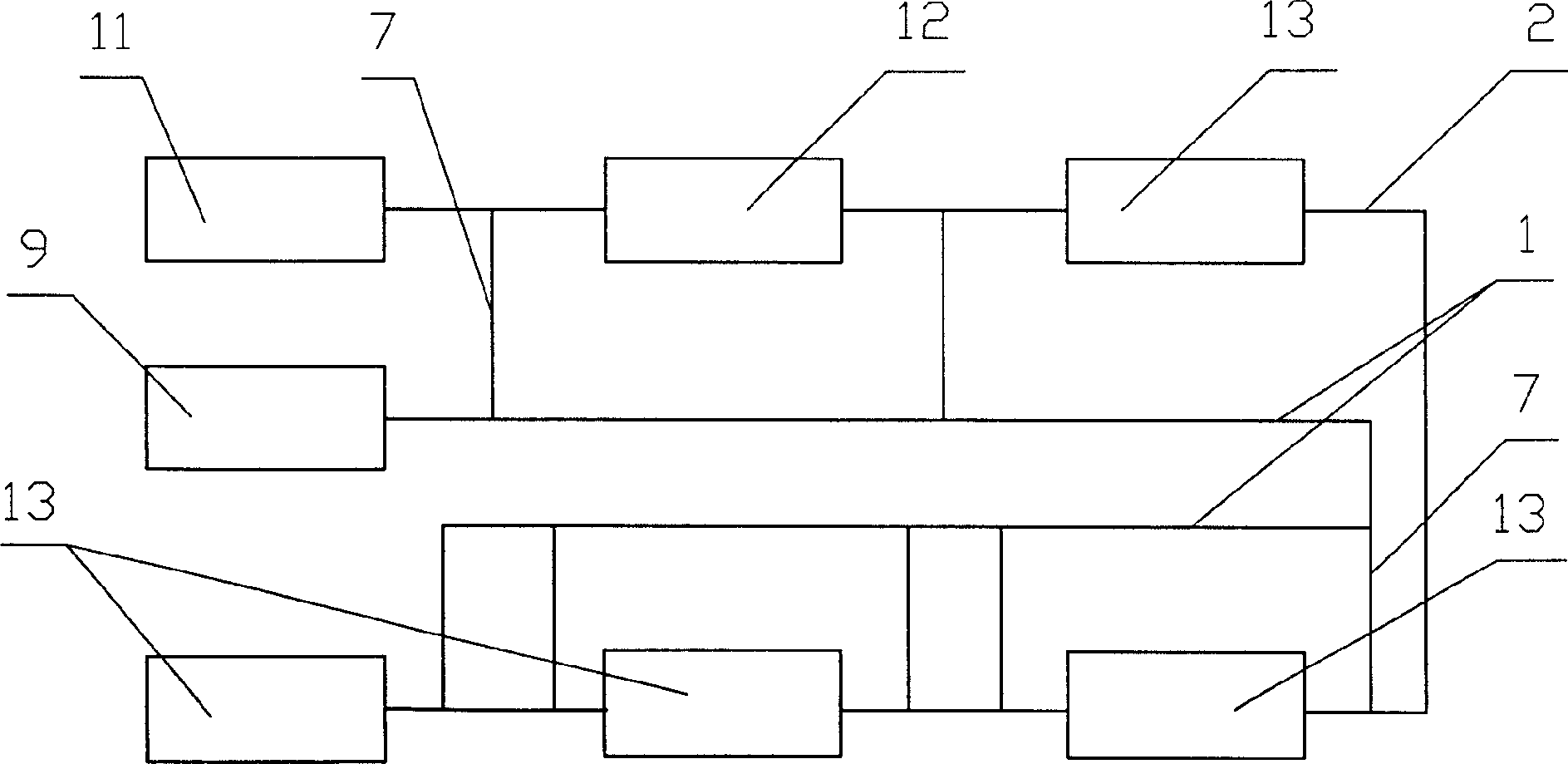

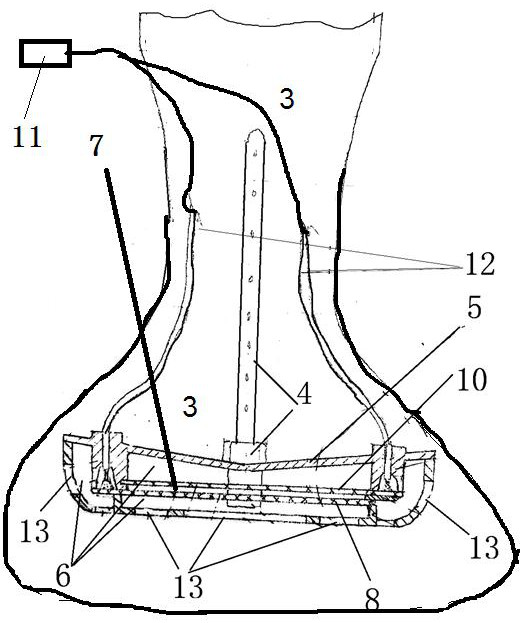

Testing method, device and system for performance curve of hydrogen storage alloy

ActiveCN105911244AAccurately obtain the change of hydrogen storageSave hydrogenTesting metalsHydrogen desorptionHydrogen absorption

The invention discloses a testing method, device and system for a performance curve of hydrogen storage alloy. The method comprises the steps that activating treatment is conducted on a hydrogen storage alloy sample contained in a testing system; the temperature of the hydrogen storage alloy sample is adjusted to a first set temperature, and hydrogen is introduced into the testing system until the testing system reaches the set pressure, so that the hydrogen absorption quantity of the hydrogen storage alloy sample at the first set temperature reaches saturation; the temperature of the hydrogen storage alloy sample is adjusted to a second set temperature, and hydrogen storage change quantity of the hydrogen storage alloy sample is determined in real time in the interval from the end of the hydrogen absorption stage at the first set temperature to the start of the hydrogen desorption stage at the second set temperature; the initial hydrogen storage quantity of the hydrogen storage alloy sample in the hydrogen desorption stage is determined according to the saturated hydrogen absorption quantity of the hydrogen storage alloy sample and the hydrogen storage change quantity, hydrogen in the testing system is gradually decreased according to a set rule, a pressure-component isothermal curve of the hydrogen storage alloy in the hydrogen desorption stage is determined, and a more complete PCT curve and platform in the hydrogen desorption stage are provided.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

A method for adsorption and desulfurization of petroleum hydrocarbons

ActiveCN105623733BReduce wearSimple structureTreatment with hydrotreatment processesGas phaseFluidized bed

A petroleum hydrocarbon adsorption desulfurization method adopts a fixed bed-fluidized bed reactor which is divided into a particle settling zone, a reaction zone and a gas buffer zone from top to bottom; the reaction zone is divided into a fixed bed layer and a fluidized bed layer in the radial direction from outside to inside or from inside to outside; a separation plate which enables gas to pass through and enables catalyst particles not to pass through is arranged between the lower part of the fixed bed layer as well as the fluidized bed layer and the gas buffer zone; a space between the upper part of the fixed bed layer and the particle settling zone is closed; the upper part of the fluidized bed layer communicates with the particle settling zone; the upper part of the fixed bed layer is provided with a fluid feed inlet; the particle settling zone is internally provided with a gas-solid separator; a gas phase outlet of the gas-solid separator is a fluid discharge outlet of the reactor; the fluidized bed layer is also provided with a fluidized catalyst inlet and outlet. The petroleum hydrocarbon adsorption desulfurization method provided by the invention simplifies device construction and operation process, saves the energy consumption, and is beneficial for realizing continuous reaction and regeneration of production.

Owner:CHINA PETROLEUM & CHEM CORP +1

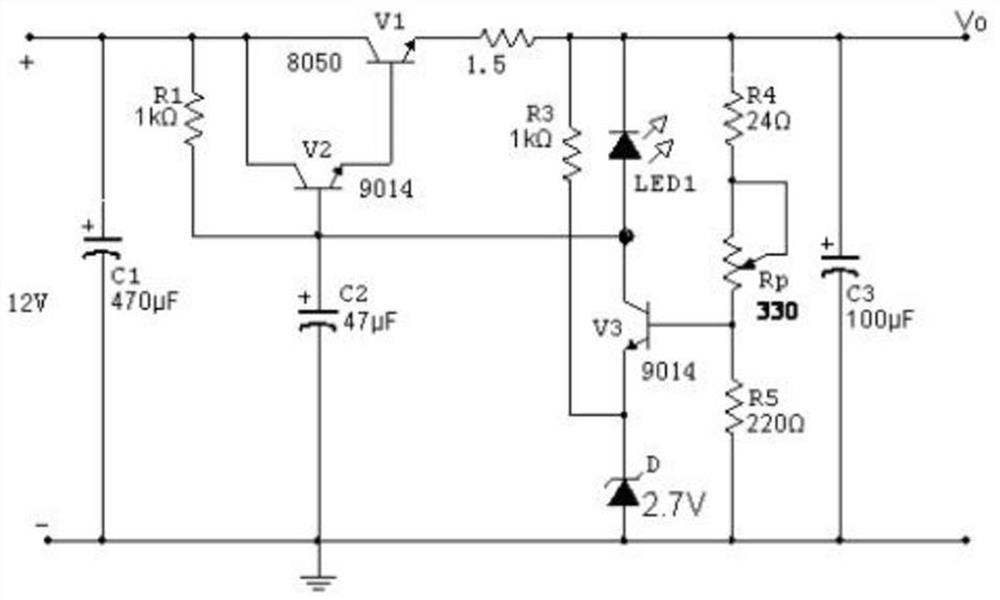

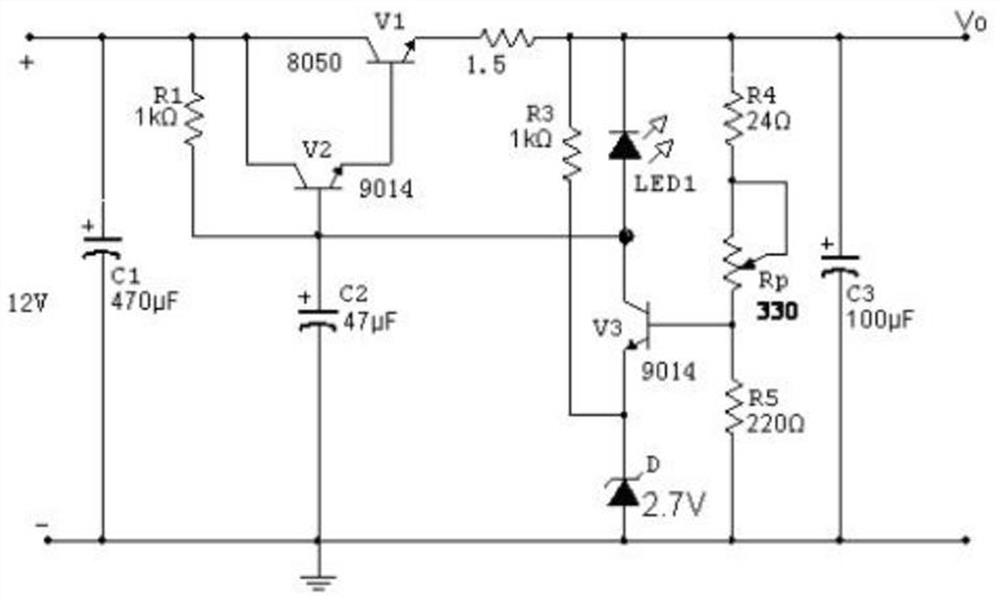

Power supply control circuit used for preparing disinfectant through direct-current electrolysis in slightly alkaline environment

The invention provides a power supply control circuit for preparing a disinfectant through direct-current electrolysis in a slightly alkaline environment. The power supply control circuit comprises alow-voltage direct-current power supply and an electrode plate array connected with the low-voltage direct-current power supply; the low-voltage direct-current power supply supplies power to the electrode plate array; the output voltage of the low-voltage direct-current power supply is 1V-24V; the electrode plate array is composed of a net-shaped anode and a net-shaped cathode which are closely arranged in parallel; the distance between the net-shaped anode and the net-shaped cathode ranges from 0.5 mm to 2.5 mm; brine between the anode and the cathode can freely flow so that the pH value range of the liquid environment in the electrolysis process can be maintained to be 8 and 10. When saline water is electrolyzed, the low-voltage direct-current power supply detects current output by the electrode plate array; when the liquid level of the saline water descends, and the area, exposed from the liquid level, of the electrode plate array is larger than a threshold value, the variable quantity of the current output by the electrode plate array is larger than the threshold value, and the power supply control circuit stops supplying power to the electrode plate array. According to the power supply control circuit, domestic disinfectant fluid can be prepared by the diaphragm-free brine electrolysis method, the problem of gas deflagration of the diaphragm-free brine electrolysis methodis solved, and the product can be safely used for domestic hygiene disinfection.

Owner:FUJIAN OSPRING TECH & DEV

Method of utilizing cracked, C5 fraction

ActiveCN100441554COptimize the marketSave hydrogenHydrocarbon by hydrogenationHydrocarbon by hydrocarbon cracking2-methylbutaneHydrogenation process

The method of utilizing cracked C5 fraction includes the first dimerizing cyclopentadiene in the cracked C5 fraction into dicyclopentadiene, separating dicyclopentadiene, selectively hydrogenating diene in the residual material into monoene and directly converting olefine to produce ethylene and propylene. The method may have etherification reaction before or after olefine conversion to produce methyl tert-amyl ether product and high purity isoamylene product further. The method may include a full hydrogenation process to produce pentane, which may be used as cracked material in a main cracking furnace or separated into n-pentane produce and isopentane product. The method is flexible and practical.

Owner:CHINA PETROLEUM & CHEM CORP

Inert gas protector

The inert gas safety device includes valve control box, inert gas container and gas pipe communicated with it, three ports are respectively equipped with three-way connection pipe of inert gas control valve, combustible gas control valve and blowdown control valve, and another ends of said three valves are respectively communication with gas pipe, combustible gas pipe and blowdown pipe, and said three valves can be controlled in the centralization mode by means of electromagentic valve and valve control switch, also can be respectively hand-controlled. It can effectively and quickly charge the inert gas into combustible gas pipe to dilute combustible gas and extinguish fire. It also can be used for gas substitution, and maintenance and retaining pressure.

Owner:BAOSHAN IRON & STEEL CO LTD

A hydrogen flow regulating device for vertical melting and sintering of tungsten alloy materials

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

Catalyst rapid reducing method

ActiveCN102335634AShorten the timeSave hydrogenCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsExhaust gasProcess engineering

The invention relates to a catalyst rapid reducing method. According to the method, with a reducing furnace reduction controlling program, a hydrogen flow and a heating rate are automatically maintained and regulated according to on-line monitored values and variation trends of water vapor content and hot spot temperature of reduction tail gas. With the method, controlling over catalyst reductionfurnace automatic reduction can be realized; an entire reduction process can be monitored; an entire catalyst reduction time can be reduced; and a hydrogen usage amount can be reduced. Therefore, theprocessing period and the processing cost of the catalyst are greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Power supply control circuit for the preparation of disinfectant by direct current electrolysis in an alkaline environment

ActiveCN112064061BSolving Gas Deflagration ProblemsSave hydrogenCellsEnvironmental engineeringElectrode array

The present invention proposes a power supply control circuit for preparing disinfectant by DC electrolysis in an alkaline environment, including a low-voltage DC power supply and an electrode sheet array connected thereto; the low-voltage DC power supply supplies power to the electrode sheet array and the output voltage is 1V~24V; The electrode sheet array is composed of mesh anodes and mesh cathodes arranged in close parallel with a spacing range of 0.5mm~2.5mm. The brine between the anodes and cathodes can flow freely to maintain the pH range of the liquid environment during the electrolysis process at pH8~pH10; When electrolyzing salt water, the low-voltage DC power supply detects the current output by the electrode array. When the liquid level of the brine drops and the area of the electrode array exposed to the liquid surface is greater than the threshold value, the change in current output by the electrode array is greater than the threshold value. Power supply The control circuit stops the power supply to the electrode sheet array; the invention can prepare household disinfectant water by electrolysis of salt water without diaphragm, and solves the problem of gas deflagration in the electrolysis of salt water without diaphragm, so that the product can be safely used for household sanitation and disinfection.

Owner:FUJIAN OSPRING TECH & DEV

Non-quenched and tempered steel, its production method, and rupture connecting rod manufactured therefrom

ActiveCN105463318BImprove fatigue toughnessHigh fatigue toughnessConnecting rodsProcess efficiency improvementToughnessImpurity

The invention provides non-quenched and non-tempered steel, a production method of the non-quenched and non-tempered steel and a cracking connecting rod manufactured through the non-quenched and non-tempered steel. The non-quenched and non-tempered steel is prepared from, by mass percent, 0.46%-0.52% of C, 0.70%-0.80% of Si, 1.53%-1.60% of Mn, 0.008%-0.015% of P, 0.02%-0.035% of S, 0.15%-0.25% of Cr, 0.20%-0.25% of Ni, 0.04%-0.07% of Mo, 0.02%-0.04% of Al, 0.14%-0.16% of V, 0.025%-0.035% of Nb, 0.001%-0.002% of B, 0.14%-0.25% of N and the balance Fe and inevitable impurity elements. The fatigue toughness of the steel can be improved through the element Nb. The element B can be segregated in a grain boundary and fused in ferrite separated out of the grain boundary, the separated-out ferrite is strengthened, and the cracking performance is improved.

Owner:SUZHOU SUXIN SPECIAL STEEL +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com