Patents

Literature

132 results about "Remontoire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mechanical horology, a remontoire (from the French remonter, meaning 'to wind') is a small secondary source of power, a weight or spring, which runs the timekeeping mechanism and is itself periodically rewound by the timepiece's main power source, such as a mainspring. It was used in precision clocks and watches to place the source of power closer to the escapement, thereby increasing the accuracy by evening out variations in drive force caused by unevenness of the friction in the geartrain. In spring-driven precision clocks, a gravity remontoire is often used to replace the uneven force delivered by the mainspring running down by the more constant force of gravity acting on a weight. In turret clocks, it serves to separate the large forces needed to drive the hands from the modest forces needed to drive the escapement which keeps the pendulum swinging. A remontoire should not be confused with a maintaining power spring, which is used only to keep the timepiece going while it is being wound.

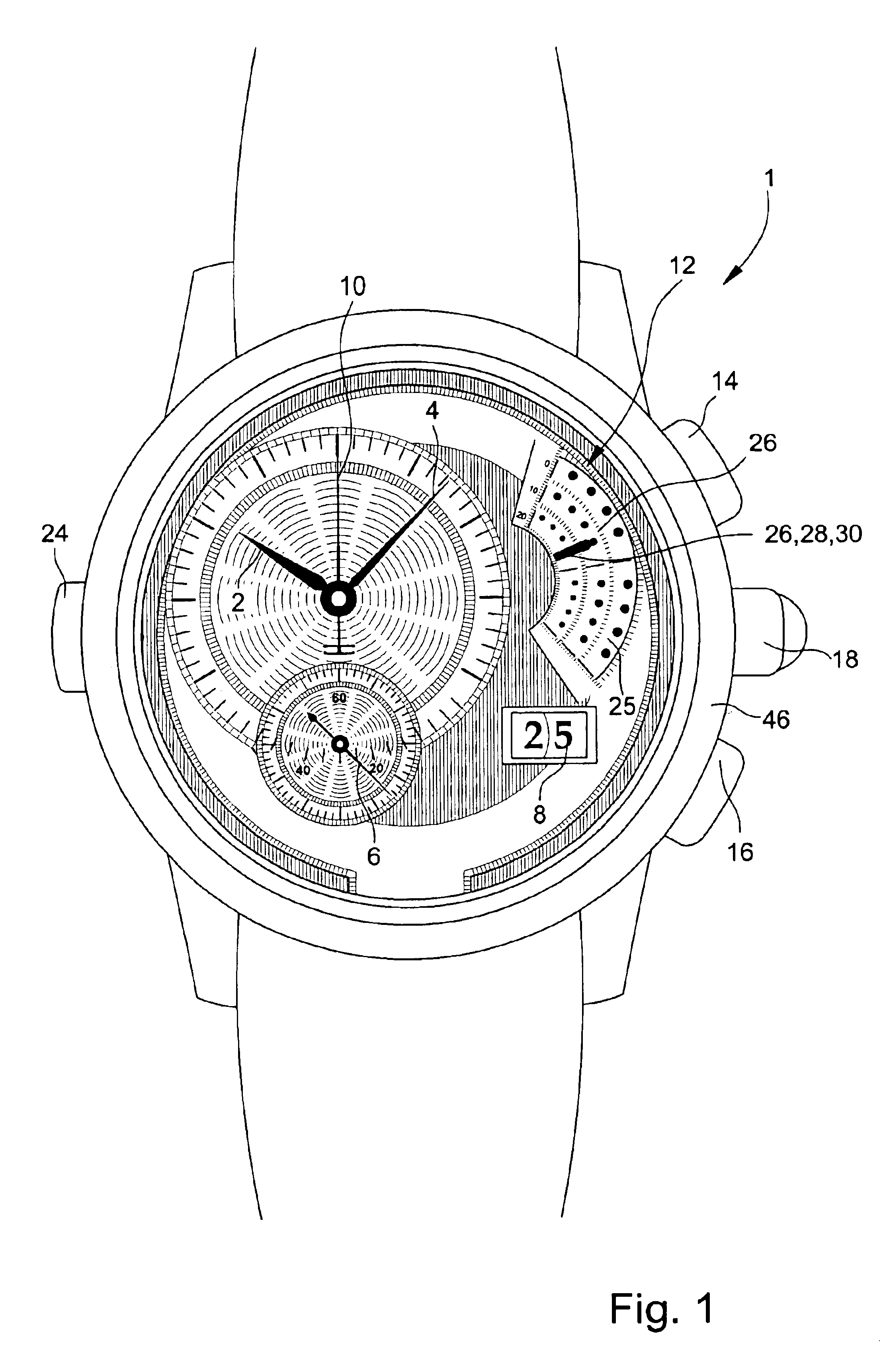

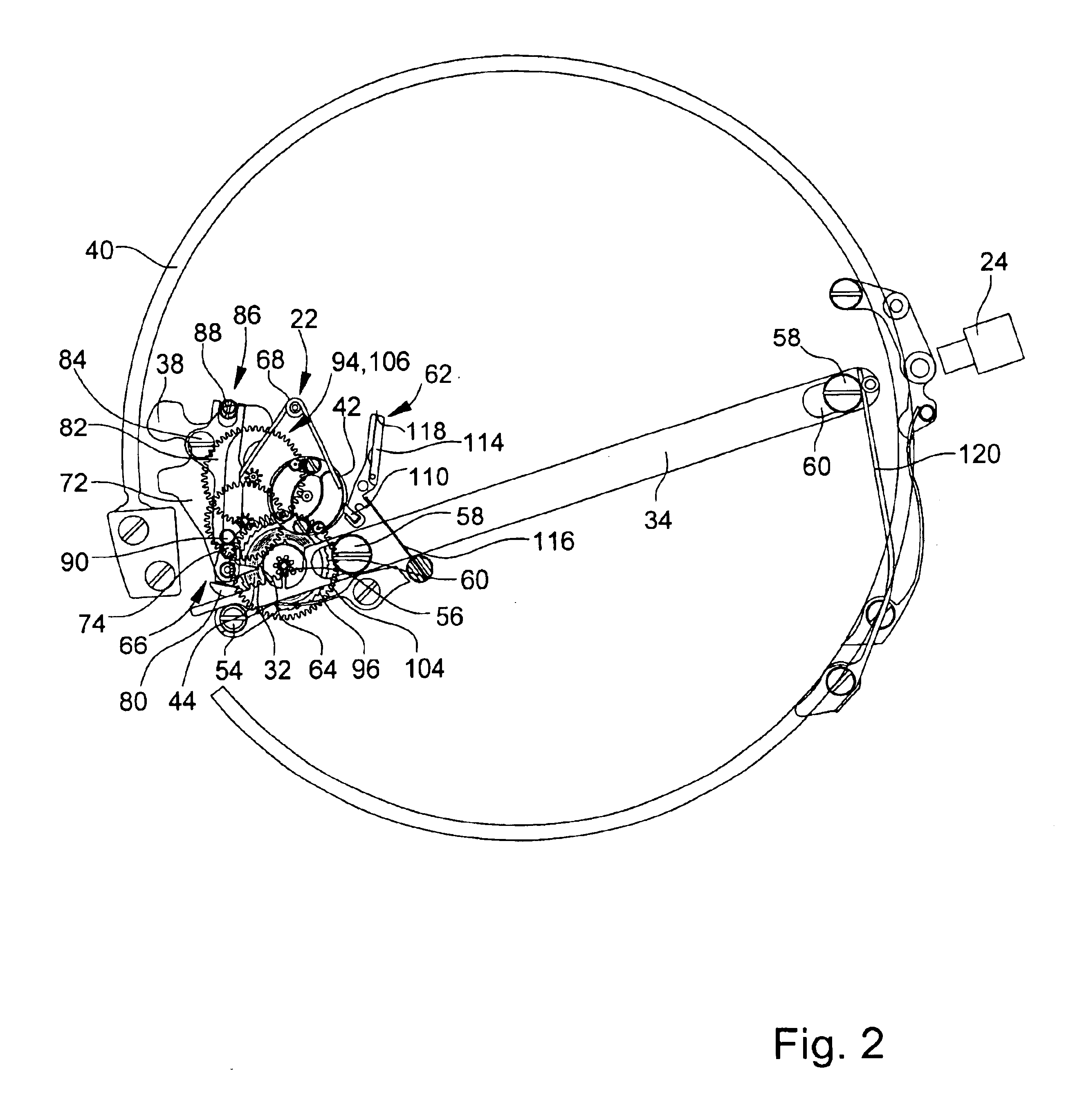

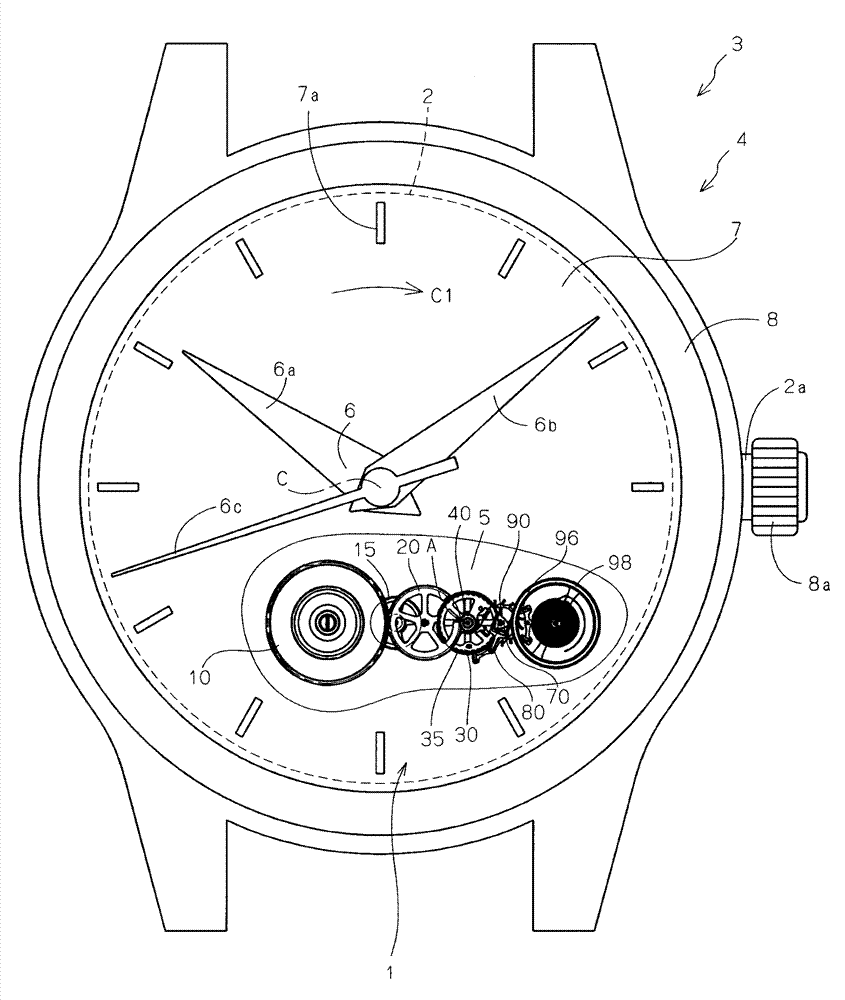

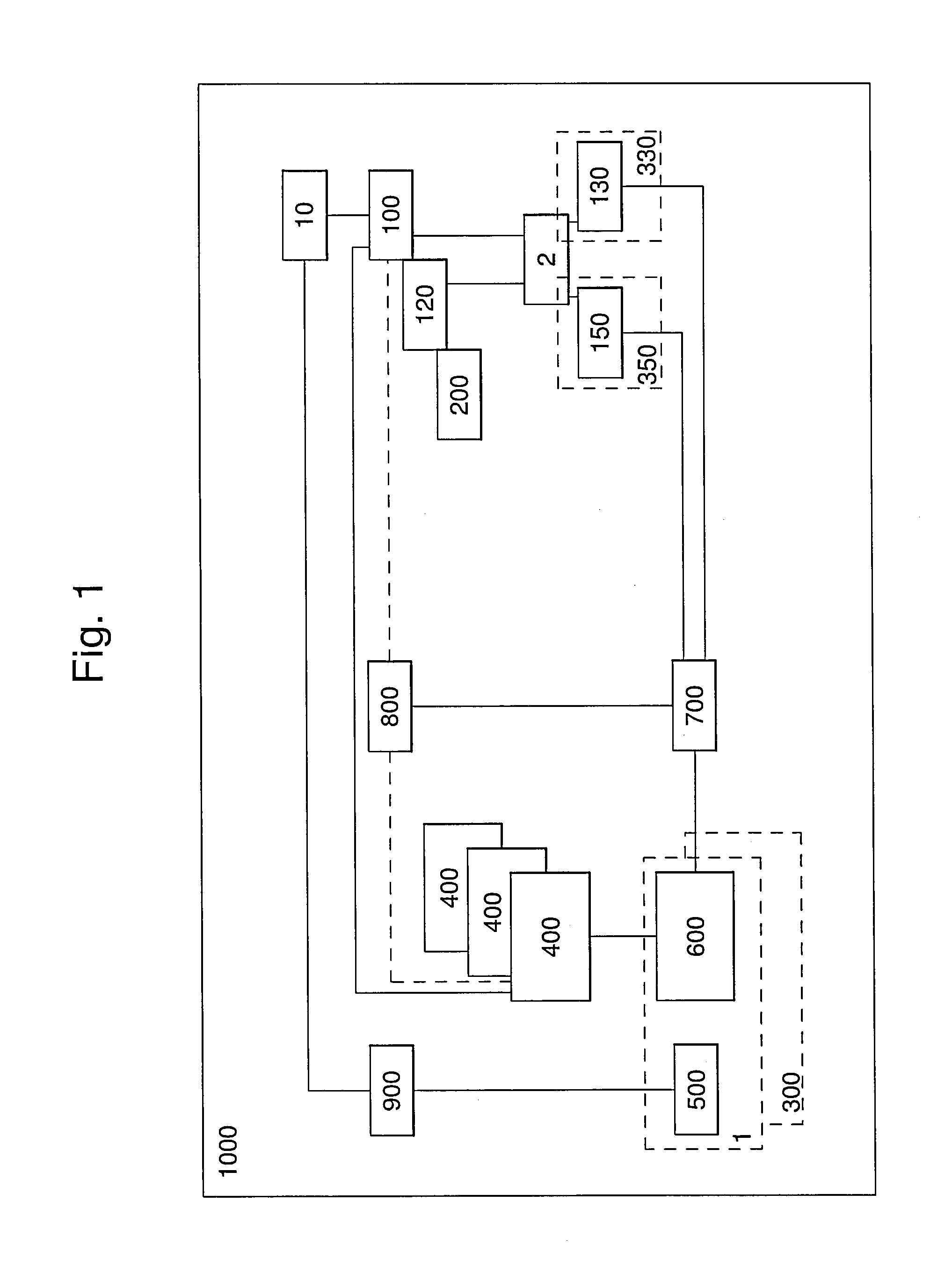

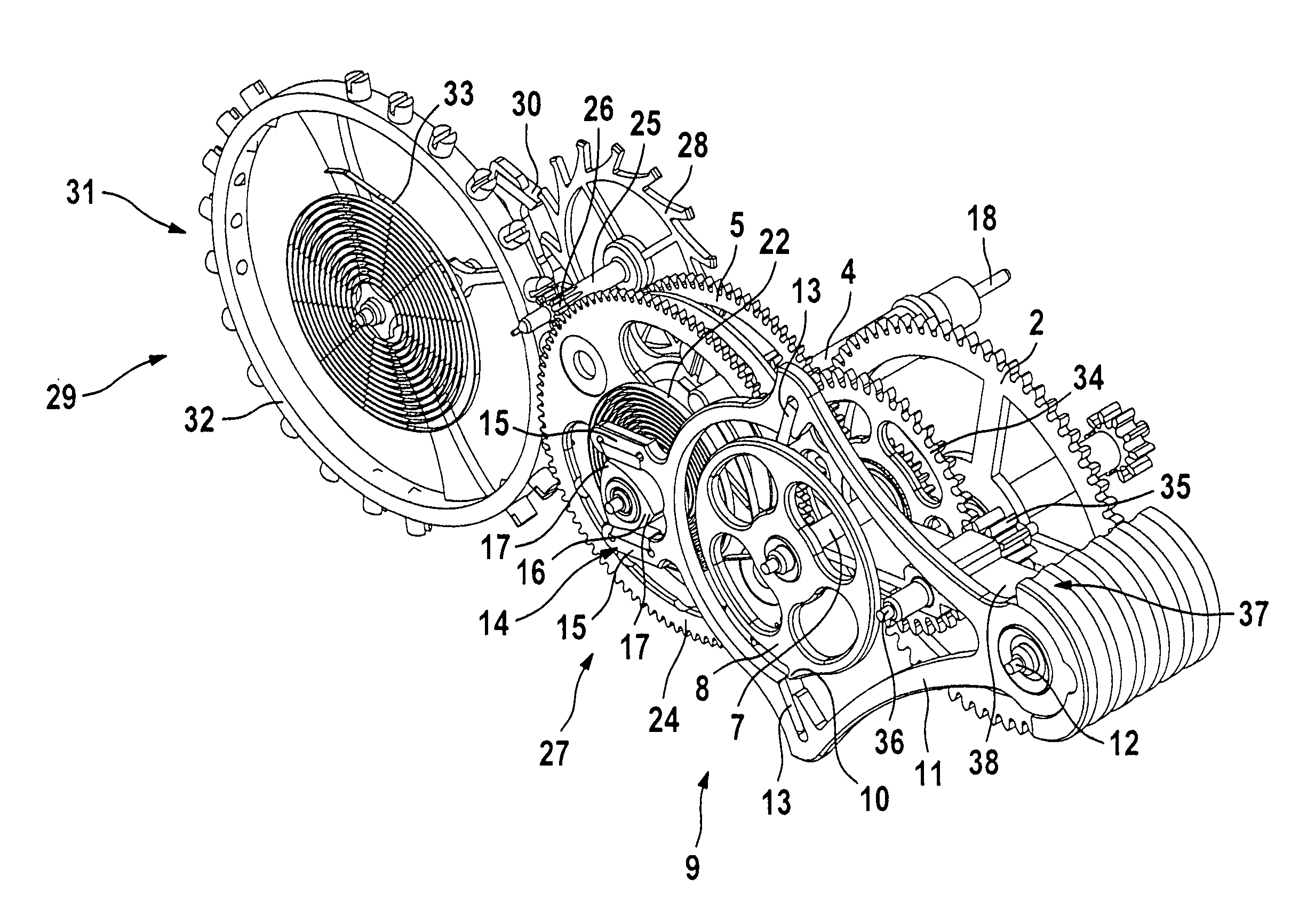

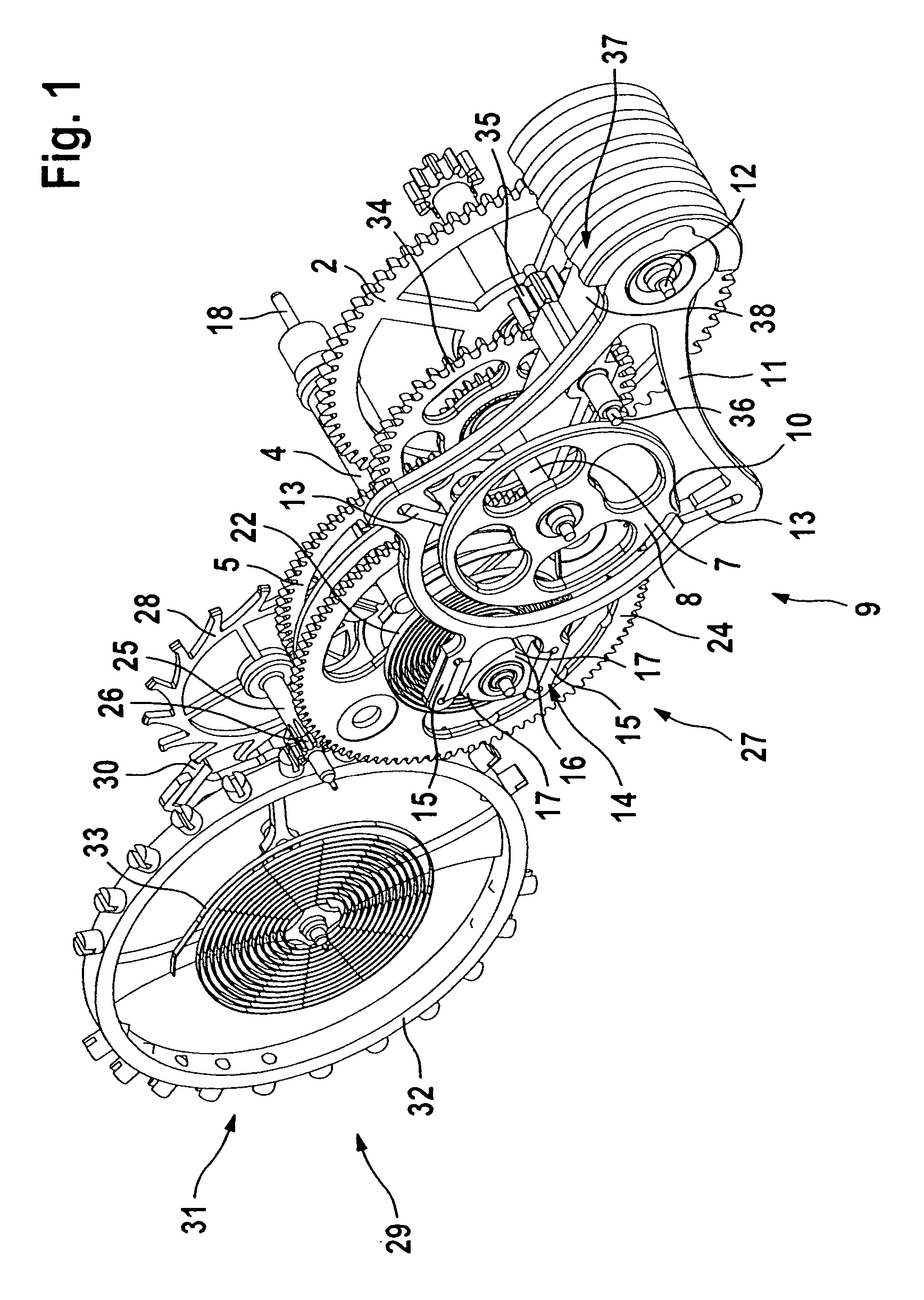

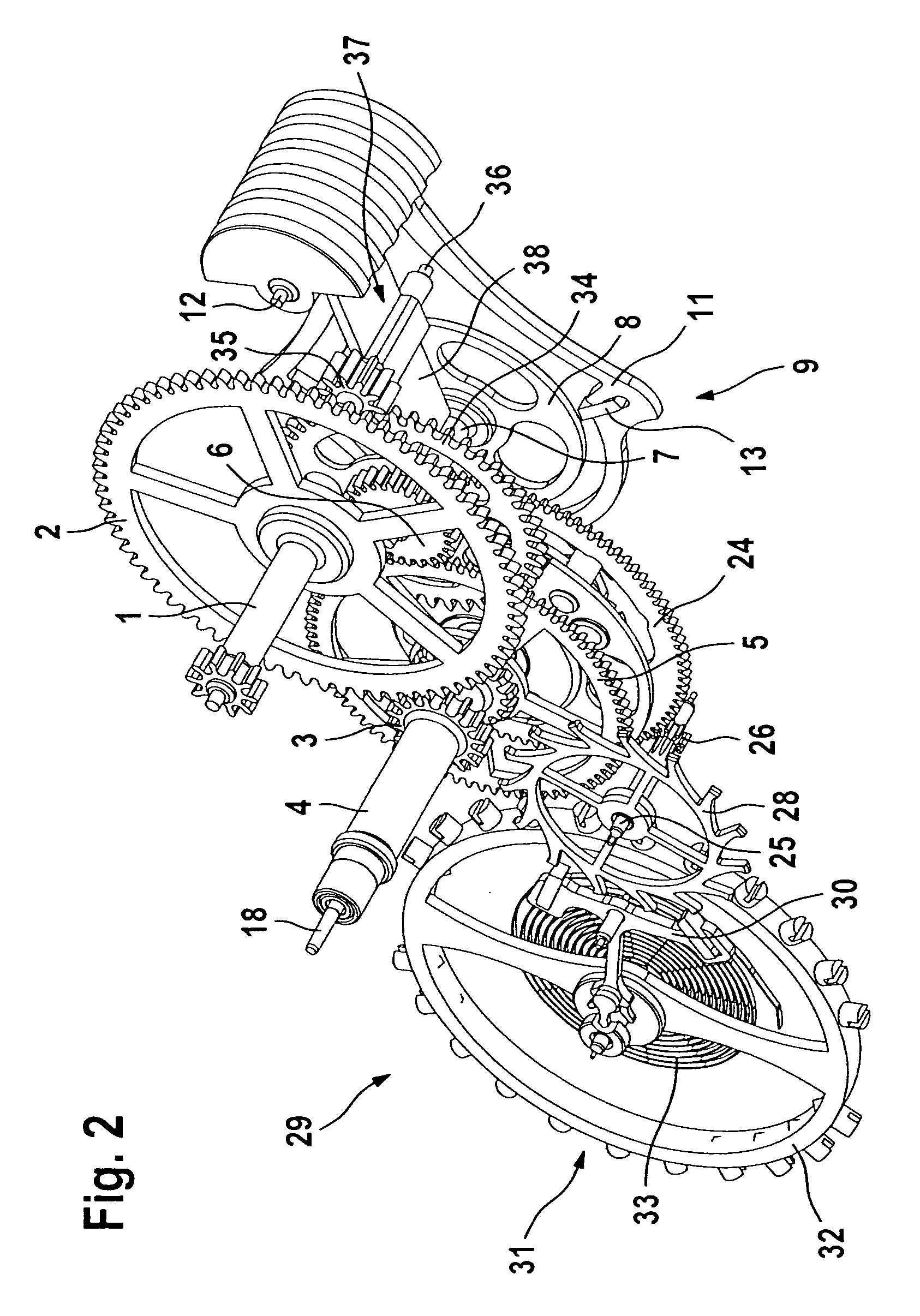

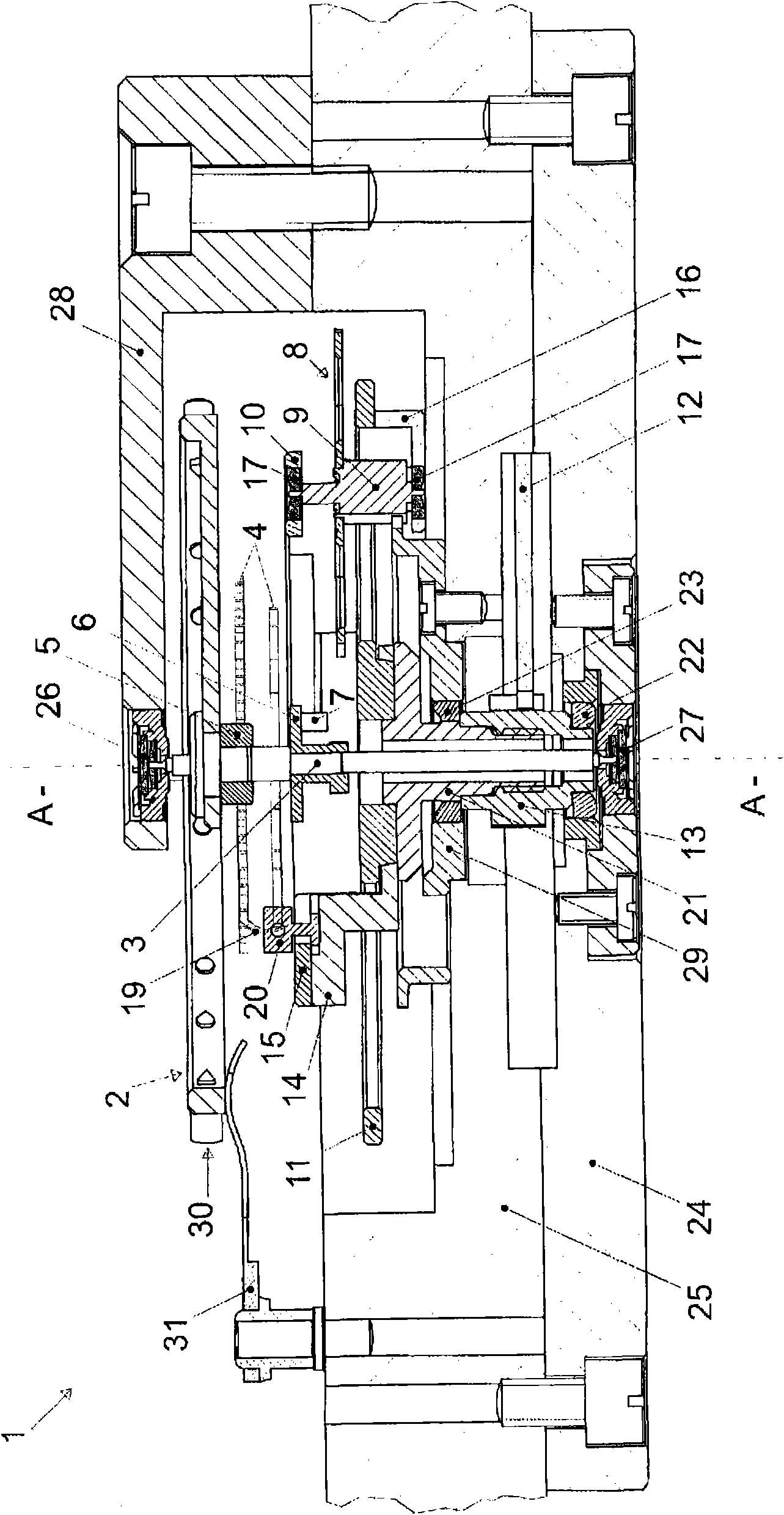

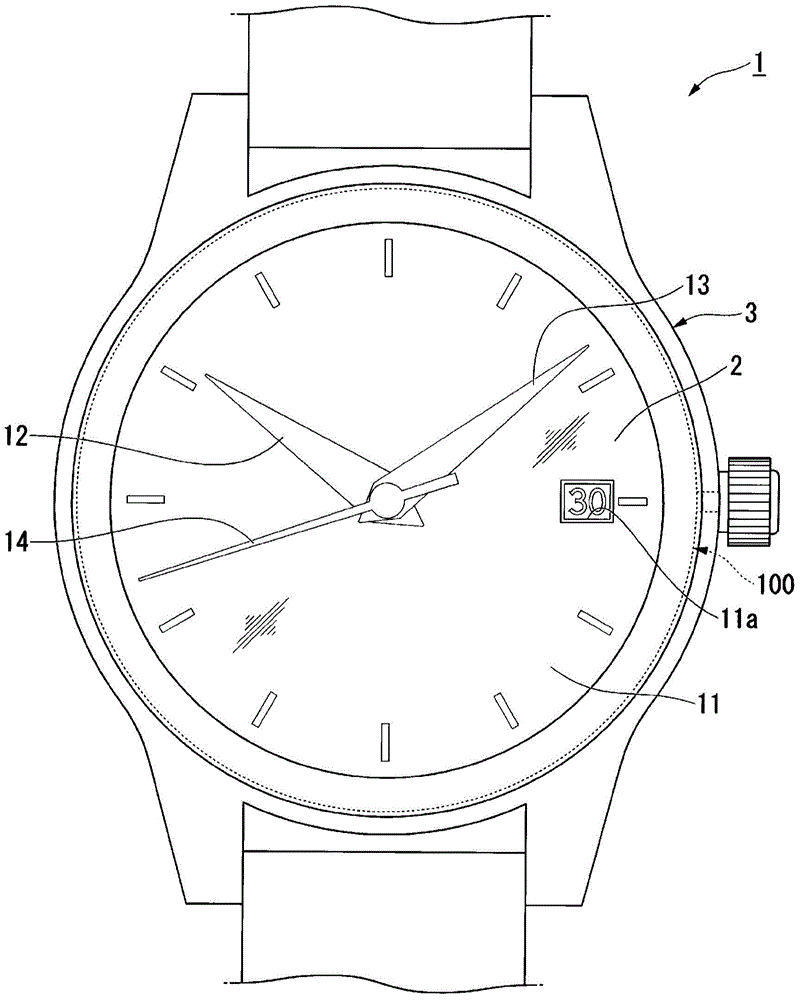

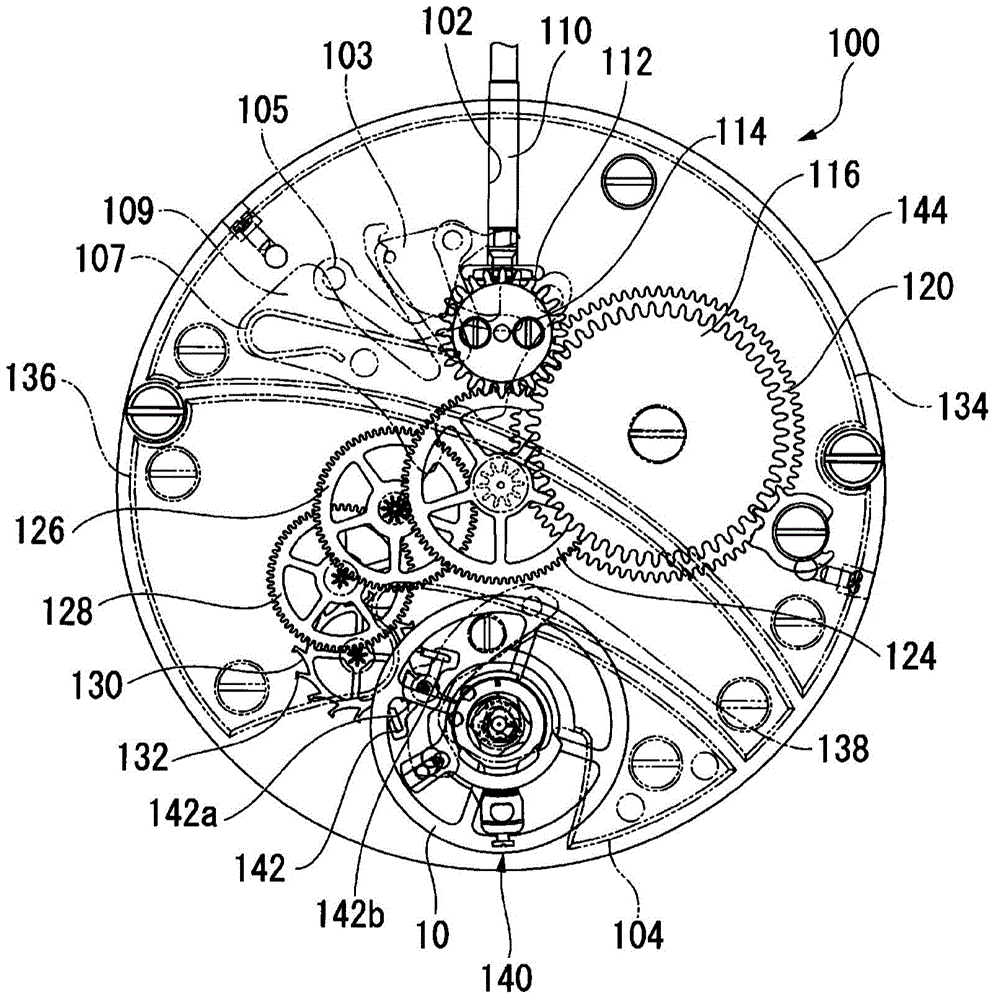

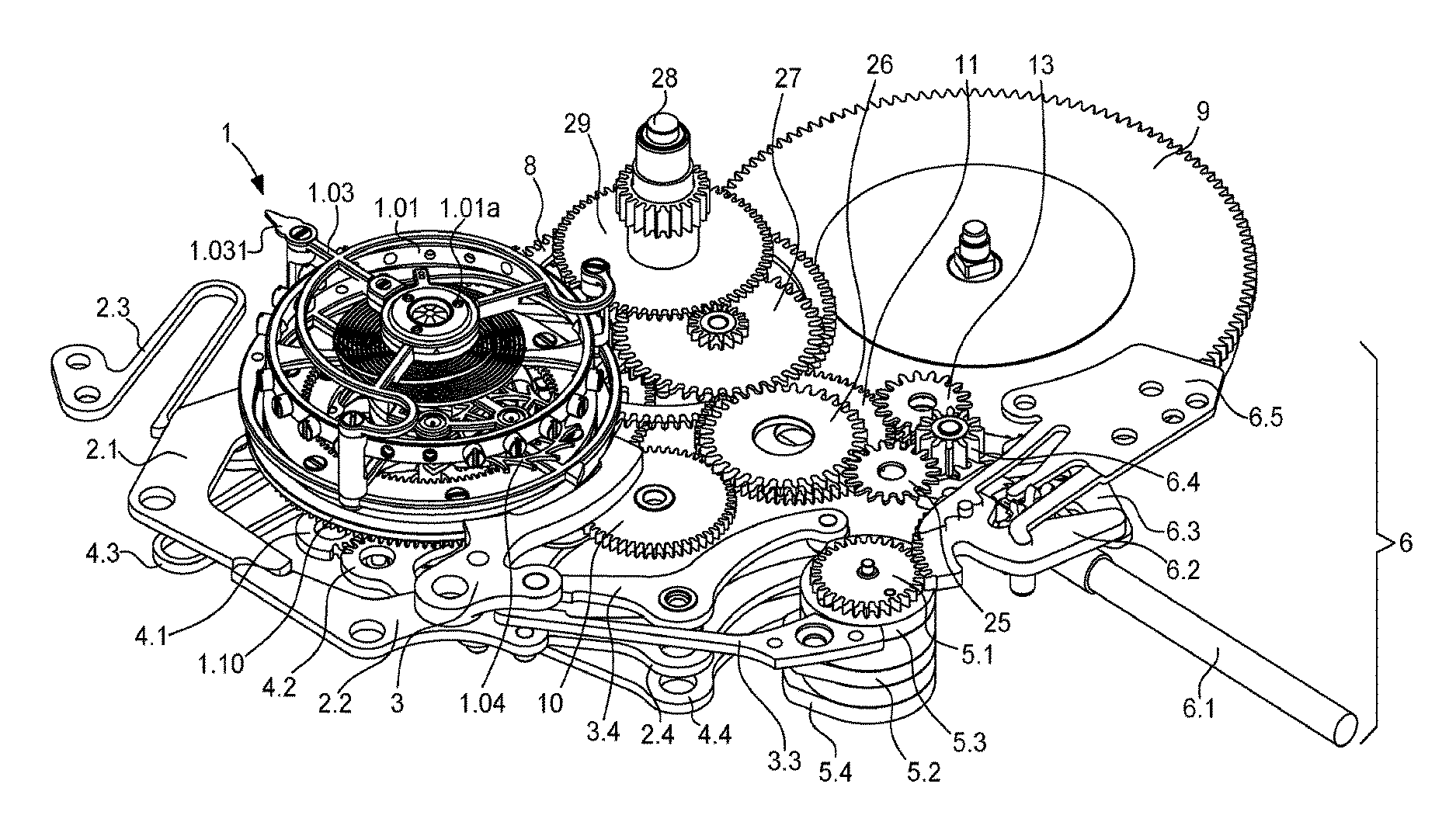

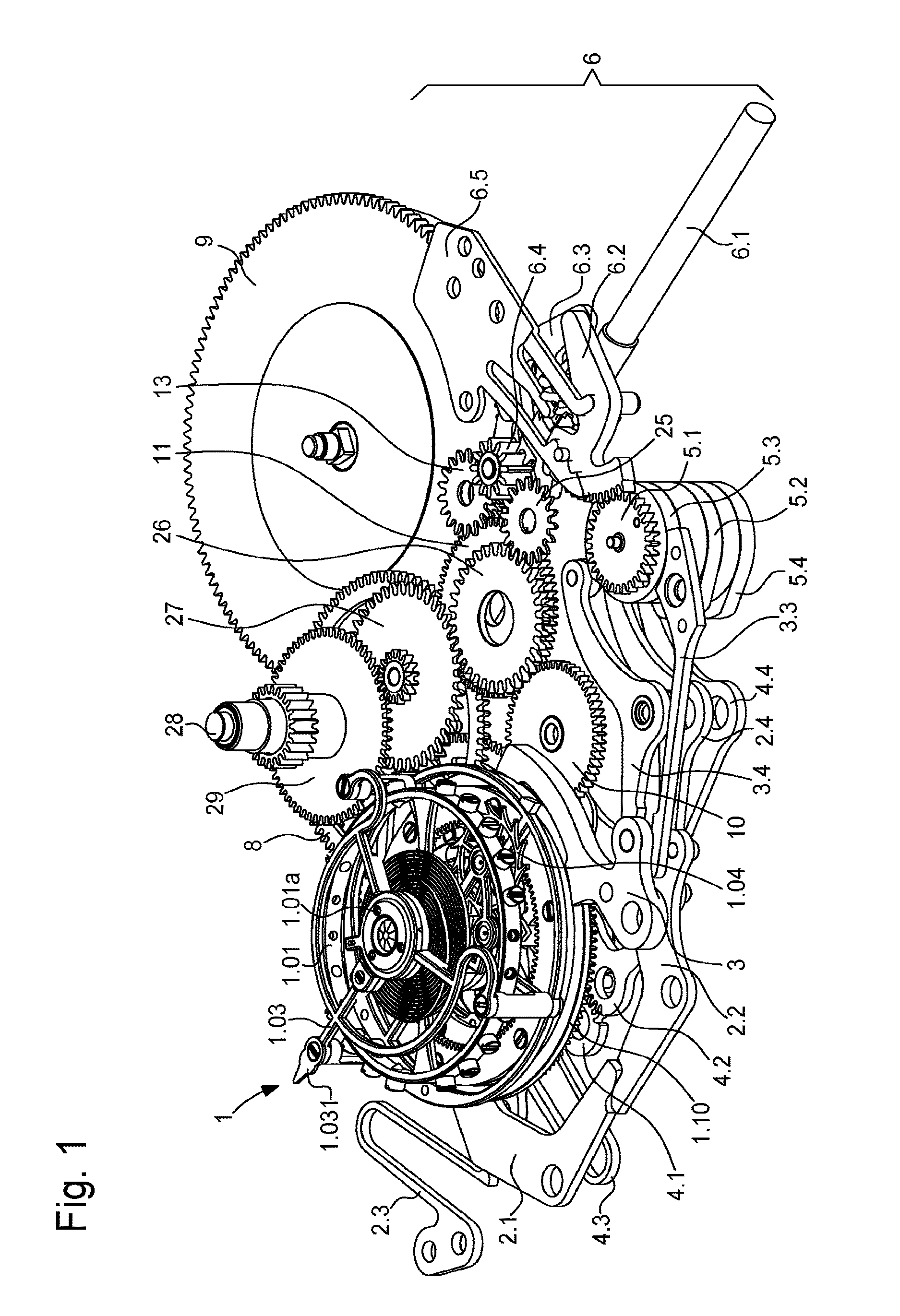

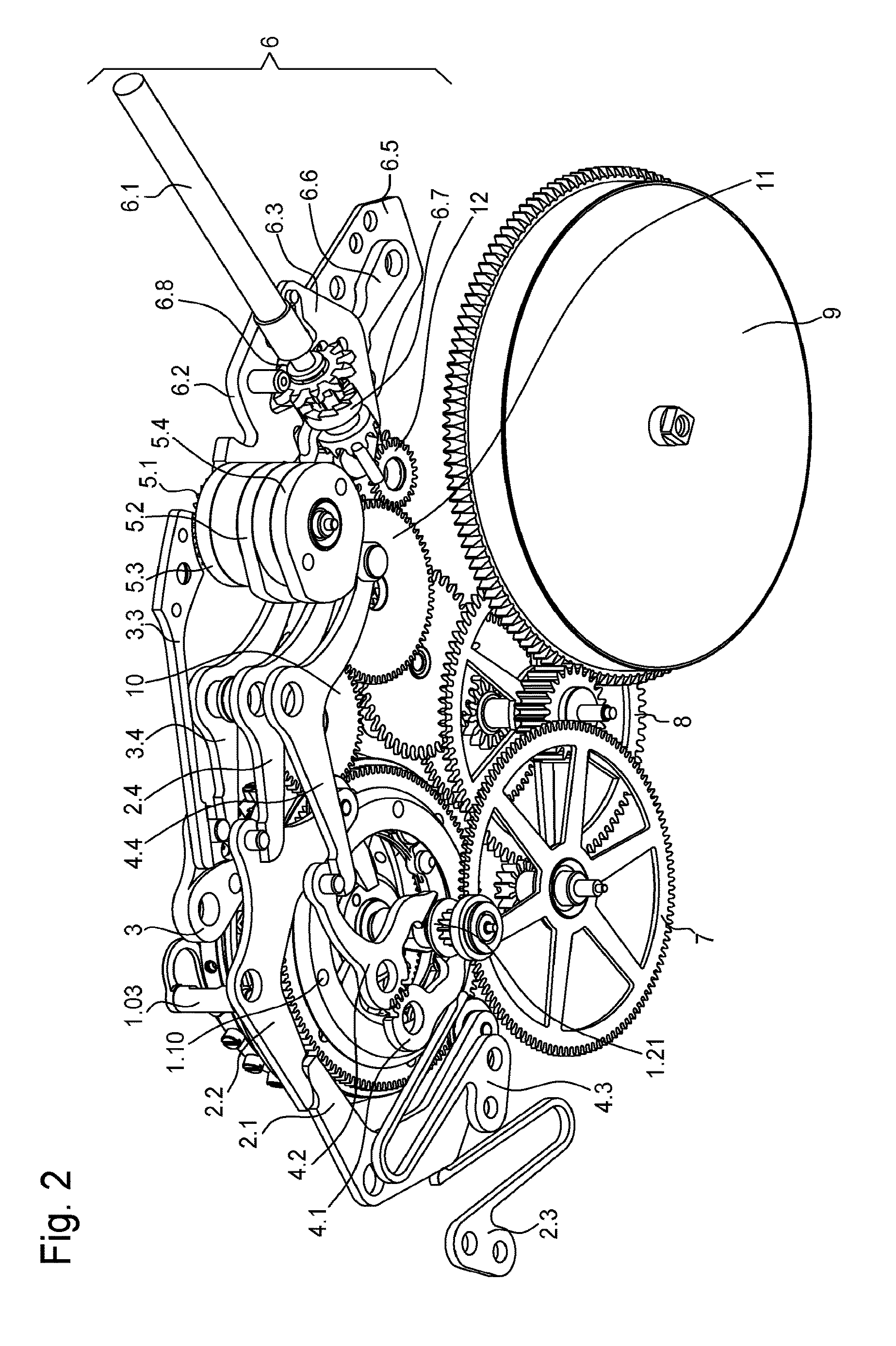

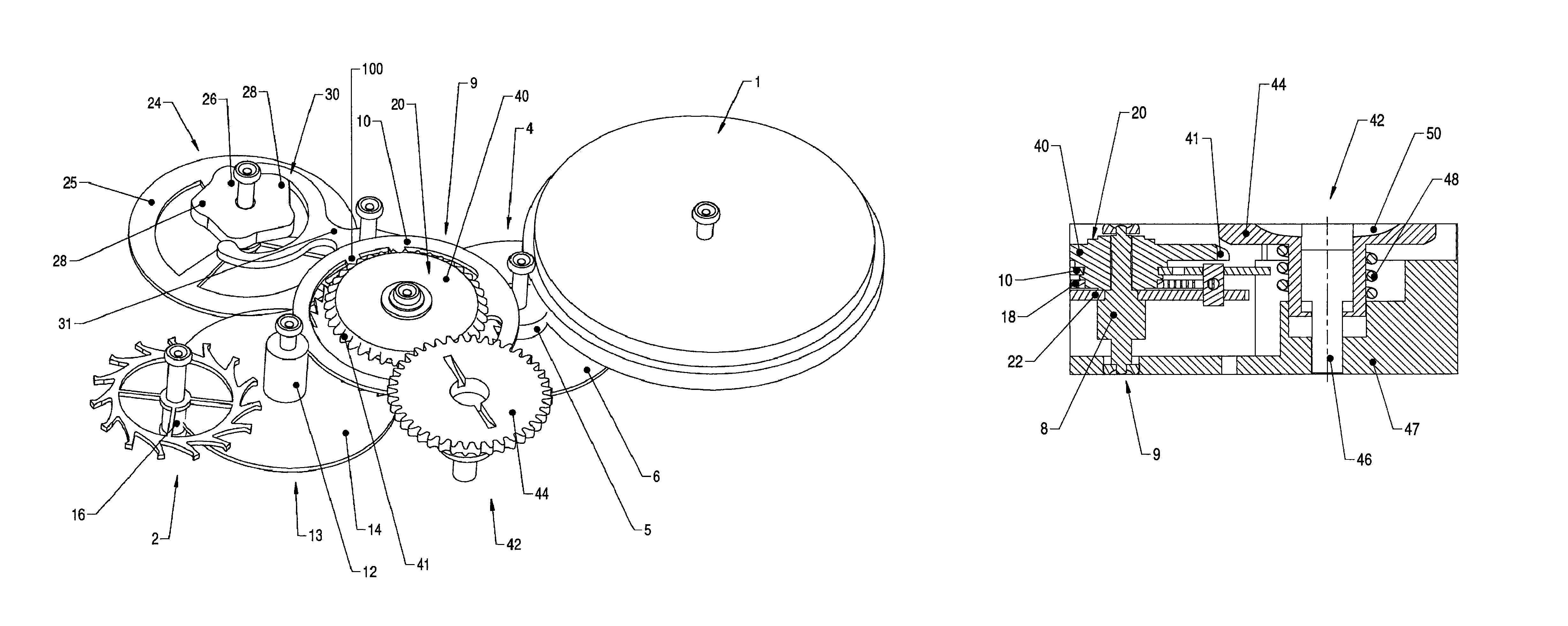

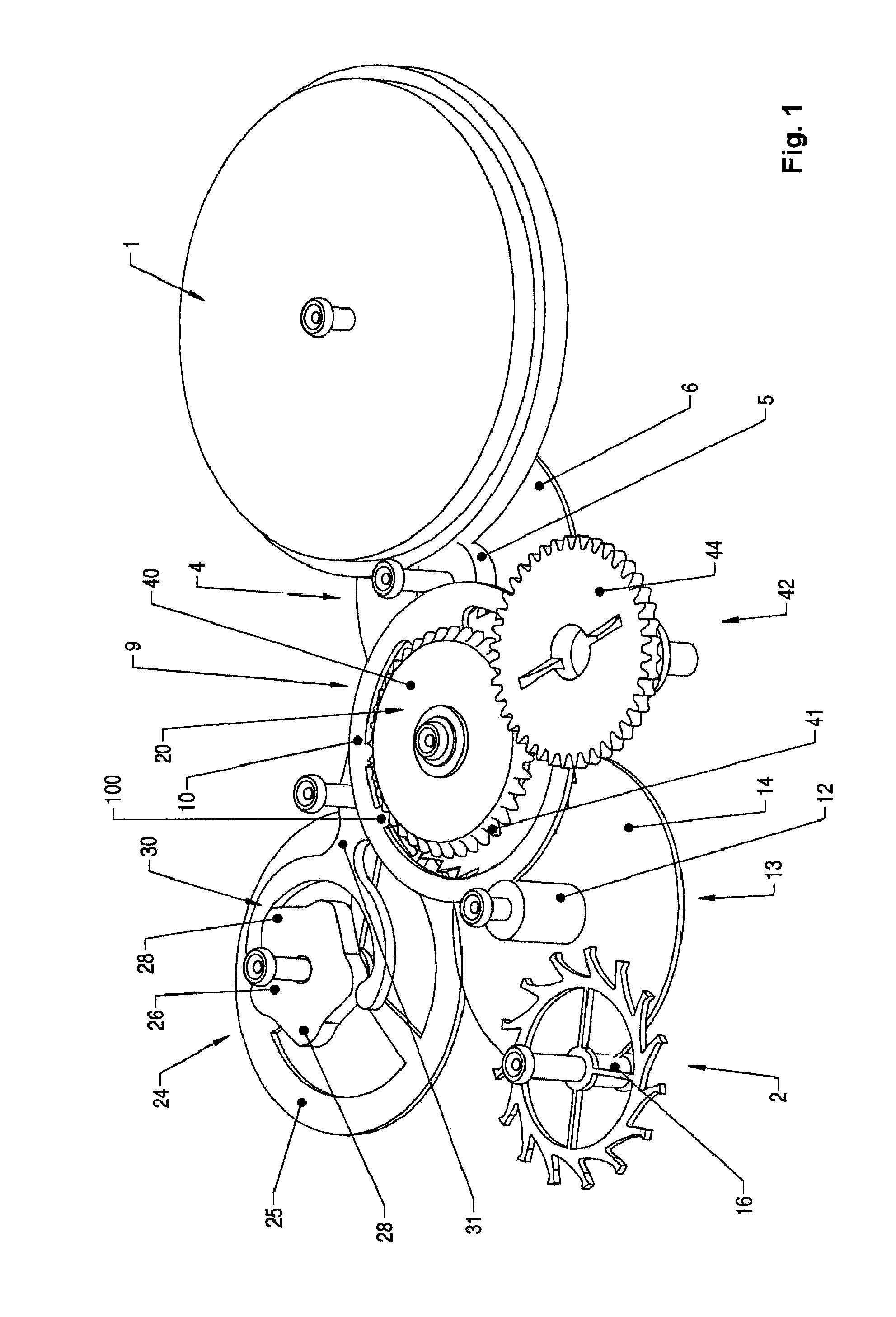

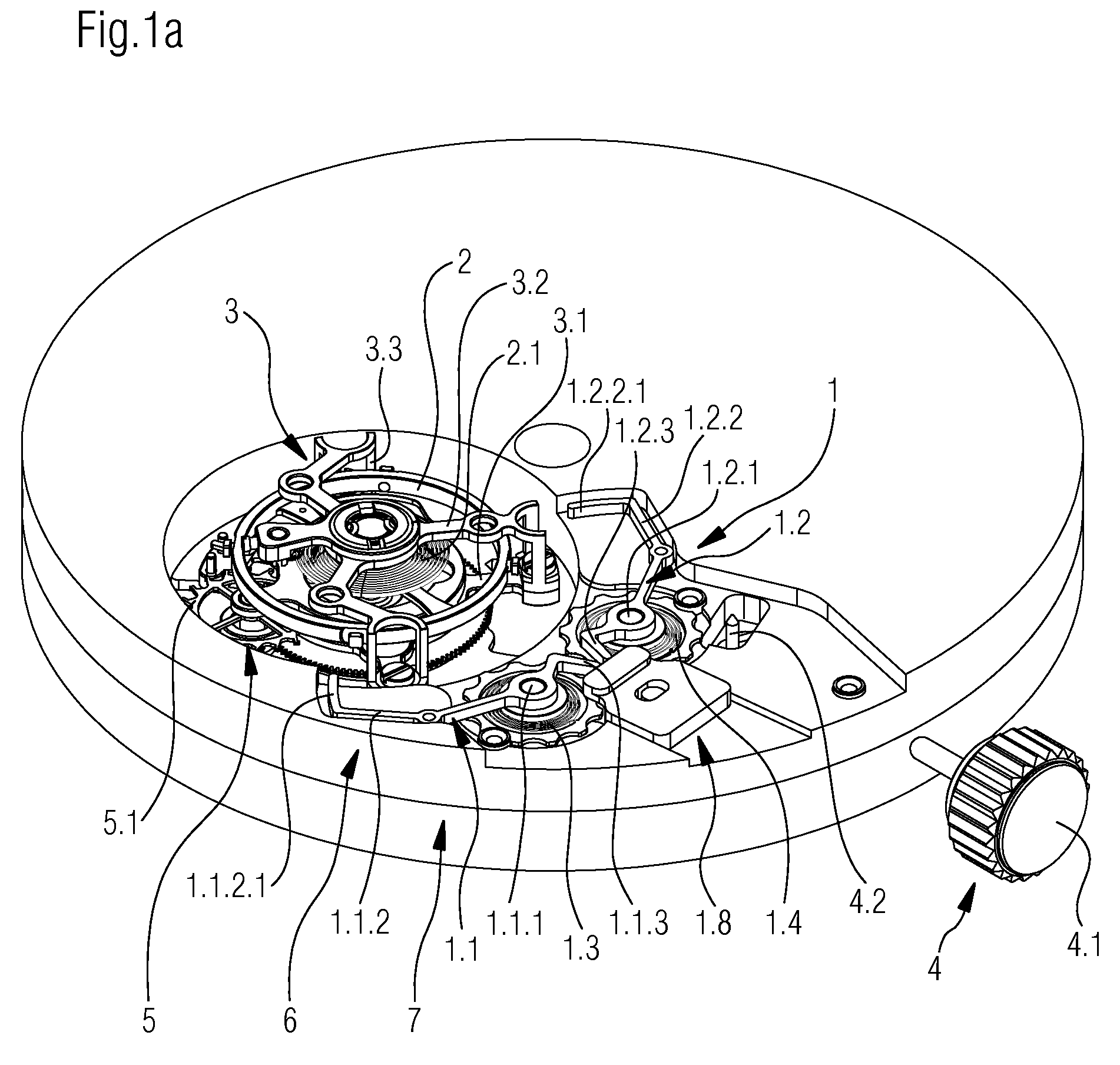

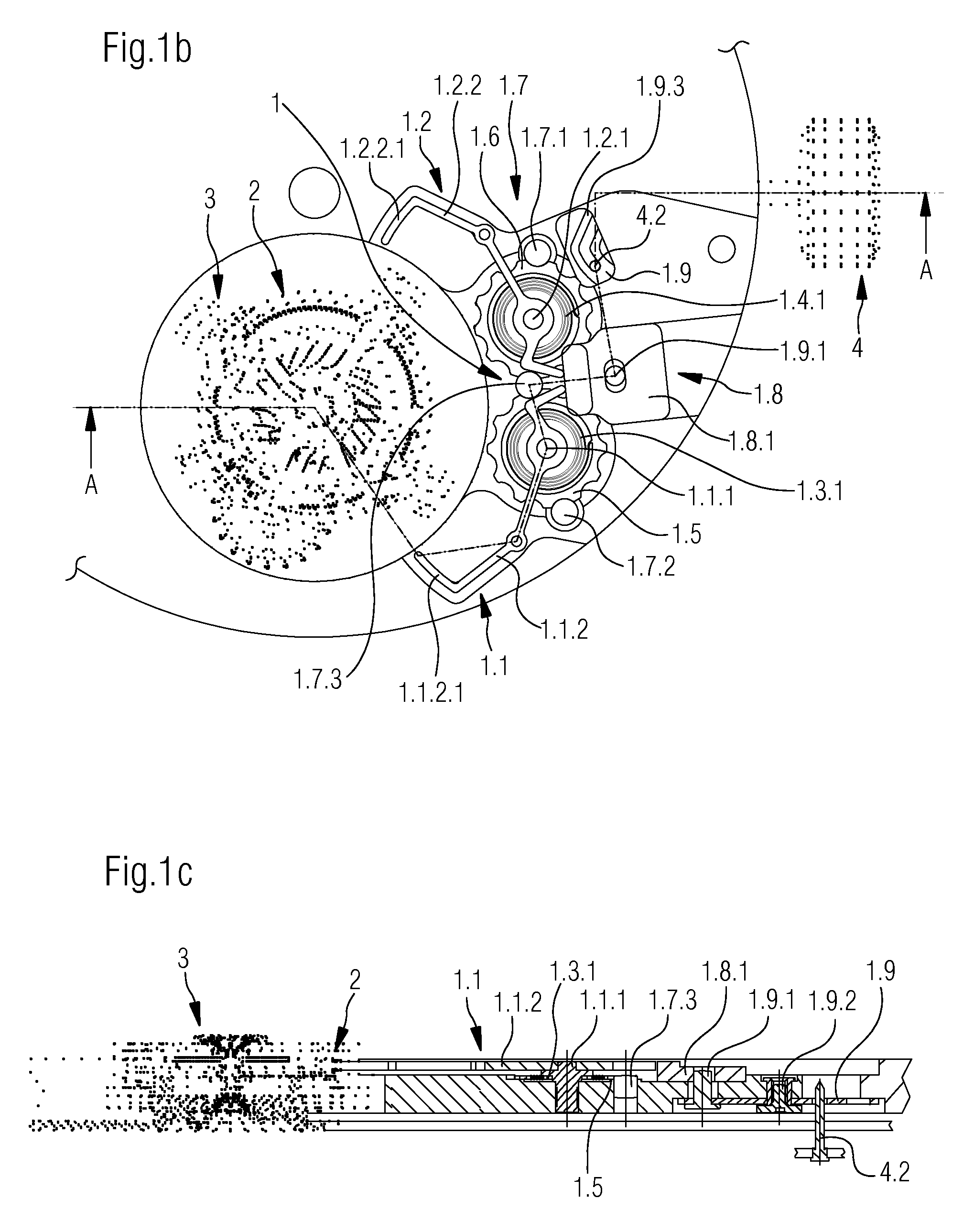

Timepiece with a constant-force device for acting on an oscillating system

ActiveUS20070147179A1Reduce the amount requiredReduce frictionElectric indicationEscapementsConstant forceEngineering

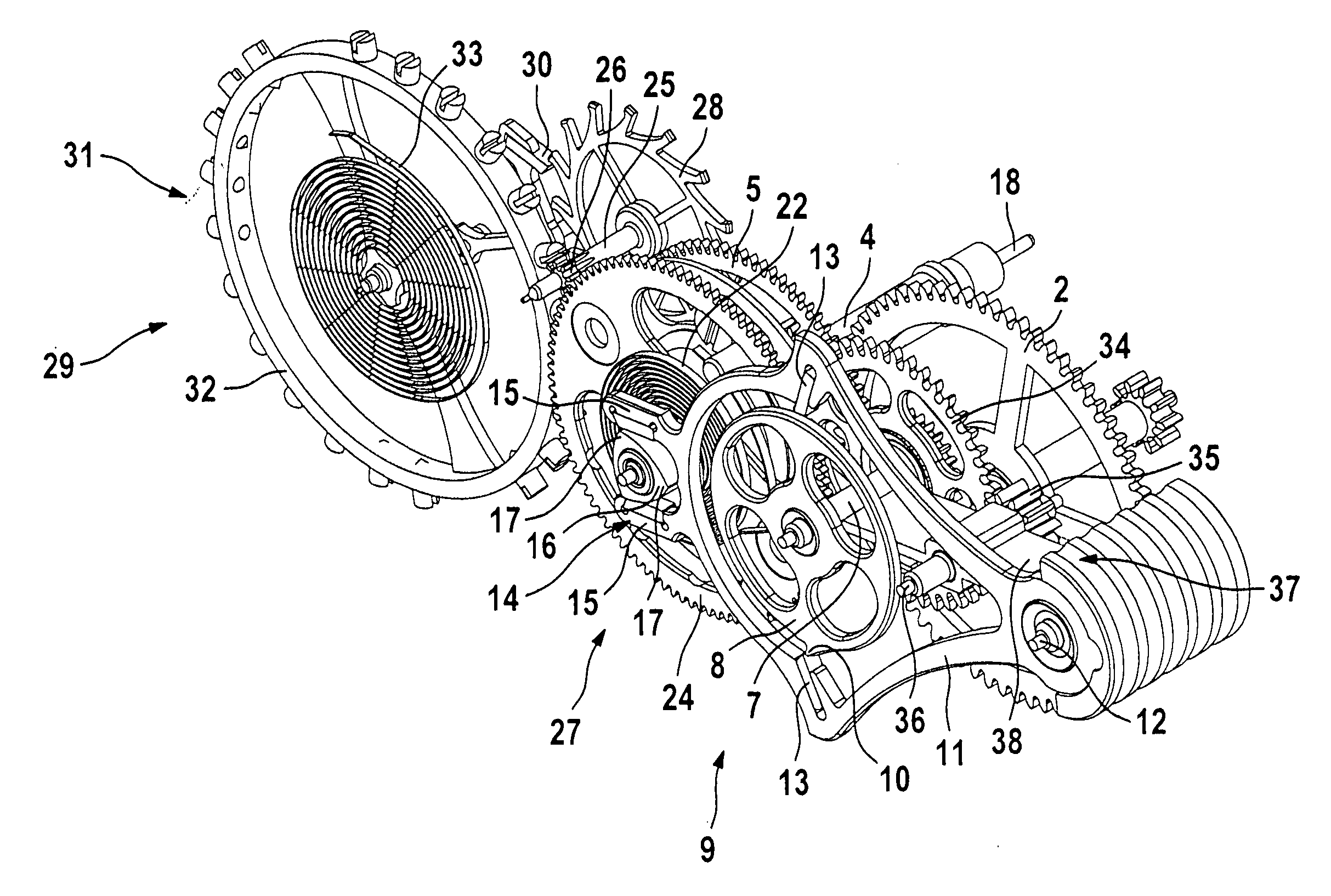

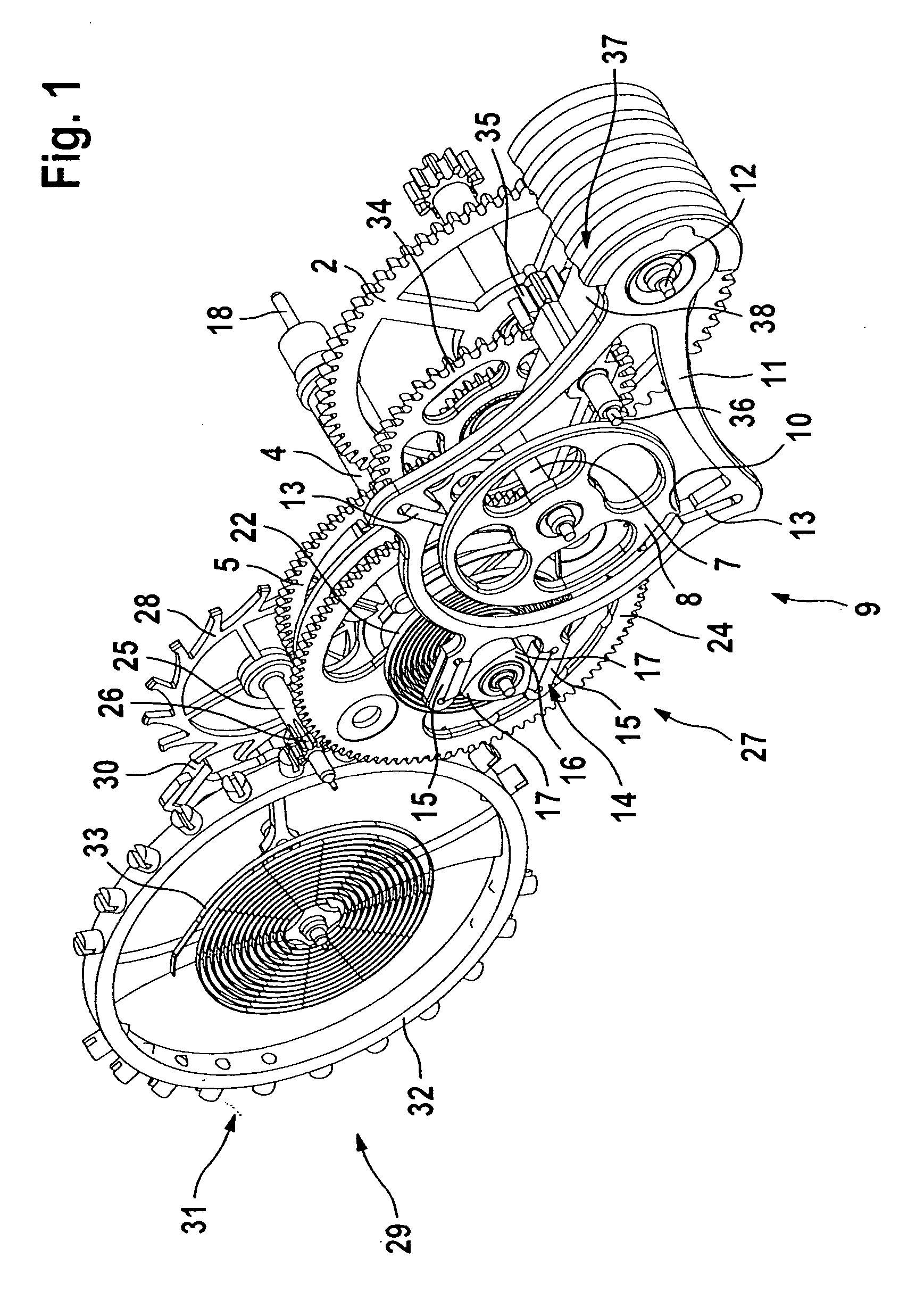

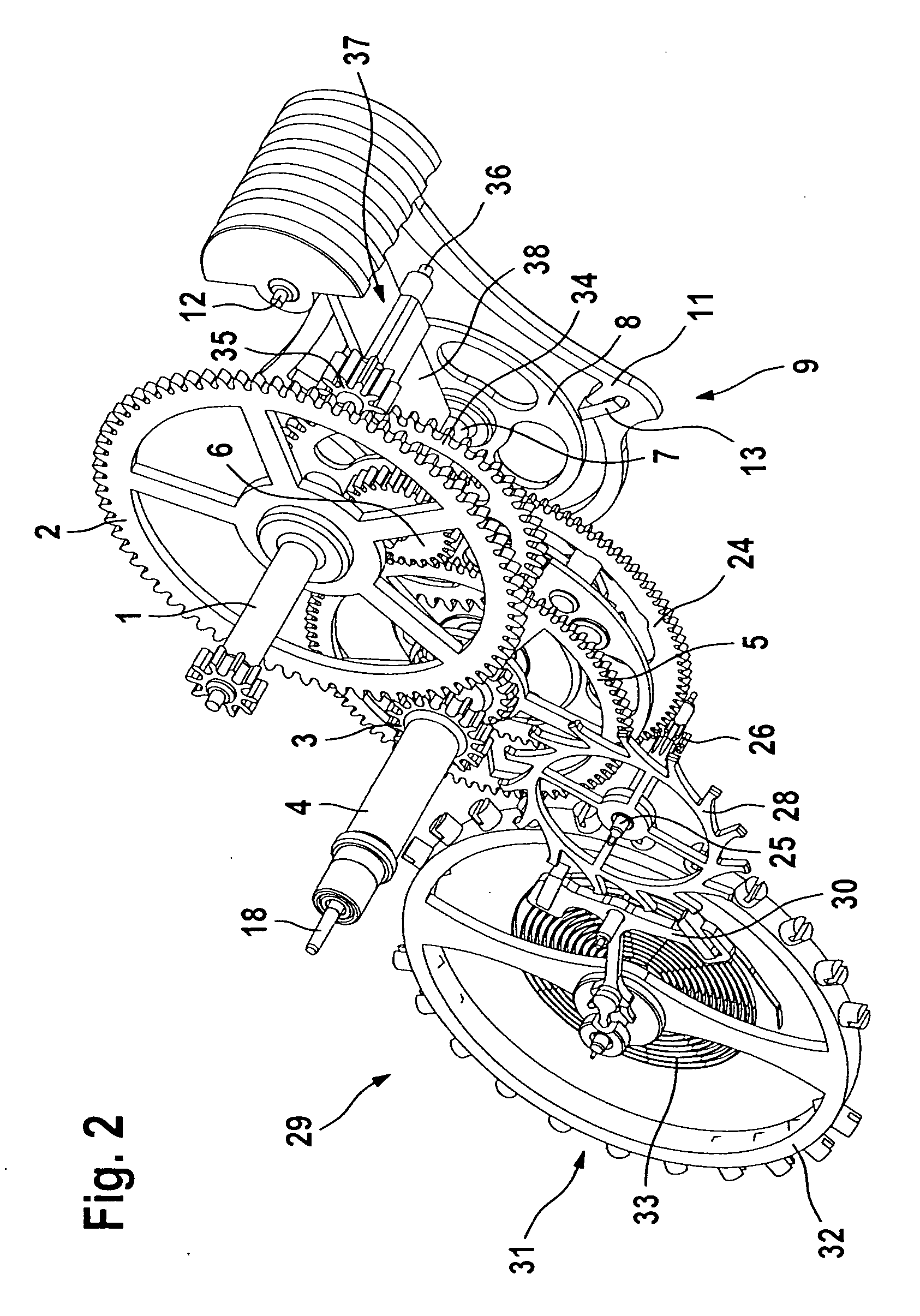

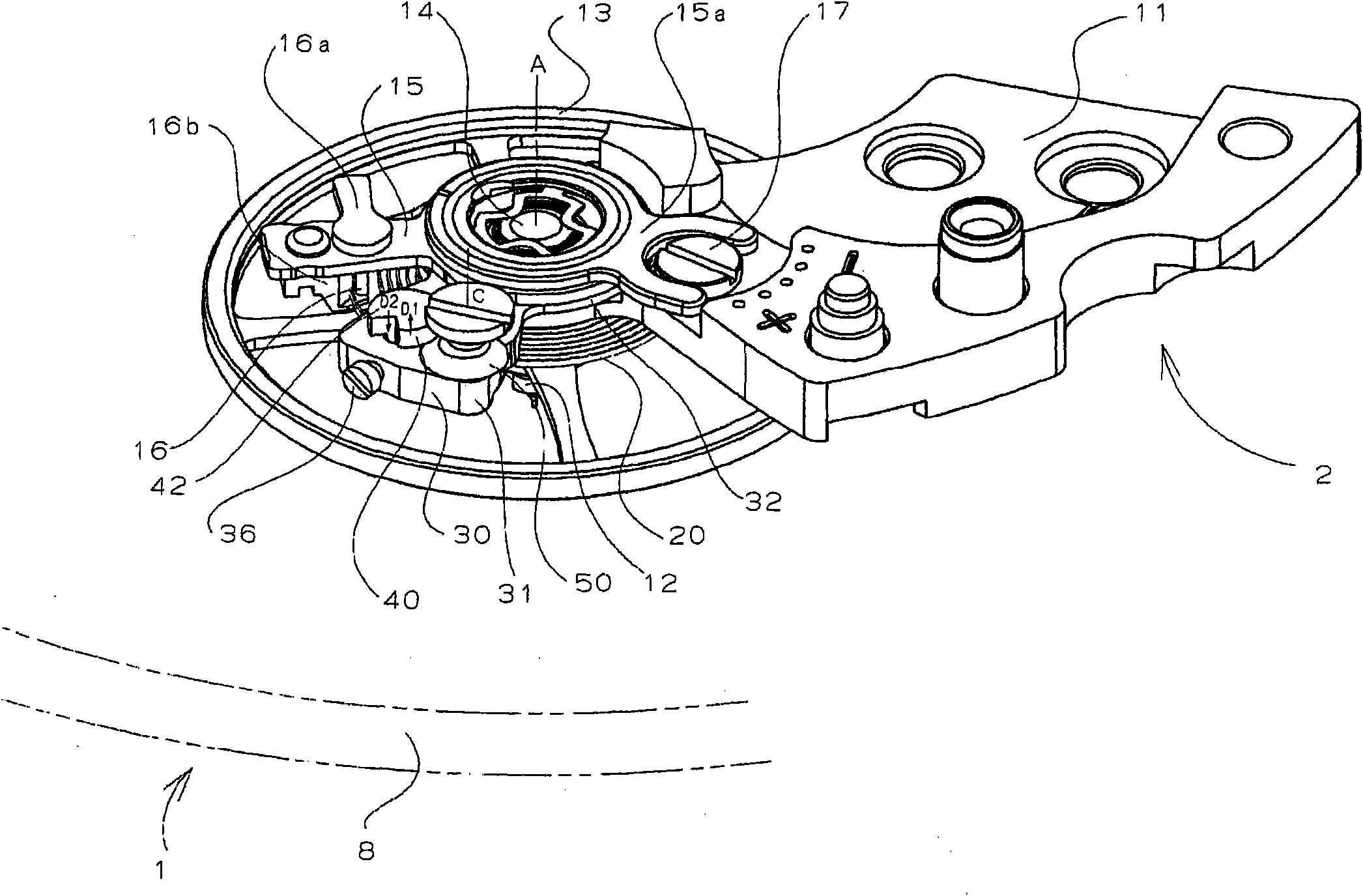

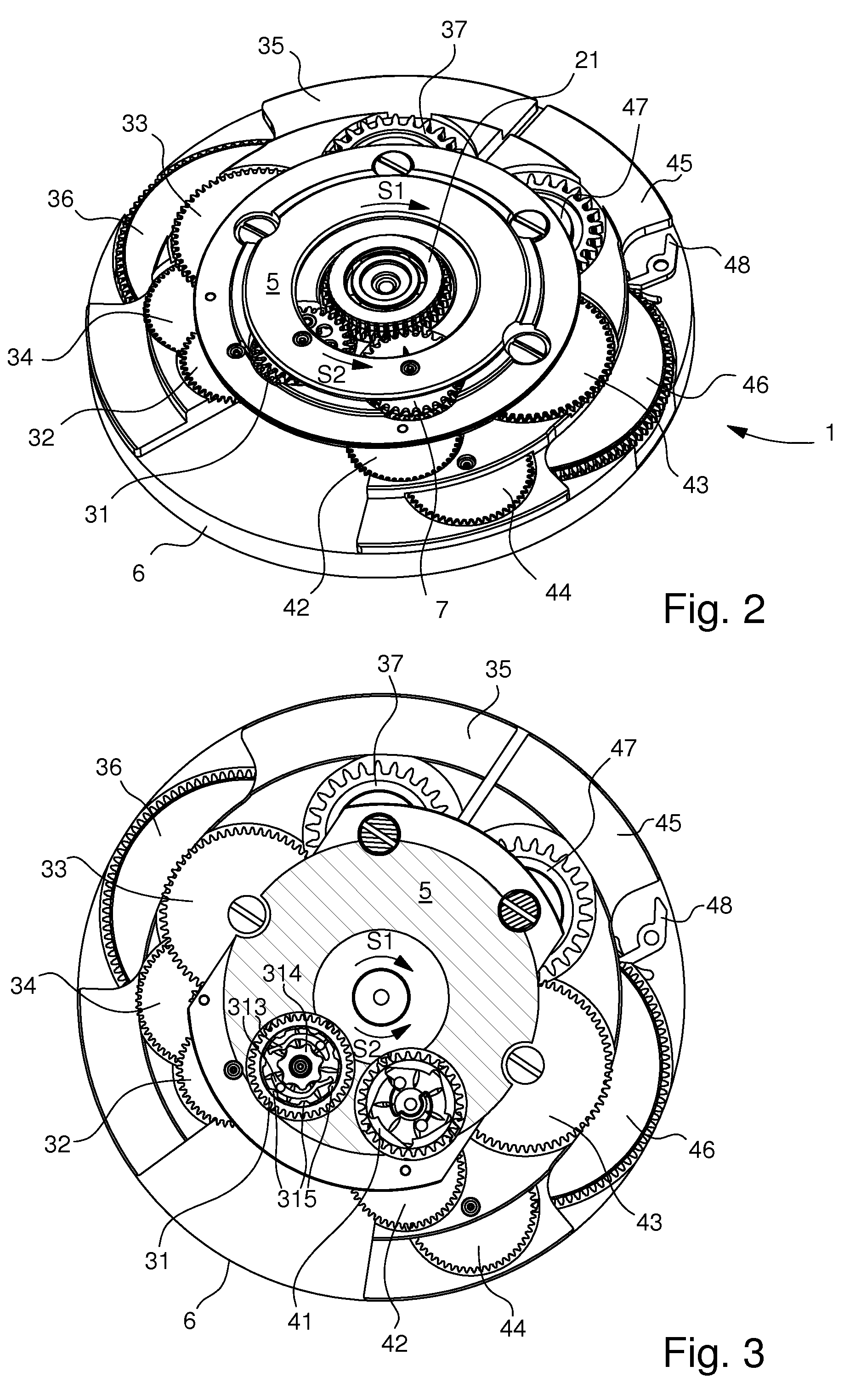

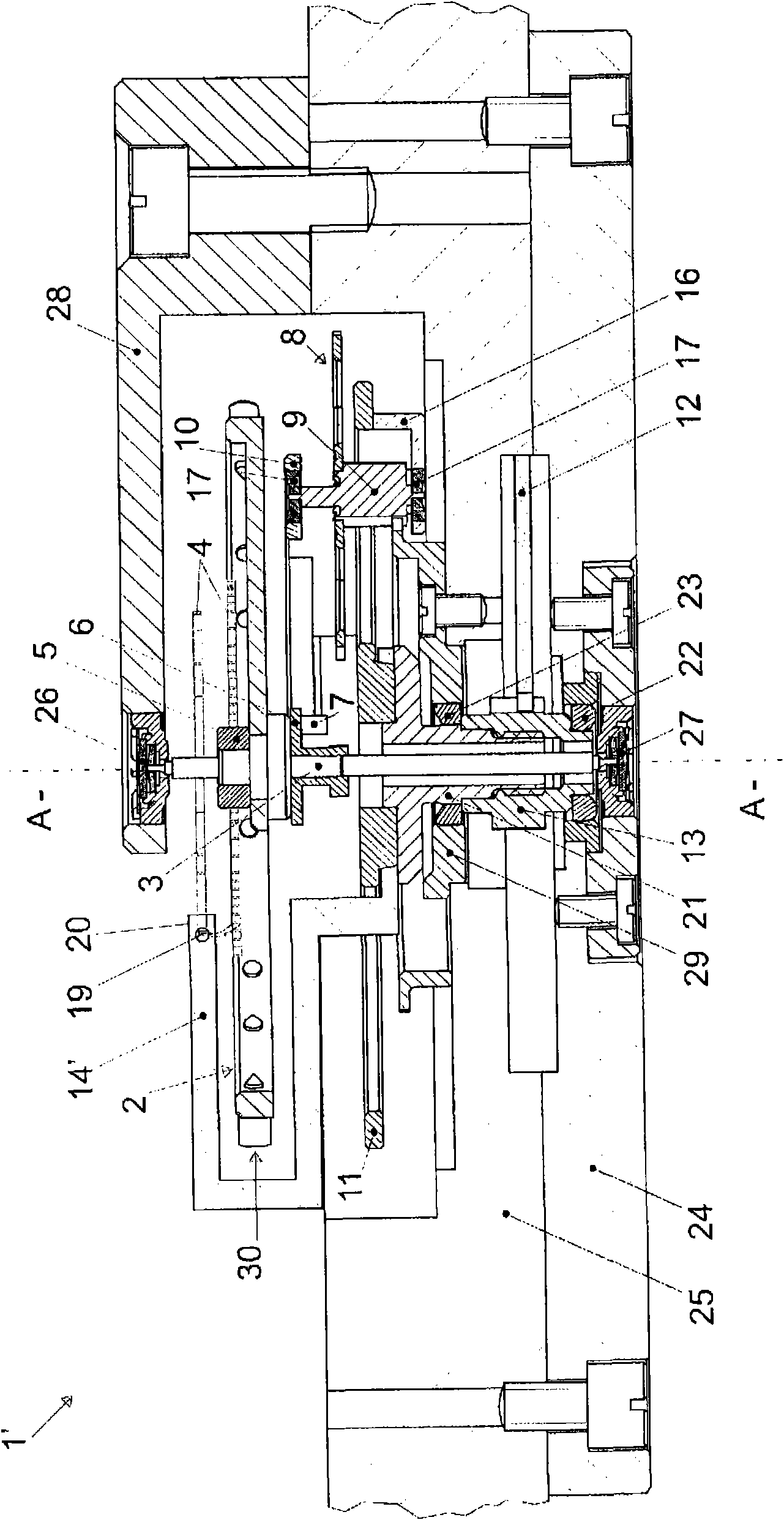

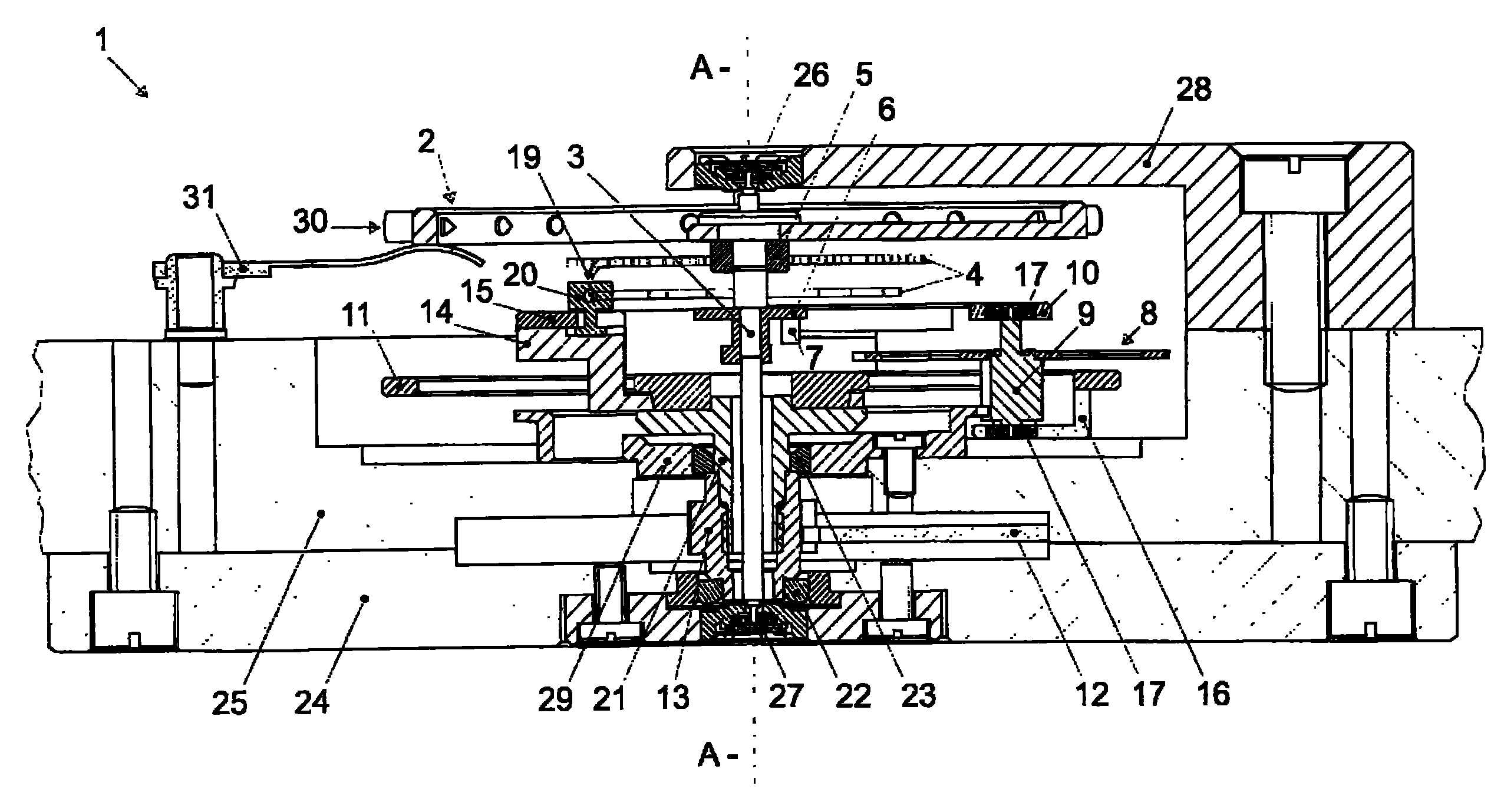

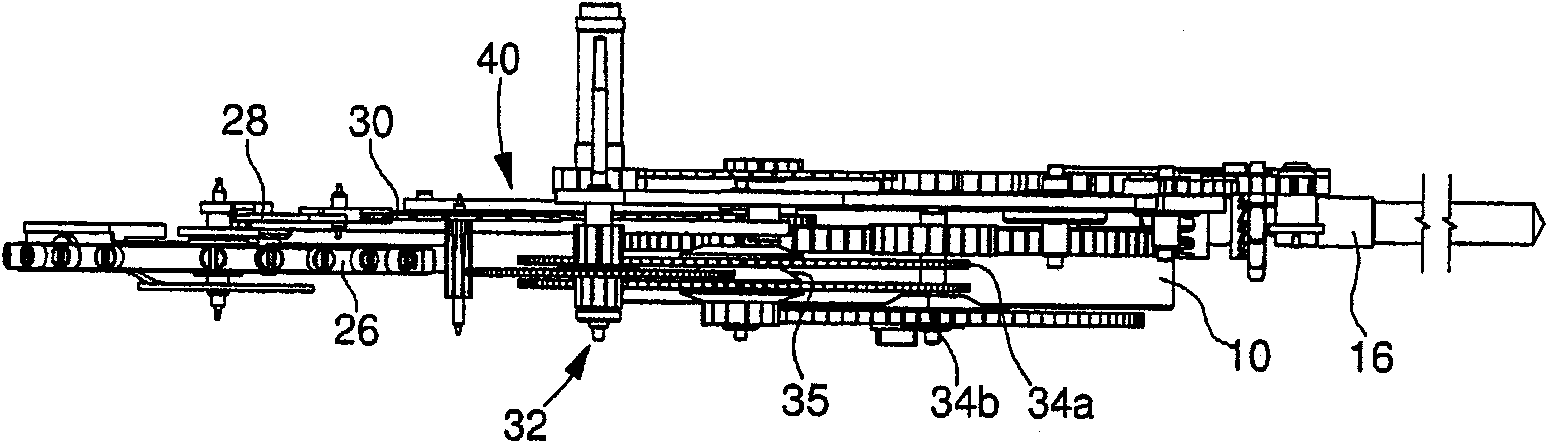

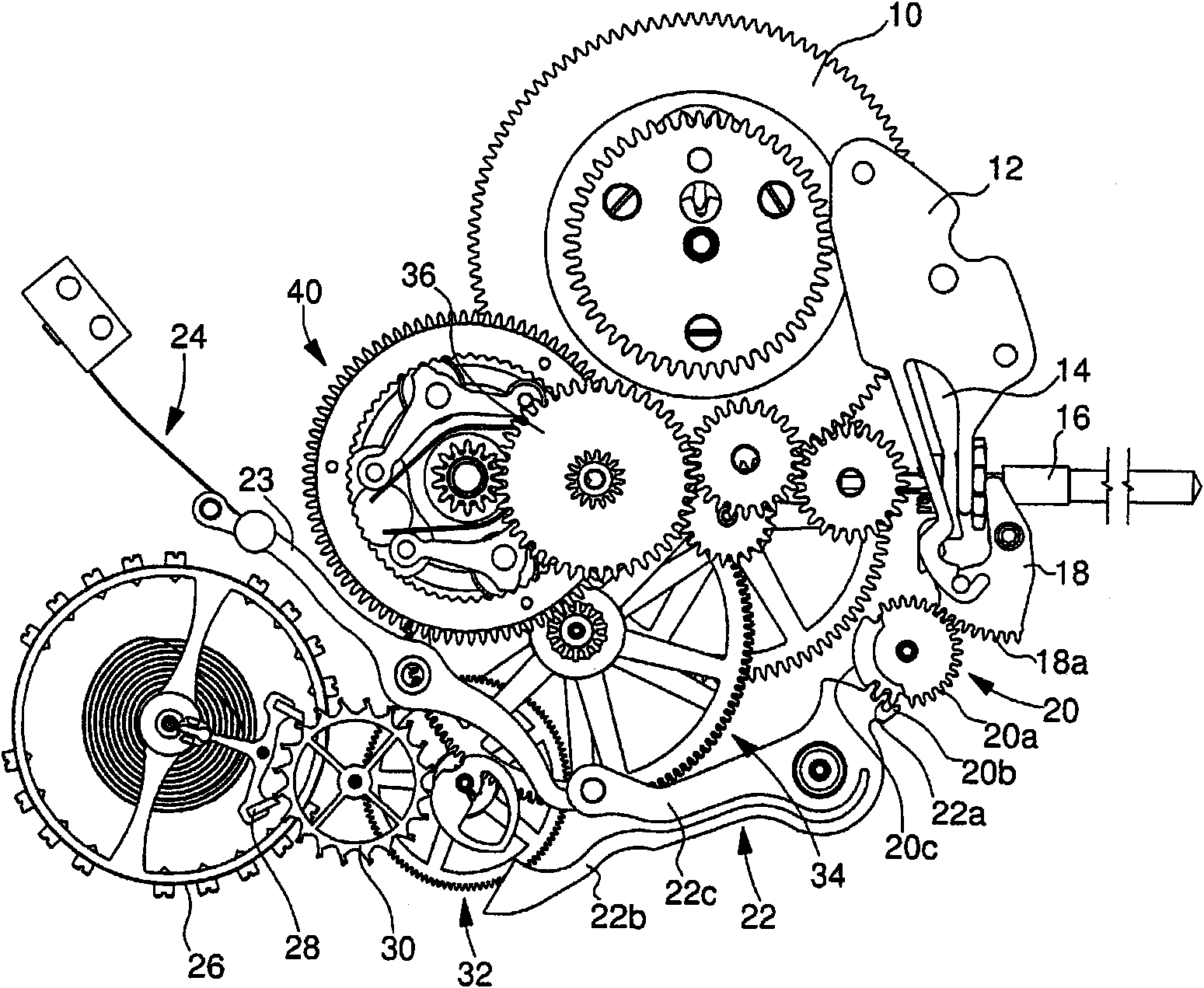

A timepiece, in particular a wristwatch, includes a constant-force device for acting on an oscillating system, the constant-force device including a switching unit and a tensioning module having a primary spring-energy store and a secondary spring-energy store. A seconds shaft bearing a seconds wheel and a cam plate is driven to rotate constantly by the secondary spring-energy store. The seconds wheel drives the oscillating system, and the cam plate acts on the switching unit for the periodic tensioning of the secondary spring-energy store by the primary spring-energy store.

Owner:LANGE UHREN

Timepiece including a striking work

InactiveUS7021819B2Sufficient travelElectric indicationMechanical unknown time interval measurementEngineeringMechanical engineering

Owner:GLASHUETTER UHRENBETRIEB GMBH

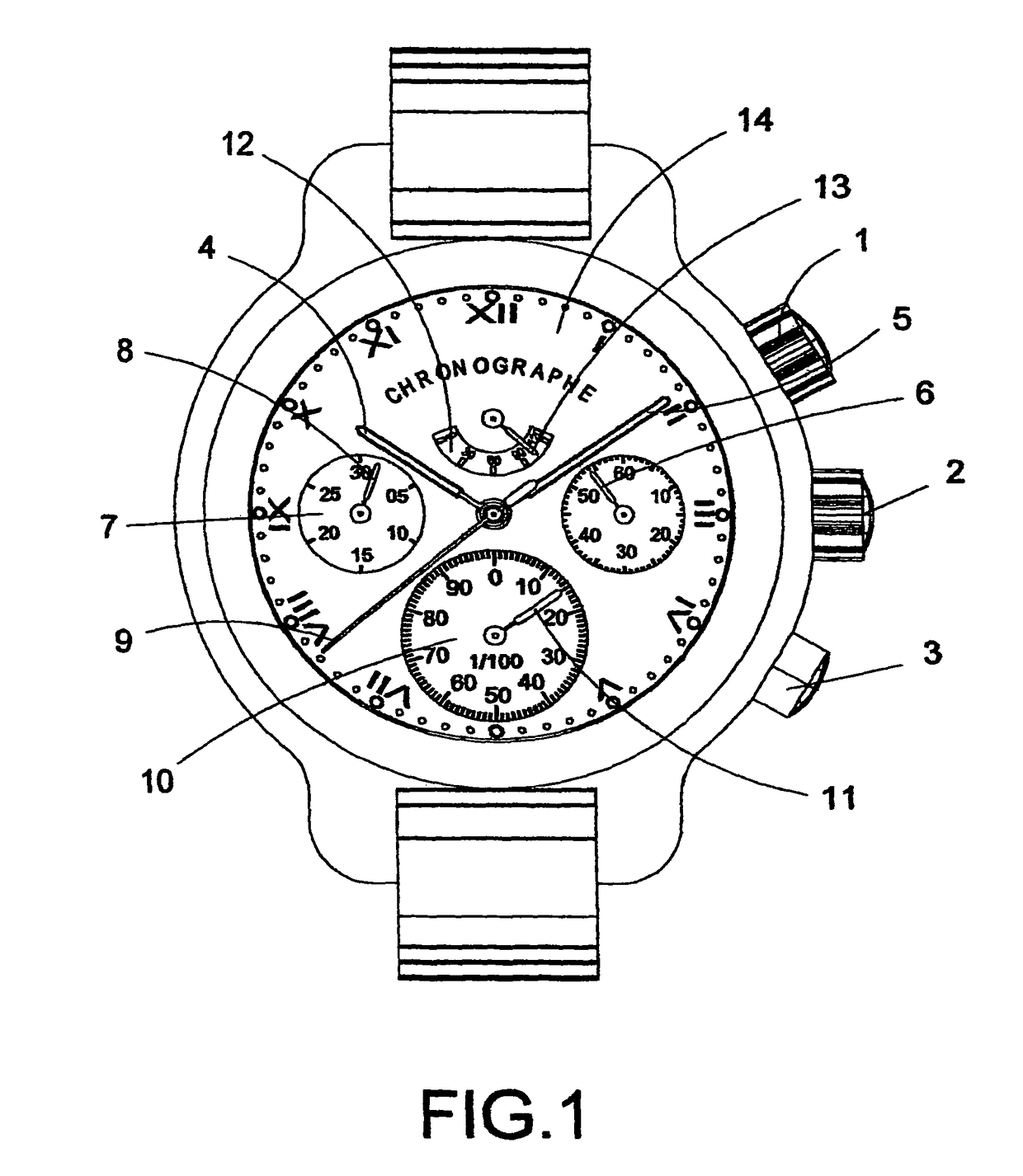

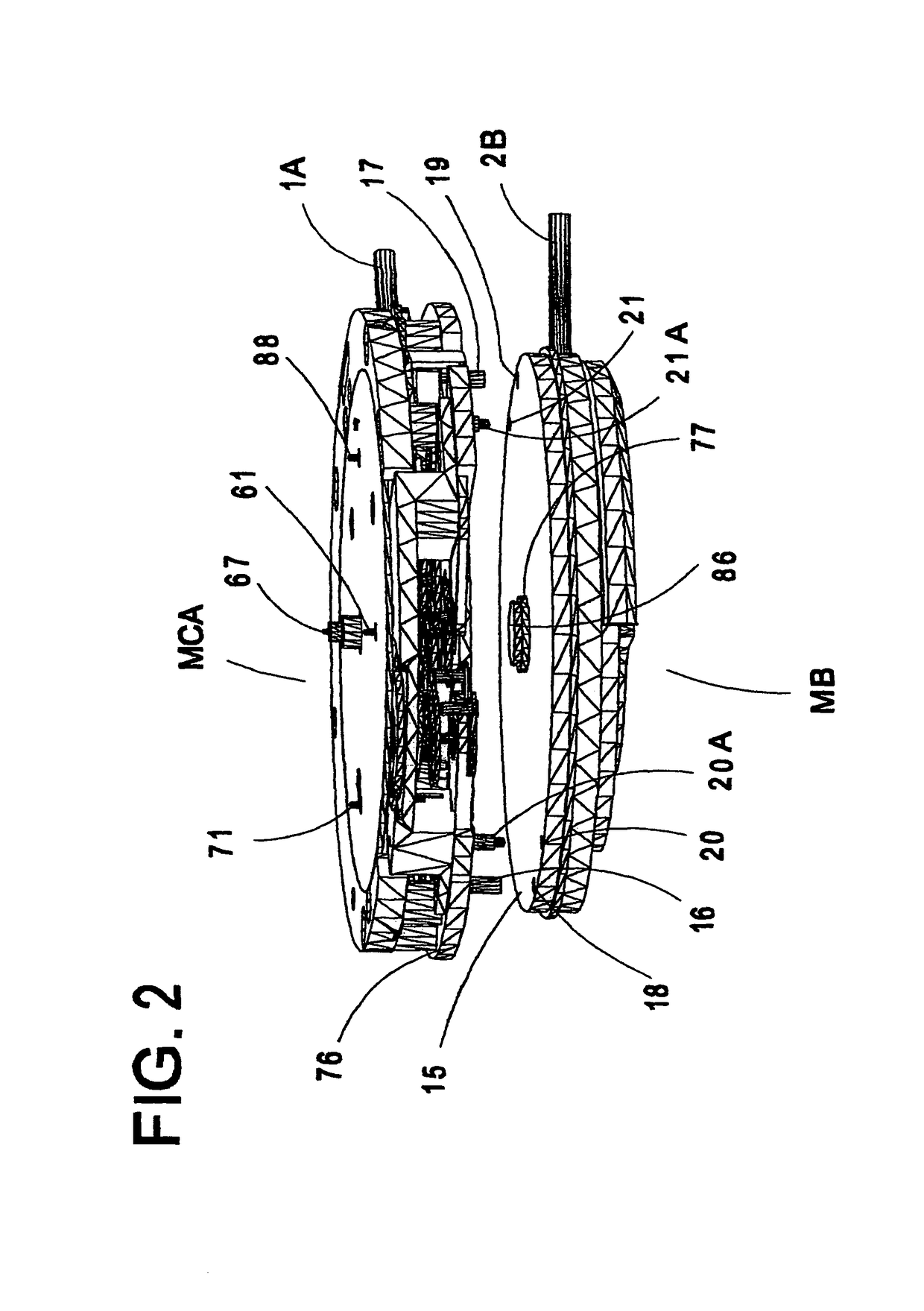

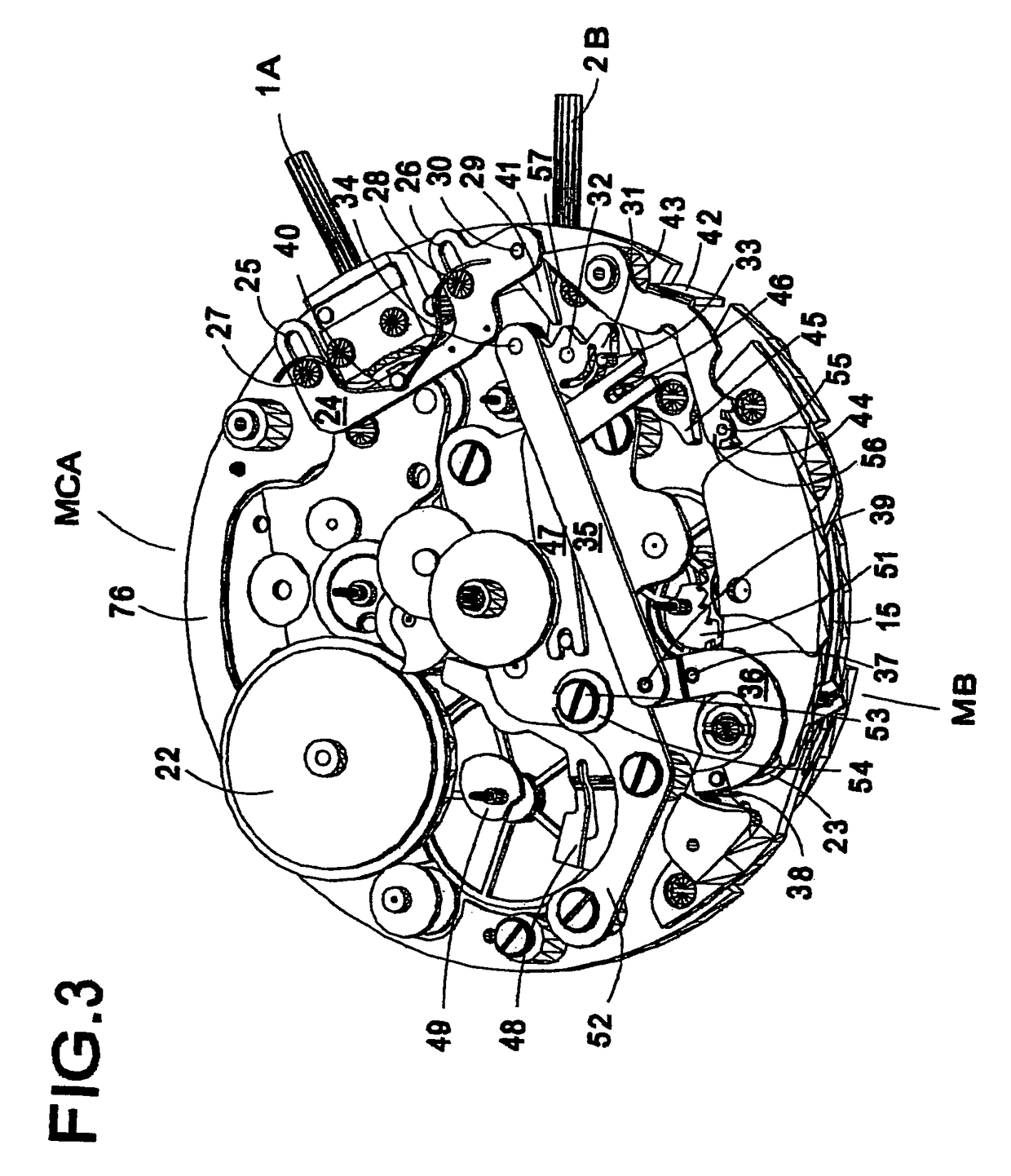

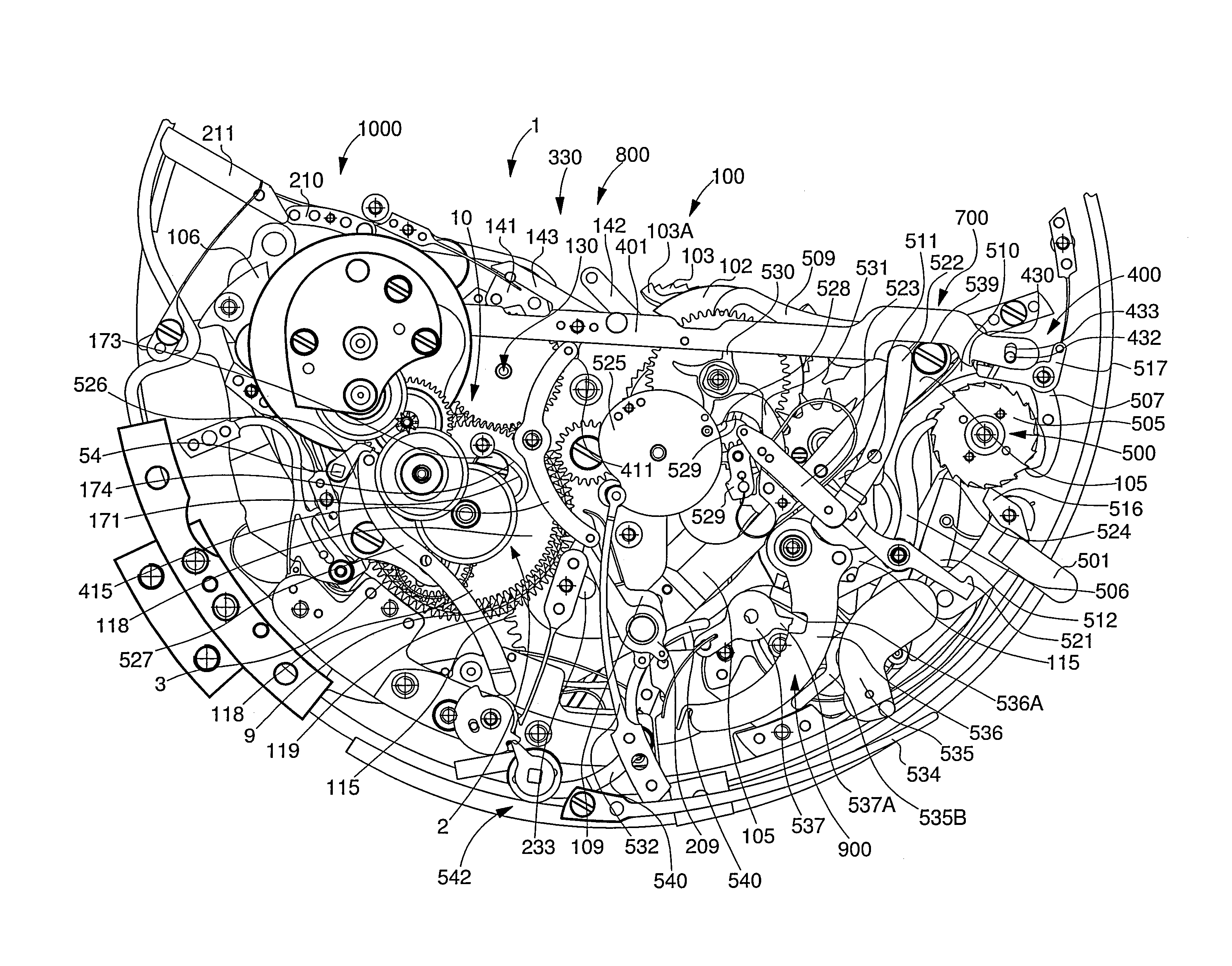

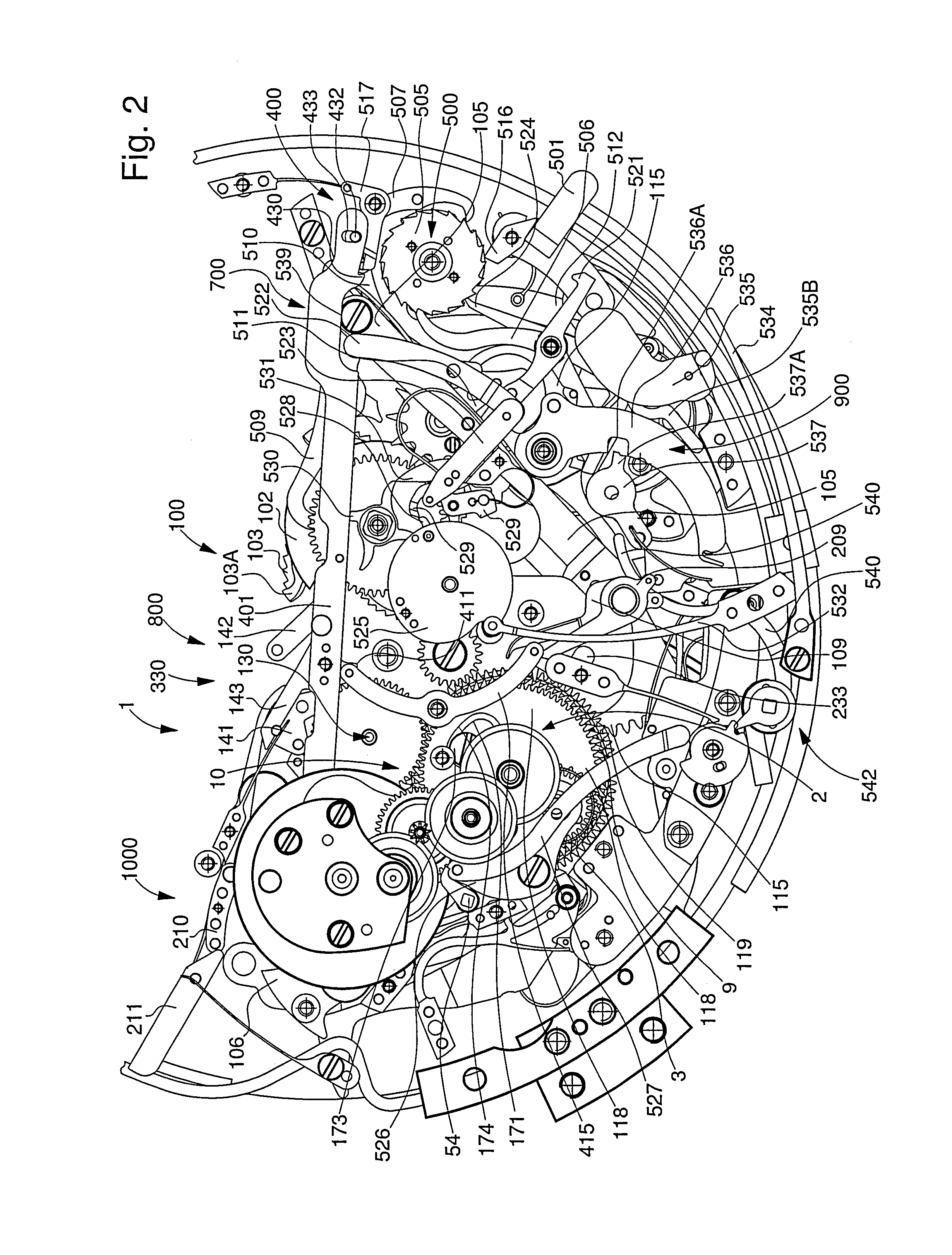

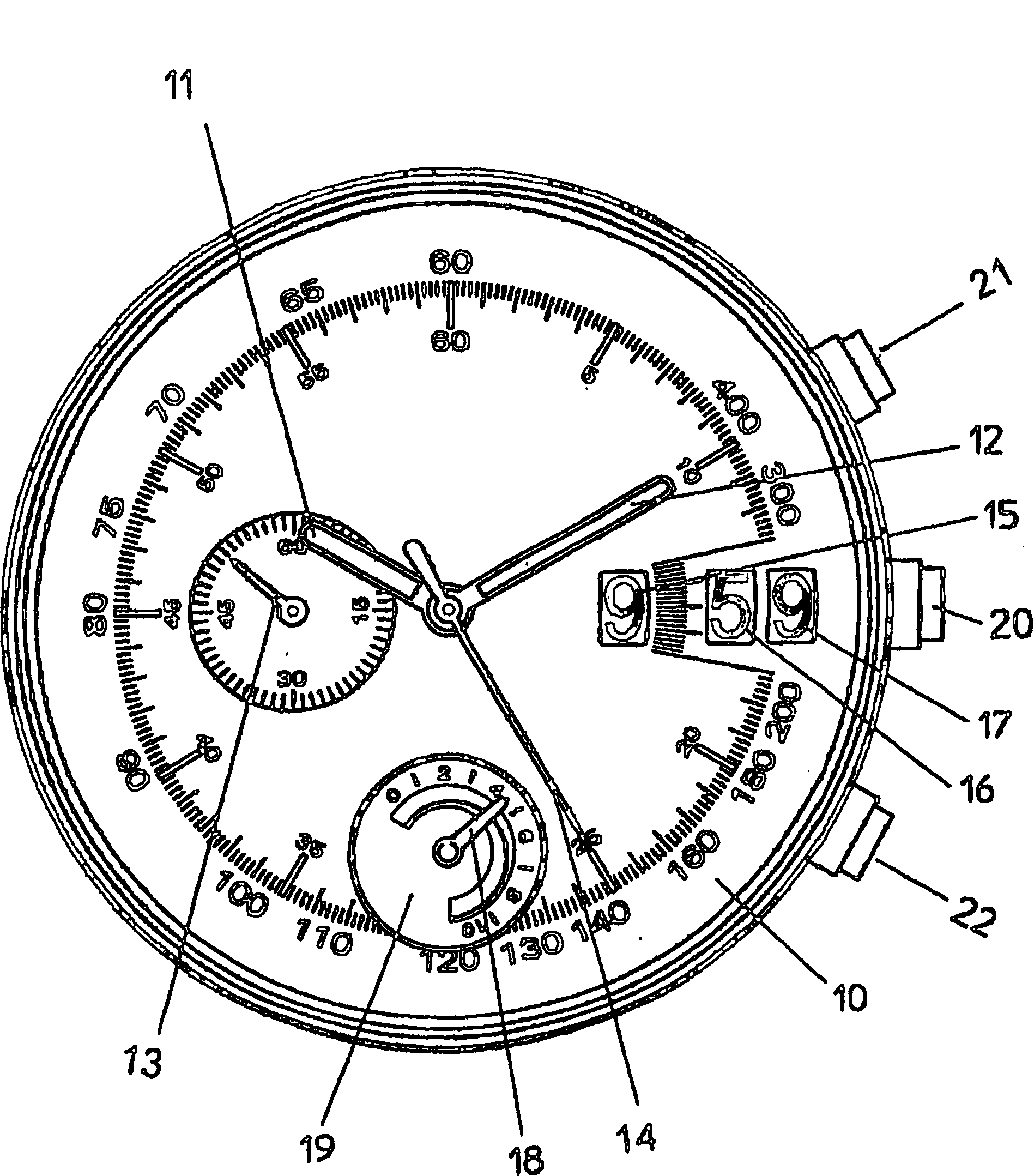

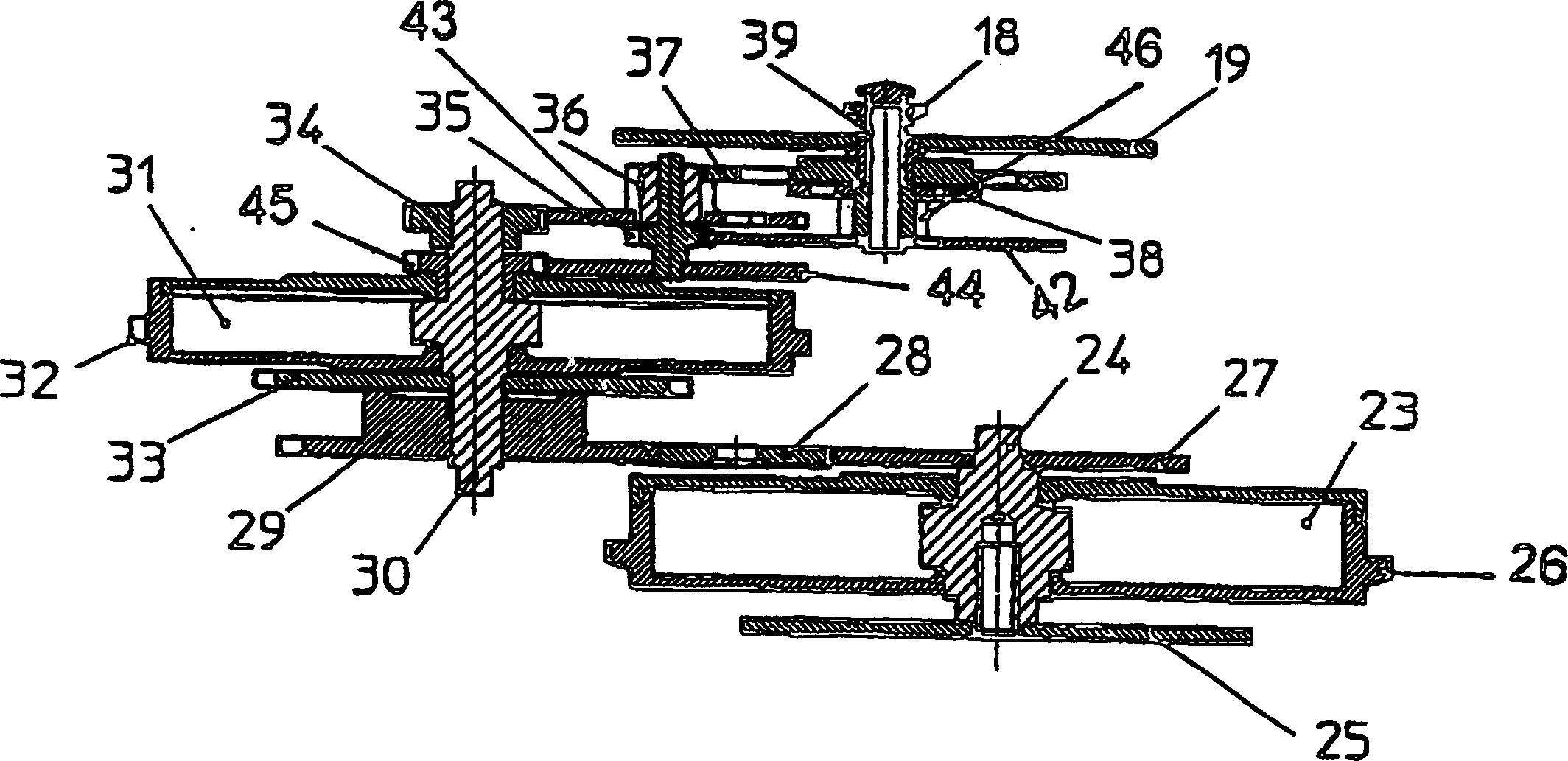

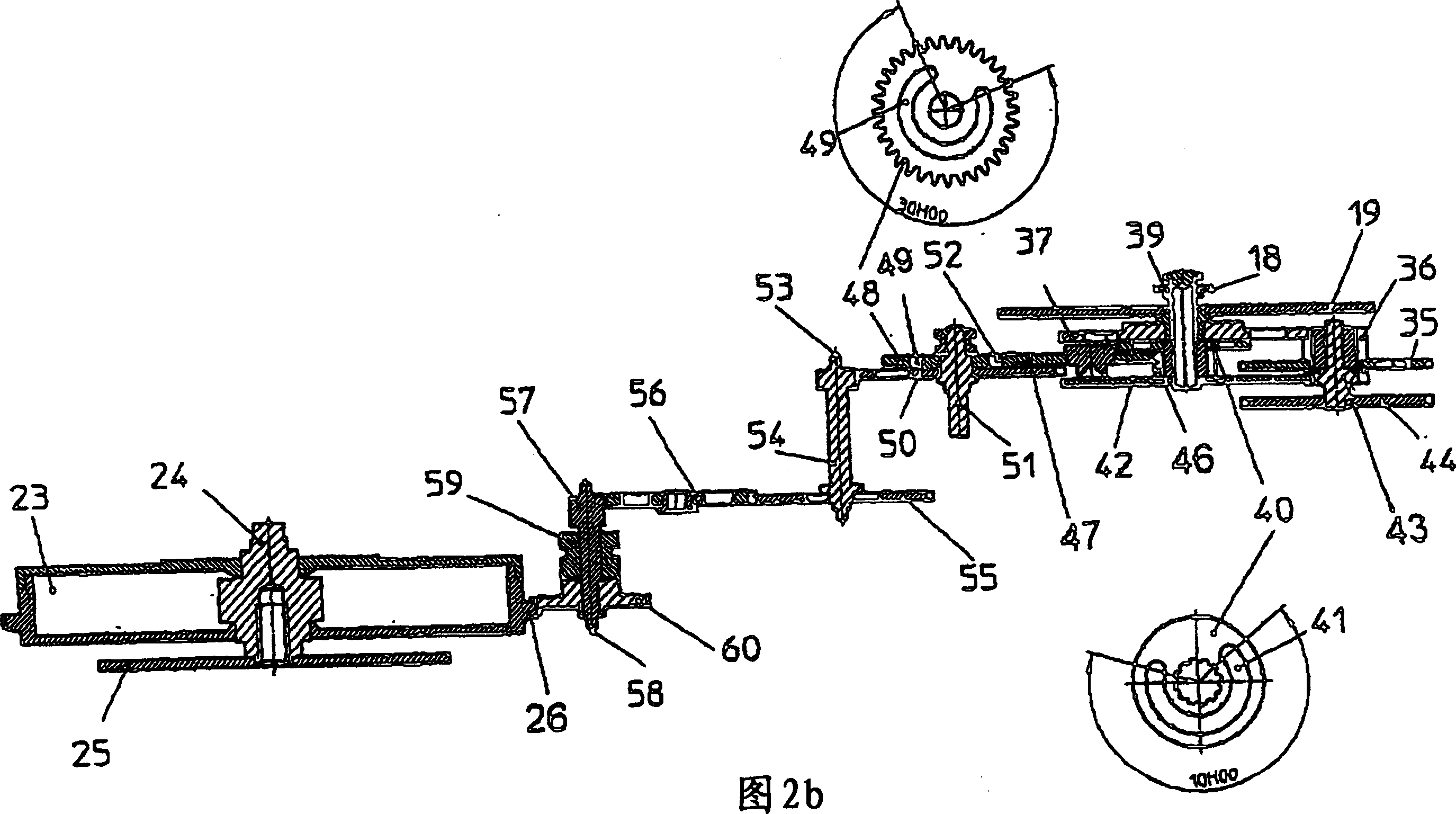

Device comprising a clock movement and a chronograph module

ActiveUS7905655B2Low costHorological winding mechanismsMechanical unknown time interval measurementComputer moduleRemontoire

A device comprises a basic clock movement MB whose time indicators are driven by a first barrel connected to a first wheelwork and a first regulator organ, and an autonomous chronograph module MCA whose indicators are driven by a second barrel independent from the first, connected to a second wheelwork and a second regulator organ. The chronograph module is exclusively composed of mechanical elements. The frequency of oscillation supplied by its regulator is equal N times the frequency of oscillation supplied by the regulator of the base movement, with the coefficient N being definable according to a specific application of the chronograph, so that any chronograph module thus previously defined can work with the same base movement. The chronograph regulator remains constantly engaged with the corresponding wheelwork. The chronograph module allows a time interval to be read with a minimum precision of a hundredth of second. The organs of the base movement and of the chronograph module are arranged in such a way that in assembled state, the height and overall diameter do not exceed 7.75 mm and 30 mm respectively, the dimensions of the chronograph itself being not greater than 4 mm (height) and 30 mm (diameter) when its elements are mounted on a bottom plate, so that the device can advantageously be integrated in the case of a wrist-watch and affords an aesthetic exterior.

Owner:LVMH SWISS MFG SA

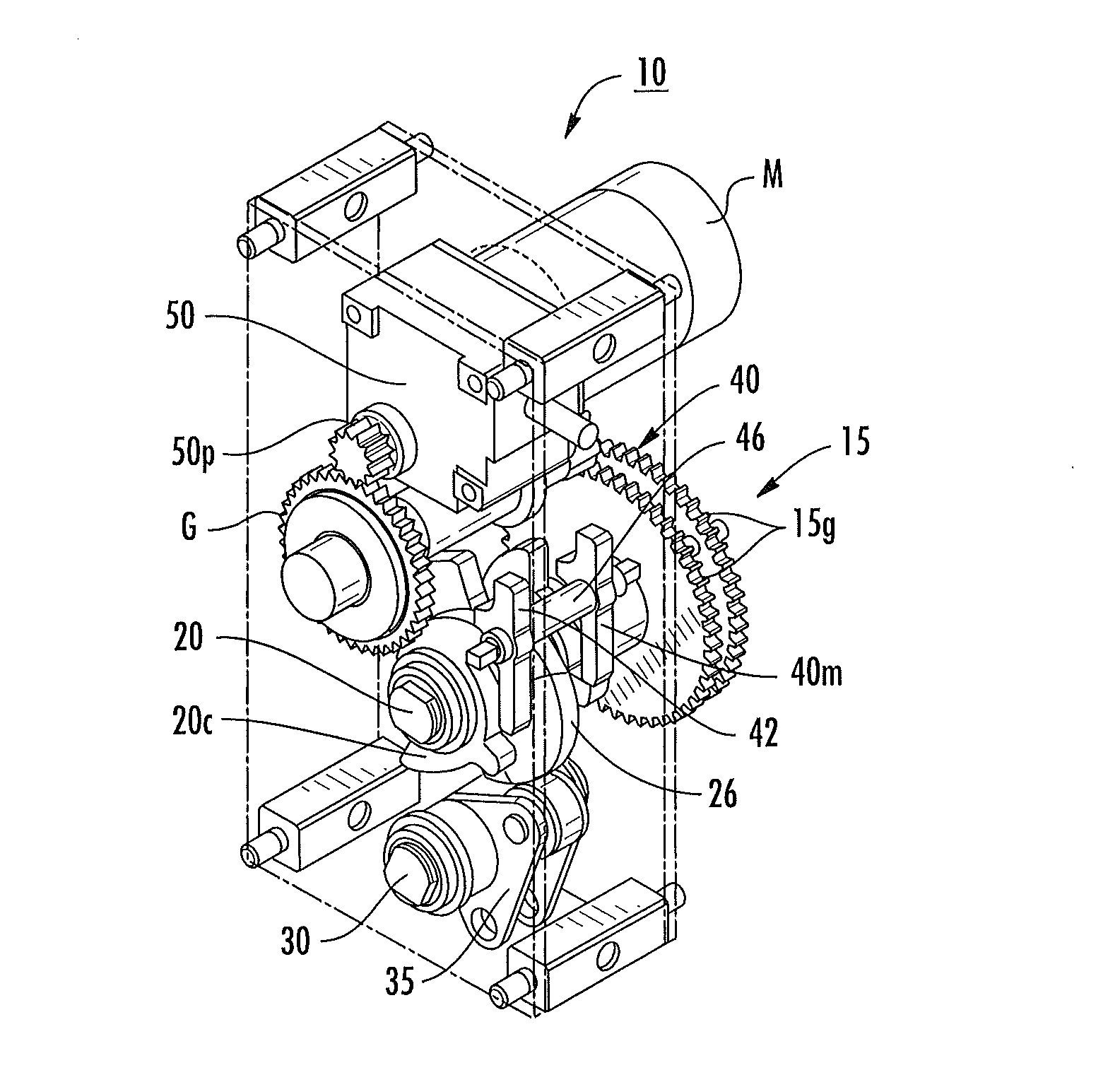

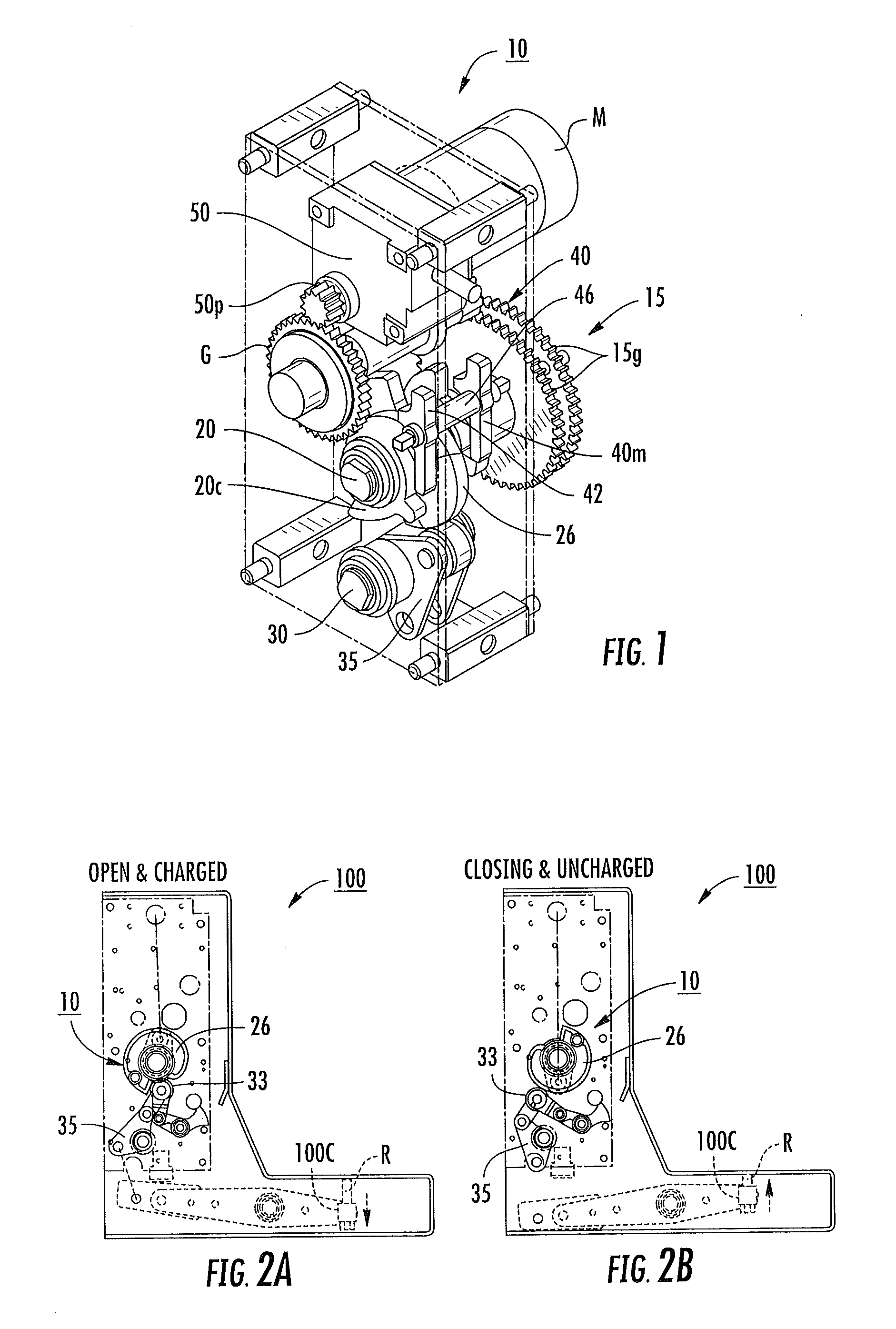

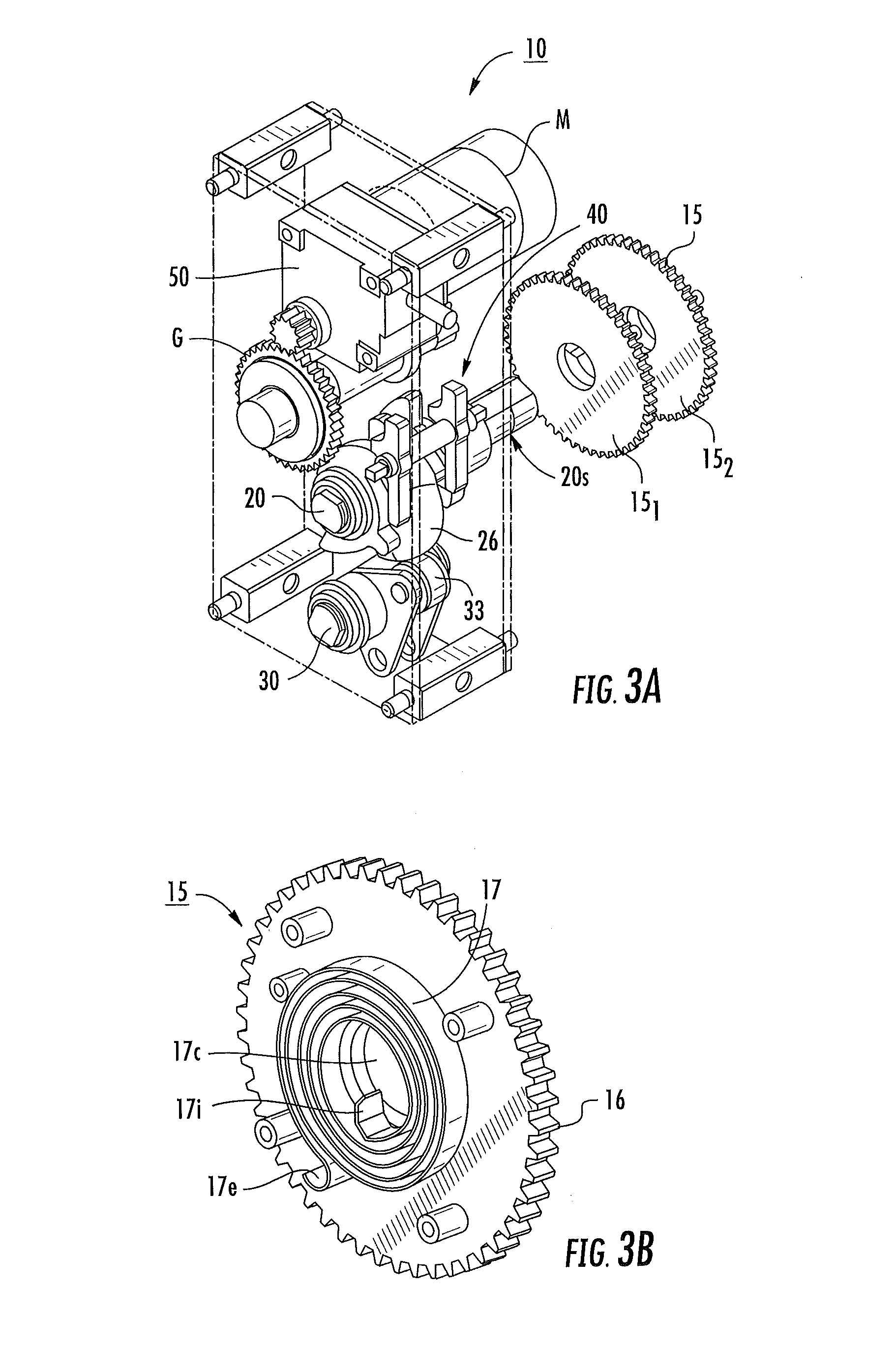

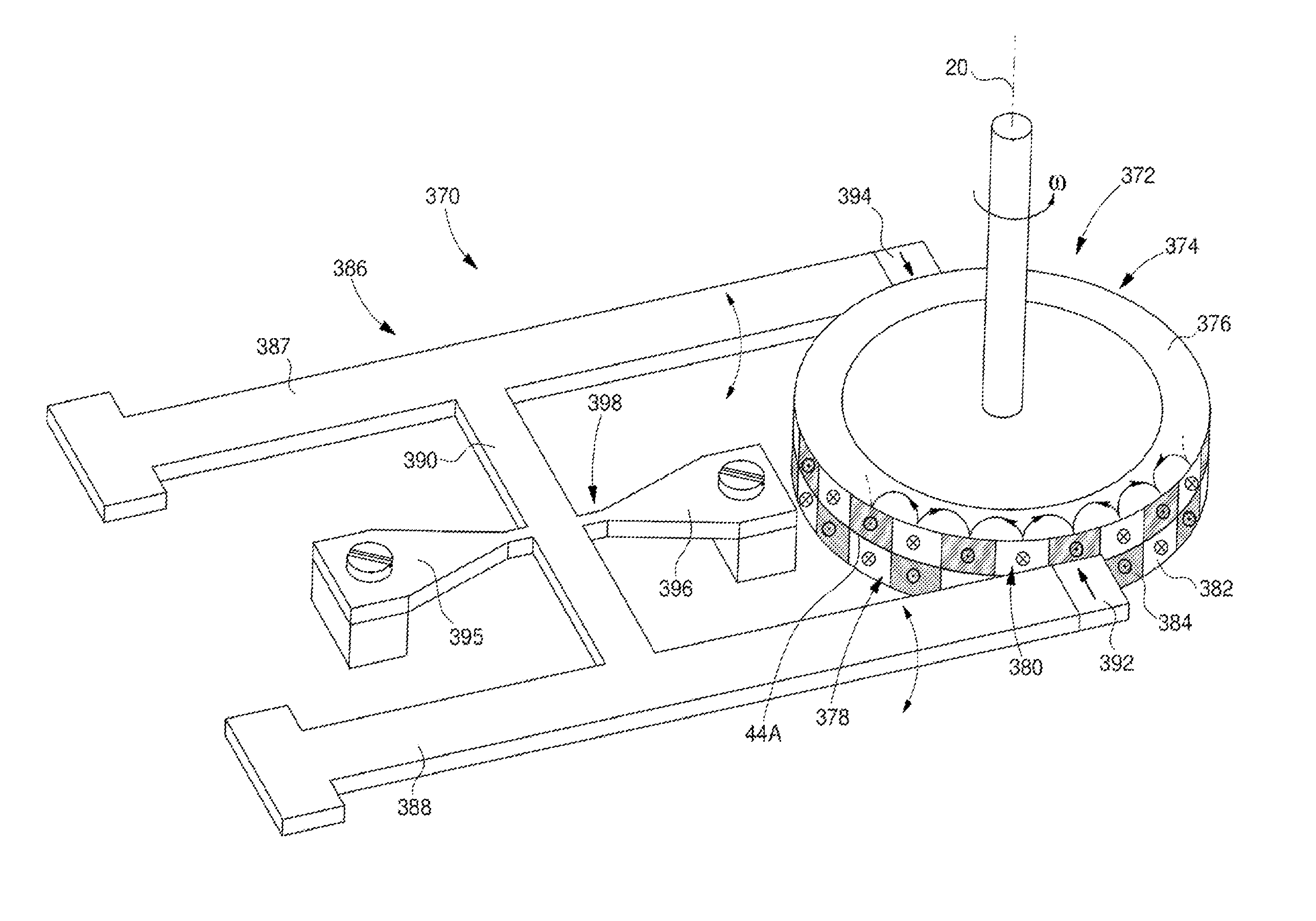

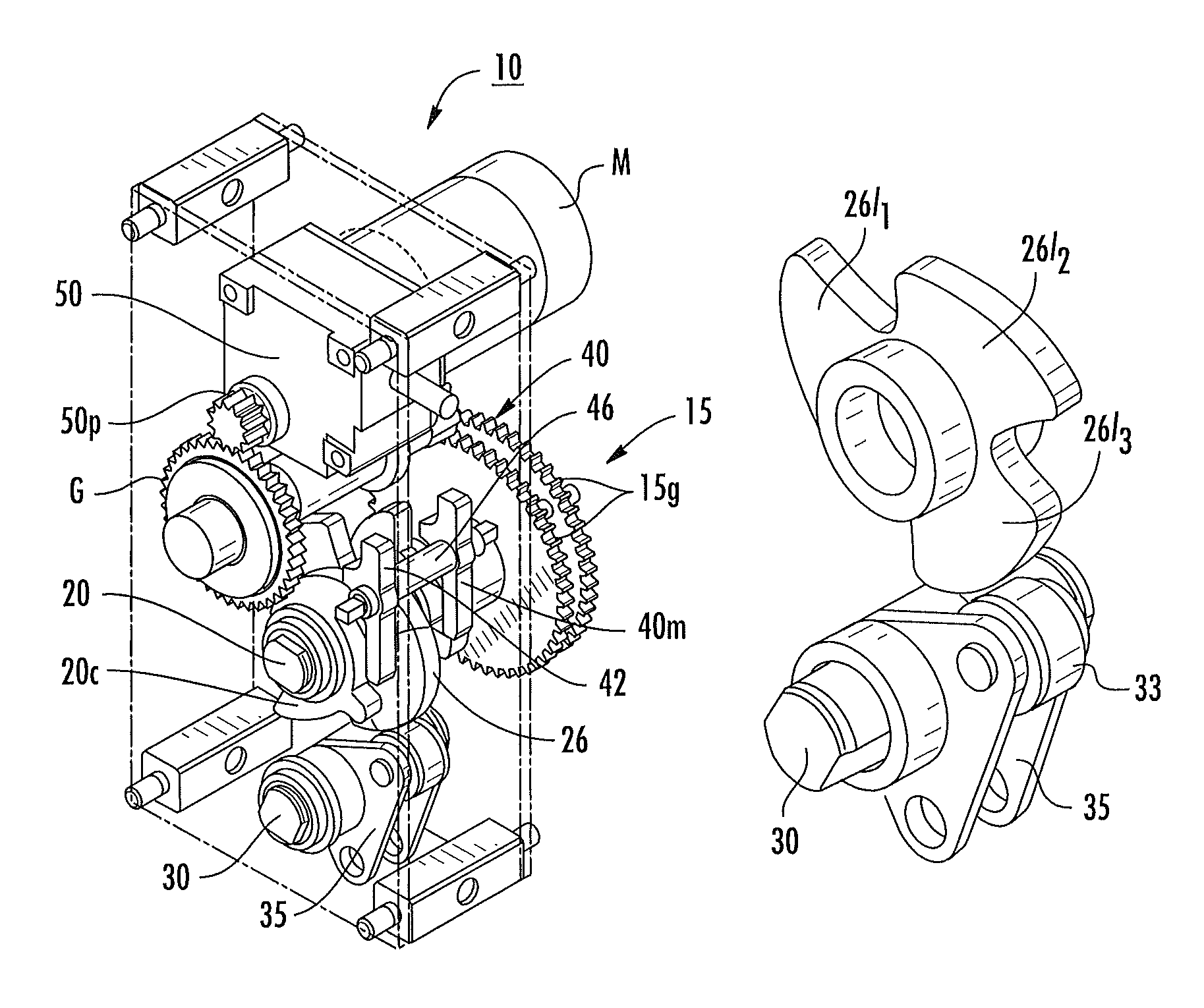

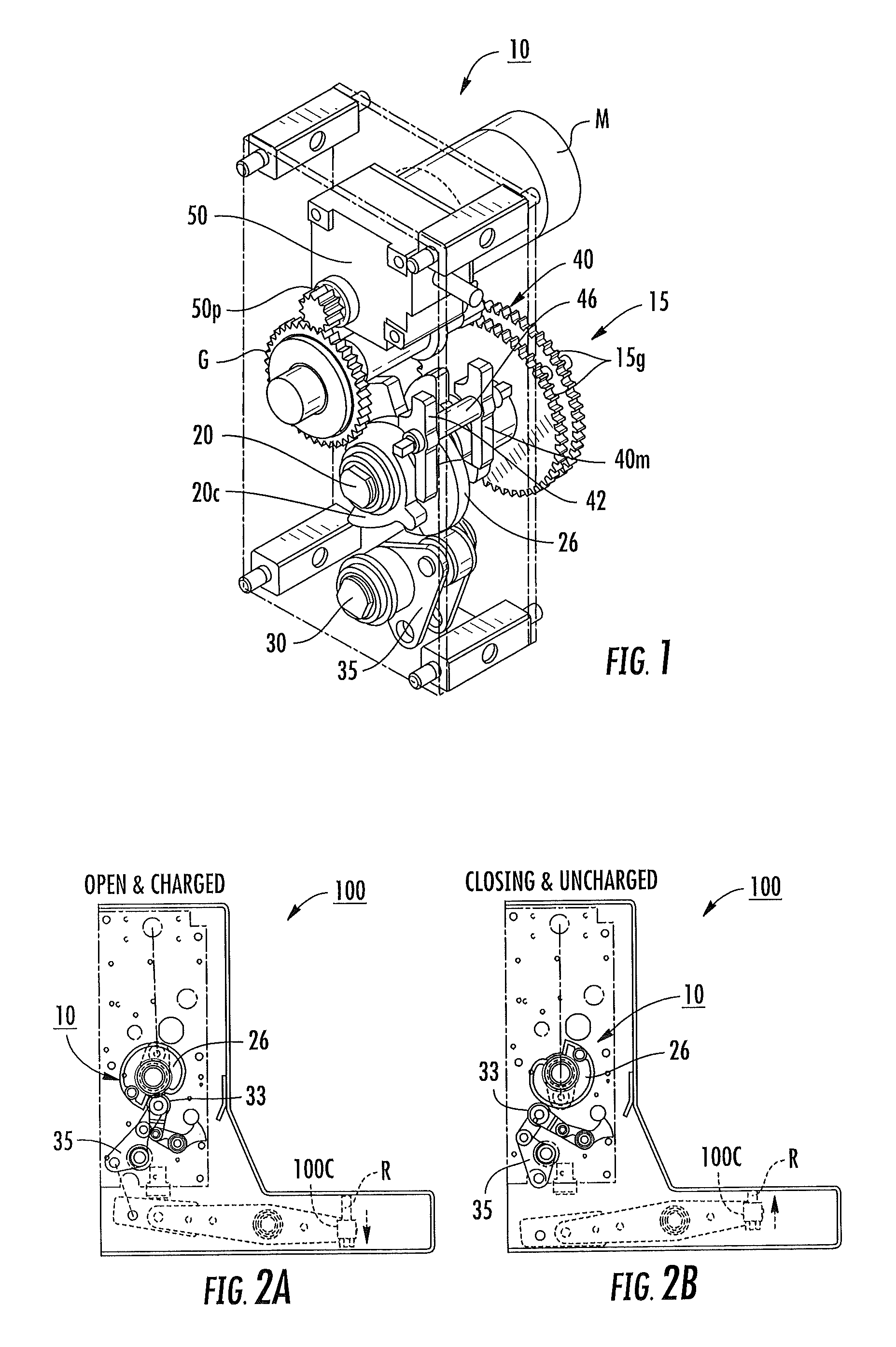

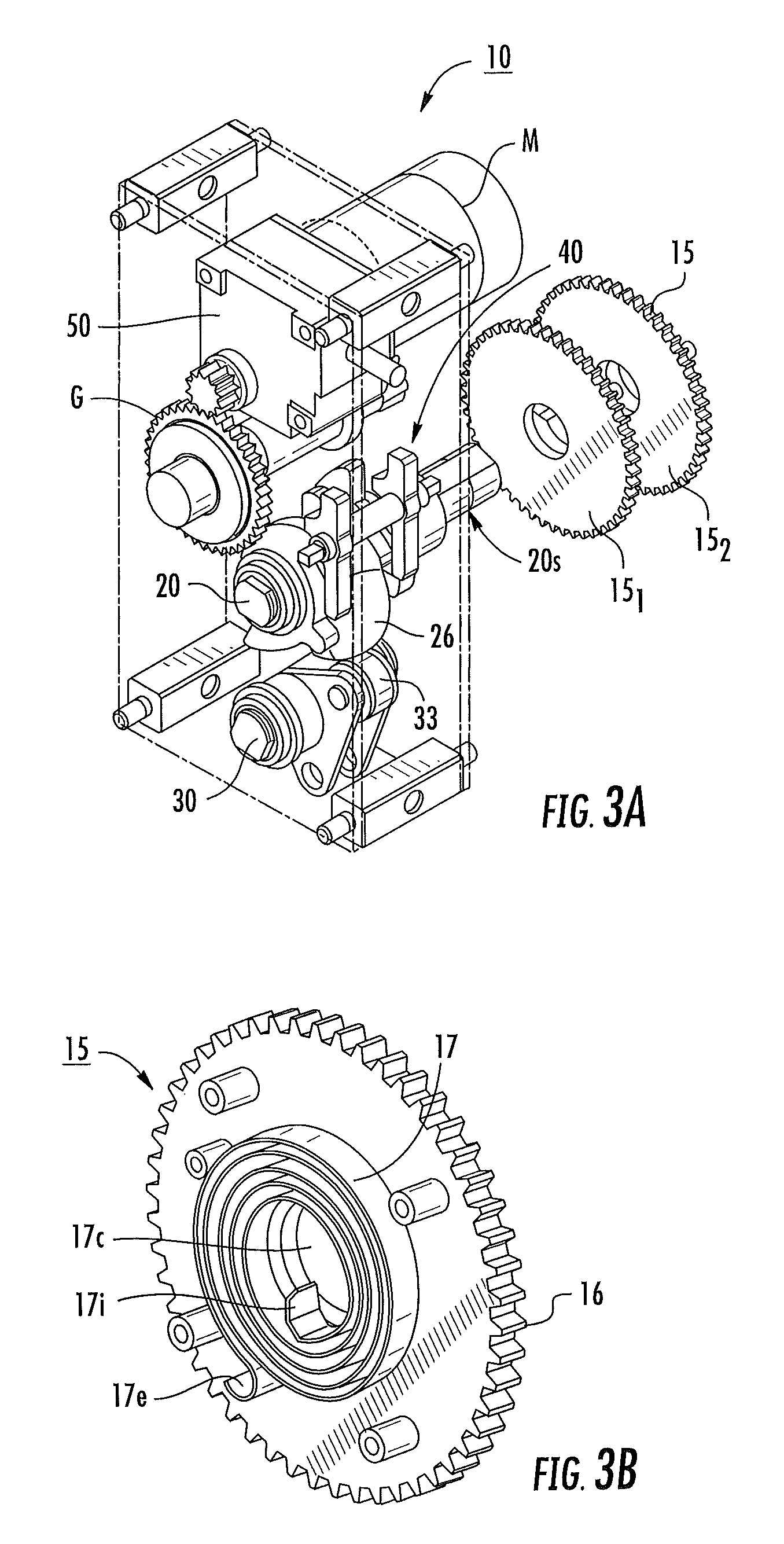

Circuit breakers with clock spring drives and/or multi-lobe drive cams and related actuators and methods

Spring operated actuator devices for an electrical circuit breaker and / or electrical switching device include at least one clock spring comprising a disc shaped body with gear teeth and a spiral spring, a cam shaft holding the at least one clock spring with an inner end portion of the spiral spring attached to the cam shaft, and a drive cam held by the cam shaft adapted to be in communication with a follower that directs an actuator to open or close a mobile contact to maintain open and closed energy status of the electrical circuit. The at least one clock spring is configured as a closing spring of the spring operated actuator.

Owner:EATON INTELLIGENT POWER LIMITED

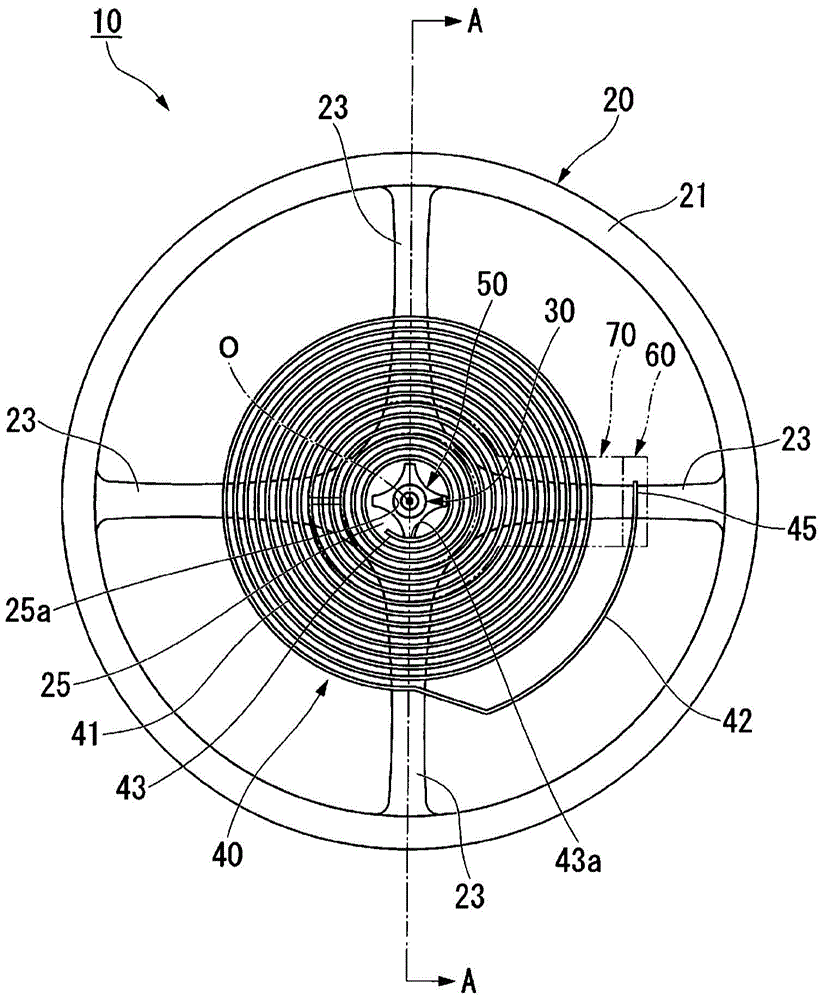

Hairspring supporting structure, hairspring balance wheel structure and mechanical clock

InactiveCN101840194AContinuous regulationSuppression frequencyFrequency stabilisation mechanismFrequency setting mechanismLower limitEngineering

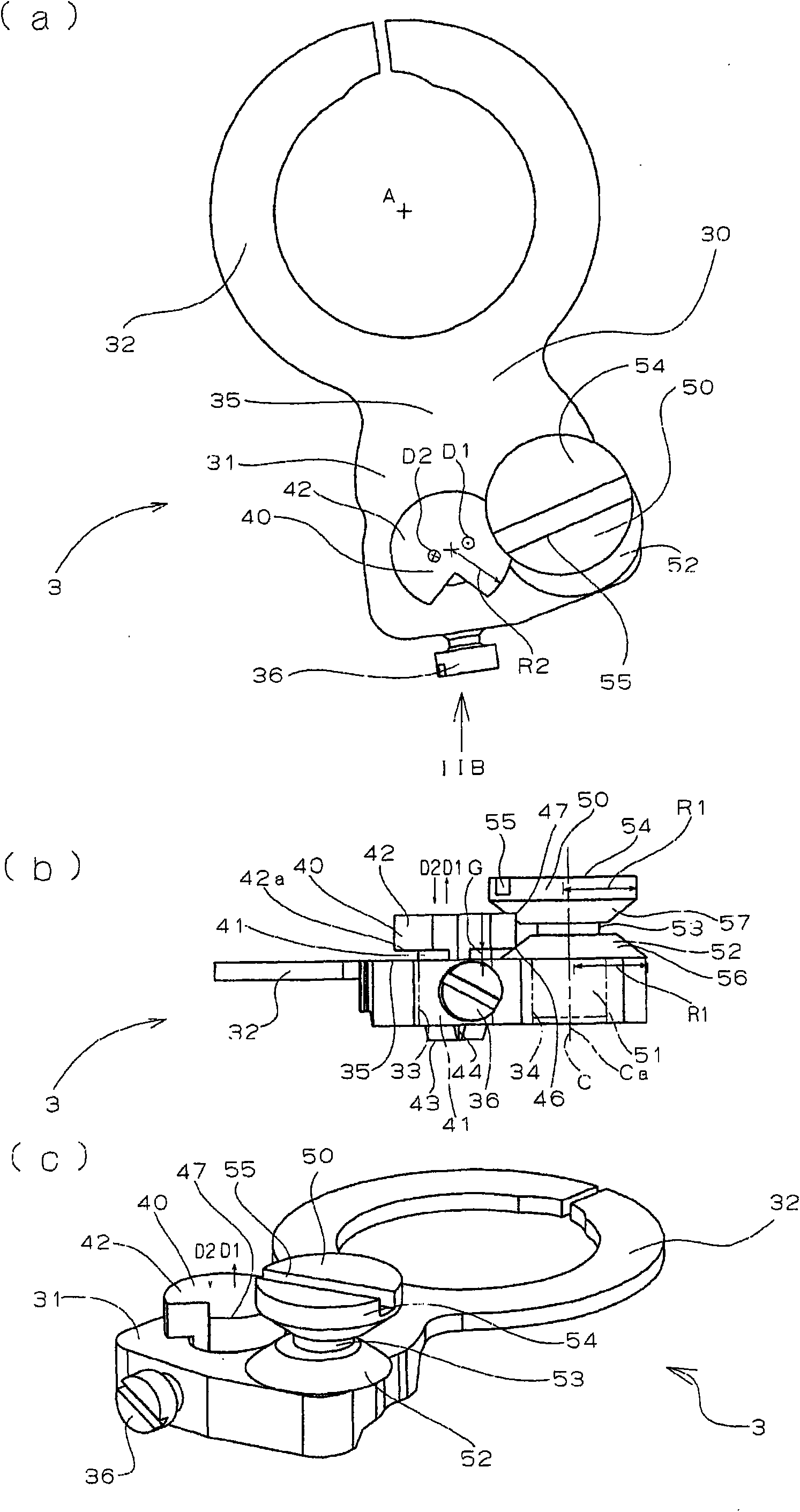

The present invention provides a hairspring supporting structure which can adjust the offset of the hairspring from a plane to a lowest limit, a hairspring balance wheel structure and a mechanical clock. The hairspring supporting structure of mechanical clock comprises a hairspring stud height position adjusting mechanism which shifts the hairspring stud in a vertical direction relatively to a hairspring stud ring. The hairspring stud is provided with a shaft which is inserted and penetrates the hairspring stud ring and a disc-shaped flange. The hairspring stud height position adjusting mechanism is provided with a hairspring stud height position adjustor which comprises the following components: an adjusting shaft which is matched with the hairspring stud ring; and an adjustor body which is provided with a reference frustum-shaped surface which is eccentric relatively the adjusting shaft at one side of the adjusting shaft. When the hairspring stud height position adjustor rotates along a central axis of the adjusting shaft, the adjustor body presses one end edge of the disc-shaped flange of the hairspring stud thereby shifting the hairspring stud upwards or downwards relatively to the hairspring stud ring.

Owner:SEIKO INSTR INC

Tuning-fork resonator for mechanical clock movement

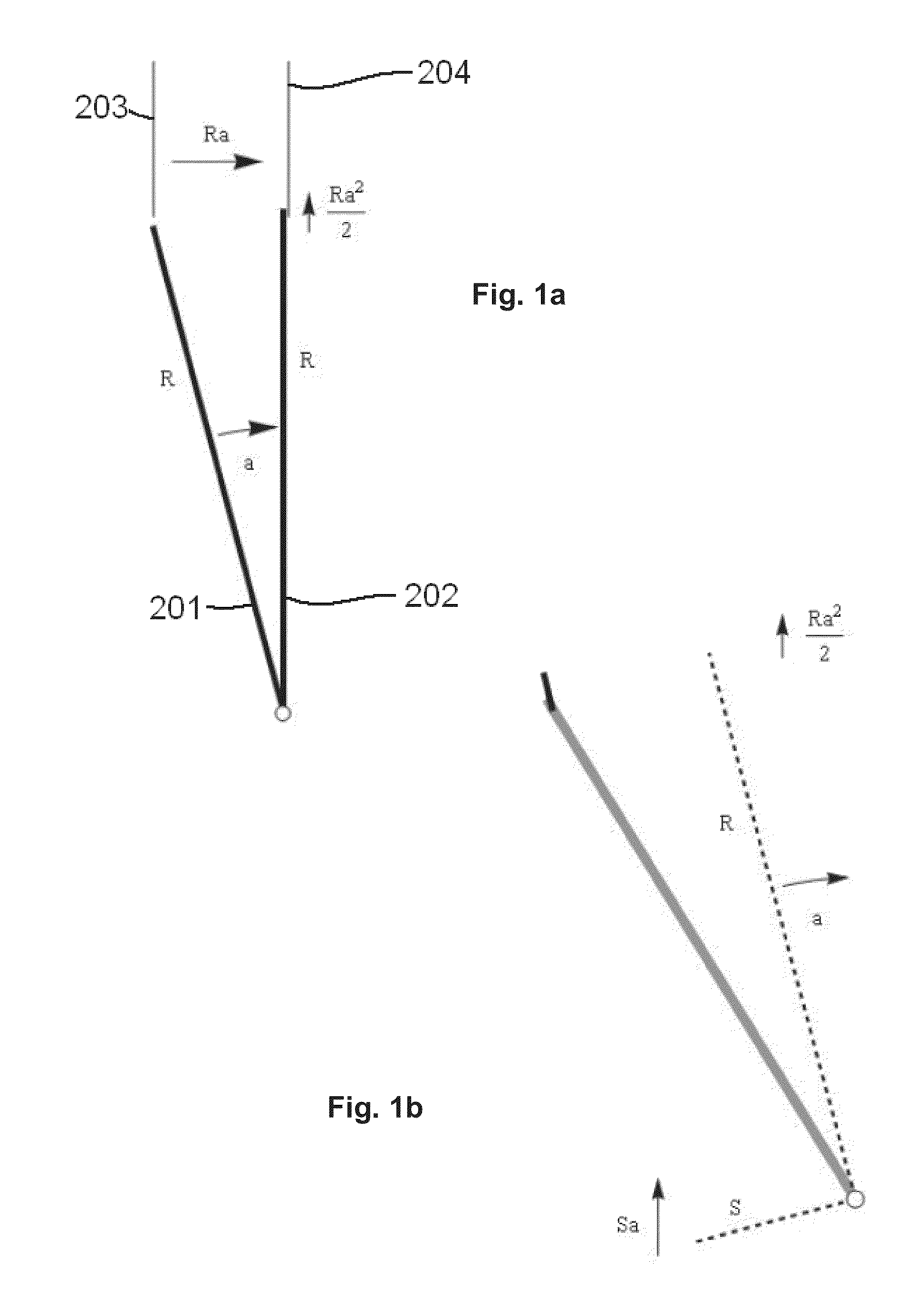

ActiveUS9134705B2High quality factorHigh degree of isochronismEscapementsFrequency stabilisation mechanismTuning forkMechanical energy

A tuning-fork mechanical resonator for a mechanical clock movement with free escapement includes an oscillator of the tuning fork type, of which at least one first prong is intended to oscillate about a first axis and bears at least one first pin associated with at least one first fork tooth of a pallet assembly to cause this assembly to pivot between first and second angular positions and alternately lock and release an escapement wheel. The resonator comprises a conversion member secured to the first pin and designed to on the one hand, convert the oscillations of the first prong of the oscillator into rotational movements of the pallet assembly by transmitting first impulses thereto, and on the other hand, transmit mechanical energy from the pallet assembly to the first prong of the oscillator in the form of impulses.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

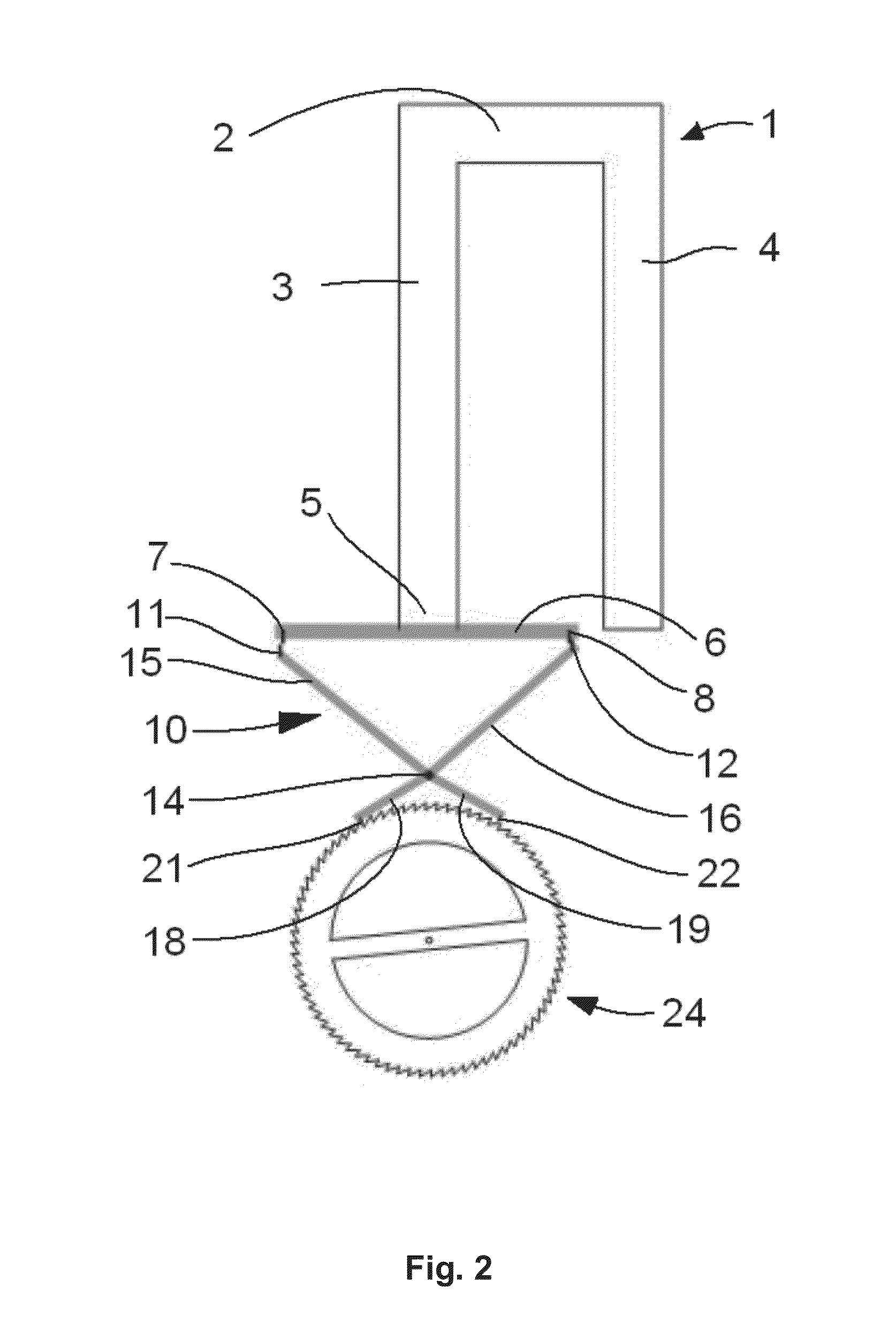

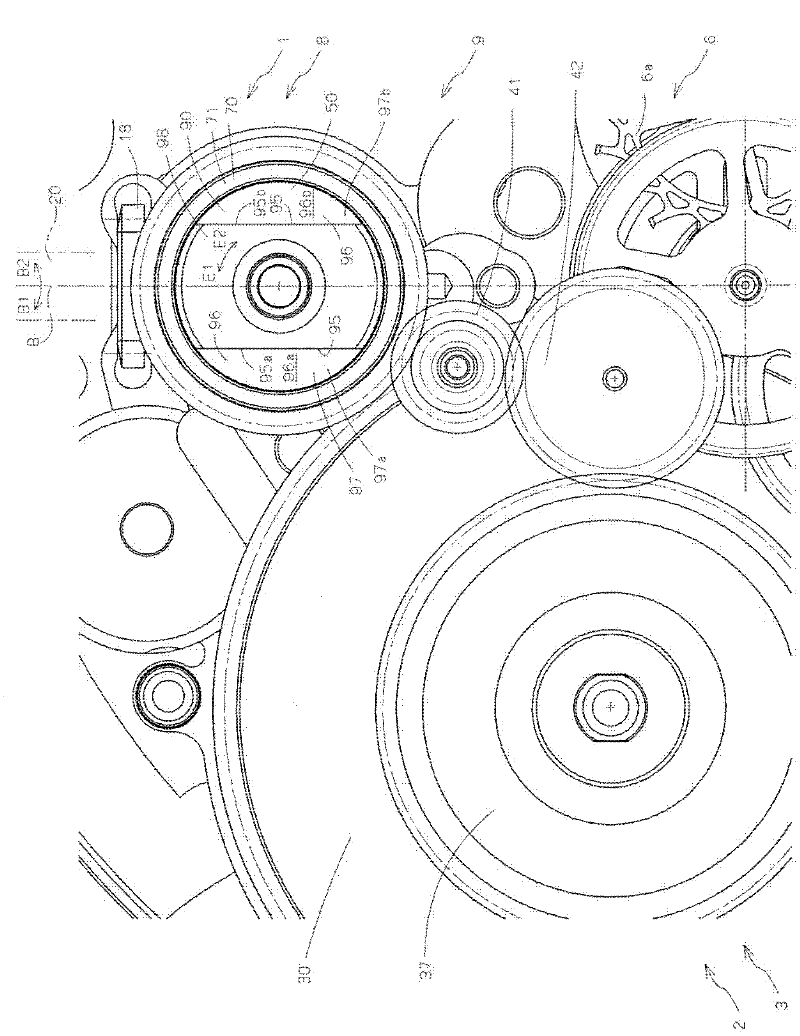

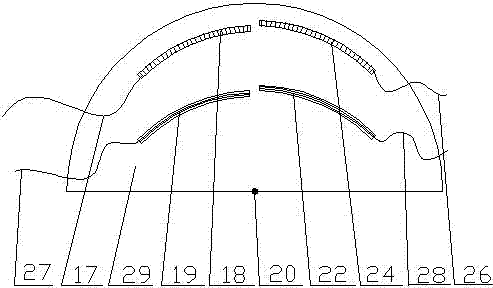

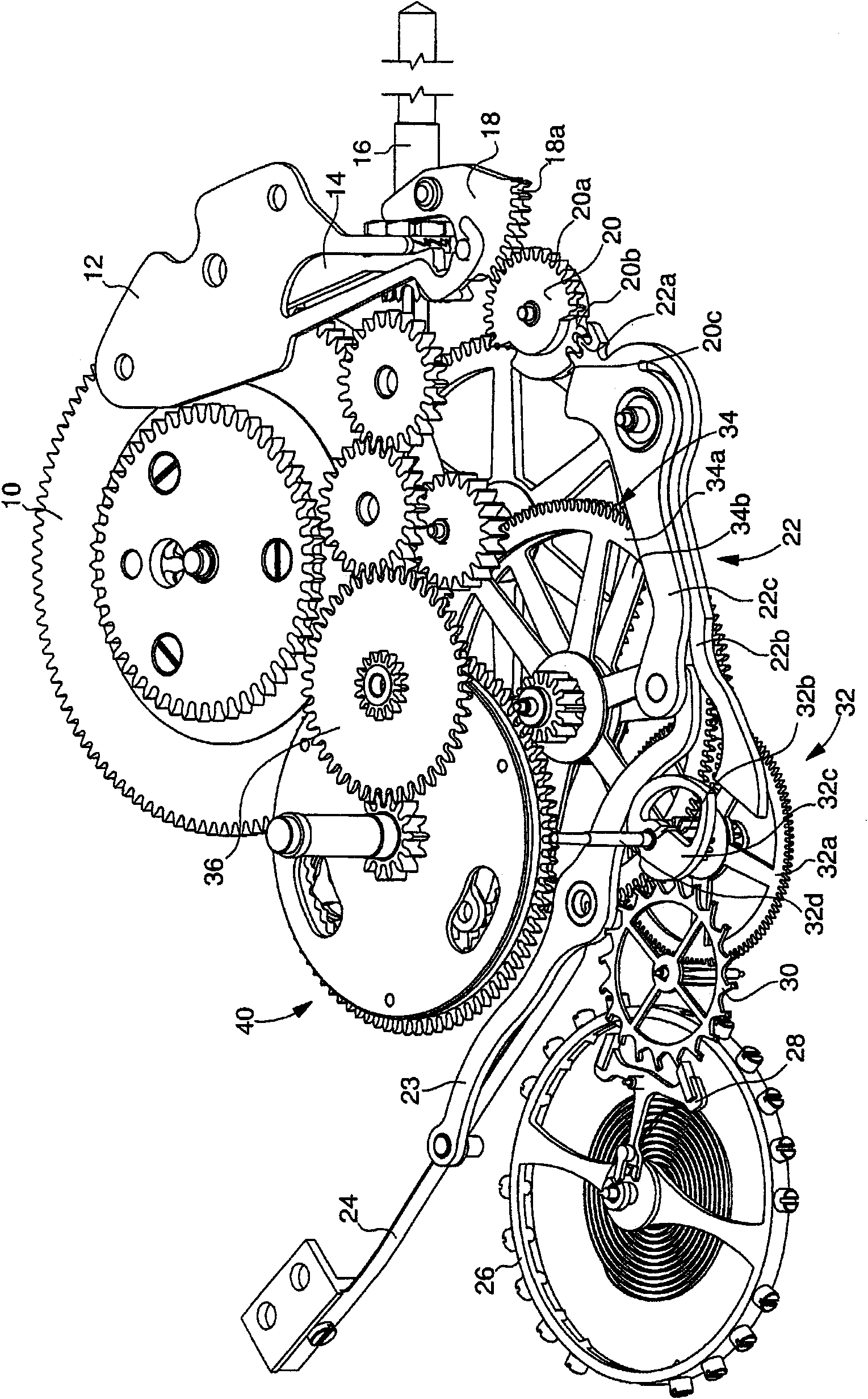

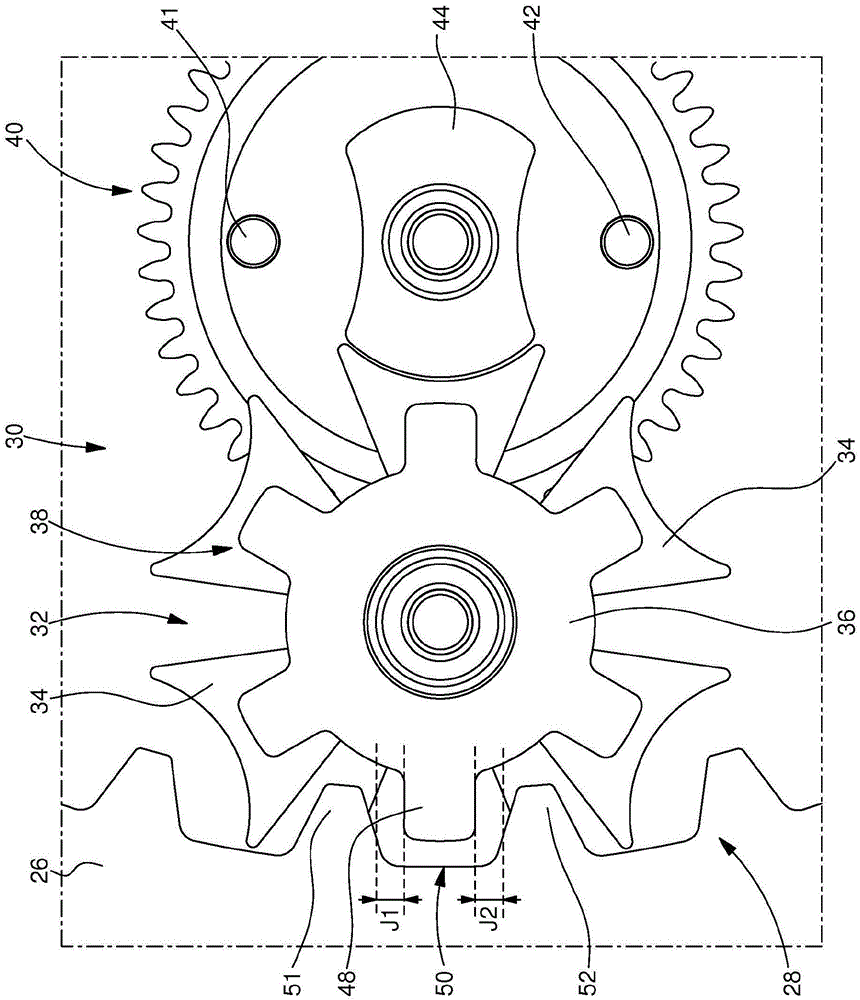

Constant-torque mechanism for clock, movement having the mechanism, and mechanical clock

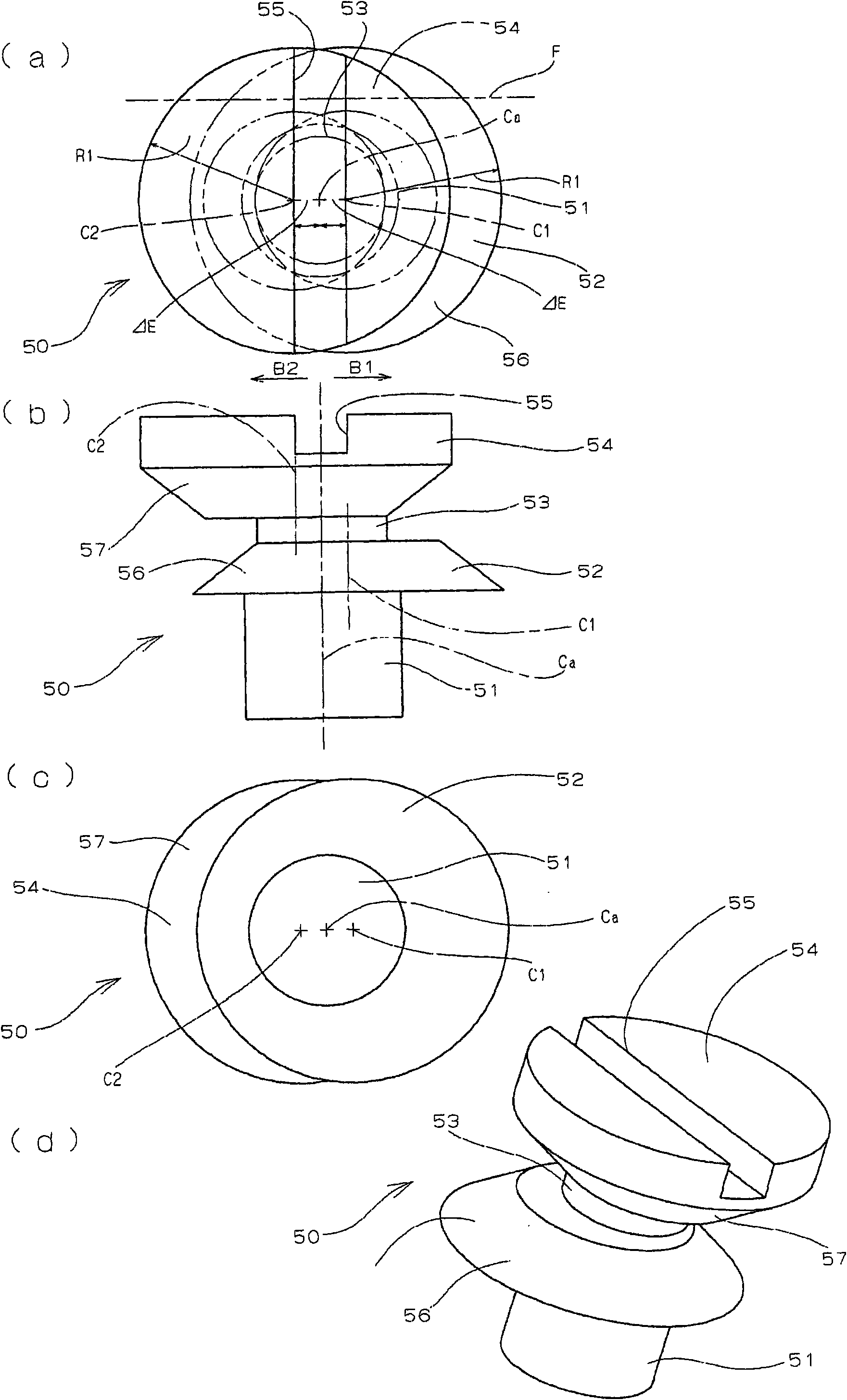

The present invention relates to and provides a constant-torque mechanism for a clock, a movement having the mechanism, and the mechanical clock, which are capable of suppressing the output torque fluctuations to a minimum level. The constant torque mechanism of the movement of the mechanical clock is disposed between a barrel wheel and a balance wheel and comprises: a first reel; a second reel which is eccentric relative to the axis; a detaching wheel which comprises a ratchet and is combined with a drive wheel and capable of rotating around the central axis of the first reel; the drive wheel which is combined with a driven side wheel column and capable of rotating around the central axis with respect to the detaching wheel; a strip which is in a form of an elastic tape member and winding between the first reel and the second reel for forming the constant-torque mechanism, wherein the first reel is mounted on one of the detaching wheel and the drive wheel and the second reel is mounted on the other one of the detaching wheel and the drive wheel; and an intermittent rotation control mechanism which allows the detaching wheel to rotate with respect to the drive wheel in an intermittent mode..

Owner:SEIKO INSTR INC

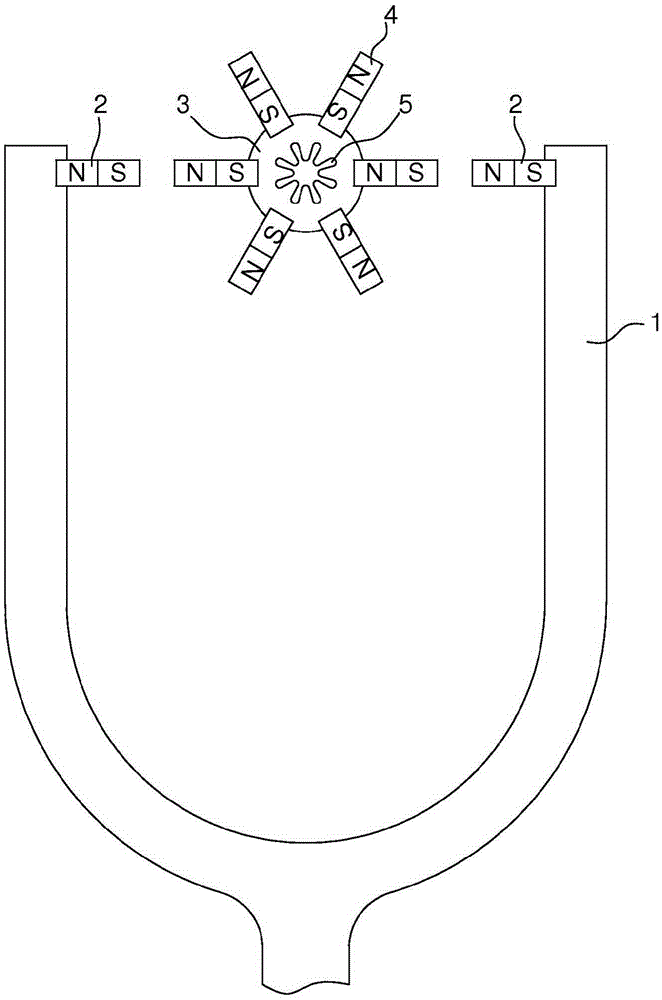

Regulator system for mechanical watch

ActiveCN105264444AImpact resistance ensuredImprove impact resistanceElectric windingTuning forkMechanical watch

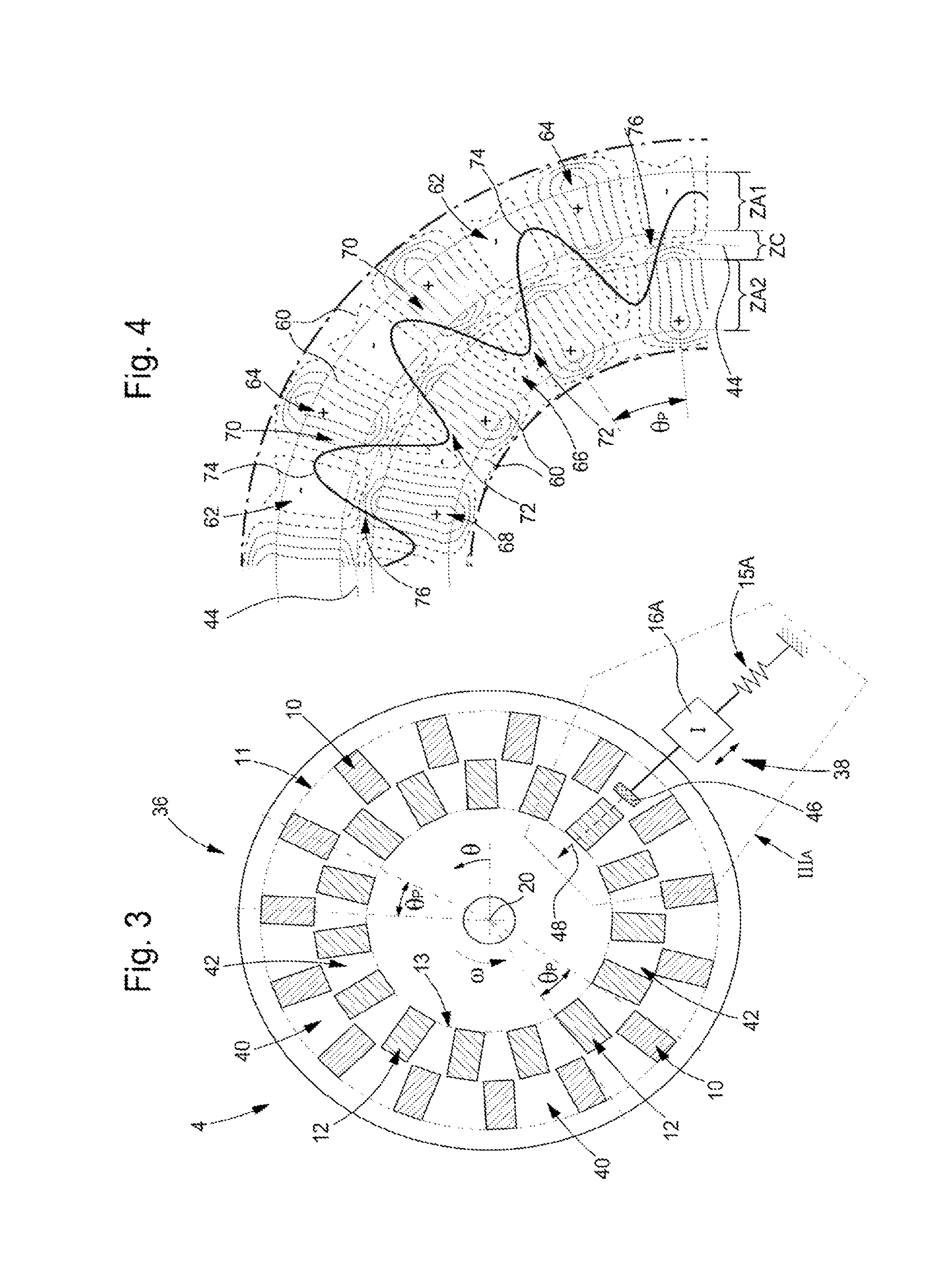

The present invention relates to regulator organs for a mechanical timepiece, specifically a system based on the magnetic interaction between a resonator, for example in the form of a tuning fork, and an escapement wheel. The system is characterised in that there are several magnetic interaction zones (25) and (26) between the resonator (14) and the escapement wheel (9) that are arranged such that the torques produced at the escapement wheel by those interactions compensate each other if the escapement wheel is not synchronised with the frequency of the resonator. This results in a negligible torque on the escapement wheel when the latter rotates slowly in the direction of the arrow (24) or in the opposite direction. This makes it possible to start the timepiece at a low torque of the barrel spring and without a launch procedure or device and allows better resistance of the timepiece to withstand a loss of synchronisation in case of impact.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

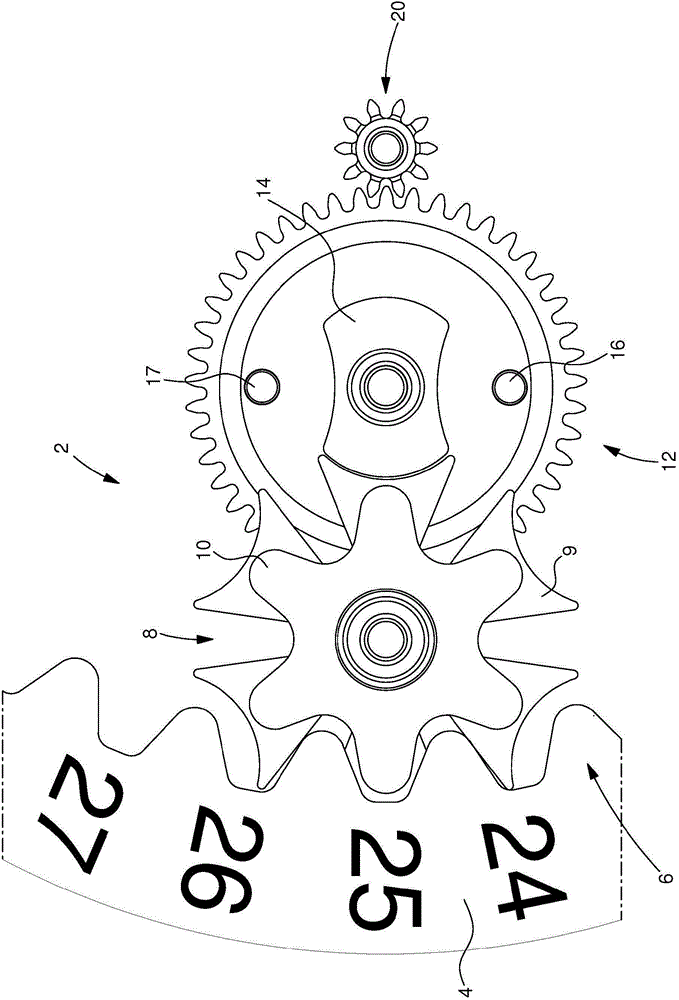

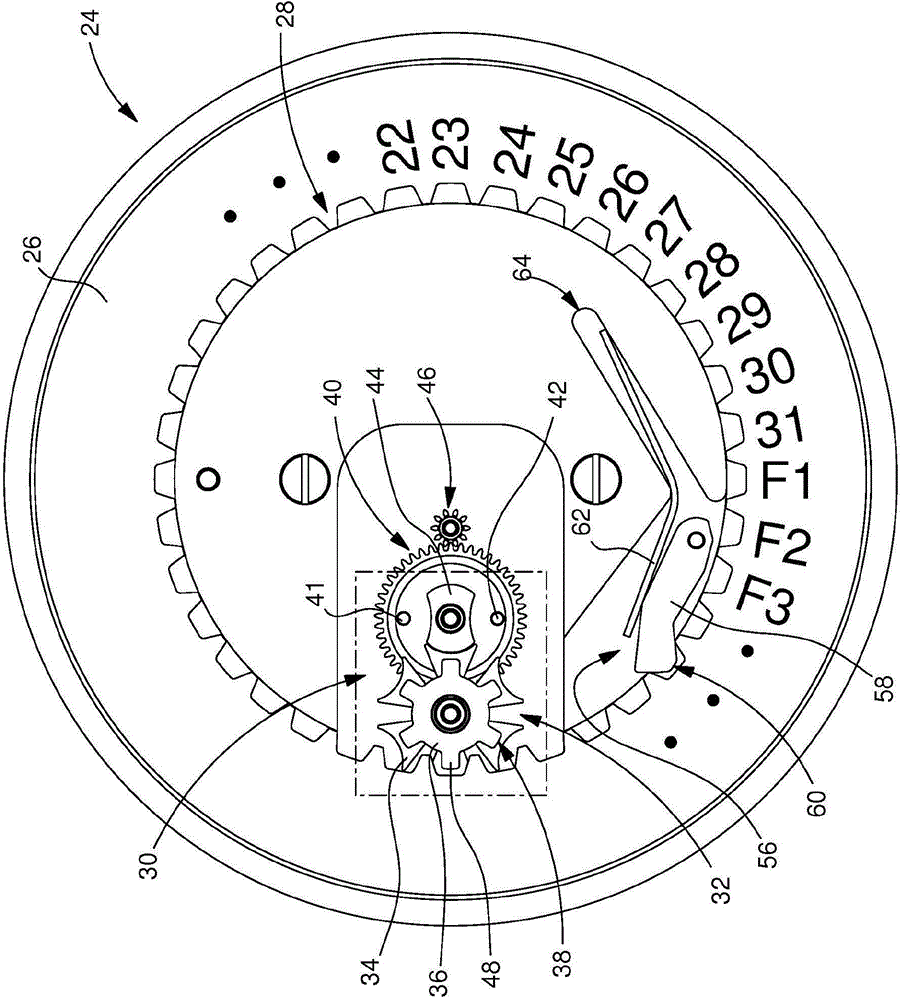

Timepiece movement provided with a drive mechanism for the periodic or intermittent movement of an analogue indicator

The timepiece movement is provided with an analogue device for displaying information whose value varies periodically or intermittently, this analogue display device including, on the one hand, an indicator provided with a first toothing, and on the other hand, a mechanism for the periodic or intermittent driving of the indicator. The drive mechanism is formed by an irreversible transmission system which ensures a shock resistant function for the indicator. The display device further includes a positioning jumper for the indicator generating a positioning force on the first toothing, which is sufficient to precisely position the indicator in a plurality of discrete display positions, but considerably insufficient to ensure a shock resistant function for the indicator. Thus, the indicator can be driven with a relatively low torque; which therefore requires less energy and makes it possible to provide a drive mechanism with a lower gear reduction for the drive torque transmission ratio.

Owner:ETA SA MFG HORLOGERE SUISSE

Mechanism for isolating timepiece mechanisms which release various acoustic signals

InactiveUS8873347B2Operational safety is enhancedEnsure safetyElectric indicationAcoustic indicationIsolating mechanismsEngineering

A timepiece includes a movement, a main striking mechanism, a secondary strike release mechanism, and a mode selecting mechanism. The main striking mechanism is controlled by a main strike control mechanism, arranged to release strikes, at times programmed by the movement, or on demand, and a sequence of each strike is determined by information gathered by feeler spindles on snails or time references driven by the movement. A coupling mechanism of the secondary strike release mechanism actuates a control rod linkage of an isolating mechanism arranged to isolate various different release mechanisms for different strikes using the main striking mechanism to play strikes. The isolating mechanism includes at least a first isolator which, in a first winding position, takes a stop position preventing the spindles from gathering information from the snails, and, in a second let down position, allows the spindles to pass to come into contact with the snails.

Owner:MONTRES BREGUET

Timepiece movement fitted with a vibrating alarm

ActiveUS7896542B2Simple and inexpensive implementationReduce in quantityVisual indicationElectric indicationKinematic chainMechanical engineering

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

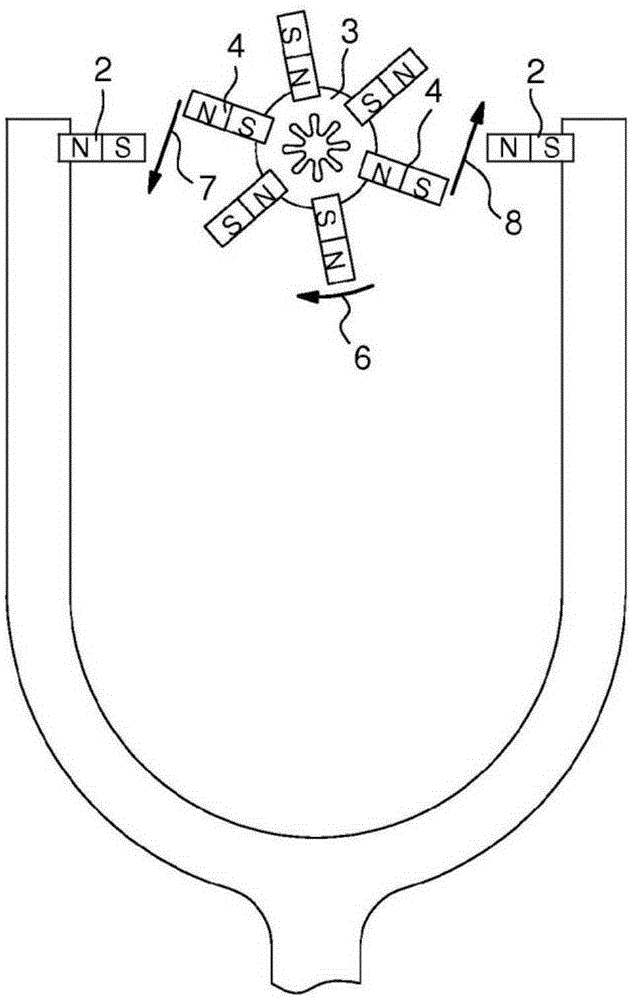

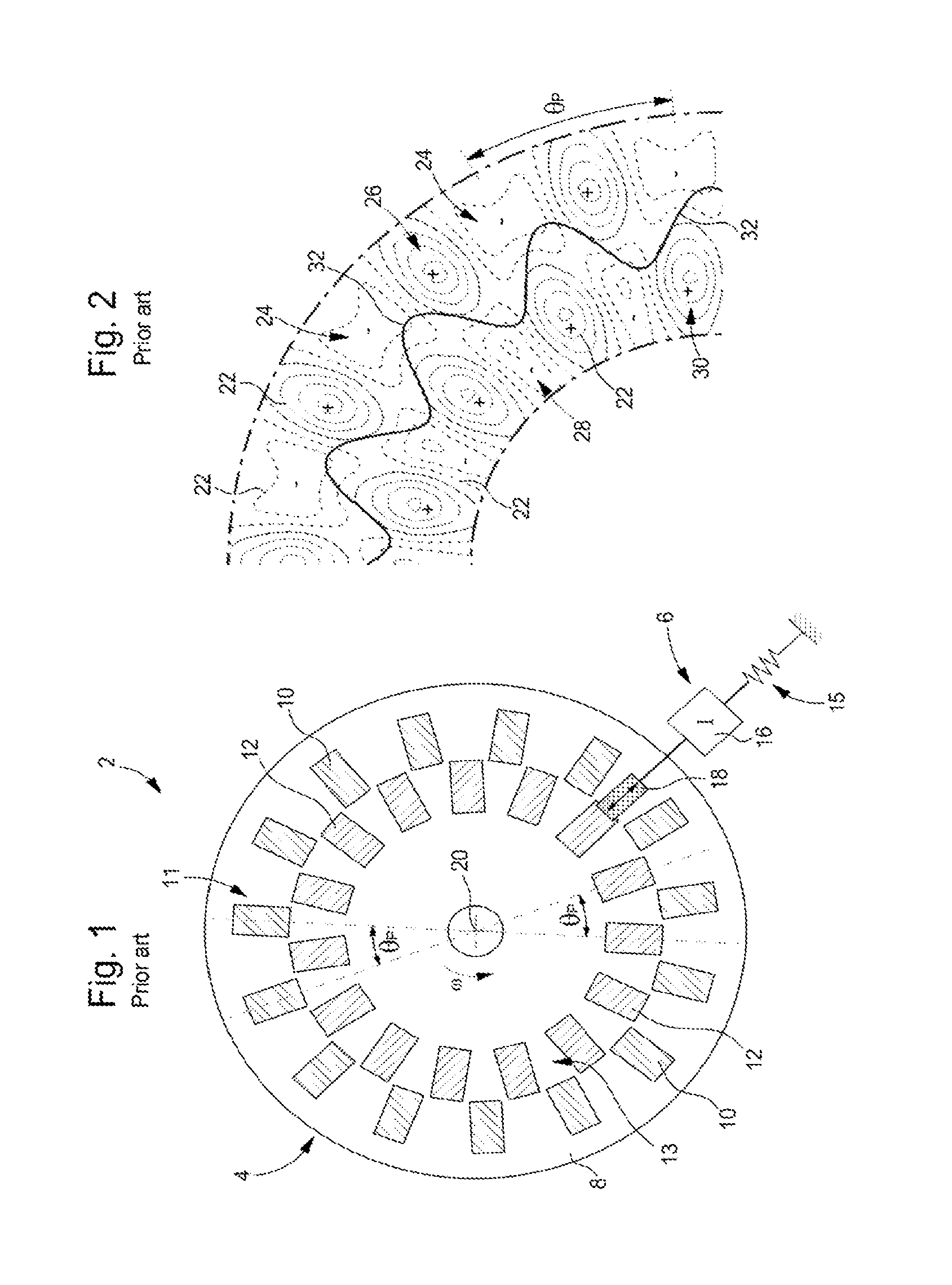

Device intended to control the angular speed of a train in a timepiece movement and including a magnetic escapement

There is provided a device for regulating the operation of a horological movement, including a magnetic escapement, which includes a resonator and a magnetic escapement mobile turning about an axis. The mobile includes at least one magnetic track with a plurality of magnets having an angular dimension that is greater than their radial dimension. The resonator includes at least one magnetic element for coupling to the magnetic track. The coupling element extends radially relative to the axis of rotation, and has a contour with a portion oriented substantially angularly when the resonator is in the rest position. When the mobile is driven in rotation, each magnet penetrates beneath the coupling element and gradually accumulates some potential magnetic energy. The magnet then exits from beneath the coupling element through the portion and the coupling element receives a pulse located around its rest position.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

Timepiece with a constant-force device for acting on an oscillating system

A timepiece, in particular a wristwatch, includes a constant-force device for acting on an oscillating system, the constant-force device including a switching unit and a tensioning module having a primary spring-energy store and a secondary spring-energy store. A seconds shaft bearing a seconds wheel and a cam plate is driven to rotate constantly by the secondary spring-energy store. The seconds wheel drives the oscillating system, and the cam plate acts on the switching unit for the periodic tensioning of the secondary spring-energy store by the primary spring-energy store.

Owner:LANGE UHREN

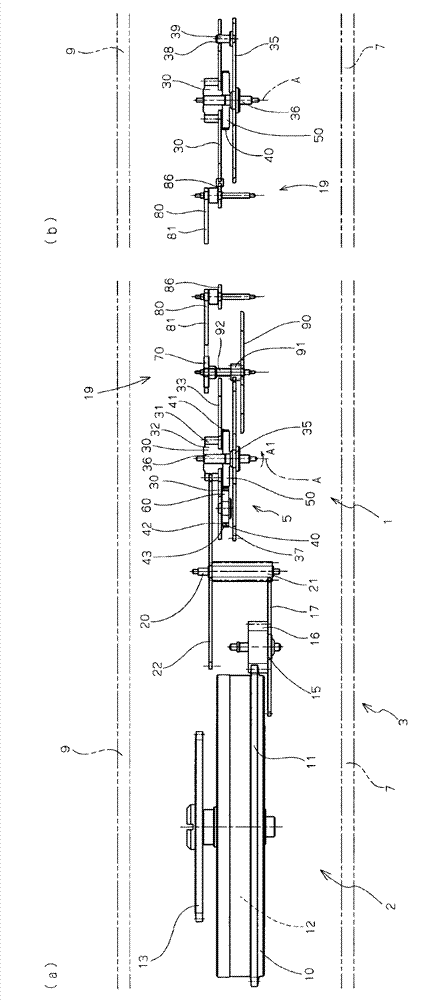

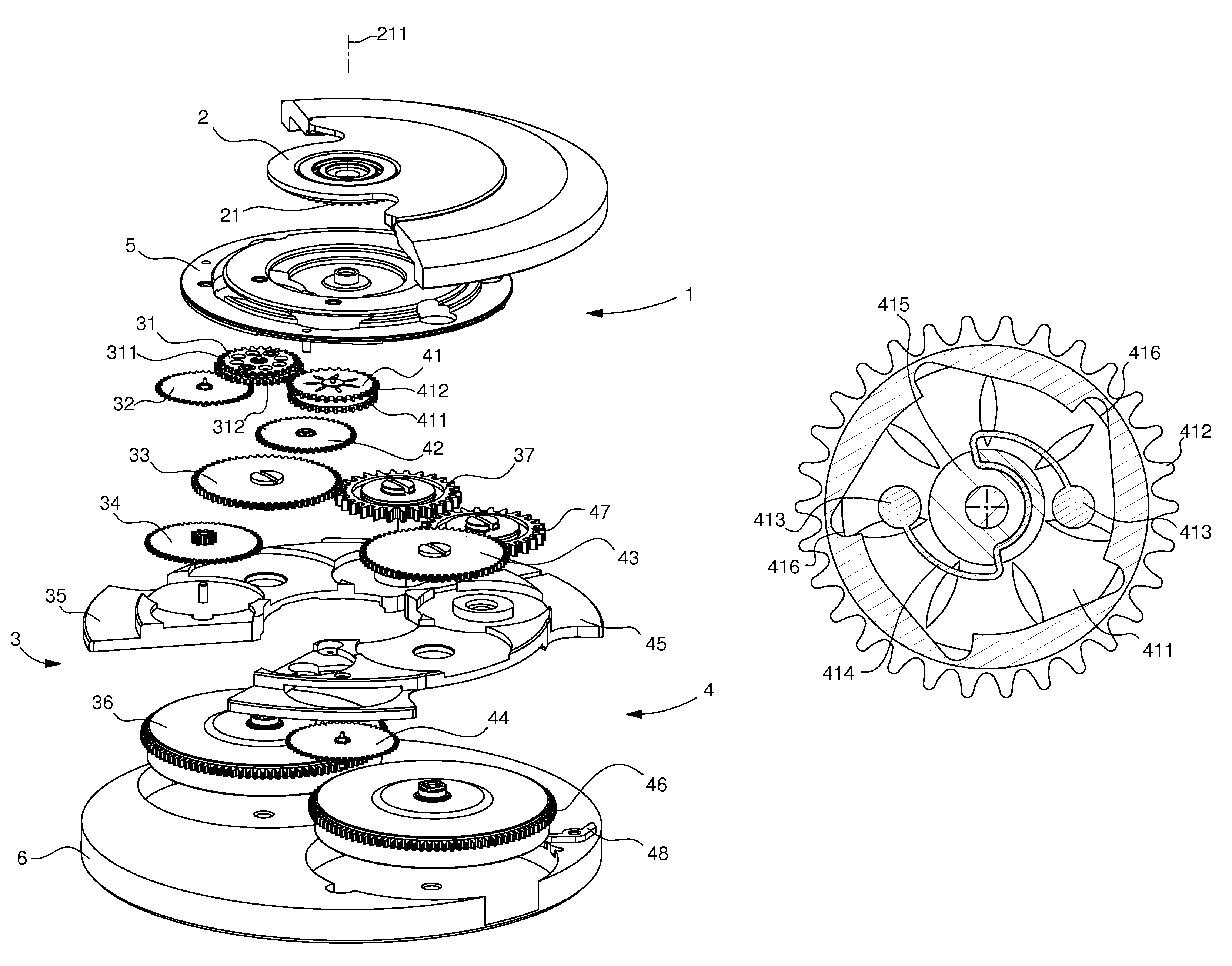

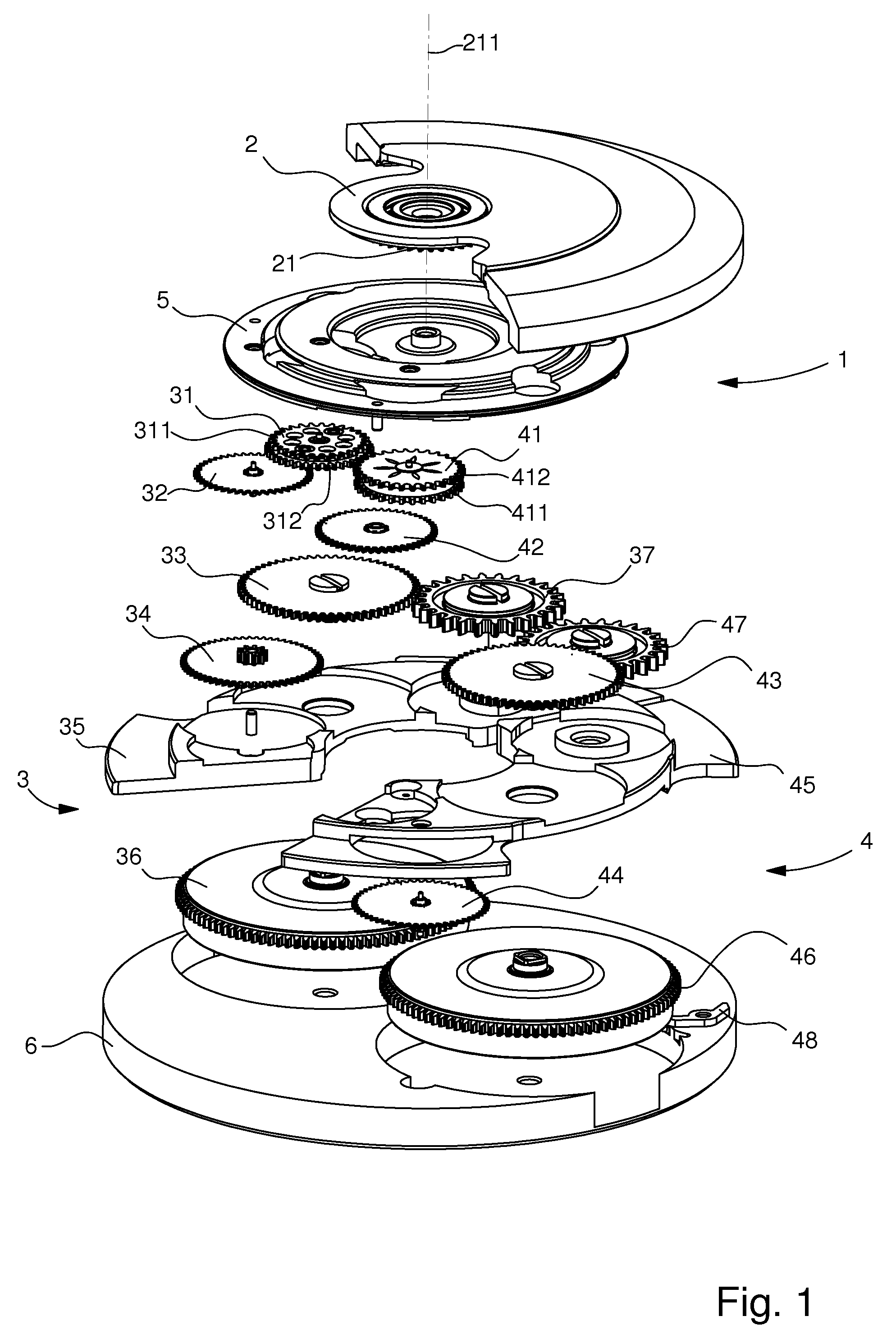

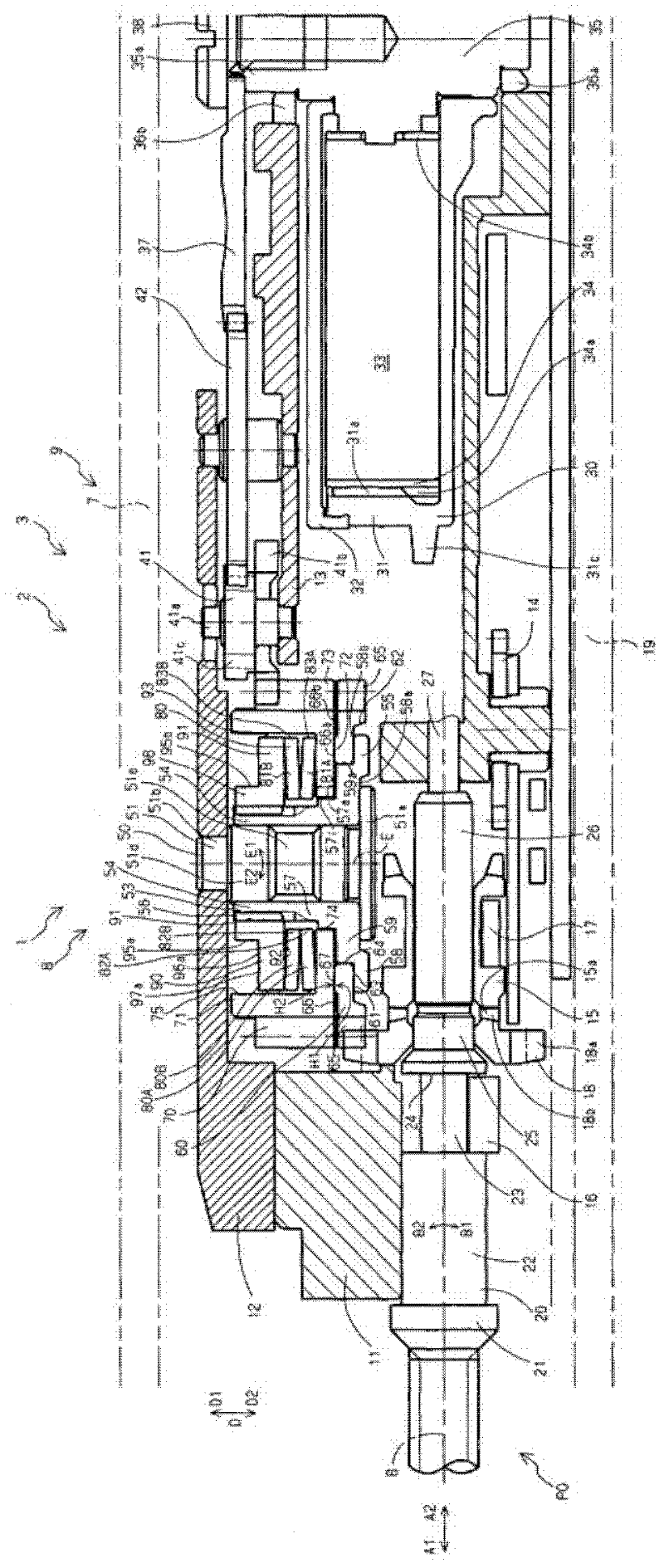

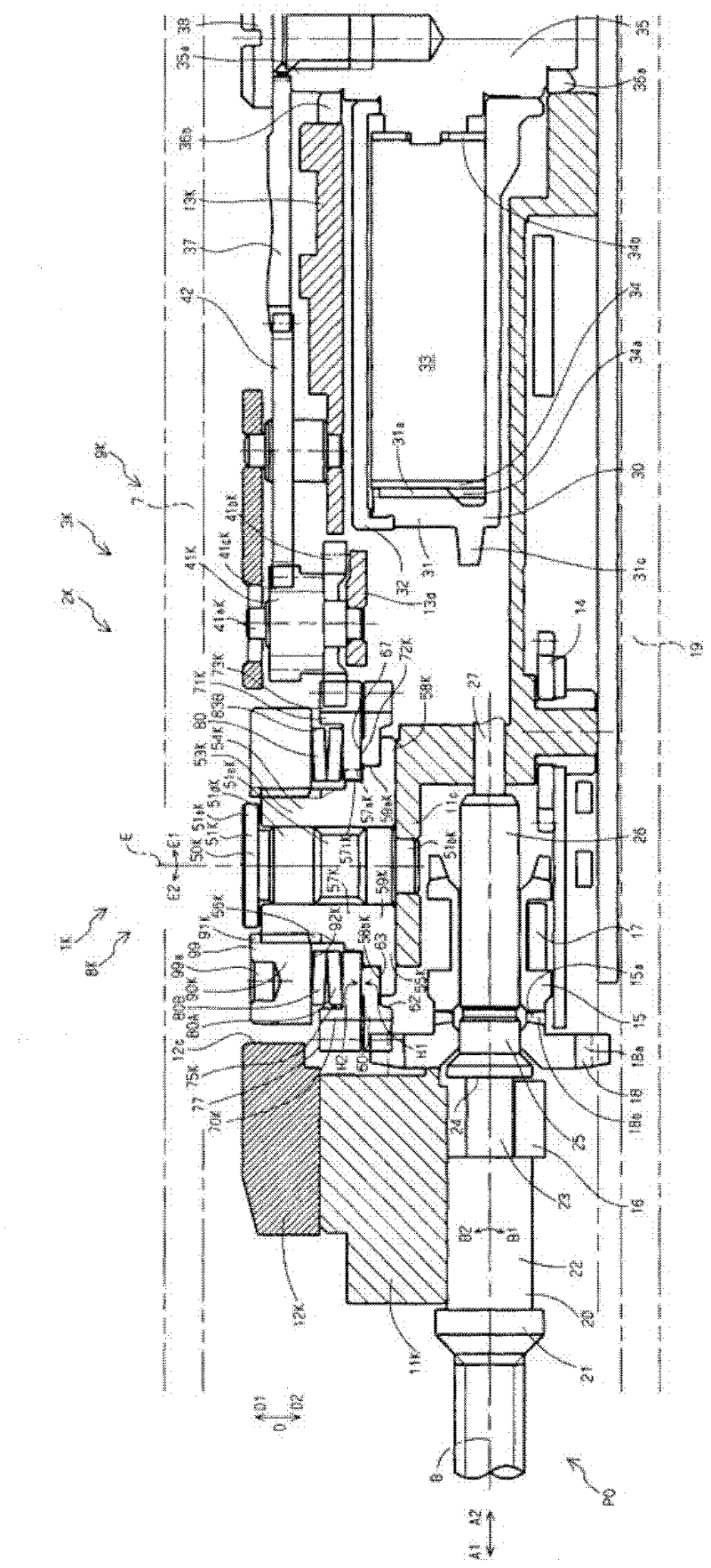

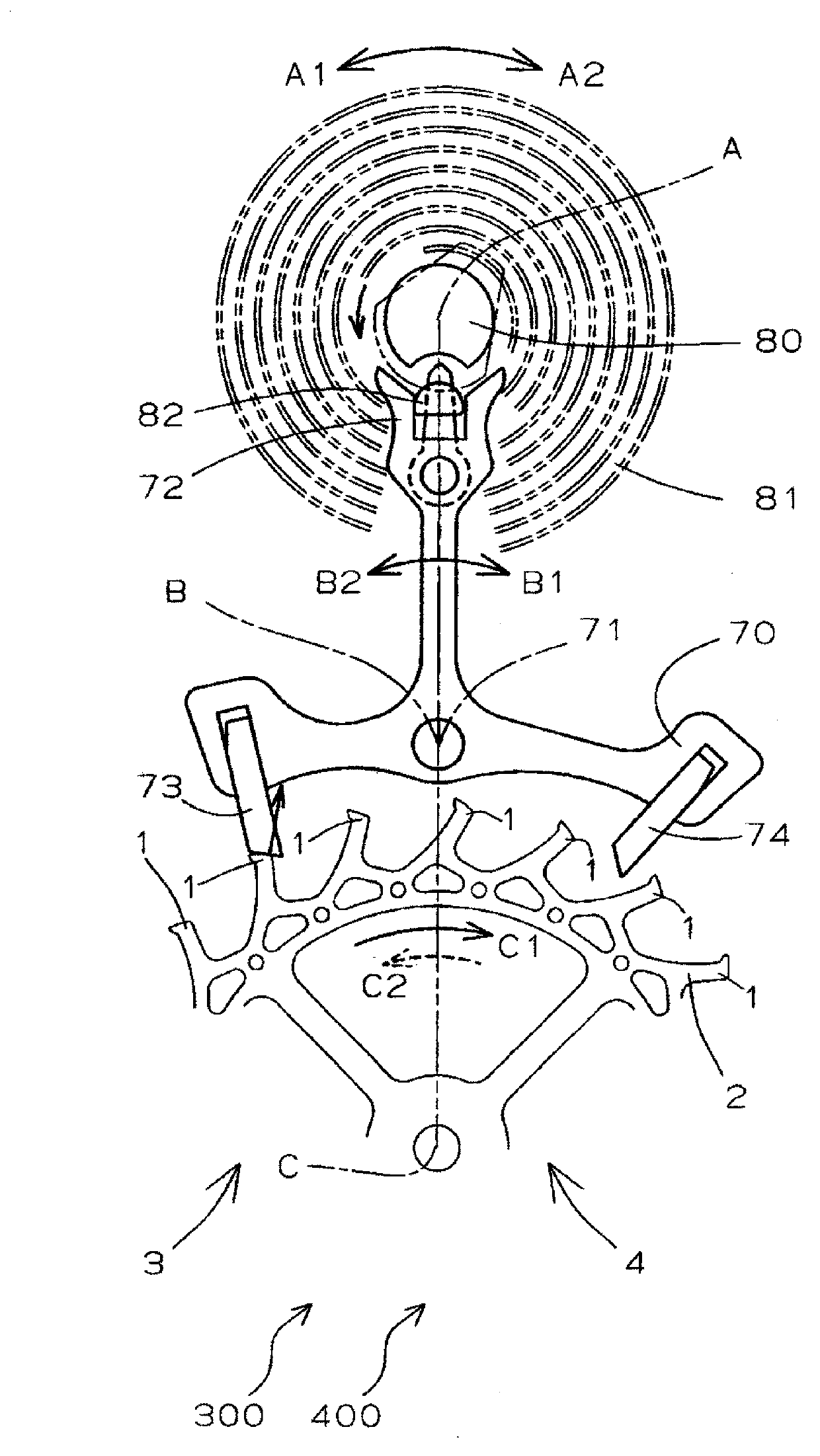

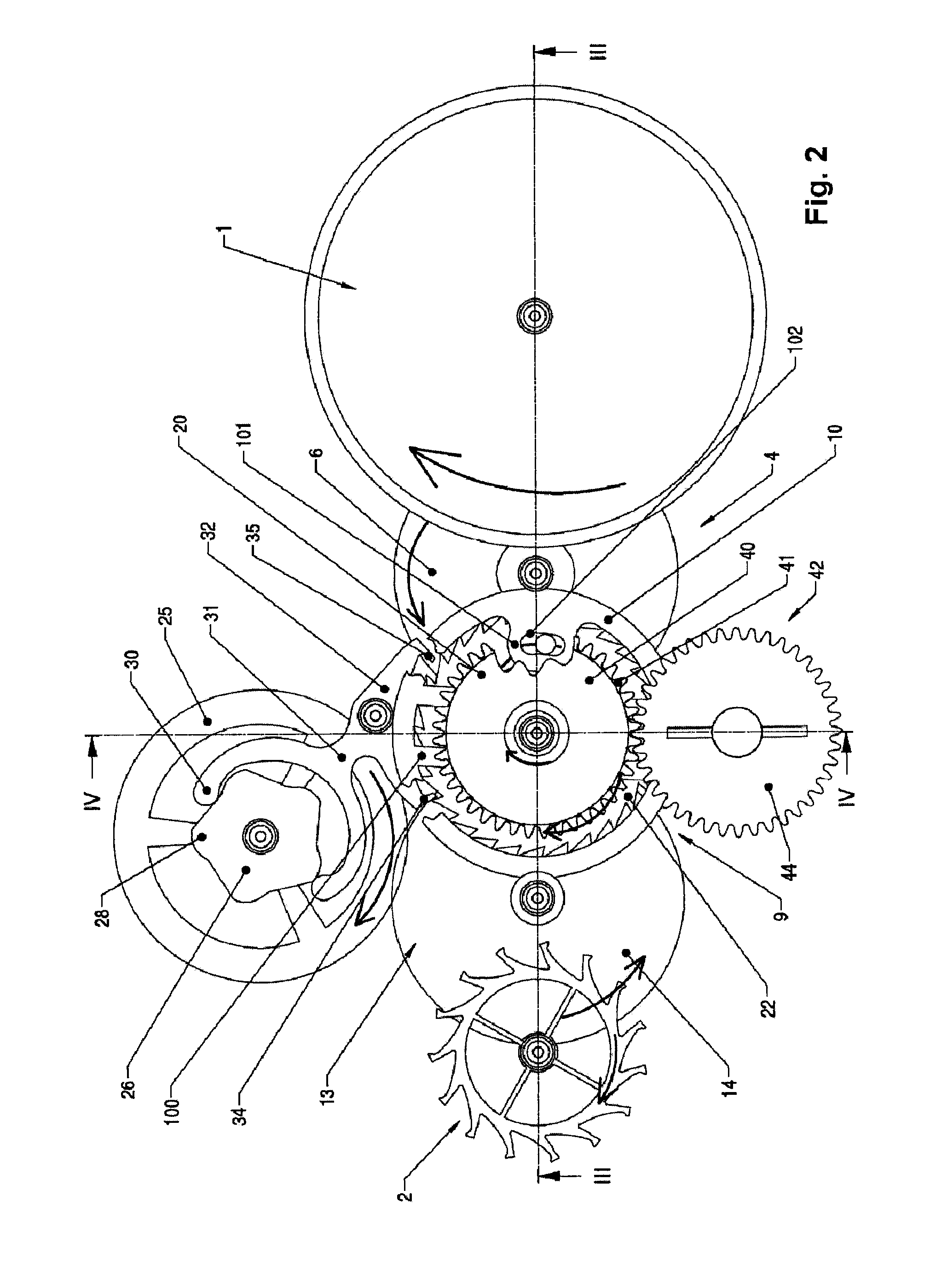

Manual winding gear train, clock machine core and clock possessing the gear train

The invention provides a manual winding gear train, a clock machine core and a clock possessing the gear train capable of making the machine core itself set a winding torque below a specified level. The manual winding gear train of the machine core(2) of the clock(3) comprises a plurality of gears(60,70,41,42) meshed with each other to transmit the rotation of a shaft to a square hole wheel(37), an input side part(60) possessing an input side friction fastening part(67(H1)) and an output side part(70) possessing an output side friction fastening part(72(H2)). The input side part(60) and the output side part(70) are arranged correspondingly to each other at the respective friction parts and are rubbed and fastened with each other at the correspondingly arranged part. The manual winding gear train of the machine core(2) of the clock(3) also comprises an elastic mechanism(80) enabling one friction fastening part(72) to pushing the other friction fastening part(67).

Owner:SEIKO INSTR INC

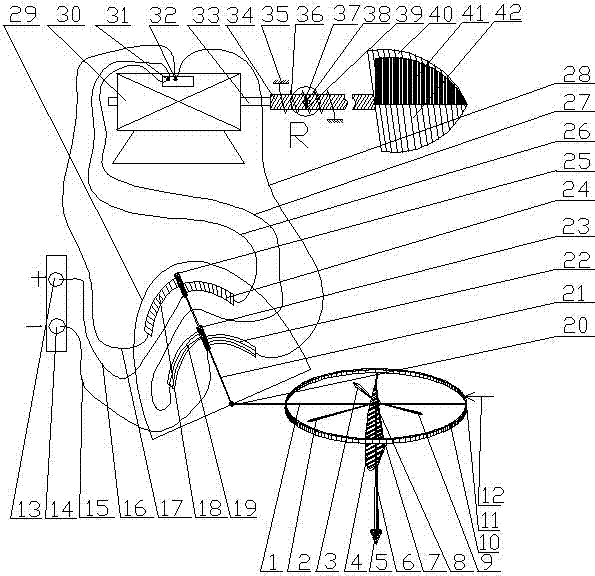

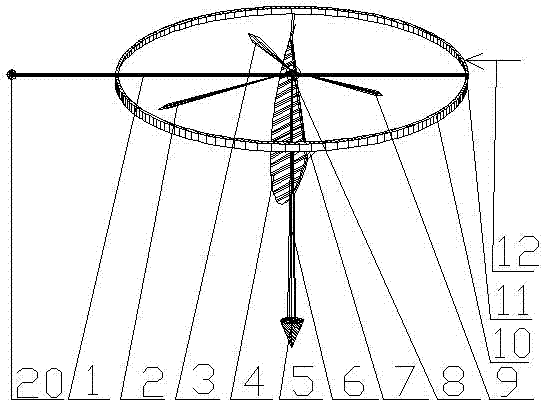

Strong current boosting rotation automatic return direction controller for clock rotating needle

ActiveCN103759589ACannot be tracked and interceptedFree from attackDirection controllersMotor driveControl system

A strong current boosting rotation automatic return direction controller for clock rotating needle comprises a clock rotating needle control system, a balancing point slipping change resistor system, a motor system and a spring torque control system, wherein the clock rotating needle control system comprises a horizontal circular and a horizontal rotating shaft, a top connection rod and a top are arranged below the centre of the rotating shaft and three rotating heavy pointers different in length and weight are arranged above the centre, the lower side of the resistor stripe fixing plate is provided with the balancing point, the middle part is provided with two conductive stripes and the upper side is provided with two resistor stripes; the spring torque control system comprises an empennage shaft and a spring wound on the shaft, two ends of the spring are fixed outer of the empennage shaft, the centre of the spring steel bar is fixed on the slot sliding block of the empennage shaft, the spring steel bar is fixed that the length of the spring steel bars at two ends of the spring is the same with the spring rotating resilience force; the changing current from the slipping change resistor is input into the motor and the motor drives the empennage shaft and the empennage to rotate together with the rotating shaft of the clock rotating needle control system synchronously.

Owner:CHANGSHU INTELLIGENT LASER EQUIP RES INST CO LTD

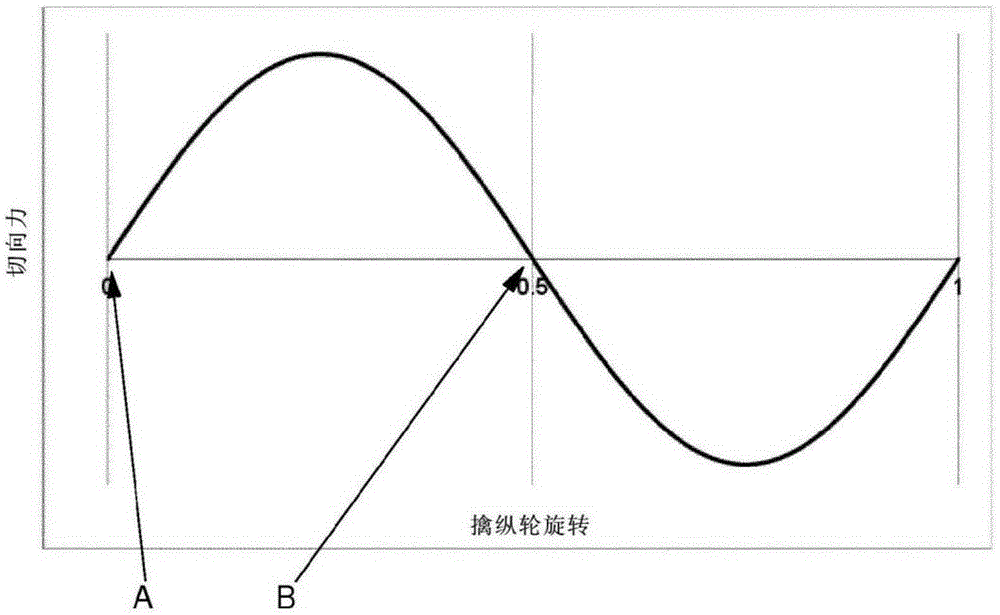

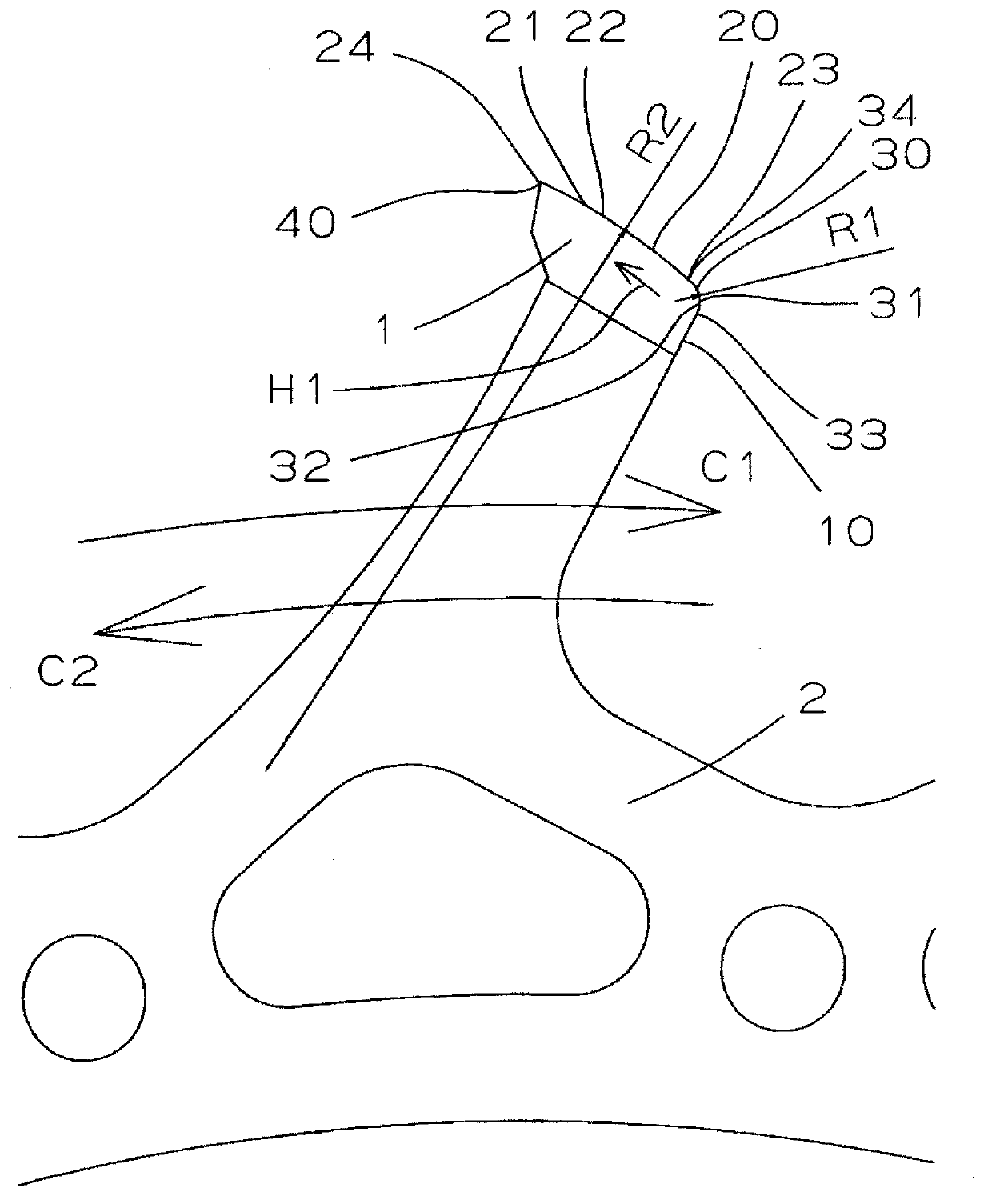

Escapement gear, escapement wheel employing the escapement gear, anchor-shaped escapement, movement, mechanical timepiece and method of torque transmission

ActiveCN103309224AEfficient torque transmissionAvoid extreme changesEscapementsTorque transmissionEngineering

The invention relates to an escapement gear, an escapement wheel employing the escapement gear, an anchor-shaped escapement, a movement, a mechanical timepiece and a method of torque transmission, capable of rapidly transmitting torque during alternating of impacting surfaces. In the escapement gear (1) of the escapement wheel (2) of the anchor-shaped escapement of the mechanical timepiece, a locking corner (30) which connects a stop surface (10) and an impacting surface (20) becomes a first convexly curved surface portion (31). A convexly curved second portion (21) is arranged on impacting surface (20) at a place being continuous with the first convexly curved surface portion (31) of the locking corner (30). The second convexly curved surface portion (21) may extend over the entire impacting surface (20). At a place further away from the locking corner (30) on the impacting surface (20), the radius of curvature R2 of the second curvedly convex surface portion (21) becomes larger. A portion which is continuous with the second curvedly convex surface portion (21) of the impacting surface (20) surface may be planar.

Owner:SEIKO INSTR INC

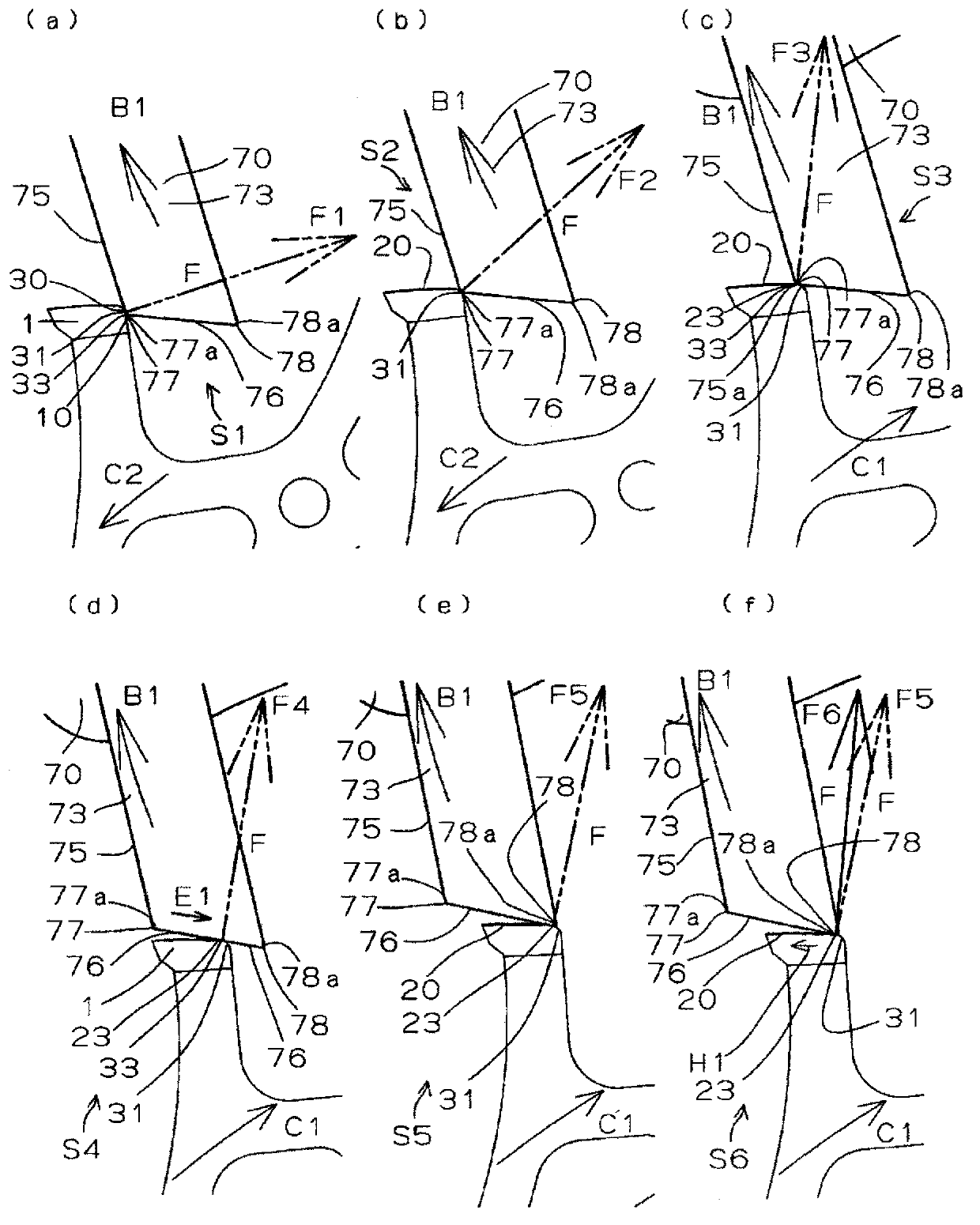

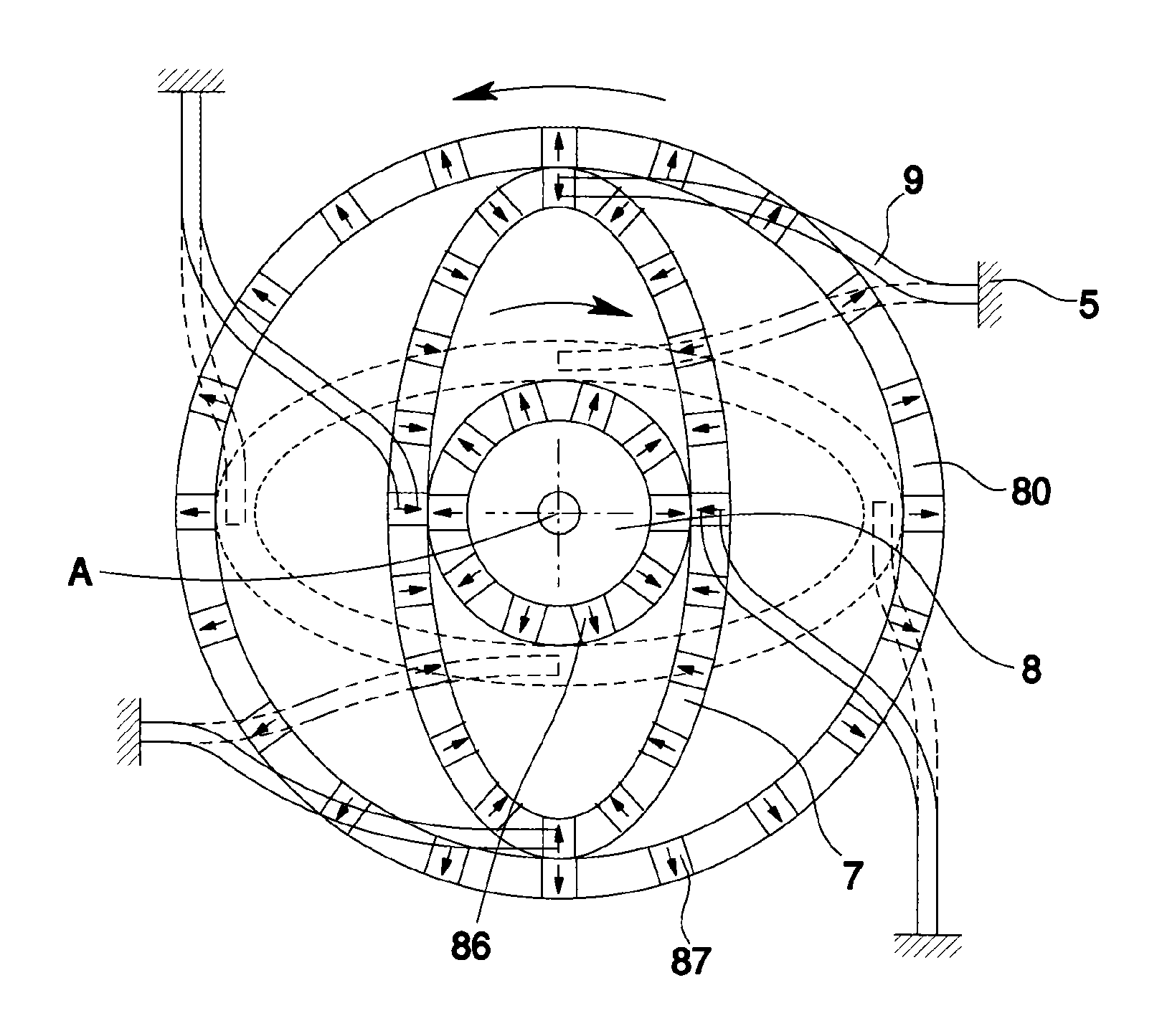

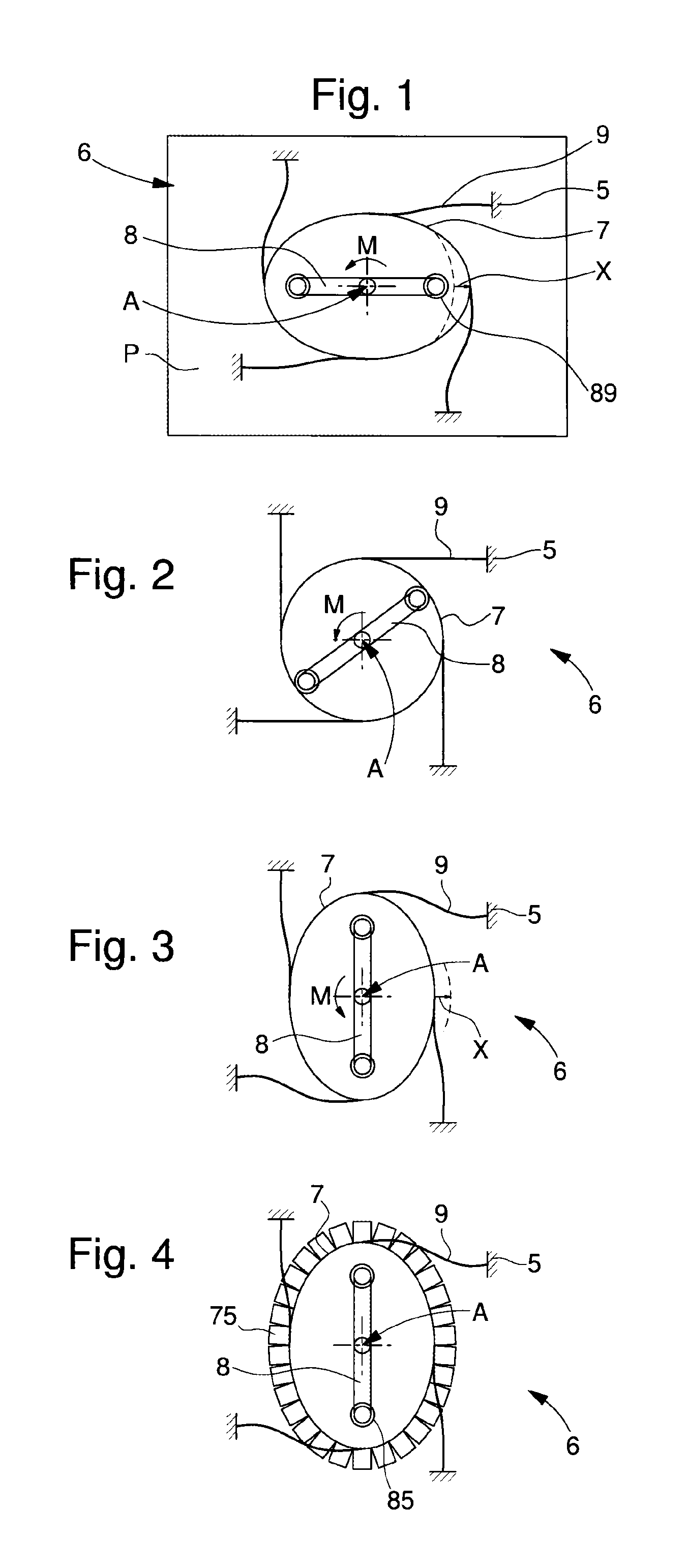

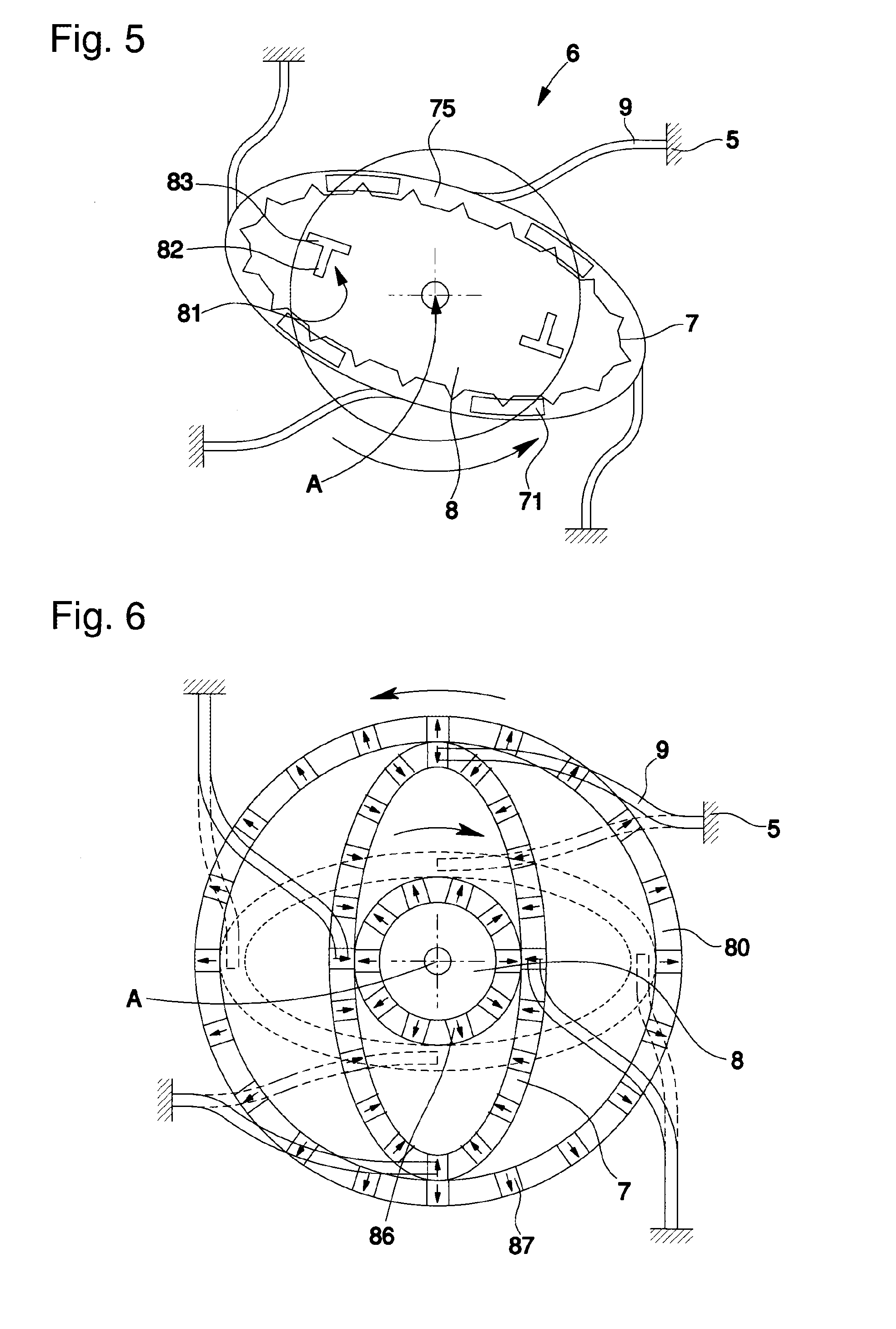

Timepiece synchronization mechanism

ActiveUS20160327908A1Improve efficiencyEscapementsFrequency stabilisation mechanismGear wheelGear train

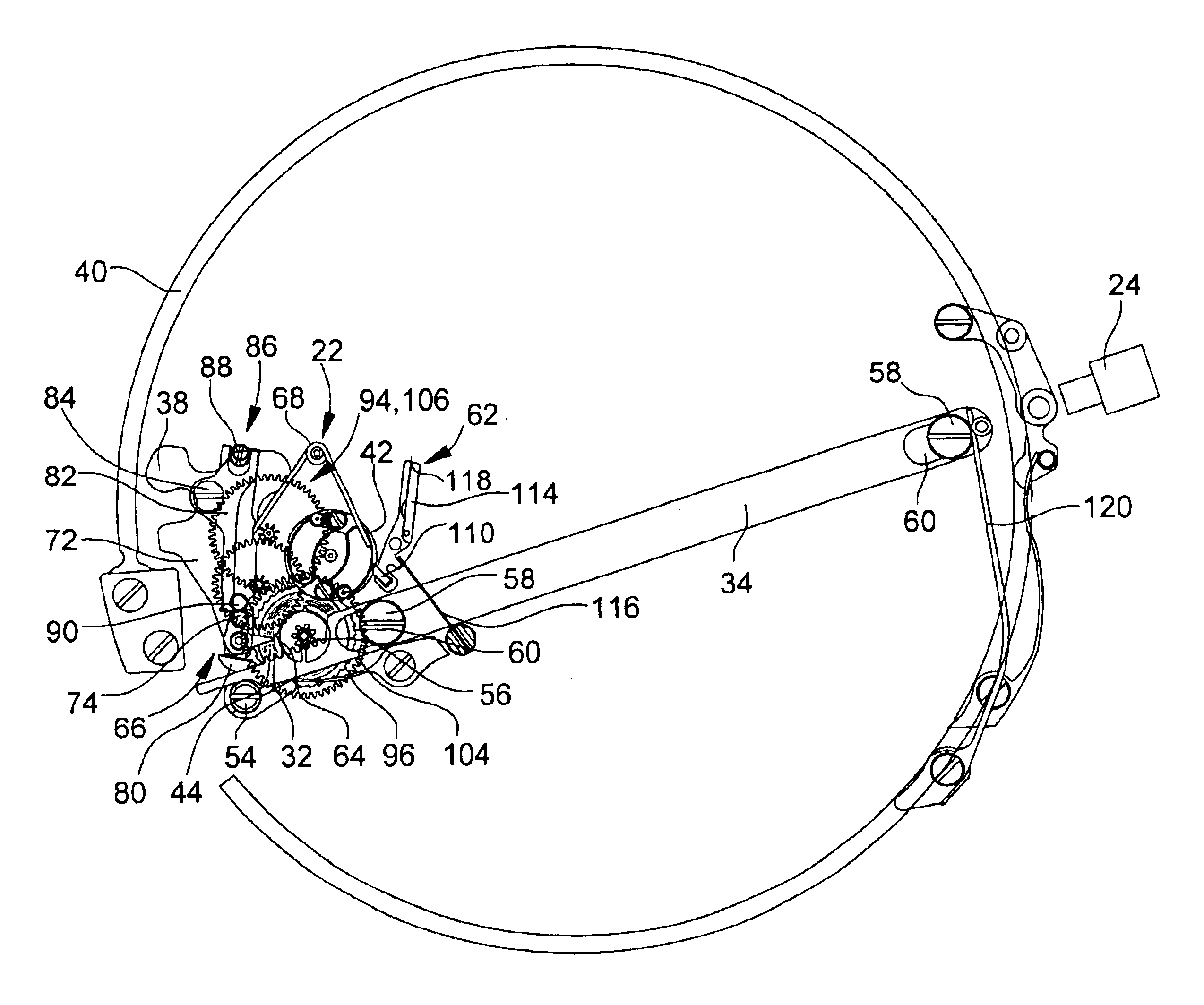

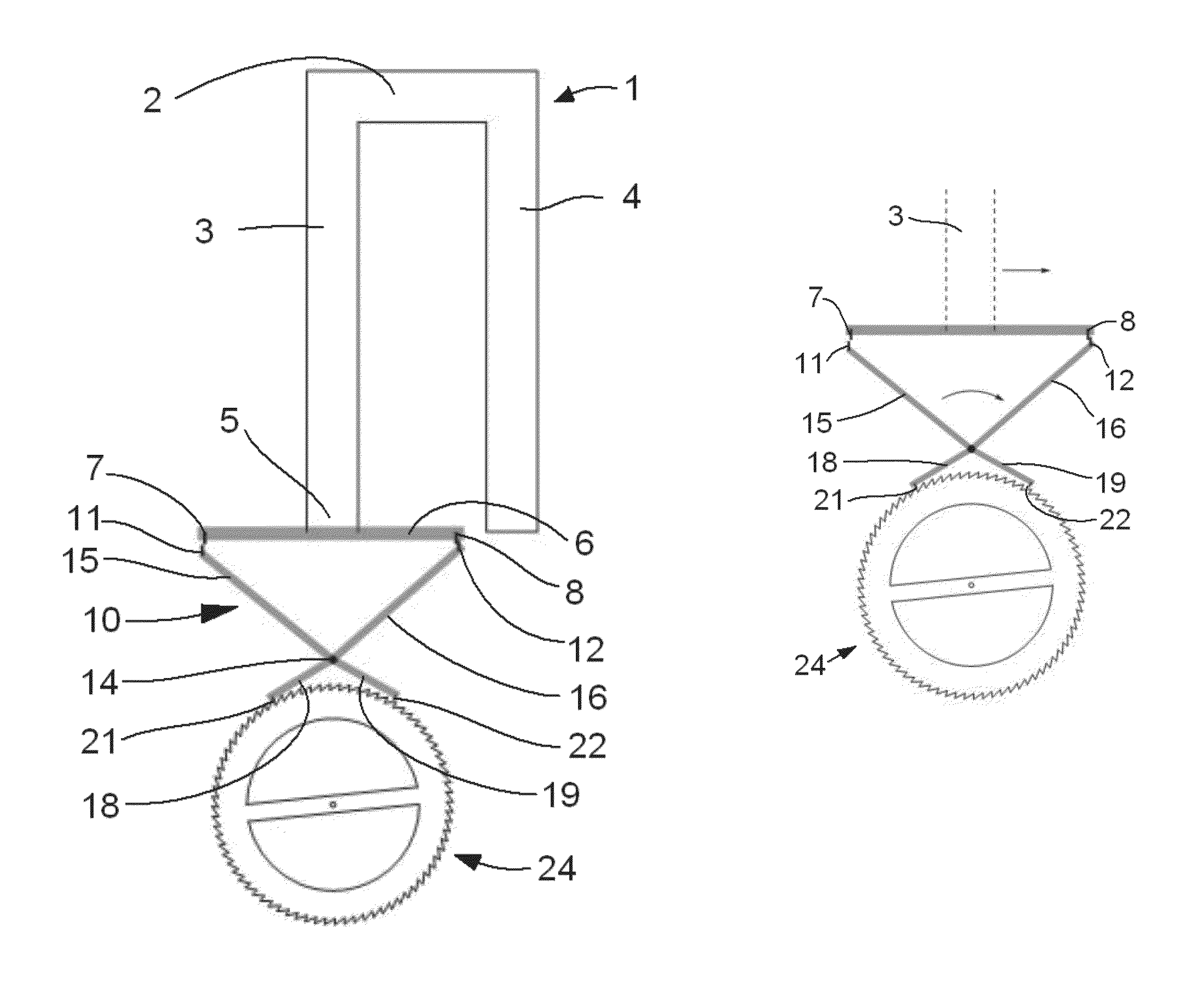

A timepiece movement including, fixed on a same plate, a gear train subjected to a torque in a timepiece movement, and an energy storage to deliver a torque to the gear train for actuating a mechanical mechanism synchronizing rotational speed of the gear train with a resonator having a given natural resonant frequency included in the timepiece movement. The resonator is an annular resonator including a ring disposed around an axis. The ring is arranged to be periodically deformed under an action induced by motion of a drive member, included in this mechanism, and the drive member is driven in a pivoting motion, directly or indirectly, by the gear train.

Owner:ETA SA MFG HORLOGERE SUISSE

Tourbillon without the balance weight

The invention relates to a tourbillon without the balance weight. Tourbillon mechanism for a watch having a turning cage mounted in pivoting manner in a first and second cage bearing lodged in fixed elements of the watch; an escapement mobile integral with the cage; and a regulating element in the form of a spiral balance capable of oscillating around a balance staff according to pulses received from the escapement mobile. The balance staff is mounted in pivoting manner in the balance bearings lodged outside the cage. The outer extremity of the spiral hairspring is fastened to the cage through a hairspring stud.

Owner:MONTBLANC MONTRE SA

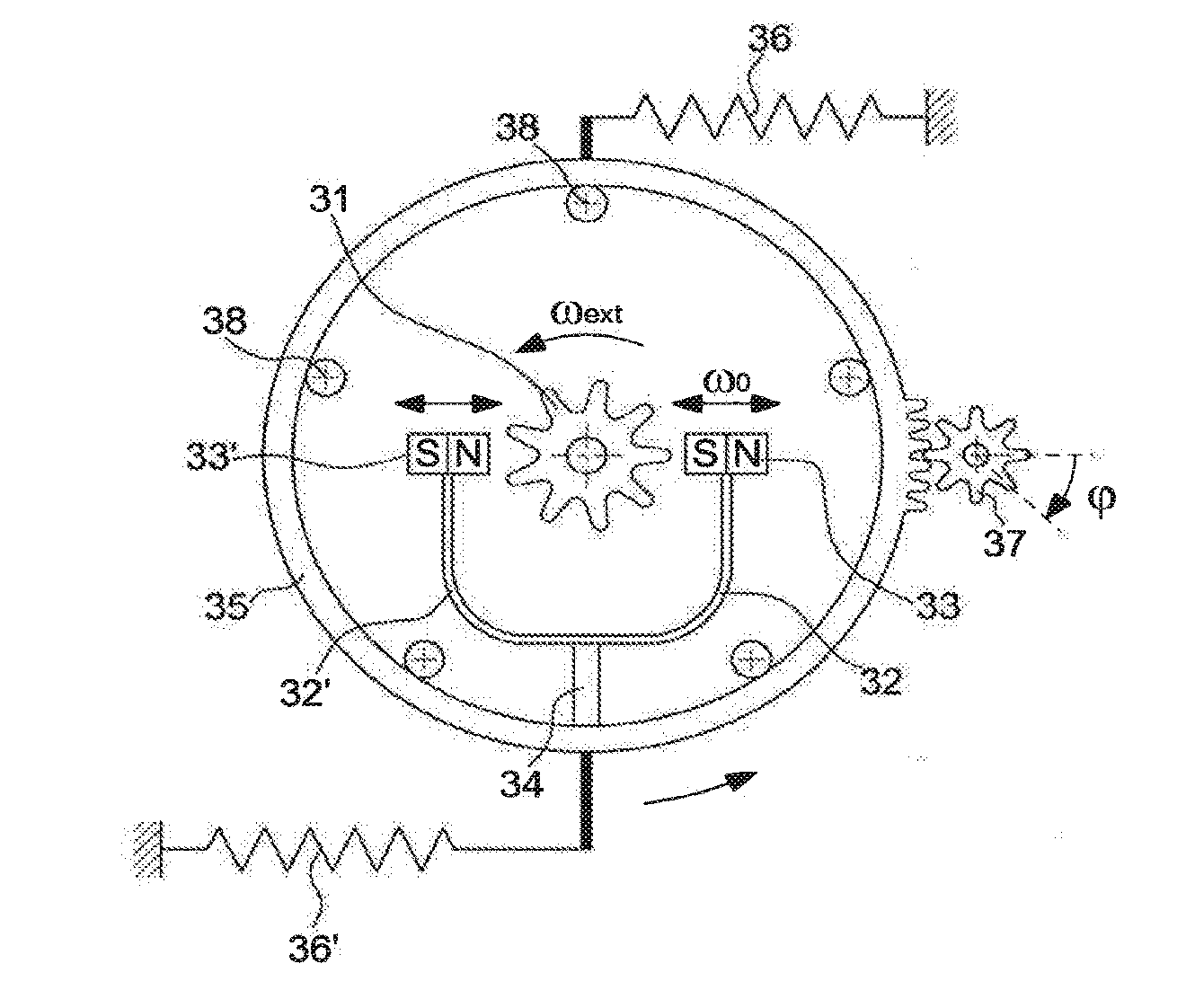

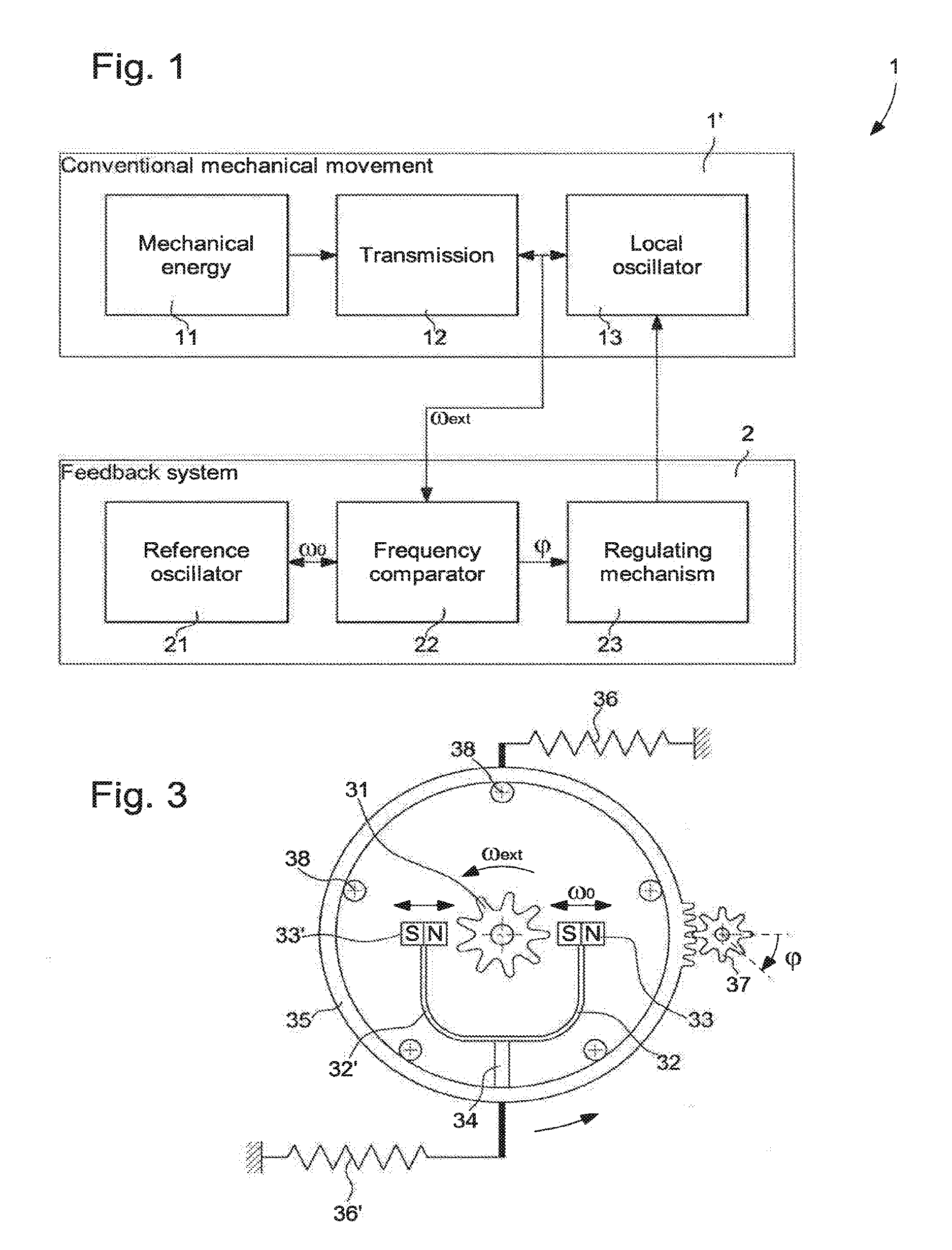

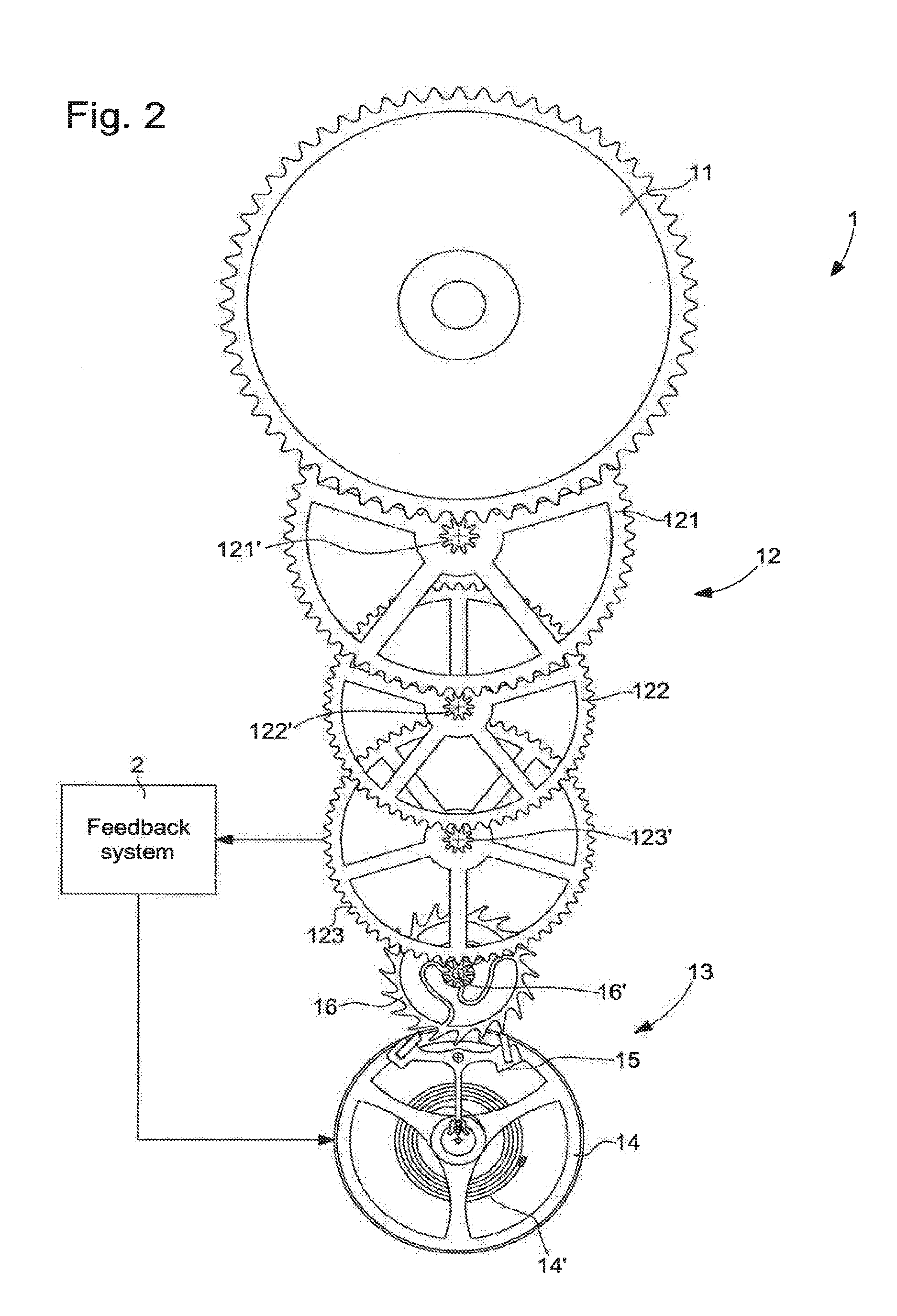

Mechanical timepiece movement provided with a feedback system for the movement

ActiveUS20170045861A1Easy to adjustExact referenceEscapementsFrequency stabilisation mechanismGear wheelLocal oscillator

The mechanical timepiece movement includes at least one barrel, a set of gear wheels driven at one end by the barrel, and an escapement mechanism of a local oscillator with a resonator in the form of a sprung balance and a feedback system for the timepiece movement. The escapement mechanism is driven at another end of the set of gear wheels. The feedback system includes at least one precise reference oscillator combined with a frequency comparator to compare the frequency of the two oscillators and a mechanism for regulating the local oscillator resonator to slow down or accelerate the resonator based on the result of a comparison in the frequency comparator.

Owner:ETA SA MFG HORLOGERE SUISSE

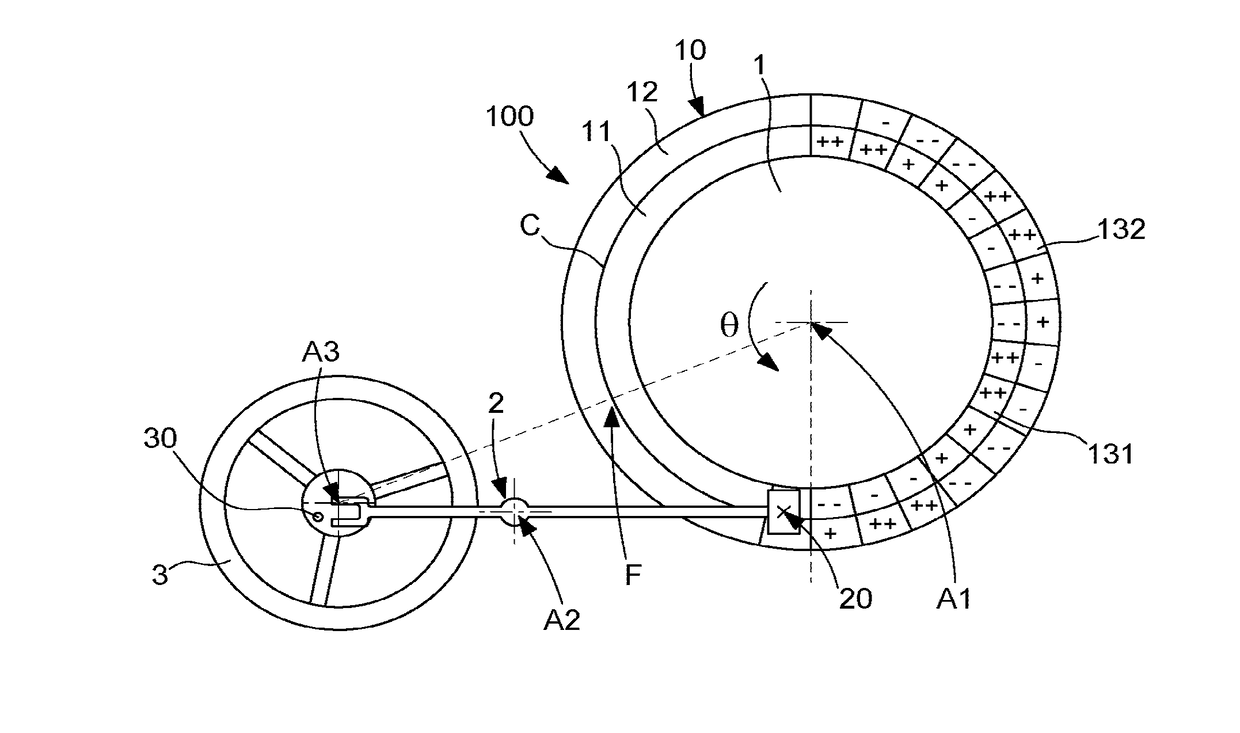

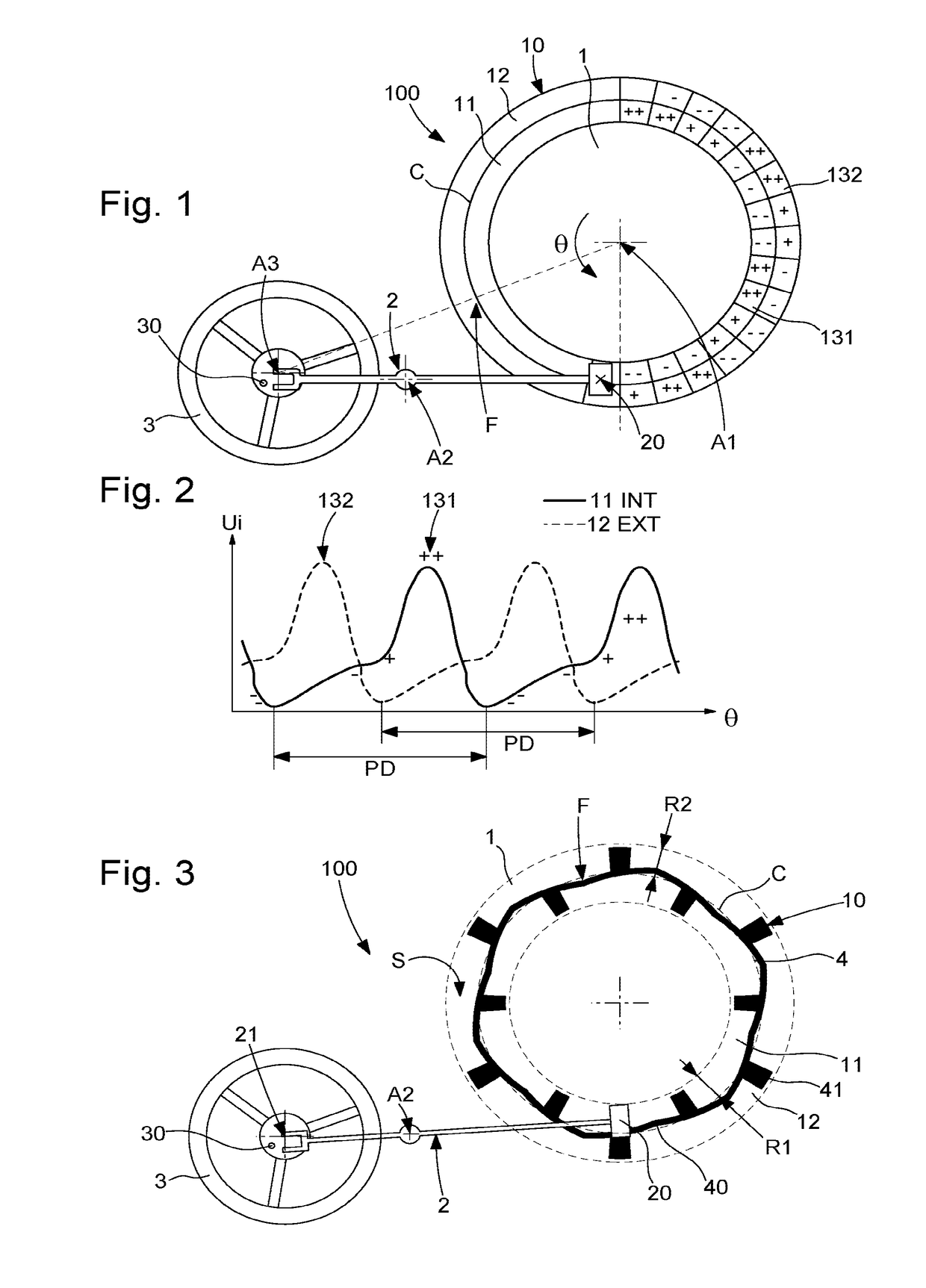

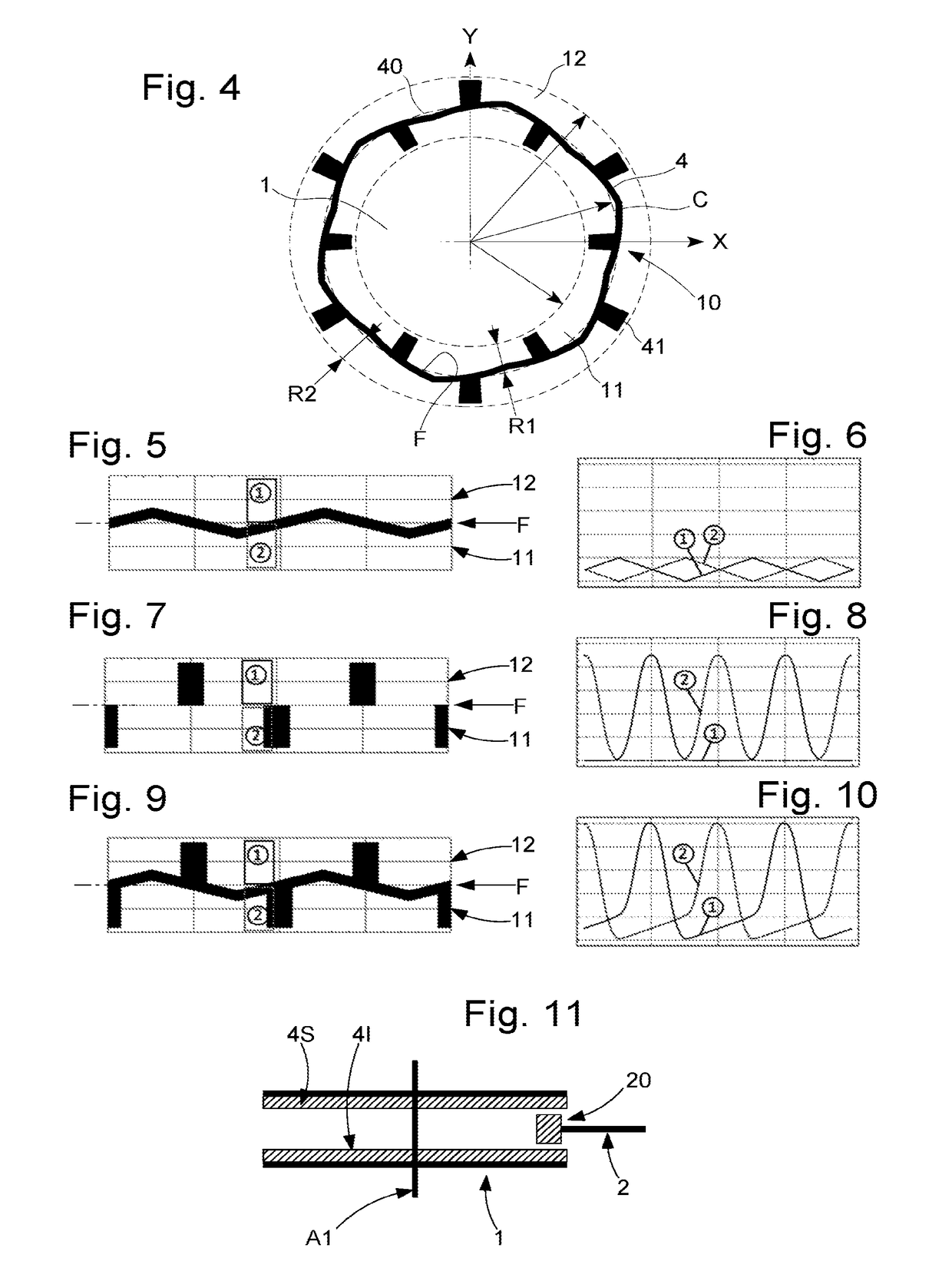

Magnetic escape wheel set for timepieces

Watch with a timepiece movement, a resonator mechanism, including a magnetic escapement mechanism including an escape wheel set including a magnetized track, with a succession of areas according to a scrolling period in which its magnetic features are repeated, each area including an increasing magnetic field ramp followed by a magnetic field barrier with an increasing field and of higher field gradient that that of the ramp, the track includes a continuous, closed magnetic layer over the entire periphery of the escape wheel set, of constant thickness and variable width, whose geometry defines these magnetic field ramps and barriers, this escape wheel set cooperating with a sprung balance via a pivoting magnetic stop member comprising a pole piece arranged to cooperate alternately with an internal track and an external track of the magnetic layer.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

Winding state indicator mechanism for a mechanical timepiece

InactiveCN1823308AHorological winding mechanismsMechanical unknown time interval measurementDefinite periodMechanical engineering

The invention relates to a running reserve indicator for a mechanical clockwork provided with a main barrel for actuating a going train and at least one second barrel for actuating a mechanism allocated to an auxiliary function which is carried out during a definite period of time. The running reserve displayed with the aid of a hand and a dial is always equal to the running reserve of the barrel having the smallest reserve.

Owner:ETERNA SA FAB D HORLOGERIE

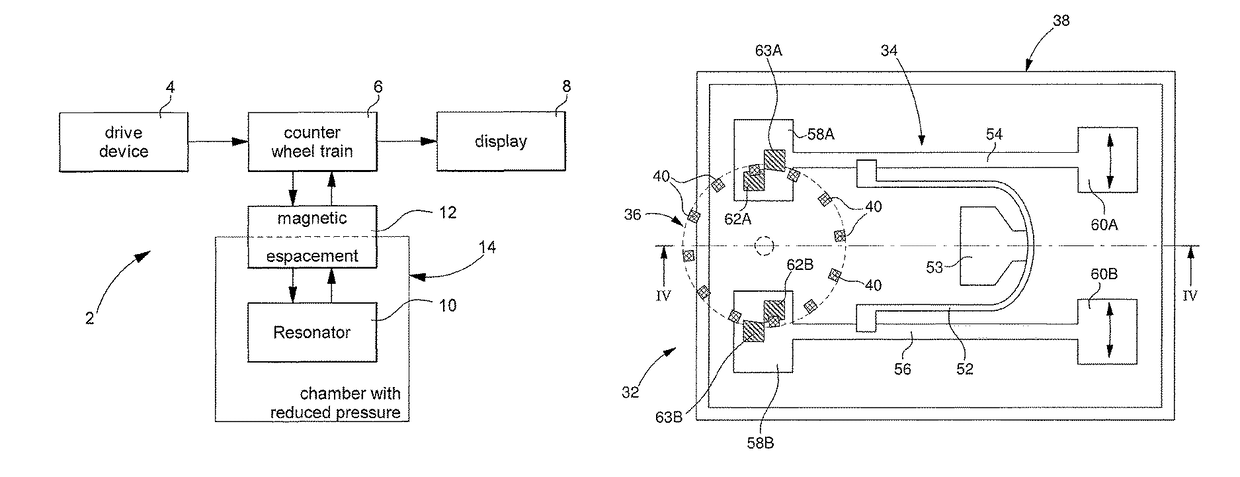

Mechanical clock movement with magnetic escapement

ActiveUS9804570B2High quality factorReduce vibrationEscapementsFrequency stabilisation mechanismTime informationDisplay device

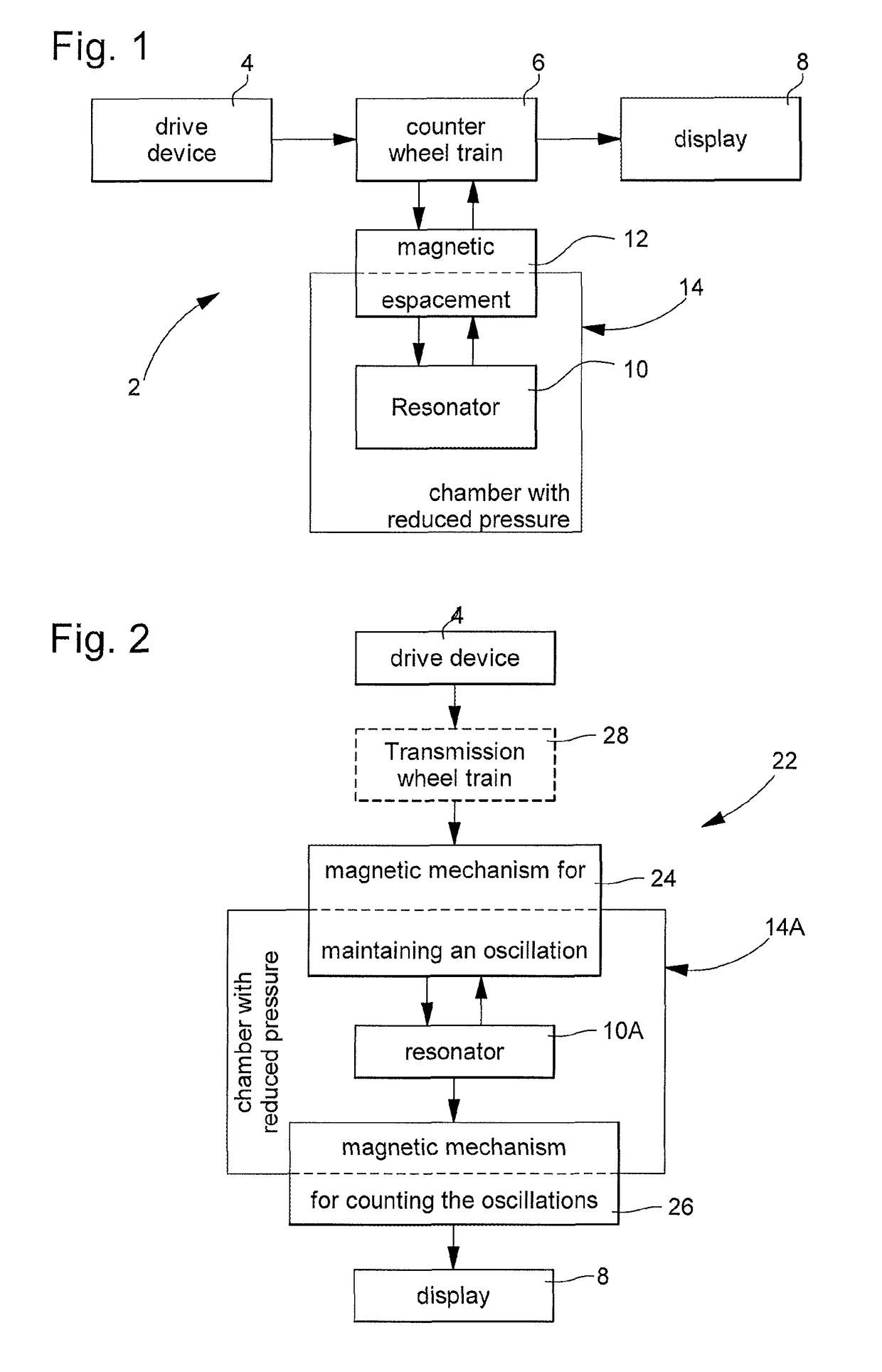

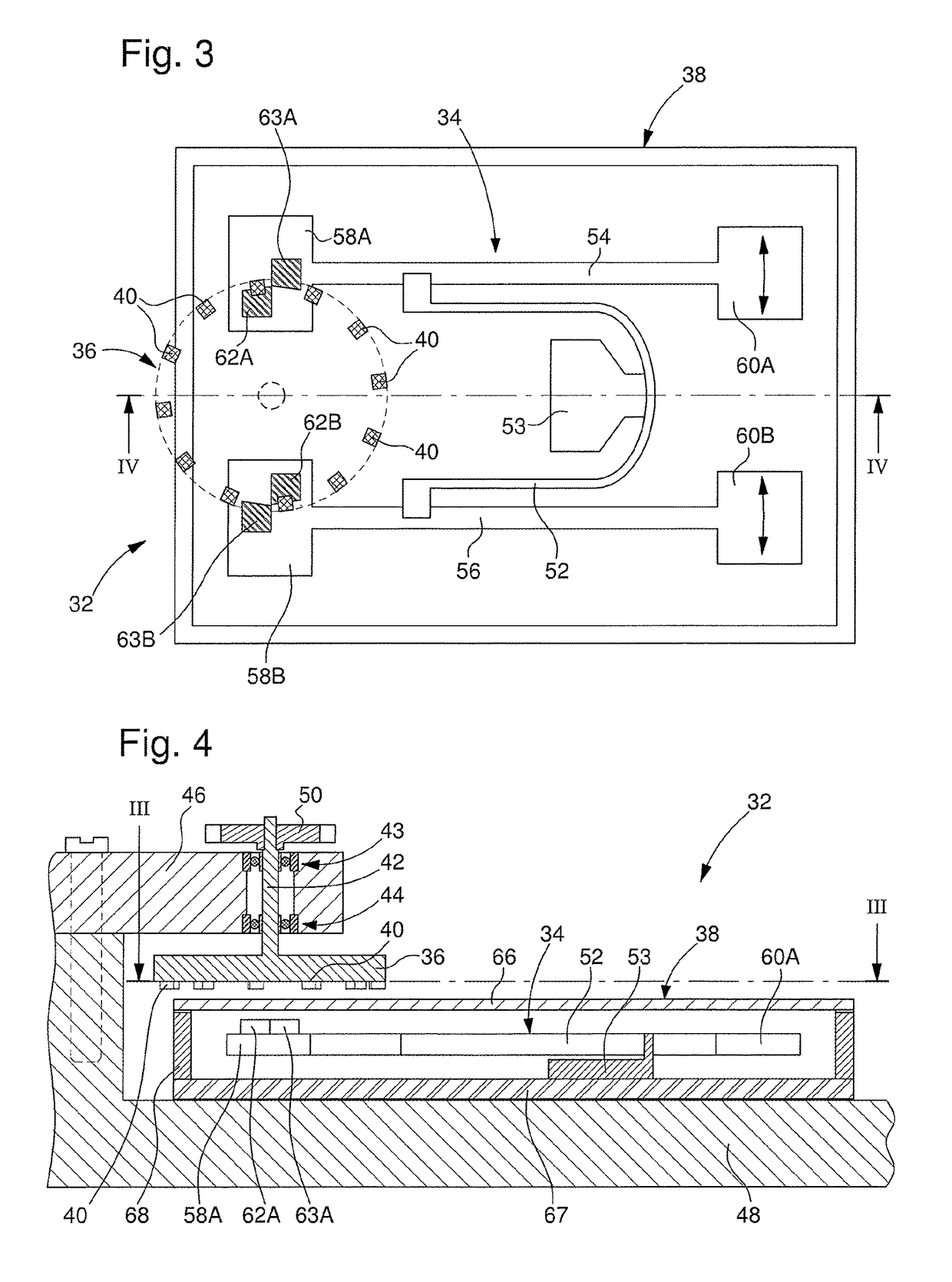

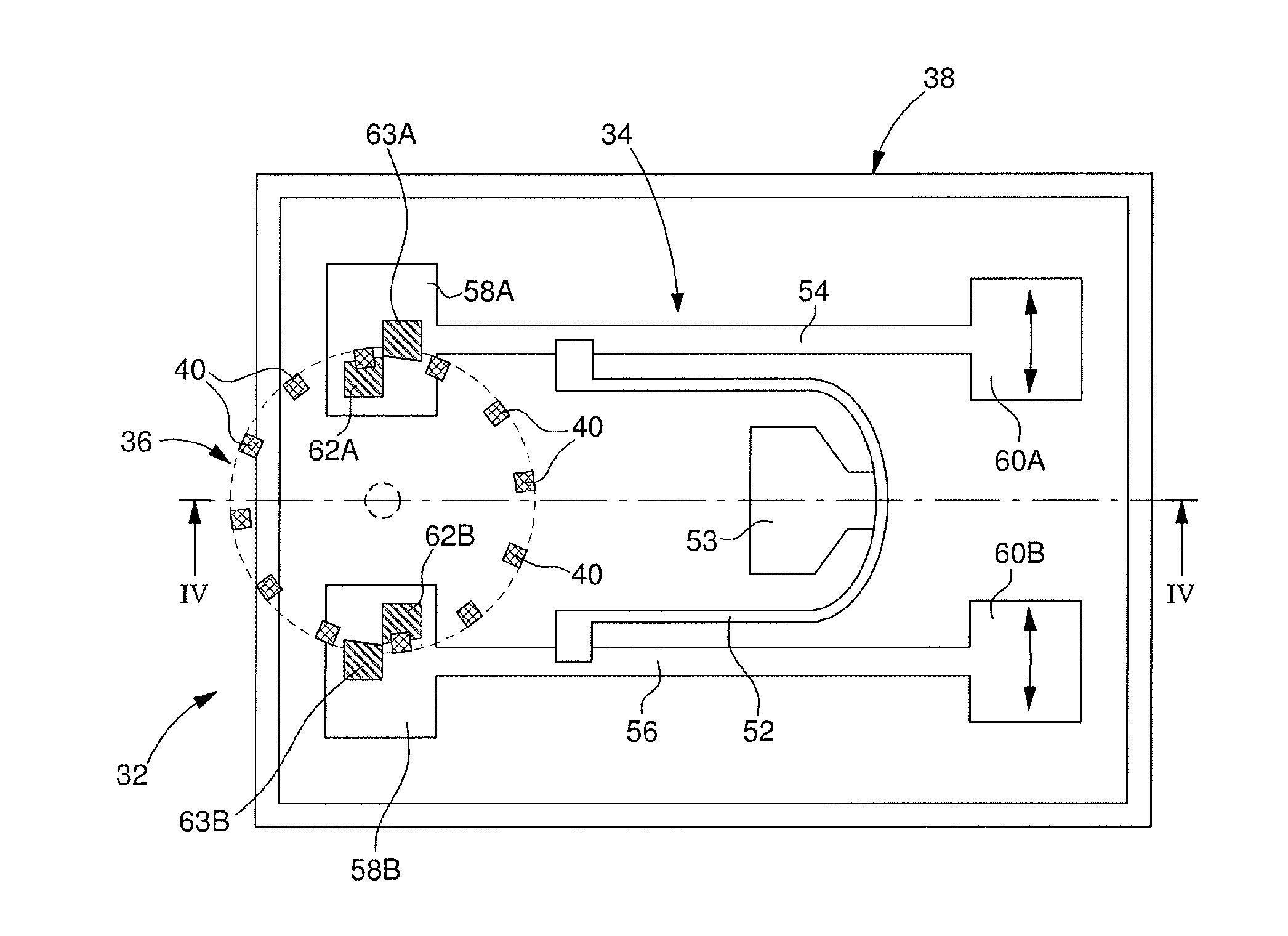

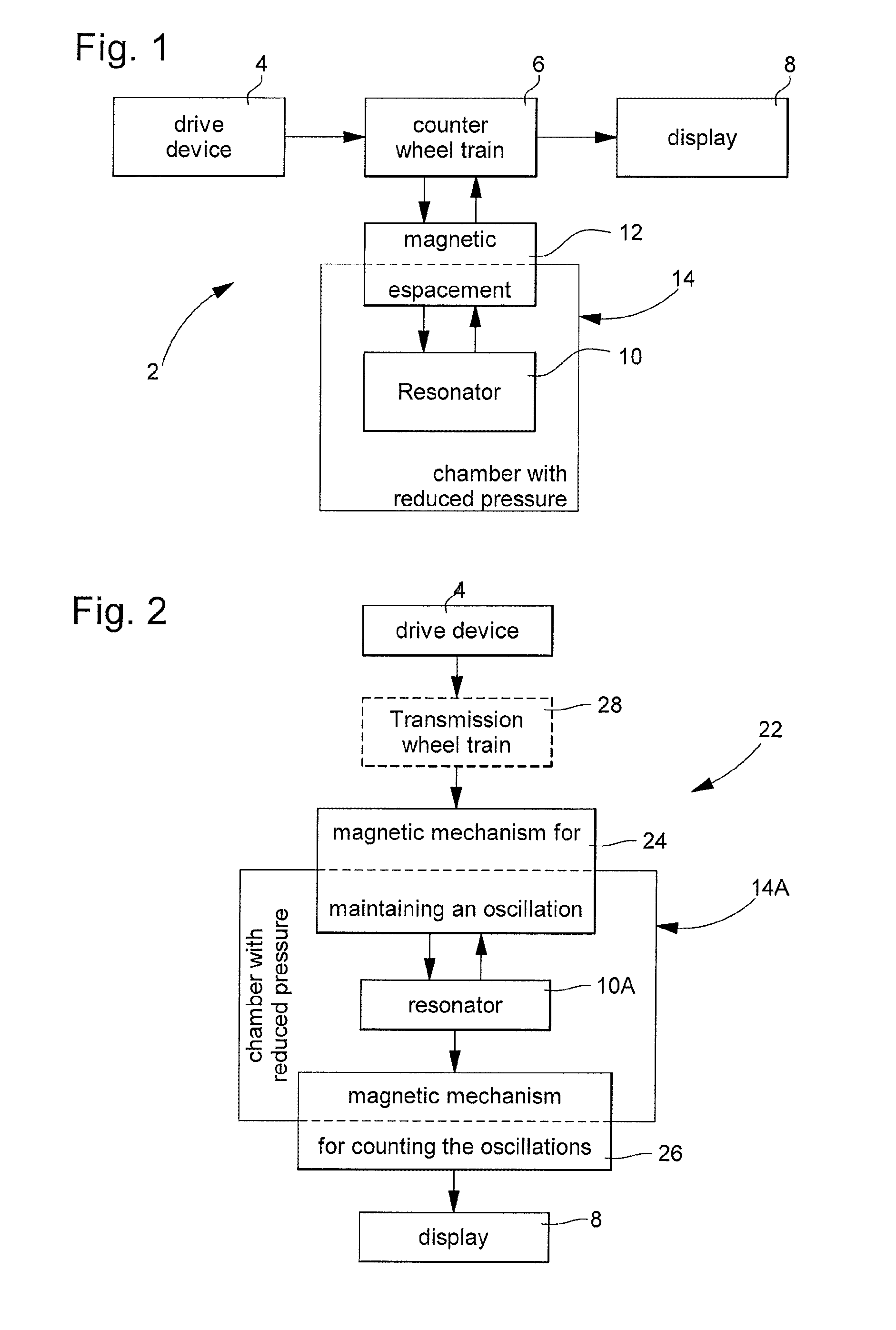

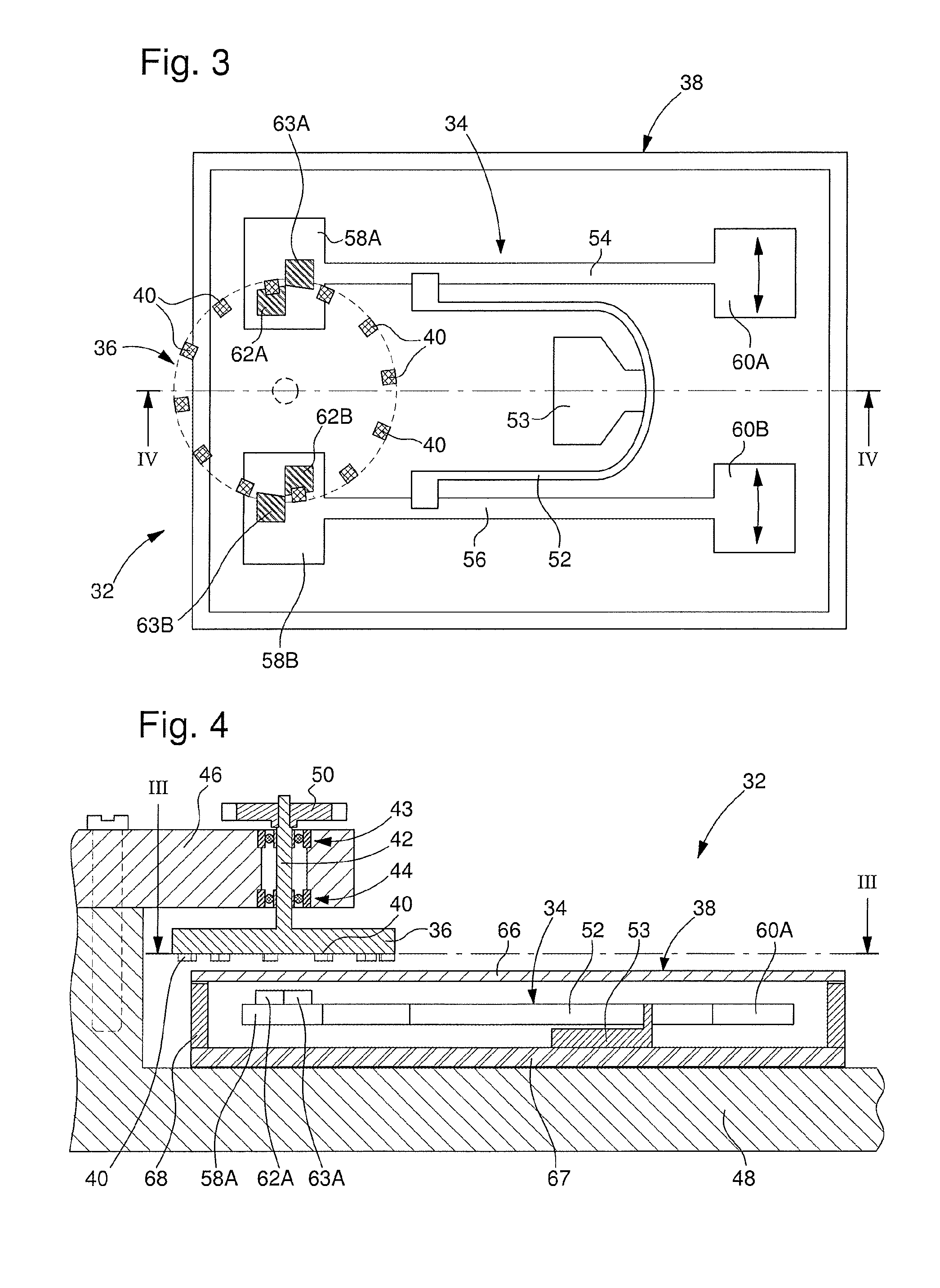

A mechanical clock movement includes a resonator, an escapement linked to the resonator, and a display of at least one item of time information. The display is driven by a mechanical drive device via a counter wheel train, the work rate of which is set by the escapement. At least the resonator is housed in a chamber, in which a reduced pressure in relation to atmospheric pressure prevails. The escapement is a magnetic escapement including an escape wheel coupled directly or indirectly to the resonator via a non-contact magnetic coupling system, wherein the magnetic coupling system is formed so that a non-magnetic wall of the chamber runs through the magnetic escapement so that a first part of the escapement is located inside the chamber whereas a second part of the escapement is located outside the chamber.

Owner:ETA SA MFG HORLOGERE SUISSE

Mechanical clock movement with magnetic escapement

ActiveUS20160370766A1High quality factorReduce vibrationEscapementsFrequency stabilisation mechanismTime informationDisplay device

A mechanical clock movement includes a resonator, an escapement linked to the resonator, and a display of at least one item of time information. The display is driven by a mechanical drive device via a counter wheel train, the work rate of which is set by the escapement. At least the resonator is housed in a chamber, in which a reduced pressure in relation to atmospheric pressure prevails. The escapement is a magnetic escapement including an escape wheel coupled directly or indirectly to the resonator via a non-contact magnetic coupling system, wherein the magnetic coupling system is formed so that a non-magnetic wall of the chamber runs through the magnetic escapement so that a first part of the escapement is located inside the chamber whereas a second part of the escapement is located outside the chamber.

Owner:ETA SA MFG HORLOGERE SUISSE

Circuit breakers with clock spring drives and/or multi-lobe drive cams and related actuators and methods

Spring operated actuator devices for an electrical circuit breaker and / or electrical switching device include at least one clock spring comprising a disc shaped body with gear teeth and a spiral spring, a cam shaft holding the at least one clock spring with an inner end portion of the spiral spring attached to the cam shaft, and a drive cam held by the cam shaft adapted to be in communication with a follower that directs an actuator to open or close a mobile contact to maintain open and closed energy status of the electrical circuit. The at least one clock spring is configured as a closing spring of the spring operated actuator.

Owner:EATON INTELLIGENT POWER LTD

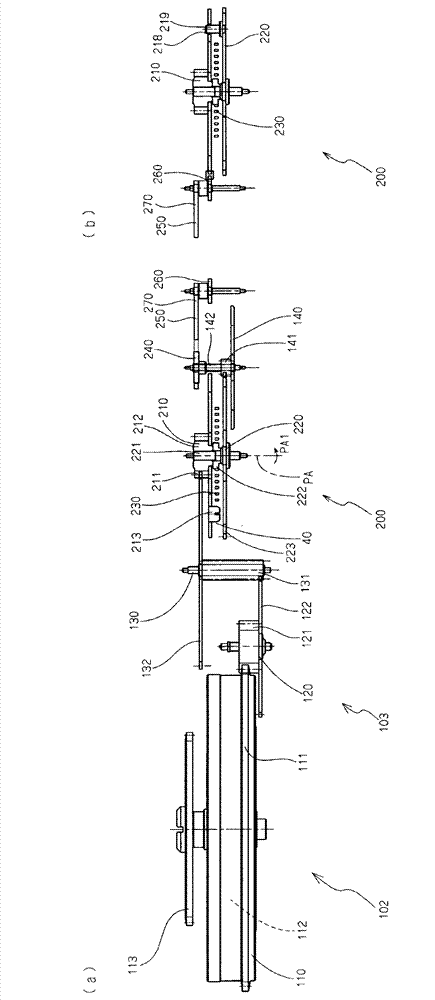

Swing wheels, clock movement and clock

InactiveCN104049519AInhibition rate reductionEasy to set upFrequency stabilisation mechanismFrequency setting mechanismEngineeringRemontoire

The invention provides swing wheels, a clock movement provided with the swing wheels and a clock provided with the clock movement. The swing wheels are capable of easily adjusting the error rate to reduce errors of a release catch so that the characteristic of stable error rate is obtained. The swing wheels are characterized in that the swing wheels are provided with a swing shaft (30) and a balance spring. A balance wheel (20) is outwardly embedded at the swing shaft (30). The inner end portion of the balance spring is connected with the swing shaft (30).The wing wheels are formed in such a manner that when the inner peripheral surface (40a) of the balance spring (40) is lengthened along an axis of the swing shaft (30), the inner peripheral surface (40a) and a central axis (O) of the swing shaft (30) are intersected.

Owner:SEIKO INSTR INC

Mechanism for setting the minute hand of a timepiece with automatic return-to-zero of the seconds hand

ActiveCN101819402AEasy to adjustReliable adjustmentGearworksMechanical devices for setting timeReturn-to-zeroLocking mechanism

The invention relates to a timekeeper, at least having a minute hand, a seconds hand and a clockwork mechanism with a mechanism for adjusting the minute hand. The mechanism comprises an adjusting shaft moving between a conventional position and an adjusting position in an axial direction, the adjusting shaft is coupled with a center-wheel group of the clockwork mechanism such that rotation of theshaft adjusts the minute hand. The adjusting shaft co-operates with a zeroing mechanism, the zeroing mechanism drives the second hand in a zero position when the adjusting shaft moves in the axial adjusting position and locks the seconds hand in the zero position when the adjusting shaft is in the adjusting position, and releases the seconds hand when the adjusting shaft moves in the conventionalposition again. According to the invention, the center-wheel group of the clockwork mechanism has a lock mechanism, the lock mechanism can obtain 60 locking positions, so that the minute hand can move among 60 positions the minute hand by rotating the adjusting shaft in the adjusting position, and each of 60 positions corresponds one minute scale.

Owner:GLASH&XFC TTER UHRENBETRIEB

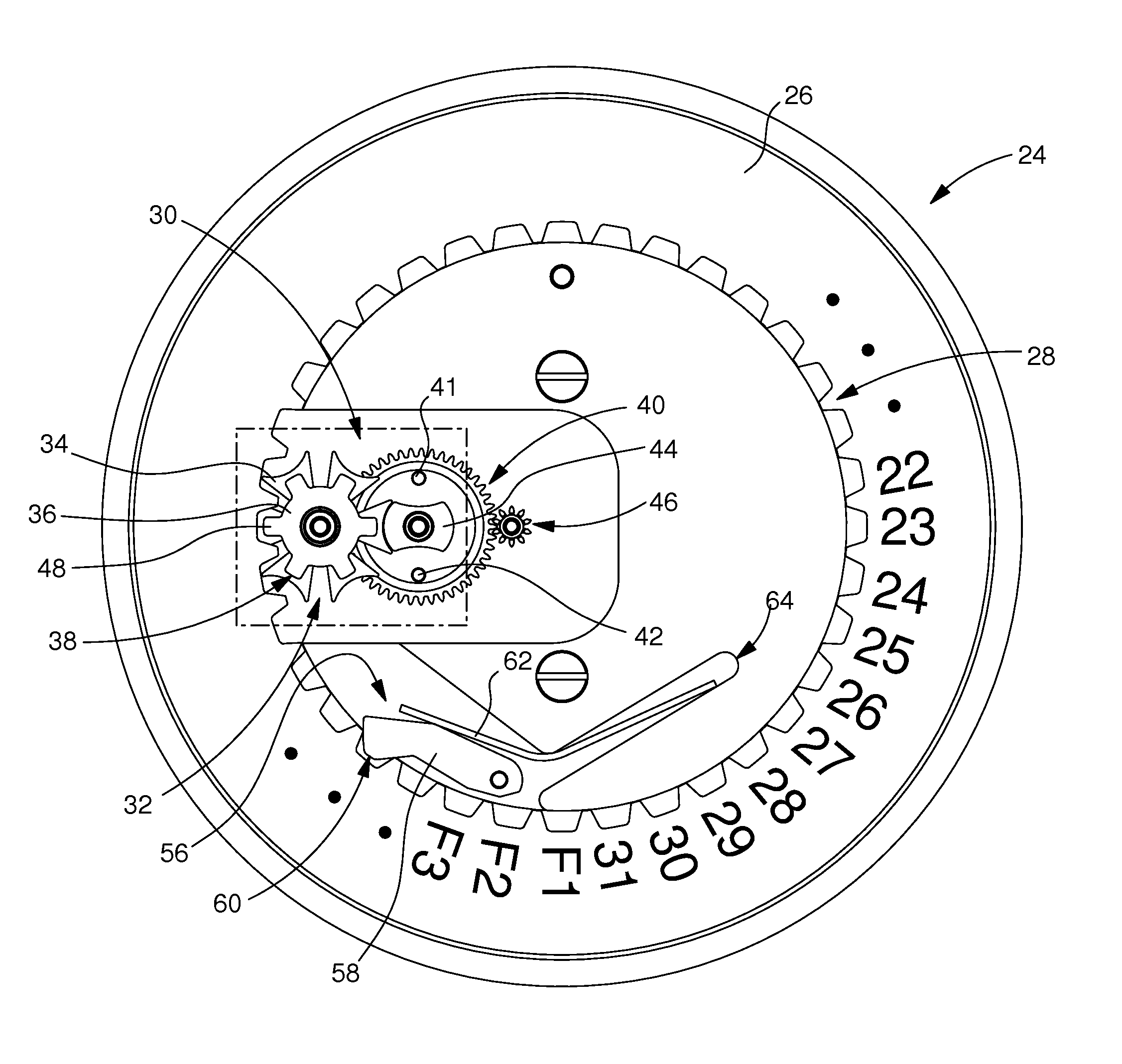

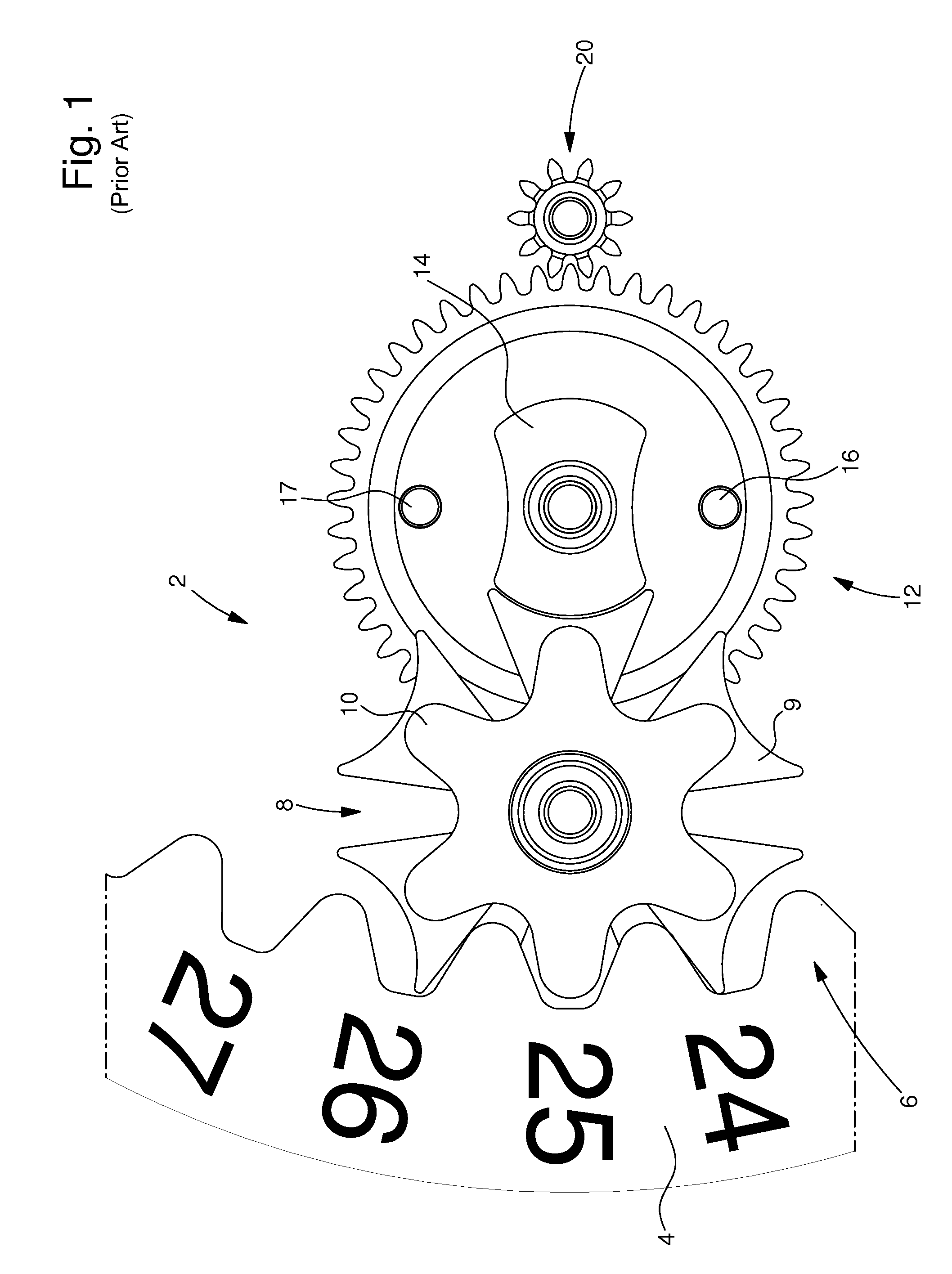

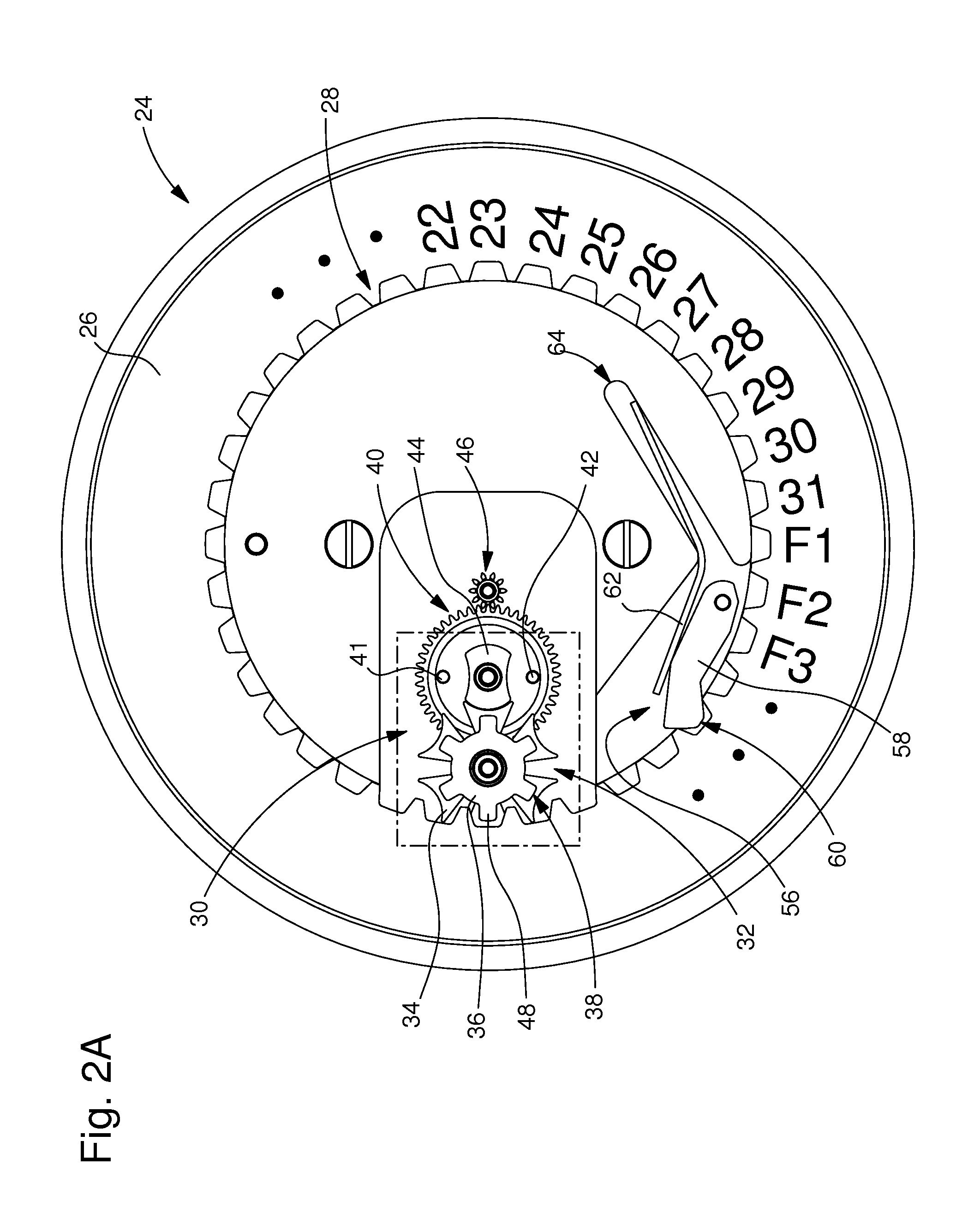

Clock movement provided with a drive mechanism for an analogue indicator with periodic or intermittent movement

The timepiece movement is provided with an analogue device for displaying information whose value varies periodically or intermittently, this analogue display device including, on the one hand, an indicator provided with a first toothing, and on the other hand, a mechanism for the periodic or intermittent driving of the indicator. The drive mechanism is formed by an irreversible transmission system which ensures a shock resistant function for the indicator. The display device further includes a positioning jumper for the indicator generating a positioning force on the first toothing, which is sufficient to precisely position the indicator in a plurality of discrete display positions, but considerably insufficient to ensure a shock resistant function for the indicator. Thus, the indicator can be driven with a relatively low torque; which therefore requires less energy and makes it possible to provide a drive mechanism with a lower gear reduction for the drive torque transmission ratio.

Owner:ETA SA MFG HORLOGERE SUISSE

Mechanical clockwork movement with an adjustable tourbillon

ActiveUS20170060090A1Improved balance stopExtended functional scopeFrequency stabilisation mechanismMechanical devices for setting timeAngular orientationEngineering

A clockwork movement with a tourbillon unit, including a base plate, a mobile cage mounted rotatably on the base plate and connected to a second pinion, a balance mounted on the mobile cage and an escape wheel mounted on the mobile cage and being in operative connection with the balance, a balance wheel stop mechanism being capable to be brought into engagement with the balance, wherein it further includes a setting mechanism controlled by an external actuating device for any angular orientation of the mobile cage.

Owner:GLASHUETTER UHRENBETRIEB GMBH

Clock movement containing a constant force device

InactiveUS8550700B2Easy constructionPrecise and simple mannerFrequency stabilisation mechanismFrequency setting mechanismConstant forceCoil spring

A clock movement is provided that contains a constant force device. In accordance with one implementation, the clock movement includes a spiral spring, and a train, having a first kinematic chain arranged to connect a main energy source to a first end of the spiral spring and a second kinematic chain for connecting a time base to a second end of the spiral spring. One of the first and second kinematic chains may contain an adjustment mobile comprising first and second members connected to each other by a friction such that a rotation of one member drives the other member during routine working of the clock movement. One of these members may include an adjustment member having at least one bearing surface arranged such that it is possible to act upon the latter so as to rotate the adjustment member without rotating the other member by dint of friction, in order to adjust the load state of the spiral spring.

Owner:LA MONTRE HERMES

Balance stop device for watch pieces with tourbillon cage

ActiveUS9354608B2Simple structureGuaranteed uptimeFrequency stabilisation mechanismMechanical devices for setting timeRest positionEngineering

A device for stopping a balance of a regulating organ mounted in a tourbillon of a timepiece. The device can be controlled by a setting device of the timepiece. The device includes at least two stop levers which are each secured pivotably to a respective lever pivot axis in such a manner that they can be brought from a rest position, in which the balance and the tourbillon are freely rotatable into a stop position, in which at least one of the stop levers acts via its free end on the balance such that the balance is stopped. The device additionally includes for each of these stop levers pre-loading structure, in such a manner that the force exerted onto the balance by each of the stop levers can act separately. The present invention also relates to a corresponding movement module equipped with such a device, respectively to a corresponding timepiece.

Owner:RICHEMONT INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com