Patents

Literature

39results about How to "Reduce hydrogen partial pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-alkalinity high-tenacity low-hydrogen agglomerated flux and preparation method thereof

ActiveCN102601544AImprove weld metal toughnessImprove low temperature impact toughnessWelding/cutting media/materialsSoldering mediaSodium silicateHydrogen content

The invention discloses a high-alkalinity high-tenacity low-hydrogen agglomerated flux, which comprises the following components by weight: 18-21.5% of MgO, 33-35% of CaF2, 15-20% of Al2O3, 17-21% of SiO2, 3.5-8% of CaO, 1-5% of MnO, 2-5% of BaCO3, and less than or equal to 3% of FeO, wherein the total weight of the components is 100%. The invention further discloses a preparation method of the high-alkalinity high-tenacity low-hydrogen agglomerated flux, which comprises the steps of: mixing the raw materials and performing dry agitation, adding sodium silicate that accounts for 20wt% of the mixed powder, performing wet agitation, sending the materials to a pelletizer to pelletize, entering into a drying furnace after being dried by hot wind, drying at 180-230 DEG C, screening after discharge and then entering into a sintering furnace, sintering in the sintering furnace at 830-860 DEG C and discharging, and finally, screening and cooling to obtain the high-alkalinity high-tenacity low-hydrogen agglomerated flux. The flux provided by the invention solves the problems that a current flux is poor in toughness of weld metal and high in diffusible hydrogen content in deposited metal.

Owner:BAOJI YUSHENG WELDING MATERIAL

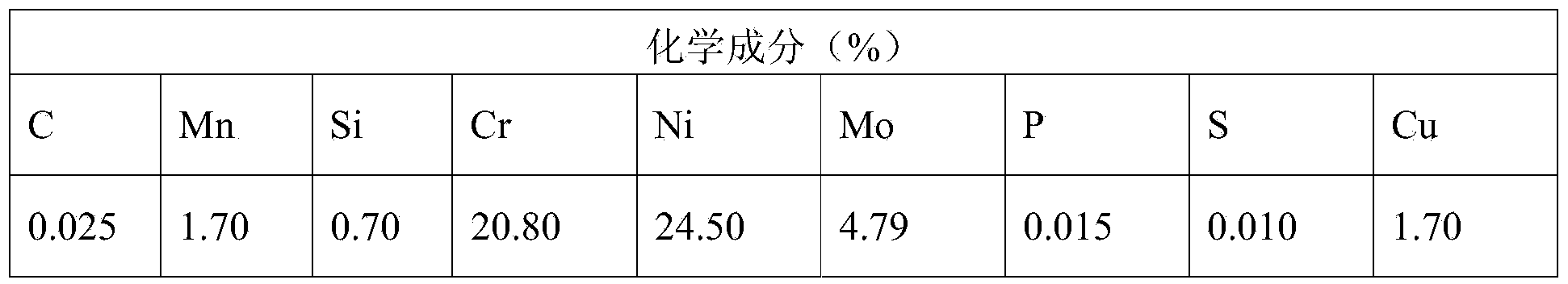

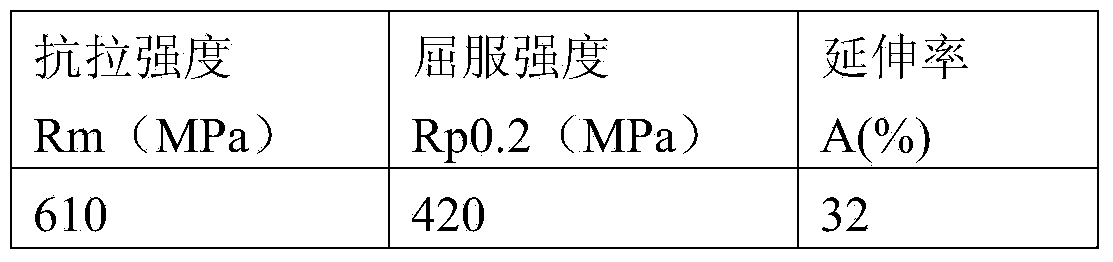

Superaustenitic stainless steel electrode

ActiveCN103921018AThe amount of addition is adaptableReduce lossWelding/cutting media/materialsSoldering mediaElectrolysisPhosphoric acid

The invention provides a superaustenitic stainless steel electrode. A coating of the superaustenitic stainless steel electrode at least comprises the following components, by mass, 35 to 45 percent of rutile, 2 to 5 percent of titanium dioxide, 6 to 12 percent of marble, 6 to 12 percent of dolomite, 1 to 3 percent of quartz, 3.5 to 6.5 percent of cryolite, 4 to 8 percent of dehydrated feldspar, 3 to 5 percent of dehydrated phlogopite, 6 to 8 percent of chromium metal, 6 to 8 percent of electrolytic manganese, 3 to 6 percent of ferrotitanium, 1 to 2 percent of chromium oxide green, 2 to 4 percent of nickel powder, 0.5 to 1.5 percent of ferromolybdenum and 0.5 to 1.5 percent of sodium alginate. The coating of the superaustenitic stainless steel electrode is formed by mixing all the components according to the proportions, potassium and sodium are added to be mixed with sodium silicate, and the coating coats a core wire H02Cr20Ni25Mo4Cu to form the electrode. Carbon content is extremely low, comprehensive corrosion of sulfuric acid and phosphoric acid can be resisted, the corrosion of acetic acid at any temperature and in any concentration under ordinary pressure can be resisted, and an ideal welding material is provided for steel for manufacturing various strong acid storing and transporting containers.

Owner:HUBEI CHUANWANG SPECIAL WELDING MATERIALS

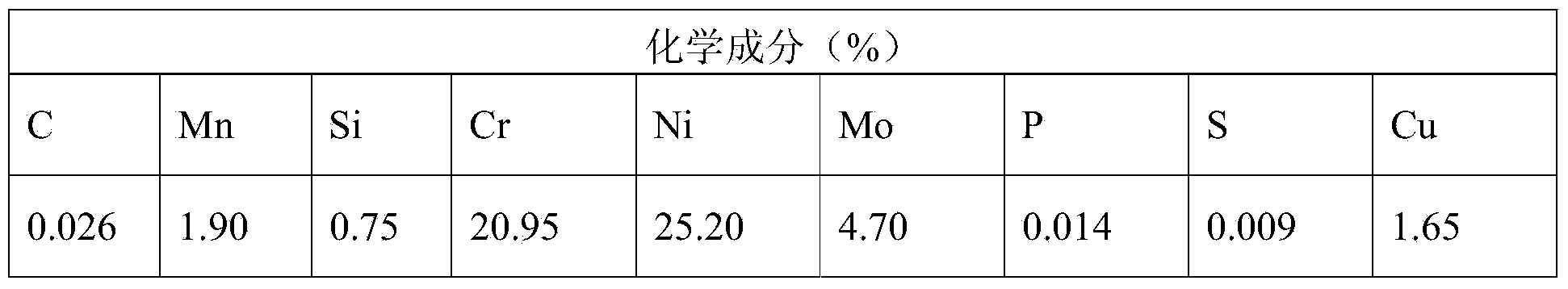

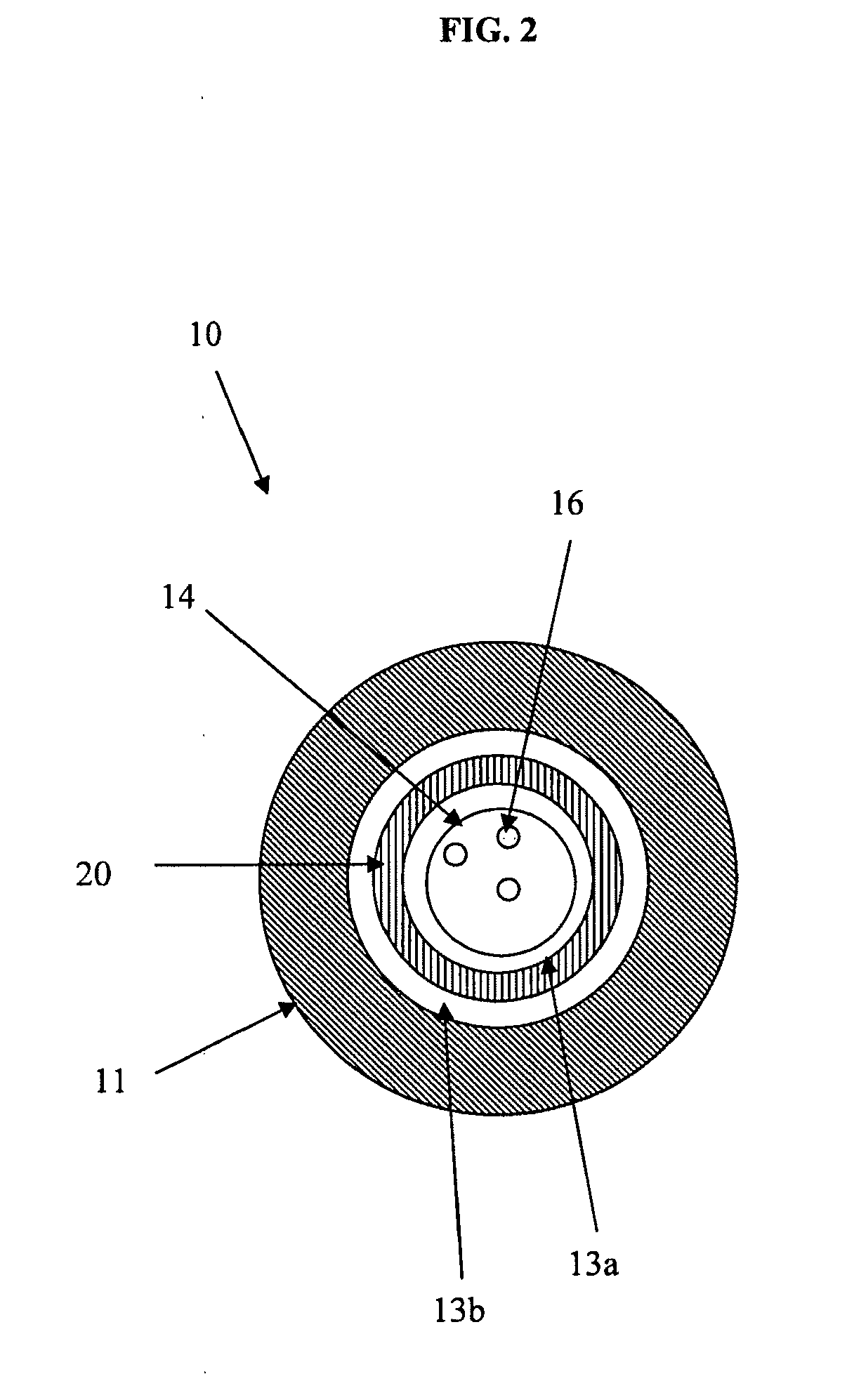

Breathable downhole fiber optic cable and a method of restoring performance

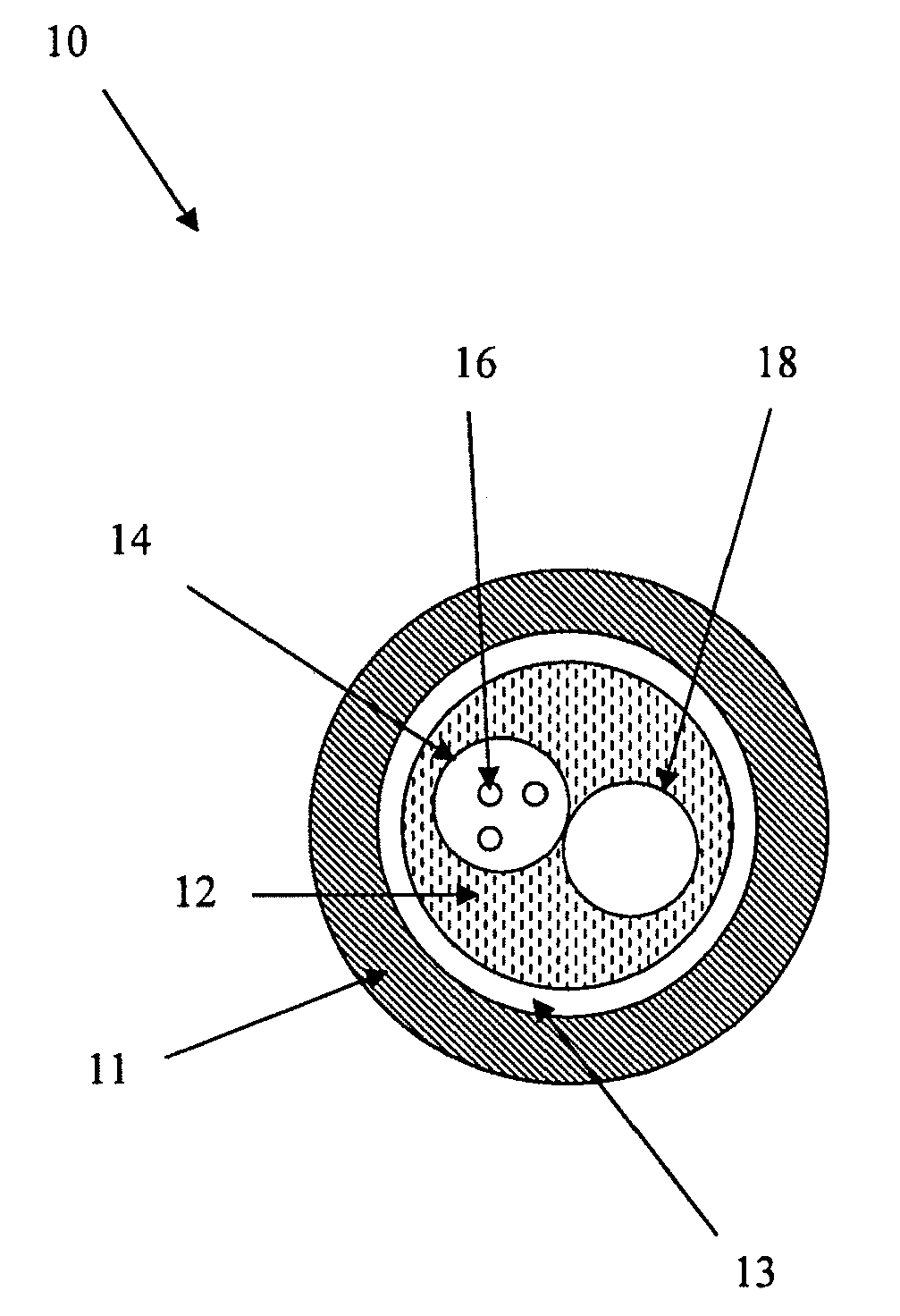

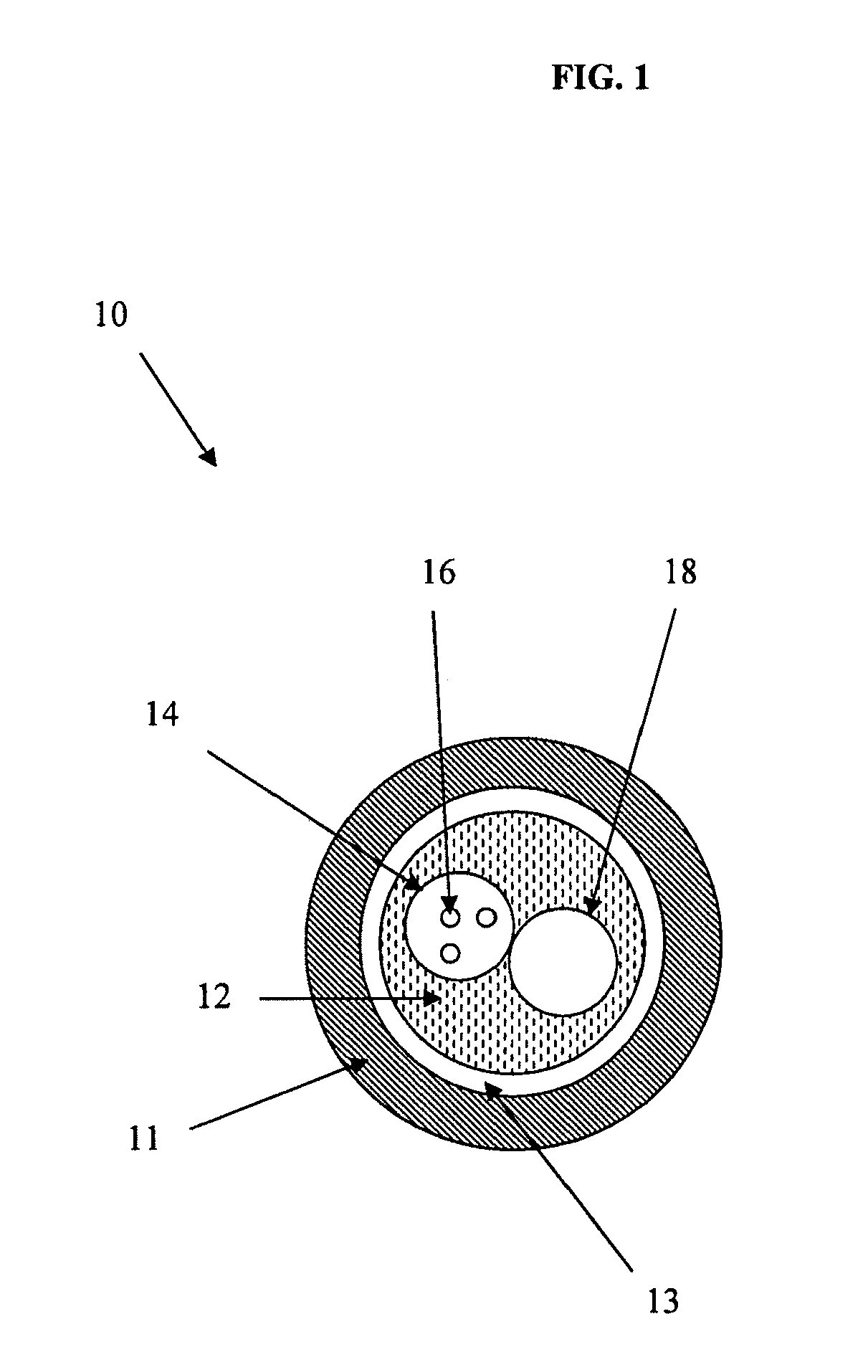

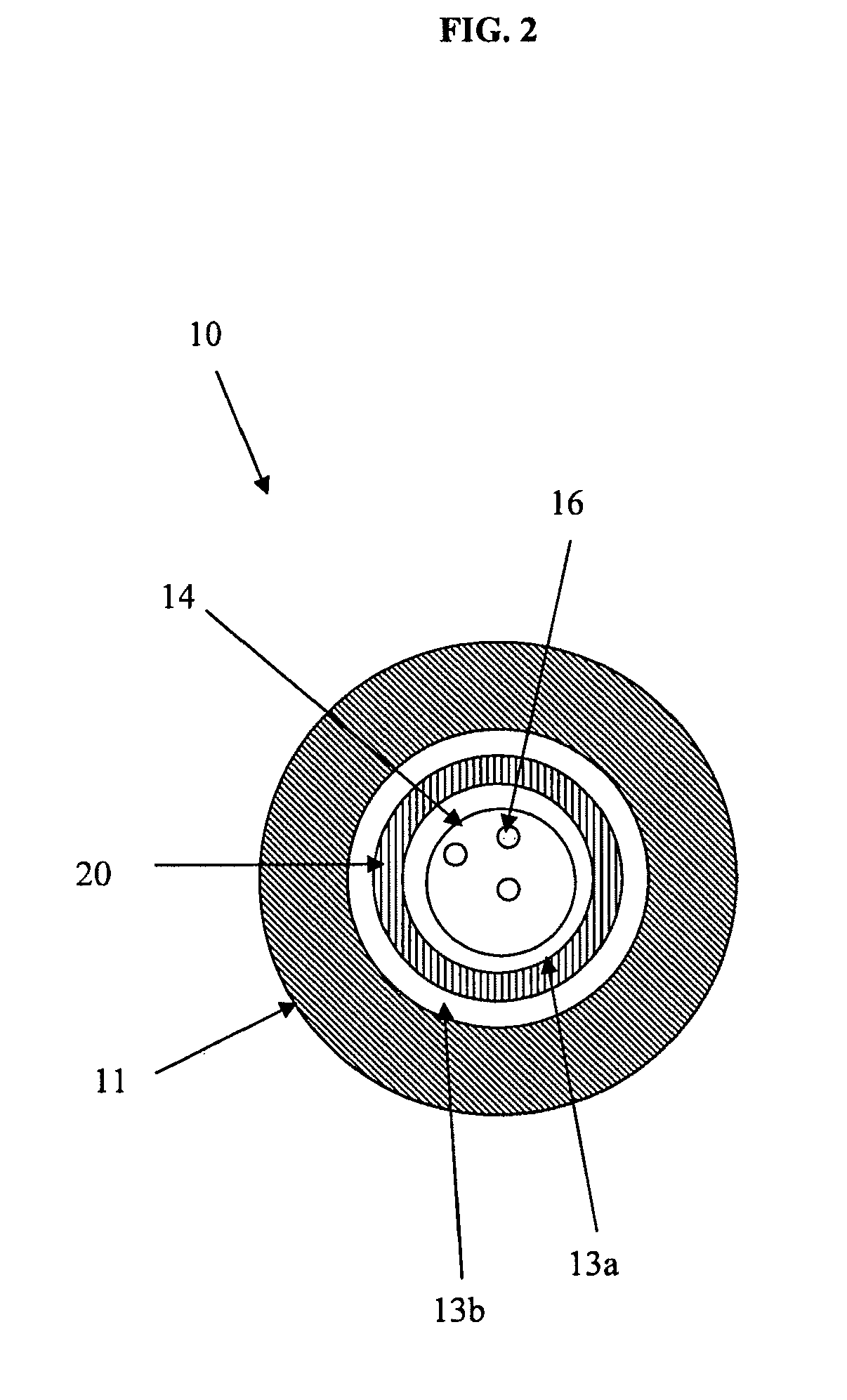

ActiveUS20100008632A1Reduce hydrogen partial pressureRestore performanceFibre mechanical structuresGas analyser construction detailsFiberHydrogen

A breathable downhole fiber optic cable is provided having an outer protective tube; a fiber optic tube having a plurality of optical fibers contained therein; at least one annulus disposed between the outer protective tube and the fiber optic tube; and at least one path, extending through the length of the fiber optic cable, which provides a channel for a purge gas to flow for removing a second gas, such as hydrogen, from the fiber optic cable.

Owner:AFL COMM LLC

Ultralow-hydrogen type high efficiency iron powder welding rod for low alloy high streagth steel

InactiveCN1657224AImprove low temperature toughnessGood pressure coating processWelding/cutting media/materialsSoldering mediaIron powderHydrogen

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

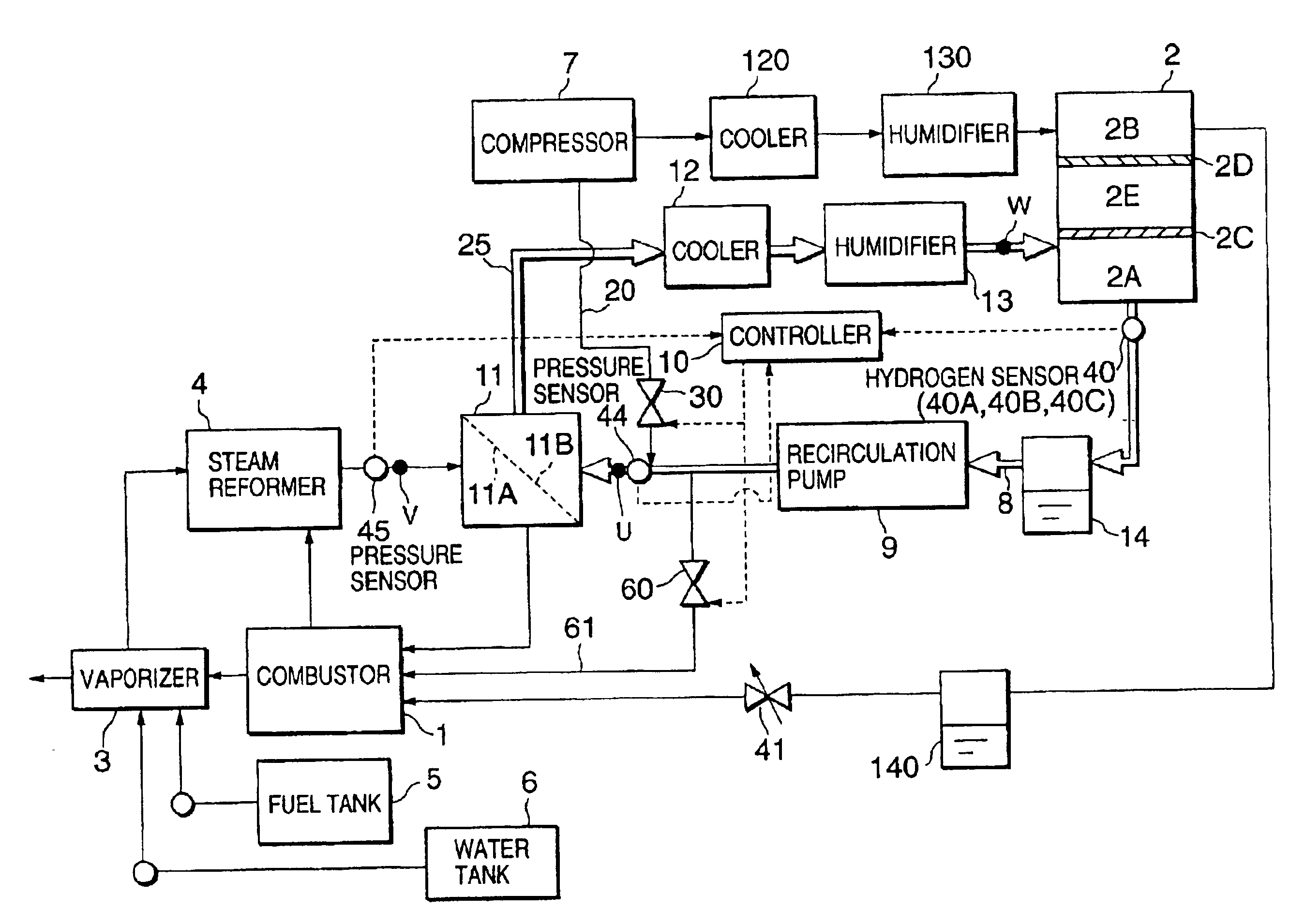

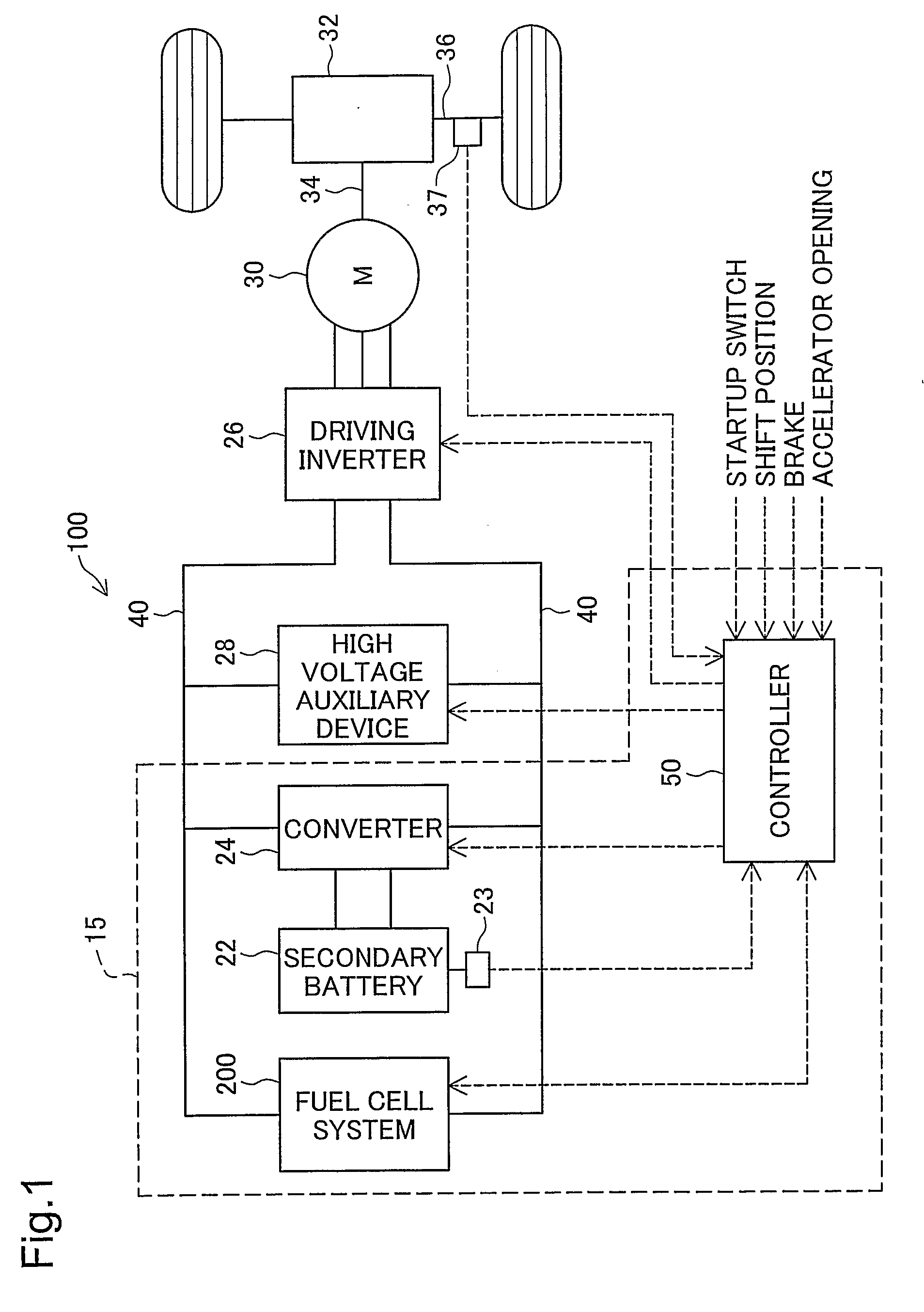

Fuel cell power plant

InactiveUS6841280B2Reduce hydrogen partial pressureMinimize equipmentFuel cells groupingHydrogen separation using solid contactProcess engineeringPower station

The hydrogen permeating to a post-separation side (11B) of the membrane hydrogen separator (11) is supplied to an anode chamber (2A) of a fuel cell stack (2) via a hydrogen supply passage (25). A hydrogen recirculation passage (8) recirculates hydrogen from the anode chamber (2A) to the post-separation side (11B). When the hydrogen partial pressure on the post-separation side (11B) increases, air is introduced into the hydrogen recirculation passage (8) from an intake valve (30). When the hydrogen partial pressure decreases, gas in the hydrogen recirculation passage (8) is discharged from an exhaust valve (60). The rate of hydrogen permeation through the membrane hydrogen separator (11) is thereby maintained to a preferred level.

Owner:NISSAN MOTOR CO LTD

Breathable downhole fiber optic cable and a method of restoring performance

ActiveUS8213756B2Reduce hydrogen partial pressureRestore performanceFibre mechanical structuresGas analyser construction detailsFiberHydrogen

A breathable downhole fiber optic cable is provided having an outer protective tube; a fiber optic tube having a plurality of optical fibers contained therein; at least one annulus disposed between the outer protective tube and the fiber optic tube; and at least one path, extending through the length of the fiber optic cable, which provides a channel for a purge gas to flow for removing a second gas, such as hydrogen, from the fiber optic cable.

Owner:AFL COMM LLC

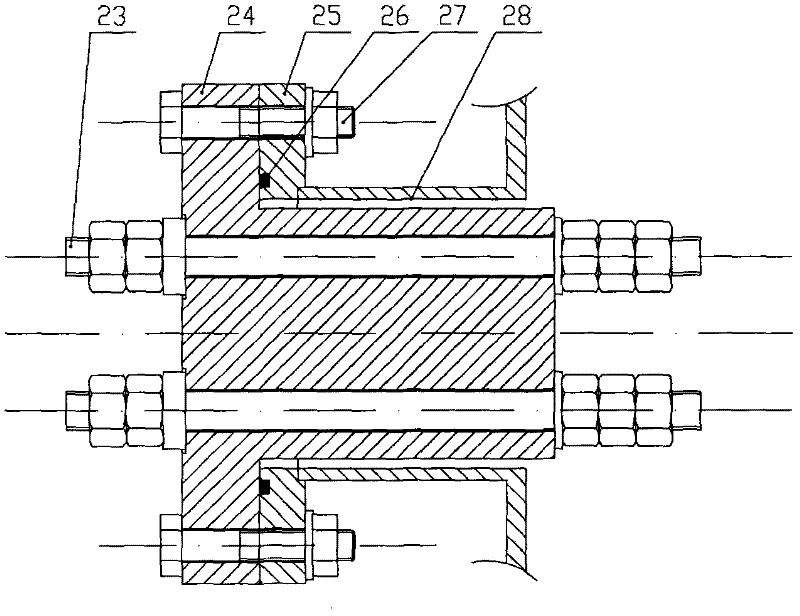

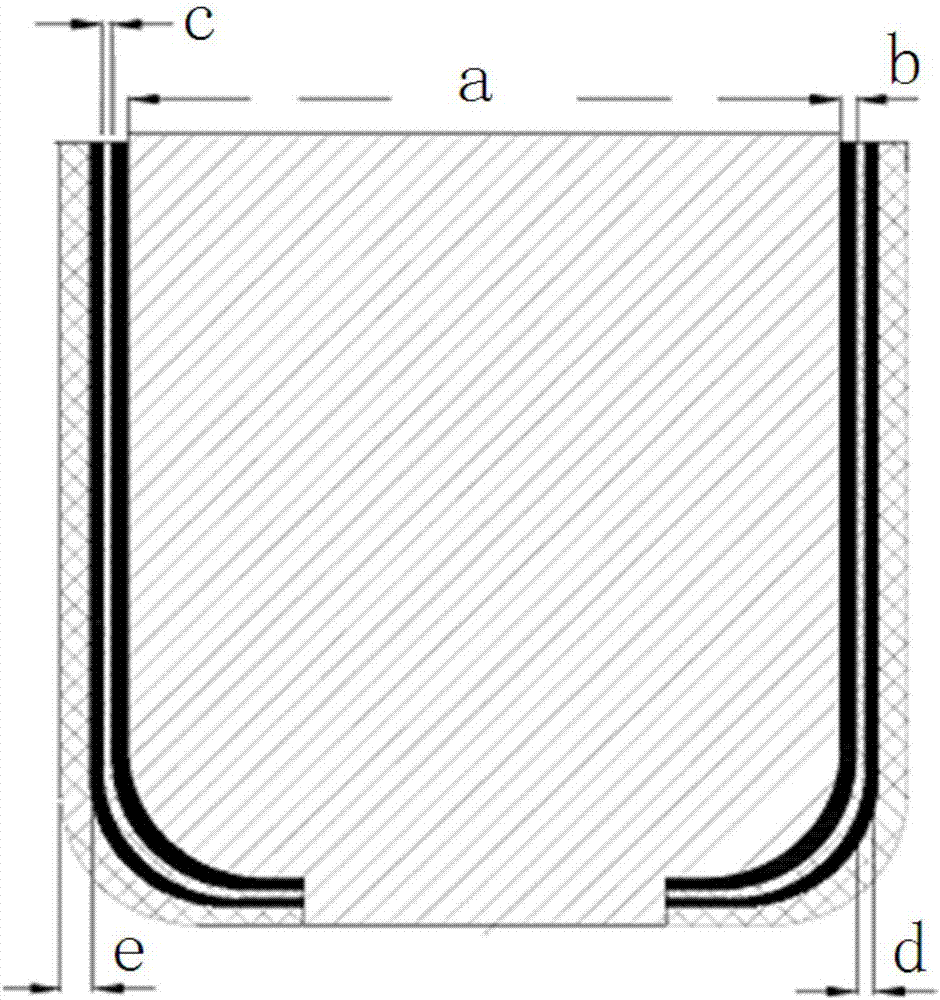

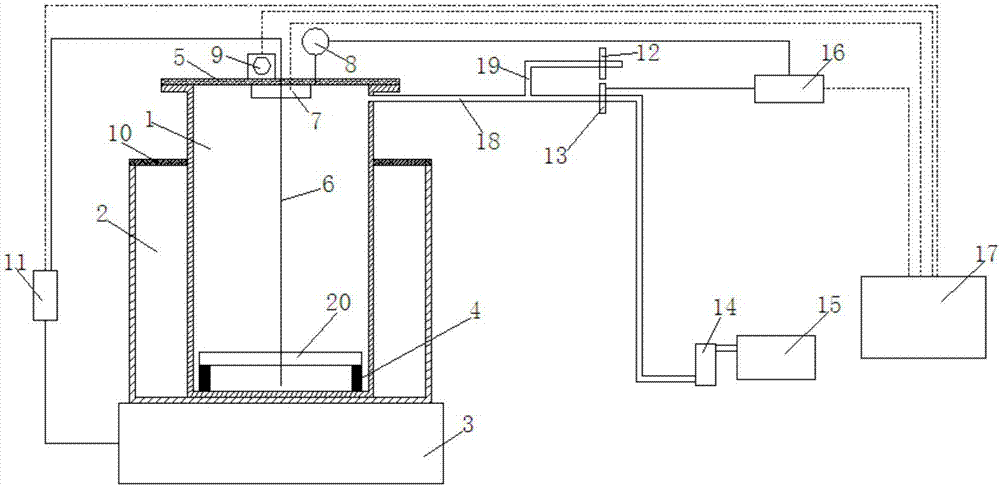

Aluminum alloy vacuum standing, gas removal and smelting device

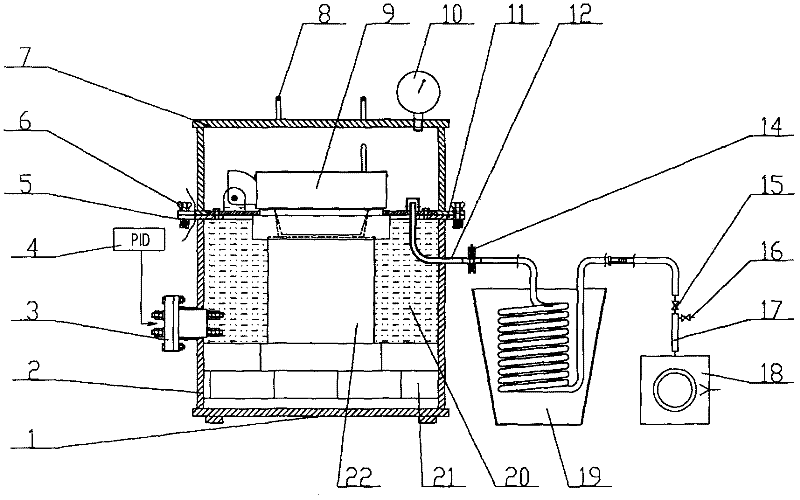

InactiveCN102560160AReduce solubilityRealize the function of removing hydrogenHydrogen contentAir tightness

The invention discloses an aluminum alloy vacuum standing, gas removal and smelting device. The aluminum alloy vacuum standing, gas removal and smelting device mainly comprises a smelting furnace body consisting of a main furnace body and a vacuum cover which is matched with the main furnace body; and a gas extraction pipe is arranged on the smelting furnace body, one end of the gas extraction pipe is positioned in the vacuum cover, the other end of the gas extraction pipe is connected with a cooling pipe, and is connected with one end of the cooling pipe through a vacuum quick release flange, and the other end of the cooling pipe is connected with a vacuumizing pump. Before casting, the vacuumizing pump is started to vacuumize the furnace body, hydrogen partial pressure in a furnace cavity is reduced, and hydrogen is continuously separated out, so the hydrogen content of melt is reduced, and vacuum is removed for casting. After the gas of the aluminum alloy melt is removed, the tendency for absorbing hydrogen is low, so after casting, the smelt can keep low hydrogen content, and the defect of hole cannot be generated easily. The aluminum alloy vacuum standing, gas removal and smelting device has a simple structure and a good hydrogen removal effect, is easy to operate, and is suitable for producing an aluminum alloy casting of which holes are easily generated, or which has the high requirement of gas tightness.

Owner:SOUTHEAST UNIV

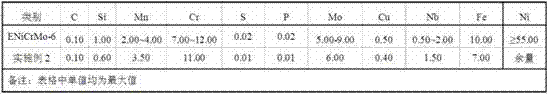

LNG structure as well as nickel-based welding rod for marine 9Ni steel welding, and preparation method thereof

ActiveCN107214434AIncrease alkalinityStrong desulfurization abilityWelding/cutting media/materialsSoldering mediaChemical compositionUltimate tensile strength

The invention discloses an LNG structure as well as a nickel-based welding rod for marine 9Ni steel welding, and a preparation method thereof. The welding rod comprises a nickel-based welding core and a coating coated on the surface of the welding core, wherein the nickel-based welding core comprises the following chemical components with percentage contents: not greater than 0.10% of C, not greater than 0.10% of Si, not greater than 0.10% of Mn, not greater than 0.10% of Cu, not greater than 0.10% of Mg, not greater than 0.005% of S, not greater than 0.40% of Fe and not less than 99.5% of Ni+Co, and the total content of the components is 100%. The welding rod disclosed by the invention is high in manufacturability, and capable of being smoothly coated in a pressing manner during a production process, the coating of the welding rod is high in strength and good in surface quality, and the welding rod is controllable in core shift; and the chemical components of deposited metal meet standards, and weld metal is free from pores and cracks, high in normal-temperature tension and low-temperature toughness, good in mechanical property, and capable of being widely applied.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

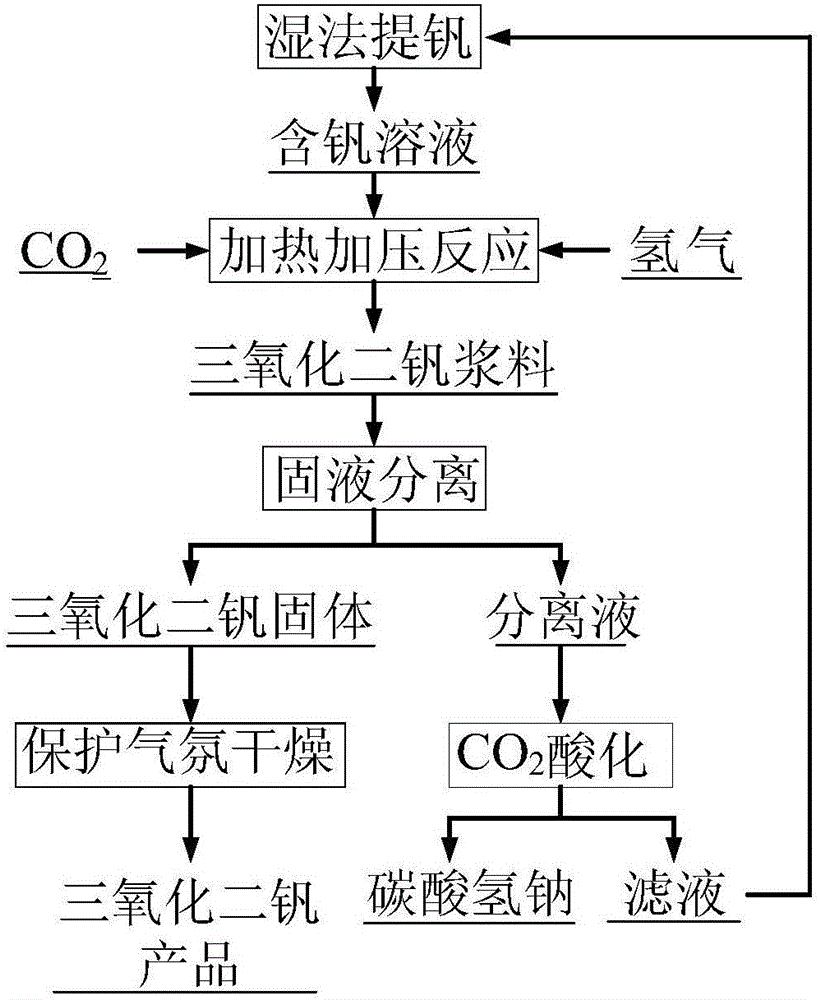

Method for preparing vanadium trioxide from vanadium-containing solution

InactiveCN107434259ALower pHHigh reactivityVanadium oxidesAlkali metal carbonatesHydrogenPhysical chemistry

The invention relates to a method for preparing vanadium trioxide from a vanadium-containing solution. The method comprises the steps of introducing CO2 and H2 into the vanadium-containing solution, carrying out a reaction under heated and pressurized conditions, and carrying out solid-liquid separation after the reaction is completed, thereby obtaining solid vanadium trioxide and a separated solution. According to the method disclosed by the invention, the gas mixture of CO2 and H2 is adopted to react with the vanadium-containing solution, so that the technical problem that a reduction reaction is difficult to carry out due to the fact that sodium hydroxide is produced in a hydrogen gas reduction process of vanadate is solved; the efficiency of reduction of the vanadate is increased, and the vanadium trioxide product with the purity higher than 99% is obtained; and meanwhile, the generation of ammonia nitrogen wastewater is effectively avoided, the cyclic utilization of water resources is achieved, and the aim of zero wastewater emission is achieved. The method has the characteristics of short process flow, high production efficiency, high-end product, environment-friendliness, low cost and the like and is applicable to industrialized popularization.

Owner:HEBEI IRON AND STEEL

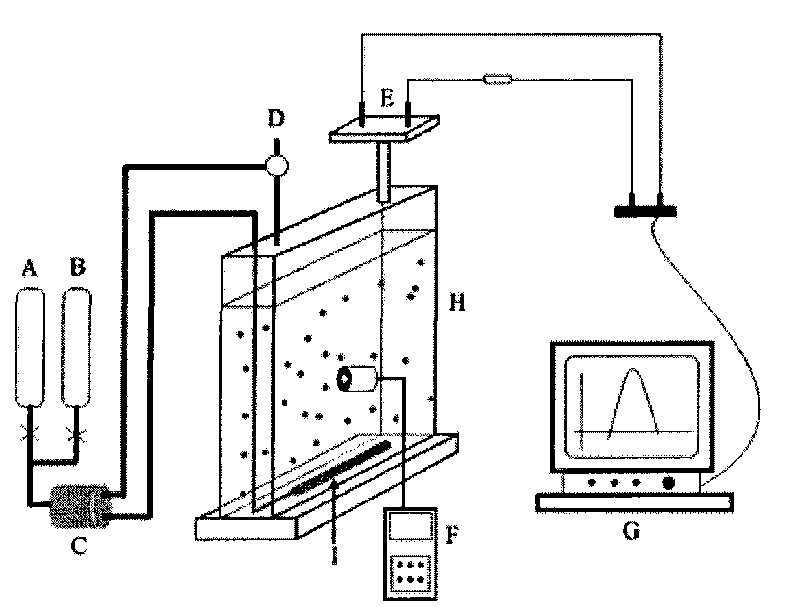

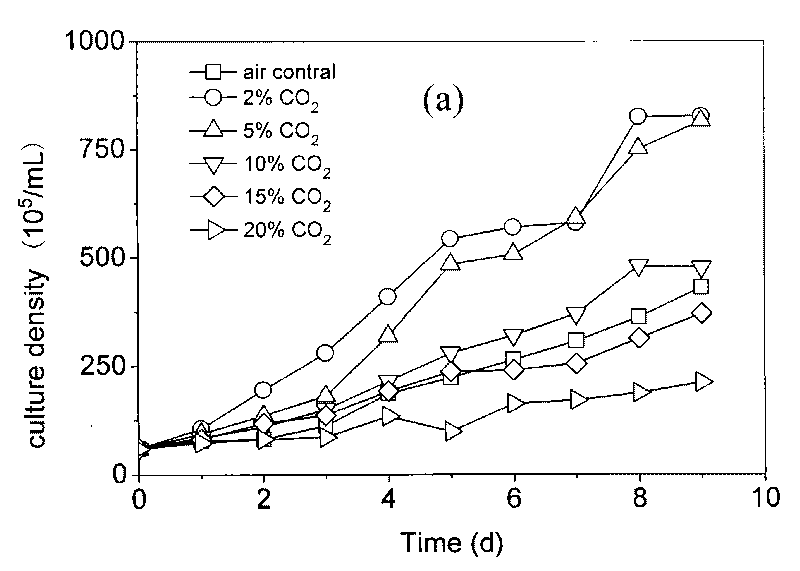

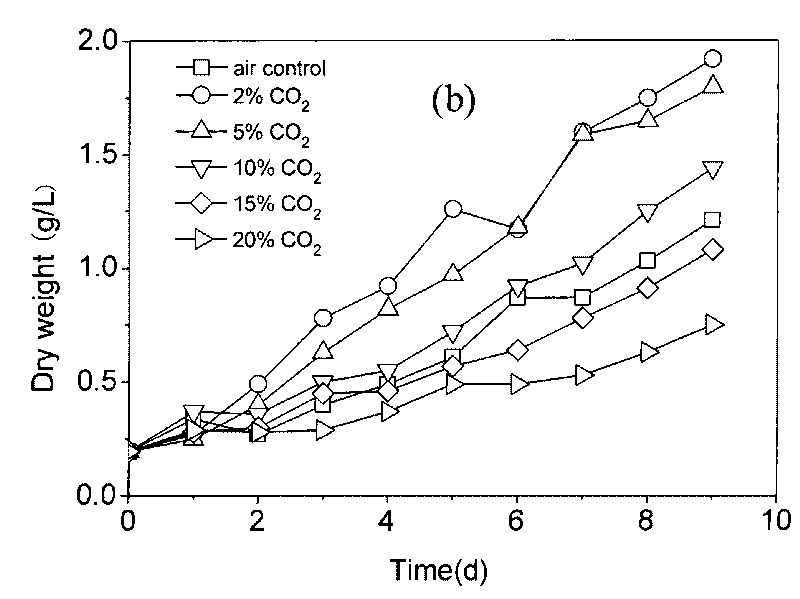

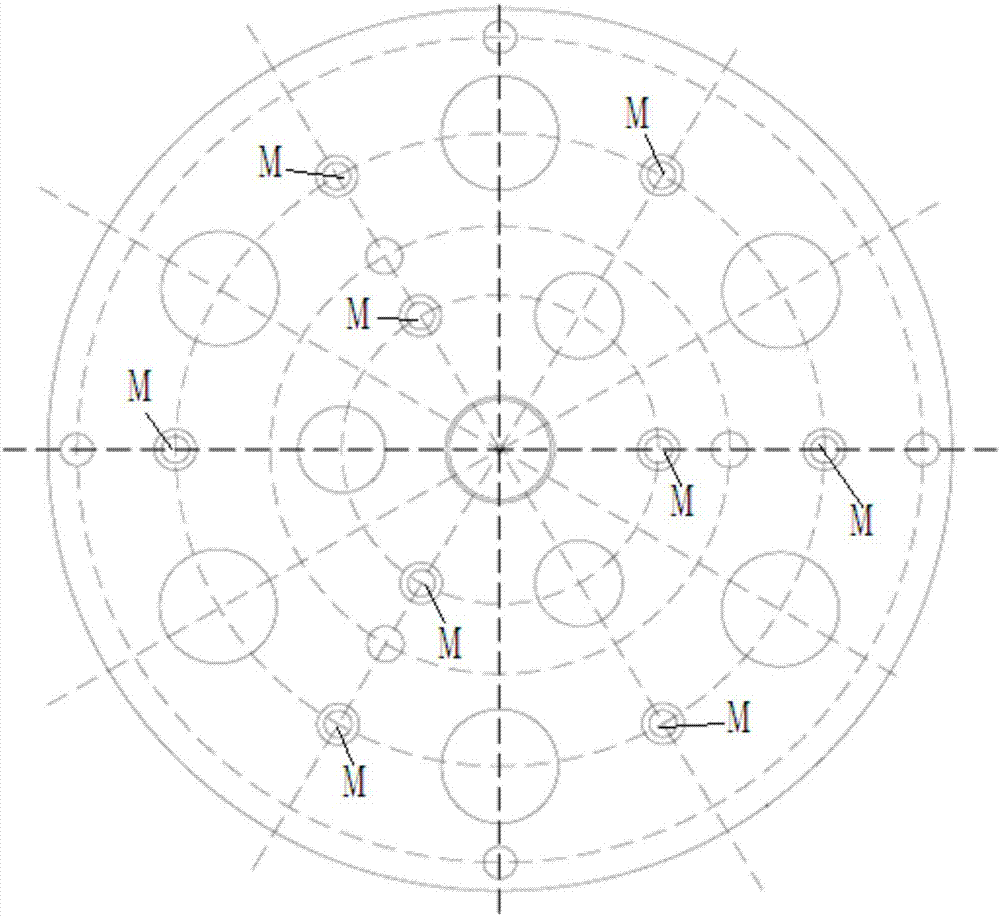

Hydrogen manufacturing method for high-density culture and hydrogen production integration of platymanas subcordiformis

InactiveCN101748154AReduce hydrogen partial pressureRemove inhibitionUnicellular algaeMicroorganism based processesShort termsHydrogen production

The invention utilizes a flat plate photobioreactor integrating a fuel battery to integrate microalgae high-density culture and irradiation hydrogen production so as to form an integrative hydrogen production system. Two sections of processes of microalgae culture and photosynthetic hydrogen production are generally divided in space time, and the cultured low-density frustule needs to be concentrated and then irradiated to produce hydrogen, so that the operations need to be respectively carried out in two photobioreactors. In the microalgae hydrogen production of the invention, the low-density microalgae is inoculated into a reactor, a culture mode of enriching carbon dioxide is utilized, the biomass required by the hydrogen production can be reached by short-term culture, then dark induction is carried out, and the operation can enter a continuous irradiation hydrogen production stage. The generated hydrogen gas can be integrated into a fuel battery on a reactor and is converted into electric energy, and the hydrogen production condition can be monitored at real time by the change of current. The invention combines the two sections of processes of the microalgae culture and the hydrogen production for the first time, utilizes the fuel battery to convert the hydrogen into the electric energy and provides reliable technical support for the large-scale microalgae hydrogen production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Firedamp biphasic anaerobic fermentation gas stirring system

InactiveCN101265447AReduce propionic acid contentAvoid accumulationBioreactor/fermenter combinationsBiological substance pretreatmentsProduction rateProcess engineering

The invention relates to a methane two-phase anaerobic fermentation gas mixing system, which belongs to a methane generator. A gas returning pipe and a gas inlet pipe are connected and installed between a hydrolytic acidification tank and a gas production tank, the both ends of the gas returning pipe are respectively connected with the upper part of the hydrolytic acidification tank and the lower part of the gas production tank, the both ends of the gas inlet pipe are respectively connected with the lower part of the hydrolytic acidification tank and the upper part of the gas production tank; an air pump and a one-way valve are arranged on the gas inlet pipe; and a normally open solenoid valve is installed on a gas collector, and is positioned at the gas collector position between the hydrolytic acidification tank and the gas production tank. The system has the advantages that the structure is simple, the operation is convenient, the running is stable, the gas production process is smooth, the gas production rate is high, and the quality is good.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

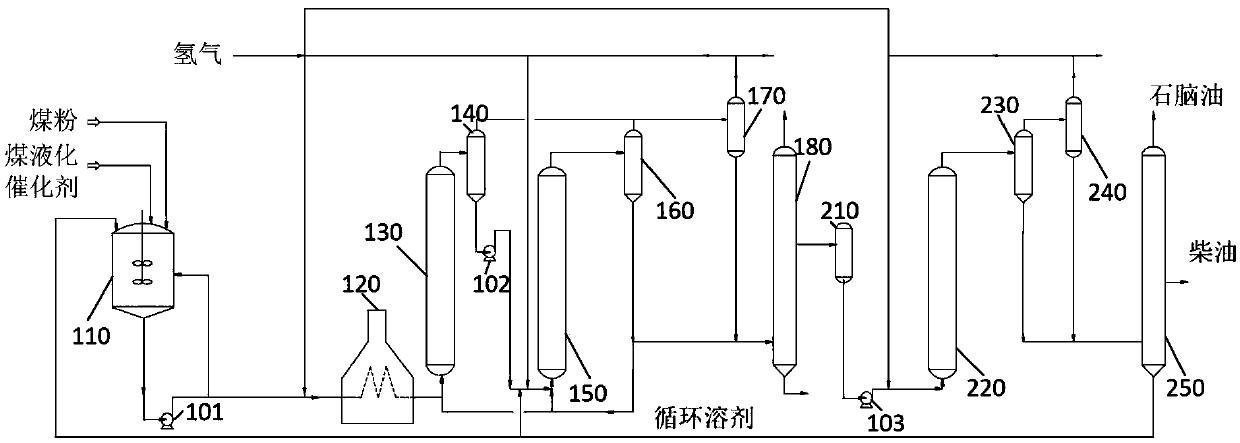

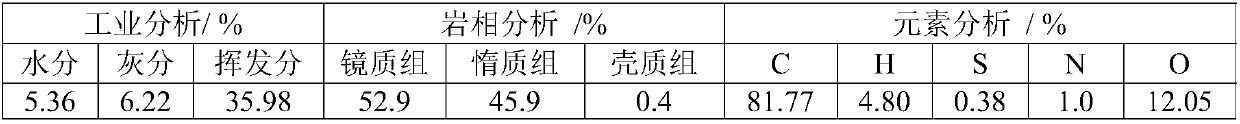

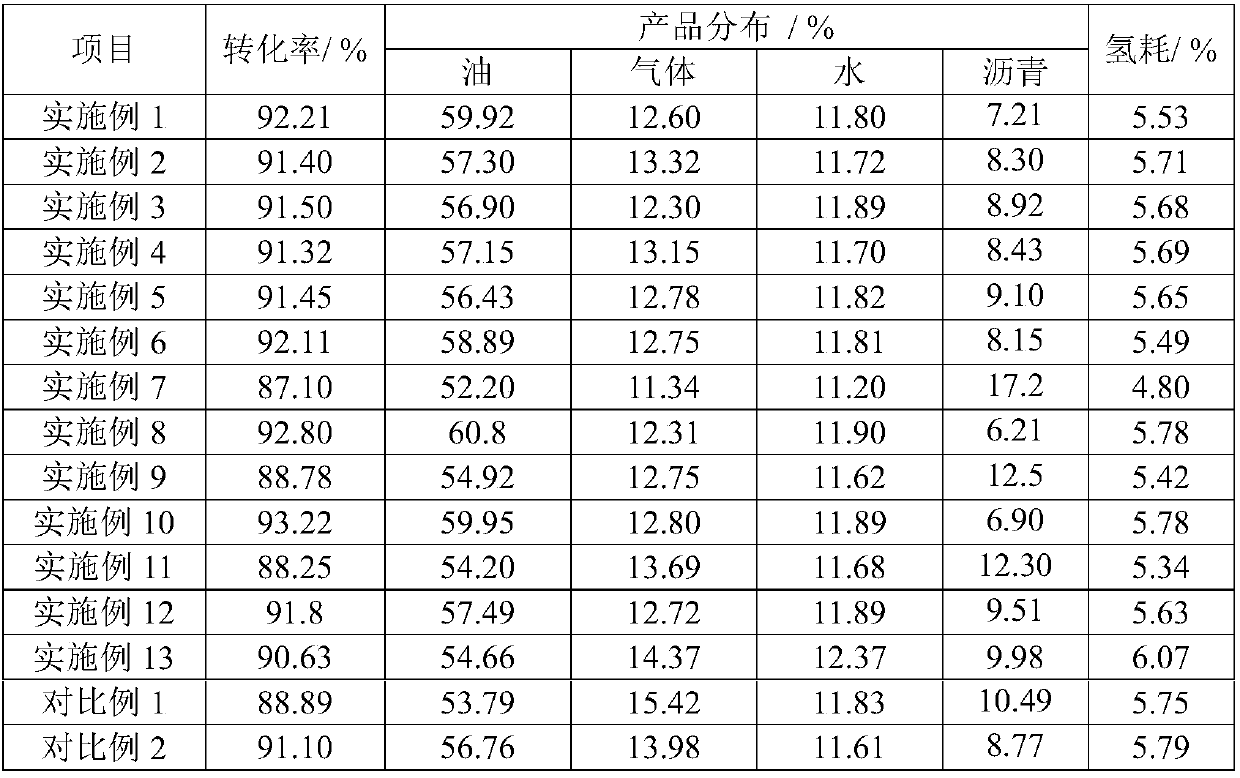

Method and device for coal direction liquefaction

ActiveCN108048121AImprove liquefaction conversionExtended stayLiquid hydrocarbon mixture productionHydrocarbon oils treatment productsLiquid productHydrogen

The invention provides a method and device for coal direction liquefaction. The method for the coal direct liquefaction includes the following steps of: S1, performing a first liquefaction reaction ona first raw material which includes coal slurry and hydrogen so as to obtain first liquefied products, and performing oil-gas separation on the first liquefied products to obtain a first liquid-phaseproduct; S2, performing a second liquefaction reaction on a second raw material which comprises the first liquid-phase product, hydrogen and a solvent so as to obtain second liquefied products, and performing oil-gas separation on the second liquefied products to obtain a second liquid-phase product; S3, performing distillation and catalytic hydrogenation treatment on a part of the second liquid-phase product so as to obtain a coal liquefaction product; and S4, performing the steps of S1-S3 repeatedly, wherein the first raw materials and / or the second raw materials also include the rest of the second liquid-phase product during the repeated operation. Through the method for the coal direct liquefaction, the liquefaction conversion rate and liquid product yield of coal can be improved, andthe resource utilization rate can be improved significantly.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

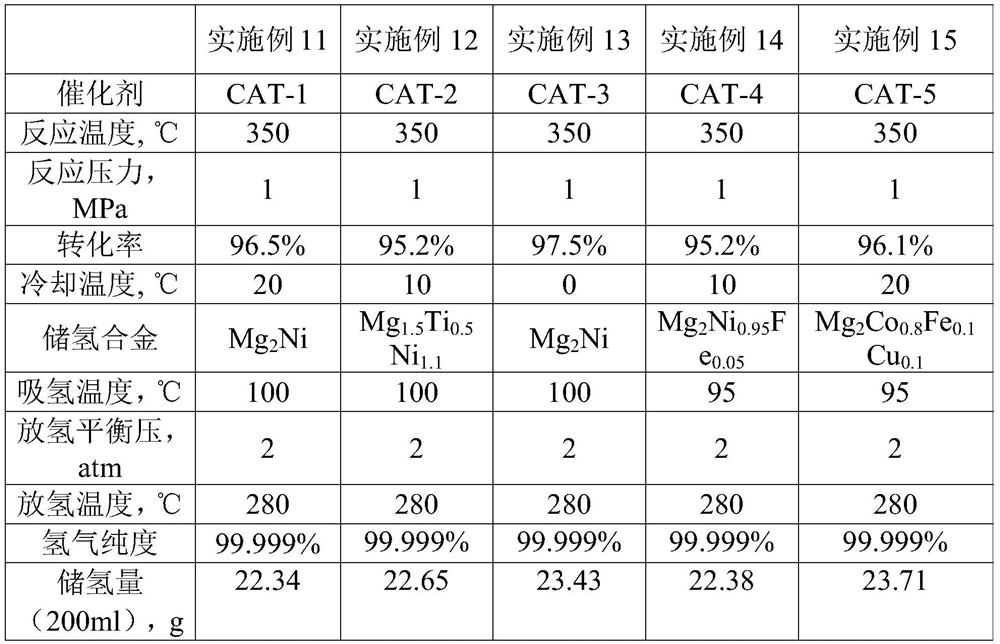

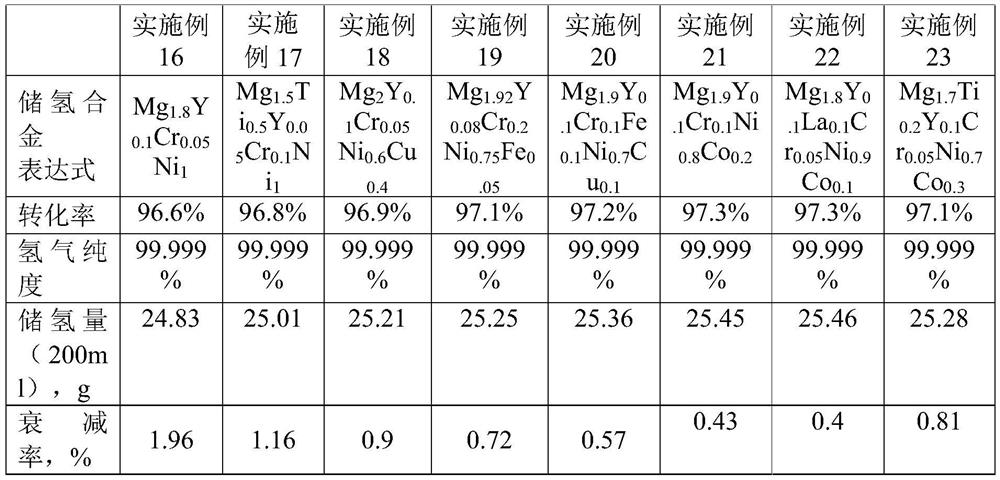

Process for providing high-purity hydrogen

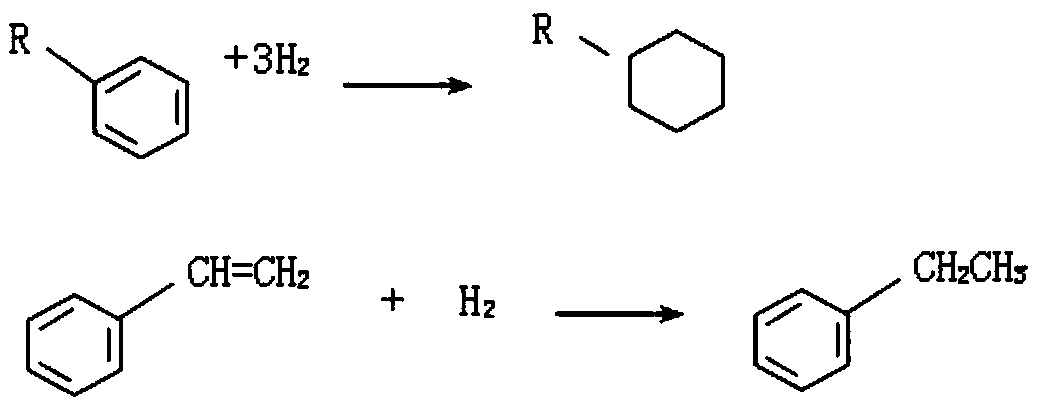

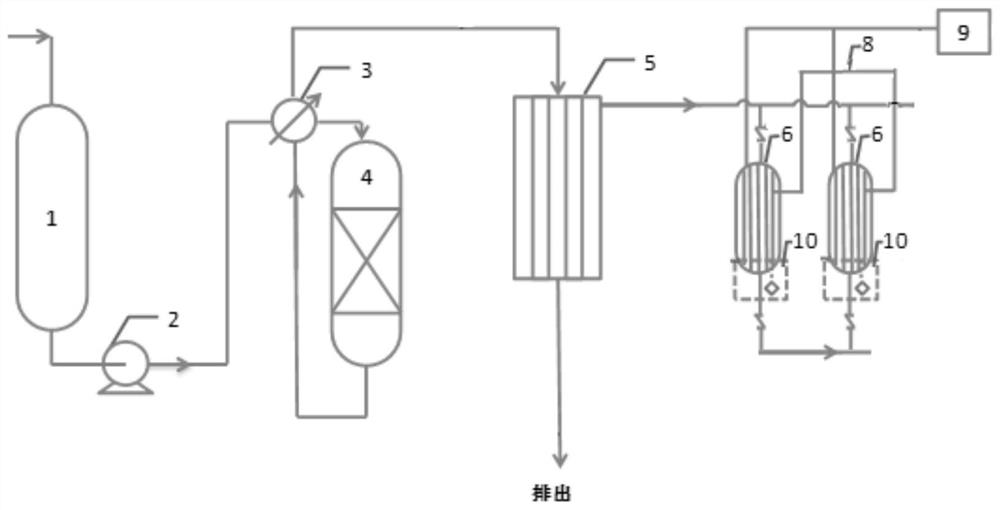

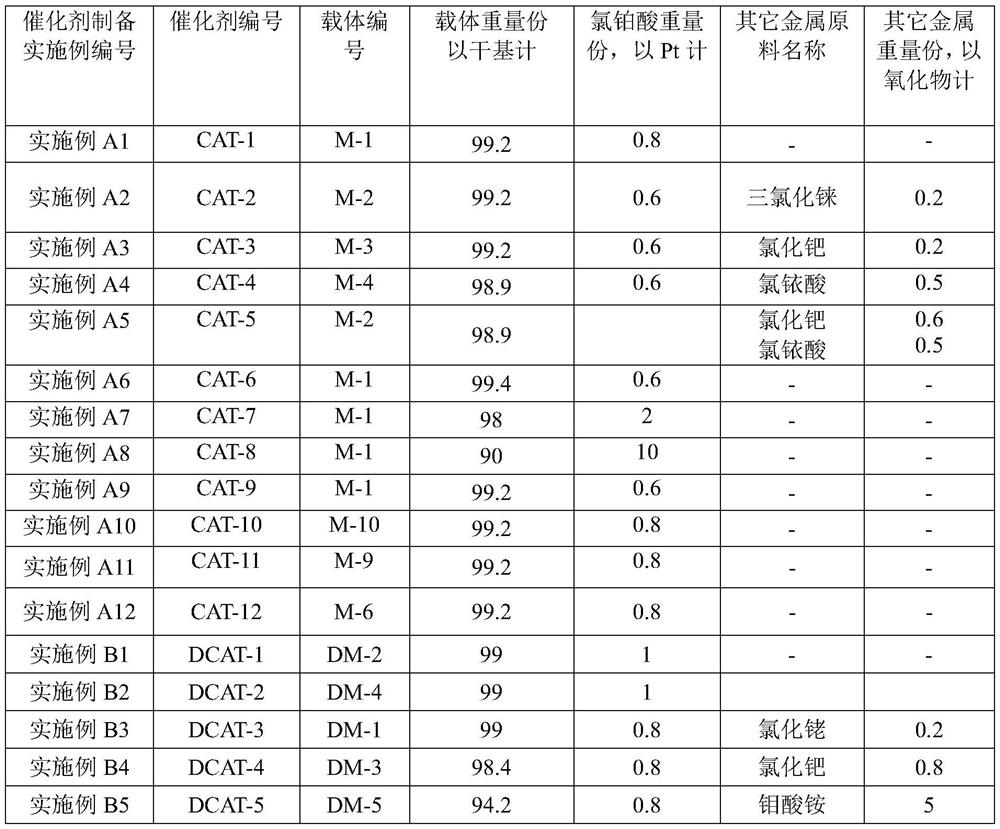

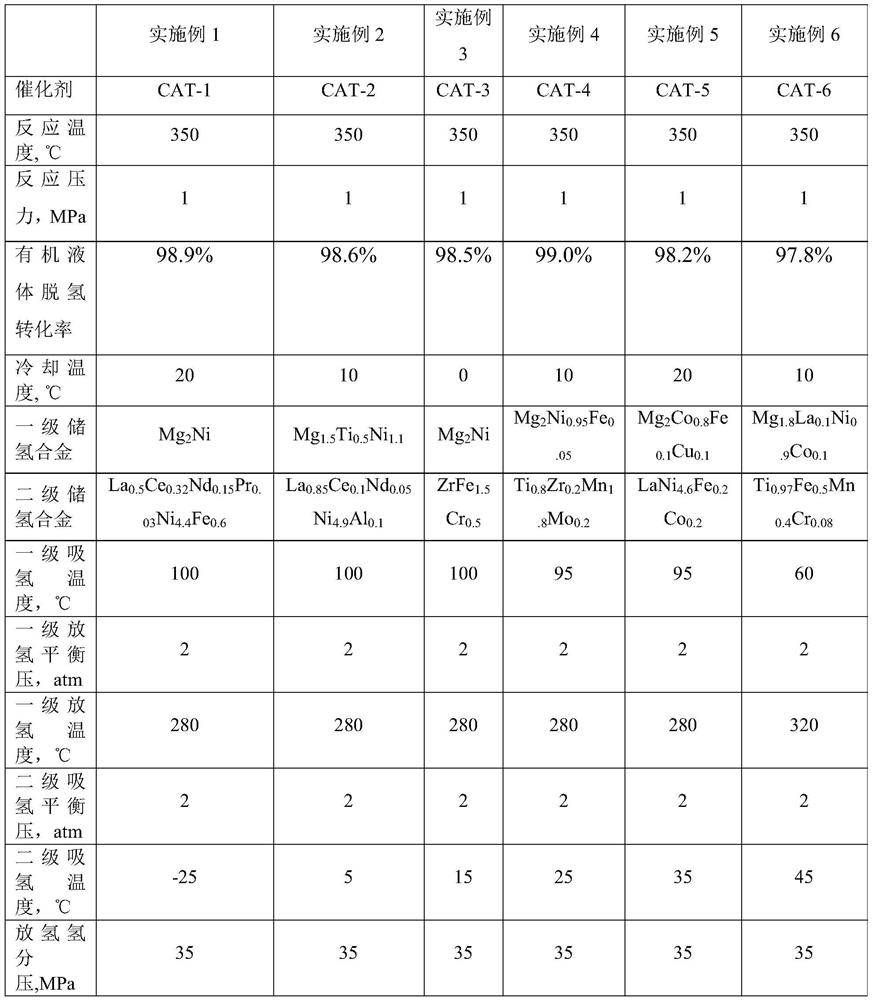

ActiveCN111892018AReduce hydrogen partial pressurePromote dehydrogenation reactionHydrogen separation by selective and reversible uptakeCatalyst activation/preparationLiquid productPtru catalyst

The invention relates to the field of hydrogen preparation and purification, and provides a method for providing high-purity hydrogen. The method comprises the following steps: (1) carrying out a contact reaction on an organic liquid hydrogen storage raw material and a dehydrogenation catalyst to obtain a hydrogen-containing dehydrogenation reaction product; (2) cooling the hydrogen-containing dehydrogenation reaction product to obtain a liquid product and a hydrogen-rich gas product, and collecting the liquid product; (3) allowing the hydrogen-rich gas to make contact with hydrogen storage alloy so as to obtain hydrogen-containing alloy, and collecting non-adsorbed gas, wherein the hydrogen storage alloy is magnesium A2B type hydrogen storage alloy; and (4) heating the hydrogen-containingalloy to release hydrogen so as to obtain high-purity hydrogen. The method provided by the invention not only can produce high-purity hydrogen with a purity of 99.999% or above, but also can reduce the hydrogen partial pressure of organic liquid dehydrogenation, promote the dehydrogenation reaction of organic liquid, reduce reaction temperature, improve reaction selection and lower operation costthrough the 100% selectivity of the hydrogen storage alloy to the hydrogen reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

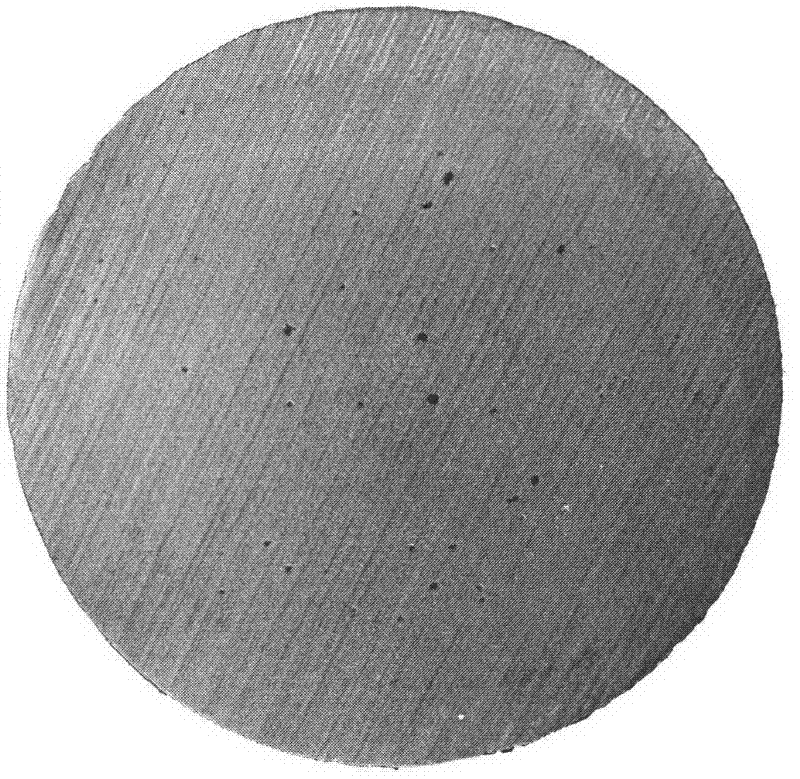

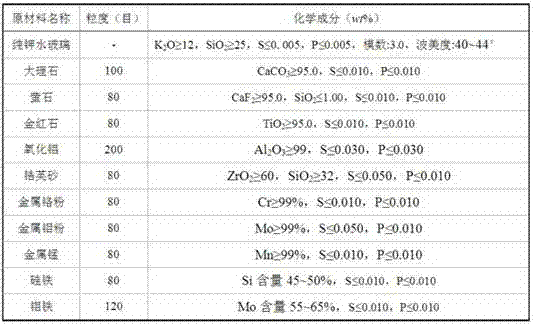

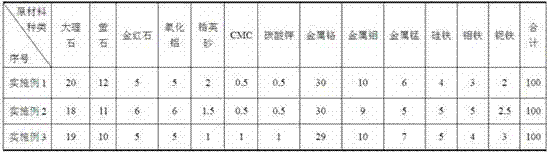

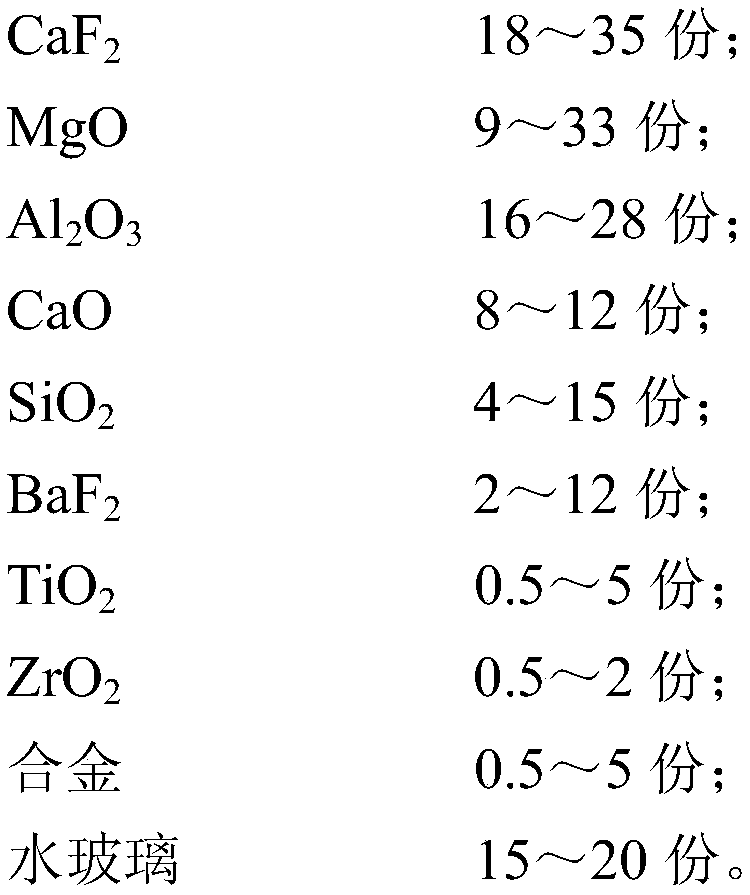

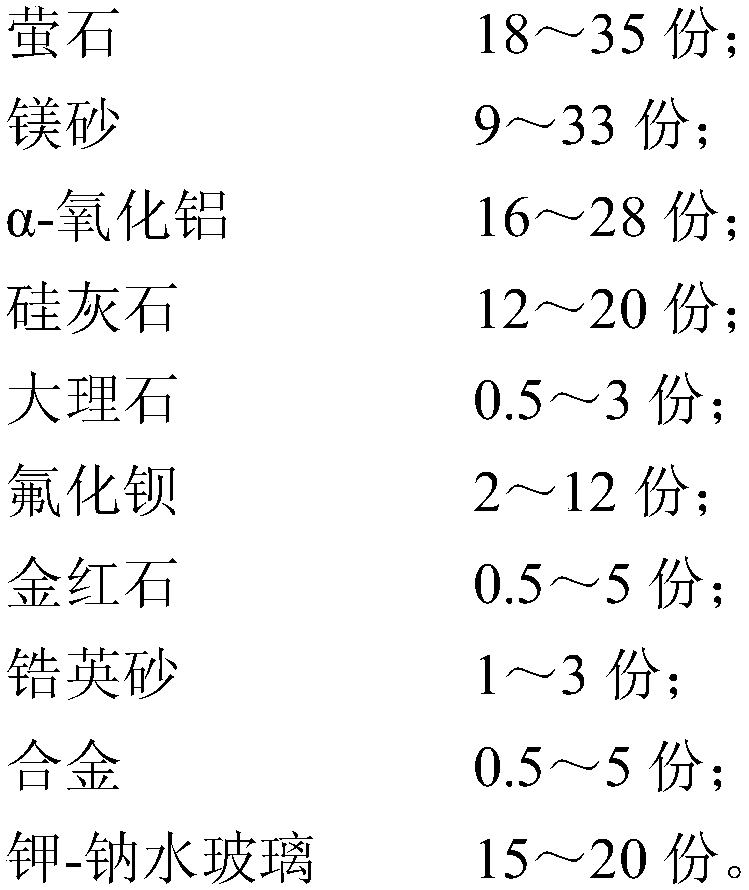

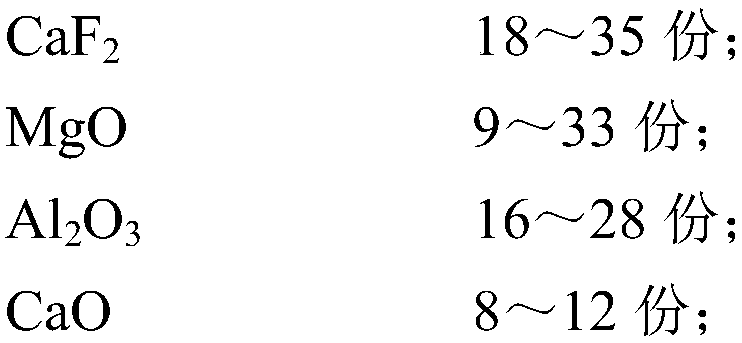

Nickel base alloy submerged arc welding sintered flux and preparation method and application thereof

InactiveCN108015453ADelay transitionImprove purityArc welding apparatusWelding/cutting media/materialsHydrogenSlag

The invention belongs to the technical field of welding materials, and particularly relates to a nickel base alloy submerged arc welding sintered flux and a preparation method and application thereof.According to the nickel base alloy submerged arc welding sintered flux, a main slag system is mainly composed of a CaF2-MgO-Al2O3-CaO-BaF2-SiO2 system, and specifically comprises the following components of, by mass, 18-35 parts of CaF2, 9-33 parts of MgO, 16-28 parts of Al2O3, 8-12 parts of CaO, 4-15 parts of SiO2, 2-12 parts of BaF2, 0.5-5 parts of TiO2, 0.5-2 parts of ZrO2, 0.5-5 parts of alloy and 15-20 parts of sodium silicate. The flux provided by the invention is good in performance and low in diffusible hydrogen, is matched with a solid welding wire ERNiCrMo-4, and is good in manufacturability, and the weld metal mechanical performance is good.

Owner:HENAN UNIV OF SCI & TECH

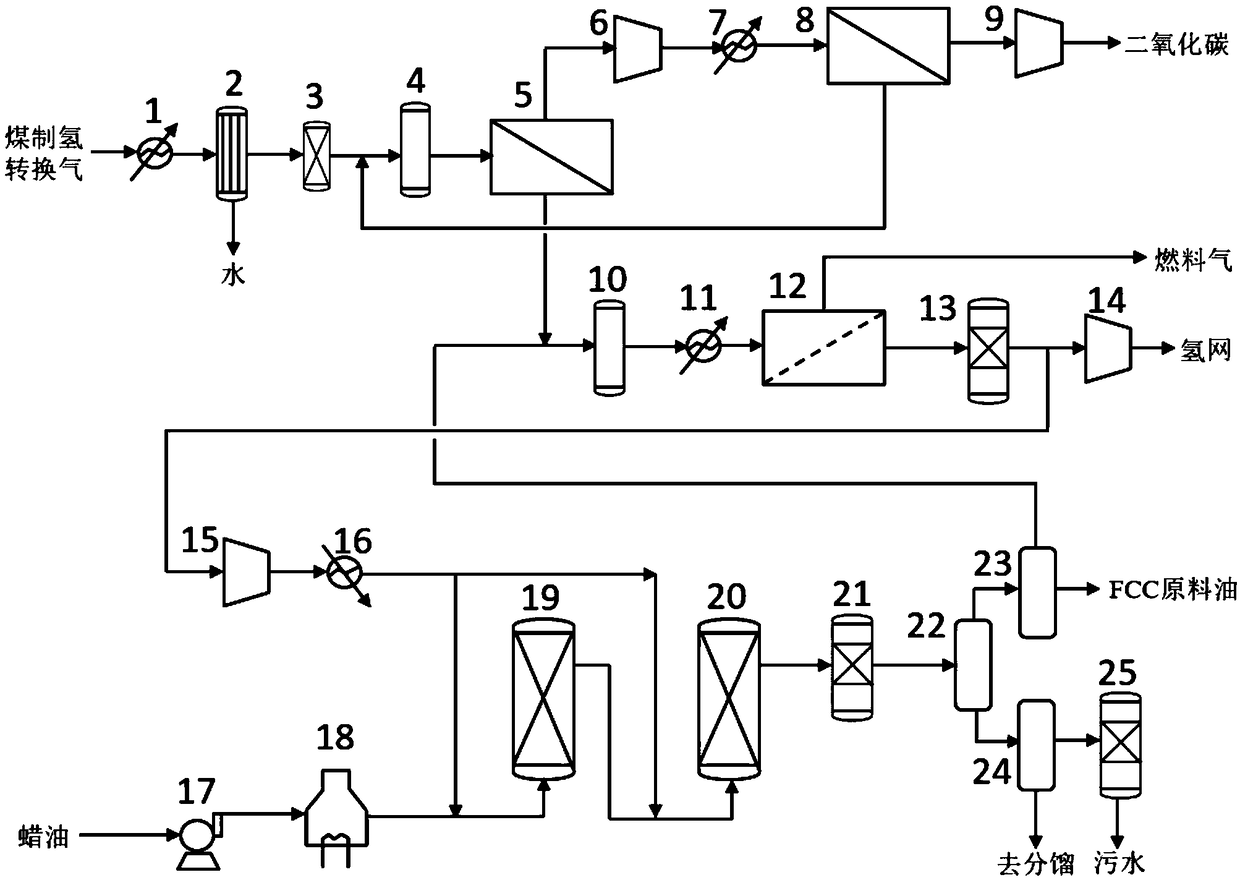

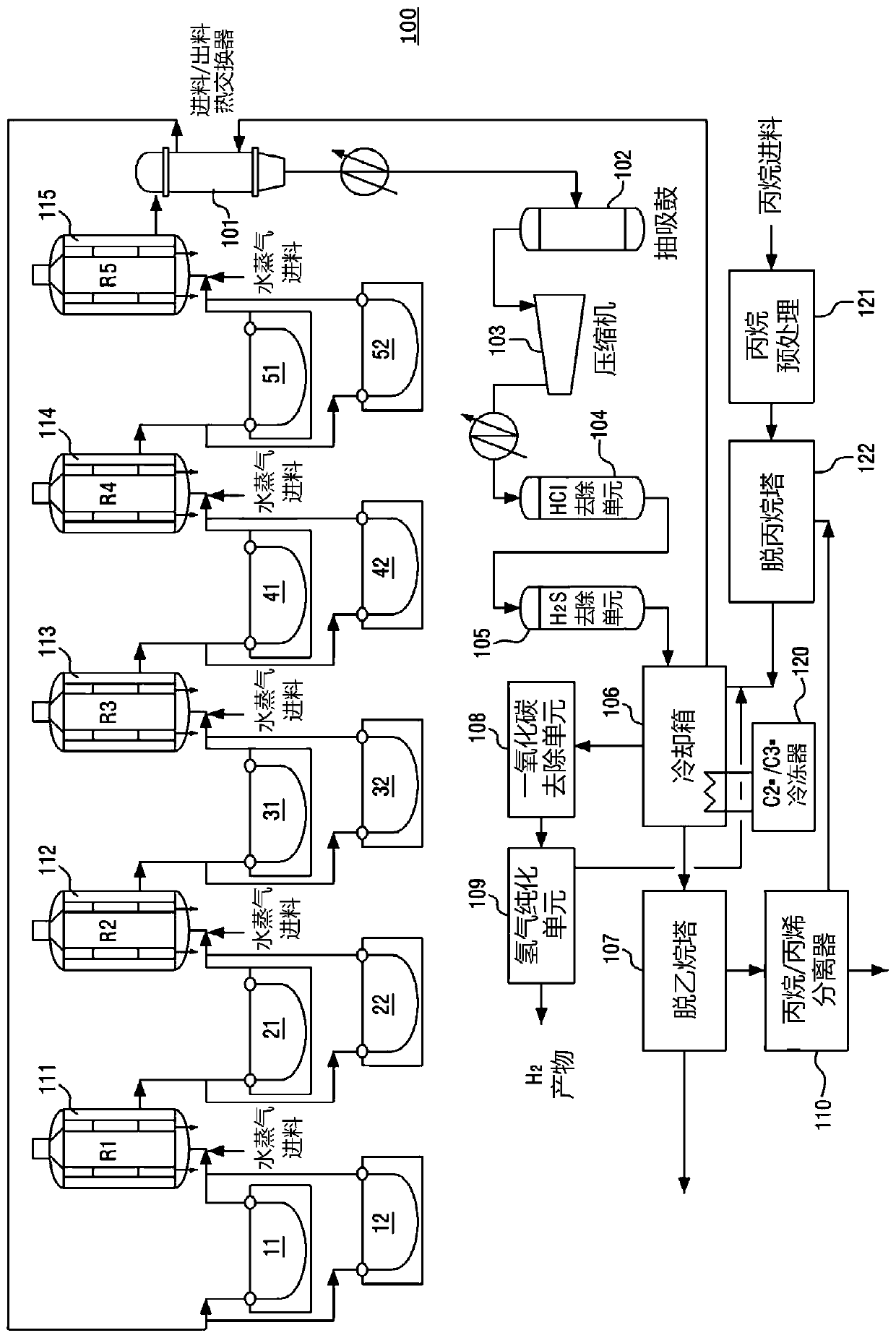

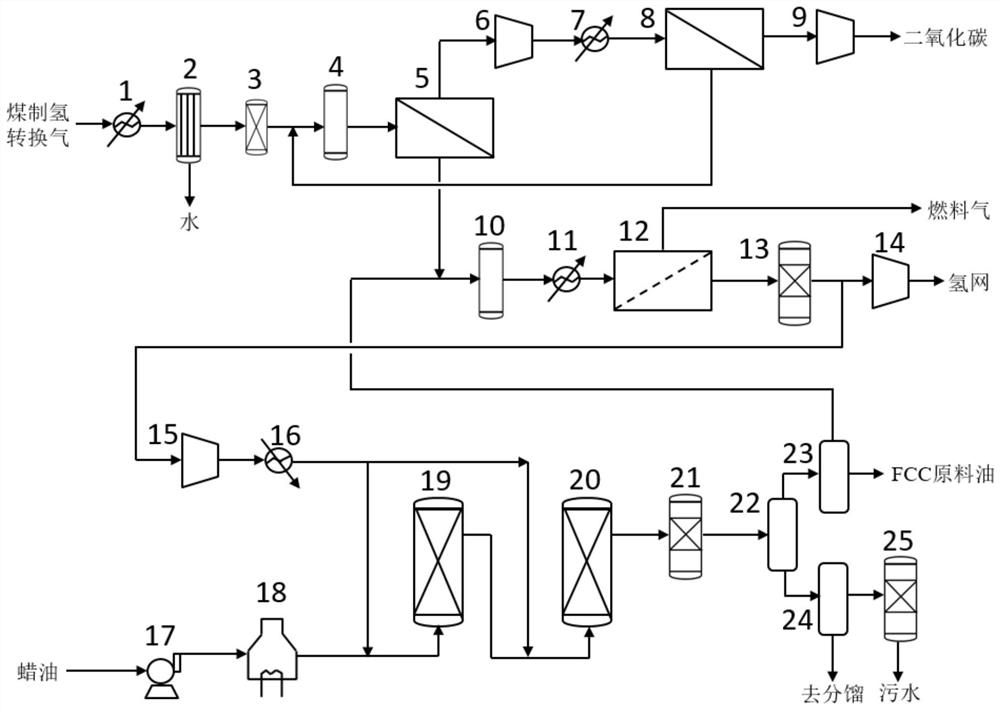

System for hydrogen purification and wax oil hydrogenation coupling in hydrogen from coal

ActiveCN109054893ALess investmentReduce hydrogen partial pressureHydrogen separationCarbon compoundsWaxHydrogen

The invention belongs to the technical field of chemical engineering and provides a system for hydrogen purification and wax oil hydrogenation coupling in hydrogen from coal. The system comprises a membrane separation based carbon dioxide separation unit in hydrogen from coal, a hydrogen purification unit, a wax oil hydrogenation refining unit and an oil-gas separation unit. By adopting the system, firstly, carbon dioxide in reforming gas of the hydrogen from coal is separated out by using a two-stage carbon membrane separator, then, residual permeate gas of a first-stage carbon membrane is mixed with circulating hydrogen from a hydrogenation unit, a mixture enters a hydrogen membrane separator, a small quantity of the carbon dioxide and sulfuretted hydrogen in the hydrogen as a product are removed, the product enters the wax oil hydrogenation refining unit for hydrogenation, finally, oil-gas separation is performed, and the circulating hydrogen enters the hydrogen membrane separator.The system provided by the invention can realizes high coupling of hydrogen purification and utilization, lowers the investment and running costs of the hydrogen purification unit as well as the hydrogenation partial pressure at the same time and improves the wax oil hydrogenation efficiency.

Owner:DALIAN UNIV OF TECH

High-purity hydrogen providing system, movable hydrogen supply system and distributed hydrogen supply device

ActiveCN111895266AReduce hydrogen partial pressurePromote dehydrogenation reactionHydrogen separation by selective and reversible uptakeCatalyst activation/preparationLiquid productPtru catalyst

The invention relates to the field of hydrogen energy, and discloses a high-purity hydrogen providing system, a movable hydrogen supply system and a distributed hydrogen supply device. The high-purityhydrogen providing system comprises an organic liquid hydrogen storage raw material storage and supply device configured to store an organic liquid hydrogen storage raw material and provide the organic liquid hydrogen storage raw material for a dehydrogenation reactor, an after-dehydrogenation liquid storage device configured to store a liquid product that is obtained after the organic liquid hydrogen storage raw material is dehydrogenated, a dehydrogenation reactor device configured to perform a dehydrogenation reaction on the organic liquid hydrogen storage raw material under the action ofa dehydrogenation catalyst, a cooling and separating device configured to separate dehydrogenation reaction products into a hydrogen-rich gas product and the liquid product, a hydrogen storage and supply device configured to perform contact hydrogen adsorption on the hydrogen-rich gas and a hydrogen-storage alloy at low temperature and low temperature and perform heating dehydrogenation after adsorption saturation, an optional purging device and a hydrogen supply unit. The high-purity hydrogen providing system can produce high-purity hydrogen and can use organic liquid as the hydrogen storageraw material, thereby solving the problems of high hydrogen transportation cost, low hydrogen storage density and poor safety.

Owner:CHINA PETROLEUM & CHEM CORP +1

Weak corrosivity removing method for aluminum and copper compound mandrel for preparing uranium-bearing hohlraum

ActiveCN107271249AReduce hydrogen partial pressureReduce lossesPreparing sample for investigationCleaning using liquidsCopper coatingUranium

The invention discloses a weak corrosivity removing method for an aluminum and copper compound mandrel for preparing a uranium-bearing hohlraum and relates to a demolding method of the uranium-bearing hohlraum. The method disclosed by the invention aims to solve the problem that in the prior art, the uranium-bearing hohlraum of the aluminum and copper compound mandrel cannot be demolded. The weak corrosivity removing method comprises the following steps: I, performing loading to obtain a sample stand containing a uranium-bearing hohlraum sample; II, performing negative pressure demolding to remove an aluminum mold core to obtain the sample stand loading a sample without the aluminum mold core; III, performing cleaning; IV, performing weak corrosivity removal of a copper coating to obtain the sample stand loading a sample without the copper coating; and V, immersing in a complexing agent, cleaning, and demolding the uranium-bearing hohlraum of the aluminum and copper compound mandrel. The method disclosed by the invention has the advantage that the molding success rate reaches 100%. The method disclosed by the invention is primarily applied to demolding the uranium-bearing hohlraum.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

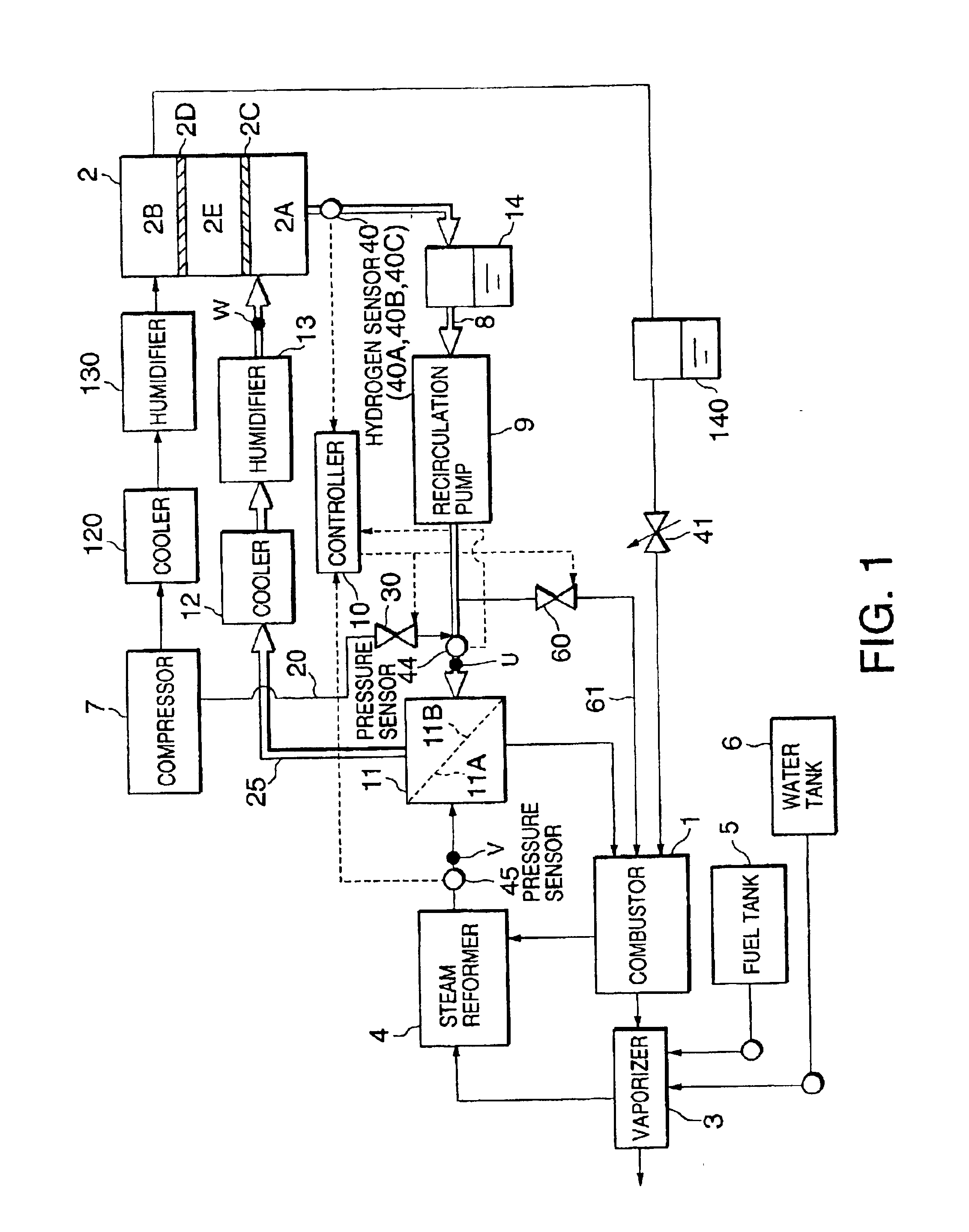

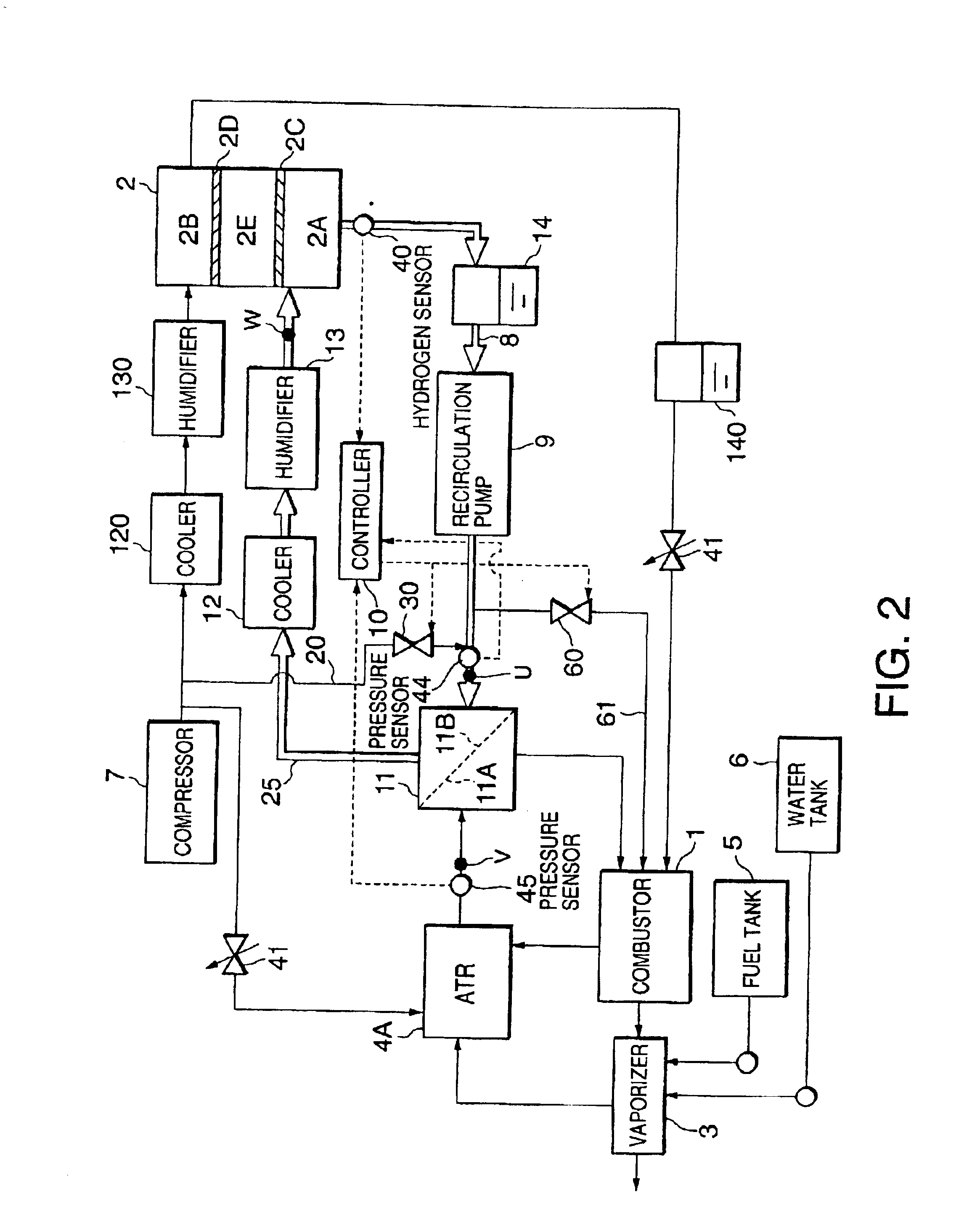

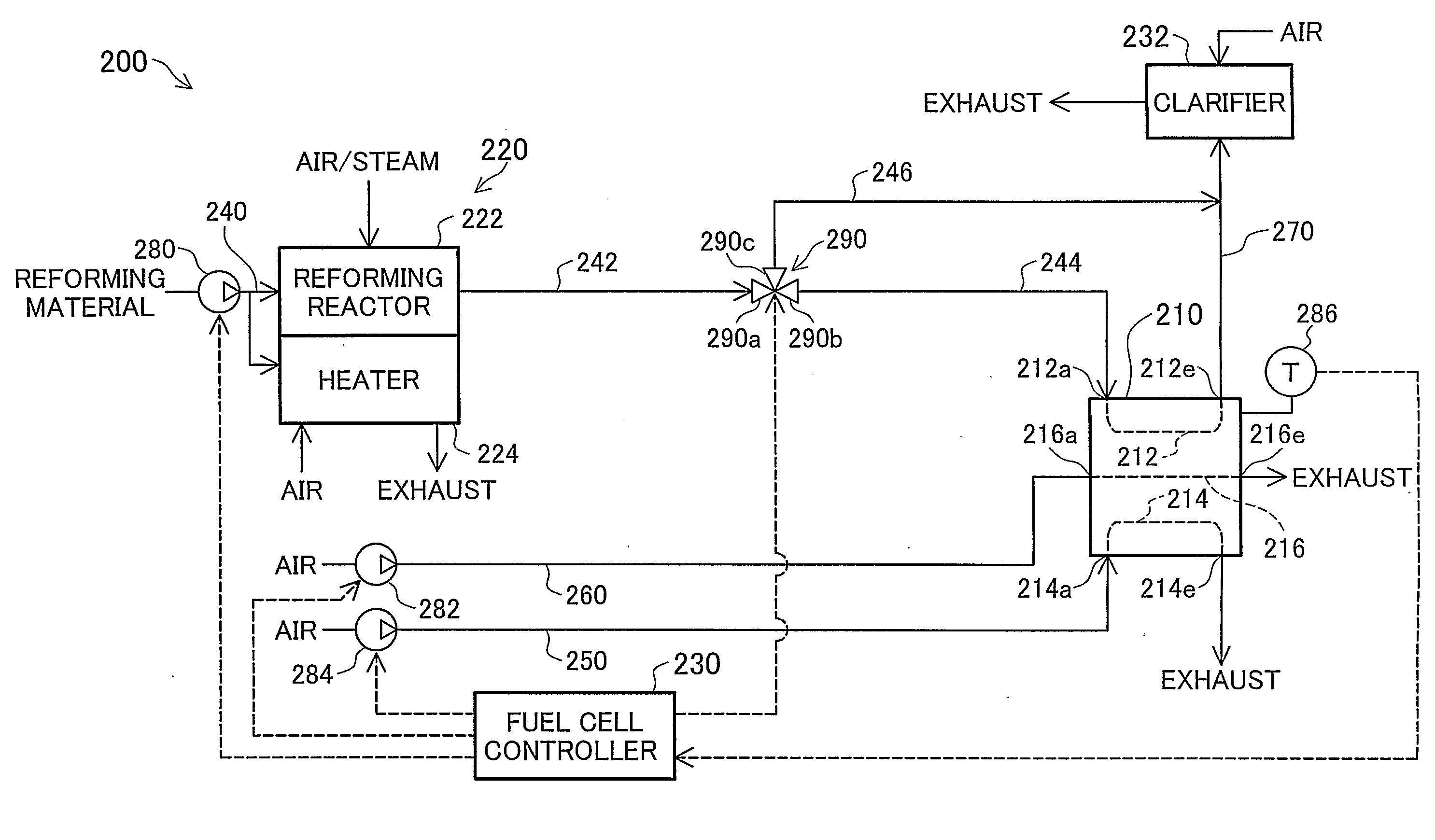

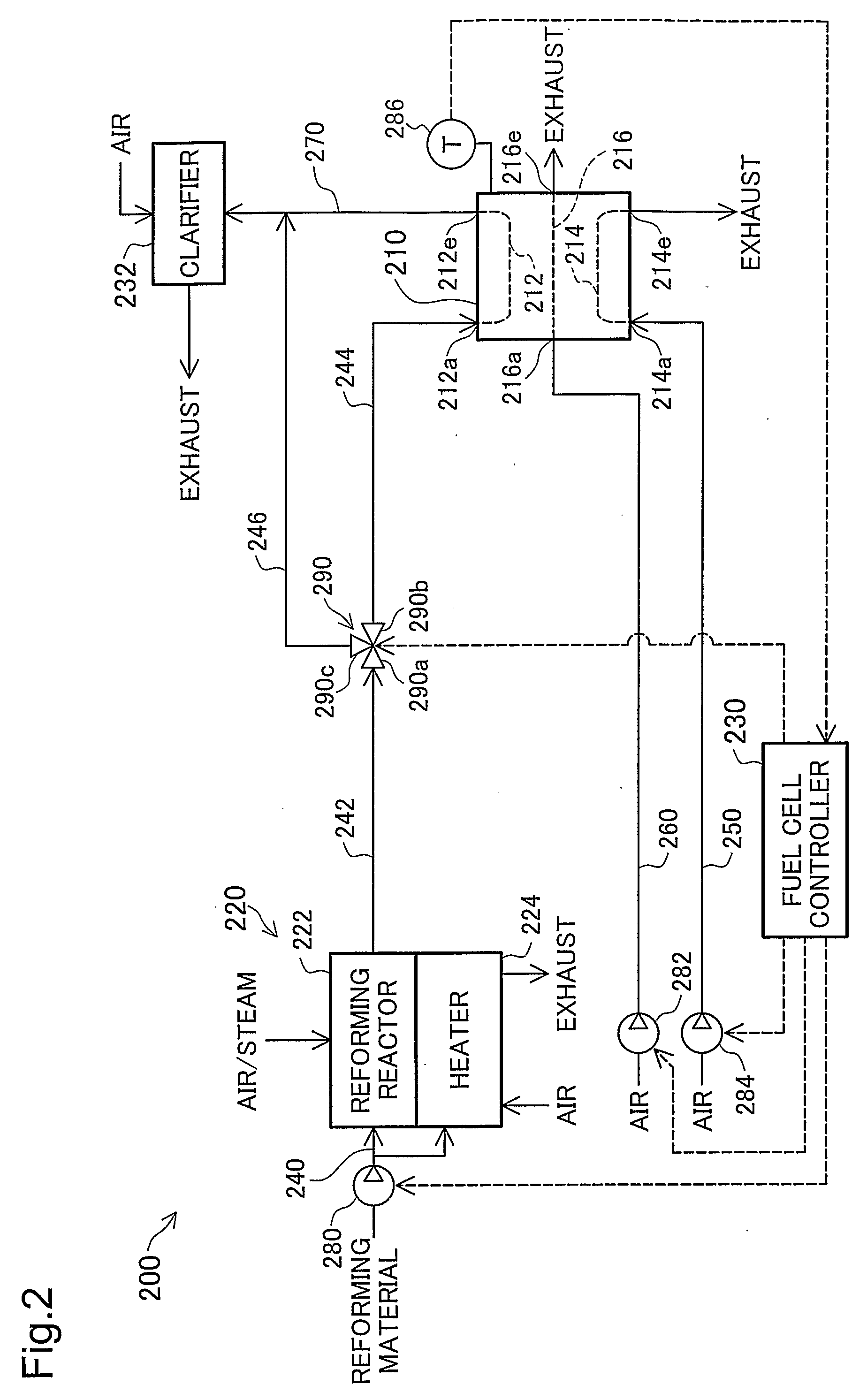

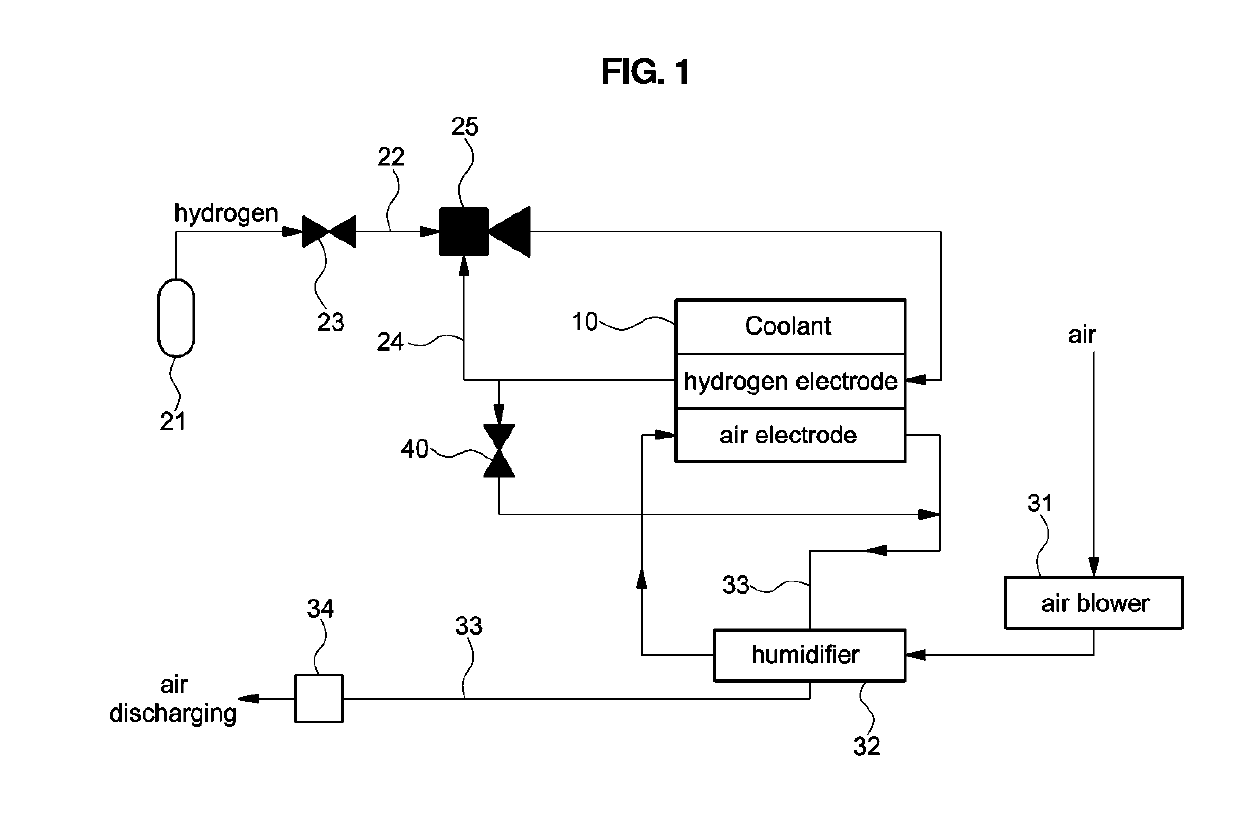

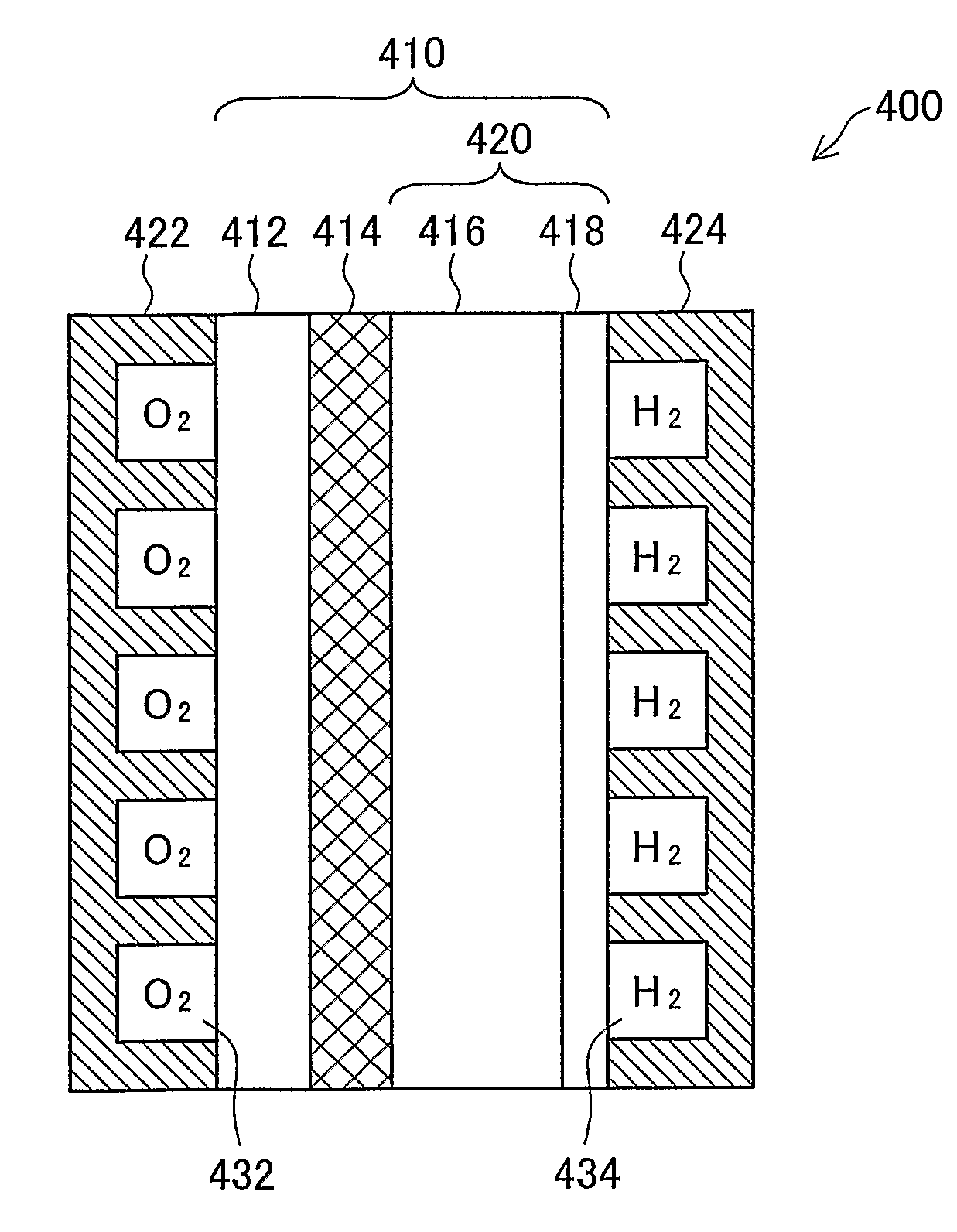

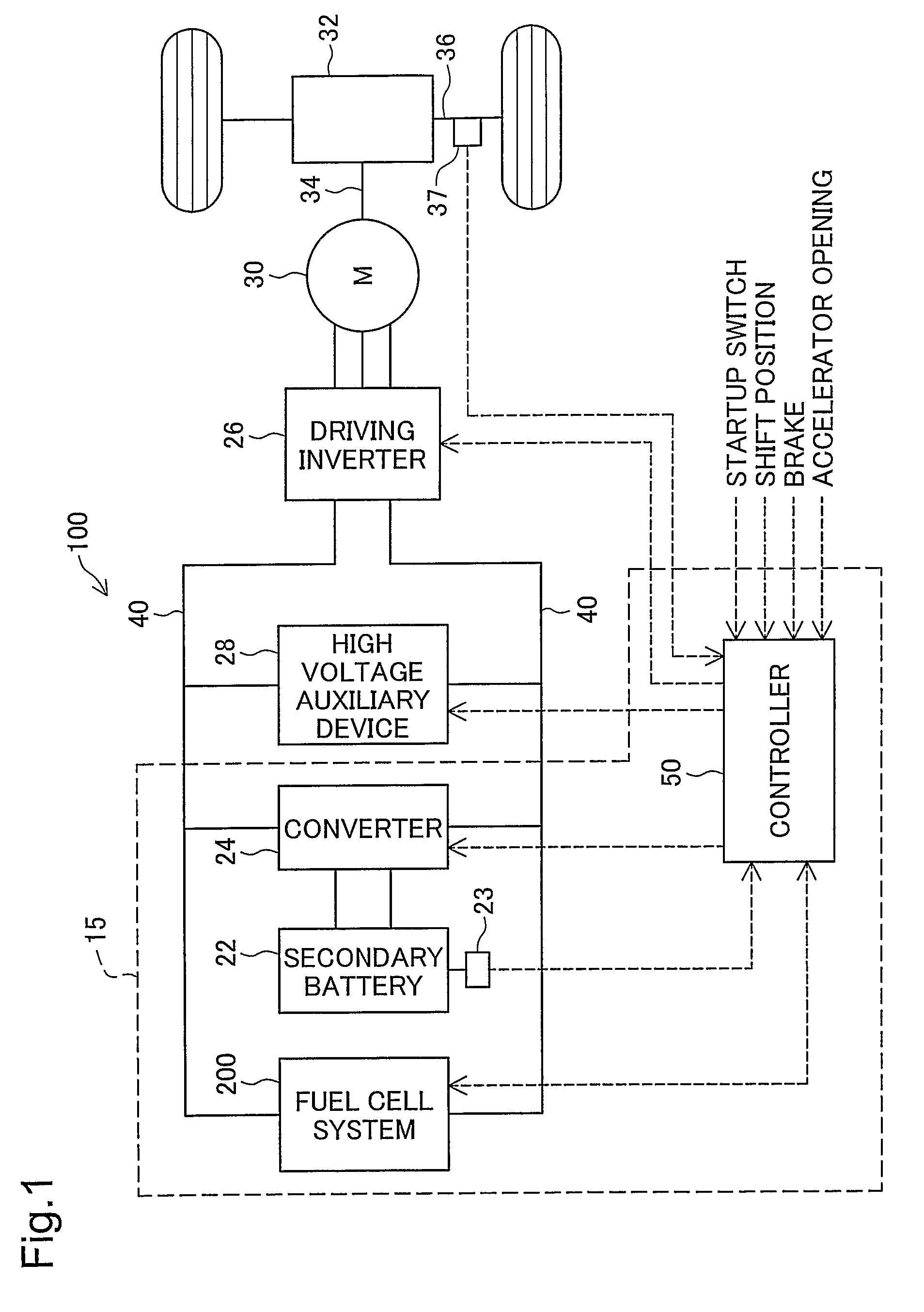

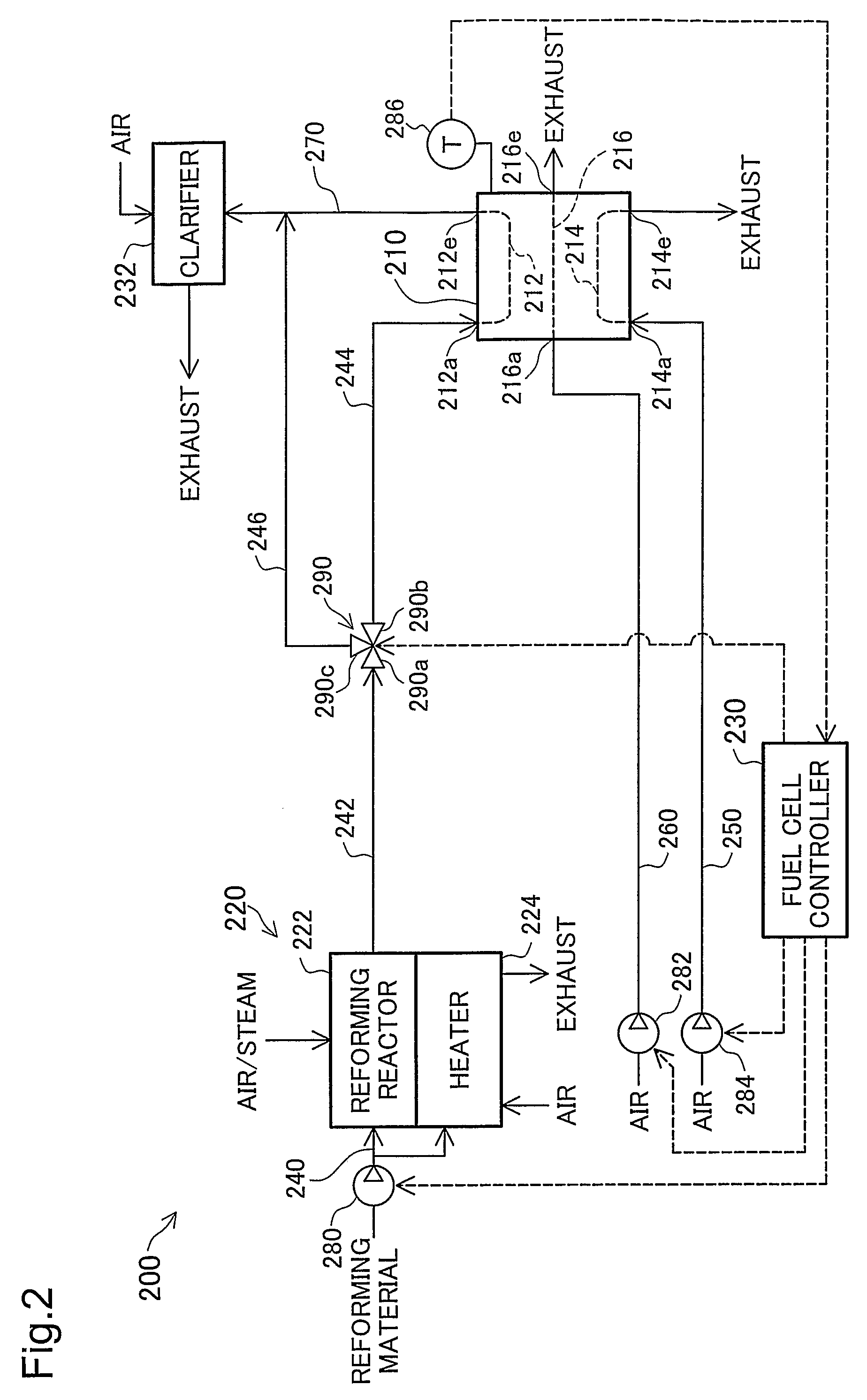

Fuel cell system

InactiveUS20070128484A1Prevent degradationReduce hydrogen partial pressureFuel cell heat exchangeCell electrodesEngineeringFuel gas

A technology for preventing degradation of a hydrogen permeable metal layer in a fuel cell 210 is provided. A fuel cell system 200 including a fuel cell 210 with an anode which has the hydrogen permeable metal layer comprises a fuel cell controller 230 for controlling the operation status of the fuel cell system 200, a temperature parameter acquisition section for acquiring a temperature parameter of the hydrogen permeable metal layer, and a hydrogen permeable metal layer degradation prevention section which reduces the hydrogen partial pressure in an anode channel 212 for supplying fuel gas to the anode. If a temperature of the hydrogen permeable metal layer represented by the temperature parameter deviates from a specified temperature range, the fuel cell controller 230 cause the hydrogen permeable metal layer degradation prevention section to operate for preventing degradation of the hydrogen permeable metal layer.

Owner:TOYOTA JIDOSHA KK

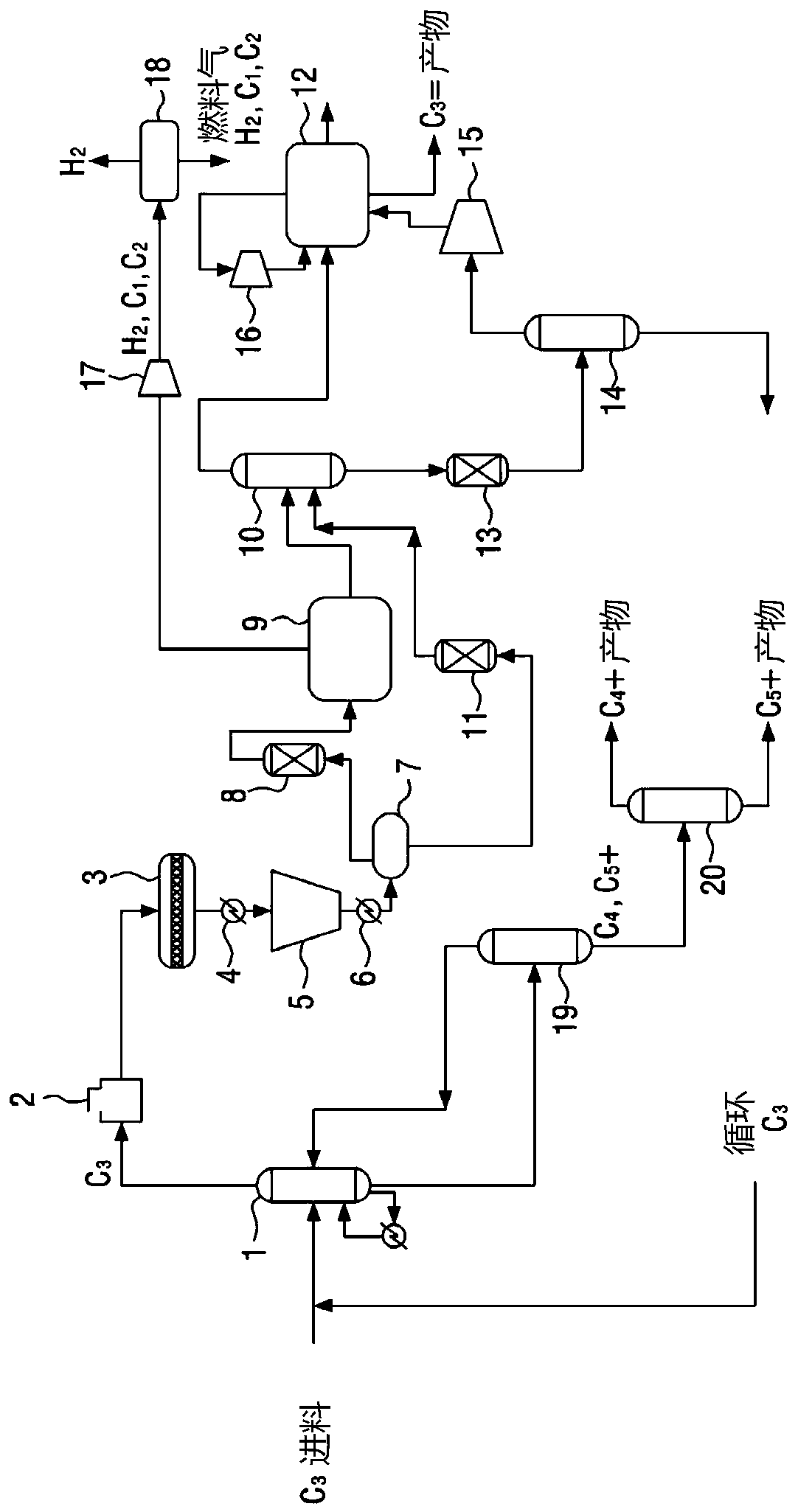

Method for dehydrogenating alkane

ActiveCN110177770AIncrease productionIncrease total heat supplyGas treatmentHydrogen separation at low temperatureAlkaneHydrogen

Owner:HYOSUNG CHEM CORP

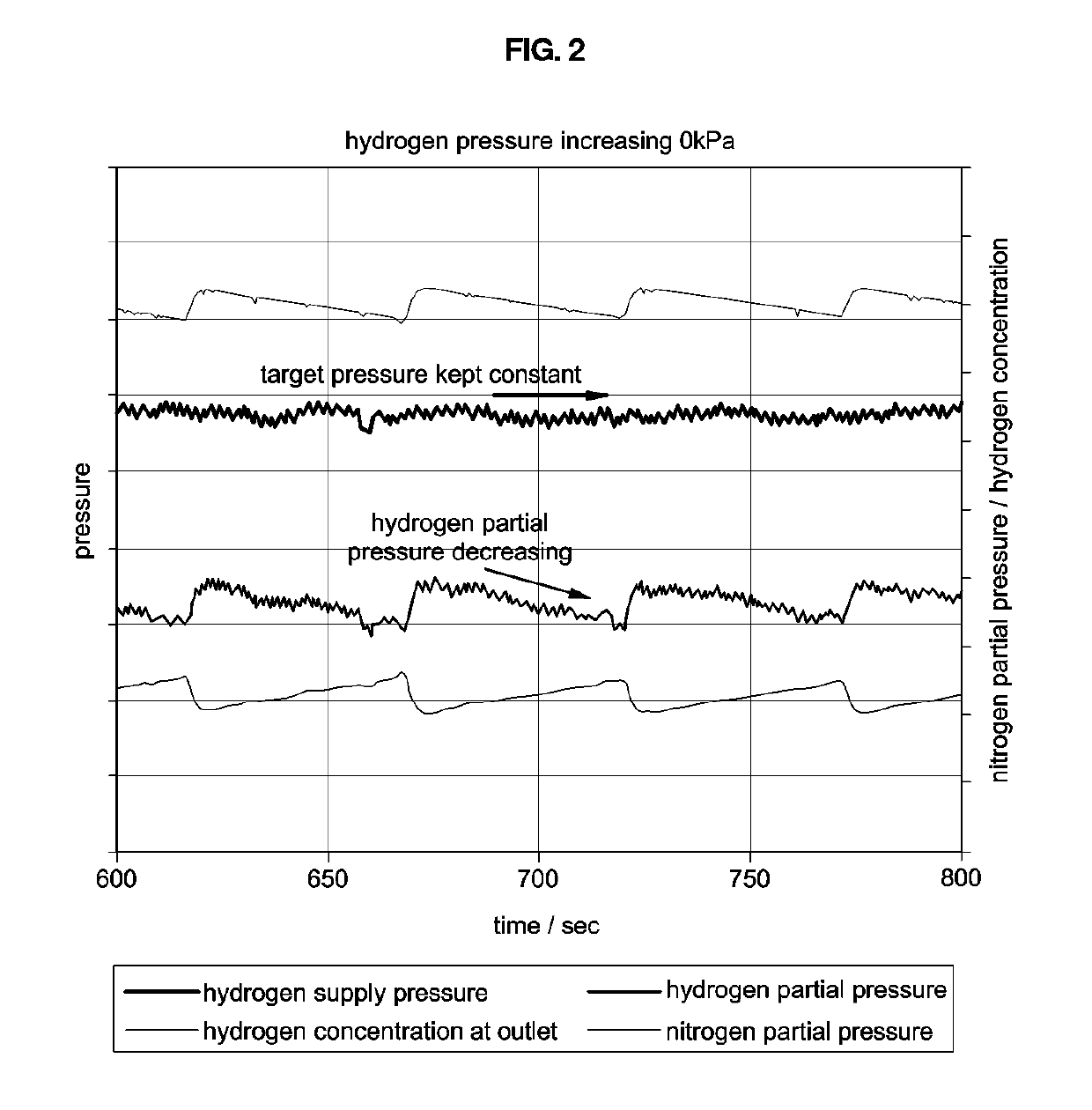

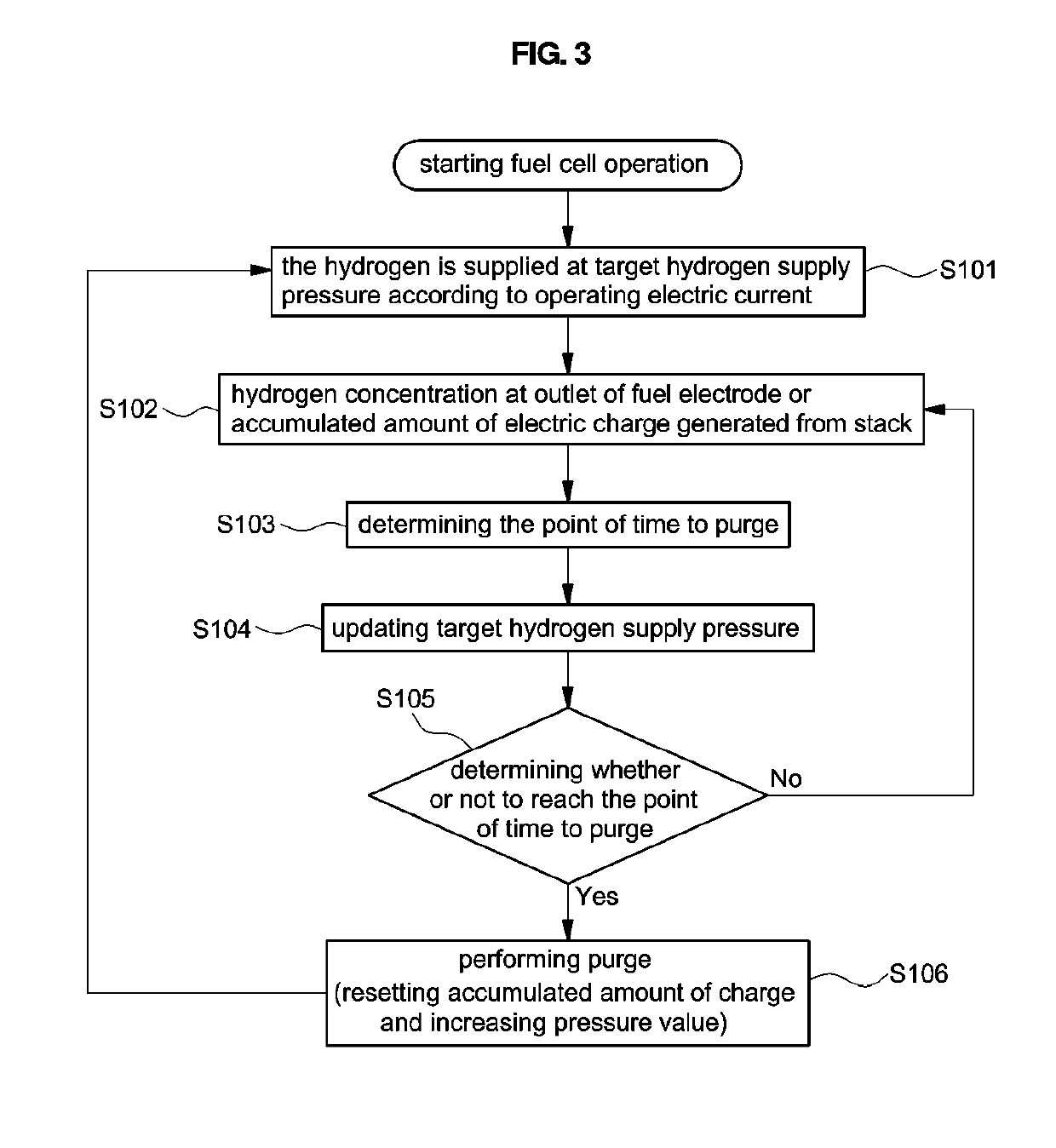

Method of controlling hydrogen partial pressure for fuel cell system

PendingUS20190207235A1Reduce hydrogen partial pressurePrevent hydrogen partial pressureFuel cellsHydrogen concentrationHydrogen pressure

A method of controlling a hydrogen partial pressure can be carried out in a fuel cell system including a stack having a hydrogen electrode and an air electrode. The method includes: determining a point of time to purge the hydrogen electrode using a hydrogen concentration at an outlet of the hydrogen electrode or an accumulated amount of charge generated in the stack; and setting a target supply pressure of hydrogen supplied to the stack, in which the target hydrogen supply pressure is set in consideration of a hydrogen pressure and a partial pressure of nitrogen resulting from crossover in the stack.

Owner:HYUNDAI MOTOR CO LTD +1

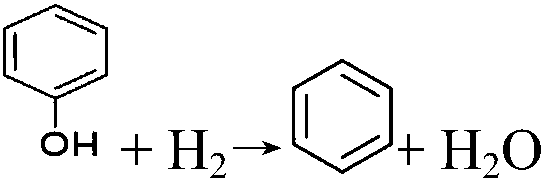

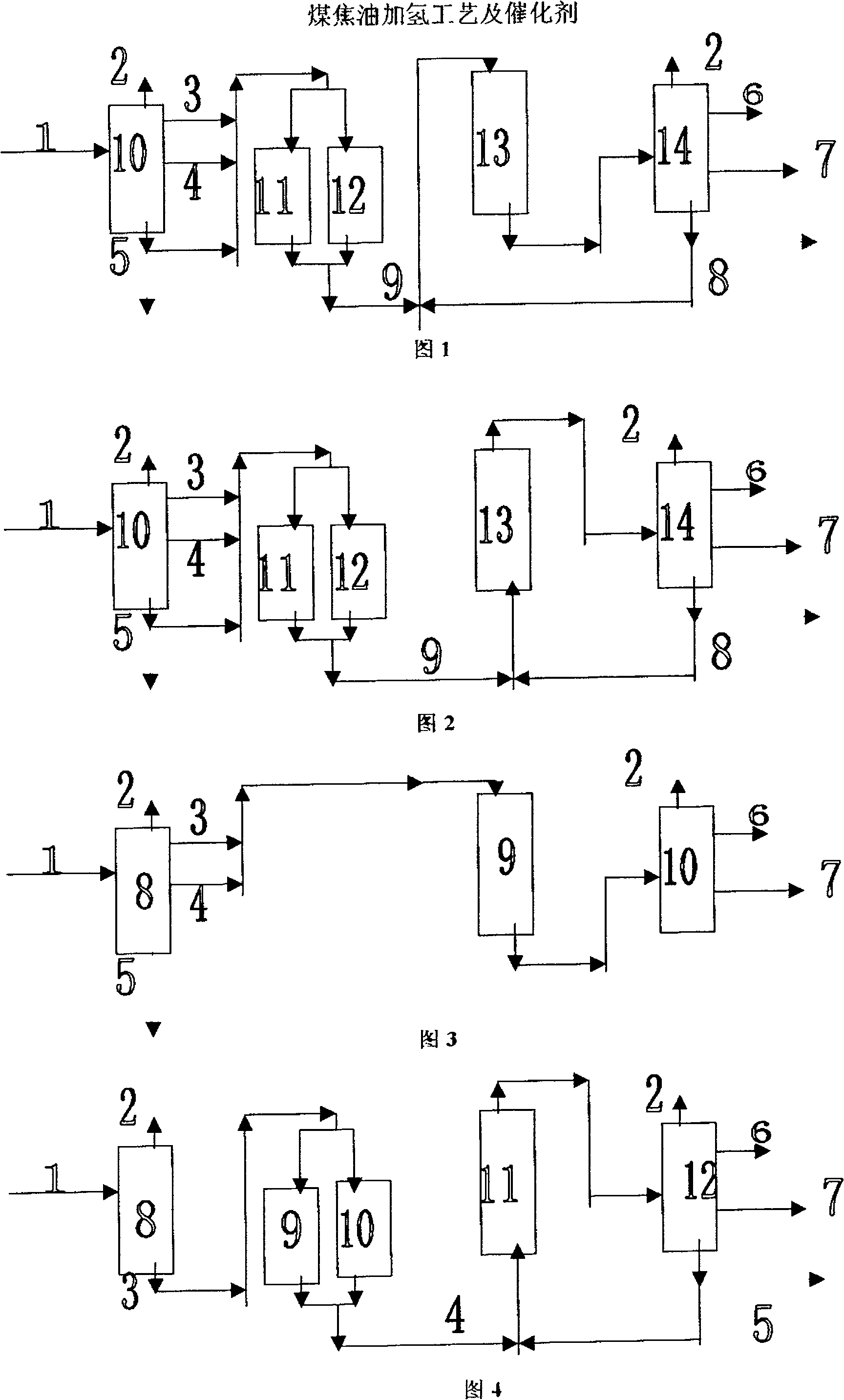

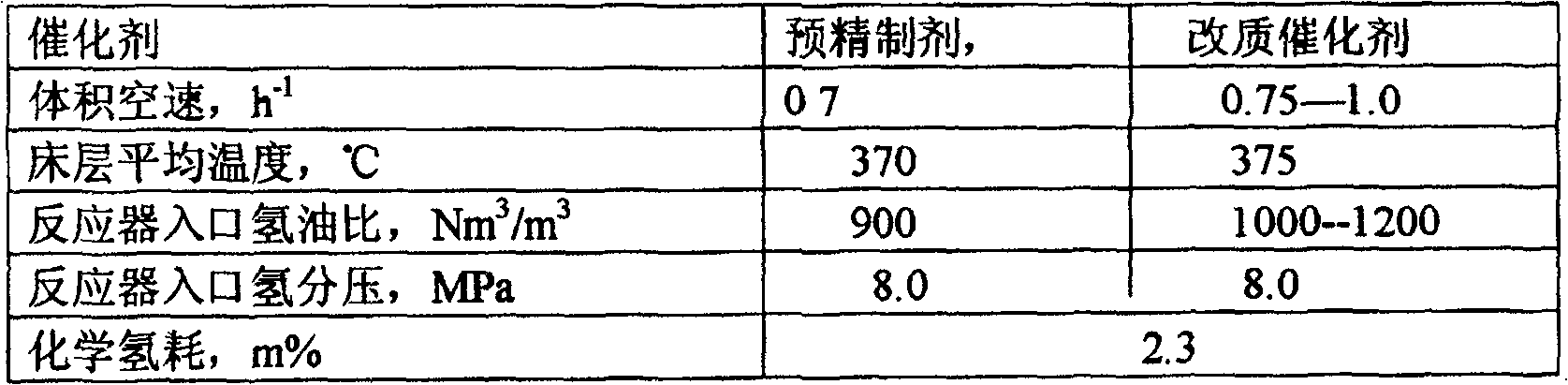

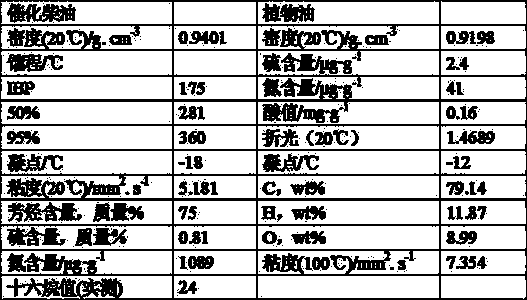

Coal tar hydrogenation process and catalyst therefor

The present invention, coal tar hydrogenating process and catalyst, has obvious economic and environment protecting significance. Different hydrogenating catalysts are developed for meeting the requirement of hydrogenating coal tar of different components. The hydrogenating reactor has inlet pressure not higher than 15.0 MPa. After coal tar is hydrogenated in proper process to modify, may be obtained high-quality naphtha, high-quality diesel oil component or diesel oil, high-quality needle coke material and high-purity chemical product. The key point of the present invention is to use the developed special hydrogenating refining and modifying catalyst in hydrogenating coal tar.

Owner:上海博申工程技术有限公司 +1

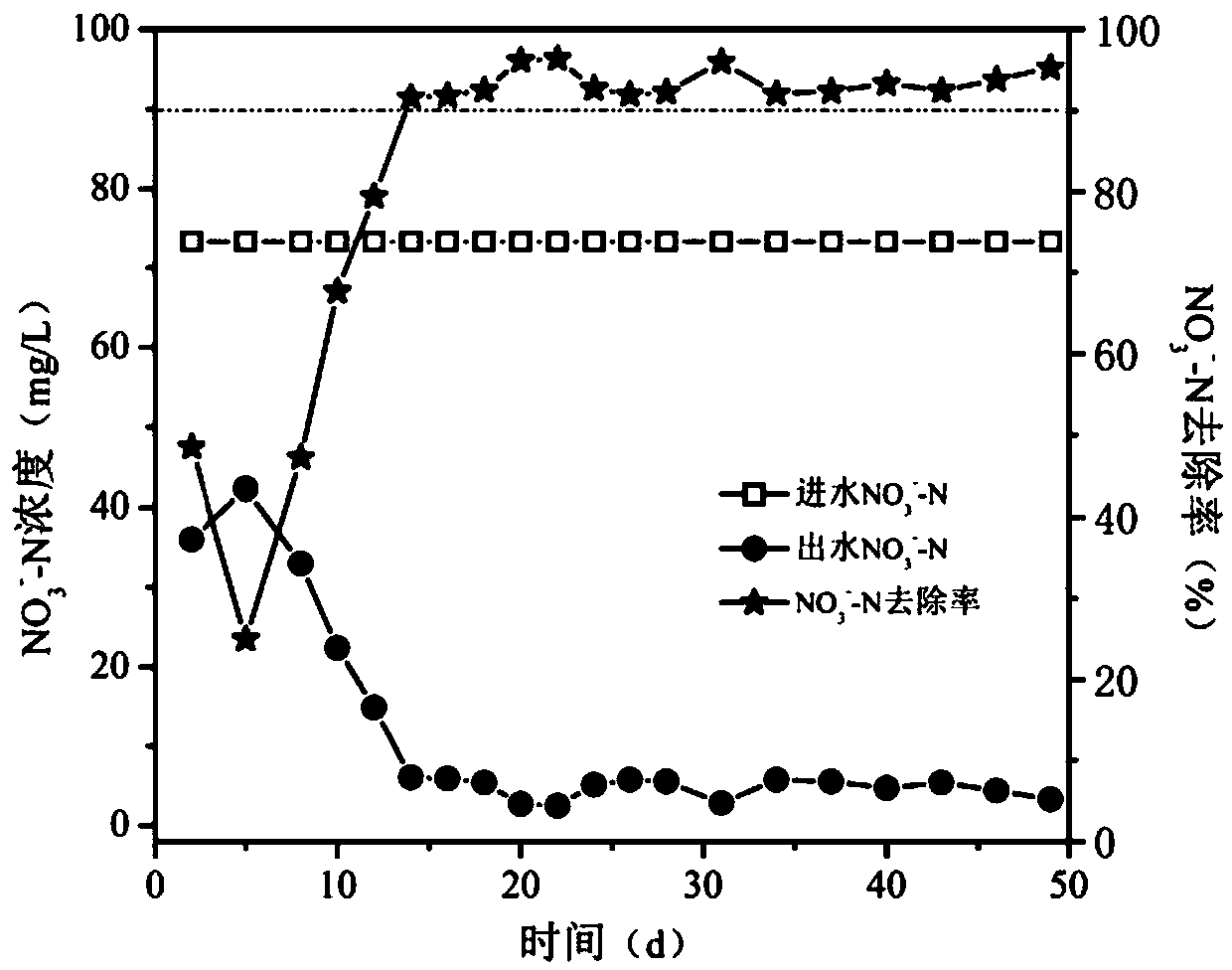

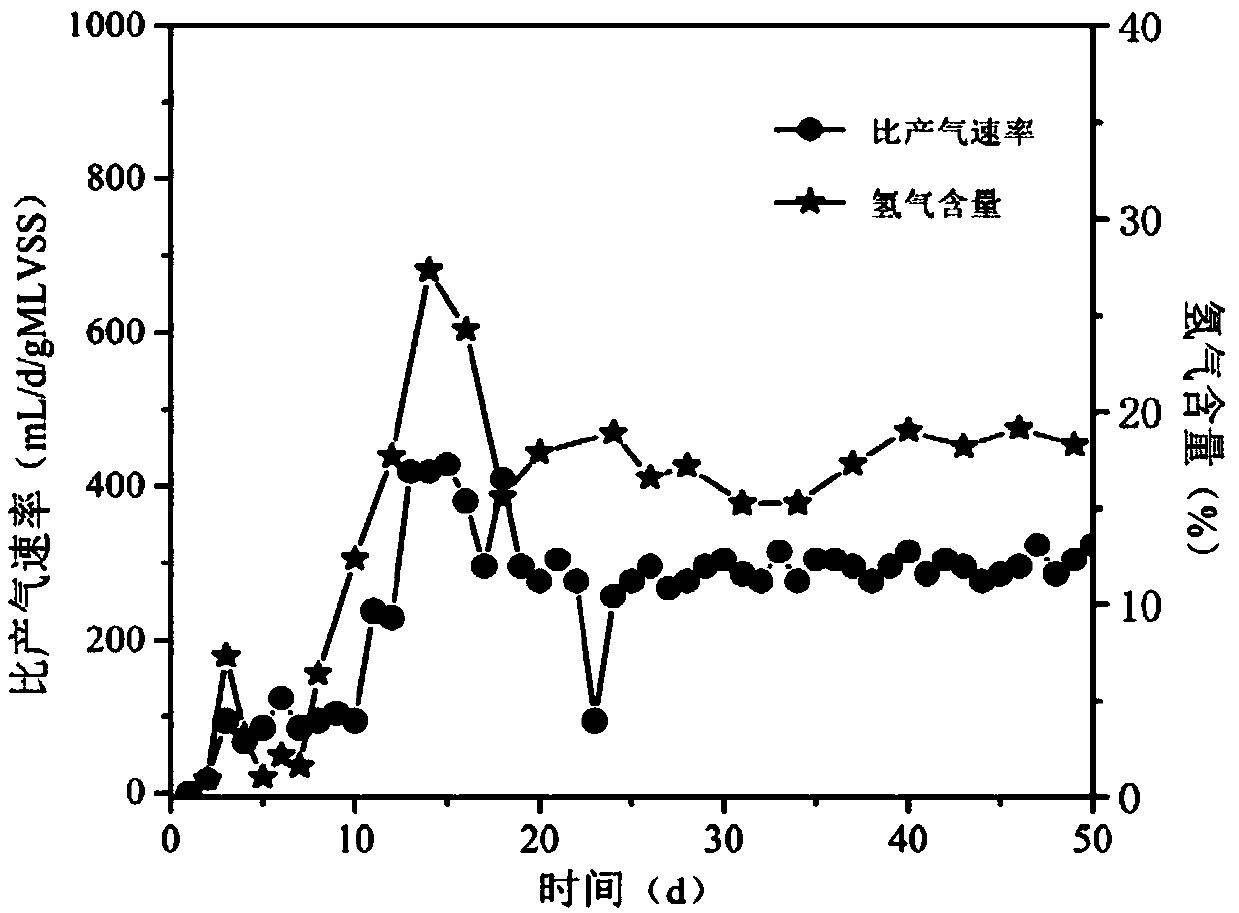

Sewage treatment method for simultaneously producing nitrogen and removing nitrogen by biological hydrogen production, coupling and denitrification

ActiveCN109081508AAchieve recyclingAchieve removalWater treatment parameter controlWater contaminantsNitrogen removalCoupling

The invention discloses a sewage treatment method for simultaneously producing nitrogen and removing nitrogen by biological hydrogen production, coupling and denitrification. The sewage treatment method for simultaneously producing nitrogen and removing nitrogen by biological hydrogen production, coupling and denitrification comprises the steps of sludge inoculation, reactor running and the like.In sludge inoculation, sludge which simultaneously comprises denitrification microorganisms and hydrogen production microorganisms in an anaerobic reactor, and thus, MLSS in the reactor is 15-20 g / L;according to running of the reactor, organic sewage is pumped into the anaerobic reactor, the running temperature of the reactor is controlled to be 25-37 DEG C, running pH of the reactor is controlled to be 4-10, oxidation reduction potential is controlled to be minus 200- minus 500 mV, and hydraulic retention time is controlled to be 4-12 h until sewage treatment is finished. In the method, theproblem that carbon sources are insufficient in a denitrification process is solved, the hydrogen production property in a hydrogen production process of dark fermenting organisms is improved, the dosage of throwing and adding of alkali in the hydrogen production process of the dark fermenting organisms is reduced, and the running cost in a process of nitrogen removal by denitrification can be reduced.

Owner:SICHUAN UNIV

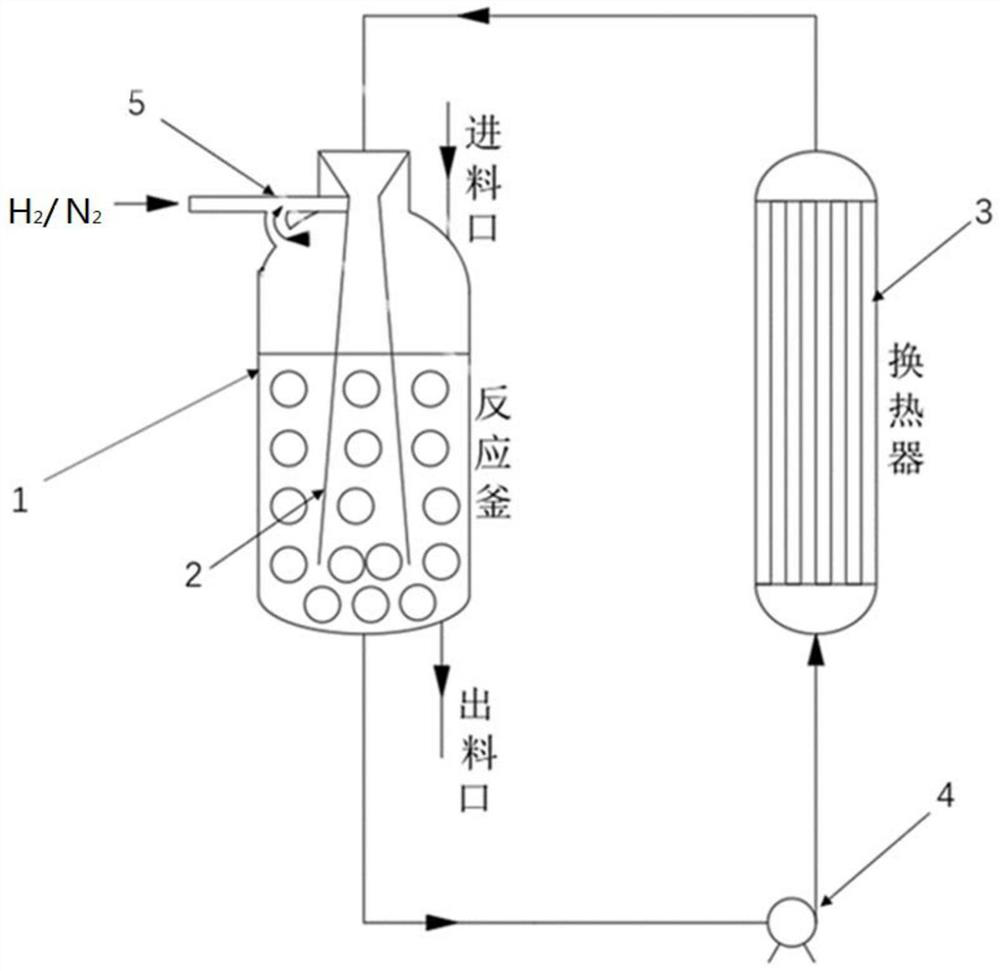

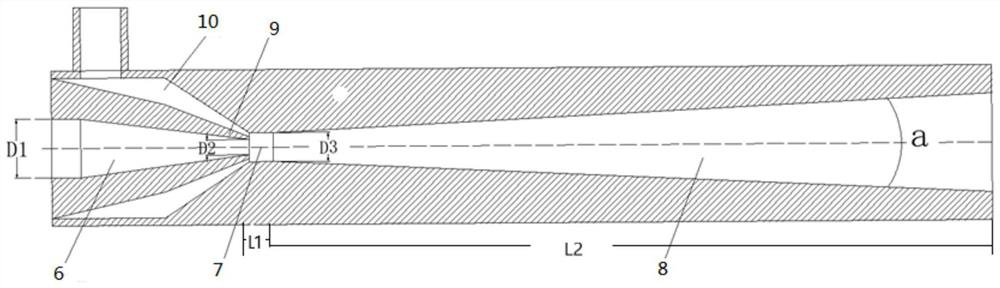

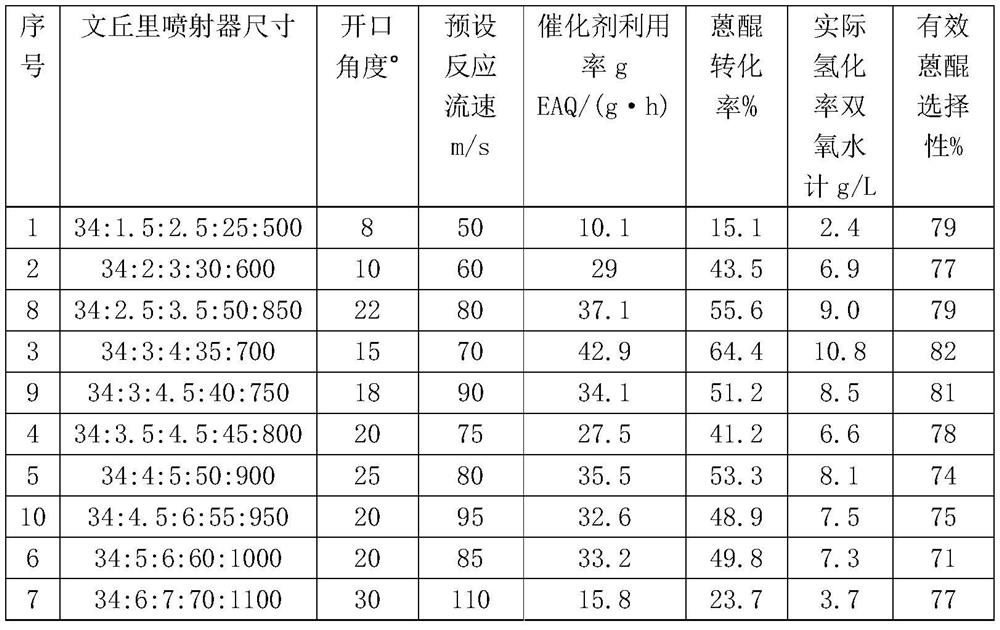

Reactor for preparing hydroanthraquinone and preparation method of hydroanthraquinone

PendingCN112915931AIncrease profitSuccessfully controlled hydrogenation depthOrganic compound preparationPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesAnthraquinonesPtru catalyst

The invention discloses a reactor for preparing hydroanthraquinone and a preparation method of hydroanthraquinone. The reactor comprises a reaction kettle, a circulating pump, a heat exchanger and a Venturi ejector, the Venturi ejector comprises an inlet section, a nozzle, a mixing section and a diffusion section which are communicated in sequence; the inlet section and the nozzle are in a reducing pipe type; the ratio of the inner diameter of an inlet section opening to the inner diameter of a nozzle to the inner diameter of an air chamber closing opening to the length of a mixing section to the length of a diffusion section of the Venturi ejector is 34: (2-5): (3-6): (30-60): (600-1000); and the opening angle of the diffusion section is 10-25 degrees. According to the present invention, the specification and the size of the reactor are optimized, such that the mass transfer process of the reaction is effectively enhanced, the catalyst liquid film thickness is reduced, the conversion from EAQ to EAQH2 can be achieved with low hydrogen partial pressure and low catalyst consumption, the hydrogenation depth is effectively controlled, and the selectivity and the utilization rate of the effective anthraquinone by the catalyst are significantly improved.

Owner:NANJING UNIV OF TECH +1

A system for coupling hydrogen purification and wax oil hydrogenation in coal-to-hydrogen

ActiveCN109054893BLess investmentReduce hydrogen partial pressureHydrogen separationCarbon compoundsWaxThermodynamics

Owner:DALIAN UNIV OF TECH

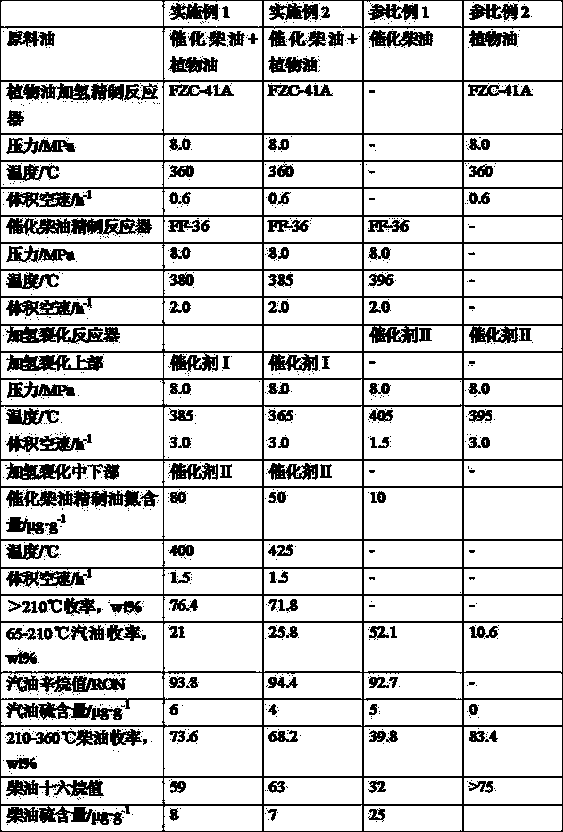

A kind of hydrocracking method for producing high-quality gasoline and diesel oil

ActiveCN106479566BScientific and effective useLowering the freezing pointTreatment with hydrotreatment processesHydrocarbon oils treatment productsVegetable oilGasoline

The invention discloses a hydrocracking method for producing high-quality gasoline and diesel. The method comprises the steps: subjecting animal and vegetable oils to hydropretreating, then, enabling the pretreated oil to enter a hydrocracking reactor, and carrying out a contact reaction with a hydrocracking catalyst I under the conditions of relatively low temperature and high volumetric space velocity; then, mixing the product with a hydrorefining product of inferior diesel, and then, carrying out a contact reaction with a hydrocracking catalyst II; and subjecting the reaction product to separation and fractionation, thereby obtaining the high-quality gasoline and diesel. According to the method, separate characteristics of animal-and-vegetable-oil hydrogenation modification and inferior diesel hydro-conversion processes are fully taken into account, and the two kinds of processes are effectively combined reasonably, so that high-octane gasoline products and diesel products can be produced simultaneously, and the lubricating property of the diesel products is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fuel cell system for preventing hydrogen permeable metal layer degradation

InactiveUS7666537B2Prevent degradationReduce hydrogen partial pressureFuel cell heat exchangeCell electrodesFuel cellsEngineering

A technology for preventing degradation of a hydrogen permeable metal layer in a fuel cell 210 is provided. A fuel cell system 200 including a fuel cell 210 with an anode which has the hydrogen permeable metal layer comprises a fuel cell controller 230 for controlling the operation status of the fuel cell system 200, a temperature parameter acquisition section for acquiring a temperature parameter of the hydrogen permeable metal layer, and a hydrogen permeable metal layer degradation prevention section which reduces the hydrogen partial pressure in an anode channel 212 for supplying fuel gas to the anode. If a temperature of the hydrogen permeable metal layer represented by the temperature parameter deviates from a specified temperature range, the fuel cell controller 230 cause the hydrogen permeable metal layer degradation prevention section to operate for preventing degradation of the hydrogen permeable metal layer.

Owner:TOYOTA JIDOSHA KK

Two-stage hydrocracking method

ActiveCN114437801AAchieve sulfur supplement effectAchieving active inhibitionTreatment with hydrotreatment processesNaphthaPtru catalyst

The invention discloses a two-stage hydrocracking method, which comprises the following steps: a first-stage hydrocracking reaction effluent enters a flash separator to separate out a liquid phase flow and a gas phase flow, the liquid phase flow enters a fractionation system to separate out heavy naphtha and tail oil, the gas phase flow is mixed with the tail oil, and then a second-stage hydrocracking reaction is performed, and carrying out gas-liquid separation on the effluent of the second-stage hydrocracking reaction, taking the separated gas phase as recycle hydrogen of the first-stage hydrocracking reaction, and separating the liquid phase into a gas phase product, light naphtha, heavy naphtha and tail oil in a fractionation system. The method can increase the selectivity of the high-quality heavy naphtha product while reducing the deactivation rate of the two-stage hydrocracking catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

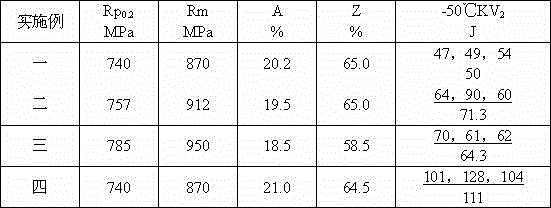

High-strength high-tenacity sintered flux for afterheat-free welding

InactiveCN103273222BRight melting pointModerate viscosityWelding/cutting media/materialsSoldering mediaSlagRare earth

The invention discloses a high-strength high-tenacity sintered flux for afterheat-free welding. The sintered flux is mixed sinter composed of dry powder and pure sodium water glass with the modulus of 2.8-3.2, and the addition amount of the water glass is 18-20% of the weight of the dry powder. The dry powder is composed of, by weight percent, 18-23% of fluorite, 33-37% of magnesia, 14-17% of bauxite, 3-5% of quartz, 7-12% of marble, 9-13% of wollastonite, 0-1.5% of ferromolybdenum, 1-3% of rare earth fluoride, 1-2% of silicon iron, 1-3% of manganese ore, and 0-3% of borax. Compared with the prior art, the sintered flux can form welding slag with an appropriate melting point and good viscosity and surface tension. In the welding process, arc combustion is stable, welding line transition is smooth, spreading is good, and appearance of welding lines is attractive. The oxygen content in the welding lines is lowered. The sintered flux can be matched with the WS80S welding wire for welding 10CrNi5MoV steel, yield strength of metal of the welding lines can reach more than 735MPa, the metal of the welding lines is -50 DEG C, impact energy can reach more than 50J, and the metal of the welding lines of afterheat-free welding can be crack-free.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

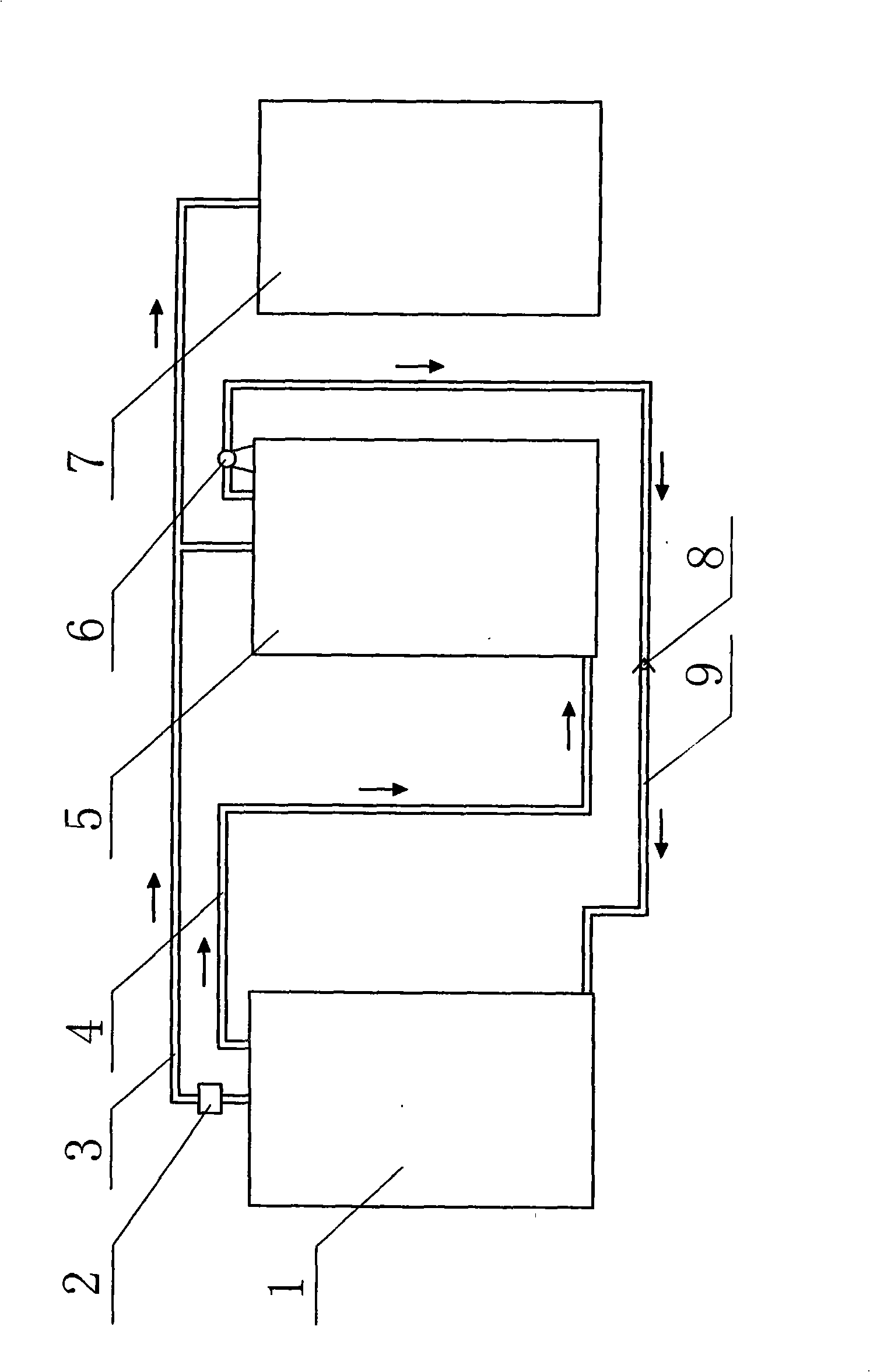

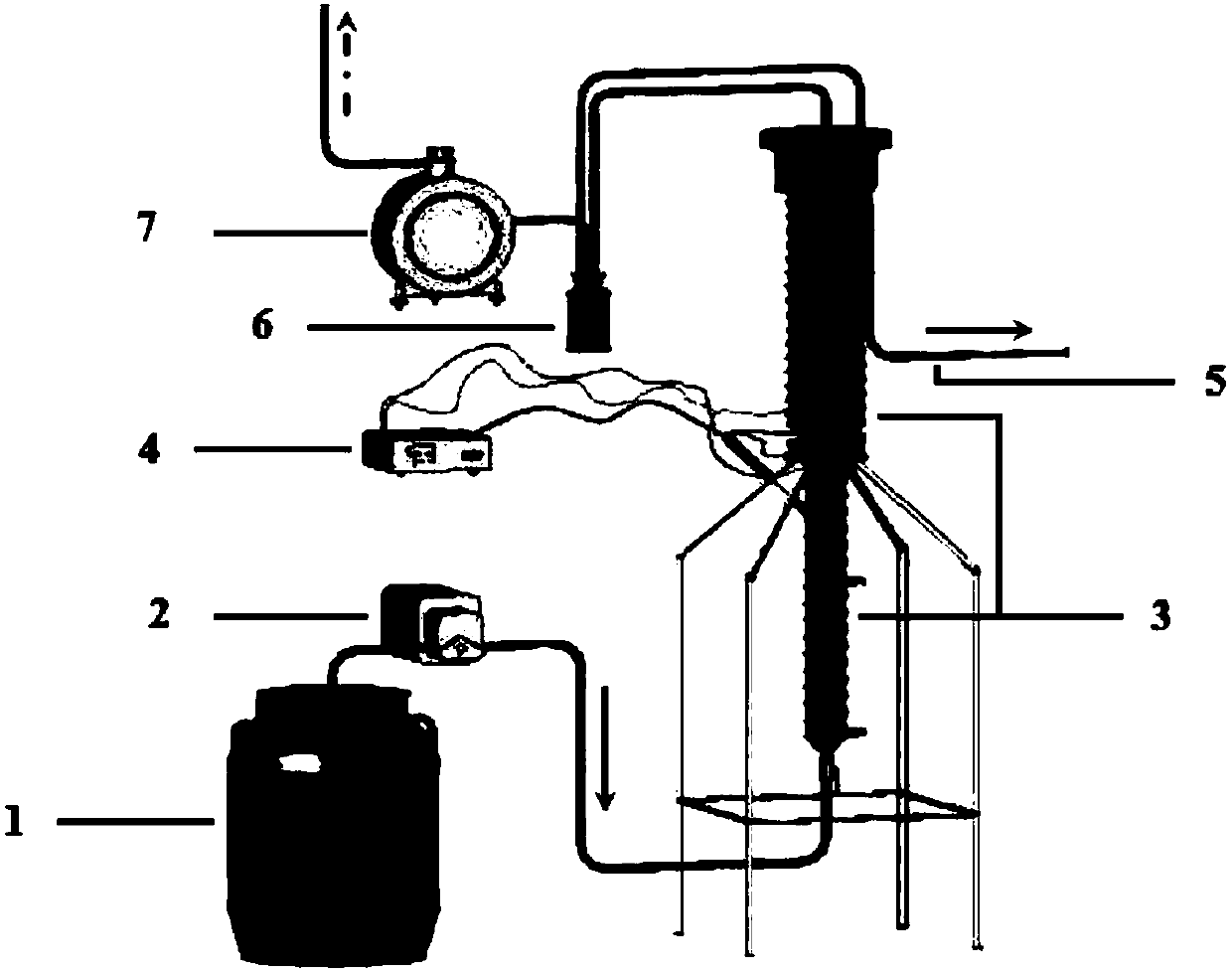

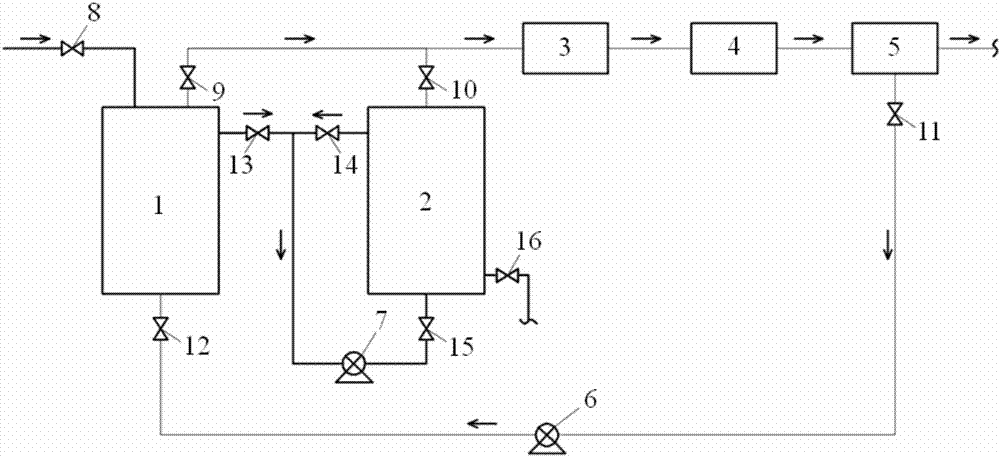

Two-phase anaerobic fermentation system applying gas-liquid combined stirring

PendingCN106906128ATake advantage ofReduce hydrogen partial pressureBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringCirculating pump

The invention discloses a two-phase anaerobic fermentation system applying gas-liquid combined stirring. A hydrolytic acidification tank 1, a gas production tank 2, a gas collection tank 3, a desulfurization drying device 4, a purifying device 5, an air pump 6, and a circulating pump 7 form two circulation of pneumatic stirring and hydraulic stirring. The two kinds of stirring modes including pneumatic stirring and hydraulic stirring are utilized to correspond to two stages of the two-phase anaerobic fermentation system respectively; meanwhile, in the pneumatic stirring circulation, CO2 which is refined and extracted from marsh gas is regarded as stirring power, thus the yield of methane is sharply increased, the organic waste is converted into energy substance methane, the greenhouse gas emission amount is reduced at the same time, and thus the two-phase anaerobic fermentation system which is simple in structure and convenient to operate is obtained.

Owner:SOUTHWEST JIAOTONG UNIV

Low-fluorine flux cored welding rod

InactiveCN104526187AWell formed weldReduce sootWelding/cutting media/materialsSoldering mediaSlagMetal alloy

The invention discloses a low-fluorine flux cored welding rod which comprises a metal casing and a filler composition. The filler composition contains, by weight, metallic oxide slag forming agent 15-70 parts, fluorinated compound 2-30 parts and metal alloy agent 5-65 parts, wherein the parts by weight of the metallic oxide slag forming agent is large than that of the fluorinated compound, the fluorine contained by the fluorinated compound is at least 15% of the weight of the filler composition, and the metal casing contains at least 70% by weight of iron. The low-fluorine flux cored welding rod is good in weld joint forming effect, little in smoke dust, small in splashing, small in welding pores and low in splashing rate.

Owner:SUZHOU LU LU SHUN ELECTRICAL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com