Drill stem with internal powder discharging function

A drill rod and short rod technology, applied in drill rods, drill bits, drill pipes, etc., can solve the problems of difficult drilling, rock powder retention in holes, blocked rock cutting forms and powder discharge forms, etc. Work efficiency, reduce labor intensity, and improve the effect of porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

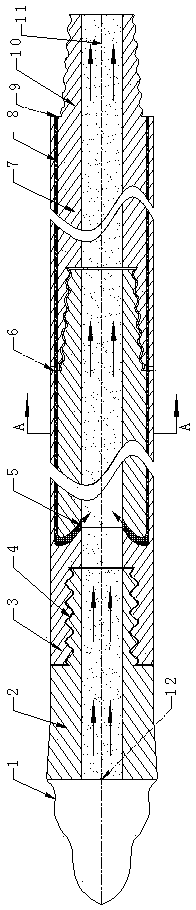

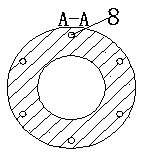

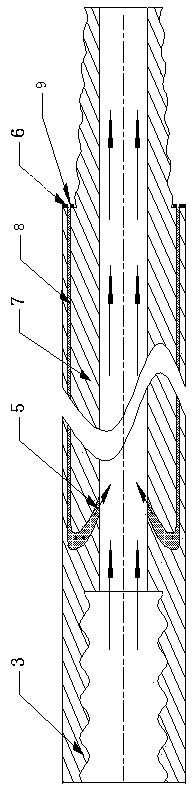

[0026] like Figure 1~Figure 5 Shown, a kind of internal powder-discharging type drill pipe, comprises front section and rear section and drill bit, and the middle part of drill pipe is hollow, and the head of front section drill pipe 3 is provided with tapered internal thread 4, and tail is provided with tapered external thread, in The inside of the center hole of the drill pipe in the front section is evenly provided with nozzles 5, which are arranged obliquely, and the nozzles 5 are installed correspondingly to the water holes 8 inside the drill pipe, and the center of the water holes 8 is arranged parallel to the center line of the drill pipe; the rear section The drill pipe includes several short rods 7 with the same structure. The head of the short rods 7 is provided with a tapered internal thread, and the tail is provided with a tapered external thread 10. The short rods are connected by a tapered thread, and the connection between adjacent short rods A sealing ring 6 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com