Patents

Literature

112results about How to "Short removal time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

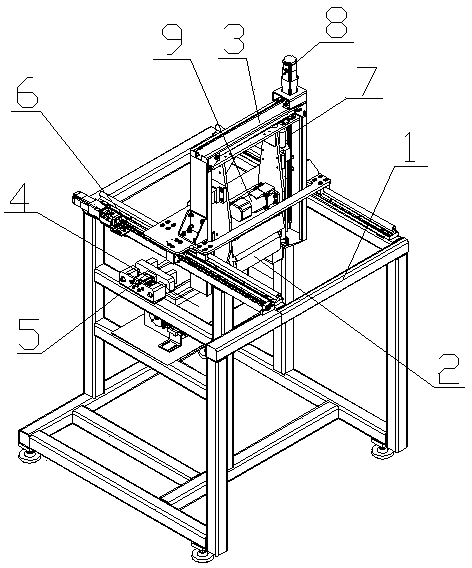

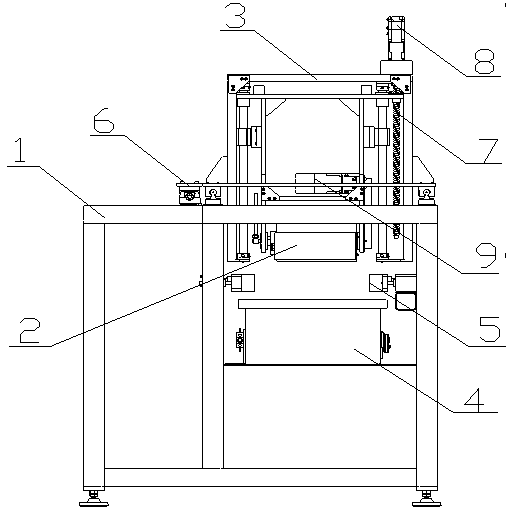

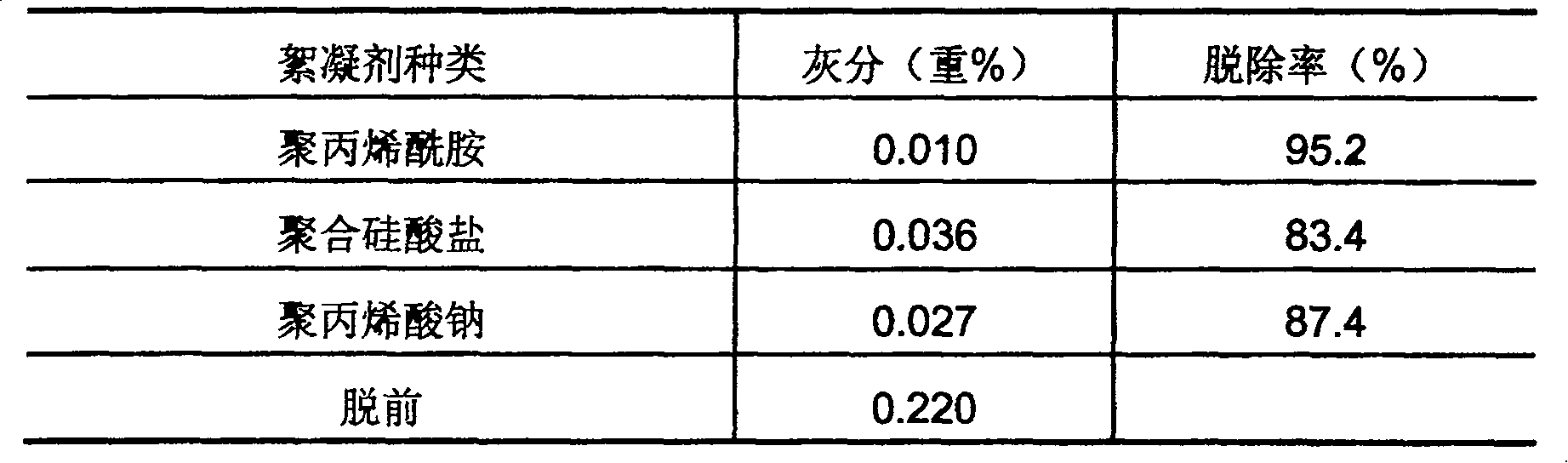

Device for removing low-melting-point alloy from inner cavity of blade

ActiveCN106761953AShort removal timeImprove work efficiencyStatorsMachines/enginesAlloyLow melting point

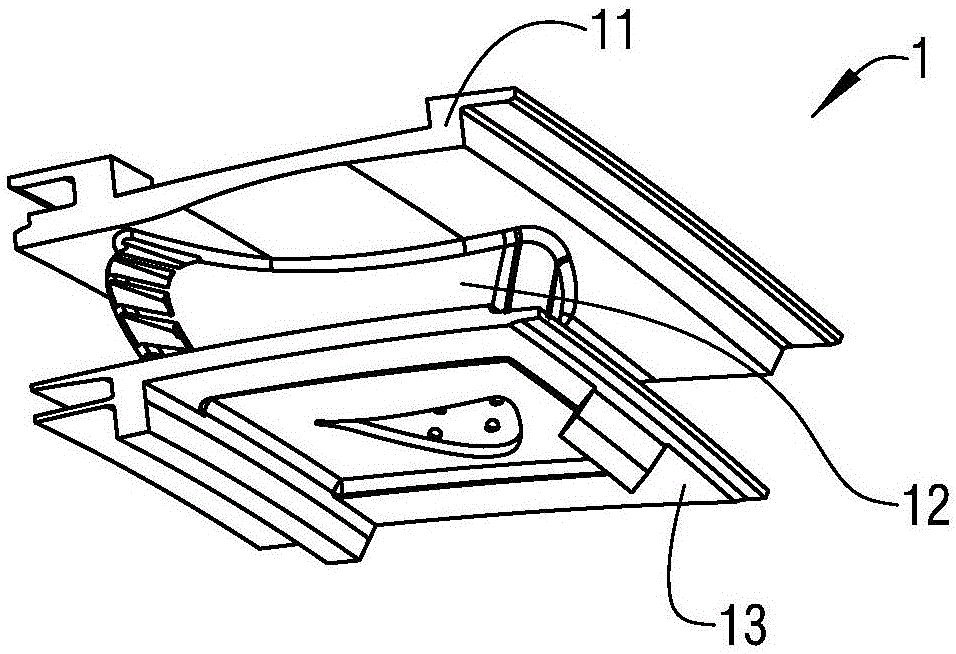

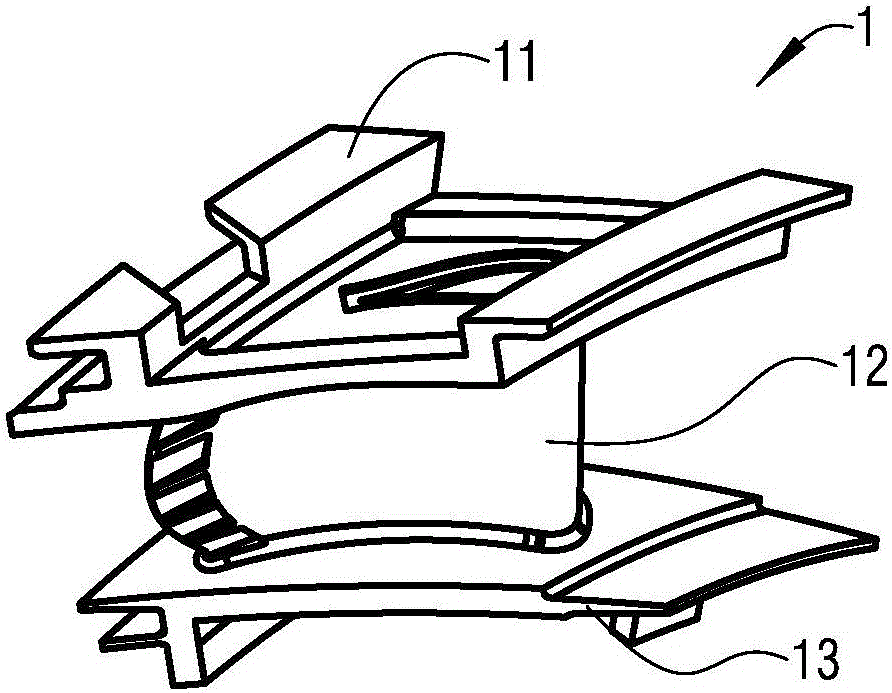

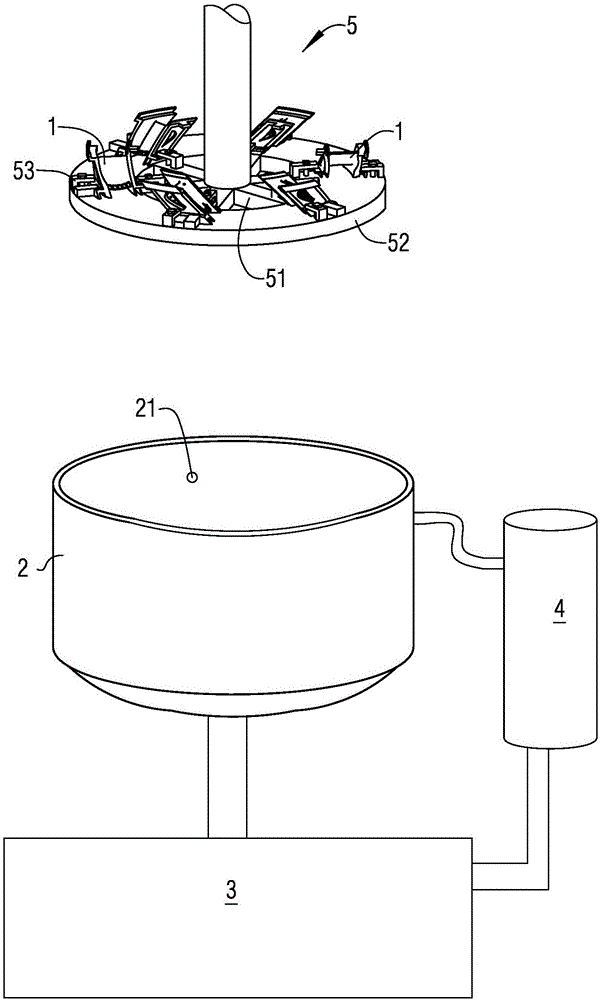

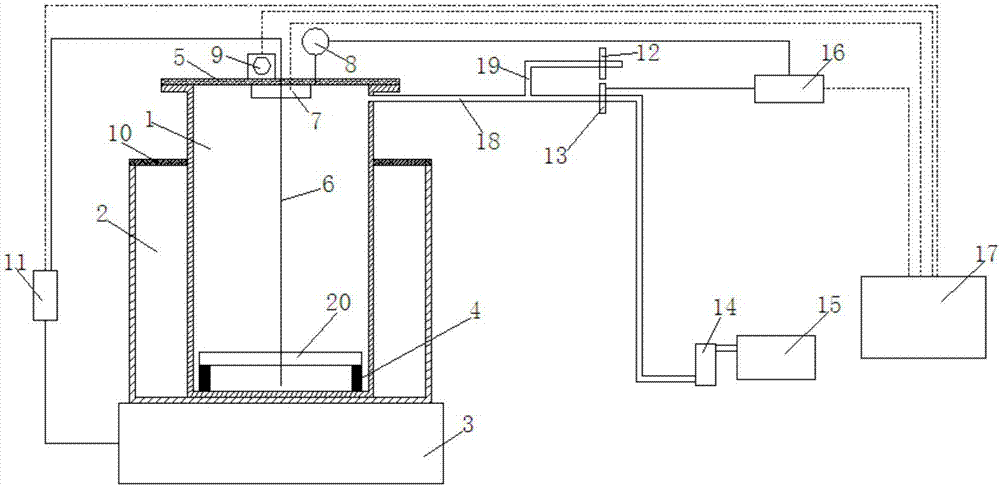

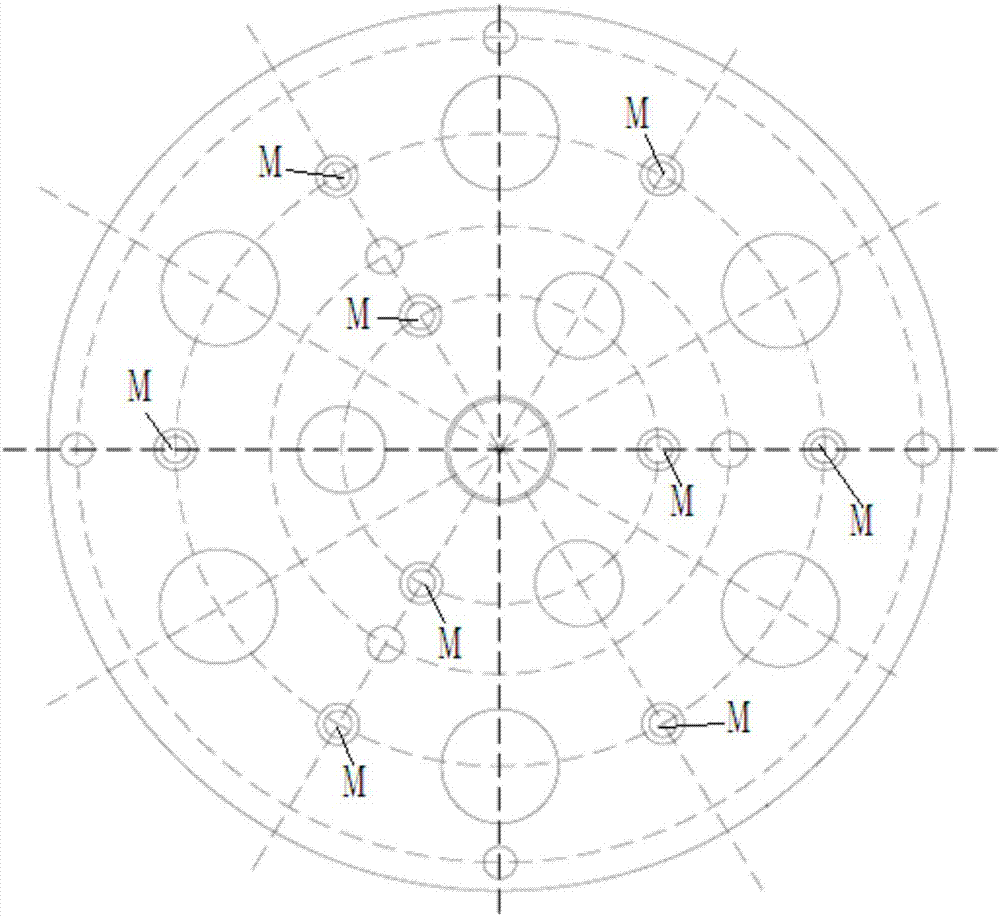

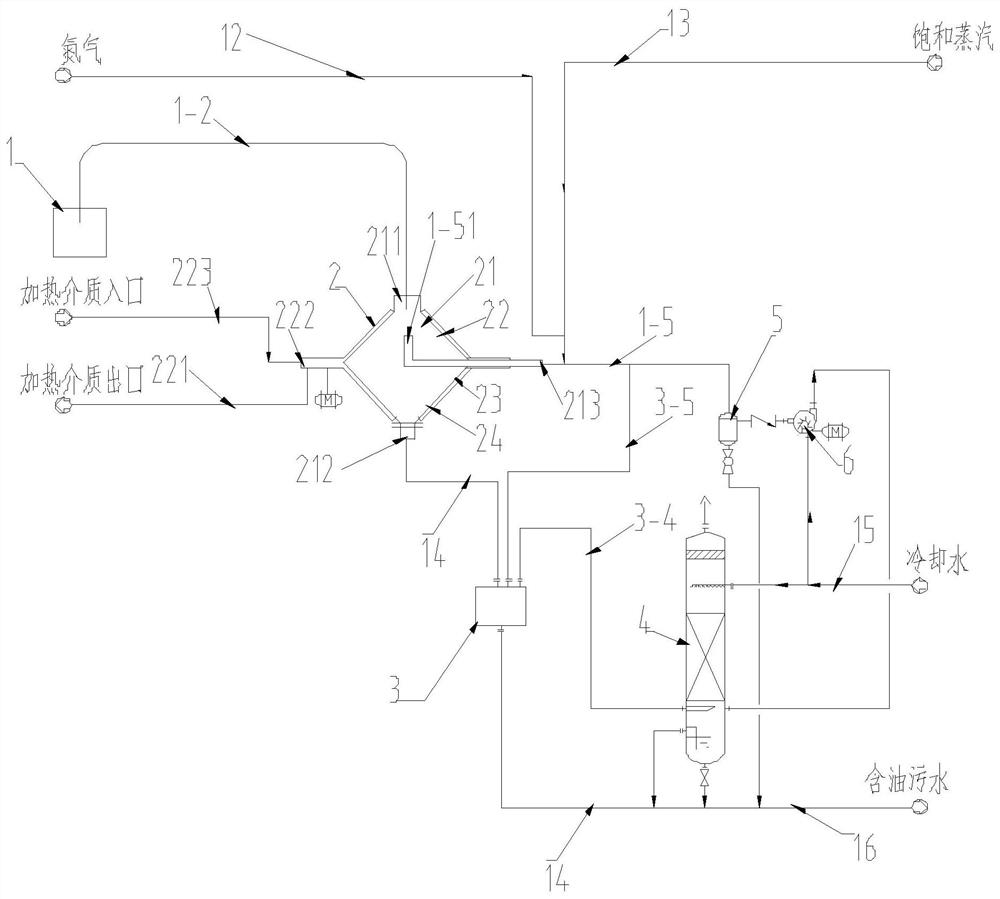

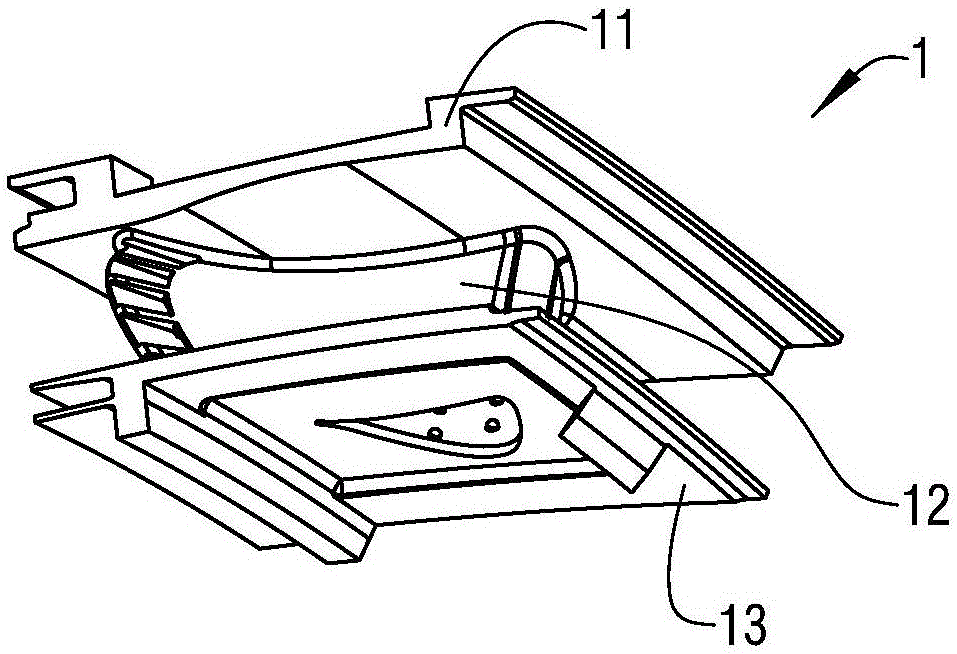

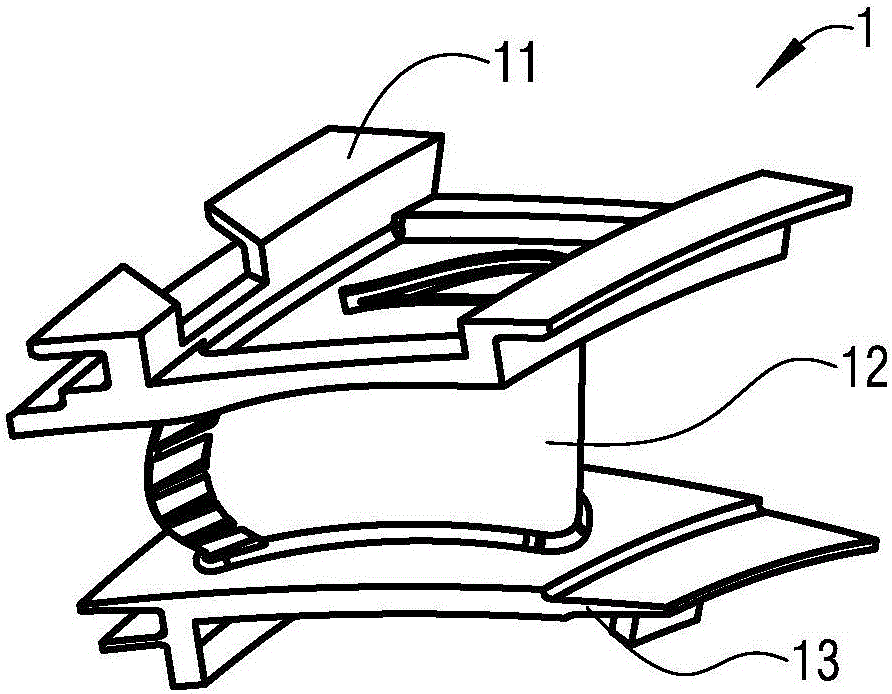

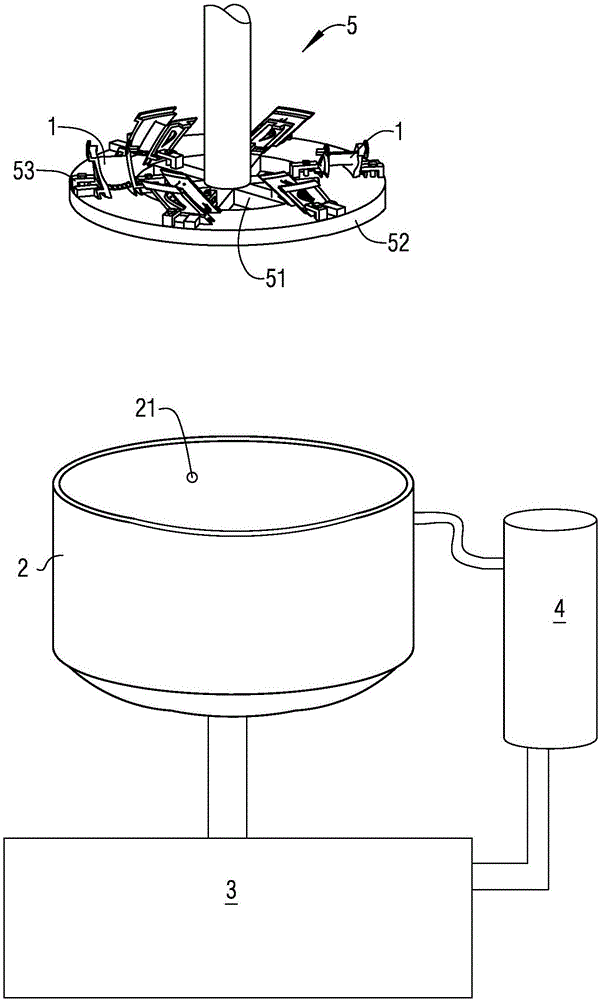

The invention discloses a device for removing low-melting-point alloy from the inner cavity of a blade. The device comprises an oil tank; the bottom of the oil tank is connected with a cooling tank through a pipeline with a valve; the cooling tank is connected with a heater with an oil pump through a pipeline; a spraying opening is formed in the side wall of the oil tank; a mounting disc which can lift and rotate is arranged above the oil tank; the mounting disc comprises a mounting ring which is connected through supporting ribs; the mounting ring is provided with a plurality of groups of mounting frames which are used for clamping blades; after the blades are clamped by the mounting frames, the overall height of the mounting ring and the blades thereon is 1 / 10 of the height of the oil tank. According to the device for removing the low-melting-point alloy from the inner cavity of the blade provided by the invention, on one hand, the low-melting-point alloy removal time is effectively shortened, and on the other hand, no residue on the inner cavity of the blade which is subjected to a removal operation is also effectively guaranteed; in addition, a low-melting-point alloy removing operation can be performed continuously in batches; the work efficiency is greatly improved.

Owner:CHINA HANGFA SOUTH IND CO LTD

Water-soluble salt core type metal powder injection molding technology

The invention provides a water-soluble salt core type metal powder injection molding technology and relates to the technical field of metal powder injection molding. The technology comprises the steps of mixing, water-soluble salt core preparing, mold core inlaying and mold clamping, injection molding, core-removing drying, degreasing and sintering. According to the technology, a fused and poured water-soluble salt core forms a part cavity and can be dissolved and removed through clean tap water at indoor temperature, the removal time is short, the safety is high, the environmental friendliness is high, and the potential problems of production insecurity, environmental pollution and strength reduction of green bodies caused by polymer core removal can be effectively solved. Part products manufactured through the technology are uniform in internal structure, high in compactness, high in surface smoothness, high in dimensional precision and stable in quality, a great deal of time and cost are saved for volume production of small and precision parts provided with closed or complicated cavity structures and made of various metal materials, the economic benefit is good, and the application prospect is good.

Owner:QILU UNIV OF TECH

Metallic powder injection molding adhesive

The invention relates to a binder which comprises the following components according to weight percentage: 15 percent to 25 percent of chlorinated polyethylene, 15 percent to 25 percent of polyformaldehyde, 3 percent to 10 percent of rubber, 20 percent to 30 percent of petroleum wax, 15 percent to 25 percent of Brazil wax (palm wax), 1 percent to 5 percent of stearic acid and 1 percent to 5 percent of epoxidized soybean oil. In the forming technique of metal powder, the binder can improve the strength of blank, reduce the damage of the blank and improve the finished yield and the production efficiency.

Owner:PINGHU HAITE ALLOY

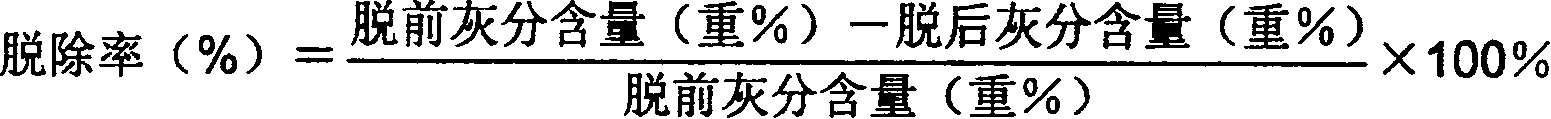

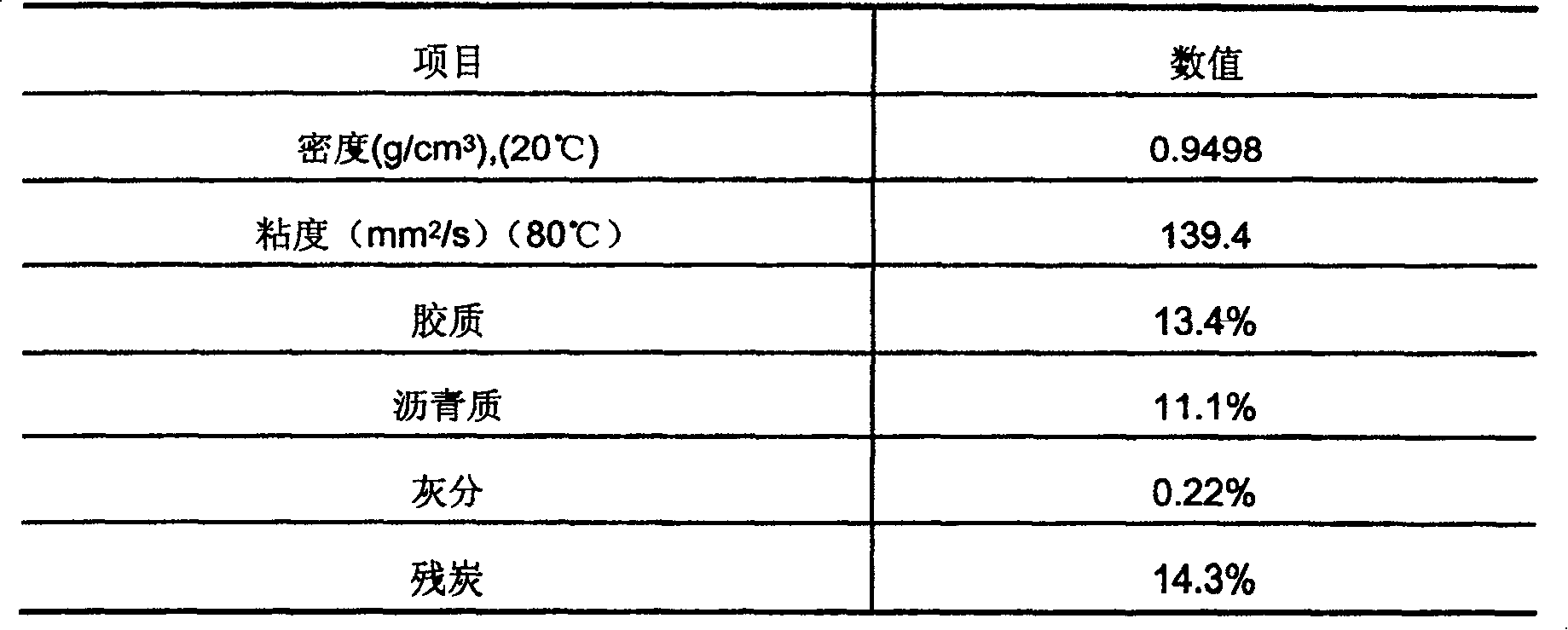

Method for removing powder of catalyst in catalytic cracking oil slurry

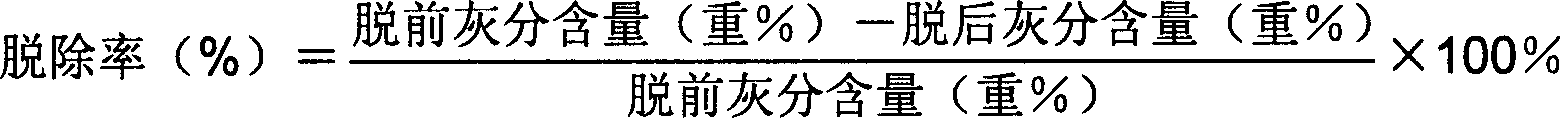

ActiveCN1958735AShort removal timeHigh removal rateDewatering/demulsification with electric/magnetic meansRefining by water treatmentDemulsifierSucrose

This invention provides two methods for removing catalyst powder from catalytic cracking oil slurry. The first method is suitable for light oil slurry whose specific gravity is lower than water, and comprises: mixing water containing demulsifier and flocculant with catalytic cracking oil slurry, demulsifying and removing the lower layer of water enriched in catalyst powder. The second method is suitable for heavy oil slurry whose specific gravity is higher than water, and comprises: adding weak electrolyte or non-electrolyte that can be dissolved in water and has higher specific gravity into water, such as ammonium acetate, ammonium citrate, fructose, glucose, sucrose, sorbitol or xylitol. The two methods have such advantages as short removing time and high rate.

Owner:CHINA PETROLEUM & CHEM CORP

Liquid detergent

InactiveCN101100629AShort removal timeConserve waterInorganic/elemental detergent compounding agentsCationic surface-active compoundsFruit juiceFatty acid

A liquid detergent consists of aliphatic alcohol polyethenoxy ether sodium sulfate 5-15 proportion, lauryl sodium benzenesulfonate 2-10 proportion, fatty acid diethanolamine 1-8 proportion, hydrogen peroxide 2-6 proportion, ammonia water 0.5-5 proportion and water 40-92 proportion. It spends 30 s-6 mins in eliminating various mechanical and edible stains, blood stain, ball-pen ink, beverage stain and tea stain. It shortens washing time to 4-8 mins and costs 0.5-0.8 yuan / kg and is economical.

Owner:周正新

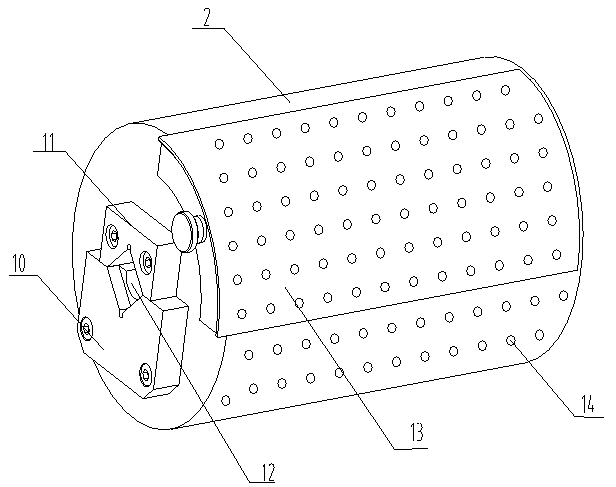

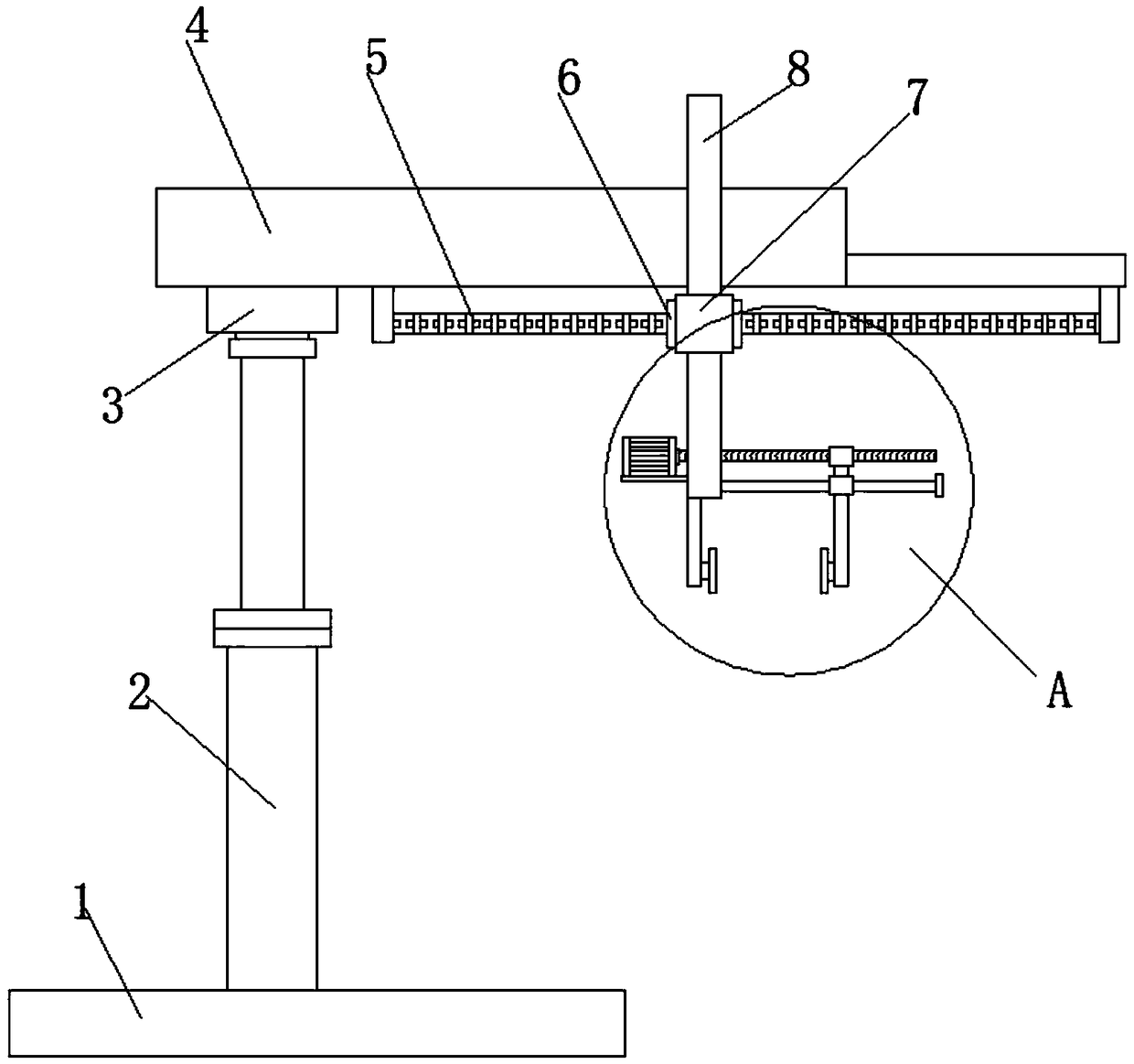

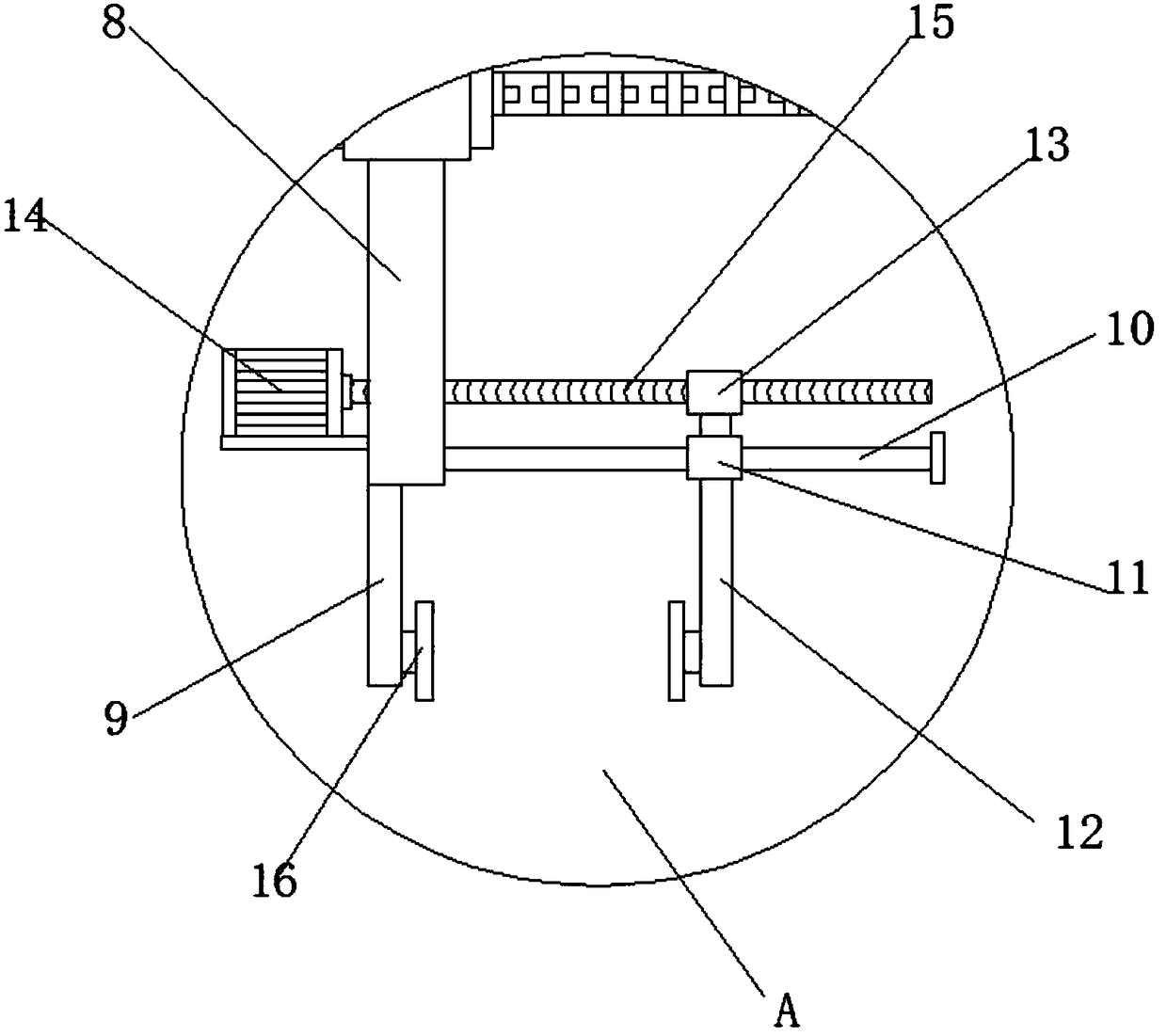

Equipment for automatically dipping fastening piece and technological process

ActiveCN103418521AShort removal timeUneven defect resolutionLiquid surface applicatorsCoatingsBall screwEngineering

The invention discloses equipment for automatically dipping a fastening piece and a technological process. The equipment for automatically dipping the fastening piece comprises a machine frame, an electrical motor, a dipping movement vehicle disposed on the machine frame, a ball screw disposed in a horizontal direction, a clamping mechanism and a dipping tank; a trapezoidal screw is vertically disposed on the dipping movement vehicle, and the dipping movement vehicle is connected with the ball screw; the dipping movement vehicle is provided with a roller, and the roller is driven to rotate by the electrical motor; the dipping movement vehicle is also provided with a servo motor which drives the ball screw and the trapezoidal screw so that the dipping movement vehicle is driven to move, and the dipping movement vehicle drives the roller to move in a horizontal direction and a vertical direction; the end face of the roller is provided with a disassembling block, a transmission block and a hot wind pipeline port; the roller is provided with a roller door and a plurality of through holes; the clamping mechanism can be horizontally disposed below the roller along the length direction of the roller; and the dipping tank is horizontally disposed on the lower part of the clamping mechanism along the length direction of the roller. The technological process comprises dipping, dipping-liquid removing and workpiece drying.

Owner:CHONGQING LANGZHENG TECH

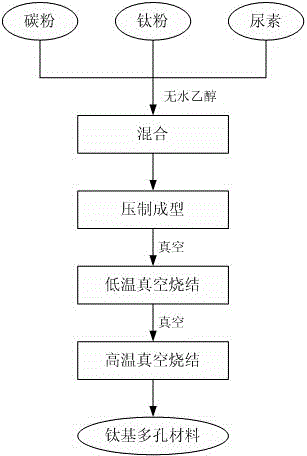

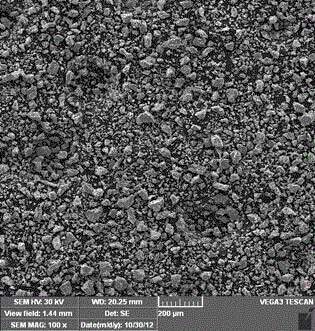

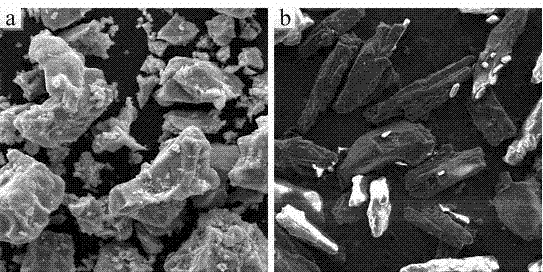

Preparing method of in-situ synthesis titanium carbide enhanced titanium-based multi-hole materials

The invention discloses a preparing method of in-situ synthesis titanium carbide enhanced titanium-based multi-hole materials. A powder metallurgy pore forming substance technology is used, and urea, carbon powder and titanium powder are used for being subjected to mixing, pressing forming and sintering to prepare the titanium-based multi-hole composite materials. The urea is used as a pore forming substance. Absolute ethyl alcohol is used as binding agents. Components of the titanium-based multi-hole materials are easy to control. Meanwhile, the advantage that raw material cost is low is achieved. A two-stage type sintering process is used for reducing energy consumption, equipment cost is lowered, and benefit is improved. In addition, the titanium-based multi-hole composite materials prepared with the preparing method of the in-situ synthesis titanium carbide enhanced titanium-based multi-hole materials are high in intensity, good in comprehensive mechanical property and high in anti-corrosion performance, the durability of the titanium-based multi-hole composite materials is improved, a new technology path is provided for sewage purification, biology implant materials and the like, and great application prospect is achieved.

Owner:CHONGQING UNIV

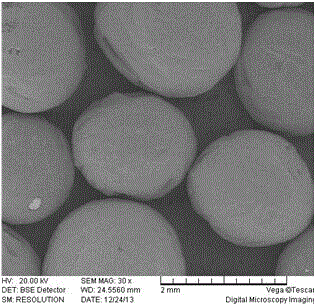

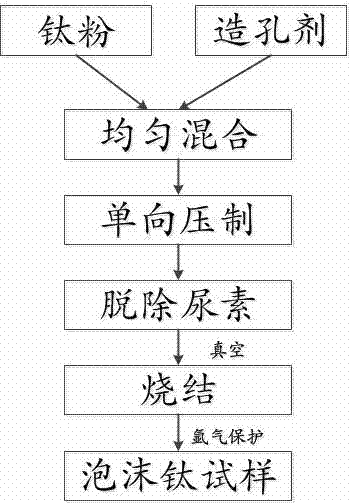

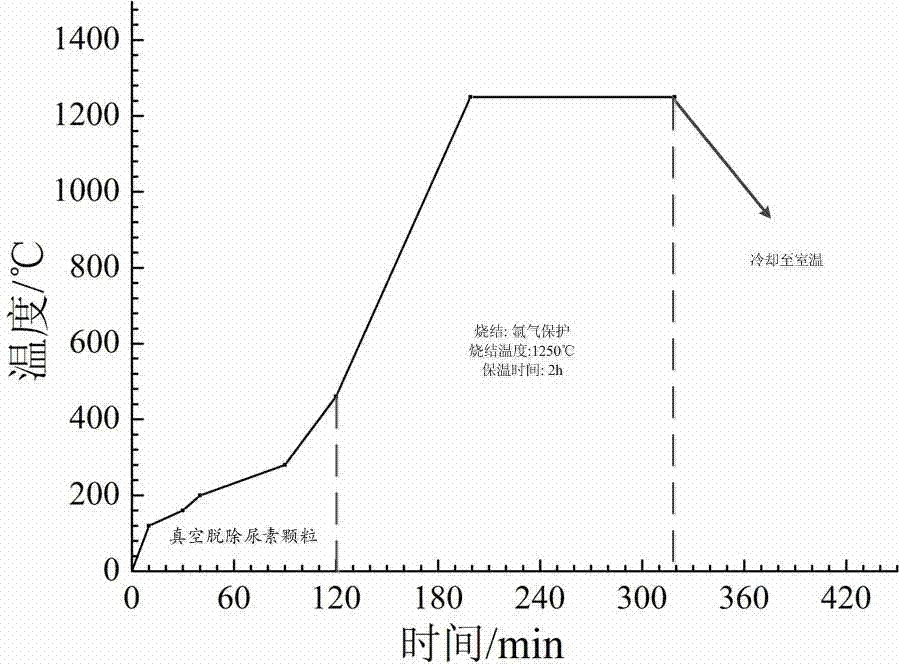

Preparation method of titanium foams for cancellous bone

The invention relates to a preparation method of titanium foams for cancellous bone. The preparation method comprises the following steps of: (1) mixing raw materials, namely selecting a primary mixture which is obtained by uniformly mixing titanium powder and a pore forming agent in a grinding body, wherein the mass part ratio of the titanium powder to the pore forming agent is (42.8-48.2):(52.8-58.2); (2) carrying out one-direction pressing on the primary mixture by adopting a universal material testing machine to prepare a green pressing body, wherein the one-direction pressure is 200-250MPa, and the pressure holding time is 1 minute; and (3) putting the green pressing body into a vacuum carbon tube furnace, sintering the green pressing body for 2 hours at 1200-1300 DEG C in an argon protective atmosphere to ensure that the pore forming agent is removed, and finally cooling along with the furnace to obtain the titanium foams. According to the titanium foams prepared by using the preparation method, the Young modulus is matched with that of the cancellous bone of the human body, therefore the stress shielding phenomenon is effectively avoided, and an implant can be permanently fixed; and meanwhile, the titanium foams can be prevented from being oxidized as far as possible by adopting the argon protective atmosphere.

Owner:CHONGQING UNIV

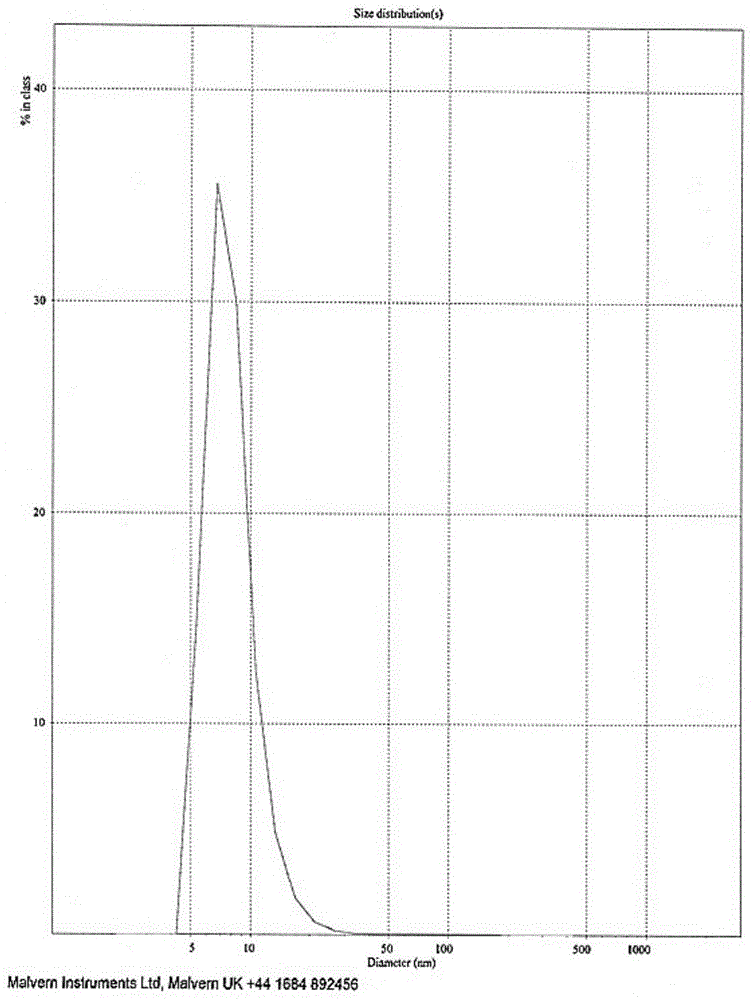

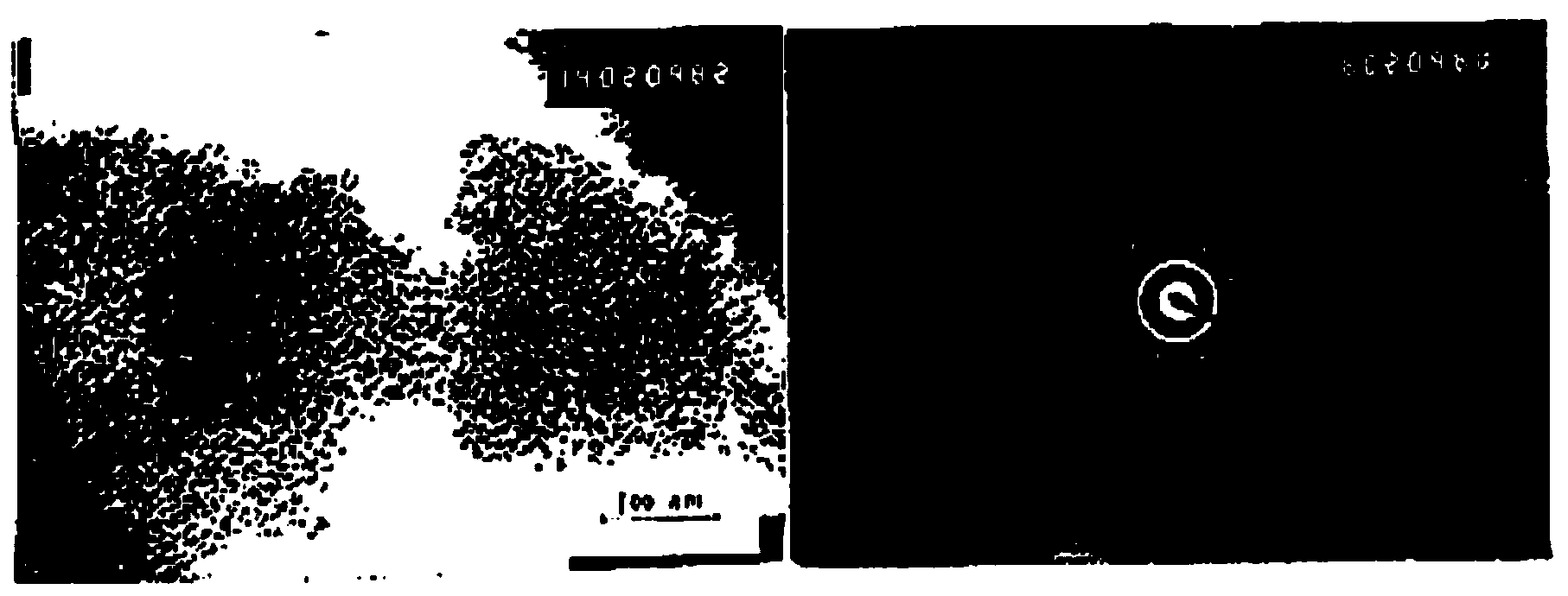

Preparation method for high-efficient photocatalyst-nanometer titanium dioxide water-based colloid

ActiveCN104098133AHigh crystallinityHigh removal ratePhysical/chemical process catalystsTitanium dioxideWater basedWater baths

The invention discloses a preparation method for a high-efficient photocatalyst-nanometer titanium dioxide water-based colloid. The preparation method comprises the following steps: adopting metal titanium as titanium source; adopting hydrogen peroxide to oxidize nulvalent metal Ti into quadrivalent TiO<2+>; further conducting complexing on the TiO<2+> and the hydrogen peroxide to obtain water-soluble TiO[H2O2]<2+> yellow complex; obtaining yellow complex colloid after evaporating and removing excess hydrogen peroxide and ammonia; conducting hydrothermal reaction by high pressure water of 150-200 DEG C; transporting the TiO[H2O2]<2+> yellow complex into pure white Ti(OH)4 water-based emulsion; adding mineral acid to adjust the pH value of the emulsion to the range of 2-4; conducting temperature control to enable the temperature of water bath to be 60-80 DEG C; continually stirring for 3-6 hours to enable the Ti(OH)4 water-based emulsion to gradually gel into nanometer titanium dioxide water-based colloid. The preparation method uses no organic solvent; no waste water or waste gas generates in the reaction process; particle diameters of colloid granular are less than 10 nanometers; degree of crystallinity is high; high photocatalytic activity is provided; coating property and film forming property on porous base material are extremely good.

Owner:江苏恒智纳米科技有限公司

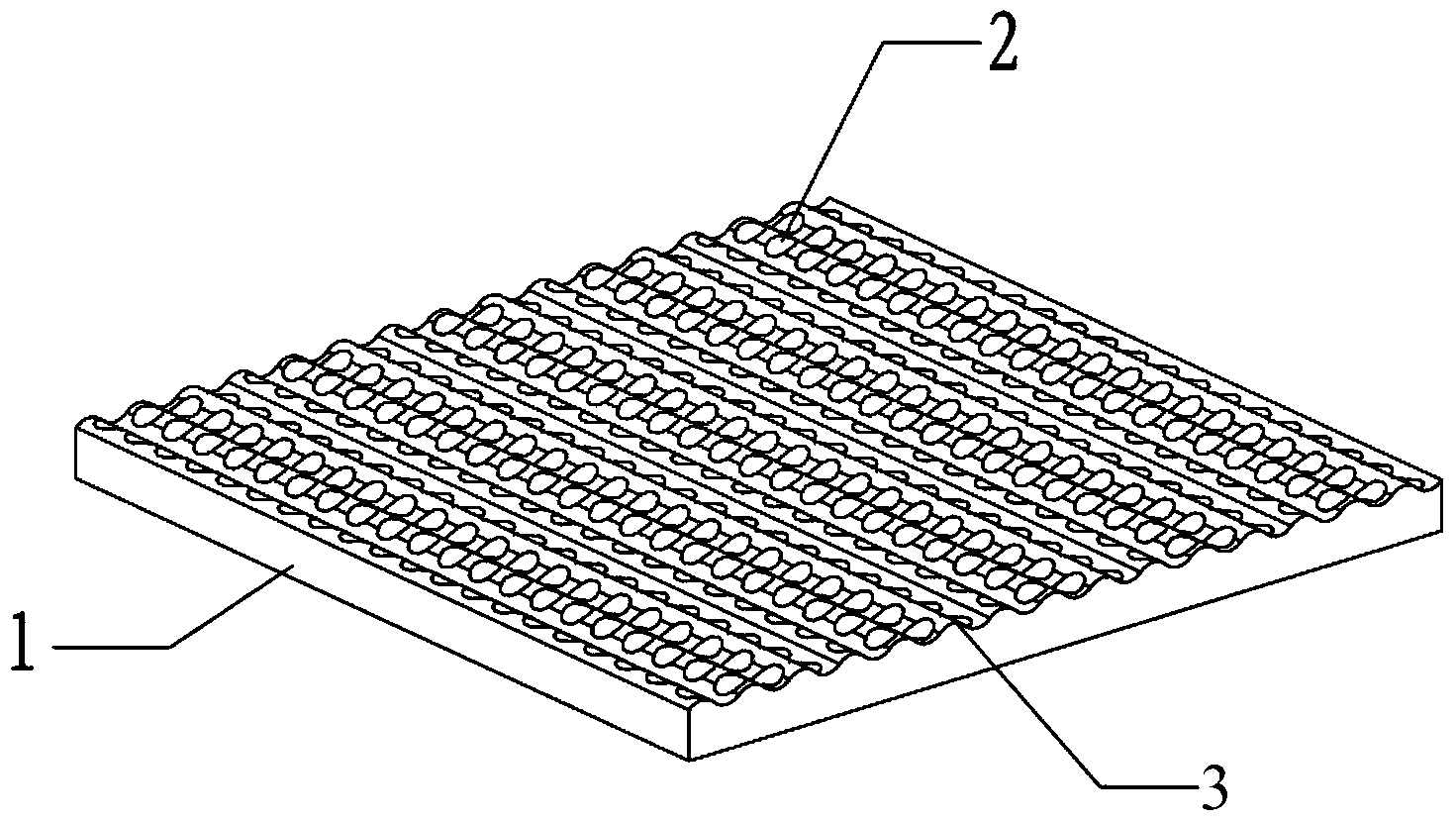

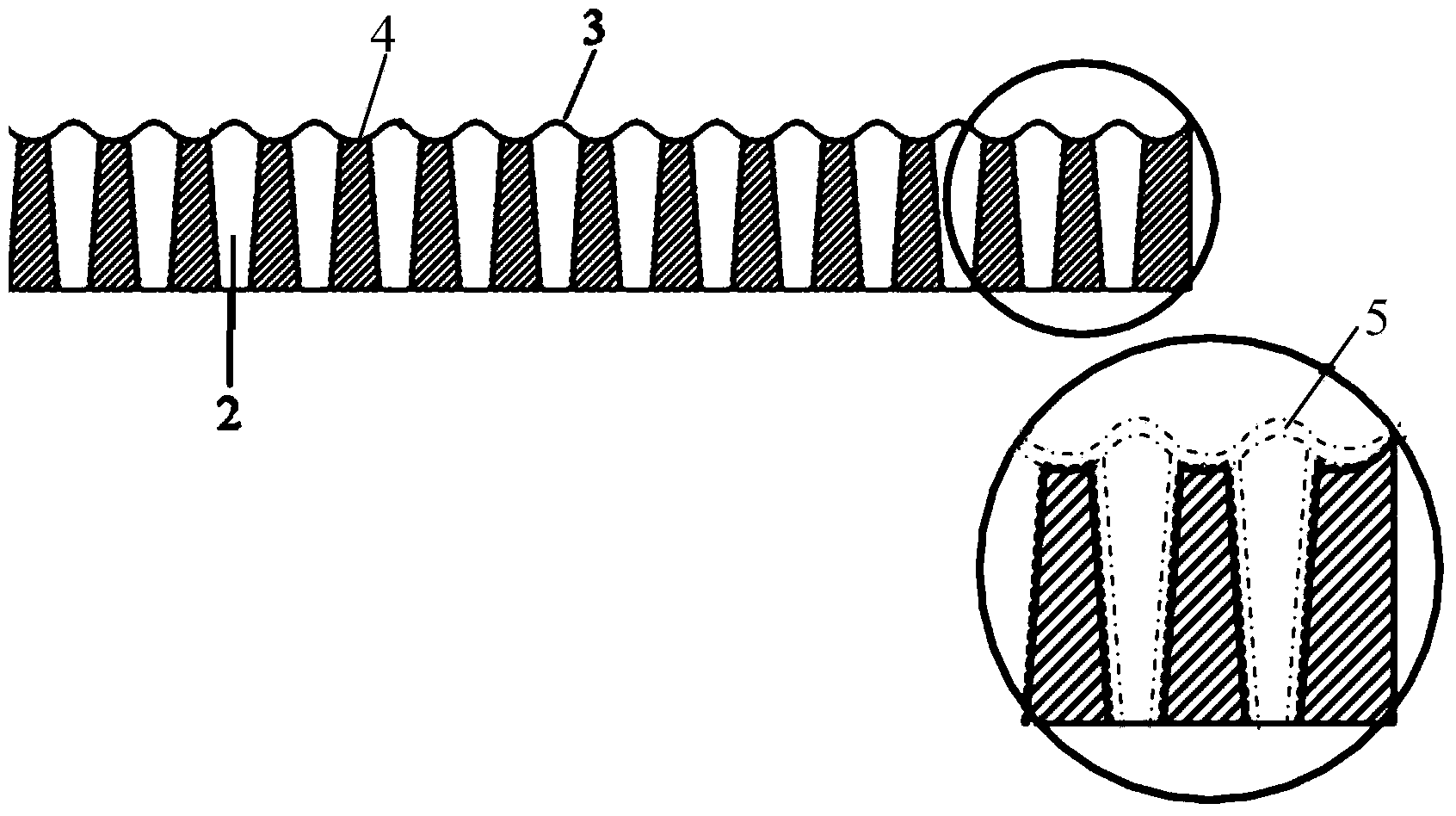

Preparation method of nano titanium dioxide photocatalyst thin film

ActiveCN104226287AHigh theoretical rate of returnHigh yieldPhysical/chemical process catalystsNanotechnologyWater bathsEvaporation

The invention discloses a preparation technology of a nano titanium dioxide thin film. The preparation technology comprises the steps of oxidizing metal titanium Ti with zero valent into tetravalent titanium TiO2<+> by using hydrogen peroxide, further complexing TiO2<+> with hydrogen peroxide to form a water-soluble TiO[(H2O2)]<2+> yellow complex, removing excessive hydrogen peroxide and ammonia during evaporation to obtain a yellow complex colloid, then converting the TiO[(H2O2)]<2+> yellow complex into pure white Ti(OH)4 aqueous emulsion by high-pressure hydrothermal reaction under the temperature of 150-200 DEG C, adding inorganic acid to adjust the PH of the emulsion to be in a range from 2 to 4, controlling the temperature of a water bath at 60-80 DEG C, continuously stirring for 3-6 hours to gradually colloidize the Ti(OH)4 aqueous emulsion into a nano titanium dioxide aqueous colloid, spraying the nano titanium dioxide aqueous colloid to the wavy surface of a multihole ceramic plate and the inner wall of a conical hole through a spraying gun, and sintering under the temperature of 400-550 DEG C to form the firm nano titanium dioxide thin film. In a reaction process, production of wastewater and waste gas is avoided, and the crystallizing degree is high; the nano titanium dioxide thin film is extremely high in light catalysis activity and high in film forming performance.

Owner:江苏恒智纳米科技有限公司

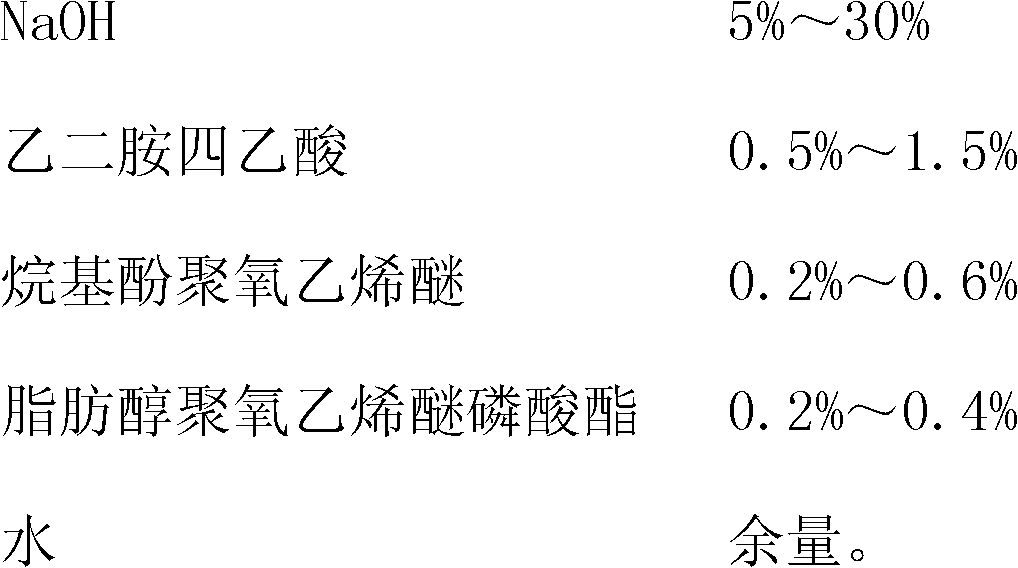

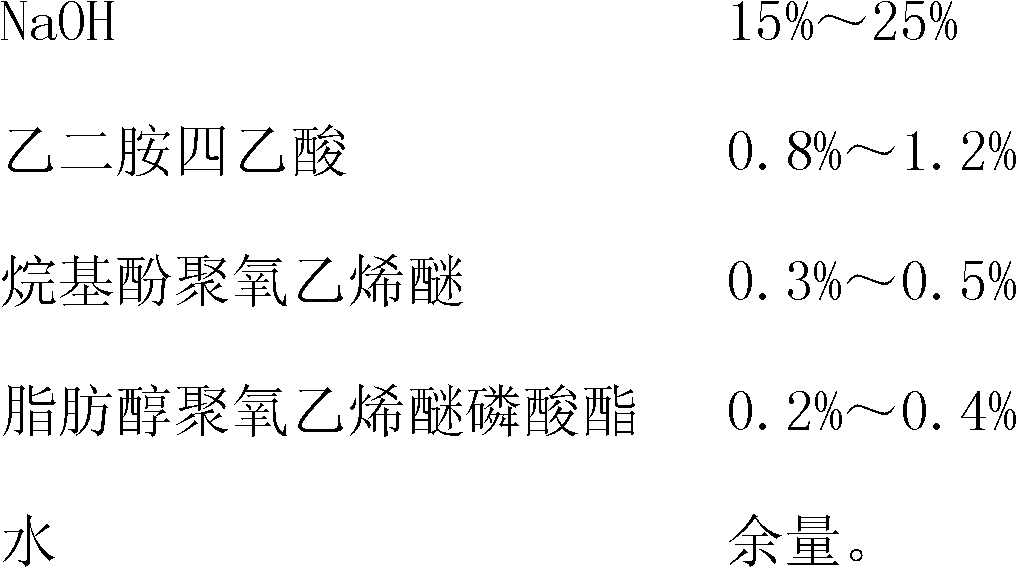

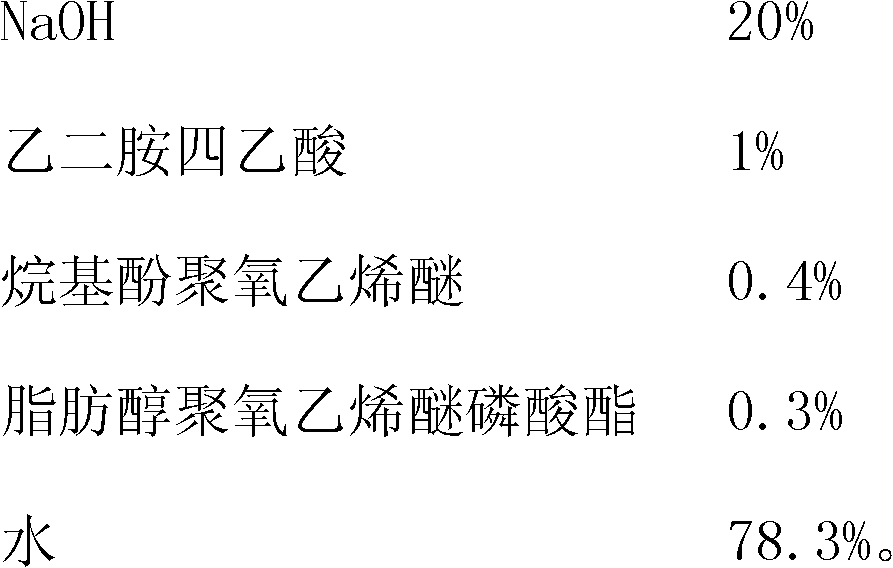

Cleaning agent and preparation process and application thereof

InactiveCN102492565AShort removal timeSimple recipeInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsChemistryAlkylphenol

The invention relates to the field of cleaning agents, in particular to a cleaning agent for cleaning calcium sulfate scales, barium sulfate scales and strontium sulfate scales. The cleaning agent comprises the following components in percentage by volume: 5-30 percent of NaOH, 0.5-1.5 percent of ethylenediamine tetraacetic acid, 0.2-0.6 percent of alkylphenol ethoxylate, 0.2-0.4 percent of fatty alcohol-polyoxyethylene ether phosphate and the balance of water. Furthermore, the invention discloses a preparation process and an application of the cleaning agent. The cleaning agent disclosed by the invention has a simple formula; and under the cooperative and synergistic actions of components, descaling capacity is increased effectively.

Owner:四川鸿康科技股份有限公司

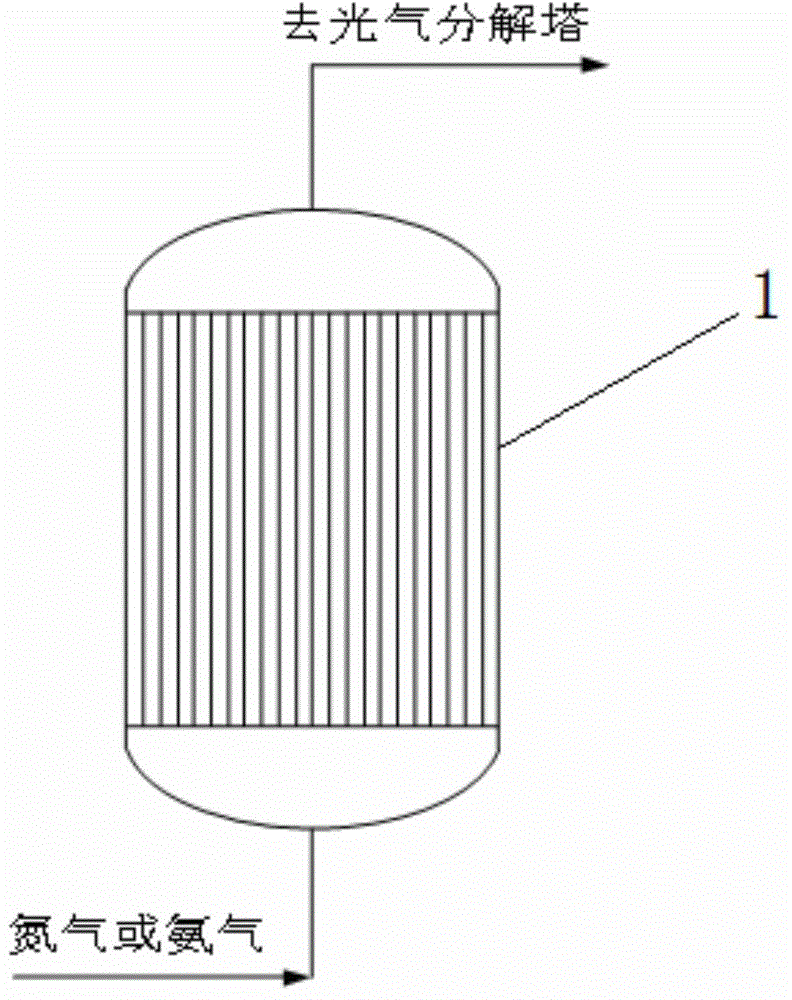

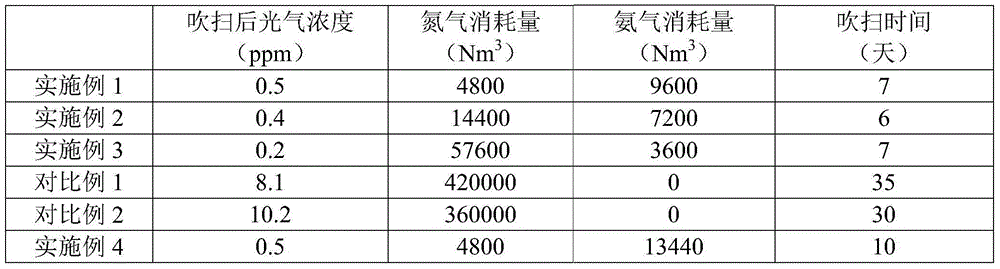

Method for replacing phosgene synthetic tower catalyst

ActiveCN105817183AShort removal timeOperational securityUrea derivatives preparationPhysical/chemical process catalystsNitrogenNitrogen gas

The invention discloses a method for rapidly removing phosgene in a catalyst when a phosgene synthetic tower catalyst is replaced. The method is characterized in that a nitrogen purging method is employed for purging phosgene which is absorbed in phosgene synthetic tower catalyst active carbon and is easily desorbed, ammonia gas is used for purging, then ammonia gas and phosgene which is difficultly desorbed in the phosgene synthetic tower catalyst are subjected to a reaction for removal, a water gun is used for flushing a phosgene synthetic tower, and then the phosgene synthetic tower is dried by hot gas. The phosgene content at an outlet of the phosgene synthetic tower after purging is carried out is lower than 0.5 ppm, phosgene purging time by the phosgene synthetic tower is obviously reduced, nitrogen consumption amount is greatly reduced, and operation security is increased.

Owner:WANHUA CHEM GRP CO LTD

Preparation method of lanthanum oxide-based ceramic core

ActiveCN105669198AHigh strengthImprove maneuverabilityFoundry mouldsFoundry coresComposite ceramicParaffin oils

The invention relates to a preparation method of a lanthanum oxide-based ceramic core. The method comprises the following steps: ball milling and mixing are carried out for lanthanum oxide powder and additive powder, after paraffin melts, the mixed powder is gradually added, mechanical stirring is carried out, and composite ceramic core slurry is obtained; an injection moulding method is used for preparing the lanthanum oxide-based ceramic core of a required shape; a powder embedded sintering process is used for sintering the lanthanum oxide-based ceramic core, and the required ceramic core is obtained; finally, the required lanthanum oxide-based ceramic core is packaged with vacuum or inert atmosphere protection in order to be isolated from air till usage. The preparation technology and method of the lanthanum oxide-based ceramic core is simple and has good operationality; the lanthanum oxide-based ceramic core has high strength and high yield, and can be used with a higher casting temperature; the core is easy to remove during the removing phase of the core, so that efficiency is improved, and production cost is reduced.

Owner:SHANGHAI UNIV

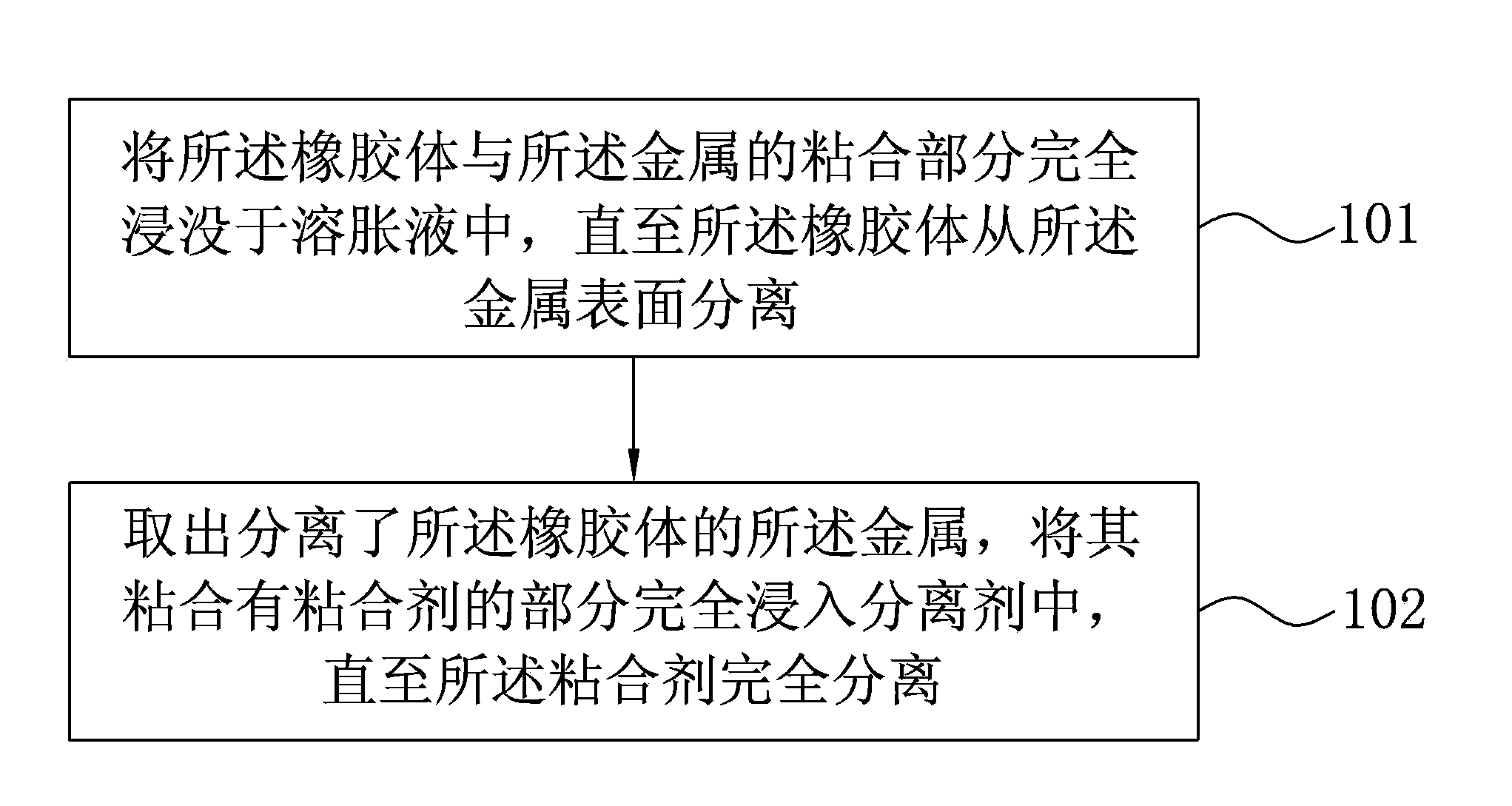

Metal surface rubber body removal method

The invention discloses a metal surface rubber body removal method, and a metal and a rubber body are bonded through an adhesive, and the method comprises the following steps: (1) a bonding part of the metal and the rubber body is completely submerged in a swelling separation solution until the rubber body is separated from the metal surface; (2) the metal with the rubber body separated is taken out, and an adhesive bonding part of the metal is completely immersed into a separating agent until the adhesive is completely separated. A chemical treatment liquid capable of dissolving the whole rubber body is not used, the swelling separation solution for swelling separation of the rubber body is used, and the used separating agent is also environmentally friendly, so that the pollution is less; the rubber body is removed by swelling of the adhesive rather than the entire dissolution, so that the removal time is shorter; the swelling can be repeatedly used, and the separating agent is environmental protection, so that the degumming wastewater treatment is relatively simple.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Method for removing cadmium from porphyra haitanensis

InactiveCN101731499AHarm reductionShort removal timeFood preparationNational standardPorphyra haitanensis

The invention discloses a method for removing cadmium off porphyra haitanensis. The method is implemented by putting fresh porphyra haitanensis and de-ionized water in weight volume ratio of 4.5-5.5:25 into a container, moving the container into an ultrasonic extractor, and performing ultrasonic treatment to the porphyra haitanensis in the container in the interval ultrasonic way of using ultrasonic wave for o.3-0.6 seconds and pausing for 0.7-0.4 seconds with ultrasonic wave temperature being 25-45 DEG C and ultrasonic wave frequency being 25kHz; after the ultrasonic treatment with the above way and conditions, the removal rate of cadmium off porphyra haitanensis can reach above 63%, the residual quantity of cadmium in porphyra haitanensis meets the requirement of national standard basically, thus reducing harm to human bodies of people and especially children after eating, not causing contamination to porphyra haitanensis, having little influence on quality of porphyra haitanensis, less removal time, high speed and high removal rate.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

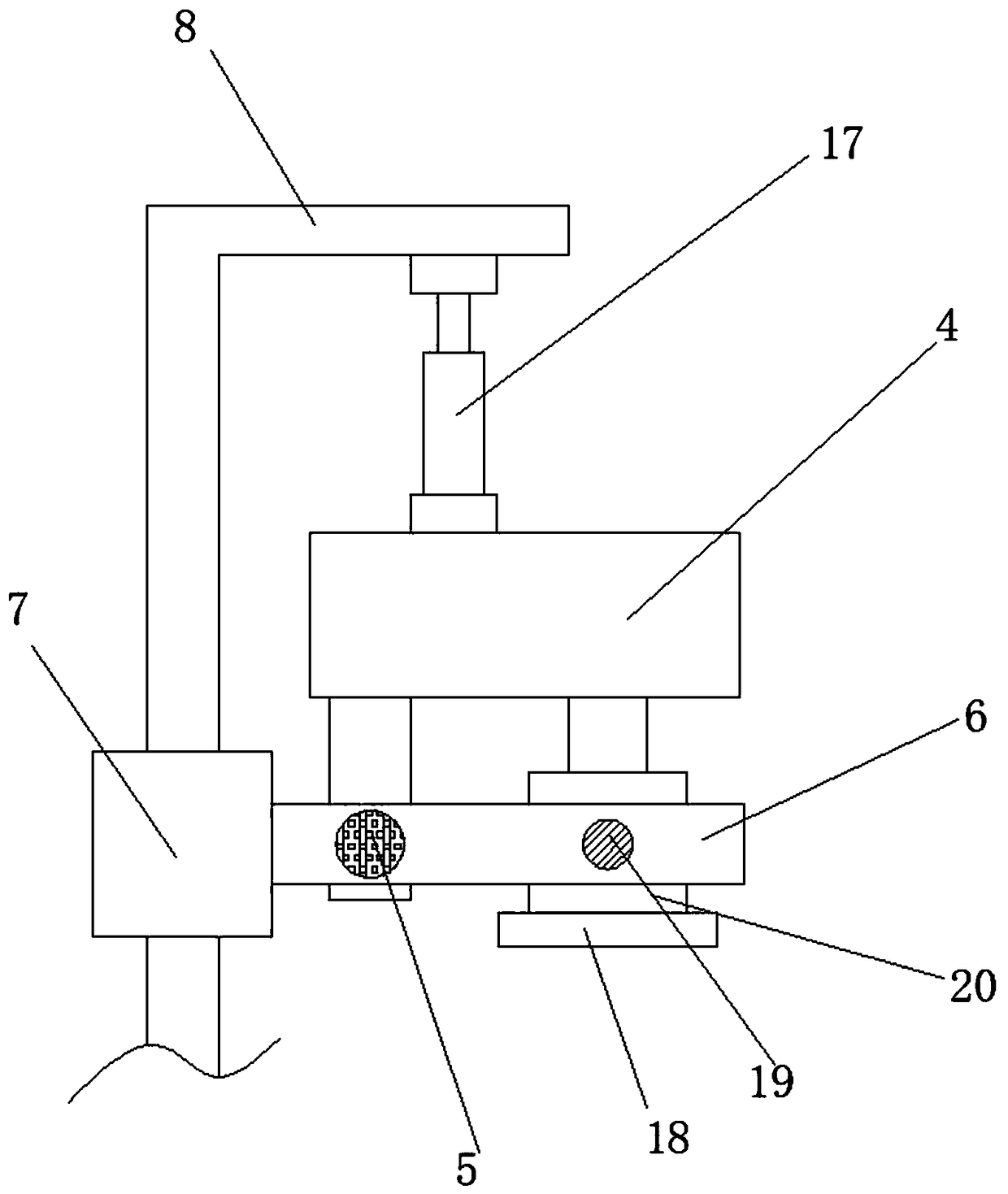

Discharging mechanical arm of injection moulding machine

InactiveCN108437382AAvoid workpiece damageImprove processing qualityInjection mouldingInjection molding machine

Owner:JINGDE COUNTY HANHAI NEBULA INTELLIGENTIZE TECH RES & DEV CO LTD

Method for rapidly removing thermal spraying coating

ActiveCN104858792AIncrease air source pressureShort removal timeAbrasion apparatusAbnormal shapedCermet

The invention discloses a method for rapidly removing a thermal spraying coating. A sand blasting material adopts alloy sand with diameters being 0.5-5.0 mm, special-shaped alloy sand with the ratio of length to width being 1.0-5.0 as well as 10-50-mesh ceramic sand, wherein the mass ratio of the alloy sand to the special-shaped alloy sand to the ceramic sand is (1-4):(1-4):1; before sand blasting, three raw materials are uniformly poured into an iron barrel simultaneously, mixing of the raw materials is facilitated, the mixed sand in the iron barrel is poured into a sand tank for sand blasting, and the air source pressure for sand blasting is 0.5-0.9 MPa. The sand composition is optimized and improved, the air source pressure is increased, the removal time of an old coating is greatly shortened, and compared with the time for old coating removal through single ceramic sand blasting, the time is shortened by 60%-75%; meanwhile, the production cost is reduced, the old coating is economically and efficiently removed, and the method is suitable for removing various metal coatings, alloy coatings and metal ceramic coatings.

Owner:XIAN THERMAL POWER RES INST CO LTD

Process of utilizing sturgeon raw material to extract collagen

PendingCN110128530AReduce in quantityEasy extractionConnective tissue peptidesPeptide preparation methodsYeastSturgeon

The invention discloses a process of utilizing a sturgeon raw material to extract collagen. The process includes following steps: 1), selecting sturgeon skin and / or swim bladder which is washed cleanas a raw material, slicing, adding into 5-10wt% sodium hydroxide solution for soaking for 5-10h, filtering, and washing the material clean; 2), adding a material obtained in the step 1) into a defatting mixed solution for defatting for 1-2h, performing ultrasonic treatment during defatting, and washing clean after ultrasonic treatment is completed; 3), adding a material obtained in the step 2) into acid for swelling, homogenizing, using a sodium hydroxide solution to adjust pH to 4.0-5.5, adding protease for enzymolysis, adding yeast powder after enzymolysis is completed, controlling temperature at 30-35 DEG C, stirring for reaction for 2h, and performing enzyme deactivation; 4), discoloring enzymolysis liquid obtained after enzyme deactivation in the step 3), centrifuging, purifying, concentrating, and spray-drying to obtain collagen powder. The process can quickly extract collagen, and the collagen extracted by the process is high in purity, small in molecular weight and easy to absorb.

Owner:湖北清江鲟龙渔业有限公司

Apparatus for removing photoresist at edge of substrate

InactiveCN103913958ANot easy to blockAvoid substrate defectsSpray nozzlesPhotosensitive material processingSpray nozzlePhotoresist

The invention relates to the technical field of an apparatus for removing a photoresist, and discloses an apparatus for removing the photoresist at edge of a substrate. The apparatus for removing the photoresist at edge of the substrate comprises a spray washing apparatus, the spray washing apparatus comprises a liquid nozzle for injecting a photoresist solvent and a gas nozzle for injecting gas, gas injected from the gas nozzle blows the photoresist solvent at the edge of the substrate to the outer side of the substrate, the gas nozzle and the liquid nozzle are respectively the slit-shape gas nozzle and the slit-shape liquid nozzle; the gas injected from the slit-shape gas nozzle is fallen on the surface of the substrate to form a first slit zone, the liquid injected from the slit-shape liquid nozzle is fallen on the surface of the substrate to form a second slit zone, and the first slit zone and the second slit zone are not overlapped. According to the technical scheme, by employing the slit-shape gas nozzle or the slit-shape liquid nozzle, gas or liquid is smoothly injected, sputtering of the photoresist solvent can be avoided, and the generation of the adverse phenomenon of the substrate due to sputtering of the photoresist solvent in the substrate can be avoided.

Owner:BOE TECH GRP CO LTD +1

Lead removal method for porphyra haitanensis

The invention discloses a lead removal method for porphyra haitanensis, which includes that fresh porphyra haitanensis and deionized water in weight volume ratio of 4.5-5.5:25 are placed in a container, the container is moved to an ultrasonic wave exactor for performing ultrasonic treatment on the porphyra haitanensis with the ultrasonic lasting time of 0.3-0.6 and interval of 0.7-0.4 sec and at the ultrasonic temperature of 25-45 DEG C and ultrasonic frequency of 25 KHz, and the total ultrasonic treatment time is 15-25 min; after the ultrasonic treatment with specific conditions, the lead removal rate of porphyra haitanensis can reach more than 92%, and the lead residual quantity of porphyra haitanensis is lower than the national standard requirement, the harmfulness to people on having porphyra haitanensis, in particular to children is reduced; besides, the lead removal method has no pollution to porphyra haitanensis, has slight influence on the quality of porphyra haitanensis, shorter removal time, high speed and higher removal rate.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

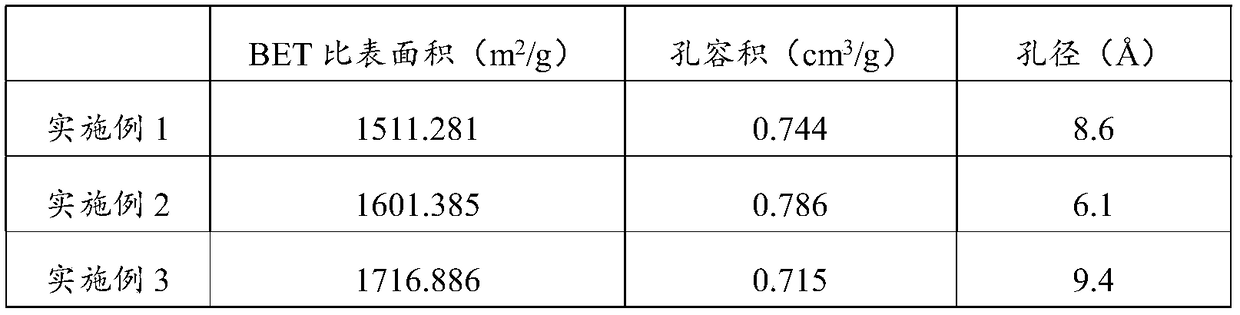

Metal-organic framework material as well as preparation method and application thereof

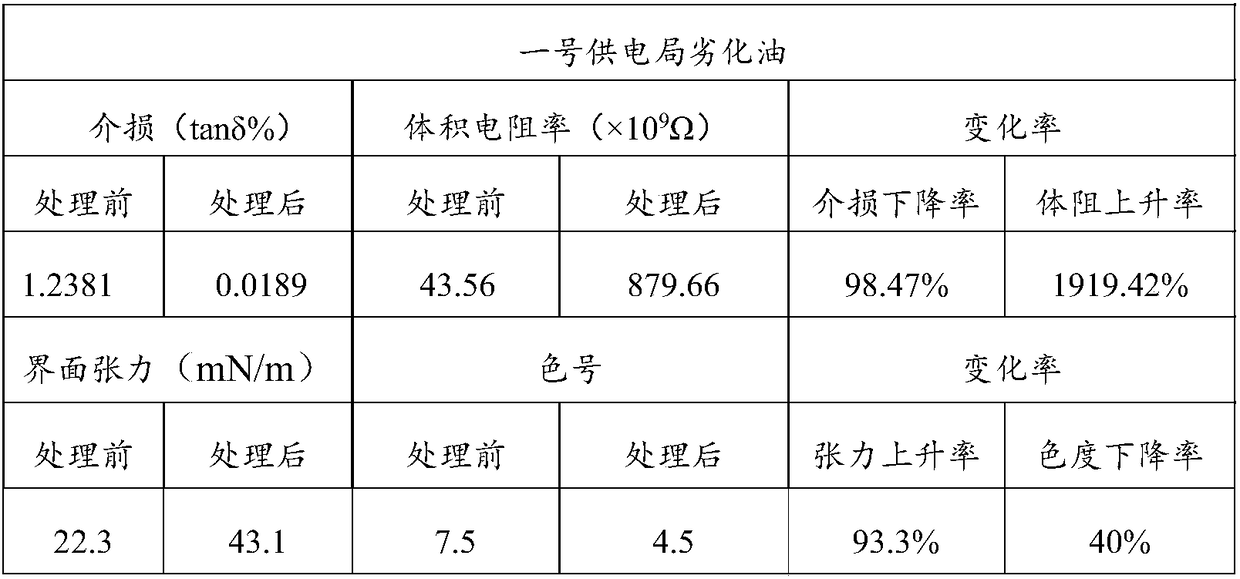

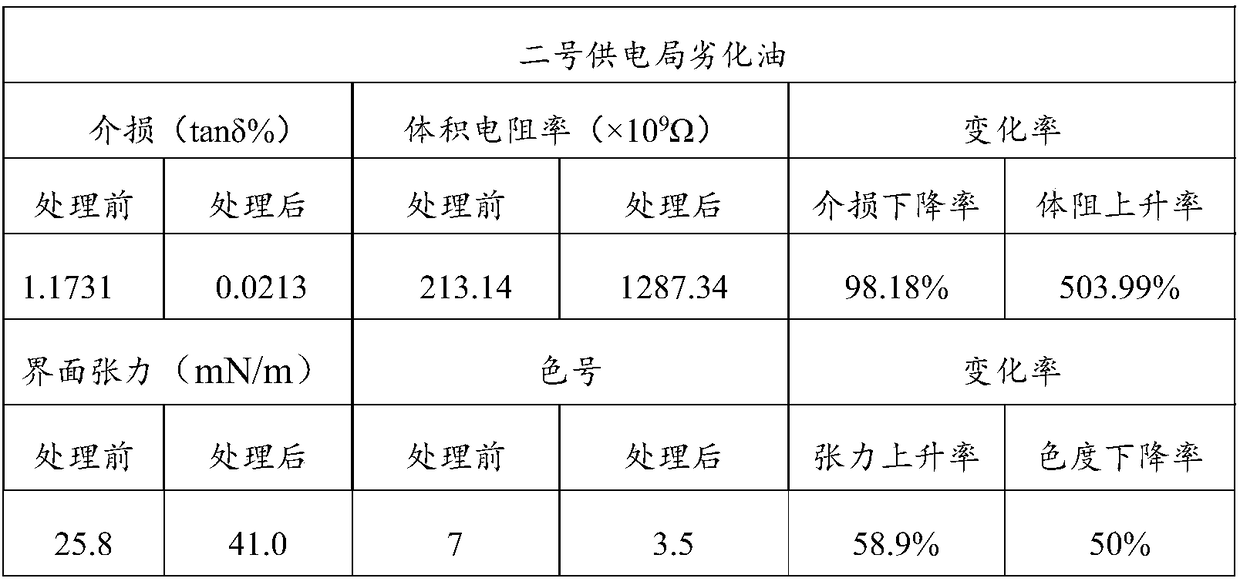

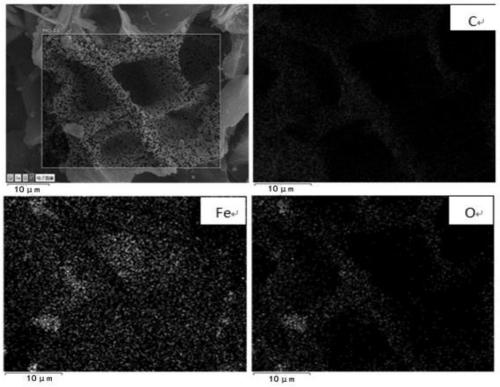

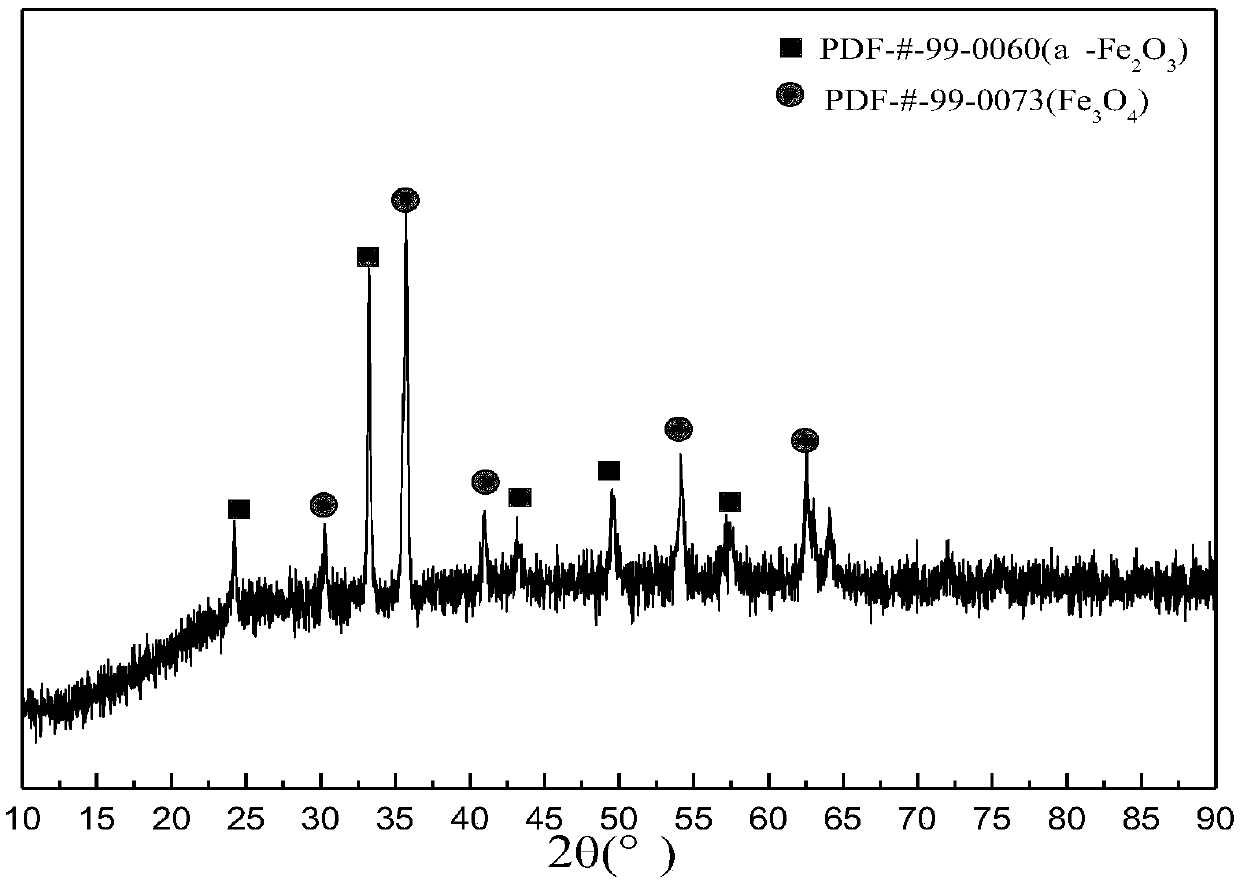

ActiveCN109317105AEasy to recycleReduce consumptionTransformers/inductances coolingOther chemical processesReduction rateInorganic salts

The invention relates to the technical field of transformer oil and in particular relates to a metal-organic framework material as well as a preparation method and application thereof. The invention provides the preparation method of the metal-organic framework material; the preparation method comprises the following steps: mixing an organic ligand, inorganic salt, ethanol water and dimethylformamide or diethylamide and reacting to obtain a powdery metal-organic framework; then granulating and molding to obtain a granular metal-organic framework. According to the method provided by the invention, the metal-organic framework material is obtained through granulation and molding, so that the metal-organic framework material has a stable shape and has large specific surface area, pore capacityand pore diameter. Compared with other adsorbents with the same use amount, the metal-organic framework material provided by the invention has a high adsorption amount on degraded transformer oil andhas high-efficiency and excellent adsorption performance, so that the dielectric loss reduction rate of the degraded transformer oil can reach 98 percent or more and the volume resistivity rising rate can reach 1919.42 percent at maximum; both the interface tension of the transformer oil and the color of an oil sample are improved.

Owner:GUANGDONG POWER GRID CO LTD +1

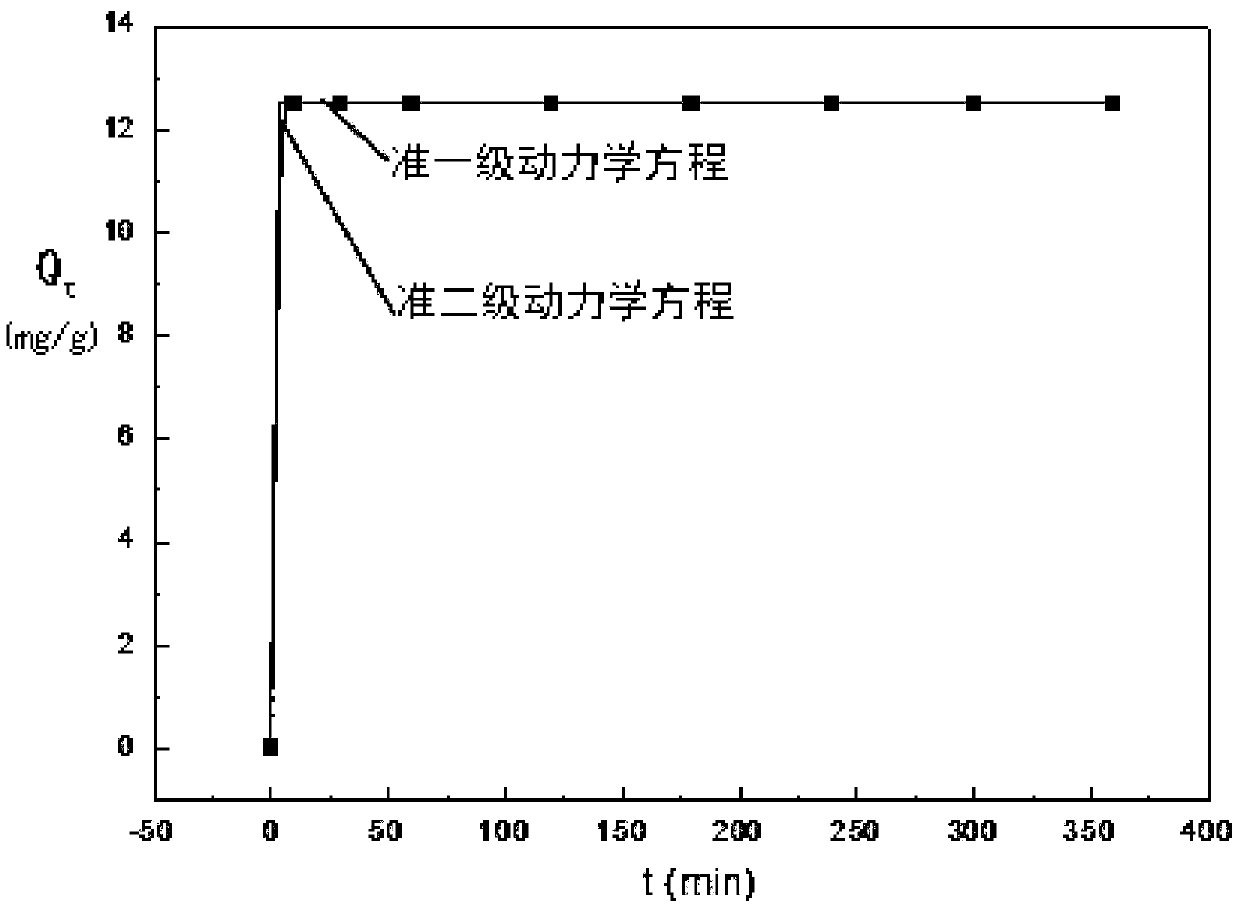

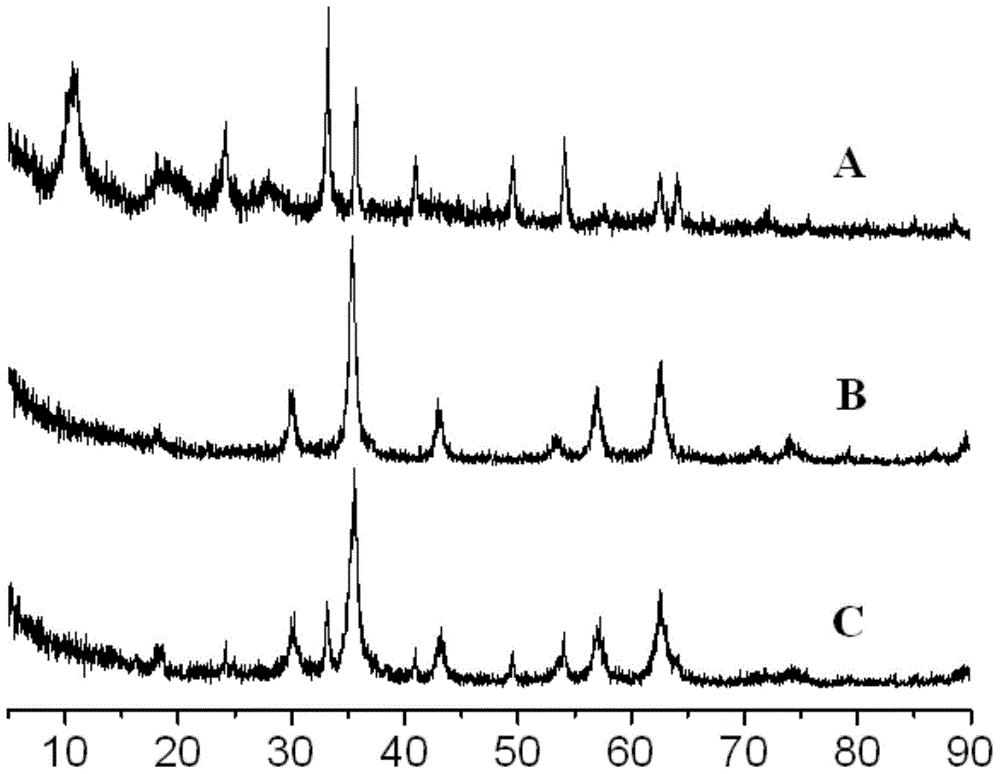

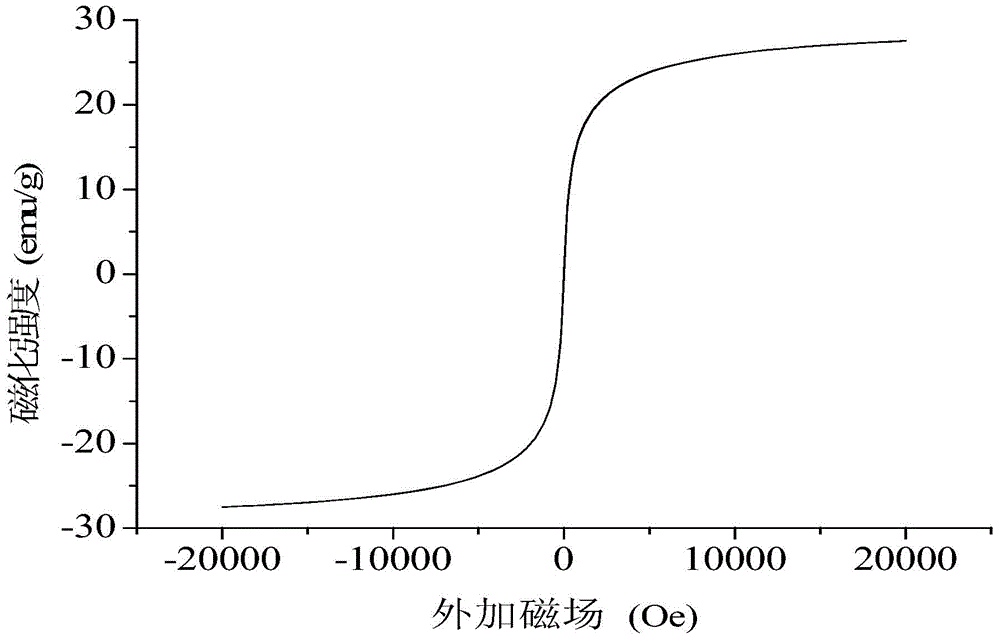

Magnetic biochar for rapidly removing methylene blue and preparation method and application thereof

PendingCN109589913AImprove protectionEasy to prepareOther chemical processesWater contaminantsOrganic dyeWastewater

The invention discloses a magnetic biochar for rapidly removing methylene blue and a preparation method and an application thereof. The preparation method comprises the following steps: (1) adding a waste biomass to a carbon steel pickling waste liquid to obtain a mixture; (2) isolating oxygen, and calcining the mixture to obtain the magnetic biochar. The preparation method is simple and few in process steps, the reutilization of the waste biomass and the carbon steel pickling waste liquid is implemented, toxic and expensive reagents or other solvents are not required for use, thereby being beneficial to cost control and environmental protection. The magnetic biochar has a porous structure and has a remarkable removal effect on an organic dye, and is short in removal time, rapid and efficient; the removal method is simple; the magnetic biochar material is directly placed in the wastewater without any other complicated device and process; and the magnetic biochar is easy to popularize and use.

Owner:广州润方环保科技股份有限公司

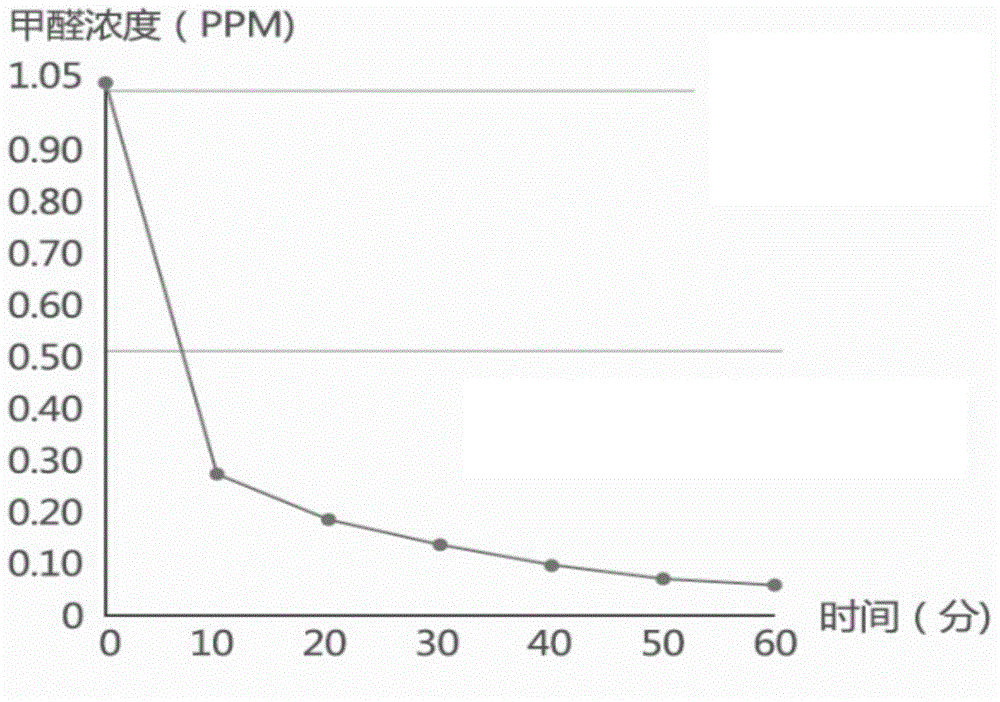

Environment purifying agent and method for environment treatment

The invention discloses an environment (including running water and air) purifying agent and a method and application for environment purifying. The environment purifying agent is prepared from activated silica or an aqueous solution containing the activated silica, wherein the activated silica is a mixture of one or more of orthosiliconic acid, metasilicic acid, disilicate, polysilicic acid, silicate, metasilicate, dipolymer silicate and polysilicate. According to the environment purifying agent, an activated silica component is added, so that free radicals with negative charges in the environment can be effectively removed, active oxygen can be effectively regulated, contaminants such as haze, formaldehyde and heavy metal ions can be effectively treated, the concentration of gas carbon dioxide can be reduced, the efficiency is high, time is short, and the environment purifying agent takes effect quickly and is green and natural without secondary pollution. According to the application of the environment purifying agent in environment treatment, operation is simple, only the environment purifying agent needs to be released to a water area which needs to be purified and stirred orsprayed to a target airspace which needs to be purified through an atomizing device or only harmful air needs to be injected into a water curtain or a water screen or a water mist formed by the environment purifying agent, the effect of environment purifying can be achieved, and accordingly the environment purifying agent is suitable for large-area utilization and popularization.

Owner:杭州舞川吉科技有限公司

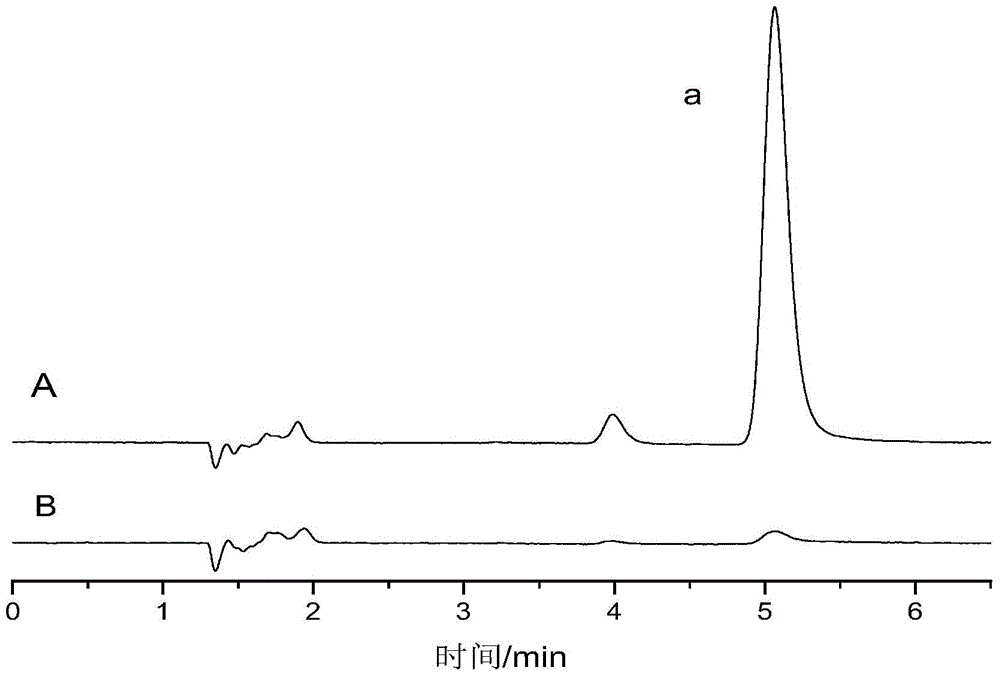

Method for removing dyes in water by utilizing magnetic metal-organic framework material

InactiveCN104030389BSimple methodImprove adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesMetal-organic frameworkTreated water

The invention provides a method for removing dyes in water by utilizing a magnetic metal-organic framework material and relates to the method for removing the dyes in the water, and the method is mainly used for solving the problems of complicated process, low treatment efficiency and high cost of the existing method for removing the dyes in the water. The method comprises the following steps: 1) preparing the metal-organic framework material so as to obtain the metal-organic framework material; 2) preparing the magnetic metal-organic framework material so as to obtain the magnetic metal-organic framework material; 3) removing the dyes in the water, namely firstly, adding the magnetic metal-organic framework material into to-be-treated water, stirring for certain time at a certain stirring speed and carrying out magnetic separation by utilizing a magnet so as to finish the removal of the dyes in the water. The method is mainly used for removing the dyes in the water.

Owner:NORTHEAST FORESTRY UNIVERSITY

Method for removing powder of catalyst in catalytic cracking oil slurry

ActiveCN100410351CShort removal timeHigh removal rateDewatering/demulsification with electric/magnetic meansRefining by water treatmentDemulsifierSucrose

This invention provides two methods for removing catalyst powder from catalytic cracking oil slurry. The first method is suitable for light oil slurry whose specific gravity is lower than water, and comprises: mixing water containing demulsifier and flocculant with catalytic cracking oil slurry, demulsifying and removing the lower layer of water enriched in catalyst powder. The second method is suitable for heavy oil slurry whose specific gravity is higher than water, and comprises: adding weak electrolyte or non-electrolyte that can be dissolved in water and has higher specific gravity into water, such as ammonium acetate, ammonium citrate, fructose, glucose, sucrose, sorbitol or xylitol. The two methods have such advantages as short removing time and high rate.

Owner:CHINA PETROLEUM & CHEM CORP

Weak corrosivity removing method for aluminum and copper compound mandrel for preparing uranium-bearing hohlraum

ActiveCN107271249AReduce hydrogen partial pressureReduce lossesPreparing sample for investigationCleaning using liquidsCopper coatingUranium

The invention discloses a weak corrosivity removing method for an aluminum and copper compound mandrel for preparing a uranium-bearing hohlraum and relates to a demolding method of the uranium-bearing hohlraum. The method disclosed by the invention aims to solve the problem that in the prior art, the uranium-bearing hohlraum of the aluminum and copper compound mandrel cannot be demolded. The weak corrosivity removing method comprises the following steps: I, performing loading to obtain a sample stand containing a uranium-bearing hohlraum sample; II, performing negative pressure demolding to remove an aluminum mold core to obtain the sample stand loading a sample without the aluminum mold core; III, performing cleaning; IV, performing weak corrosivity removal of a copper coating to obtain the sample stand loading a sample without the copper coating; and V, immersing in a complexing agent, cleaning, and demolding the uranium-bearing hohlraum of the aluminum and copper compound mandrel. The method disclosed by the invention has the advantage that the molding success rate reaches 100%. The method disclosed by the invention is primarily applied to demolding the uranium-bearing hohlraum.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

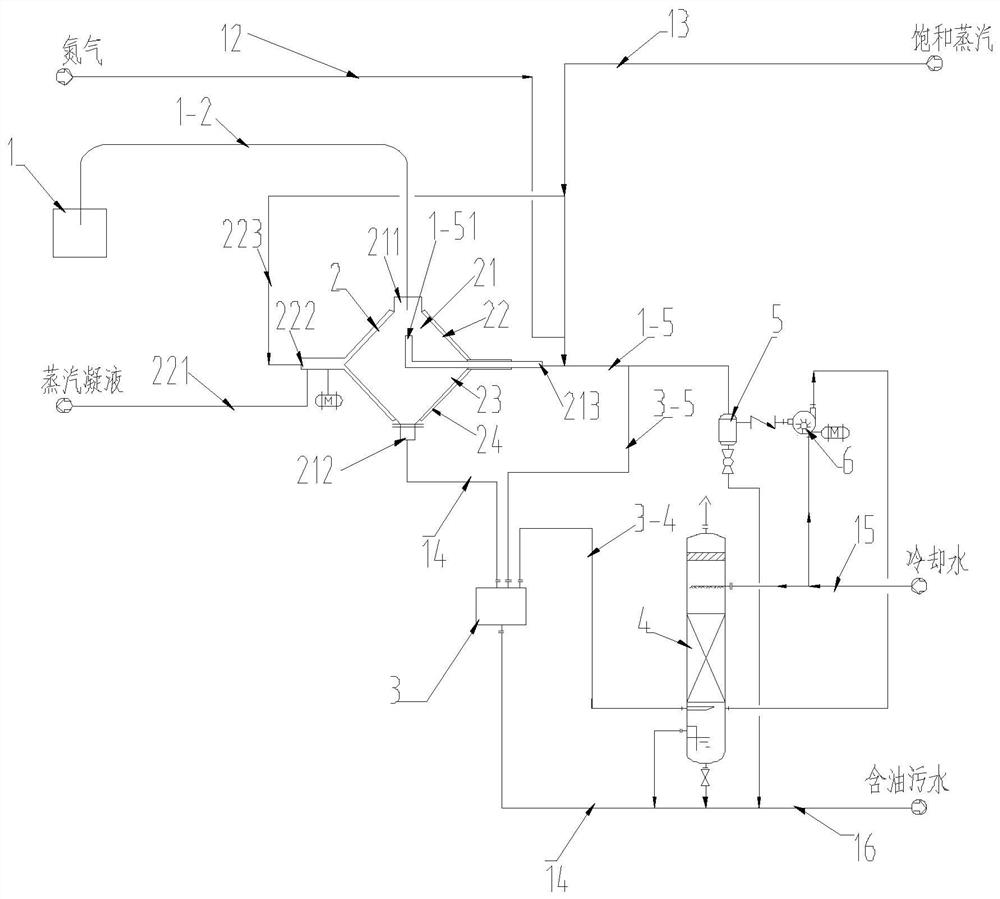

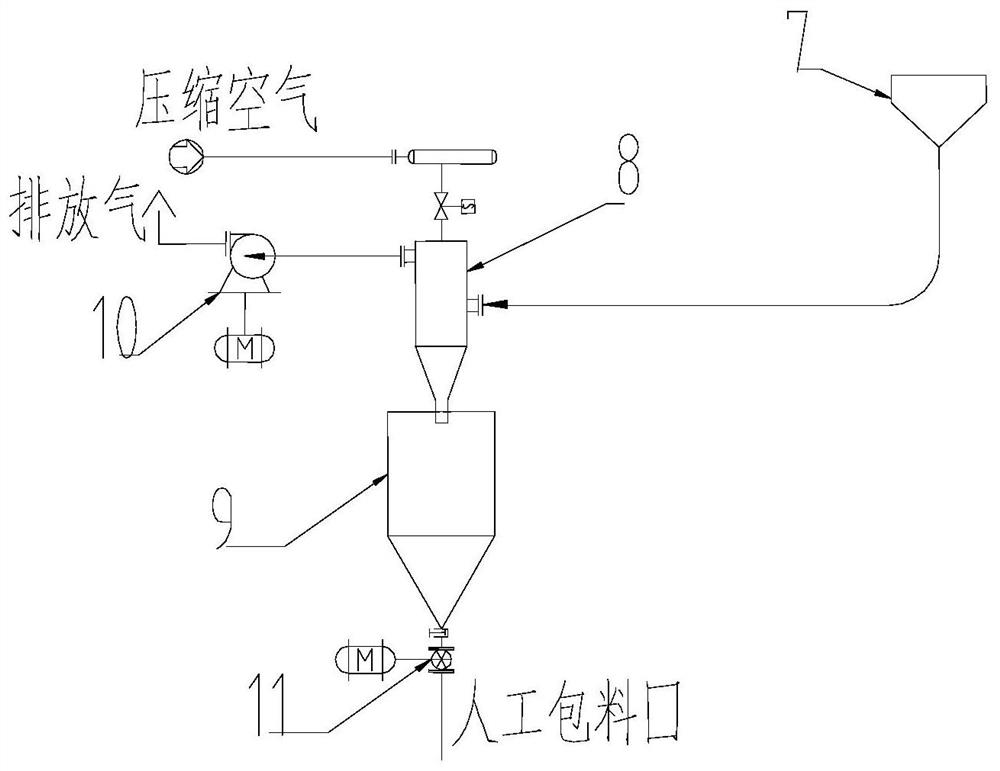

System and method for deeply removing VOC from polypropylene material and drying polypropylene material

PendingCN111790317AAvoid oxidation reactionsSmall footprintChemical/physical processesAir quality improvementPolymer sciencePolypropylene

The invention relates to a system for deeply removing VOC from a polypropylene material and drying the polypropylene material. The system comprises a raw material tank for placing a polypropylene material to be treated; a steam reactor, which comprises an inner shell and an outer shell, wherein a space between the inner shell and the outer shell is an interlayer, a space in the inner shell is an inner container, the inner shell is provided with a material inlet / outlet, a condensate outlet and a vacuum interface, the outer shell is provided with a heating medium inlet / outlet, the material inlet / outlet is communicated with the raw material tank through a feeding pipeline, and the heating medium inlet / outlet is communicated with a steam pipeline; a condensate tank, which is communicated withthe condensate outlet of the steaming reactor through a condensate pipeline; a vacuum pump, which is communicated with the vacuum interface of the steam reactor through a vacuum pipeline, wherein thevacuum interface is also communicated with the steam pipeline; and a product bin, which is used for placing the treated polypropylene material. The invention also relates to a method for deeply removing VOC from a polypropylene material and drying the polypropylene material.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION +1

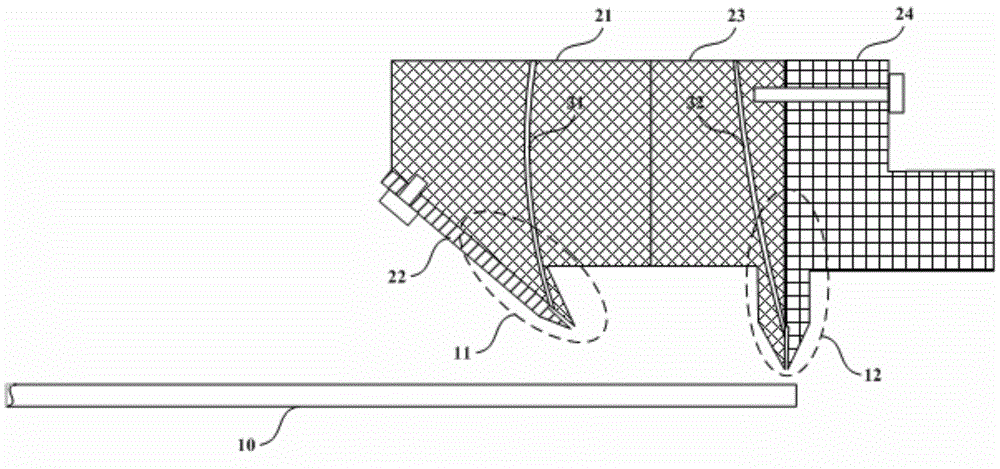

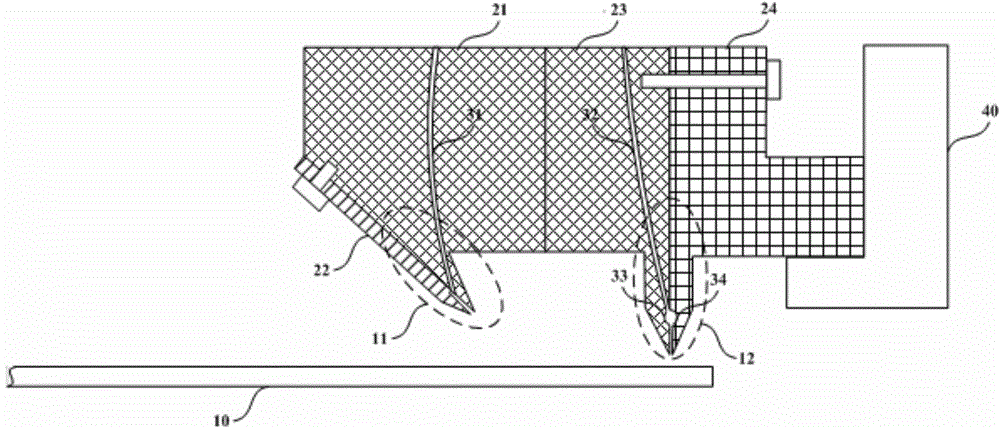

Eliminating method for low-melting-point alloy of blade inner cavities

The invention provides an eliminating method for low-melting-point alloy of blade inner cavities. The eliminating method comprises the following steps that (A) a plurality of blades are clamped on a mounting disc through mounting frames according to the same encircling direction, conveyed oil in a cooling tank is sprayed into an oil barrel through a spraying opening after being heated till the temperature is 180 DEG C, and the mounting disc is lowered to enable the blades to be stored in the hot oil of the oil barrel for 5-8 min; and (B) the mounting disc begins to revolve according to the speed being 20-30 RPM, after revolving is conducted for 8-10 min, the mounting disc is lifted to enable the bottom face of the mounting frames to rise to the position above the oil barrel, and thus eliminating of the low-melting-point alloy of the blades is completed. According to the eliminating method for the low-melting-point alloy of the blade inner cavities, on the one hand, the eliminating time of the low-melting-point alloy is effectively reduced; and in addition, the effect that the blade inner cavities after eliminating operation is free of residues is effectively guaranteed, and additionally, low-melting-point alloy eliminating operation can be continuously conducted in batches, so that working efficiency is greatly improved.

Owner:CHINA HANGFA SOUTH IND CO LTD

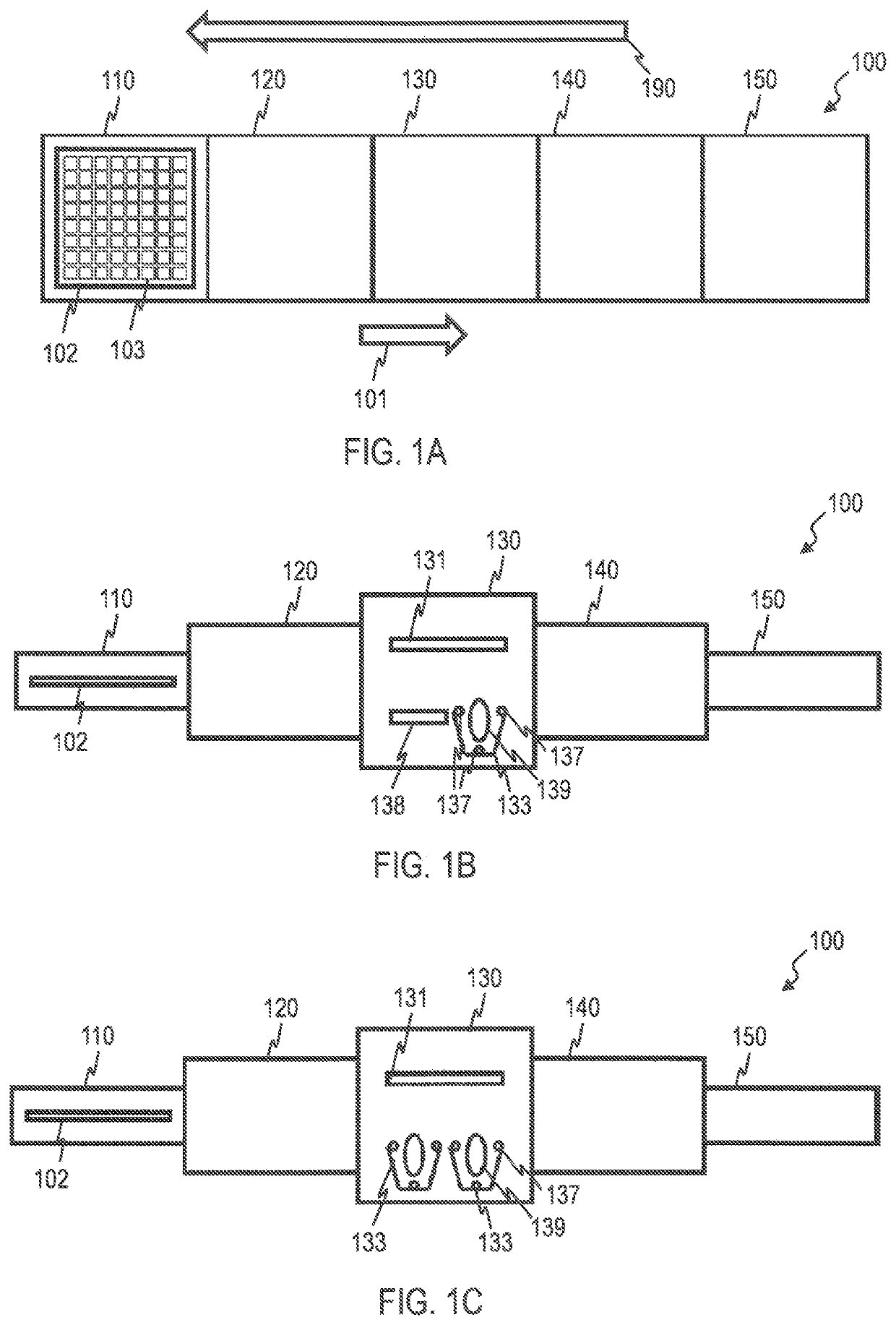

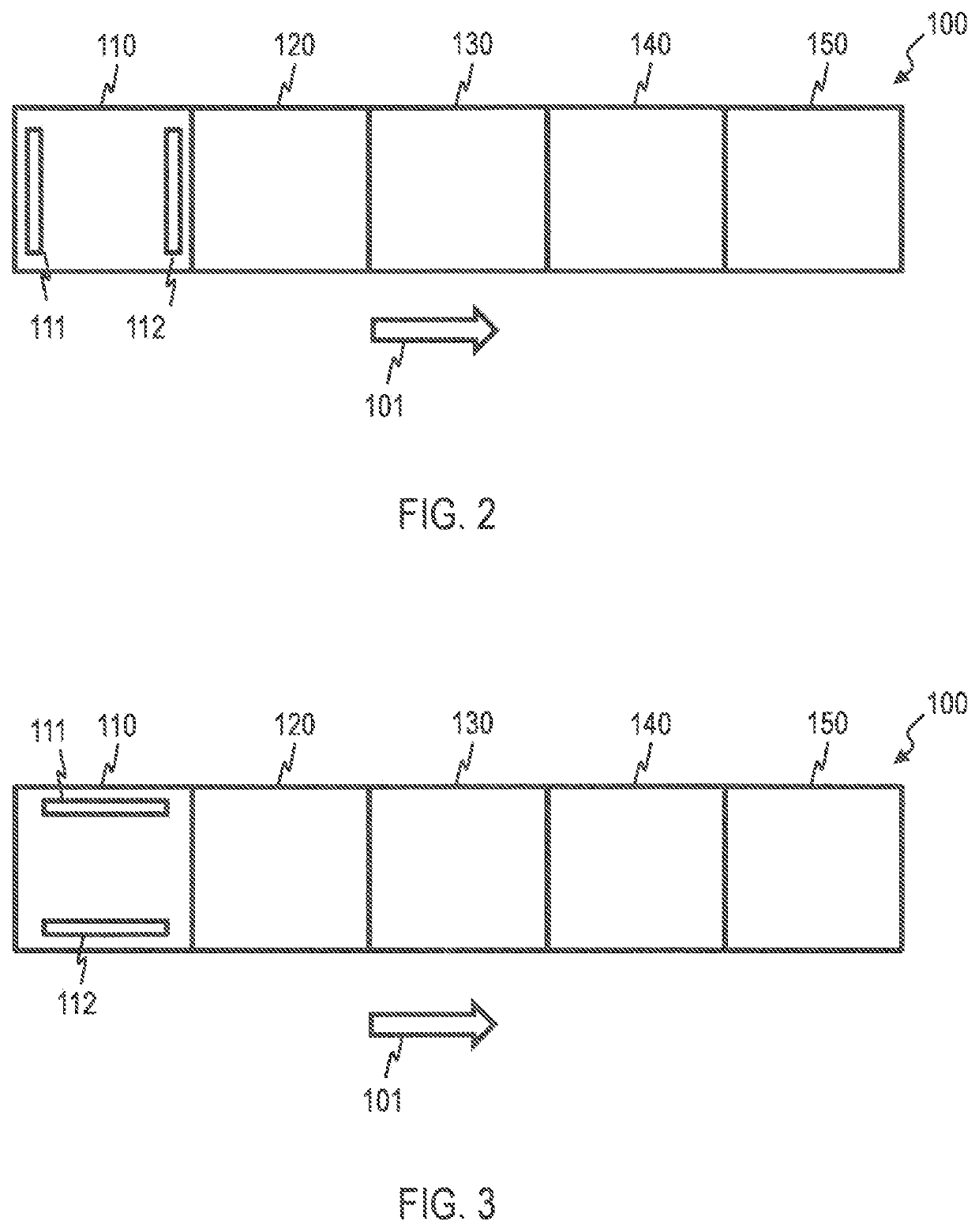

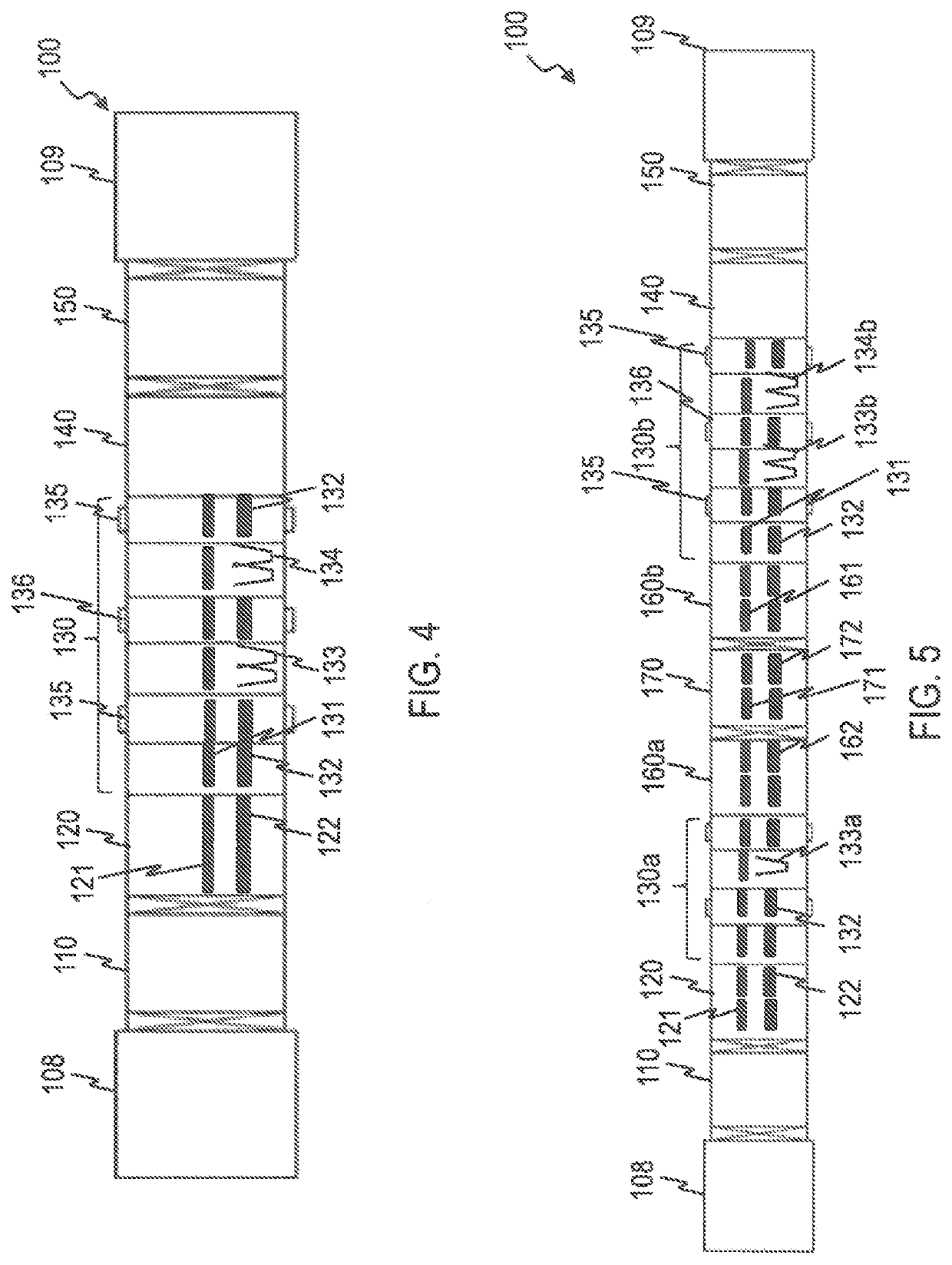

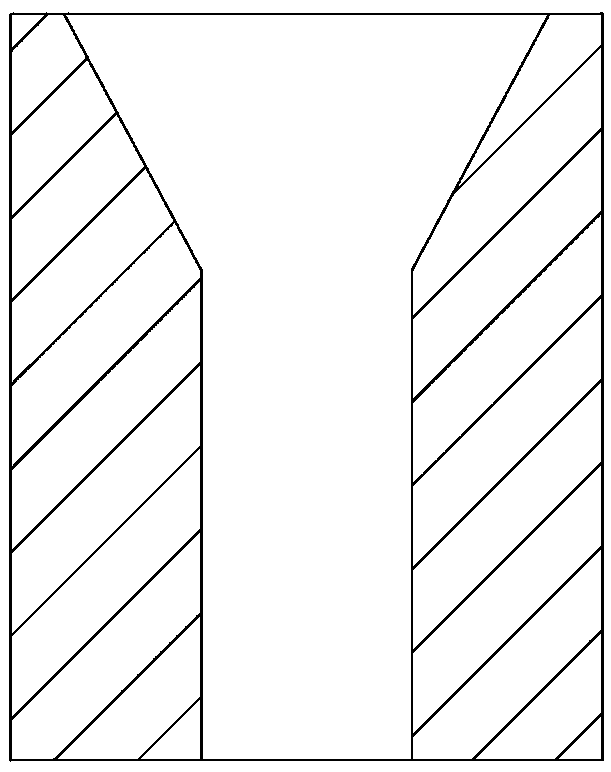

Continuous flow system and method for coating substrates

PendingUS20210335585A1Short introductionShort removal timeElectric discharge tubesFinal product manufacturePhysicsPumping vacuum

A continuous machine (100) for coating substrates (103) comprises a process module (130) and a vacuum lock (110, 150) for introducing the substrates (103) or removing the substrates (103). The vacuum lock (110, 150) comprises a chamber for receiving a substrate carrier (102) with a plurality of substrates (103) and a flow channel arrangement for evacuating and venting the chamber. The flow channel arrangement comprises a first channel for evacuating and venting the chamber and a second channel for evacuating and venting the chamber, wherein the first channel and the second channel are arranged at opposing sides of the chamber.

Owner:SINGULUS TECHNOLGIES AG

Processing method for hard alloy extrusion mould

The invention discloses a processing method for a hard alloy extrusion mould. The processing method comprises the following steps: according to the shape of the hard alloy extrusion mould, designing electroplated diamond grinding wheels with corresponding matched shapes; arranging the electroplated diamond grinding wheels on a milling machine and a processing centre, and driving the electroplateddiamond grinding wheels to grind a semi-finished product of the hard alloy extrusion mould to remove a remaining material of the semi-finished product of the hard alloy extrusion mould; and after theelectroplated diamond grinding wheels finish grinding, trimming the hard alloy extrusion mould by utilizing an electrical discharge machine to complete a preset shape. According to the processing method for the hard alloy extrusion mould, the remaining material of the hard alloy extrusion mould is ground by utilizing the electroplated diamond grinding wheels, so that the remaining material removaltime is shortened; the processing efficiency is improved; and the production cost is reduced.

Owner:河源富马硬质合金股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com