Manual winding gear train, clock machine core and clock possessing the gear train

A string wheel and clock technology, applied in the field of clocks and watches, can solve the problems of crown hypertrophy, not easy to slip torque retention, unnatural, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

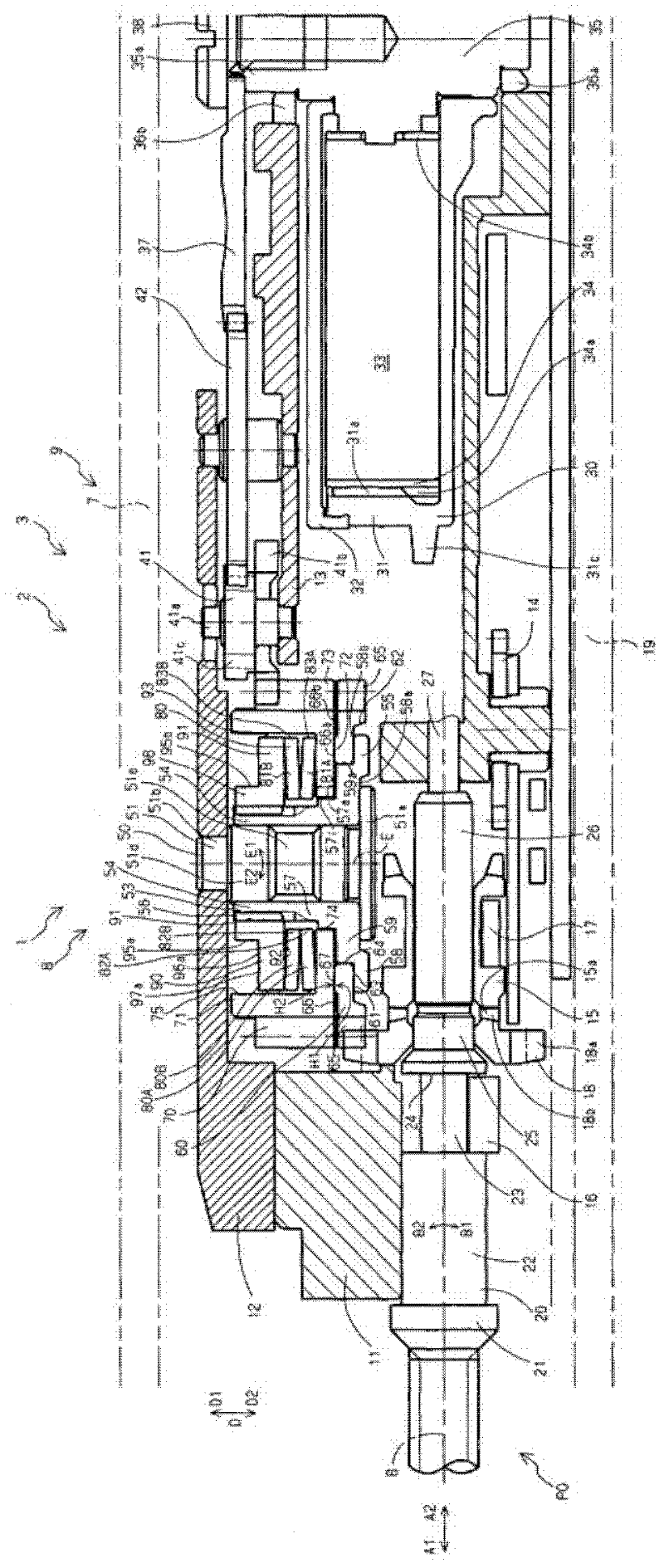

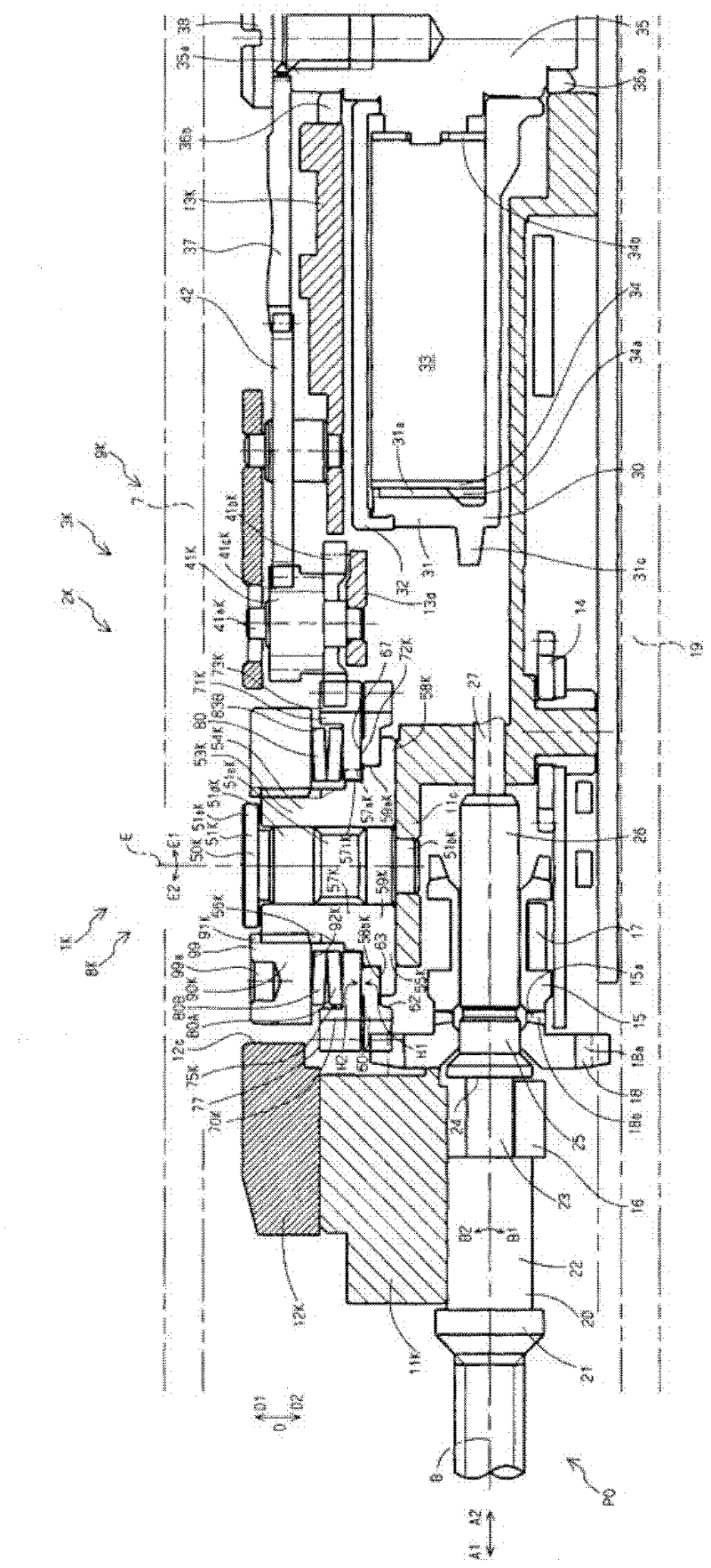

[0158] A preferred embodiment of the present invention will be described on the basis of preferred embodiments shown in the drawings.

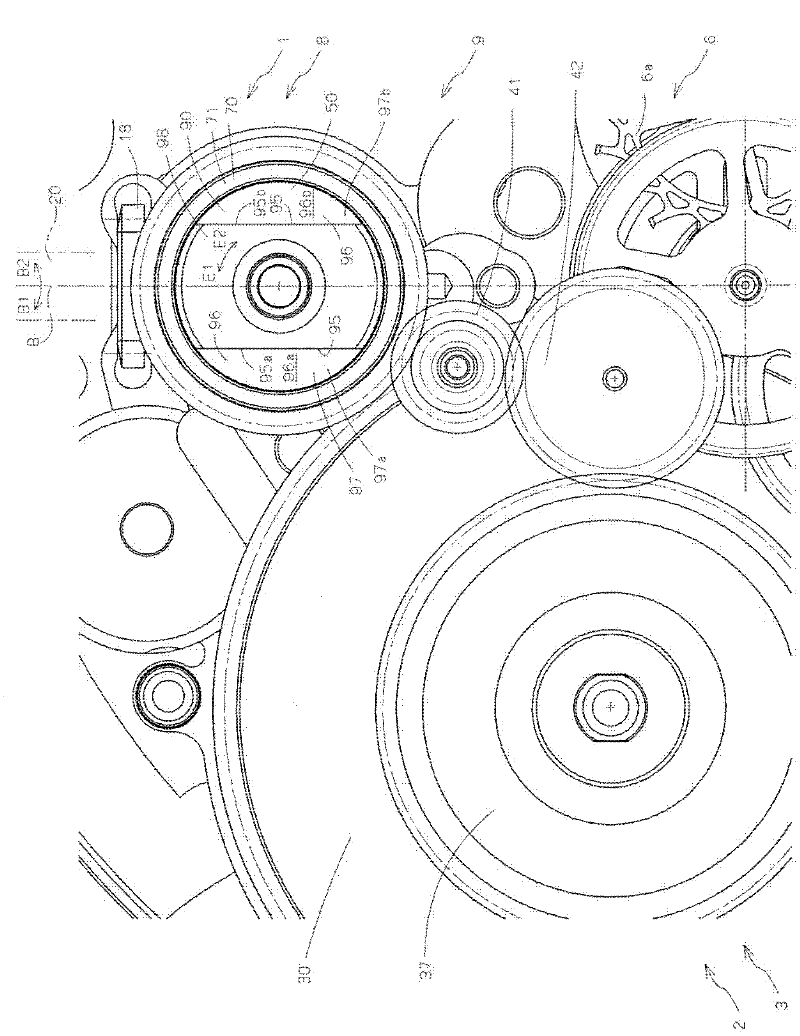

[0159] A hand-wound timepiece 3 of a preferred embodiment of the invention has a movement 2 of a preferred embodiment of the invention having figure 1 sectional illustration of and figure 2 The top view illustrates a hand-wound gear train 1 according to a preferred embodiment of the invention as shown.

[0160] From figure 1 It can be seen from the cross-sectional view of the timepiece 3 that the movement 2 of the timepiece 3 has a base plate 11 at the central part in the thickness direction D, and the winding stem (winding stem) 20 can move in and out in the directions A1 and A2 and can move around the central axis B in the directions B1 and B2. It is supported on the base plate 11 in a rotating manner.

[0161] The stem 20 has a large-diameter flange portion 21 , a large-diameter cylindrical portion 22 , a small-diameter portion 23 , a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com