Patents

Literature

68results about How to "Drilling to achieve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

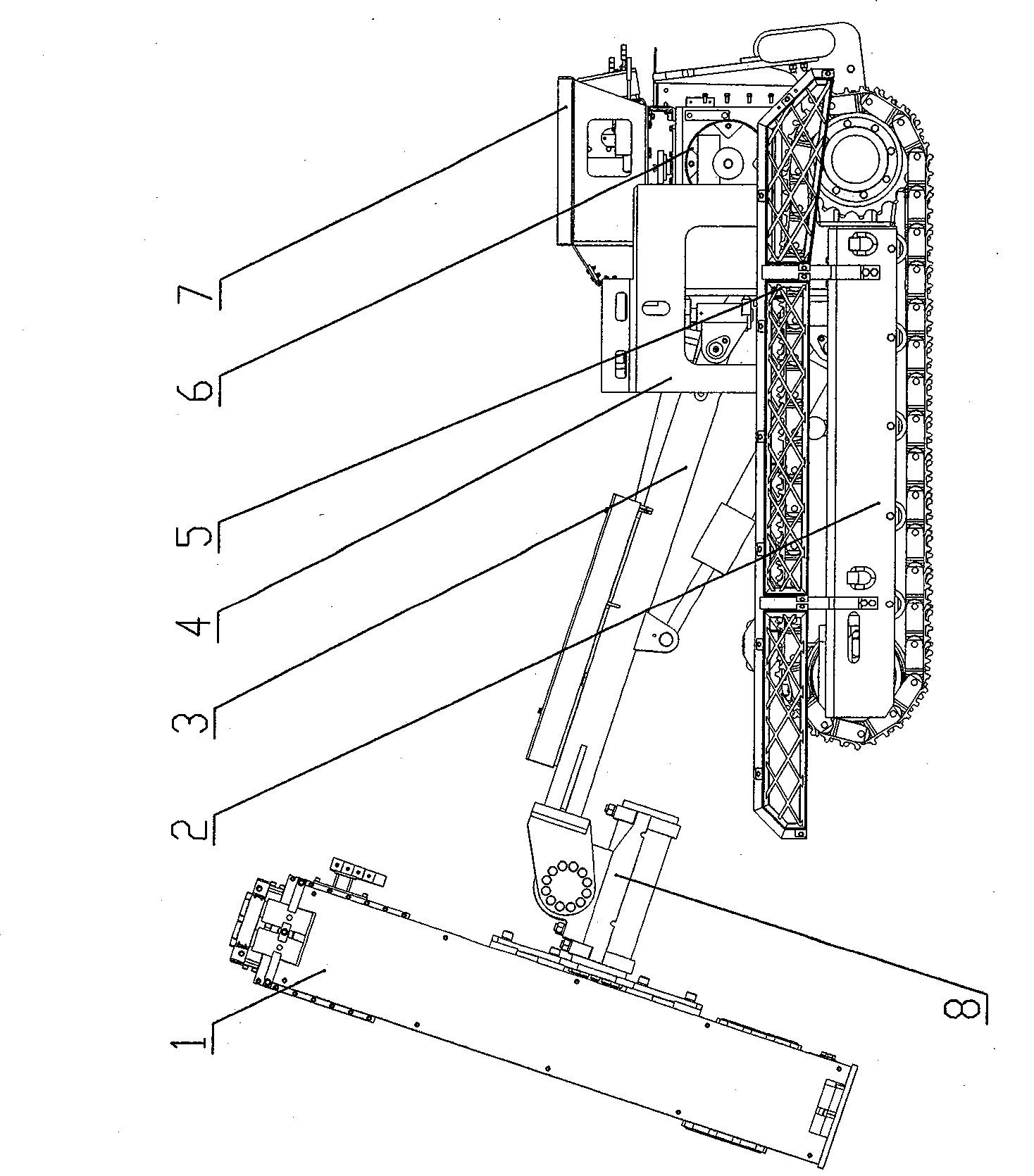

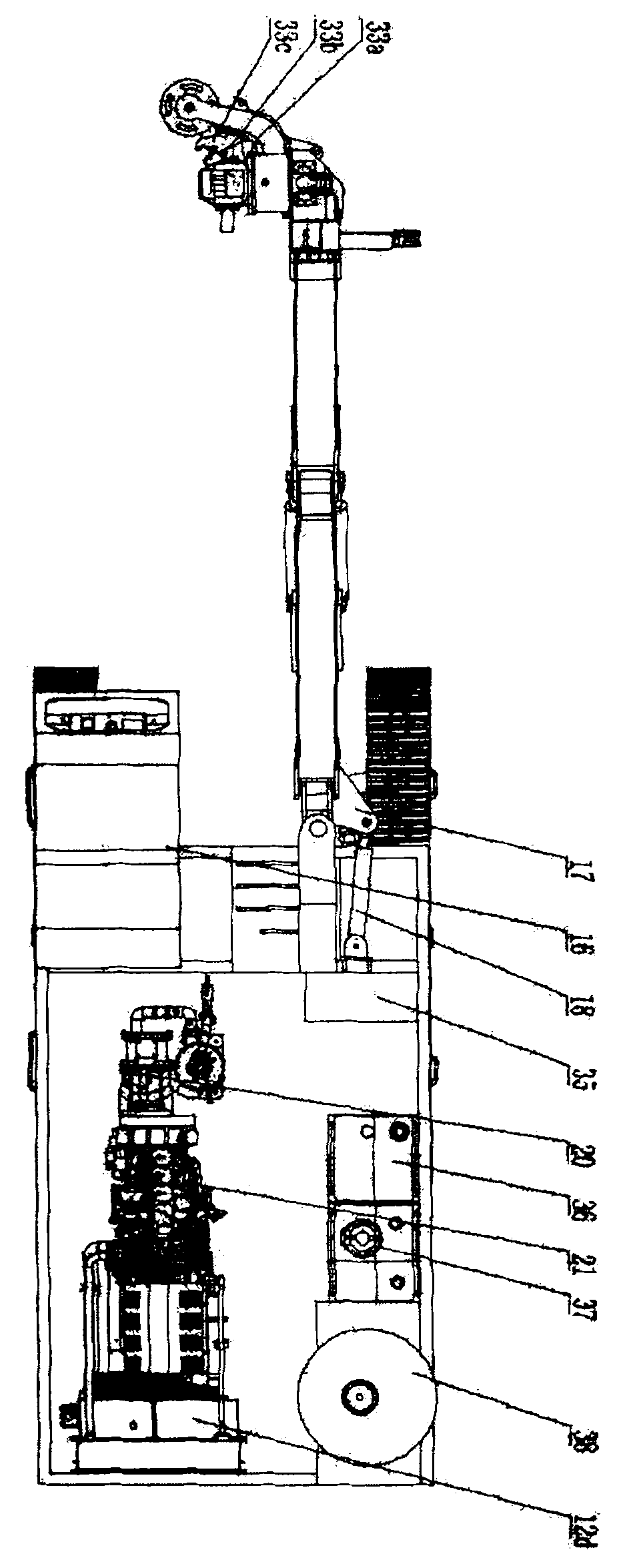

Pneumatic crawler hydraulic jumbo

InactiveCN101509350AAvoid it happening againTimely processingConstructionsDrilling drivesClosed loop designElectric devices

The invention discloses a pneumatic crawler-type hydraulic drill carriage which comprises a carriage body, a travelling gear, a working device for drilling connected with the carriage body, a hydraulic system for driving the devices, and an operating device; a pneumatic motor is used as power of the hydraulic system and operation of the drill carriage; an operating device, which adopts closed loop design, is used for driving the pneumatic motor, the pneumatic system, the hydraulic system and the various acting components to act; the travelling device is crawler-typed; a swinging device, which consists of a swinging arm and a cylinder, is arranged at the front of the carriage body; the front end of the swinging device is connected with the working device for drilling by a universal rotating device; the working device consists of a feeding device which comprises a supporting device, a secondary cylinder, and a chain pushing mechanism; and the pneumatic crawler-type hydraulic drill carriage uses a method combining water and gas to clean the boreholes. The pneumatic crawler-type hydraulic drill applies especially to mass drilling work sites of which change continuously; the whole carriage is free of electric devices and the pneumatic crawler-type hydraulic drill applies particularly to high gassy mine and can carry out universal hole drilling.

Owner:JIKAI EQUIP MFG CO LTD

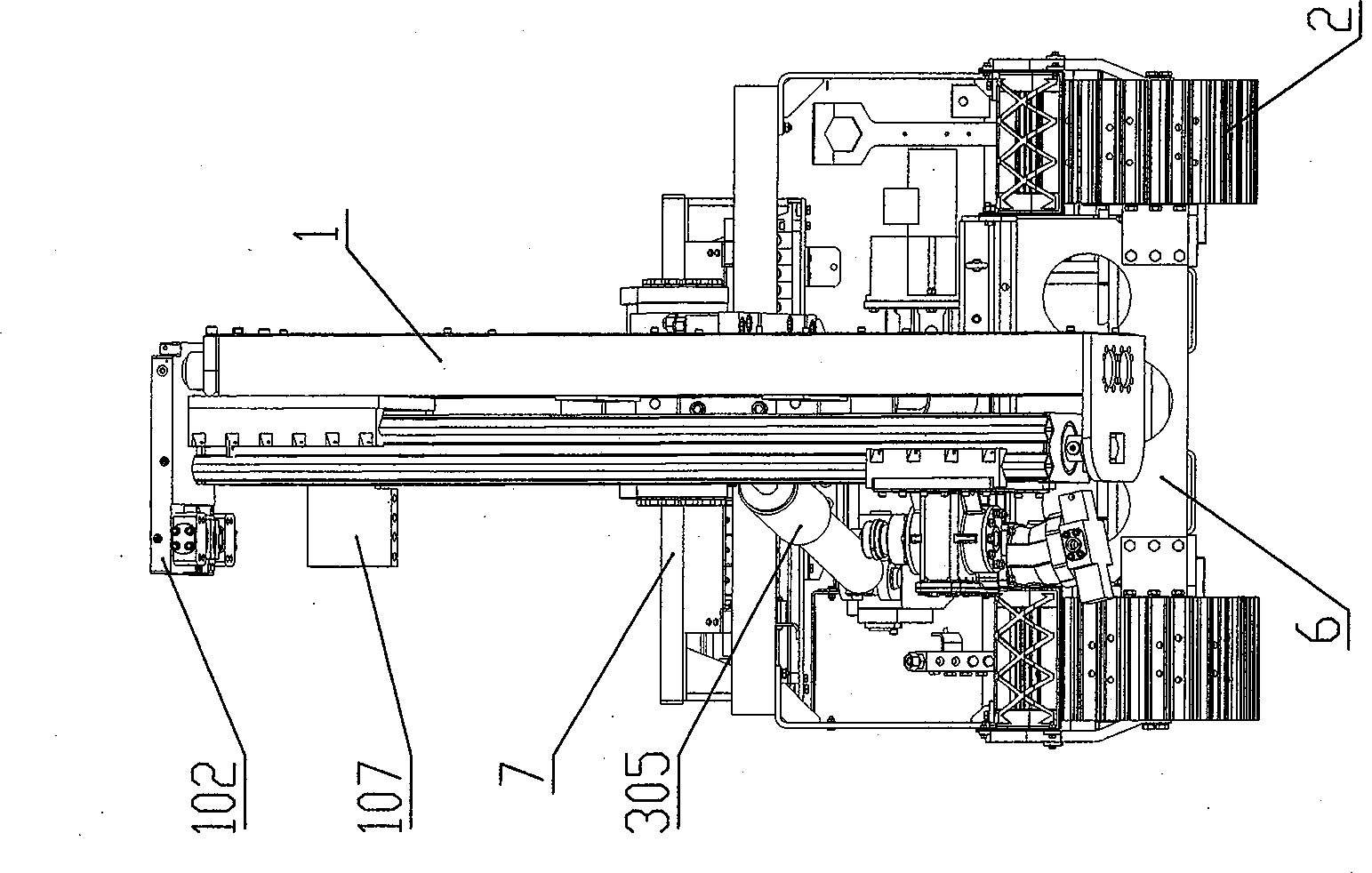

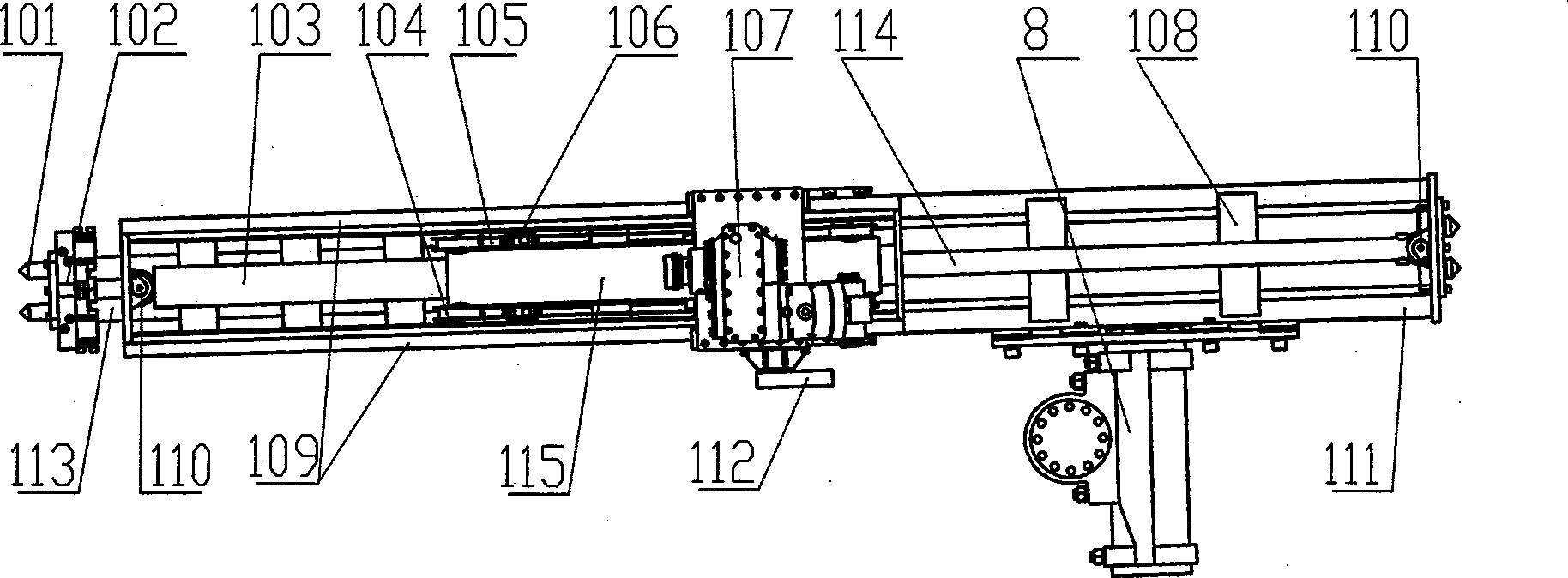

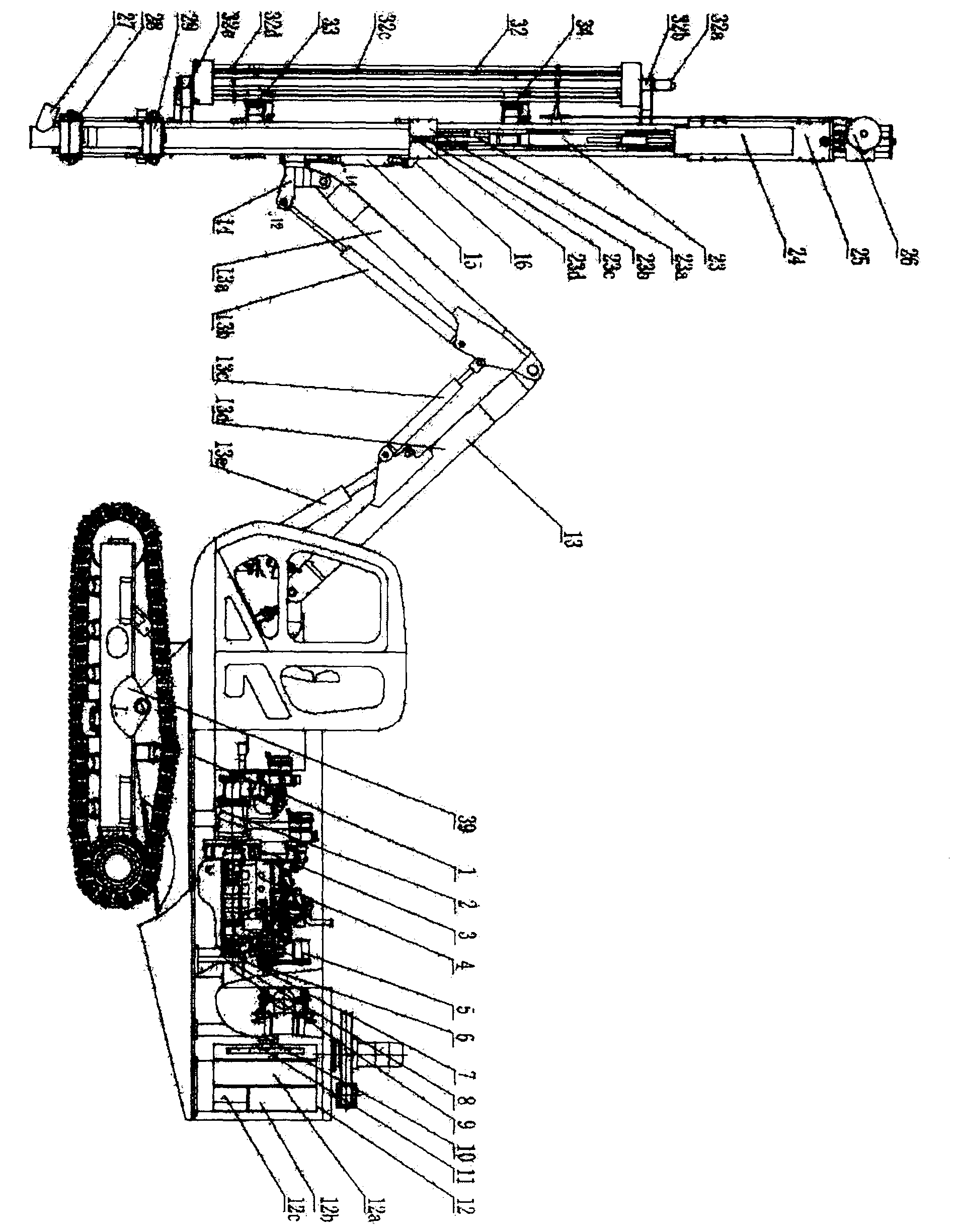

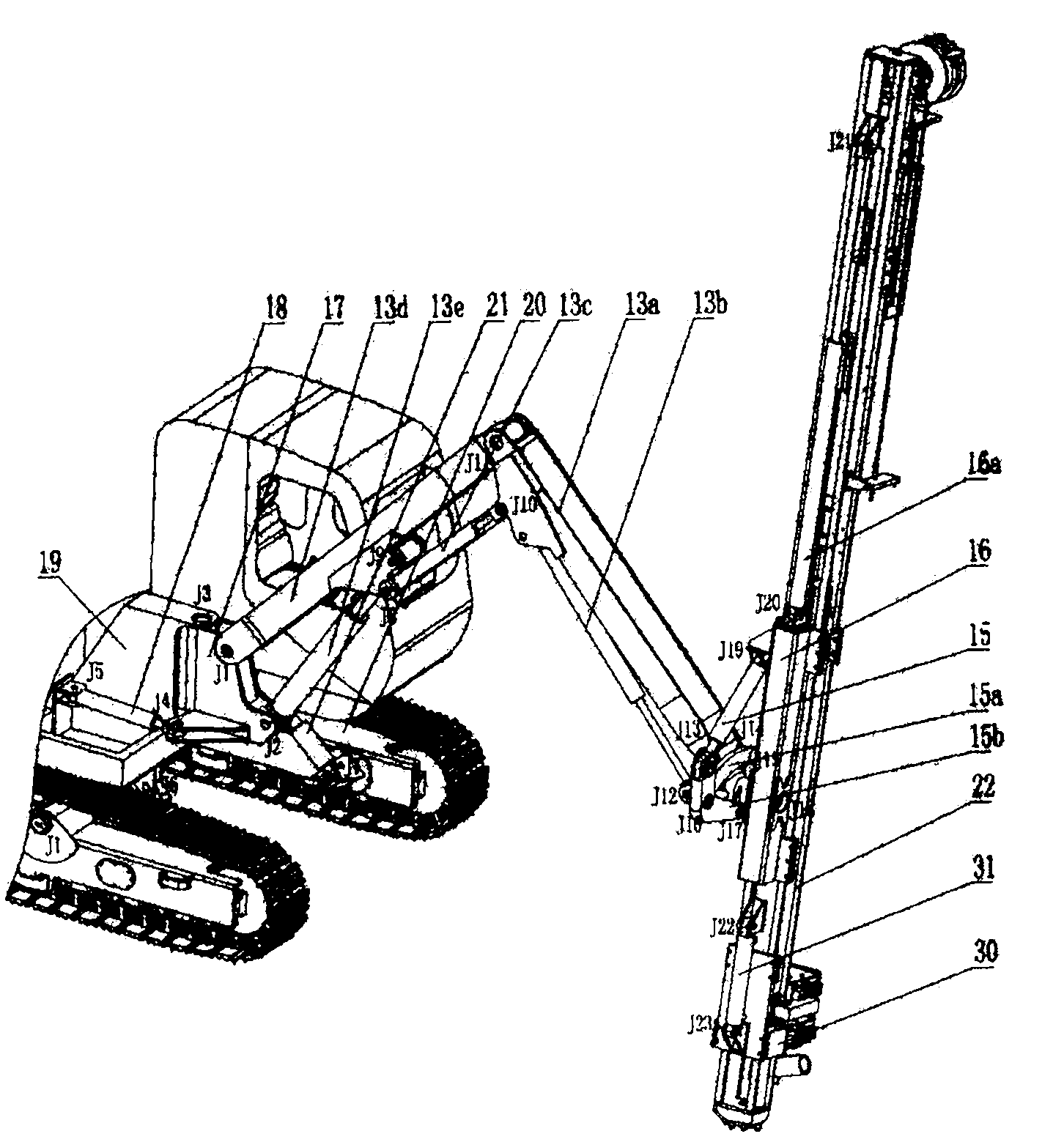

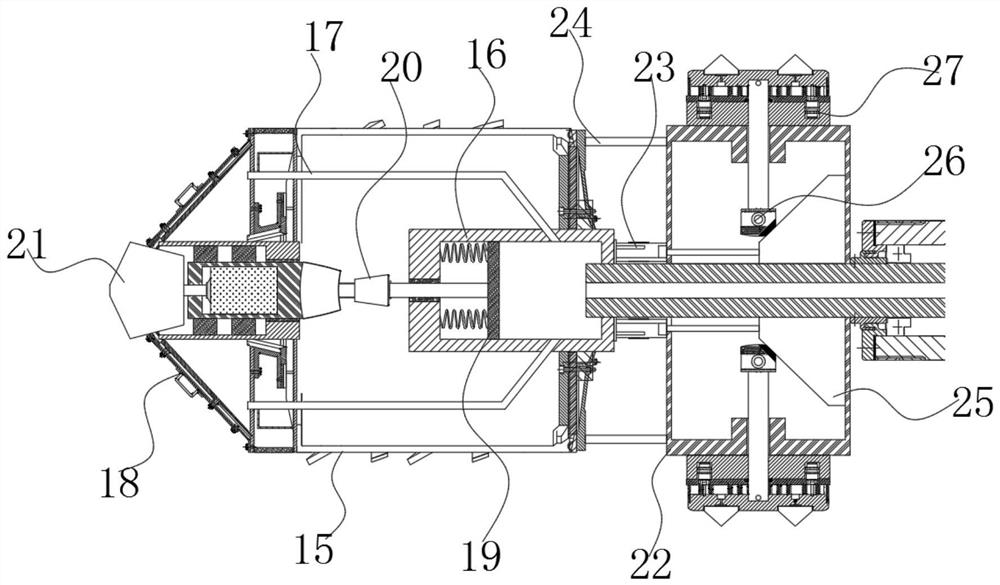

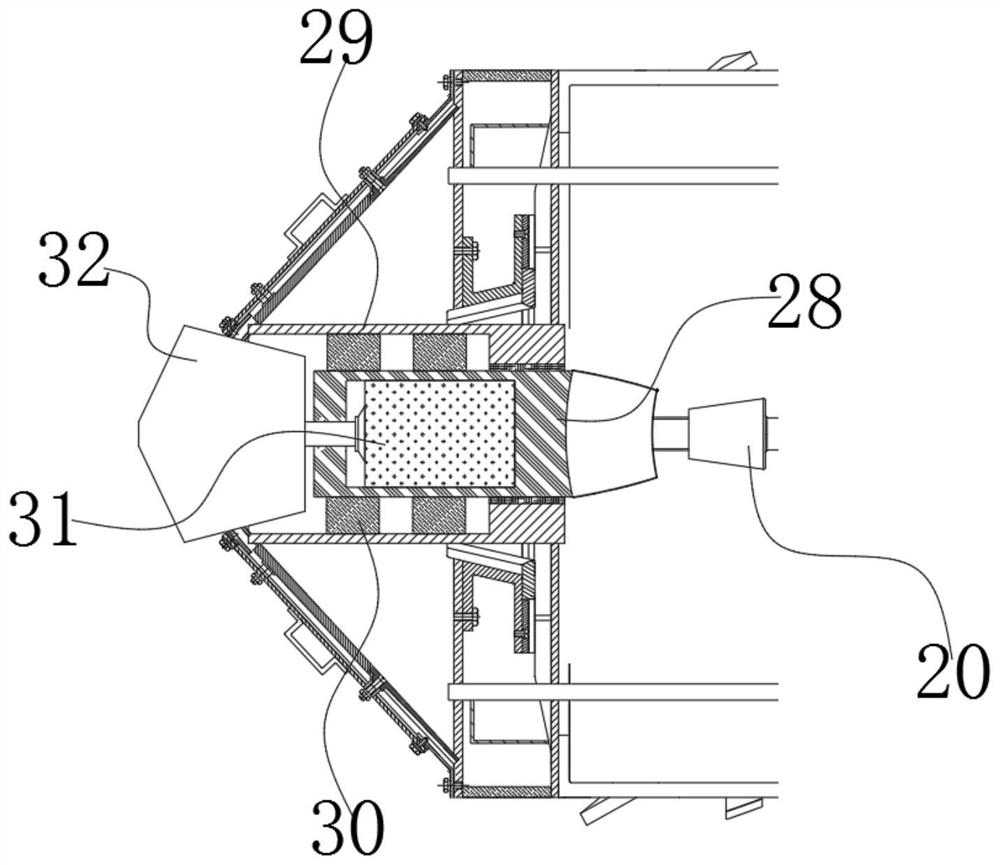

Multidirectional hydraulic rock drilling machine with integrated drives

InactiveCN102003143ACompact structureImprove energy efficiencyDrilling rodsDerricks/mastsElectronic control systemControl system

The invention relates to a multidirectional hydraulic rock drilling machine with integrated drives, and discloses multidirectional hydraulic rock drilling equipment with the integrated drives, which is composed of a rack, a drilling mechanism, a rod breaker mechanism, a drill hole angle adjustment mechanism, a crawler-type walking mechanism, an air compressor, an engine, a hydraulic system, an electronic control system, a dust removing system and the like, wherein, the crawler-type walking mechanism of a track frame the angle of which can be oscillated and is arranged below the rack; the air compressor, a hydraulic control system, an electrical apparatus control system, a power system and the dust removing system are arranged on the rack; the right front end of the rack is provided with afolded arm rack or a flexible arm rack; the front end of the arm rack is provided with a rotary head and the drilling mechanism; and the rod breaker mechanism, a pipe reeling mechanism, a propelling mechanism and a hydraulic rock drilling machine are arranged on a drilling rack of the drilling mechanism. The multidirectional hydraulic rock drilling machine integrating drive of the invention integrates the drives, can drill holes in multidirection, simultaneously has low energy consumption, high efficiency, compact structure and light and flexible operation, and is simple and convenient for maintenance.

Owner:吴亦舟

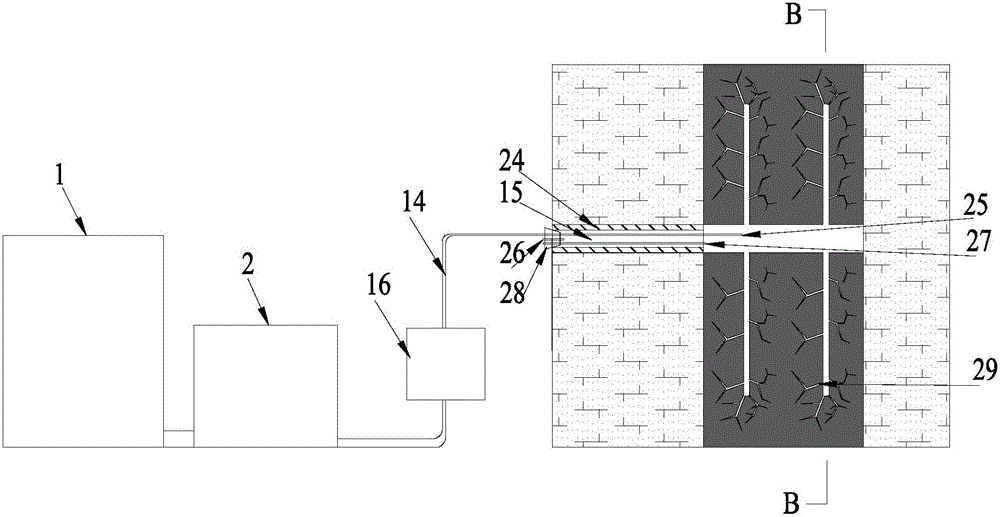

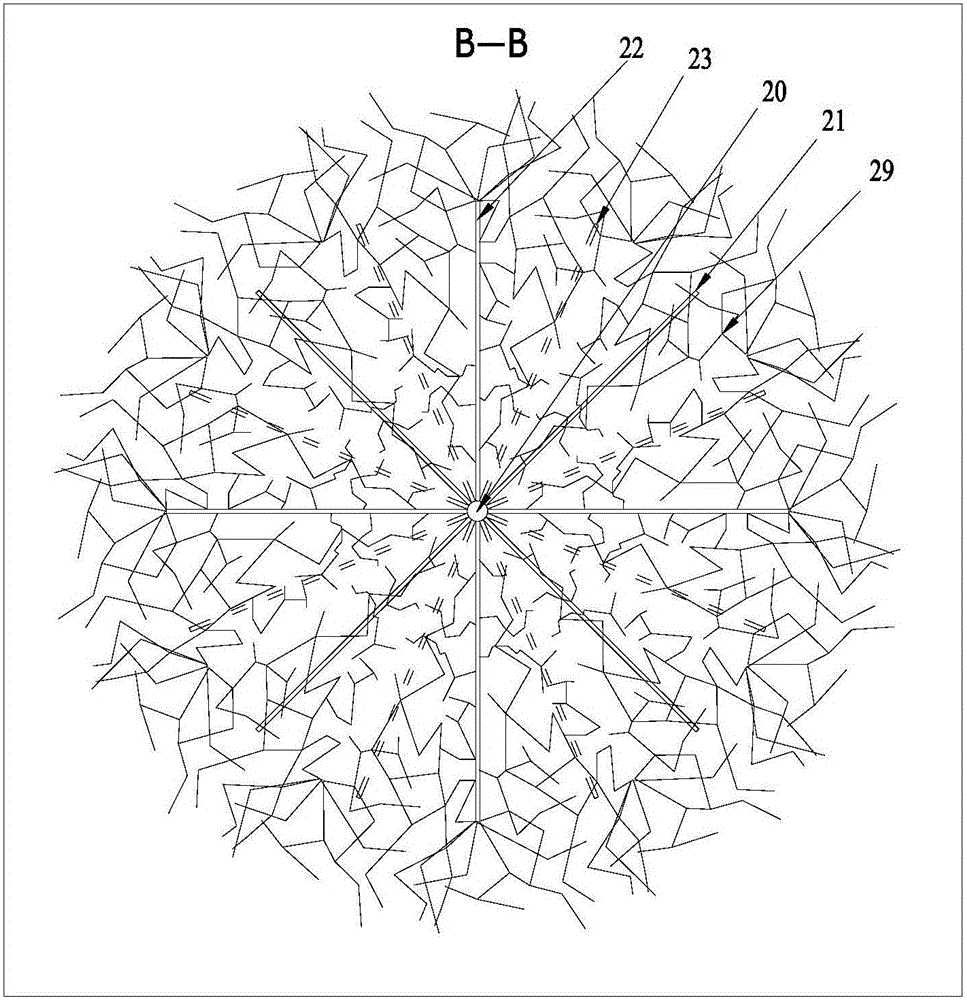

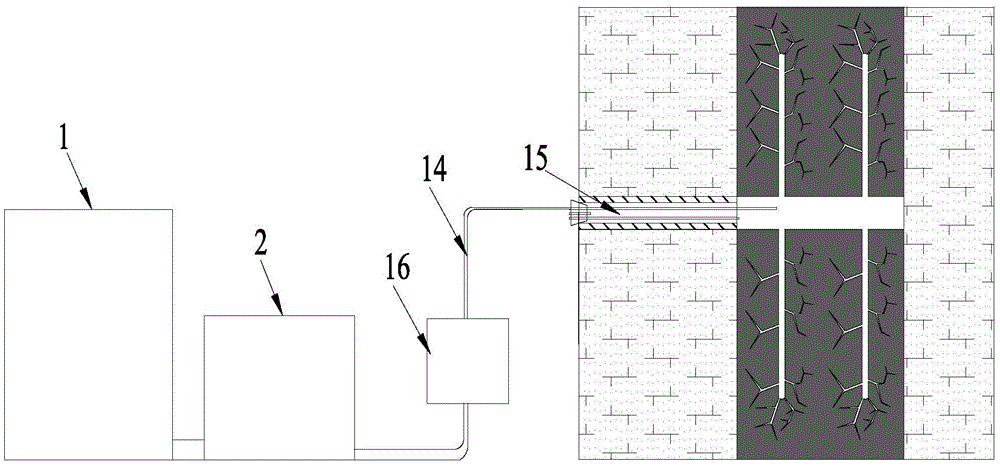

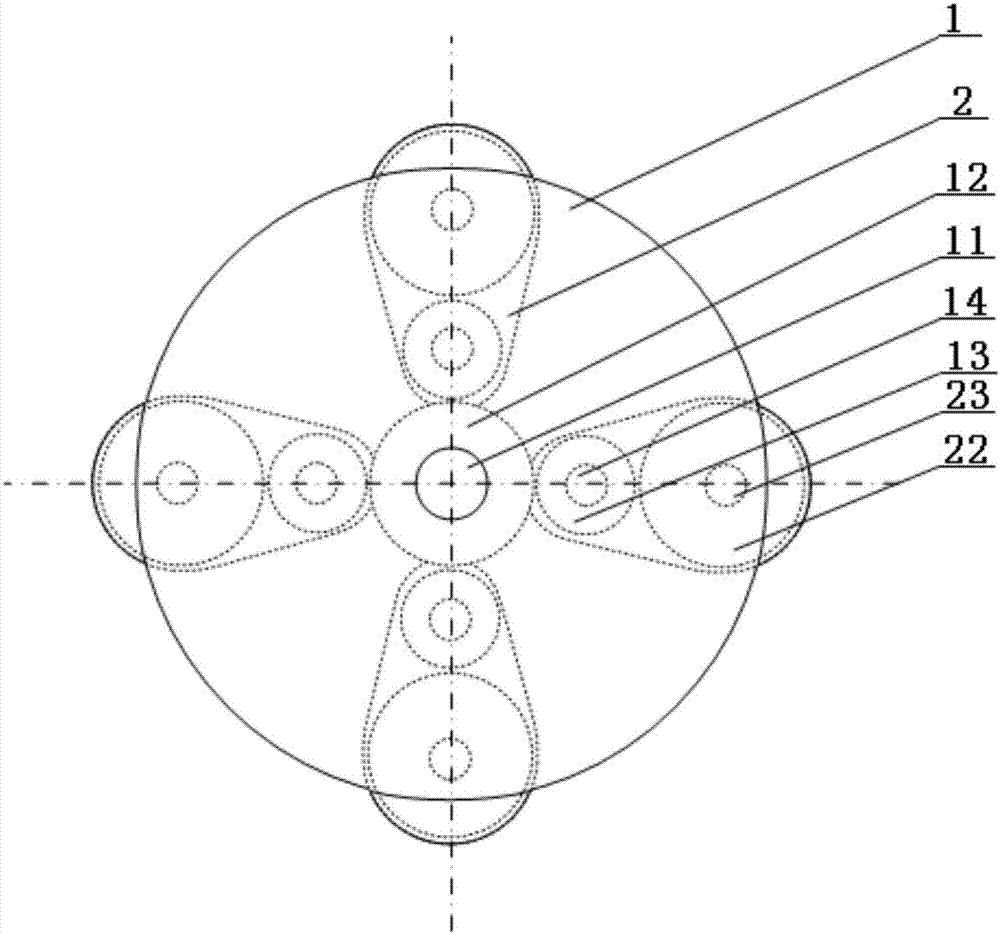

Composite fracturing and uniform permeability-improving method for tree-like boreholes in coal seams of underground coal mine

ActiveCN105156085AReduce workloadCompact and reasonable structure designFluid removalSealing/packingDrill holeCoal

The invention discloses a composite fracturing and uniform permeability-improving method for tree-like boreholes in coal seams of an underground coal mine. The composite fracturing and uniform permeability-improving method is suitable for permeability improvement of soft low-permeability coal seams, and is characterized in that a gas exhausting and mining hole serve as a mother hole, uniformly distributed self-advancing boreholes serve as tree-like son boreholes, and a tree-like borehole net is subjected to hole-sealing fracturing. Compared with a conventional hydraulic fracturing method, the composite fracturing and uniform permeability-improving method can realize uniform fracturing of the low-permeability coal seams to enlarge the fracturing range of single crossing boreholes, so that uniform permeability improvement is achieved, and the shortcomings that the crossing boreholes subjected to conventional hydraulic fracturing are low in utilization ratio, and a single major fracture can damage top and bottom beds are overcome. The composite fracturing and uniform permeability-improving method is simple to operate, large in permeability improvement range and good in permeability improvement effect and provides a guarantee for safety production of the underground coal mine.

Owner:CHONGQING UNIV

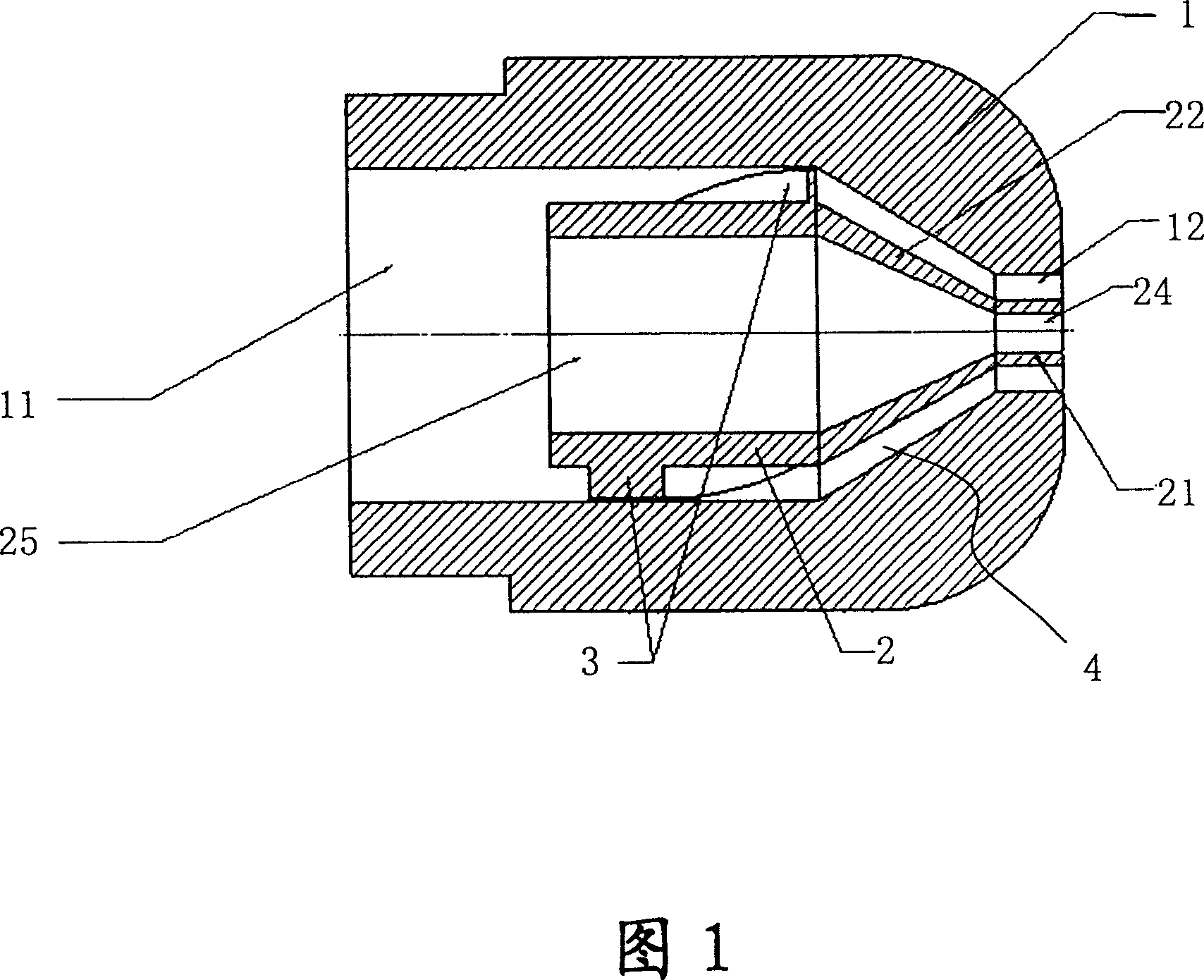

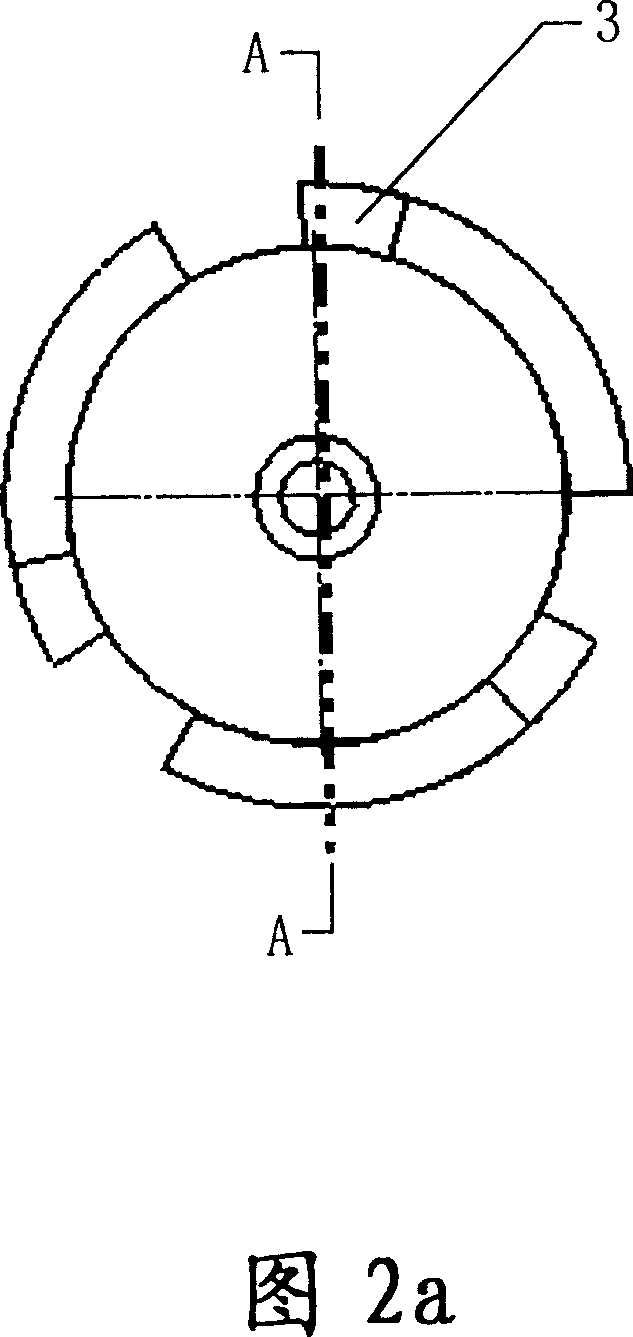

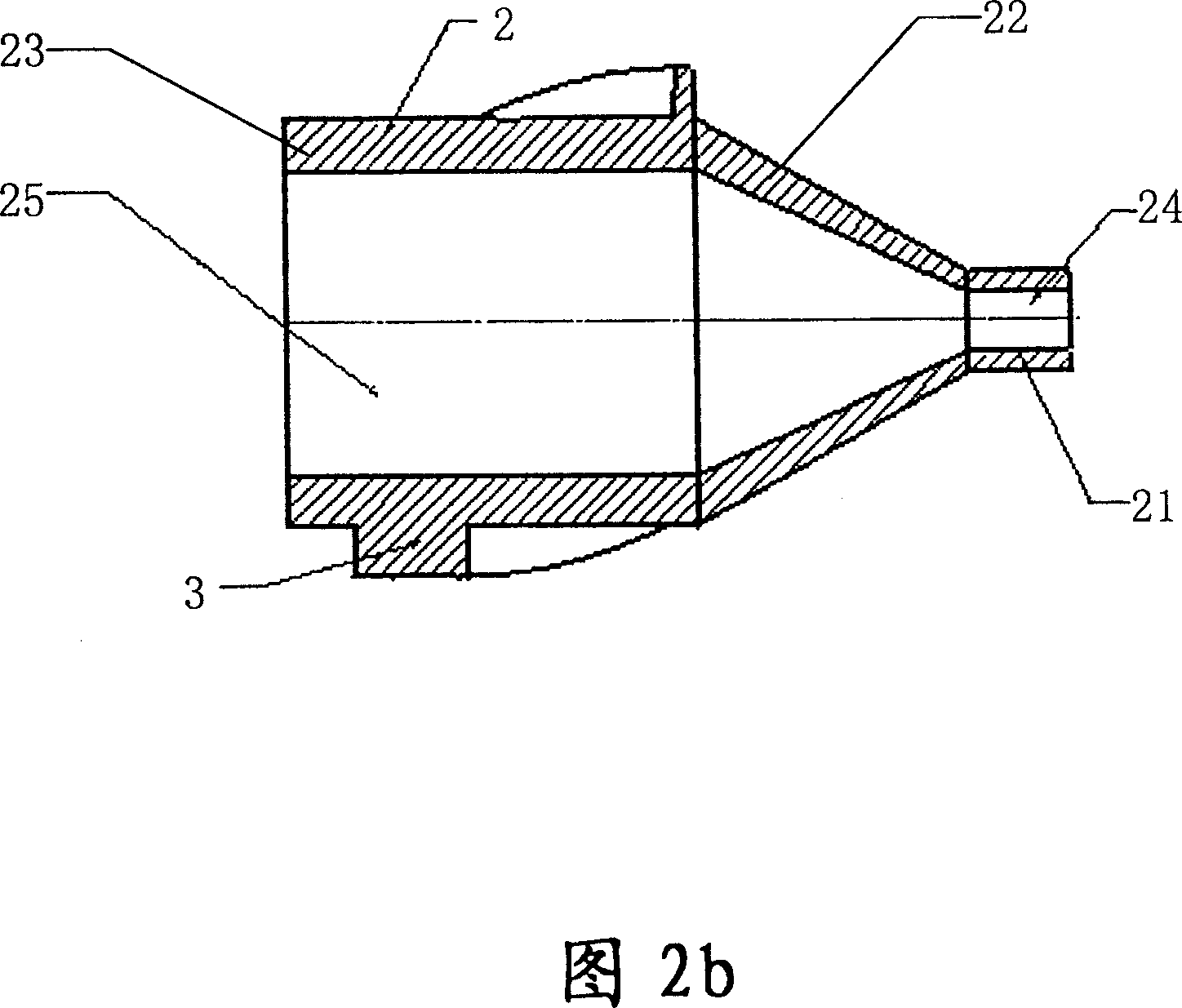

Boring system of rotary dual jet flows under high pressure, and rotary dual jet flows nozzle under high pressure

InactiveCN1959058AIncrease the crushing areaImprove utilization efficiencyLiquid/gas jet drillingEnergy transferJet flow

The present invention relates to a high-pressure rotary double-jet drilling method. It is characterized by simultaneously using rotary jetting method and straight jetting method. Said rotary jetting method can form large energy transfer area zone in targent zone and the straight jetting method can partially form energy transfer area zone in the centre of target zone, the rotary jetting method and straight jetting method are formed into a mutual shearing relationship, the mutual shear of the above-mentioned two jetting methods can produce cavitation action. The high-pressure rotary double-jet nozzle used for said method includes external nozzle and internal nozzle; said internal nozzle is placed in the external nozzle interior. Said invention can make straight jetting method and rotary jetting method be combined together so as to raise utilization efficiency of jetting energy and can drill metal or high-strength non-metal material.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

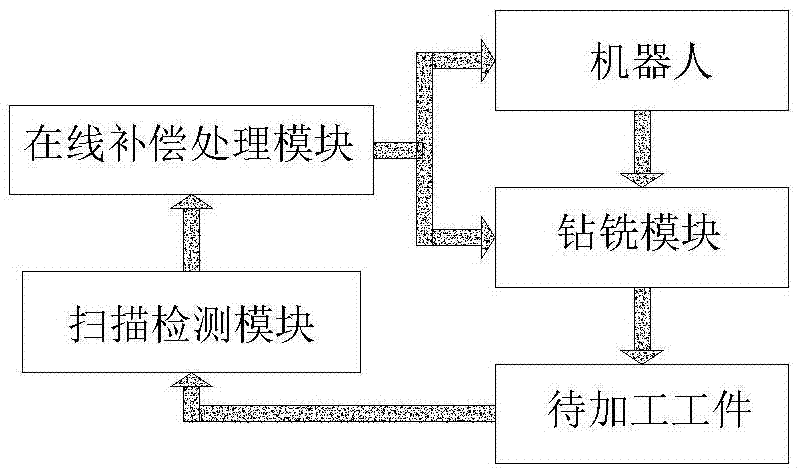

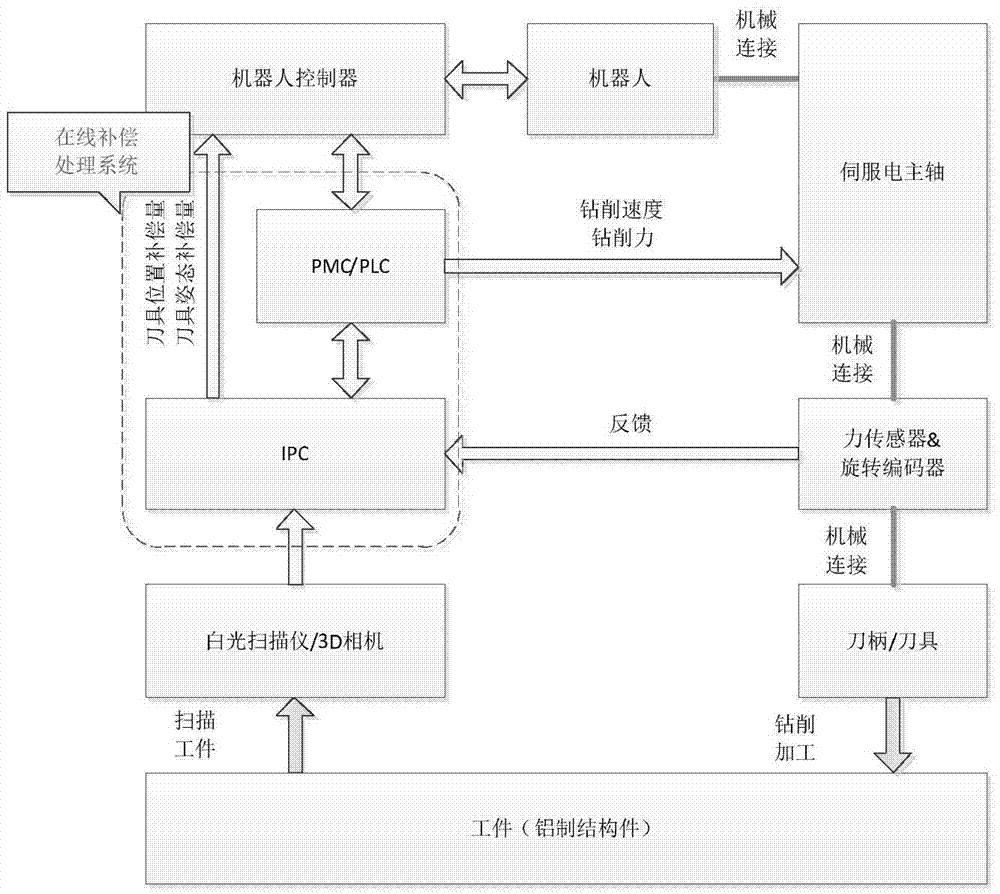

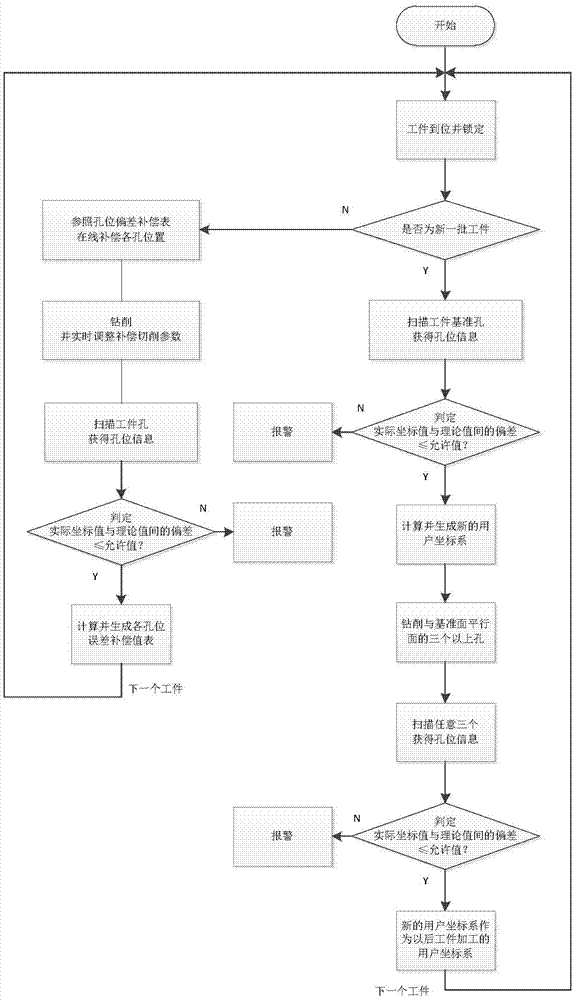

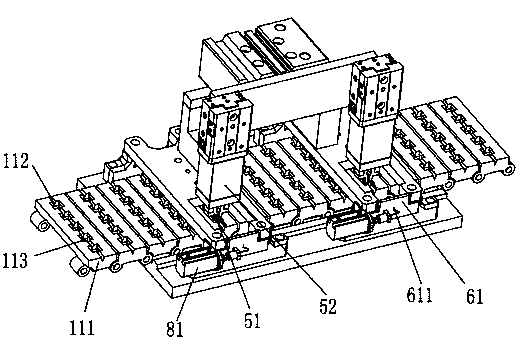

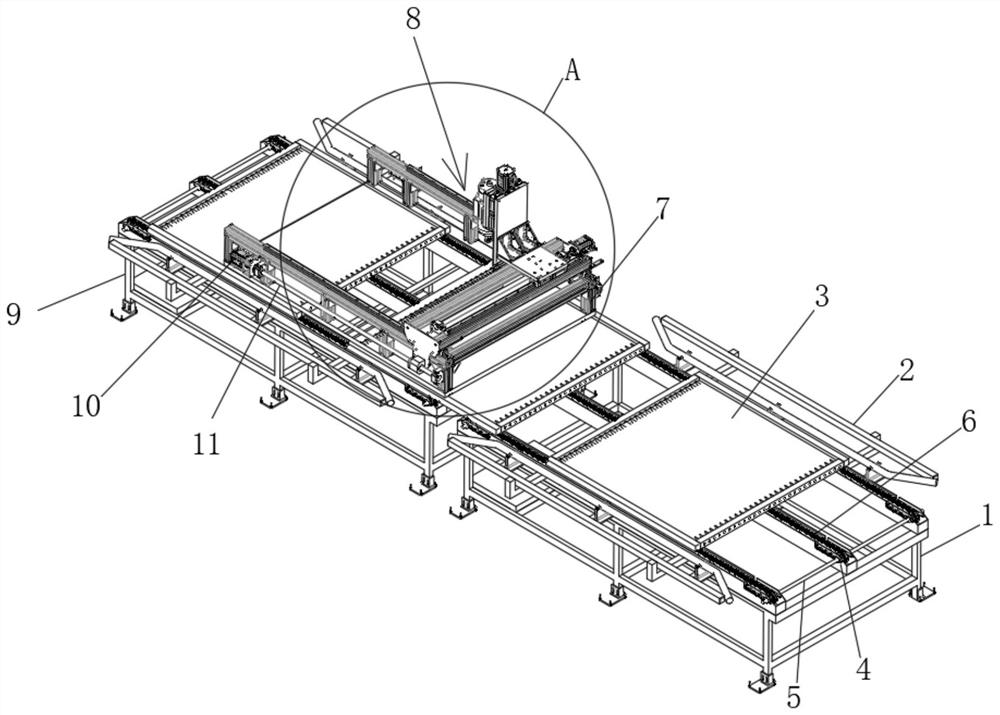

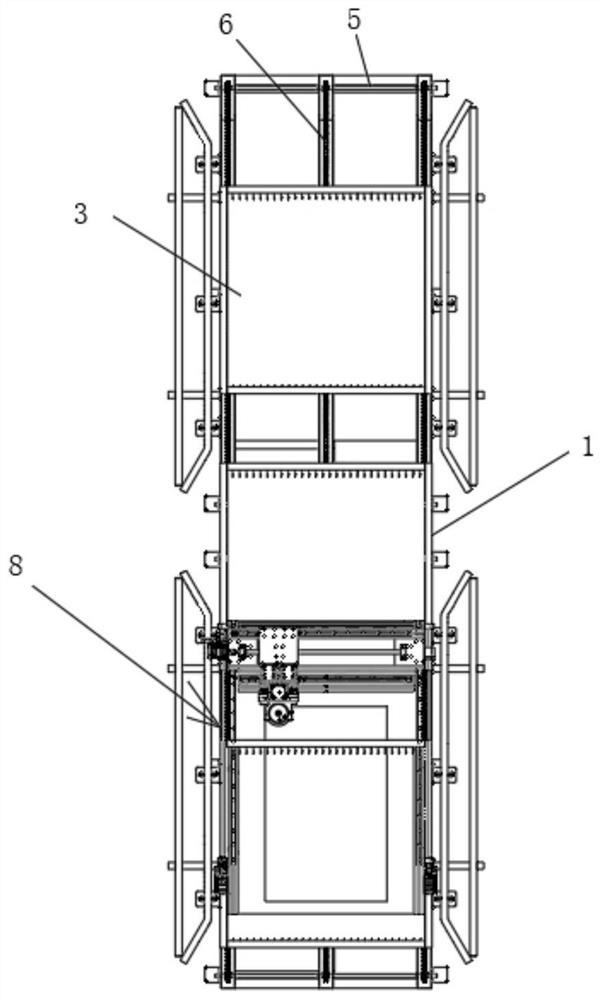

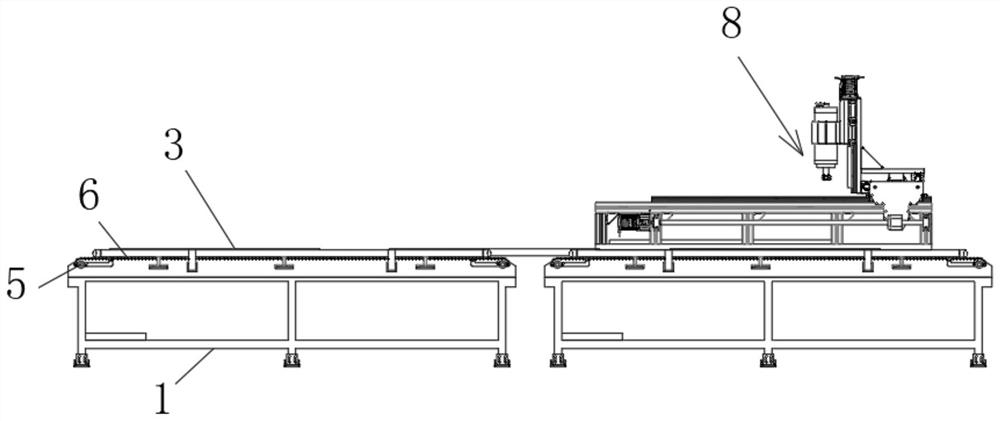

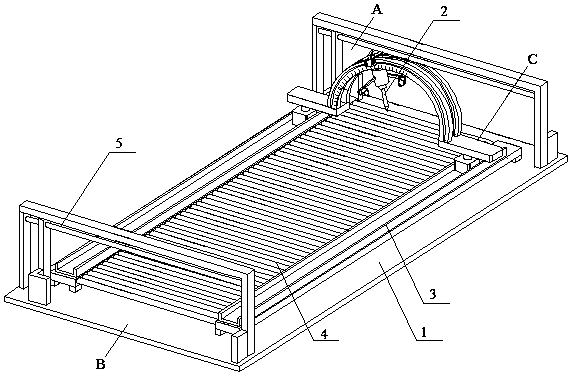

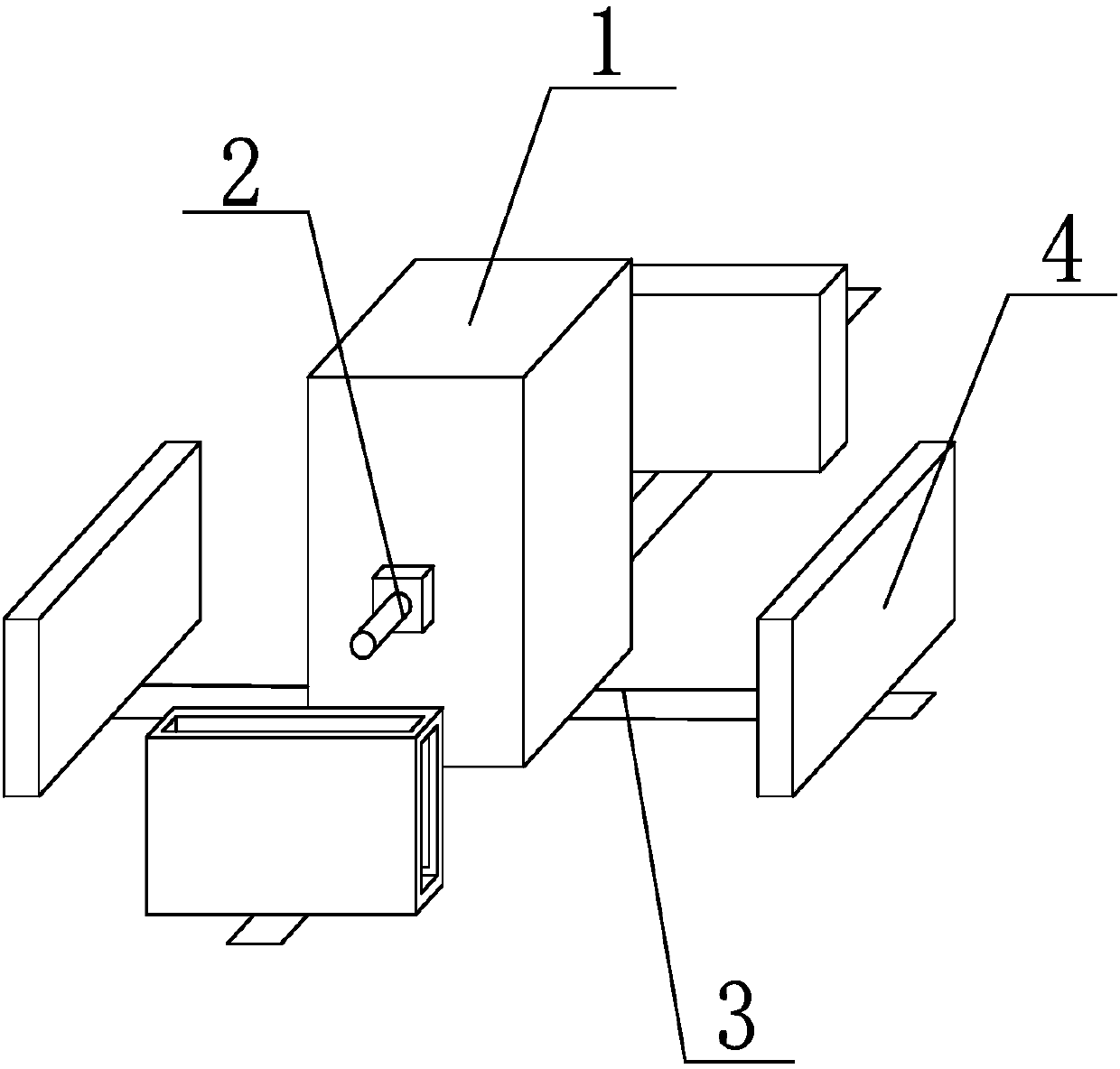

Automatic drilling and milling system and method and drilling and milling production line

PendingCN106925997AImprove processing efficiencyImprove flexibilityAutomatic control devicesMeasurement/indication equipmentsProduction line3d scanning

The invention discloses an automatic drilling and milling system and method and a drilling and milling production line, and relates to the technical field of electromechanical machining. The automatic drilling and milling system and method and the drilling and milling production line can be applied to the process of machining to-be-machined aluminum workpieces and the like through a milling machining center and / or an automatic robot drilling and milling system and the like; and in other words, 3D scanning and other surveillance technologies are utilized for conducting online surveillance and compensation on the robot track, and accordingly accurate machining of the to-be-machined workpieces is achieved.

Owner:SHANGHAI FANUC ROBOTICS

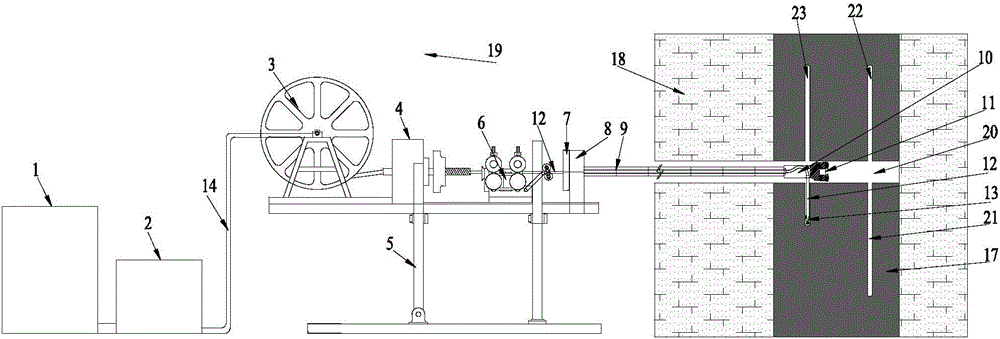

Reverse circulation drilling device and process for soft projecting coal seam

InactiveCN104514487AImprove drilling efficiencyImprove porosityFlushingDrilling machines and methodsCoalDrill bit

The invention provides a reverse circulation drilling device for a soft projecting coal seam. The device comprises a drilling machine, an active double-wall drilling rod, a double-channel pneumatic faucet; a power head is arranged on the drilling machine; the active double-wall drilling rod passes through the power head to be mounted; an inner pipe at one end of the active double-wall drilling rod is connected with a rubber pipe through the double-channel pneumatic faucet; a pulverized coal receiving device is connected to the tail end of the rubber pipe; an air box which communicates with internal and external pipe annular channels of the active double-wall drilling rod is arranged on the double-channel pneumatic faucet; the air box is connected with an air compressor through an air pipe; a drill bit is connected to the other end of the active double-wall drilling rod. With the adoption of the device, the disturbance to the coal seam can be minimized, so that the collapse in holes can be effectively prevented, and that the frequent drilling blocking accidents can be avoided; the circumstance that gas is concentrated is prevented, and therefore, the phenomenon of blowout through the holes can be effectively avoided; the production cost is low; in addition, the working environment at the construction field can be effectively improved; the purpose of drilling in collapse and reducing stratums synchronously by one drilling rod can be achieved.

Owner:周升风

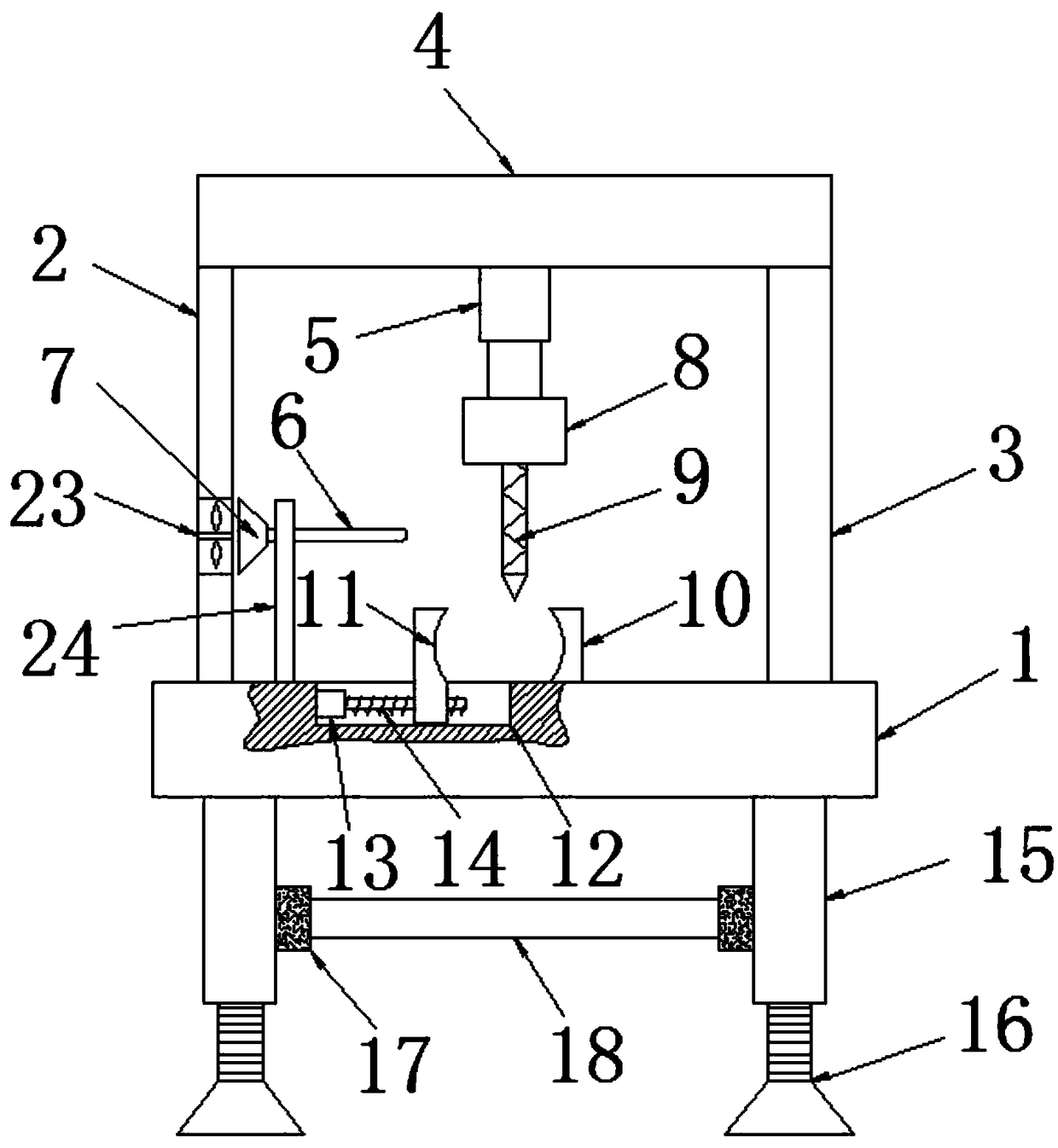

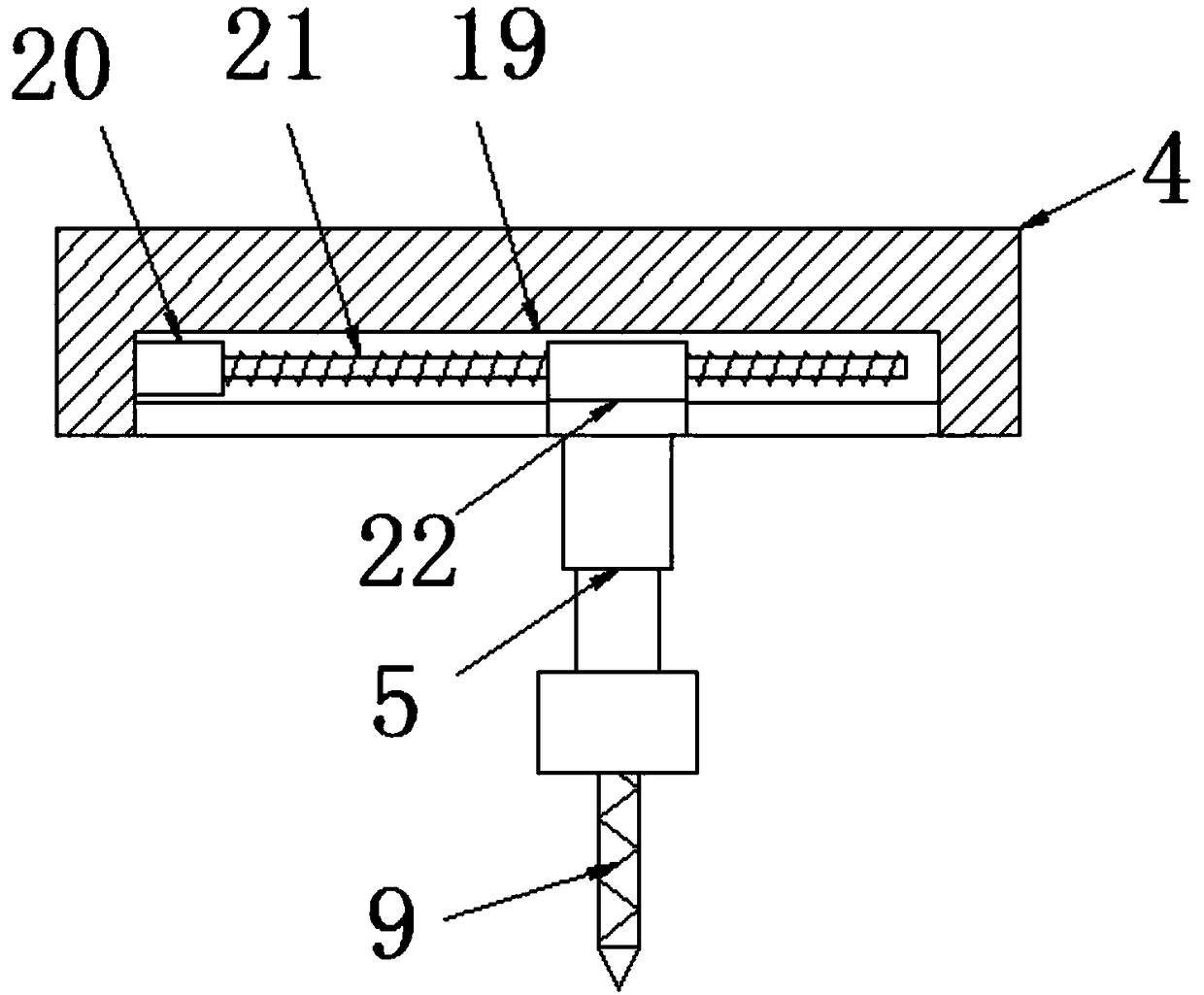

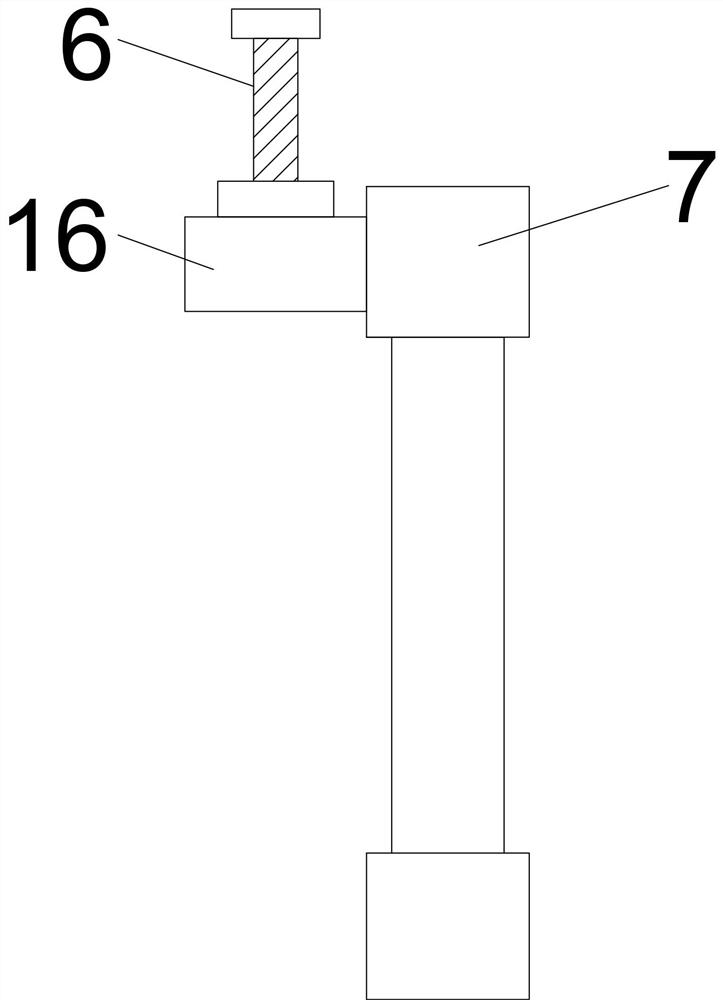

Steel tube drilling device

InactiveCN108274032AImprove stabilityAffect the service lifeLarge fixed membersPositioning apparatusCouplingTransverse plane

The invention discloses a steel tube drilling device. The steel tube drilling device comprises a base as well as a first supporting plate and a second supporting plate which are arranged at left and right sides of the upper end of the base, wherein the upper end of the first supporting plate and the upper end of the second supporting plate are connected with the same transverse plate; a T-shaped slide slot is longitudinally formed in the lower end of the transverse plate; the T-shaped slide slot is in sliding connection with a T-shaped slide block; the left side wall of the T-shaped slide slotis fixedly equipped with a first motor; the output end of the first motor is fixedly equipped with a first screw which is in threaded connection with the T-shaped slide block through a shaft coupler;the lower end of the T-shaped slide block is fixedly equipped with an air cylinder; the lower end of the air cylinder is fixedly equipped with a second motor; the output end of the second motor is fixedly equipped with a drill bit through a shaft coupler; the upper end of the base is fixedly equipped with a first clamping plate; a slide slot is horizontally formed in the upper end of the base; and the slide slot is in sliding connection with a second clamping plate. The steel tube drilling device is convenient to operate, can improve steel tube clamping stability and can dissipate heat for the drill bit; and the service life of the steel tube drilling device is prevented from being affected as a result of a too high drill bit temperature.

Owner:安徽雄风防护设施有限公司

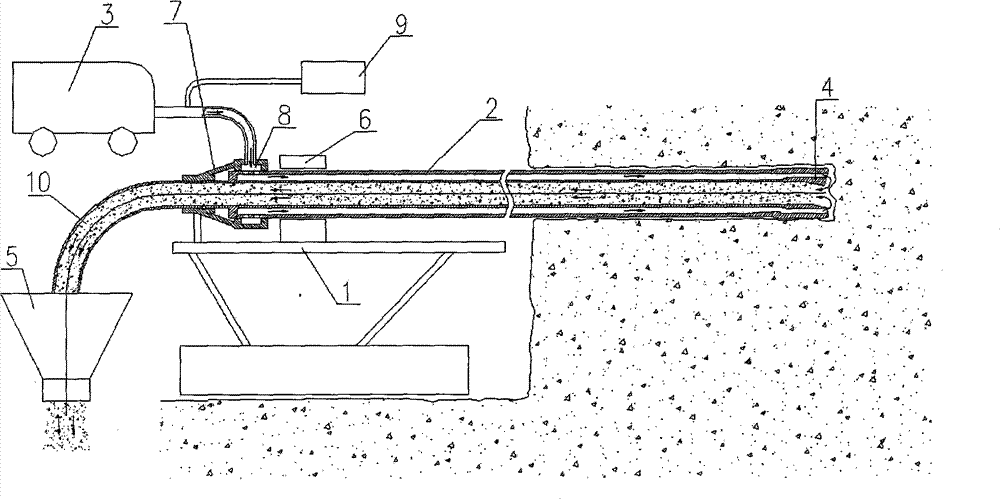

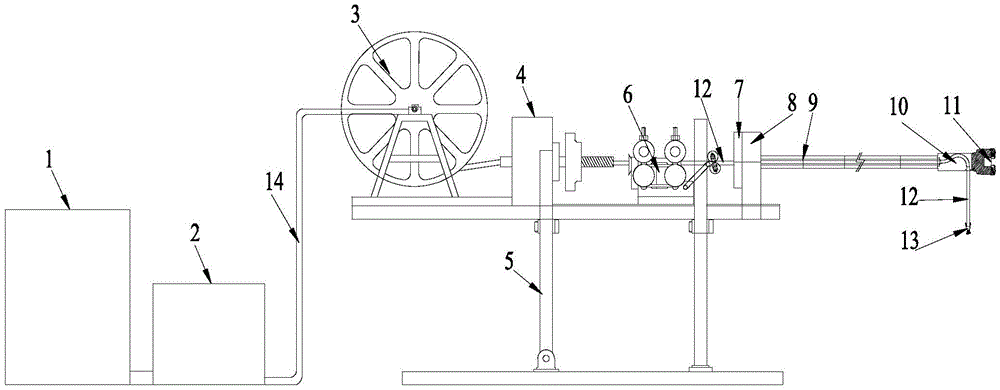

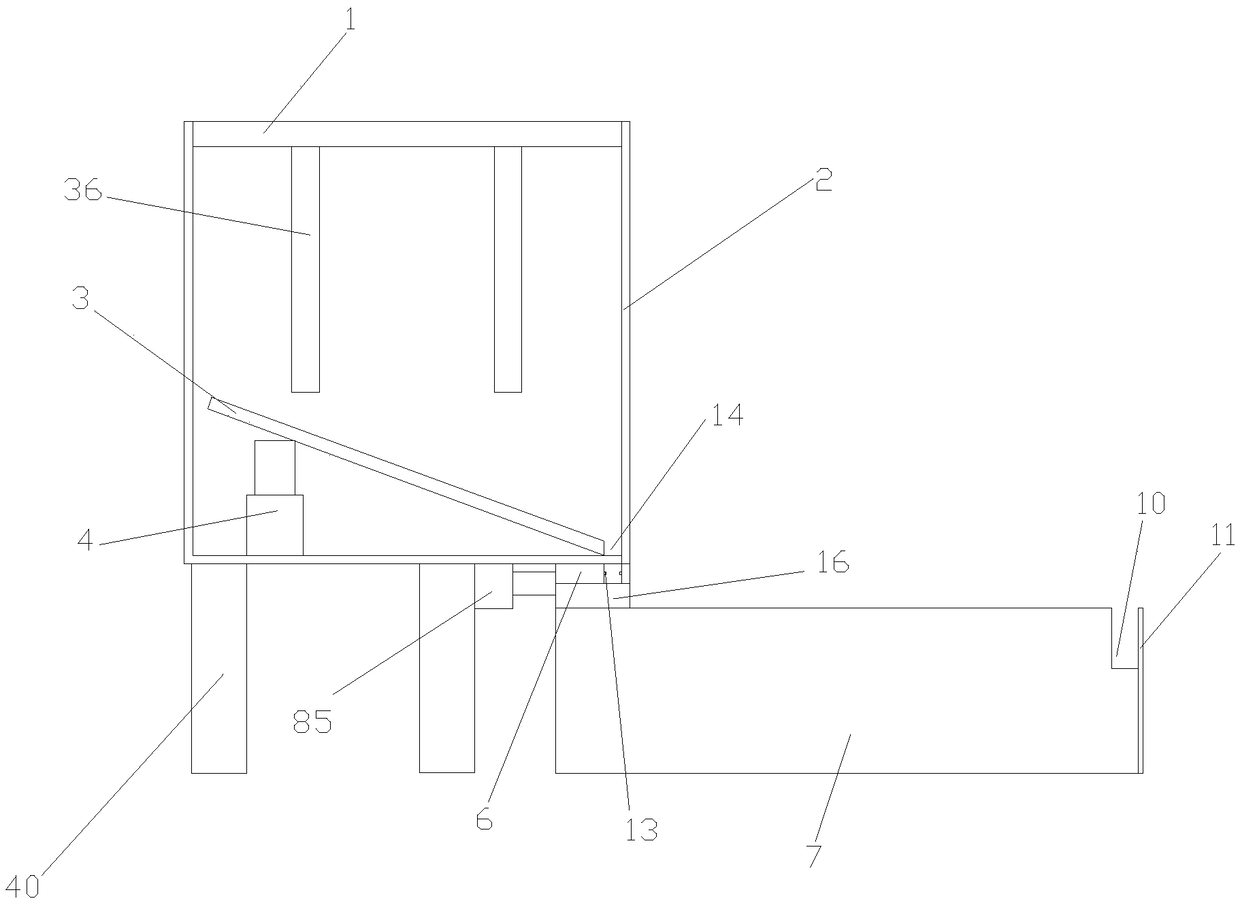

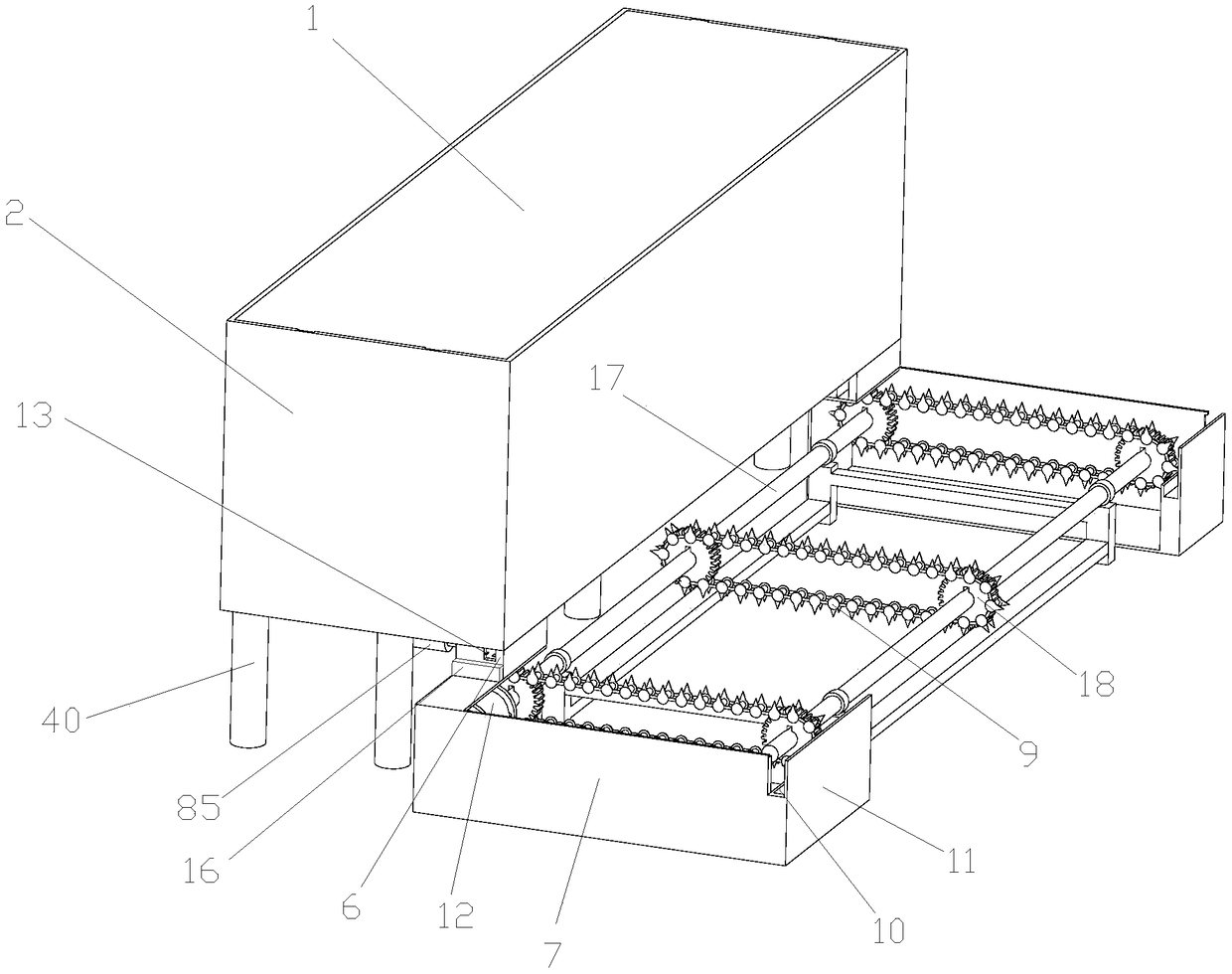

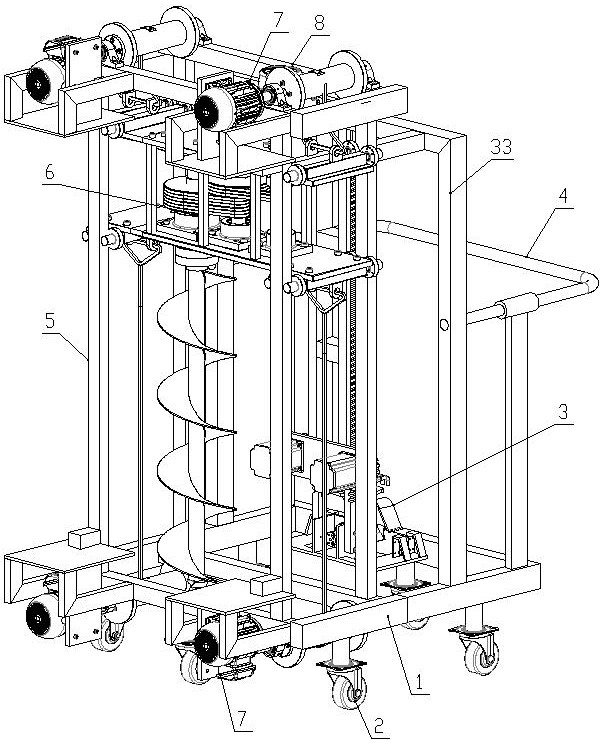

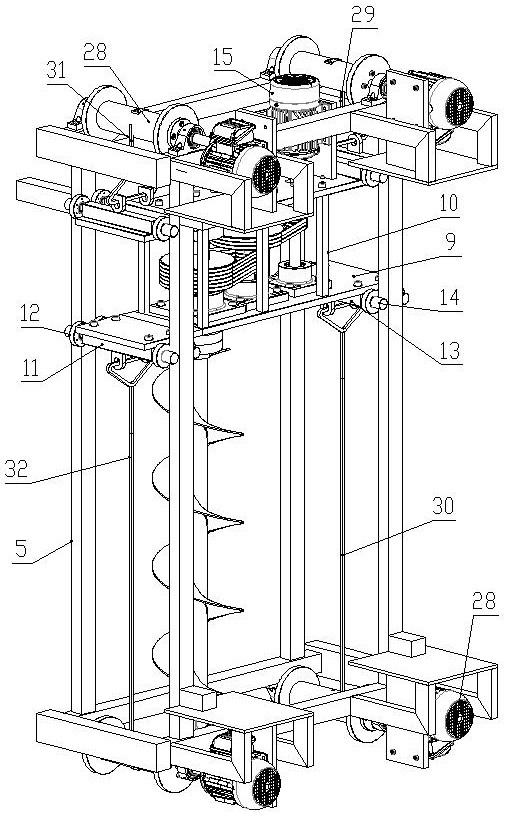

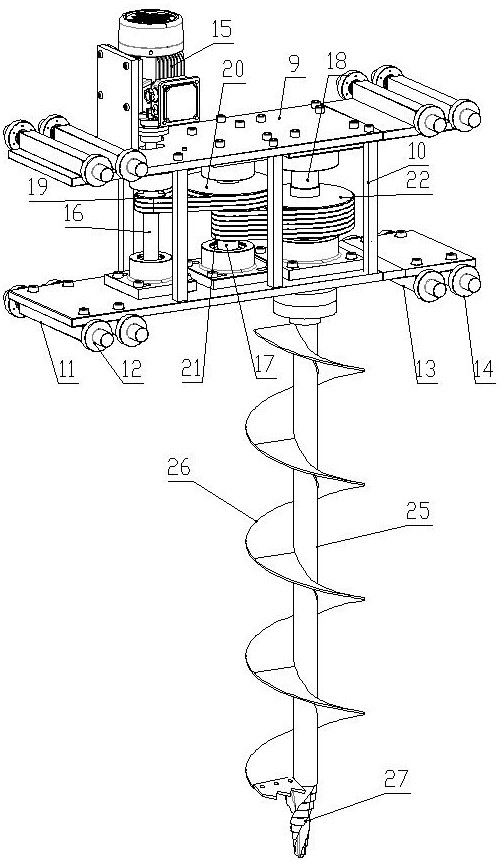

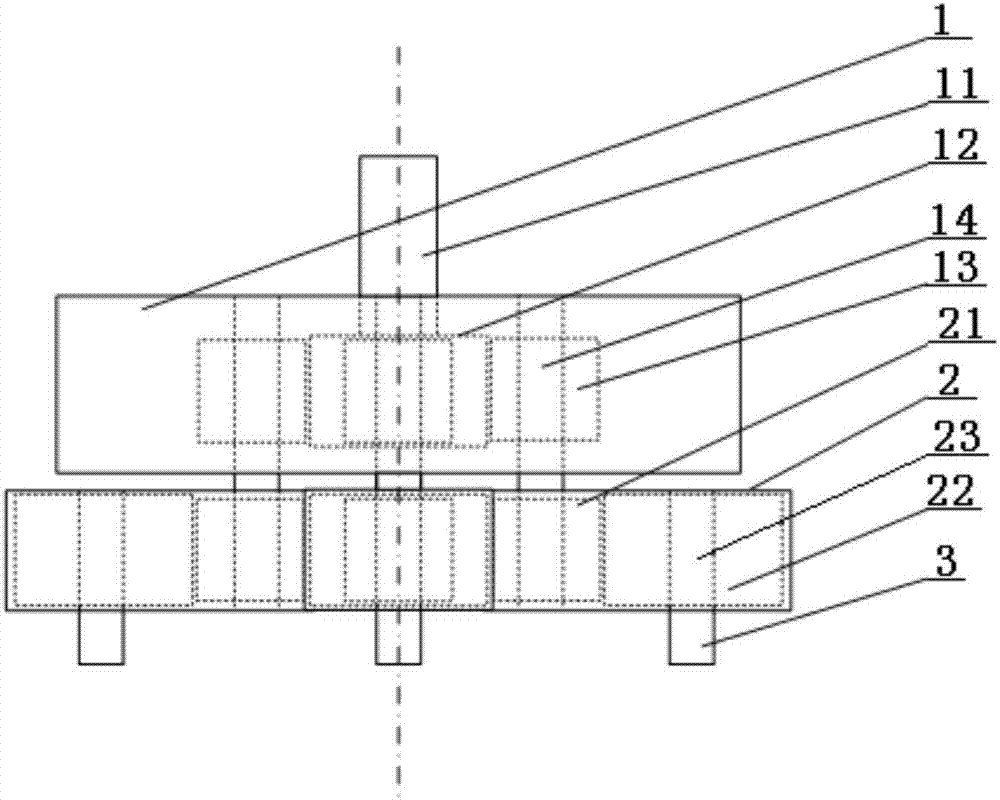

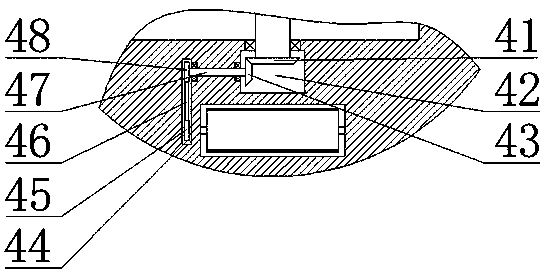

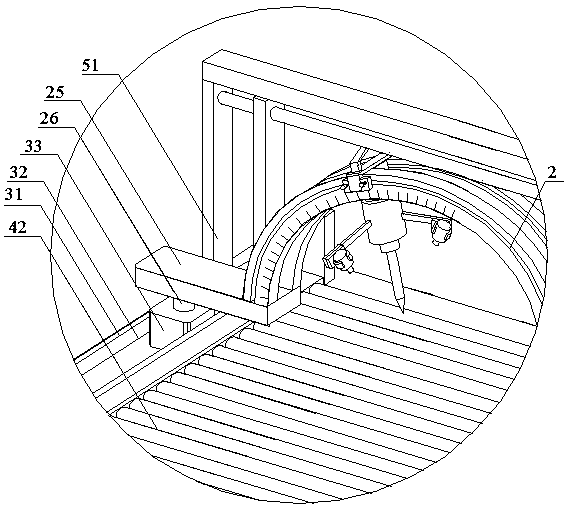

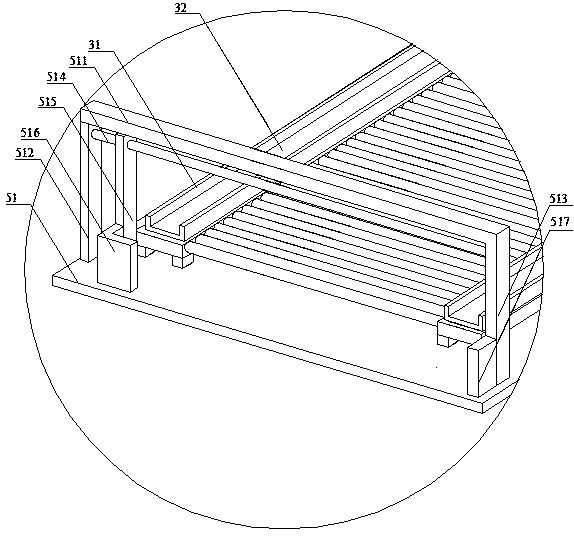

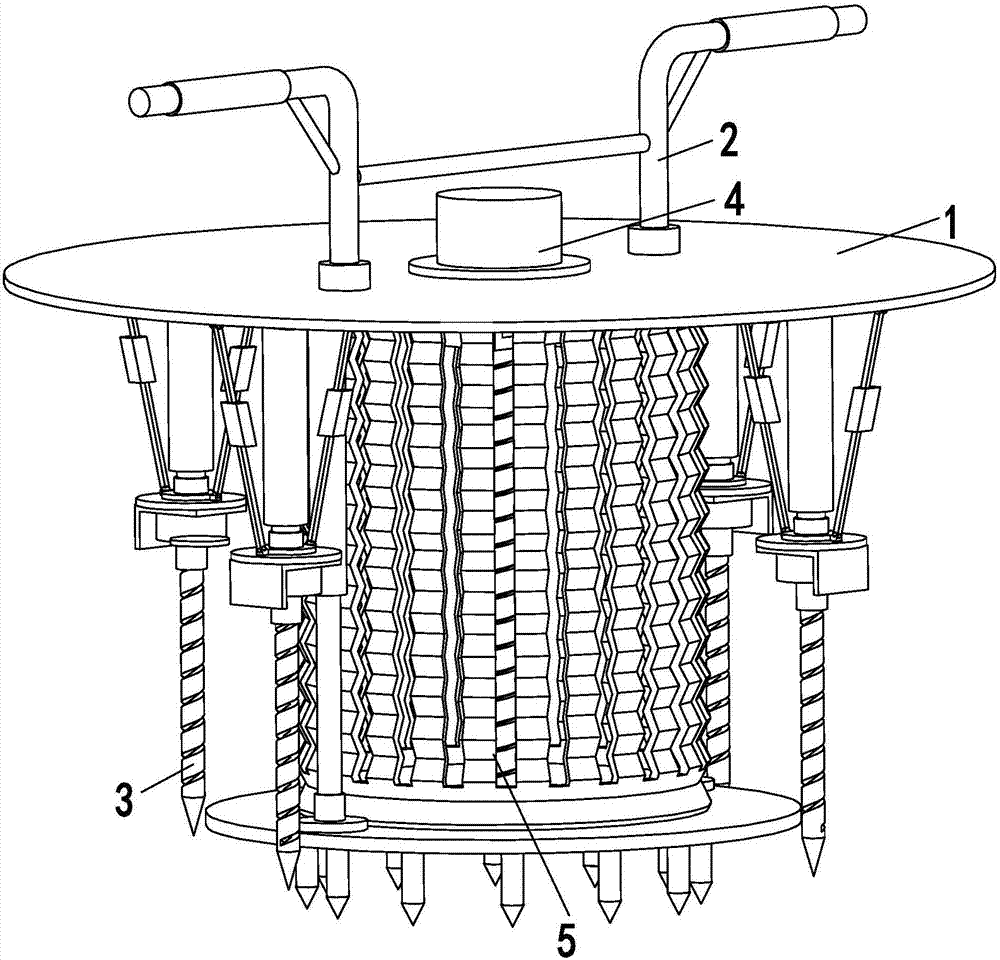

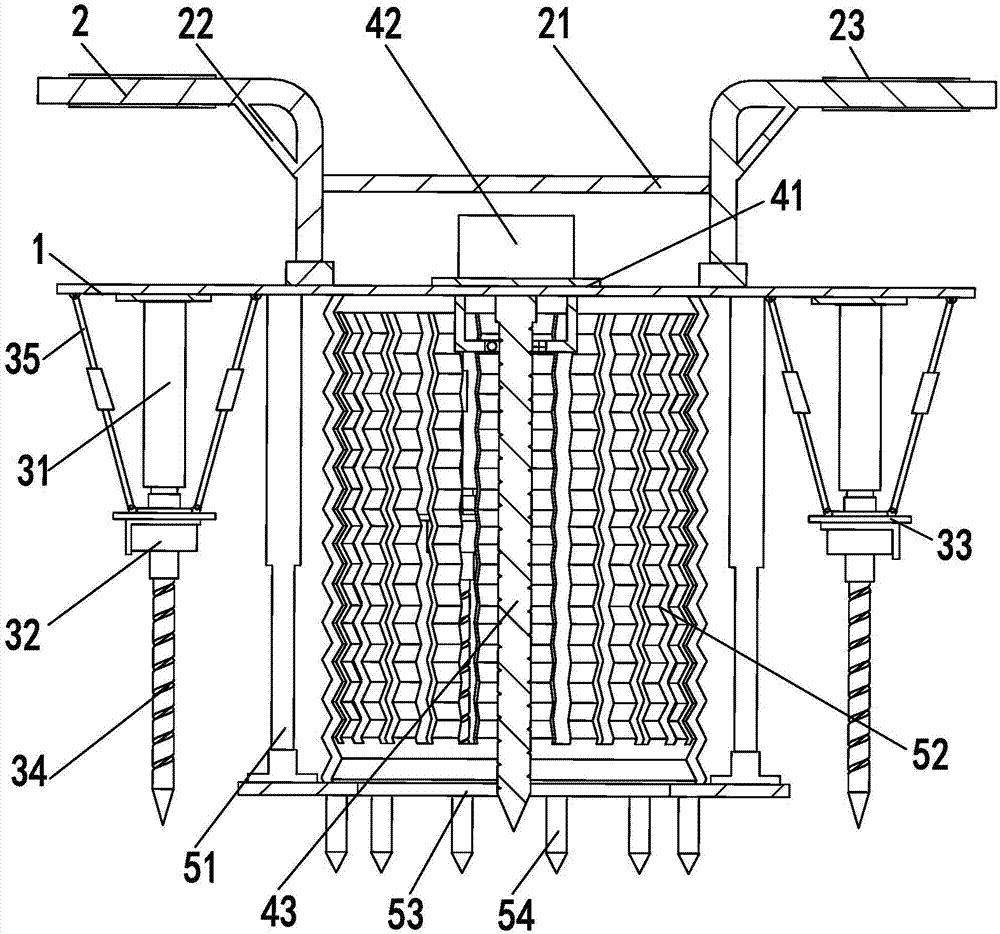

Composite fracturing and uniform permeability increasing equipment for treelike drilling in coal seam of underground coal mine

The invention discloses composite fracturing and uniform permeability increasing equipment for treelike drilling in a coal seam of an underground coal mine. The whole equipment can be divided into a hole forming system and a fracturing system. The hole forming system comprises a drilling machine, a drill stem, a drill bit, a support, a water tank, a high-pressure pump, a winch, a propelling mechanism, a chuck, a high-pressure hose, a self-propelled drill bit and the like. The fracturing system comprises the water tank, the high-pressure pump, a pressure meter, a high-pressure rubber pipe, a hole sealing device and the like. The composite fracturing and uniform permeability increasing equipment is suitable for carrying out volume fracturing on the coal seam of the underground coal mine, can reach the effects of carrying out uniform permeability increasing on the coal seam and increasing the gas extraction rate, and is easy to operate and good in economic performance.

Owner:CHONGQING UNIV

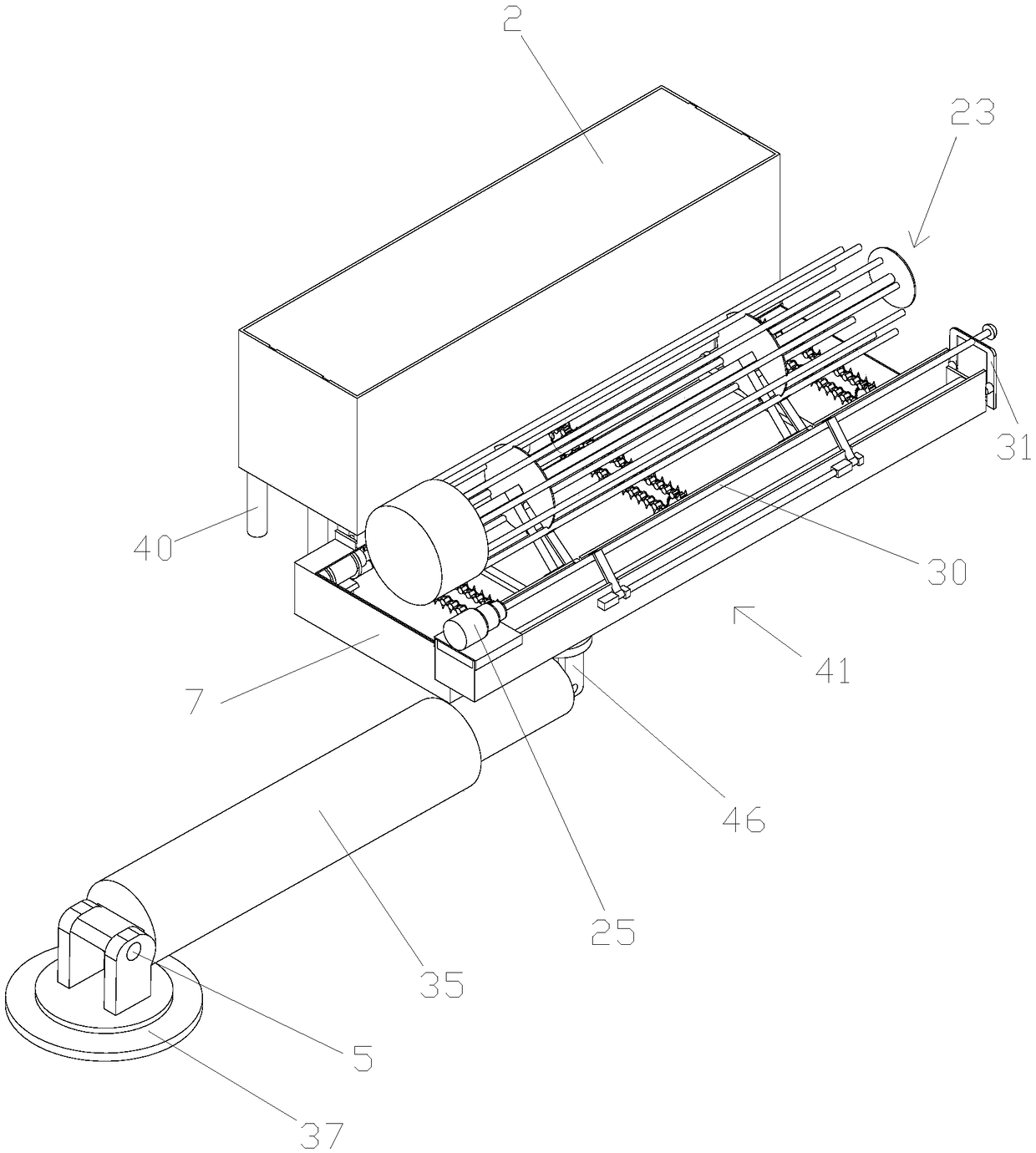

Coal mine anchor drilling robot autonomous anchor drilling device and method

The invention discloses a coal mine anchor drilling robot autonomous anchor drilling device and method. The coal mine anchor drilling robot autonomous anchor drilling device comprises a control module, an anchor rod warehouse, an anchor rod conveying mechanism and an anchor drilling mechanism. The anchor drilling mechanism includes a hydraulic telescoping mechanism, a drilling mechanism and an anchor bolt frame, an anchor rod feeding mechanism and an anchor rod installation frame. The drilling mechanism includes a drill pipe feeding mechanism, a drilling machine, a drill pipe adjusting mechanism, a drill pipe and a hydraulic clamping mechanism. The method comprises the following steps of 1, inspection and initialization of coal mine anchor drilling robot autonomous anchor drilling device;2, anchor rod feeding operation; 3, rod drilling; and 4, anchor bolt installation. The coal mine anchor drilling robot autonomous anchor drilling device and method is reasonable in design, realizes the robot drilling, anchor rod feeding and anchor rod installation, effectively improves the underground support efficiency of a coal mine, reduces the labor intensity of underground workers, maximizesthe liberation of productivity, and realizes the automation of the fully mechanized excavation face support of the coal mine, and is high in practicability.

Owner:XIAN UNIV OF SCI & TECH

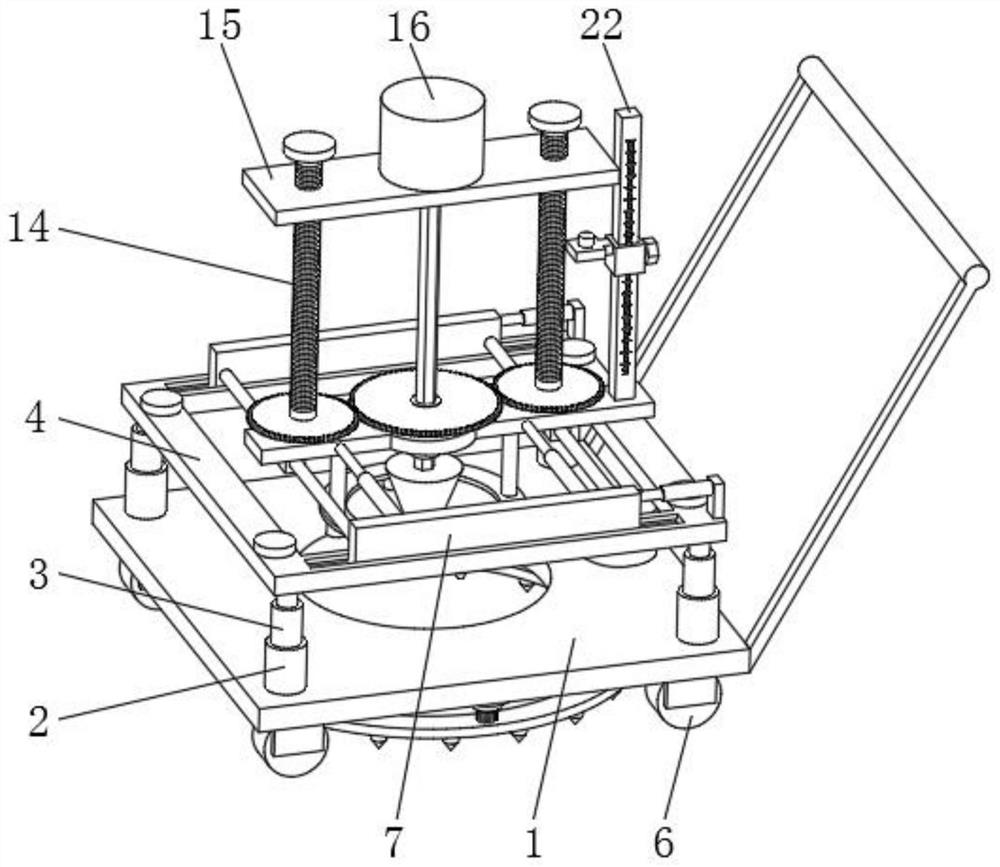

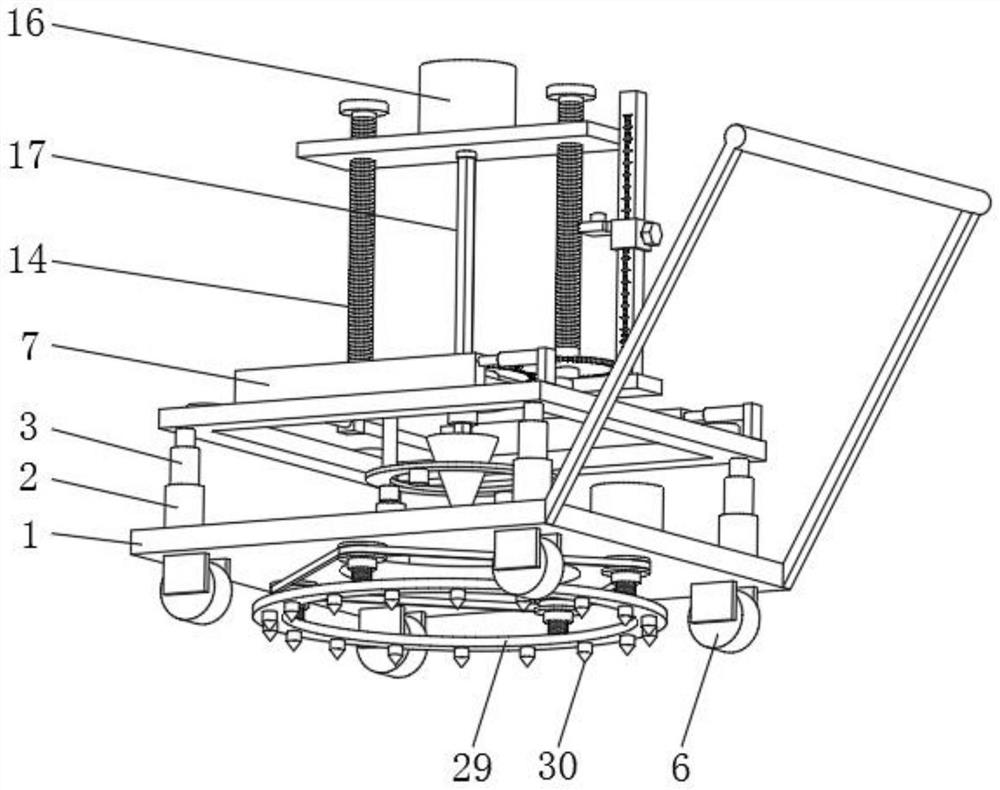

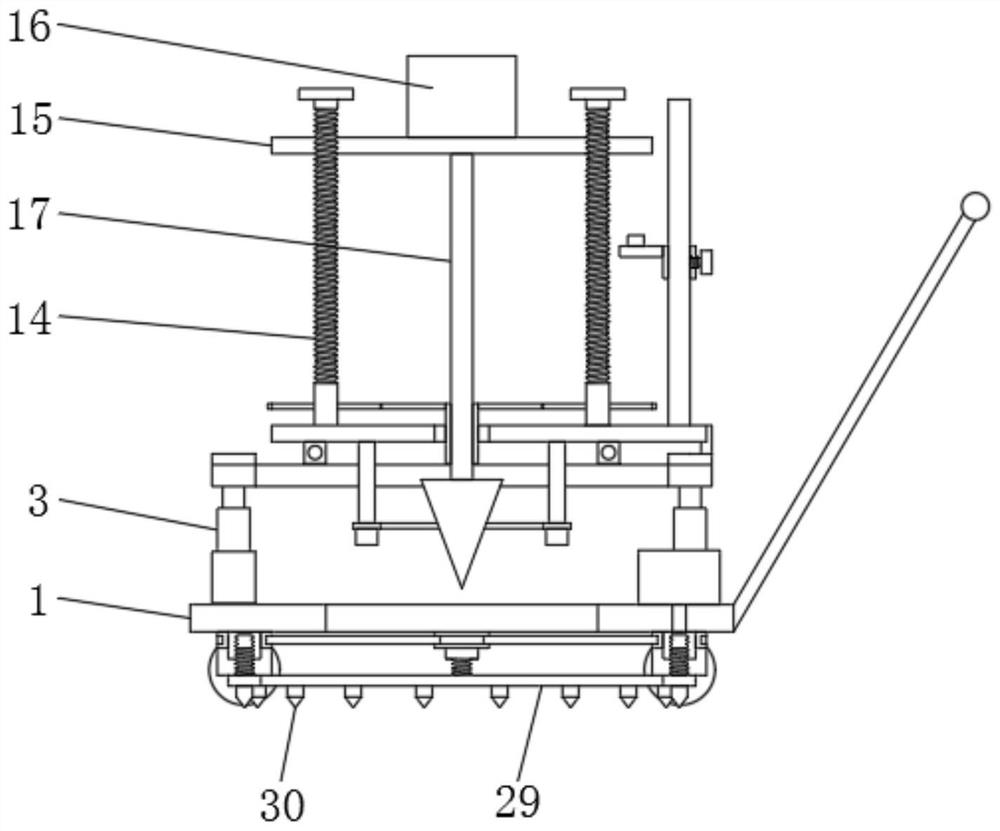

Novel soil sampling device for geological exploration, and soil sampling method thereof

ActiveCN112444428AReduce speedIncrease torqueWithdrawing sample devicesWater resource assessmentSoil scienceGeological exploration

The invention provides a novel soil sampling device for geological exploration, and a soil sampling method thereof. The novel soil sampling device for geological exploration comprises a horizontally-arranged bottom frame, wherein a plurality of bearing universal wheels are arranged on the periphery of the bottom of the bottom frame, and a soil drilling system, a soil sampling system and an armrestframe are sequentially arranged on the bottom frame from front to back. According to the invention, the device not only can realize soil sampling of a geological surface layer, but also can realize sampling of stratum soil with different depth requirements through an automatic soil drilling mode, can understand the difference of soil components of the surface layer stratum at different depths ingeological exploration, realizes automatic drilling and soil collection sampling in the whole soil sampling process, is relatively high in sampling efficiency, and achieves the full coverage of soil sampling at different depths of a shallow stratum.

Owner:CHINESE ACAD OF GEOLOGICAL SCI

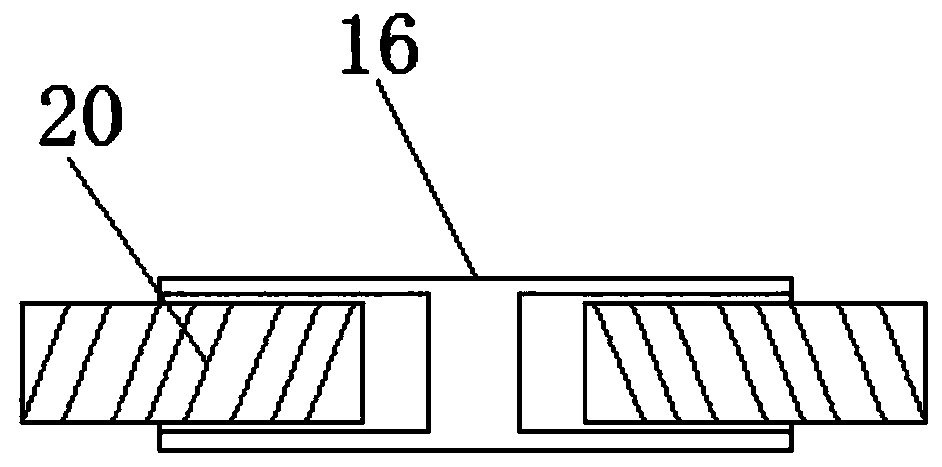

Busbar drilling device

InactiveCN107350506ASolve the problem of drilling holes one by oneSimple structureBoring/drilling machinesMarine engineeringGear wheel

Owner:LIAOYANG POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

Drilling tool for drag link connector body

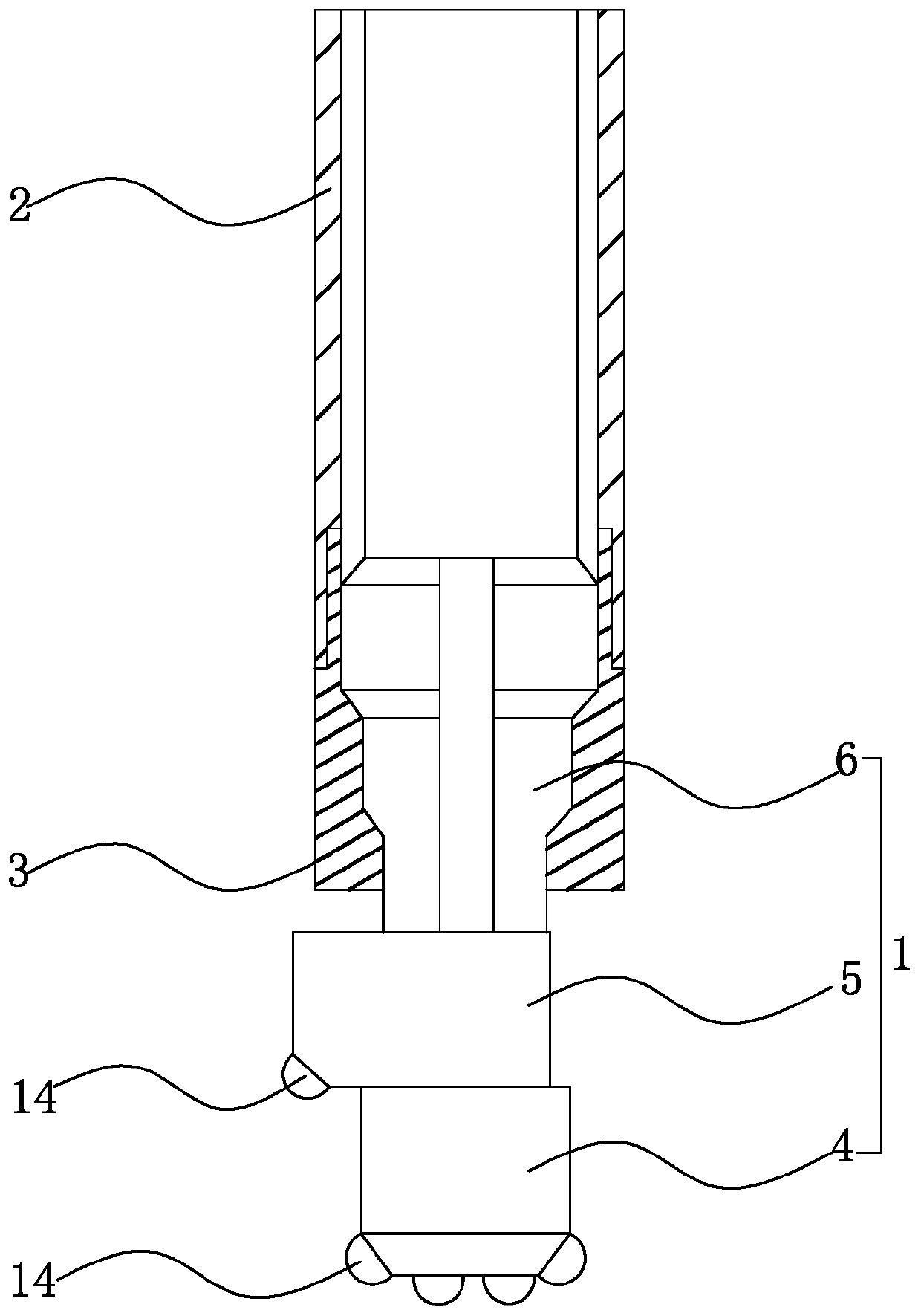

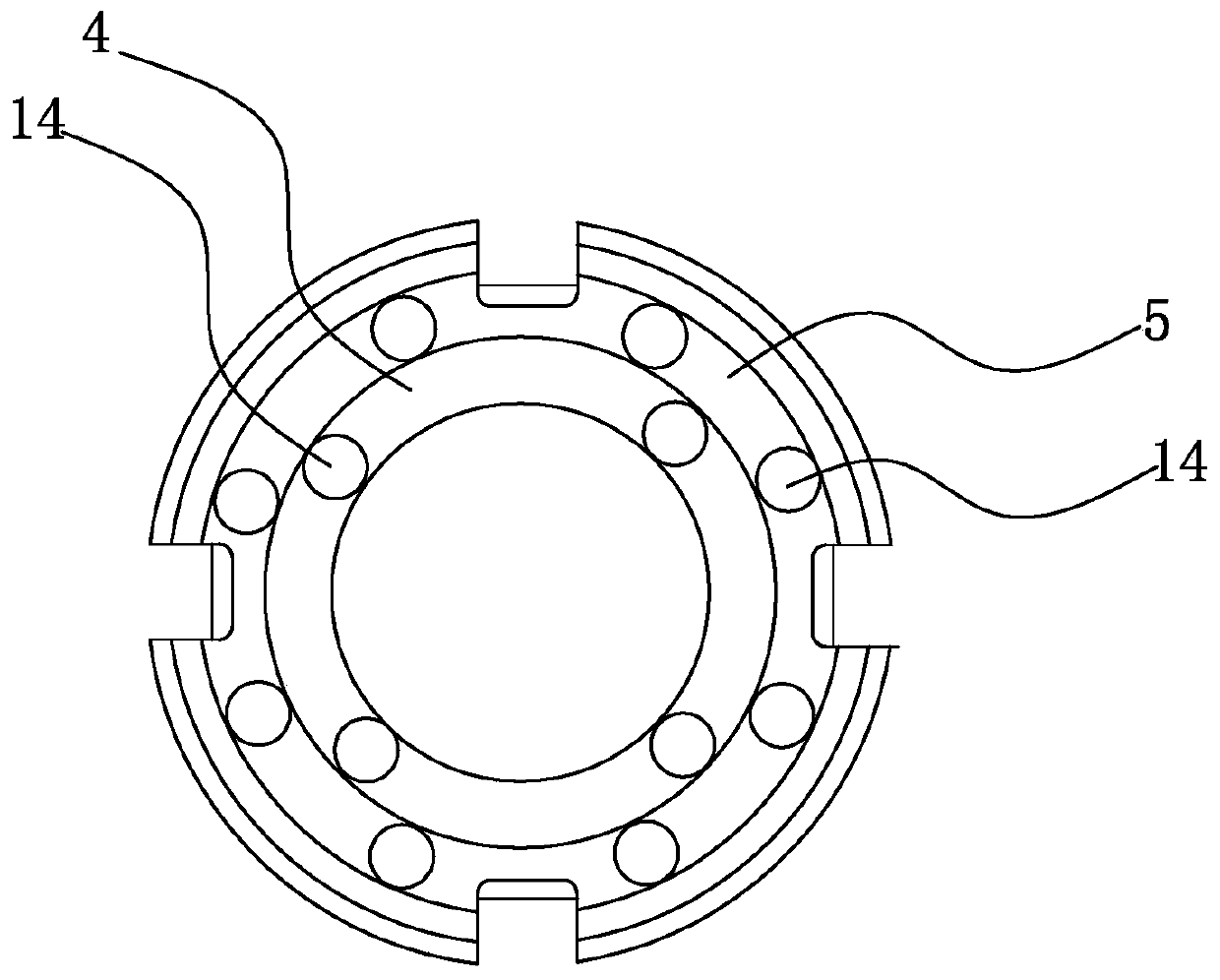

InactiveCN110732880ADrilling to achieveImprove drilling efficiencyFeeding apparatusOther manufacturing equipments/toolsElectric machineryEngineering

The invention discloses a drilling tool for a drag link connector body, and belongs to the technical field of machining. The drilling tool comprises two supporting columns, wherein a connecting plateis arranged on the tops of the supporting columns; lifting columns are arranged between the two supporting columns in a sliding manner; a rotating shaft is rotatably arranged between the two lifting columns; a vertical bar is vertically and rotatably arranged on the rotating shaft; a twist drill is fixedly arranged at the bottom of the vertical bar; adjusting rods are horizontally arranged at thetwo sides of the top of the vertical bar in a sliding manner; a polishing block is arranged at one end of each adjusting rod; lifting rods are vertically arranged on the top of the connecting plate ina sliding manner and are connected to the lifting columns in a transmission manner; and a push rod motor is arranged on the connecting plate. The drilling tool realizes drilling, has high drilling efficiency and high construction project accuracy, is electrically operated, meanwhile can polish holes with different inner diameters, saves manual labor and is easy to popularize.

Owner:湖北正航汽车部件有限公司

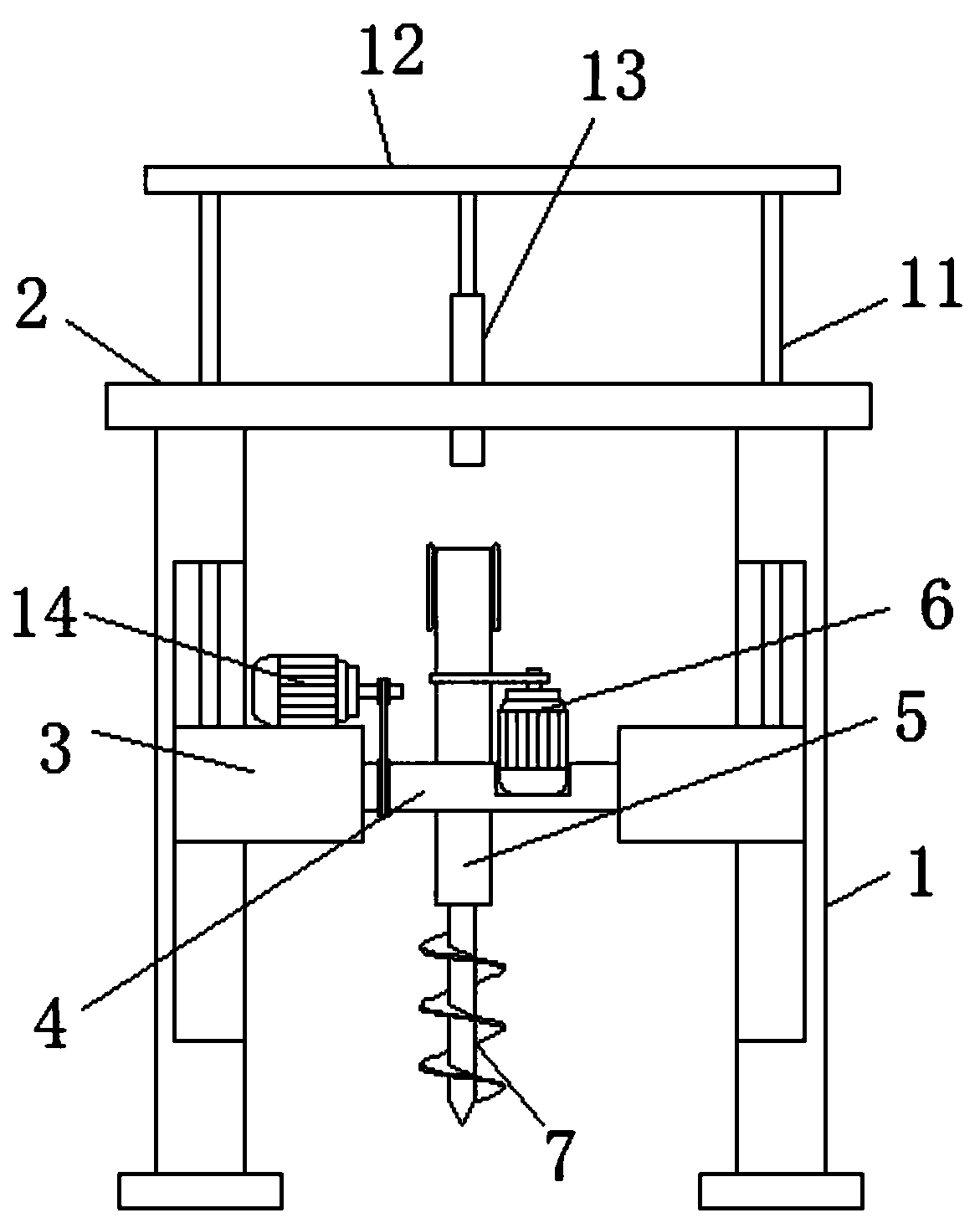

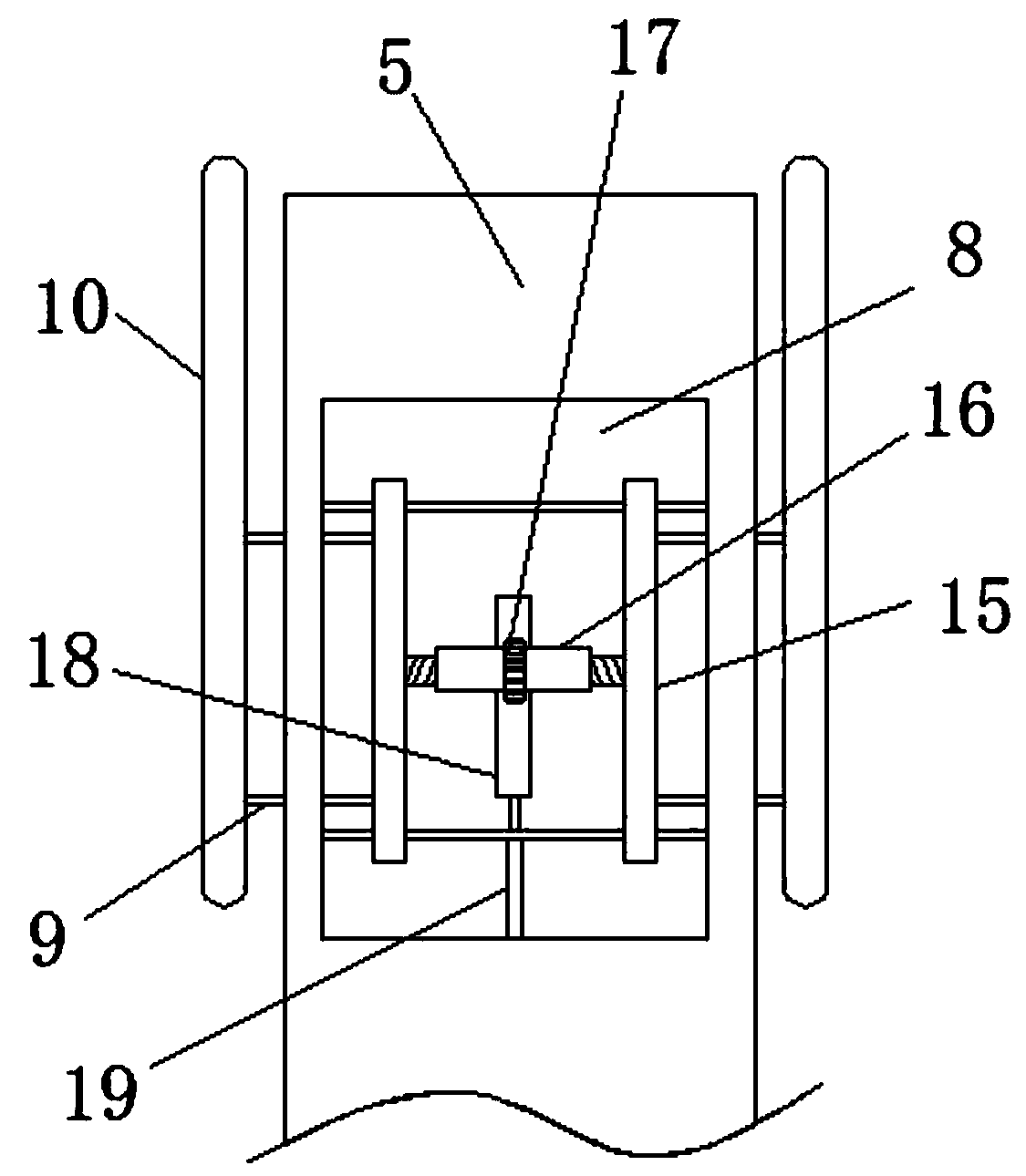

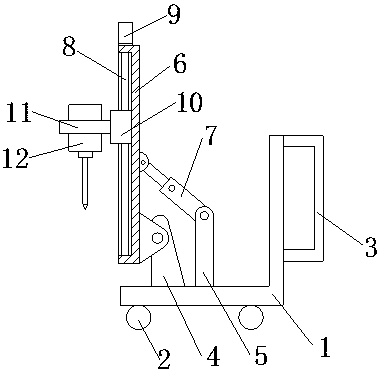

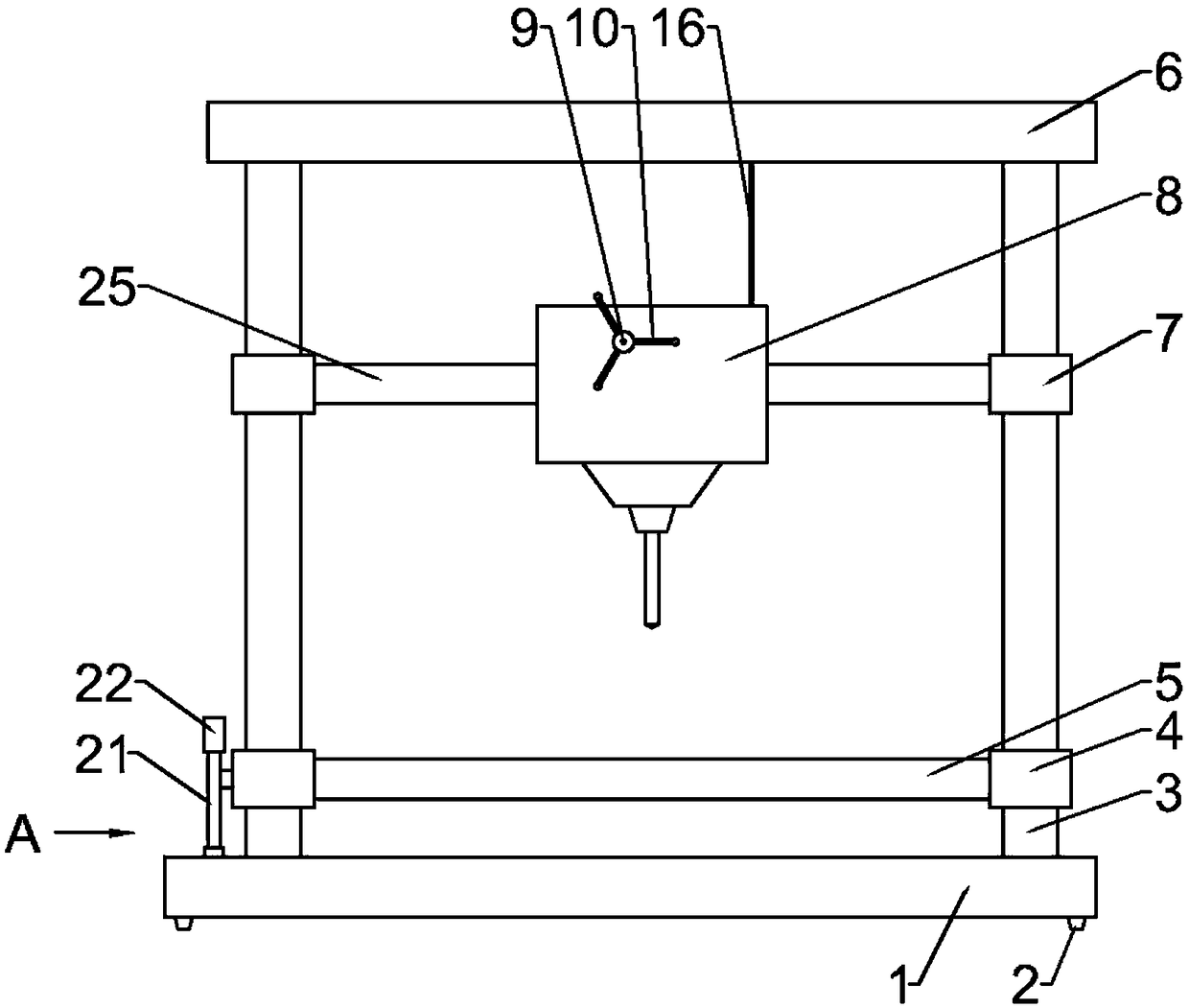

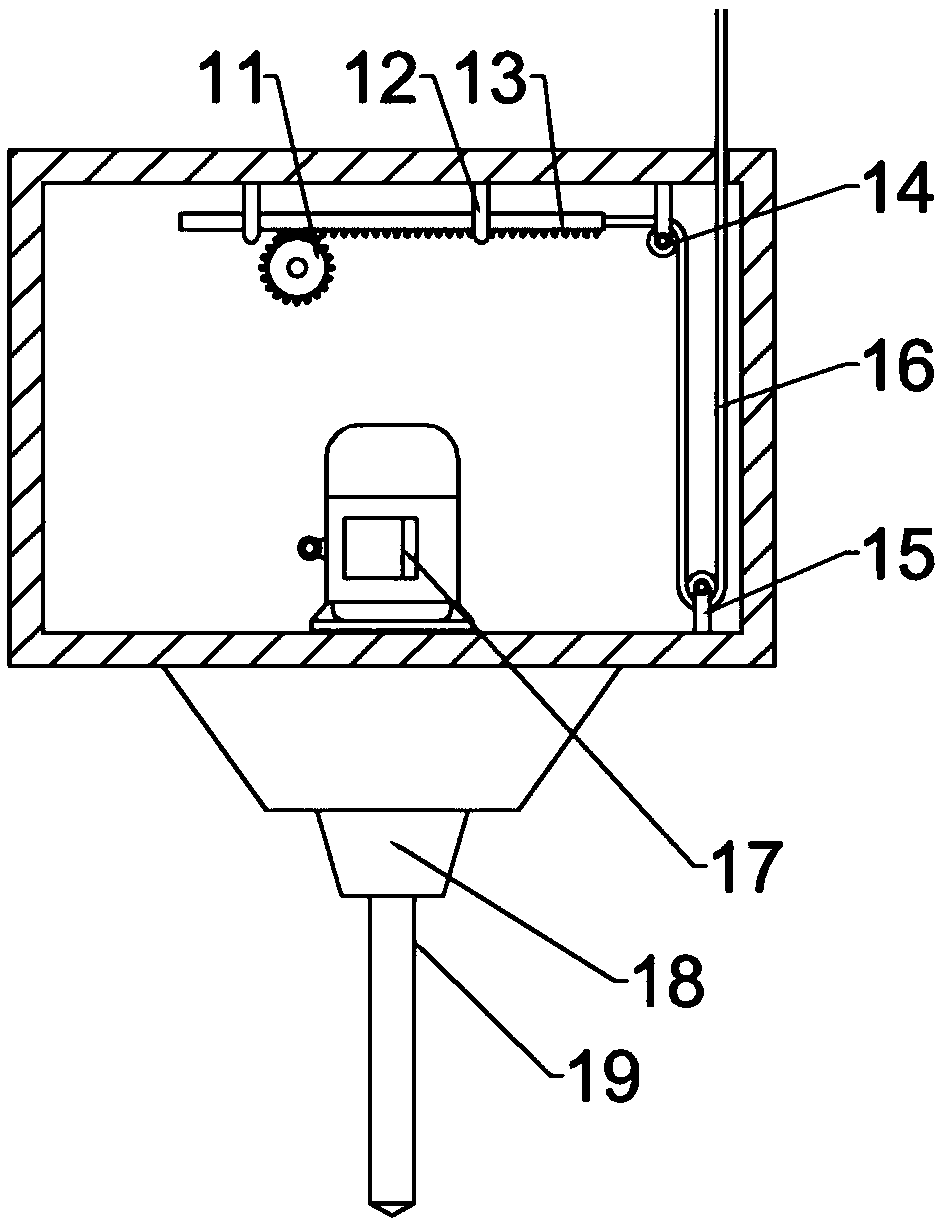

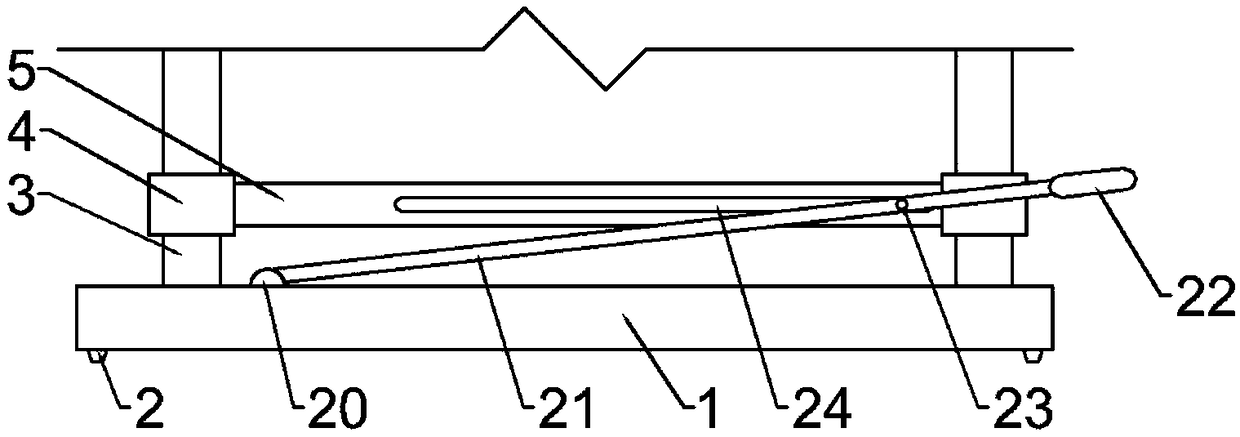

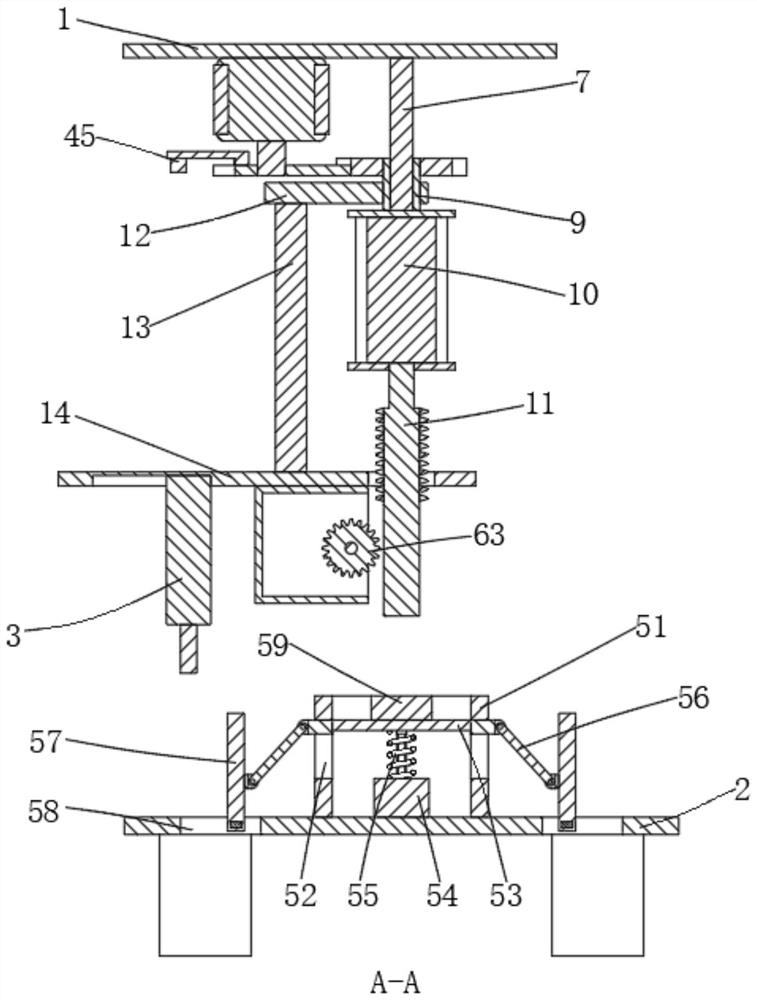

Drilling machine for engineering

InactiveCN108436144ADrilling to achieveImprove drilling efficiencyWork benchesPortable drilling machinesDrilling machinesPetroleum engineering

The invention relates to a drilling machine for engineering. The drilling machine comprises a drilling rack and a drilling device, a horizontal segment of the drilling rack is provided with a plurality of trolley wheels, a vertical segment of the drilling rack is provided with a trolley handle, the horizontal segment of the drilling rack is provided with a first fixed rack and a second fixed rack,the first fixed rack is connected with a guide rail in a hinged manner, the position between the guide rail and the second fixed rack is provided with an adjusting rod, the guide rail is internally provided with a feeding screw rod, one end of the feeding screw rod is connected with a feeding motor, the feeding motor is connected with a sliding sleeve, and one side of the sliding sleeve is connected with the drilling device through a fixed sleeve. According to the drilling machine for engineering, when the drilling machine for engineering performs drilling, the drilling device is adjusted toa proper height and drilling angle, drilling of the drilling device is realized, the drilling machine for engineering is convenient to operate, the drilling efficiency and precision are high, the labour intensity is low, and requirements of people are met.

Owner:ZHANGZHOU PULIHUI TECH SERVICE CO LTD

Wall drilling device

InactiveCN108687969AImprove drilling efficiencyImprove drilling accuracyWorking accessoriesStone-like material working toolsFixed frameDrive motor

The invention relates to a wall drilling device. The wall drilling device includes a supporting bottom plate, a fixed rod is arranged at the upper end of the supporting bottom plate, and a moving rodis connected with one side of the fixed rod through two sliding sleeves. A fixed plate is connected with one side of the upper end of the moving rod, a vertically-arranged limiting plate is connectedwith one end of the fixed plate, a driving motor is arranged on side of the upper end of the moving rod, and the driving motor is connected with one end of a driving screw. The driving screw is connected with a fixed frame, the fixed frame is connected with a drilling motor, and a drill spindle is connected with the output end of the drilling motor. During drilling of the wall drilling device, thedrilling motor is adjusted to an appropriate height to realize drilling of the drilling motor, the operation is convenient, the drilling efficiency and accuracy are high, the labor intensity is low,and the requirements of people are met.

Owner:ZHANGZHOU PULIHUI TECH SERVICE CO LTD

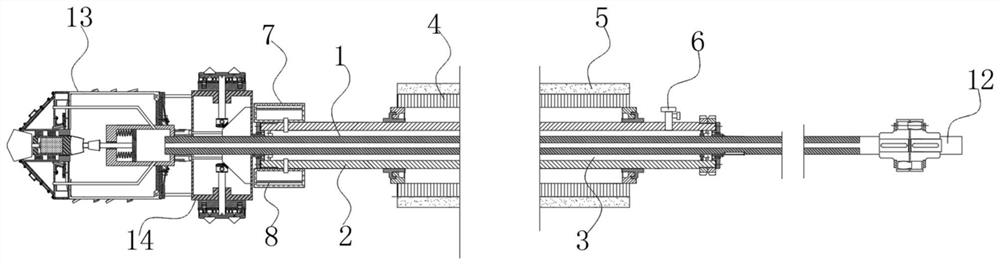

Variable diameter chamfering-based top plate high-directional drilling gas extraction device

ActiveCN111706252APrevent leakageImprove drilling efficiencyDrill bitsDrilling rodsDrill holeDrill bit

The invention discloses a variable diameter chamfering-based top plate high-directional drilling gas extraction device, which comprises a drill rod, an extraction drum, a drill bit component, a variable diameter chamfering component and a supporting component, wherein a center hole in one end, away from a drill hole, of the drill rod is connected with a water supply pipeline by a rotating joint; the water supply pipeline can supply flushing fluid to the center hole of the drill rod; the extraction drum is arranged on the outer circumference of the drill rod in the drill hole in a sleeving manner; during drilling and variable diameter chamfering, gas in the drill hole can enter the extraction drum, and is collected into an external storage tank through a gas collection pipe, thus realizingpreliminary extraction and preventing gas leakage; the drill rod is hermetically and rotatably arranged in the extraction drum; furthermore, one end, away from the drill hole, of the drill rod is driven by an underground drill rig, and the other end of the drill rod is provided with the variable diameter chamfering component and the drill bit component in sequence; meanwhile, during drilling and variable diameter chamfering, the drill rod extends into the drill hole, and then is supported by the supporting component into the inner wall of the drill hole.

Owner:GUIZHOU UNIV OF ENG SCI

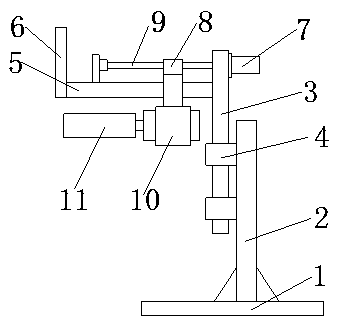

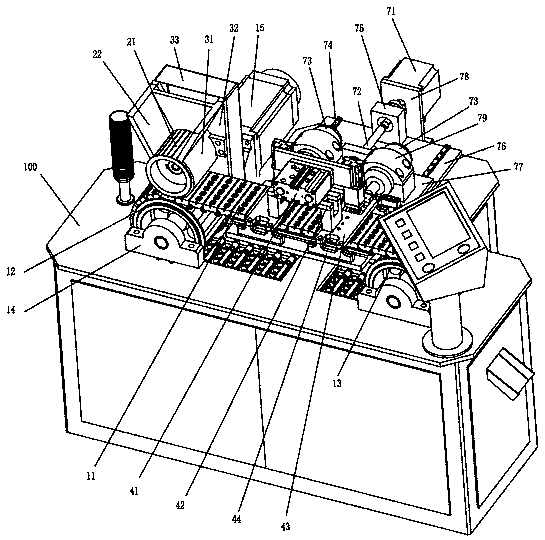

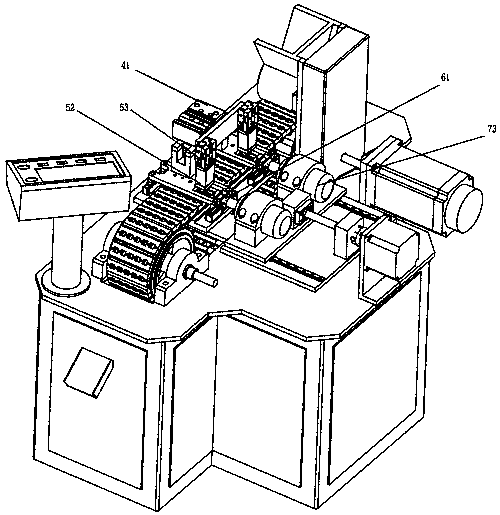

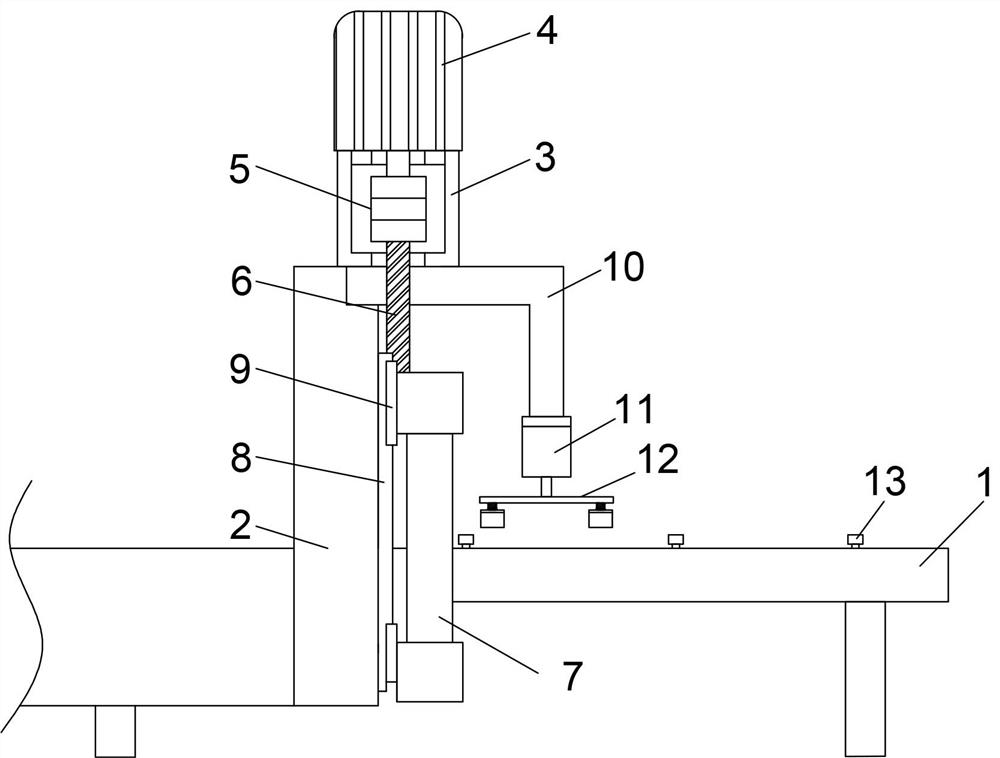

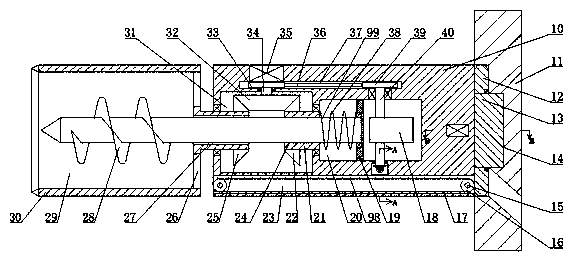

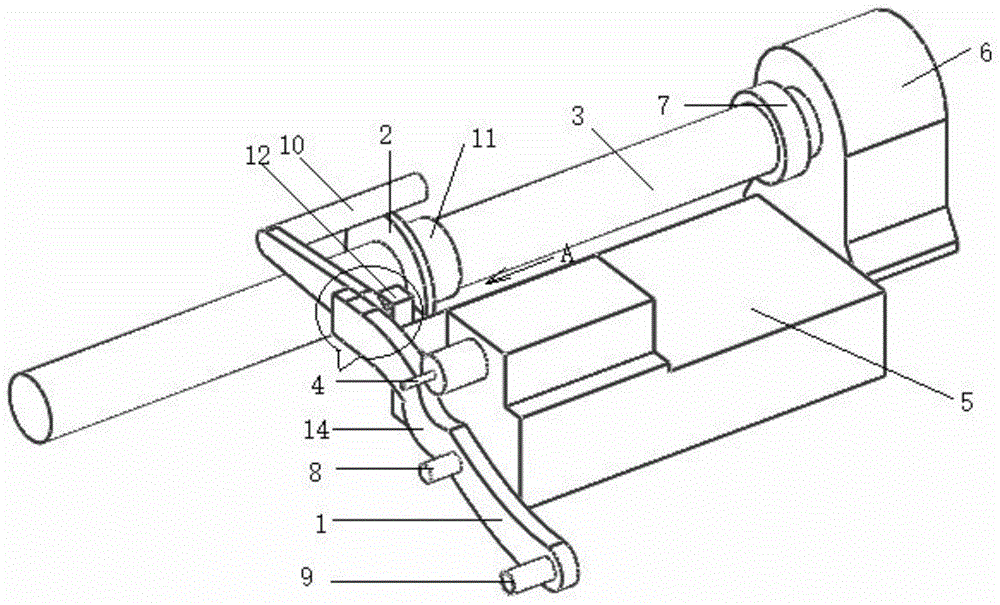

Drilling device for tiny hole at needle end of medical suture needle with thread

ActiveCN103447577ARealize mechanical automationDrilling to achievePositioning apparatusMetal working apparatusSuturing needleBiomedical engineering

The invention discloses a drilling structure for a tiny hole at a needle end of a medical suture needle with a thread. The drilling structure comprises a conveying chain device, wherein a feeding device is arranged above one end of the conveying chain device; a clamping device is arranged above the middle section of the conveying chain device and is connected with a pushing device; a drilling structure is arranged on one side of the conveying chain device; during rotation, a division wheel transfers the suture needle in a hopper to a conveying chain, the conveying chain transfers the suture needle to the clamping device, and the clamping device transfers the suture needle to the drilling structure; the suture needle is drilled by the drilling hole. According to the drilling structure, mechanical automation for drilling of the tiny hole at the needle end of the suture needle can be realized.

Owner:王华江

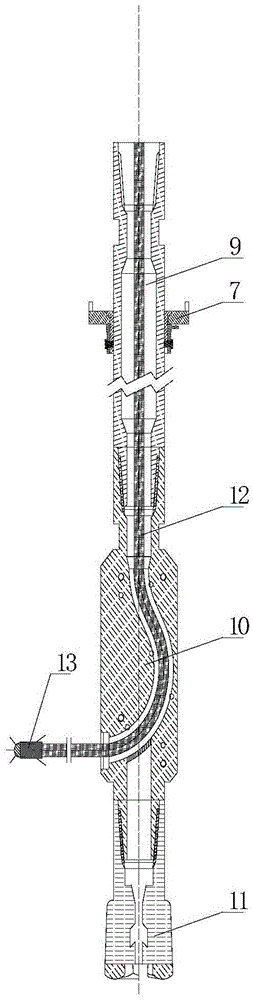

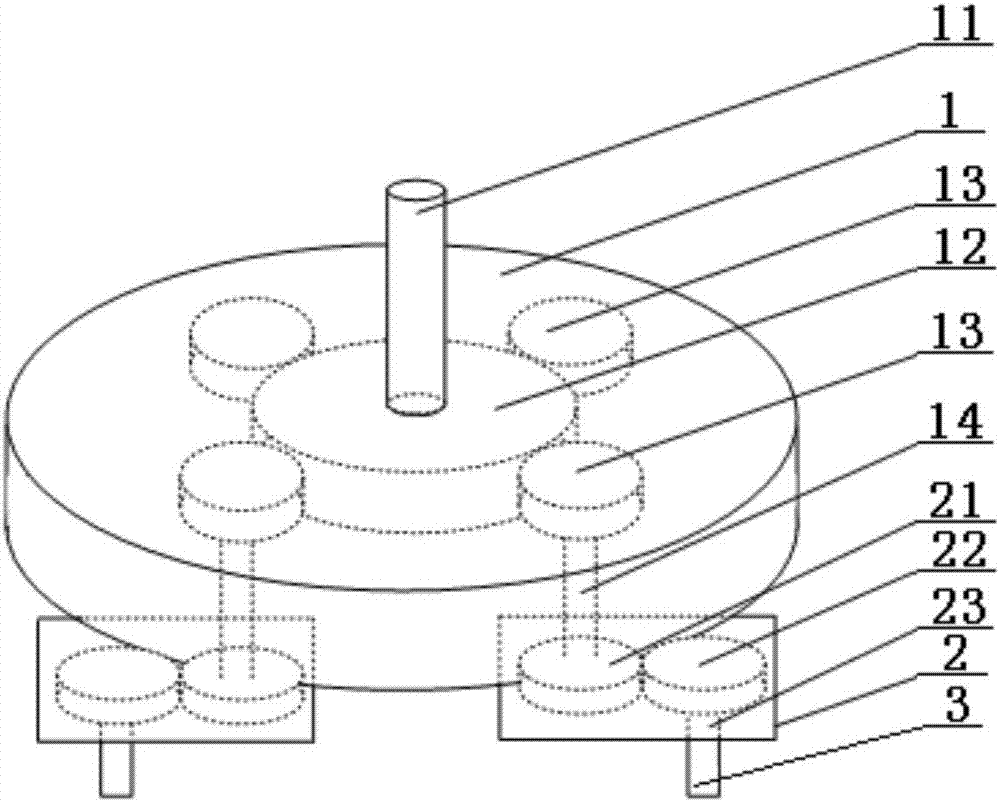

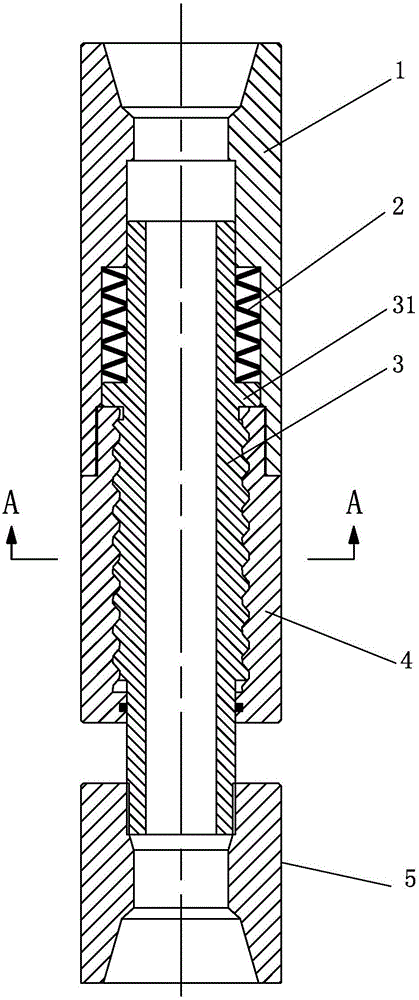

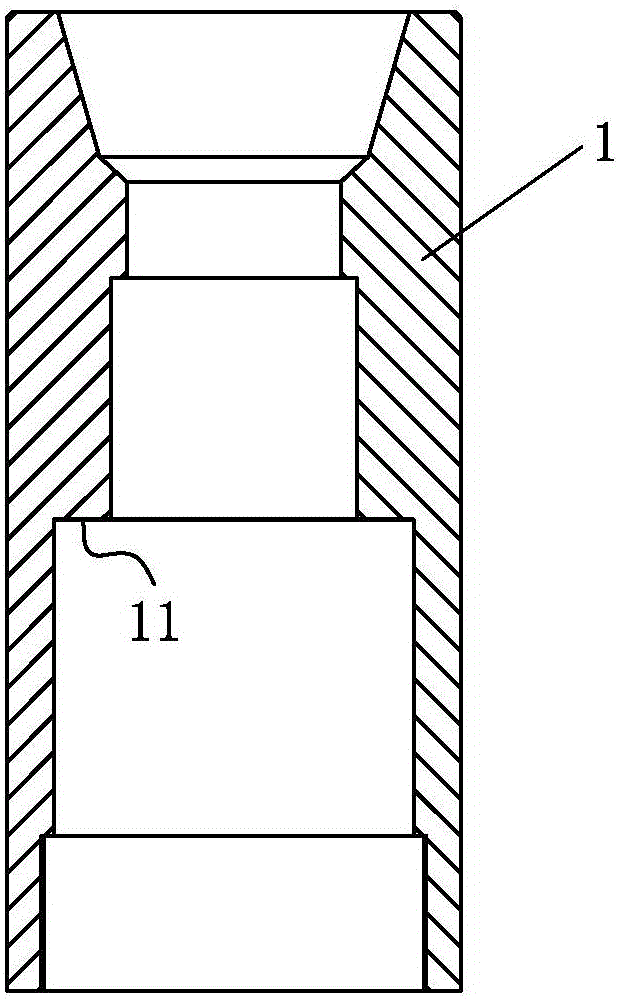

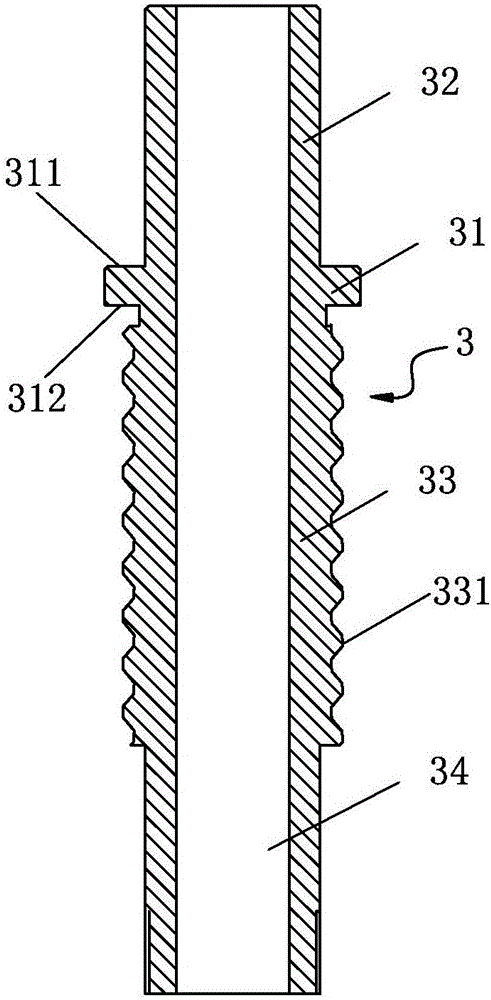

PDC (polycrystalline diamond compact) bit vibration reduction and torque increase device

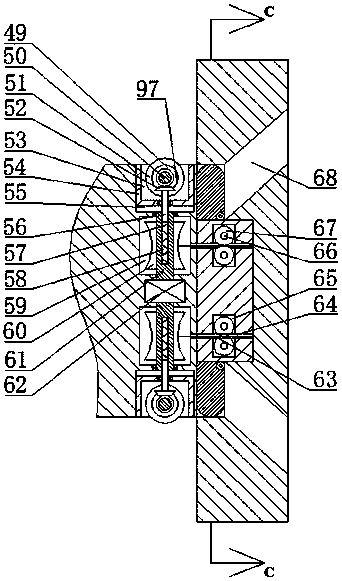

InactiveCN105952385AReduce vibrationExtended service lifeEarth drilling toolsUpper jointPolycrystalline diamond

The invention discloses a PDC (polycrystalline diamond compact) bit vibration reduction and torque increase device. The PDC bit vibration reduction and torque increase device comprises a barrel formed by connection of an outer barrel and an upper joint, an annular retaining plate is arranged on the outer periphery of a core tube which is arranged in an inner cavity of the barrel body, and the lower surface of the annular retaining plate is supported on the upper end face of the outer barrel. A portion below the annular retaining plate is a lower core tube section in spiral spline connection with the outer barrel, and the lower end of the lower core tube section extends out of the outer barrel to be connected with a lower joint. A portion above the annular retaining plate is an upper core tube section, a Belleville spring is arranged in an annular space formed by the upper core tube section and the upper joint, the upper end of the spring is abutted against an inner step surface of the lower portion of the upper joint, and the lower end of the spring is abutted against the upper surface of the annular retaining plate. The PDC bit vibration reduction and torque increase device has advantages that flexible connection between a drill bit and a drill stem is realized, vibration generated in a drilling process of a PDC bit is weakened, damages of cutting teeth due to vibration are avoided, and the service life of the drill bit is prolonged; during spiral ascending of the drill bit, contact area of the cutting teeth and rock is reduced while cutting acting force is increased, and rock breaking performance of the drill bit is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Vertical machining machine tool for steel machining

InactiveCN113369534ASimple structureReasonable designMetal working apparatusBoring/drilling machinesDrive shaftElectric machinery

The invention discloses a vertical machining machine tool for steel machining. The vertical machining machine tool for steel machining comprises a supporting frame, assembling components of the supporting frame comprise a drilling tool and a pushing mechanism, the drilling tool comprises a drilling tool mounting frame and a bottom plate, edge protection legs are mounted at the supporting positions of the drilling tool mounting frame, the supporting ends of the side protection legs are installed on the two sides of the table top of the bottom plate, a table top box is installed at the top ends of the side protection legs, and a motor body is installed at one end of the table top box. According to the vertical machining machine tool for steel machining, a motor is controlled to operate to drive a driving shaft to rotate, after the driving shaft rotates, a cavity threaded block which is connected to the outer wall of the driving shaft in a threaded mode can be driven to move front and back, a side plate fixed on one side of the cavity threaded block can drive a groove sliding block below the table top box to slide on double rail bodies, and therefore back-forth movement of a vertical plate on the a frame of the supporting frame can be achieved, and then longitudinal drilling of a steel plate to be processed can be achieved.

Owner:WENZHOU POLYTECHNIC

Photovoltaic glass perforating machine

PendingCN114147867ADrilling to achieveEasy to useWorking accessoriesVibration suppression adjustmentsPortal framePhysics

The invention relates to the technical field of perforating machines, in particular to a photovoltaic glass perforating machine which comprises a conveying device used for conveying glass, a portal frame is arranged on the outer side of the conveying device, a moving frame is arranged on one side of the feeding end of the portal frame, and the two ends of the moving frame are slidably connected with the portal frame through guide mechanisms. The top of the portal frame is further provided with a driving mechanism used for driving the movable frame to move in the vertical direction, the outer side of the portal frame is fixedly connected with a plurality of evenly-distributed L-shaped fixing rods, the bottom ends of the L-shaped fixing rods are provided with positioning devices used for positioning glass, and the movable frame is provided with a plurality of evenly-distributed drilling mechanisms. When glass is punched, the conveying device moves the glass to a designated position, the positioning device fixes the glass, then the moving frame moves downwards, the moving frame drives the drilling mechanism to move downwards synchronously, glass drilling is achieved, use is convenient, and work is efficient.

Owner:SHAANXI TOPRAY SOLAR

Rock soil deep hole drilling equipment

ActiveCN111021945AConvenient continuous outputDrilling to achieveEarth drilling toolsBorehole drivesSoil scienceAnnular cutter

The invention relates to the field of rock soil drilling, in particular to rock soil deep hole drilling equipment. The rock soil deep hole drilling equipment comprises a machine body and a stop blocklocated on the right side of the machine body. A rotating cavity is formed in the end wall of the left side of the machine body. A rotating cylinder is rotationally arranged in the end wall of the left side of the rotating cavity. A spline sleeve is rotationally arranged in the end wall of the right side of the rotating cavity. An annular cutter used for rock soil drilling is fixedly arranged at the tail end of the rightmost side of the rotating cylinder. A crushing cavity with a leftward opening is formed in the end wall of the left side of the annular cutter. Through holes communicated withthe outside are formed in the right side end wall of the crushing cavity in a central symmetry manner. According to the rock soil deep hole drilling equipment, deep hole drilling of the rock soil canbe achieved, the equipment can crush the waste rock soil after drilling, then the rock soil is output through a conveying device arranged in the equipment, the equipment adopts the annular cutter to cut the rock body, cut inner holes are smoother, the equipment can conveniently continuously output the rock soil in deep holes, and higher efficiency is achieved.

Owner:湖北省水文地质工程地质勘察院有限公司

Drilling equipment used for machine parts

InactiveCN109352004ASimple structureEasy to useLarge fixed membersBoring/drilling componentsMachine partsBilateral symmetry

The invention discloses drilling equipment used for machine parts. The drilling equipment comprises a fixed base. Guide supporting columns are fixedly connected to the upper portion of the fixed basein bilateral symmetry. Lower sliding sleeves are in sliding connection to the outer sides of the guide supporting columns in bilateral symmetry. A supporting bottom plate is fixedly connected betweenthe lower sliding sleeves. A horizontal cross beam is fixedly connected to the tops of the guide supporting columns. Upper sliding sleeves are in sliding connection to the upper portions of the outersides of the guide supporting columns. A drilling box is connected between the upper sliding sleeves through a horizontal fixed rod. A drive rotating shaft is rotationally connected with the front side wall of the drilling box, and the inner end of the drive rotating shaft is fixedly connected with a transmission gear. Compared with the prior art, the drilling equipment has the advantages that thestructure is simple, and use is convenient; during use, the height of the drilling box can be adjusted up and down through the drive rotating shaft, and therefore the height position of a drill bit is adjusted to achieve drilling; and meanwhile, the equipment can achieve drilling by adjusting the height of the supporting bottom plate, then a proper drilling adjusting manner can be selected according to the quality of to-be-drilled objects, and more labor is saved.

Owner:宁波帮手机器人有限公司

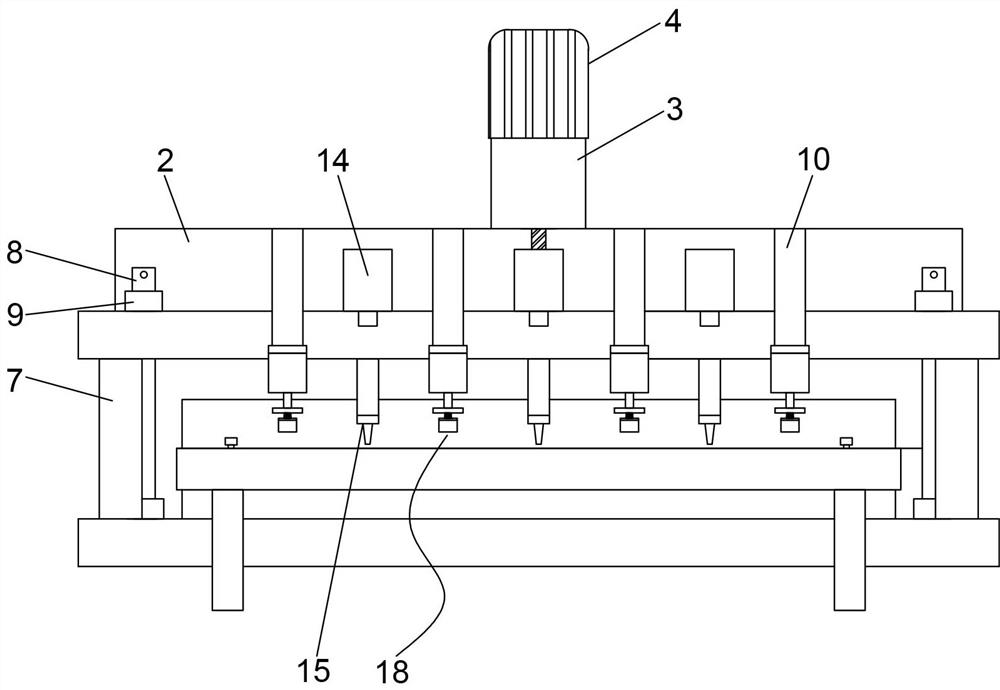

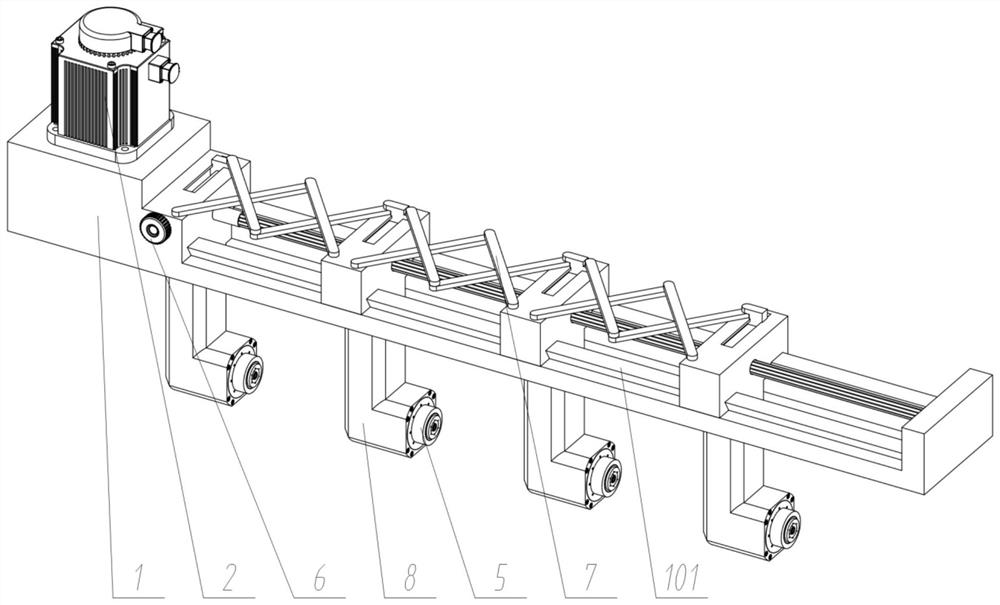

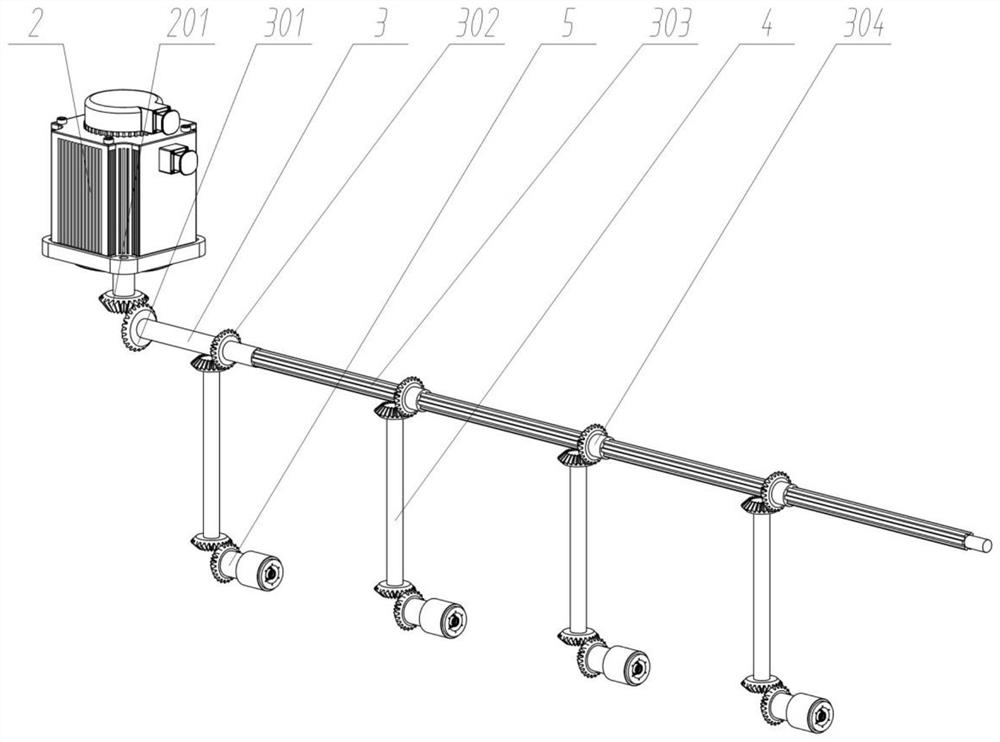

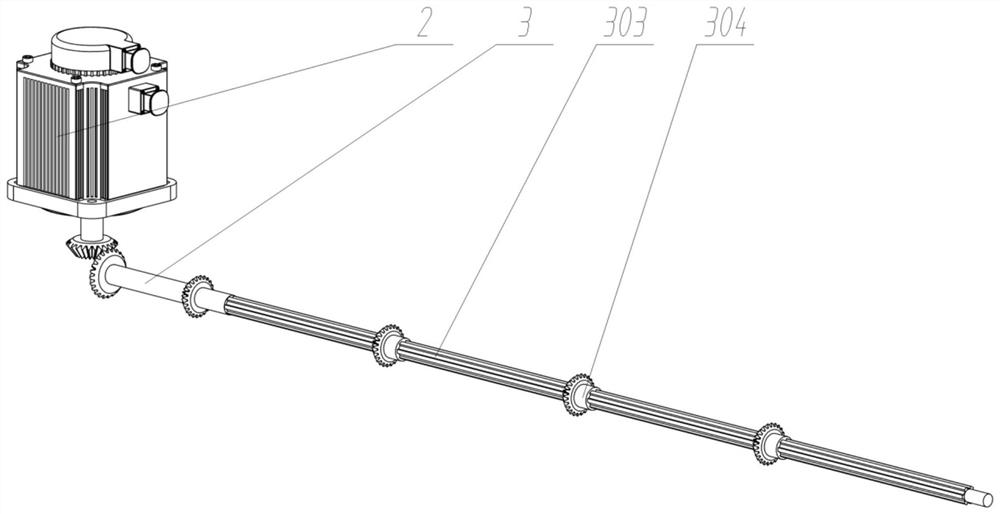

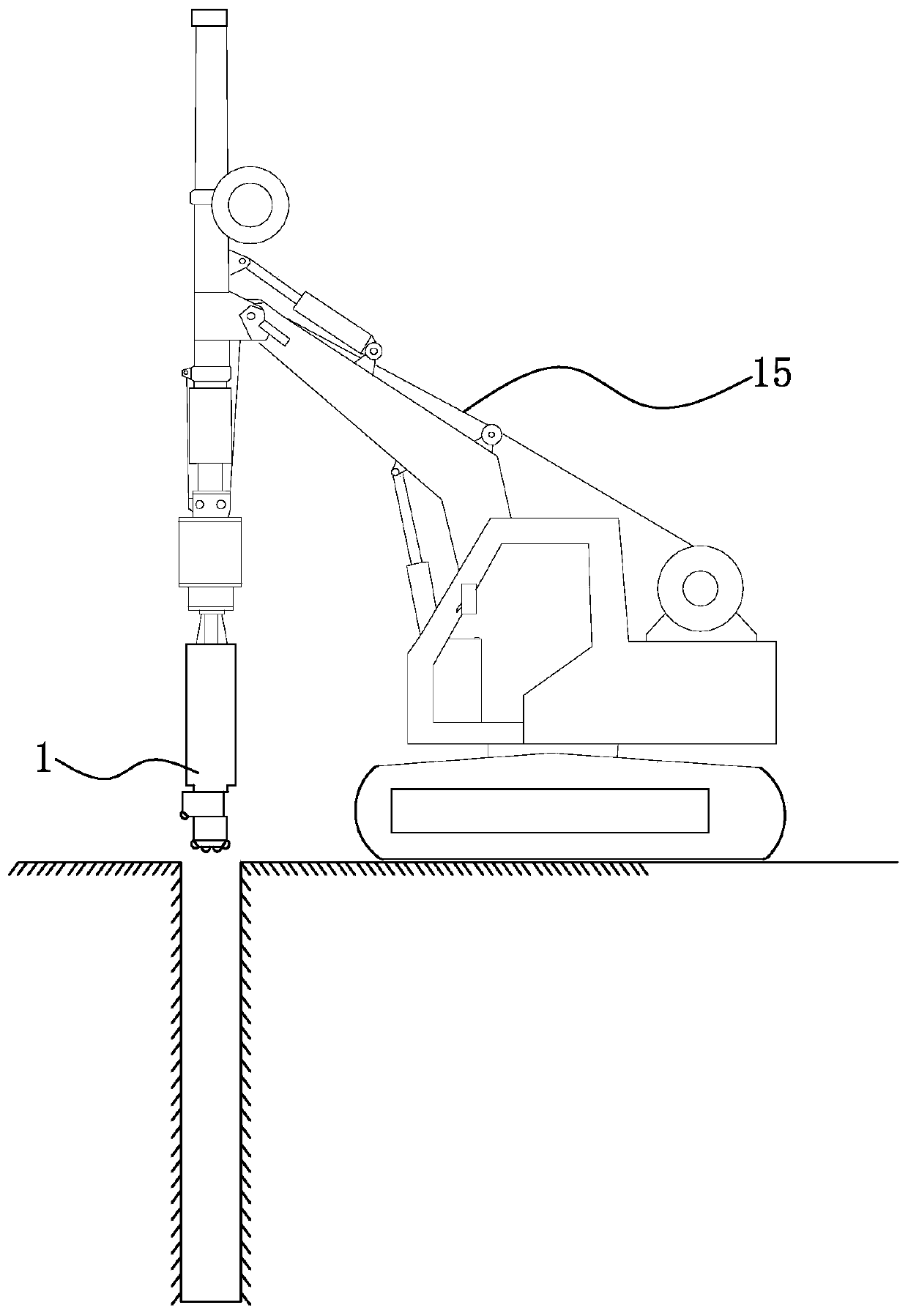

Matched drill boom facility of mining equipment bucket

PendingCN113059209ADrilling to achieveEven distance adjustmentLarge fixed membersBoring/drilling machinesStructural engineeringMachining

The invention discloses a matched drill boom facility of a mining equipment bucket, relates to the technical field of equipment processing, and solves the problems that repeated positioning errors easily occur during the processing of existing bucket lug plate holes, the form and location tolerance of the bucket lug plate holes is influenced, and the bucket lug plate holes are inconsistent. The matched drill boom facility comprises a drill boom body, wherein the top of the left side of the drill boom body is fixedly connected with a group of drilling driving pieces, a group of drilling middle transmission transverse shafts are rotationally connected into the drill boom body, and four groups of drilling bases are uniformly arranged at the lower part of the drilling boom body. By arranging the four groups of drilling bases, four groups of holes in a vertical plate can be drilled at the same time, the working efficiency is improved, meanwhile, repeated positioning errors are avoided, the machining precision is guaranteed, the problem that bucket lug plate holes are inconsistent is effectively solved, meanwhile, the distances between the four groups of drilling bases are evenly adjusted and can be adjusted according to needs in use, machining of buckets of different models is met, practicability is improved, and adjusting operation is easy.

Owner:张芳

A kind of drilling tool and drilling method

ActiveCN108049808BStable supportPrecise positioningDirectional drillingEngineeringPetroleum engineering

The invention discloses a hole drilling tool and method. The hole drilling tool comprises a drilling tool body, a casing pipe and a pipe boot. The drilling tool body comprises a center drill bit, an eccentric drill bit and a centralizer. The eccentric drill bit is arranged between the centralizer and the center drill bit, the centralizer is arranged in the pipe boot, the top end of the pipe boot is connected with the casing pipe, the centralizer is connected with the eccentric drill it through an eccentric shaft, and a locking mechanism is arranged between the centralizer and the center drillbit. According to the hole drilling tool, good reliability of connection between the center drill bit and the centralizer is ensured, and the problem of falling of the drilling tool is thoroughly solved.

Owner:浙江化工工程地质勘察院有限公司

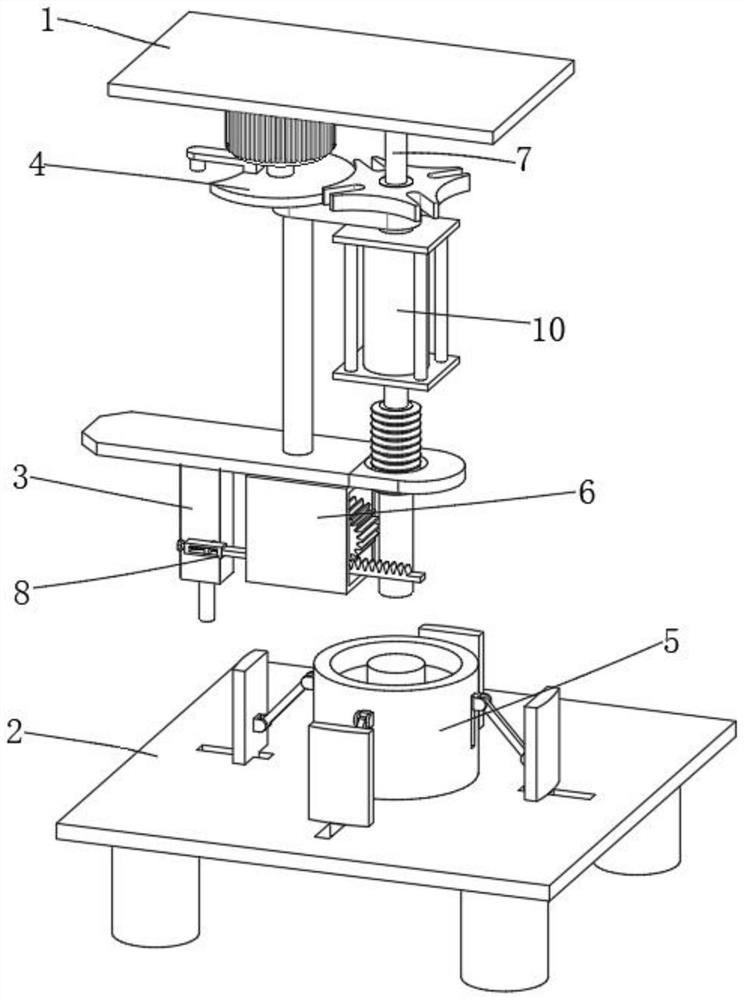

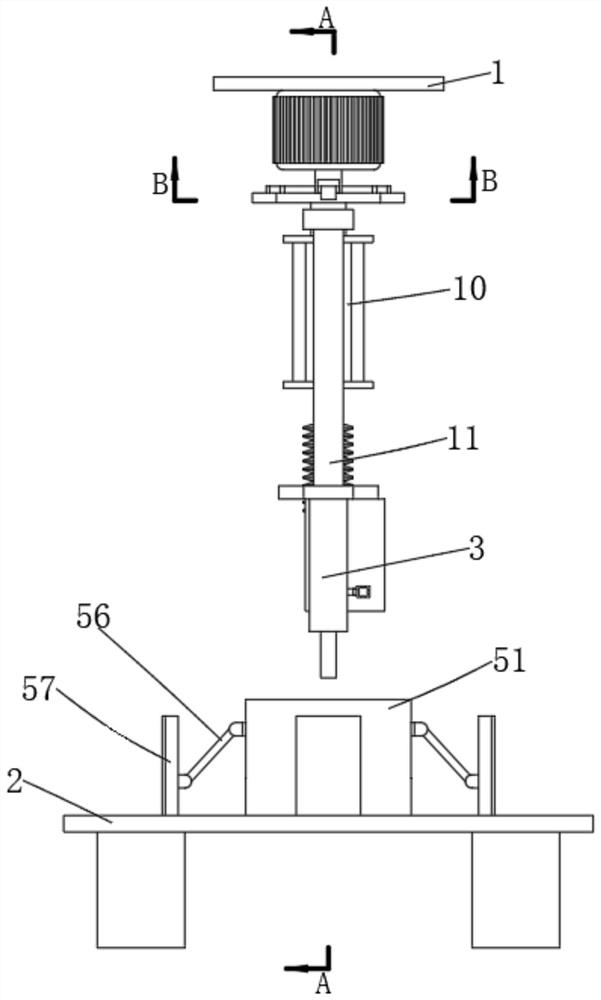

Flange plate producing and machining device for pipe fitting connection

InactiveCN114083018AAchieve peace of mindRealize the clamping effectPositioning apparatusBoring/drilling componentsPipe fittingEngineering

The invention discloses a flange plate producing and machining device for pipe fitting connection. The device comprises a top plate and a working platform, the top of the working platform is provided with an inner diameter clamping mechanism for centering a flange plate, the inner diameter clamping mechanism comprises an annular mounting cylinder, the annular mounting cylinder is fixedly connected to the top of the working platform, the annular mounting cylinder is in a hollow pipe shape, a plurality of mounting grooves are formed in the outer wall of the annular mounting cylinder in a circumferential array penetrating mode, sliding blocks are slidably connected to the inner walls of the mounting grooves, and a pressure plate is connected to the inner wall of the annular mounting cylinder in an up-down sliding mode. Through cooperation of the above structures, the device achieves the function of fixing and clamping flange plates with different inner diameters and different heights, can drill positioning holes in the flange plates in a circumferential equally-divided mode, and can adjust the drilling position of a drilling machine according to the inner diameters of the flange plates, so that the drilling requirements of positioning holes of the flange plates of different specifications are met.

Owner:张富博

Mechanical part positioning and drilling integrated machine

InactiveCN105562760ASimple processing technologyDrilling to achievePositioning apparatusBoring/drilling componentsDesign technologyMotor shaft

The invention discloses a mechanical part positioning and drilling integrated machine, and belongs to the technical field of small machine tool designing. The mechanical part positioning and drilling integrated machine comprises a rotating arm, angle iron, a cam, a rotating shaft, a drill bit, a workbench and a motor. A rotation pair is formed through the rotating arm and the angle iron. The angle iron is fixed to the workbench through a screw. The cam is arranged outside the rotating shaft in a sleeving manner, and the cam and the rotating shaft are fixed into a whole through a screw. The rotating shaft is connected with a motor shaft through a coupler and rotates along with the motor. The drill bit is fixed to the workbench. The workbench can do reciprocated feeding on a machine tool body in the longitudinal direction, the drill bit longitudinally moves along with the reciprocated feeding of the workbench, and workpiece drilling is achieved. According to the designed mechanical part positioning and drilling integrated machine, before drilling, a positioning pin and a cylindrical pin are used in cooperation so that a workpiece can be pressed to the appropriate depth of a chuck, workpiece position adjustment and drilling are conducted on the same structure, and the structure of the mechanical part positioning and drilling integrated machine is very simple.

Owner:CHIZHOU UNIV

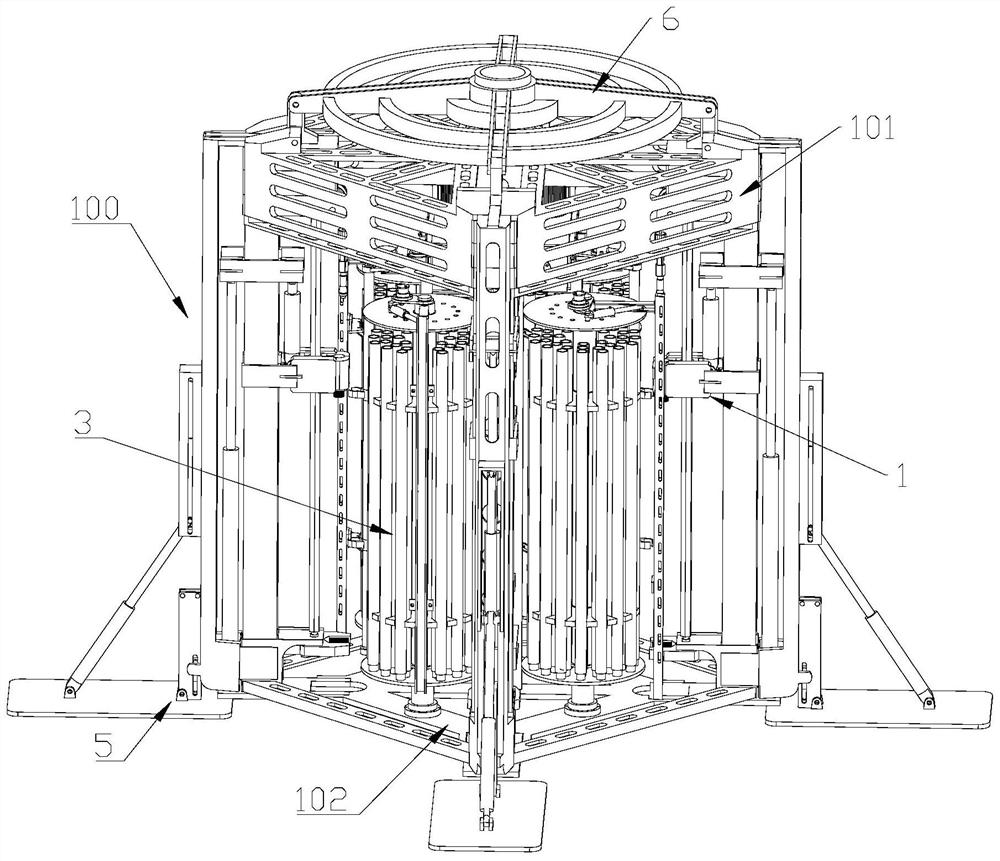

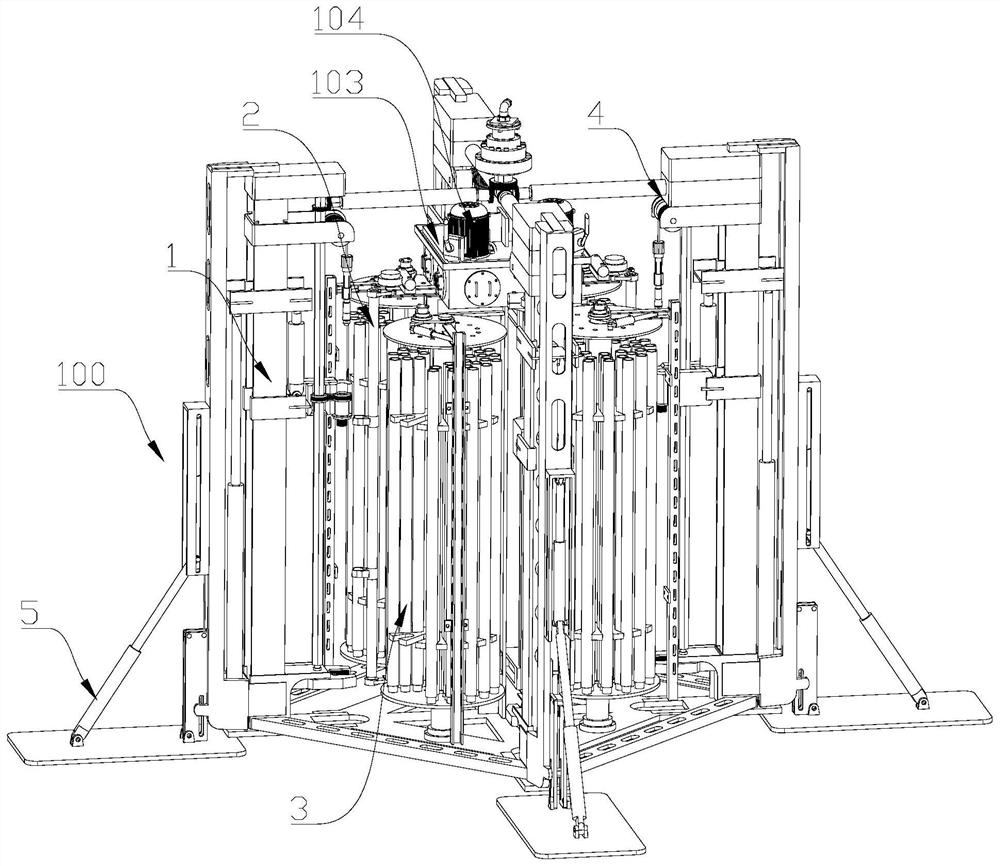

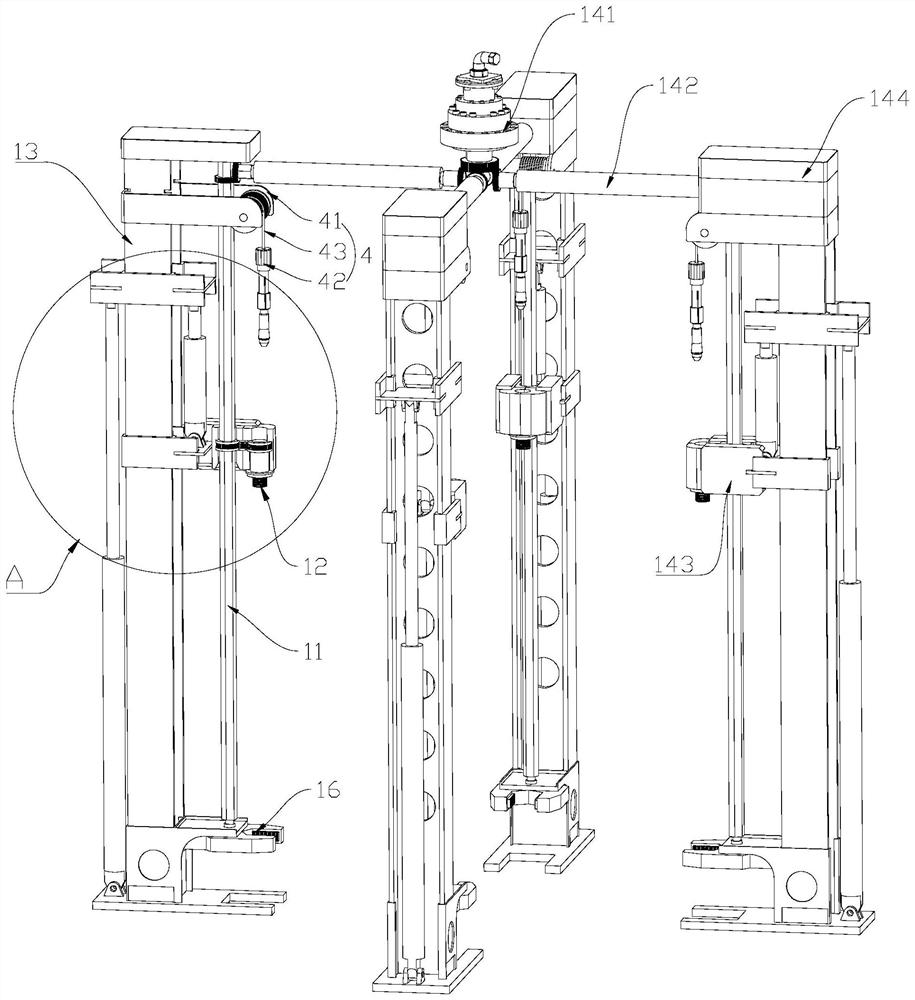

Seabed multi-head continuous sampling drilling machine

ActiveCN114000828AIncrease the number of samplesImprove work efficiencyDrilling rodsConstructionsStructural engineeringDrill pipe

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Plate machining device with multi-angle drilling function

InactiveCN109278117ARealization of multi-angle drillingDrilling to achieveStationary drilling machinesReciprocating motionDrill bit

The invention discloses a plate machining device with a multi-angle drilling function. The plate machining device comprises an operation table, a plate conveying mechanism arranged in the length direction of the operation table, and a multi-angle drilling mechanism arranged above the plate conveying mechanism. The multi-angle drilling mechanism can do horizontal reciprocating motion in the lengthdirection of the plate conveying mechanism. The multi-angle drilling mechanism comprises a drill bit. The drill bit can do half-circular motion on the plate conveying mechanism, and the drilling direction of the drill bit is toward the circle center of the half-circular motion locus all the time. Through the plate machining device, multi-angle inclined hole drilling can be achieved, and automaticcontinuous drilling operation can also be achieved.

Owner:HEFEI HUIZHI NEW MACHINERY TECH CO LTD

Geotechnical engineering ore cutting mining drilling mechanical equipment

InactiveCN107503676AReduce workloadAvoidance of injuryEarth drilling toolsConstructionsCrushed stoneMechanical equipment

The invention relates to a mine drilling mechanical equipment for mining ore in geotechnical engineering, which includes a top plate, a handle, a fixing device, a drilling device and a protection device. The upper end of the top plate is equipped with a drilling device, the lower end of the top plate is symmetrically provided with two fixing devices, and the lower end of the top plate is equipped with a protective device. Due to the limited technical level, the current mining drilling equipment has poor stability, needs manual fixing, is easy to slip, poor drilling accuracy, and the gravel and soil clods generated during drilling are likely to cause harm to users, high work intensity, and low safety. Low disadvantage, the present invention can solve the above problems, realize the function of drilling and protecting the specific position of the mountain, reduce the work intensity and improve the safety.

Owner:俞樑兵

Intelligent drilling device for urban rail transit and urban rail transit construction system

PendingCN114809911AAvoid offsetReasonable structureEarth drilling toolsConstructionsStructural engineeringMechanical engineering

The invention discloses an intelligent drilling device for urban rail transit and an urban rail transit construction system, and relates to the field of rail transit, the intelligent drilling device comprises a base, a plurality of supporting columns are uniformly and fixedly mounted at the top of the base, and first electric push rods are fixedly mounted at the tops of the supporting columns; the top ends of the output ends of the multiple first electric push rods are fixedly provided with the same fixing frame. According to the drilling device, through arrangement of a first electric push rod and a leveler, the fixing frame can be adjusted to be in a horizontal state, it is guaranteed that the inclination phenomenon does not occur in the drilling process, through arrangement of an accurate drilling part, accurate positioning of the drilling position and control over the drilling depth can be achieved, manual pressing of workers is not needed any more, time and labor are saved, and the drilling efficiency is improved. And by arranging the stabilizing part, the stability of the device can be effectively improved, and the situation that the drilling position deviates due to the fact that the device shakes in the drilling process is avoided.

Owner:邓建国

High-efficiency and high-quality plate drilling method

InactiveCN107650210AReduce brittlenessNo crackingStationary drilling machinesWood treatment detailsWaxUltimate tensile strength

The invention discloses a high-efficiency and high-quality board drilling method, which comprises the following steps: grinding the surface of the board; putting the board into a heating box, steaming it with steam, and drying the water drops; placing the board in a On the drilling equipment, determine the drilling position; paste the ring cylinder on the plate where the hole needs to be drilled; drill the hole; apply wax, heat and dry. In the drilling method of the present invention, the wood is "softened" by humidifying the wood before drilling, thereby improving the quality of the drilling and avoiding damage to the cutter or the plate, wherein the drilling cutter is reversed to be set horizontally, In this way, the board can stand upright. With one device, not only can the board be drilled from four directions at the same time, which greatly improves the processing efficiency, but also can not only realize the drilling of the front side of the board, but also quickly Realize the conversion from front to side drilling, without manual operation, and reduce labor intensity.

Owner:张杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com