Patents

Literature

34results about How to "Improve porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

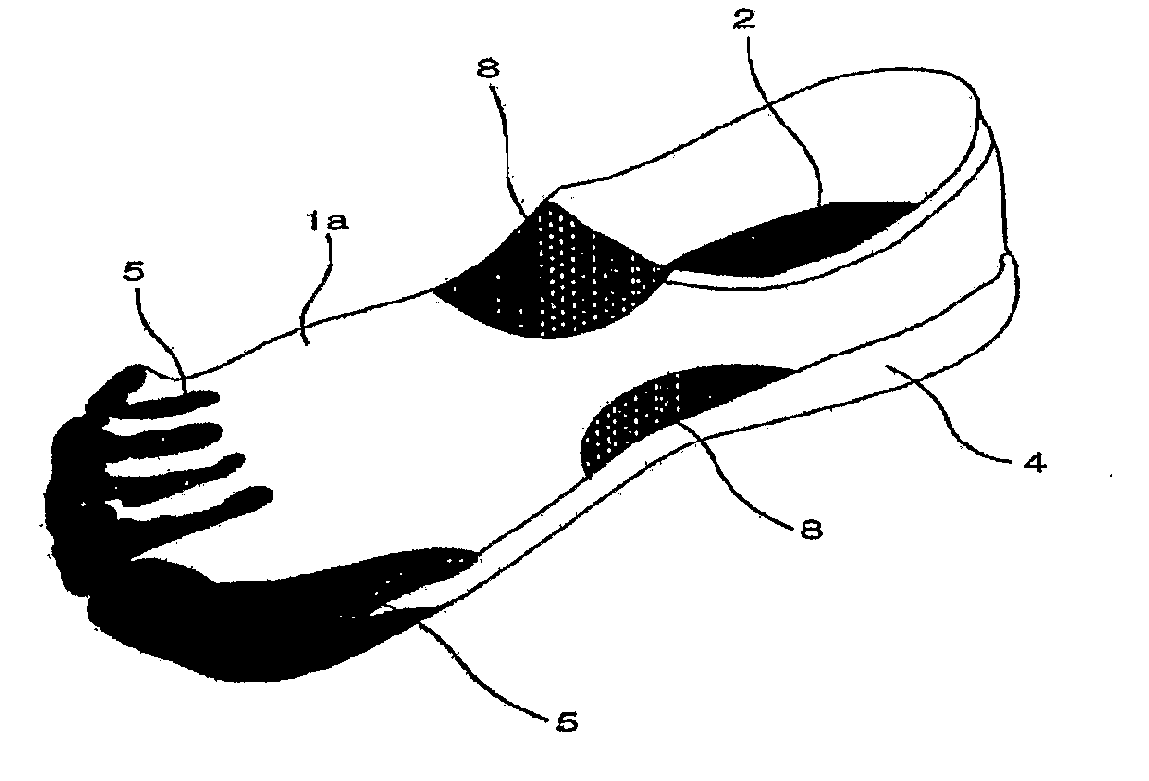

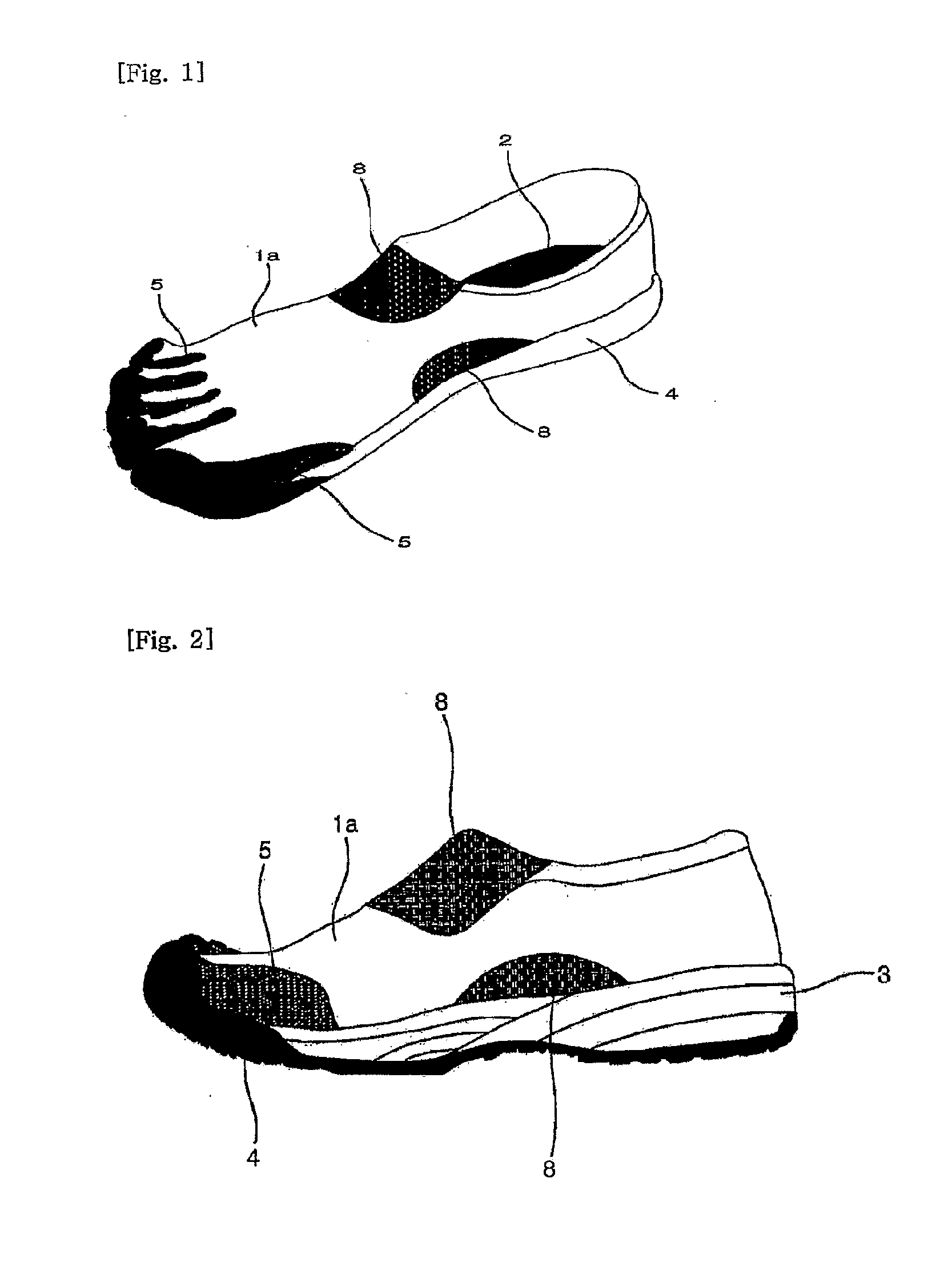

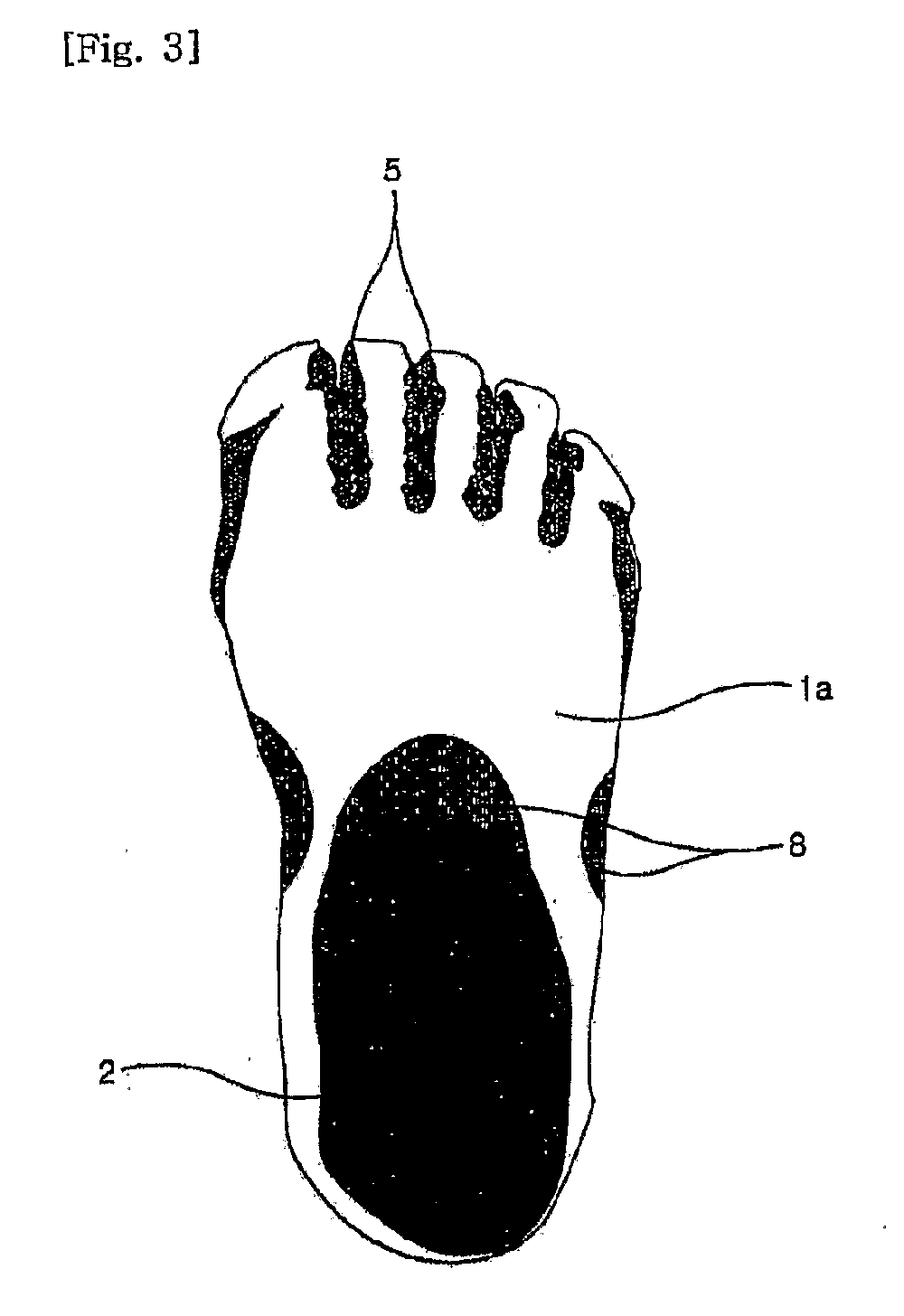

Five toe shoes

InactiveUS20110005105A1Improve porosityImproves activity and landing performanceUpperBootlegsMetal meshEngineering

The invention relates to five toe shoes for protecting feet while working or taking part in leisure activities on land or water and in the mountains. In particular, a five toe shoe comprises: an upper which is made out of a moisture-permeable fiber material and has a toe area to encase each toe separately according to the shape; an insole which is made out of a porous material; a midsole which is placed underneath the insole and has a metal mesh to allow water in the shoe to exit therethrough; and an outsole which has a drain formed in coincidence with the metal mesh of the midsole and a toe area for each toe separately according to the shape, being connected to the toe area of the upper in a one-to-one correspondence therebetween. Thus, five toe shoes may contribute greatly to foot health of wearers by improving breathability as water from the inside of the shoes drains naturally by gravity via the insole, midsole and outsole and evaporates quickly through the upper at the same time, and offer more convenience in activities with the toe area encasing each toe separately according to the shape.

Owner:HONG SOON KYUNG

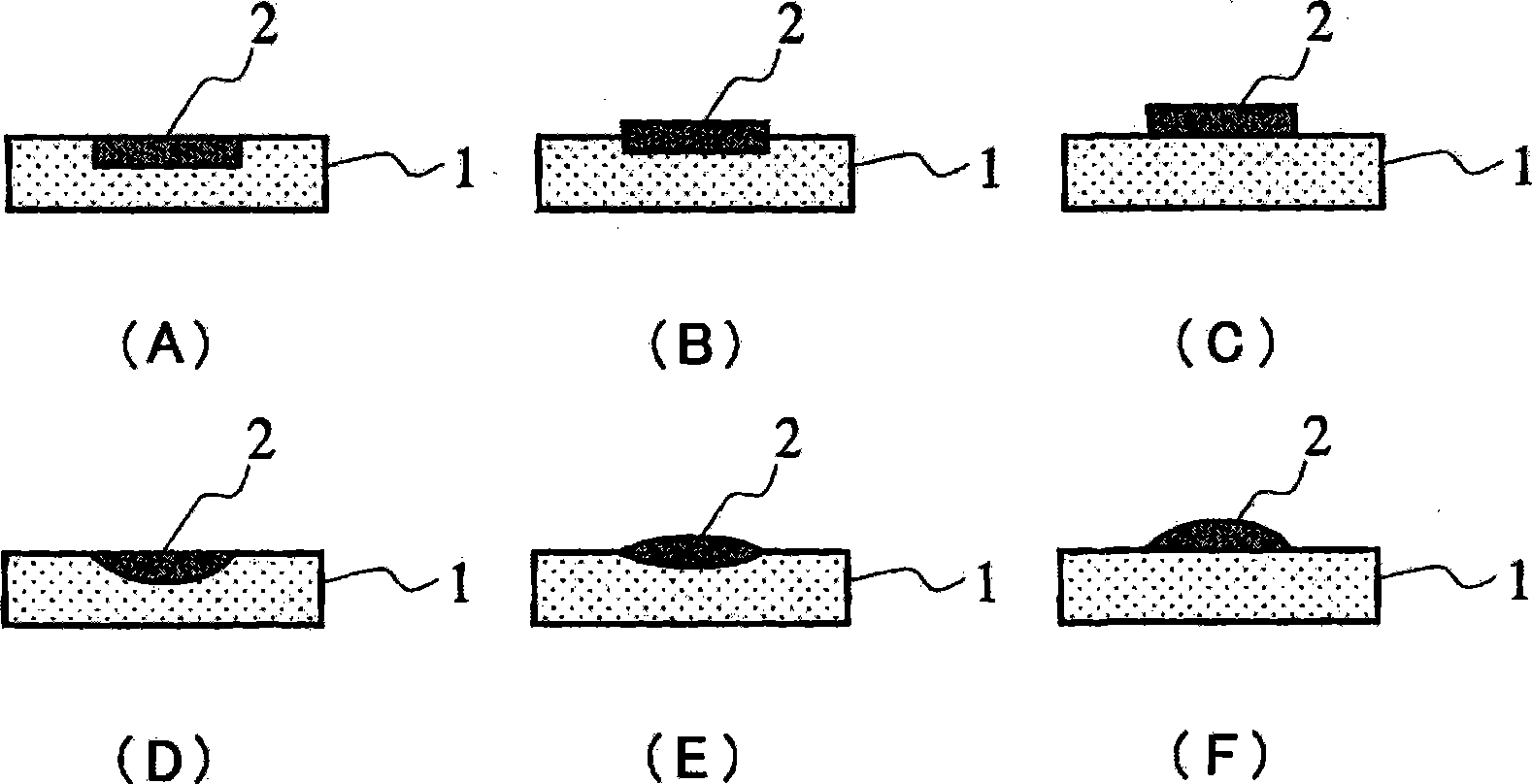

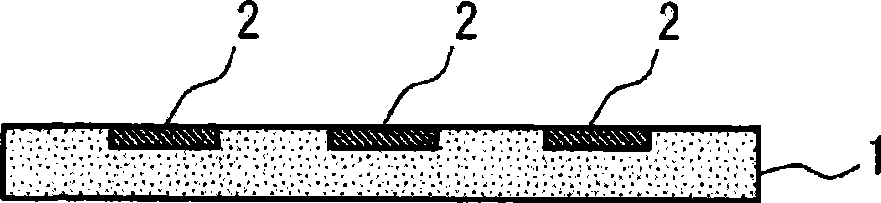

Porous film and multilayer assembly using the same

InactiveCN101384425ASmall widthImprove adhesionLayered productsPrinted circuit manufactureAdhesive beltPorous layer

To provide a porous-film layered product which has excellent porousness, has flexibility, and is excellent in handleability and formability; and a process for producing the layered product. [MEANS FOR SOLVING PROBLEMS] The porous-film layered product comprises a base and, superposed on at least one side thereof, a porous layer having many fine interconnecting pores having an average pore diameter of 0.01-10 [mu]m, and is characterized by suffering no interfacial separation between the base and the porous layer when examined in a tape peeling test by the following method. Tape peeling test A 24 mm-wide masking tape [Film Masking Tape No. 603(#25)] manufactured by Teraoka Seisakusho Co., Ltd. is applied to the surface of the porous layer of the porous-film layered product and press-bonded thereto with a roller having a diameter of 30 mm and a load of 200 gf. Thereafter, this sample is subjected to a T-peel test with a tensile tester at a peeling rate of 50 mm / min.

Owner:DAICEL CHEM IND LTD

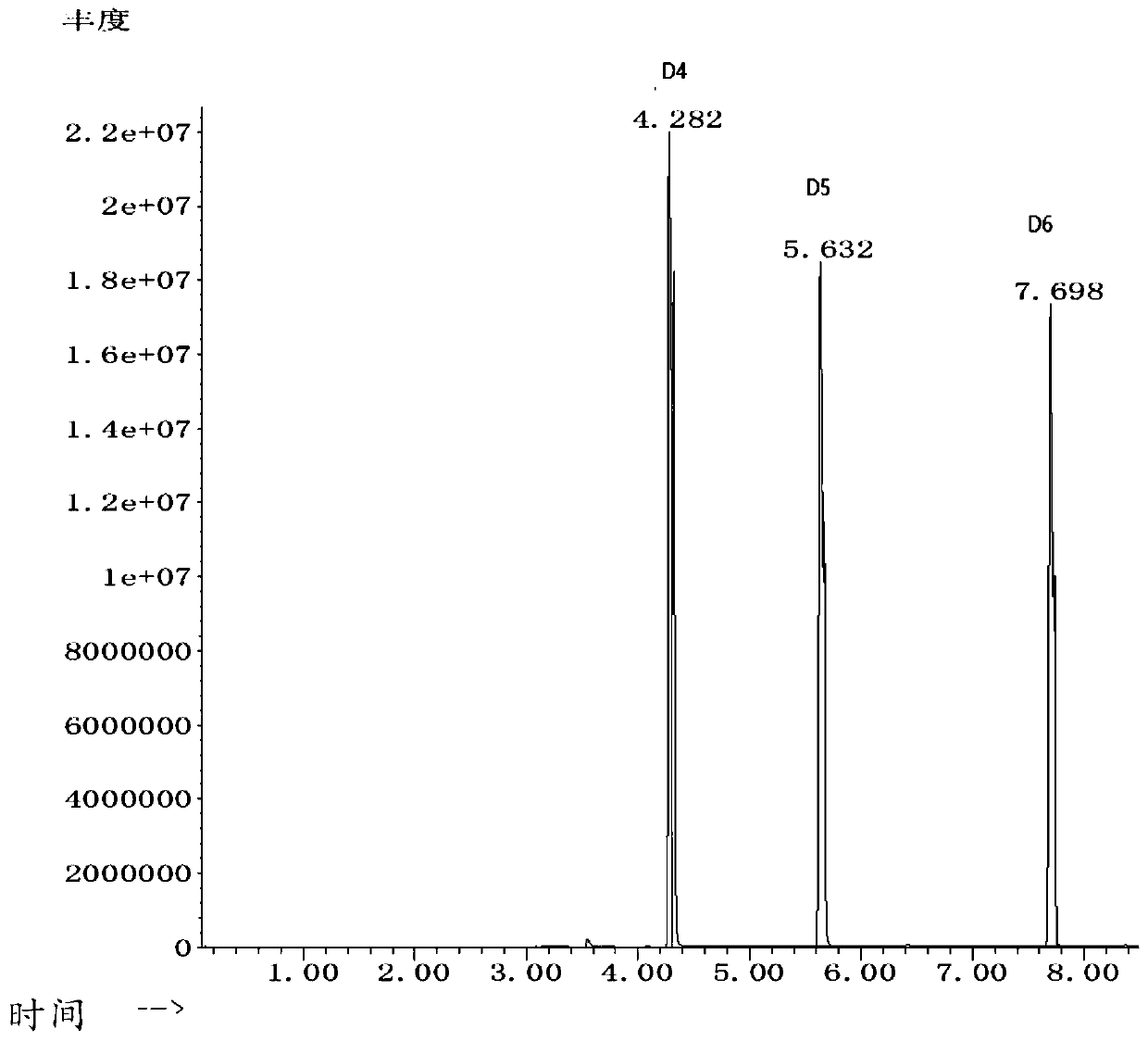

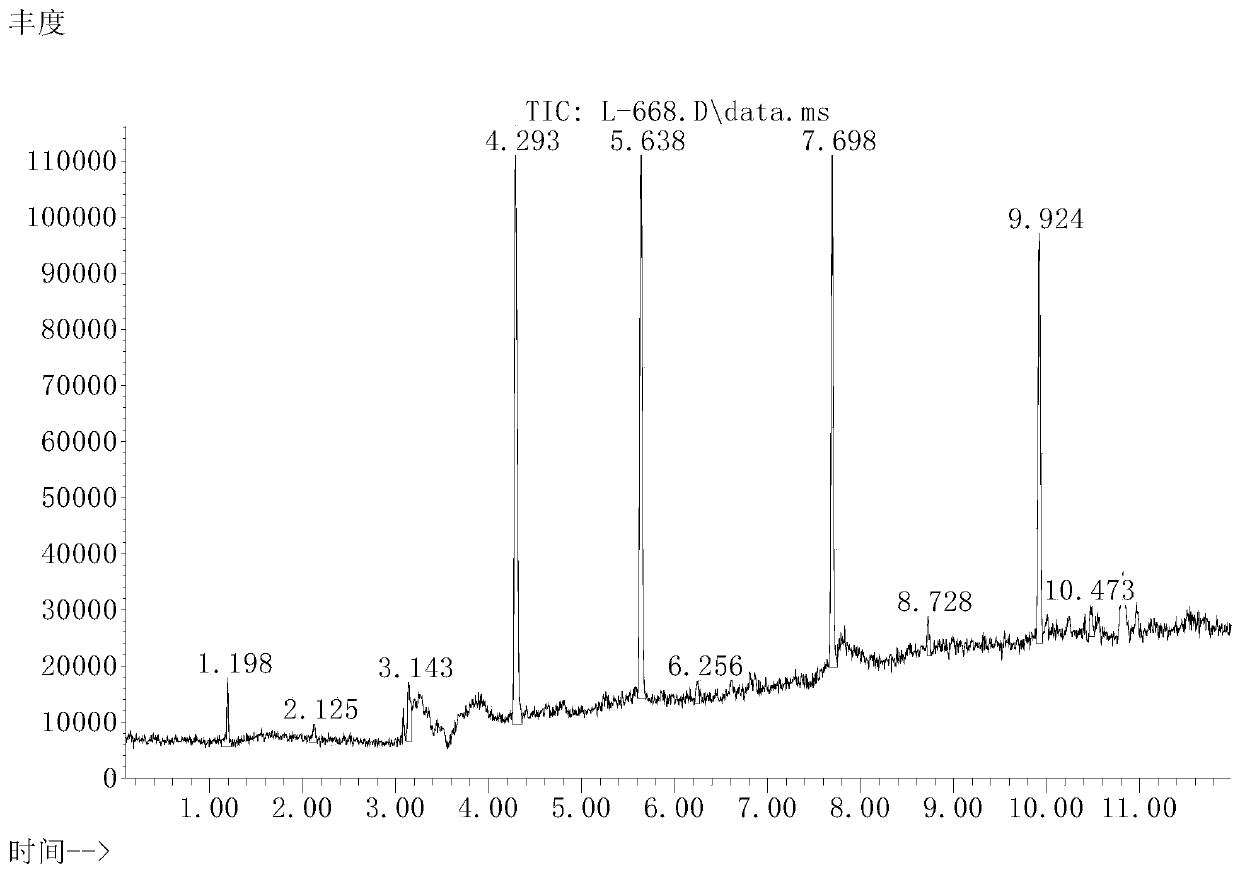

Hole filling liquid medicine for direct current electroplating of micro blind hole

ActiveCN108166028AImprove wettabilityAvoid it happening againPrinted element electric connection formationCopper platingDiameter ratio

The invention discloses a hole filling liquid medicine for direct current electroplating of a micro blind hole. The hole filling liquid medicine comprises a wetting agent, an efficient inhibitor, an accelerator and a leveling agent, wherein the wetting agent plays a role in increasing the wettability of a copper surface, so that holes in the hole are prevented from being generated due to the factthat copper ions in the hole are not consumed in time. According to the hole filling liquid medicine, the efficient inhibitor is effectively adsorbed in the vicinity of a hole opening, and copper growth of the hole opening is prevented, so that the hole wrapping phenomenon caused by too fast growth of the electroplating copper at the hole opening of the fine blind hole is improved; the acceleratorcan enter the hole and can be rapidly enriched with electroplating, so that the plating speed in the hole is higher than the plating speed of the exterior of the hole, and the effect of efficiently filling the hole is achieved; the leveling agent is combined with a part with dense negative charges at the hole opening, the copper plating speed of the hole openning is inhibited, and holes in the hole are prevented from being generated; by means of the synergistic effect of the components, efficient electroplating filling of fine and high-thickness-diameter-ratio blind holes is realized, the hole filling process can be completed through direct current plating, cost is low, the hole filling efficiency is high, the quality is high, and the equipment requirement is low, and the hole filling liquid medicine is suitable for a blind hole filling process with the processing aperture being lower than 60 microns and the thickness-diameter ratio being greater than 1.

Owner:SHENZHEN BANMING SCI & TECH CO LTD

Complex medium for producing functional red yeast rice and preparation method and fermentation method thereof

ActiveCN103740762AImprove porosityImprove fermentation effect and product qualityMicroorganism based processesFermentationSucroseYeast

The invention discloses a complex medium for producing functional red yeast rice and a preparation method and fermentation method thereof. The complex medium is prepared by granulating powder and nutrient solution, wherein the powder comprises the following raw materials in percentage by weight: 24-38% of long-shaped rice powder, 42-55% of oat powder and 7-34% of soybean meal; the nutrient solution is prepared from water and the following raw materials: 38-76g / L sucrose, 5-12g / L yeast powder, 5-12g / L ox bone peptone, 1-5g / L compound amino acid, 2-5g / L magnesium sulfate, 1-5g / L sodium nitrate and an acidity regulator for regulating the pH value of the nutrient solution to 3.5-4.5; the weight ratio of the powder to the nutrient solution is 1:(0.2-0.6). The complex medium with nutritional ingredients and material characteristics better conforming to monascus fermentation is prepared by optimizing the ratio of raw materials; the looseness, air permeability and mass and heat transfer effect of the medium are improved through raw material granulation, and the complex medium adapts to the growth of monascus strains and the metabolism of monacolin K, thus the fermentation effect and product quality of the functional red yeast rice are effectively improved.

Owner:CHENGUANG BIOTECH GRP CO LTD

Using method for soil curing agent

InactiveCN101100856AImprove compactnessImprove the modulus of resilienceSoil preservationWater solubleFly ash

Owner:张京杰

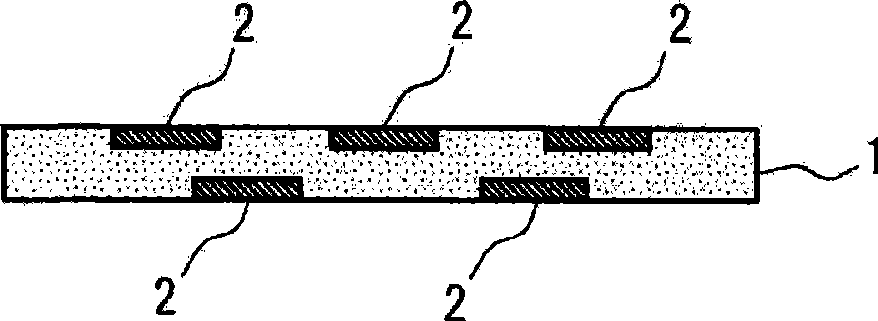

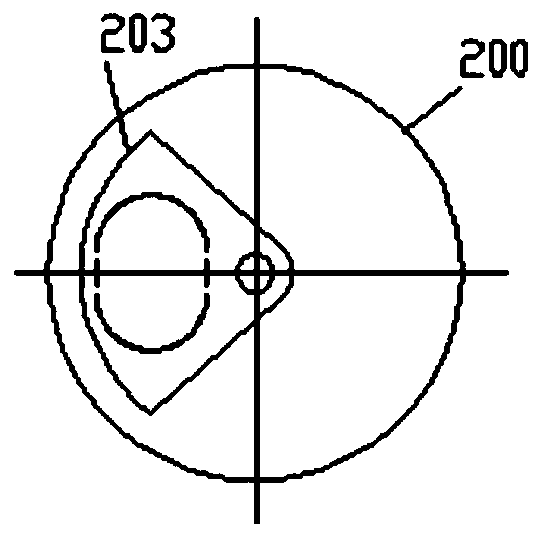

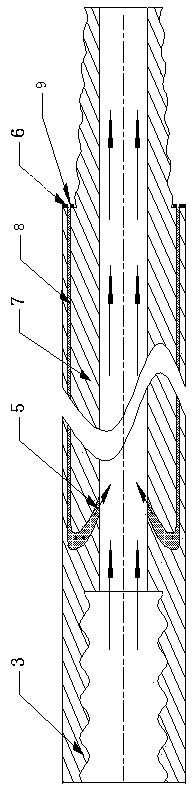

Reverse circulation drilling device and process for soft projecting coal seam

InactiveCN104514487AImprove drilling efficiencyImprove porosityFlushingDrilling machines and methodsCoalDrill bit

The invention provides a reverse circulation drilling device for a soft projecting coal seam. The device comprises a drilling machine, an active double-wall drilling rod, a double-channel pneumatic faucet; a power head is arranged on the drilling machine; the active double-wall drilling rod passes through the power head to be mounted; an inner pipe at one end of the active double-wall drilling rod is connected with a rubber pipe through the double-channel pneumatic faucet; a pulverized coal receiving device is connected to the tail end of the rubber pipe; an air box which communicates with internal and external pipe annular channels of the active double-wall drilling rod is arranged on the double-channel pneumatic faucet; the air box is connected with an air compressor through an air pipe; a drill bit is connected to the other end of the active double-wall drilling rod. With the adoption of the device, the disturbance to the coal seam can be minimized, so that the collapse in holes can be effectively prevented, and that the frequent drilling blocking accidents can be avoided; the circumstance that gas is concentrated is prevented, and therefore, the phenomenon of blowout through the holes can be effectively avoided; the production cost is low; in addition, the working environment at the construction field can be effectively improved; the purpose of drilling in collapse and reducing stratums synchronously by one drilling rod can be achieved.

Owner:周升风

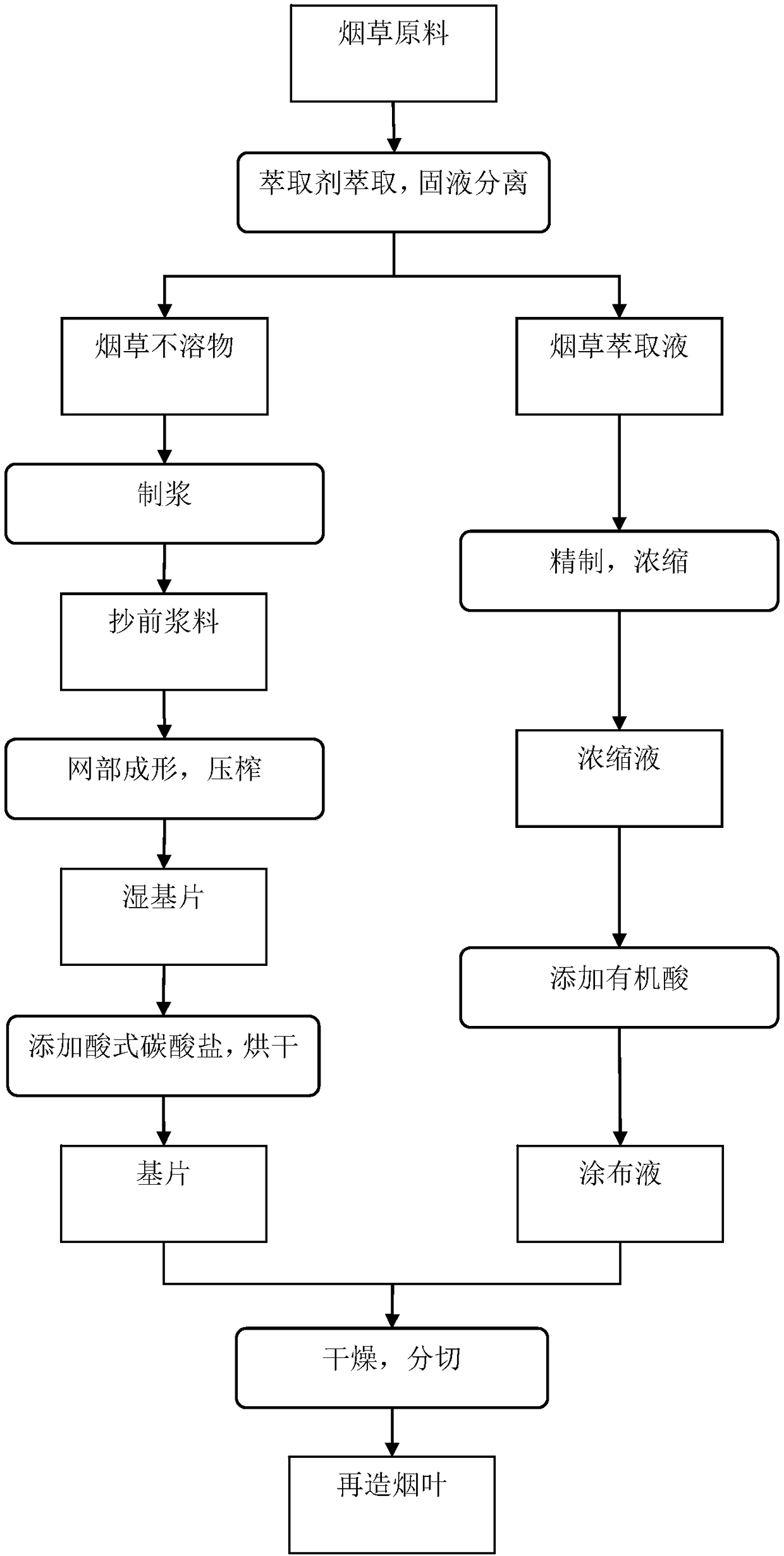

Paper-making reconstituted tobacco preparation method and method for improving coating liquid absorbability of paper-making reconstituted tobacco substrate

The invention provides a paper-making reconstituted tobacco preparation method and a method for improving coating liquid absorbability of a paper-making reconstituted tobacco substrate. The paper-making reconstituted tobacco preparation method includes steps: 1) after extracting with an extracting agent, performing solid-liquid separation to obtain tobacco insoluble matters and tobacco extract liquid; 2) subjecting the tobacco insoluble matters to pulping, and performing net forming and pressing to obtain a wet substrate; 3) subjecting the wet substrate to drying, coating of bicarbonate and drying to obtain a substrate; 4) subjecting the tobacco extract liquid to refining concentration to obtain coating liquid; or adding organic acid after refining concentration to obtain the coating liquid; 5) coating the substrate with the coating liquid, and drying and slitting to obtain reconstituted tobacco. Liquid absorbability of the substrate is improved by thermal decomposition action of bicarbonate; preferably, coating liquid absorbability of the paper-making reconstituted tobacco substrate is improved by improving substrate infiltration performance of the coating liquid through reductionof residue content of the coating liquid.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

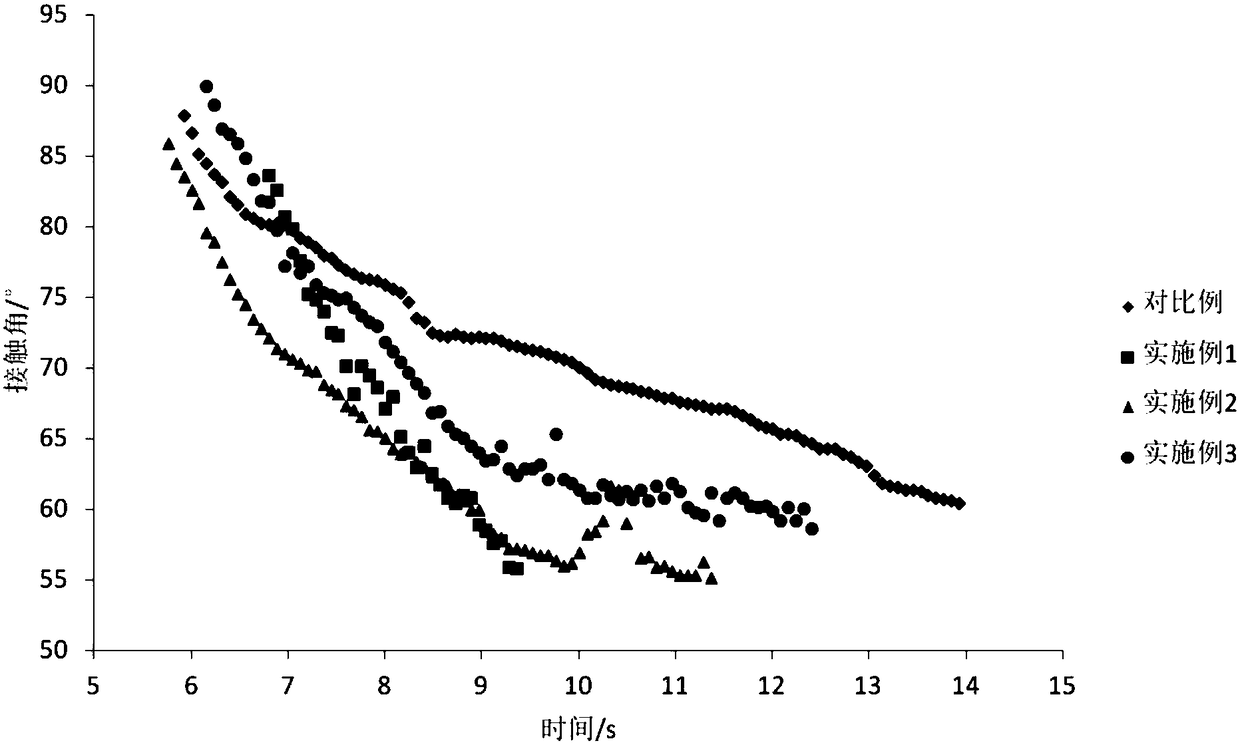

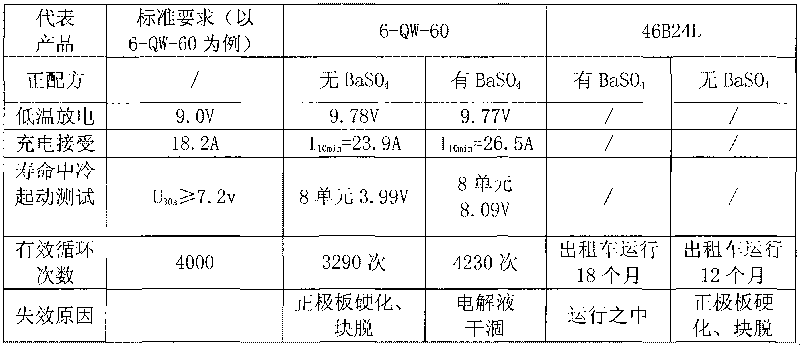

Storage battery anode lead plaster capable of enhancing SAE standard high temperature service life and preparation method

InactiveCN101707249AMeet the requirements of high temperature lifeResolve shrinkageLead-acid accumulator electrodesPorosityFiber

The invention discloses a storage battery anode lead plaster capable of enhancing SAE standard high temperature service life and a preparation method, aiming at solving the problem of high temperature service life of lead-acid storage batteries. The technical scheme is that the lead plaster raw materials are prepared by the following substances in parts by weight: 100 of lead powder, 0.05-0.1 of fiber, 0.1-1.0 of superfine barium sulfate, 0.05-0.2 of carbon black, and 0.1-0.4 of magnesium sulfate. The invention selects superfine barium sulfate as anode additive, thus delaying contraction and rigidification of anode plate under high temperature and prolonging service life of the storage battery; magnesium sulfate and carbon black improve the porosity of the anode active substance, facilitates dispersion of sulfuric acid and is beneficial for starting performance of the storage battery. Proved by test data, main technical performance index can perfectly achieve and surpass the standard requirement, and satisfy the requirement of the automobile on the high temperature service life of the storage battery.

Owner:中国船舶重工集团动力股份有限公司

Red mud-added ecological concrete and application of same in sewage purification

InactiveCN102951887ARich sourcesReduce manufacturing costBiological water/sewage treatmentSlagRed mud

The invention provides a red mud-added ecological concrete which comprises a cementing material, aggregate, water and a naphthalene-based superplasticizer, wherein the cementing material includes red mud and slag portland cement. According to the invention, through application of the red mud in ecological concrete, a pollutant purifying effect of the ecological concrete can be improved, the waste is turned into the valuable at the same time, and the red mud can be used to replace cementing materials like cement; thus, production cost of the ecological concrete is substantially reduced, and the ecological concrete has good strength and considerable practical application values.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +1

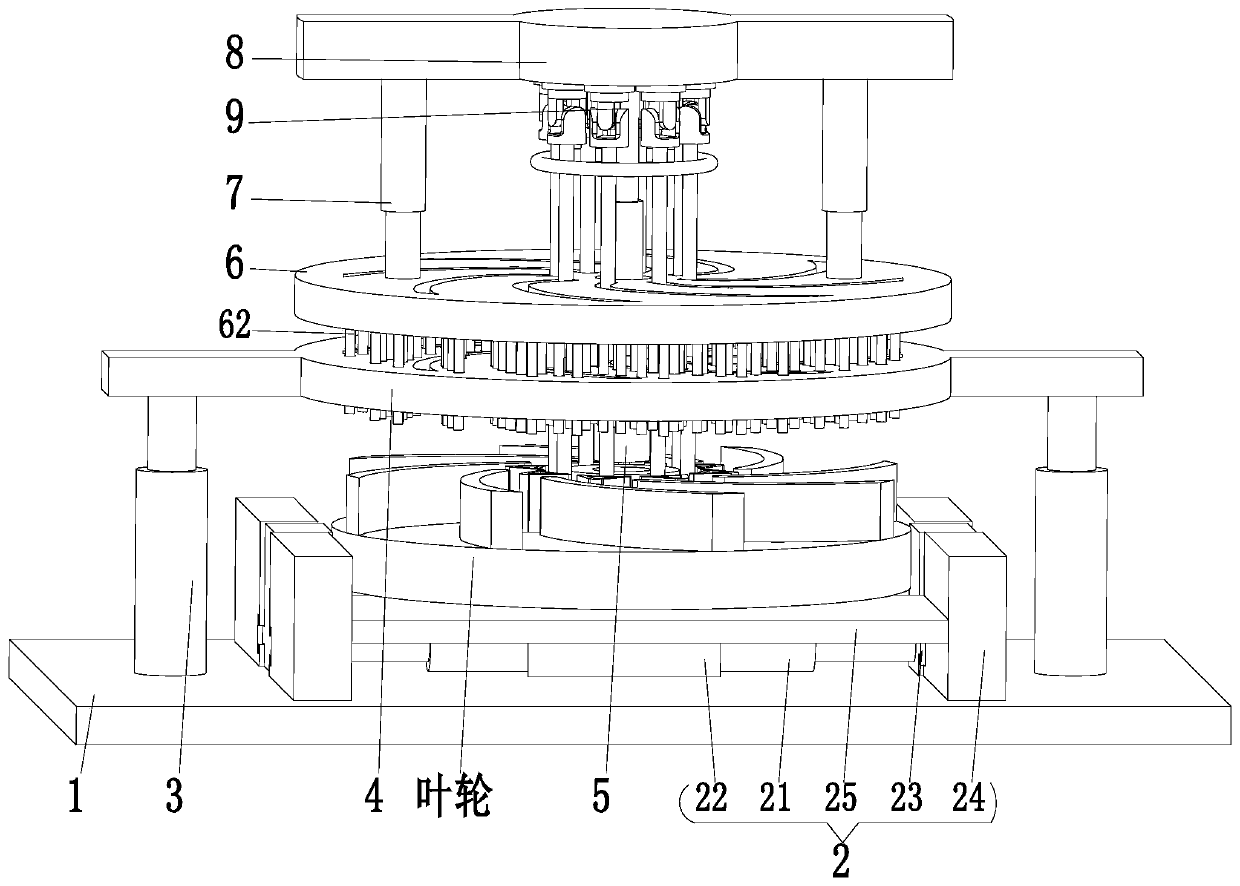

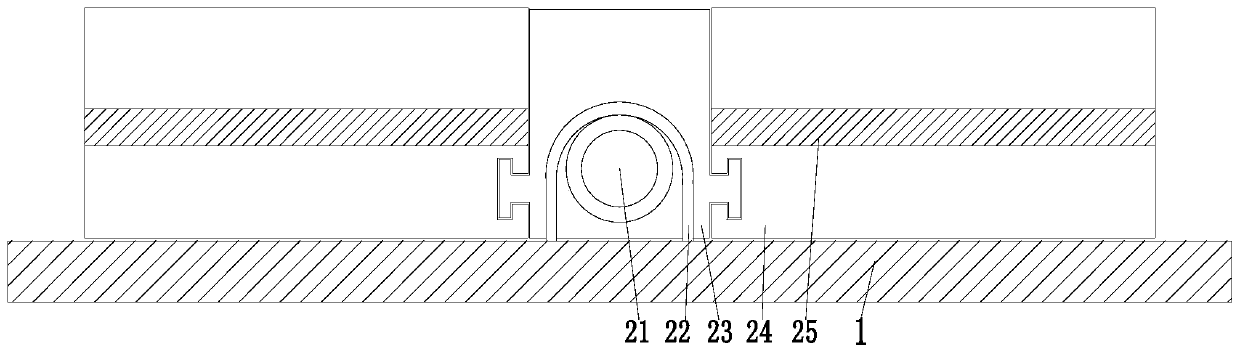

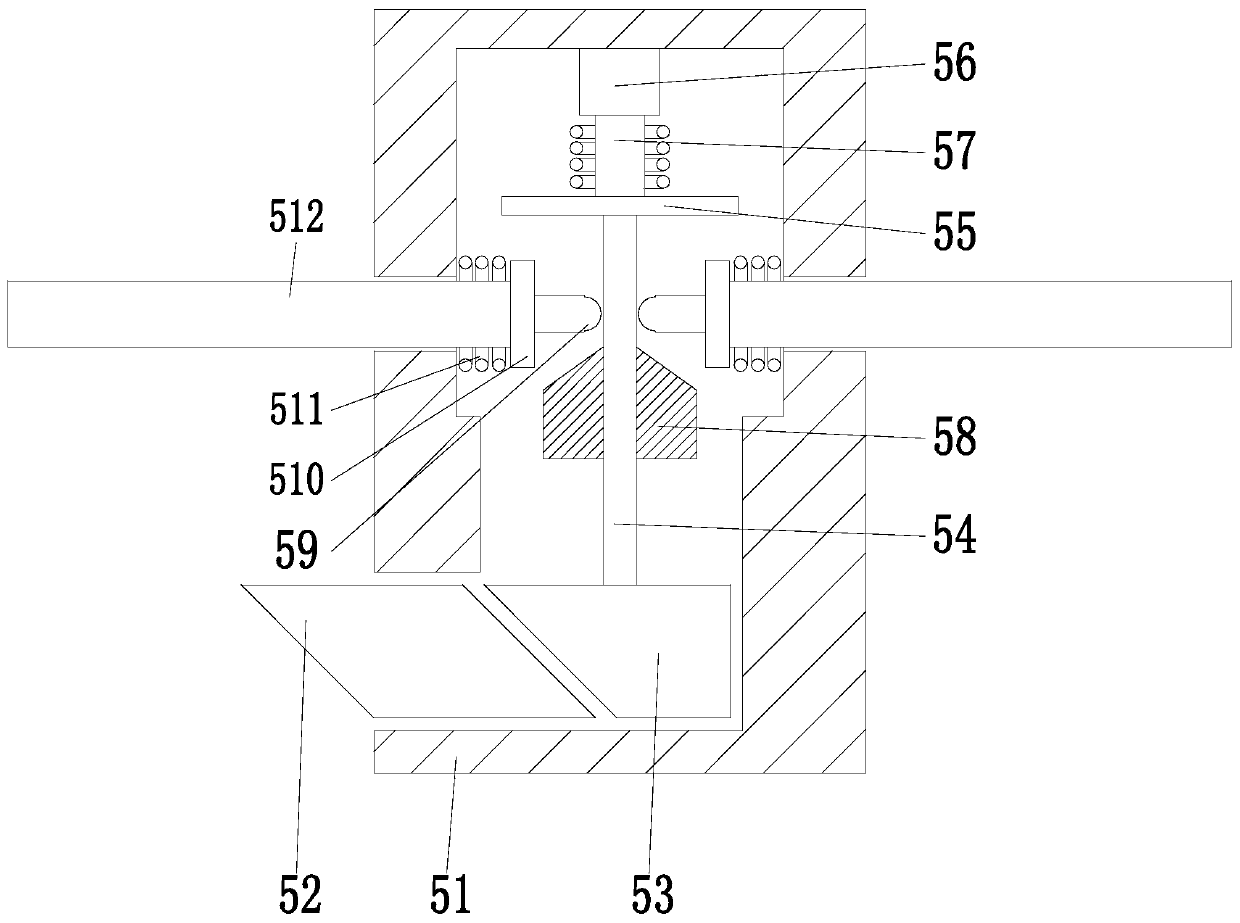

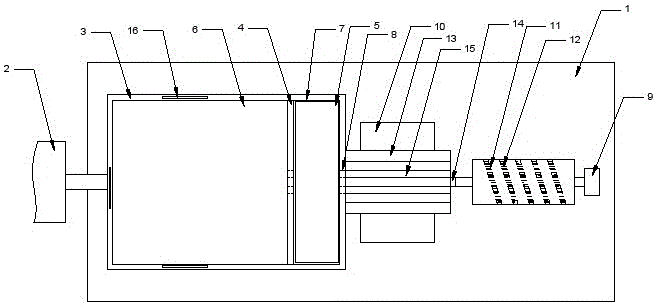

Water pump impeller manufacturing forming shakeout processing system

The invention relates to a water pump impeller manufacturing forming shakeout processing system. A base, a clamping mechanism, supporting air cylinders, a guide plate, an auxiliary mechanism, a loosening mechanism, adjusting air cylinders, a mounting plate and a cleaning mechanism are included. The clamping mechanism is arranged on the upper end surface of the base, the supporting air cylinders are installed symmetrically on the left side and the right side of the clamping mechanism, the guide plate is installed at the top end of the supporting air cylinders, the auxiliary mechanism is installed under the guide plate, the loosening mechanism is arranged above the guide plate, the adjusting air cylinders are installed symmetrically on the left side and the right side of the upper end surface of the loosening mechanism, the mounting plate is installed at the upper ends of the adjusting air cylinders, the cleaning mechanism is installed on the middle part of the lower end surface of the mounting plate, and the cleaning mechanism is installed on the upper end surface of the guide plate. The problems that the automation degree is low, the efficiency is low, the surface of an impeller isprone to being damaged in the beating process, and potential quality hazard exists when the impeller is subjected to shakeout processing in the prior art, and the sand between blades of the impelleris not easy to clean up are solved.

Owner:JINING ANTAI MINING EQUIP MFG CO LTD

Blasting construction method for freezing shaft and unstable rock stratum

The invention discloses a blasting construction method for a freezing shaft and an unstable rock stratum. The blasting construction method is characterized by comprising the technological steps of (1) punching a hole: the hole can be punched according to blasting hole depth and blasting hole diameter set by a blasting technology requirement; (2) installing a pipe: a PVC (Poly Vinyl Chloride) pipe which is matched with the blasting hole diameter is arranged in a blasting hole; (3) loading explosive: the PVC pipe is internally filled with the explosive and a detonator; (4) connecting a wire: a detonating wire of the detonator is connected with a power supply; (5) blasting: a detonating power supply can be powered on for blasting. Compared with the prior art, the hole wall of the blasting hole is protected by using the PVC pipe, thus the blasting hole quality is ensured, the hole forming of the blasting hole is ensured, and a hole forming rate of the blasting hole is increased; on one hand, the hole forming rate of the blasting hole is effectively increased, and on the other hand, the explosive quality is prevented from being reduced by water entering the blasting hole in a working area.

Owner:中煤第五建设有限公司第四十九工程处

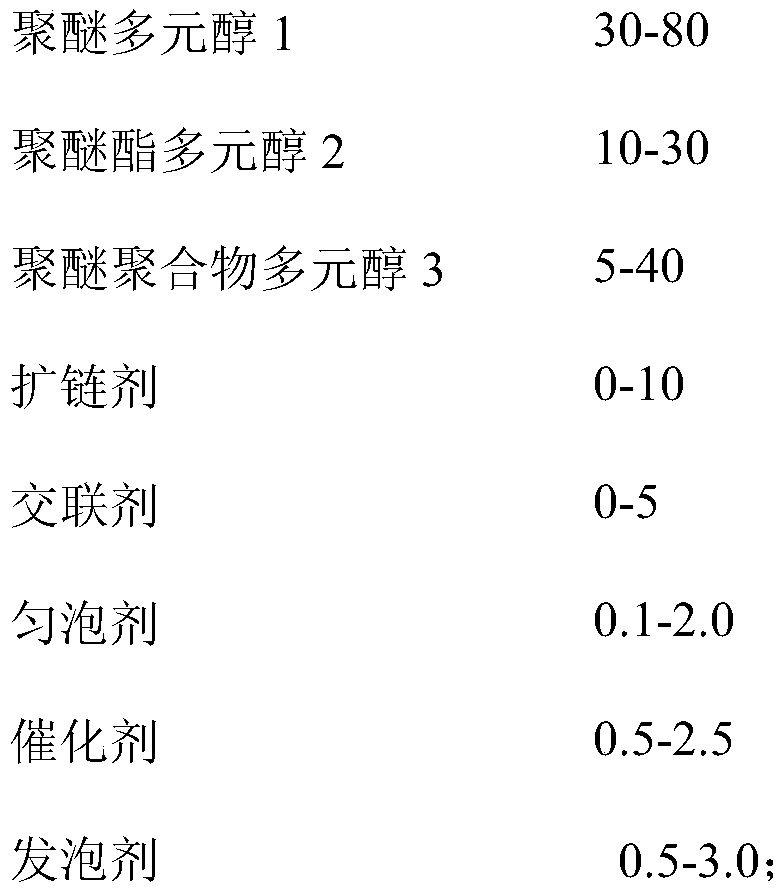

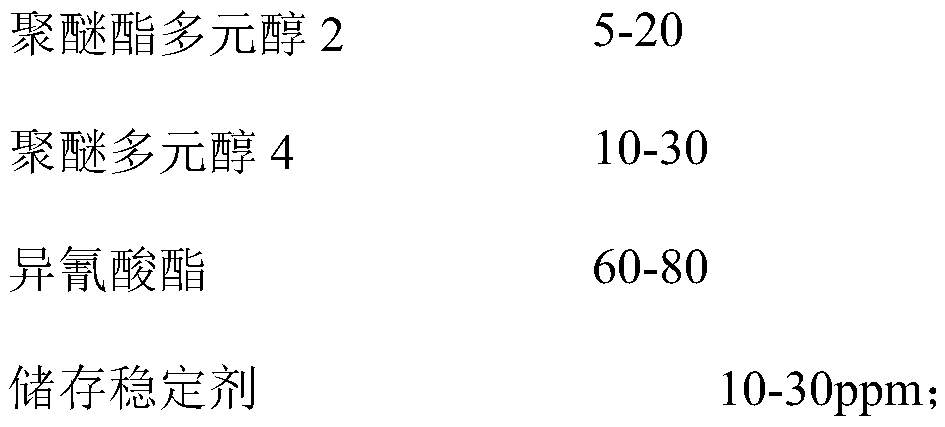

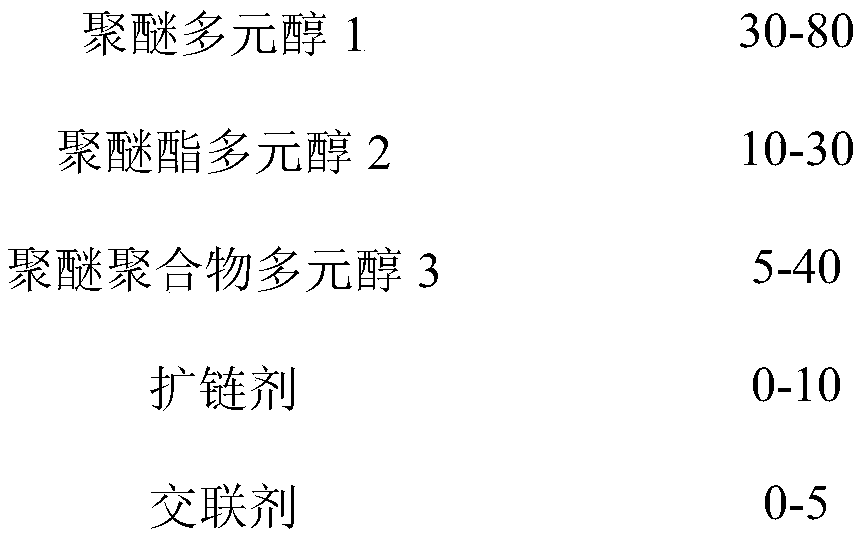

Directly-formed high-air-permeability polyurethane insole composite material and preparation method thereof

PendingCN110964169AImprove porosityImprove breathabilityInsolesTextile/flexible product manufactureIsocyanateCyanate ester

The invention relates to a directly-formed high-air-permeability polyurethane insole composite material and a preparation method thereof, and belongs to the technical field of polyurethane. The directly-formed high-air-permeability polyurethane insole composite material is prepared from a component A and a component B, wherein the component A is prepared from polyether polyol 1, polyether ester polyol 2, polyether polymer polyol 3 and other auxiliary agents, and the component B is prepared from polyether ester polyol 2, polyether polyol 4, isocyanate and 10-30 ppm of a storage stabilizer. According to the directly-molded high-air-permeability polyurethane insole composite material disclosed by the invention, the air permeability of an insole prepared from the directly-molded high-air-permeability polyurethane insole composite material is remarkably enhanced. The invention also provides a simple and feasible preparation method.

Owner:SHANDONG INOV POLYURETHANE

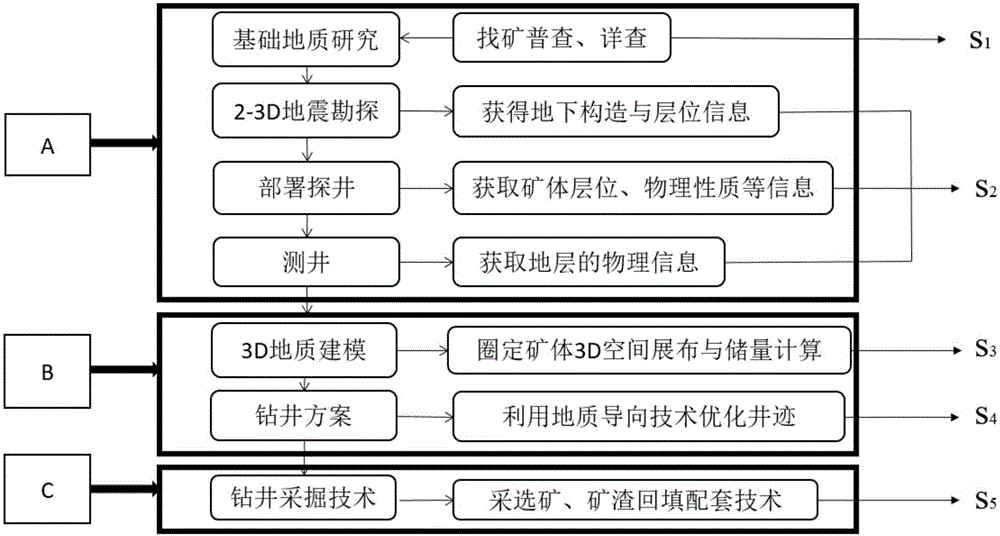

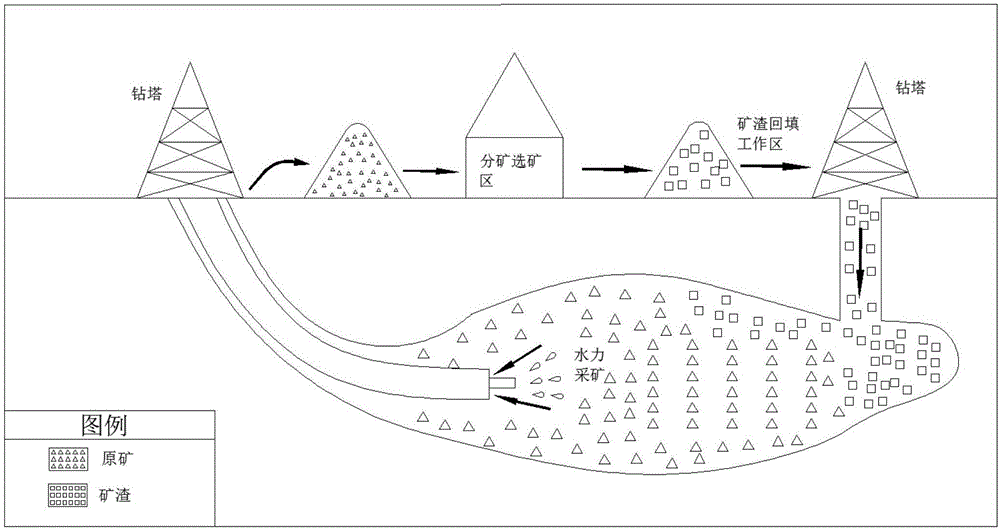

Deep intelligent coal mining method based on GGD (Geology Geophysics Drilling) concept

InactiveCN106640084AIntelligent intelligent constructionEnvironmentally friendly and intelligent constructionDetails involving processing stepsMaterial fill-upWell loggingSlurry

The invention provides a deep intelligent coal mining method based on a GGD (Geology Geophysics Drilling) concept. The deep intelligent coal mining method comprises the following steps: S1, carrying out general investigation and detailed investigation of ore prospecting according to a research theory of fundamental geology; S2, deploying well prospecting and well logging; carrying out 2D to 3D seismic prospecting to obtain physical properties and ore body position information of strata of a prospecting region; S3, carrying out 3D geological modeling, and delineating 3D space spreading of a ore body and calculating reserves; S4, designing a well drilling plan and optimizing a well track by utilizing a geology steering technology; S5, finishing an intelligent flow from mining to backfilling of whole deep ores by utilizing a well drilling and mining technology matched with mining and dressing, ore slurry reverse discharging and ore residue backfilling. According to the deep intelligent coal mining method, the drilling efficiency and quality are improved by utilizing a remote intelligent coal mining technology; meanwhile, safety accidents and environment pollution problems caused by the safety accidents are reduced and the mine exploring cost is saved; efficient, safe and environment-friendly intelligent construction of the deep ores is realized and a direction can be appointed to future development of an ore industry; upgrading of a traditional mine manufacturing industry is promoted.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Reinforced treatment method of spring steel surface blueing coating

ActiveCN105063600AExcellent corrosion and wear resistanceImprove uneven film formationAnodisationMetallic material coating processesSpring steelWear resistance

The invention relates to a reinforced treatment method of a spring steel surface blueing coating, which comprises the following steps: carrying out deoiling treatment on spring steel, washing with hot water, washing with cold water, and blueing to obtain blued spring steel; and carrying out constant-potential polarization treatment on the blued spring steel, washing with hot water, washing with cold water, saponifying, flushing with water, drying, soaking in hot oil, and controlling oil. The electrochemical method is utilized to carrying out anodic polarization on the blueing coating to reinforce the blueing coating and fill up the film formation clearance, so that the blueing coating has higher corrosion resistance and wear resistance.

Owner:BAOSTEEL GRP NANTONG WIRE PROD

Drying furnace for preparing calcium oxide from acetylene sludge

InactiveCN105776297ASimple structureReasonable designDrying solid materials with heatChemical industrySludgeImpurity

The invention discloses a drying furnace for preparing calcium oxide from acetylene sludge.The drying furnace comprises a furnace body, a feeding opening is formed in one side of the top of the furnace body, two material delivering plates are arranged below the feeding opening and arranged in the furnace body in an embedded mode in a V shape, and the ends, located at the side of the feeding opening, of the two material delivering plates are connected with vibration motors outside the furnace body respectively; a discharging opening is formed in the position, at the bottom of the material delivering plate on the lower layer, of the furnace body; a dust-absorbing and impurity-removing device is connected to the side, opposite to the feeding opening, of the top of the furnace body.The drying furnace for preparing calcium oxide from the acetylene sludge is simple in structure and reasonable in design, and through structural design of the material delivering plates, drying efficiency and the loosening characteristic of materials are effectively improved; through design of the dust-absorbing device, dust and harmful substance absorption efficiency is improved, and the absorbing device is prevented from being corroded or blocked; the drying furnace has the advantages that energy conservation, environmental protection and high efficiency are achieved, is a good drier for preparing calcium oxide from the acetylene sludge and is good in application prospect.

Owner:CHANGSHU HONGYU CALCIFICATION CO LTD

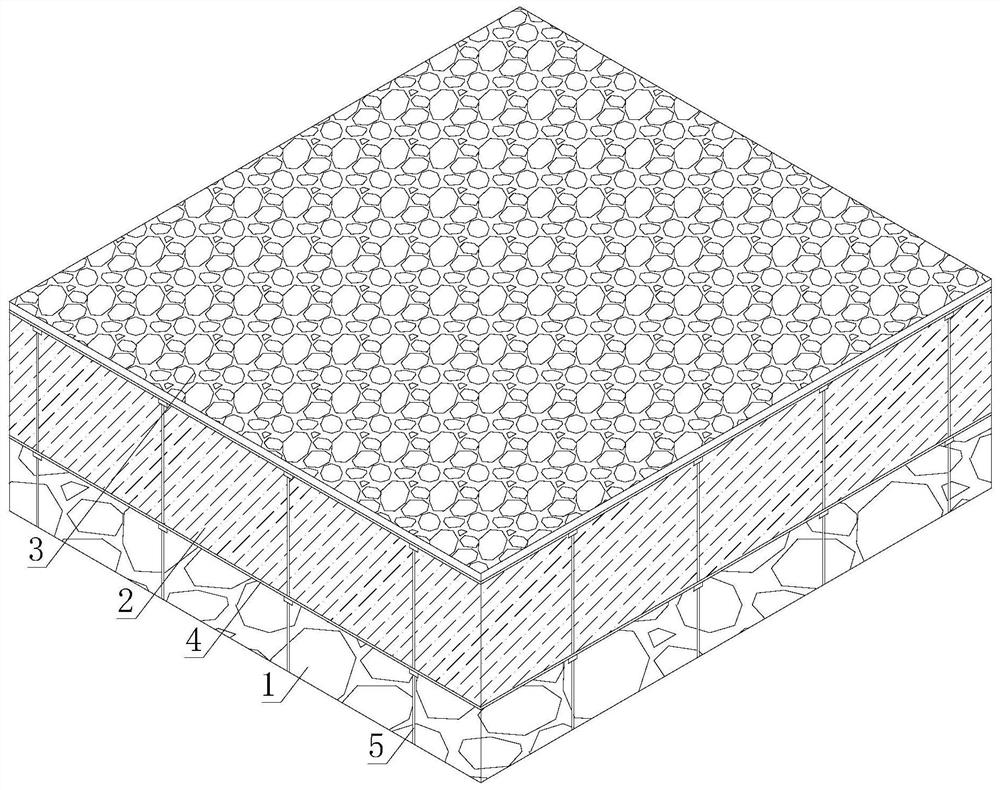

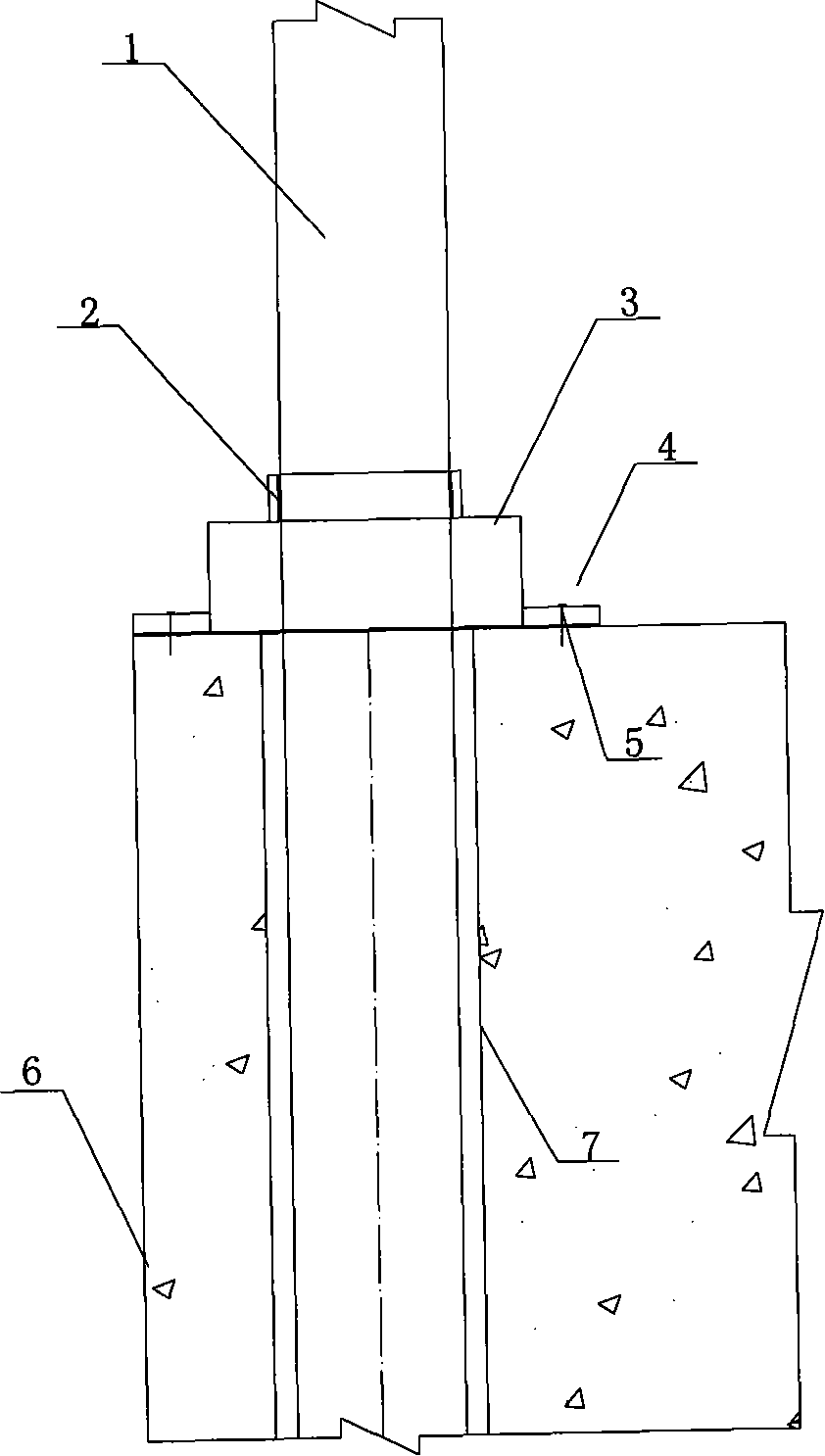

Connection method for wall sections of ultra-deep anti-seepage wall

ActiveCN111042060AImprove porosityCompressed drilling volumeFoundation engineeringMarine site engineeringGeotechnical engineeringStructural engineering

The invention discloses a connection method for the wall sections of an ultra-deep anti-seepage wall. The connection method for the wall sections of the ultra-deep anti-seepage wall comprises the steps of sequentially arranging downwards a plurality of joint pipes onto the end head of a slotted hole, and pulling out the joint pipes in a process of pouring concrete into the slotted hole, wherein the step of sequentially arranging downwards a plurality of joint pipes onto the end head of the slotted hole comprises the following steps: arranging a valve assembly and an adjustment assembly at oneend of a bottom pipe of each of the plurality of joint pipes; arranging downwards each bottom pipe with the valve assembly and the adjustment assembly at the bottom of the slotted hole, configuring one end of each of the valve assembly and the adjustment assembly to face the bottom of the hole, so that in the process of pouring the concrete, the adjustment assembly adjusts the opening degree of the valve assembly of the bottom pipe, and the phenomenon of pipe casting is prevented; and when the joint pipes are pulled out in the process of pouring the concrete, a pulling-out time for the joint pipes is controlled according to the components of the concrete and an environment temperature, so that the concrete cannot be adhered to the outer walls of the joint pipes. According to the method, the concrete cannot be adhered when the joint pipes are pulled out, a high hole-forming rate is achieved, the drilling amounts of the concrete joints are greatly reduced, the comprehensive working efficiency of the anti-seepage wall is increased, and the ultra-deep anti-seepage wall without wall breakage is formed.

Owner:SINOHYDRO FOUND ENG

Organosilicon surfactant and application thereof in preparation of slow-rebound polyurethane foam body

InactiveCN111471180AImprove porosityPrevent shrinkageTransportation and packagingMixingActive agentPropanol

The invention discloses an organosilicon surfactant, which has the following general formula shown in the specification. The invention also provides an application of the organosilicon surfactant in preparation of a slow-rebound polyurethane foam body. The invention also provides a preparation method of the organosilicon surfactant, which comprises subjecting terminated alkynediol polyether, terminated allyl alcohol polyether and low-hydrogen-content polysiloxane to a hydrosilylation reaction under the action of a platinum catalyst to prepare the organosilicon surfactant containing carbon-carbon double bonds. The balance between the opening property and the stability of the polyurethane foam is realized by designing the quantity and the structure of the polyether and the low-hydrogen-content silicone oil.

Owner:SHANGHAI MAIPU NEW MATERIAL TECH CO LTD

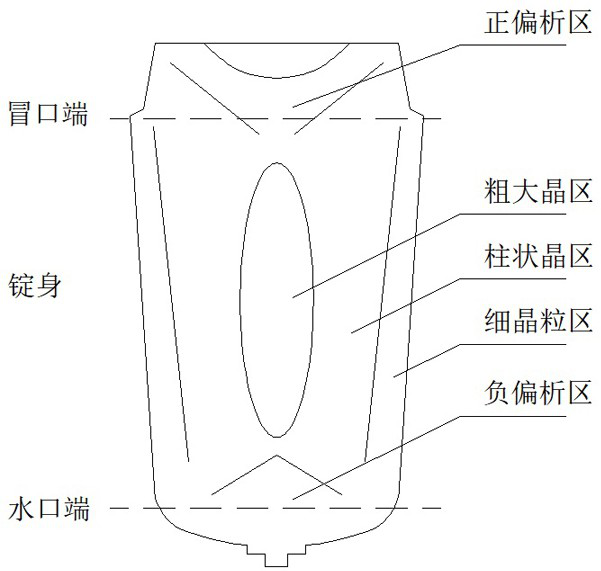

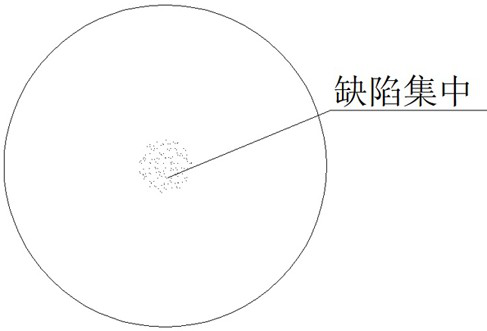

Direction-changing forging process for large cake forgings

PendingCN114147157ALarge amount of deformationReduce the number of defectsMetal-working apparatusIngotForge

The invention relates to a turning forging process for large cake forgings. The turning forging process comprises the steps that firstly, steel ingots are chamfered and drawn out, and risers are chopped; step 2, upsetting the forge piece; thirdly, transverse flattening is conducted; turning forging is conducted on the steel ingot, and transverse flattening is conducted; step 4, squaring and chamfering; transversely flattening, transversely forging to form a square shape, and then chamfering; step 5, rolling and forming; and after transverse forging rounding, rotary upsetting is conducted, and then leveling is conducted to the forge piece forming size. According to the invention, the steel ingot is flattened in a variable direction, and the axis direction of the steel ingot is changed, so that defects in the center of the steel ingot are scattered, inclusion defects are not gathered any more but scattered all around, the number of defects in unit area is greatly reduced, the product quality is improved, and the yield is higher.

Owner:江阴市龙玉锻压有限公司

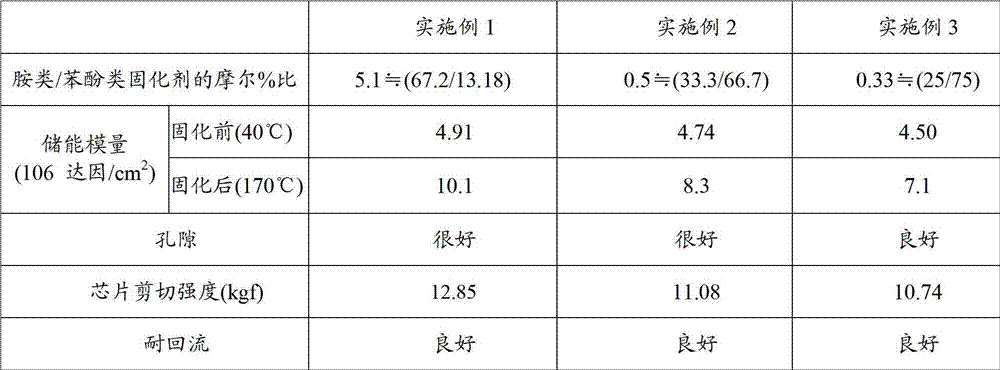

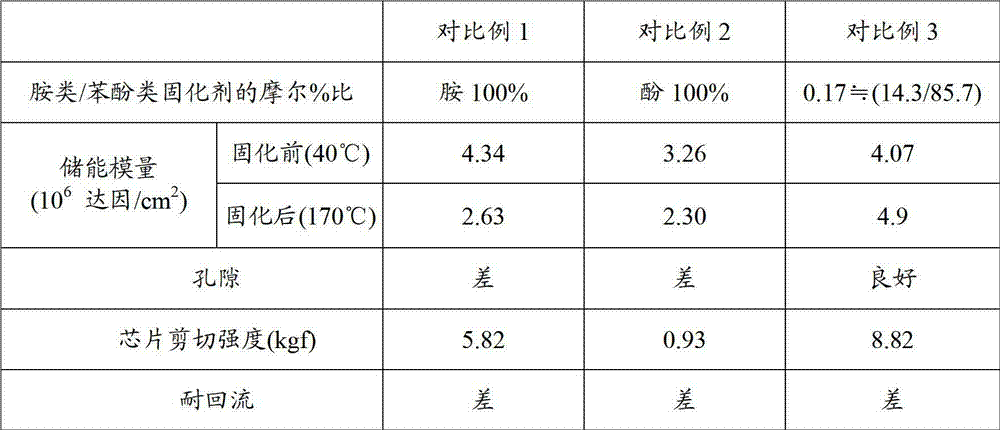

Adhesive film and electronic device including the same

ActiveCN103160220AIncreased shear strengthHigh reflow resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesEpoxyHardness

Embodiments provide an adhesive film that contains both an amine curing agent and phenolic curing agent. In more detail, embodiments may provide an adhesive film for semiconductors that may exhibit excellent properties in terms of void characteristics and reliability using an amine curing agent and a phenolic curing agent in a suitable ratio in manufacture of the adhesive film. More particularly, the adhesive film may exhibit a high variation rate of 1.5 to 3.0 between storage modulus before curing and storage modulus after 80% curing. The adhesive film may have flexibility to suppress void generation upon die attachment. The adhesive film may facilitate removal of voids to control a void area on an attachment interface upon EMC (Epoxy Molding Compound) molding. The adhesive film may have hardness to provide good die-shear strength and reflow resistance after curing, thereby ensuring good void characteristics and high reliability.

Owner:CHEIL IND INC

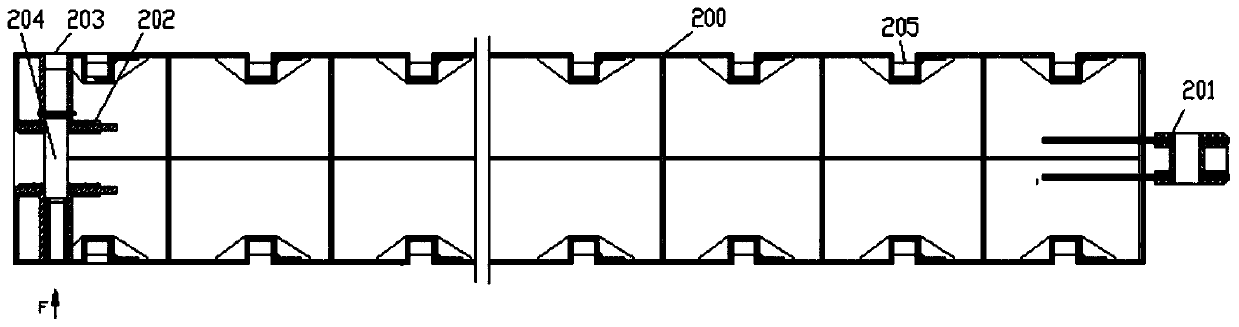

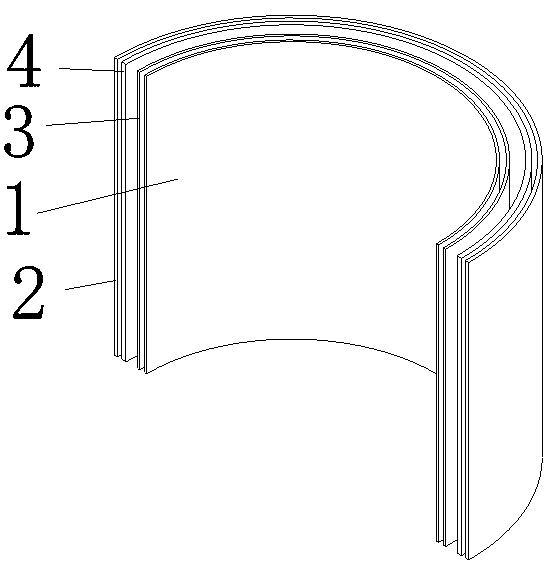

Battery diaphragm having fast charging function

PendingCN110265609AGood heat resistance and puncture strengthImprove porosityCell seperators/membranes/diaphragms/spacersEngineeringElectrolyte

The invention relates to the technical field of a battery diaphragm and discloses a battery diaphragm having a fast charging function. The battery diaphragm comprises an anode, a cathode, a diaphragm a and a diaphragm b. The diaphragm a and the diaphragm b are arranged between the anode and the cathode; the diaphragm a is arranged at the inner side of the diaphragm b; the diaphragm a and the diaphragm b are same in manufacturing process and material; and the diaphragm b is provided with holes. According to the battery diaphragm having the fast charging function, the diaphragm b is provided with horizontal grooves, vertical grooves and the holes; the horizontal grooves and the vertical grooves allow electrolyte between the anode and the cathode to flow better but not be slowed down by the diaphragm a and the diaphragm b, so that influence of normal use of the battery due to too low power can be prevented; the holes can make the flow surface of the electrolyte wider, and the electrolyte can permeate from all aspects to the diaphragm a through the holes, thereby increasing fluidity of the electrolyte between the diaphragm a and the diaphragm b as well as between the anode and the cathode and ensuring normal use of the battery.

Owner:河南曼博睿新材料科技有限公司

Water-lily-powder composition with function of compensating estrogen

InactiveCN1850168AInhibit peroxidation reactionPrevent agingOrganic active ingredientsSkeletal disorderWater lilyIsoflavones

The present invention relates to a natural nutrient preparation, in particular, it relates to a lotus flower pollen composition with the action of supplementing female hormone, its preparation method and application. Said described lotus flower pollen composition contains lotus flower pollen, soybean isoflavone and edible acceptable carrier. It can be used for improving and relieving female climacteric state, delaying climacterium and improving osteoporosis.

Owner:XINSHIJI HAILUN MEDICINE SCI TECH BEIJING

Processing device of dried bean curds

InactiveCN106819138AImprove porosityImprove tasteCheese manufactureFood scienceKnife bladesEngineering

The invention discloses a processing device of dried bean curds. The processing device comprises a rack, a conveying mechanism and a pushing mechanism, wherein the conveying mechanism and the pushing mechanism are arranged on the rack; the conveying mechanism comprises a crane and a processing box connected with the crane; the processing box comprises a box body, a separation plate and a blade; the box body is divided into a first chamber and a second chamber through a separation plate; a plurality of through holes are formed in side walls, relative to the separation plate, of the separation plate and the second chamber; the blade is in sliding connection with the second chamber; the pushing mechanism comprises an air pump, a flow splitting processing platform and a vibrator; the air pump is connected with a spiral rail filled with pork skins; the flow splitting processing platform is connected with one end, far away from the air pump, of a conveying rail; the flow splitting processing platform comprises a U-shaped processing plate and a plurality of flow splitting cutters; the processing plate is provided with a plurality of conveying channels separated by the plurality of flow splitting cutters; the conveying channels are communicated with the through holes; the vibrator is fixedly connected with the processing plate. By adopting the processing device of the dried bean curds, the problem that inner parts of the dried bean curds are tight so that the rigidity is relatively great when the dried bean curds are eaten in the future is mainly solved.

Owner:重庆渝金源食品有限公司

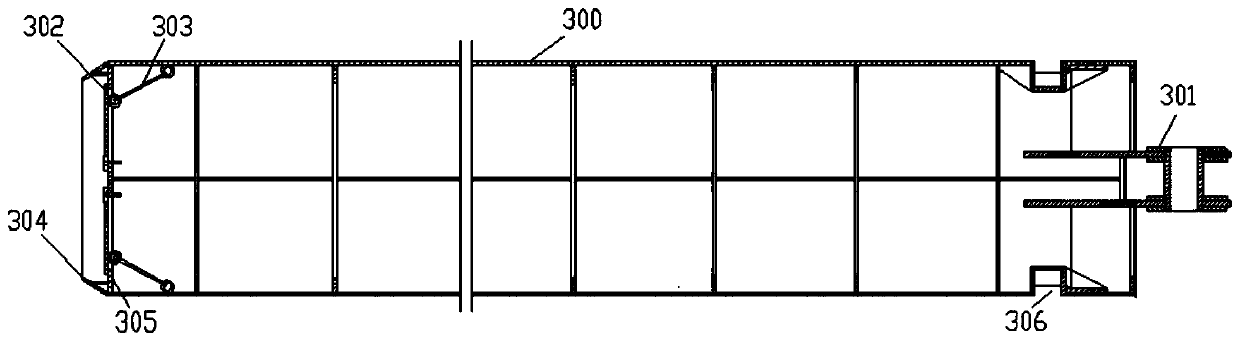

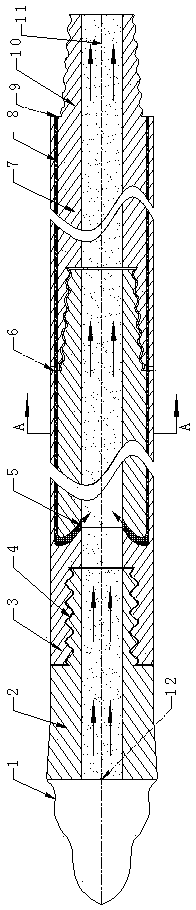

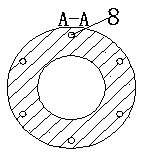

Drill stem with internal powder discharging function

The invention discloses a drill stem with an internal powder discharging function. The drill stem comprises a front segment, a rear segment and a drill bit, wherein the drill stem is hollow, a tapered internal thread is arranged at the head part of the front segment of the drill stem, a tapered external thread is arranged at the tail part of the front segment of the drill stem, nozzles are uniformly arranged in a center hole of the front segment of the drill stem, and the nozzles are inclined and are mounted corresponding to water holes formed in the drill stem; the rear segment of the drill stem comprise a plurality of short rods adopting the same structure, a tapered internal thread is arranged at the head part of each short rod, a tapered external thread is arranged at the tail part of each short rod, the short rods are connected with one another through the tapered threads, a sealing ring is arranged at the joint of every two adjacent short rods, and water holes are formed in the short rods, and communicate with those in the front segment of the drill stem; and the front segment of the drill stem is connected with the drill bit, the drill bit is shaped like a stepped taper, the water holes are just aligned after the front segment of the drill stem is fastened with the short rods of the rear segment of the drill stem, and high-pressure water is introduced into the end parts of the water holes of the rear segment of the drill stem. Through adoption of the drill stem with the internal powder discharging function, provided by the invention, the hole-forming rate can be improved, the hole-forming shape can be kept, and the incidence of such accidents as hole collapse and drill wedging can be reduced in a drilling process.

Owner:TAIYUAN UNIV OF TECH

Preparation method for polyurethane netted material special for foamed ceramics

The invention discloses a preparation method for a polyurethane netted material special for foamed ceramics, relating to the technical field of the polyurethane netted material. The method comprises the following steps: adding polyether polyol, an amines catalyst, a surfactant, a foaming agent and a pore-forming agent into a container, uniformly mixing and stirring, thereby acquiring a mixed solution; vacuumizing for two times in a vacuum drying oven; adding a tins catalyst, uniformly stirring, adding TDI 80 / 20 and uniformly stirring, thereby acquiring a mixture; quickly pouring the mixture into a mold, placing into a stove, foaming and keeping temperature, thereby acquiring soft pored polyurethane foams; placing the polyurethane foams into a netting solution, extruding the foams and exhausting; cleaning the polyurethane foams and then drying, thereby acquiring the netted polyurethane foams. The polyurethane netted material prepared according to the invention is uniformly pored; the aperture ratio can reach up to 98%; the foam pore net is smooth; the preparation method adopts a simple process, and is easy to operate and suitable for industrial application.

Owner:江西鸿司远特种泡沫材料有限公司

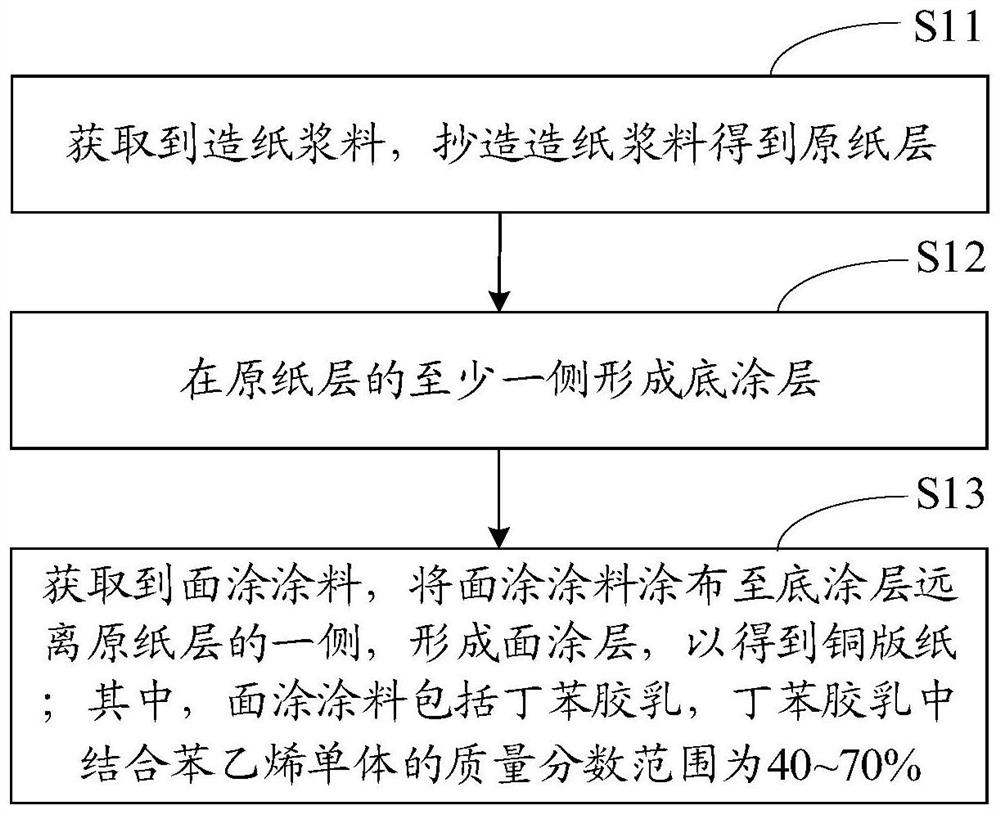

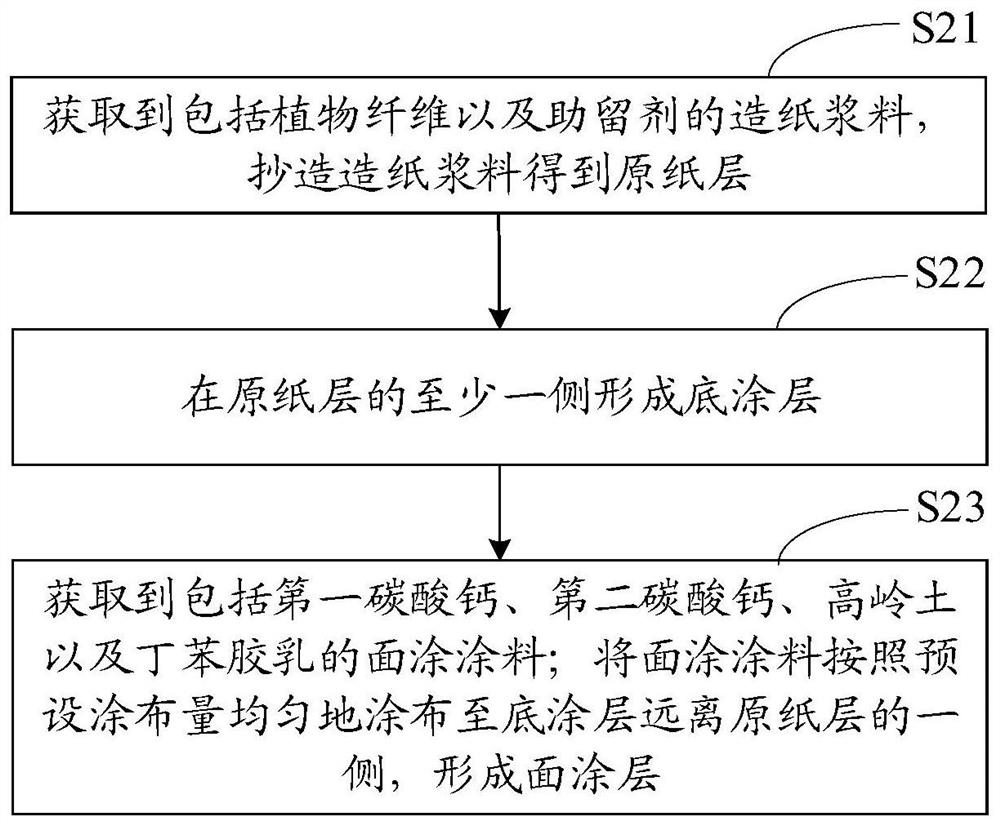

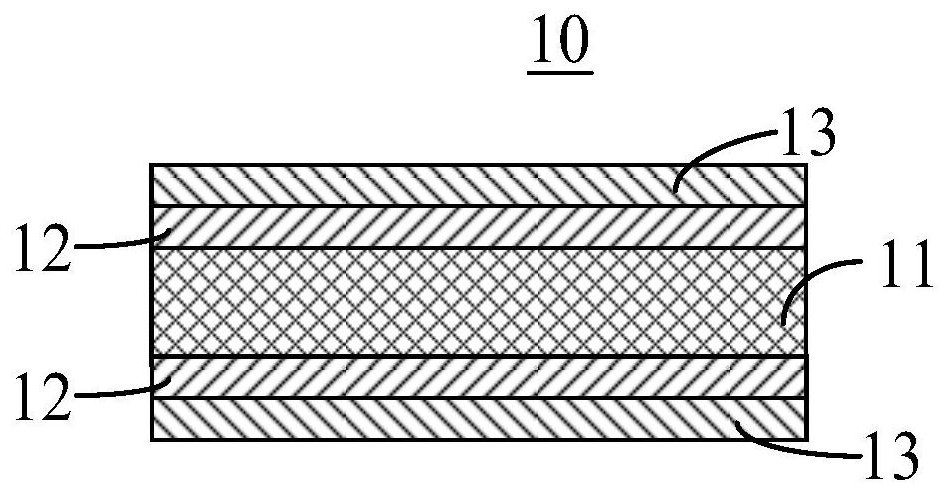

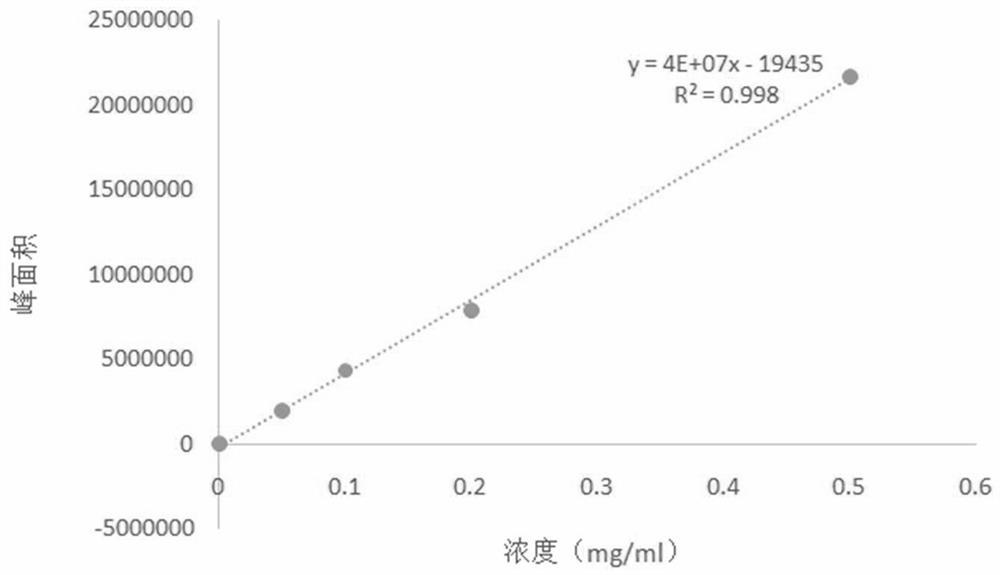

Coated paper and preparation method thereof

ActiveCN113279286AImprove porosityImprove ink absorptionSpecial paperPaper coatingPulp (paper)Paper sheet

The invention discloses coated paper and a preparation method thereof. The preparation method of the coated paper comprises the following steps of obtaining papermaking pulp, and making the papermaking pulp to obtain a raw paper layer, forming a bottom coating on at least one side of the raw paper layer, obtaining a top coating, and coating the top coating to one side, far away from the raw paper layer, of the bottom coating to form a top coating, so as to obtain the coated paper, wherein the top coating comprises styrene-butadiene latex, and the mass fraction range of a styrene monomer combined in the styrene-butadiene latex is 40-70%. According to the method, the printing ink absorbency and the printing ink drying capacity of the paper can be improved, and then the lithographic printing speed is increased.

Owner:GOLD EAST PAPER JIANGSU

Resource utilization method of ageratina adenophora

PendingCN114521612AImprove bioavailabilityImprove porosityClimate change adaptationAnimal feeding stuffCarbonyl groupBiology

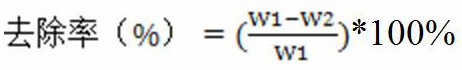

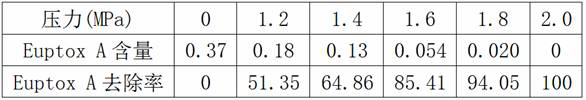

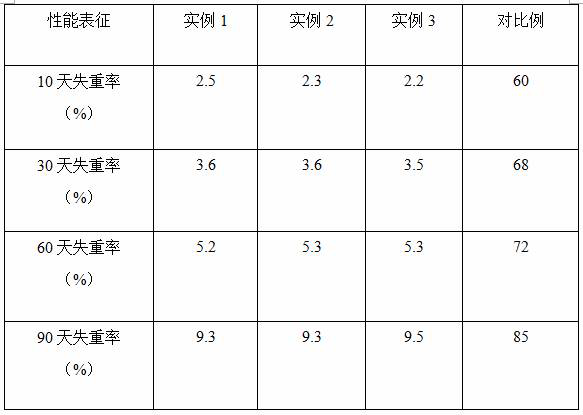

The invention discloses a resource utilization method of ageratina adenophora, which comprises the following steps: drying and crushing fresh plants of the overground part of harvested ageratina adenophora, passing through a 1cm analysis sieve, filling the crushed ageratina adenophora stems and leaves into a steam explosion device, carrying out steam explosion treatment under the steam explosion condition that the pressure is 1.2-2.0 MPa, the pressure is maintained for 20-200 seconds, and then instantaneous explosion is carried out; after the eupatorium adenophorum is subjected to steam explosion treatment, the removal rate of the toxic component (9-carbonyl-10.11-dehydro-eupatolone) Euptox A of the eupatorium adenophorum can reach 95-100% according to the steam explosion pressure and the pressure maintaining time. According to the method, the eupatorium adenophorum is utilized in a resource mode, the damage degree of the eupatorium adenophorum to the ecological environment can be reduced to a certain degree, the eupatorium adenophorum can be turned into treasure, great economic benefits and ecological benefits are achieved, and a new effective way is provided for resource utilization of the eupatorium adenophorum. The method is short in detoxification time, high in efficacy, low in energy consumption and easy for industrial production.

Owner:SOUTHWEST FORESTRY UNIVERSITY

Preparation method of a controllable edible fungus stick water-retaining agent material

ActiveCN110122184BGood water absorption, water retention and salt resistanceReduced structural compactnessCultivating equipmentsMushroom cultivationEnzymatic hydrolysisMicrobiology

The invention relates to a preparation method of a controllable edible fungus stick water-retaining agent material, which belongs to the technical field of edible fungi. The technical solution of the present invention uses bentonite to compound acrylic acid and acrylamide substances, and the two are combined together through polymerization to cause physical crosslinking. The product has good water absorption, water retention and salt resistance. Filled with protease material, in the initial stage of water-retaining agent use, a large amount of silk fibroin inside the water-retaining agent is decomposed and the macromolecular chain is enzymatically hydrolyzed into a small molecule polypeptide structure, which effectively reduces the compactness of the material structure, greatly reduces the water retention performance, and accelerates water loss. In the late stage of enzymatic hydrolysis, the small molecule peptides in the water-retaining agent material are absorbed by the fungus sticks. After being used as nutrients, the water-retaining performance is greatly reduced, and the water retention is low, preventing excessive water in the later use of the fungus sticks, and effectively controlling the water in the growth process of edible fungi. Slowly decrease, thus effectively improving the water retention and controllable performance of the water retaining agent material.

Owner:桂林灌阳桂灌菌业科技开发有限公司

Porous titanium-based photocatalytic material and preparing method thereof

InactiveCN106582594AImprove porosityLarge specific surface areaGas treatmentPhysical/chemical process catalystsPhotocatalytic degradationVolatile organic compound

The invention relates to a porous titanium-based photocatalytic material and a preparing method thereof. The preparing method of the porous material includes the following steps that beta-cyclodextrin (beta-CD) is used as a raw material, and beta-CD microspheres uniform in size are synthesized through an inverse emulsion polymerization; with the beta-CD microspheres as the template, a gel-shaped titanium-based catalytic material precursor is prepared through a sol-gel method, and the porous material is prepared through aftertreatment technologies such as drying, calcining and grinding. The porous titanium-based photocatalytic material prepared through the method is loose in structure and has a great number of pores. The method is simple in process and easy to operate, the preparing process is clean, and the obtained photocatalytic material represents good photocatalytic degradation capacity to printing and dyeing wastewater and volatile organic compounds and has broad application prospects.

Owner:QIQIHAR UNIVERSITY

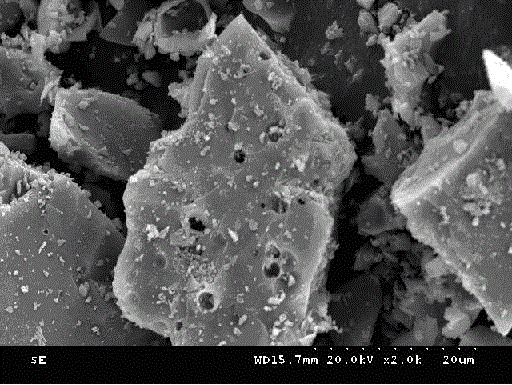

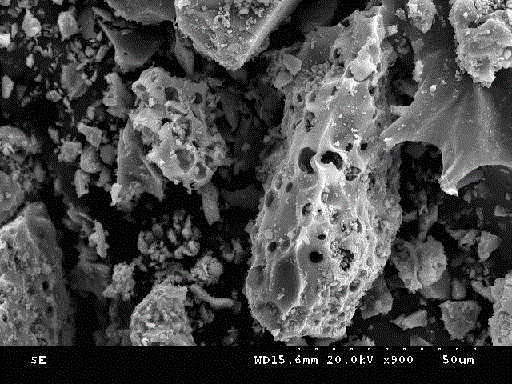

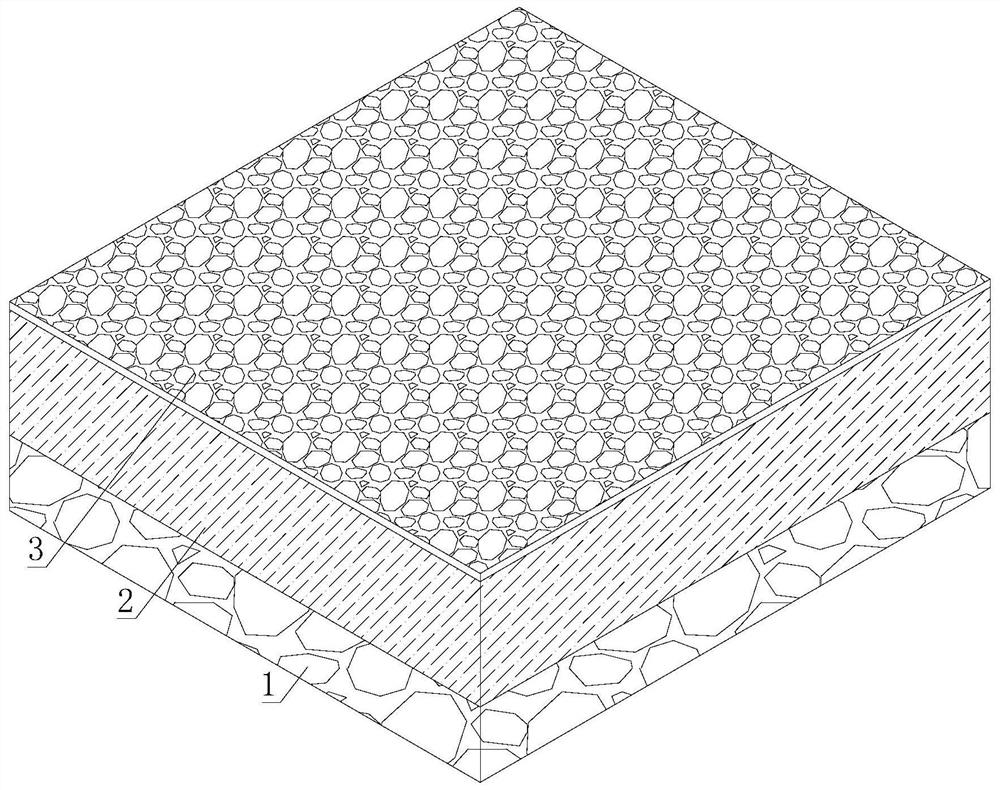

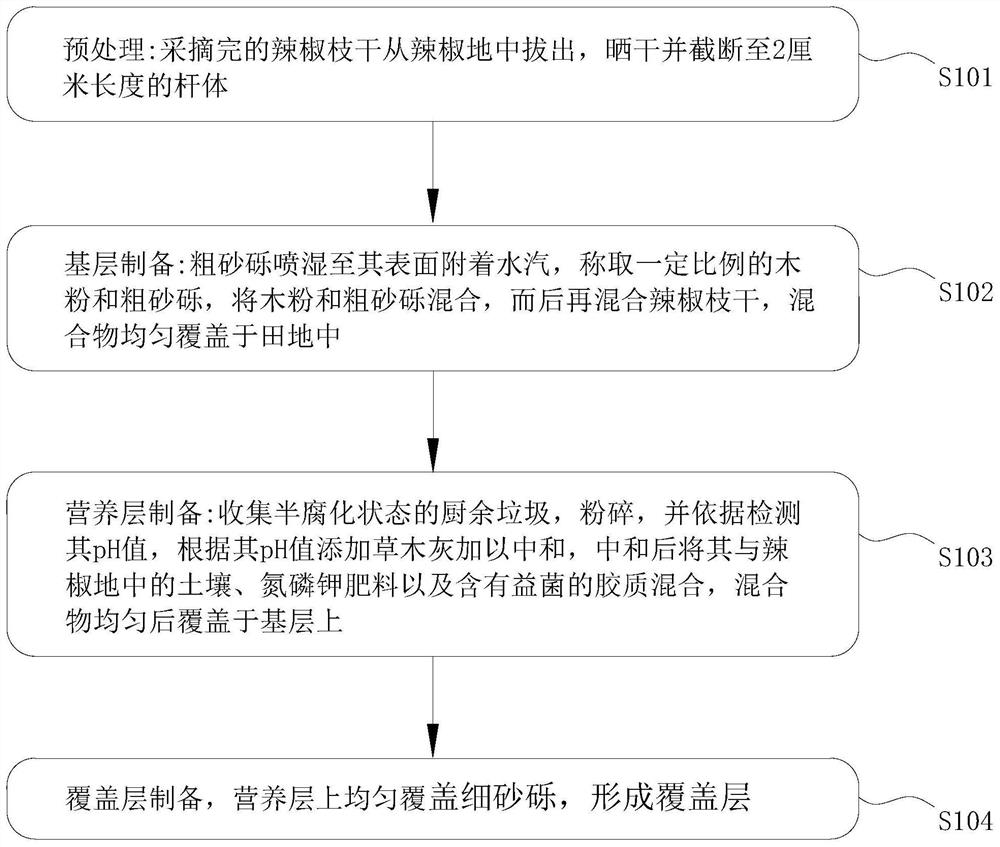

Air-permeable and heat-insulating pepper seedling substrate and preparation method thereof

InactiveCN113519373AGuaranteed breathabilityGood moisturizing effectGrowth substratesCulture mediaSeedlingWood flour

The invention discloses an air-permeable and heat-insulating pepper seedling substrate and a preparation method thereof, and belongs to the technical field of pepper seedling substrates. The air-permeable and heat-insulating pepper seedling substrate comprises a base layer, a nutrition layer and a covering layer, the base layer is located below the nutrition layer, and the covering layer is located above the nutrition layer. The base layer is prepared from the following components in percentage by mass: 12%-45% of pepper branches and trunks, 50%-80% of filler and 5%-8% of wood flour. The base layer and the covering layer with large material particles are arranged as an upper layer and a lower layer of the nutrition layer, and air permeability of pepper seedlings buried in the nutrition layer is ensured; and the wood flour adhered to the surfaces of the coarse sand grains is arranged to improve the moisture retention and heat preservation of the base layer, and under the conditions of water shortage and cold, the tentacles at the roots of the pepper seedlings are stimulated to grow downwards, so that the survival rate of the pepper seedlings is increased.

Owner:安徽皖东农业科技有限公司

Construction method for accurate locating small distance air face hole-drilling

InactiveCN101250981AImprove porosityImprove hole position accuracyDerricks/mastsDirectional drillingMiddle lineSteel plates

The invention discloses a construction method of precisely positioning minor distance free face drilling, comprising the following steps of: selecting steel plate or profiled bar as the materials for making die according to the dimension of the aperture of a drill hole, drilling holes on the steel plate or profiled bar according to the aperture; pulling out and marking the center lines of each hole with a measuring apparatus according to requirements of design drawing; precisely positioning a hole die according to the position of the pulled center line of each hole on site so as to ensure the centerline of the positioned hole on the die to be aligned with the centerline of the hole on site, then fixing the holes with steel support feet welded on the hole die and using expansion bolts to fix the holes on a base plane so as to secure the die; mounting a core drill, placing a bit at a corresponding center of hole and drilling, a set of fixture is arranged on the drill pipe to avoid drill pipe swaying during drilling and pressing lightly and rotating slowly when drilling so as to reduce the vibration of the drill. The construction method solves the problem of low drilling rate of holes on free face with minor distance and poor precision of holes drilled and is an economical and practical drilling construction method.

Owner:CHINA GEZHOUBA GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com