Weak corrosivity removing method for aluminum and copper compound mandrel for preparing uranium-bearing hohlraum

An aluminum-copper composite and corrosive technology, which is applied in the cleaning methods using liquids, the preparation of test samples, chemical instruments and methods, etc. The effect of inhibiting the corrosion effect of micro-battery, shortening the removal time, reducing the probability of hydrogen embrittlement failure and cavity damage failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Specific Embodiment 1: This embodiment is a weakly corrosive removal method for an aluminum-copper composite mandrel prepared by a uranium-containing black cavity, which is specifically completed by the following steps:

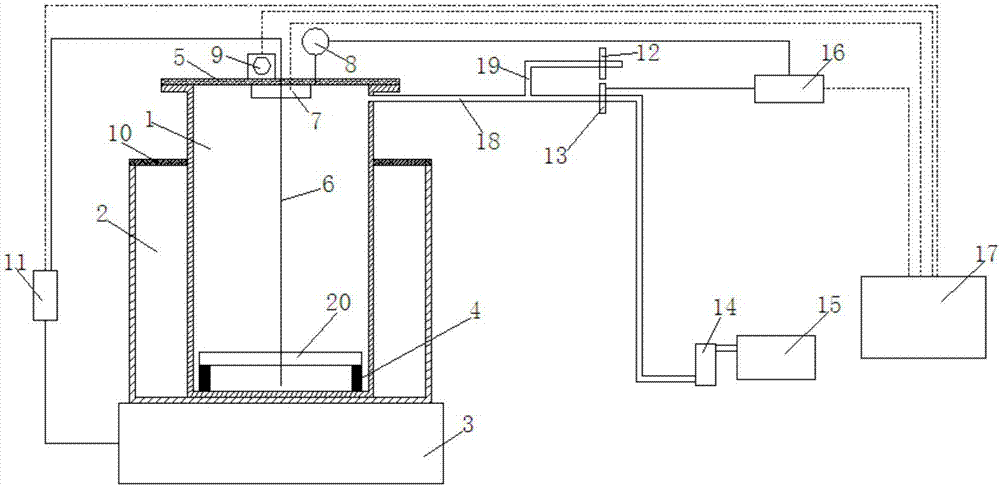

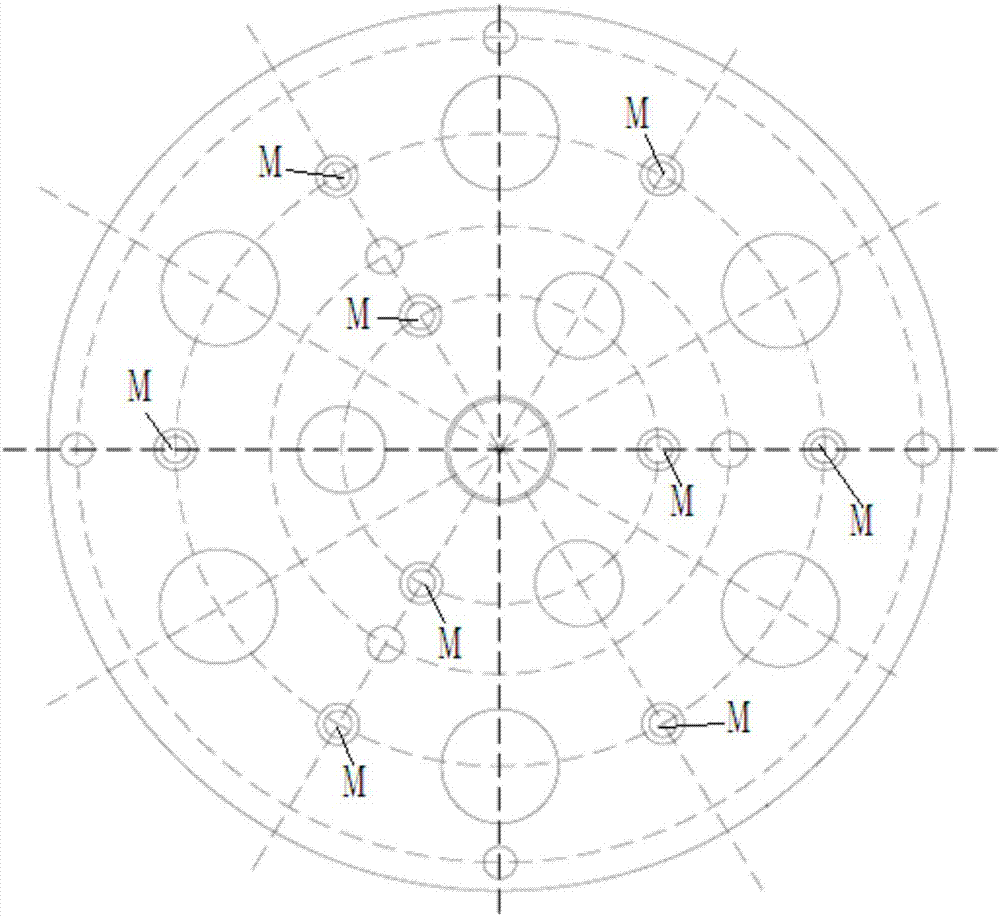

[0021] 1. Put the uranium-containing black chamber sample into the sample hole of the sample holder, and fasten the sample holder plate to obtain a sample holder carrying the uranium-containing black chamber sample; the uranium-containing black chamber sample is an aluminum-copper composite mandrel uranium-containing black cavity; 2. Add alkaline solution into the negative pressure demoulding reactor, and when the temperature is constant at 15-60°C, put the sample holder containing the uranium-containing black cavity sample into the negative pressure demoulding reactor, React at a stirring speed of 50-500r / min, a temperature of 15-60°C and an air pressure of 4.0kPa-7.0kPa until no bubbles are generated, and then continue at a stirring speed of 50-500r / m...

specific Embodiment approach 2

[0029] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the uranium-containing black cavity sample described in step 1 is sequentially composed of aluminum mold core, copper coating, gold protective layer, and uranium conversion layer from inside to outside. and gold support layer. Others are the same as the first embodiment.

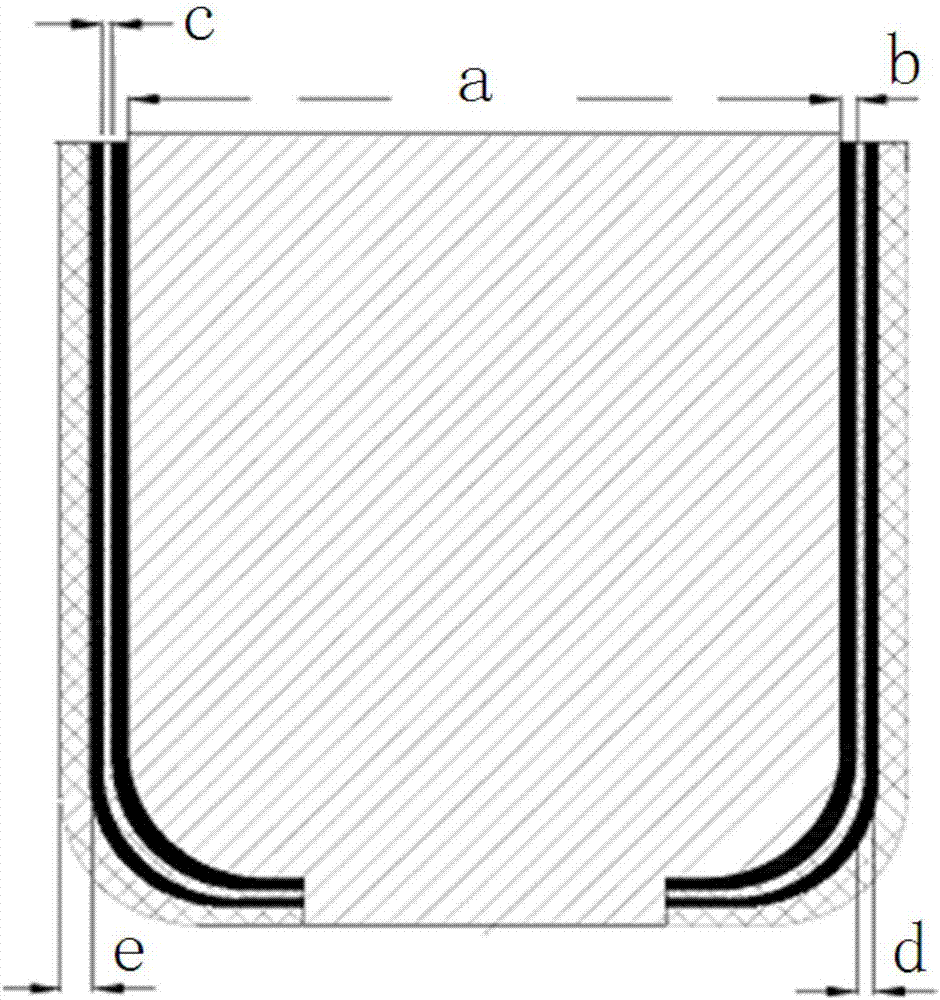

[0030] figure 1 It is a schematic diagram of the sample structure of the uranium-containing black chamber described in Embodiment 2. In the figure, a represents the aluminum mold core, b represents the copper coating, c represents the gold protection layer, d represents the uranium conversion layer, and e represents the gold support layer.

specific Embodiment approach 3

[0031] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the aluminum mold core of the uranium-containing black cavity sample carried in the sample rack containing the uranium-containing black cavity sample described in step 2 The volume ratio of mass to alkaline solution (0.6~16) mg:1mL. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com