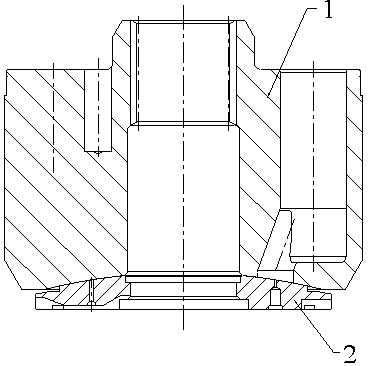

Technological method for improving friction pair between plunger pump cylinder and valve plate

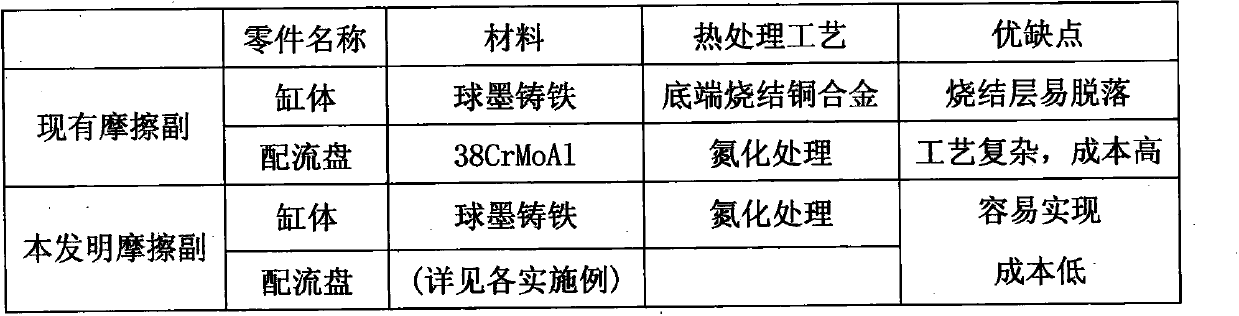

A technology of plunger pump and friction pair is applied in the field of improving the friction pair between the cylinder block of the plunger pump and the valve plate, which can solve the problems of easy falling off of sintered copper, high processing difficulty and high cost, so as to increase the stability of the product and prolong the service life. , cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

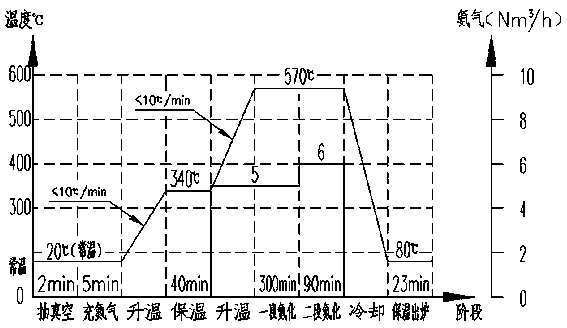

Embodiment 1

[0017] (1) smelting: the copper 62wt%, nickel 2.6wt%, iron 0.85wt%, cobalt 0.4wt%, aluminum 3.8wt%, lead 0.05wt% and the zinc of surplus are mixed by weight percentage, drop into smelting furnace, After melting at 1023°C, keep the temperature for 22 minutes, vacuumize the container, and fill it with nitrogen; heat the mixture to 340°C, keep it warm for 40 minutes, the ammonia decomposition rate is 18%, and the ammonia flow rate is 4Nm 3 / h; heat the mixture in the second step to 570°C, keep it warm for 300min, the decomposition rate of ammonia gas is 50%, and the flow rate of ammonia gas is 8Nm 3 / h. While raising the temperature and feeding ammonia, it is necessary to feed CO 2 , other flows are 5Nm in the first 300min 3 / h, the last 90min is 6Nm 3 / h. Then keep it warm for 90 minutes, the ammonia gas decomposition rate is >80%, and the ammonia gas flow rate is 2Nm 3 / h;

[0018] (2) Vertical semi-continuous casting: the smelted liquid copper alloy is poured into the ve...

Embodiment 2

[0022] (1) smelting: the copper 65wt% by weight percentage, nickel 3.0wt%, iron 1.1wt%, cobalt 0.6wt%, aluminum 4.2wt%, lead 0.15wt% and the zinc of surplus are mixed, drop into smelting furnace, After melting at 1053°C, the temperature is maintained for 24 minutes. After the container is evacuated, nitrogen is filled; the mixture is heated to 340°C and kept for 40 minutes. The ammonia decomposition rate is 25%, and the ammonia flow rate is 6Nm. 3 / h; heat the mixture in the second step to 570°C, keep it warm for 300min, the decomposition rate of ammonia gas is 60%, and the flow rate of ammonia gas is 10Nm 3 / h. While raising the temperature and feeding ammonia, it is necessary to feed CO 2 , other flows are 5Nm in the first 300min 3 / h, the last 90min is 6Nm 3 / h. Then keep it warm for 90 minutes, the ammonia gas decomposition rate is >80%, and the ammonia gas flow rate is 4Nm 3 / h;

[0023] (2) Vertical semi-continuous casting: the smelted liquid copper alloy is poured...

Embodiment 3

[0027] (1) Smelting: 63wt% of copper, 2.8wt% of nickel, 0.9wt% of iron, 0.5wt% of cobalt, 4.0wt% of aluminum, 0.10wt% of lead and the zinc of the balance are mixed in copper, and put into the smelting furnace. After melting at 1108°C, keep the temperature for 26 minutes, vacuumize the container, and fill it with nitrogen; heat the mixture to 340°C, keep it warm for 40 minutes, the ammonia decomposition rate is 20%, and the ammonia flow rate is 5Nm 3 / h; heat the mixture in the second step to 570°C, keep it warm for 300min, the decomposition rate of ammonia gas is 55%, and the flow rate of ammonia gas is 9Nm 3 / h. While raising the temperature and feeding ammonia, it is necessary to feed CO 2 , other flows are 5Nm in the first 300min 3 / h, the last 90min is 6Nm 3 / h. Then keep it warm for 90 minutes, the ammonia decomposition rate is >80%, and the ammonia flow rate is 3Nm 3 / h;

[0028] (2) Vertical semi-continuous casting: the smelted liquid copper alloy is poured into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com