Hose reel system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

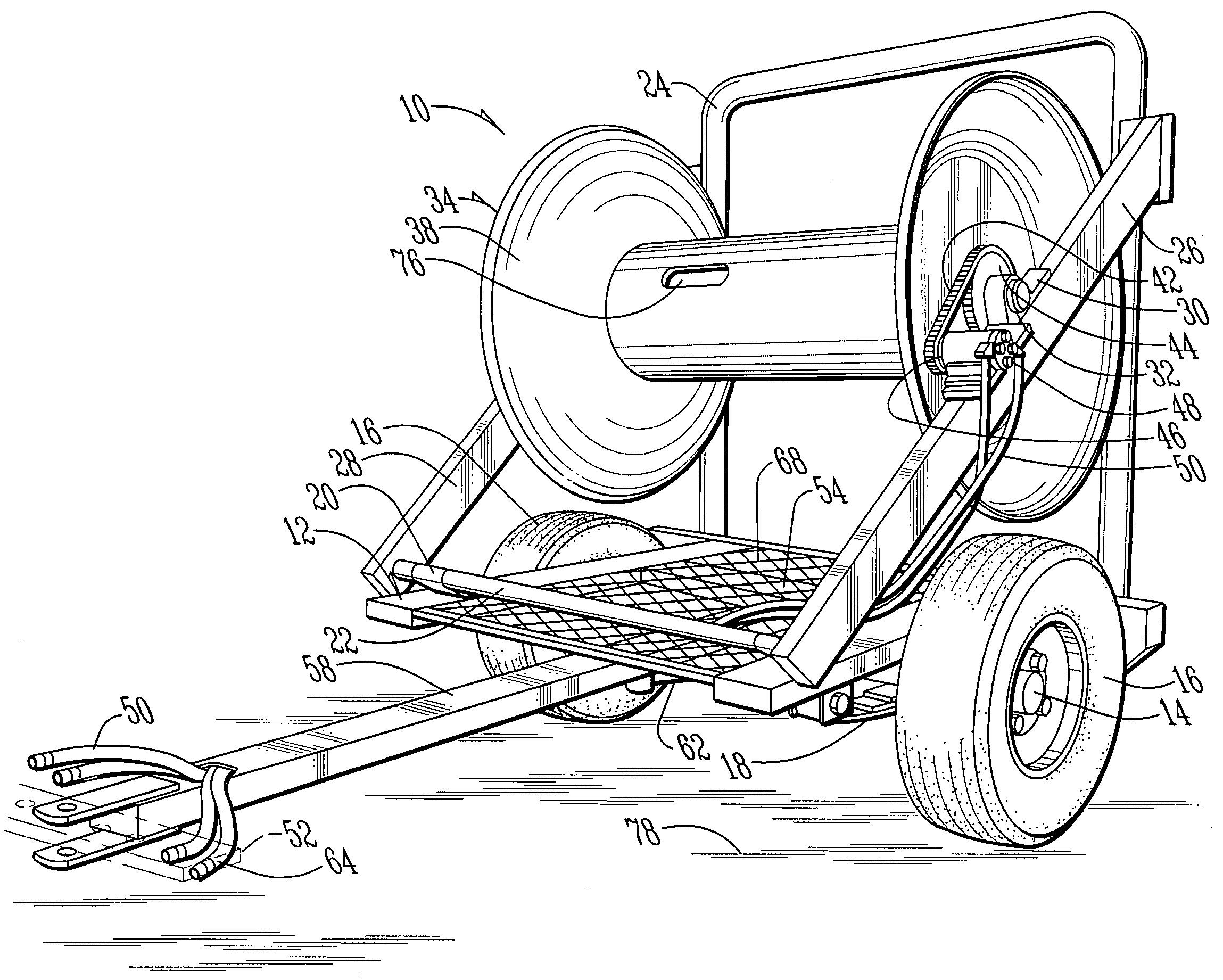

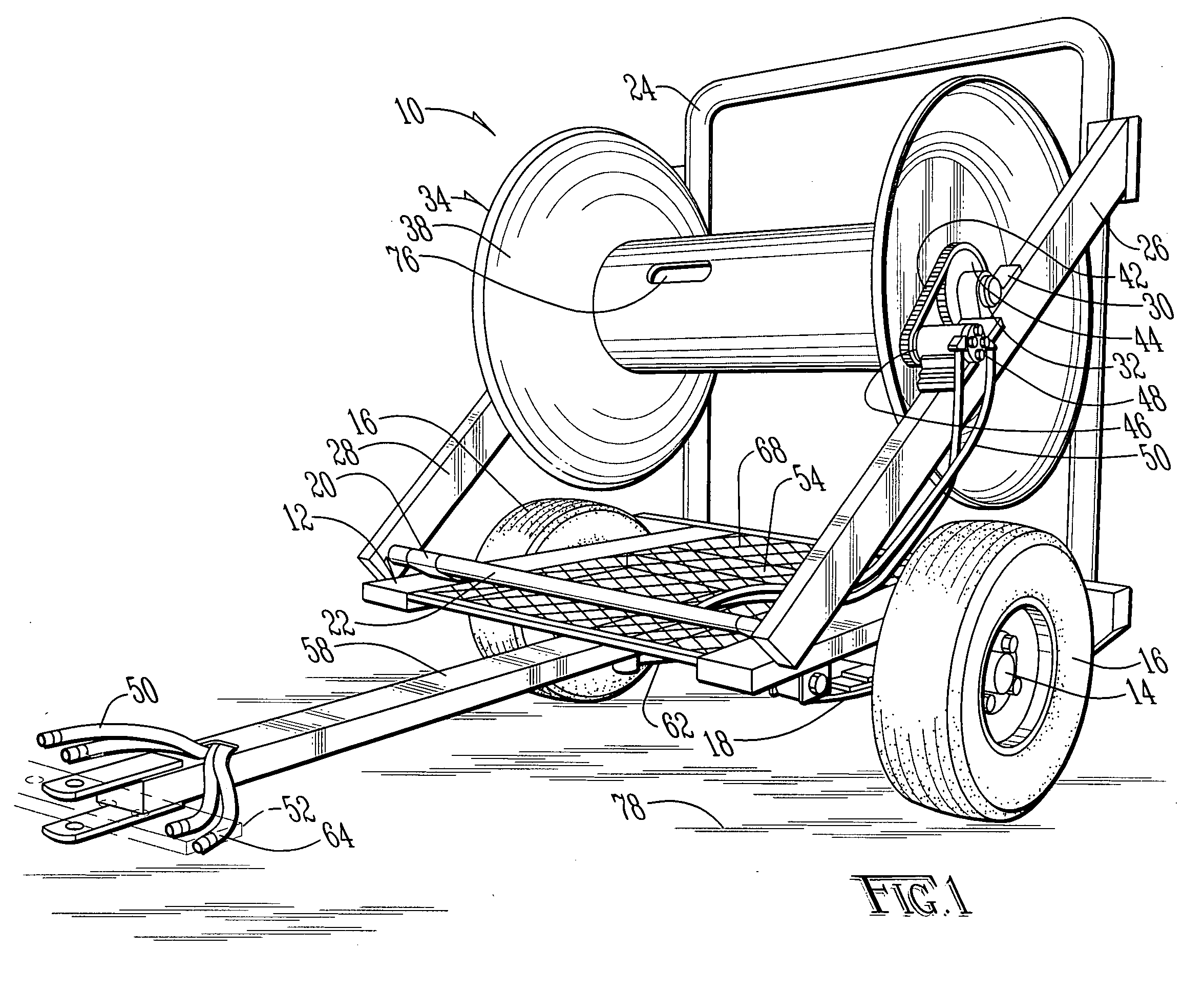

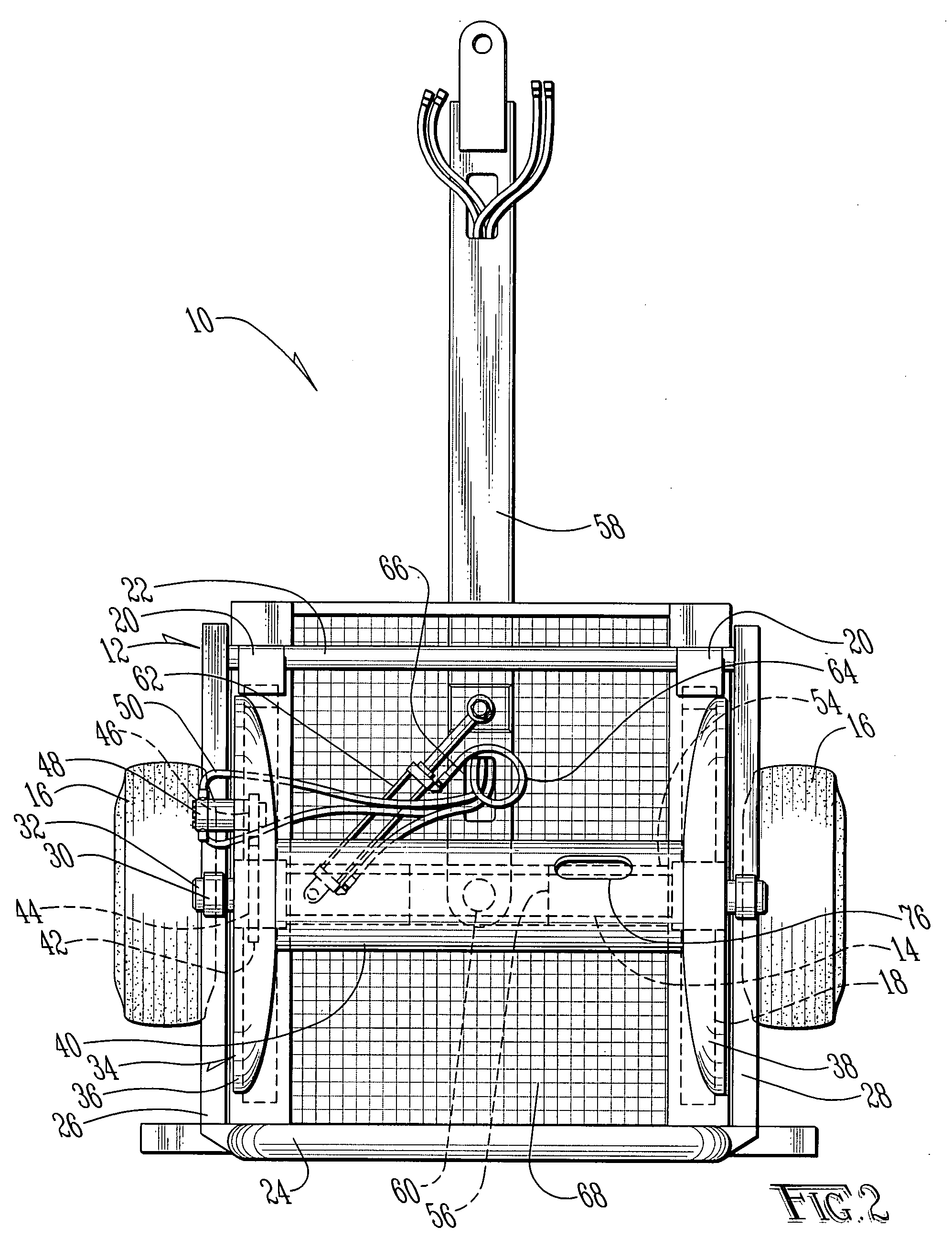

[0021]A hose reel according to the present invention is shown generally as (10) in FIG. 1. The hose reel (10) includes a frame (12). Journaled to the frame (12) is an axle (14) coupled to a pair of wheels (16). The axle (14) is coupled to the frame (12) by leaf springs (18), such as those known in the art.

[0022]Provided on the frame are a pair of support bars (20), supporting a shoulder (22). Coupled between the shoulder (22) and an arch guard (24) are a first angled support arm (26) and a second angled support arm (28). Provided on the angled support arms (26) and (28) are support brackets (30). Journaled between the support brackets (30) is an axle (32) around which is journaled a spool (34). The spool (34) includes a first curved dome (36) and a second curved dome (38), coupled to one another by a sleeve (40). Secured to the spool (34) is a large gear (42). The large gear (42) is coupled by a chain (44) to a small gear (46). As shown in FIG. 1, the small gear is driven by a hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com