Driver for automatic focusing lens

A driver and automatic technology, applied in the direction of instruments, focusing devices, installation, etc., can solve the problems of reducing the yield of the workpiece, difficult to control, low heat conduction efficiency, etc., to improve the yield of the workpiece, avoid damage to the workpiece, and save cleaning procedures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

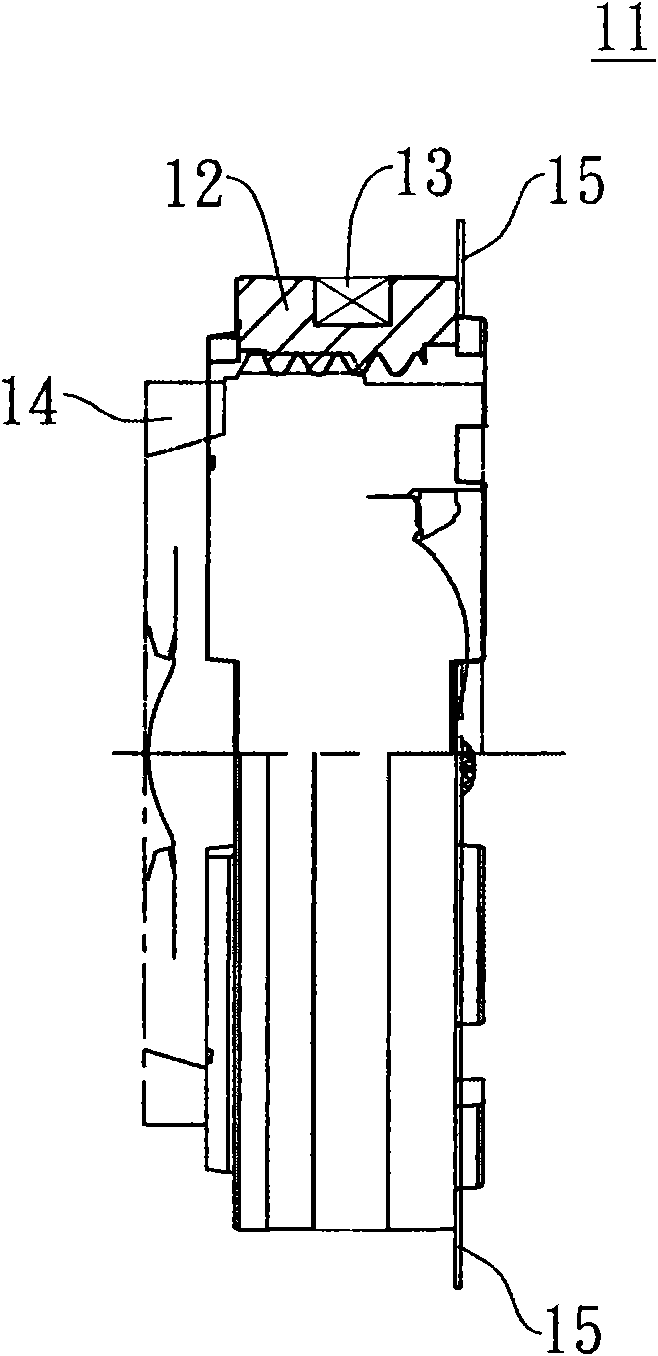

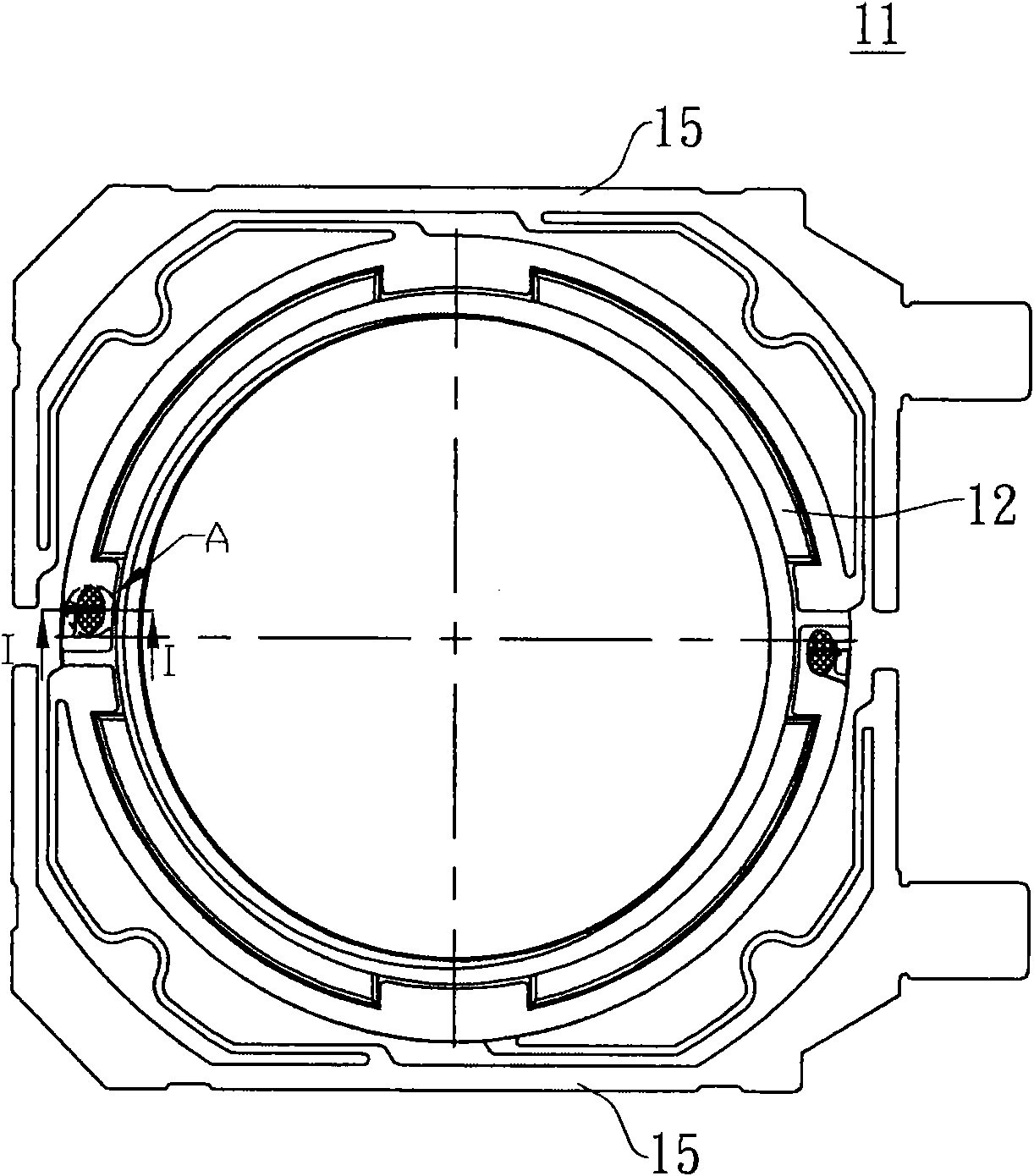

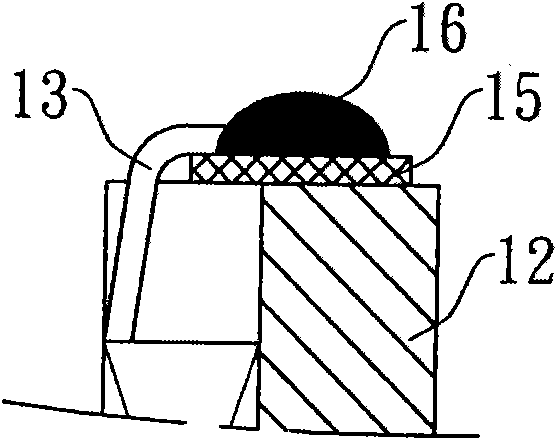

[0029] The auto-focus lens driver of the present invention will be described in detail through the following specific embodiments with accompanying drawings.

[0030] See Figure 5 versus Image 6 , Respectively show the side view and the rear view of the autofocus lens driver 1 of the present invention, and refer to Figure 7 , Is showing Image 6 An enlarged detailed perspective view of part B in the middle. In this specific embodiment, the auto-focus lens driver 1 of the present invention uses a voice coil motor structure to drive the lens for auto-focusing. The auto-focus lens driver 1 has a fixed side part (not shown) and a movable side part. The fixed side component includes a housing, a yoke made of soft iron and other magnetic materials, and a permanent magnet installed inside the housing and installed on the inner side wall of the yoke. Since the fixed side component is a known structure commonly used in the industry in the voice coil motor structure, in order to avoid t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com