Patents

Literature

43results about How to "Yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

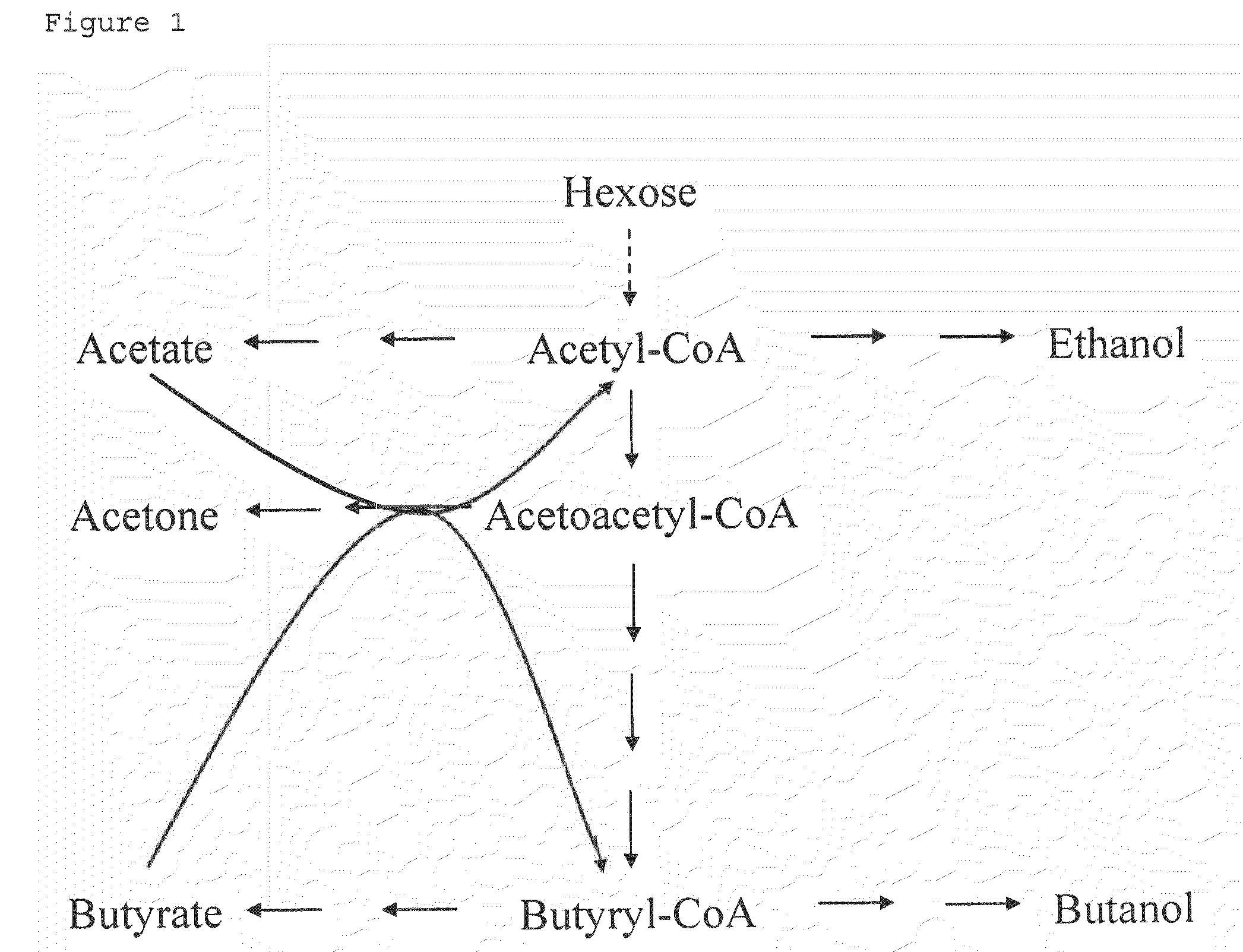

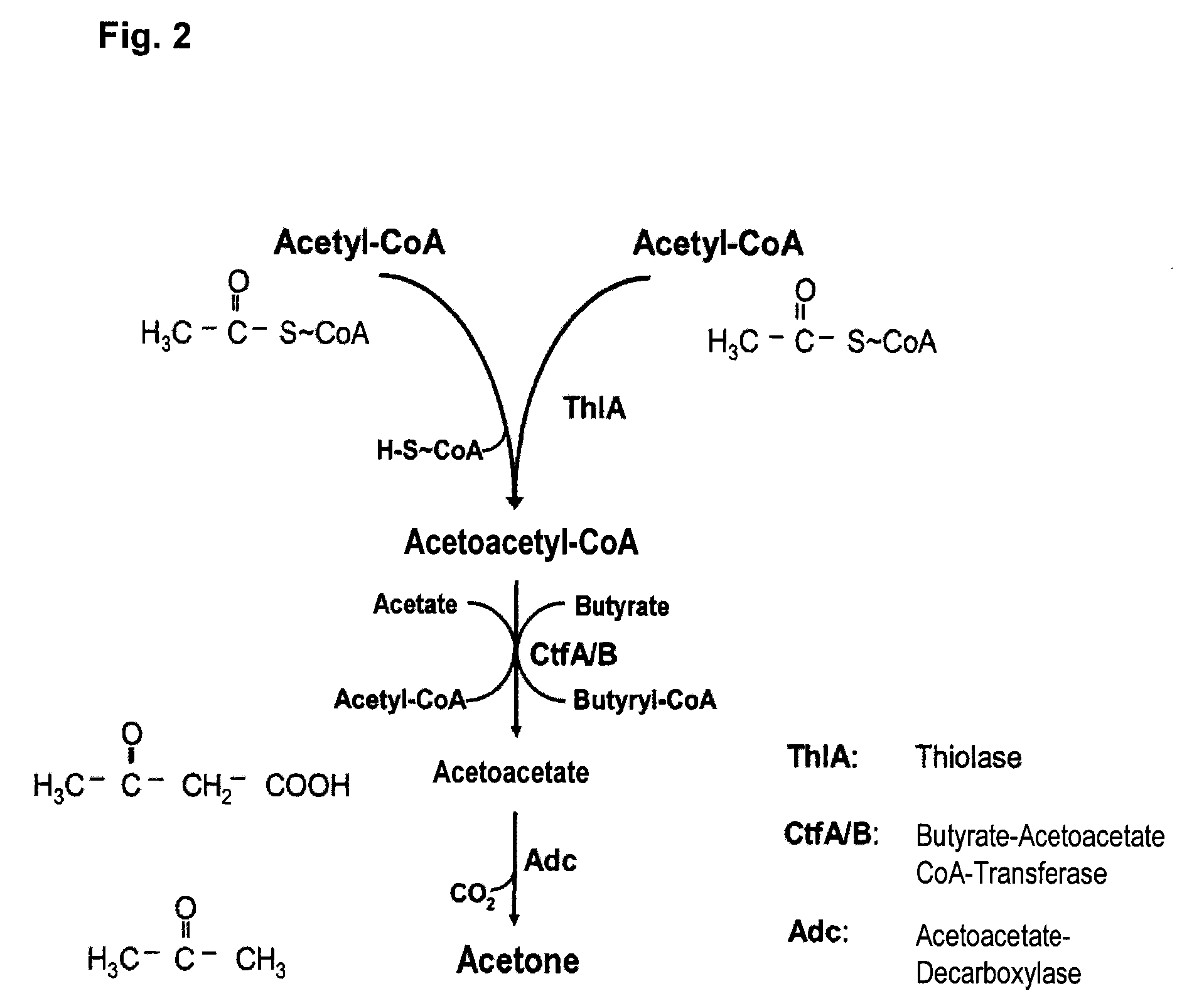

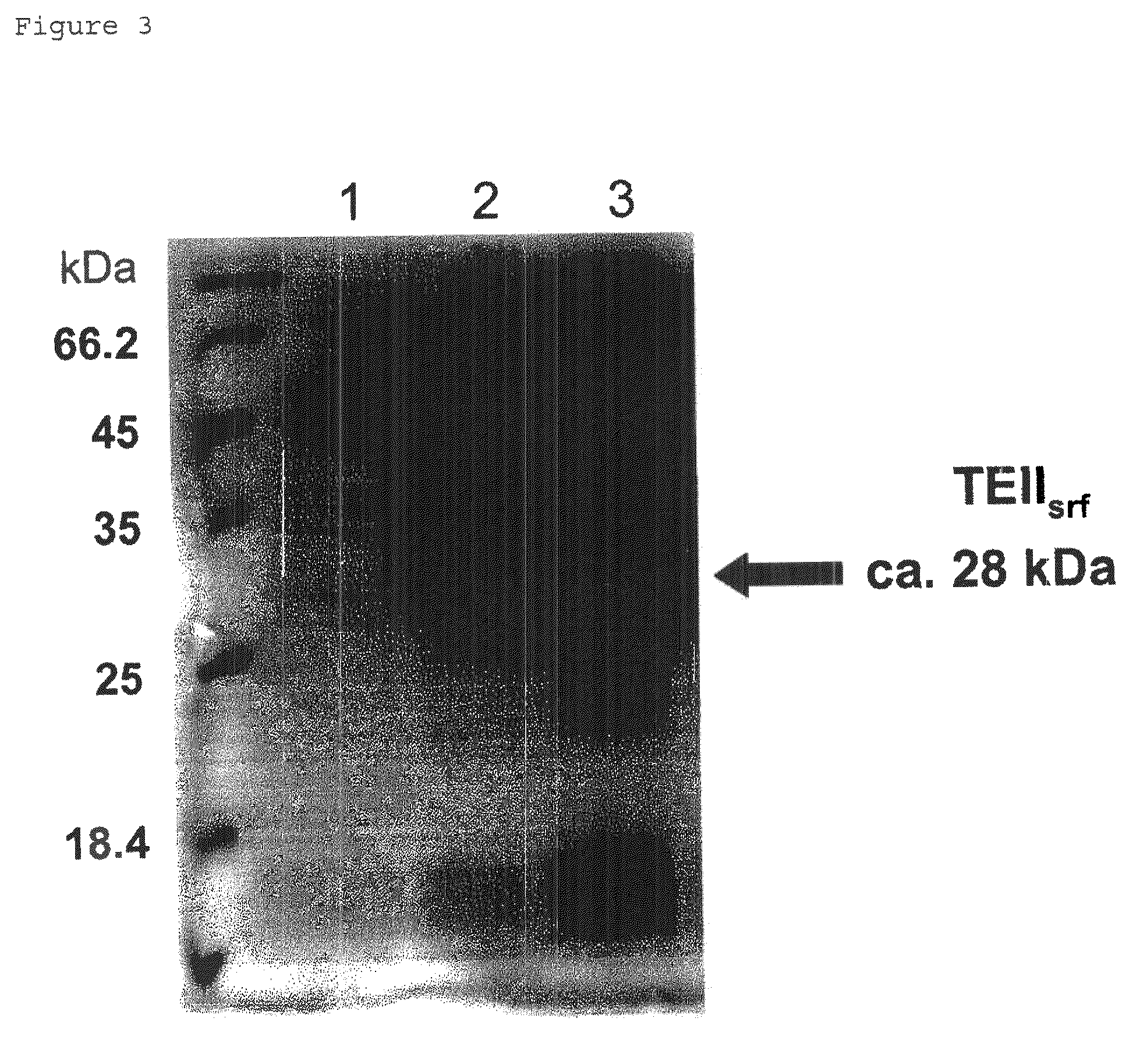

Fermentative production of acetone from renewable resources by means of novel metabolic pathway

ActiveUS20100261237A1YieldHigh yieldSugar derivativesHydrolasesAcyl Coenzyme A SynthetasesAcyl-CoA synthetase

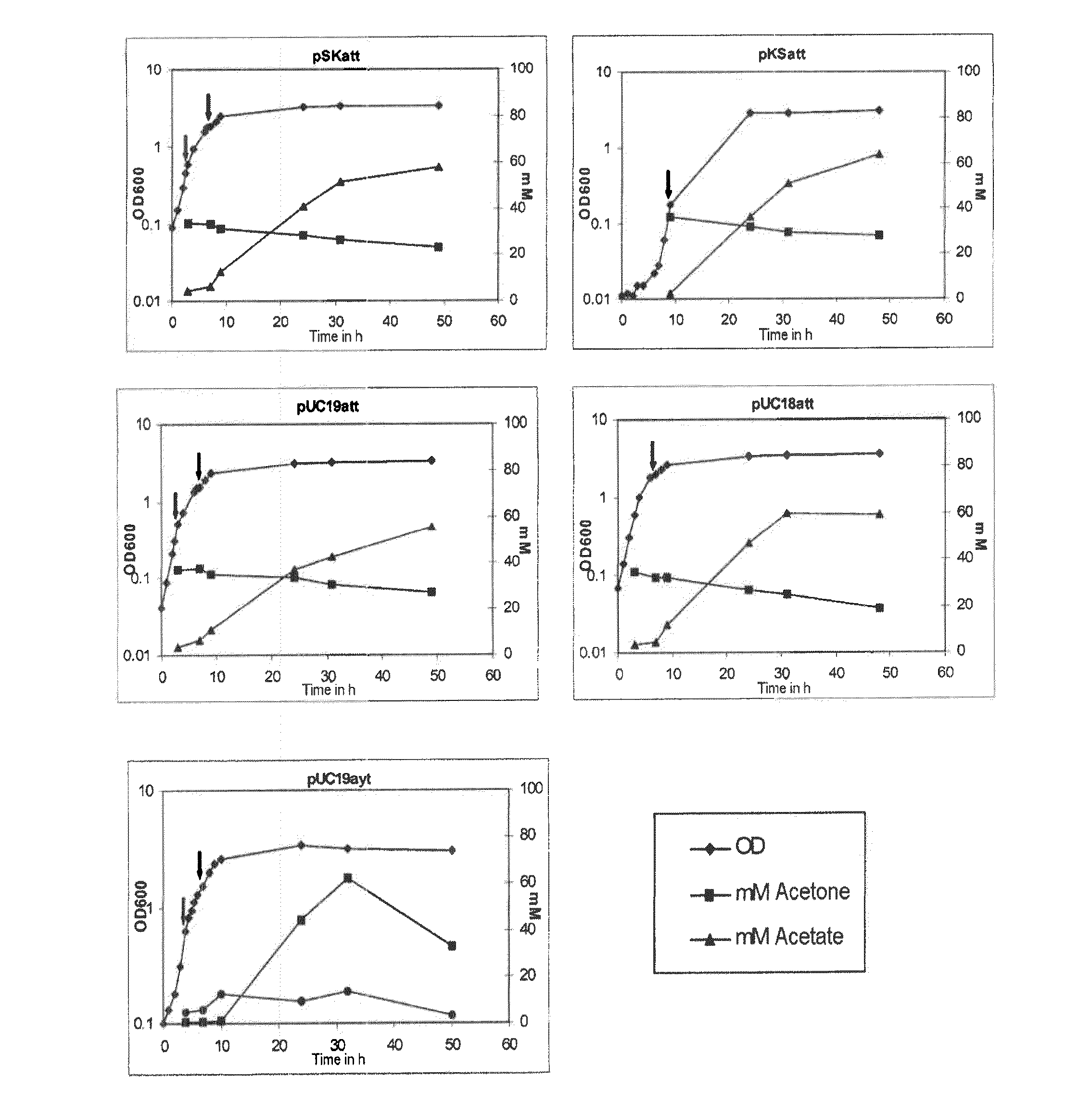

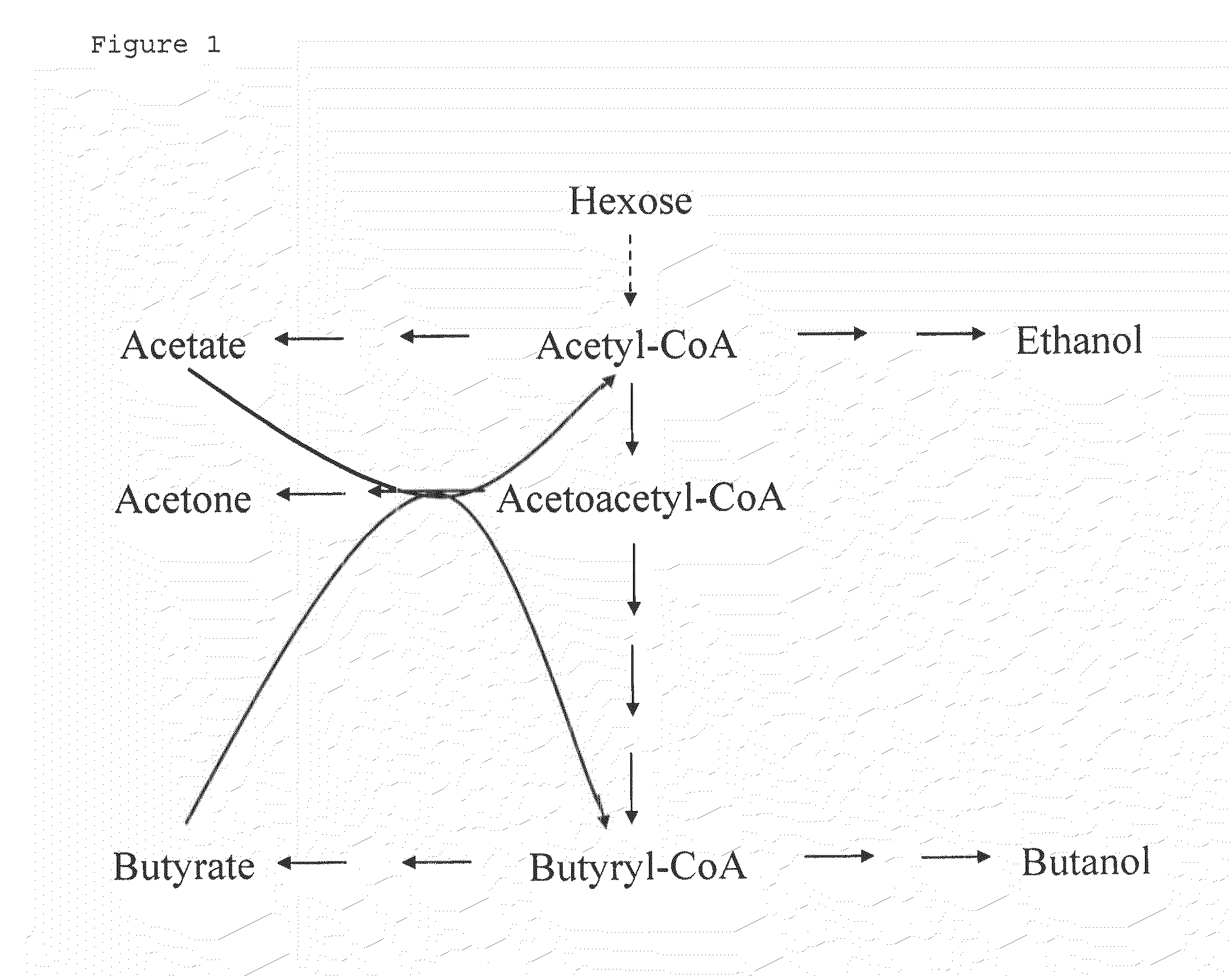

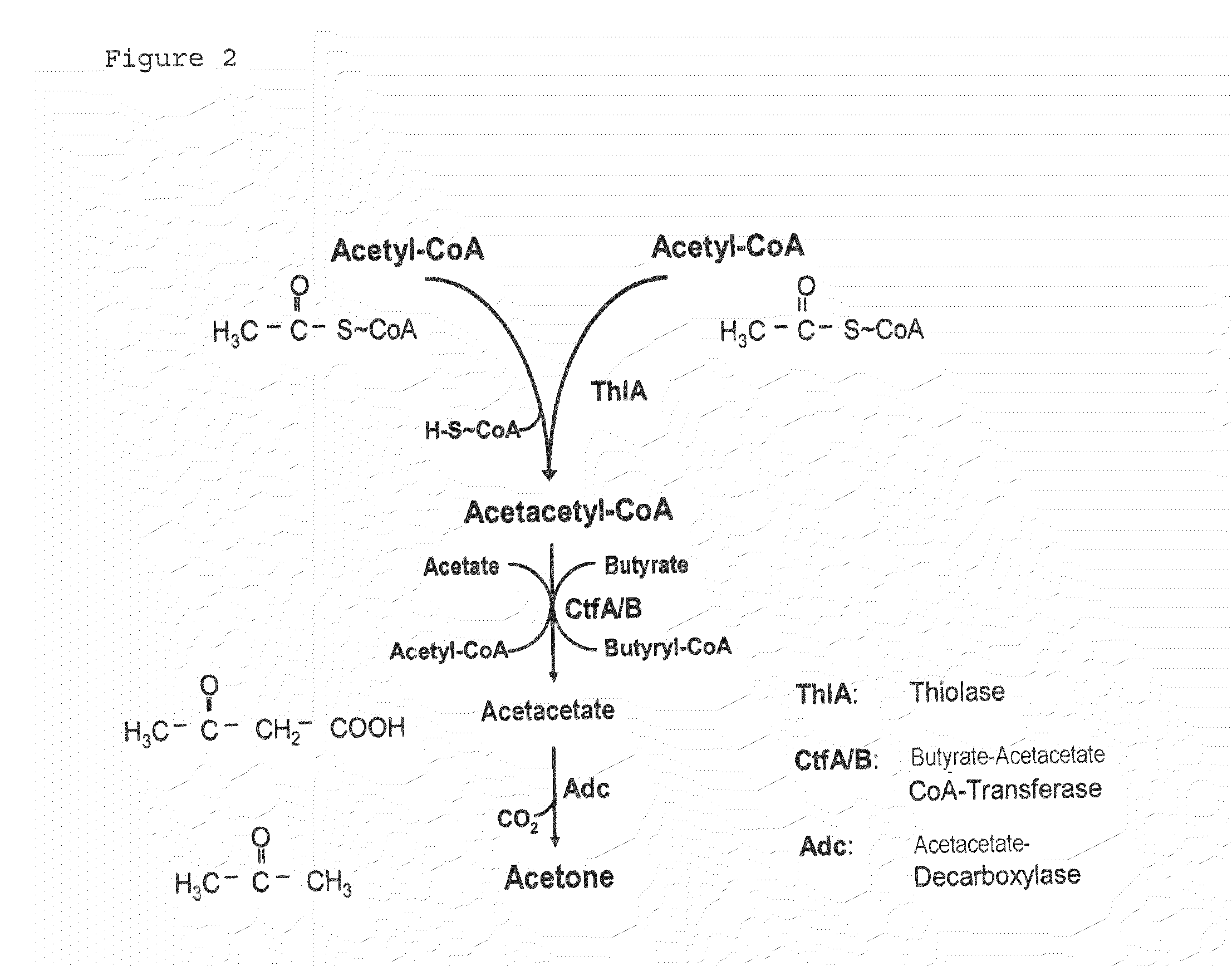

The invention describes a process for preparing acetone starting from acetyl-coenzyme A comprising process steps A. enzymatic conversion of acetyl-CoA into acetoacetyl-CoA B. enzymatic conversion of acetoacetyl-CoA into acetoacetate and CoA and C. decarboxylation of acetoacetate to acetone and CO2, which is characterized in that the coenzyme A is not transferred in process step B to an acceptor molecule. In addition, process step B is surprisingly catalysed by enzymes of the classes of acyl-CoA thioesterase, acyl-CoA synthetase or acyl-CoA thiokinase.A completely novel metabolic pathway is concerned, because the enzymatic hydrolysis of acetoacetyl-CoA without simultaneous transfer of CoA to a receptor molecule has never previously been described for any microbial enzyme.

Owner:EVONIK OPERATIONS GMBH

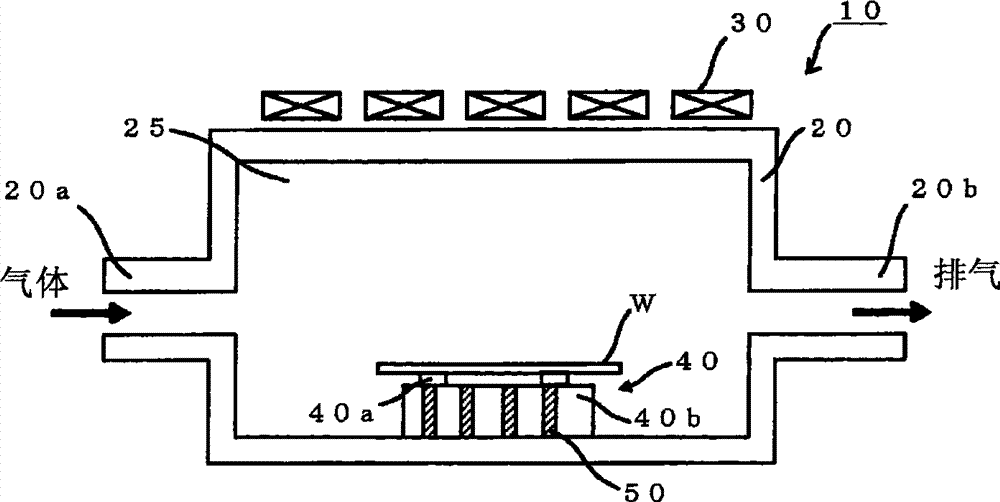

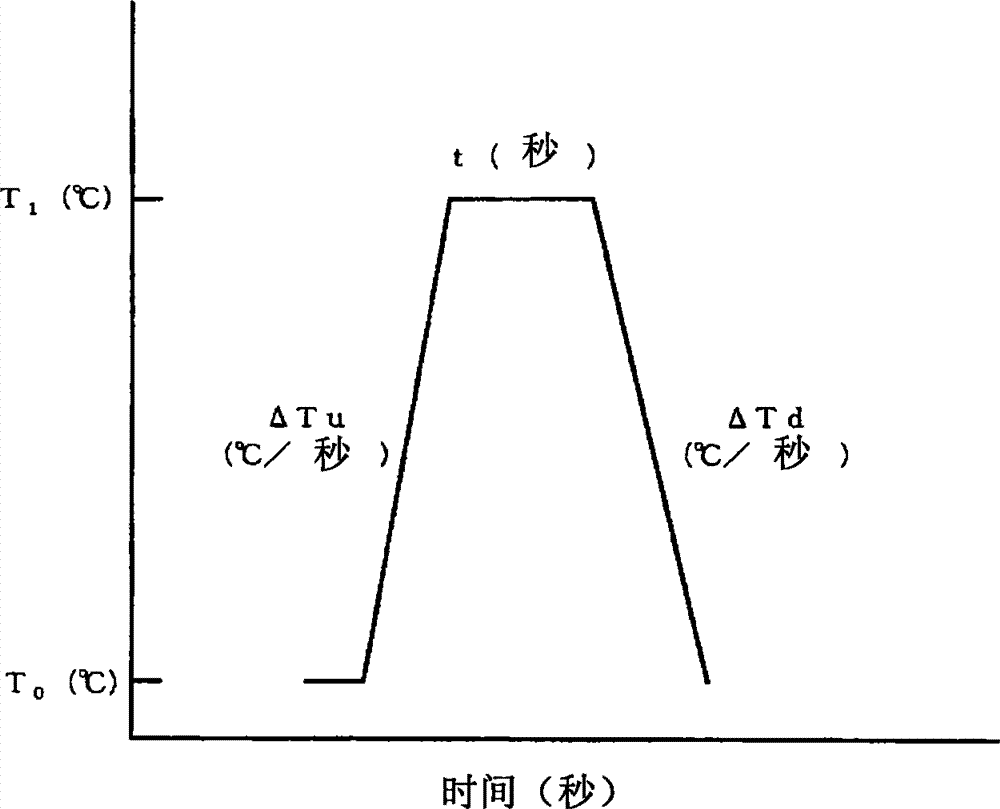

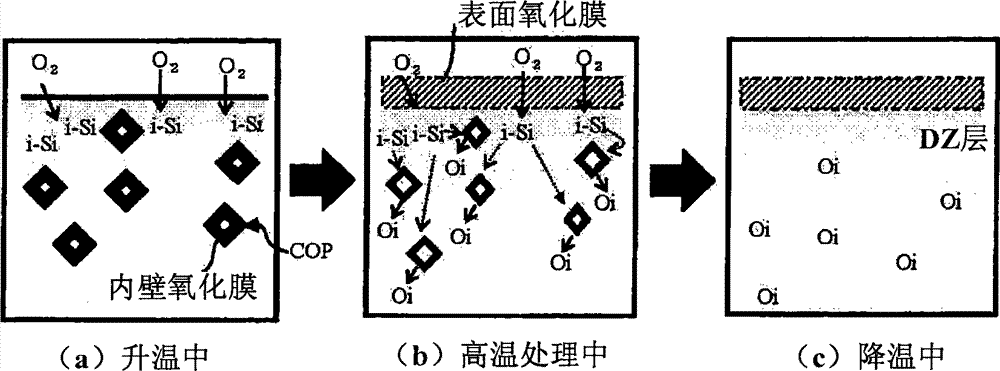

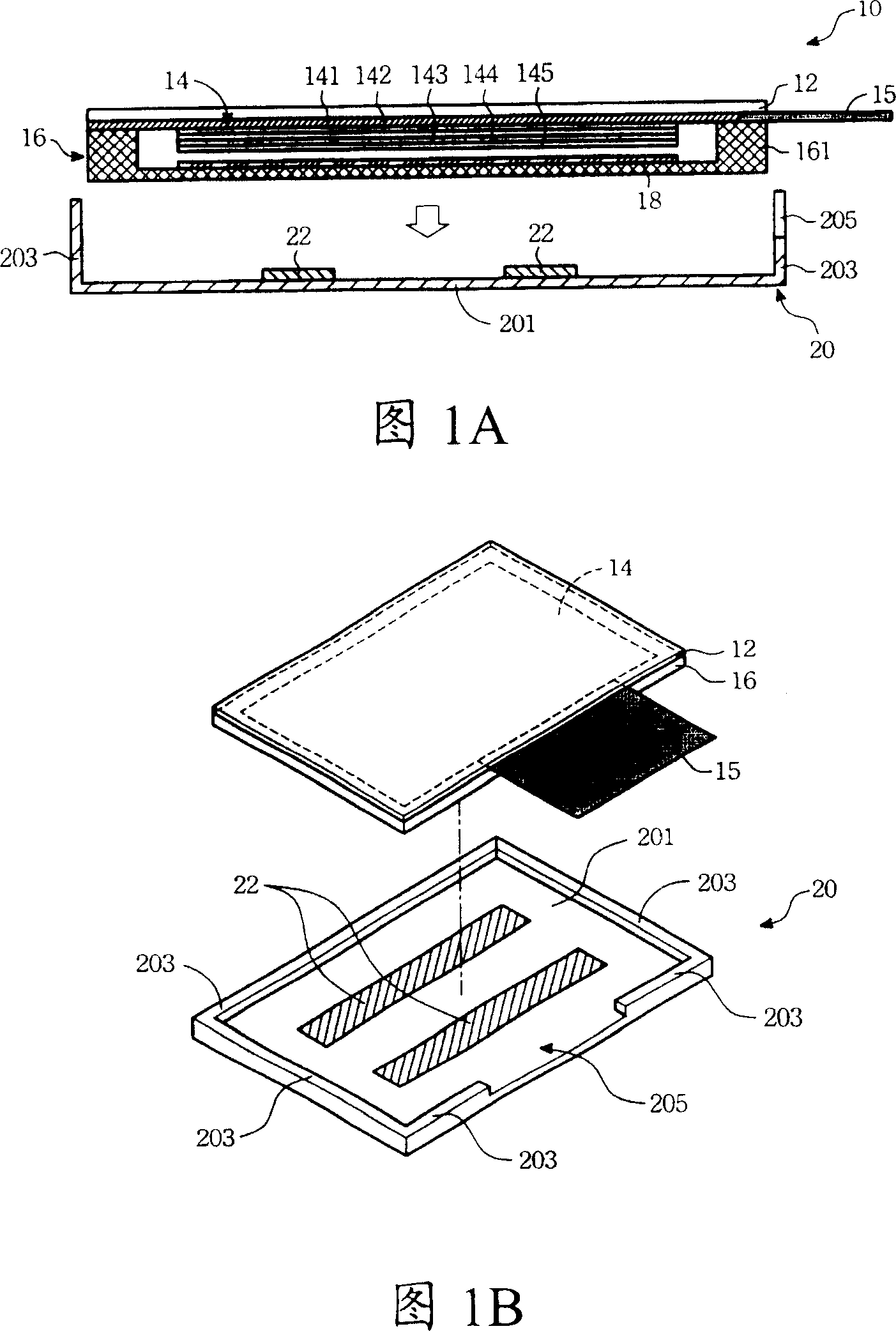

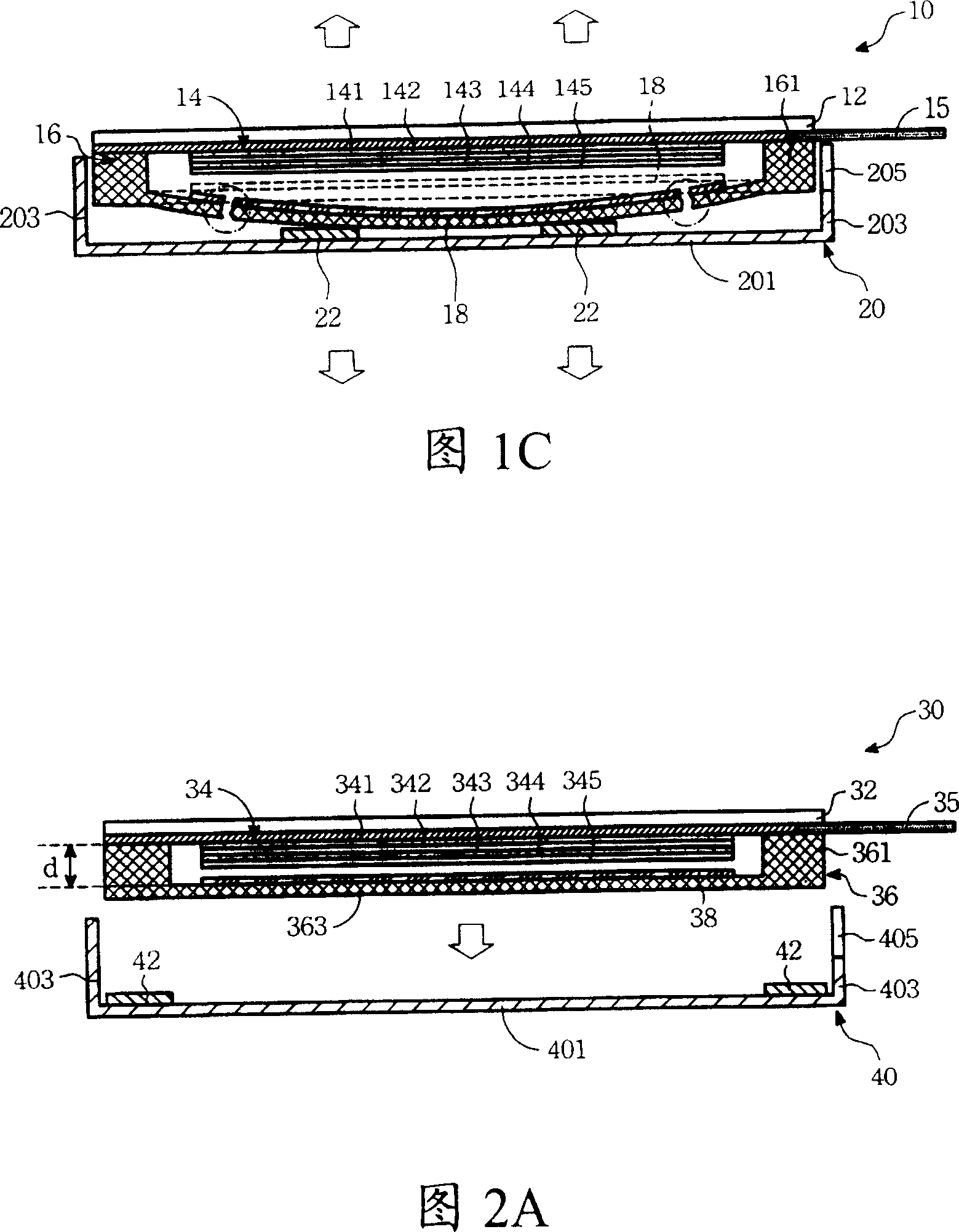

Silicon wafer, method for manufacturing the same and method for heat-treating the same

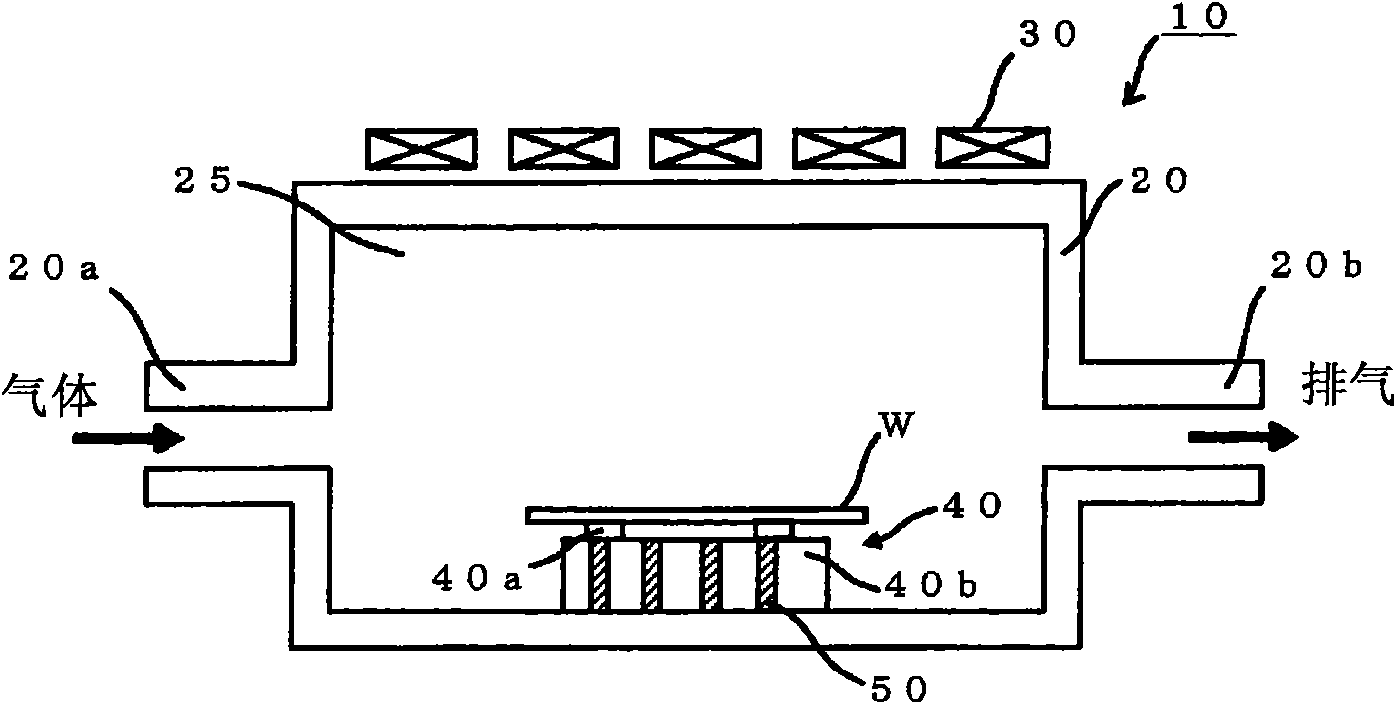

ActiveCN101638807AThe preparation method is simple and easyImprove productivityPolycrystalline material growthAfter-treatment detailsSingle crystalIngot

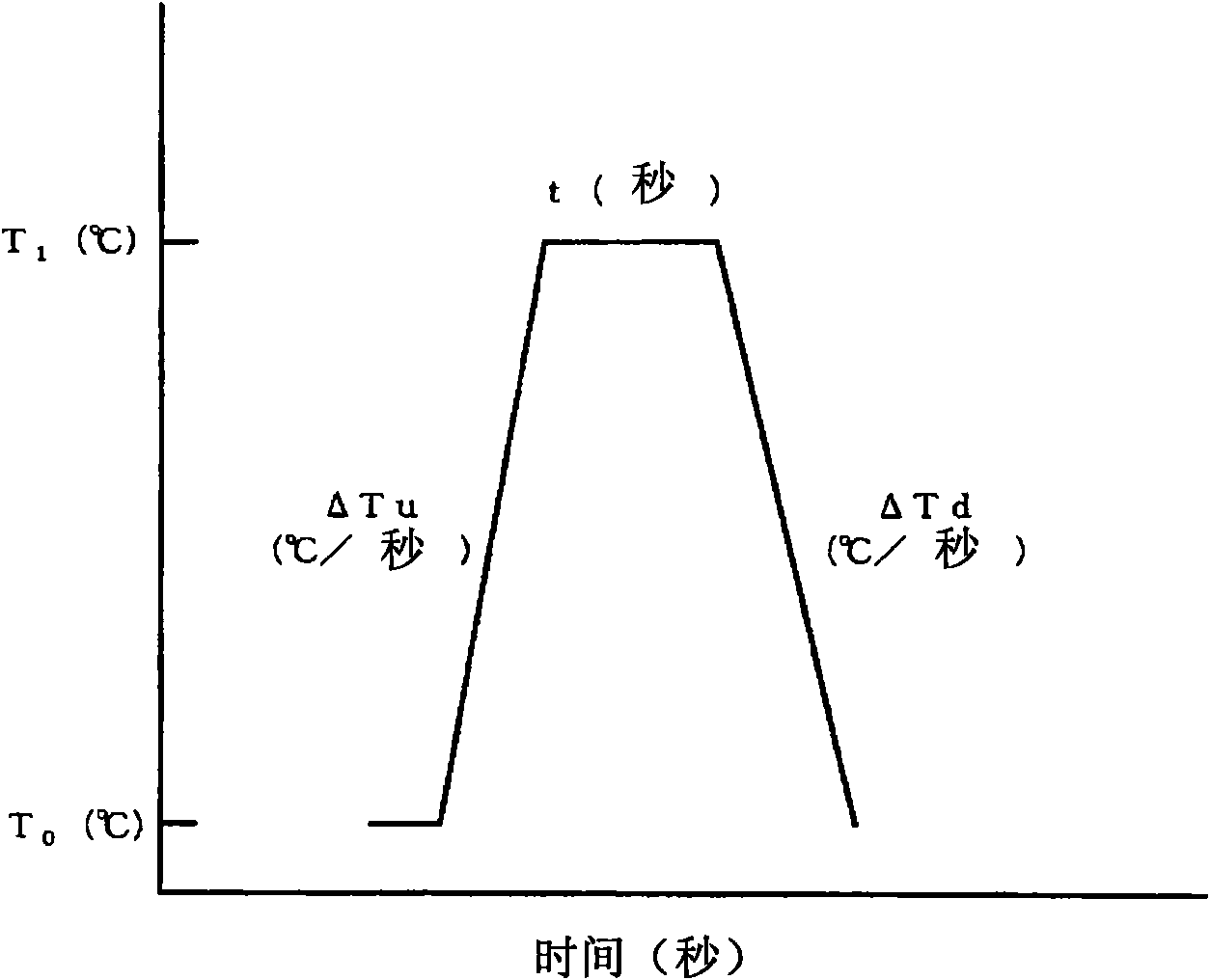

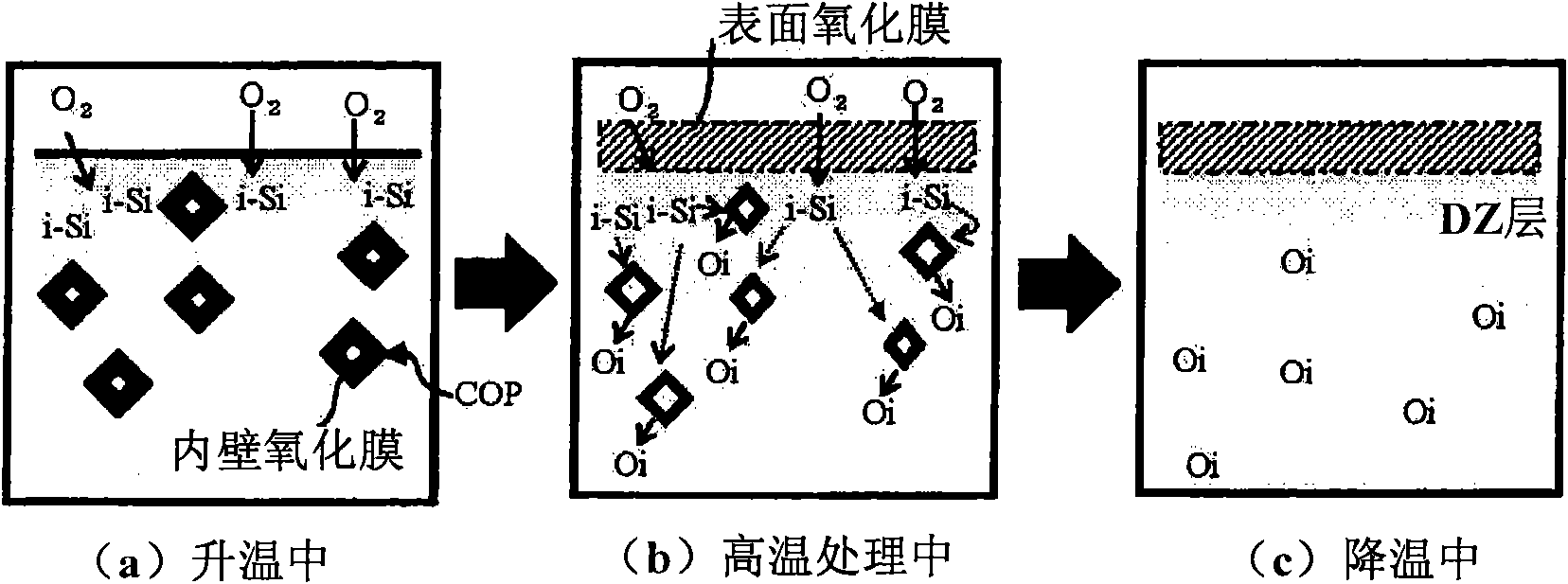

A silicon wafer produced from a silicon single crystal ingot grown by Czochralski process is subjected to rapid heating / cooling thermal process at a maximum temperature (T1) of 1300 DEG C or more, but less than 1380 DEG C in an oxidizing gas atmosphere having an oxygen partial pressure of 20% or more, but less than 100%. The silicon wafer (10) according to the invention has, in a defect-free region (DZ layer) (12) including at least a device active region of the silicon wafer, a high oxygen concentration region (12) having a concentration of oxygen solid solution of 0.71018 atoms / cm3 or more and at the same time, the defect-free region contains interstitial silicon (14) in supersaturated state.

Owner:GLOBALWAFERS JAPAN

Adhesive sheet for manufacturing semiconductor device, and semiconductor device manufacturing method using the sheet

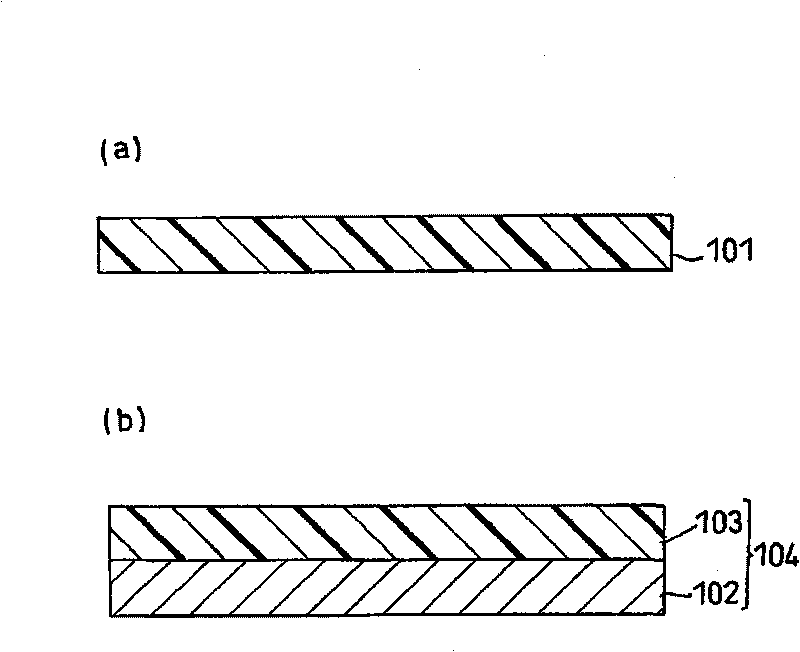

InactiveCN101765909AEasy to identifyReduce downtimeNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsEngineeringWavelength range

Owner:NITTO DENKO CORP

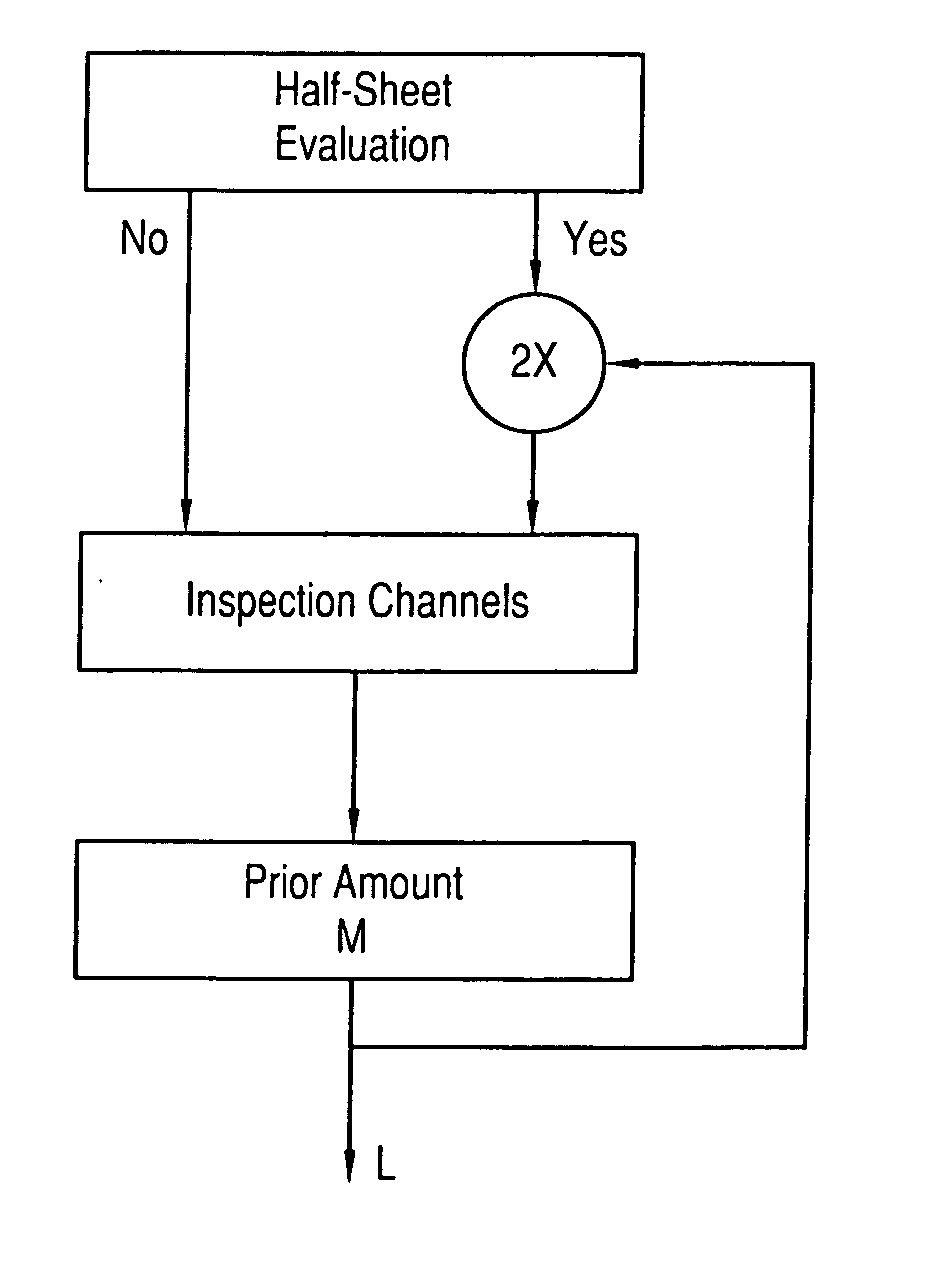

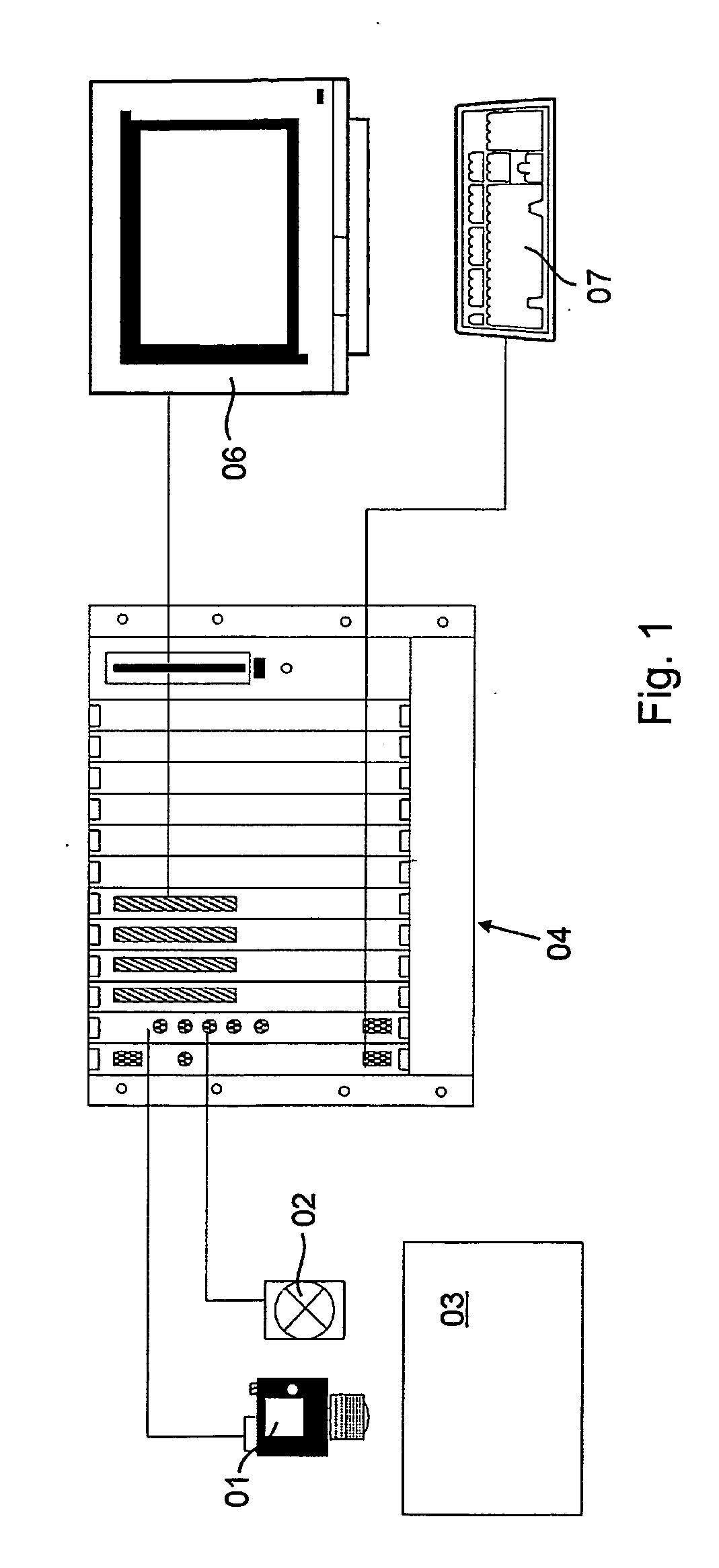

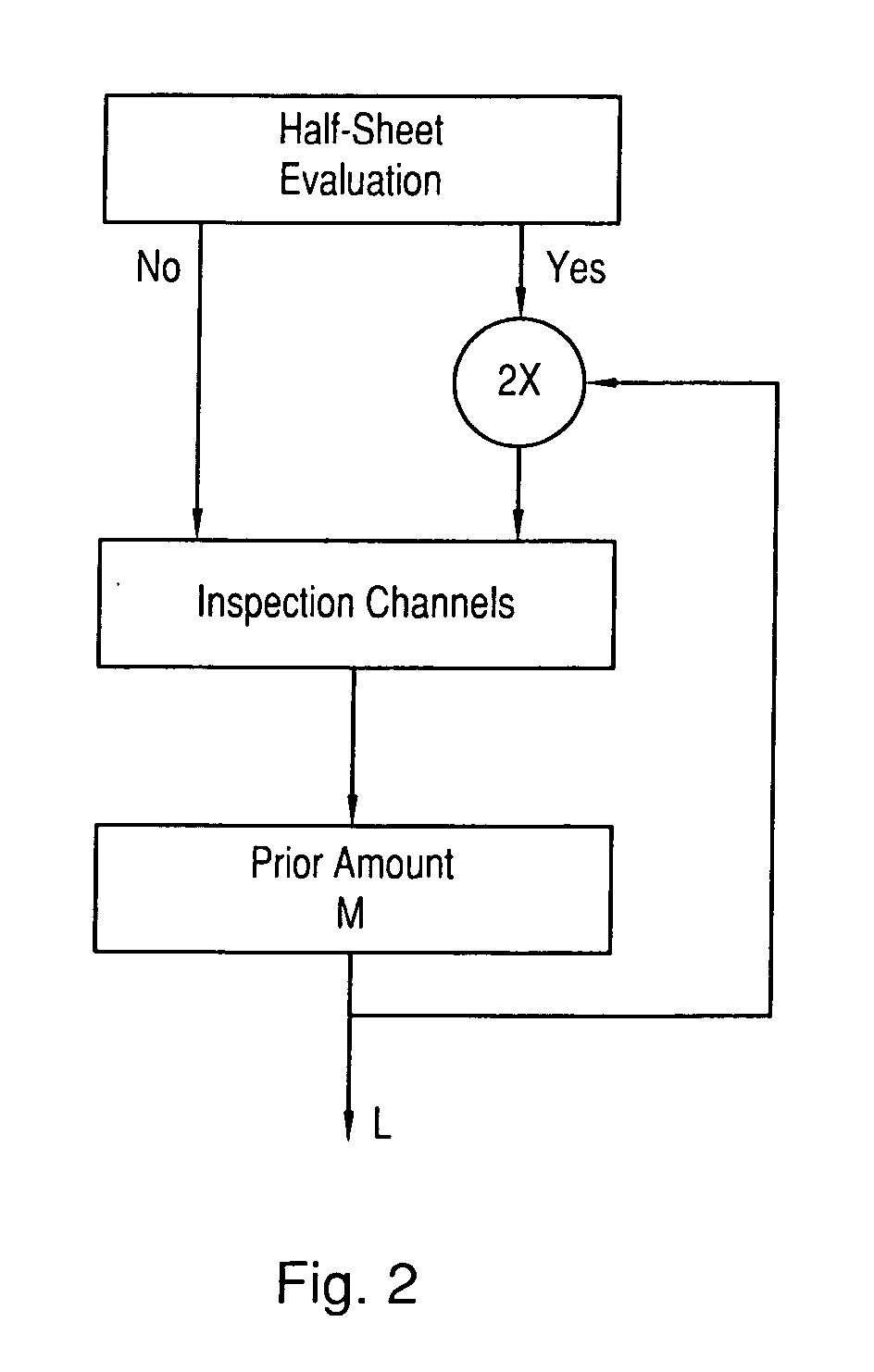

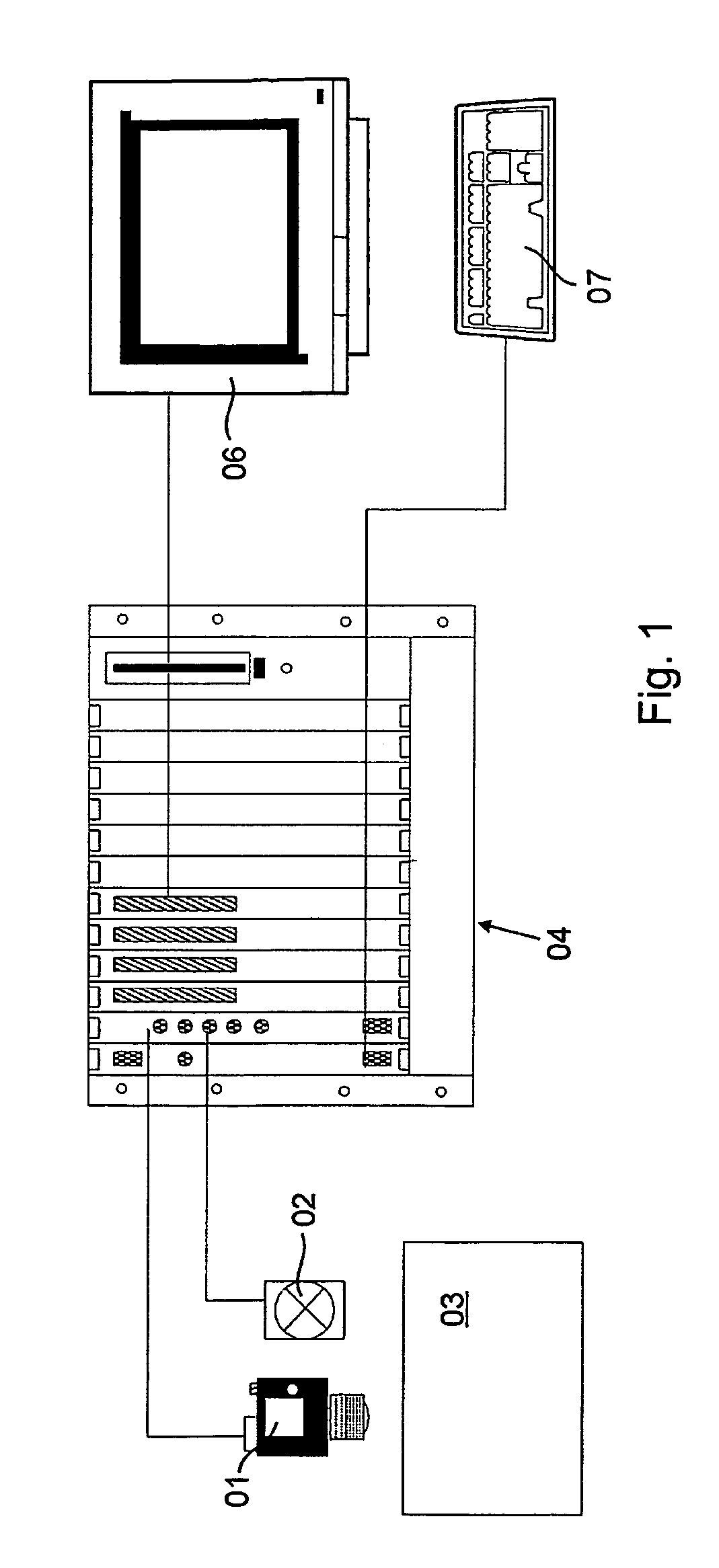

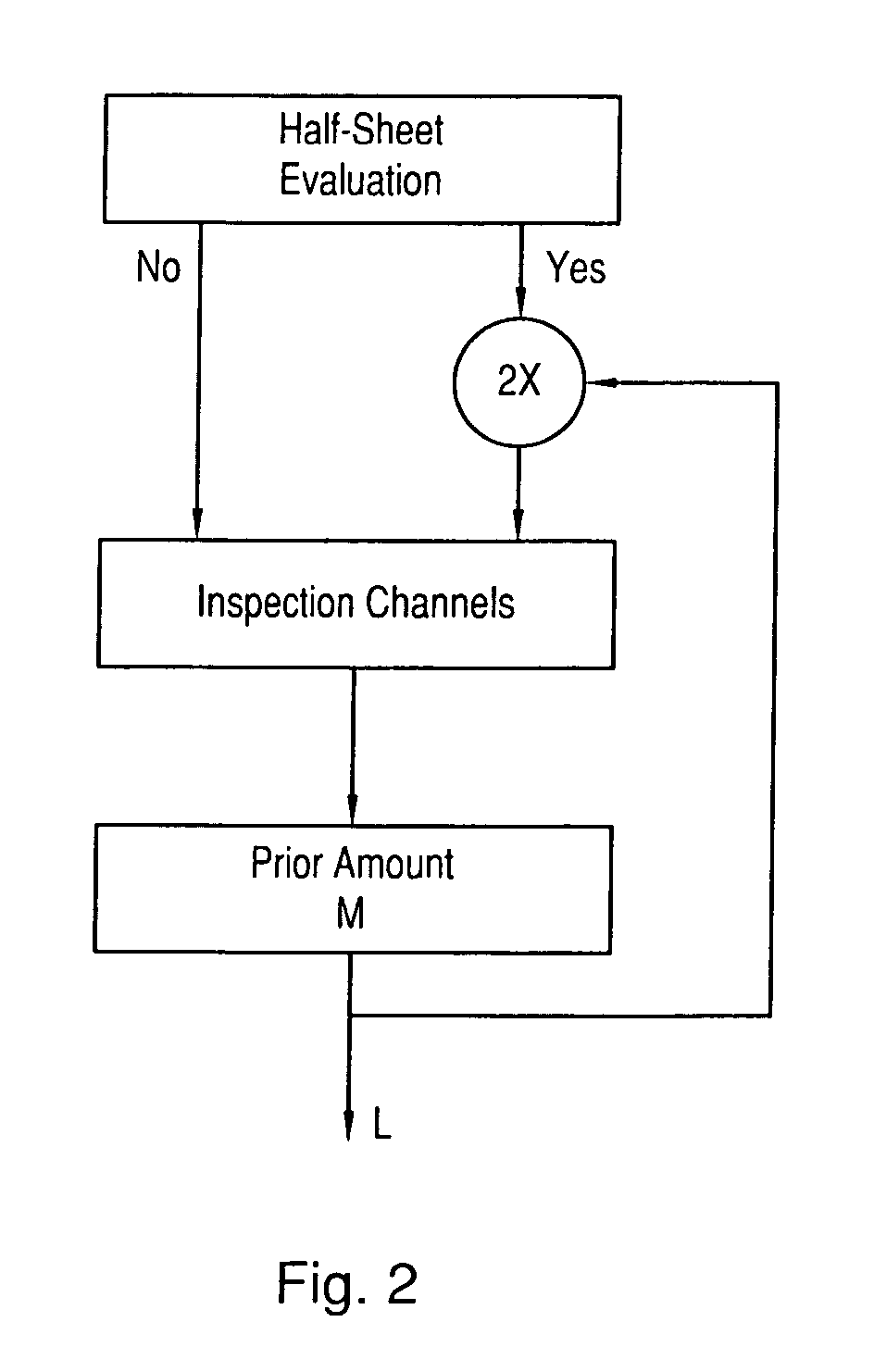

Method for Evaluating the Quality of a Printed Matter, Provided by a Printing Machine

InactiveUS20070223789A1Increase productivityImprove economyImage analysisRegistering/indicating quality control systemsEngineeringImaging data

The quality of printed matter, which is one of several copies of the same printed matter produced by a printing machine, is evaluated. An amount of copies of the printed matter is selected from the total production of this printed matter. The selected amount of these copies are evaluated with regard to at least one error type which belongs to an amount of different error types or with regard to at least one feature of the error. Within the selected amount of copies, an error of a defined error type or of a defined feature, which is detected on at least one of the copies, is evaluated in relation to at least one error of another type or feature detected on the same copy, or another copy of the selected amount. The printed matter is classified as having good or bad quality based on that evaluation. A common reading, producing image data, is obtained by an image sensor from the selected copies. All of the errors to be evaluated in relation to each other are detected from image data gathered during the same common recording.

Owner:KOENIG & BAUER AG

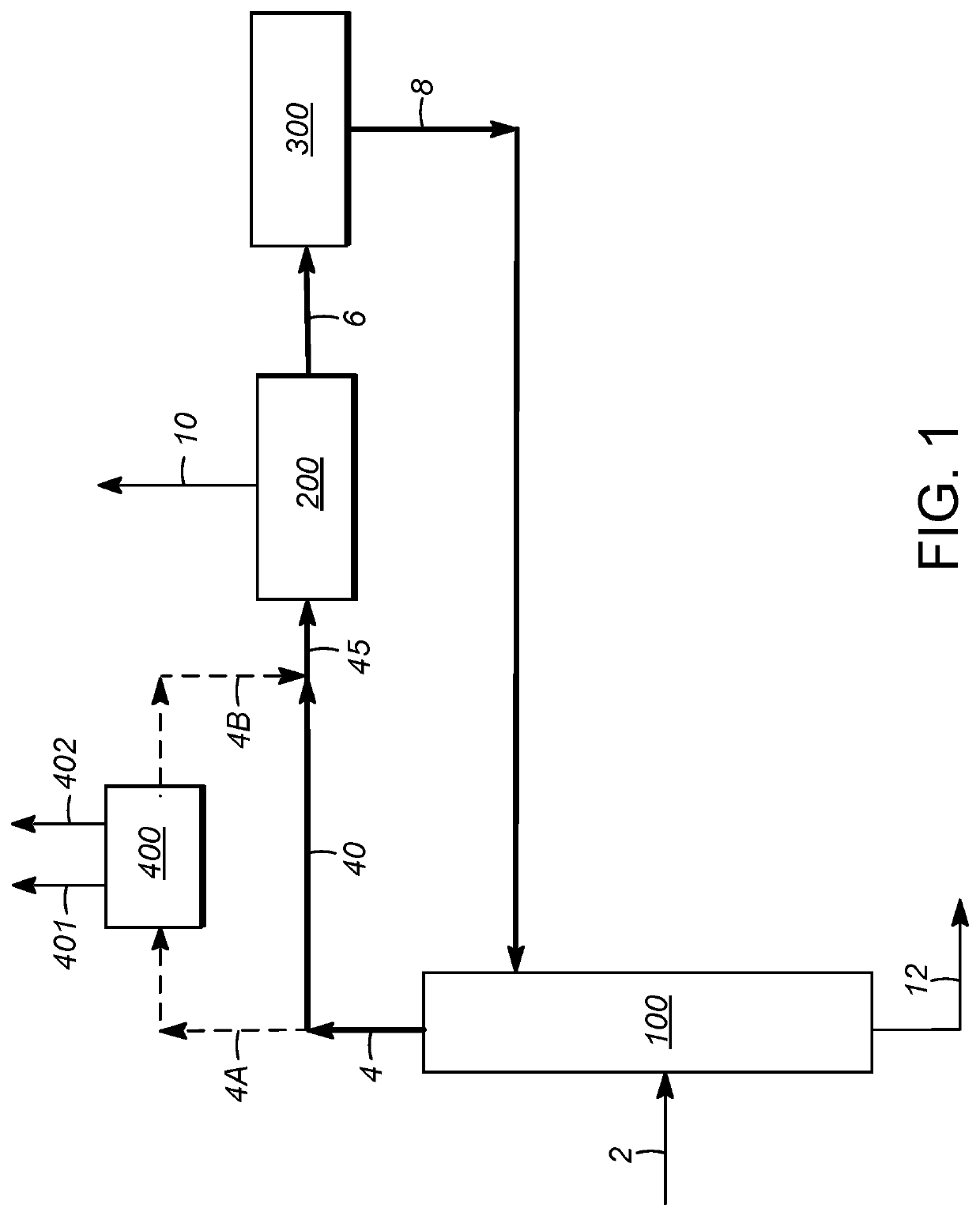

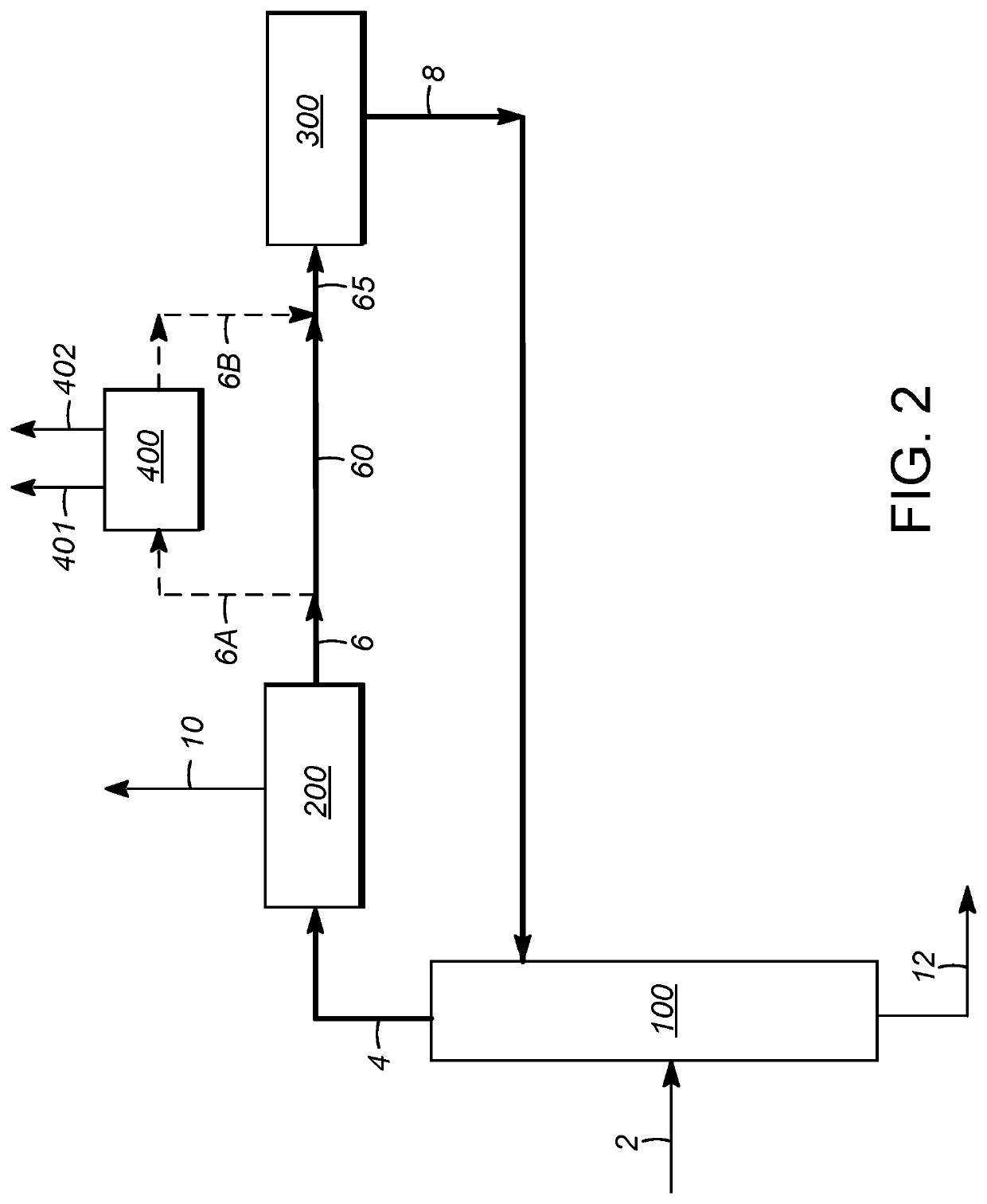

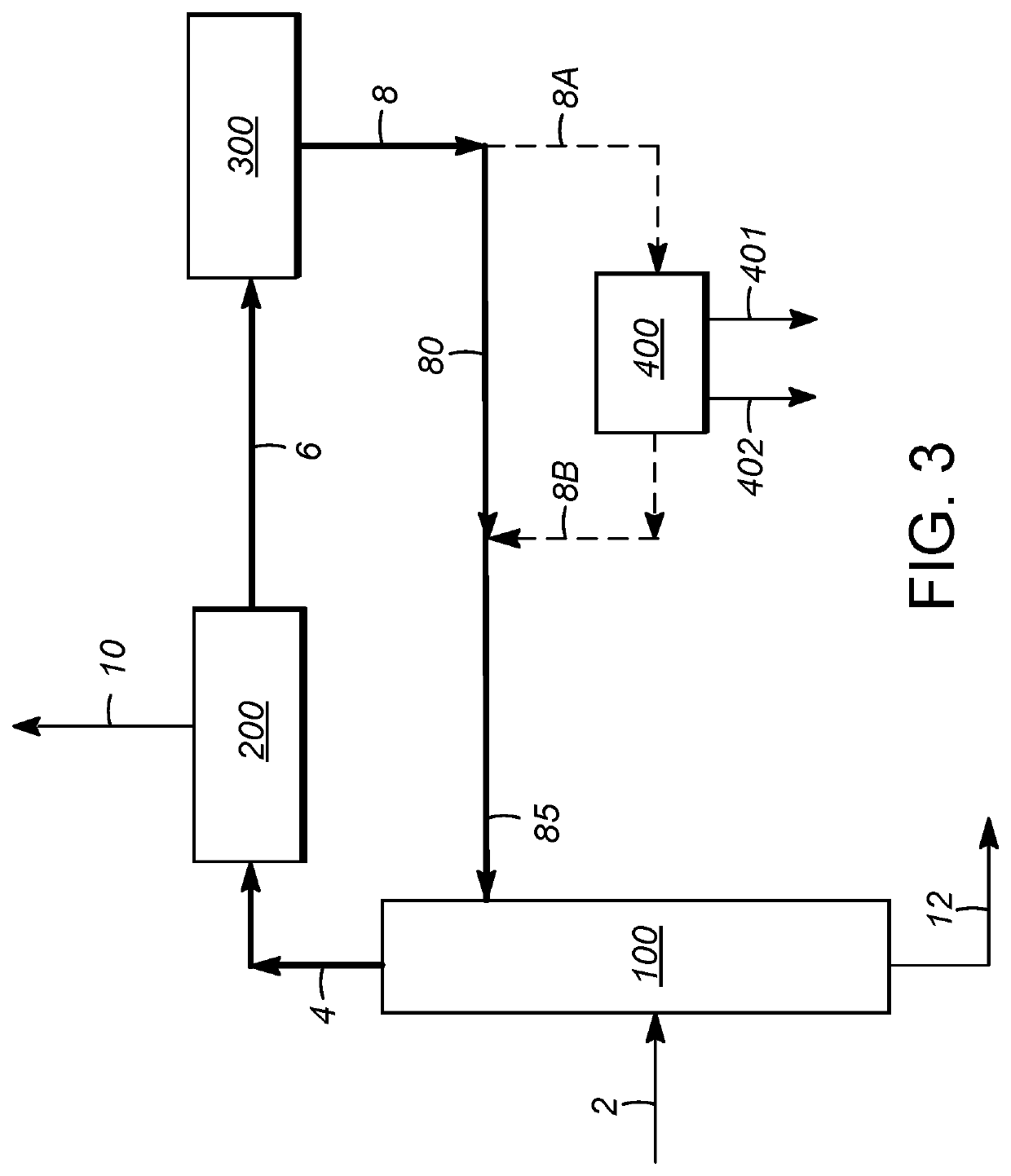

Process for producing BTX from a mixed hydrocarbon source using pyrolysis

ActiveUS10131853B2YieldIncrease productionTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrocarbonPyrolysis

The present invention relates to a process for producing BTX comprising pyrolysis, aromatic ring opening and BTX recovery. Furthermore, the present invention relates to a process installation to convert a pyrolysis feedstream into BTX comprising a pyrolysis unit, an aromatic ring opening unit and a BTX recovery unit.

Owner:SAUDI BASIC IND CORP SA +1

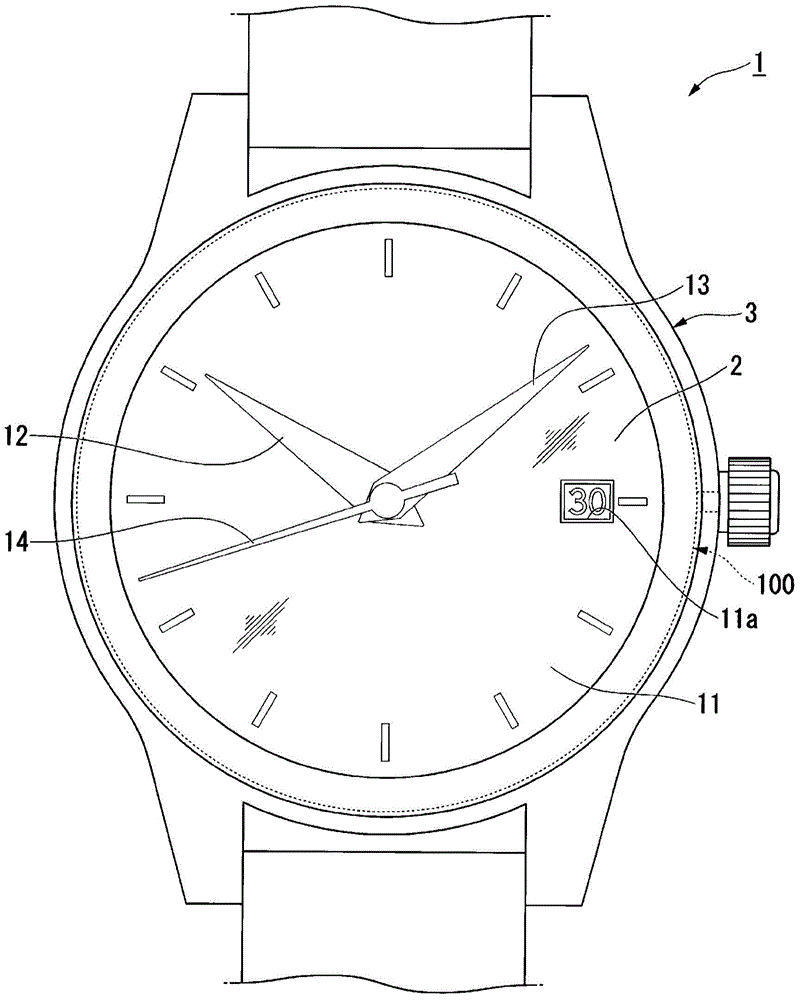

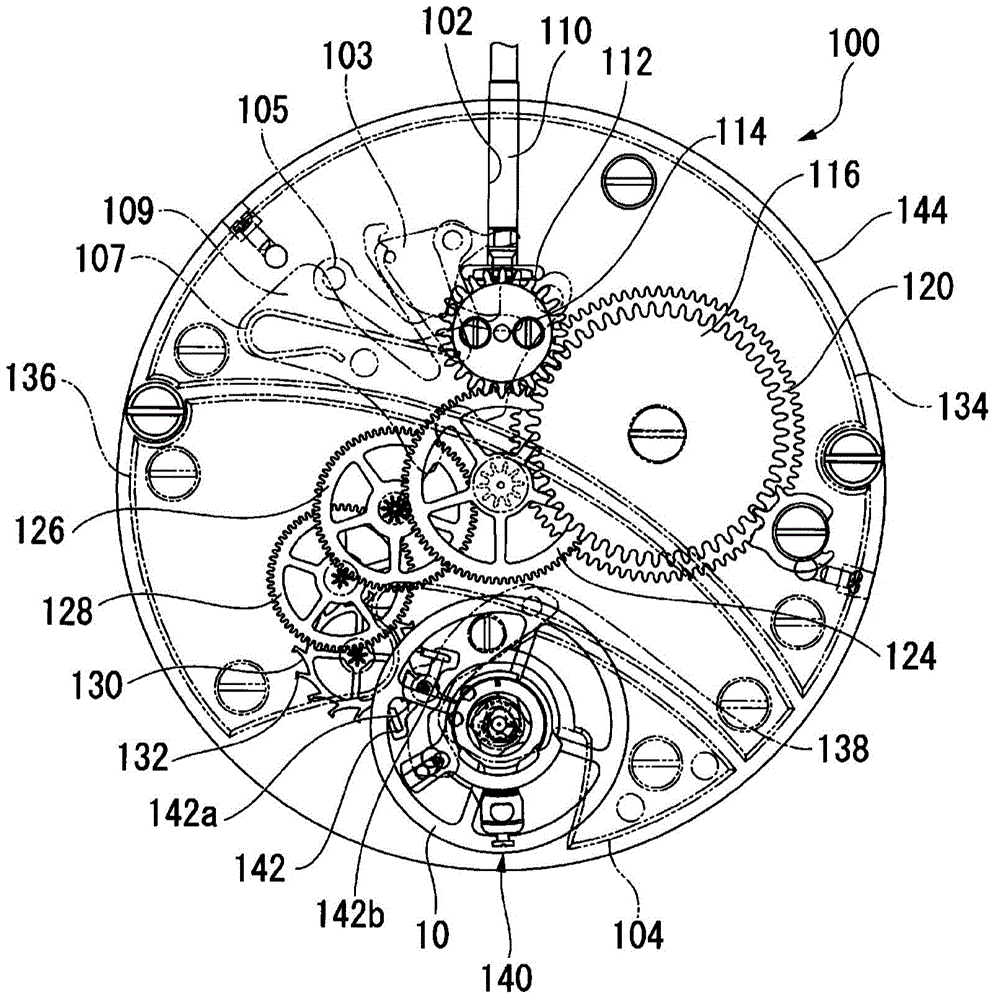

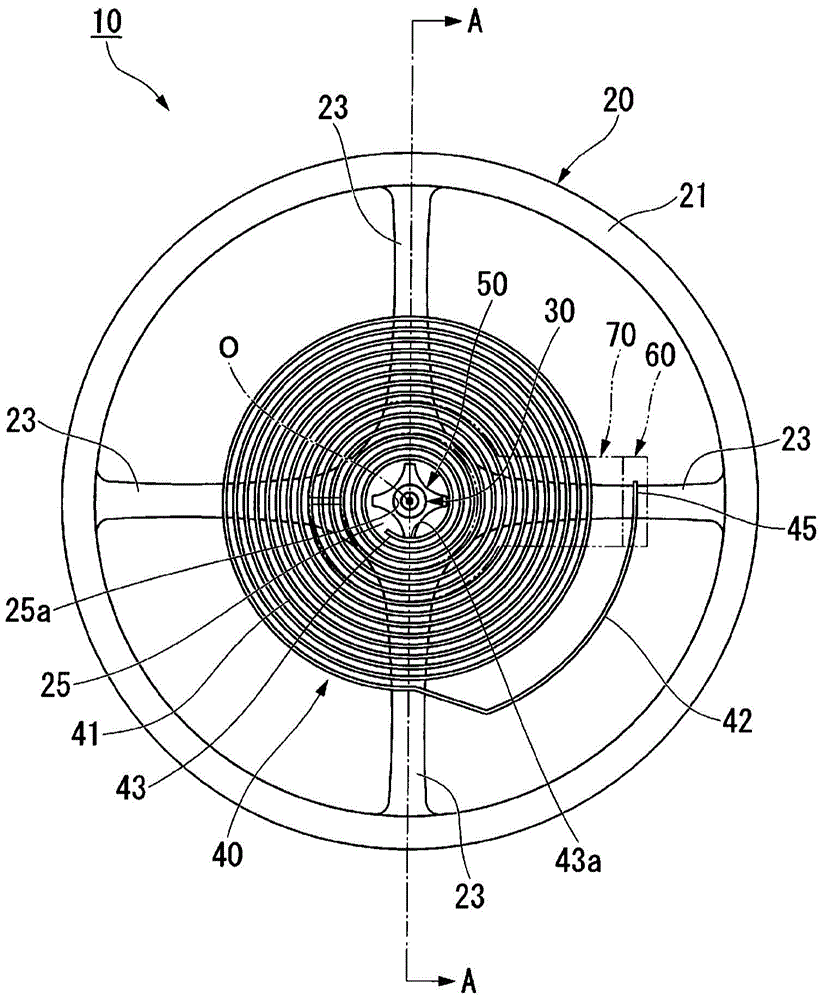

Swing wheels, clock movement and clock

InactiveCN104049519AInhibition rate reductionEasy to set upFrequency stabilisation mechanismFrequency setting mechanismEngineeringRemontoire

The invention provides swing wheels, a clock movement provided with the swing wheels and a clock provided with the clock movement. The swing wheels are capable of easily adjusting the error rate to reduce errors of a release catch so that the characteristic of stable error rate is obtained. The swing wheels are characterized in that the swing wheels are provided with a swing shaft (30) and a balance spring. A balance wheel (20) is outwardly embedded at the swing shaft (30). The inner end portion of the balance spring is connected with the swing shaft (30).The wing wheels are formed in such a manner that when the inner peripheral surface (40a) of the balance spring (40) is lengthened along an axis of the swing shaft (30), the inner peripheral surface (40a) and a central axis (O) of the swing shaft (30) are intersected.

Owner:SEIKO INSTR INC

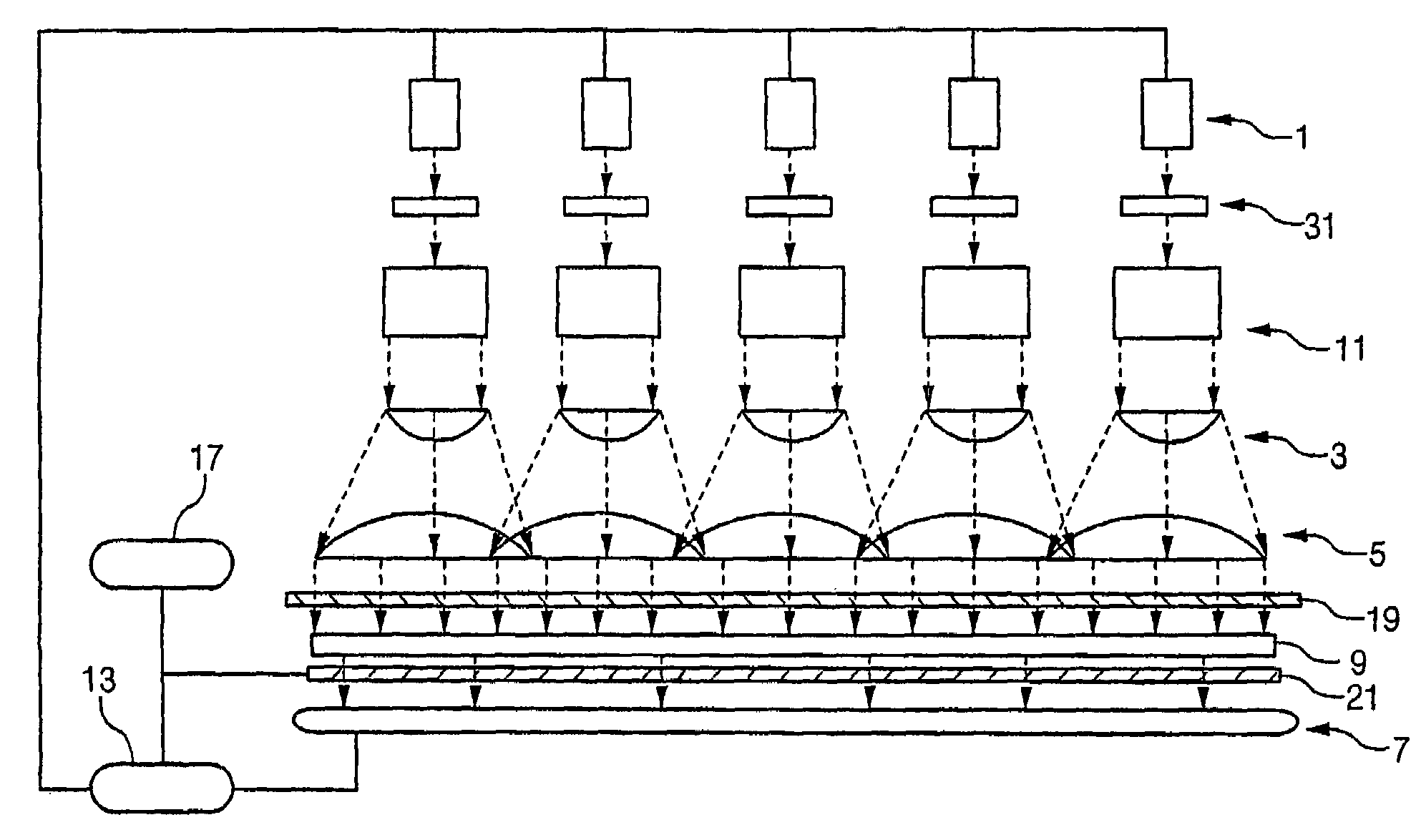

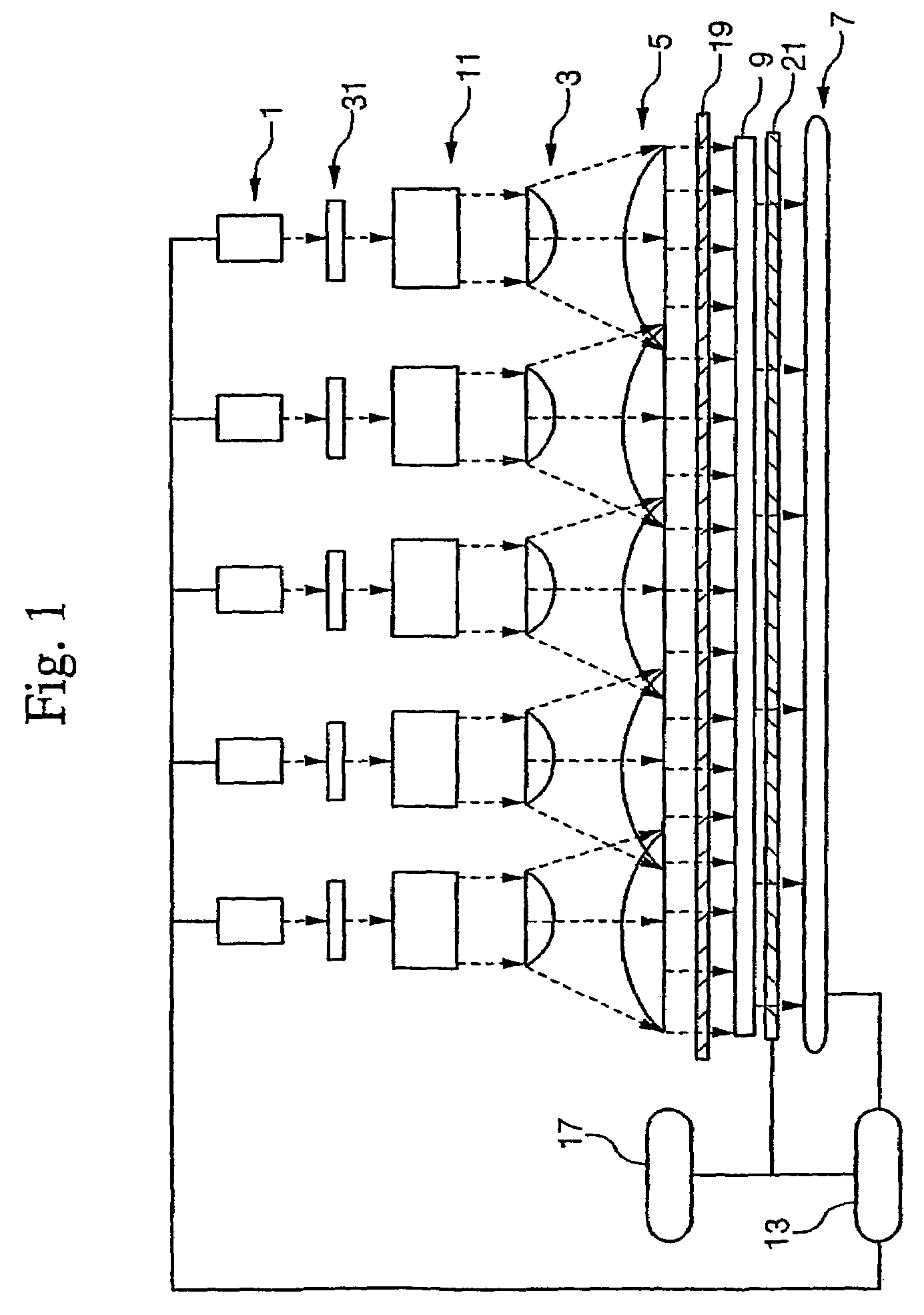

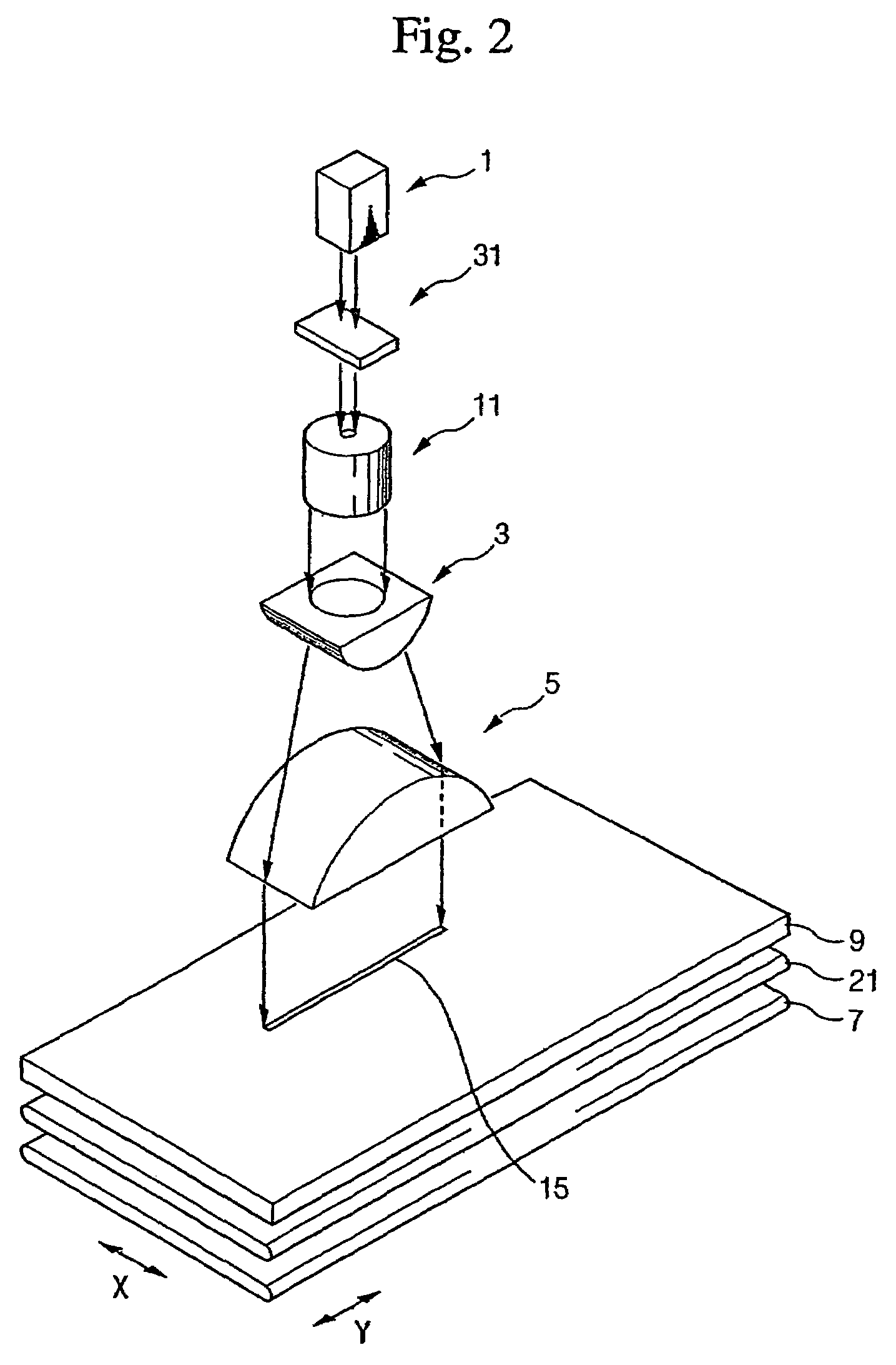

Liquid crystal process defect inspection apparatus and inspection method

InactiveUS7113278B2% yieldMaterial analysis by optical meansLight polarisation measurementLight beamPolarizer

The glass substrate test apparatus of the liquid crystal cell process comprises a laser unit for generating a laser beam, a beam shaper and beam collimator for shaping the laser beam emitted from the laser unit so as to have an elongated cross section and parallelizing the shaped laser beam, a photo detector for detecting an intensity of double refraction of the shaped laser beam transmitted over the whole glass substrate, a phase defector for measuring the laser double refraction detected by the photo detector and comparing the measured double refraction with a standard laser double refraction, and a polarizer arranged between the laser unit and the beam shaper or between the beam shaper and the beam collimator for polarizing the laser beam to a parallel ray.

Owner:SAMSUNG DISPLAY CO LTD

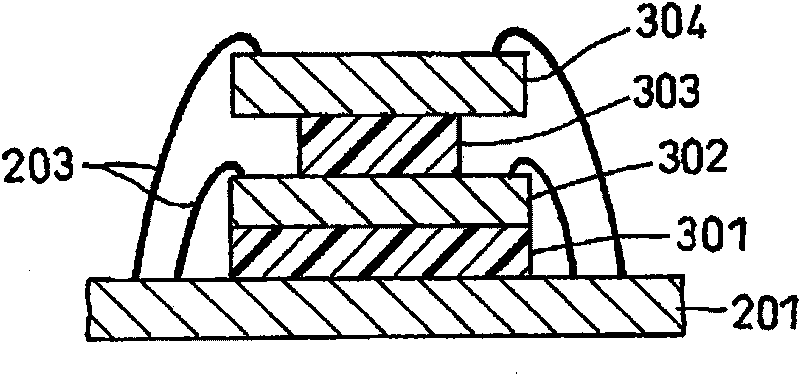

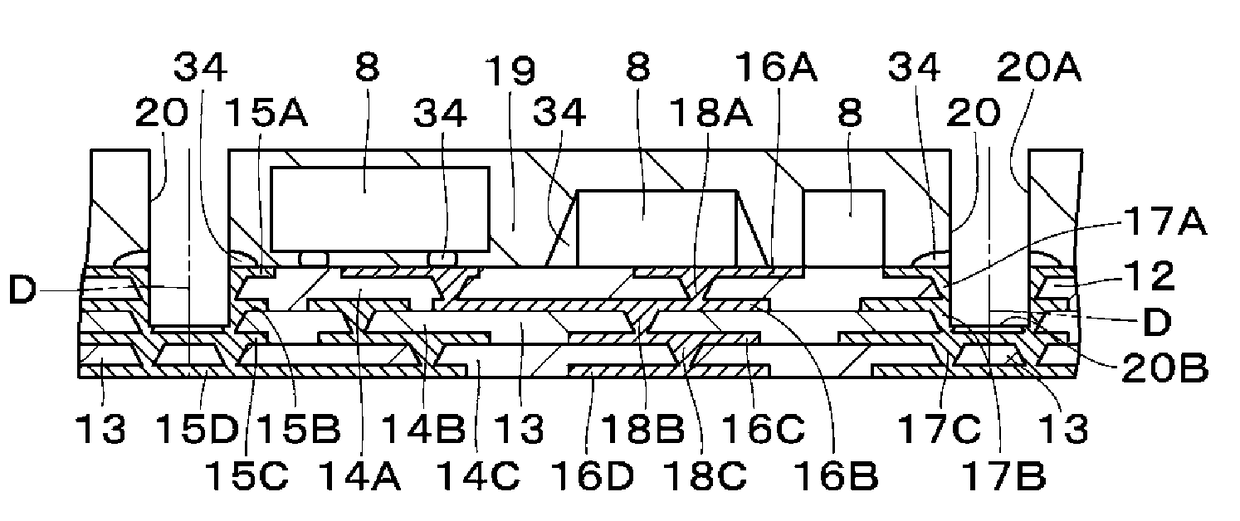

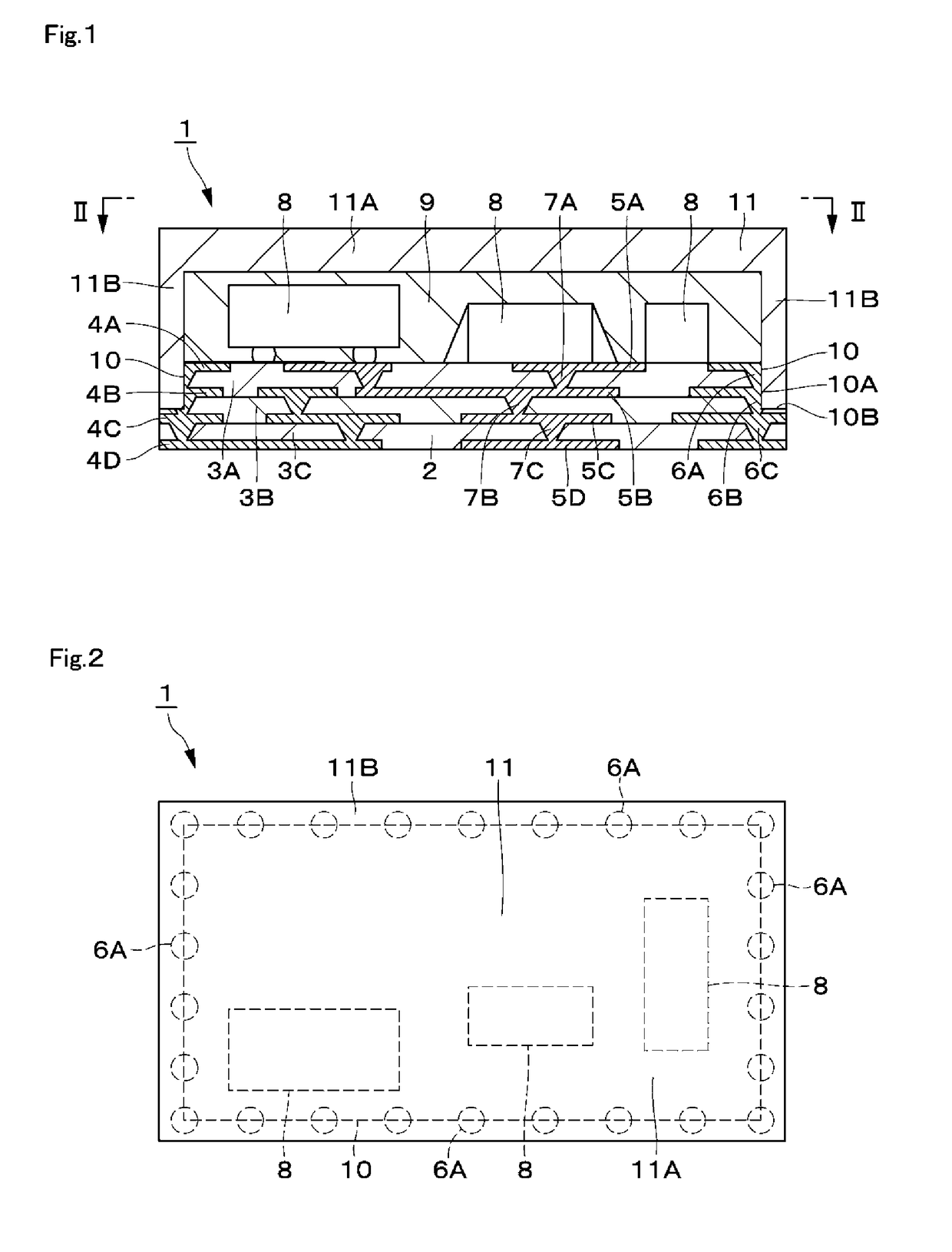

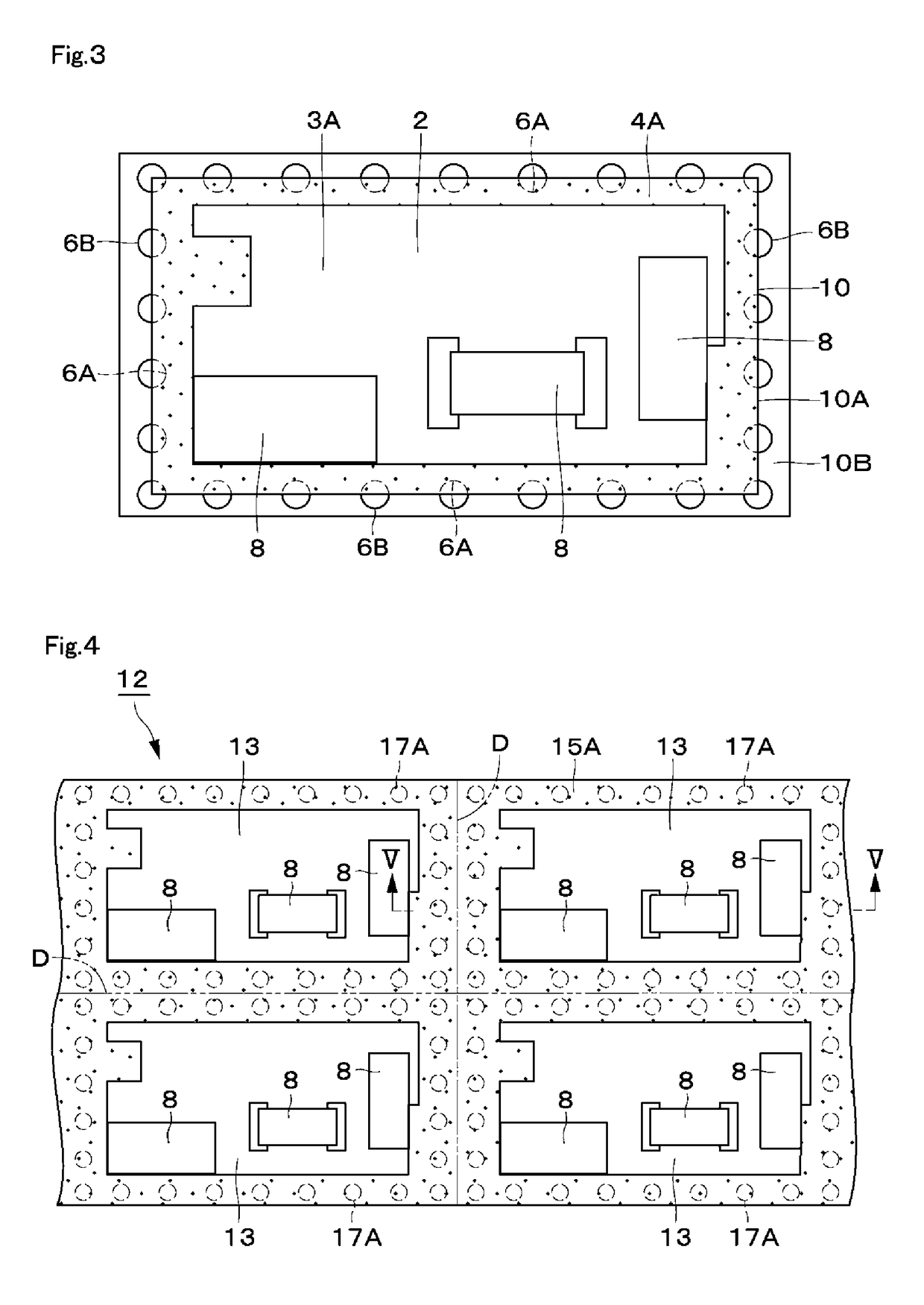

Circuit module and method for manufacturing the same

InactiveUS20170098637A1Improve connection reliabilityYieldCross-talk/noise/interference reductionSemiconductor/solid-state device detailsComputer moduleElectronic component

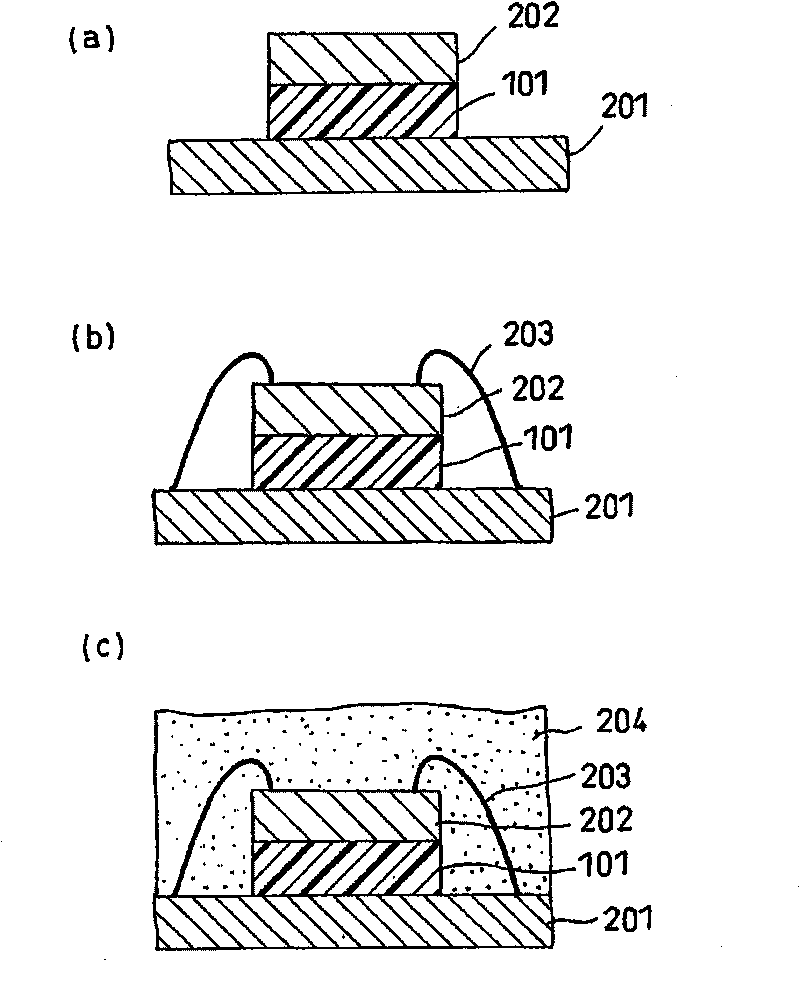

A module board includes insulating layers, ground electrodes, signal electrodes, and interlayer vias. Electronic components are mounted on a front surface of the module board, and a sealing resin layer covers the electronic components. A half-cut portion is provided in the module board at an outer peripheral edge thereof and recessed to an intermediate position in a thickness direction of the module board. A shield layer cover the sealing resin layer. The shield layer includes a frame portion that extends into the half-cut portion. The frame portion is electrically connected to ground interlayer vias that are exposed at an end surface and a bottom surface of the half-cut portion.

Owner:MURATA MFG CO LTD

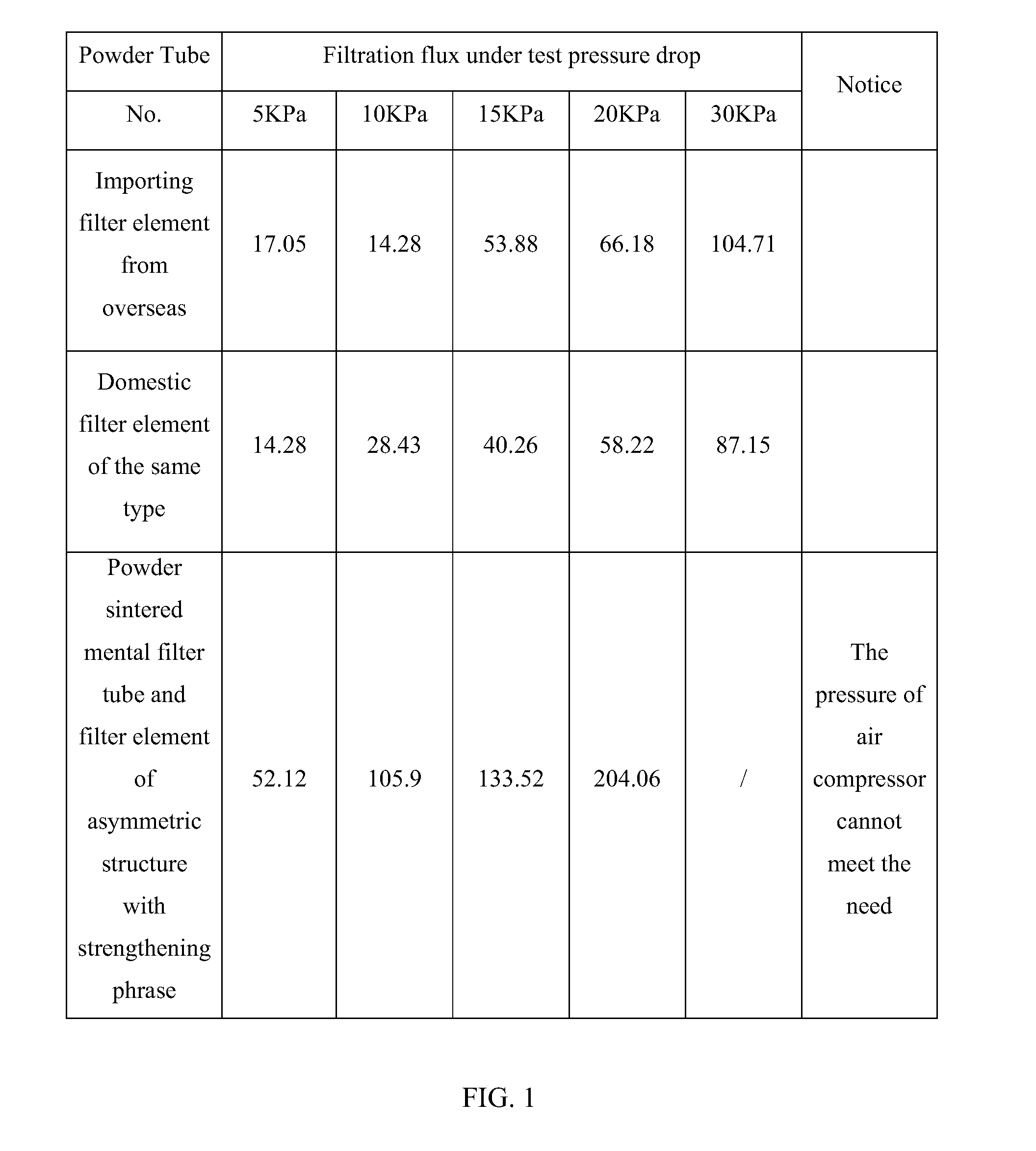

Method for producing composite filter tube and filter element made of multilayer metal mesh and metal powders

ActiveUS20150352469A1Low filtration resistanceLarge filtration fluxArc welding apparatusMembrane filtersMolding machineComposite filter

A method for producing a composite filter tube and filter element made of a multilayer metal mesh and metal powders, including: knitting to obtain metal meshes of different mesh numbers, obtaining a layered structure by means of a lamination method, then putting the layered structure in a vacuum furnace for sintering processing, sintering a metal composite layer to obtain a composite filter sheet and tube made of a multilayer metal mesh and metal powders with a multilayer metal mesh as a structure support layer and a metal powder sinter structure as a filter layer, then rolling the composite filter sheet and tube into a tubular filter element by using a shaping machine, and welding to obtain a composite filter tube and filter element product made of a multilayer metal mesh and metal powders.

Owner:WANG DONGWEI

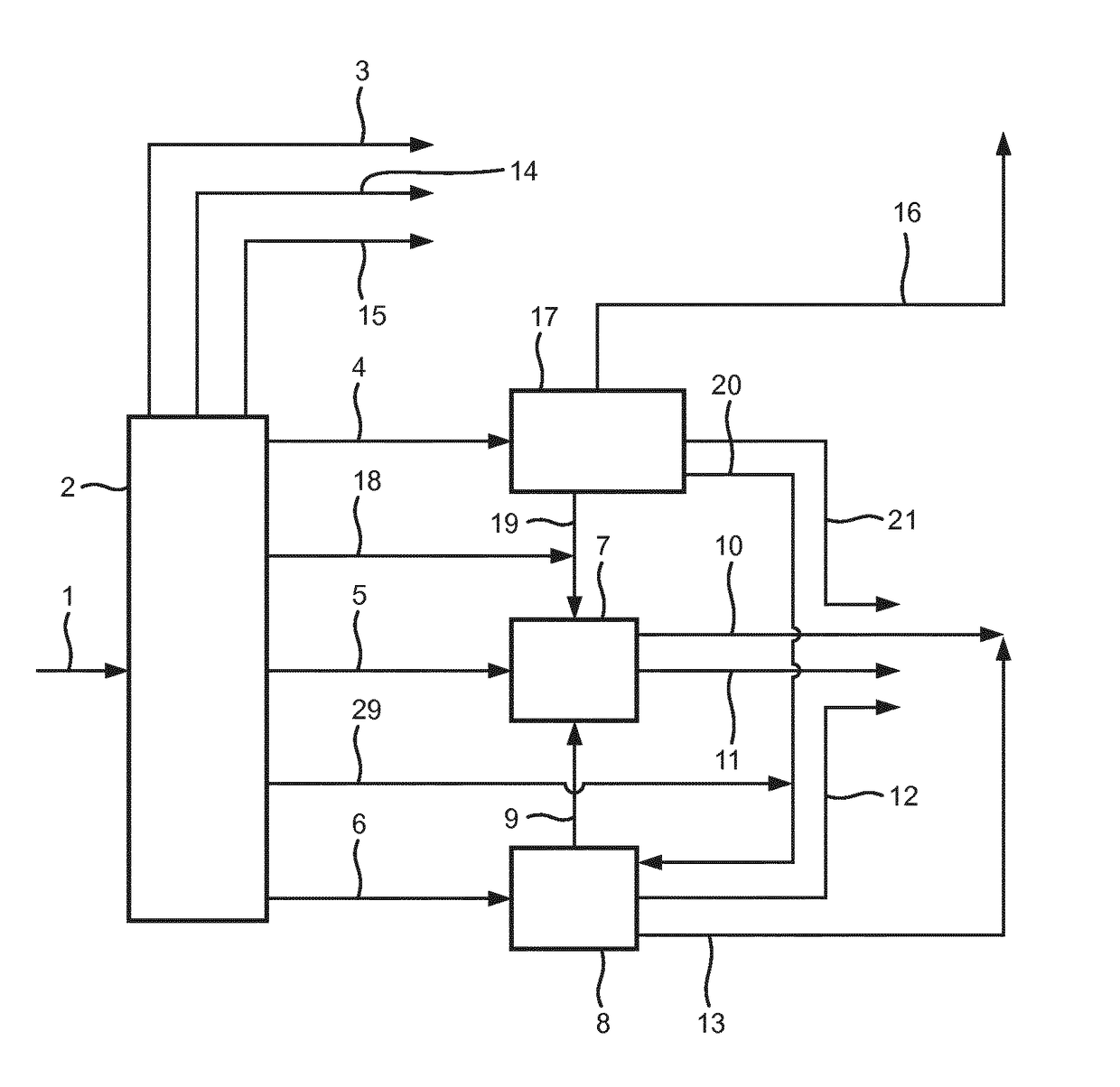

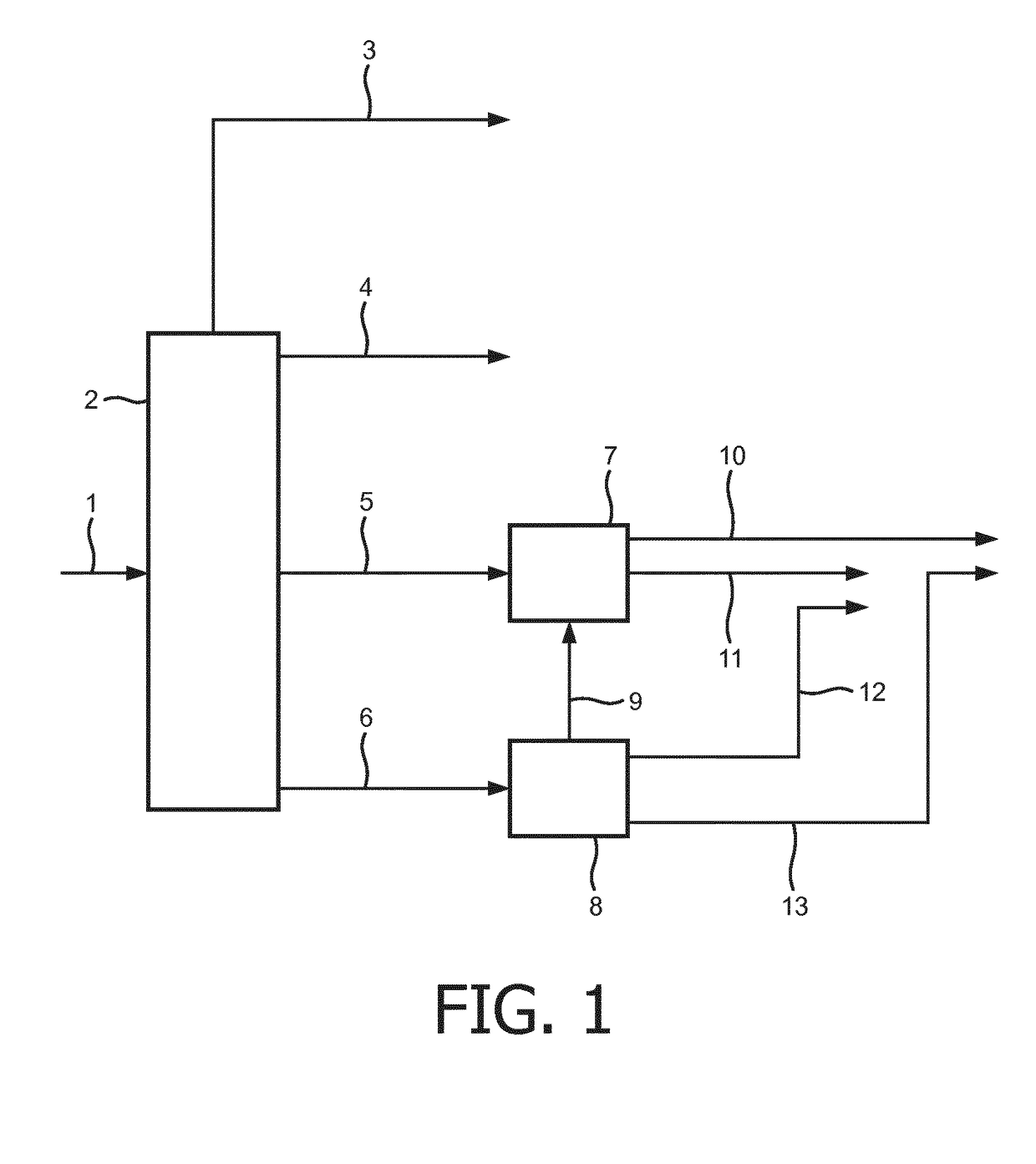

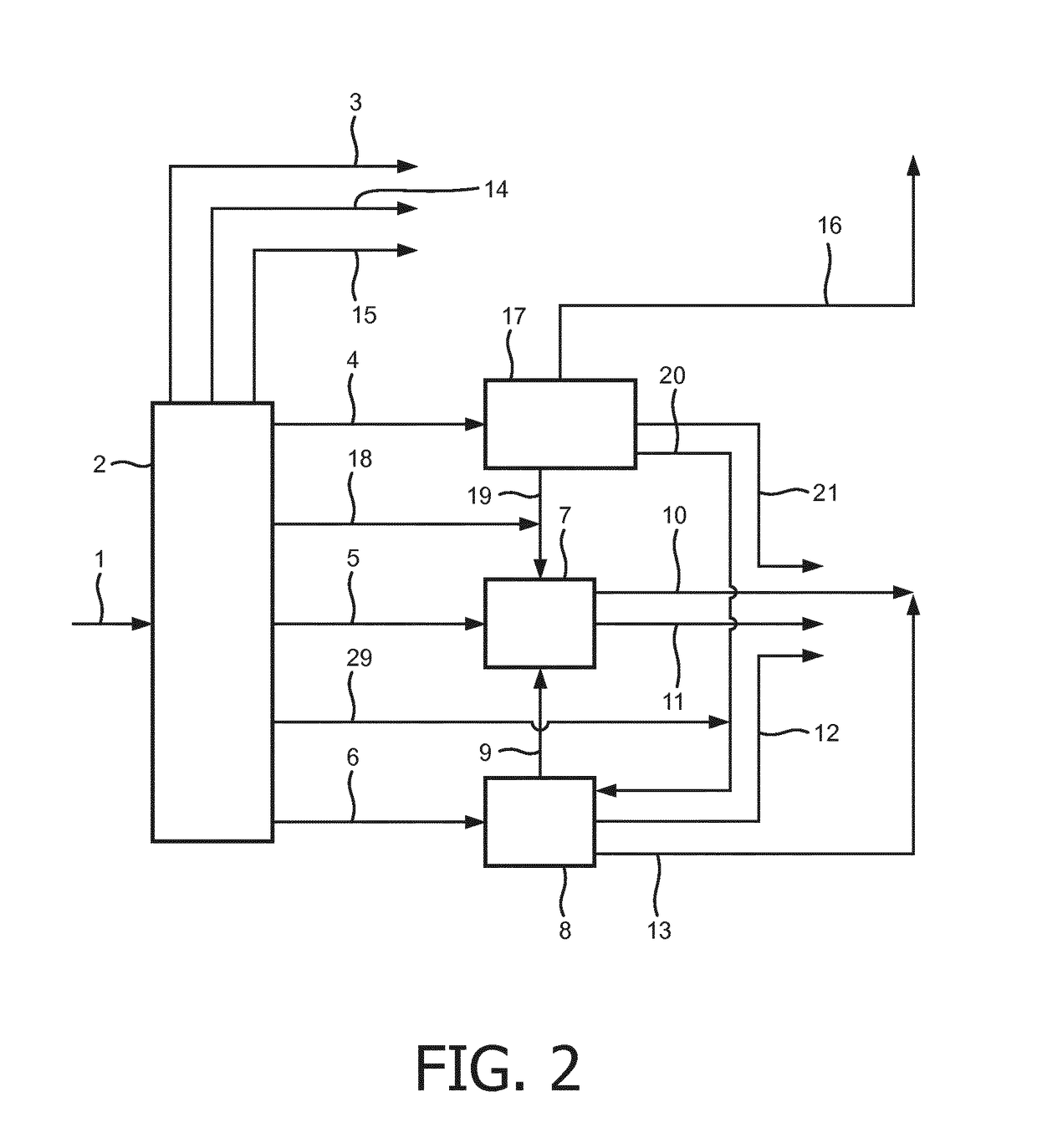

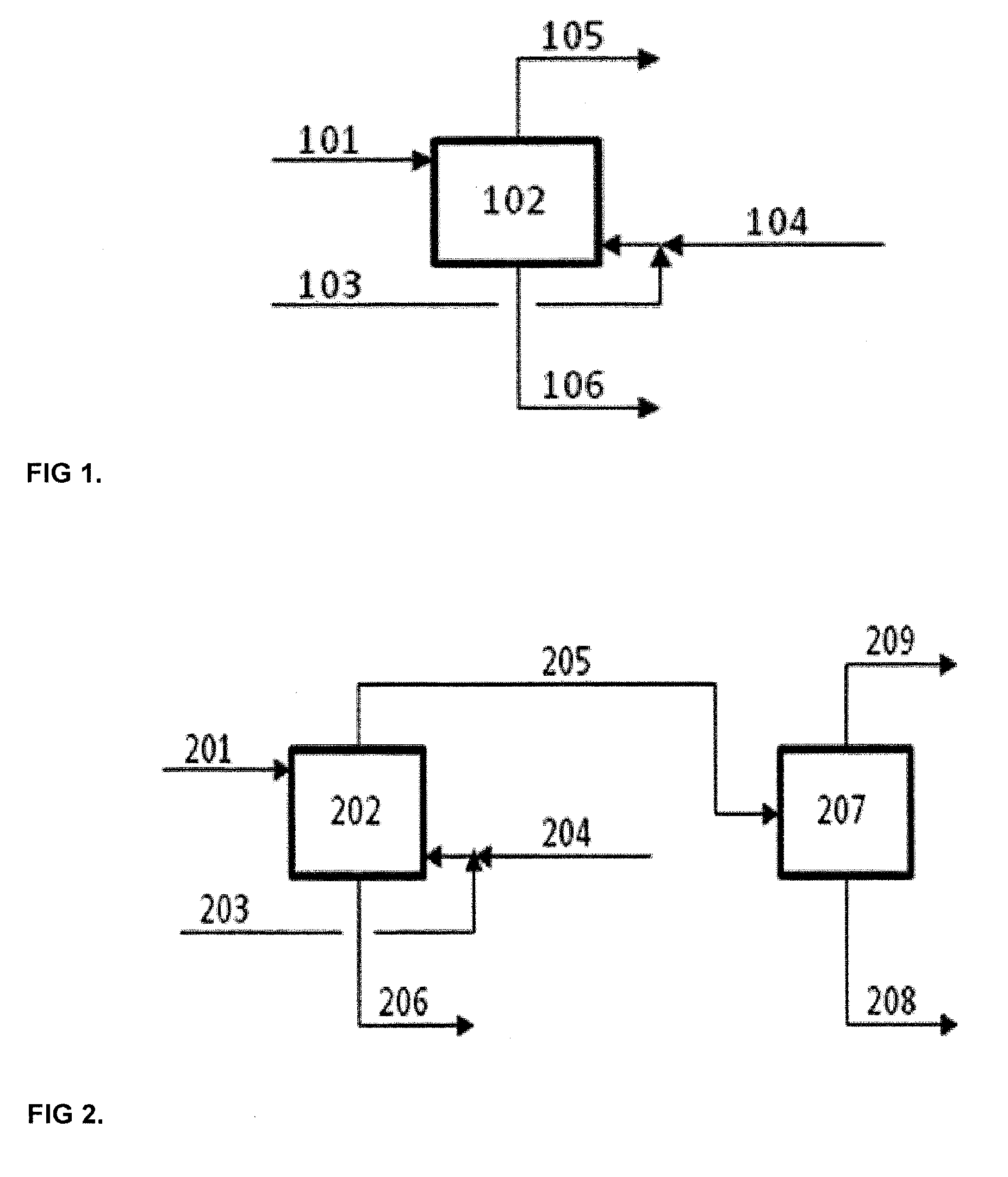

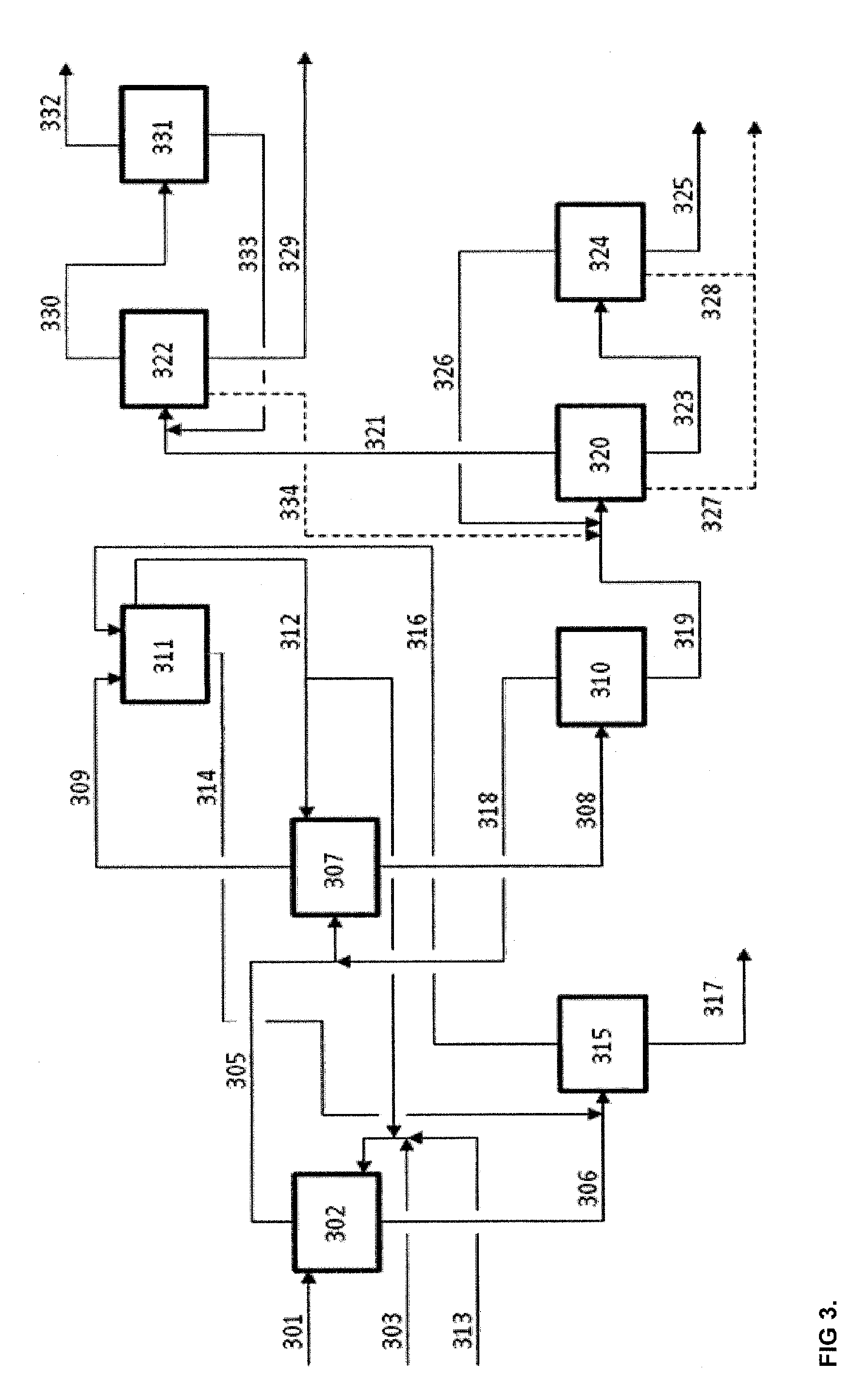

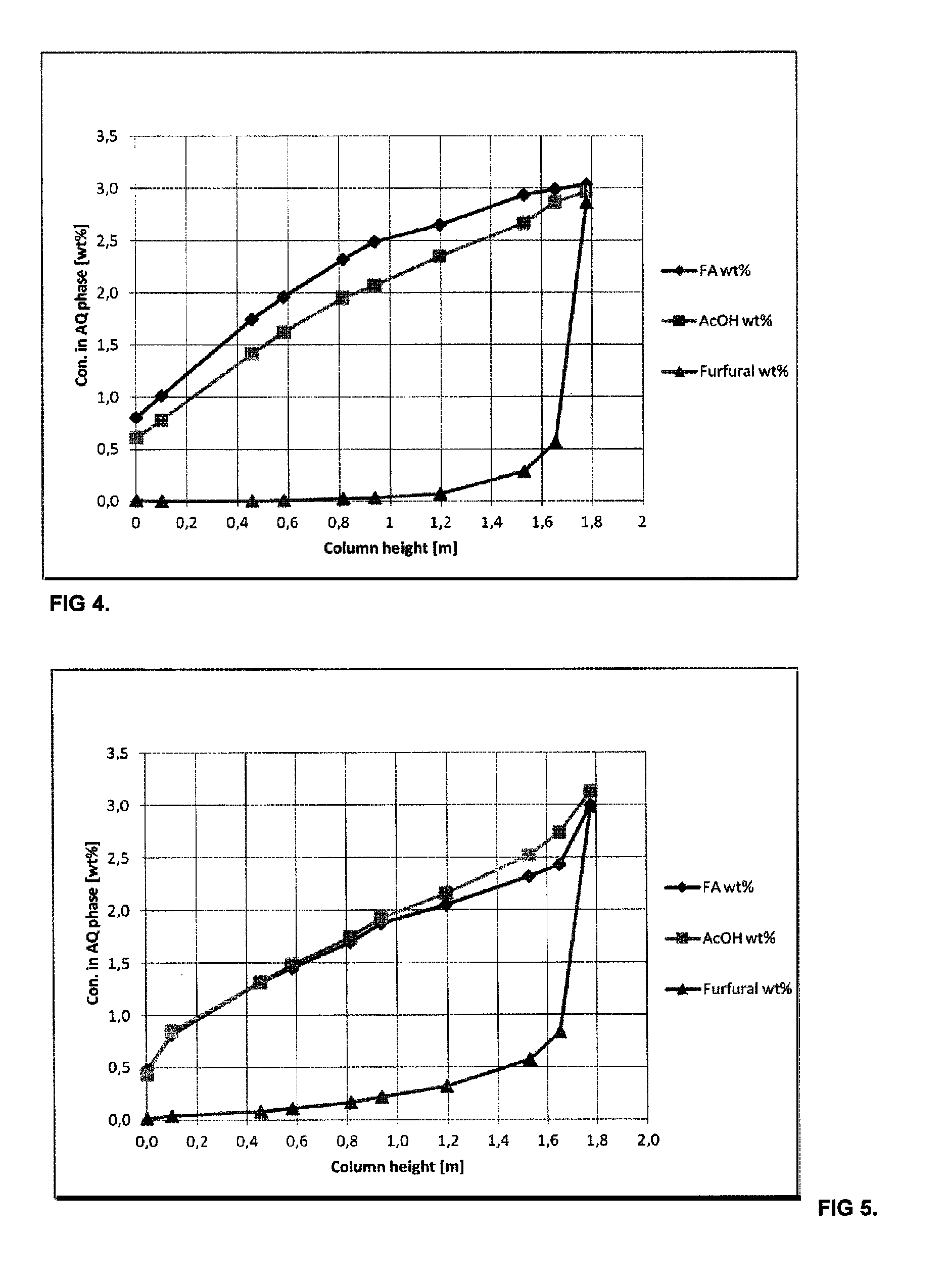

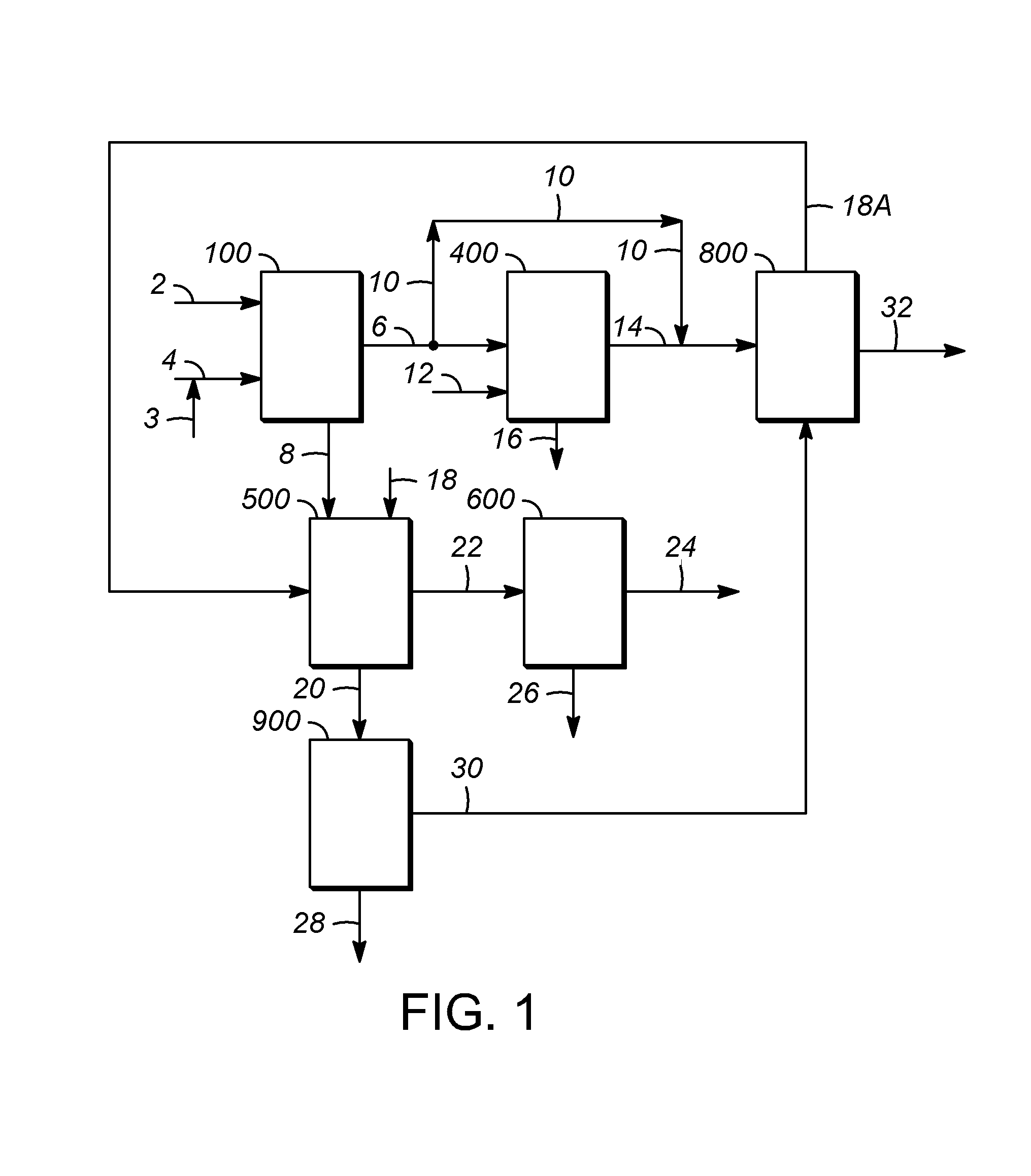

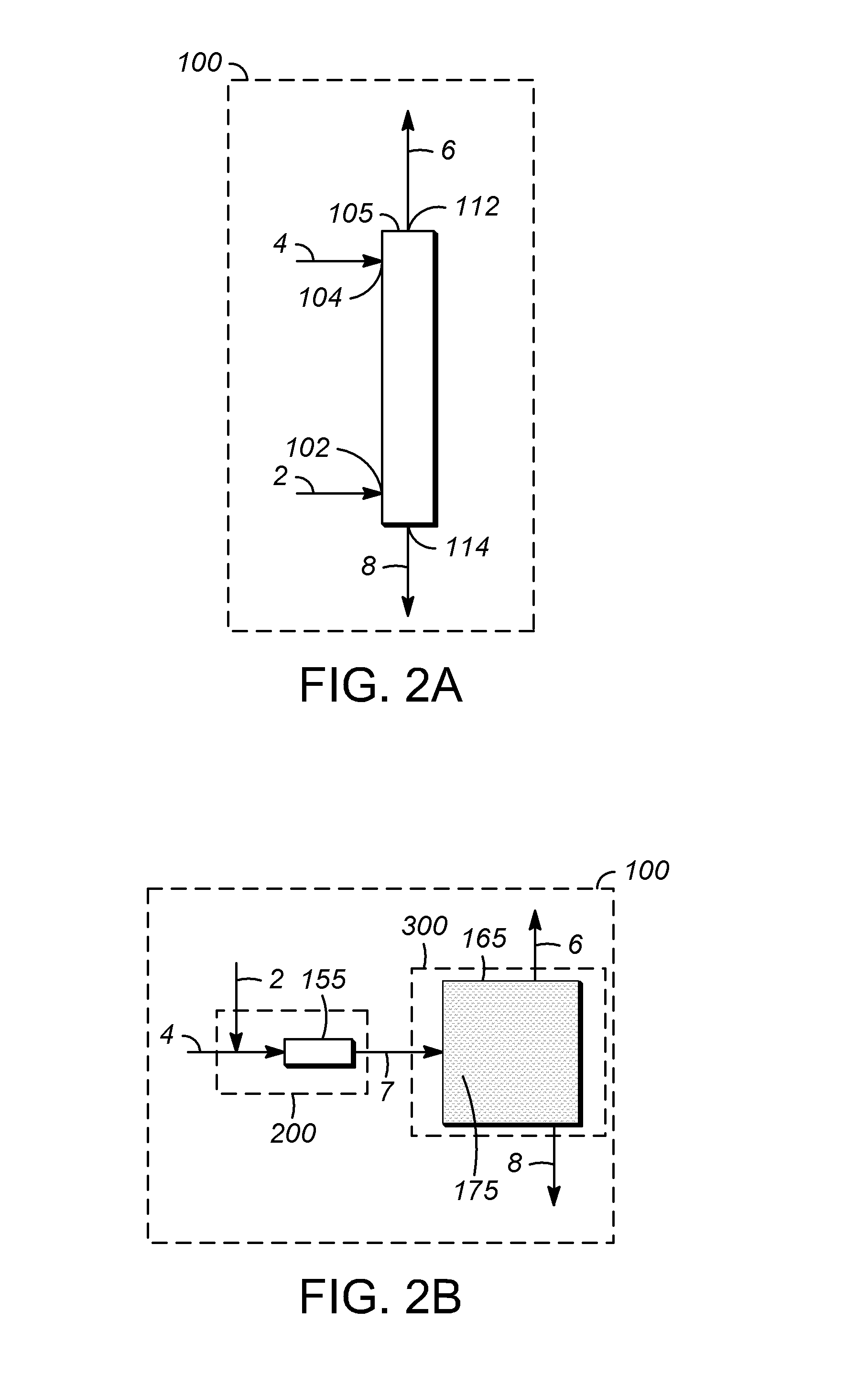

Method and an arrangement for separating at least one carboxylic acid and furfural from a dilute aqueous mixture thereof

ActiveUS9073847B2Easy extractionEfficient extractionLiquid solutions solvent extractionCarboxylic compound separation/purificationDistillationCarboxylic acid

The present invention relates to a method and an arrangement for separation and recovery of at least one carboxylic acid and furfural from a dilute aqueous mixture thereof. In the method of the present invention a dilute aqueous mixture comprising at least one carboxylic acid and furfural is extracted with methyltetrahydrofurane, and at least one carboxylic acid and furfural are recovered. The arrangement of the present invention comprises an extraction unit 302 for carrying out extraction of at least one carboxylic acid and furfural from dilute aqueous mixture with methyltetrahydrofuran, connected to distillation unit 307 for carrying out distillation of the extract 305 from the extraction unit 302, and connected to acids distillation unit 320 for carrying out distillation of the bottom stream 308 from the distillation unit 307 to separate at least one carboxylic acid and furfural.

Owner:TAMINCO FINLAND

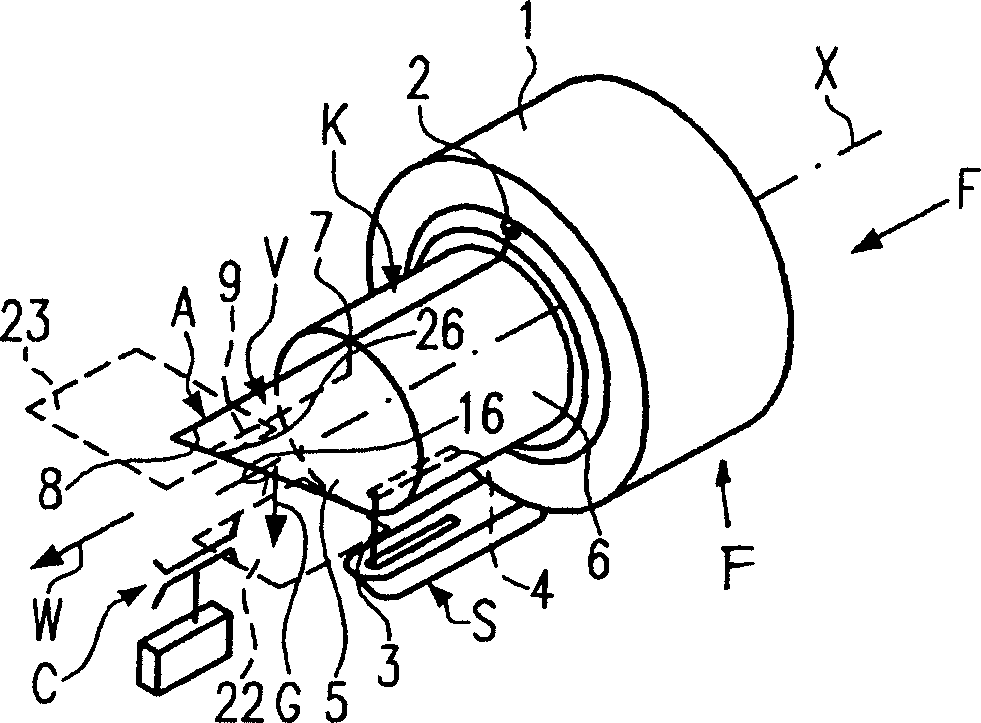

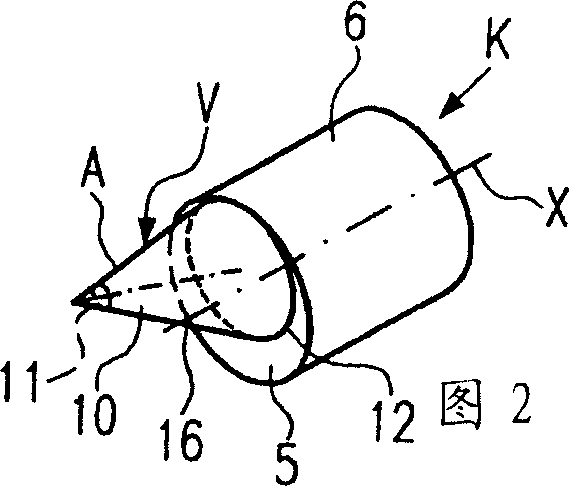

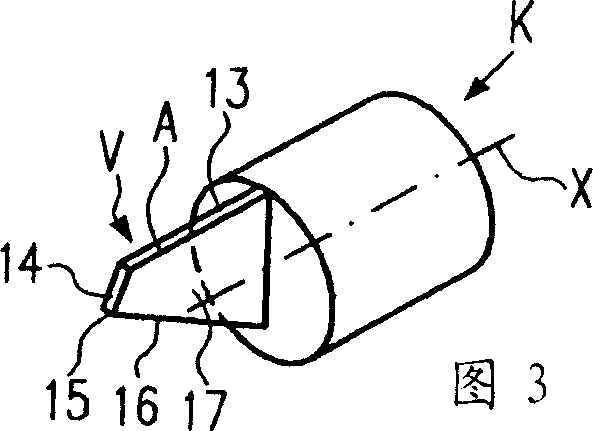

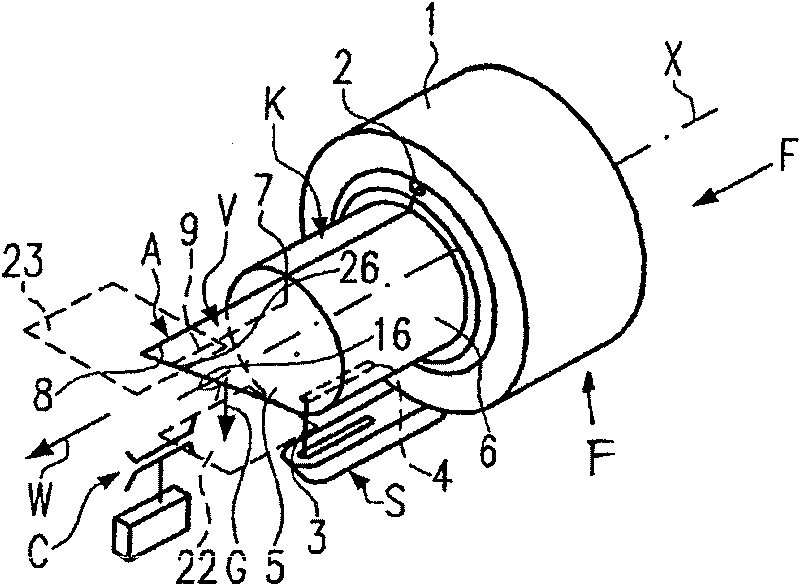

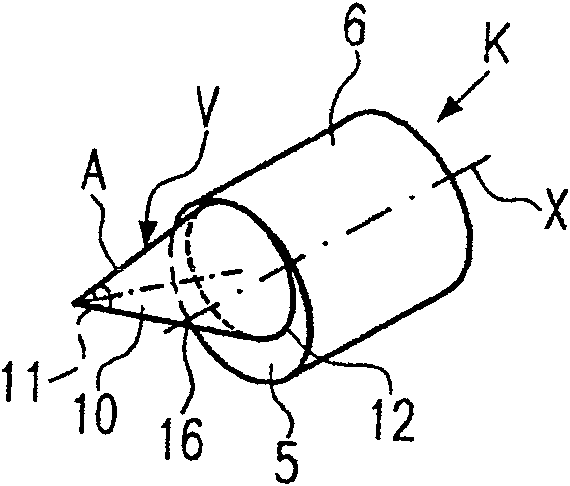

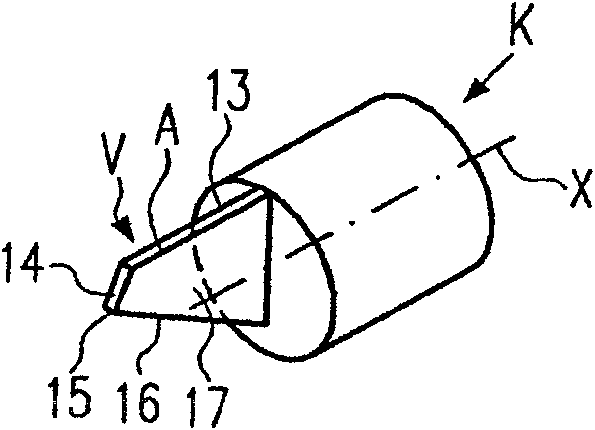

Thread-measuring feeding device

InactiveCN1898139AAppropriate useOrderly and continuous useLoomsFilament handlingBobbinConductor Coil

A yarn length measuring and feeding device (F) according to the present invention comprises a fixed yarn storage body (K), a winding element (2) and a brake device (S). The yarn storage body (K) defines a substantially cylindrical storage surface (6) for weft yarn winding, said winding element (2) being rotatable relative to the storage body (K) along the axis (X) of the storage body (K) Ground drive, said braking device (S) is used to measure the length of yarn. The brake device (S) is provided with at least one brake pin (3). At least one extension (V) is provided on the yarn storage body (K), which protrudes from the front end (5) of the yarn storage body (K) in the unwinding direction (W) and is relatively Axis (X) is asymmetrical. The extension (V) forms an at least linear winding support (A) which continues the yarn storage surface (6) of the yarn storage body in the unwinding direction (W). Furthermore, at least approximately diametrically opposite to the winding support (A) there is provided a counter surface (16) which tapers in the unwinding direction (W) and protrudes beyond the front end (5 ).

Owner:IRO AB

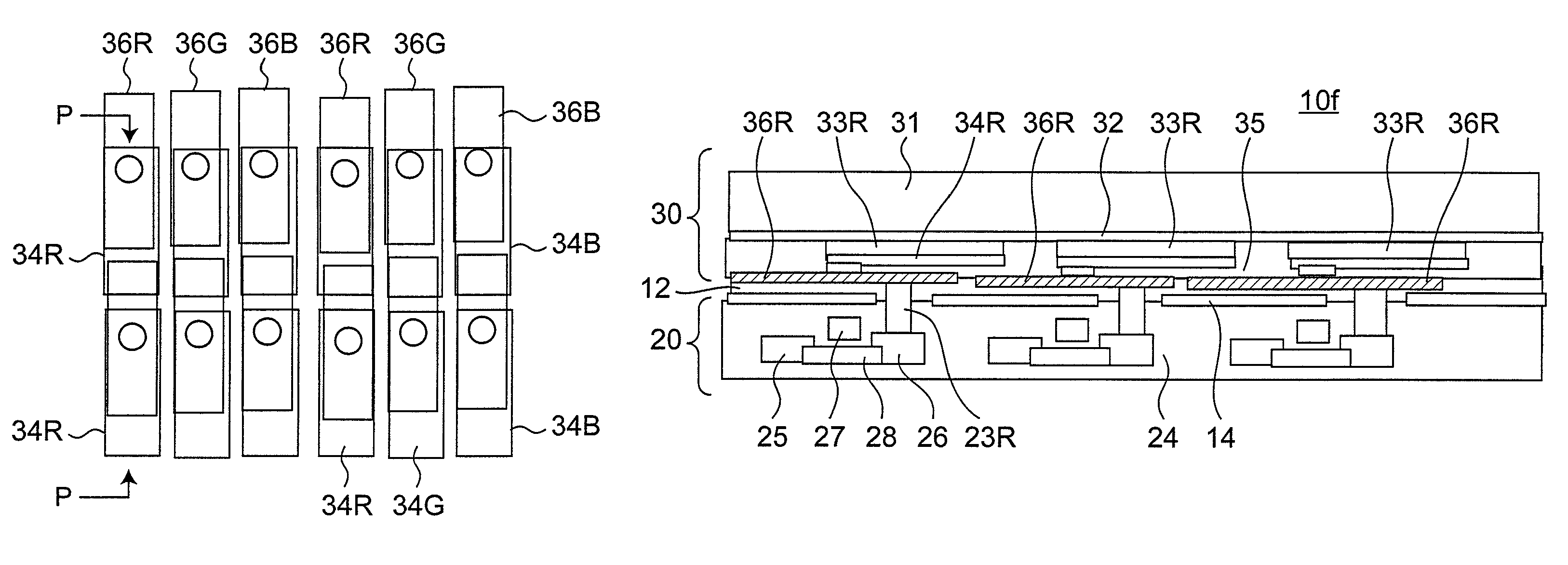

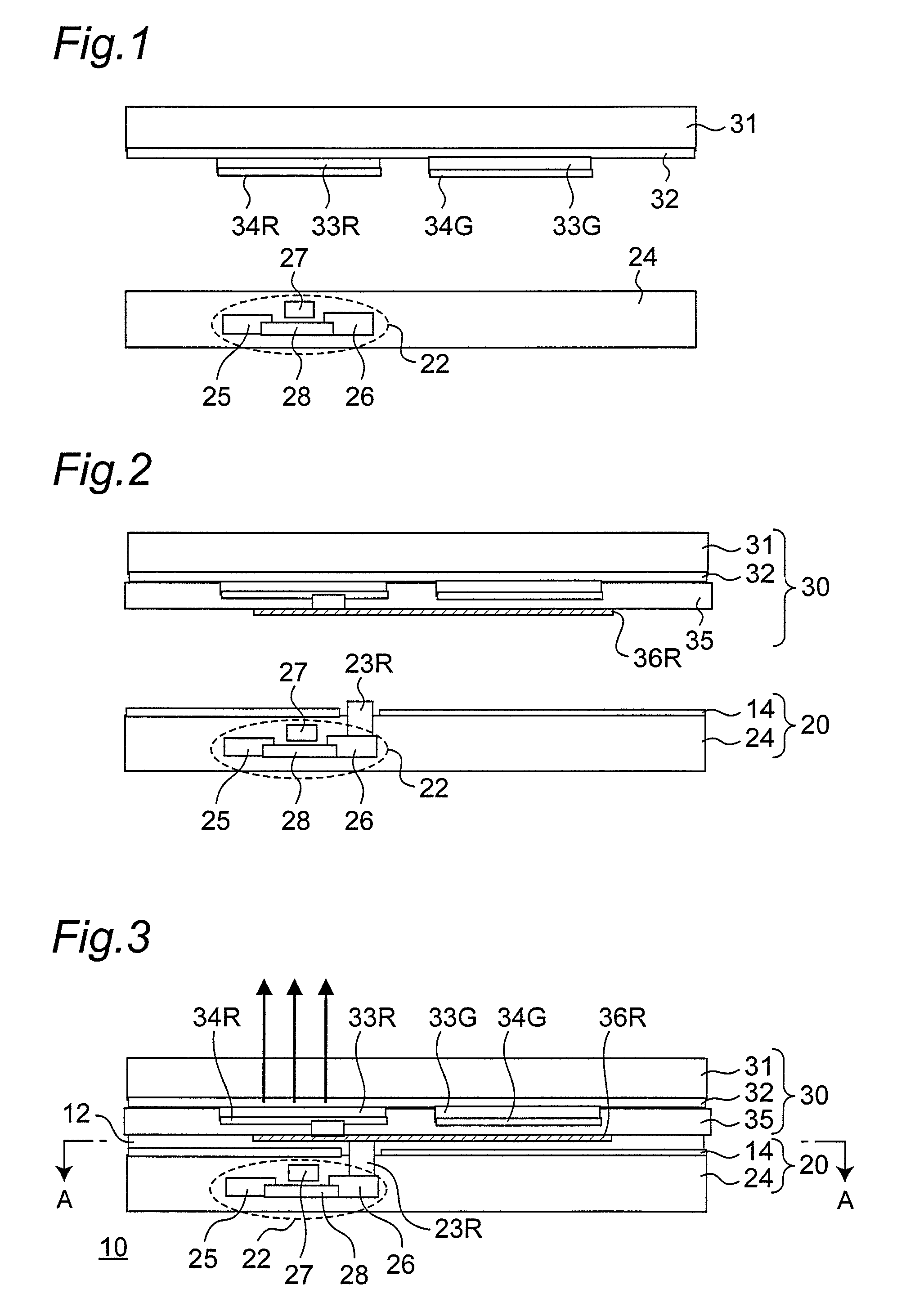

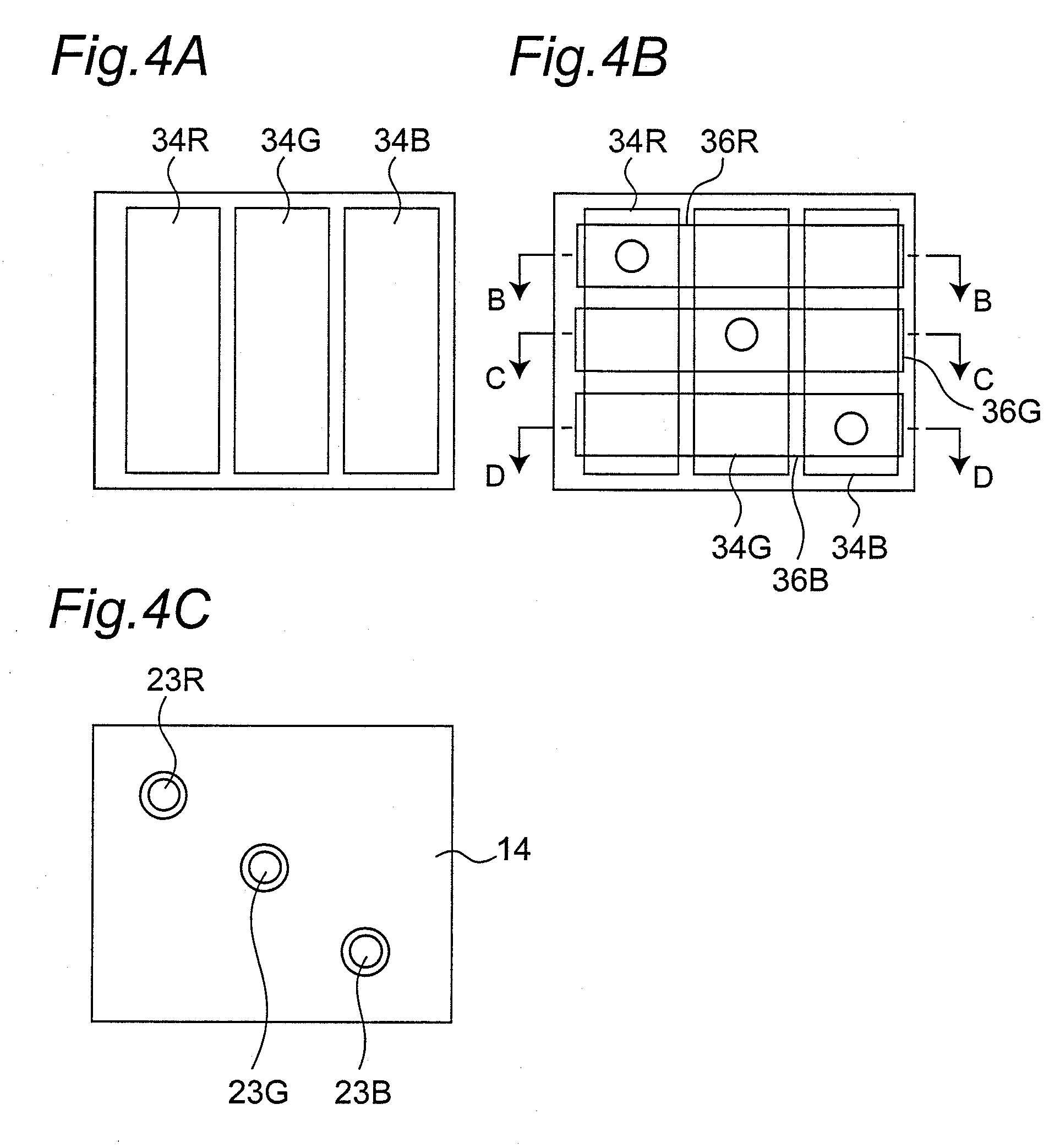

Display apparatus

ActiveUS8237359B2Long emission lifetimeSmall fluctuationDischarge tube luminescnet screensStatic indicating devicesDriving circuitElectrical and Electronics engineering

Owner:JOLED INC

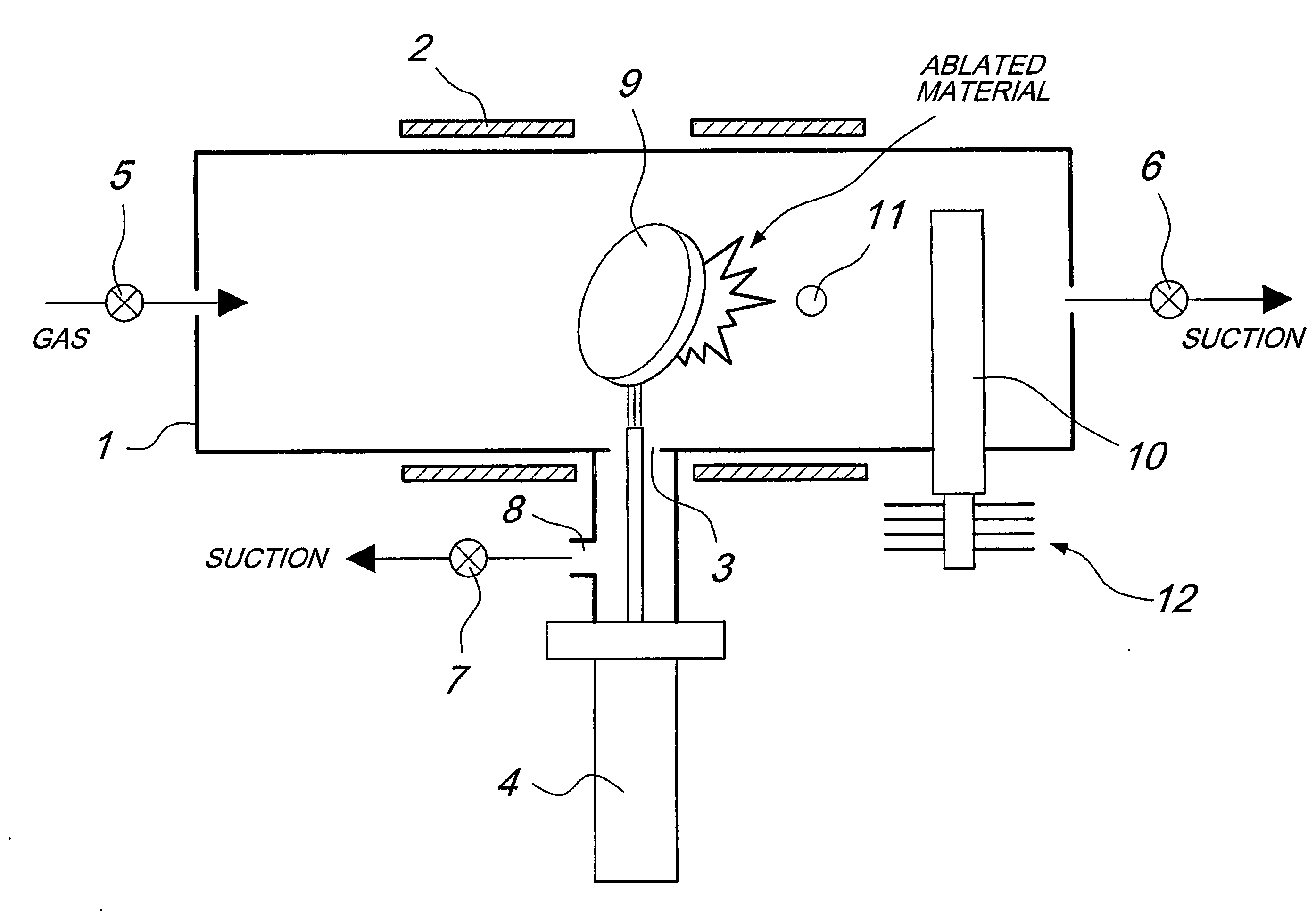

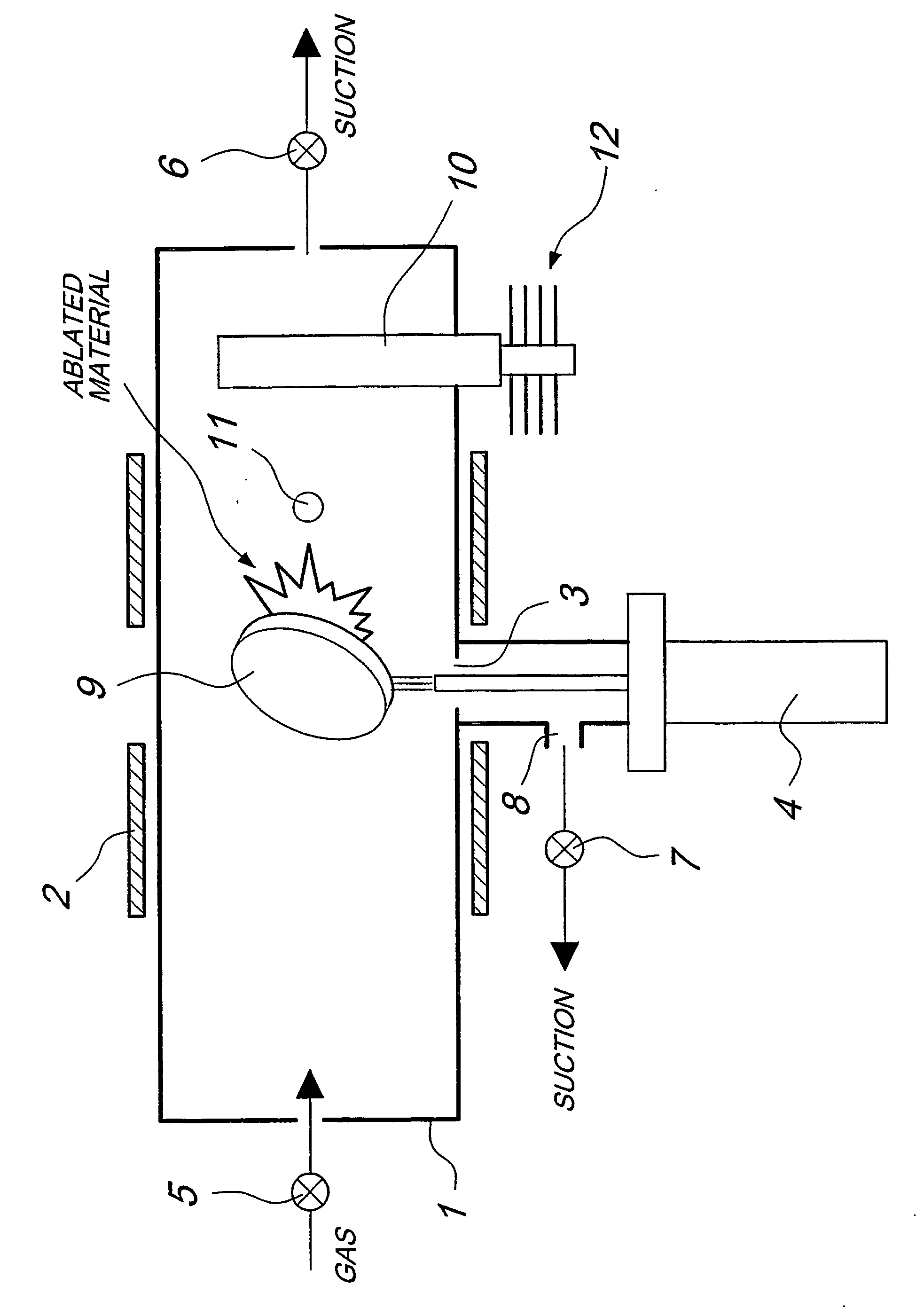

Process for manufacturing single-wall carbon nanotubes

InactiveUS20090246116A1Increase contentThe process is simple and effectiveMaterial nanotechnologyElectric discharge tubesCarbon nanotubeGraphite

Owner:DEDIU VALENTIN +3

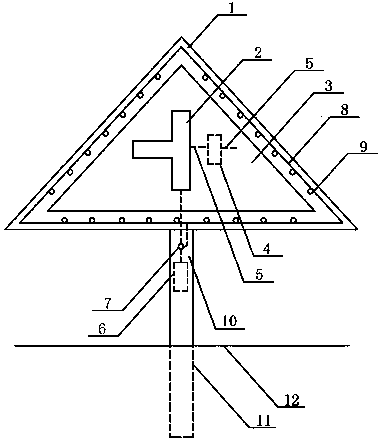

Illumination device applying thin film solar battery to luminous plastic traffic sign board

InactiveCN103775957AYieldIncrease power generationBatteries circuit arrangementsElectric circuit arrangementsTraffic crashElectrical battery

The invention relates to an illumination device applying a thin film solar battery to a luminous plastic traffic sign board, and belongs to the technical field of new energy source power generation culture. Through the increase of haze days and haze concentration in partial regions, the visibility on roads is reduced, so drivers cannot clearly see the original traffic sign boards, and the traffic accident increase is caused. The luminous plastic traffic sign board made of luminous plastics made of long-afterglow luminous materials can emit light rays to increase the power generating quantity of the thin film solar battery, current output from the thin film solar battery is input into a controller to be regulated through a conducting wire, and current output from the controller realizes the power supply and illumination to a T-shaped sign LED (light emitting diode) luminous module through a conducting wire. When the illumination is insufficient, a photosensitive self control switch is automatically switched on, and the circuit is conducted. The current output from a lithium-ion battery realizes the supplementary power supply to the T-shaped sign LED luminous module through the conducting wire and the photosensitive self control switch, and certain brightness is ensured, so the drivers can clearly see signs on the sign board.

Owner:WUXI TONGCHUN NEW ENERGY TECH

Hydrocarbon conversion processes using ionic liquids

InactiveUS20140353208A1YieldIncrease productionTreatment with plural serial stages onlyHydrocarbon oils refiningIonic liquidHydrocarbon

A method of hydrocarbon conversion is described. The hydrocarbon feed is decontaminated using an ionic liquid and introduced into a conversion zone. The conversion of the decontaminated feed is increased compared to the conversion of the contaminated feed and the yield of the desired product made from the decontaminated hydrocarbon feed is increased compared to the yield of the desired product made from the contaminated hydrocarbon feed.

Owner:UOP LLC

Technique for producing continuous yarn basic cloth without twist compound felt

The invention relates to a technique for filament untwisted base fabric compositing filter mat, which is a filter mat technique in high-density and high-strength filter materials used in industry and environmental protection. Traditional filter mat is produced by needling twisted staple base fabric and is easy to deform, and hole distance and density thereof are changed after use and use period is short. The technique of the invention comprises spinning preparation, weft yarn preparation, spinning on machines, base fabric forming, measuring the weight of compositing filter mat raw material and base fabric, extruding and thermoforming, cutting, punching and edge sealing. The filament untwisted base fabric compositing filter mat produced by the technique has smooth surface, fast filtering speed, no deformation after washing for a plurality of times, long use period, guarantee of effective filtering area and unchanged hole distance, is acid and alkaline resistant and easy for disassembly and assembly and cleaning, has little water consumption for cleaning and maintenance and low labor intensity, achieves the optimal effects of yield, output, quality and emission reduction, and is energy-saving, emission-reducing and cost-saving. Products produced by the technique can be applied to the high-tech fields of petroleum, optical fiber, concrete, metallurgy, soybean fiber, bioengineering, textile printing, environmental protection, etc.

Owner:杜勇

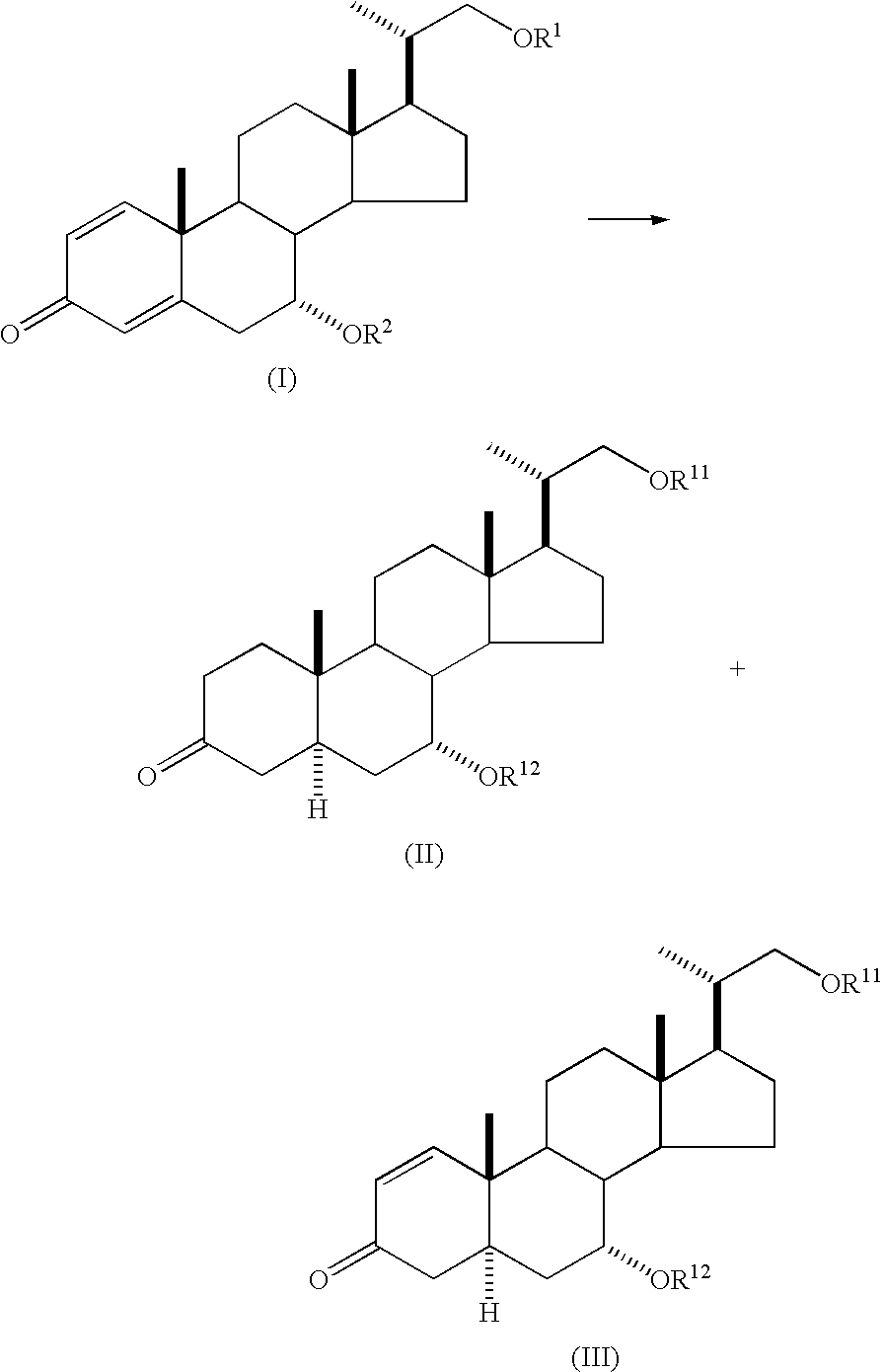

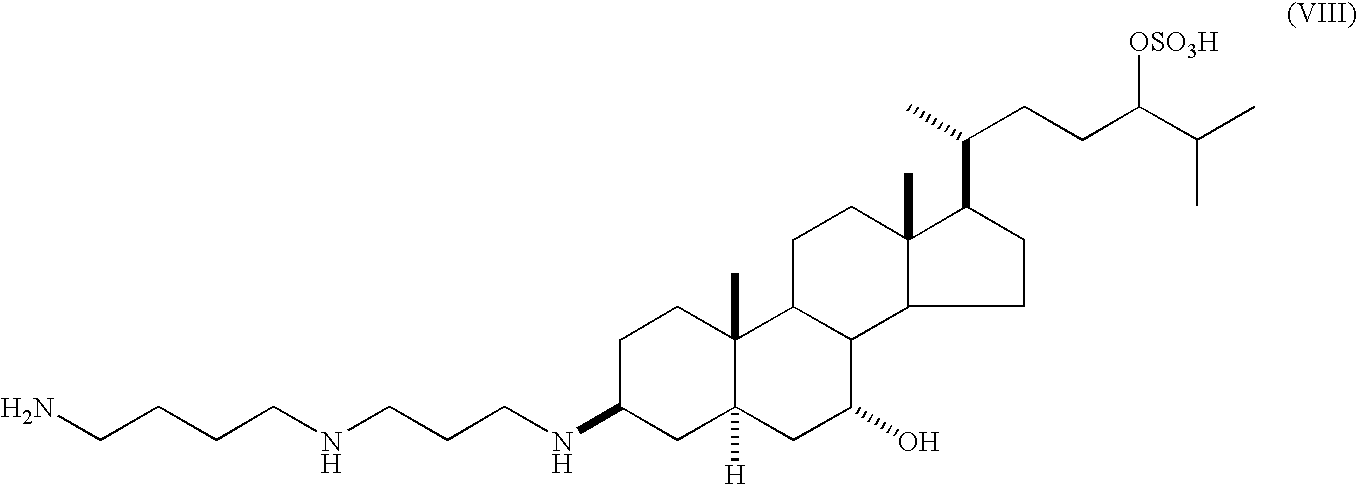

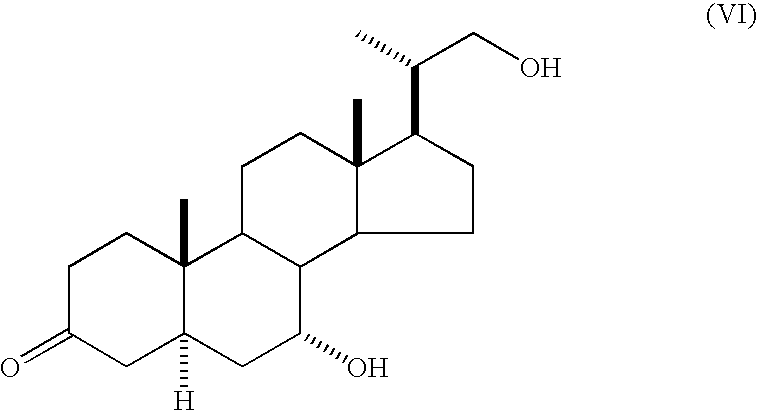

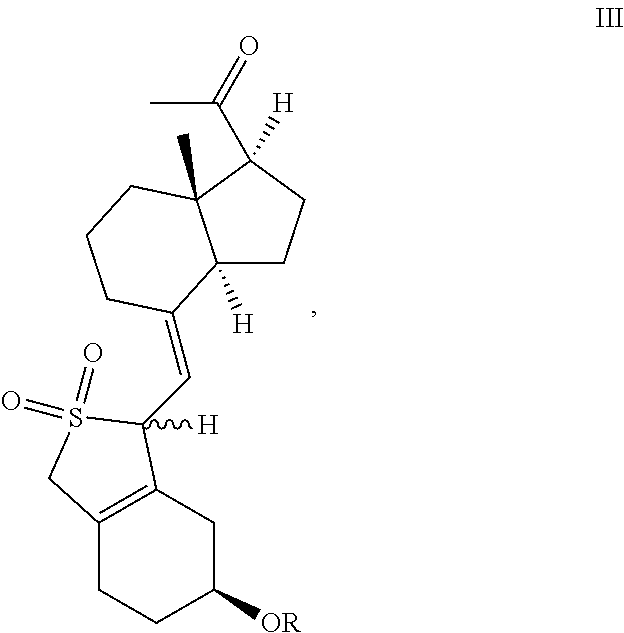

Method for producing 5alpha-pregnane derivative

InactiveUS20070197490A1High yieldInhibition decreasedOrganic active ingredientsSteroidsAlkaline earth metalSqualamine

The present invention relates to a method of producing a mixture of 5α-pregnane derivatives represented by the formula (II) and the formula (III), which is characterized by reacting a pregnane derivative represented by the formula (I) with a metal selected from alkali metals and alkaline earth metals in the presence of a proton donor and an amine and / or ammonia. According to the present invention, a method capable of producing 5α-pregnane derivatives useful as synthetic intermediates for squalamine, in a high yield from easily available raw materials, can be provided: wherein R1 is a hydroxyl-protecting group, and R2, R11 and R12 are each independently a hydrogen atom or a hydroxyl-protecting group.

Owner:KURARAY CO LTD

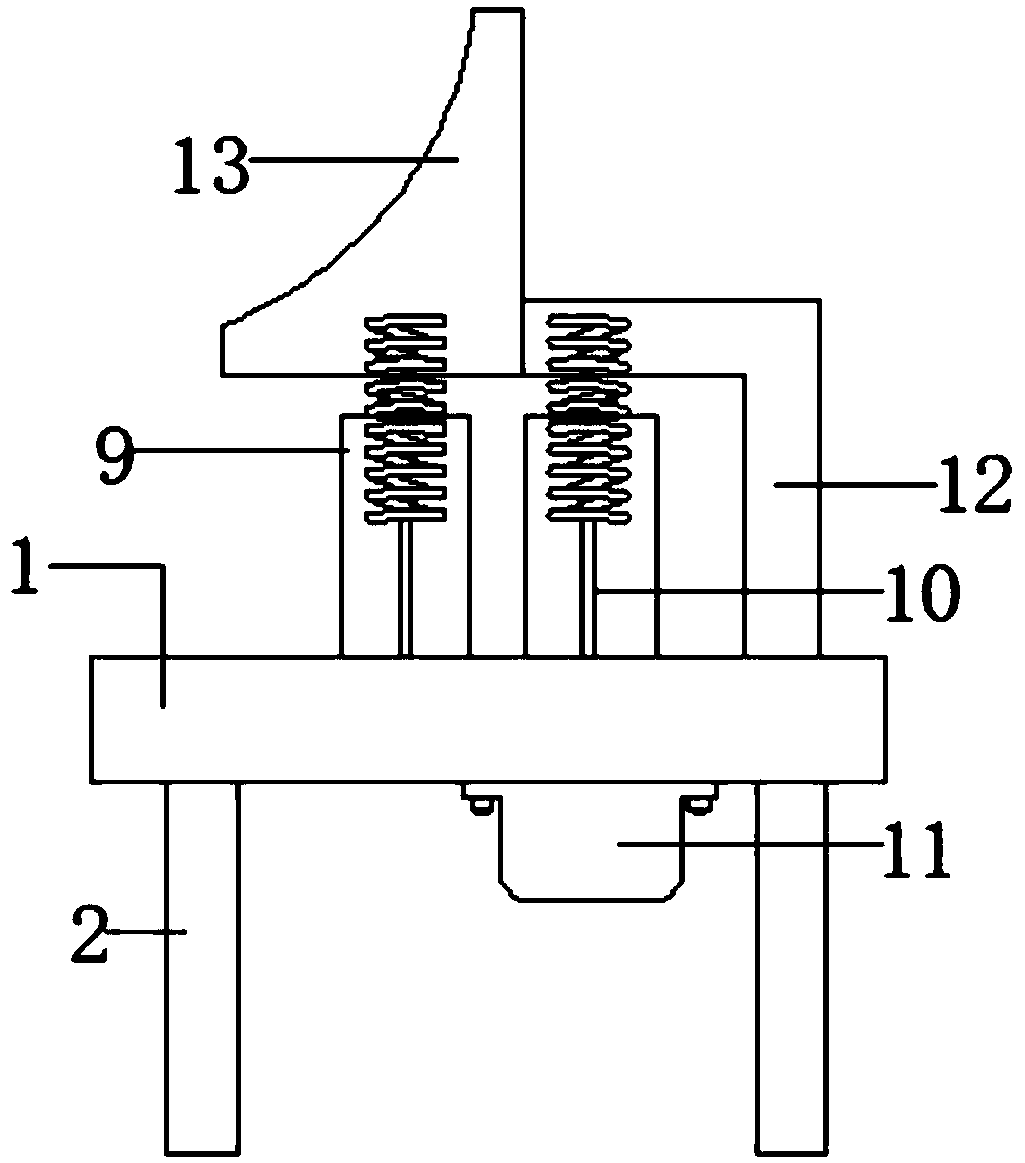

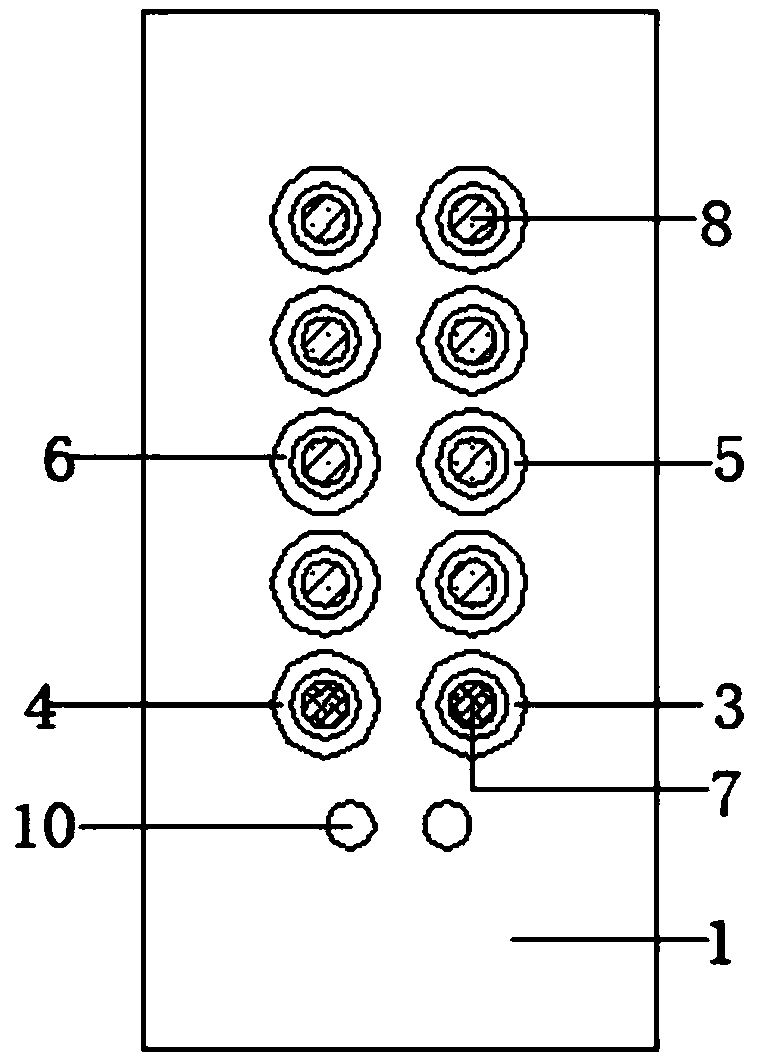

Bridge cover plate flanging device and bridge cover plate machining method

The invention belongs to the technical field of bridge cover plate production, and particularly discloses a bridge cover plate flanging device and a bridge cover plate machining method. The bridge cover plate flanging device comprises a workbench, stand bars and a motor; a first bearing and a second bearing are symmetrically embedded in the left side and the right side of a workbench body, third bearings are uniformly and longitudinally embedded in the right side of the workbench body, and fourth bearings are uniformly and longitudinally embedded in the left side of the workbench body; the outer wall of the first rotary shaft and the outer wall of the second rotary shaft are sleeved with rotary rollers; a right-angle supporting plate is welded to the right side of the top of the workbench;and a spiral baffle is welded to the left end of the right-angle supporting plate. A machining method of the bridge cover plate flanging device comprises the specific following steps that S1, a coverplate is put between the two rotary rollers to be clamped, and S2, the device is started so that the cover plate can move backwards at the constant speed, the cover plate is limited by the spiral baffle, and accordingly, flanging is conducted on the cover plate. Through the scheme, the machining steps are simplified, and the machining efficiency and the product percent of pass are improved.

Owner:天长市福骏金属制品有限公司

Fermentative production of acetone from renewable resources by means of novel metabolic pathway

ActiveUS8986961B2YieldHigh yieldSugar derivativesHydrolasesAcyl Coenzyme A SynthetasesAcyl-CoA synthetase

The invention describes a process for preparing acetone starting from acetyl-coenzyme A comprising process steps A. enzymatic conversion of acetyl-CoA into acetoacetyl-CoA B. enzymatic conversion of acetoacetyl-CoA into acetoacetate and CoA and C. decarboxylation of acetoacetate to acetone and CO2, which is characterized in that the coenzyme A is not transferred in process step B to an acceptor molecule. In addition, process step B is surprisingly catalyzed by enzymes of the classes of acyl-CoA thioesterase, acyl-CoA synthetase or acyl-CoA thiokinase.A completely novel metabolic pathway is concerned, because the enzymatic hydrolysis of acetoacetyl-CoA without simultaneous transfer of CoA to a receptor molecule has never previously been described for any microbial enzyme.

Owner:EVONIK OPERATIONS GMBH

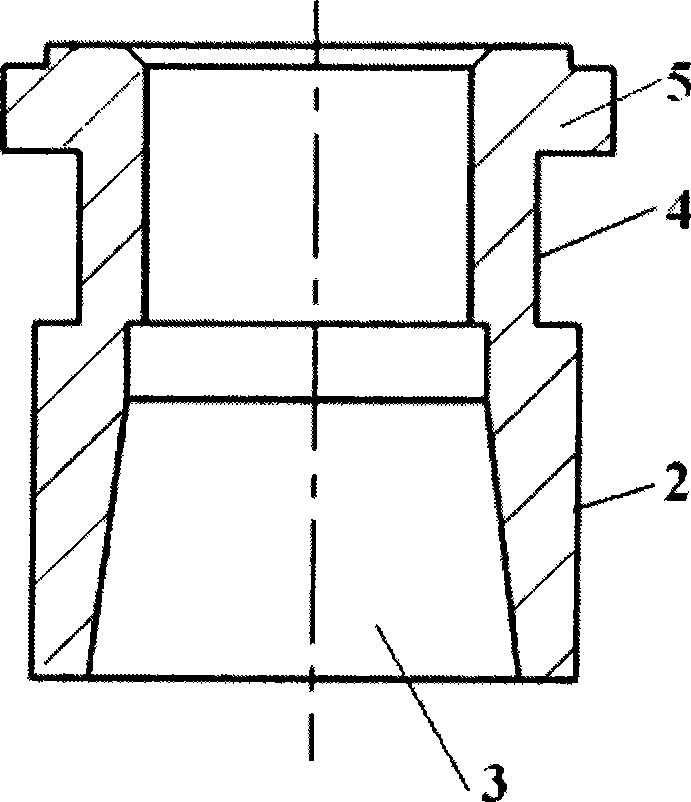

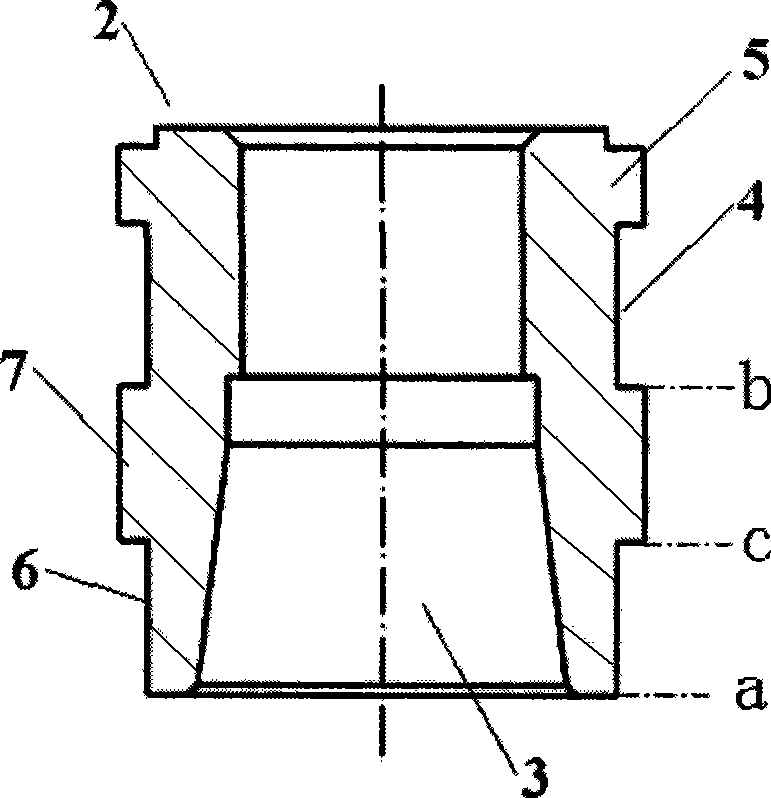

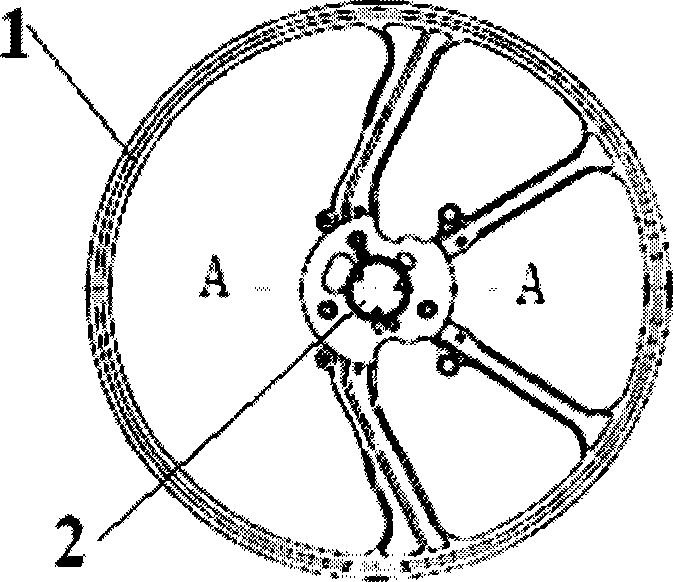

Mounting structure of steering wheel central bush

The invention discloses a structure for mounting a central liner of a steering wheel. The structure is provided with two steps; and one is an end part lug boss (5) positioned at one end of a cylindrical hole of a bearing sleeve (2) of the steering wheel, and the other one is a middle lug boss (7) axially positioned on an outer circle at the smallest aperture part of a taper hole (3). With the technical proposal, the structure solves the problem of deformation when an inner taper of the bearing liner of the steering wheel is subjected to die casting, is simple and convenient to implement and improves production efficiency.

Owner:THIXOMAG TECHNOLOGH WUHU

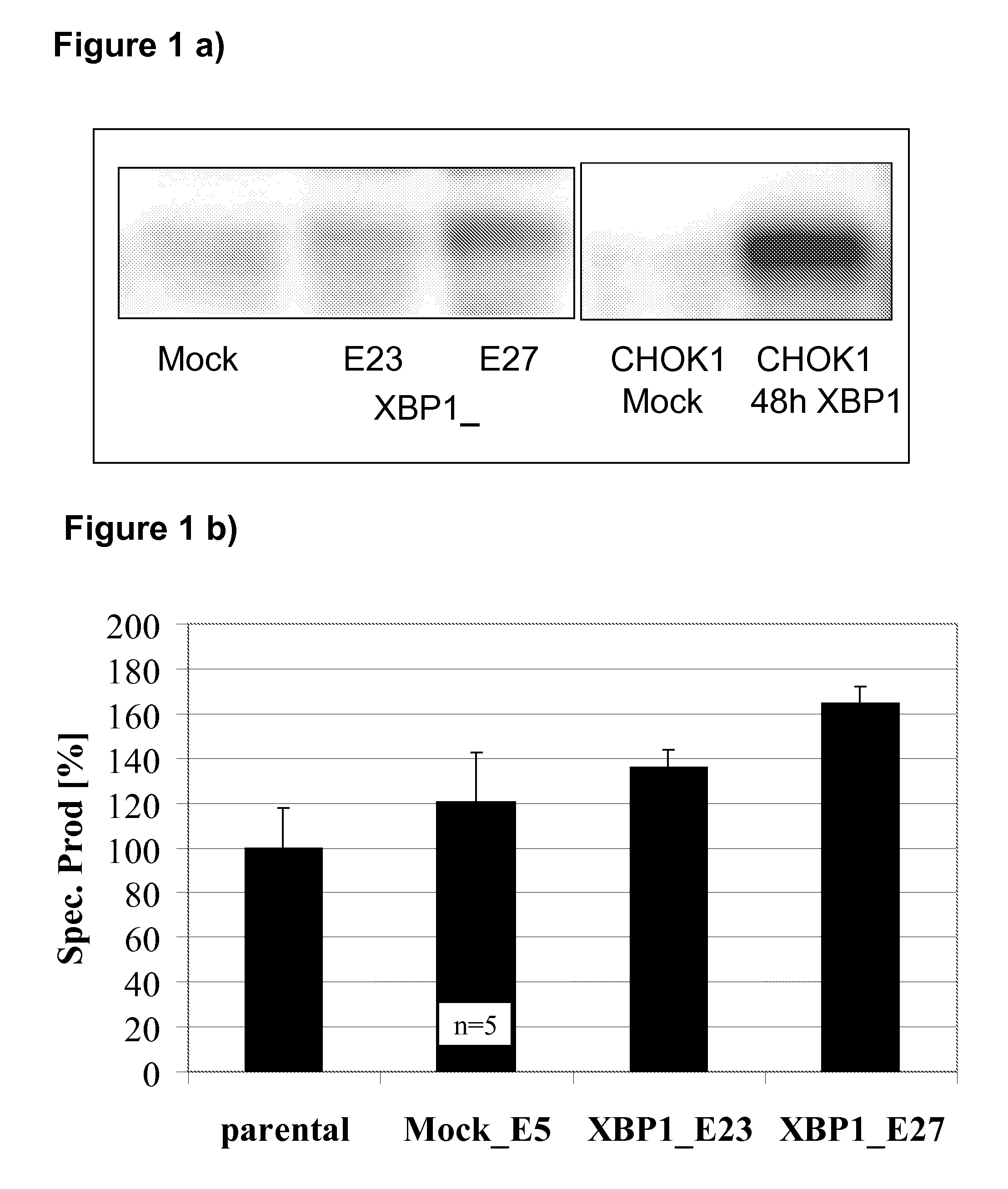

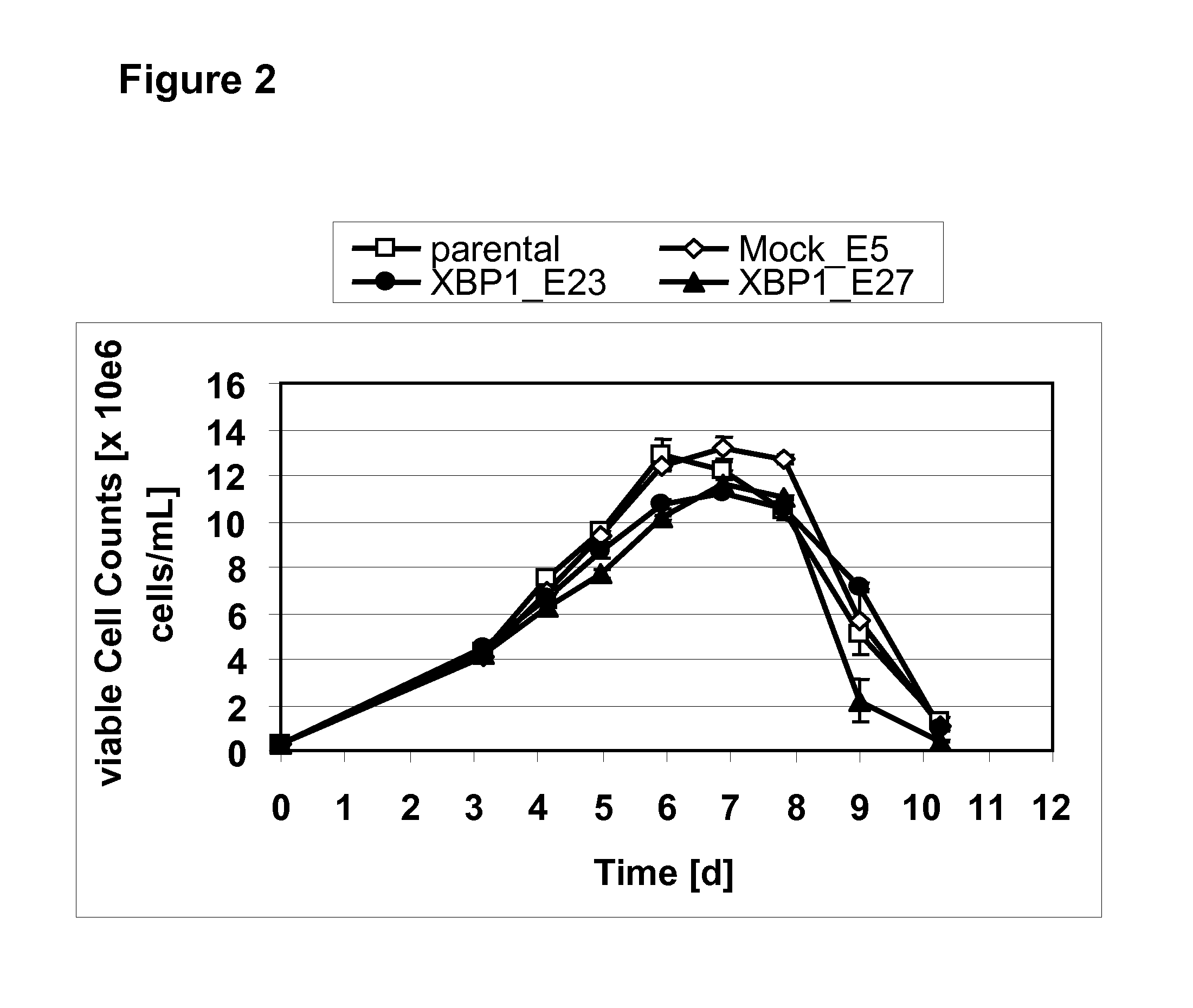

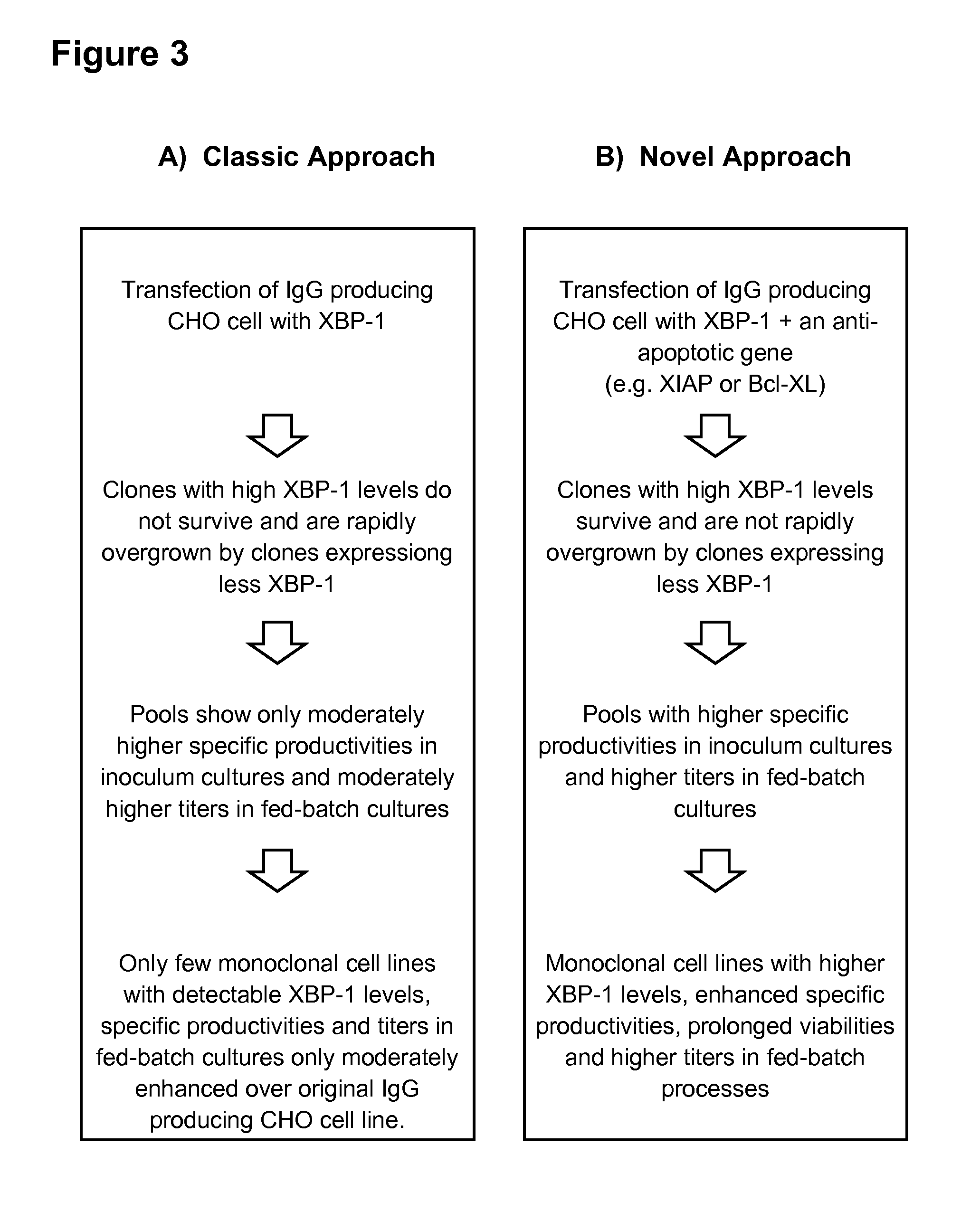

The secretory capacity in host cells

InactiveUS20110281301A1Improve production yieldIncrease capacityAnimal cellsGenetically modified cellsHeterologousEndoplasmic reticulum overload response

The invention concerns the field of protein production and cell culture technology. It describes a method of producing a heterologous protein of interest in a cell comprising a. Increasing the expression or activity of a secretion enhancing gene, and b. Increasing the expression or activity of an anti-apoptotic gene, and c. Effecting the expression of said protein of interest, whereby the secretion enhancing gene is a gene encoding a protein whose expression or activity is induced during one of the following cellular processes: plasma-cell differentiation, unfolded protein response (UPR), endoplasmic reticulum overload response (EOR).

Owner:BOEHRINGER INGELHEIM PHARM KG

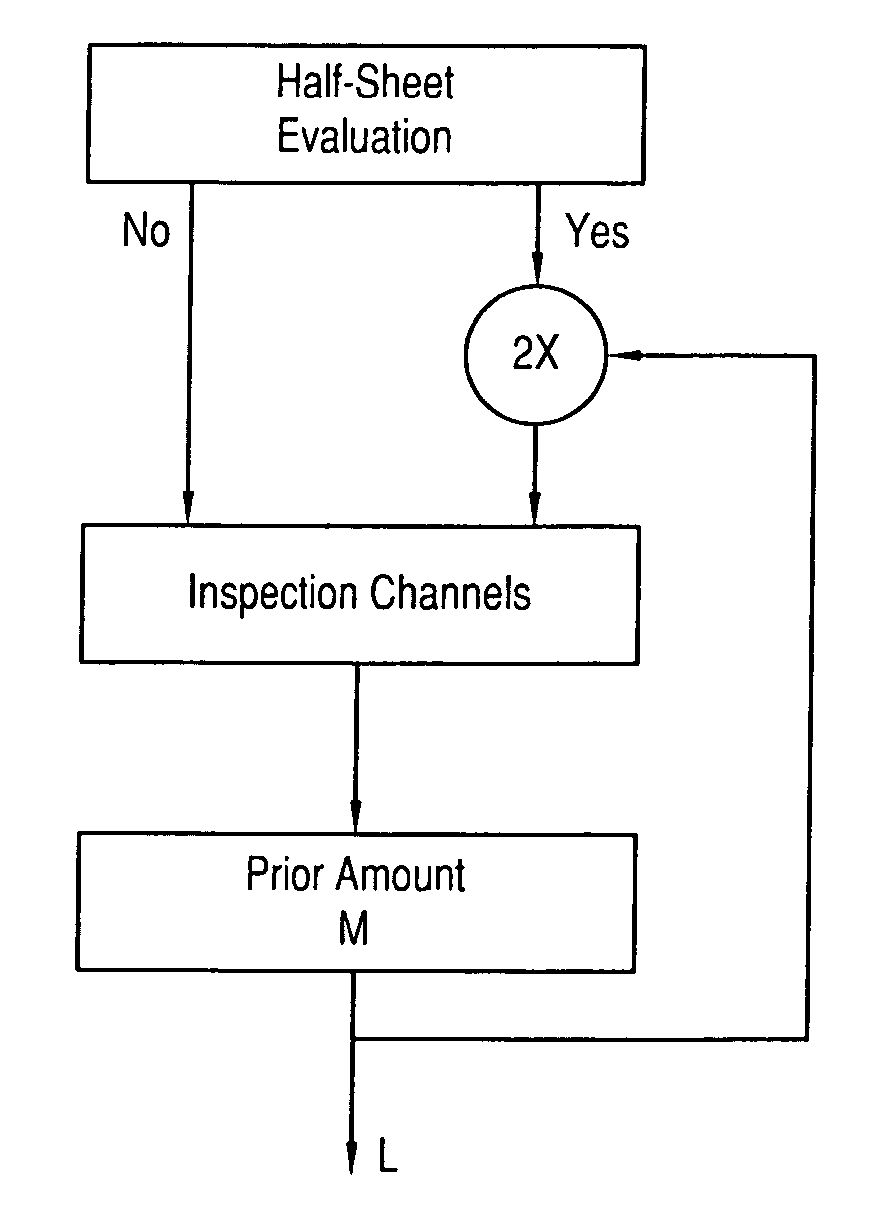

Method for evaluating the quality of a printed matter, provided by a printing machine

InactiveUS7672486B2Increases productivity and economyYieldImage analysisRegistering/indicating quality control systemsEngineeringImaging data

The quality of printed matter, which is one of several copies of the same printed matter produced by a printing machine, is evaluated. An amount of copies of the printed matter is selected from the total production of this printed matter. The selected amount of these copies are evaluated with regard to at least one error type which belongs to an amount of different error types or with regard to at least one feature of the error. Within the selected amount of copies, an error of a defined error type or of a defined feature, which is detected on at least one of the copies, is evaluated in relation to at least one error of another type or feature detected on the same copy, or another copy of the selected amount. The printed matter is classified as having good or bad quality based on that evaluation. A common reading, producing image data, is obtained by an image sensor from the selected copies. All of the errors to be evaluated in relation to each other are detected from image data gathered during the same common recording.

Owner:KOENIG & BAUER AG

Silicon wafer, method for manufacturing the same and method for heat-treating the same

ActiveCN101638807BThe preparation method is simple and easyImprove productivityPolycrystalline material growthAfter-treatment detailsSingle crystalIngot

A silicon wafer produced from a silicon single crystal ingot grown by Czochralski process is subjected to rapid heating / cooling thermal process at a maximum temperature (T1) of 1300 DEG C or more, but less than 1380 DEG C in an oxidizing gas atmosphere having an oxygen partial pressure of 20% or more, but less than 100%. The silicon wafer (10) according to the invention has, in a defect-free region (DZ layer) (12) including at least a device active region of the silicon wafer, a high oxygen concentration region (12) having a concentration of oxygen solid solution of 0.71018 atoms / cm3 or more and at the same time, the defect-free region contains interstitial silicon (14) in supersaturated state.

Owner:GLOBALWAFERS JAPAN

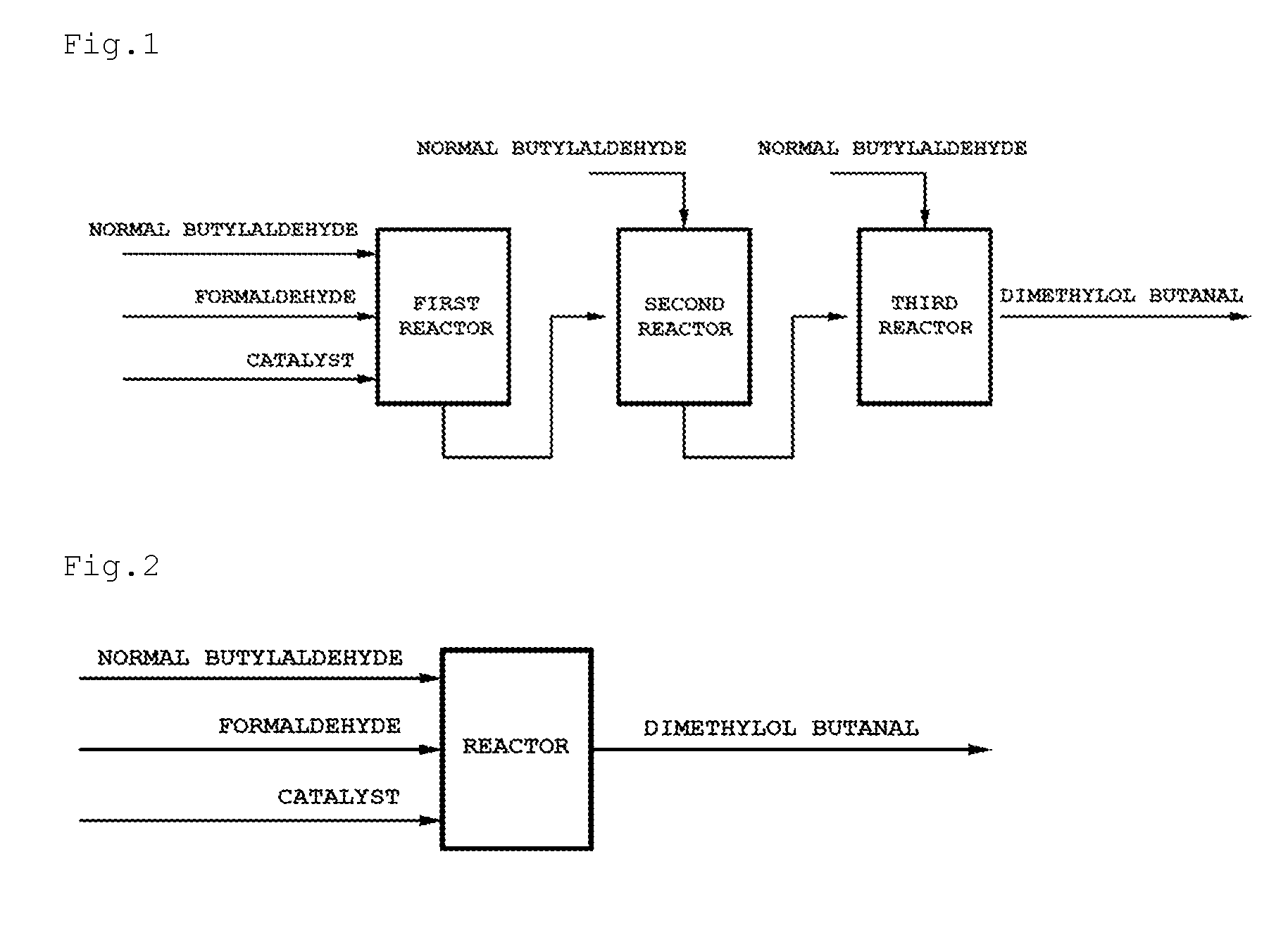

Method for preparing methylol alkanal

ActiveUS9487461B2YieldIncreased hydrogenationOrganic compound preparationCarbonyl compound separation/purificationWastewaterFormaldehyde

Disclosed is a method of preparing methylol alkanal. According to the present invention, a yield of methylol alkanal may be improved without using formaldehyde in an excess amount of a theoretical minimum molar ratio or more, formaldehyde wastewater may be reduced, and the amount of formaldehyde remainder, which may act as a hydrogenation catalyst poison, comprised in the methylol alkanal is decreased when the prepared methylol alkanal is hydrogenated resulting in improvement in efficiency of the hydrogenation.

Owner:LG CHEM LTD

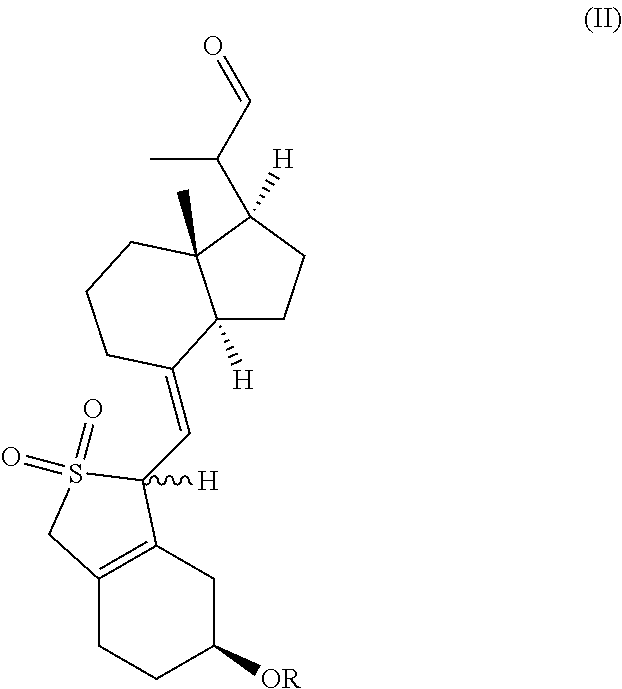

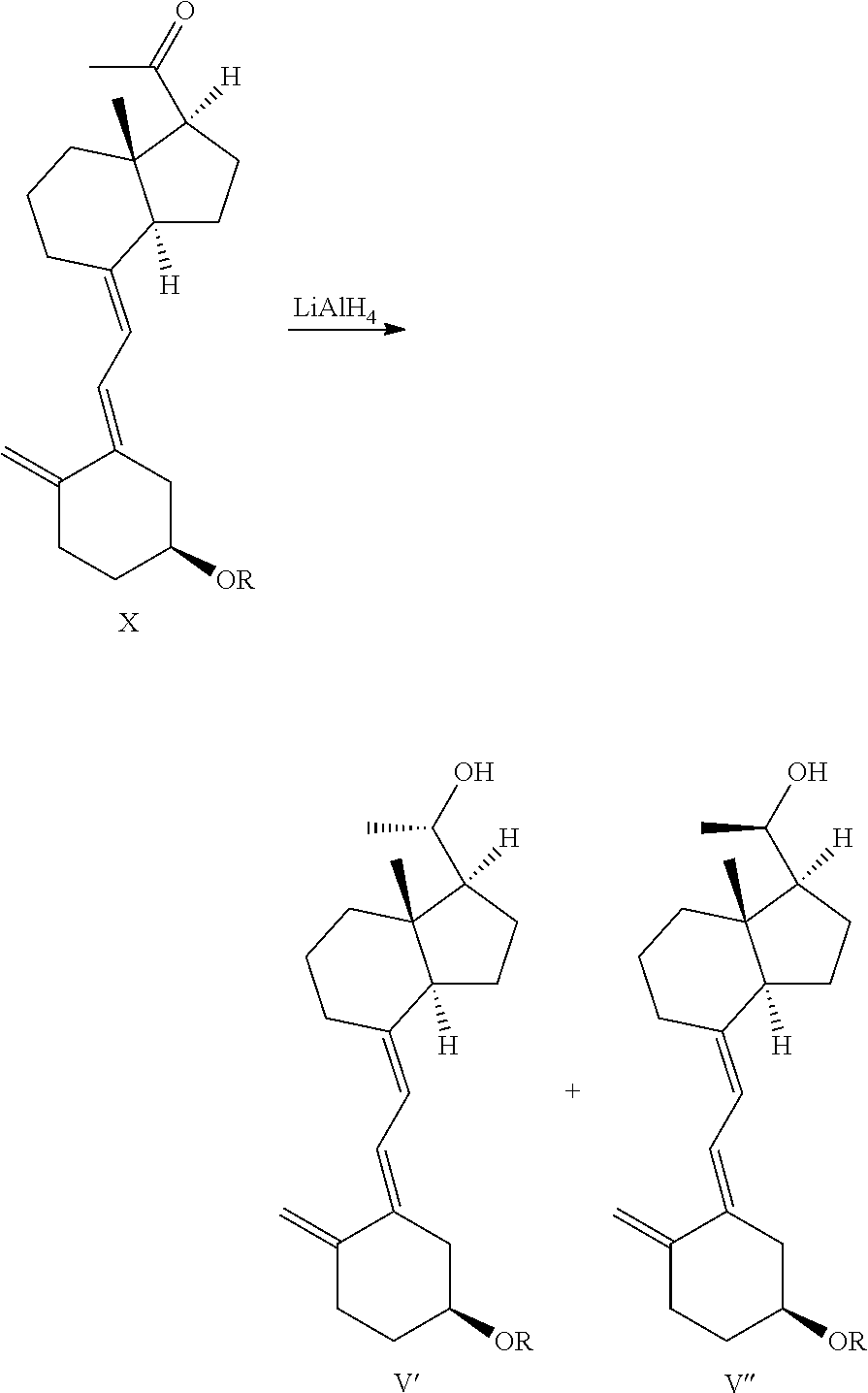

Synthetic intermediate of maxacalcitol, preparation method therefor and use thereof

InactiveUS20160237030A1YieldHigh yieldGroup 4/14 element organic compoundsOrganic compound preparationVitamina D2Side chain

The present invention provides a new method for synthesizing maxacalcitol and an intermediate thereof. According to the method, the maxacalcitol is creatively synthesized through the steps of: taking vitamin D2 as an initial raw material, obtaining a compound represented by formula II, oxidizing, chirally reducing, grafting with a side chain, introducing a hydroxyl group on the C-1 position, and photochemically overturning.

Owner:ZHEJIANG HISUN PHARMA CO LTD

Integrated processes for para-xylene production

ActiveUS20200024216A1Reduce hydrogen consumptionIncrease productionHydrocarbon by isomerisationMolecular sieve catalystXylyleneIsomerization

Para-xylene production processes are disclosed, with such processes being integrated with extractive distillation or other separation to effectively separate, for example to remove and recover, ethylbenzene and other components that co-boil with the isomers of xylene. This allows for xylene isomerization, downstream of the separation of para-xylene from its other isomers, to be operated under milder conditions (e.g., liquid phase, absence of added hydrogen) without the need for ethylbenzene conversion. The associated decreased yields of byproducts such as light gases and non-aromatic hydrocarbons, together with the generation of purified ethylbenzene having value for styrene monomer production, can significantly improve overall process economics.

Owner:SULZER MANAGEMENT AG +1

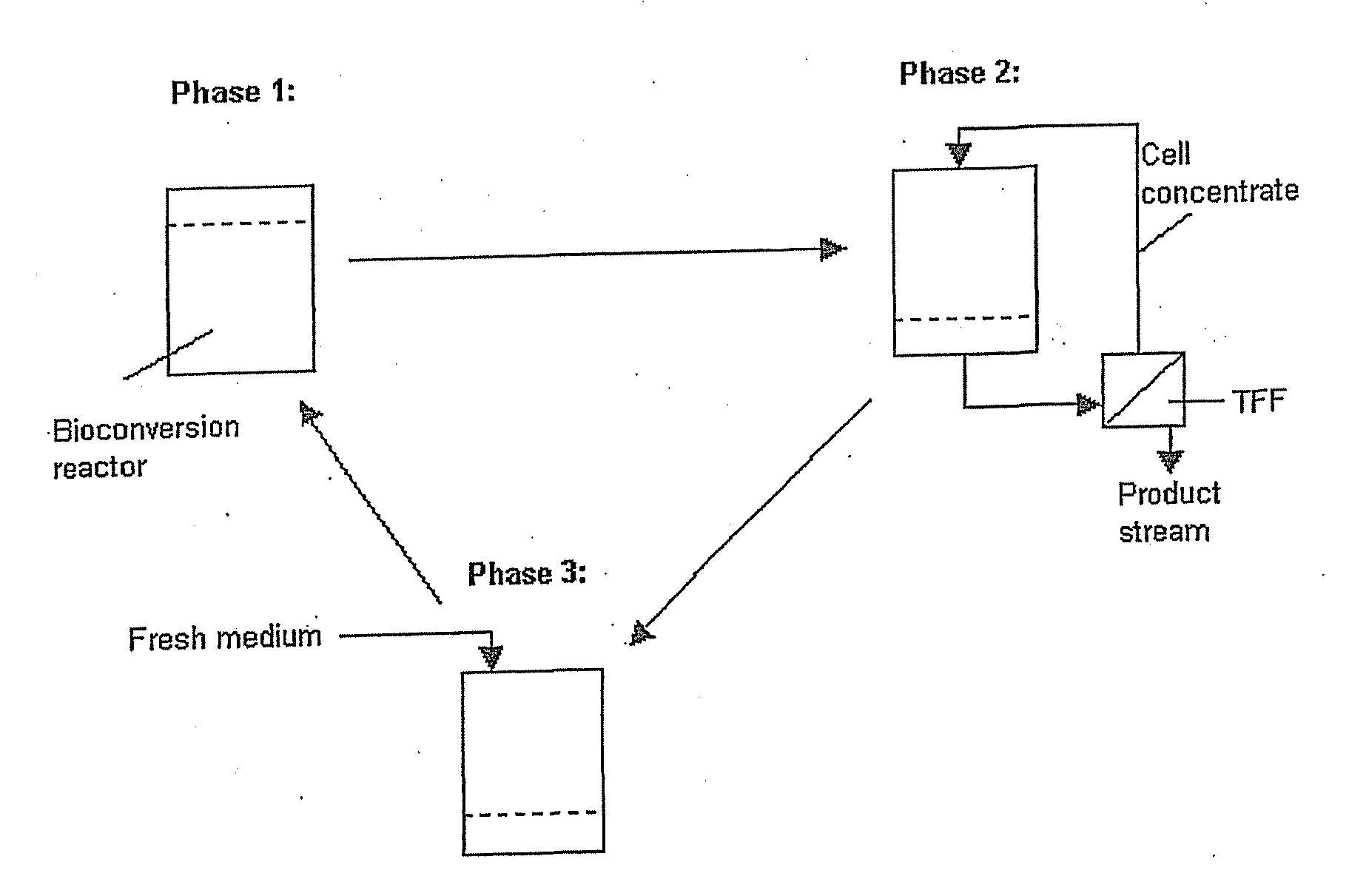

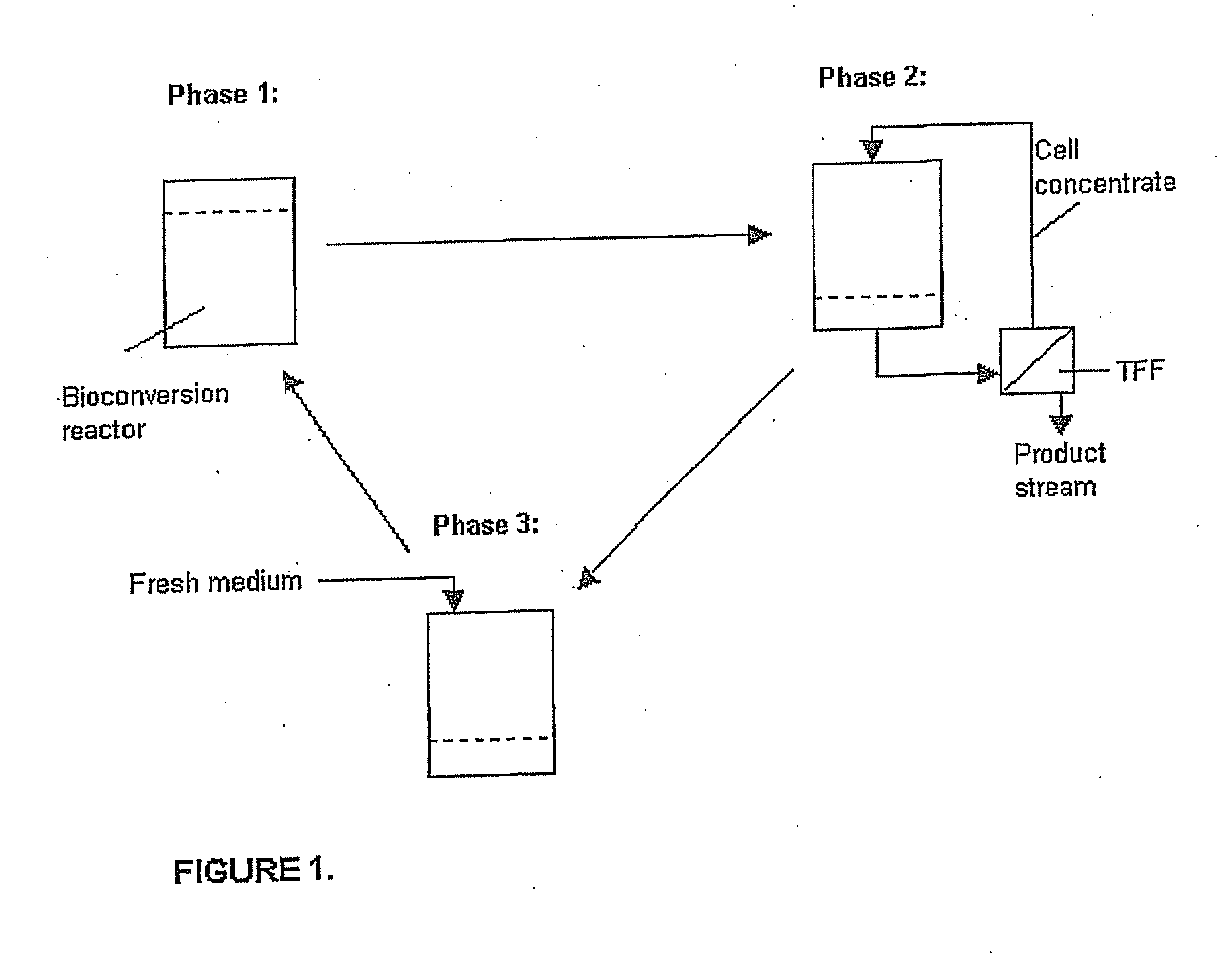

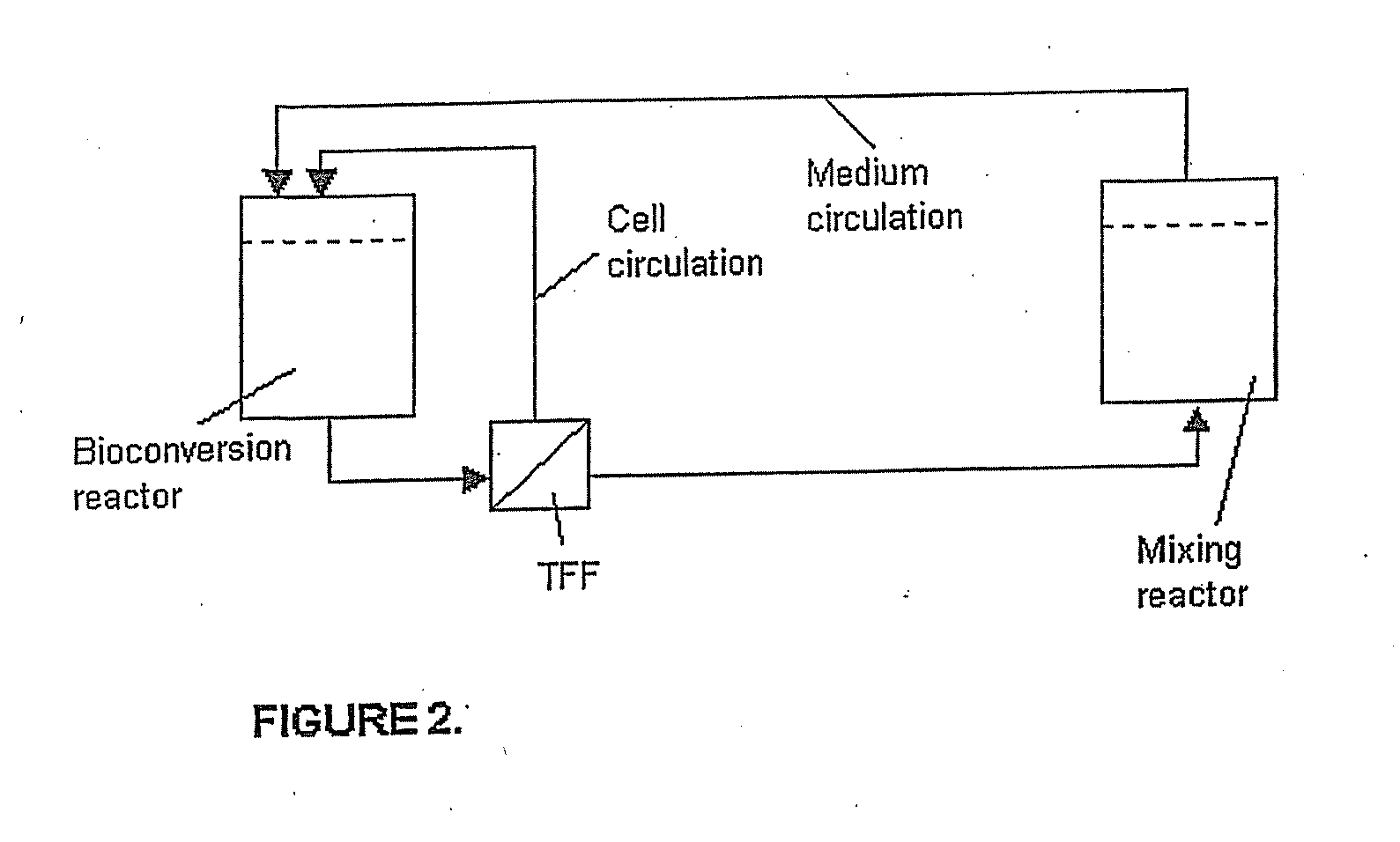

Process for Producing D-Mannitol

InactiveUS20110091949A1Efficient and robust production process% yieldBacteriaFermentationFructokinase deficiencyProduction rate

High concentration of free cells of heterofermentative lactic acid bacteria (LAB) in a resting or slowly growing state are used to convert fructose into mannitol. Efficient volumetric mannitol productivities and mannitol yields from fructose are achieved in a process applying cell-recycle, continuous stirred tank reactor and / or circulation techniques with native LAB cells or with LAB cells with inactivated fructokinase gene(s). Mannitol is recovered in high yield and purity with the aid of evaporation and cooling crystallization.

Owner:ZUCHEM

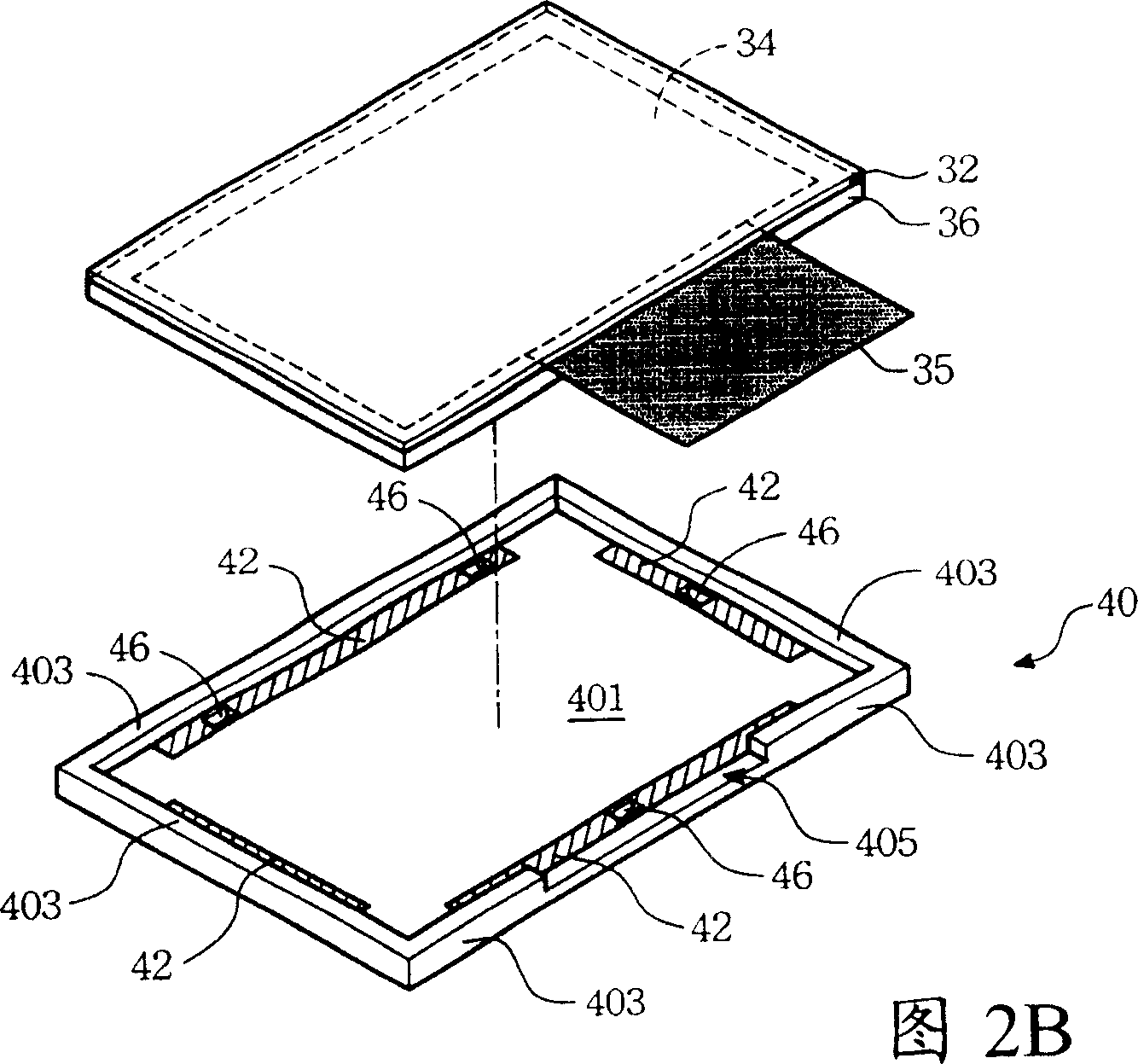

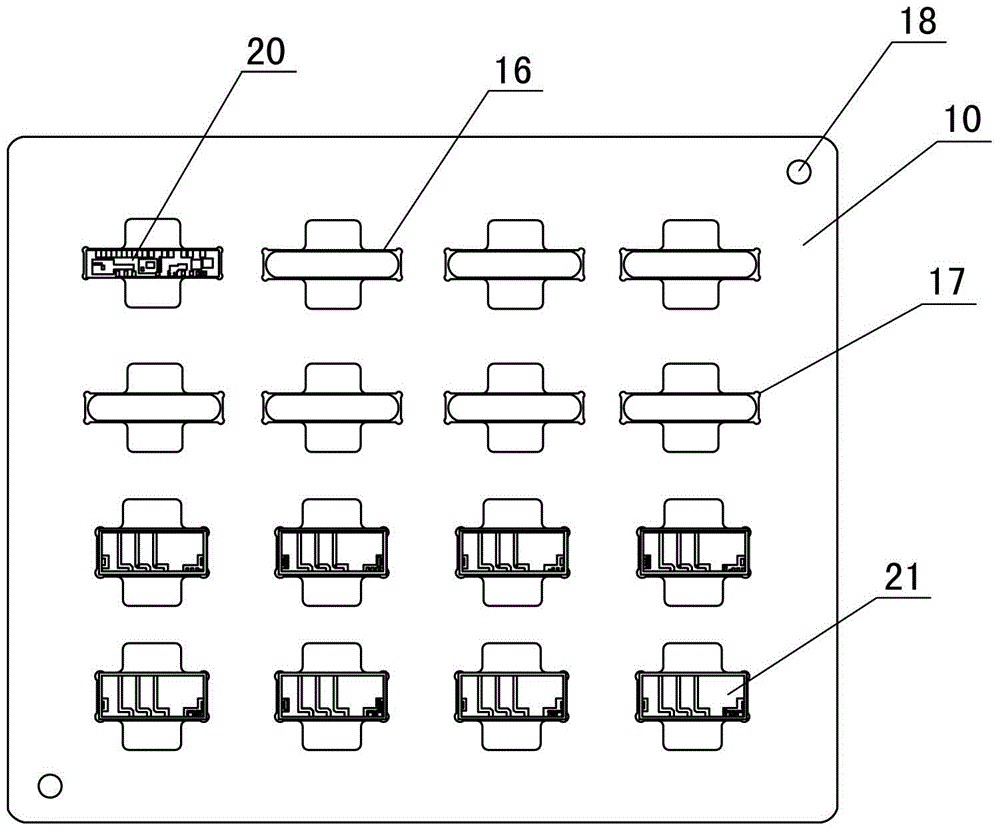

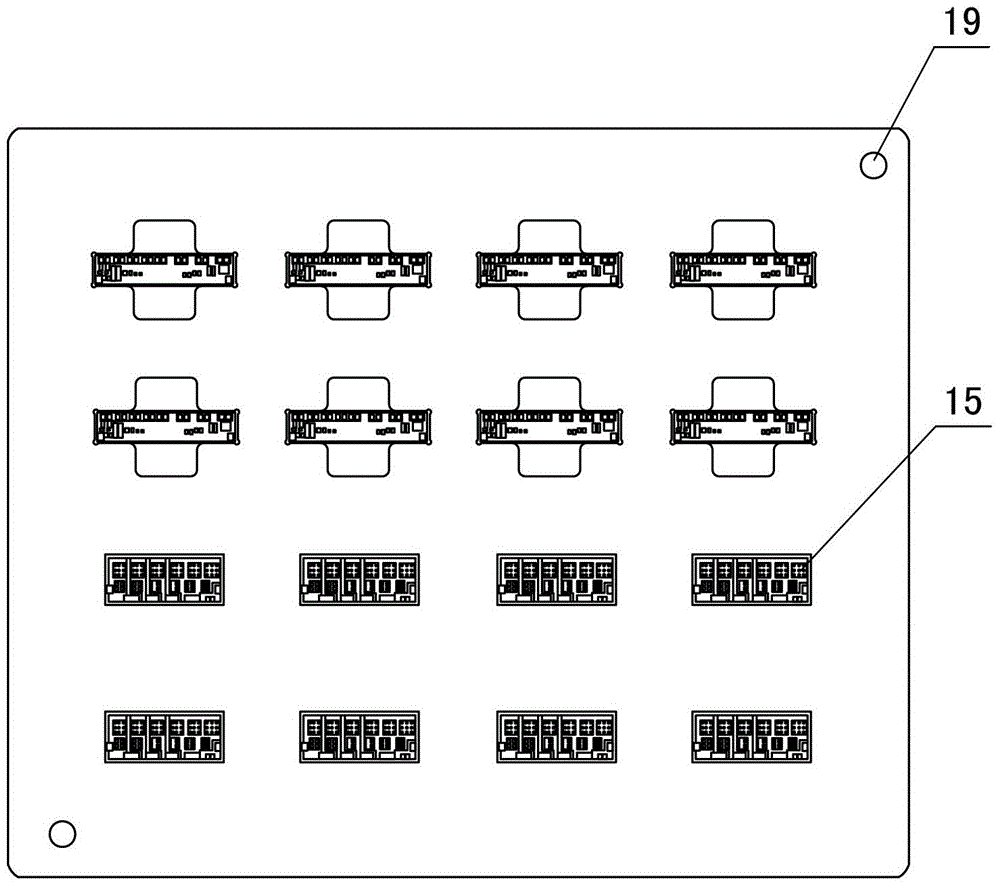

Electroluminescent diode panel mould set with separated casing

ActiveCN100353822CContribute to process efficiencyYieldElectrical apparatus contructional detailsIdentification meansEngineeringSurface plate

Owner:테스콤가부시키가이샤

Thread-measuring feeding device

Owner:IRO AB

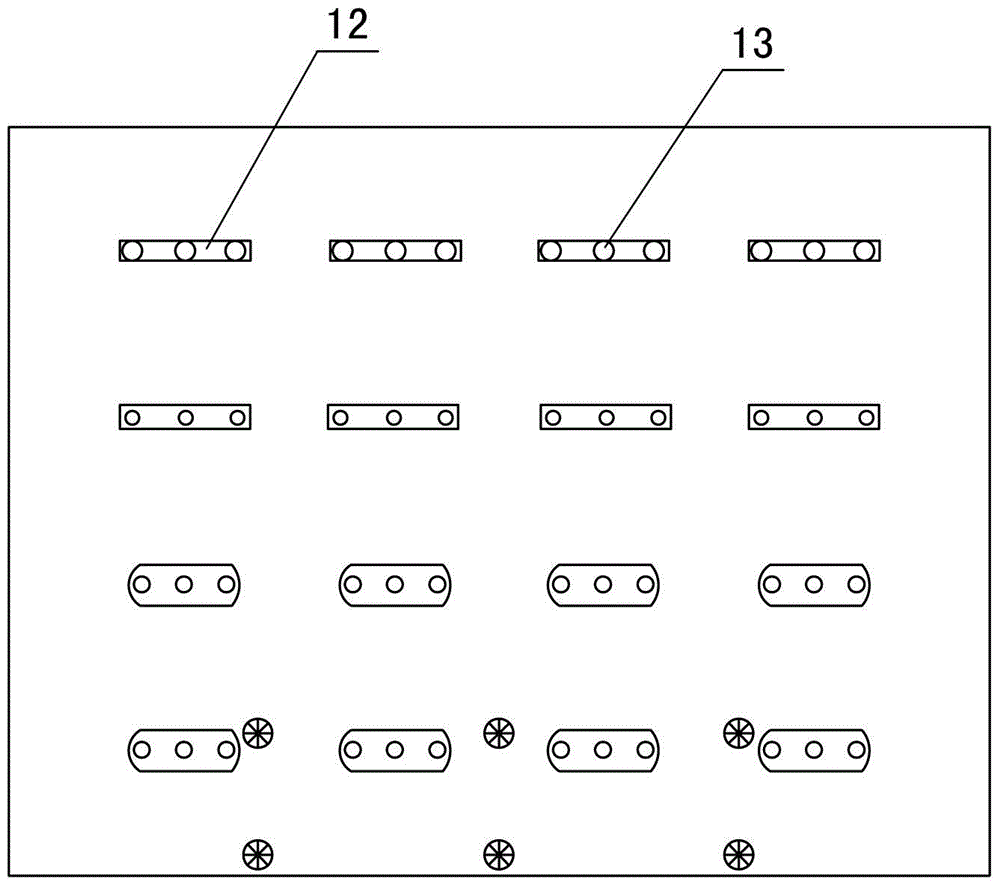

Realize the processing technology and fixture structure of multi-material substrates with simultaneous printing and patching

ActiveCN104228316BBalance processingAvoid wastingScreen printersOther printing apparatusTinningMaterial balance

The invention discloses a machining technology for conducting printing and surface mounting on substrates made of various materials simultaneously and a jig structure thereof. The jig structure comprises a bearing jig, a vacuum jig and a printing silk screen, wherein the bearing jig comprises a body, a plurality of kinds of substrate positioning grooves are formed in the body, the number of each kind of substrate positioning grooves is matched with the number of substrates corresponding to the product requirement, the vacuum jig is located below the bearing jig and comprises supporting columns, the number of the supporting columns corresponds to the number of the substrate positioning grooves, a plurality of vacuum holes are formed in each supporting column, the printing silk screen comprises a silk screen body, and a mesh used for tinning of a product located at the corresponding position is arranged at the position, corresponding to each substrate positioning groove, of the silk screen body. According to the machining technology for conducting printing and surface mounting on the substrates made of various materials simultaneously and the jig structure thereof, printing and surface mounting are conducted on all kinds of substrates simultaneously by placing the substrates on the bearing jig, then assembling, returning and cleaning are conducted, the production technology is simplified, the production efficiency is improved effectively, material balance is achieved, waste is reduced, and cost is reduced.

Owner:WUXI CHINA RESOURCE MICRO ASSEMBLY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com