Non-quenched and tempered steel, its production method, and rupture connecting rod manufactured therefrom

A production method and technology of non-quenched and tempered steel, which are applied in the direction of connecting rod, process efficiency improvement, mechanical equipment, etc. Good low temperature impact toughness, high fatigue strength, and the effect of improving fatigue toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

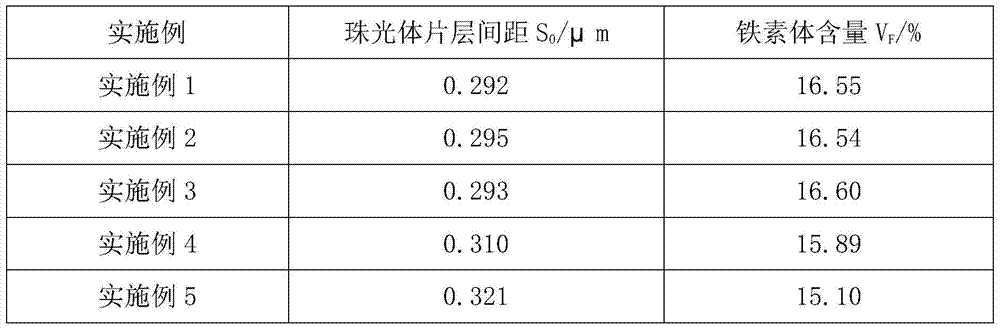

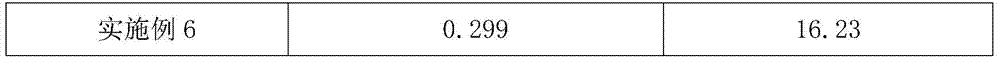

Examples

Embodiment 1

[0040] This embodiment provides a production method of non-quenched and tempered steel, which mainly includes electric furnace smelting steps, LF furnace refining steps, VD furnace refining steps, continuous casting steps, hot rolling steps and cooling steps, wherein:

[0041] In the electric furnace smelting step, the C content of the molten iron is 0.05%, and the control range of the end point temperature is 1620°C.

[0042] In the refining step of LF furnace, niobium iron ore is added, and white slag is made for deoxidation. Nb element can refine austenite grains, increase the interface, facilitate the uniform precipitation of ferrite, and improve the fatigue toughness of steel; at the same time, The white slag used is composed of ferrosilicon powder and silicon carbide, and the white slag retention time is 20min. Using the white slag and keeping it for 20min can fully reflect the steel slag interface, reduce the oxygen content and sulfur content in the steel; control the Mn...

Embodiment 2

[0055] This embodiment provides a production method of non-quenched and tempered steel, which mainly includes electric furnace smelting steps, LF furnace refining steps, VD furnace refining steps, continuous casting steps, hot rolling steps and cooling steps, wherein:

[0056] In the electric furnace smelting step, the C content range of the molten iron is 0.25%, and the control range of the end point temperature is 1680°C.

[0057] In the refining step of LF furnace, niobium iron ore is added, and white slag is made for deoxidation. Nb element can refine austenite grains, increase the interface, facilitate the uniform precipitation of ferrite, and improve the fatigue toughness of steel; at the same time, The white slag used is composed of ferrosilicon powder and silicon carbide, and the white slag retention time is 20min. Using the white slag and keeping it for 20min can fully reflect the steel slag interface, reduce the oxygen content and sulfur content in the steel; control ...

Embodiment 3

[0070] This embodiment provides a production method of non-quenched and tempered steel, which mainly includes electric furnace smelting steps, LF furnace refining steps, VD furnace refining steps, continuous casting steps, hot rolling steps and cooling steps, wherein:

[0071] In the electric furnace smelting step, the C content range of the molten iron is 0.15%, and the control range of the end point temperature is 1650°C.

[0072] In the refining step of LF furnace, niobium iron ore is added, and white slag is made for deoxidation. Nb element can refine austenite grains, increase the interface, facilitate the uniform precipitation of ferrite, and improve the fatigue toughness of steel; at the same time, The white slag used is composed of ferrosilicon powder and silicon carbide, and the white slag retention time is 20min. Using the white slag and keeping it for 20min can fully reflect the steel slag interface, reduce the oxygen content and sulfur content in the steel; control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com