Common mode inductor

A common-mode inductance and magnetic core technology, applied in the field of inductance coils, can solve the problems of loose winding and magnetic flux leakage, and achieve the effects of low cost, high inductance and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will now be further described in conjunction with specific examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention.

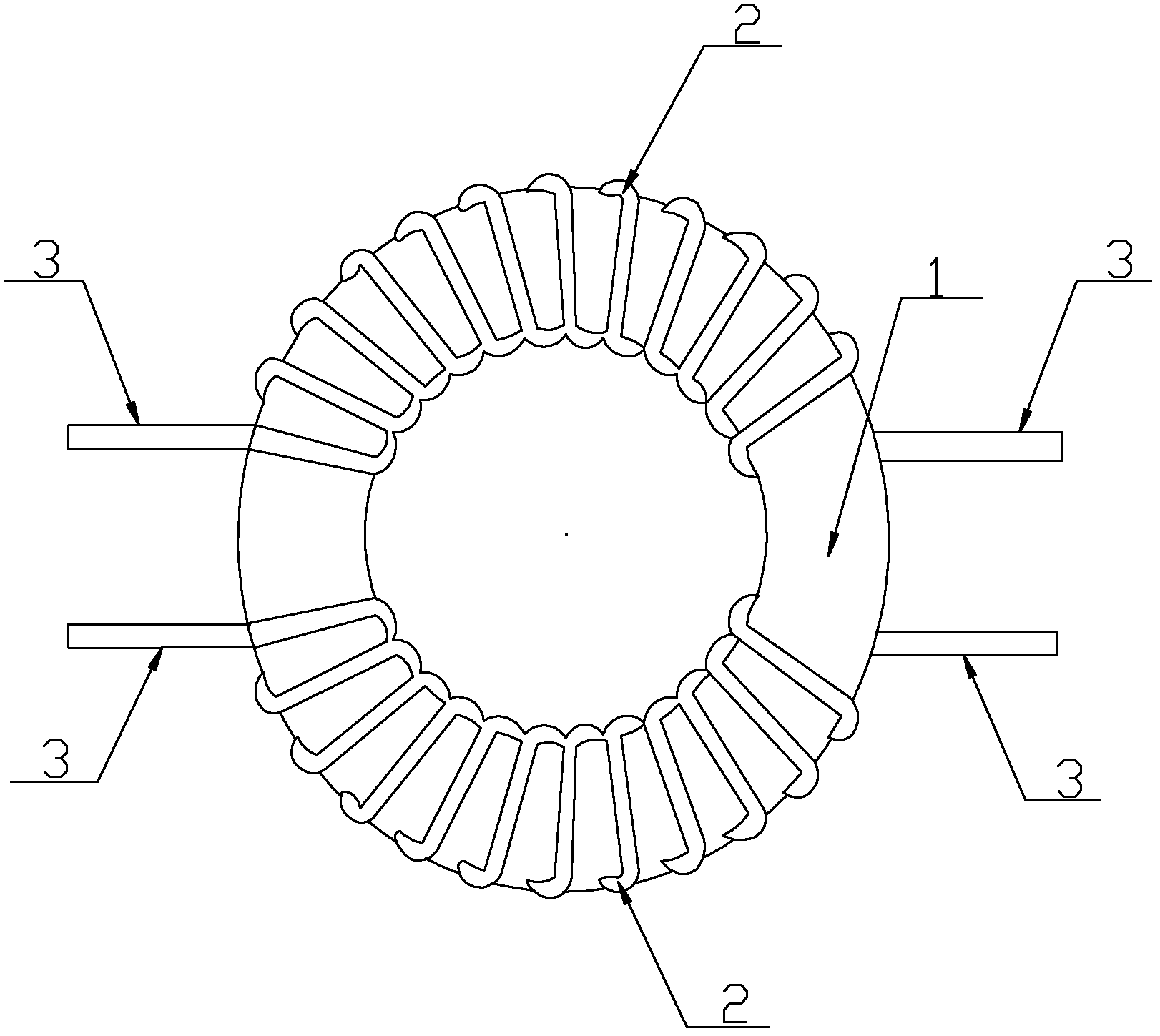

[0011] Such as figure 1 The common mode inductor shown includes a magnetic core 1, two coils 2 wound on the magnetic core 1, and four terminals 3. The two coils 2 have the same size, the same number of turns, and opposite winding directions. The magnetic core 2 It is a ferrite ring magnetic core, and the coil 2 is an insulated wire, which is wound on the magnetic core 1 in a single layer.

[0012] There is an insulating layer between the magnetic core 1 and the coil 2 to prevent breakdown between the two under the action of instantaneous overvoltage.

[0013] During specific implementation, when the normal current in the circuit flows through the common-mode inductor, the current generates a reverse magnetic field in the inductance coil 2 wound in the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com