Sewage treatment method for simultaneously producing nitrogen and removing nitrogen by biological hydrogen production, coupling and denitrification

A sewage treatment method and biological hydrogen production technology, applied in the direction of biological water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve problems such as insufficient carbon source, reduce the operating cost of denitrification and denitrification process, etc. , to achieve the effect of reducing infrastructure costs, reducing consumption, and improving hydrogen production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

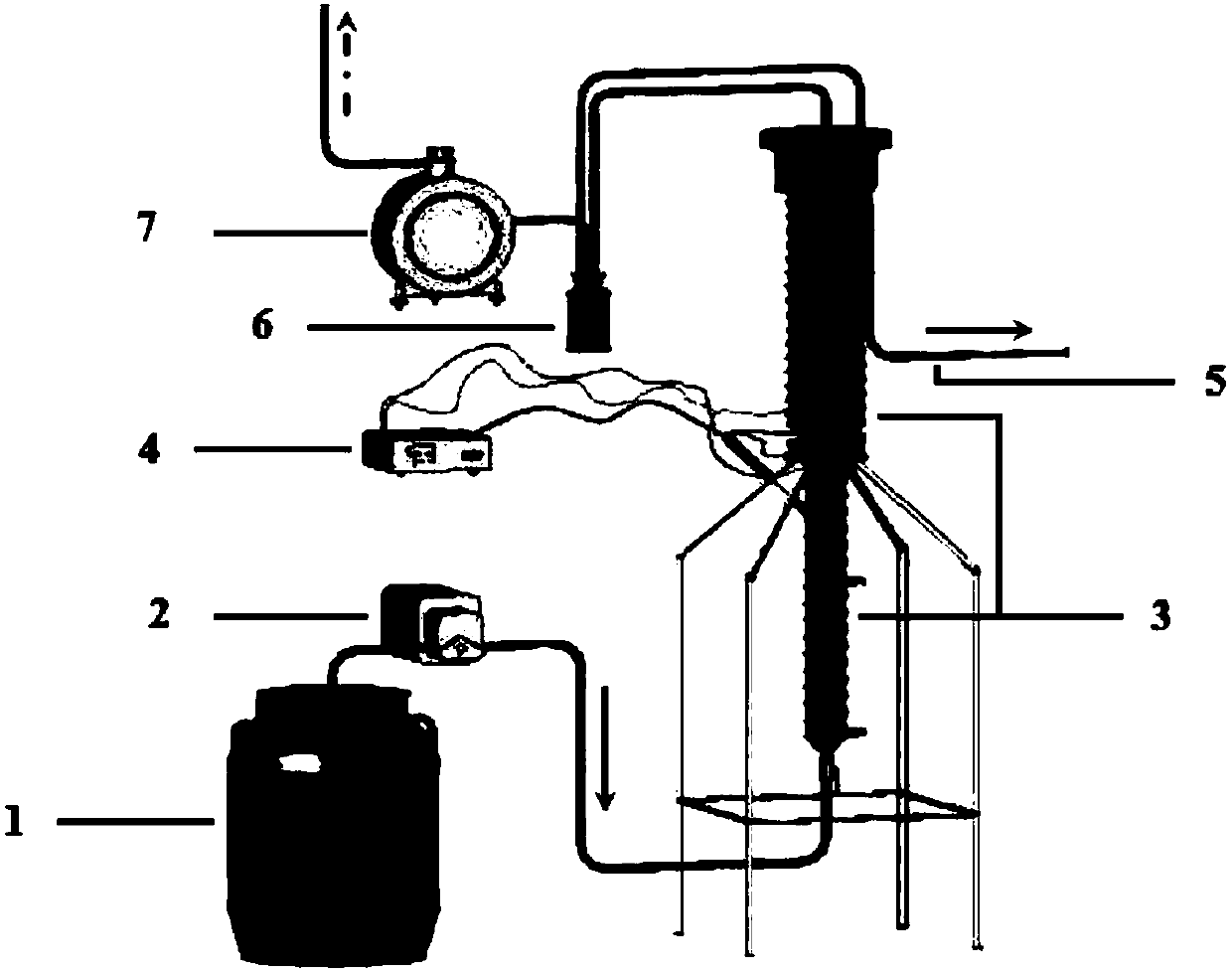

[0044] A sewage treatment method for simultaneous hydrogen production and denitrification by coupling denitrification with biological hydrogen production, the specific steps are as follows:

[0045] (1) Sludge inoculation: Take the sludge from the secondary sedimentation tank of a municipal sewage treatment plant, use a sieve with a pore size of 0.5 mm to remove the larger impurities, then aerate for 40 hours, and then take 4 L of it to inoculate in In the biochemical reaction zone in the AICHP reactor, the MLSS of the AICHP reactor as a whole is 18.51g / L, and the MLVSS is 11.40g / L;

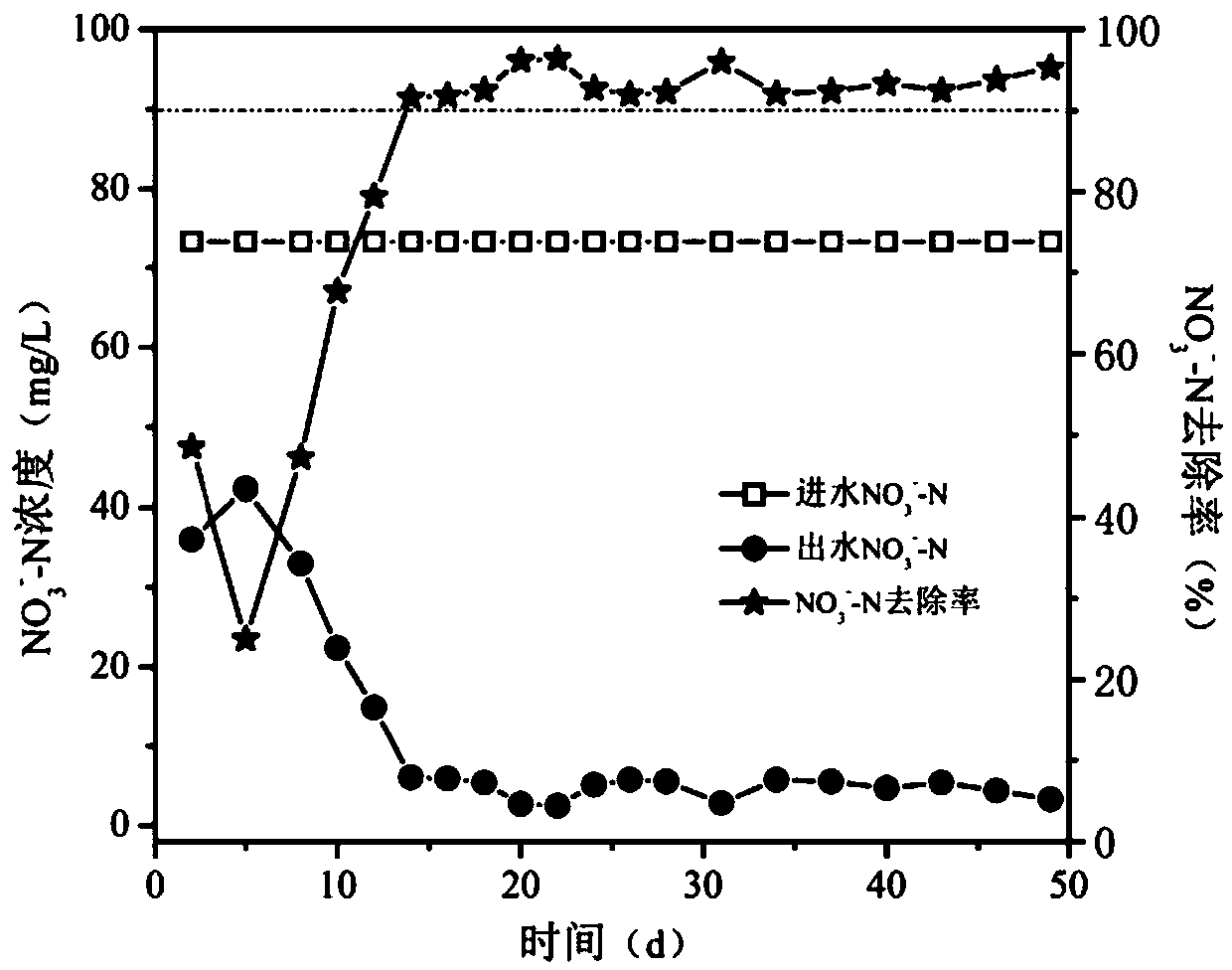

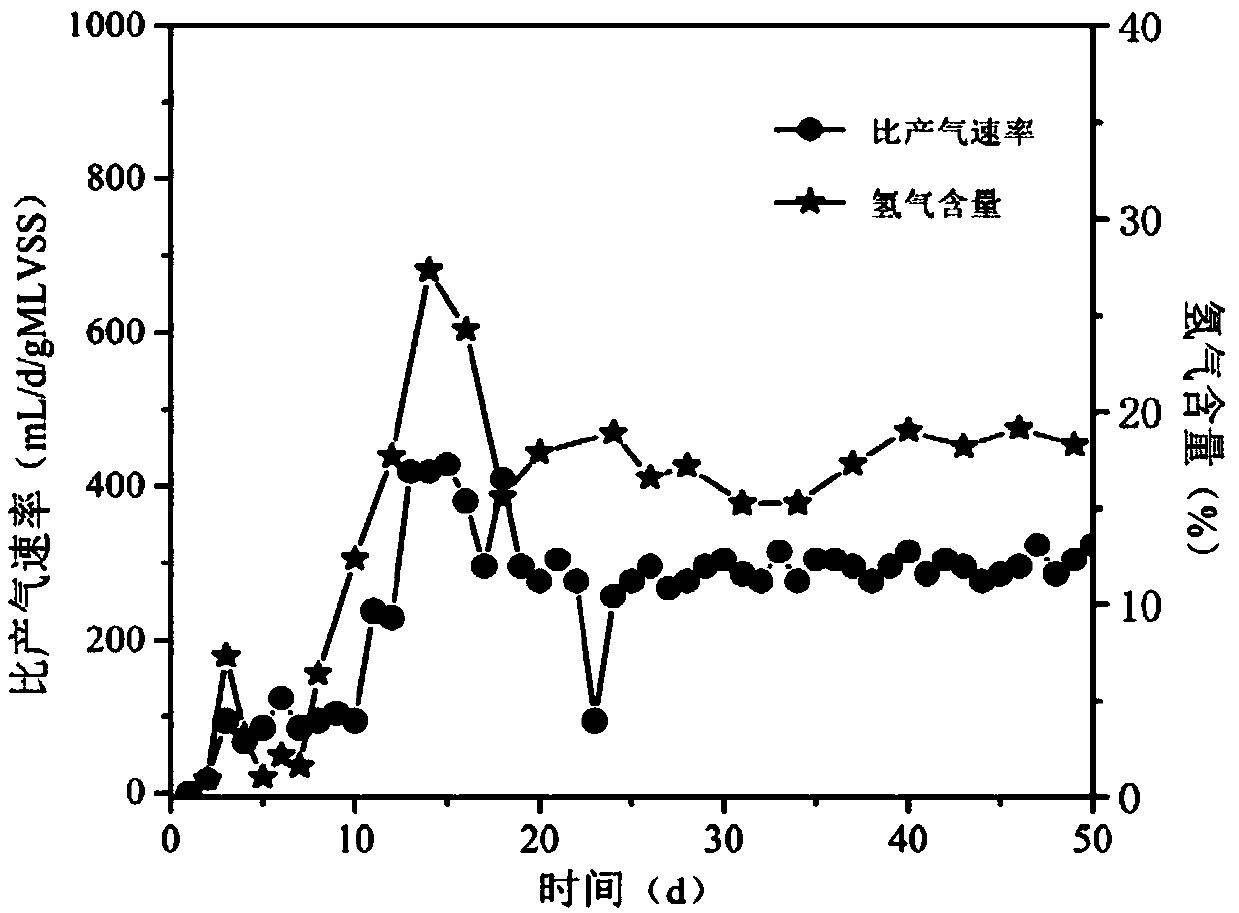

[0046] (2) Start-up of water intake: pump the organic sewage into the reactor with a peristaltic pump. The COD of the influent organic sewage is 8800mg / L, the pH of the influent is 7.8-8.0, and the NO 3 - -N concentration is 73.3mg / L, influent COD / NO 3 - -N value is 120; In addition, before organic sewage enters water, add trace element solution to organic sewage according to the ratio of V (o...

Embodiment 2

[0050] A sewage treatment method for simultaneous hydrogen production and denitrification by coupling denitrification with biological hydrogen production, the specific steps are as follows:

[0051] (1) Sludge inoculation: take river bottom sludge, use a screen with a pore size of 1mm to remove larger impurities, then aerate for 48 hours, and then take 4L of it and inoculate it in the biochemical reaction area of the AICHP reactor In the interior, the MLSS of the AICHP reactor as a whole is 15.20g / L, and the MLVSS is 13.45g / L;

[0052] (2) Start-up of water intake: Use a peristaltic pump to pump the organic sewage into the reactor. The COD of the organic sewage is 4000mg / L, the pH of the influent is 7.8-8.0, and the NO of the influent is 3 - -N concentration is 50mg / L, influent COD / NO 3 - -N value is 80; In addition, before the organic sewage enters water, add the trace element solution to the organic sewage according to the ratio of V (organic sewage): V (trace element s...

Embodiment 3

[0055] A sewage treatment method for simultaneous hydrogen production and denitrification by coupling denitrification with biological hydrogen production, the specific steps are as follows:

[0056] (1) Sludge inoculation: Take the sludge from the secondary settling tank and the anaerobic hydrogen-producing sludge of a municipal sewage treatment plant, and use a sieve with a pore size of 0.5 mm to remove the larger impurities, and mix them at a ratio of 1:1 The mass ratio is uniformly mixed, and then aerated for 45 hours, and then 4L of it is inoculated in the AICHP reactor, so that the overall MLSS of the AICHP reactor is 20g / L, and the MLVSS is 12.45g / L;

[0057] (2) Start-up of water intake: pump the organic sewage into the reactor with a peristaltic pump. The COD of the influent organic sewage is 8800mg / L, the pH of the influent is 7.8-8.0, and the NO 3 - -N concentration is 44mg / L, influent COD / NO 3 - -N value is 200; In addition, before the organic sewage enters water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com