Analytical method of adsorption column for polysilicon tail gas dry separation system

A separation system and analysis method technology, which is applied in the field of adsorption column analysis of polysilicon tail gas dry separation system, can solve the problems of hydrogen shortage, hydrogen waste, hydrogen flammability and explosion, and achieve the effect of saving hydrogen and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

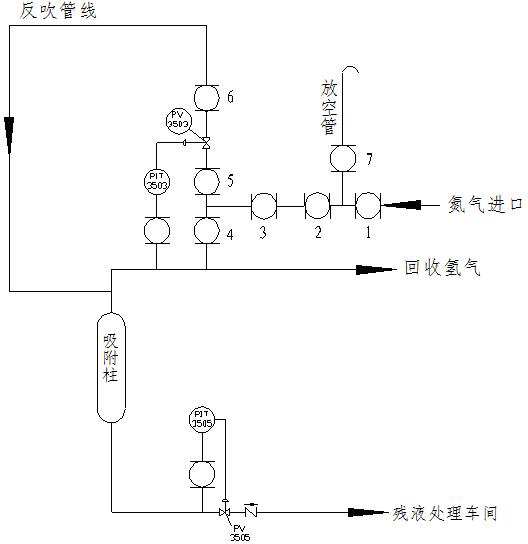

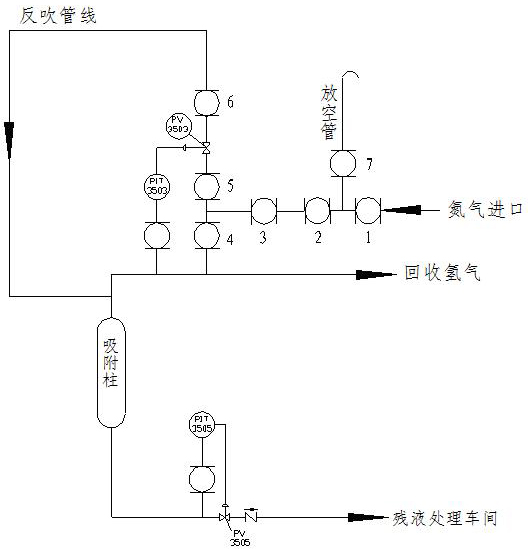

[0026] Such as figure 1 As shown, a polysilicon tail gas dry separation system adsorption column analysis method includes the following steps:

[0027] a) First use nitrogen gas to backflush the adsorption column, close vent valve 7 and valve 4, open valve 1, valve 2, valve 3, valve 5, regulating valve PV3503, valve 6, regulating valve PV3505, and the inlet pressure is 1.12 The nitrogen gas of MPa is used to backflush the adsorption column for 6000 seconds, and the flow rate of nitrogen gas is 100Nm 3 / h.

[0028] b) Replace the adsorption column with hydrogen, close valve 1, open valve 7, open valve 4, valve 5, regulating valve PV3503, valve 6, regulating valve PV3505, and introduce hydrogen with a pressure of 1.12MPa to replace the adsorption column 1200 seconds.

[0029] c) After backflushing, the nitrogen or hydrogen with a large amount of chlorosilane is cooled by circulating water and refrigerant. After the chlorosilane is separated, the nitrogen or hydrogen is sent t...

Embodiment 2

[0032] Such as figure 1 As shown, a polysilicon tail gas dry separation system adsorption column analysis method includes the following steps:

[0033] a) Use nitrogen gas to backflush the adsorption column first, close vent valve 7 and valve 4, open valve 1, valve 2, valve 3, valve 5, regulating valve PV3503, valve 6, regulating valve PV3505, and the inlet pressure is 1.15 The nitrogen gas of MPa is used to backflush the adsorption column for 6000 seconds, and the flow rate of nitrogen gas is 100Nm 3 / h.

[0034] b) Replace the adsorption column with hydrogen, close valve 1, open valve 7, open valve 4, valve 5, regulating valve PV3503, valve 6, regulating valve PV3505, and introduce hydrogen with a pressure of 1.15MPa to replace the adsorption column 1200 seconds.

[0035] c) After backflushing, the nitrogen or hydrogen with a large amount of chlorosilane is cooled by circulating water and refrigerant. After the chlorosilane is separated, the nitrogen or hydrogen is sent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com