Novel winding needle mechanism

A new type of winding needle technology, applied in the field of battery core winding, can solve the problems of difficult production, complex structure, poor reliability of diaphragm clamping, etc., to simplify winding action, reduce deformation, and improve production efficiency and technology. horizontal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

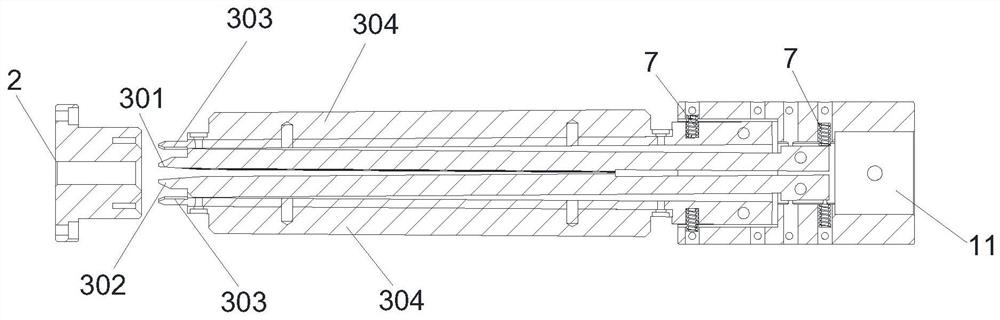

[0019] Special Note, Figure 5 The arrow on the left indicates the movement direction of the needle nozzle, and the arrow on the right indicates the movement direction of the needle rolling assembly. Figure 6 Arrows indicate the direction of insertion.

[0020] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

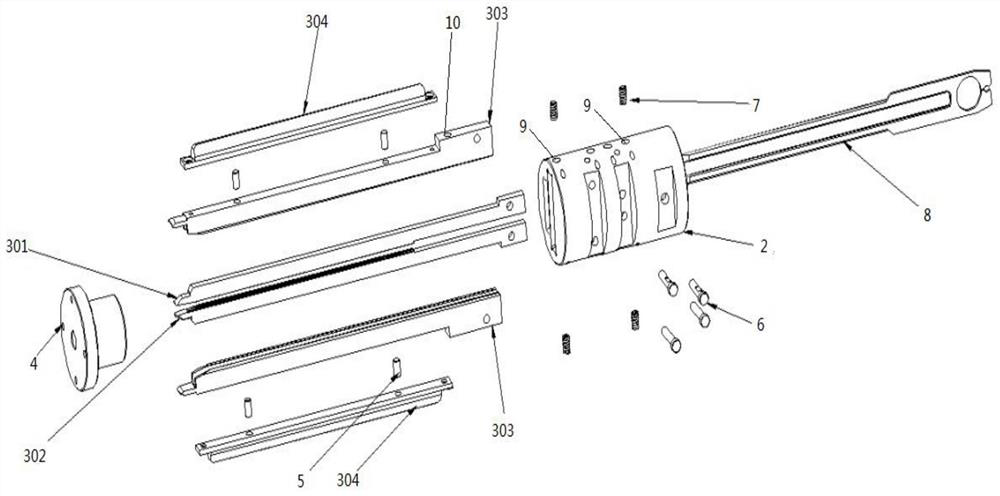

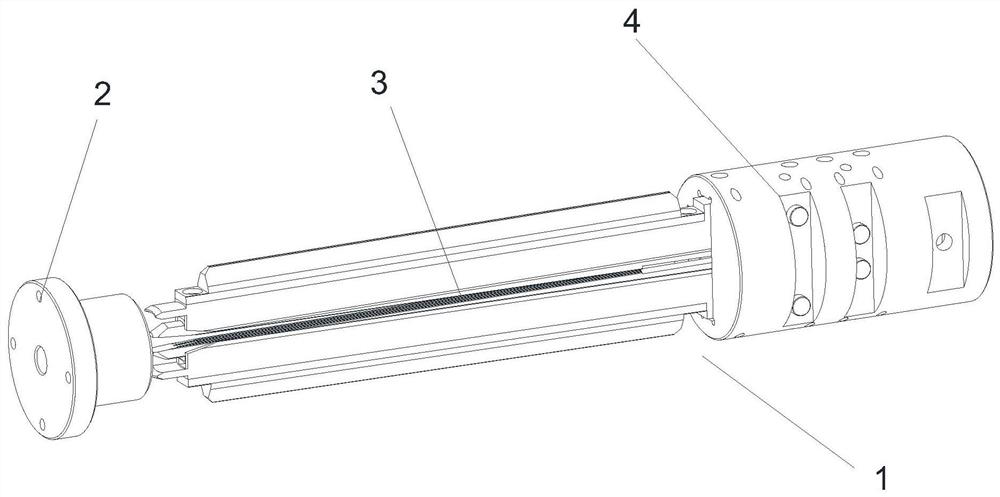

[0021] As shown in Figure 1-6, the structure setting of a new type of needle rolling mechanism provided by this embodiment:

[0022] Structural main body 1, the structural main body 1 is composed of a needle roll connector 2, a needle roll assembly 3 and a needle tip 4, the needle tip 4 is arranged at the head end of the needle roll assembly 3, and the needle roll connector 2 Located at the tail end of the needle roller assembly 3, the needle roller assembly 3 includes a first inner needle 301, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com