Mechanical clock movement with magnetic escapement

a mechanical clock and escapement technology, applied in the field of mechanical clock movement, can solve the problems of reducing pressure affecting etc., and achieves the effects of reducing mechanical friction, reducing power, and increasing the working precision of the watch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

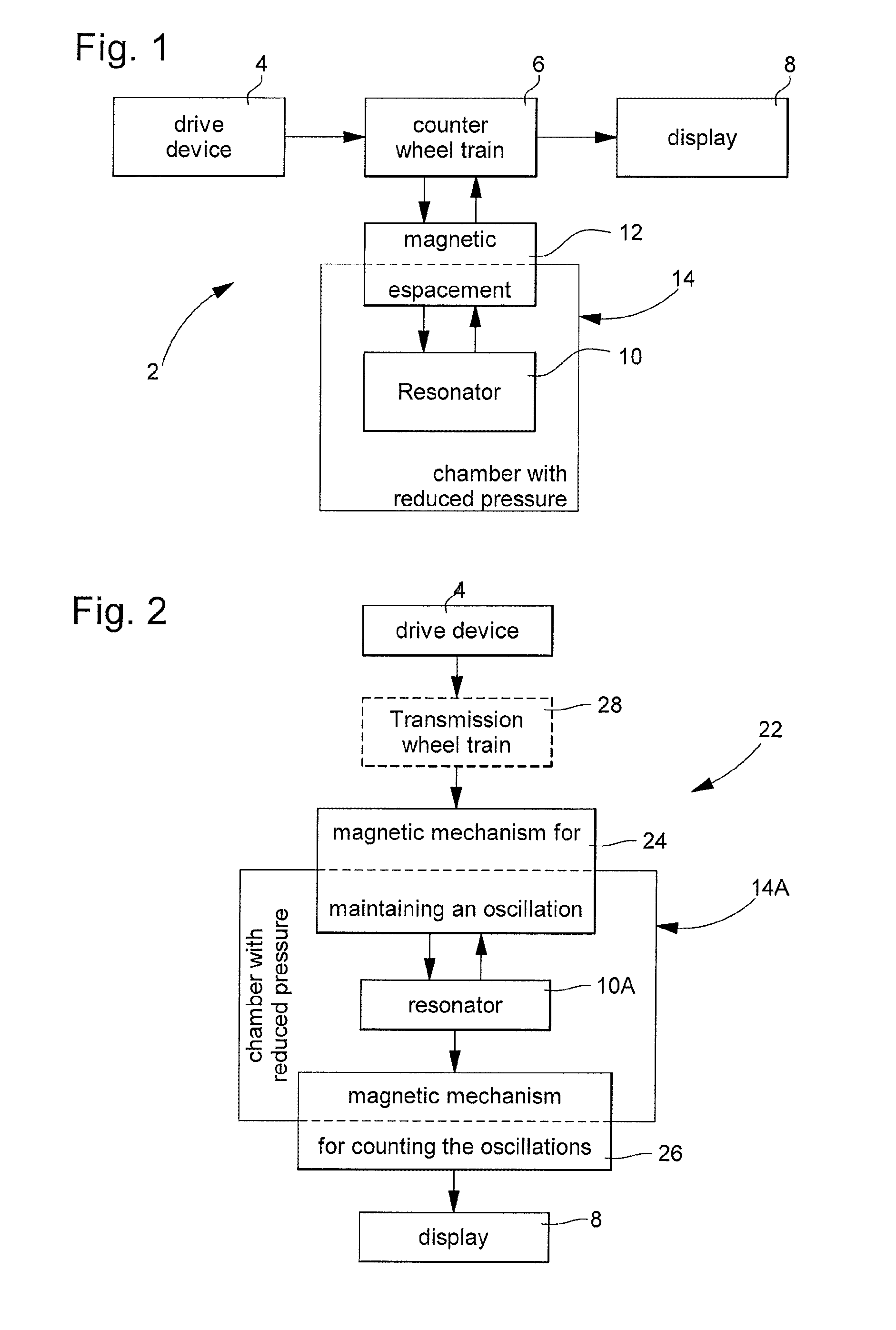

first embodiment

[0027]It will be observed that the magnetic mechanism for maintaining oscillation can be similar in design to a magnetic escapement such as that of the first embodiment, and can therefore correspond, for example, to one of the particular embodiments that will be described below. The same observation applies to the counting and drive magnetic mechanism. In particular, at least one of these two magnetic mechanisms comprises an escape wheel coupled directly or indirectly to the resonator 10A via a magnetic coupling system. This magnetic coupling system is formed from at least one first magnetic element and a second magnetic element that exhibit at least periodically a magnetic interaction between them. According to the invention there is provided a hermetically sealed chamber 14A, which comprises a wall running between the first and second magnetic elements, so that the first magnetic element is inside the chamber, whereas the second magnetic element and the escape wheel are outside th...

third embodiment

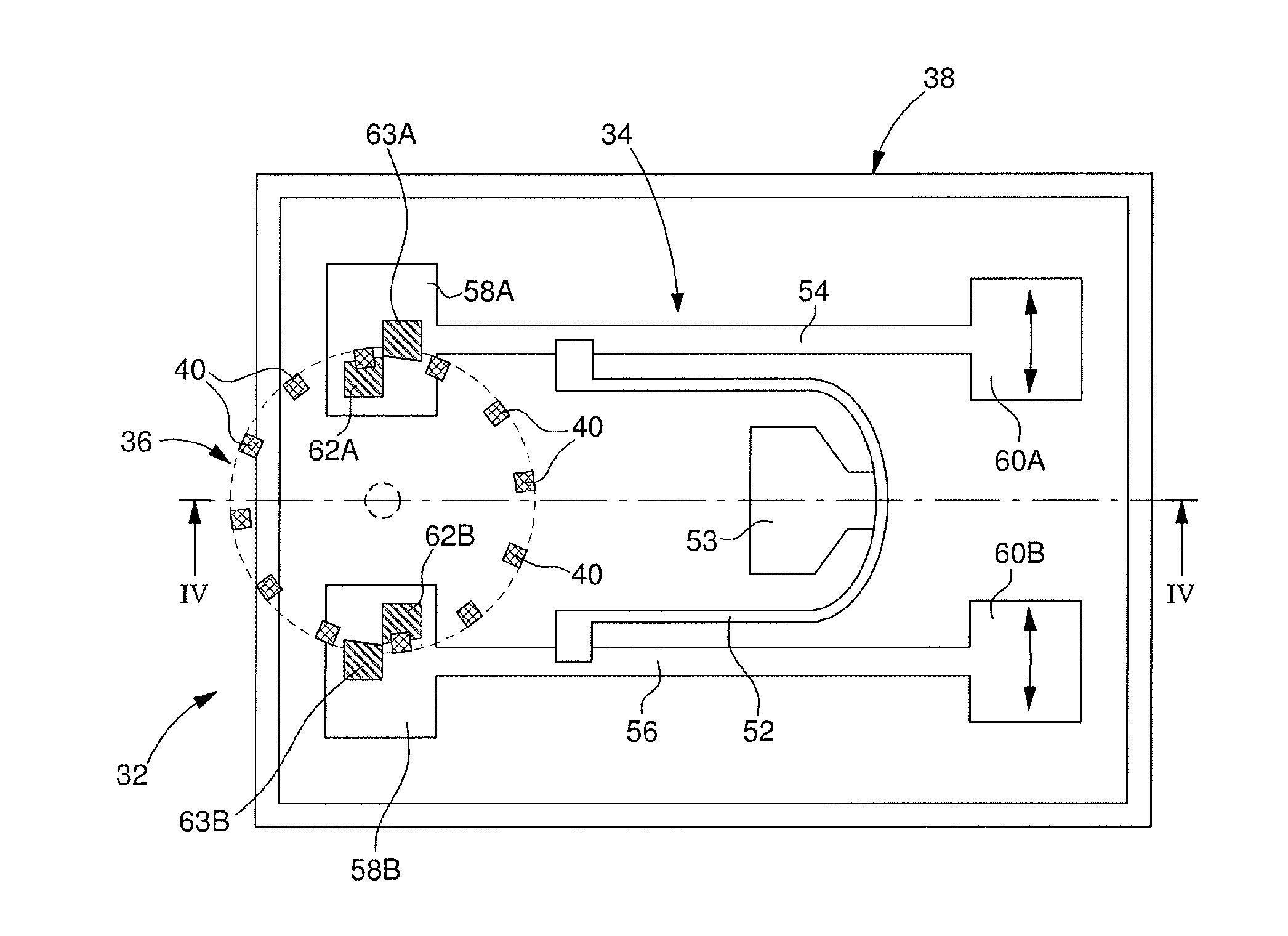

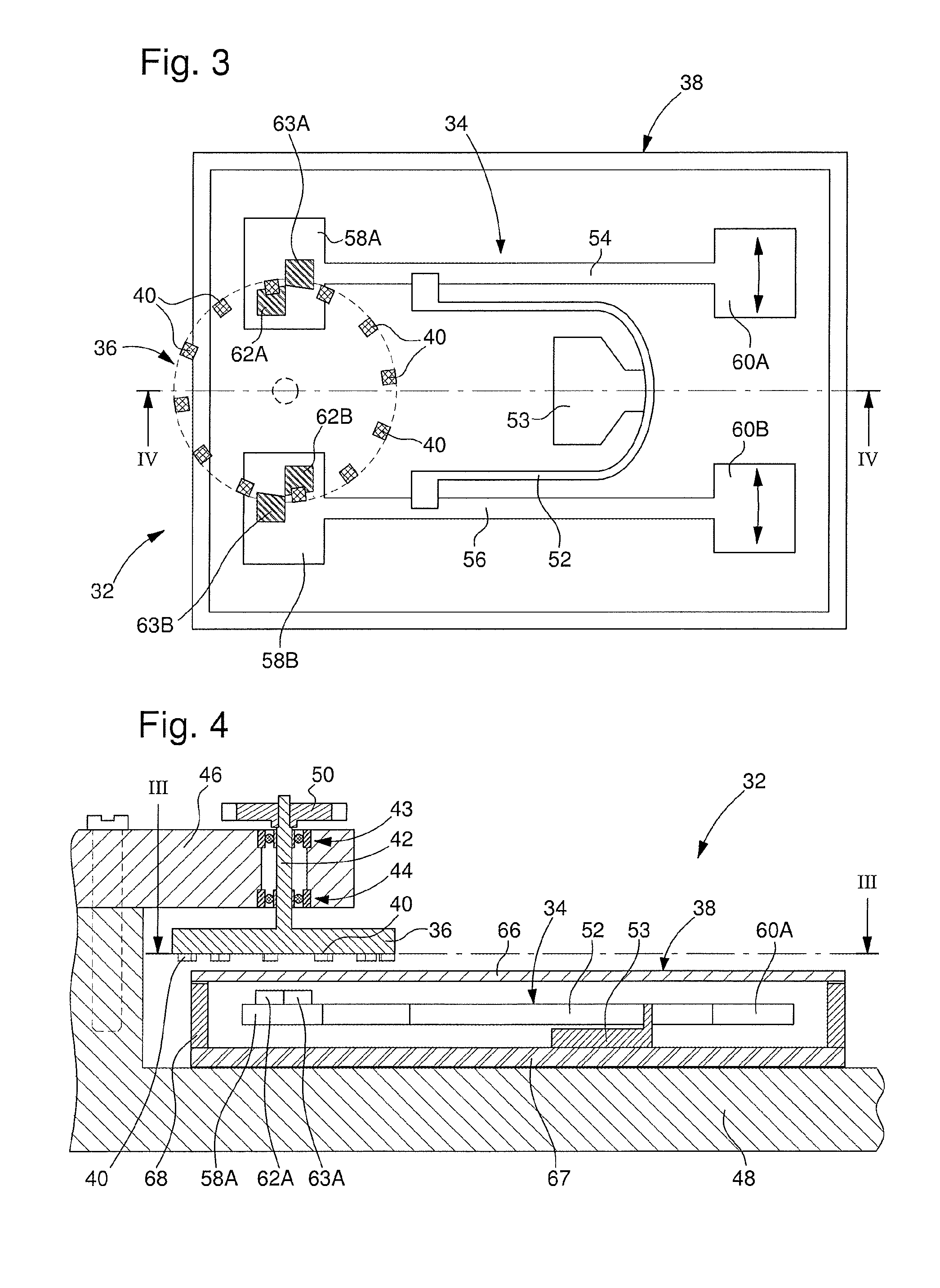

[0029]a clock movement according to the invention is described below with reference to FIGS. 3 and 4. The mechanical clock movement 32 is shown only partially in the figures in order to reveal the features specific to the invention that relate to the regulating device of this movement. This third embodiment as well as the other embodiments that will be described below are particular configurations of the first general embodiment described above. Apart from a wheel or a pinion used for mechanical coupling of the escape wheel to the drive device and to the counter wheel train, this drive device and this counter wheel train as well as the display device are not shown in the figures nor described in detail, since they are known to the person skilled in the art. In fact, the present invention is noteworthy because of these parts of the mechanical movement and the devices that are generally associated with them, in particular the winding device, the device for correcting time information ...

fourth embodiment

[0042]The variant of the fourth embodiment shown in FIGS. 5 and 6 is noteworthy in that the clock movement 72 largely incorporates components and elements of traditional clockmaking while using a magnetic coupling system without contact between the anchor and the escaped wheel to allow a wall 112 of a hermetically sealed chamber 80 to be located between first and second parts of this magnetic coupling system of the escapement.

[0043]A fifth embodiment of a clock movement according to the invention is described below with reference to FIGS. 7, 8 and 9A to 9D. The mechanical clock movement 152 comprises a resonator 154 and a magnetic escapement 156 shown in the figures. As in the fourth embodiment, this magnetic escapement comprises an escape wheel 158, which is coupled to the resonator by an intermediate member 160 formed by an anchor defining a bistable retaining catch. In contrast, this fifth embodiment differs from the previous embodiment in that the magnetic coupling system of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com