Material of thrust plate for plunger pump, and heat treatment technology thereof

A valve plate, plunger pump technology, applied in metal material coating process, coating, solid diffusion coating and other directions, can solve the problems of high material cost and long heat treatment time, achieve fine and uniform organization, prolong service life, The effect of improving strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] 1. Weigh C0.35wt%, Si0.14wt%, Mn0.56wt%, Cr1.36wt%, Cu0.25wt%, Al1.1wt%, and the rest of Fe.

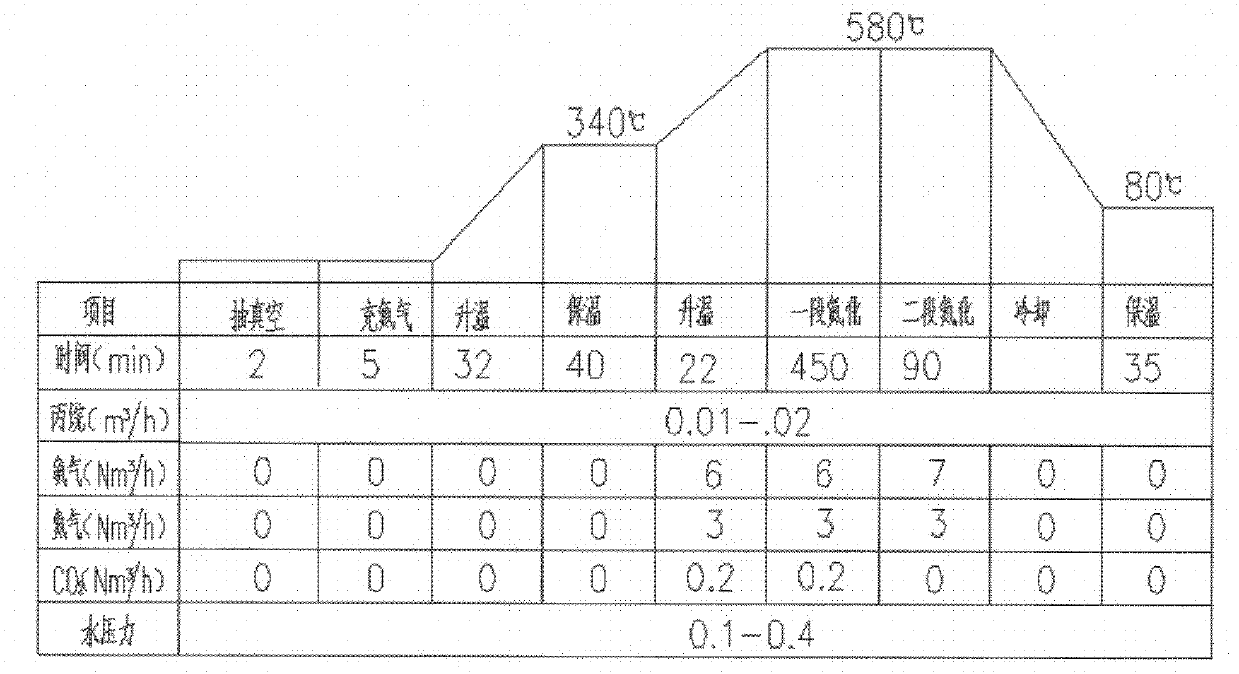

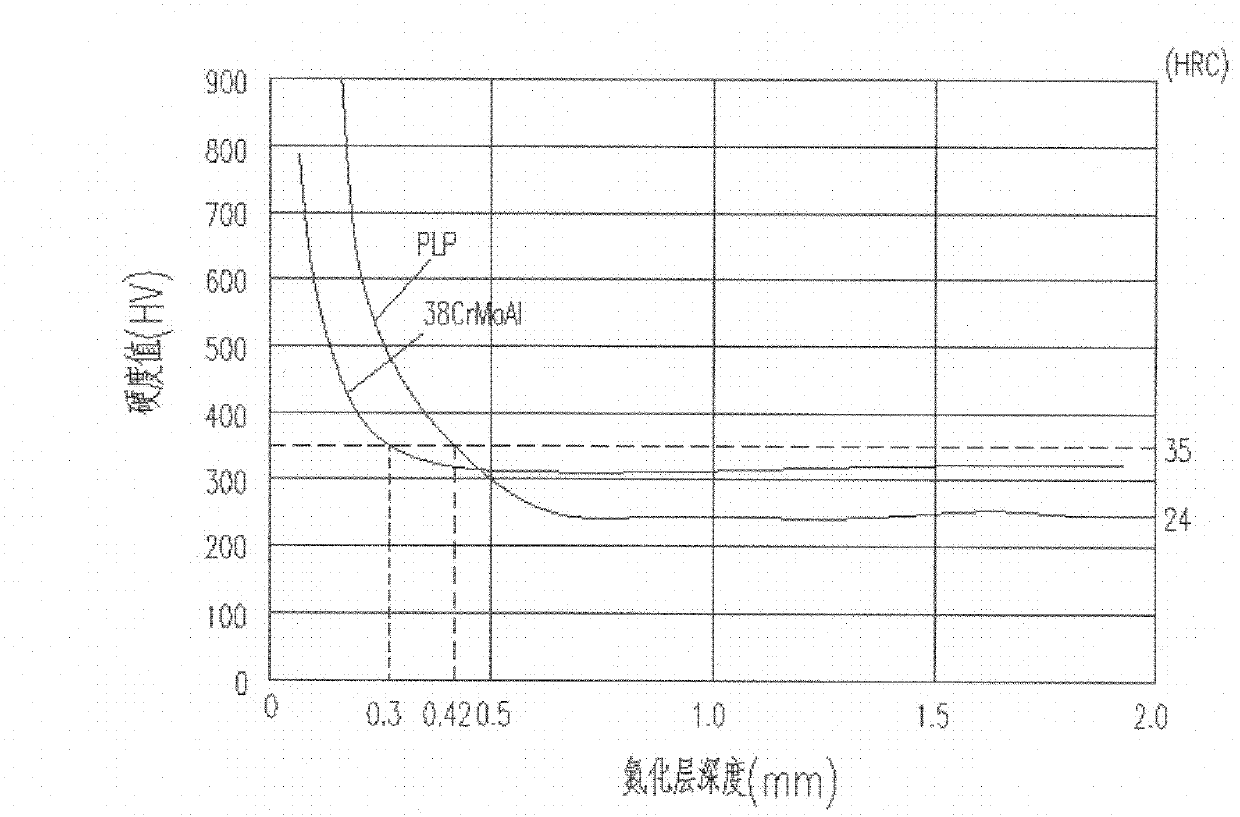

[0023] 2. If figure 1 As shown, the heat treatment process diagram for the material (PLP) of the plunger pump valve plate provided by the present invention, the specific steps of the heat treatment process are as follows:

[0024] The first step: put each raw material in the container in proportion, vacuumize the container, and fill it with nitrogen;

[0025] The second step: heat the mixture obtained in the first step to 340°C and keep it warm for 40 minutes;

[0026] The third step: heating the mixture obtained in the second step to 580° C., while feeding ammonia, carbon dioxide and nitrogen;

[0027] The fourth step: keep the mixture obtained in the third step at 580°C for 450 minutes, and at the same time pass through ammonia, carbon dioxide and nitrogen to carry out a stage of nitriding;

[0028] The fifth step: keep the mixture obtained in the fourth step at 580°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com