Hairspring supporting structure, hairspring balance wheel structure and mechanical clock

A technology of supporting structure and hairspring, which is applied to mechanically driven clocks, clocks, clock driving mechanisms, etc., can solve the problem that the spring structure is not easy to realize, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

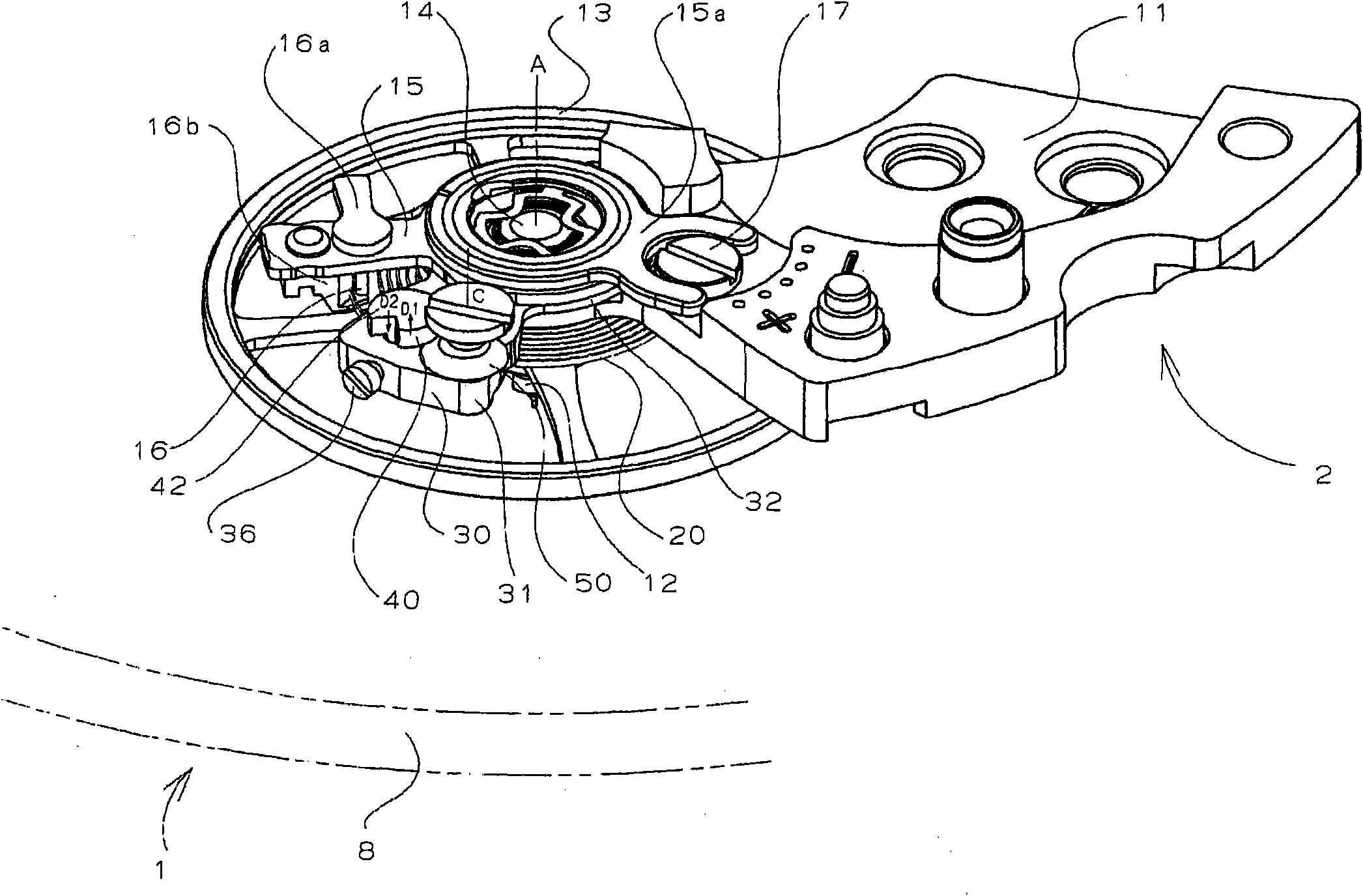

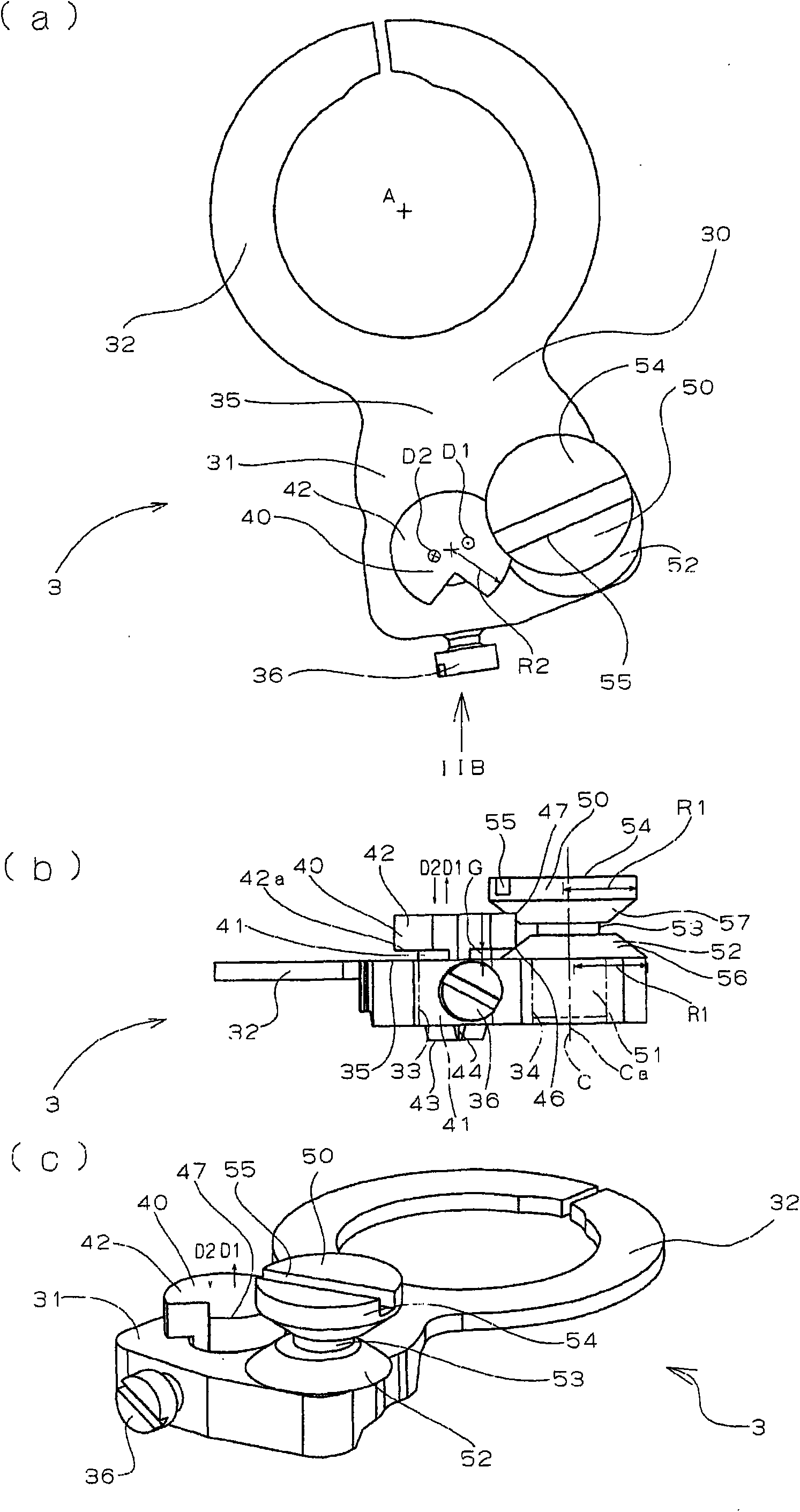

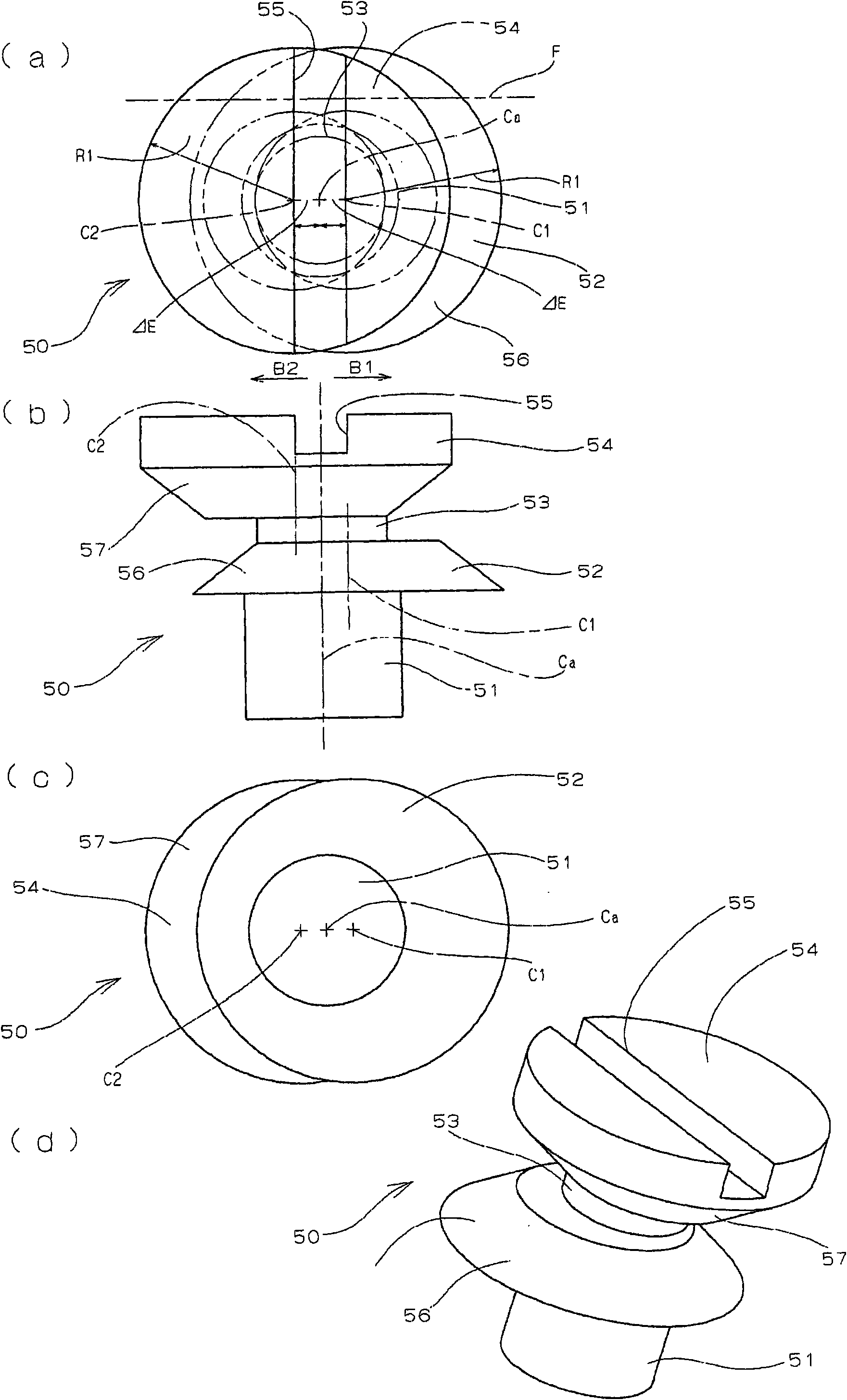

[0031] exist figure 1 shows a hairspring balance structure 2, which is mounted on a supporting substrate such as a main board (not shown) through a hairspring balance bridge 11 in the case 8 of the mechanical wristwatch 1, and figure 2 The hairspring supporting structure 3 is shown in , and the hairspring supporting structure 3 includes a hairspring stud ring 30 , a hairspring stud 40 and a hairspring stud height adjustment pin 50 .

[0032] The hairspring balance wheel structure 2 has a balance wheel 13 fixed to the balance shaft 12 and a hairspring 20 in the form of a spiral spring. The inner peripheral end of the hairspring 20 is fixed to a hairspring collet (not shown) which is fixed to the balance spring collet. The shaft 12 and the outer peripheral ends of the balance spring 20 are fixed to the balance spring stud 40 , and the balance spring stud 40 is supported by the balance spring stud ring 30 . The balance spring 20 is engaged with the adjustment pin 16 supported b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com