Patents

Literature

36results about How to "Avoid workpiece damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

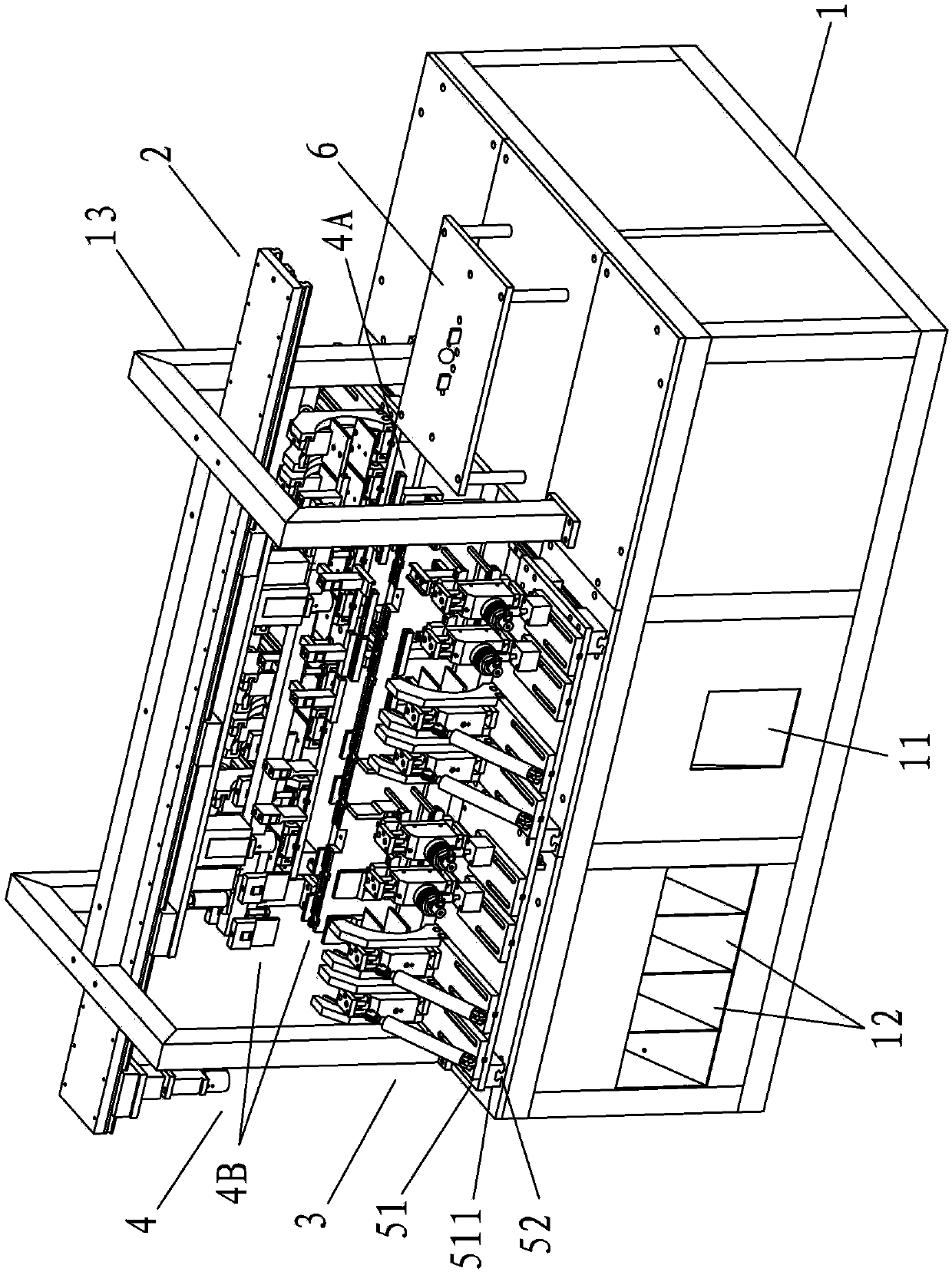

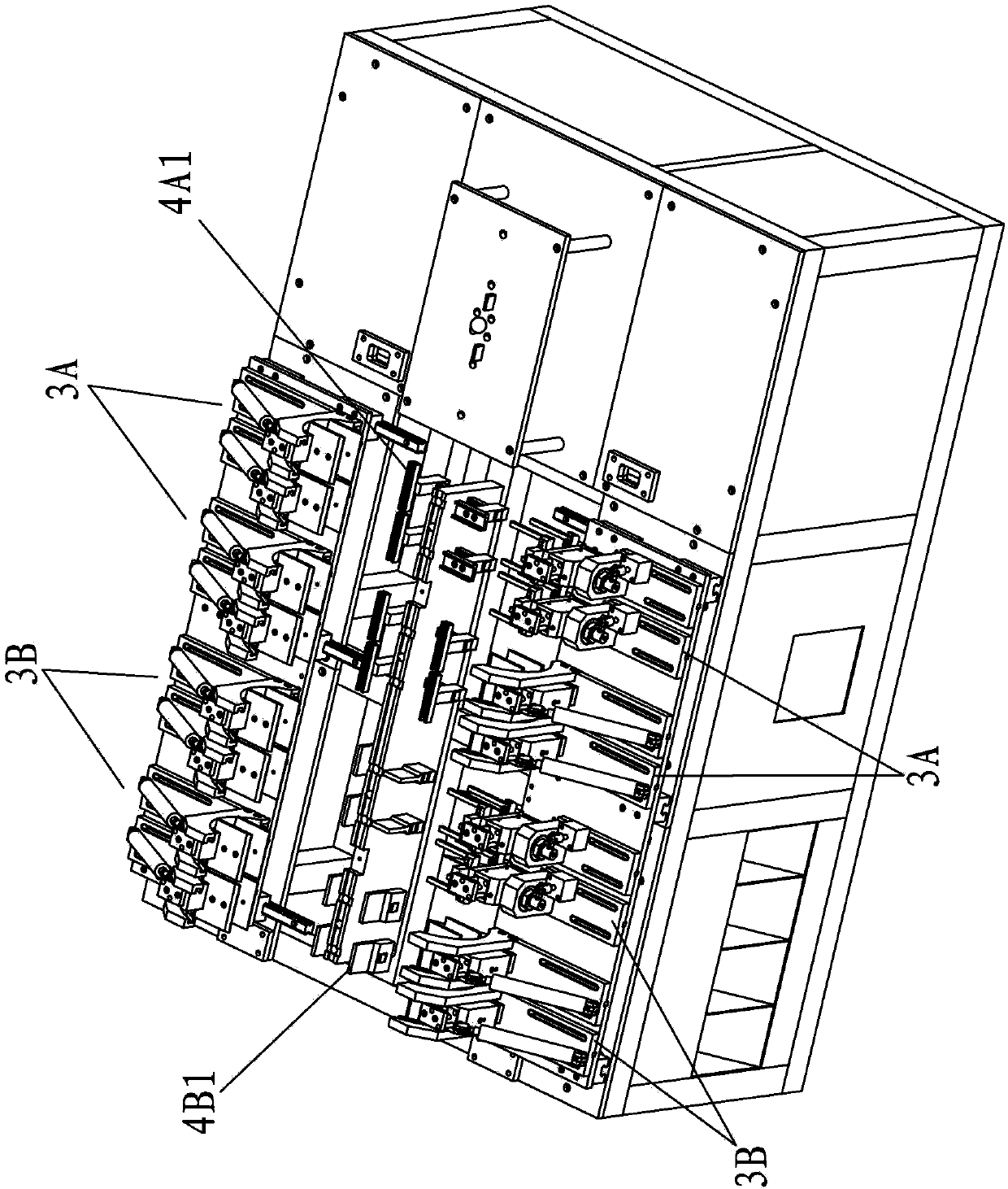

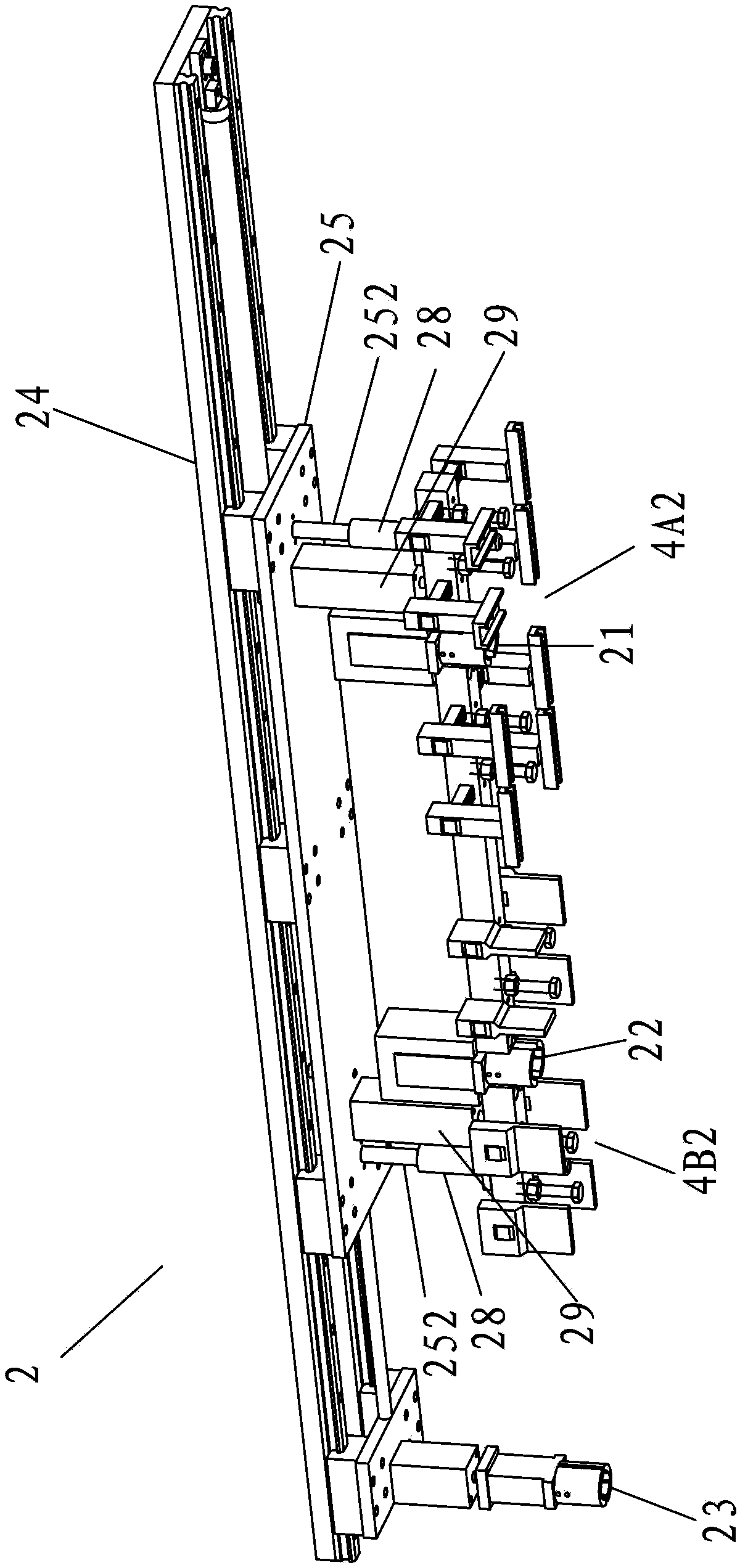

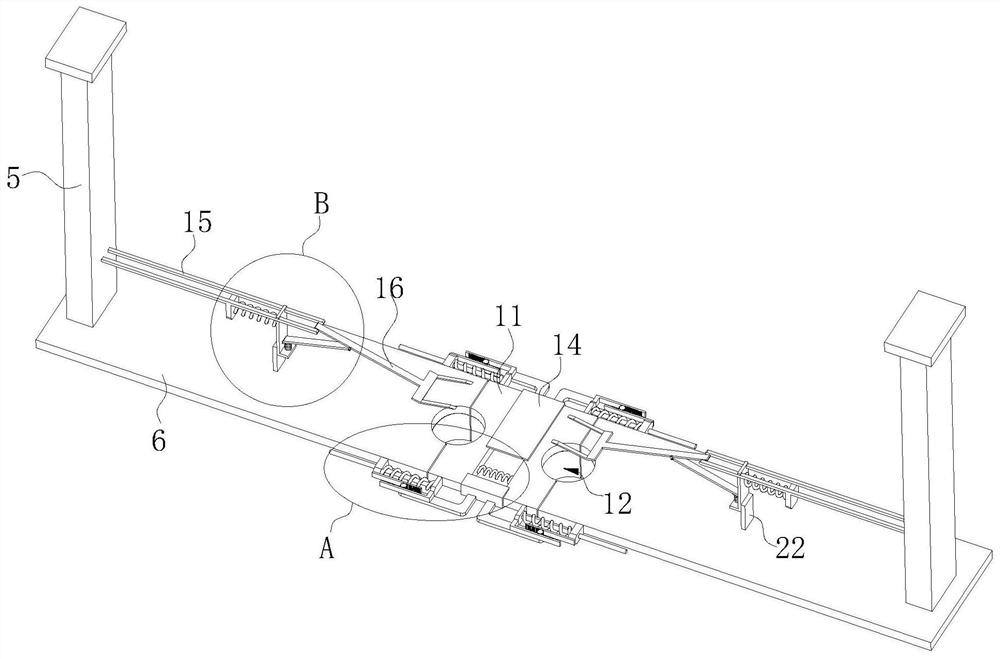

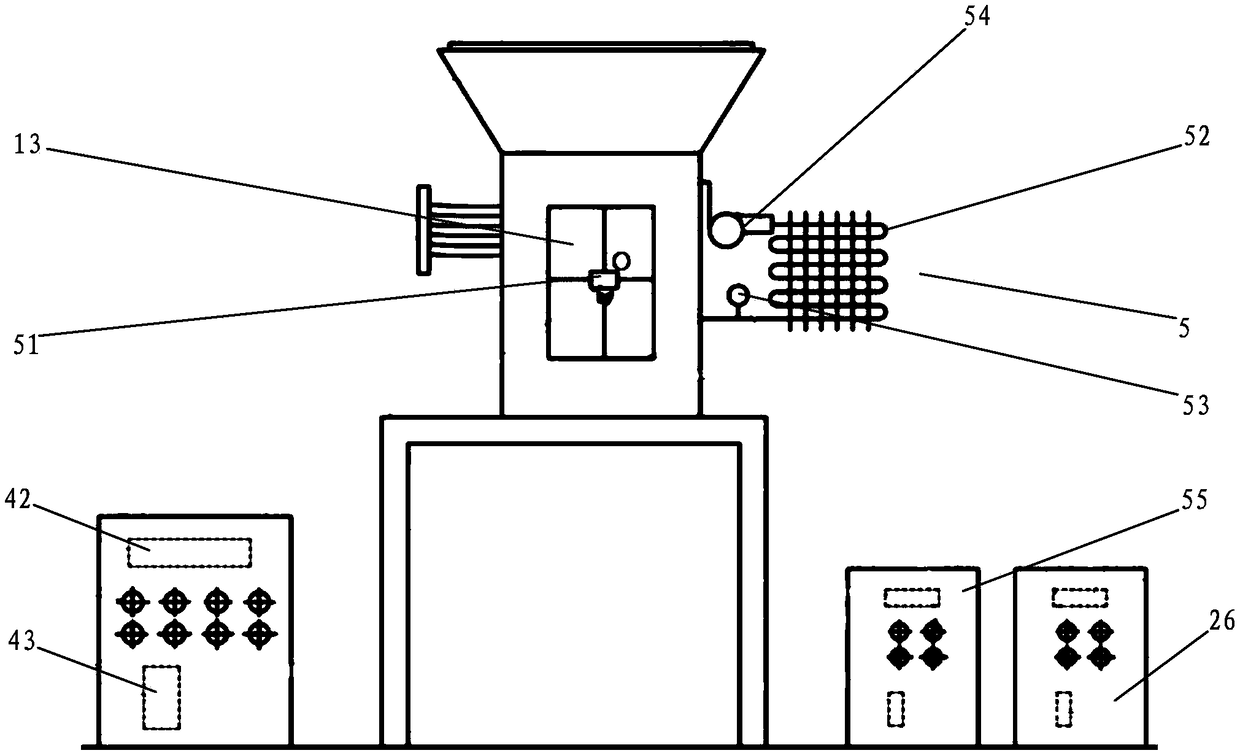

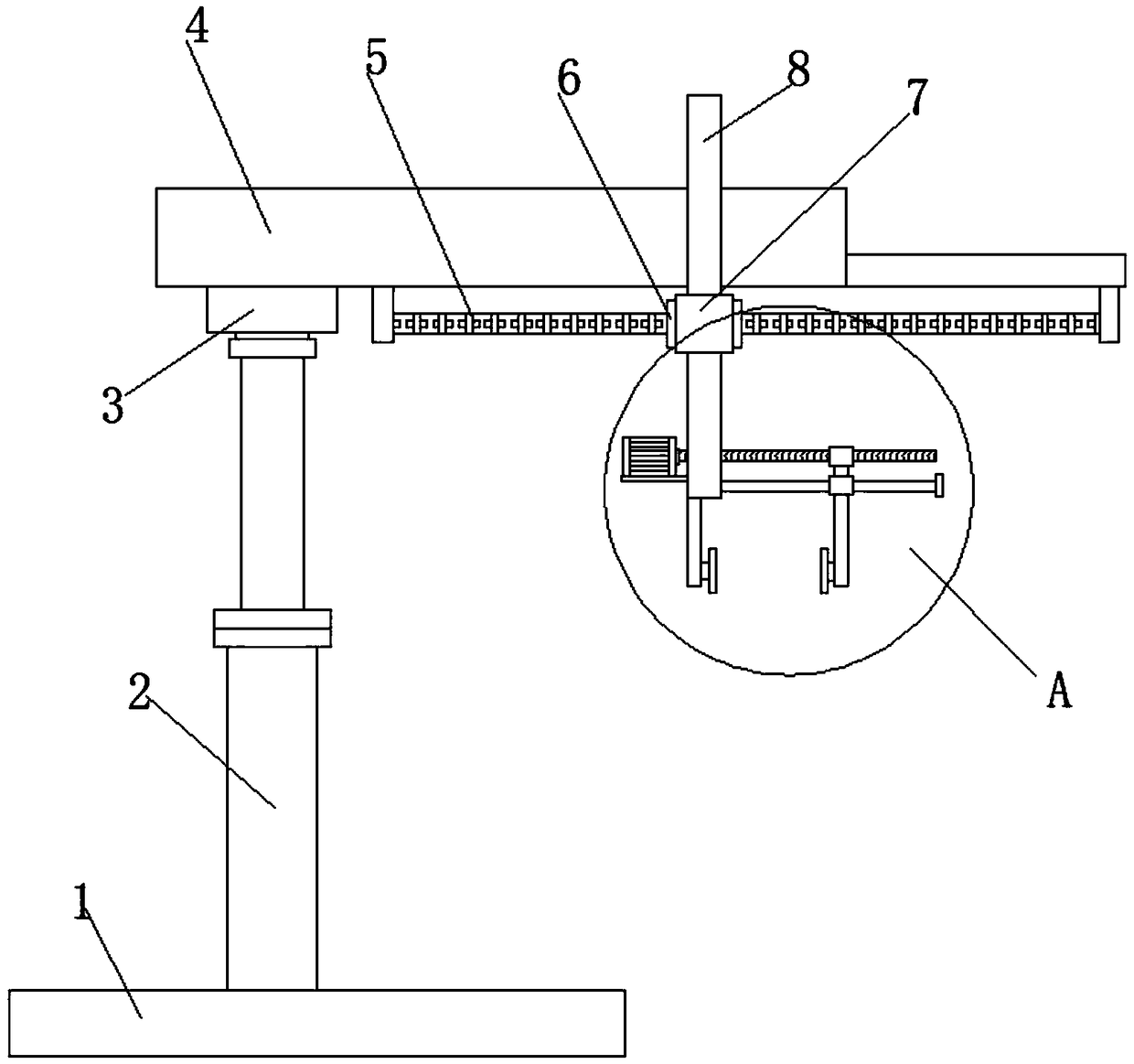

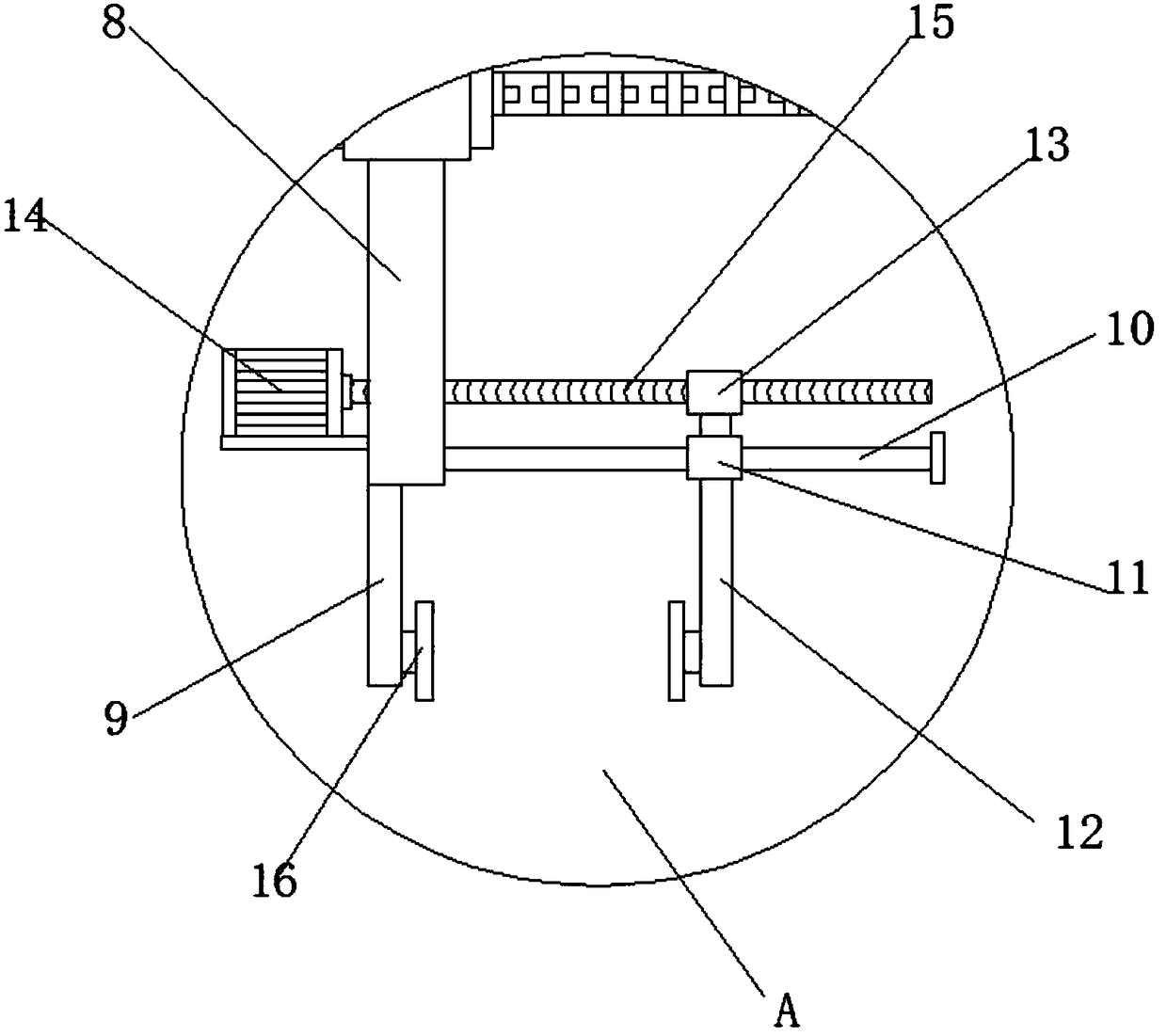

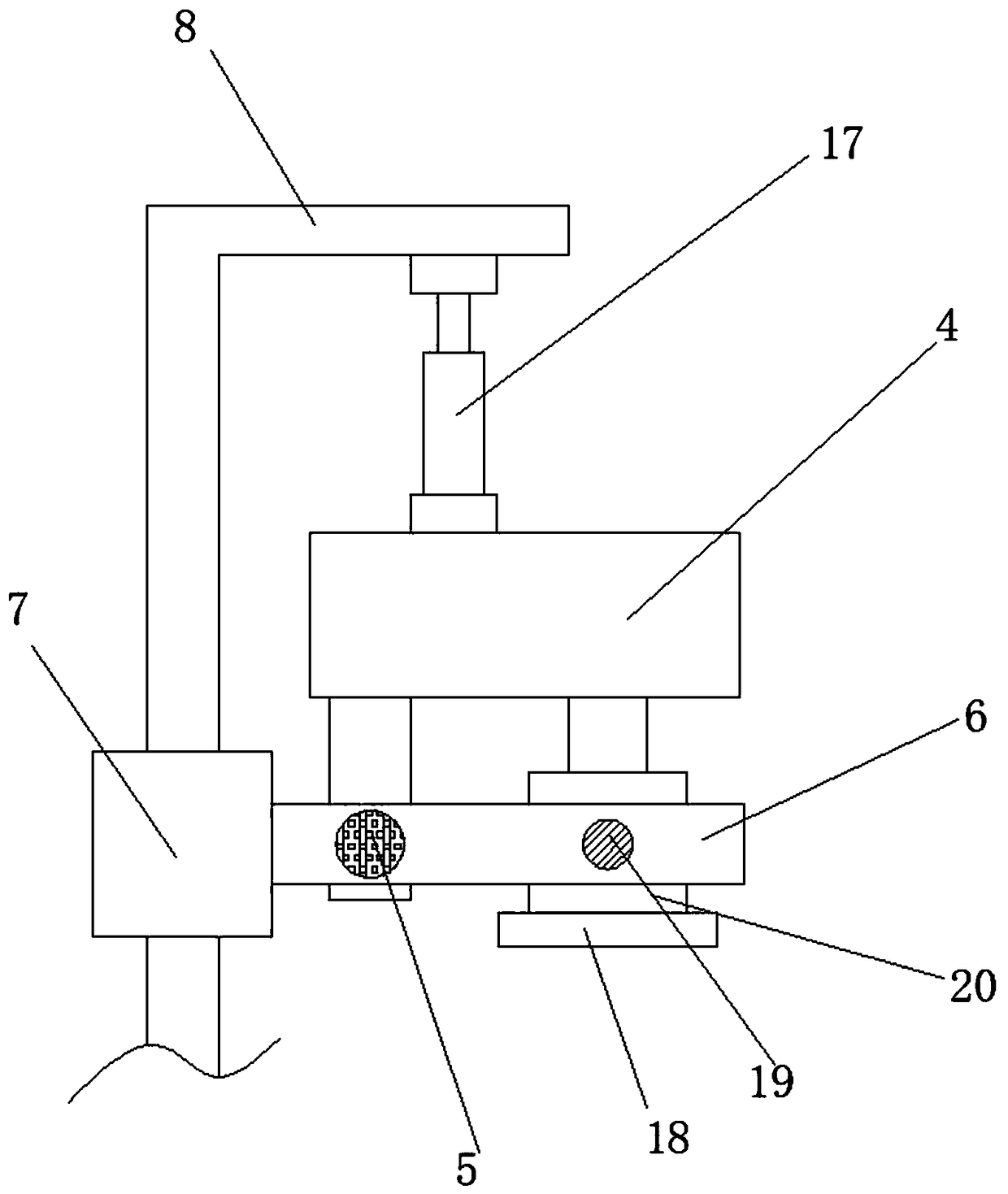

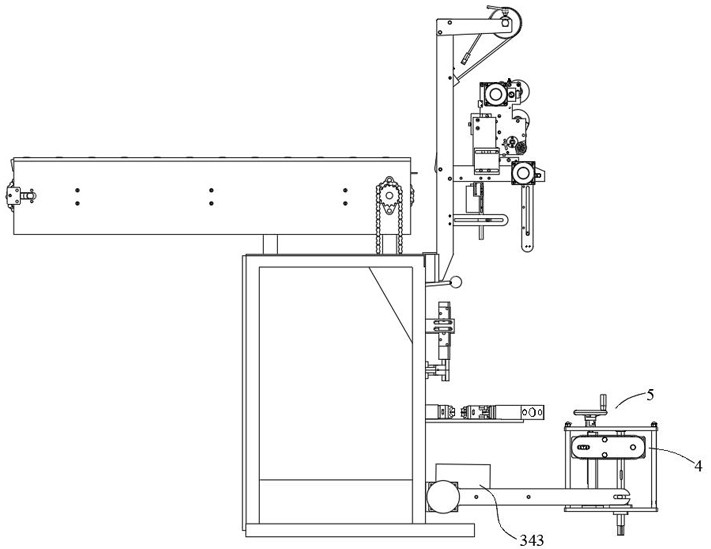

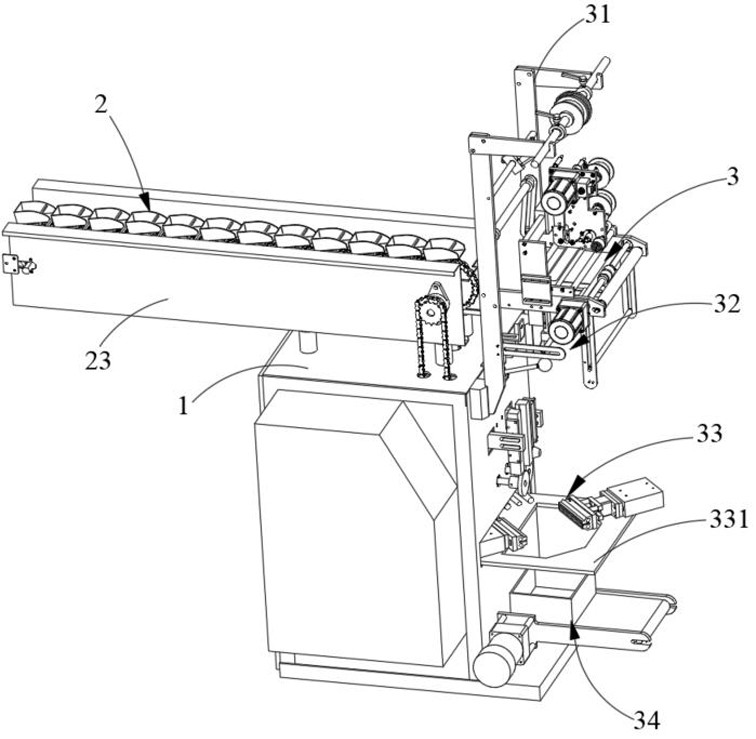

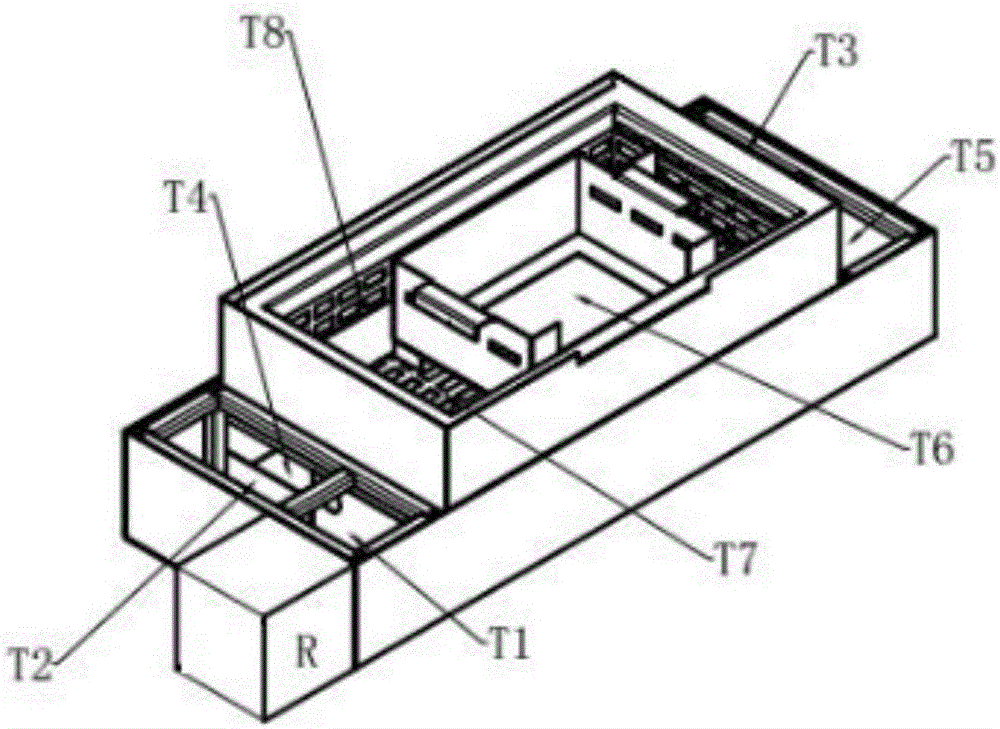

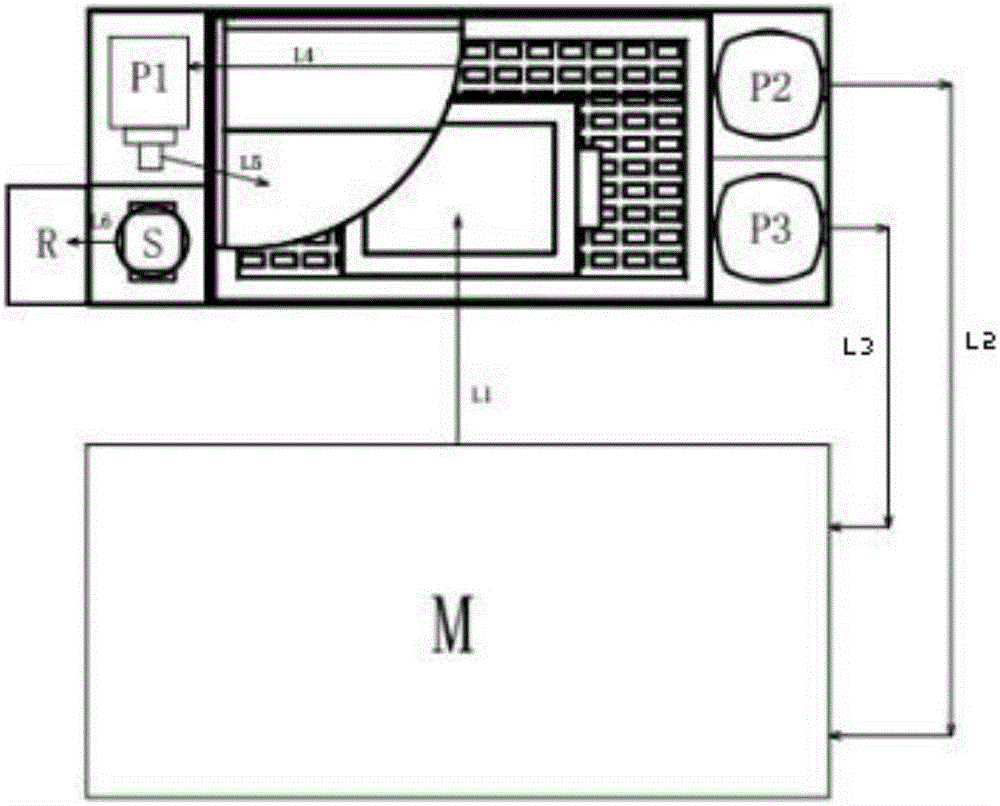

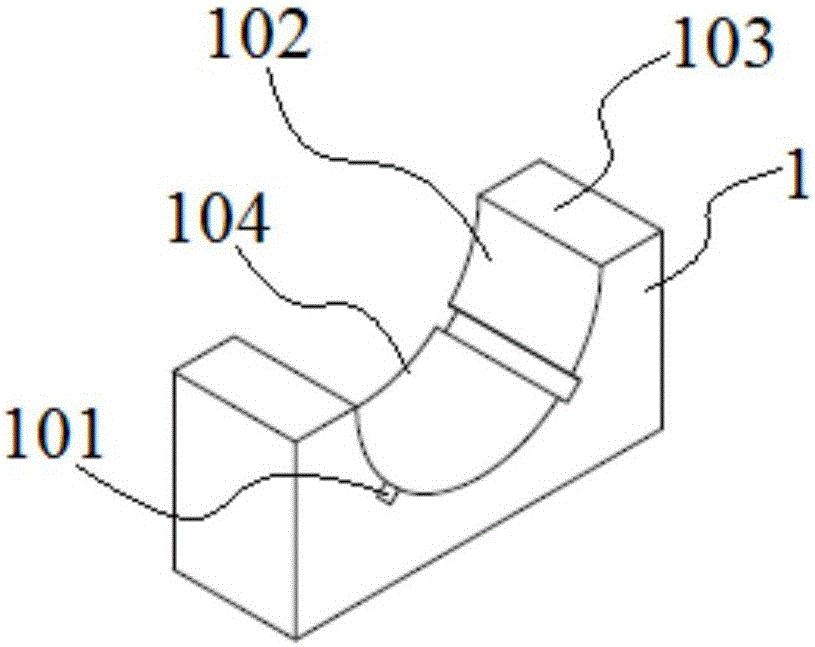

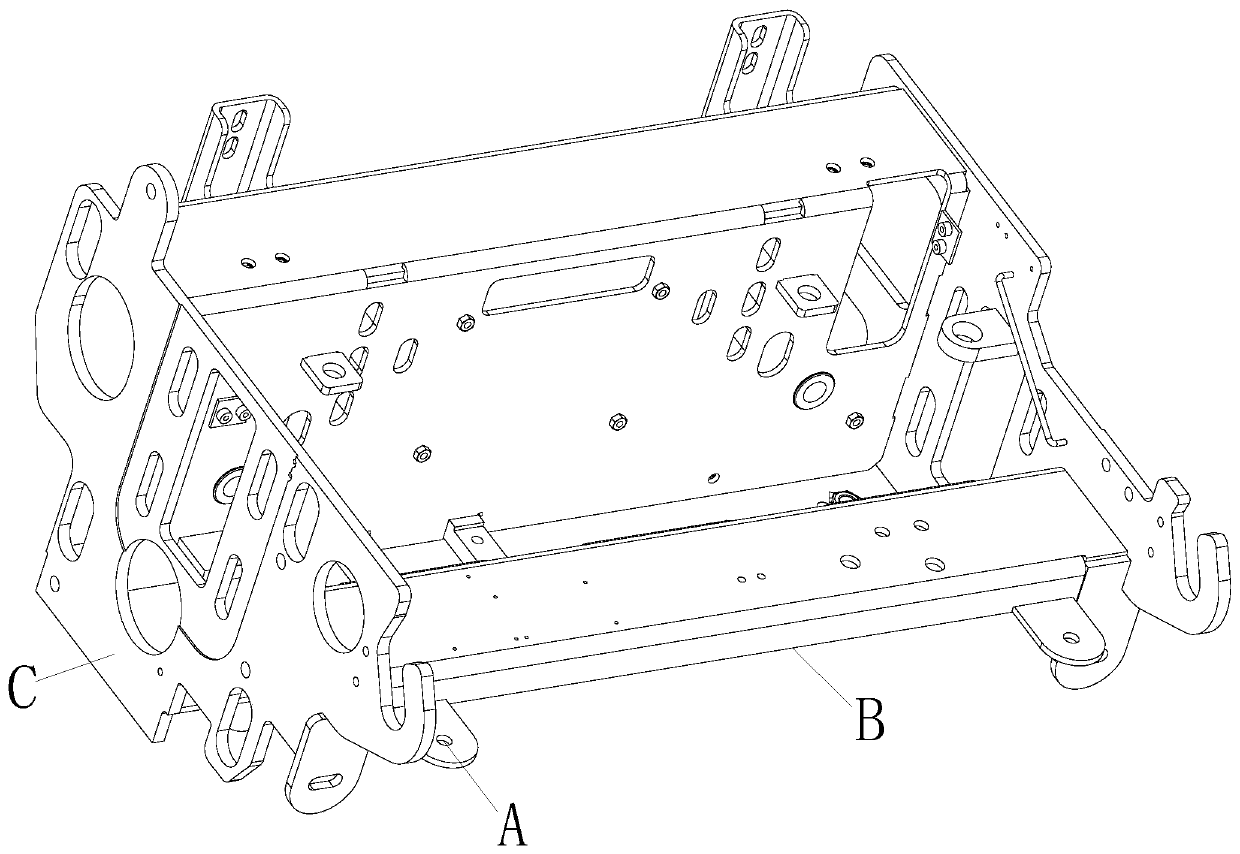

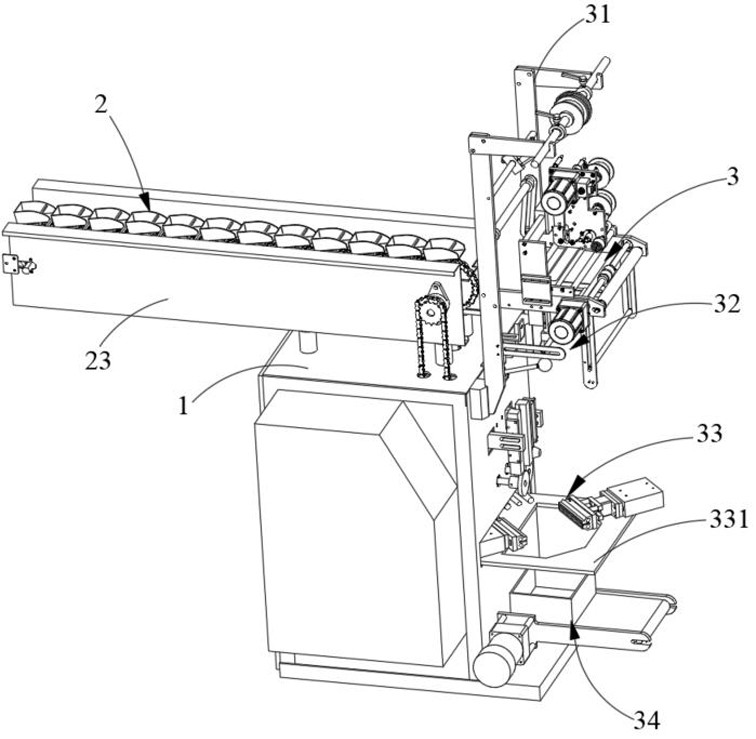

Automatic material distribution machine

ActiveCN103394665AImpact damageAvoid affecting the normal operation of the machineMaterial distributionManipulator

The invention discloses an automatic material distribution machine. The automatic material distribution machine mainly comprises a main machine body, a transporting device, a mechanical arm device and a pressing device. The mechanical arm device comprises first mechanical arm device bodies and second mechanical arm device bodies. The transporting device is arranged above the mechanical arm device. The transporting device comprises first pneumatic fingers, second pneumatic fingers and a third pneumatic finger, wherein the first pneumatic fingers and the second pneumatic fingers are respectively arranged in parallel in a left and right mode and can respectively and synchronously move left and right and respectively and synchronously move up and down. The pressing device comprises a first pressing device body and a second pressing device body, wherein the first pressing device body and the second pressing device body are arranged in parallel in a left and right mode. The first pressing device body comprises first upper pressing device main bodies and first lower pressing device main bodies, wherein the first upper pressing device main bodies are correspondingly matched with each other and can move downward, and the first lower pressing device main bodies are arranged between the two sets of first mechanical arm device bodies. The second pressing device comprises second upper pressing device main bodies and second lower pressing device main bodies, wherein the second upper pressing device main bodies are correspondingly matched with each other and can move downward, and the second lower pressing device main bodies are arranged between the two sets of second mechanical arm device bodies. The automatic material distribution machine is simple in structure, free of a cooling device, good in material distributing effect, and extremely high in automatic degree and efficiency.

Owner:吴芳艺

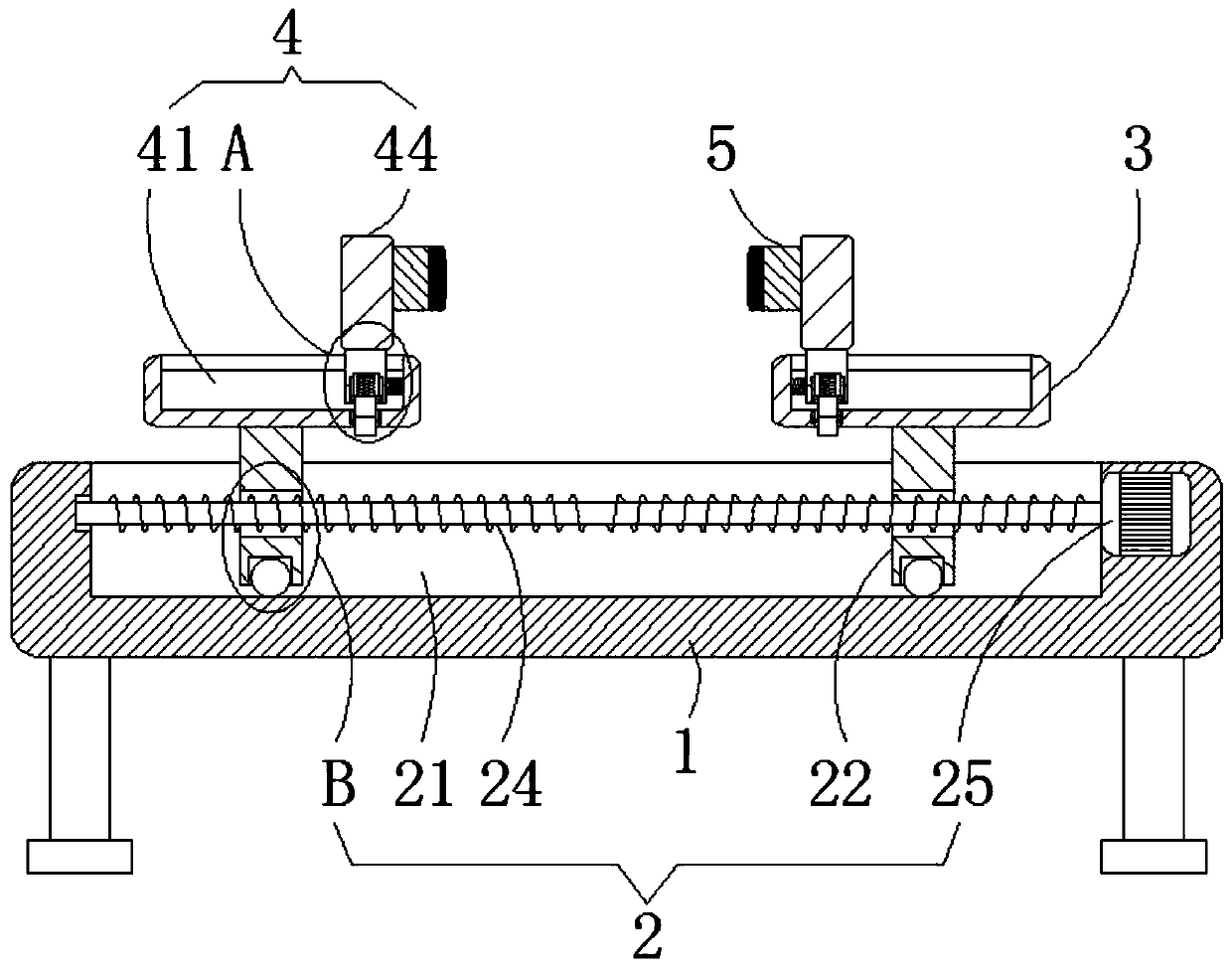

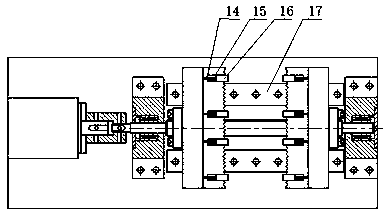

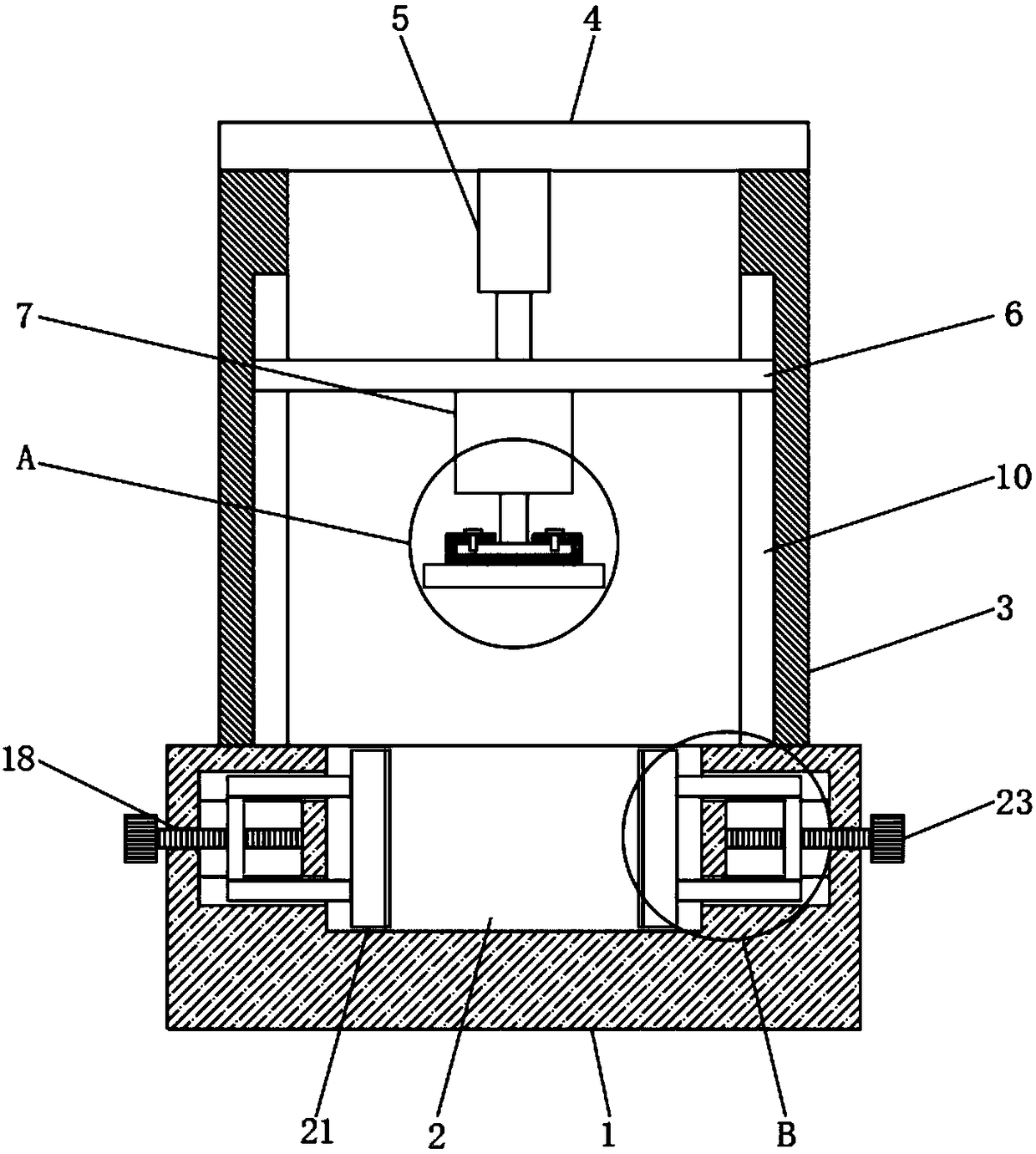

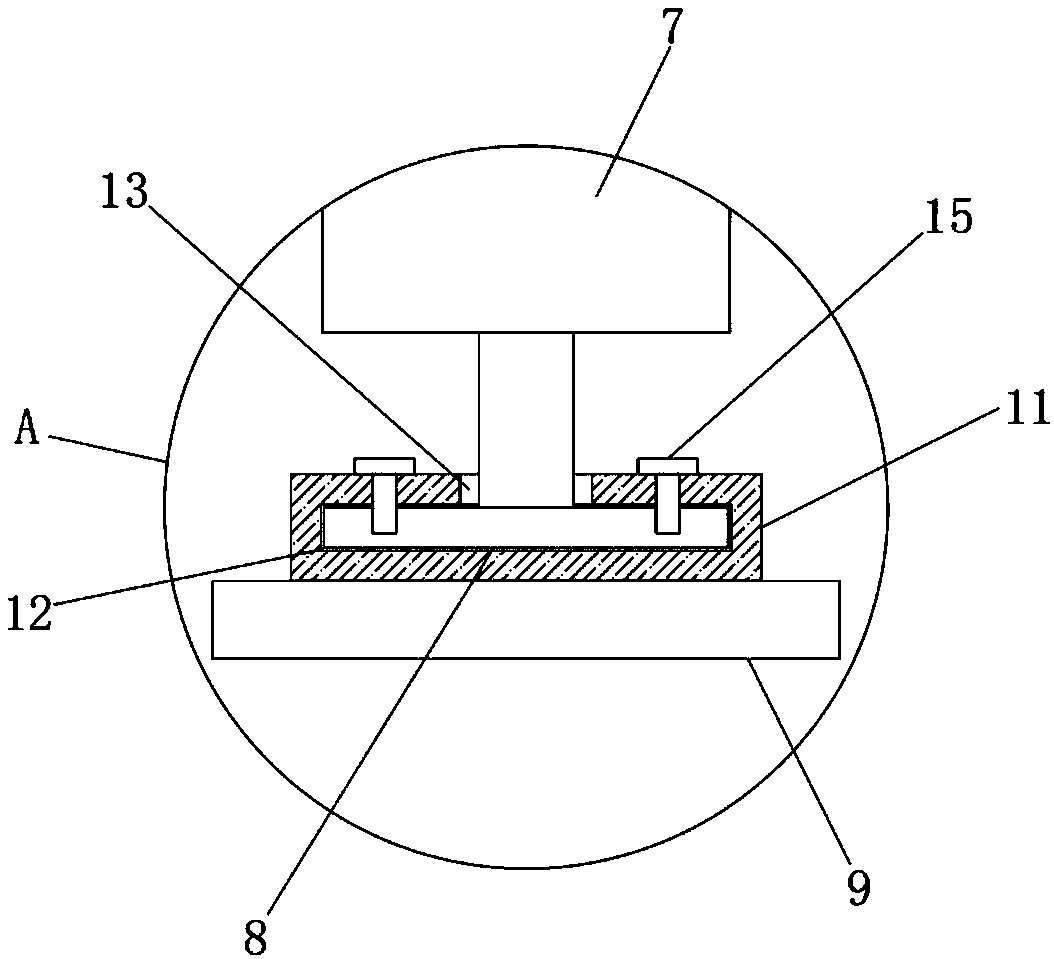

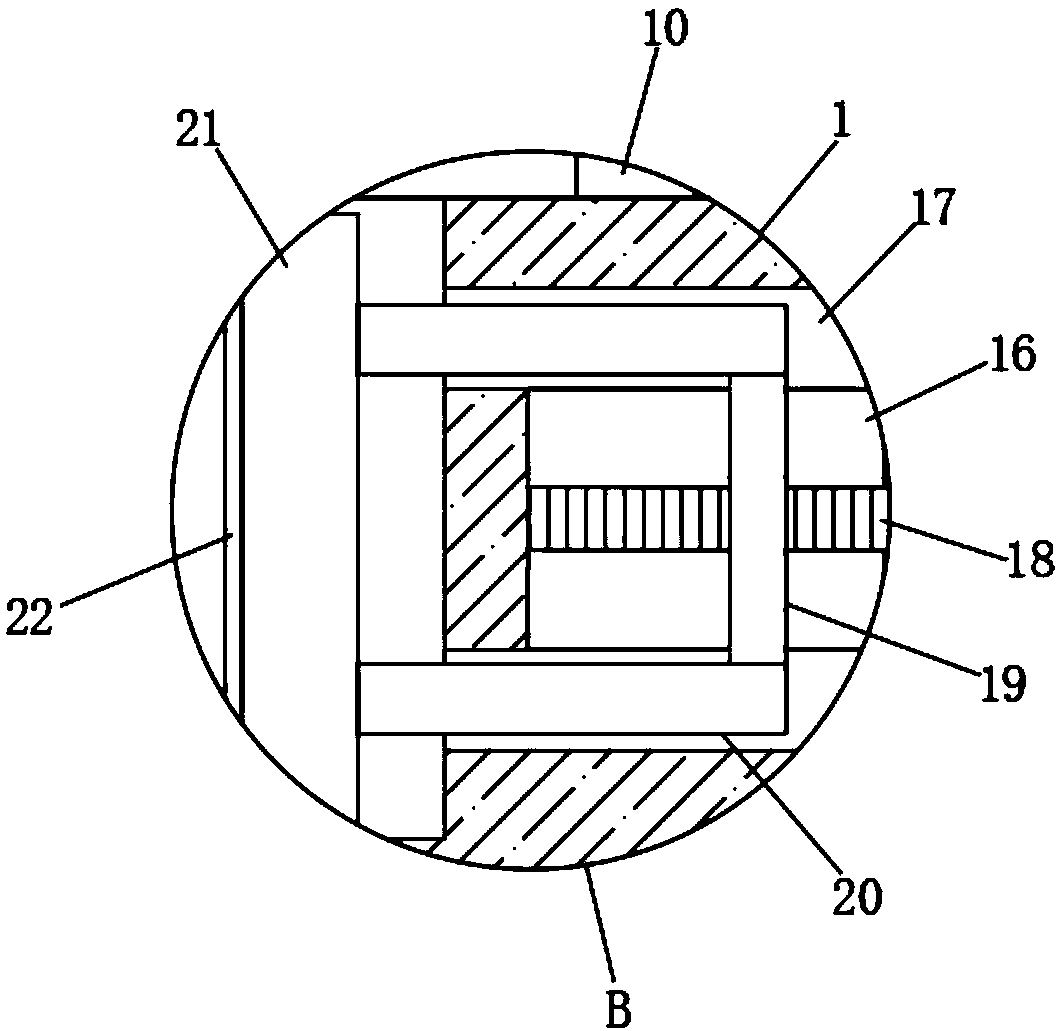

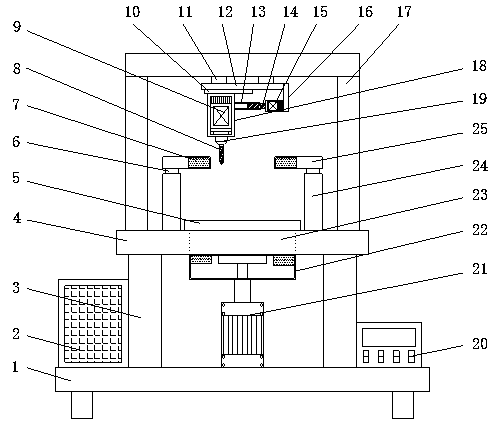

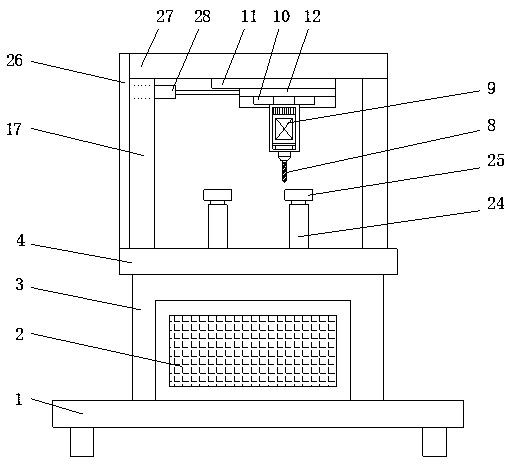

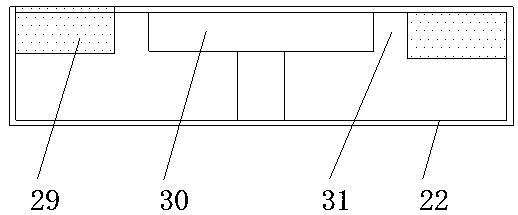

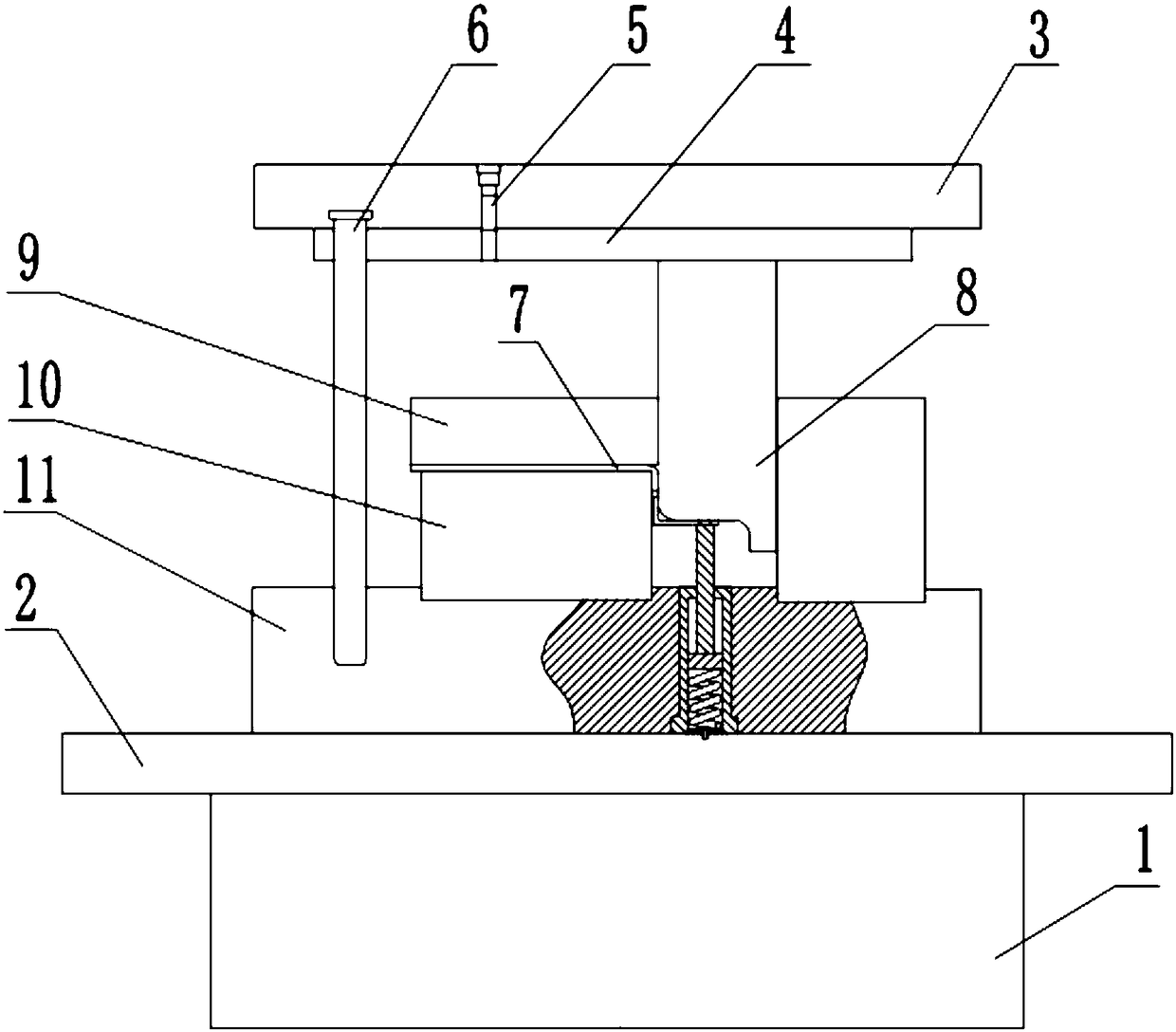

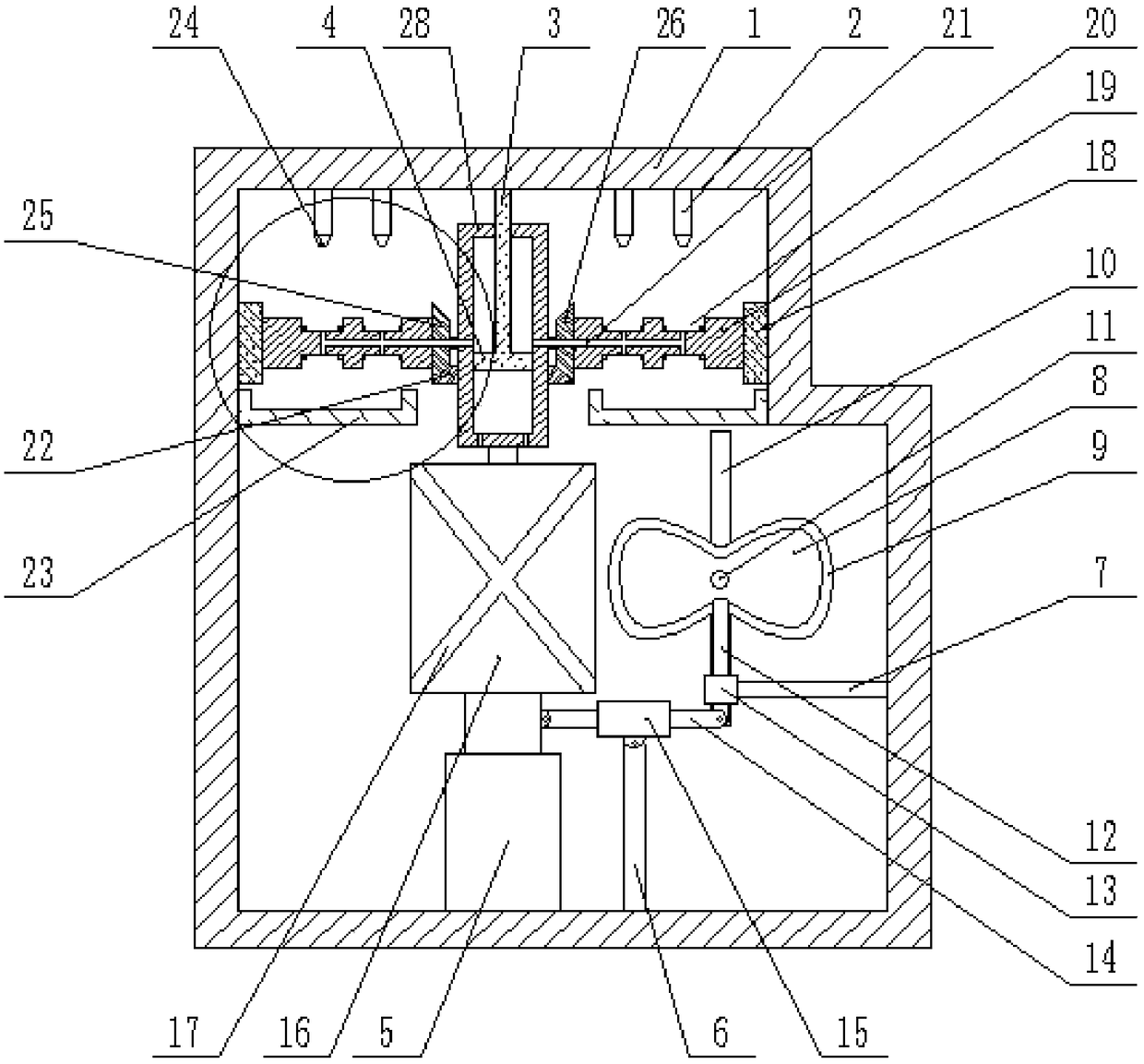

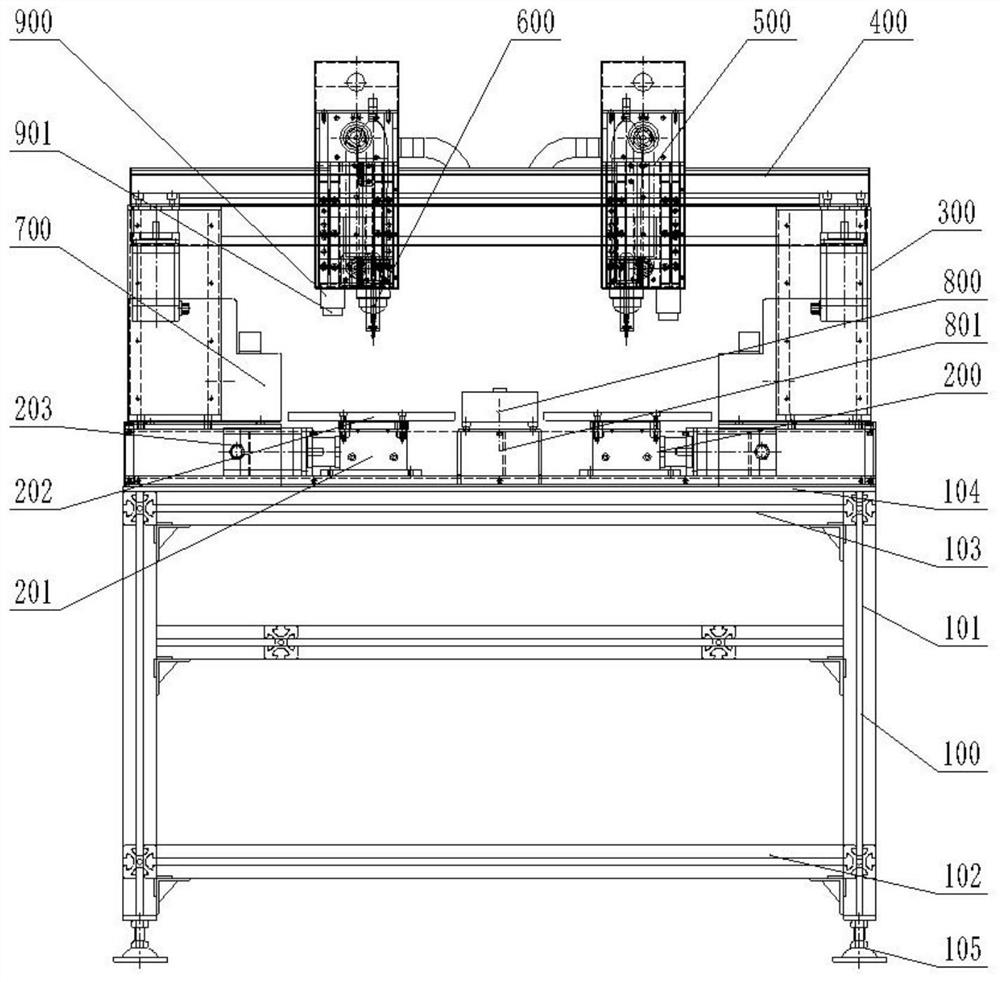

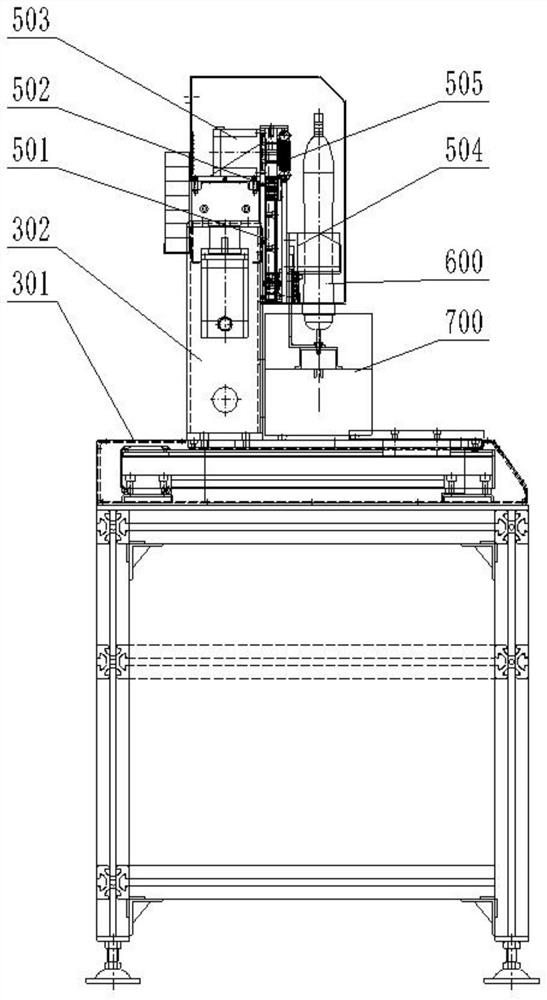

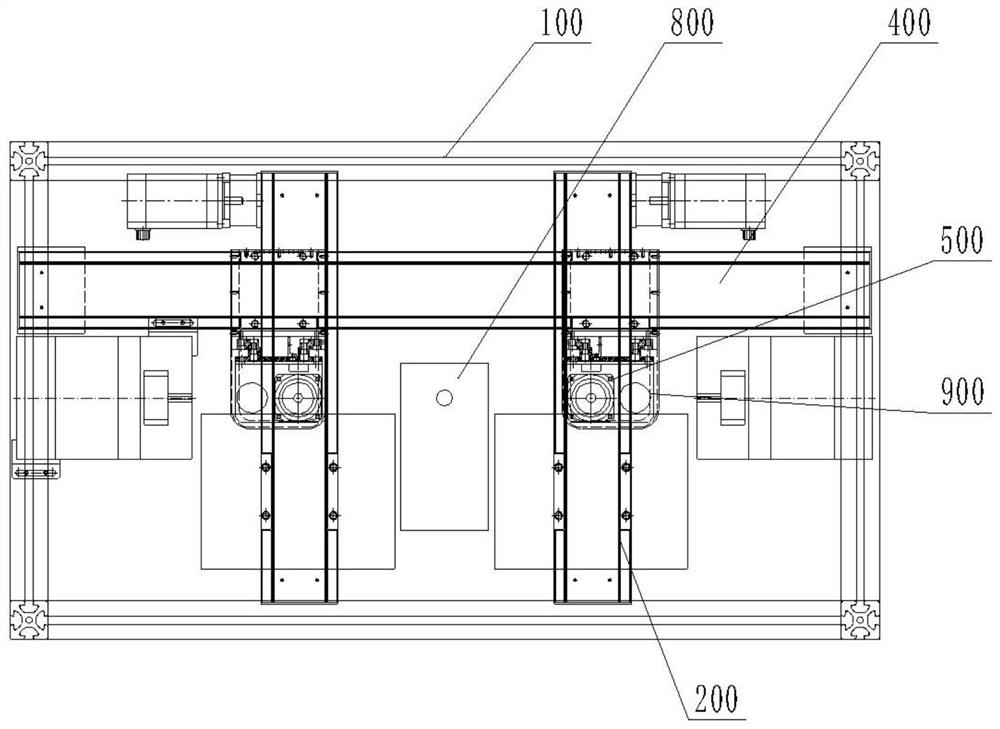

High precision double spindle machine tool for rear axle production

ActiveCN110238674AFixed and accurateAvoid damage to the workpiecePositioning apparatusMetal working apparatusEngineeringMachine tool

The invention relates to the technical field of processing machine tools and discloses a high precision double spindle machine tool for rear axle production. The high precision double spindle machine tool comprises a machine tool body, wherein moving plates are symmetrically connected to the top of the machine tool body through an adjusting mechanism, and the tops of the two moving plates are connected to clamping blocks through connecting mechanisms; each connecting mechanism comprises a T-shaped chute, a clamping hole, a T-shaped slide block, a connecting plate, a first spring, a spring slot, a second spring and a clamping rod. The T-shaped chute is formed in the top side wall of each moving plate, the two clamping holes which are formed symmetrically are formed at the bottom of the T-shaped chute, the T-shaped slide block is slidably connected in the T-shaped chute, the upper end of the T-shaped slide block penetrates the notch of the T-shaped chute and stretches upward, and the connecting plate is fixedly connected to the upper end of the T-shaped chute. The high precision double spindle machine tool for rear axle production fix workpieces of a same batch conveniently, do not damage the workpieces and fix workpieces of different batches conveniently.

Owner:徐州玉伟机械设备有限公司

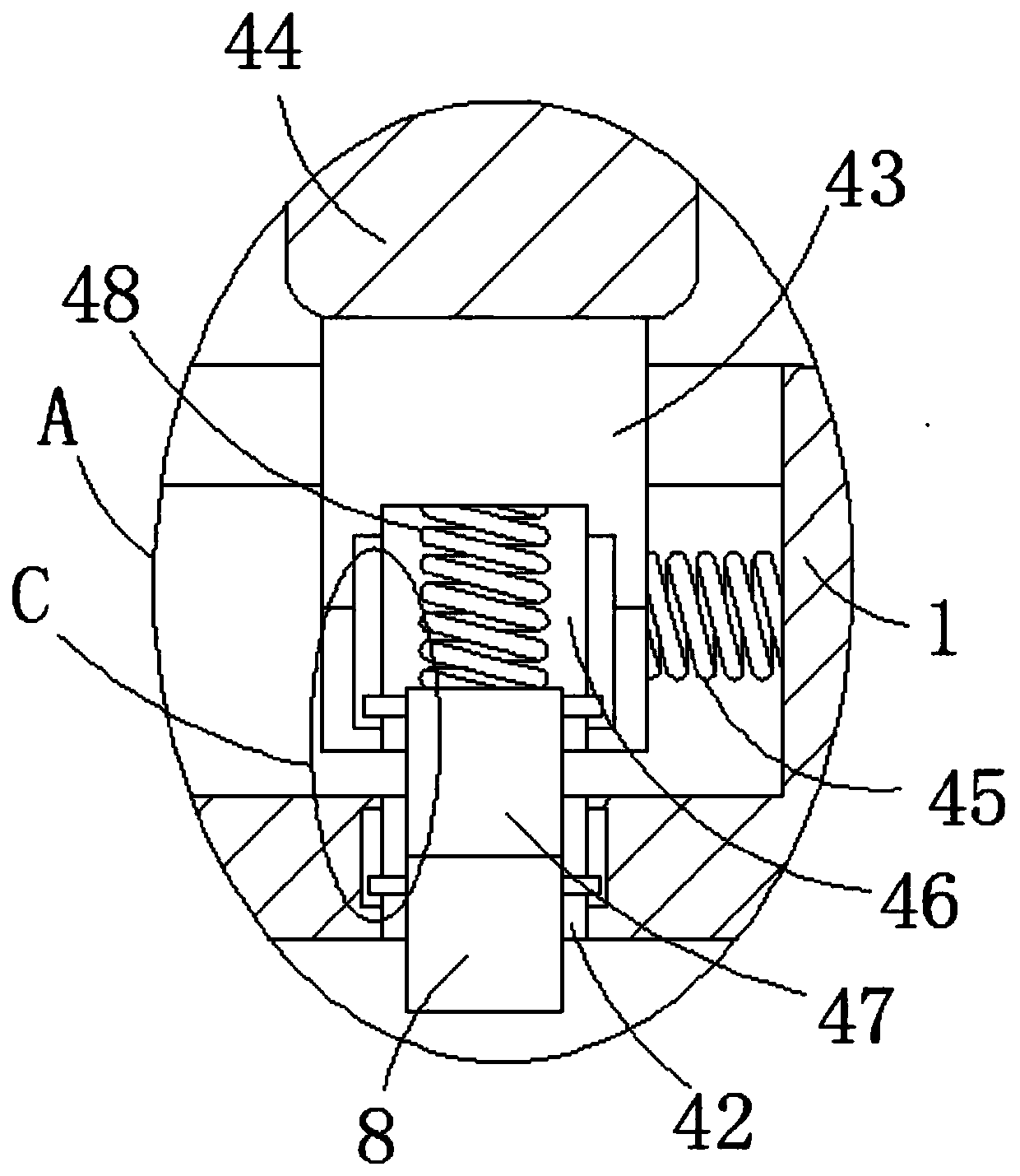

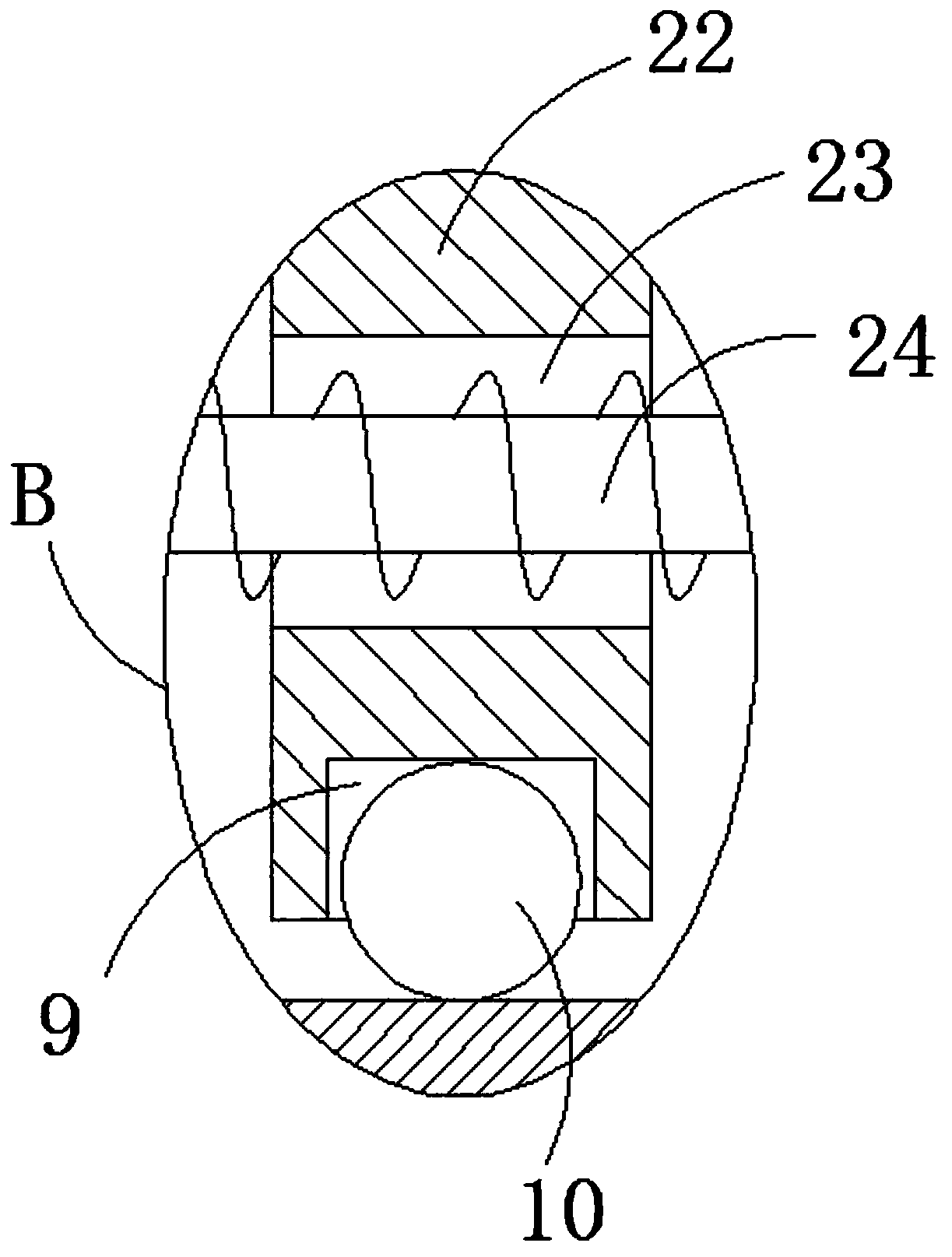

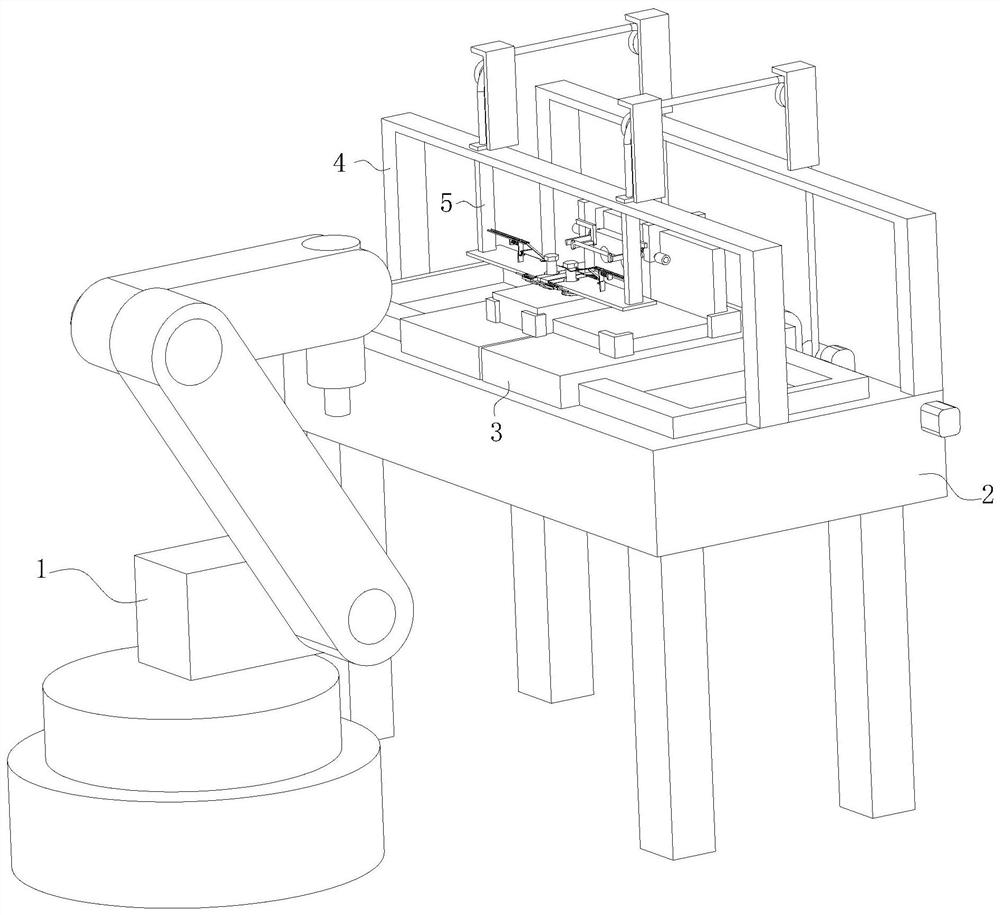

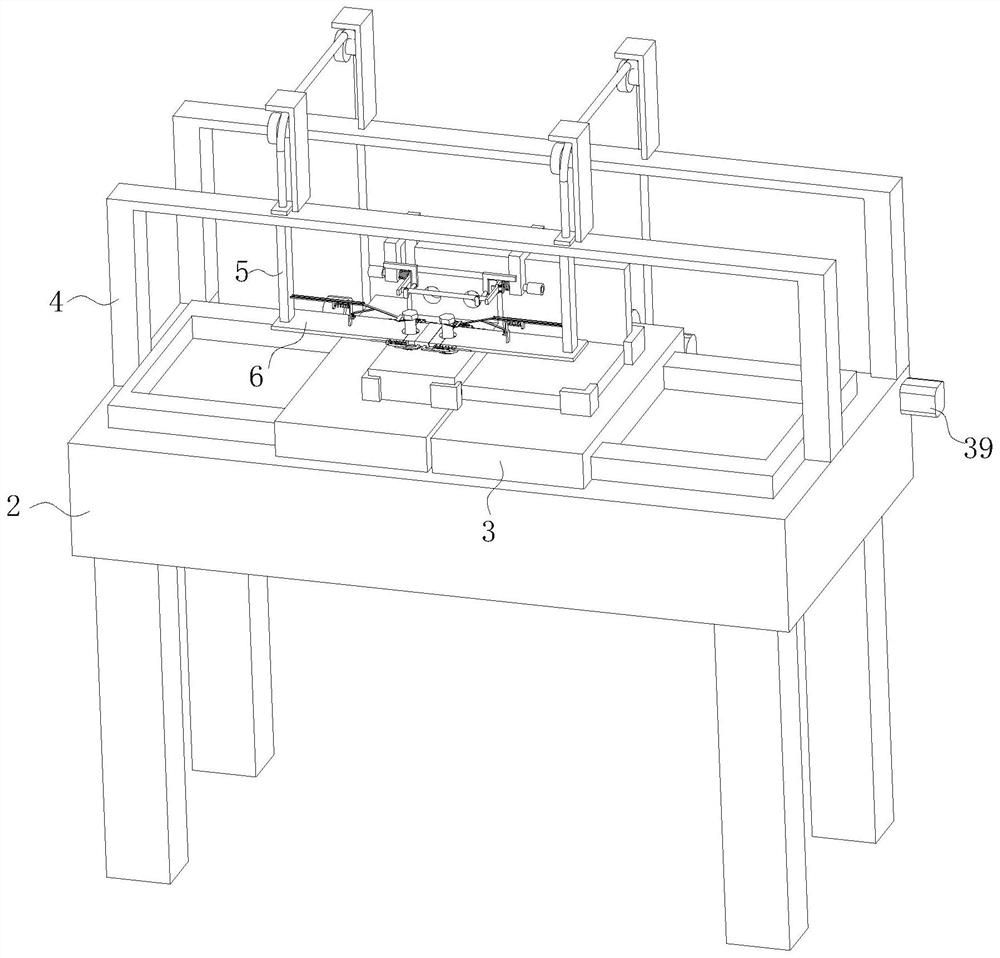

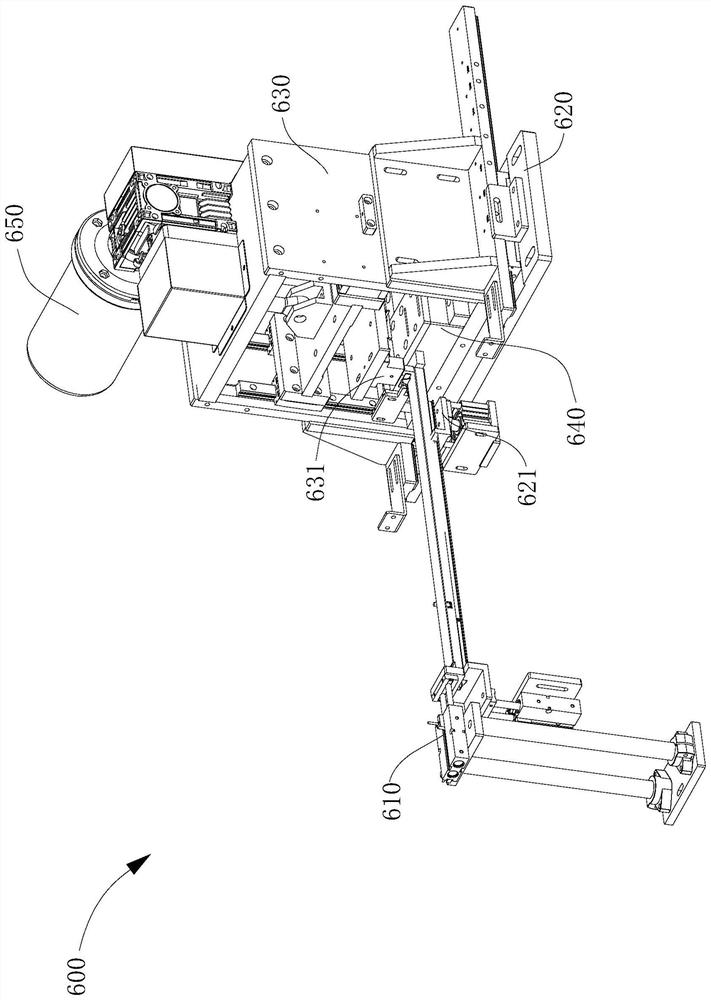

Precise six-degree-of-freedom assembly robot

InactiveCN113182832AEnsure safetyAvoid workpiece damageMetal working apparatusControl engineeringStructural engineering

The invention discloses a precise six-degree-of-freedom assembly robot, and belongs to the technical field of six-degree-of-freedom assembly robots. The precise six-degree-of-freedom assembly robot comprises a six-axis robot and an assembly table, wherein the six-axis robot is located on the front side of the assembly table; two symmetrically-arranged shelving plates are slidably connected to the top of the assembly table; and a driving mechanism used for driving the two shelving plates to move towards the middle of the assembly table simultaneously is connected to the top of the assembly table. When the six-axis robot is used for fastening a bolt every time, the bolt is guided through a through groove formed by a first connecting plate and a second connecting plate, so that the bolt can be smoothly aligned with a threaded hole of a workpiece every time, the bolt does not need to be clamped by the six-axis robot for thread fastening, the situation that the bolt cannot be aligned with the threaded hole of the workpiece and the workpiece is damaged due to track change caused by deviation or fixing looseness in operation of the six-axis robot is avoided, and the working safety is guaranteed.

Owner:北京瓢虫星球信息技术有限公司

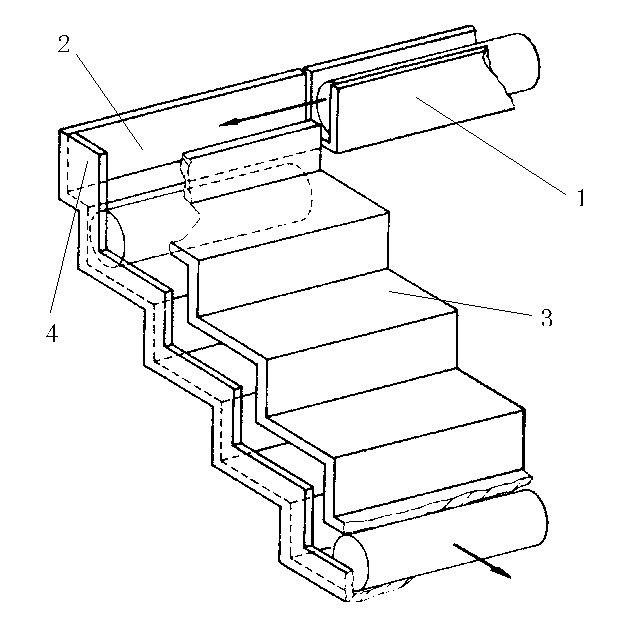

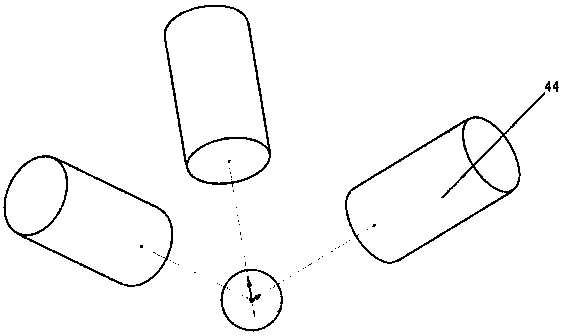

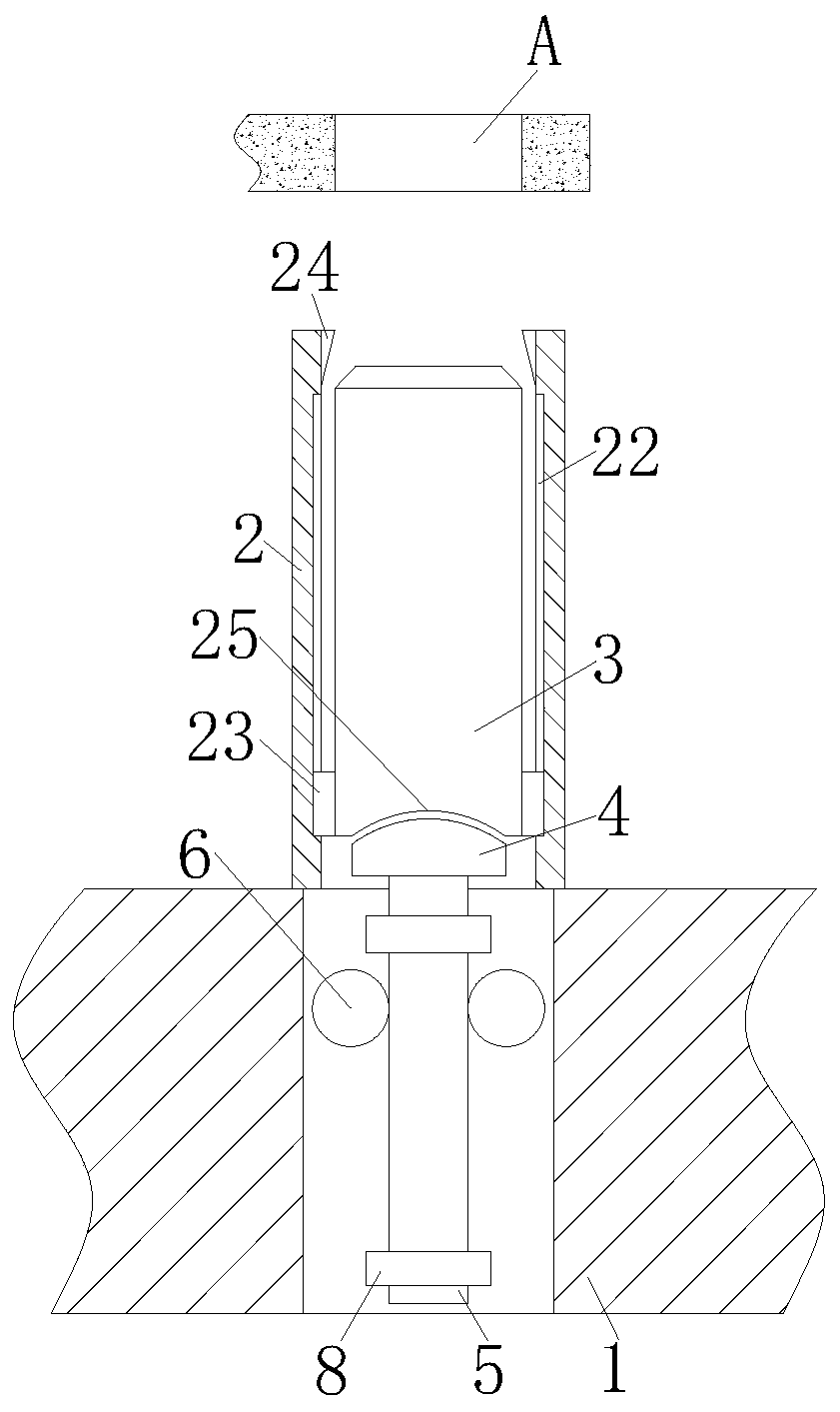

Cylindrical workpiece stepped sliding chute feed device

InactiveCN103101709AAvoid situations where automatic scrolling down is not possibleAvoid workpiece damageChutesEngineeringMechanical engineering

The invention belongs to the field of workpiece convey, and particularly relates to a cylindrical workpiece stepped sliding chute feed device. The cylindrical workpiece stepped sliding chute feed device comprises a feed convey device and an output device. The feed convey device is a horizontally-arranged feed sliding chute. The output device comprises a stepped sliding rail and a stepped cover arranged on the stepped sliding rail, and a stepped cavity is formed between the stepped sliding rail and the stepped cover and is equal to a workpiece in size. The bottom surface of the feed sliding chute and a first step surface of the stepped sliding rail are arranged on the same plane and are close to each other. According to the cylindrical workpiece stepped sliding chute feed device, the workpiece can flow out in a horizontal state, and workpieces can be fed in a single mode.

Owner:CHONGQING JUKANG BUILDING MATERIAL

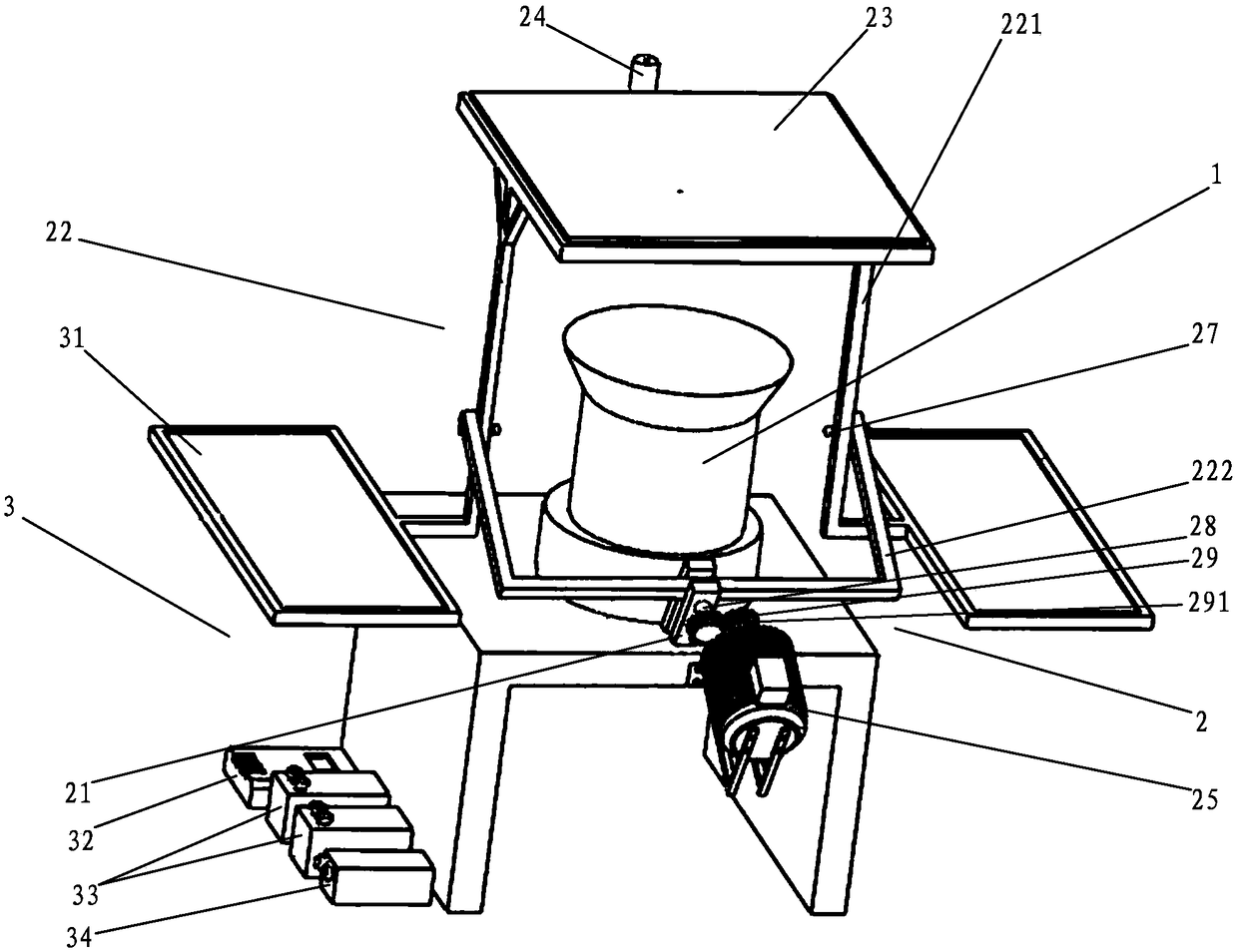

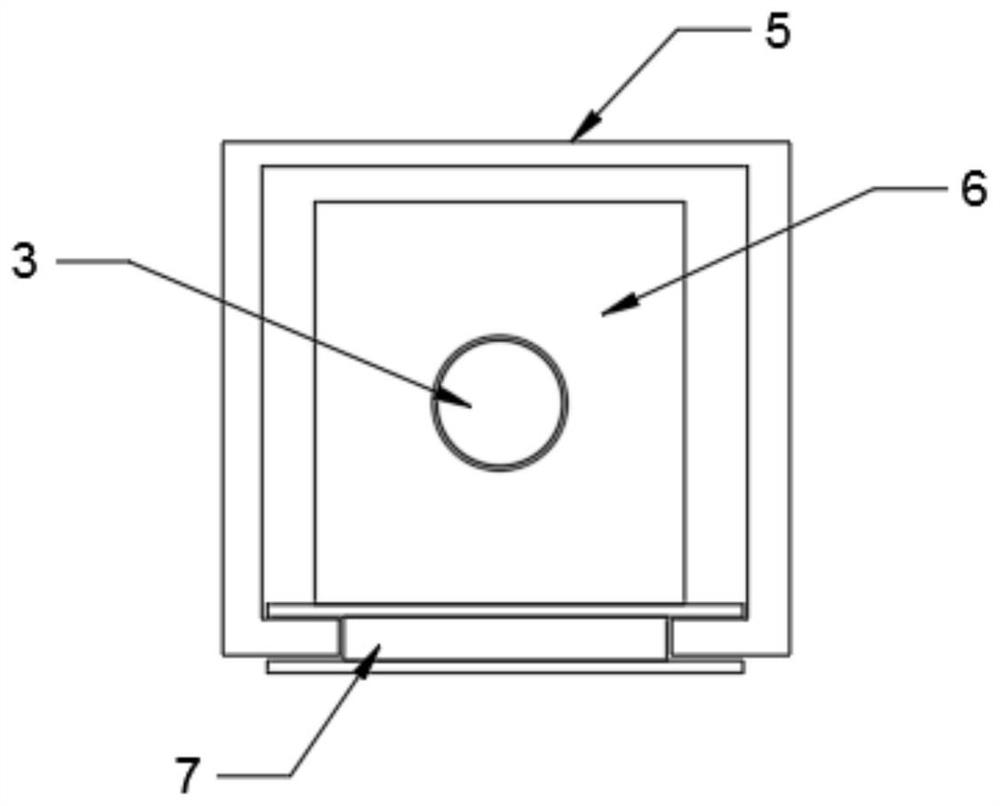

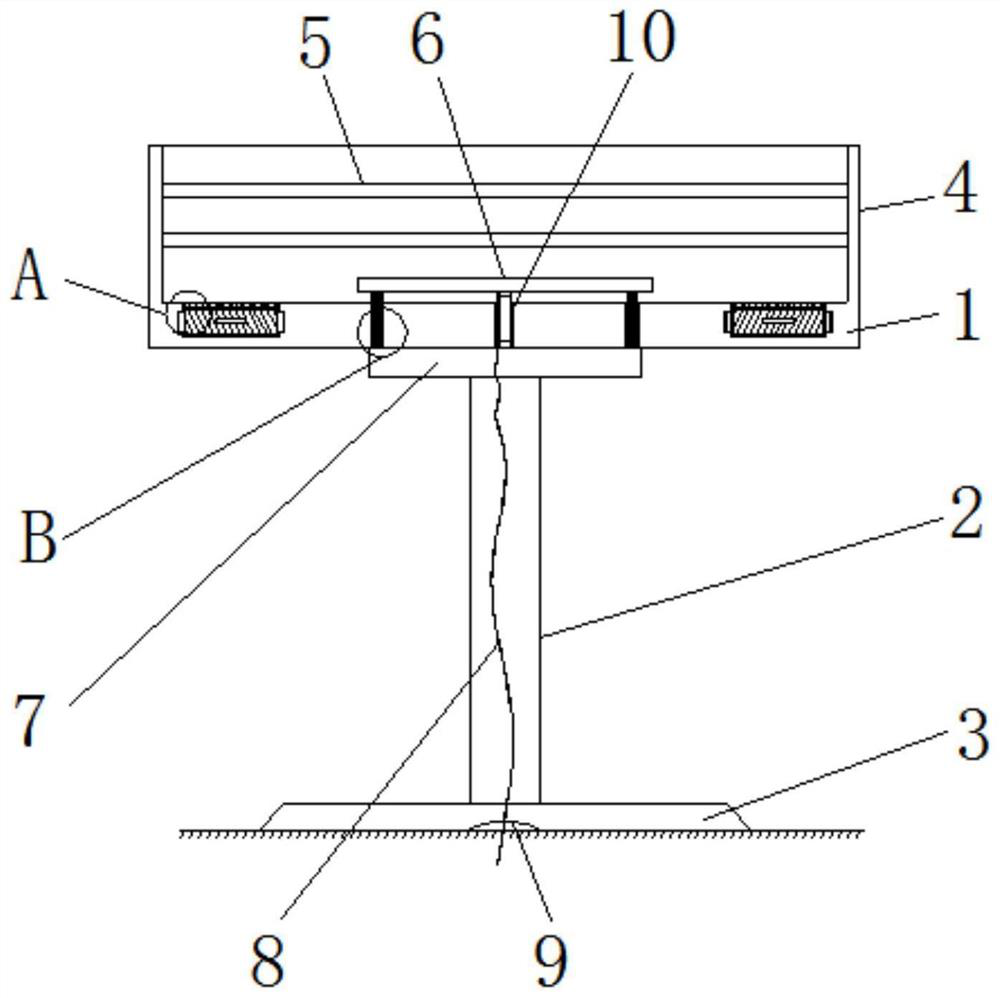

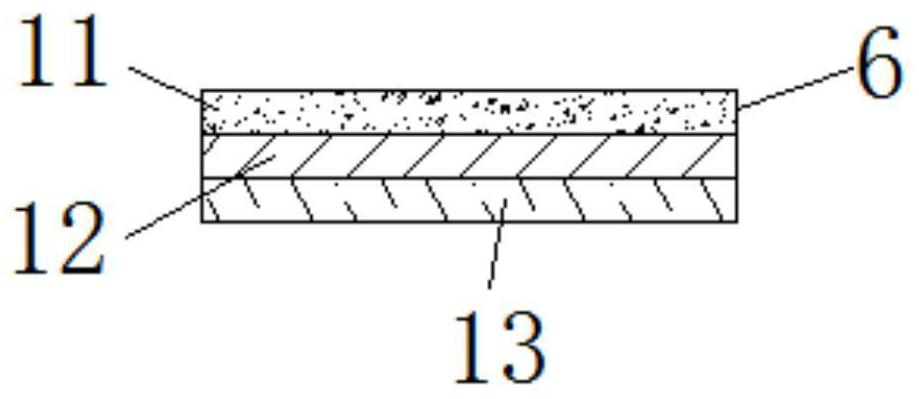

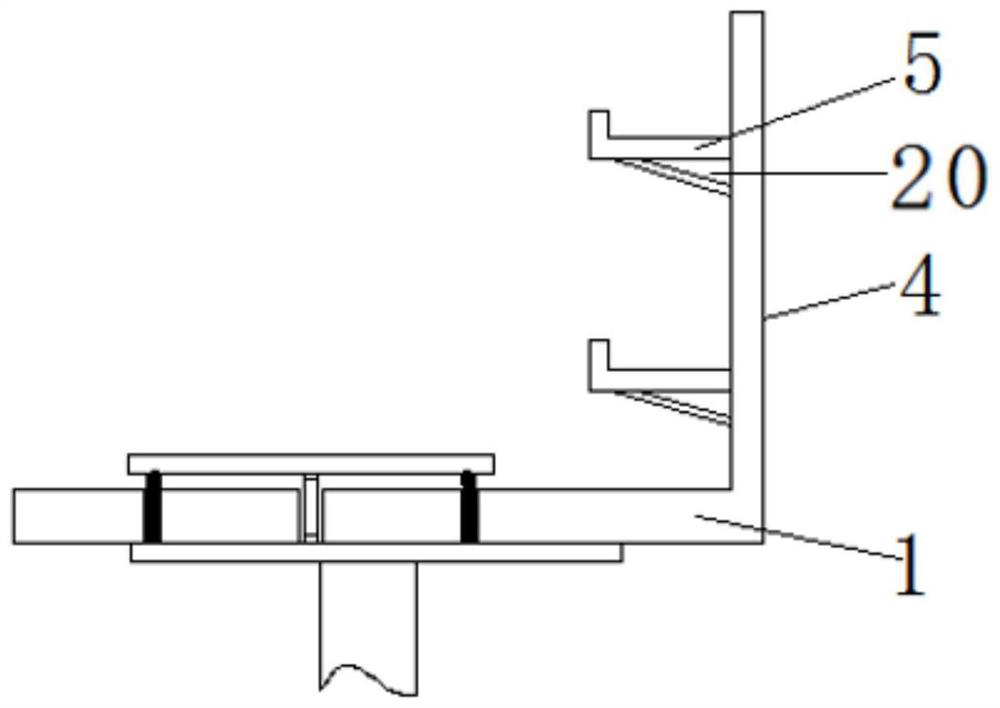

Electromagnetic suspension type solar heat treatment furnace

PendingCN108491008AGuaranteed uniformityPrevent damage to the workpiecePhotovoltaic supportsSolar heating energyTemperature controlFresnel lens

The invention discloses an electromagnetic suspension type solar heat treatment furnace comprising a furnace body, a solar automatic tracking and heating system, a solar photovoltaic power supply system, an electromagnetic suspension system and a temperature control system. A to-be-processed workpiece is arranged in the furnace body; and the focal point formed by the solar automatic tracking and heating system is located on the to-be-processed workpiece. The solar photovoltaic power supply system receives sunlight and transforms the sunlight into the electric energy and is used for providing power for the solar automatic tracking and heating system, the electromagnetic suspension system, and the temperature control system. The electromagnetic suspension system generates a multi-dimensionalmagnetic force to control the to-be-processed workpiece to be suspended and rotate. According to the invention, the to-be-processed workpiece is heated by using the sunlight directly and is controlled to be suspended and rotate by using the multi-dimensional magnetic force generated by the electromagnetic suspension system, so that the to-be-processed workpiece is heated by the focal point of a Fresnel lens uniformly. Therefore, the uniformity of heating of the to-be-processed workpiece is ensured and a phenomenon that the to-be-processed workpiece is damaged due to the too high local temperature is avoided.

Owner:GUANGDONG UNIV OF TECH

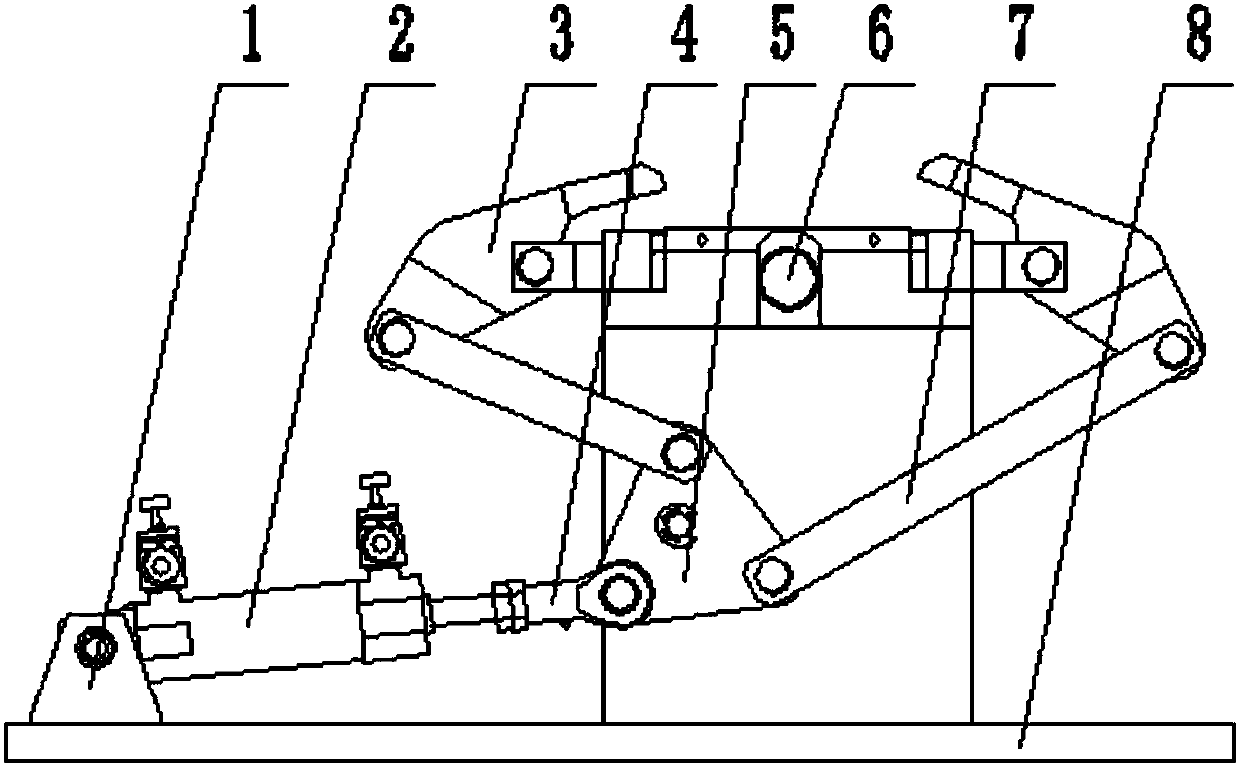

Special clamping equipment for double-sided pressing of plate workpieces

InactiveCN107775403AGuaranteed machining accuracyAvoid workpiece damagePositioning apparatusMetal-working holdersBackplaneHinge angle

The invention relates to a special clamping device for double-sided pressing of plate workpieces, which includes a base plate, a support frame, a cylinder, a turntable, a connecting rod and a pressure plate. A support frame is installed on one side of the upper surface of the base plate. The back plate and the top plate are composed of a workpiece installation area on the top surface of the top plate, a vertical positioning column is installed on the rear end of the top plate surface, and a horizontal top wire is installed on the front surface of the top plate; a hinge is installed on the other side of the bottom plate surface A cylinder is installed on the hinge seat, and the cylinder is connected with an active push rod. The upper ends of the two connecting rods are hinged with a pressing plate, and the two pressing plates are respectively located above the left and right sides of the top plate. The invention is a special clamping device for double-sided pressing of plate workpieces with a high degree of automation. Using the device can increase the clamping speed, ensure the processing quality, improve the product qualification rate, and save the raw material and labor costs of the enterprise.

Owner:TIANJIN BAOLAI PRECISION MACHINERY

Discharging mechanical arm of injection moulding machine

InactiveCN108437382AAvoid workpiece damageImprove processing qualityInjection mouldingInjection molding machine

Owner:JINGDE COUNTY HANHAI NEBULA INTELLIGENTIZE TECH RES & DEV CO LTD

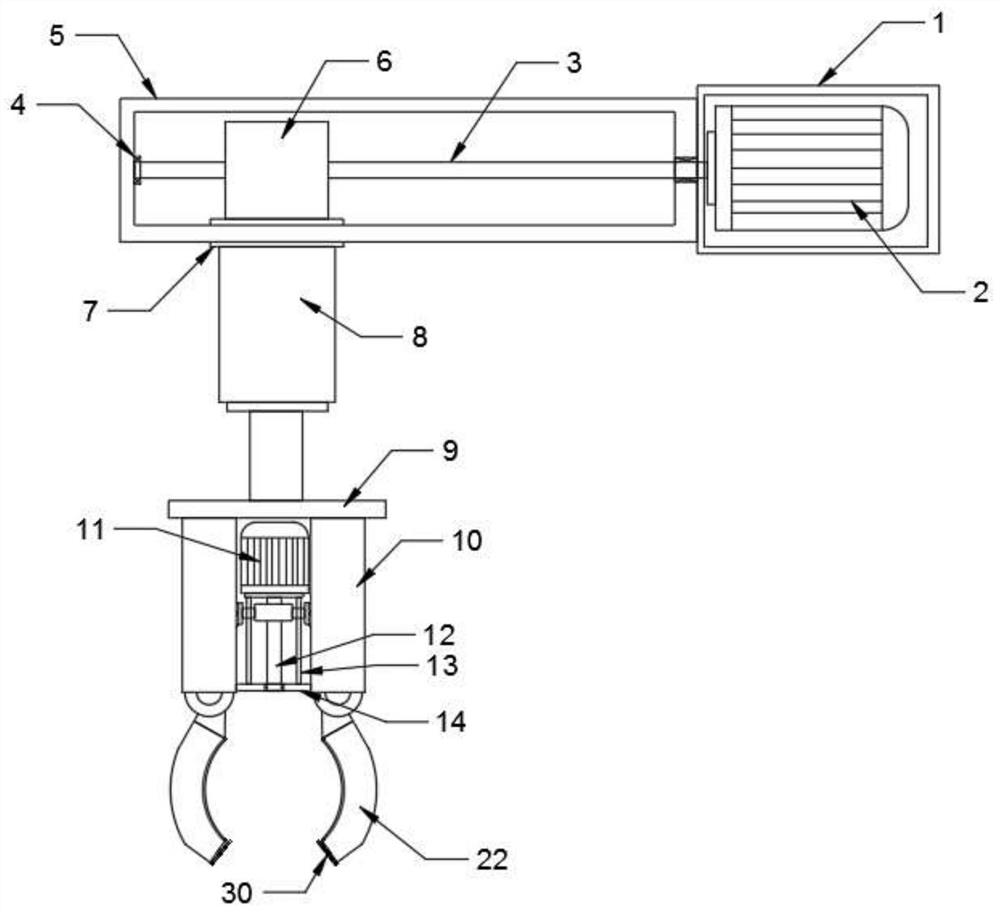

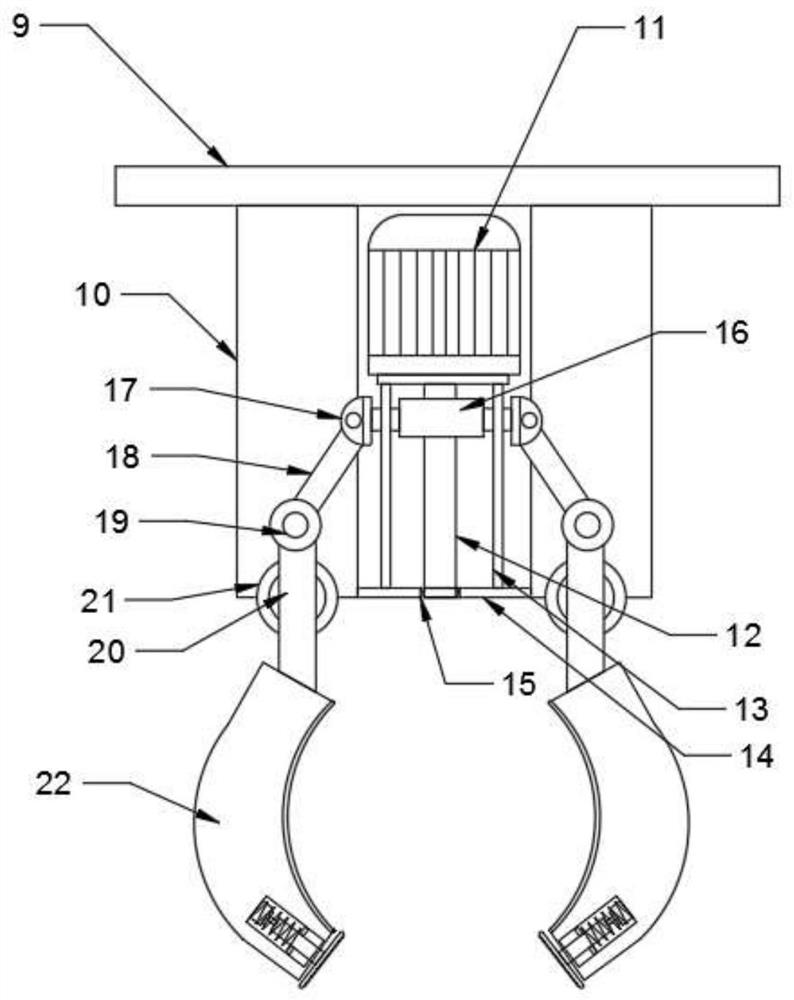

Manipulator device with stable clamping function

InactiveCN111872924AGuaranteed clamping forceSmooth rotationProgramme-controlled manipulatorGripping headsClassical mechanicsElectric machinery

The invention discloses a manipulator device with a stable clamping function. The device comprises a motor frame, a fixing frame and a fixing bracket, a first motor and a first threaded rod are installed at the inner side of the motor frame, and a sliding block and the fixing frame are arranged at the outer side of the first threaded rod; a limiting plate is installed at the bottom end of the sliding block, a telescopic motor and a fixing plate are installed at the bottom end of the limiting plate, a second motor and a second threaded rod are installed in the middle of the bottom end of the fixing plate, and limiting rods are arranged at the left and right sides of the second threaded rod; a cylinder is installed at the outer side of the second threaded rod, a first rotating shaft, a firstconnecting rod, a second rotating shaft, a second connecting rod and a third rotating shaft are installed at the outer side of the cylinder, and a clamping plate is installed at the bottom end of thesecond connecting rod; and a groove is formed in the bottom end of the clamping plate, a pressure sensor is installed at the bottom end of the inner side of the groove, a short rod is installed at the front end of the pressure sensor, a limiting ring and a spring are installed at the outer side of the short rod, and a pressing plate is installed at the front end of the short rod. The manipulatordevice is reasonable in structure, a manipulator can conveniently clamp a workpiece, the workpiece is effectively protected, and the working efficiency is improved.

Owner:熊祥

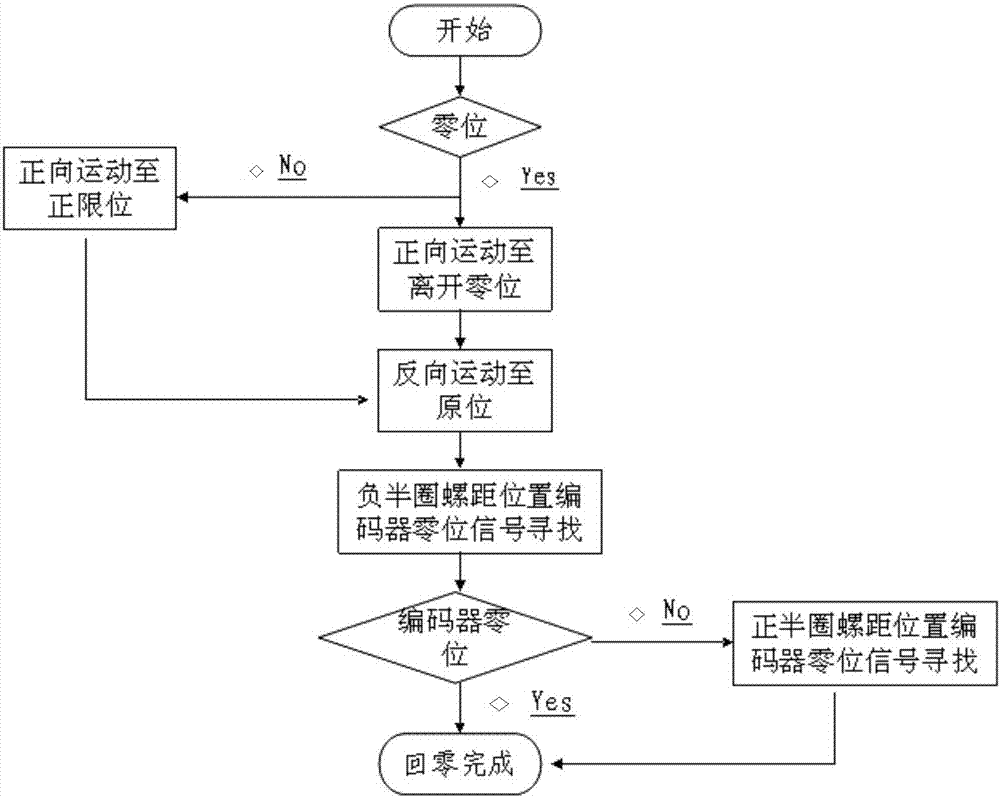

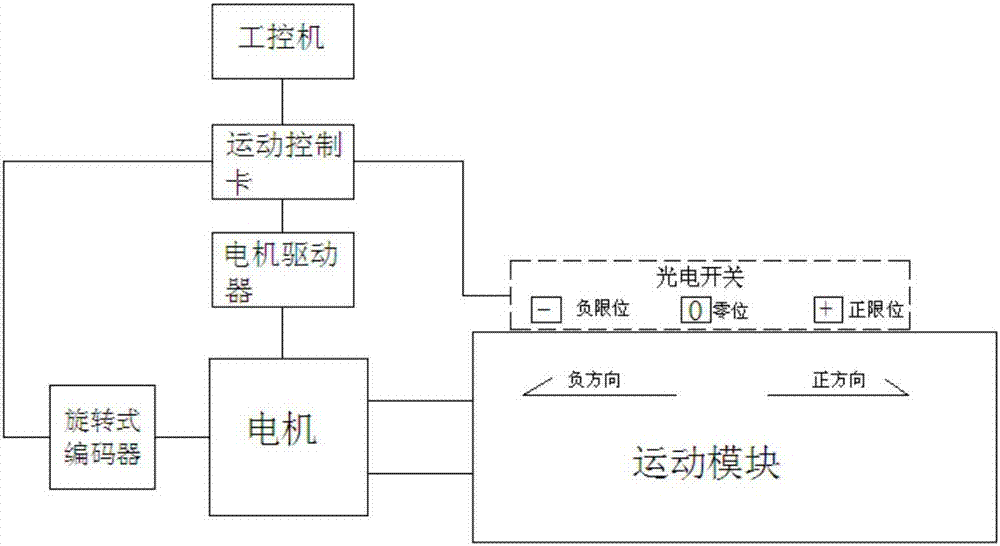

Return-to-zero system and method for electric discharge machining machine tool

InactiveCN106975805AAvoid workpiece damageReduce machine downtime lossesElectric circuitsReturn-to-zeroPersonal computer

The invention discloses a return-to-zero system and a return-to-zero method for an electric discharge machining machine tool. The system comprises an industrial personal computer, a motor driver, a motion control card, a motion module, a rotary coder, a photo-electronic switch and a motor, wherein the industrial personal computer is used for controlling the motion control card; the motion control card is connected with the motor driver, the rotary coder and the photo-electric switch respectively; the motor driver is used for controlling a shaft to move by virtue of the motor and driving the motion module; the rotary coder is used for feeding back the motion information of the shaft to the motion control card in real time; and the photo-electric switch is used for receiving signals and feeding back the signals to the motion control card. By adopting the method, high consistency of a zero position is realized; the consistency of a coordinate system of the machine tool which is repeatedly powered and powered off is guaranteed; the repeat accuracy is guaranteed; collision caused by machining or program running is prevented; damages and scrapping of work pieces and precision reduction of the machine tool are prevented, so losses caused by shutdown of the machine tool are reduced, the machine debugging cost is lowered, the cost for replacing shaft accessories and dismounting the shaft is lowered, the work efficiency is improved, the maintenance cost is lowered, and durable machining precision of the machine tool is guaranteed.

Owner:WUXI MICRO RES PRECISE MACHINERY TECH CO LTD

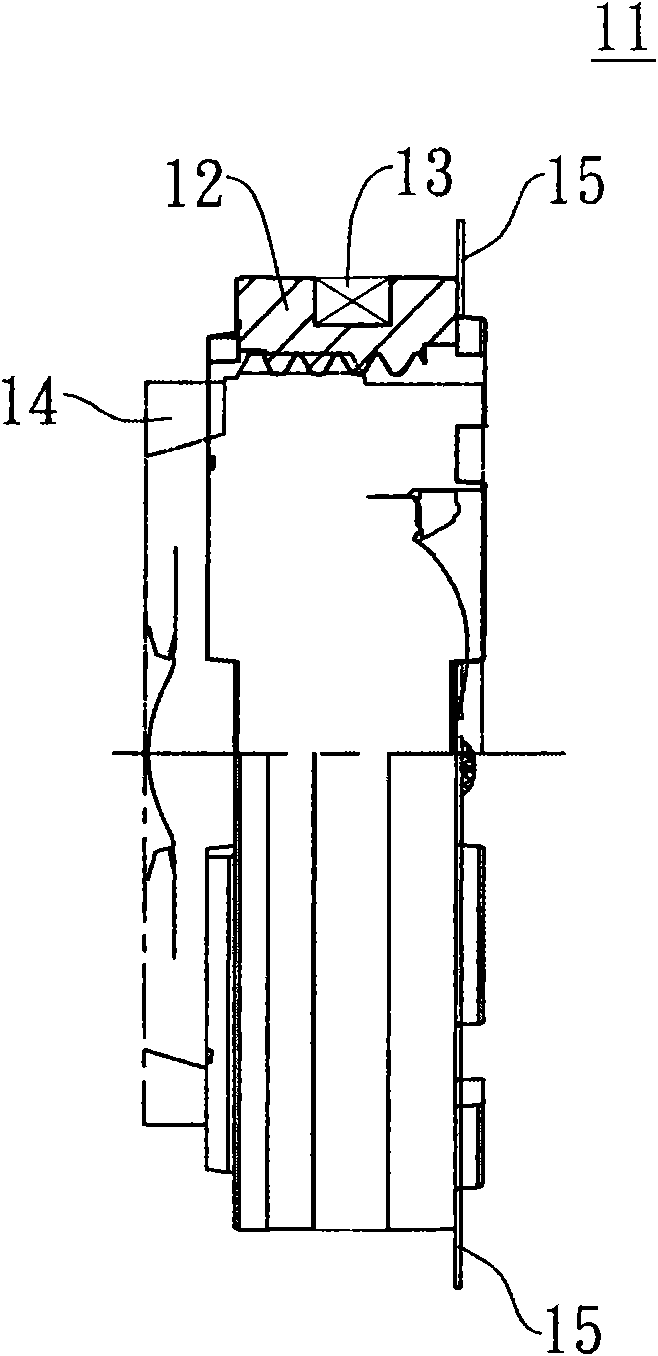

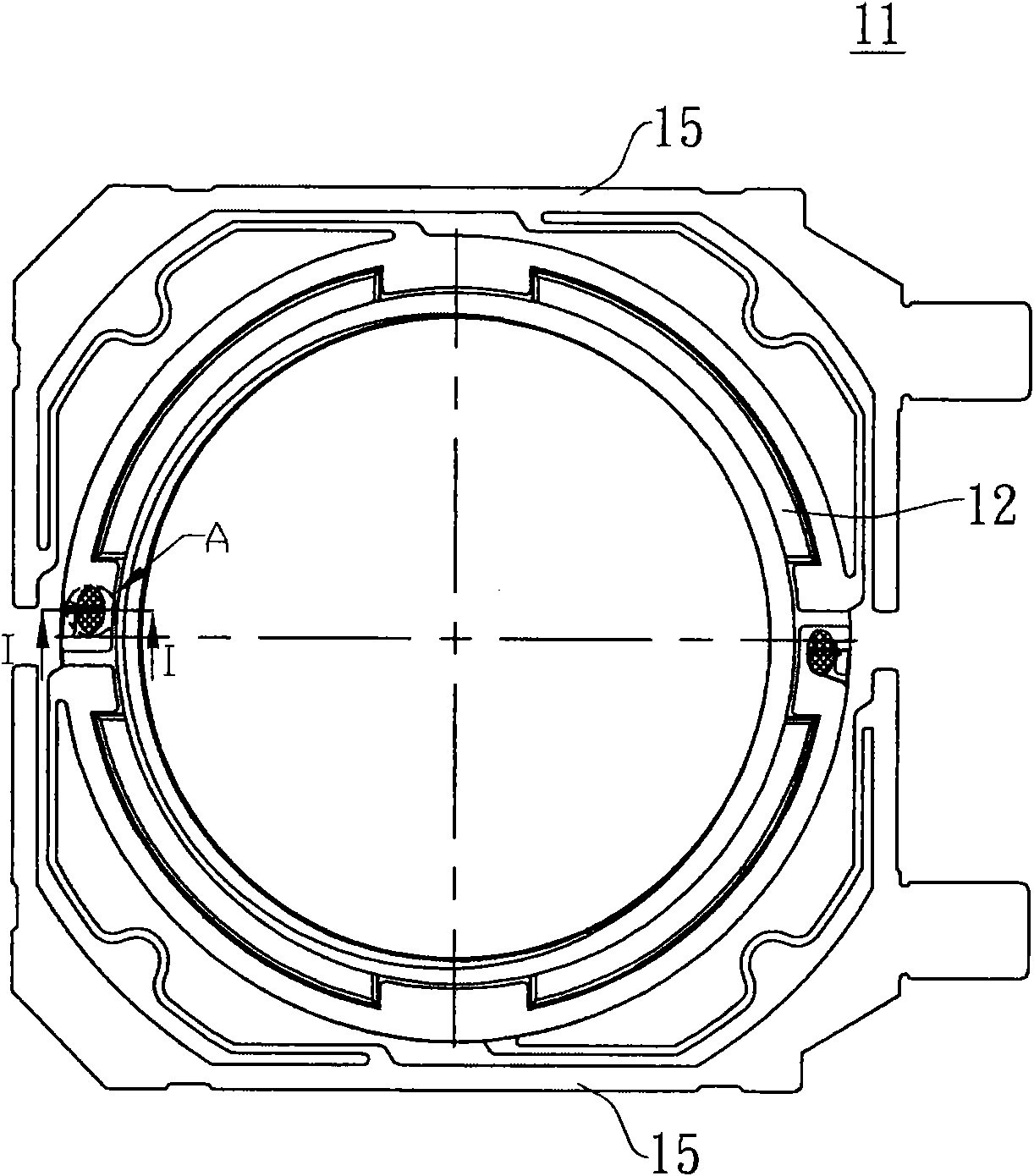

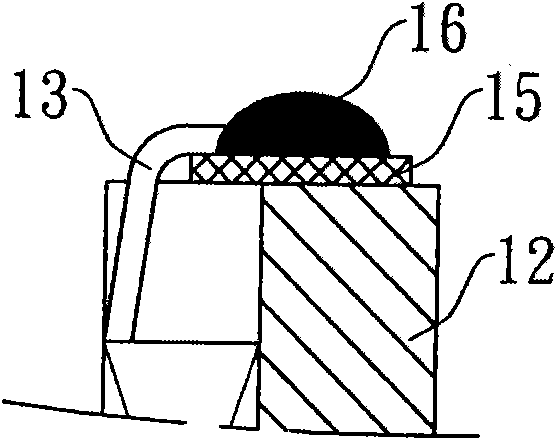

Driver for automatic focusing lens

InactiveCN102338921AAvoid workpiece damageImprove workpiece yieldMountingsFocusing aidsHot pressEngineering

Owner:LARGAN PRECISION

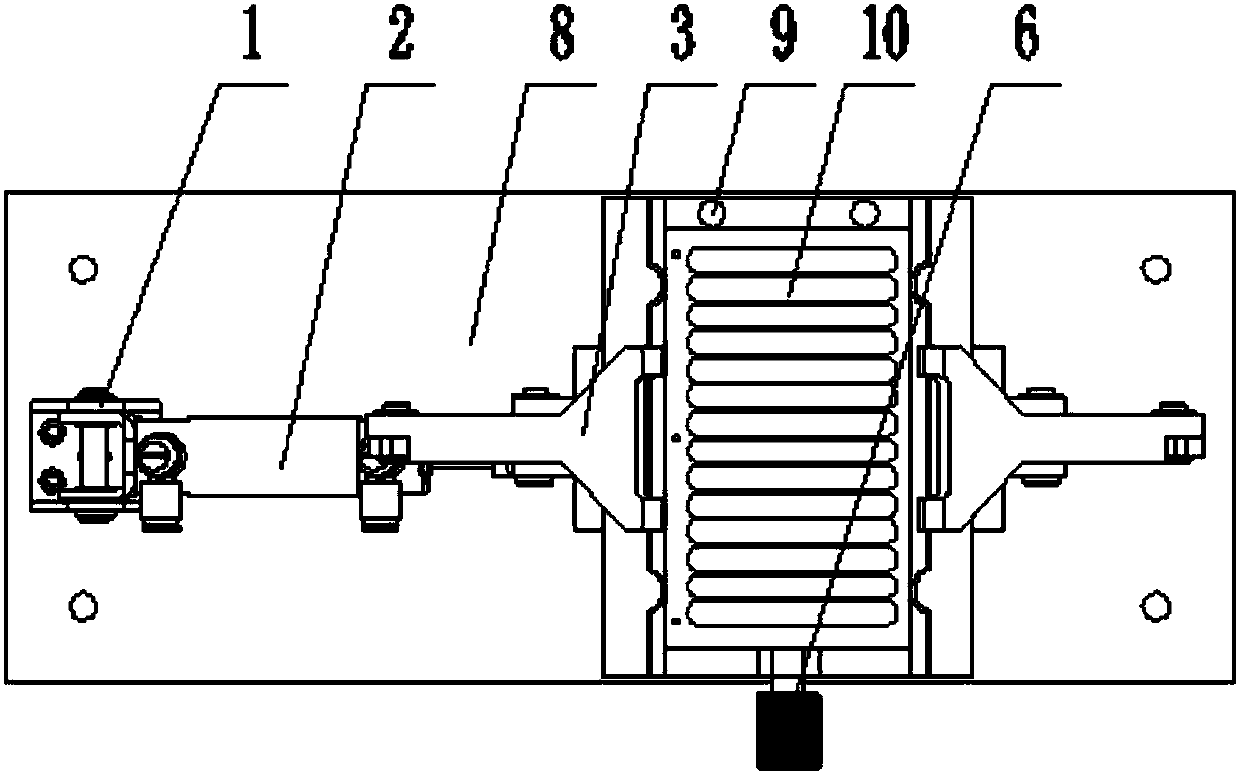

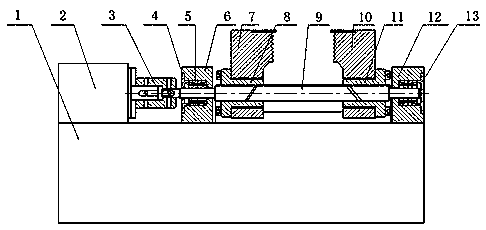

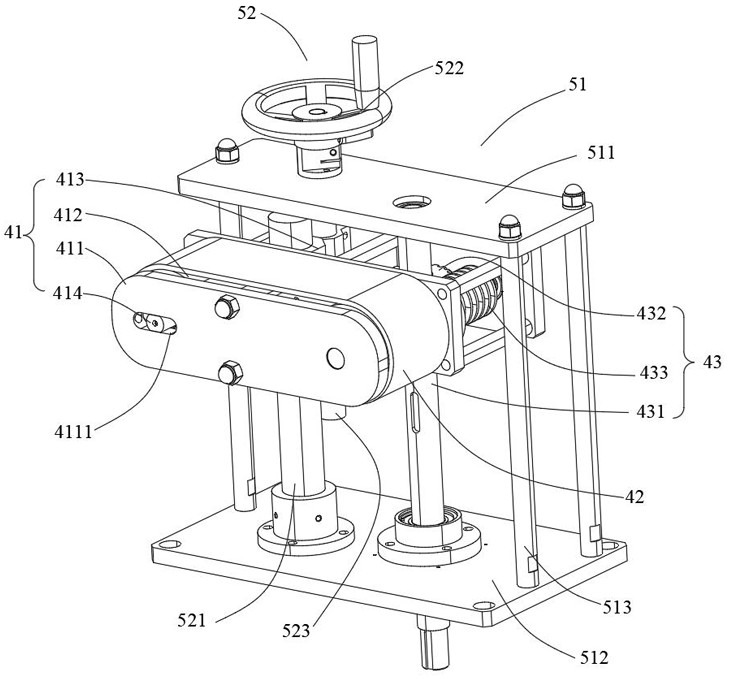

Automatic clamping jaw vice with adjustable flexible clamping force

The invention discloses an automatic clamping jaw vice with adjustable flexible clamping force, and belongs to the technical field of machining application. A servo motor is arranged on a worktable, the servo motor is connected with a dual-way ball screw through a coupler, the left end of the dual-way ball screw is provided with a pair of angular contact ball bearings, the angular contact ball bearings are arranged in a left bearing support, a left end cover is arranged on the left end of the left bearing support, a left screw nut is arranged on the thread position of the left end of the dual-way ball screw, the left screw nut is fixed to a left jaw vice body through a bolt, a right screw nut is arranged on the thread position of the right end of the dual-way ball screw, the right screw nut is fixed to a right jaw vice body through a bolt, the right end of the dual-way ball screw is provided with a pair of angular contact ball bearings, the angular contact ball bearings are arranged ina right bearing support, and a right end cover is arranged on the right end of the right bearing support; detection object structures and pressure sensors are arranged on the upper ends of the left jaw vice body and the right jaw vice body, and can detect whether an object is touched or not, the rotating speed is adjusted, when the pressure is achieved, the motor is stopped, the structure is novel and reliable, and work efficiency and product quality are effectively improved.

Owner:HARBIN UNIV OF SCI & TECH

Machining and polishing device

InactiveCN109227342AAvoid damage to workpiecesAdjust Dimensional AccuracyPolishing machinesGrinding drivesEngineeringMachining

The invention discloses a machining and polishing device. The machining and polishing device comprises a base, a placement groove is formed in the side wall of the upper end of the base, the side wallof the upper end of the base is fixedly connected with two mutually symmetric support plates, a first fixing plate is fixedly connected to the side walls of the upper ends of the two support plates,an air cylinder is fixedly connected to the side wall of the lower end of the first fixing plate, a connecting plate is fixedly connected to an output end of the air cylinder, and a driving motor is fixedly connected to the side wall of the lower end of the connecting plate. Mechanical workpieces to be polished and machined can be stably and firmly clamped, the situation that the mechanical workpieces slide and are damaged since the mechanical workpieces are not clamped stably and firmly in the process of polishing and machining is avoided, the polishing height can be adjusted according to themechanical workpieces different in size, the polishing size and precision can be adjusted according to different polishing requirements, the polishing and machining precision is improved, and convenience is provided for replacing polishing discs different in specification; the machining and polishing device is very easy to assemble and disassemble, and the polishing efficiency is improved.

Owner:盐城市同俊精密机械制造有限公司

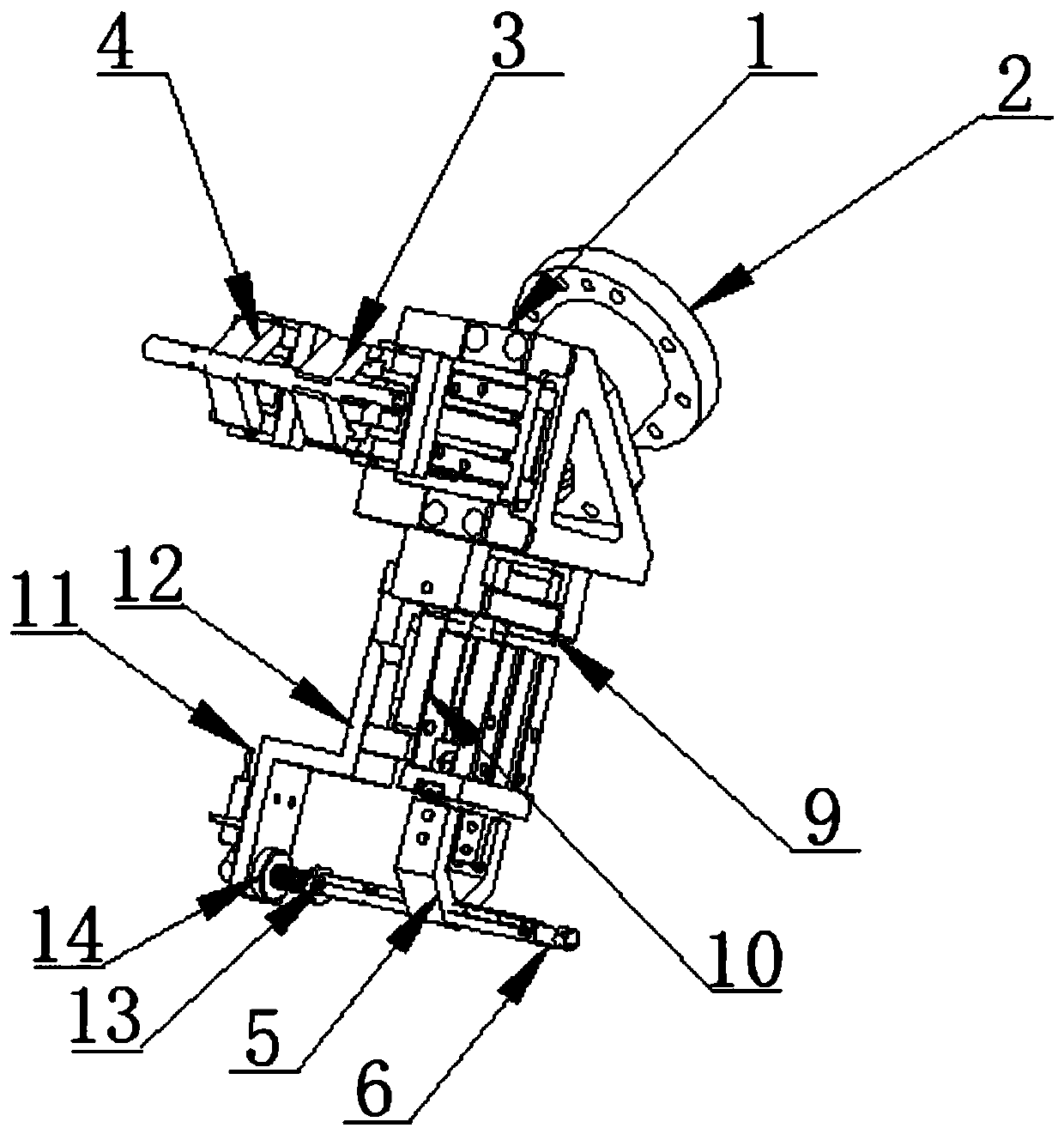

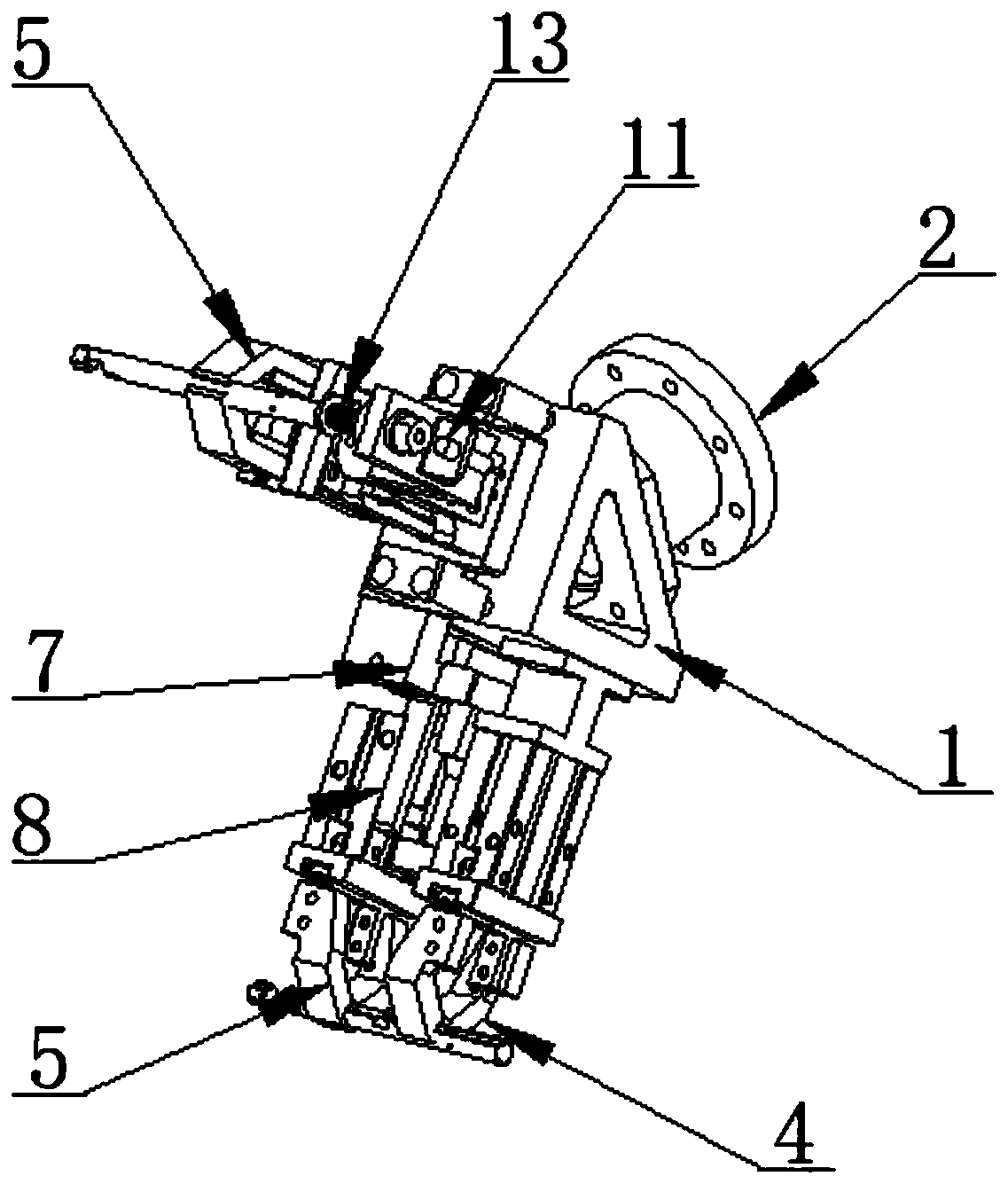

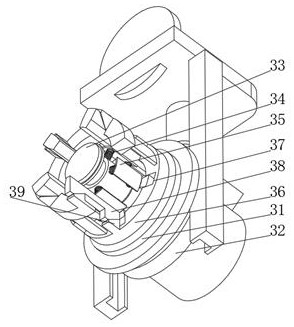

Clamping jaw mechanism for round tube loading and unloading

PendingCN110757015AHigh dimensional accuracyAvoid damage to the workpieceLaser beam welding apparatusControl systemJaw fixation

The invention discloses a clamping jaw mechanism for round tube loading and unloading. The mechanism comprises a clamping jaw installation base, a connecting base, an unloading clamping jaw of a roundtube finished product, an unloading clamping jaw of round tube waste, a round tube loading clamping jaw, a clamping jaw conversion driving device and a control system, wherein the clamping jaw installation base can be installed on the connecting base in a rotatable manner; the clamping jaw installation base is driven by the clamping jaw conversion driving device to rotate; first and second installation faces are disposed at an interval on a clamping jaw fixation base along a rotation direction; the unloading clamping jaw of the round tube finished product and the unloading clamping jaw of theround tube waste are coaxially installed on the first installation face at an interval; the round tube loading clamping jaw is installed on the second installation face; the finished product and thewaste obtained after round tube cutting can be clamped or loosened by the unloading clamping jaw of the round tube finished product and the loading clamping jaw of the round tube waste respectively; ato-be-cut round tube can be clamped or loosened by the round tube loading clamping jaw; and running of the clamping jaw conversion driving device and each of the clamping jaws can be controlled by the control system. The clamping jaw mechanism disclosed by the invention has the beneficial effects that full-automatic intelligent loading and unloading of cutting of round tube type work pieces are realized; and manual operations are avoided.

Owner:苏州艾欧科机器人科技有限公司

Medical needle box packaging machine capable of working continuously

ActiveCN113815926AAvoid damage to workpiecesEasy to coverLiquid surface applicatorsWrapper twisting/gatheringEngineeringMedical treatment

The invention relates to the technical field of medical instruments, in particular to a medical needle box packaging machine capable of working continuously. The machine comprises a packaging device and a material pressing mechanism located at the position of a discharging port of the packaging device; the packaging device is used for placing workpieces in a needle collecting box and conveying the workpieces backwards; and the material pressing mechanism is installed on a lifting mechanism. In the backward conveying process of the needle collecting box, after the needle collecting box is conveyed to the position below the material pressing mechanism, the lifting mechanism drives the material pressing mechanism to descend, and after the material pressing mechanism descends to be attached to the top of the needle collecting box, the material pressing mechanism pushes the workpiece erected on the needle collecting box into the needle collecting box. By means of the mode, the situation that workpieces are damaged when the upper box cover is covered on the needle collecting box is avoided, and meanwhile convenience is provided for covering of the box cover of the needle collecting box.

Owner:常州市天磊传动机械有限公司 +1

Electronic component control board punching device

PendingCN109014320AAvoid circuit damageAvoid workpiece damagePositioning apparatusMetal-working holdersMagnetEngineering

The invention discloses an electronic component control board punching device. The electronic component control board punching device comprises a base, a drilling machine and an air cylinder. A support plate is mounted on the upper portion of the base. A workbench is mounted on the upper portion of the support plate. The air cylinder is mounted on the upper portion of the part, on the inner side of the support plate, of the base. The output end of the air cylinder is provided with a control console. The upper portion of the workbench is provided with a pillar. The top of the pillar is providedwith a top plate. The bottom of the top plate is provided with a second sliding rail. The bottom of the second sliding rail is provided with a mounting plate. The bottom of the mounting plate is provided with a first sliding rail. A side plate is mounted on one side of the mounting plate. A motor is mounted on the inner side of the side plate. A screw is mounted on the output end of the motor. Byarranging a first magnet, a second magnet, the air cylinder, the control console, the first sliding rail, the motor, an electric push rod, the drilling machine and a controller structure, the problems that a pressing mechanism is not perfect, and the drilling operation precision is low are solved.

Owner:HENAN NORMAL UNIV

Intelligent machine part assembling platform

InactiveCN112296665APlay a supporting roleAvoid collisionAssembly machinesWork holdersRotational axisButt joint

The invention discloses an intelligent machine part assembling platform. The intelligent machine part assembling platform comprises an assembling table, a rotating shaft and an assembling moving plate. A clamping plate is arranged above the assembling table, a rotating motor is installed at the front end of the clamping plate, an electric guide rail is arranged in the assembling table, the assembling moving plate is arranged in the electric guide rail, and the rotating shaft is connected to the rear end of the clamping plate. According to the intelligent machine part assembling platform, by arranging the rotating shaft, a clamping connecting piece can be driven to rotate, so that a workpiece is driven to rotate, the butt joint angle of the workpiece and an assembling tool is adjusted, thenthe workpiece is assembled, and the assembling speed is increased. By arranging a clamping push rod, a workpiece can be clamped; and by arranging a movable lead screw, a movable nut can move on the movable lead screw, so that the clamping plate is driven to move up and down, the height of the clamping plate is adjusted, and the workpiece is prevented from impacting the upper end face of the assembling table in the overturning process.

Owner:广州卓邦科技有限公司

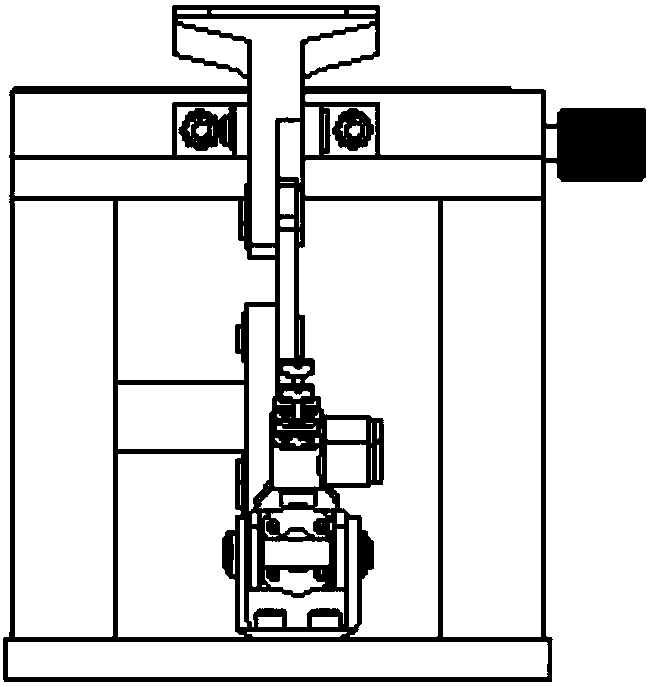

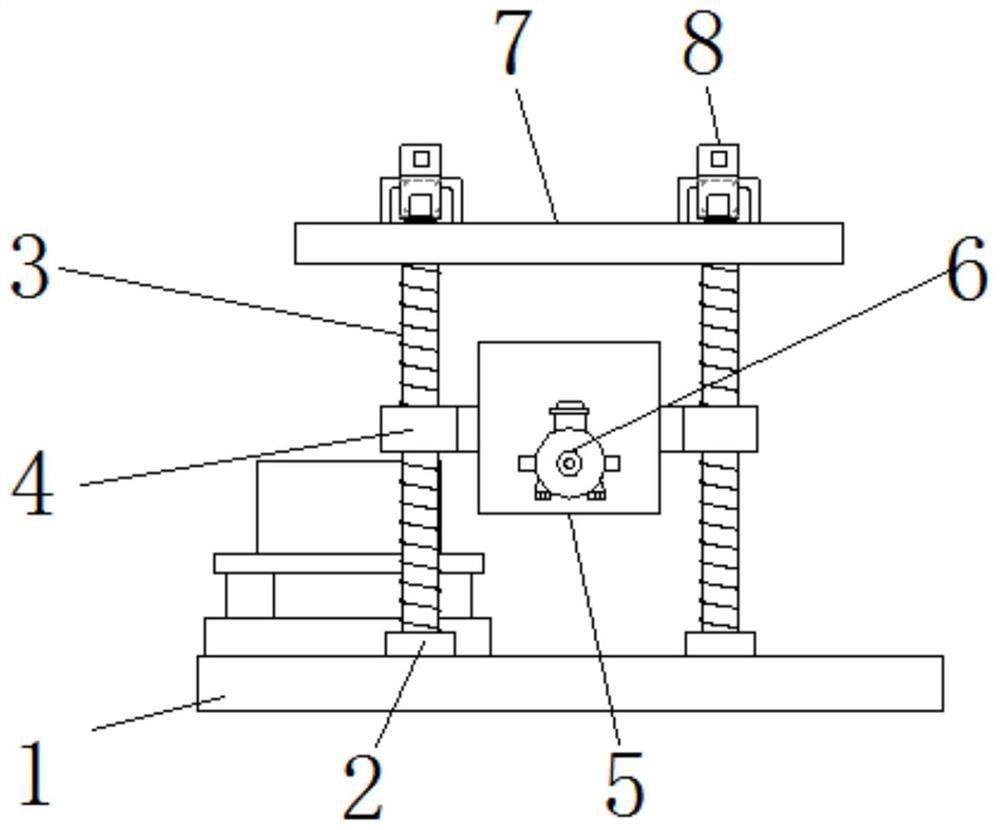

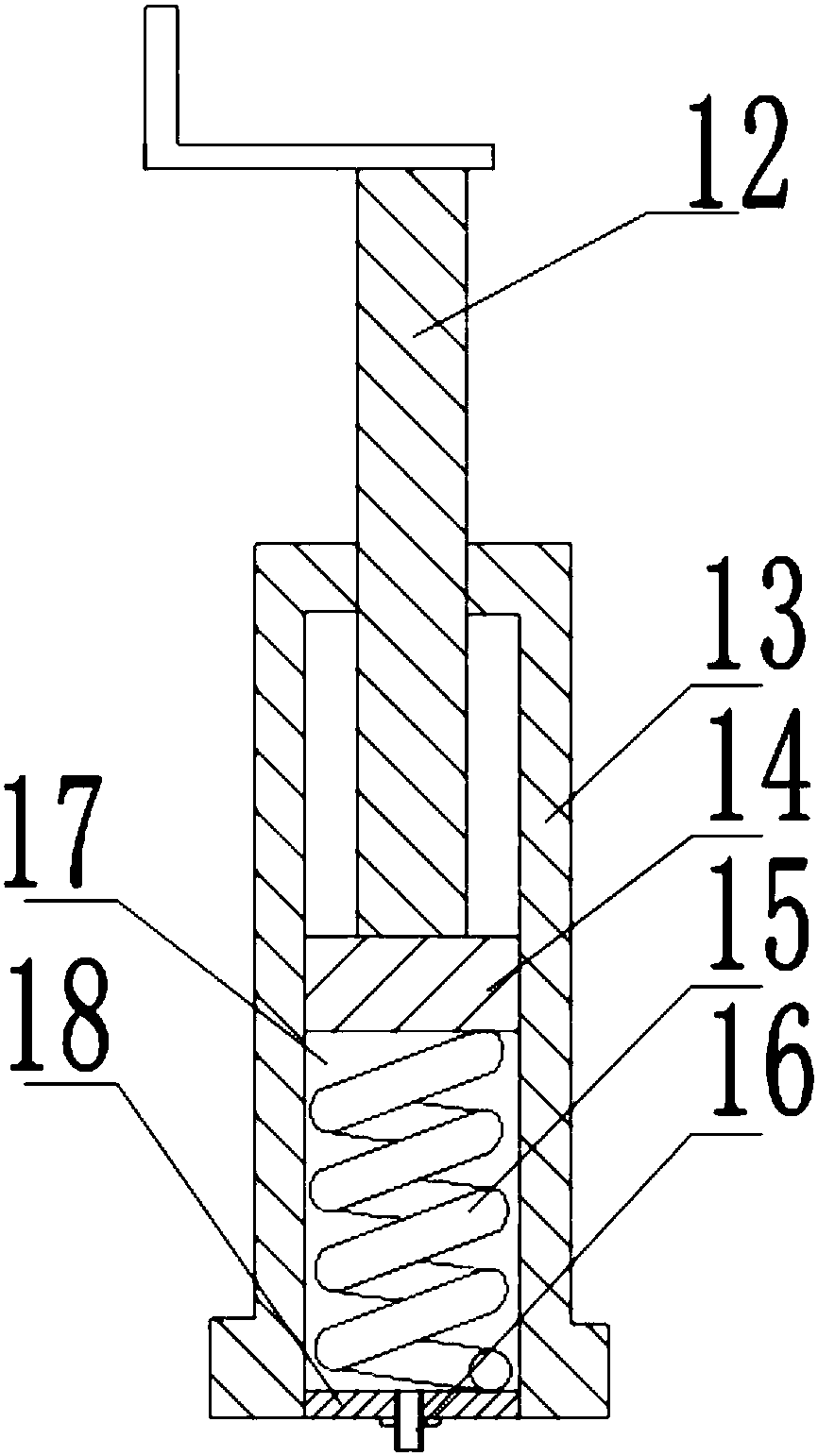

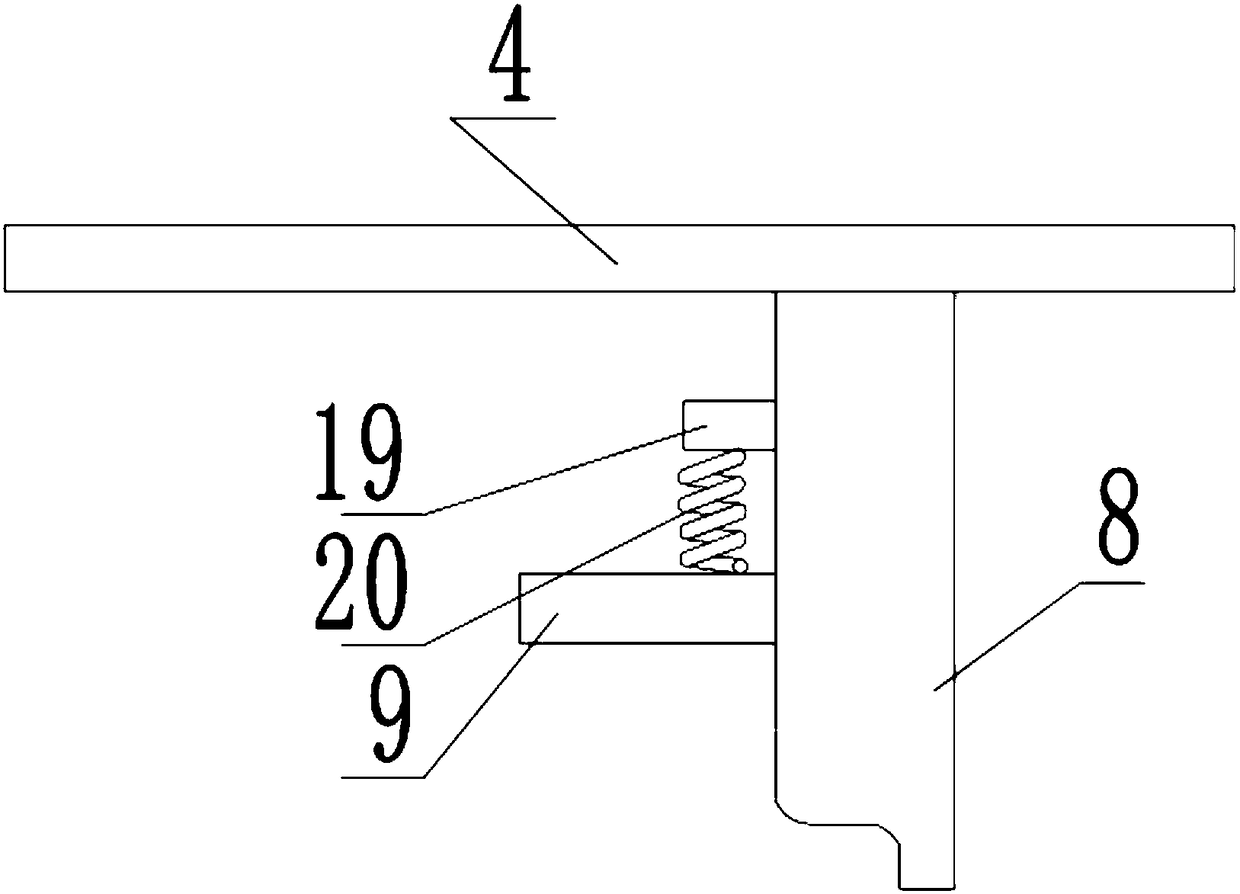

Flanging die with automatic jacking mechanism

InactiveCN108097805AProtect workpieceAvoid workpiece damageShaping toolsEjection devicesPistonFlanging

The invention discloses a flanging die with an automatic jacking mechanism. The flanging die comprises a machine frame, a platen, an upper die plate, an upper die, a punch block, a lower die and a lower die plate. The machine frame is provided with the platen, the platen is provided with the lower die plate, the lower die plate is provided with the lower die where a workpiece is placed, the upperdie plate and the upper die are arranged over the lower die, the upper die plate and the upper die are fixed through a fastening screw, the upper die is provided with the punching block for flanging the workpiece, the bottom of the punching block is provided with a protrusion, the protrusion is arranged at the end, away from the workpiece, of the punching block, and the lower die plate is furtherprovided with the automatic jacking mechanism for automatically jacking the workpiece. The flanging die has the beneficial effects that after flanging is completed for the workpiece, the workpiece canbe jacked automatically through a jacking rod, manual material taking is not needed, the condition that a piston is moved upwards suddenly, and therefore the jacking rod damages the workpiece can beprevented, and the workpiece can be protected.

Owner:ZHENGZHOU CHENGHE INFORMATION TECH CO LTD

Machine tool oil separation and high-precision filtering equipment for machining center

InactiveCN105854404AEfficient separationEffective filteringLiquid separationFiltration circuitsOil spillOil separation

The invention discloses machine tool oil separation and high-precision filtering equipment for a machining center. The filtering equipment comprises a dirty oil tank, a coarse filtration device, a precision filtering device and an oil spill scraping device, wherein the inner space of the oil spill scraping device is divided into a clean fluid entering area, an oil spill concentration area, an oil spill scraping area, a clean fluid area and an oil spill temporary storage area; refined oil filtered by the precision filtering device passes through the clean fluid entering area, the clean fluid area, the oil spill temporary storage area, the oil spill concentration area and the oil spill scraping area which are sequentially communicated with one another, and a hollow square shaped flow line is formed, so that oil spill is concentrated in the oil spill scraping area to scrape. According to the invention, the oil spill scraping device is increased and is separated into several blocks, the oil spill is concentrated in the oil spill temporary storage area, enters the oil spill concentration area and finally enters the oil spill scraping area, oil and liquid can be effectively separated, and the condition that cutting fluid is deteriorated to be stinky so as to further cause air pollution and environmental pollution because the oil spill is not scraped is avoided.

Owner:SUZHOU YONGTIAN TECH EQUIP

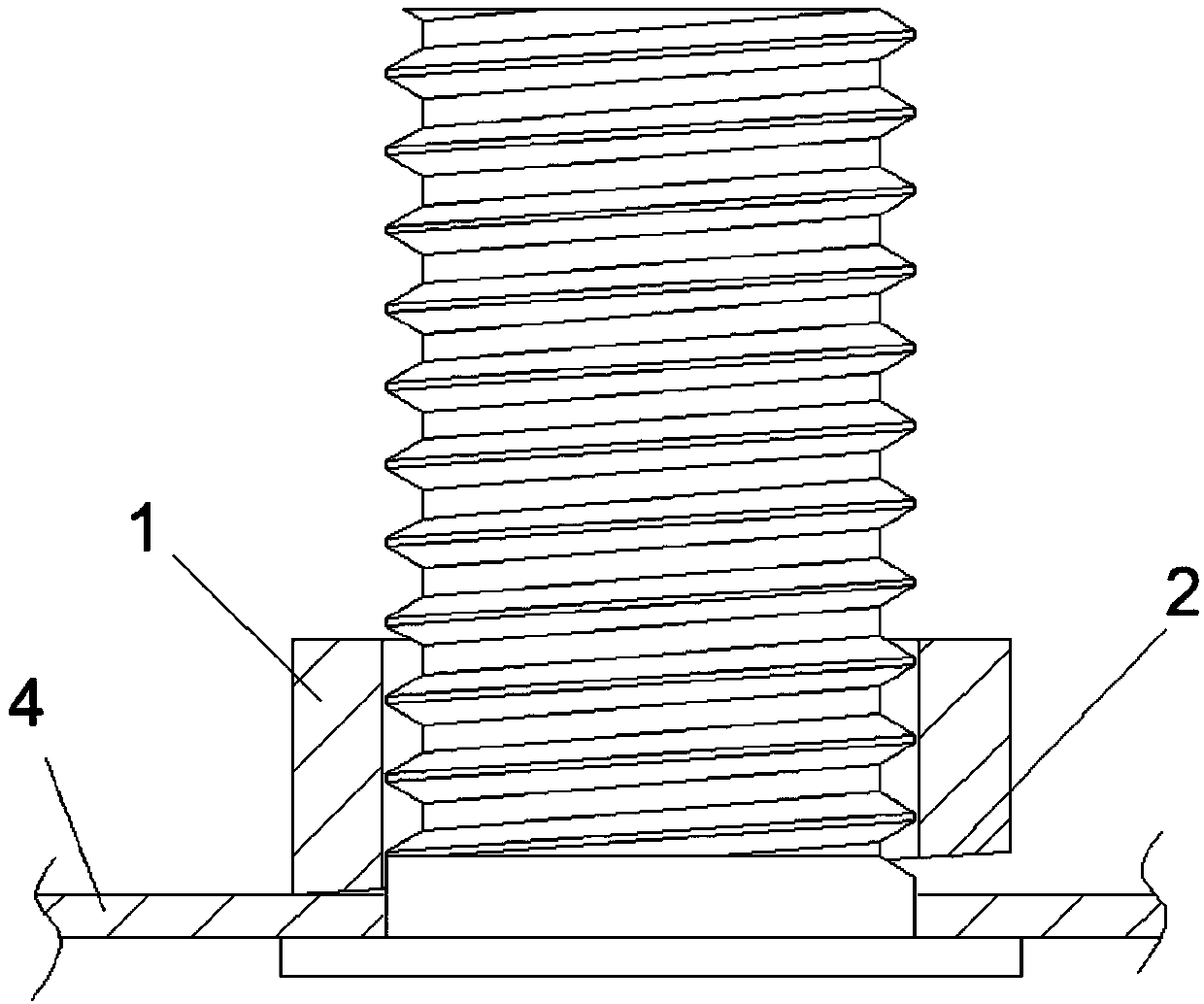

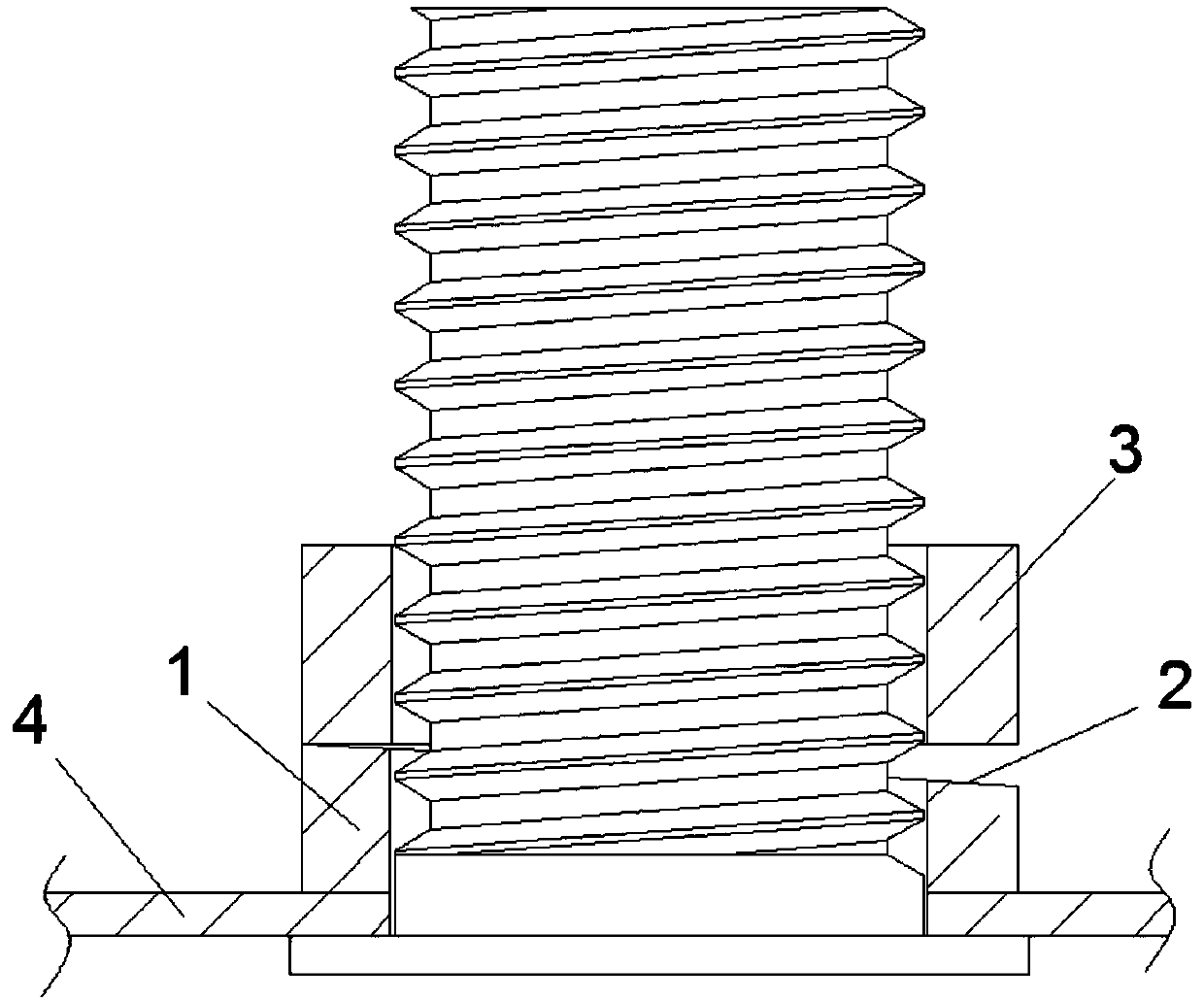

Check nut, check gasket and check bolt

The invention belongs to the technical field of fasteners, and particularly relates to a check nut, a check gasket and a check bolt. A slope is arranged on a nut body or a gasket body, by screwing thenut body or a fastening nut, the nut body fits the surface of a workpiece or the end face of the fastening nut fits the slope, the elastic deformation happens to an internal thread of the nut body orthe fastening nut and an external thread of a screw or a bolt, and therefore the meshing force between the internal thread of the nut body or the fastening nut and the external thread of the screw orthe bolt is increased, and the check effect is achieved. A slope is arranged on the head portion of the check bolt, when the check bolt is installed on the workpiece, the slope fits the surface of the workpiece or the gasket, the elastic deformation happens to the external thread of the screw in the check bolt and an internal thread of the workpiece, and therefore the meshing force between the external thread of the screw and the internal thread of the workpiece is increased, and the check effect is achieved.

Owner:GUANGDONG BINYU TECH CO LTD

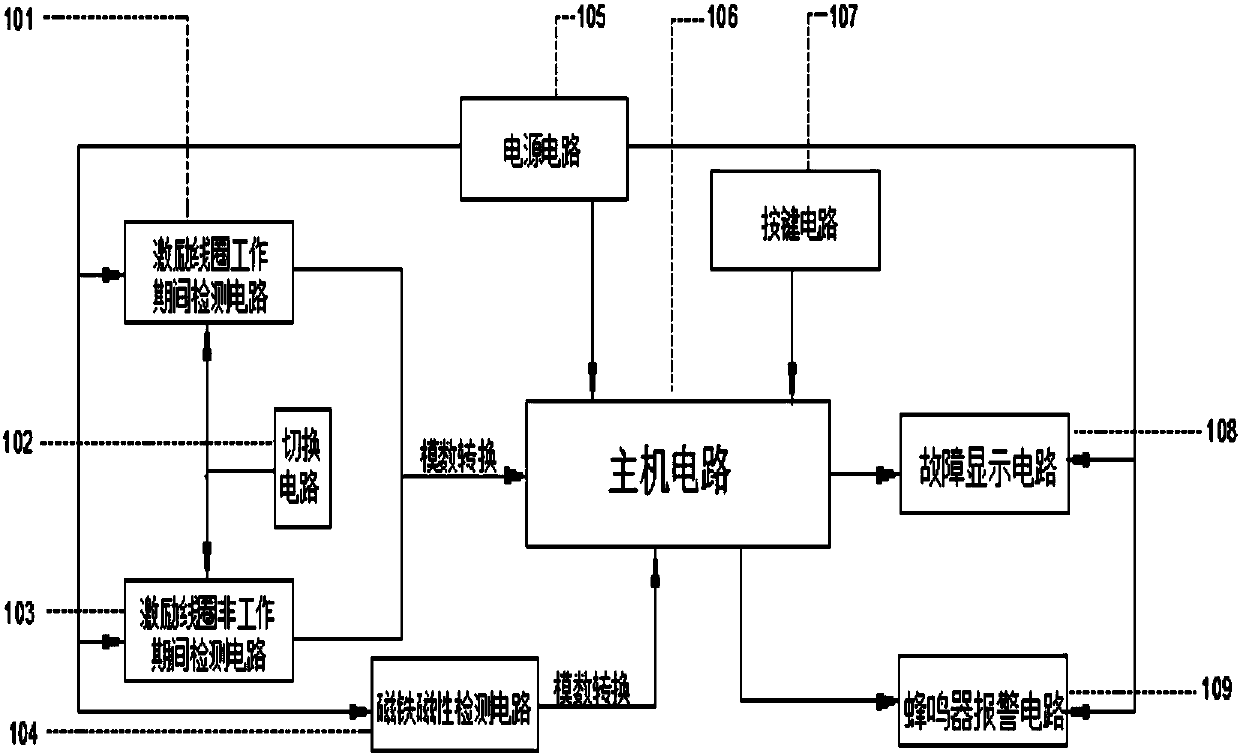

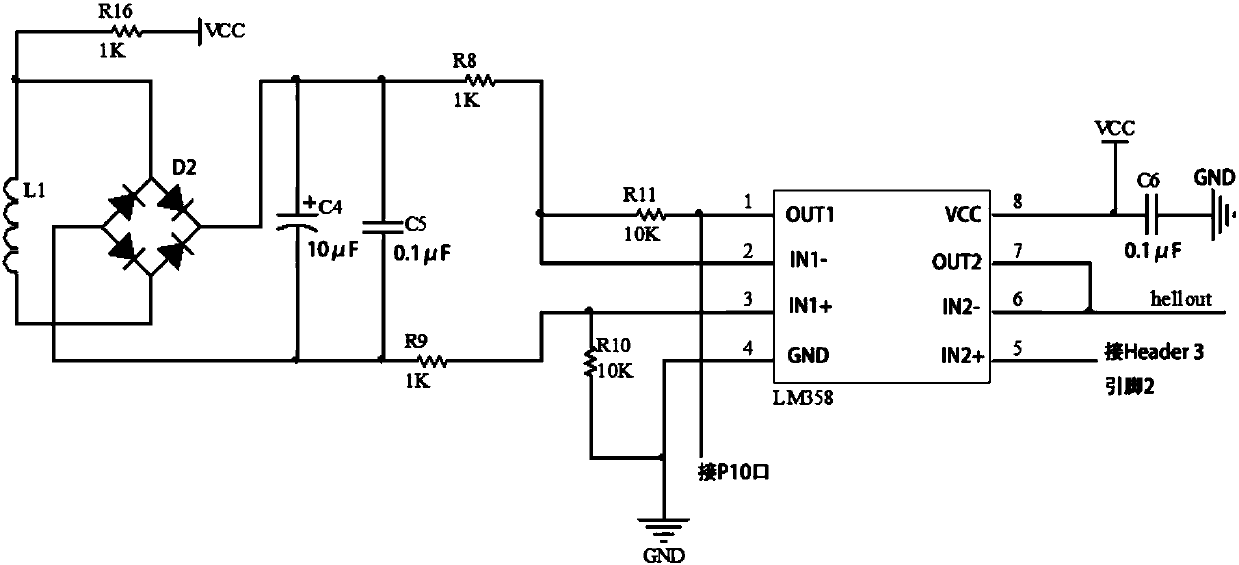

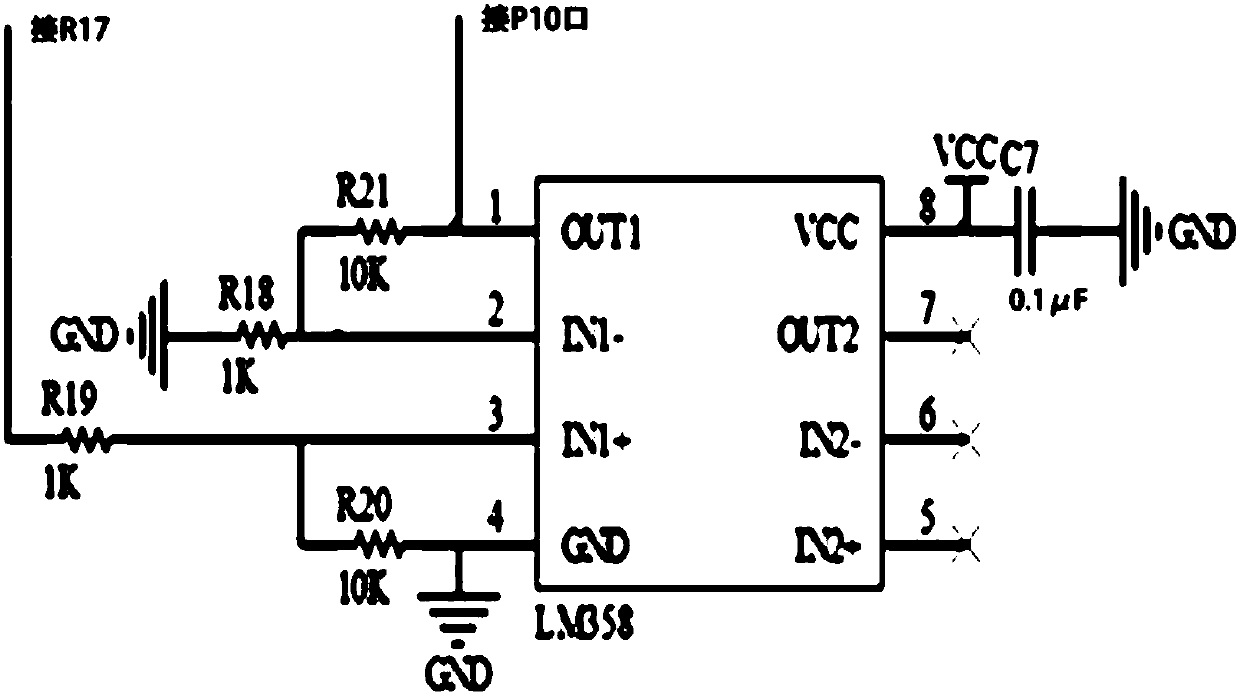

Integrity detection system for in-service electromagnetic ultrasonic transducer

PendingCN107843654AEliminate casualties and property damageAvoid workpiece damageMaterial analysis using sonic/ultrasonic/infrasonic wavesPhysicsPower circuits

The invention belongs to the field of electromagnetic ultrasonic detection, and relates to an integrity real-time detection system for an electromagnetic ultrasonic transducer. The integrity real-timedetection system comprises an exciting coil working period detection circuit, a switching circuit, an exciting coil non-working period detection circuit, a magnet magnetism detection circuit, a powersupply circuit, a host circuit, a key circuit, a fault display circuit and a buzzer alarm circuit. A singlechip is used as a main control chip, data acquisition is carried out by utilizing a sensor and the like, programming is carried out by software to complete functions of each part, and display is carried out by a liquid crystal screen so as to complete design on the integrity detection systemfor the in-service electromagnetic ultrasonic transducer.

Owner:SHENYANG POLYTECHNIC UNIV

Paint spraying device for round block hole type graphite heat exchanger

A paint spraying device for a round block hole type graphite heat exchanger, disclosed by the present invention, specifically comprises a fixing support, wherein sliding ways are formed in the two sides of the fixing support, positioning devices are slidably connected to the inner walls of the sliding ways, and one ends of the positioning devices extend to the outer side of the fixing support; a fixed top plate of which the bottoms at the two ends are fixedly connected with the top of the fixing support, wherein the parts, located on the inner side of the fixing support, of the two ends of the fixed top plate are fixedly connected with hydraulic lifting rods and fixed sliding ways, and the fixed sliding ways are arranged on the fixed top plate and fixedly connected with the fixed top plate. The present invention relates to the graphite heat exchanger paint spraying technical field, and according to the paint spraying device for the round block hole type graphite heat exchanger, positioning can be completed only by moving a positioning disc during positioning, the use and operation are easy, the clamping force can be freely and slowly increased or decreased, the situation that a workpiece is damaged due to the fact that the clamping force borne by the heat exchanger is too large is avoided, the workpiece does not need to be lifted to a clamping station for positioning and clamping, and the manpower and material resources are conveniently saved.

Owner:江苏苏宇化工设备有限公司

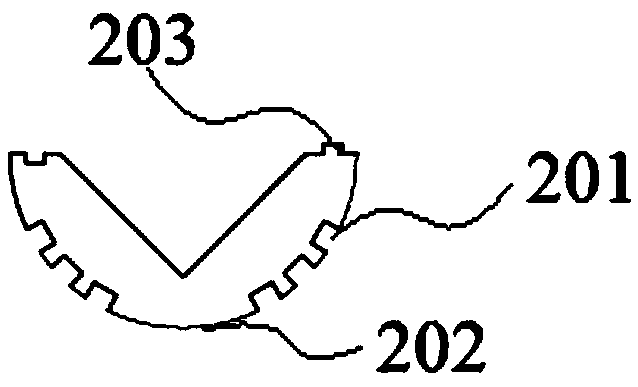

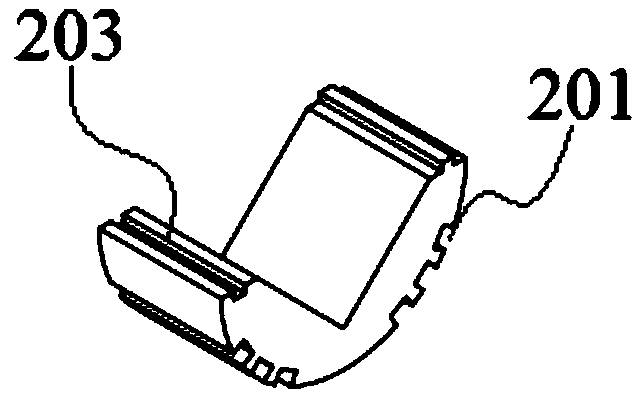

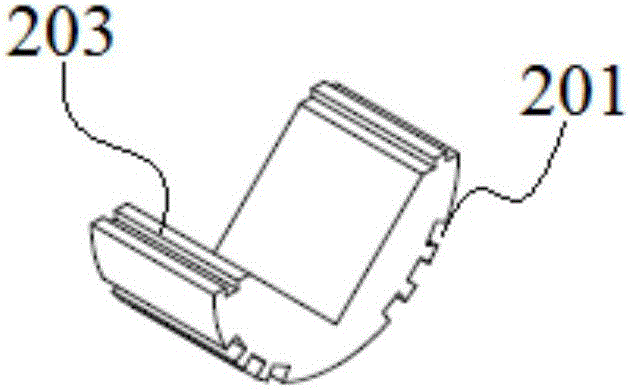

Positioning method for multi-angle milling rotary clamping tool

ActiveCN109333103APrevent rotationPlay a positioning rolePrecision positioning equipmentPositioning apparatusEngineeringMachining

The invention discloses a positioning method for a multi-angle milling rotary clamping tool, and belongs to the technical field of mechanical processing tools. The multi-angle milling rotary clampingtool comprises a base, a clamp and a positioning mechanism, wherein the clamp is positioned in the base; the clamp and the base are matched with each other; the positioning mechanism is blocked between the clamp and the base; the base comprises a roller path and a base upper end surface; the roller path comprises a base roller path surface; the clamp is placed on the roller path of the base; the base roller path surface is matched with the clamp; the roller path of another base covers the clamp; a to-be-milled workpiece is placed in the clamp; the outer part of the clamp is covered by the base; the positioning mechanism is clamped between the clamp and the base to achieve the positioning effect, and the effect of regulating relative positions of the clamp and the base; and through the fixing effect of the positioning mechanism, a fixed workpiece can be regulated to rotate to different angles in the peripheral direction. The multi-angle milling rotary clamping tool can clamp a to-be-processed workpiece, does not affect surface precision of the workpiece, and realizes multi-angle processing of the workpiece.

Owner:MAANSHAN CHENXU MASCH MFG CO LTD

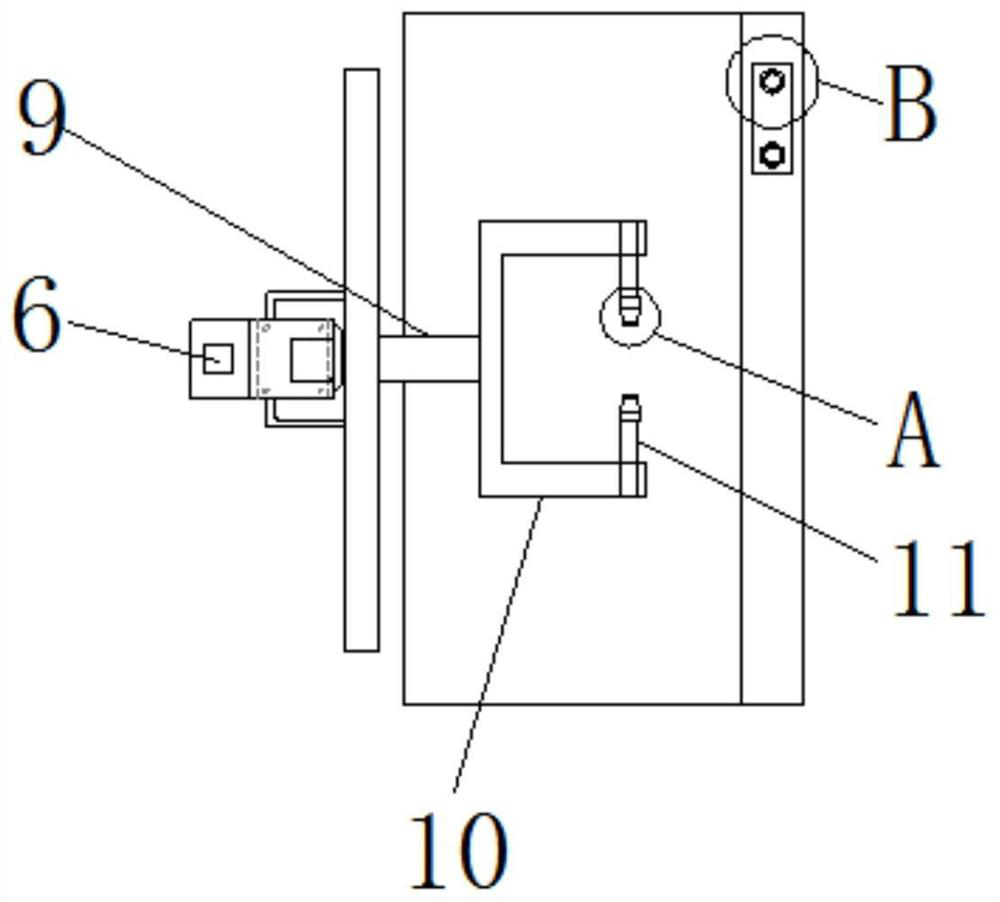

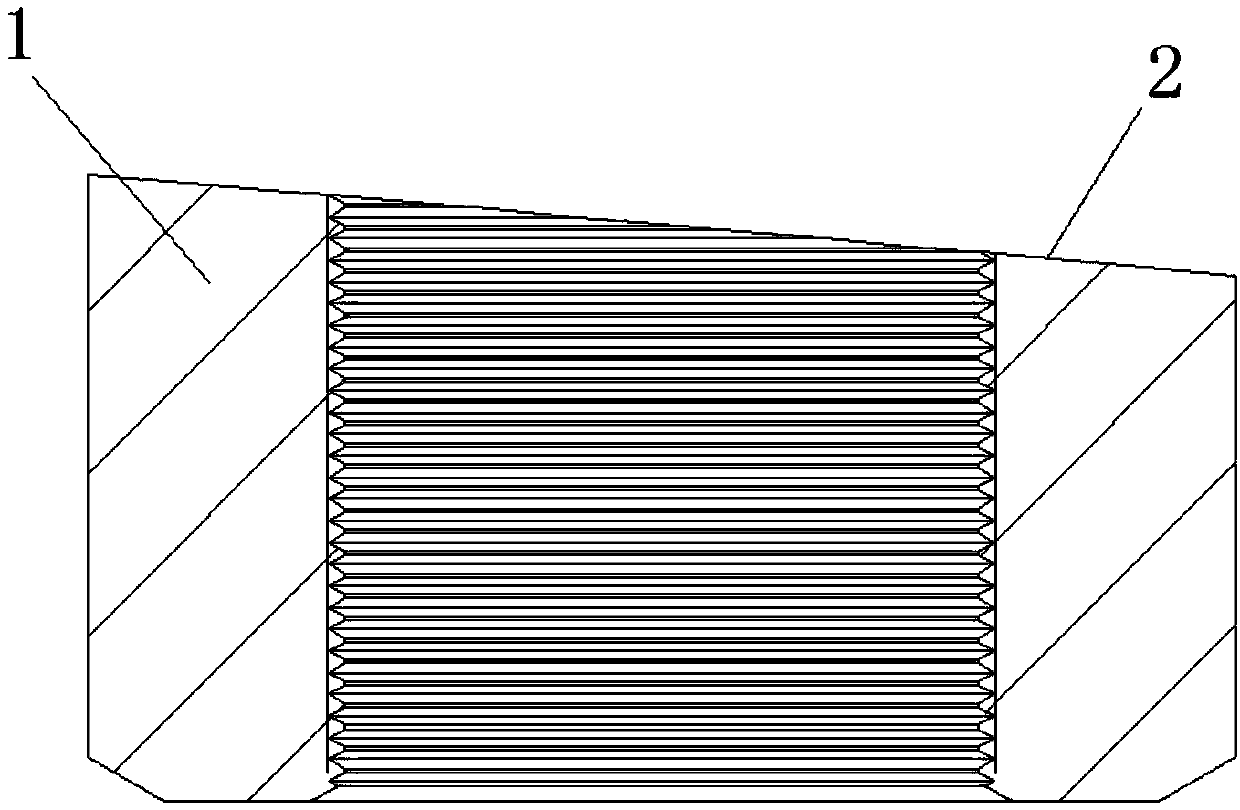

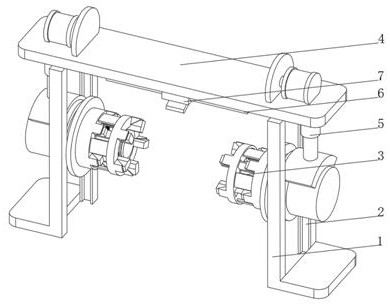

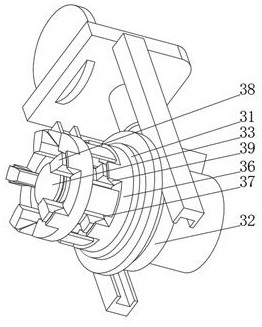

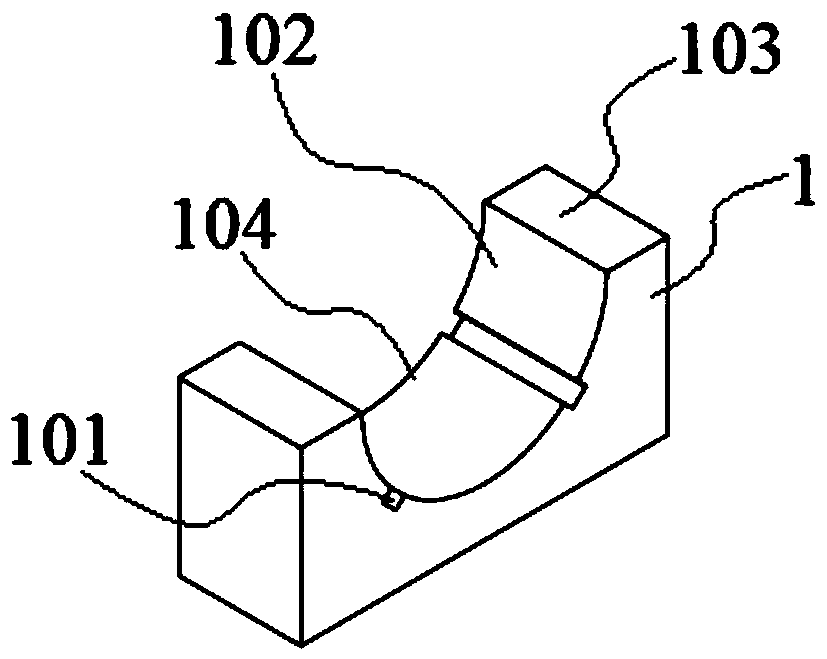

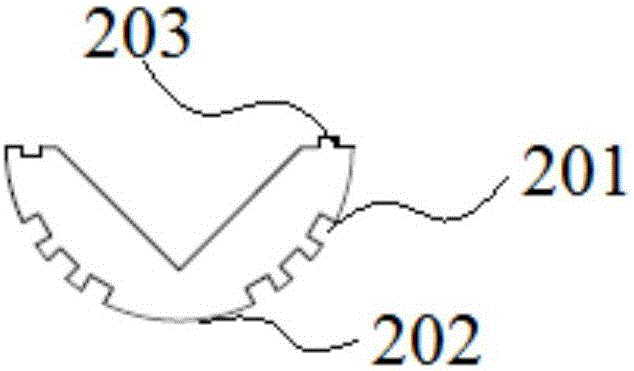

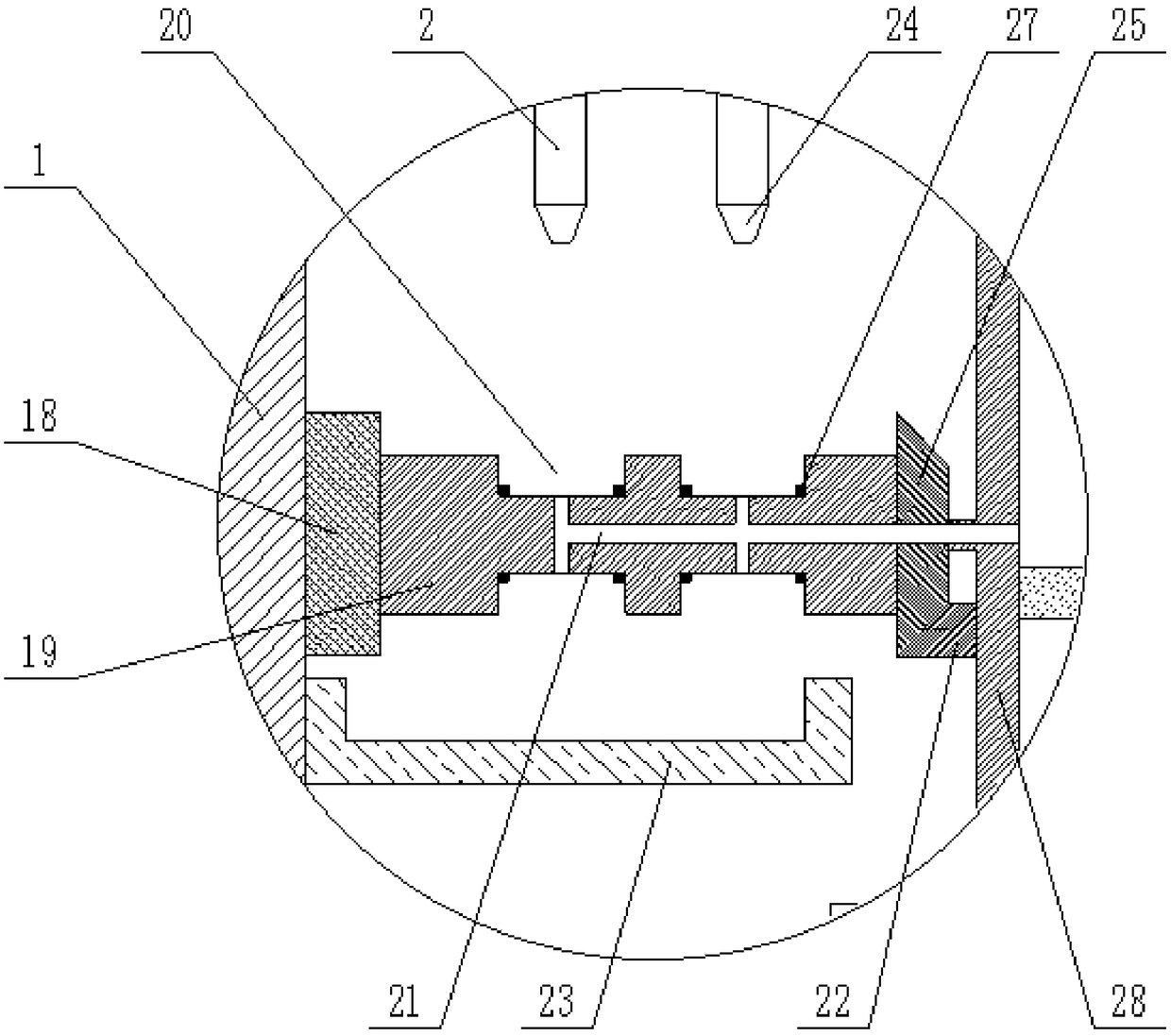

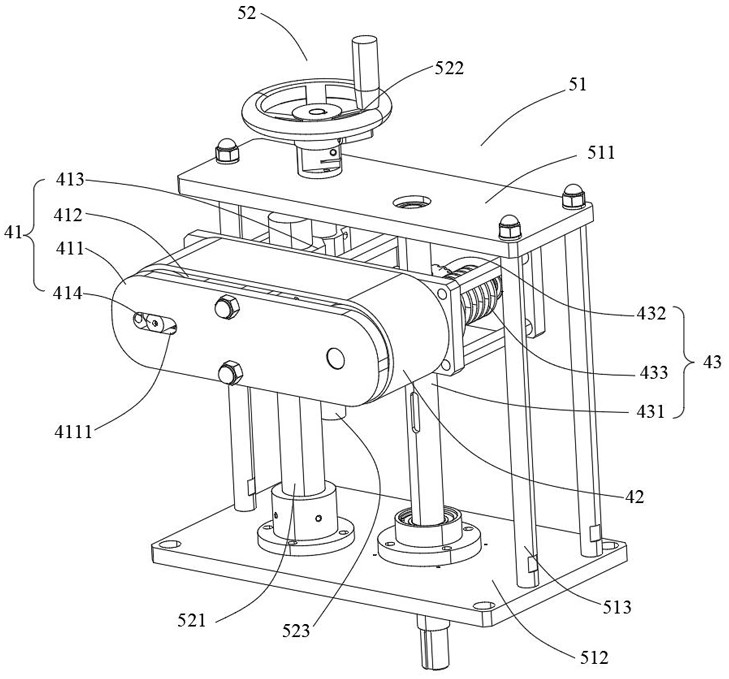

Multi-angle milling and rotary clamping tool and operating method thereof

ActiveCN106563959AAccuracy impactAvoid damage to the workpiecePrecision positioning equipmentPositioning apparatusEngineeringMachining

The invention discloses a multi-angle milling and rotary clamping tool and an operating method thereof, and belongs to the technical field of mechanical processing tools. The multi-angle milling and rotary clamping tool comprises bases, a clamp and a positioning mechanism, wherein the clamp is positioned in the bases; the clamp is mutually matched with the bases; the positioning mechanism is clamped between the clamp and the bases; each base comprises a roller path and a base upper end surface; the roller path comprises a base roller path surface; the clamp is arranged on the roller path of one base; the base roller path surface is matched with the clamp; the roller path of the other base covers the clamp; a to-be-milled workpiece is put into the clamp; the outer part of the clamp is covered by the bases; the positioning mechanism is clamped between the clamp and the bases to achieve positioning effect; relative positions of the clamp and the bases are regulated; and through fixing effect of the positioning mechanism, a fixed workpiece can be regulated to rotate to different angles in the peripheral direction. The multi-angle milling and rotary clamping tool can be used for clamping a to-be-processed workpiece without affecting surface precision of the workpiece, so that multi-angle processing of the workpiece is realized.

Owner:MAANSHAN CHENXU MACHINERY MFG

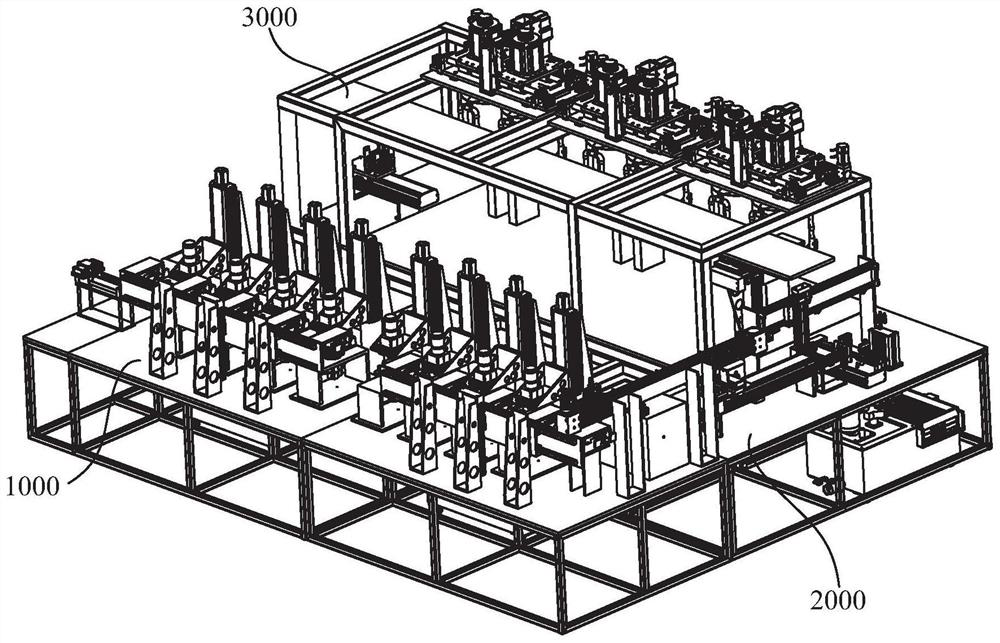

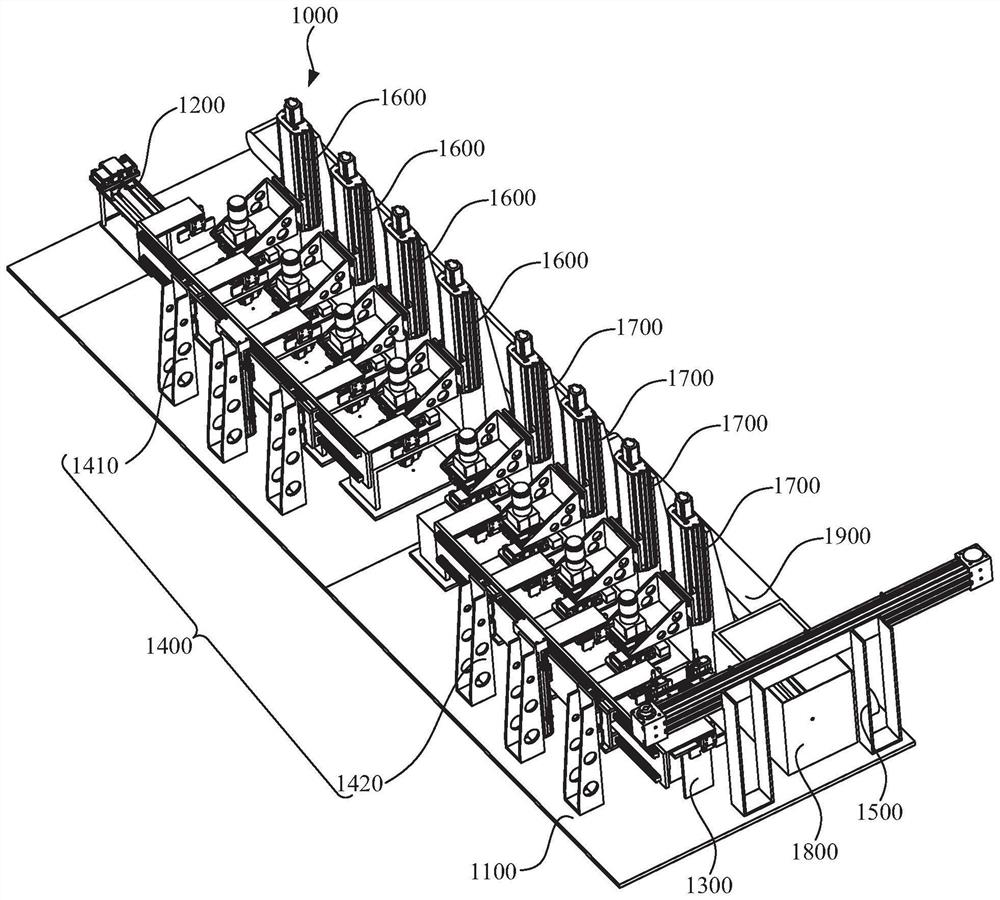

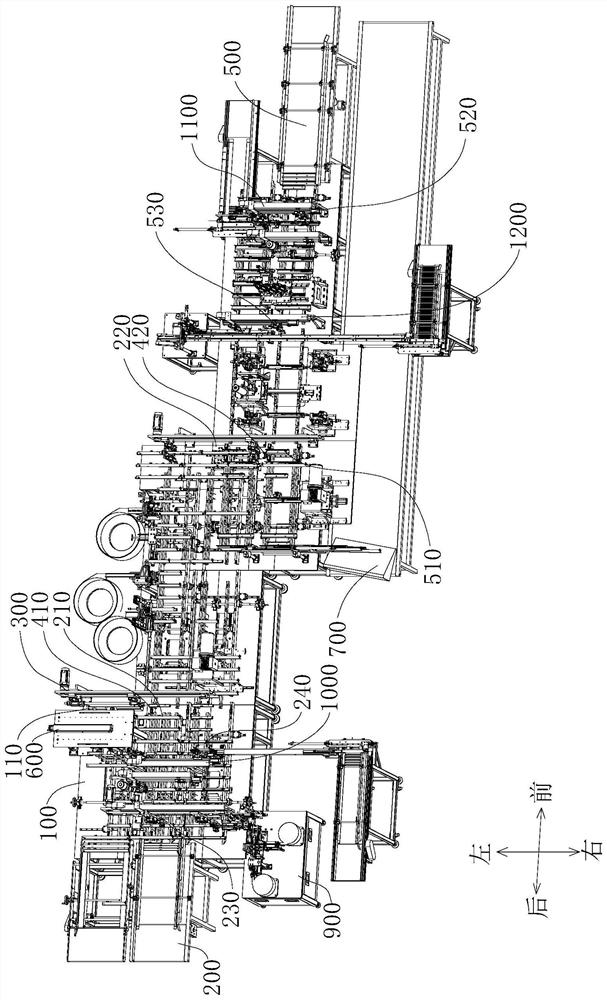

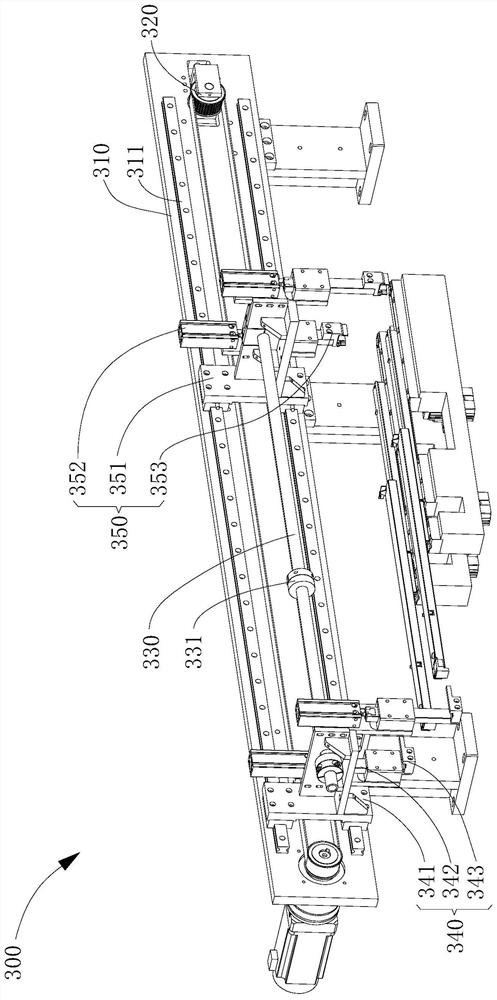

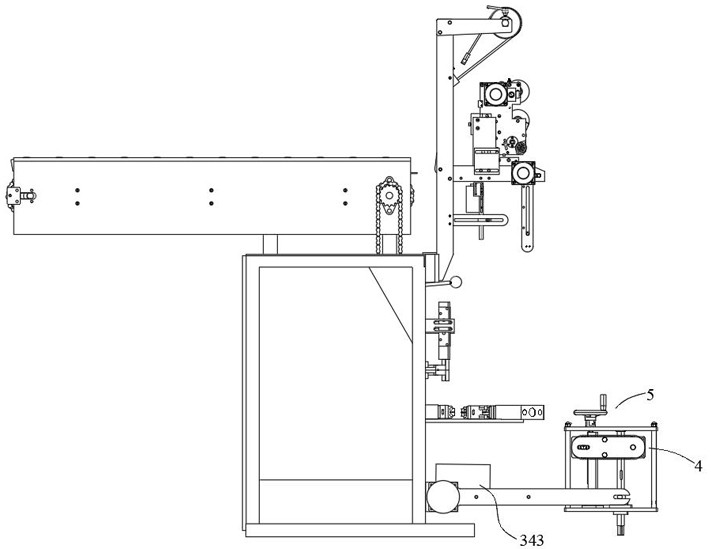

Automatic polishing production line

PendingCN114131496AImprove polishing efficiencyAvoid damage to the workpiecePolishing machinesGrinding machinesProduction linePolishing

The automatic polishing production line comprises hole polishing equipment, transfer equipment and peripheral polishing equipment, and the hole polishing equipment comprises a first rack, a feeding platform, a first transfer platform, a first transfer device, a second transfer device, a rough hole polishing device and a fine hole polishing device; the first transfer device is used for sequentially transporting workpieces among the feeding platform, the rough hole polishing device, the fine hole polishing device and the first transfer platform; the second transfer device is used for placing the workpieces on the first transfer platform on transfer equipment; the transfer equipment comprises a second rack, a second transfer platform, a positioning device and a third transfer device, the second transfer platform receives the workpieces on the second transfer device, and the third transfer device grabs the workpieces on the second transfer platform to the positioning device; and the peripheral polishing equipment comprises a third rack, a fourth transfer device and a peripheral polishing device, and the fourth transfer device grabs the workpieces on the positioning device to the peripheral polishing device. The polishing efficiency can be improved, and damage to workpieces is avoided.

Owner:SHENZHEN CITY POSONWONE TECH

Assembly production line of hidden rail

The invention discloses a hidden rail assembling production line which comprises an upper rail conveying mechanism, a lower rail conveying mechanism, a first assembling station and a second assembling station. A second assembly station is arranged on the middle rail conveying mechanism; the rail penetrating mechanism comprises a synchronous belt assembly, a synchronous rod, a pushing assembly and a guiding assembly, the first guiding rail extends left and right, and the pushing assembly and the guiding assembly are both in sliding connection with the first guiding rail; the synchronous belt assembly is used for driving the pushing assembly to move left and right, the right end of the synchronous rod is fixedly connected with the pushing assembly, and the left end of the synchronous rod is slidably connected with the guide assembly; the rail penetrating mechanisms are arranged at the first assembling station and the second assembling station; and the first limiting air cylinder is used for fixing the middle rail to the second assembling station, under the action of the rail penetrating mechanism, connection between the layer rails can be automatically achieved, and the assembling efficiency can be improved.

Owner:东莞心野机电科技有限公司

Sectional material drilling technology

InactiveCN108422108AAvoid workpiece damageDrilling to achieveLaser beam welding apparatusScrapCarbon dioxide

The invention belongs to the technical field of equipment or a special method for machining workpieces through laser beams, and particularly discloses a sectional material drilling technology. The sectional material drilling technology comprises the following steps that firstly, a gas laser device, a workpiece positioning mechanism and a drive mechanism are prepared, and laser mixed gas is prepared and comprises 2 parts of carbon dioxide, 4 parts of nitrogen and 19 parts of helium; secondly, a workpiece is fixed to the workpiece positioning mechanism; thirdly, the gas laser device is started,and the wavelength of lasers emitted by the gas laser device is 9.2-10.8 microns; fourthly, the drive mechanism is controlled to make the workpiece positioning mechanism upwards move and overturn at the same time, and when the workpiece positioning mechanism arrives at the highest point, drilling is started; and fifthly, the drive mechanism is controlled after drilling is finished, the workpiece positioning mechanism downwards moves in the vertical direction and overturns at the same time, and when the workpiece positioning mechanism arrives at the lowest point, the workpiece is unloaded, anddrilling is finished. According to the purpose, the problem that in the prior art, when table legs are drilled, a large number of splashing scraps exist in the drilling process is solved.

Owner:CHONGQING JIANLONG FURNITURE CO LTD

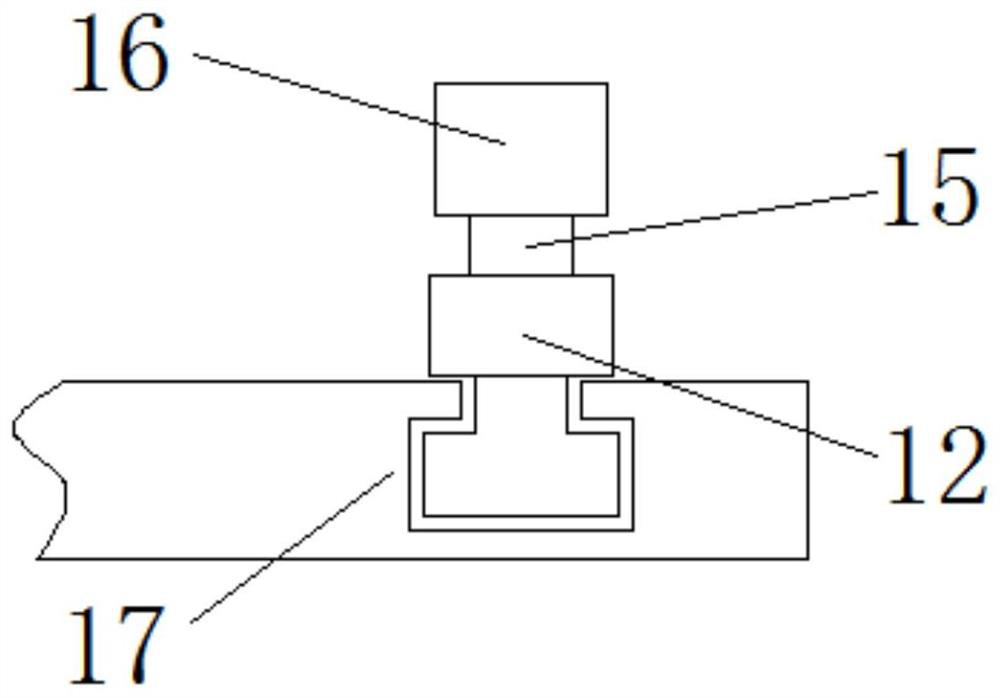

Telescopic screed overlap welding die jig

InactiveCN109736172AInhibit sheddingRealize automatic positioningRoads maintainenceScreedElectric machinery

The invention relates to the technical field of jigs, in particular to a telescopic screed overlap welding die jig, which comprises a bottom plate, a positioning barrel is arranged on the bottom plate, a positioning column is arranged in the positioning barrel, a push block is arranged below the positioning column, the push block is fixedly connected with a rack, and gears are meshed with the twosides of the rack. A supporting rod is arranged on the bottom plate, and the top of the supporting rod is rotationally connected with a U-shaped frame. A pressing block is further arranged on the bottom plate and fixedly connected with a connecting rod, the connecting rod is inserted into a sleeve, and a stud is arranged in the sleeve and fixedly connected with an output shaft of an air cylinder.According to the jig, a workpiece is coarsely positioned by moving the supporting rod to ensure that the positioning column can smoothly extend into the positioning hole, a motor drives the gears andthe rack to drive the positioning column to extend out, automatic positioning is achieved, the workpiece can be prevented from falling off the positioning column, the workpiece is pressed through theair cylinder, in this way, automatic pressing can be achieved, the pressing force of the pressing block on the workpiece can be adjusted by rotating the sleeve, and therefore the situations that pressing is not firm and the workpiece is damaged due to too large pressing force can be avoided.

Owner:合肥佳恩特机械制造有限公司

A continuous working medical needle box packaging machine

ActiveCN113815926BAvoid workpiece damageEasy to coverLiquid surface applicatorsWrapper twisting/gatheringMedical equipmentEngineering

Owner:常州市天磊传动机械有限公司 +1

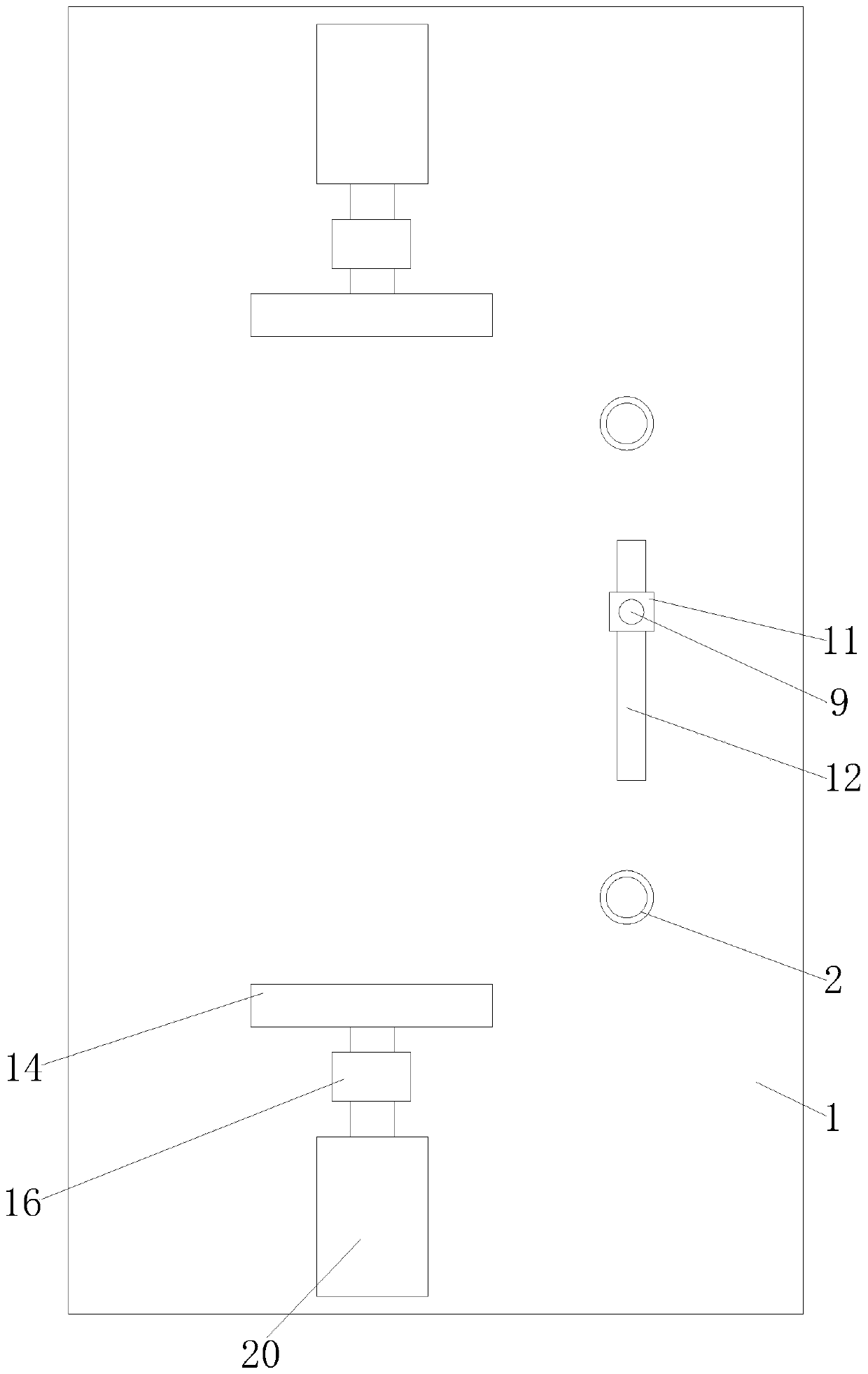

Double-station visual locking machine for purifier of ultrapure water machine

PendingCN113997061APrevent damage to the workpiecePrevent the phenomenon that the lock is not tightMetal working apparatusMachineControl theory

The invention discloses a double-station visual locking machine for a purifier of an ultrapure water machine. The double-station visual locking machine comprises a rack, a feeding and discharging device, side frames, a horizontal displacement device, vertical displacement devices, electric screwdrivers and a screw feeder, wherein the feeding and discharging devices are installed at the top of the rack, the two feeding and discharging devices are symmetrically arranged left and right, the group of side frames is further fixedly installed at the top of the rack, the horizontal displacement device is horizontally installed at the top of the side frames, and the vertical displacement devices are slidably arranged on the horizontal displacement device. The electric screw drivers are fixedly mounted at the front end of the vertical displacement devices, and the screw feeder is further fixedly mounted on the inner side of the side frames. According to the invention, the working efficiency is greatly improved, the labor intensity is reduced, the structure is more compact, the occupied space is smaller, and the cost is lower; the phenomenon that a workpiece is damaged due to the fact that the torque force of the electric screwdriver is too large in the screw locking process is prevented;and the screw locking quality is ensured.

Owner:上海乐枫生物科技有限公司

Maintenance platform with anti-static structure for computer maintenance

InactiveCN112338877AAvoid scatterPlay anti-static effectWork benchesCleaning using gasesSoftware engineeringStructural engineering

The invention discloses a maintenance platform with an anti-static structure for computer maintenance. The maintenance platform comprises a computer maintenance table, a buffer placement table and a part storage box, a back plate is arranged at the upper end of the computer maintenance table, a tray is arranged at the front end of the back plate, the part storage box is arranged in the computer maintenance table, a telescopic rod is arranged in the part storage box, the buffer placement table is arranged at the upper end of the telescopic rod, connecting springs are arranged on the left side and the right side of the telescopic rod, maintenance table grooves are formed in the outer surface of the telescopic rod and the outer surfaces of the connecting springs correspondingly, a connectingplate is arranged at the lower end of the computer maintenance table, and platform supporting columns are arranged at the lower end of the connecting plate. According to the maintenance platform withthe anti-static structure for computer maintenance, through an arranged part filter screen, parts can penetrate through the part filter screen to fall into the part storage box on the lower portion, and therefore the parts detached from a computer are collected in a unified mode, and scattering of the parts is avoided.

Owner:广州集佳科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com