Metal-organic framework material as well as preparation method and application thereof

An organic framework and metal technology, which is applied in the field of metal-organic-framework materials and their preparation, can solve the problems of low processing efficiency, easy rebound of oil performance, and heavy labor, and achieve the effect of reducing consumption and dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

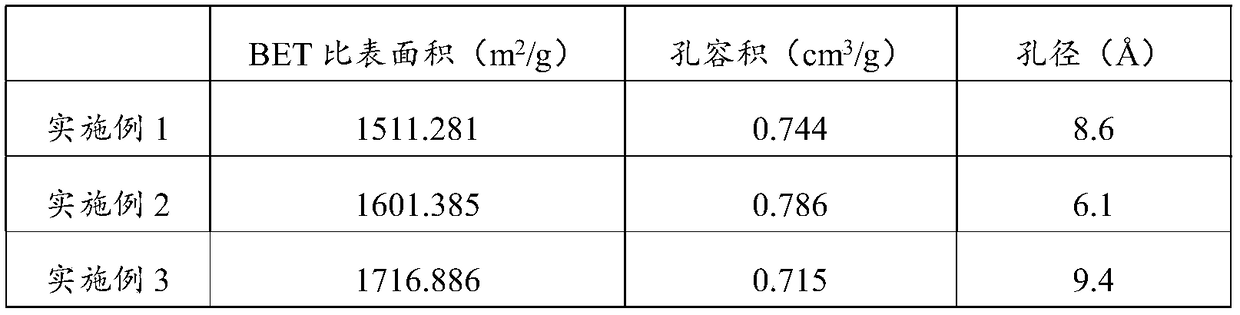

Embodiment 1

[0042] 1. Preparation of metal-organic framework materials: first, 0.94g terephthalic acid (C 8 h 6 o 4 ) with 3.72g ZrCl 4 (The molar ratio of organic ligands to inorganic salts is 0.35:1) Transfer to a polytetrafluoroethylene liner, then add dimethylformamide, ethanol and water in a ratio of 21mL: 21mL: 14mL, then stir and mix for 5 minutes , moved to a stainless steel reaction kettle after being covered, and sealed the reaction kettle, then placed in an electric blast constant temperature drying oven, reacted at a temperature of 60°C for 23 hours, and then centrifuged at a speed of 5000rpm for 4min to obtain The product was then washed with 50 mL of acetone and activated for 72 hours at room temperature, during which the activation solution was replaced 6 times, and then the washed product was obtained by centrifugation, and vacuum-dried at 150°C for 7 hours to obtain powdered metal -Organic framework materials.

[0043] 2. Molding of metal-organic framework materials: ...

Embodiment 2

[0046] One, prepare metal-organic framework material: first 0.84g tribenzenetricarboxylic acid (C 9 h 6 o 6 ) and 2.42g Cu(NO 3 ) 2 ·3H 2 O (the molar ratio of organic ligand to inorganic salt is 0.40:1) was transferred to the polytetrafluoroethylene liner, and then dimethylformamide, ethanol and water were added in the ratio of 24mL: 24mL: 16mL, and then stirred and mixed for 5 Minutes, capped and moved to a stainless steel reaction kettle, and the reaction kettle was sealed, then placed in an electric blast constant temperature drying oven, reacted at a temperature of 65°C for 24 hours, and then centrifuged at a speed of 6000rpm for 5min. The product was obtained, and then washed with 50 mL of acetone and activated for 72 hours at room temperature, during which the activation solution was replaced 6 times, and then the washed product was obtained by centrifugation, and vacuum-dried at 150 ° C for 8 hours to obtain a powder Metal-organic framework materials.

[0047] 2....

Embodiment 3

[0050] 1. Preparation of metal-organic framework materials: first, 0.68g terephthalic acid (C 8 h 6 o 4 ) and 3.2gCr(NO 3 ) 2 9H 2 O (the molar ratio of organic ligand to inorganic salt is 0.50:1) was transferred to the polytetrafluoroethylene liner, and then dimethylformamide, ethanol and water were added in the ratio of 21mL: 21mL: 14mL, and then stirred and mixed for 5 Minutes, covered and moved to a stainless steel reaction kettle, and sealed the reaction kettle, then placed in an electric blast constant temperature drying oven, reacted at a temperature of 70 ° C for 24 hours, and then centrifuged at a speed of 7000 rpm for 7 minutes. The product was obtained, and then washed with 50 mL of acetone and activated for 72 hours at room temperature, during which the activation solution was replaced 6 times, and then the washed product was obtained by centrifugation, and vacuum-dried at 150 ° C for 9 hours to obtain a powder Metal-organic framework materials.

[0051] 2. M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com