Preparation method of a controllable edible fungus stick water-retaining agent material

A technology of water-retaining agent and edible fungus, which is applied in botany equipment and methods, applications, gardening, etc. It can solve the problems of sudden changes in water-retaining performance and unstable water-retaining performance of water-retaining agents, so as to reduce compactness and improve controllable water-retaining performance , the effect of abundant natural reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

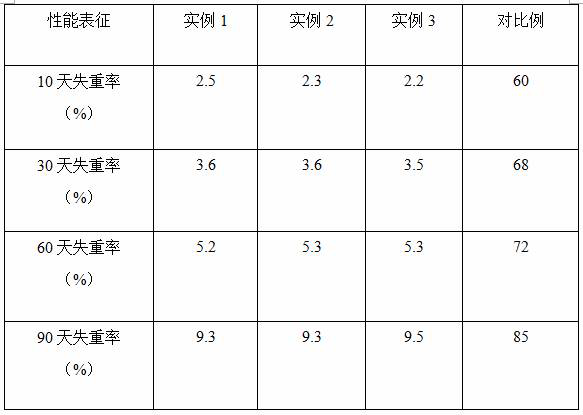

Examples

example 1

[0030] In terms of parts by weight, weigh 45 parts of deionized water, 3 parts of montmorillonite, 10 parts of polysiloxane and 1 part of silane coupling agent in a three-necked flask, stir and mix them, and place them at 75°C for heat preservation and reaction 2h, get the reaction dispersion liquid, and weigh 45 parts of deionized water, 10 parts of reaction dispersion liquid, 10 parts of carboxymethyl cellulose, and 3 parts of humic acid respectively in Erlenmeyer flask according to parts by weight, stir and mix And use 0.5mol / L sodium hydroxide solution to adjust the pH to 8.5, stir and mix, place it under 200W for ultrasonic dispersion for 105min, and collect the matrix dispersion liquid; in parts by weight, weigh 45 parts of deionized water and 10 parts of matrix dispersion solution, 10 parts of acrylic acid, 8 parts of 1% sodium hydroxide solution by mass fraction, 3 parts of acrylamide, 6 parts of N, N-dimethylformamide, 1 part of ammonium persulfate and 6 parts of bento...

example 2

[0032] In terms of parts by weight, weigh 48 parts of deionized water, 4 parts of montmorillonite, 13 parts of polysiloxane and 1.5 parts of silane coupling agent and place them in a three-necked flask, stir and mix them and place them at 80°C for heat preservation and reaction 2.5h, get the reaction dispersion liquid, then weigh 48 parts of deionized water, 13 parts of reaction dispersion liquid, 13 parts of carboxymethyl cellulose, and 4 parts of humic acid respectively in Erlenmeyer flask by parts by weight, stir Mix and adjust the pH to 8.5 with 0.5mol / L sodium hydroxide solution, stir and mix and place it under 250W for ultrasonic dispersion for 13min, and collect the matrix dispersion liquid; weigh 47 parts of deionized water and 13 parts of matrix respectively in parts by weight Dispersion, 13 parts of acrylic acid, 9 parts of 1% sodium hydroxide solution by mass fraction, 4 parts of acrylamide, 7 parts of N, N-dimethylformamide, 1.5 parts of ammonium persulfate and 7 pa...

example 3

[0034] In terms of parts by weight, weigh 50 parts of deionized water, 5 parts of montmorillonite, 15 parts of polysiloxane and 2 parts of silane coupling agent and place them in a three-necked flask, stir and mix them and place them at 85°C for heat preservation and reaction 3h, get the reaction dispersion liquid, then weigh 50 parts of deionized water, 15 parts of reaction dispersion liquid, 115 parts of carboxymethyl cellulose, and 5 parts of humic acid respectively in Erlenmeyer flask by parts by weight, stir and mix And use 0.5mol / L sodium hydroxide solution to adjust the pH to 8.5, stir and mix, place it under 300W for ultrasonic dispersion for 15min, and collect the matrix dispersion liquid; in parts by weight, weigh 50 parts of deionized water and 15 parts of matrix dispersion Liquid, 15 parts of acrylic acid, 10 parts of 1% sodium hydroxide solution by mass fraction, 5 parts of acrylamide, 8 parts of N, N-dimethylformamide, 2 parts of ammonium persulfate and 8 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com