Drying furnace for preparing calcium oxide from acetylene sludge

A technology of calcium oxide and drying furnace, which is applied in the direction of drying solid materials, heating to dry solid materials, calcium/strontium/barium oxide/hydroxide, etc., which can solve the problems of high dust concentration in exhaust gas, sticking of dust collection equipment, Carbide slag stacking and other problems, to improve absorption efficiency, avoid corrosion, and improve drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to make a clearer and clearer definition of the protection scope of the present invention.

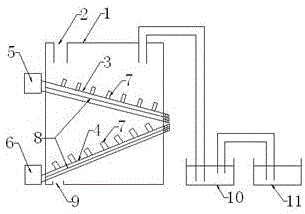

[0014] See figure 1 , The embodiment of the present invention includes:

[0015] A drying furnace for preparing calcium oxide from calcium carbide slag, comprising a furnace body 1, one side of the top of the furnace body 1 is provided with a feed port 2, and the lower part of the feed port 2 is provided with two sections for receiving and receiving calcium oxide slag. The feed plates 3 and 4, and the two sections of feed plates 3 and 4 are embedded in the furnace body 1 in a V shape. The tilt angle of the feed plate 3 from the furnace wall on the side of the feed inlet to the furnace wall on the opposite side is 30°. The inclinati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com