Superaustenitic stainless steel electrode

A technology of austenitic stainless steel and electrode, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve halide pitting corrosion, pitting corrosion, crevice corrosion stress corrosion, lack of corrosion resistance, sulfuric acid resistance , poor phosphoric acid, etc., to achieve the effect of improving moisture resistance, reducing powder loss, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: the percentage by weight of each component in the drug skin is shown in the following table:

[0024] Raw material name

weight percentage

Raw material name

weight percentage

35

metal chrome

6

Titanium dioxide

5

Electrolytic manganese

6.5

marble

12

ferro-titanium

3

6

Chrome Oxide Green

1

3

2

6.5

0.5

Dehydrated feldspar

8

0.5

Dehydrated Phlogopite

5

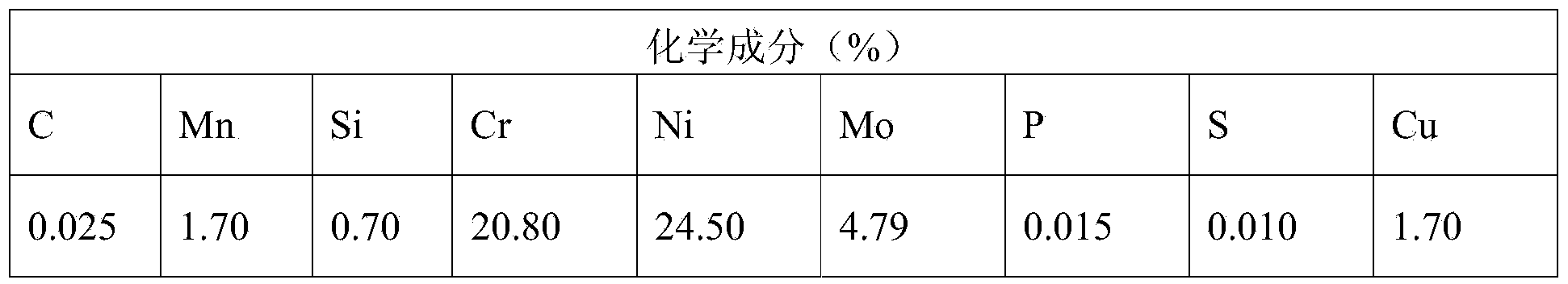

[0025] The deposited metal composition of the electrode prepared according to the above ratio is shown in the following table:

[0026]

[0027] The mechanical properties of the deposited metal of the electrode prepared according to the above ratio are shown in the following table:

[0028]

Embodiment 2

[0029] Embodiment 2: the percentage by weight of each component in the drug skin is shown in the following table:

[0030] Raw material name

weight percentage

Raw material name

weight percentage

45

metal chrome

8

Titanium dioxide

2

Electrolytic manganese

8

marble

6

ferro-titanium

4.5

7.5

Chrome Oxide Green

1.5

1

nickel powder

4

3.5

1

Dehydrated feldspar

4

1

Dehydrated Phlogopite

3

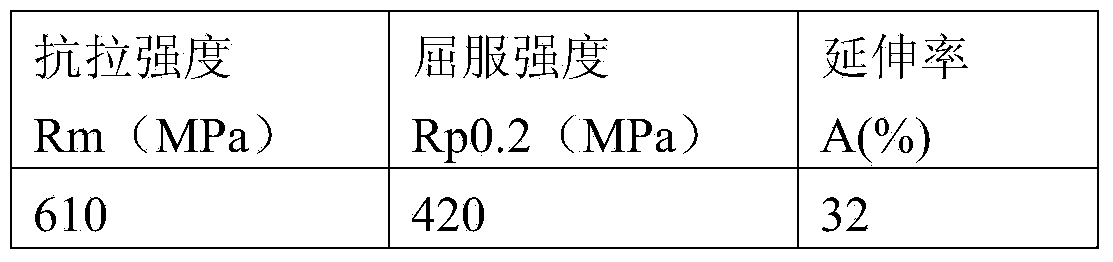

[0031] The deposited metal composition of the electrode prepared according to the above ratio is shown in the following table:

[0032]

[0033] The mechanical properties of the deposited metal of the electrode prepared according to the above ratio are shown in the following table:

[0034]

Embodiment 3

[0035] Embodiment 3: the percentage by weight of each component in the drug skin is shown in the following table:

[0036] Raw material name

weight percentage

Raw material name

weight percentage

rutile

40

metal chrome

6

Titanium dioxide

3.5

Electrolytic manganese

5.5

marble

8

ferro-titanium

4

dolomite

8

Chrome Oxide Green

2

quartz

2

nickel powder

3

cryolite

5

1.5

Dehydrated feldspar

6

1.5

Dehydrated Phlogopite

4

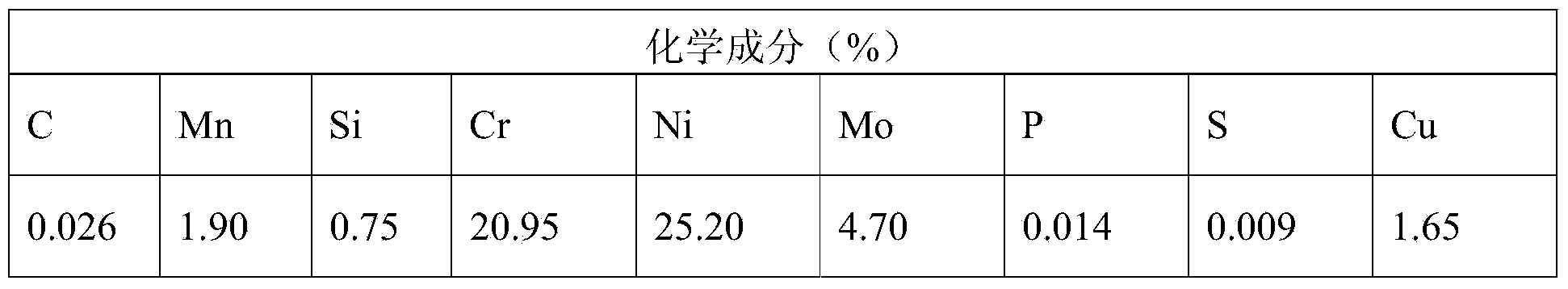

[0037] The deposited metal composition of the electrode prepared according to the above ratio is shown in the following table:

[0038]

[0039]

[0040] The mechanical properties of the deposited metal of the electrode prepared according to the above ratio are shown in the following table:

[0041]

[0042] It can be seen from the above three em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com