Patents

Literature

218 results about "Toroidal coil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A toroid is a coil of insulated or enameled wire wound on a donut-shaped form made of powdered iron. A toroid is used as an inductor in electronic circuits, especially at low frequencies where comparatively large inductances are necessary.

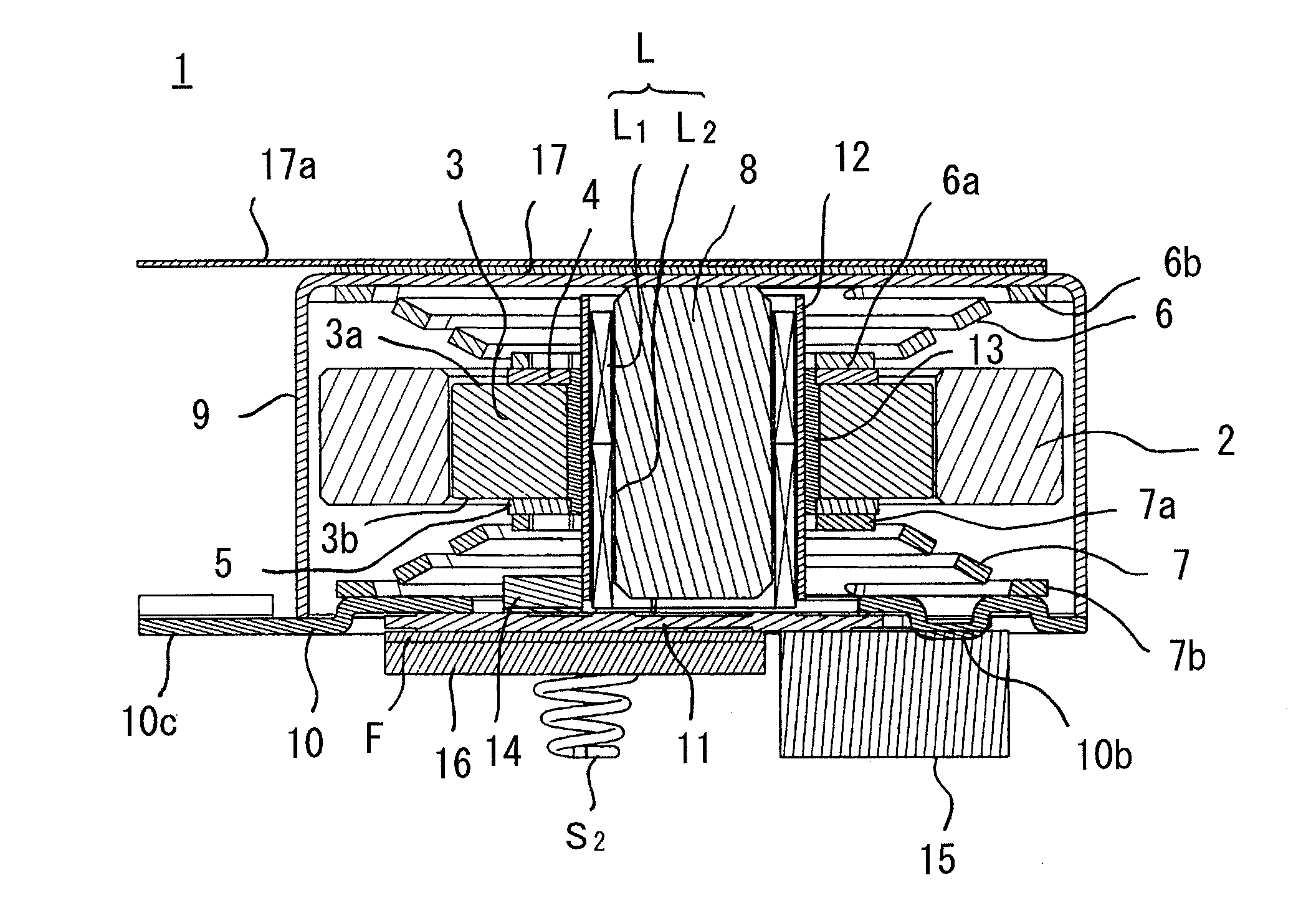

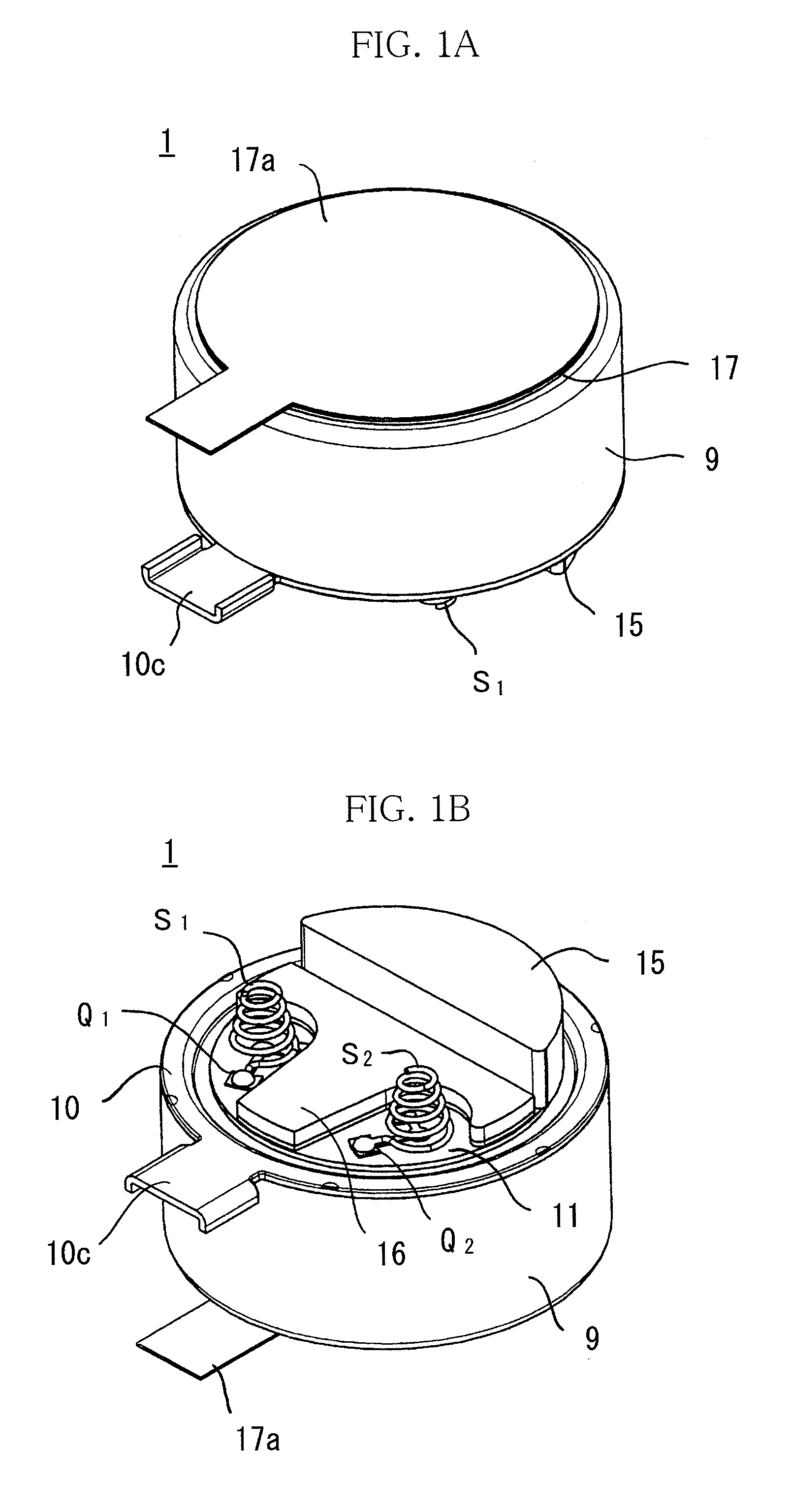

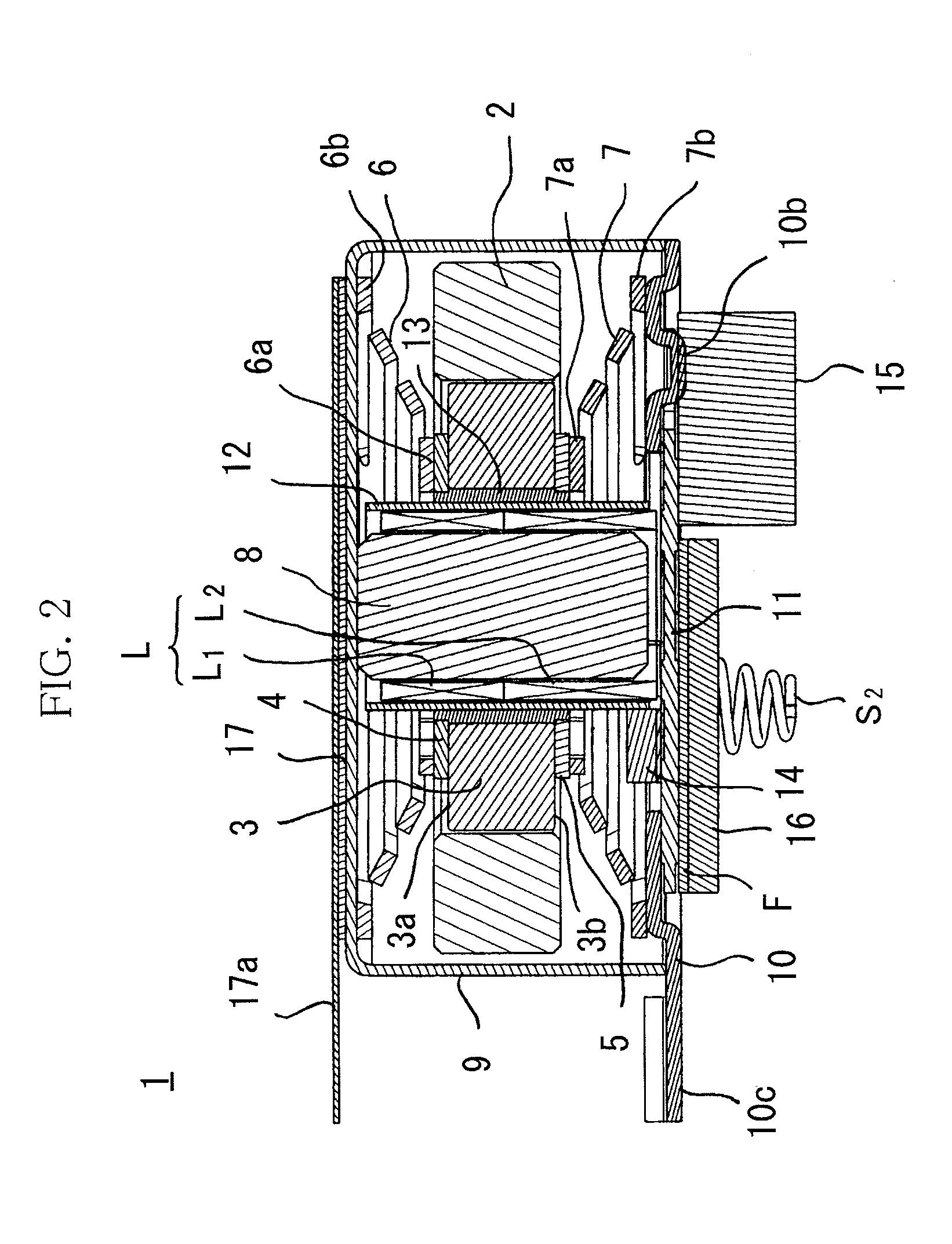

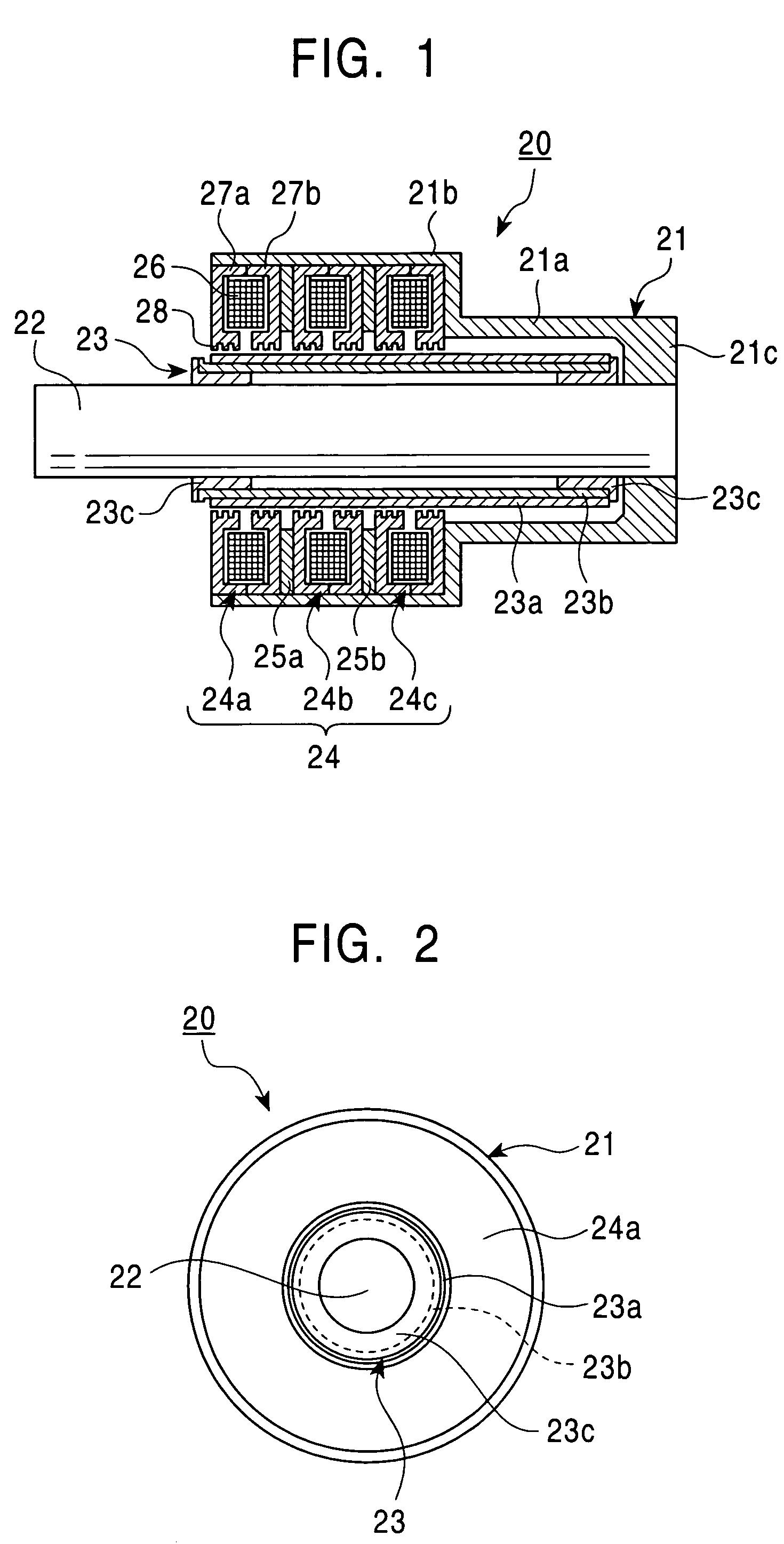

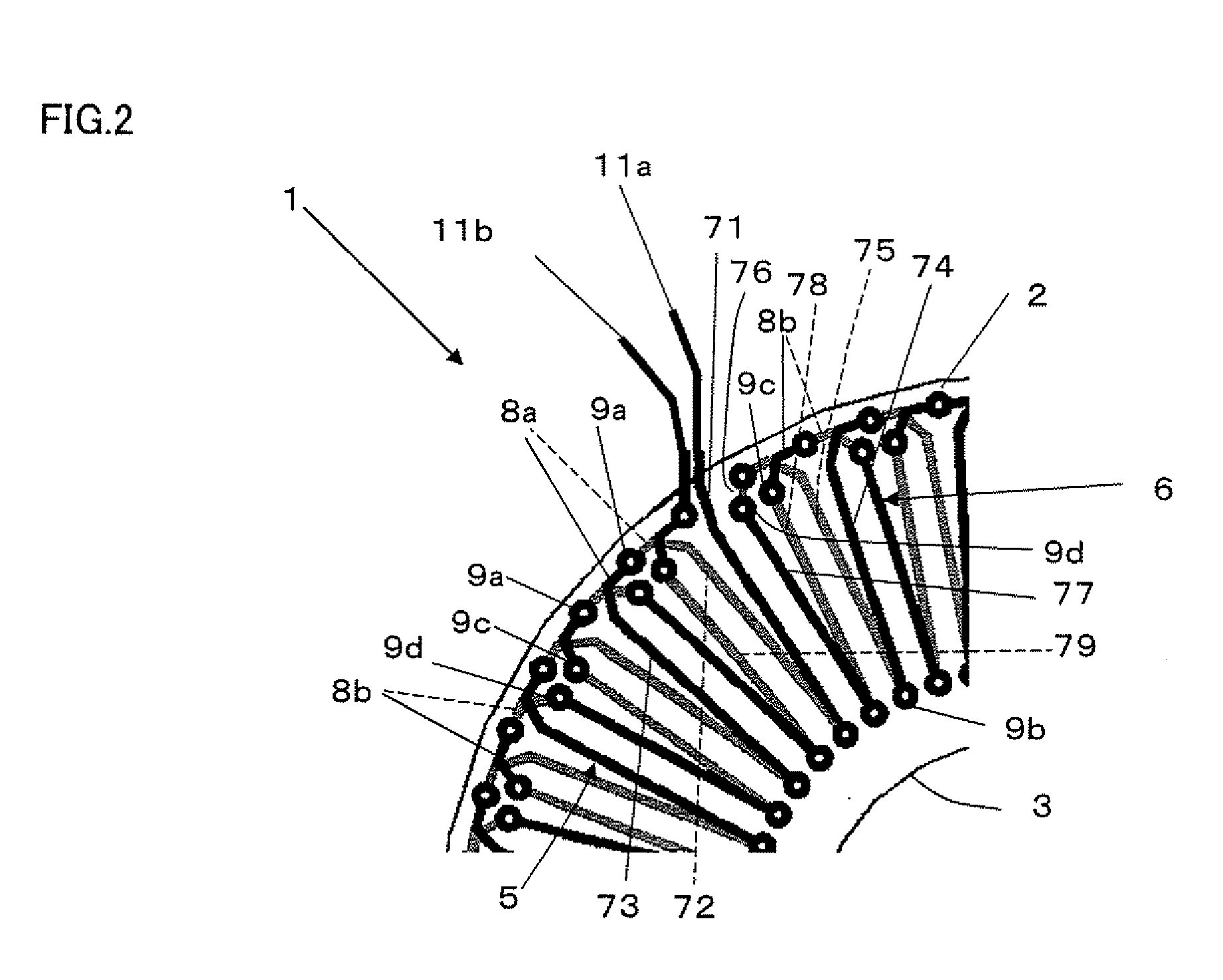

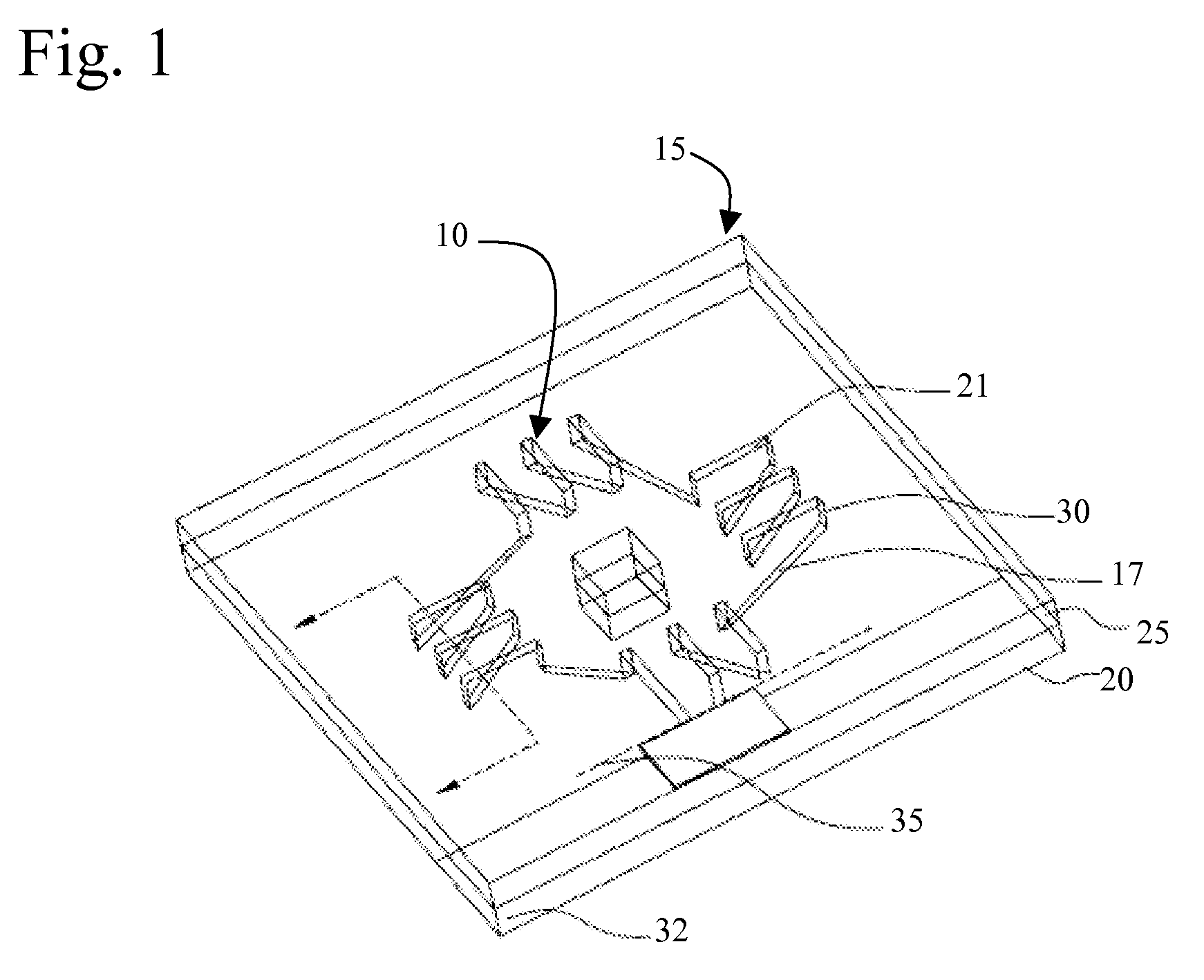

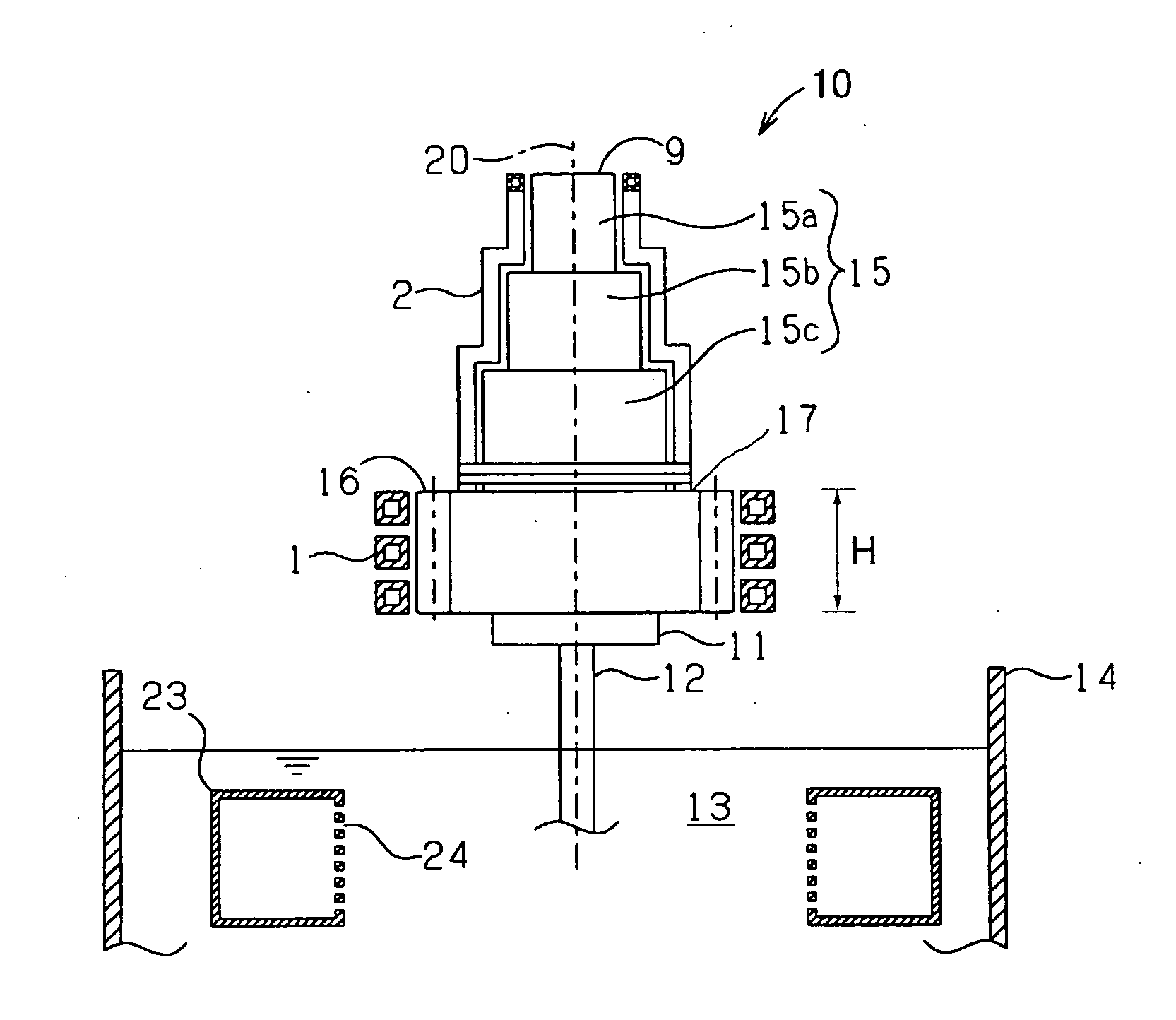

Vibration generator

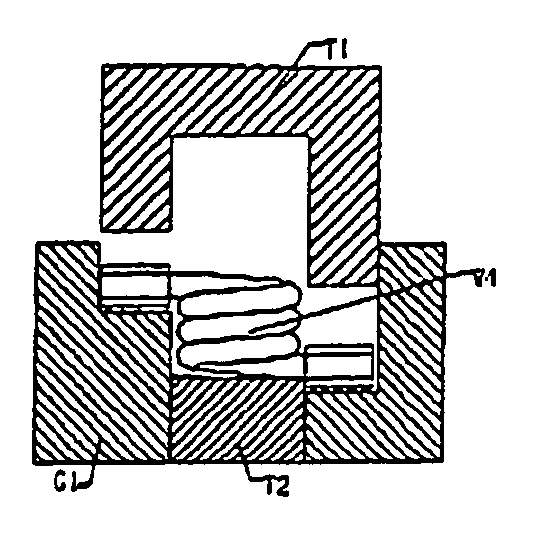

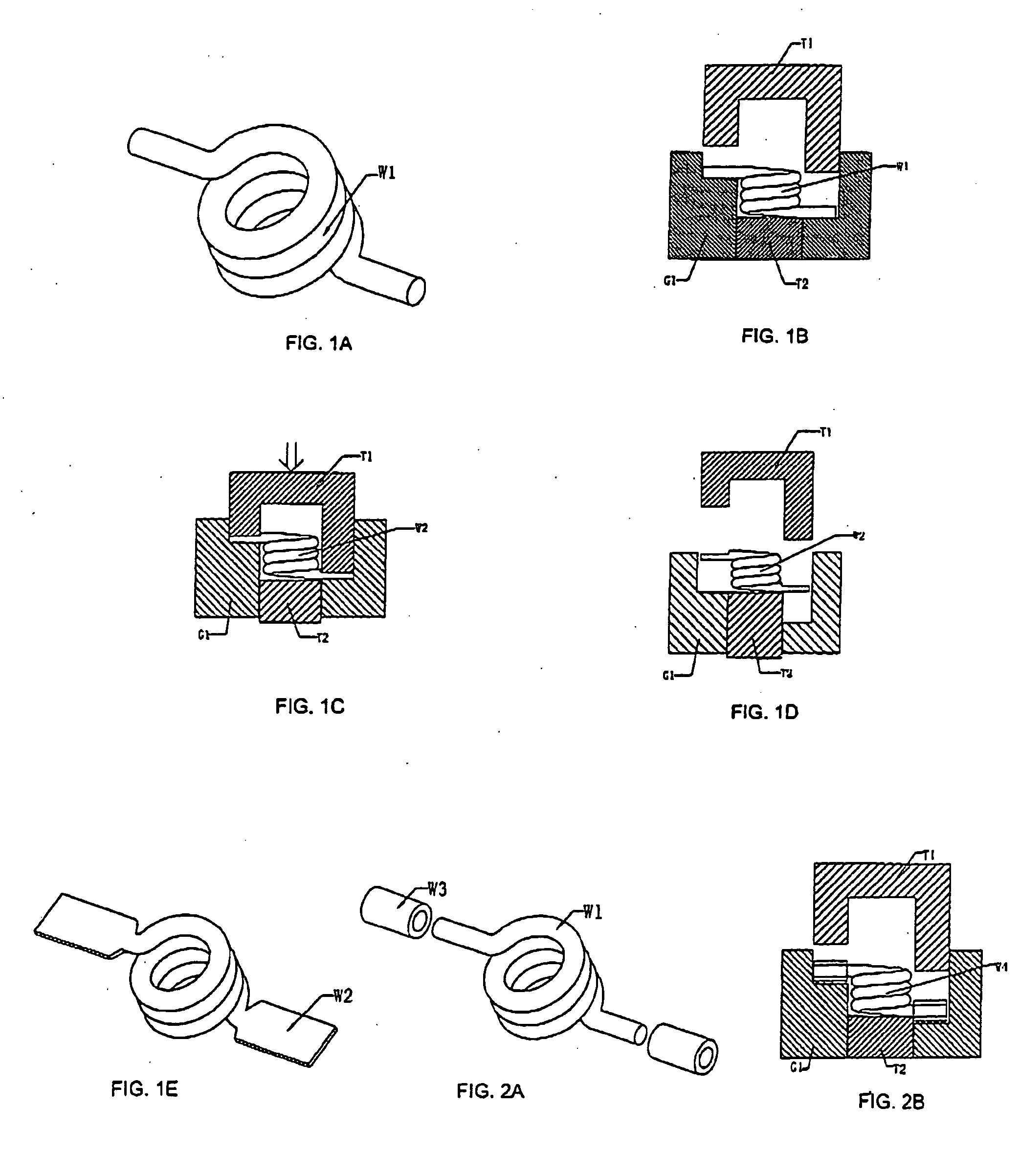

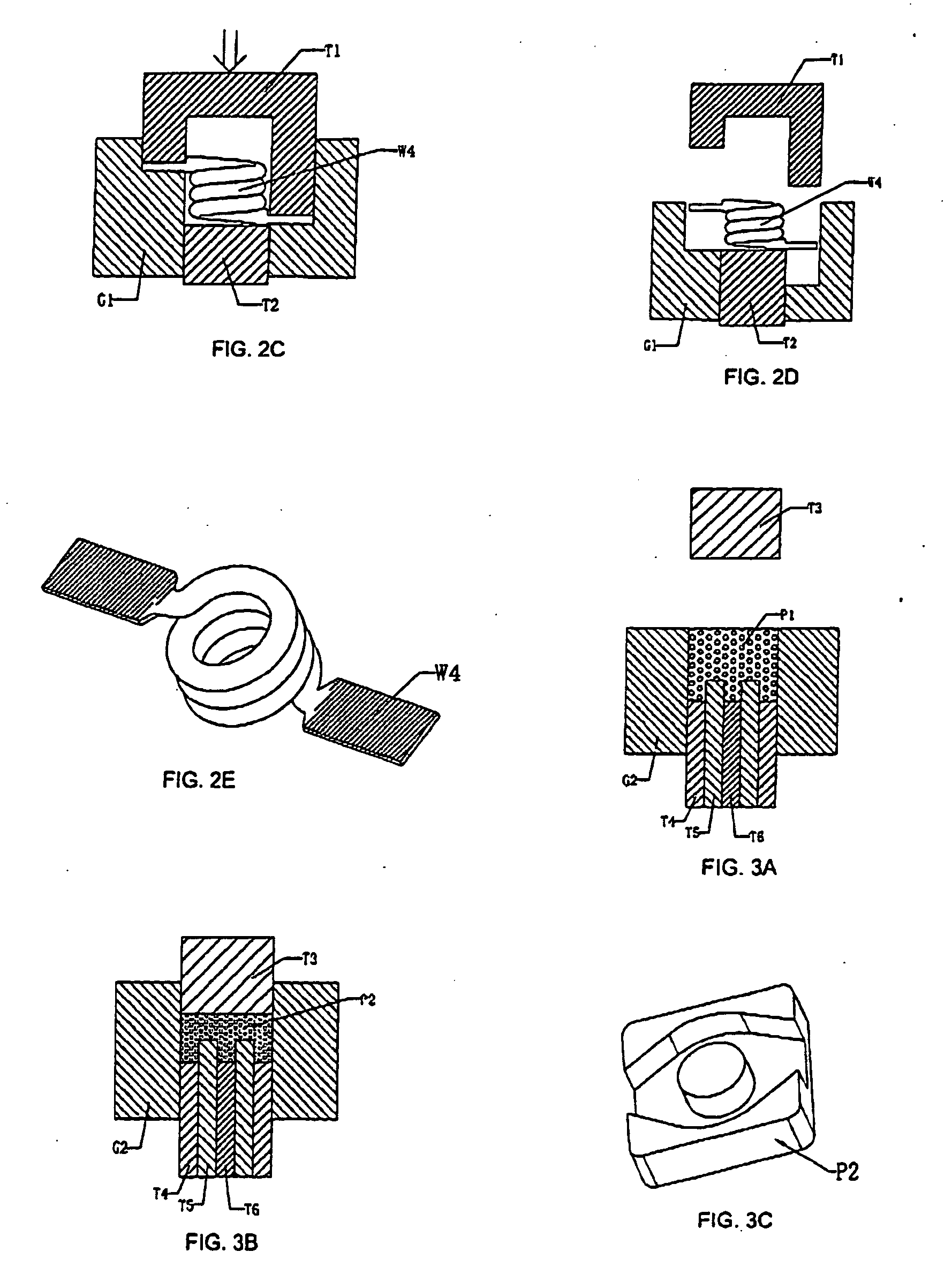

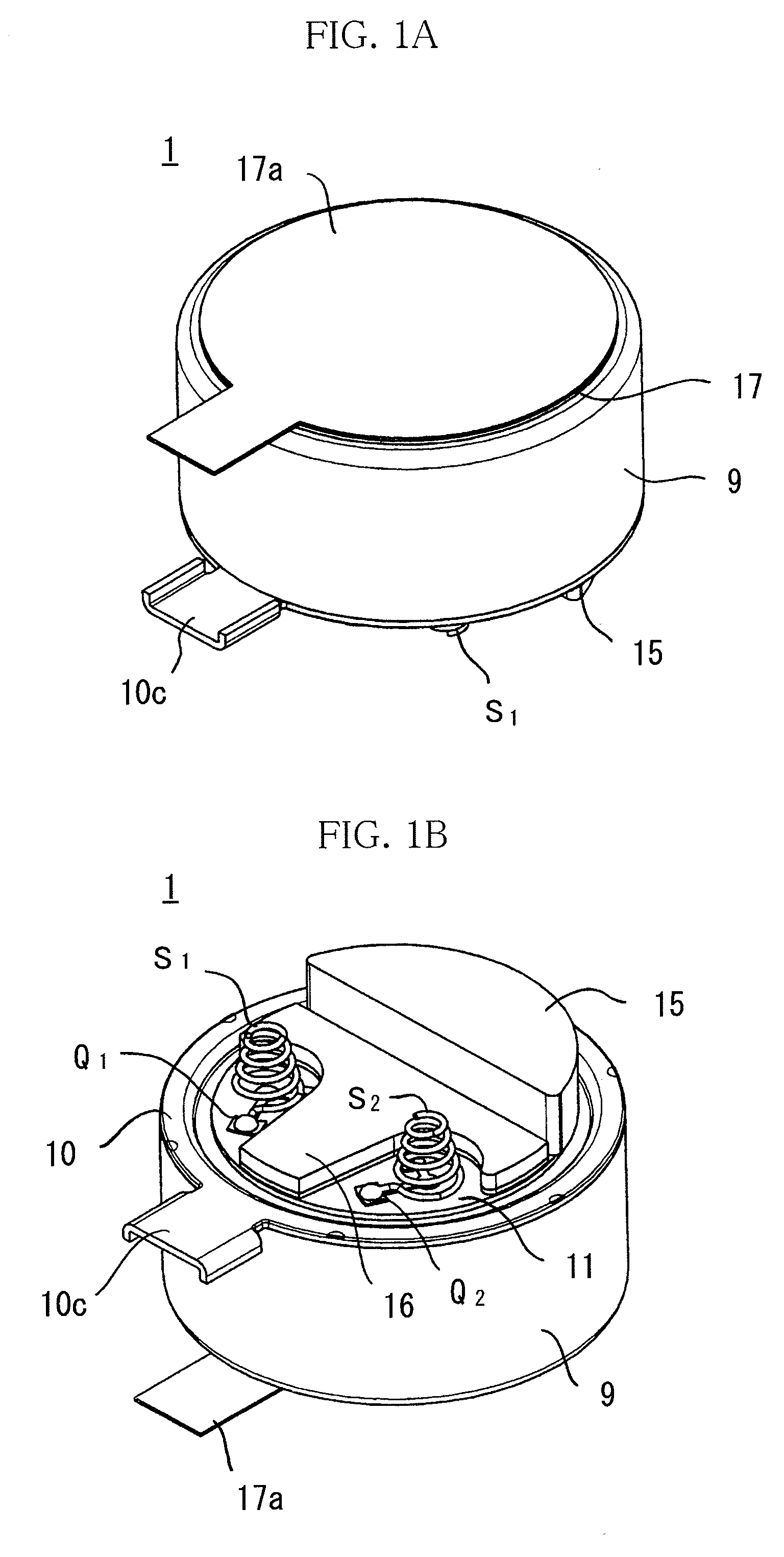

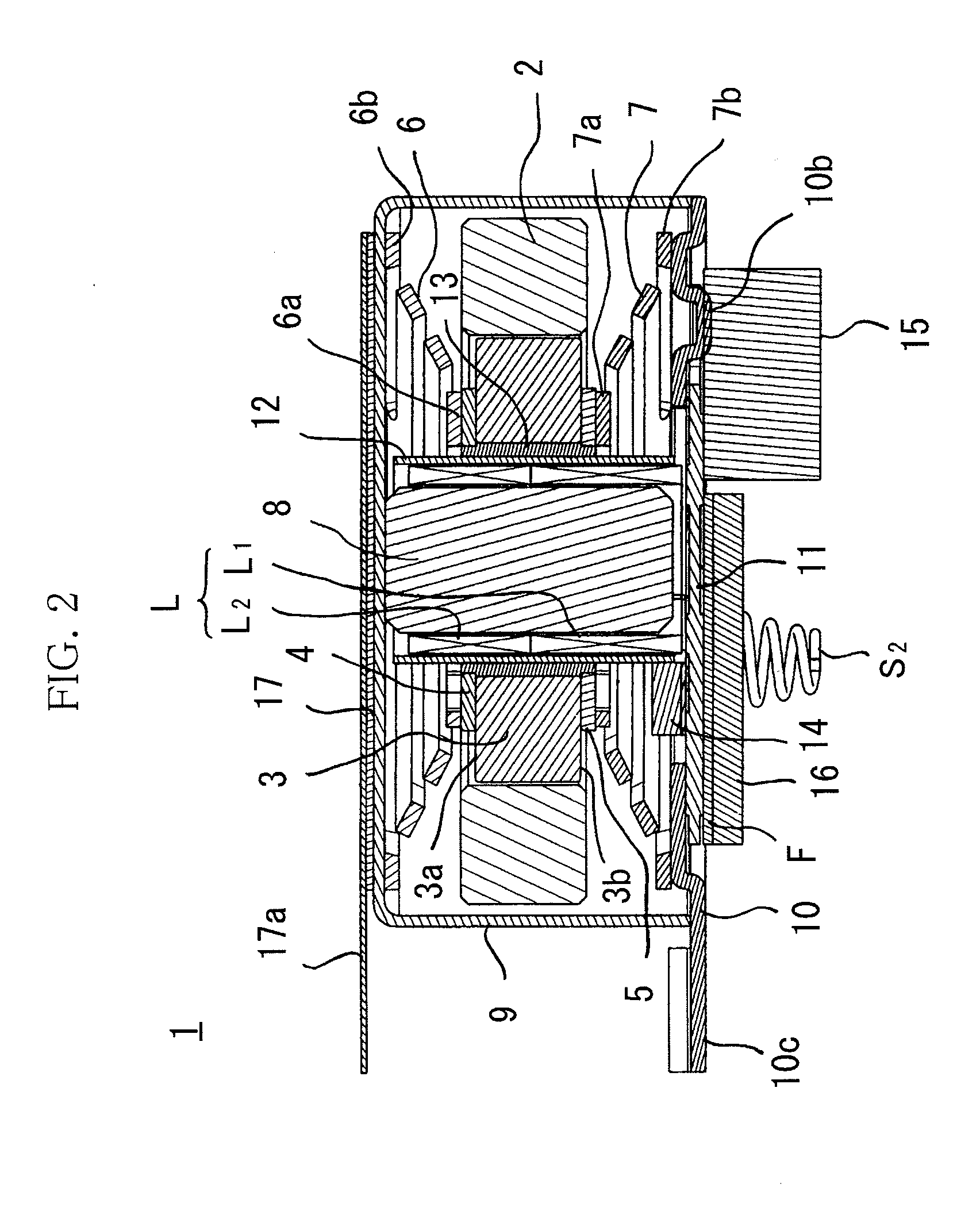

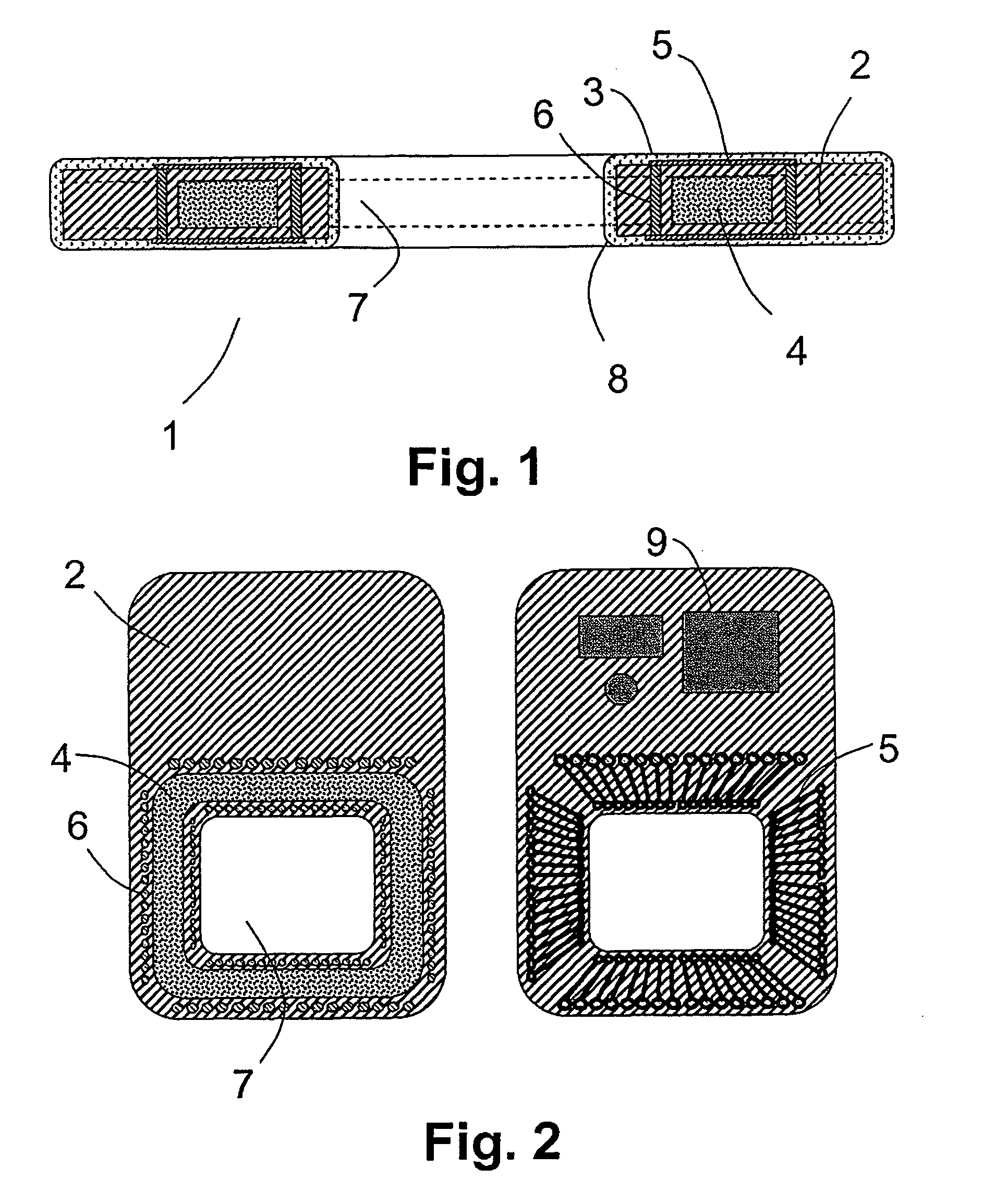

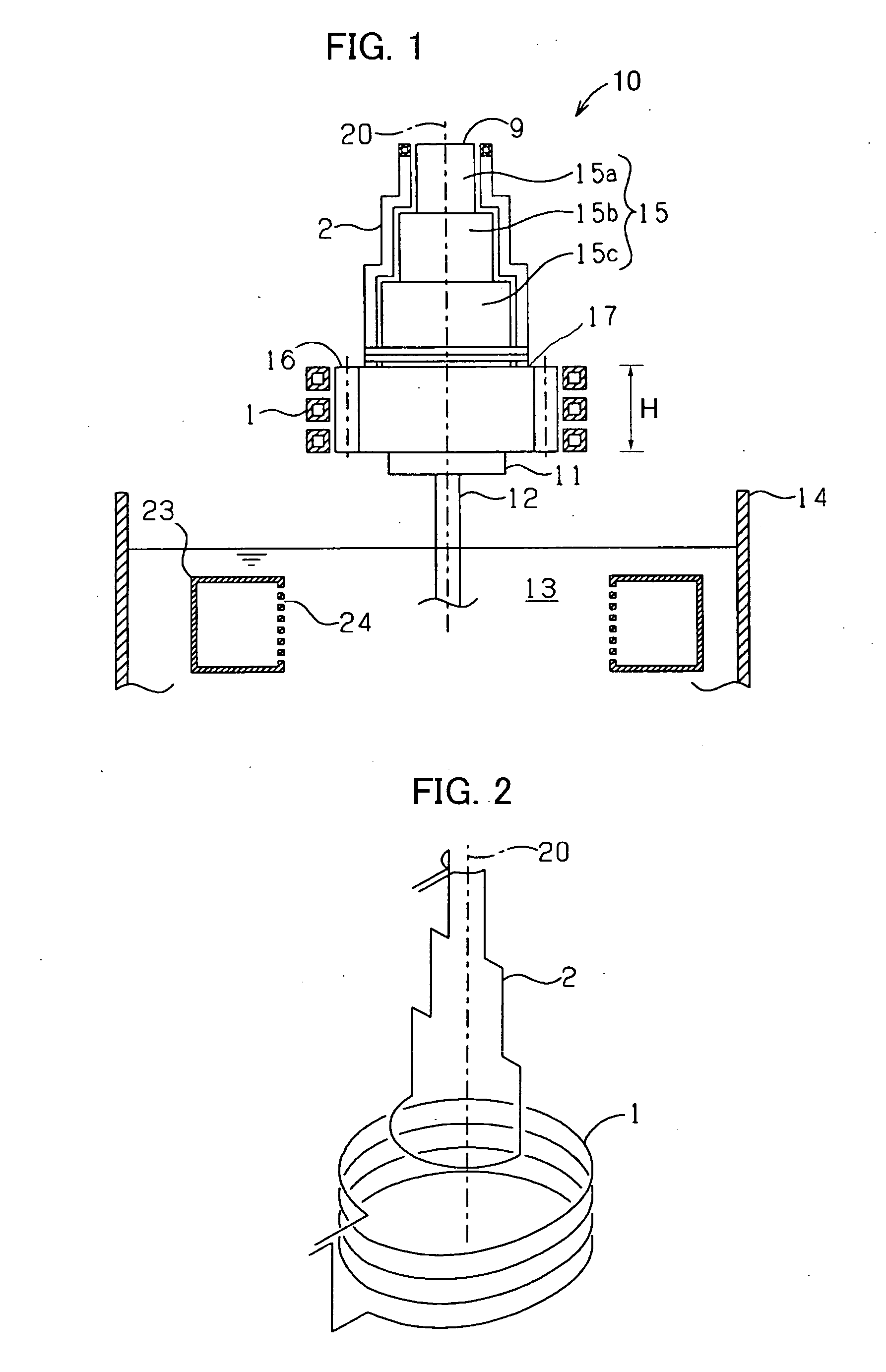

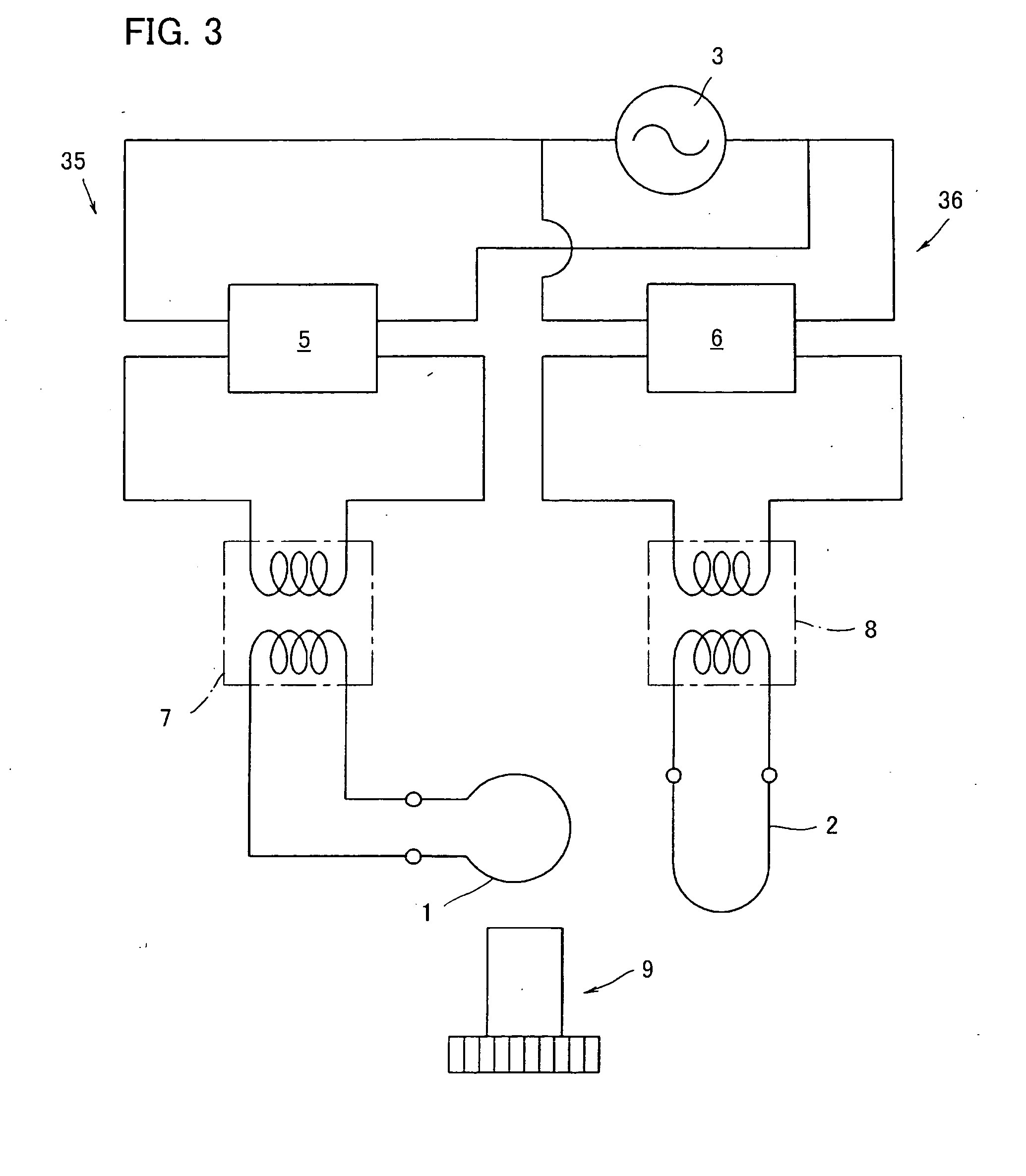

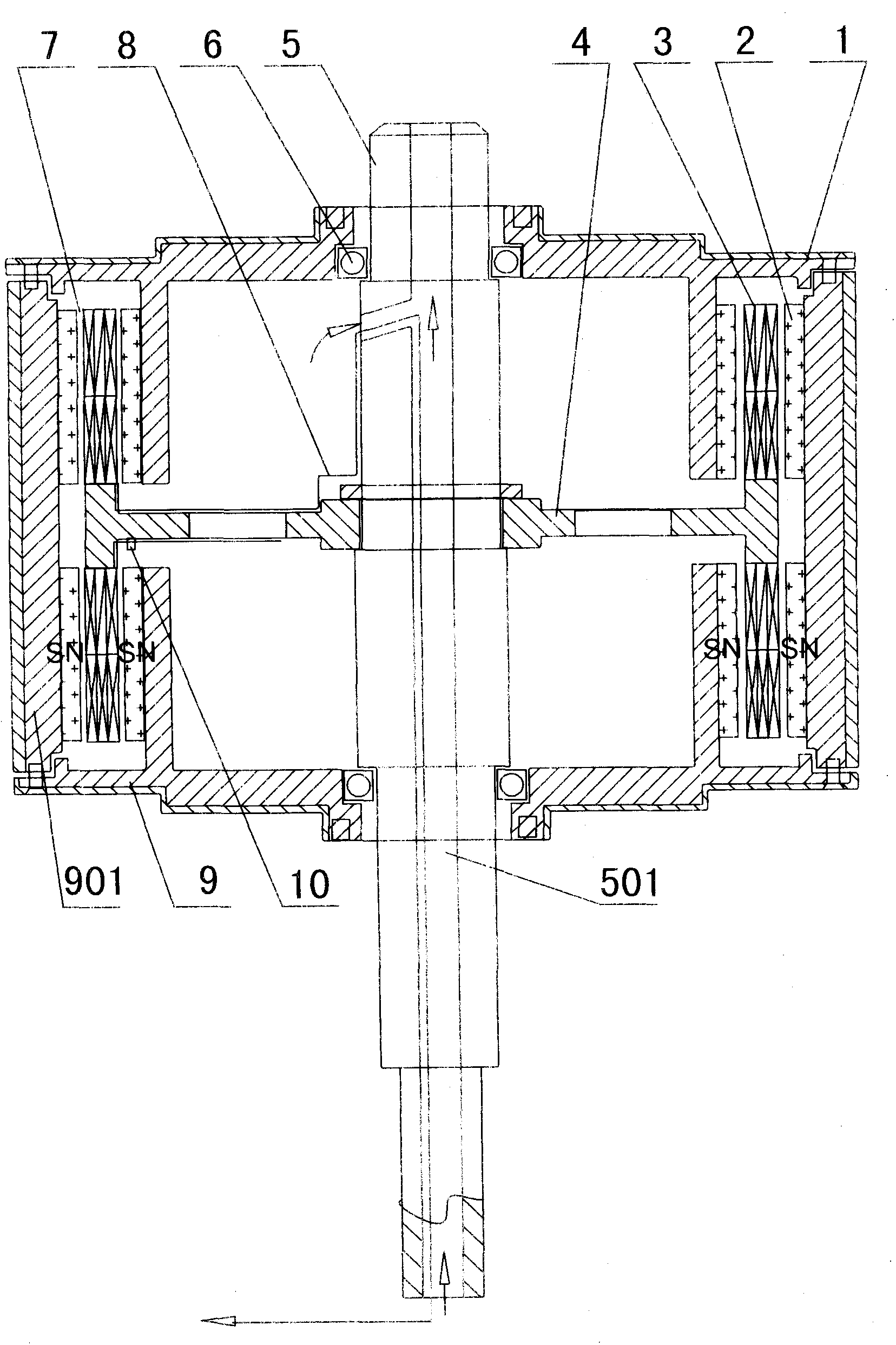

A vibration generator making a closed loop of a magnetic circuit of a permanent magnet to obtain a high vibrating force while kept small in size, including a reciprocating vibrator having a ring-shaped permanent magnet in a center hole of a ring-shaped weight, a first and second plate springs supporting this reciprocating vibrator at a recessed case and end plate to be able to elastically displace in a thickness direction spanning a first and a second end faces, a tubular toroidal coil passing through a center hole of the permanent magnet and generating a reciprocating vibrating magnetic field for reciprocatingly driving the permanent magnet in the thickness direction, and a columnar core passing through this toroidal coil, the ring-shaped permanent magnet being magnetized in the thickness direction, and the toroidal coil having a lower toroidal coil and an adjoining reversely wound series connected upper toroidal coil coaxial with the same.

Owner:SANYO SEIMITSU

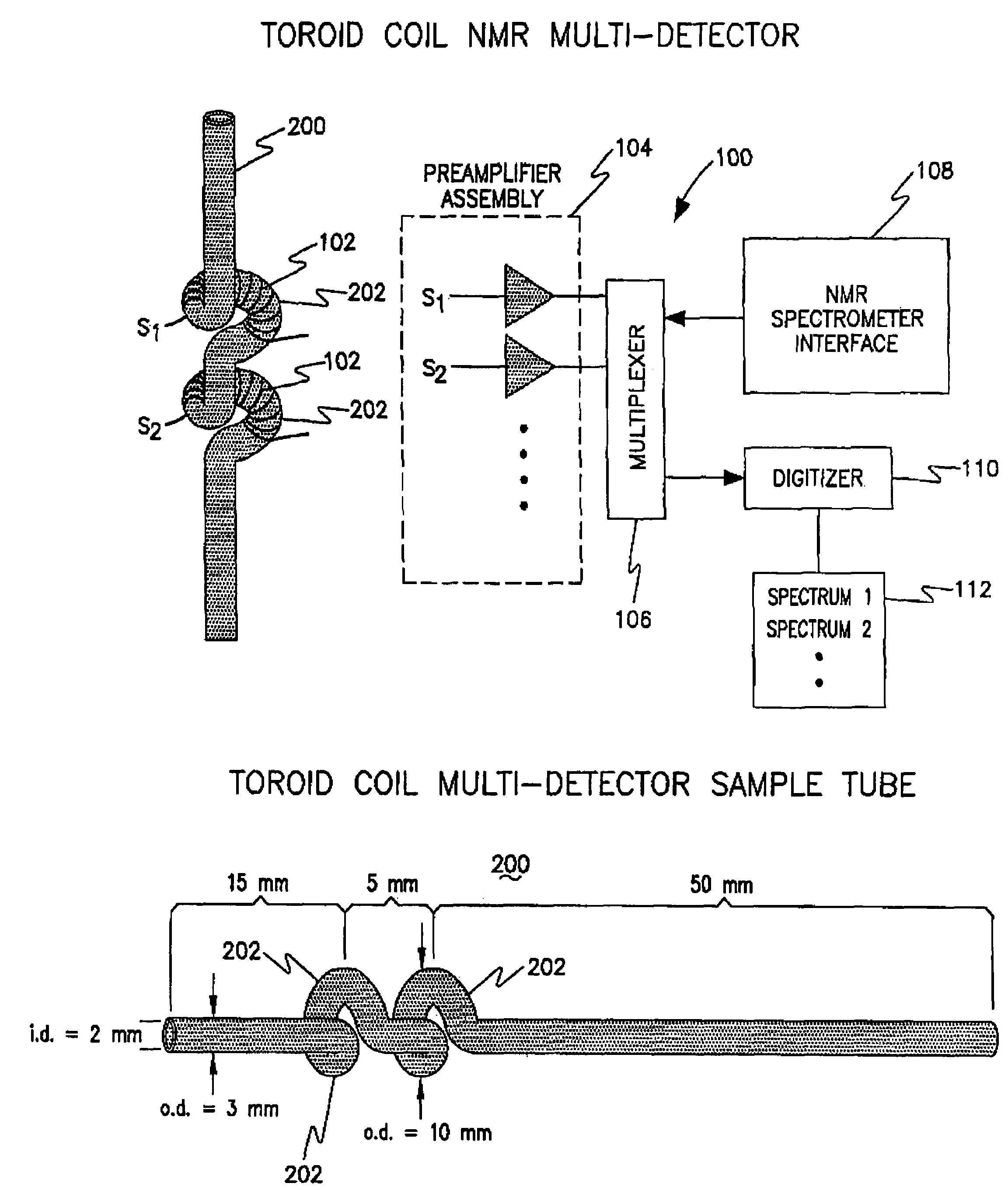

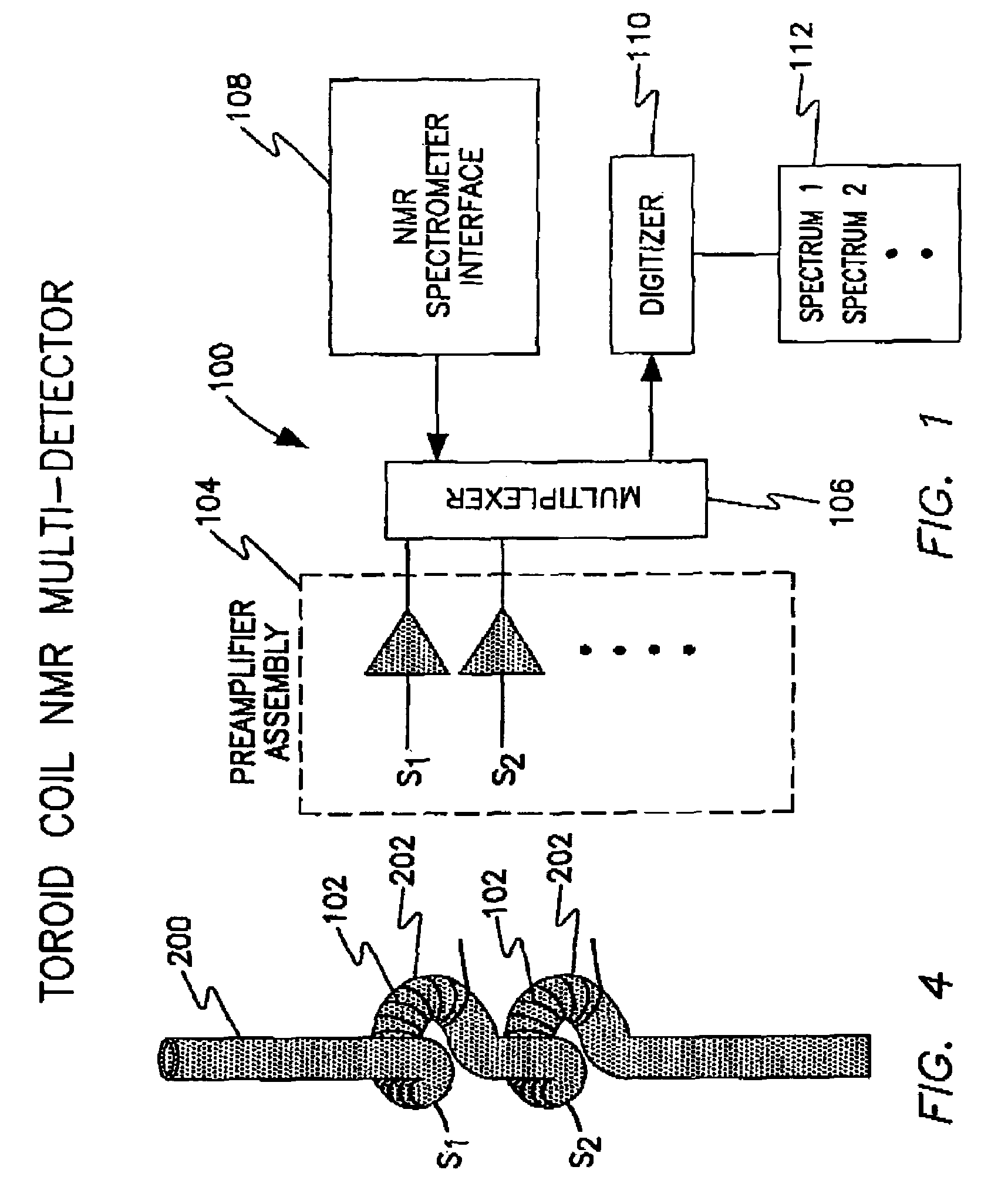

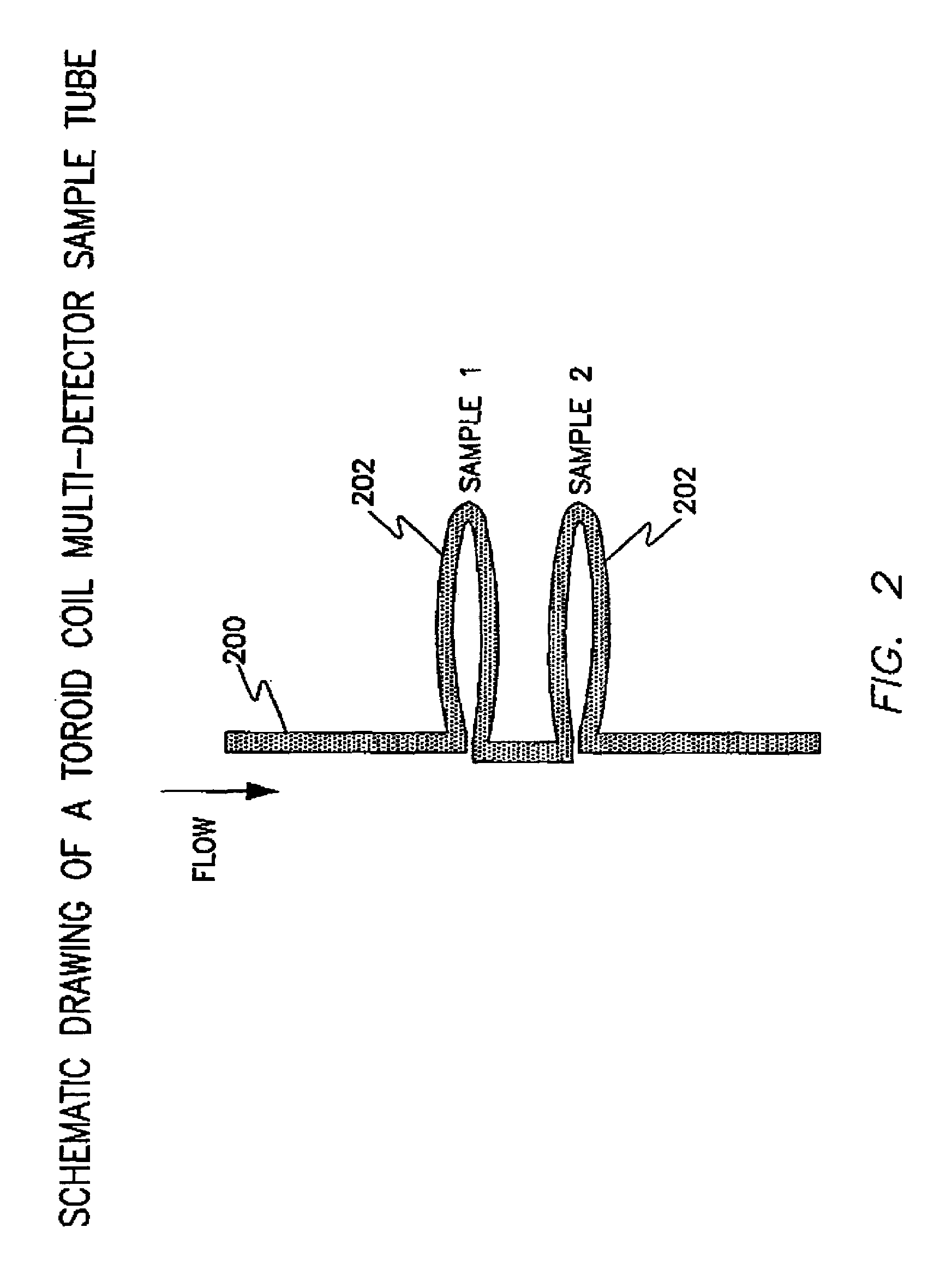

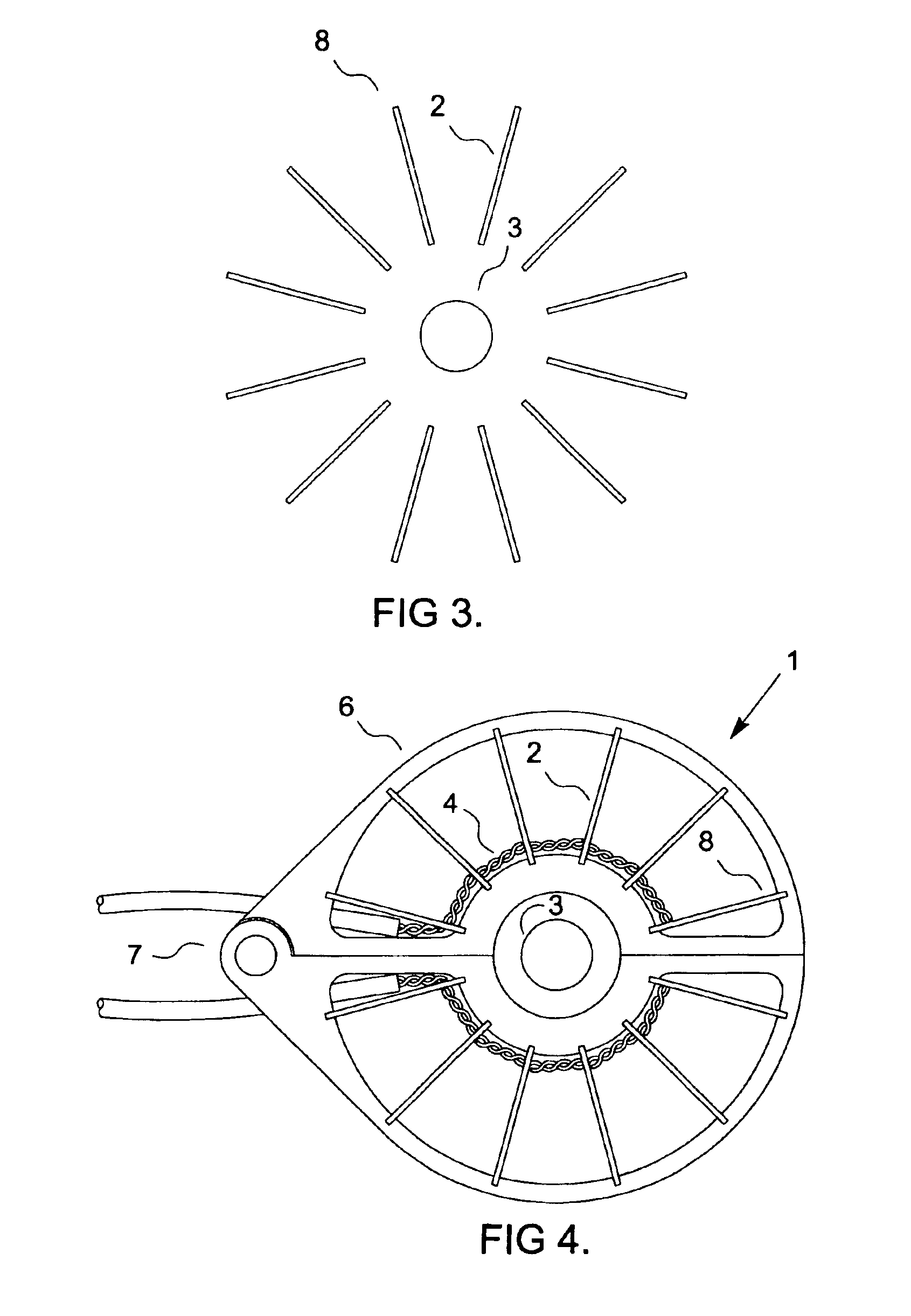

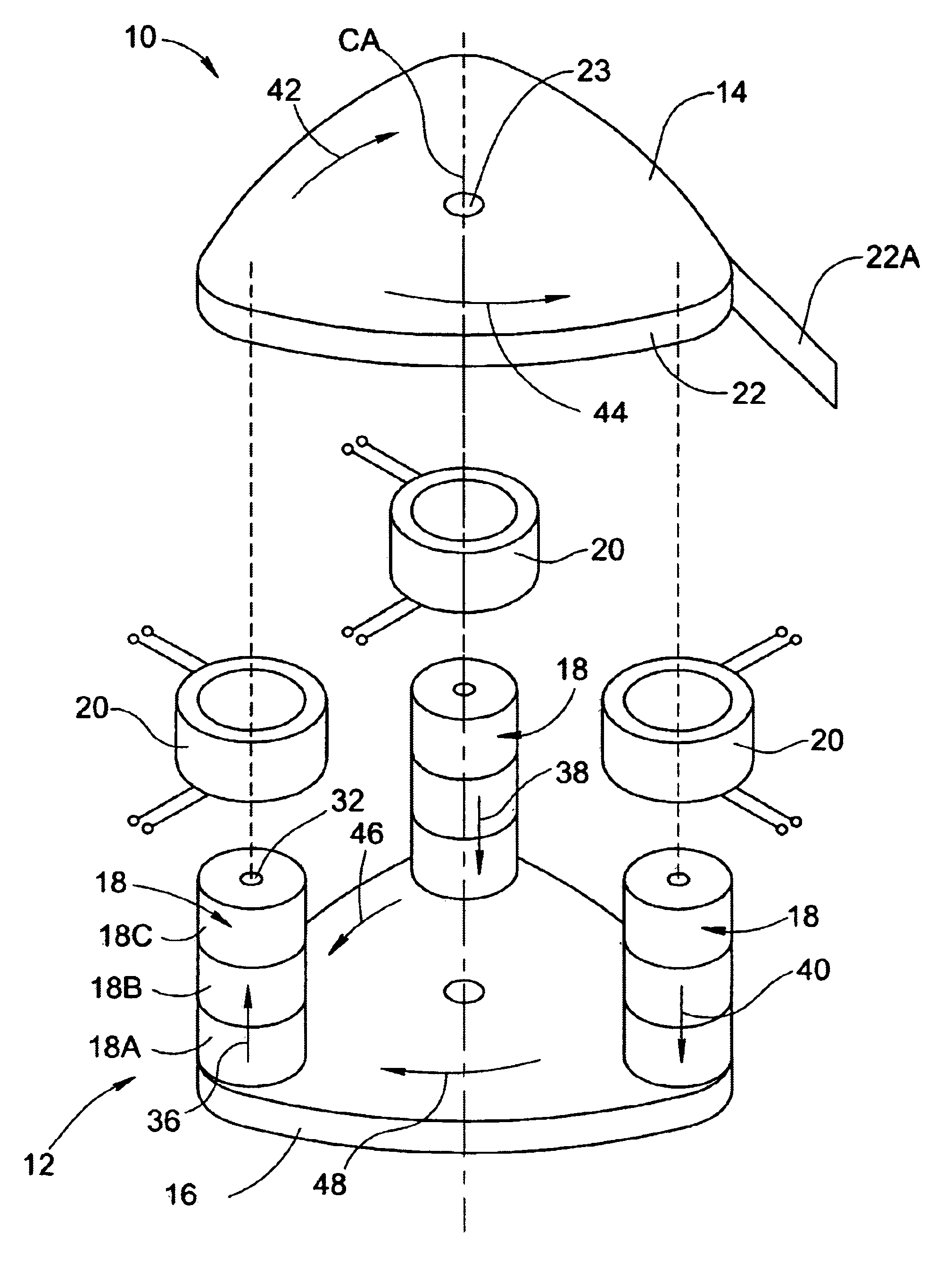

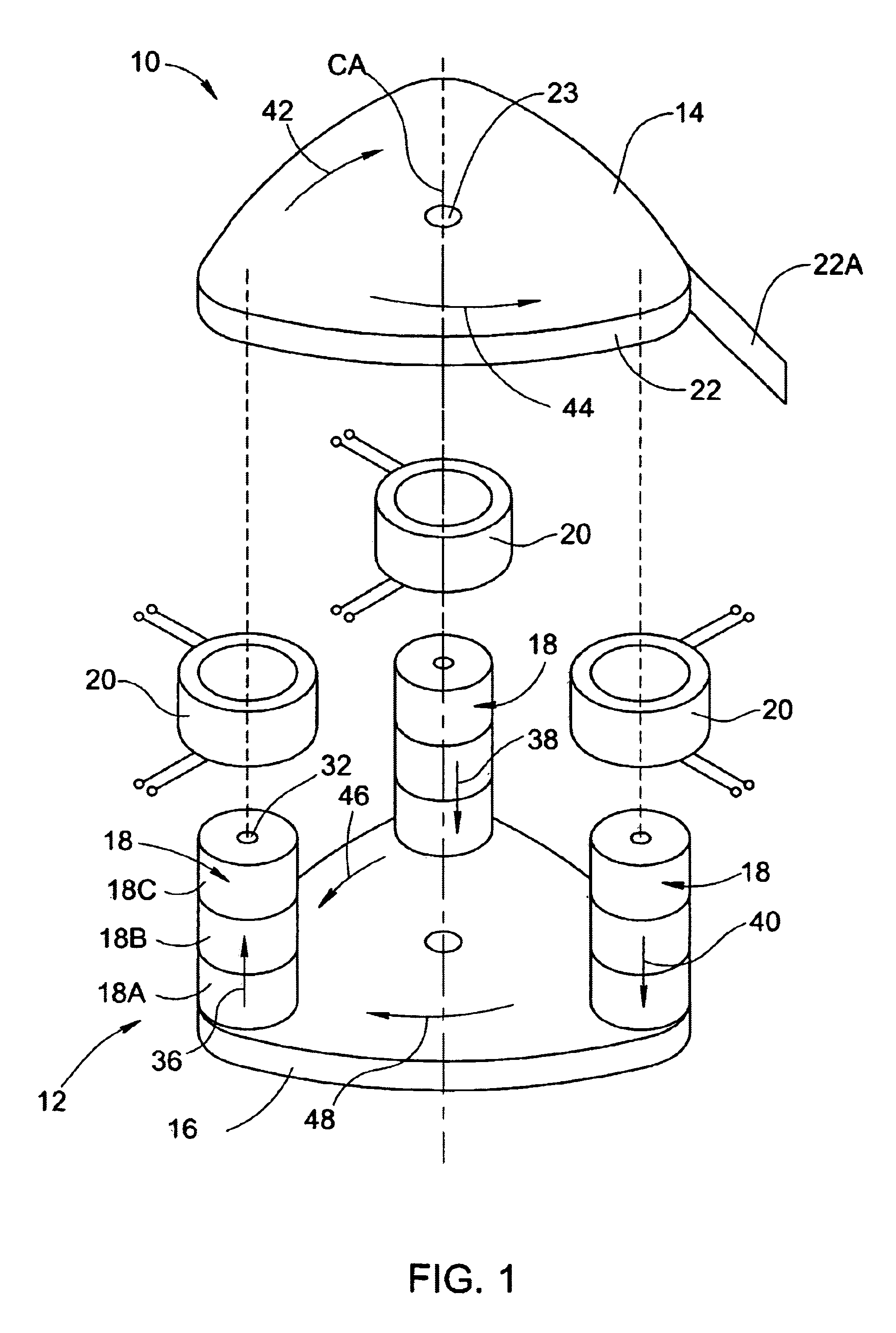

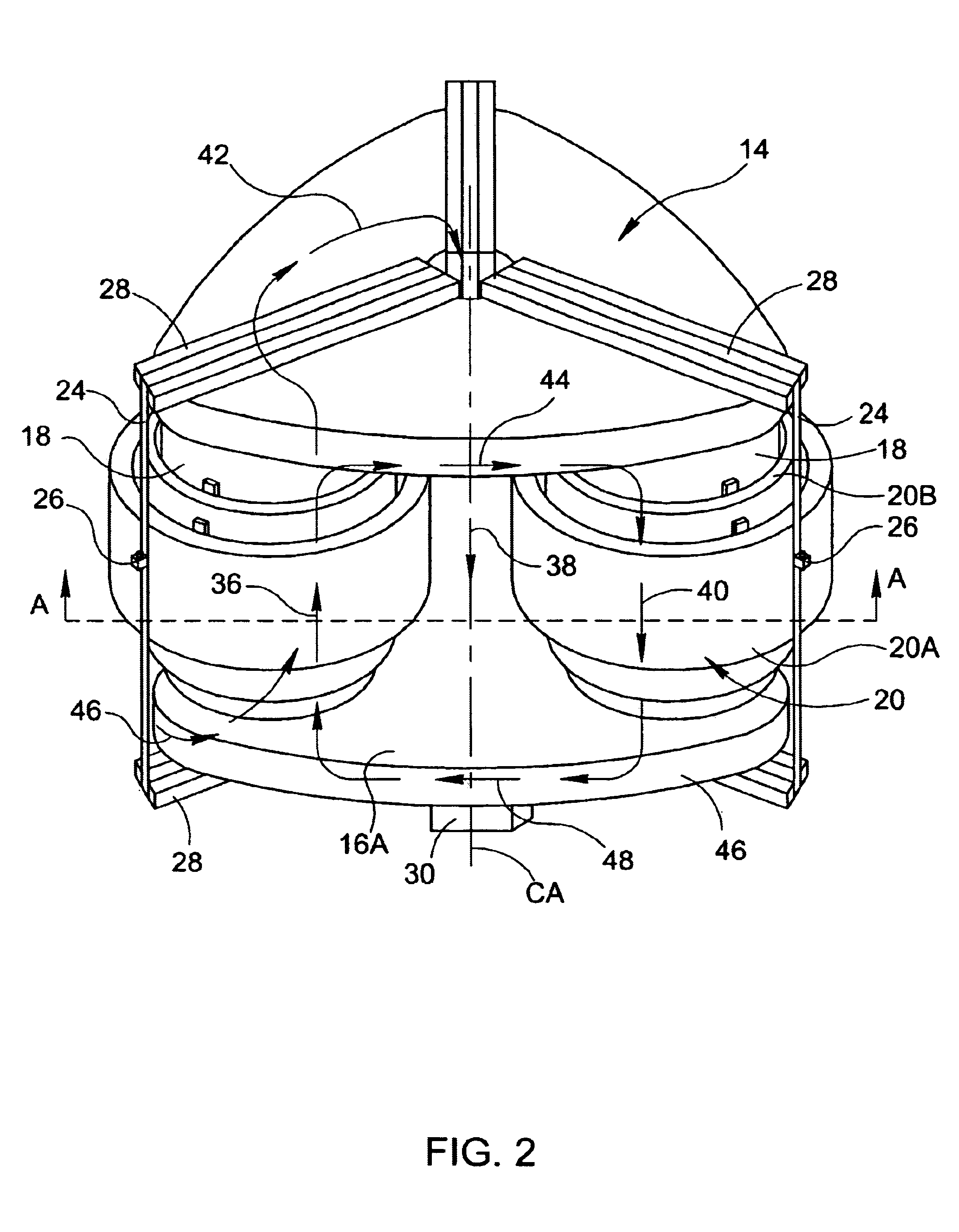

Toroid cavity/coil NMR multi-detector

InactiveUS7271592B1Rapid and non-invasive nuclear magnetic resonance (NMR) spectroscopyElimination of poor magnetic field homogeneityMagnetic measurementsElectric/magnetic detectionElectrical conductorHelmholtz coil

An analytical device for rapid, non-invasive nuclear magnetic resonance (NMR) spectroscopy of multiple samples using a single spectrometer is provided. A modified toroid cavity / coil detector (TCD), and methods for conducting the simultaneous acquisition of NMR data for multiple samples including a protocol for testing NMR multi-detectors are provided. One embodiment includes a plurality of LC resonant circuits including spatially separated toroid coil inductors, each toroid coil inductor enveloping its corresponding sample volume, and tuned to resonate at a predefined frequency using a variable capacitor. The toroid coil is formed into a loop, where both ends of the toroid coil are brought into coincidence. Another embodiment includes multiple micro Helmholtz coils arranged on a circular perimeter concentric with a central conductor of the toroid cavity.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

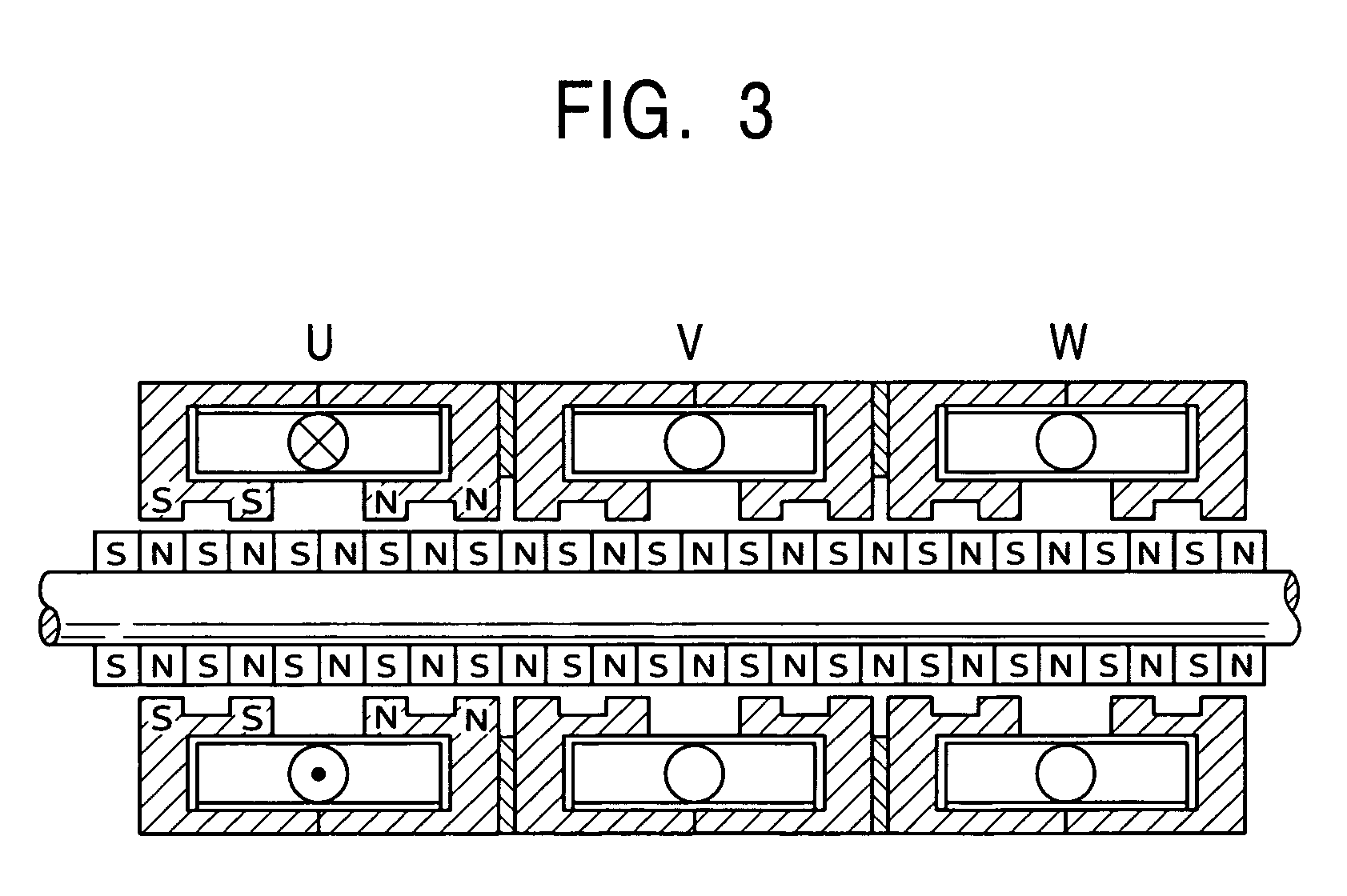

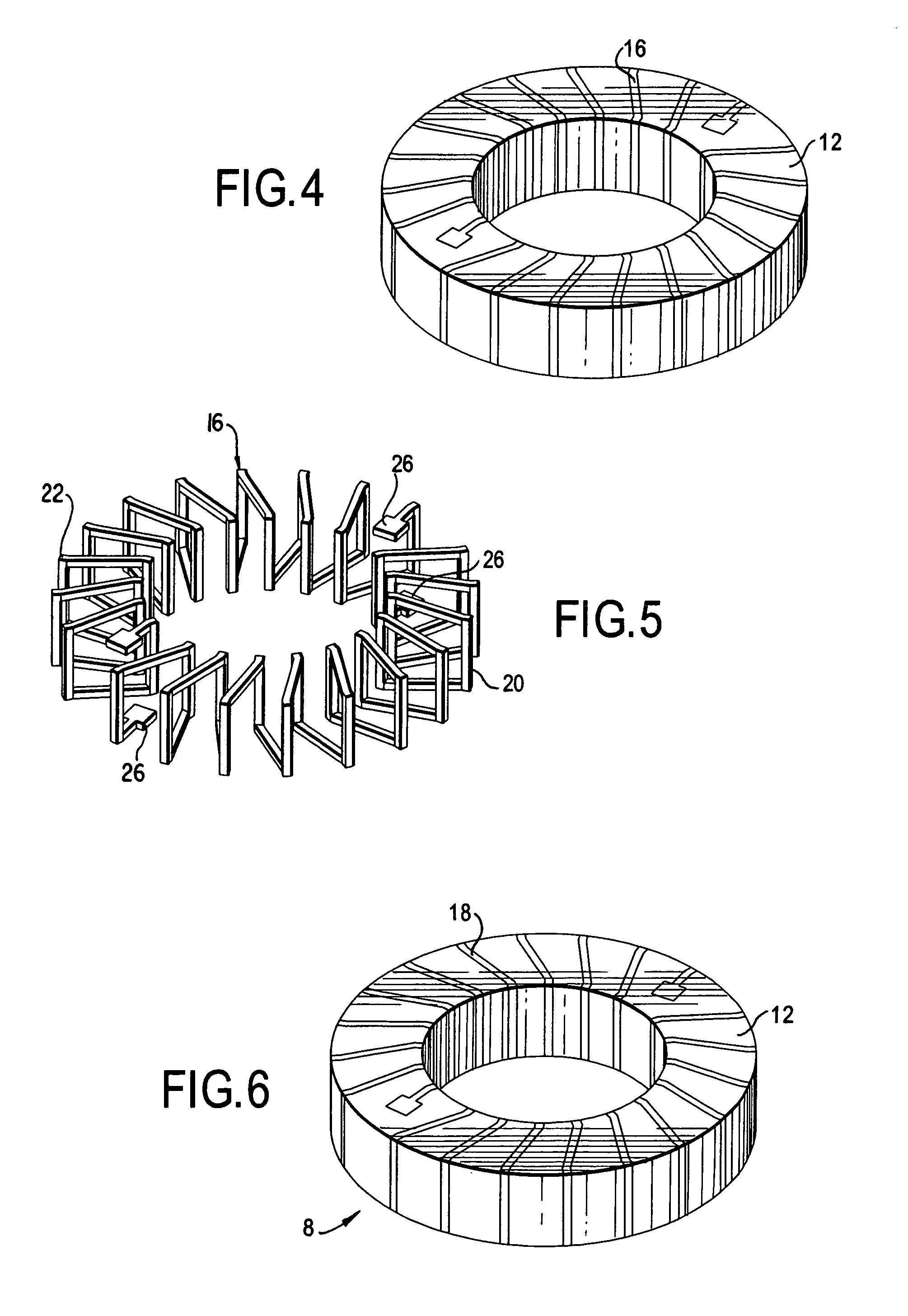

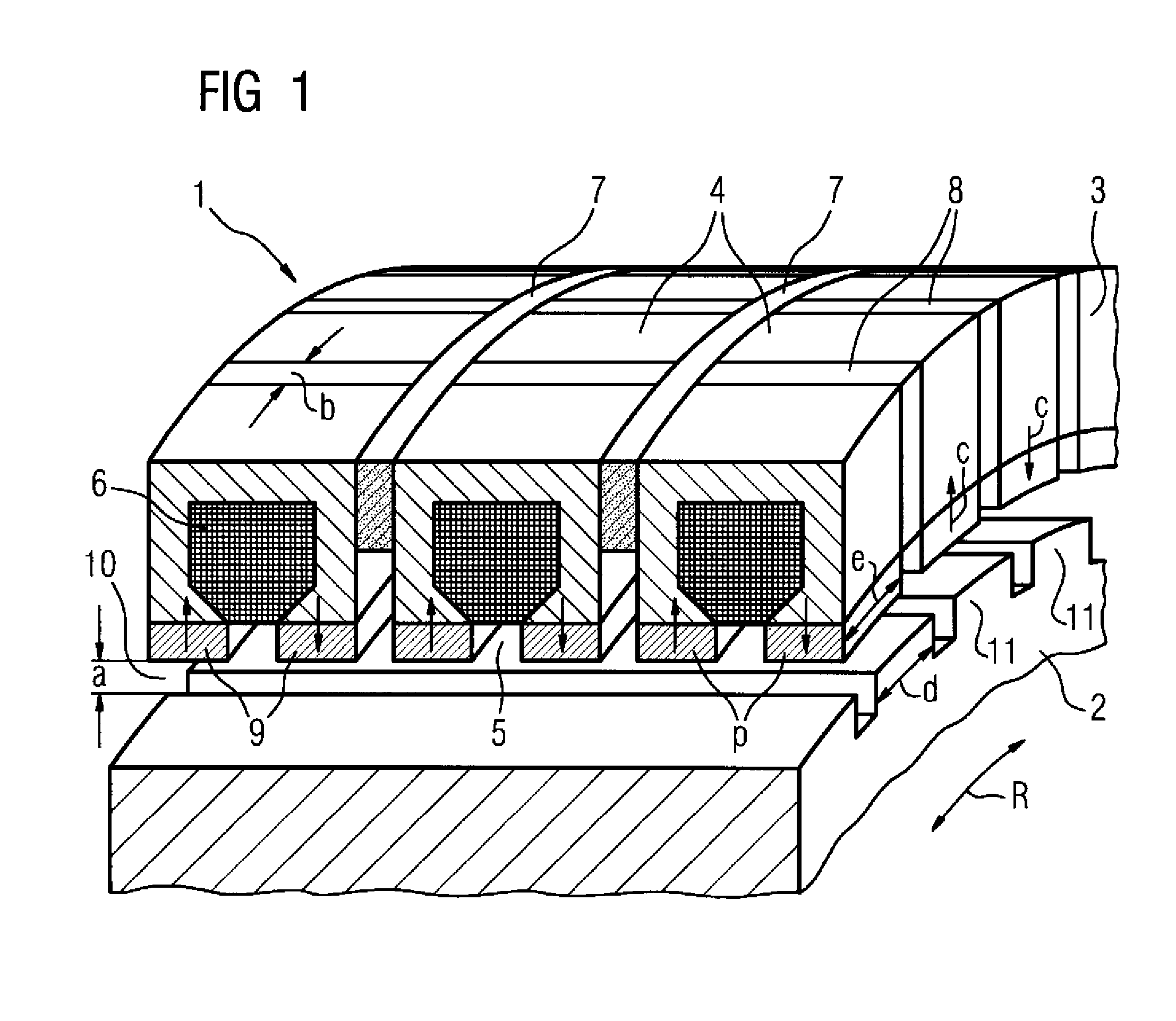

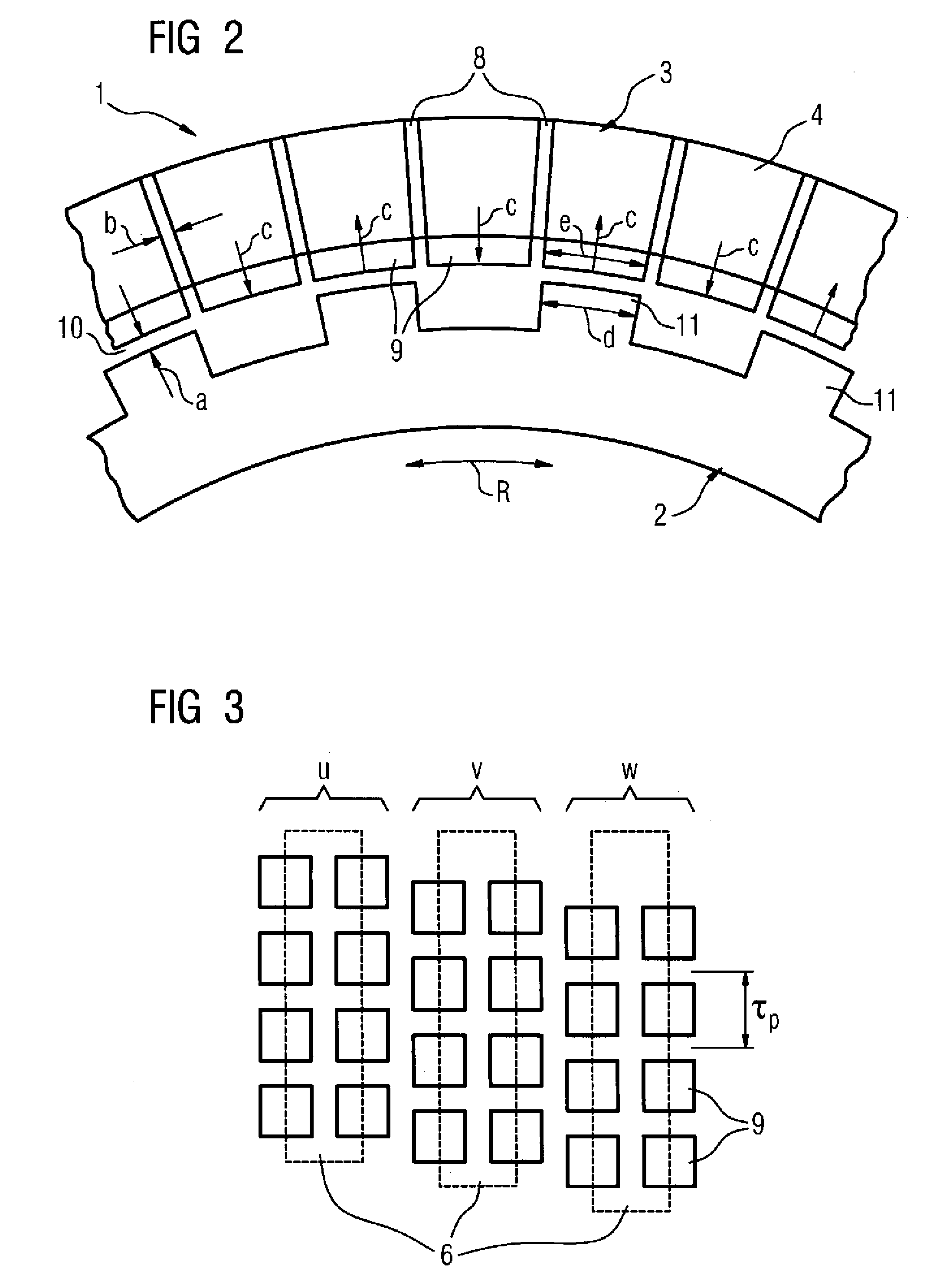

AC motor having stator windings formed as loop coils, and control apparatus for the motor

ActiveUS20050099082A1Easy to assembleEasy constructionTorque ripple controlWindingsToroidal coilConductor Coil

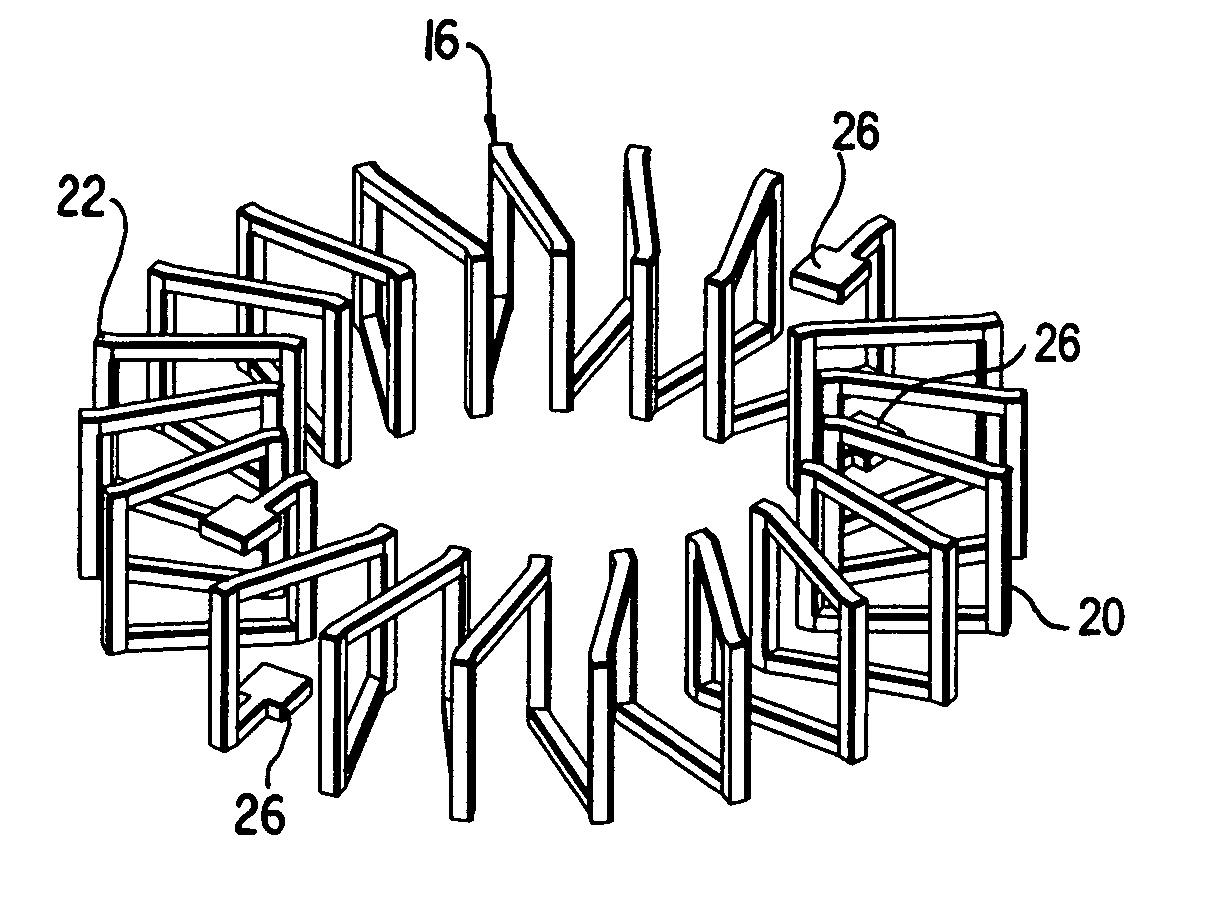

A synchronous AC motor has a stator with stator poles arranged as a plurality of circumferentially extending stator pole groups, with each stator pole group having a pair of corresponding circumferentially extending loop-configuration stator windings disposed adjacent on either side or a single such winding disposed adjacent at one side, adjacent stator pole groups being mutually circumferentially displaced by a fixed amount corresponding to a specific electrical phase angle. A rotating magnetic field is produced by applying respective polyphase AC voltages to the windings, such that currents of mutually opposite direction flow in each pair.

Owner:DENSO CORP

Coreless current sensor

InactiveUS6965225B2Easy to installLarge signal outputMeasurement using dc-ac conversionMagnetic measurementsElectrical conductorSurface coil

A time varying current sensor is constructed using surface coils uniformly spaced around a central cavity adapted to receive the conductor through which the current to be measured flows. Accurate and uniform coil geometry is achieved using printed circuit board technology, thereby eliminating the high cost of precision toroidal coil winding. An optional hinge in the housing can allow the sensor to be easily installed on existing conductors without the need to disconnect and reconnect.

Owner:GRID2020

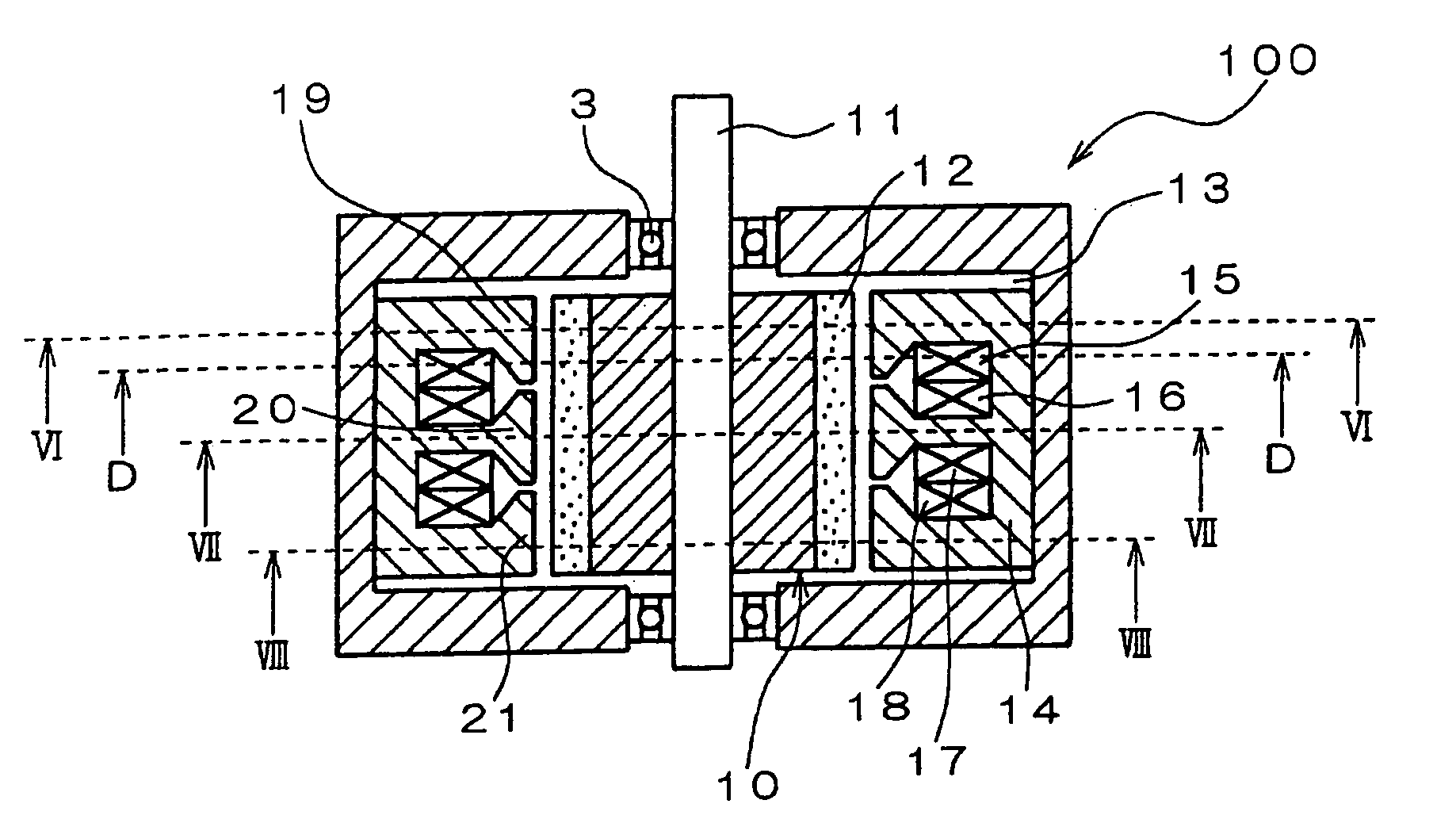

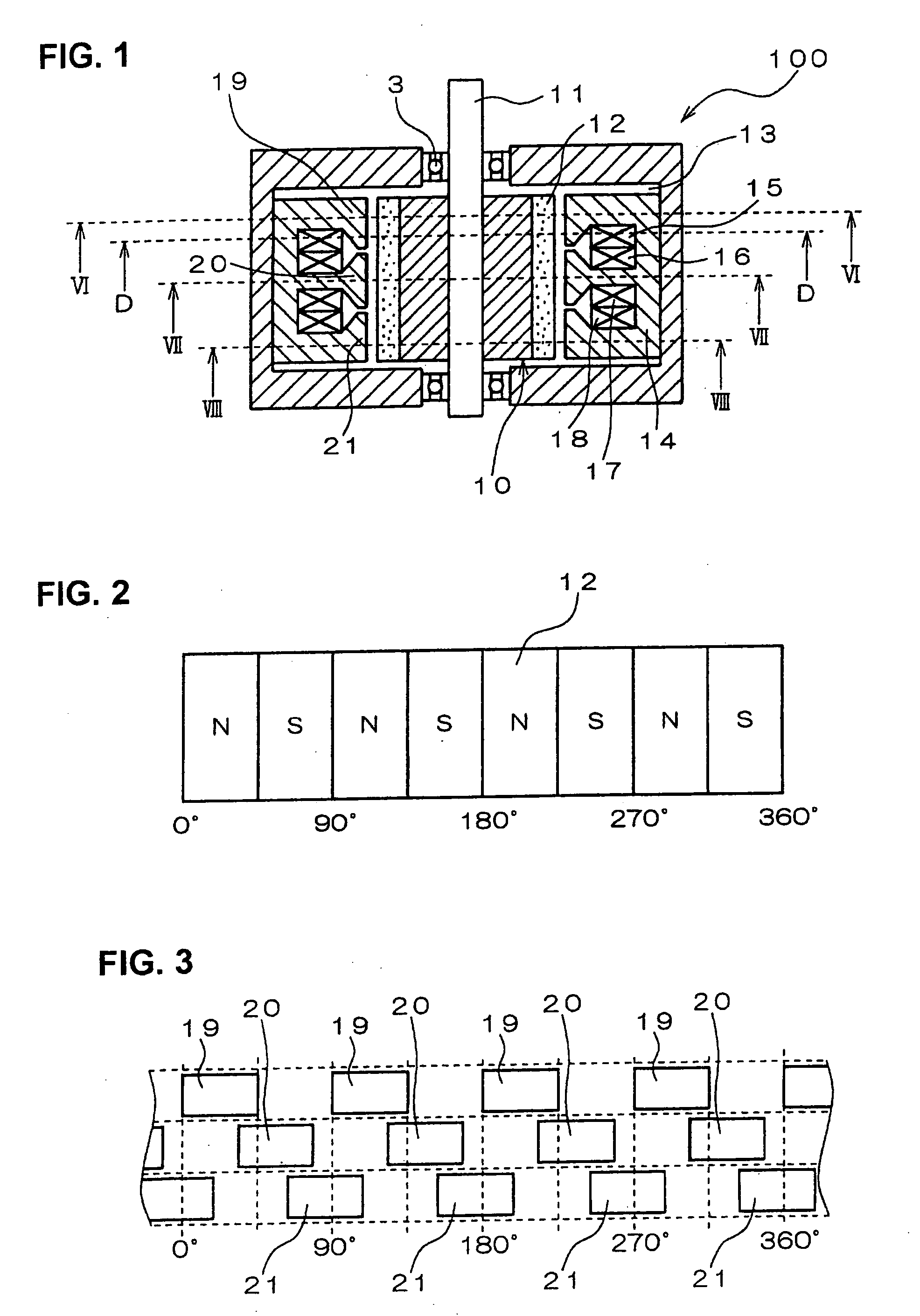

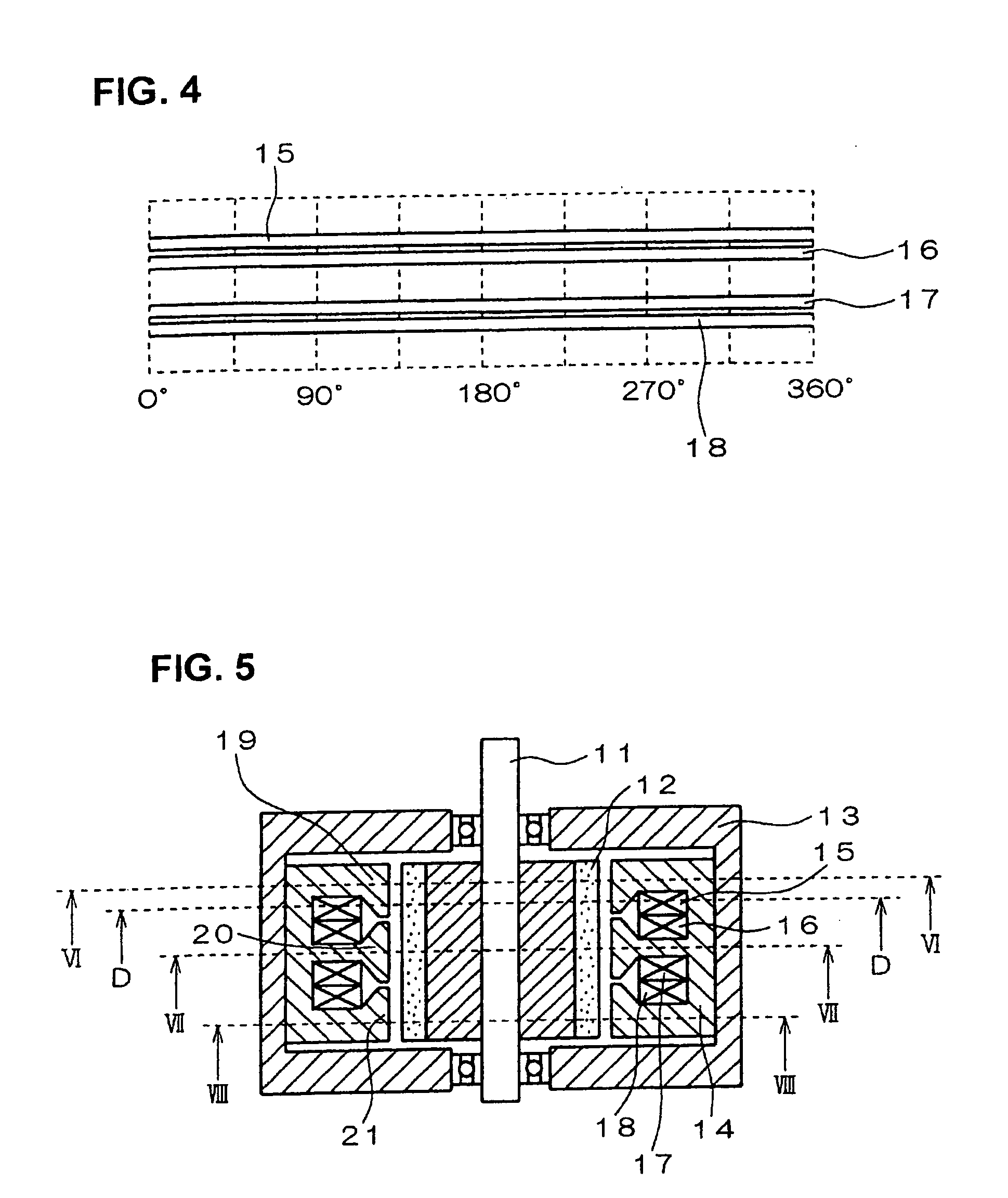

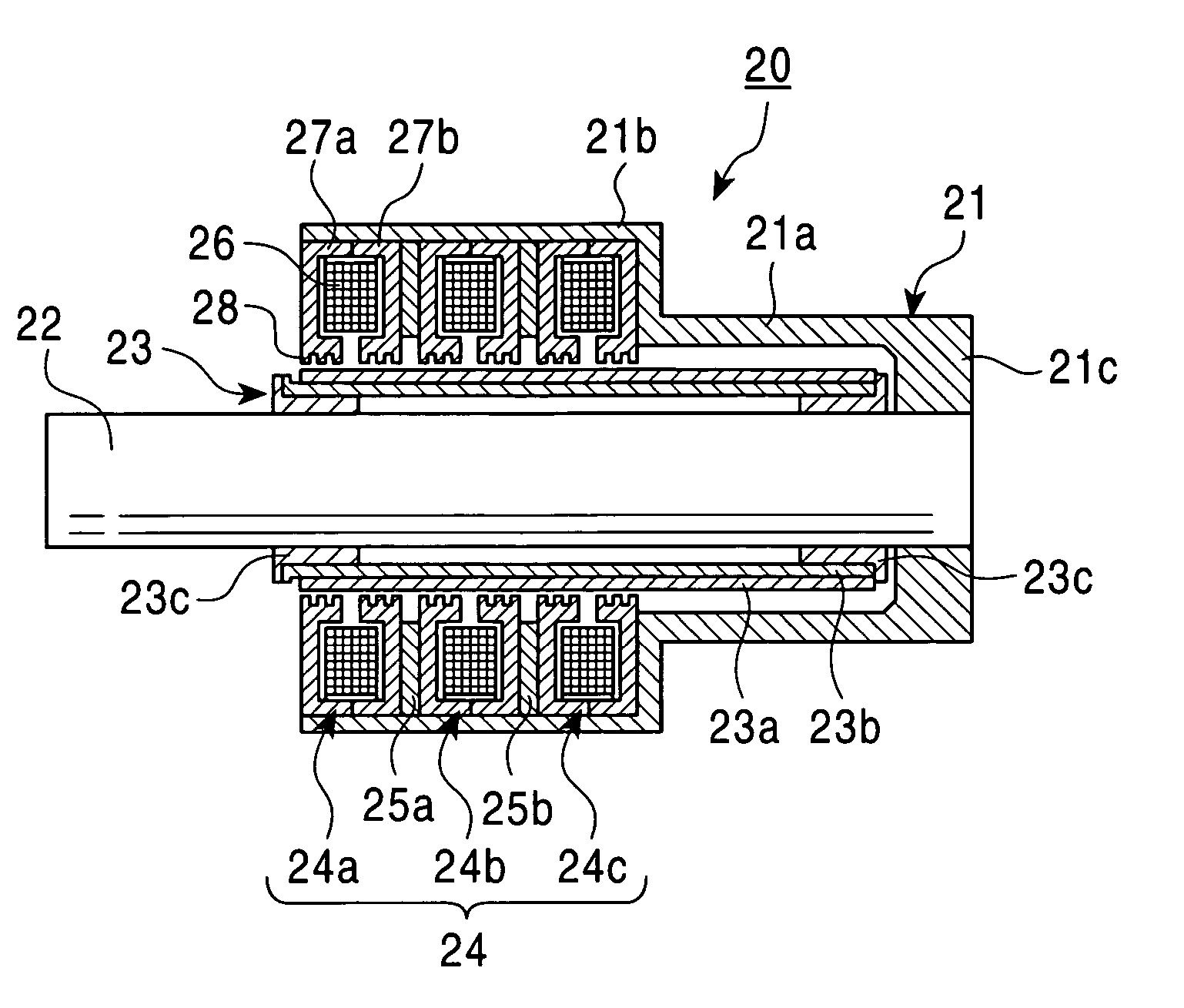

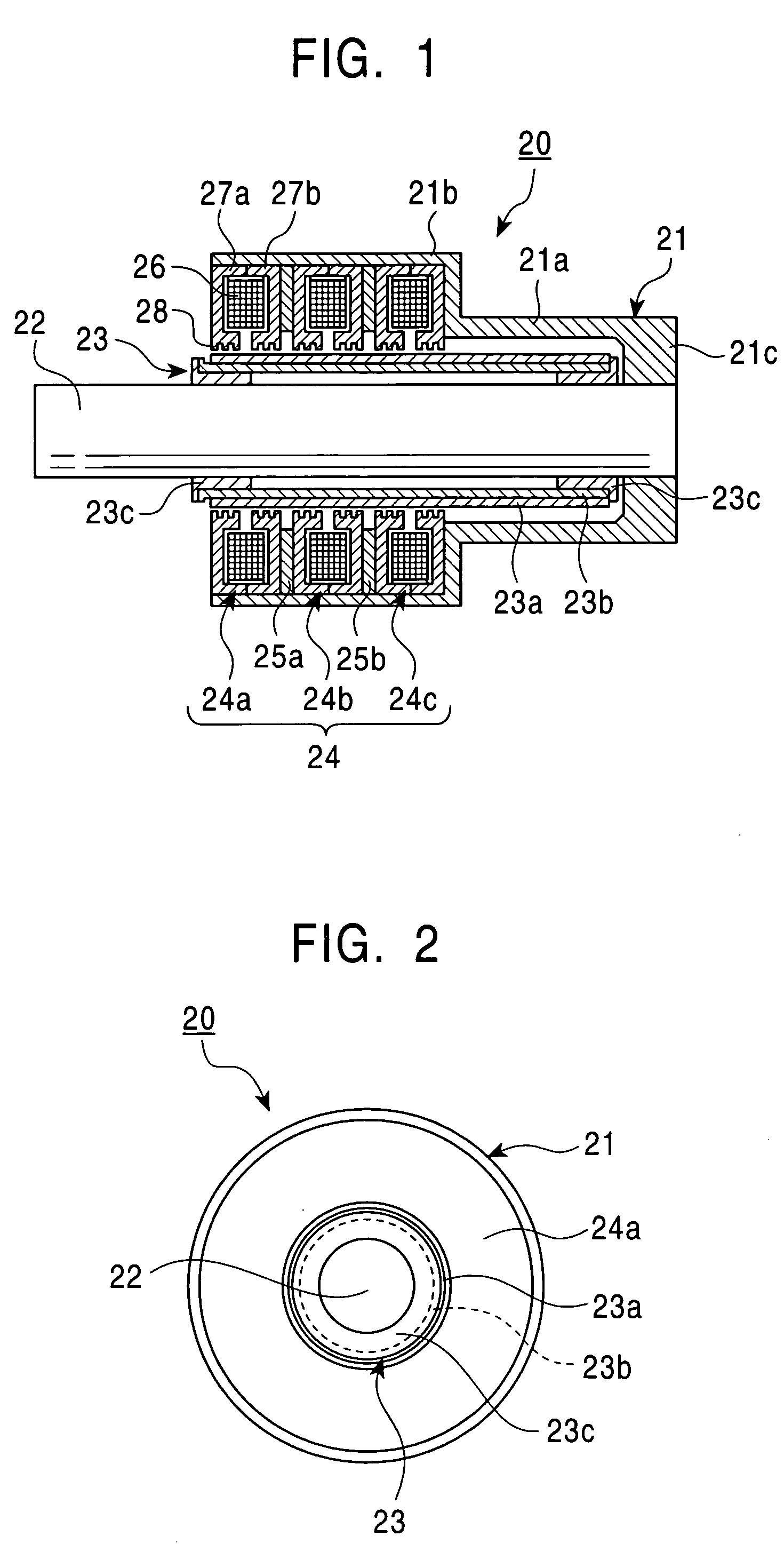

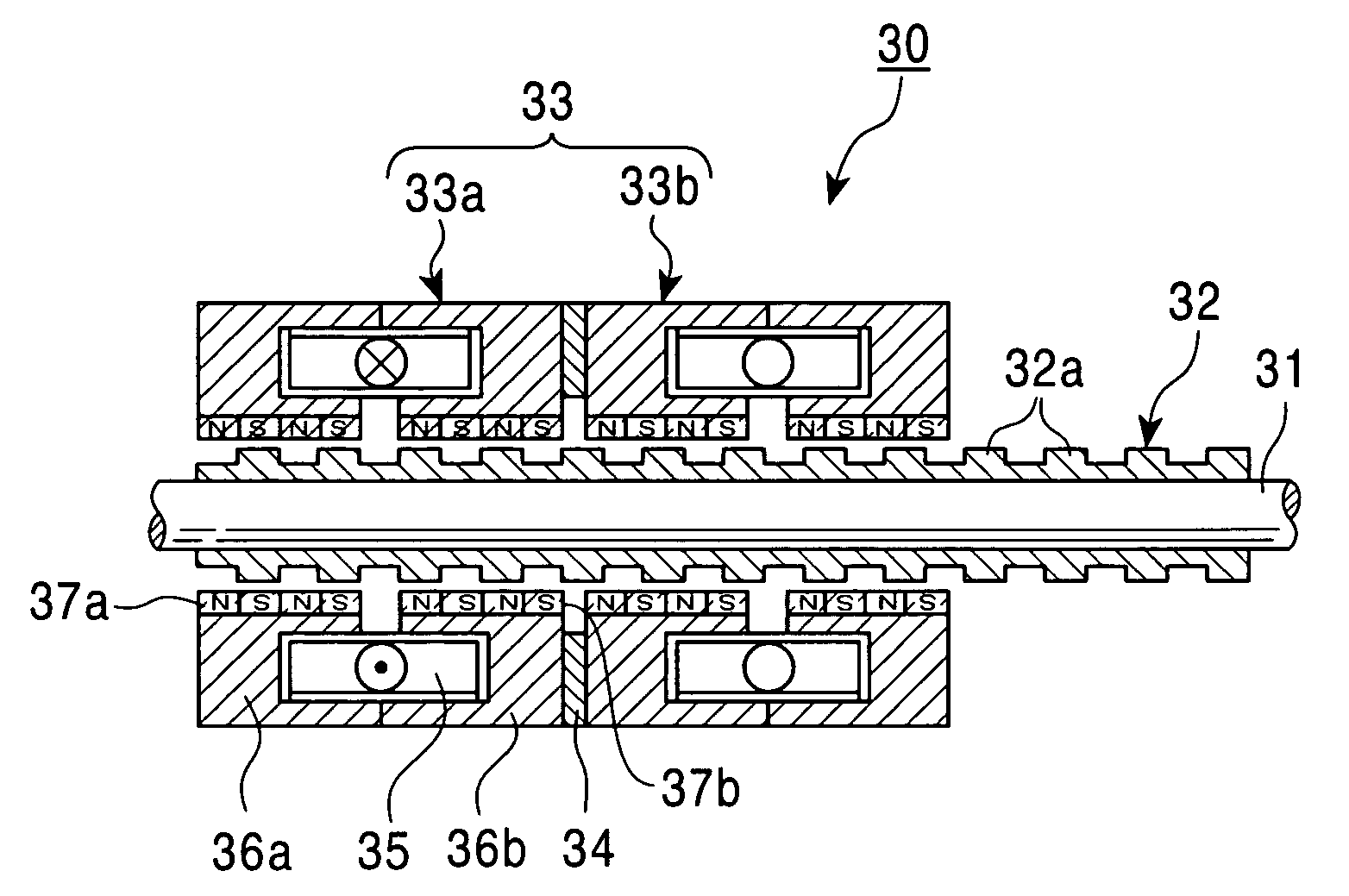

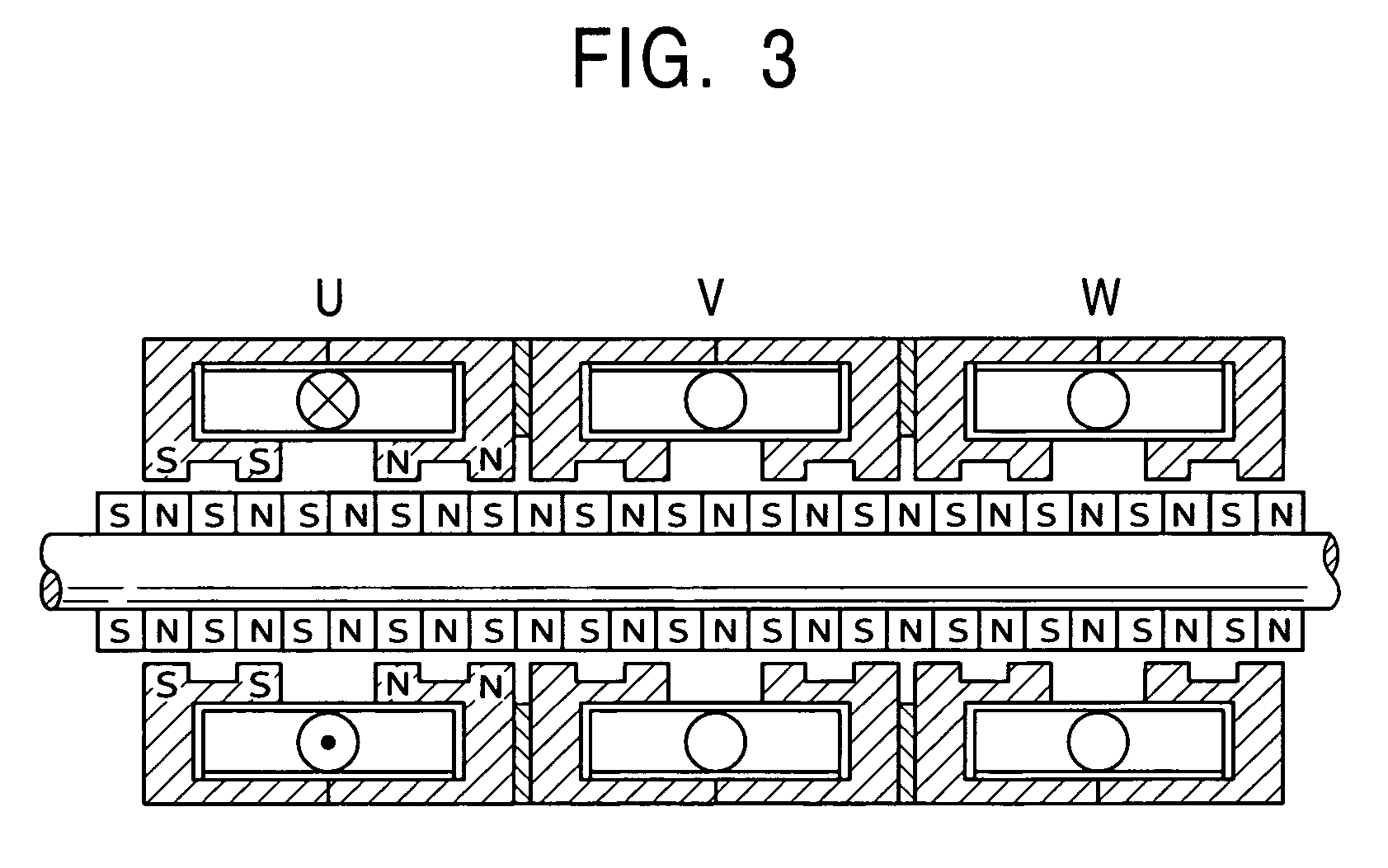

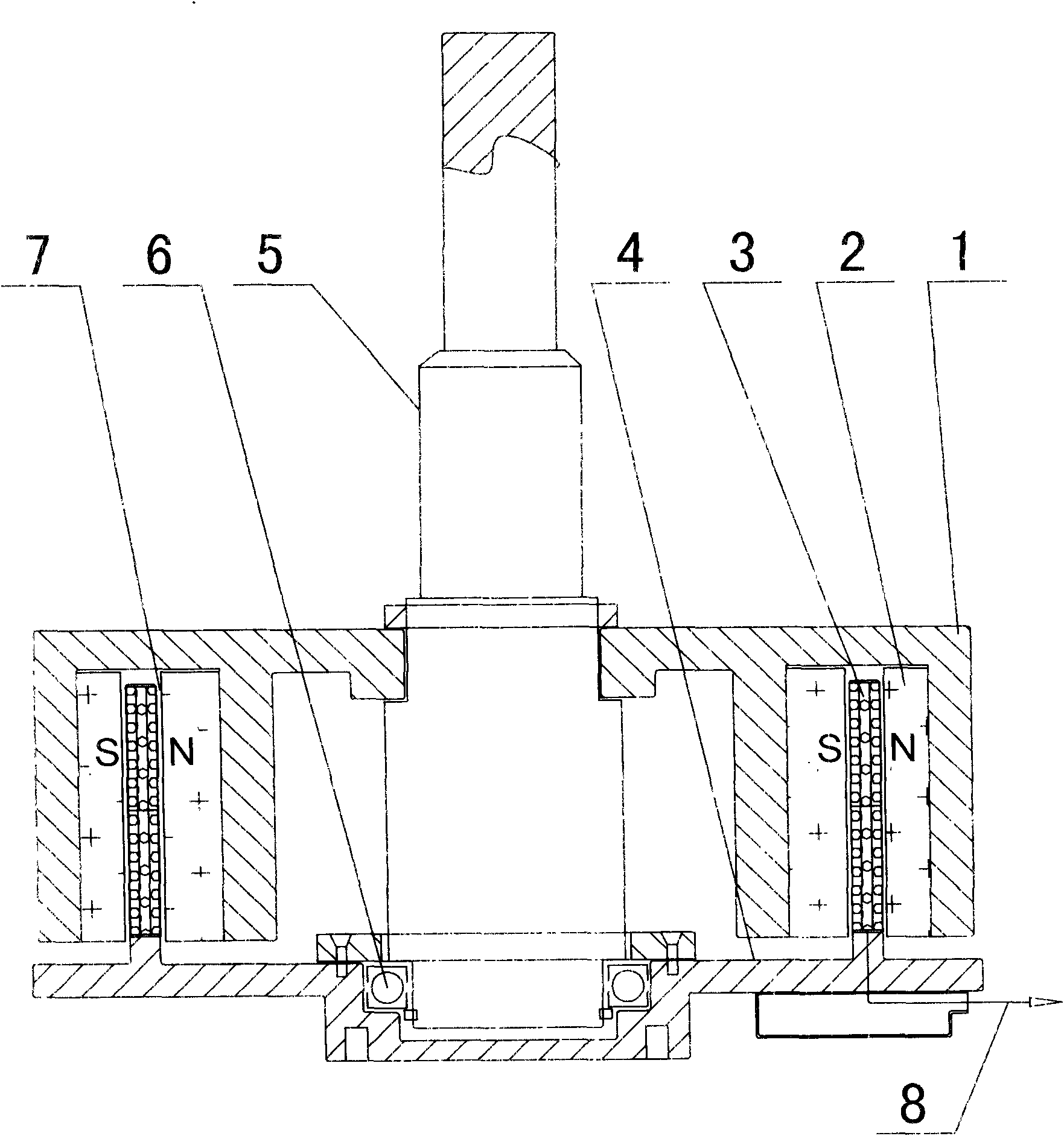

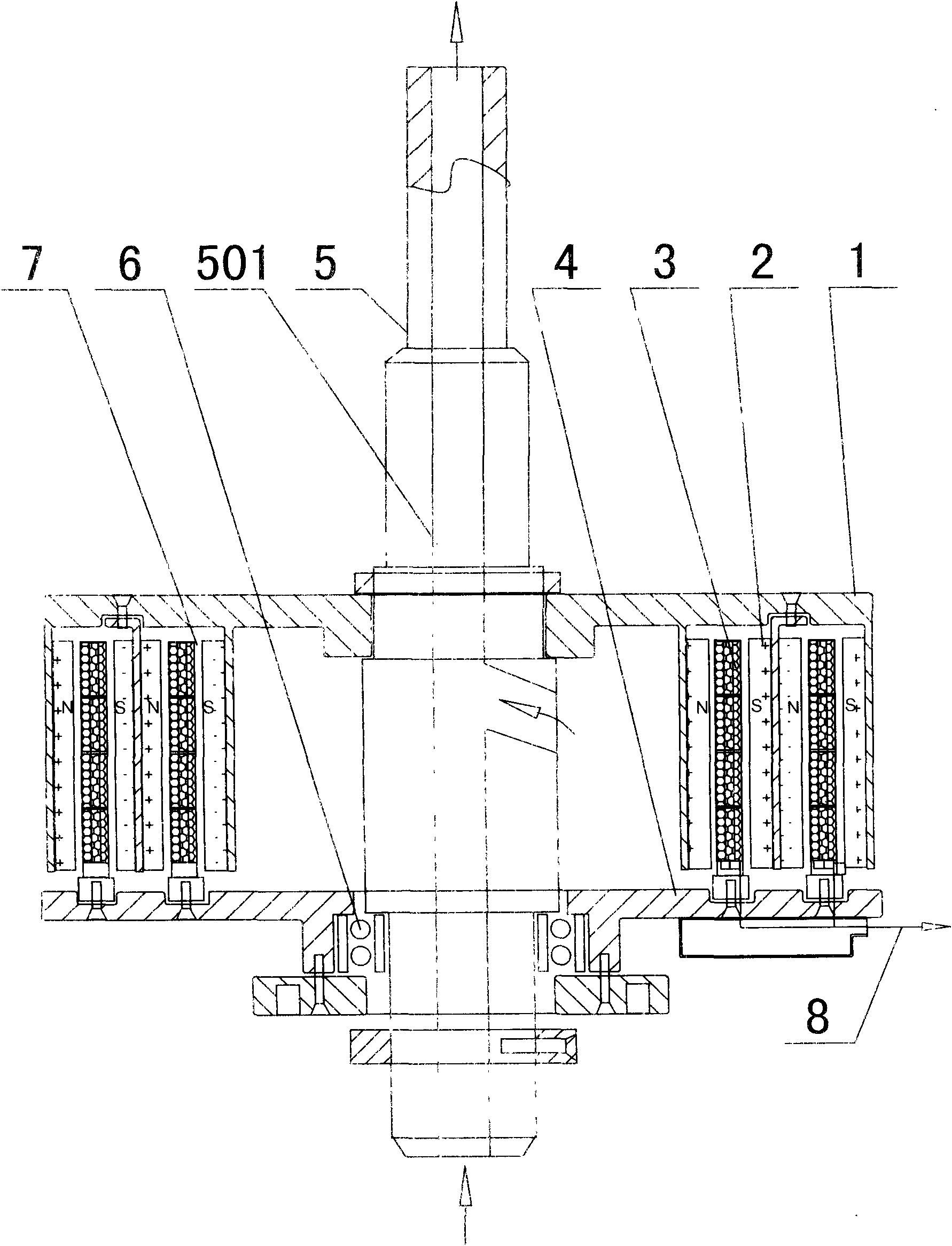

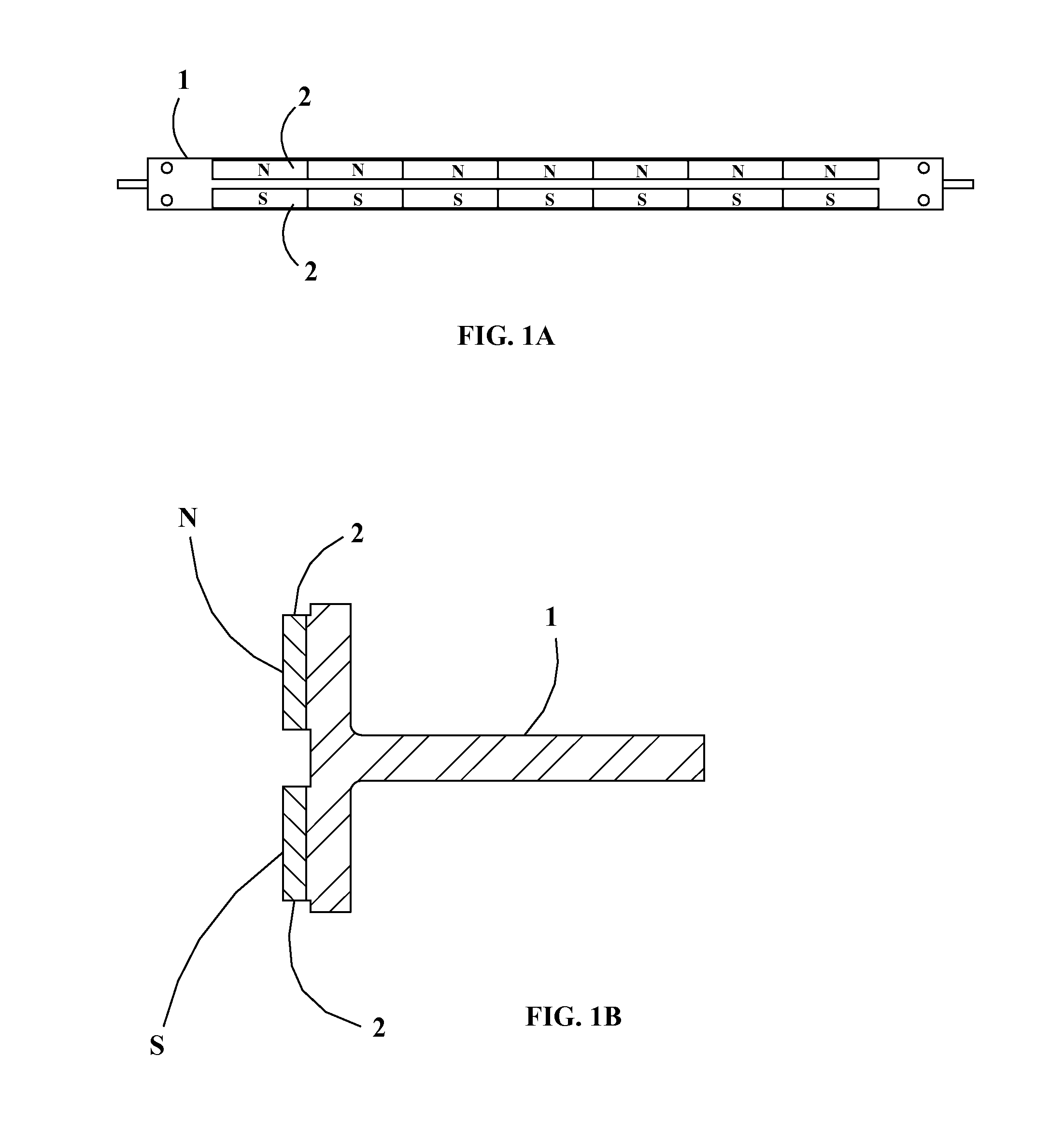

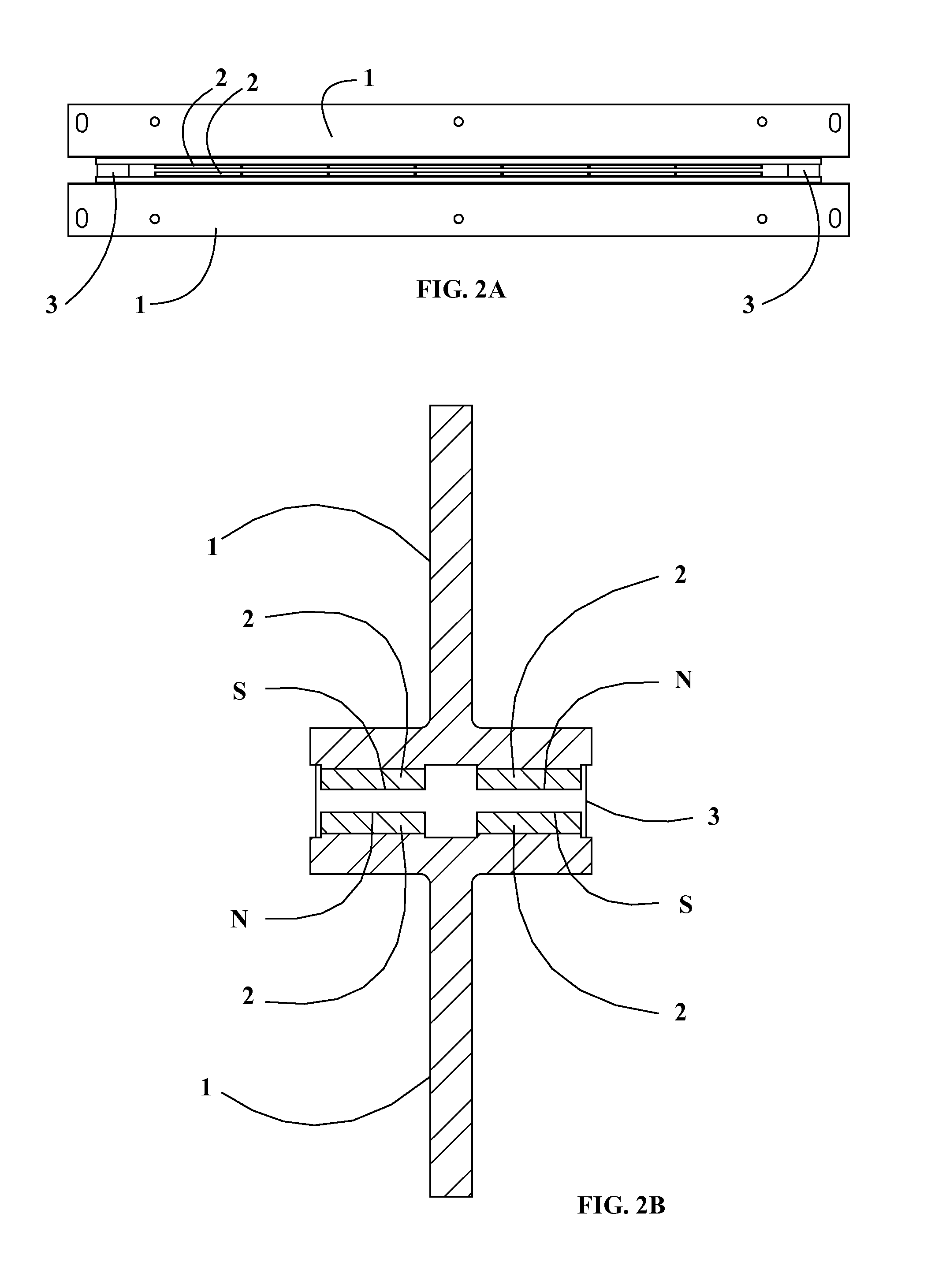

Toroidal-coil linear stepping motor, toroidal-coil linear reciprocating motor, cylinder compressor and cylinder pump using these motors

InactiveUS20050023905A1High positioning accuracyReduce loadPropulsion systemsElectric machineToroidal coil

A toroidal-coil multi-phase linear stepping motor includes a cylindrical housing, an axis coaxially arranged inside the housing, a cylindrical element supported by the axis and an armature fixed to the housing around the cylindrical element through an air gap in the radial direction. The axis is fixed to the housing and the cylindrical element linearly moves along the axis. The cylindrical element has toroidal permanent magnets that are alternately magnetized in N pole and S pole in the axial direction. The armature consists of armature units arranged around the axis. Each armature unit has a toroidal coil and a pair of armature yokes that hold the toroidal coil. Each armature yoke has toroidal magnetic teeth on its inner surface. The invention also includes a toroidal-coil single-phase linear reciprocating motor and a cylinder compressor and a cylinder pump using these motors.

Owner:JAPAN SERVO CO LTD

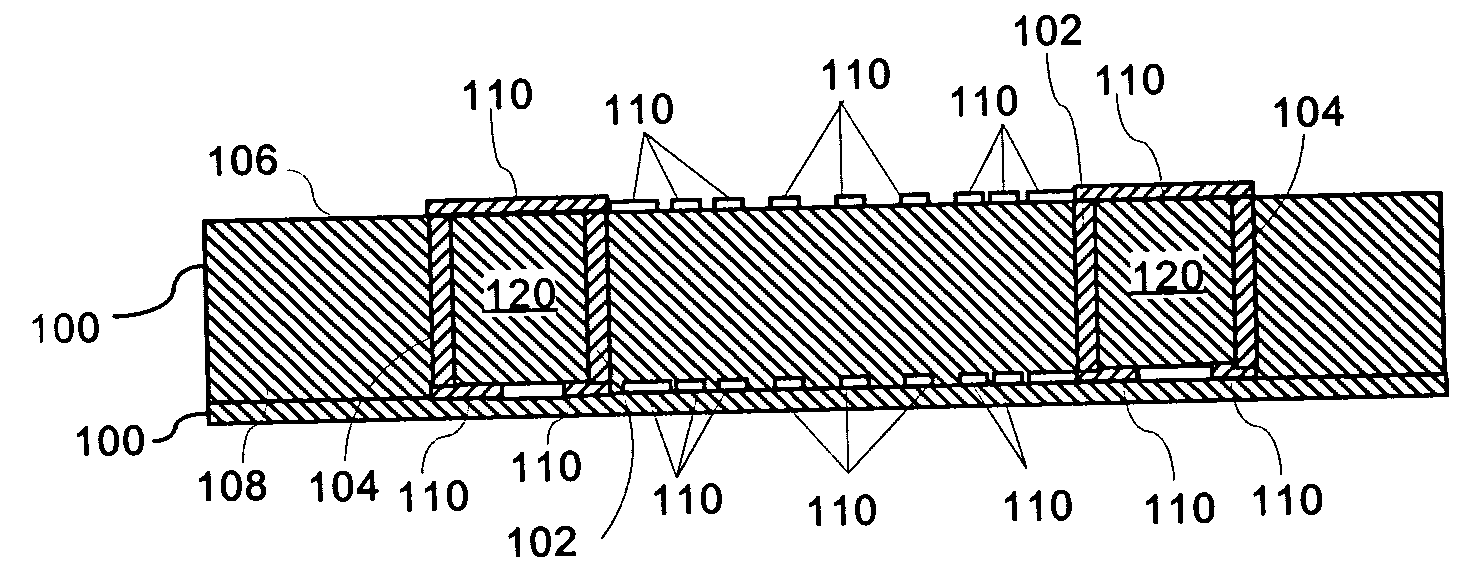

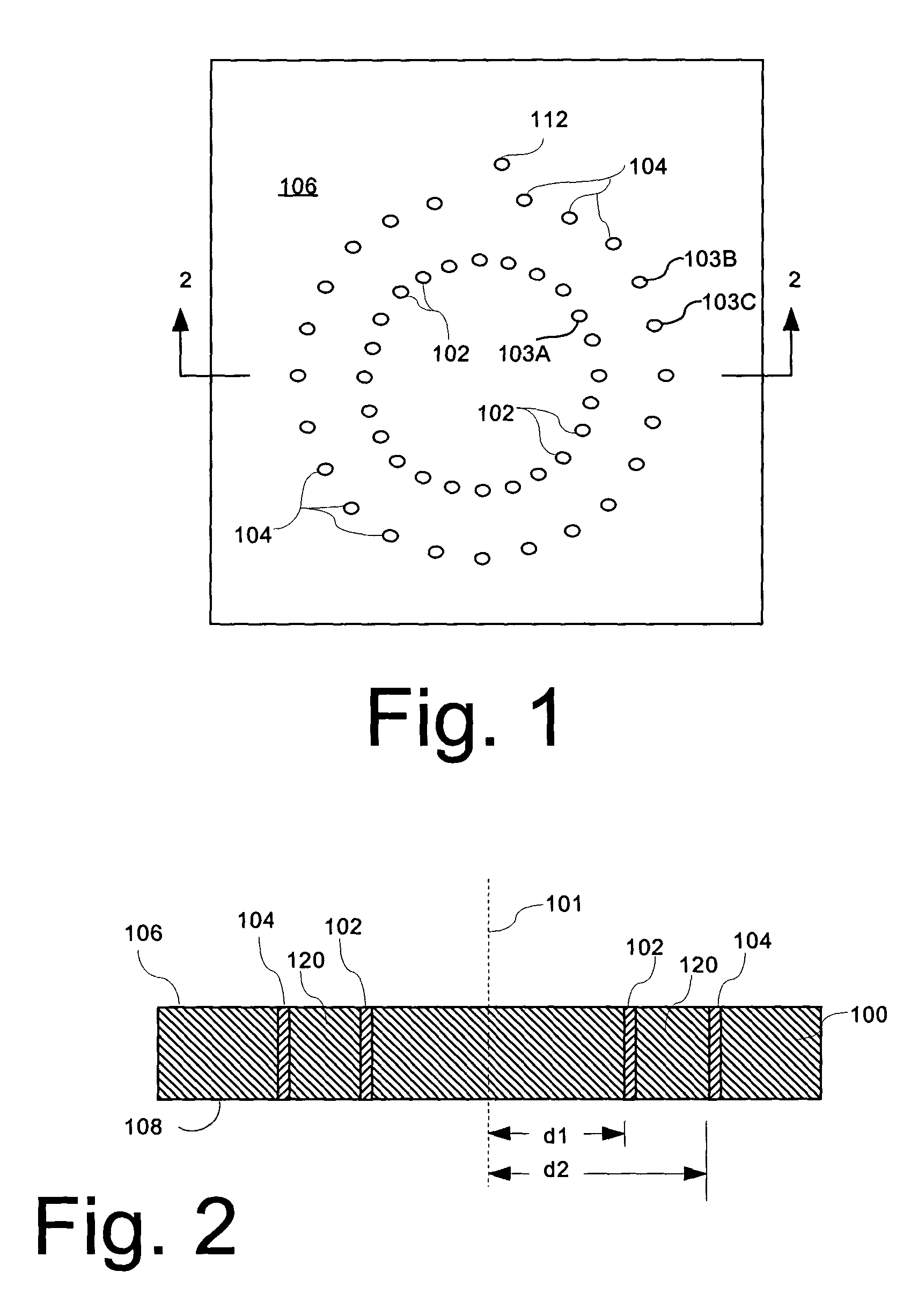

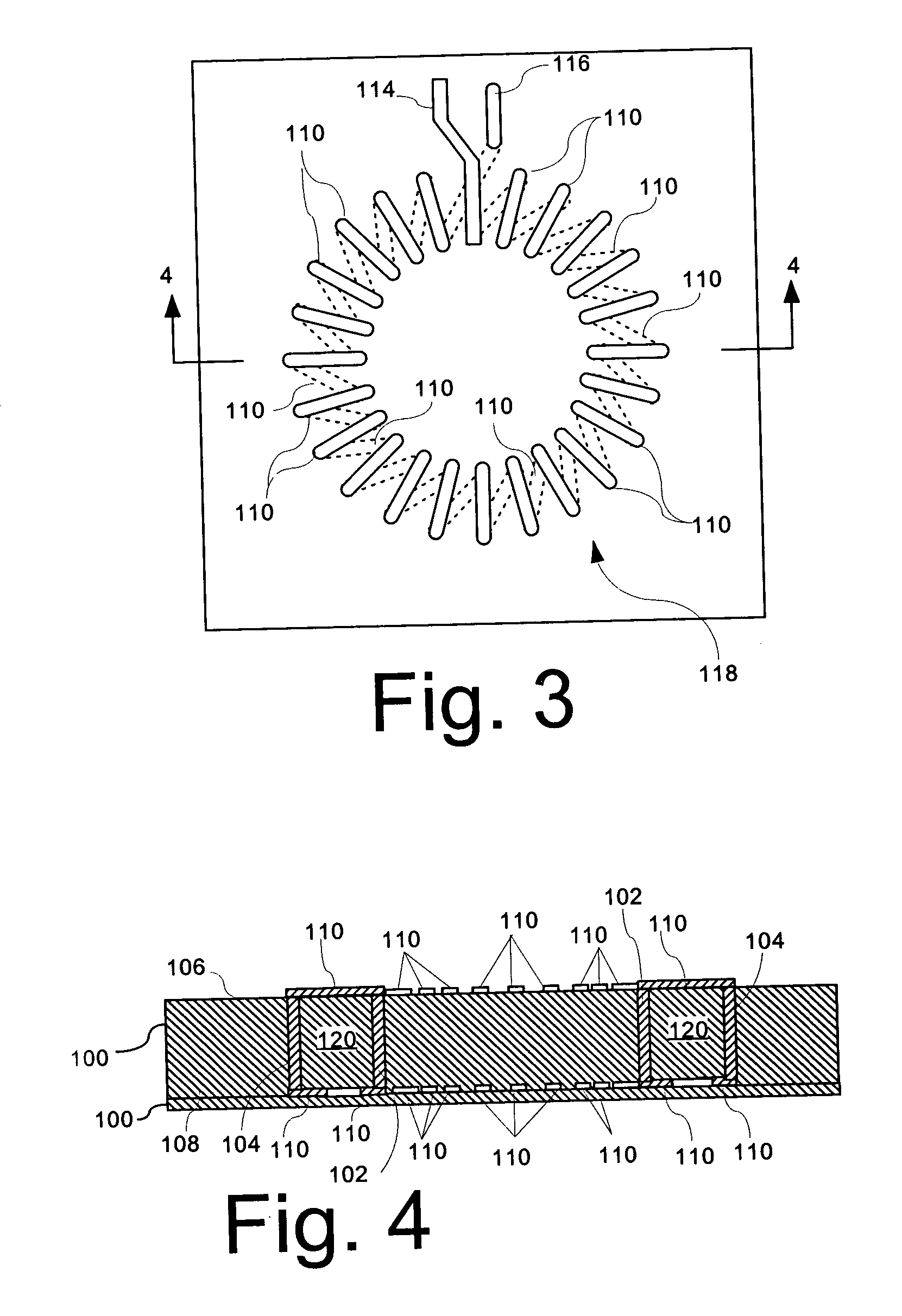

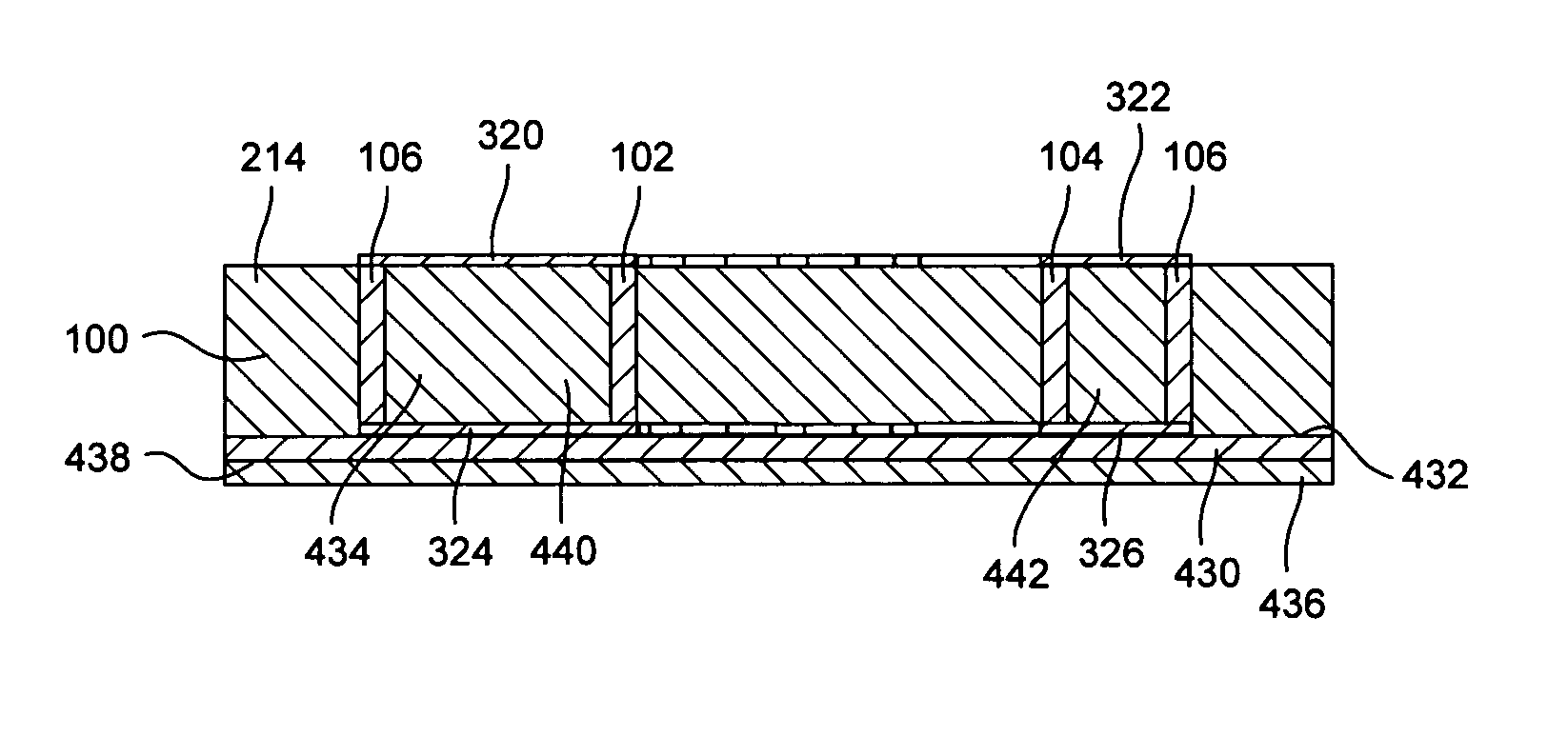

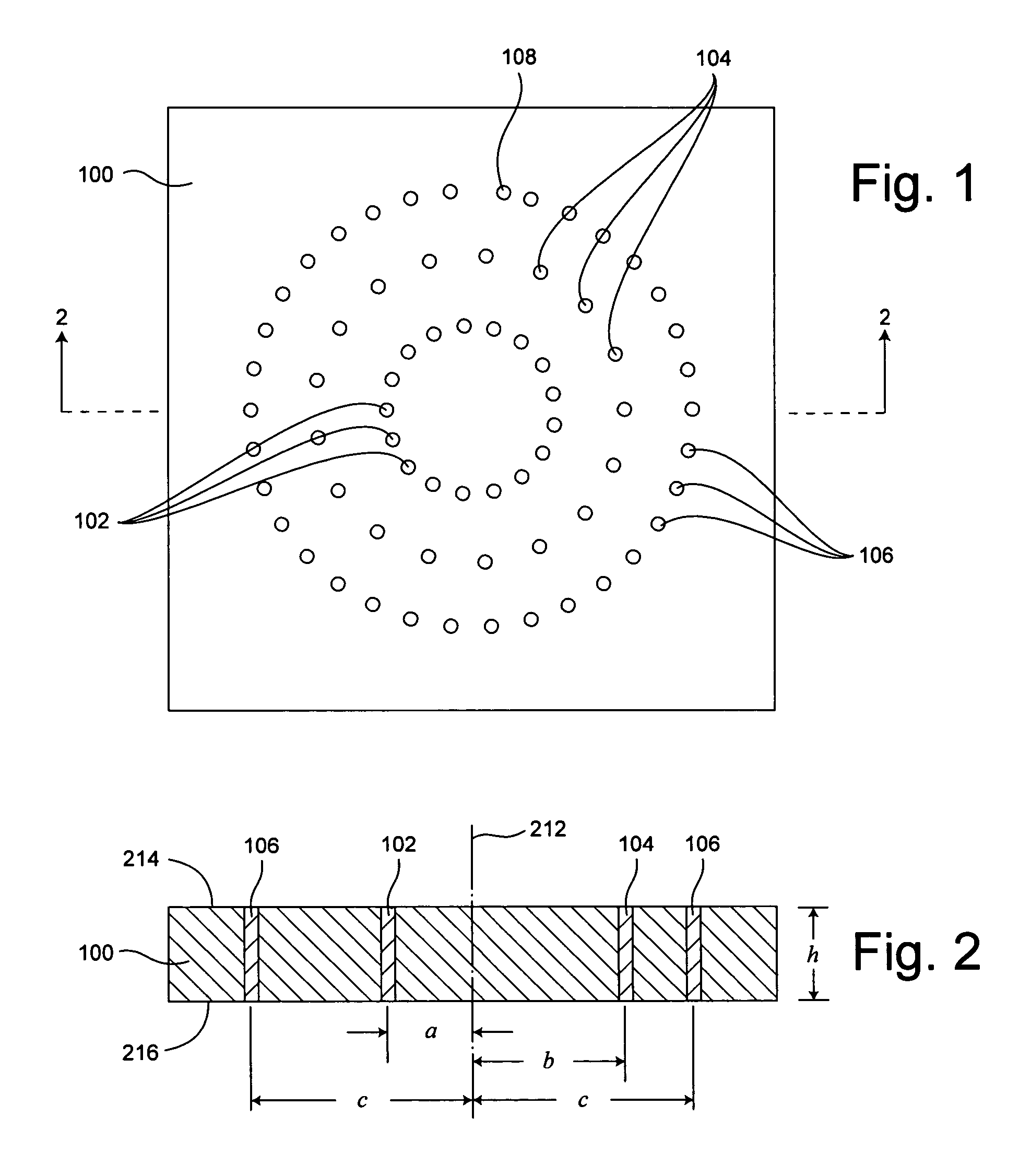

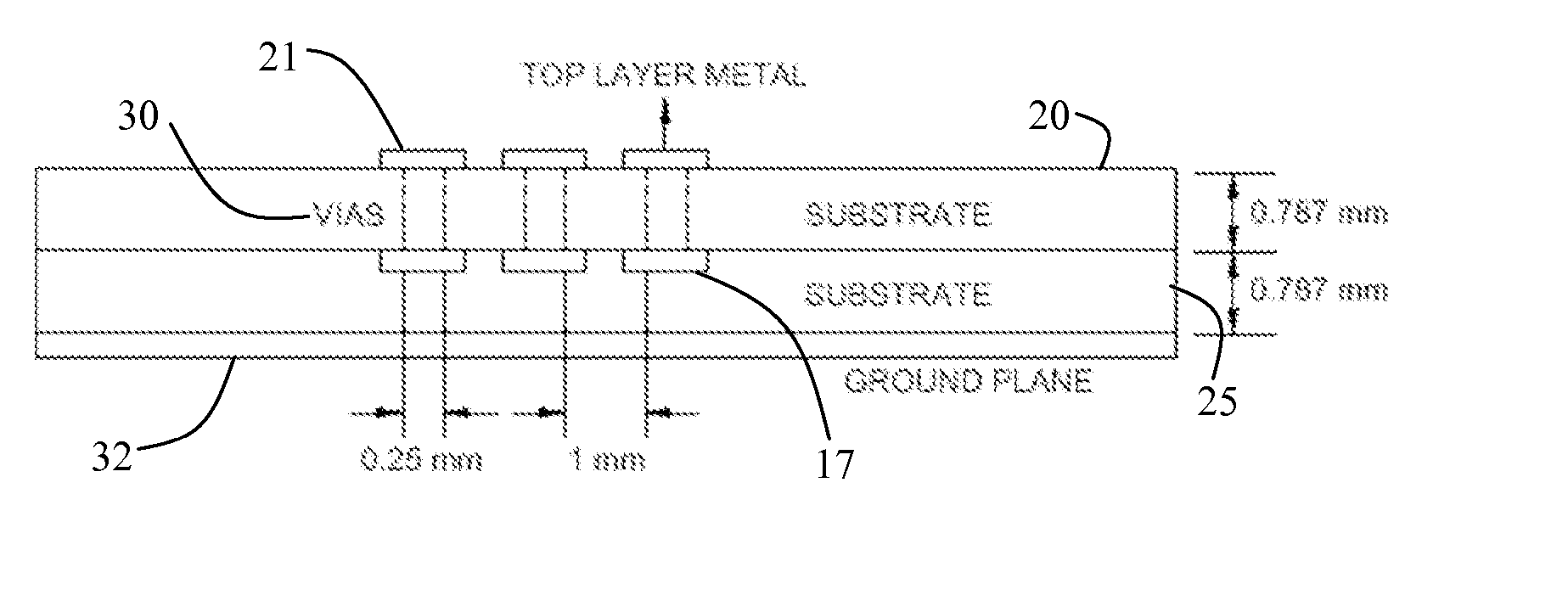

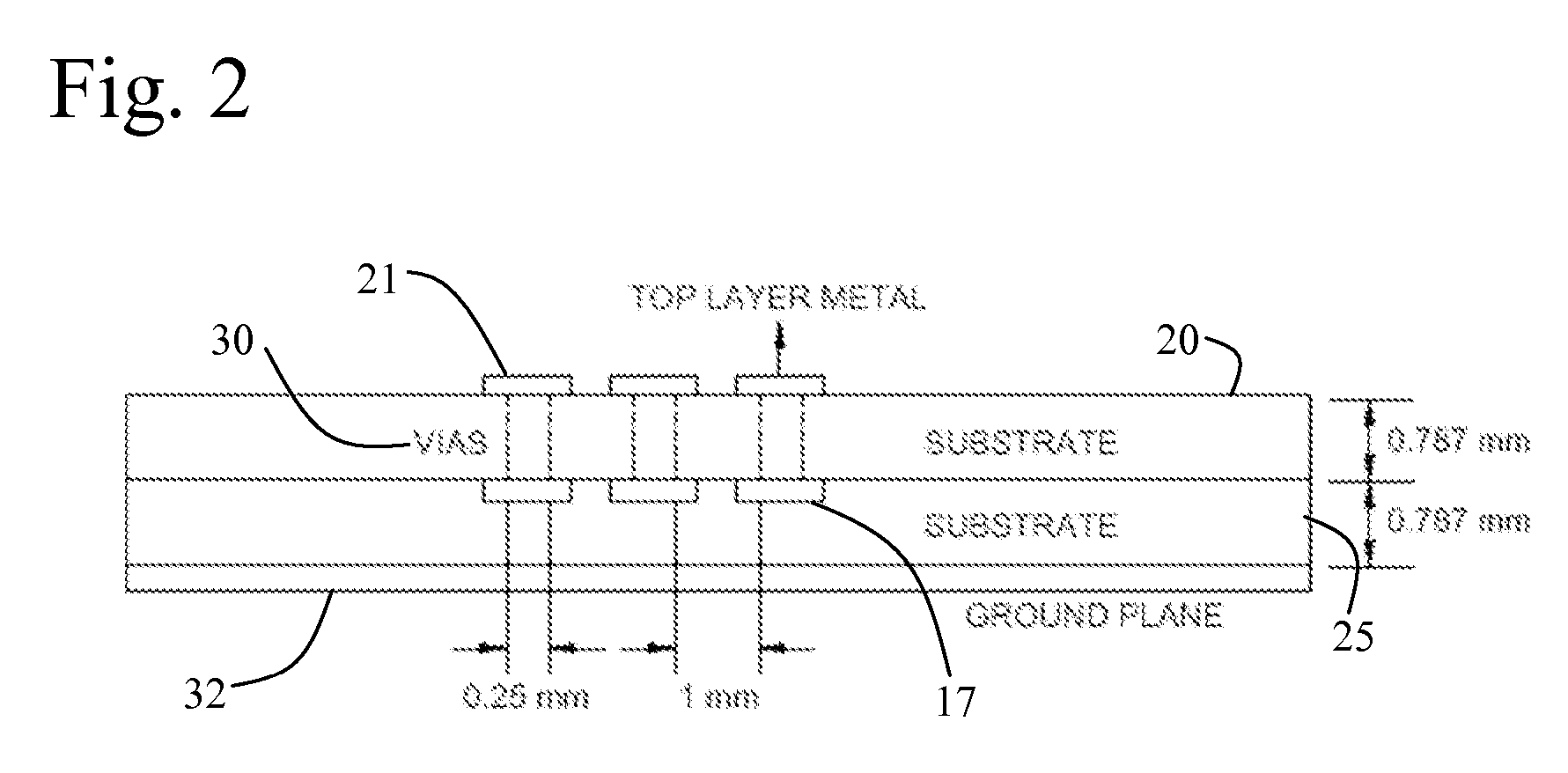

Embedded toroidal inductors

InactiveUS20050052268A1Semiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsElectrical connectionInductor

A method for making an embedded toroidal inductor (118) includes forming in a ceramic substrate (100) a first plurality of conductive vias (102) radially spaced a first distance from a central axis (101) so as to define an inner circumference. A second plurality of conductive vias (104) is formed radially spaced a second distance about the central axis so as to define an outer circumference. A first plurality of conductive traces (110) forming an electrical connection between substantially adjacent ones of the first and second plurality of conductive vias is formed on a first surface (106) of the ceramic substrate. Further, a second plurality of conductive traces (110) forming an electrical connection between circumferentially offset ones of the first and second plurality of conductive vias is formed on a second surface of the ceramic substrate opposed from the first surface to define a three dimensional toroidal coil.

Owner:HARRIS CORP

Toroidal-coil linear stepping motor, toroidal-coil linear reciprocating motor, cylinder compressor and cylinder pump using these motors

InactiveUS7242118B2High positioning accuracyReduce loadPropulsion systemsElectric machineEngineering

A toroidal-coil multi-phase linear stepping motor includes a cylindrical housing, an axis coaxially arranged inside the housing, a cylindrical element supported by the axis and an armature fixed to the housing around the cylindrical element through an air gap in the radial direction. The axis is fixed to the housing and the cylindrical element linearly moves along the axis. The cylindrical element has toroidal permanent magnets that are alternately magnetized in N pole and S pole in the axial direction. The armature consists of armature units arranged around the axis. Each armature unit has a toroidal coil and a pair of armature yokes that hold the toroidal coil. Each armature yoke has toroidal magnetic teeth on its inner surface. The invention also includes a toroidal-coil single-phase linear reciprocating motor and a cylinder compressor and a cylinder pump using these motors.

Owner:JAPAN SERVO CO LTD

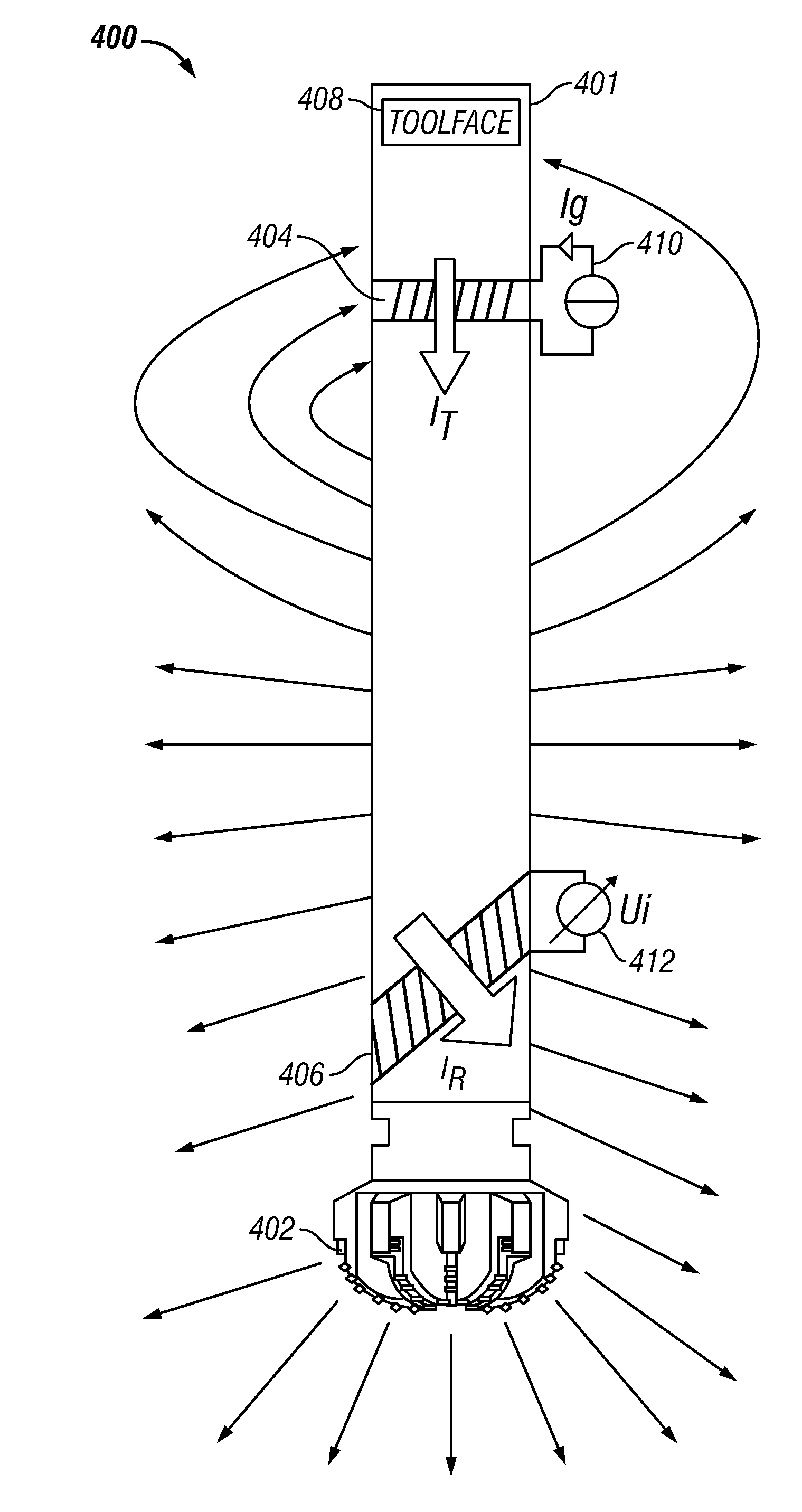

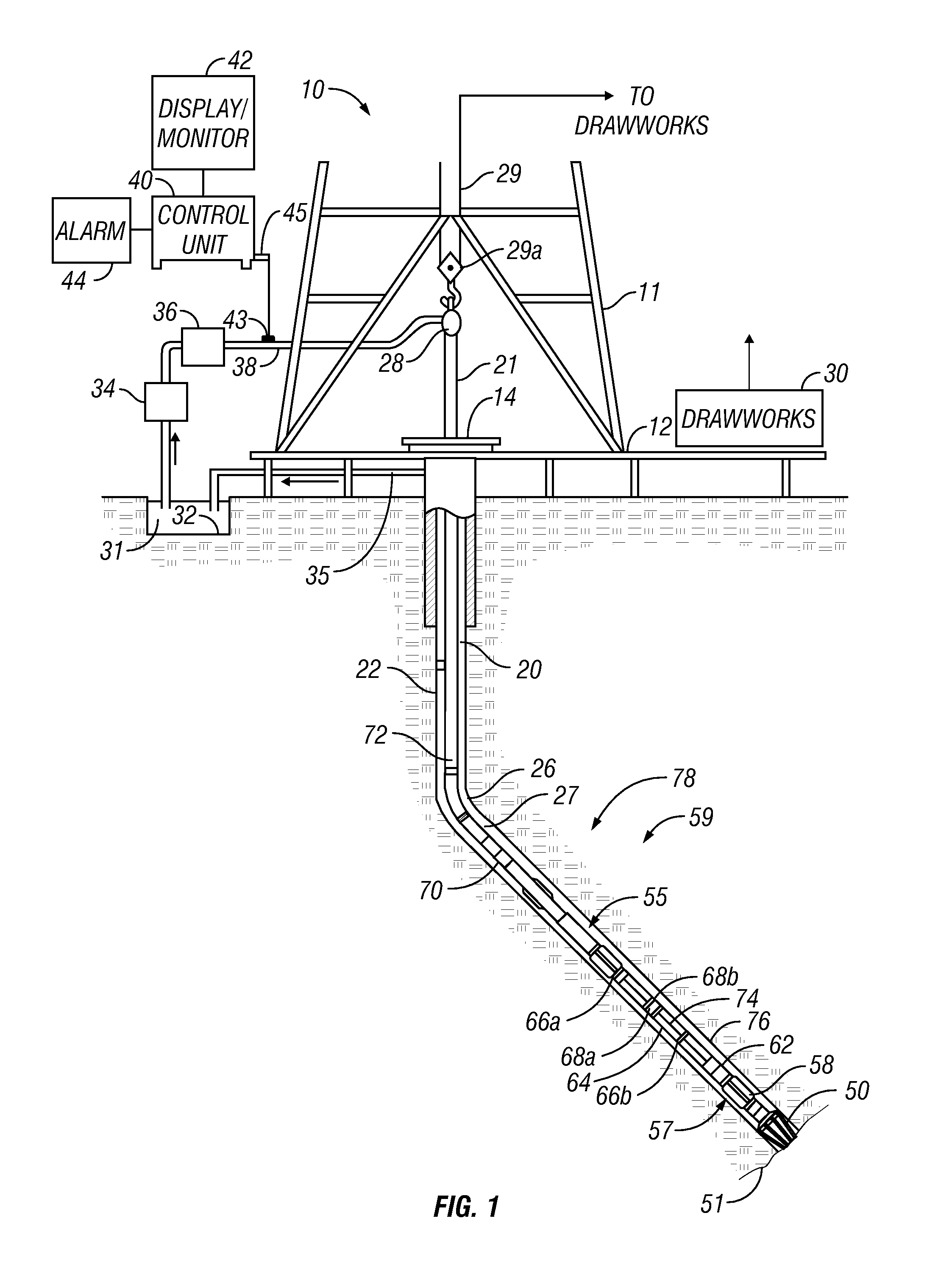

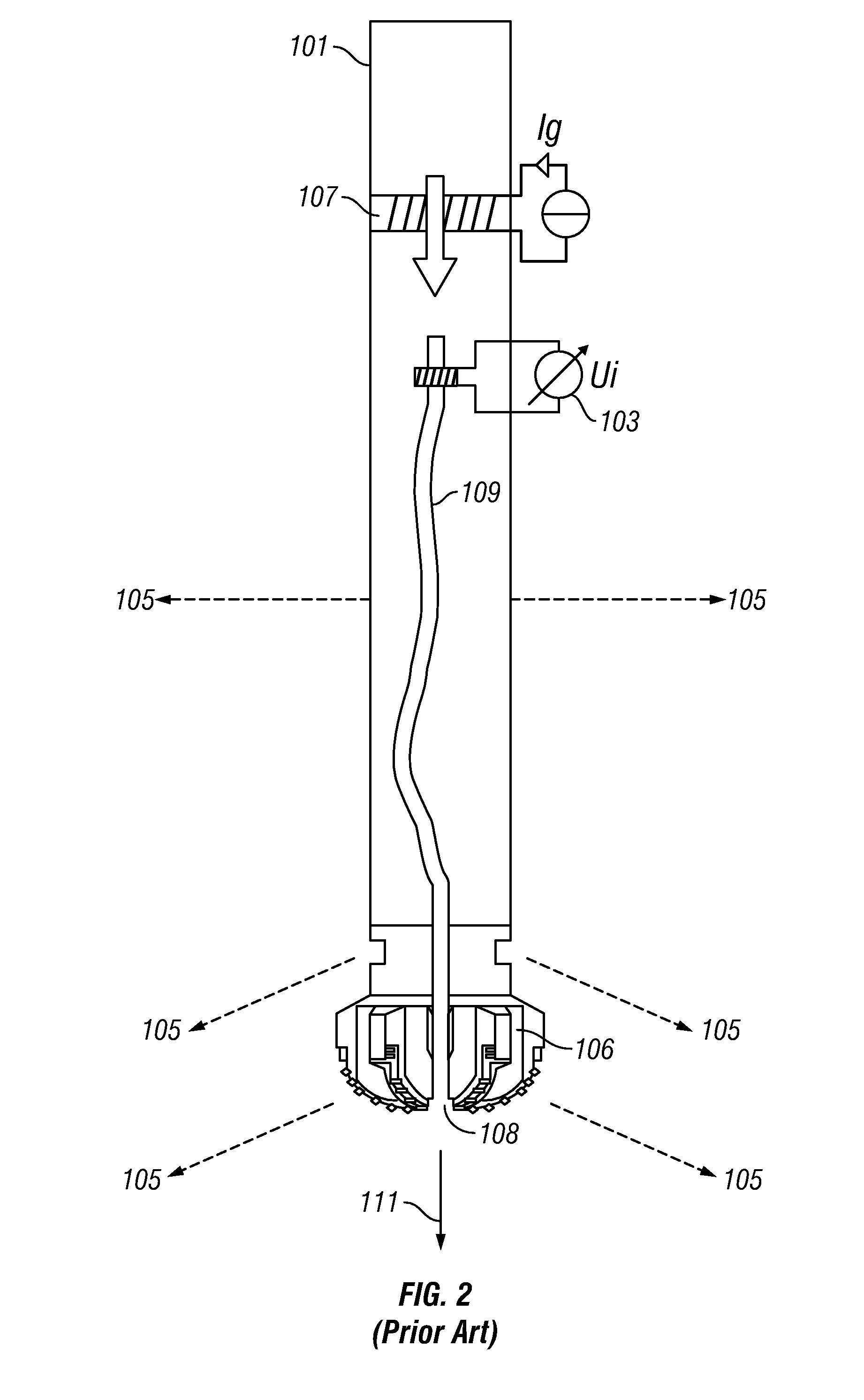

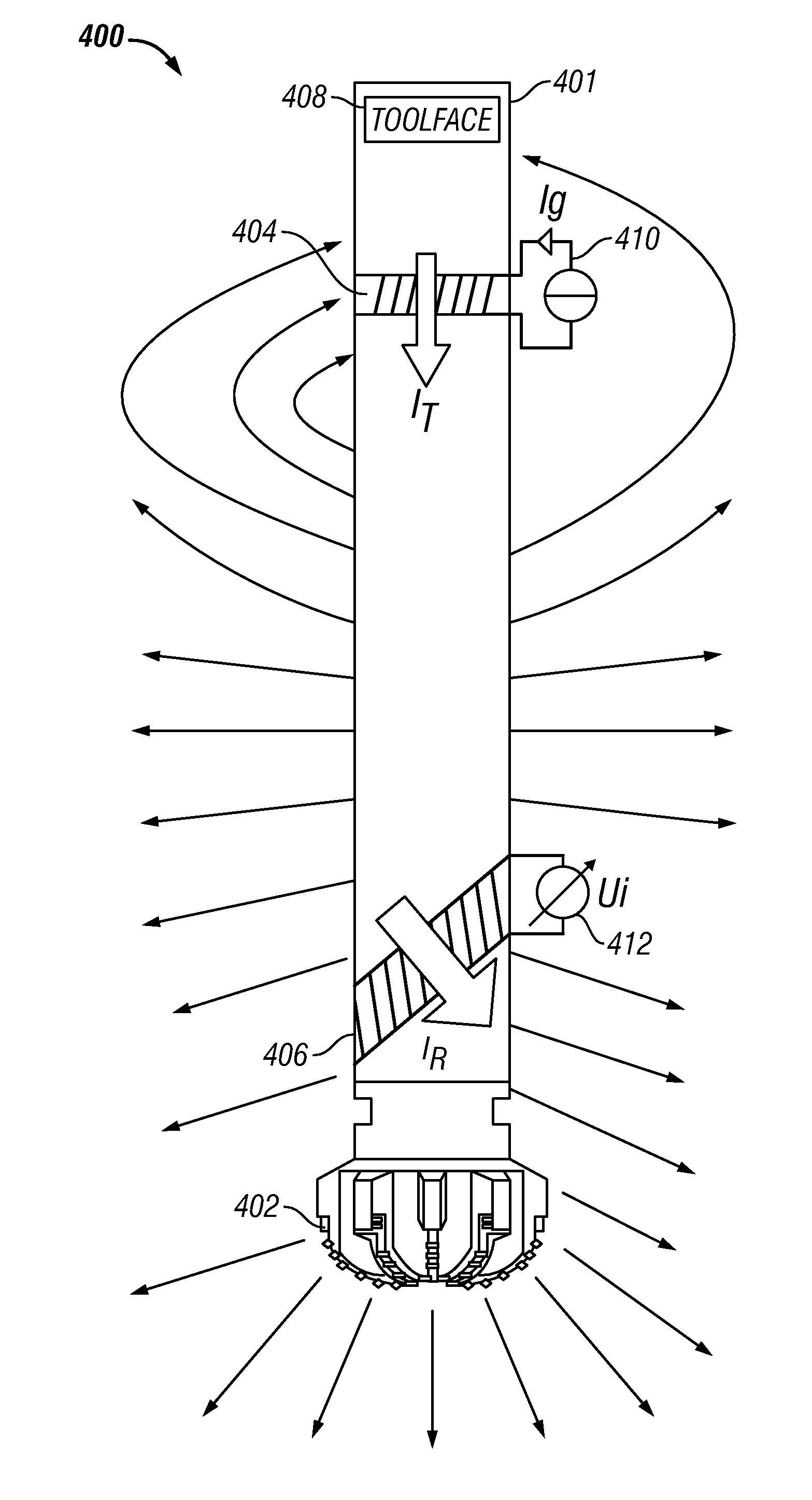

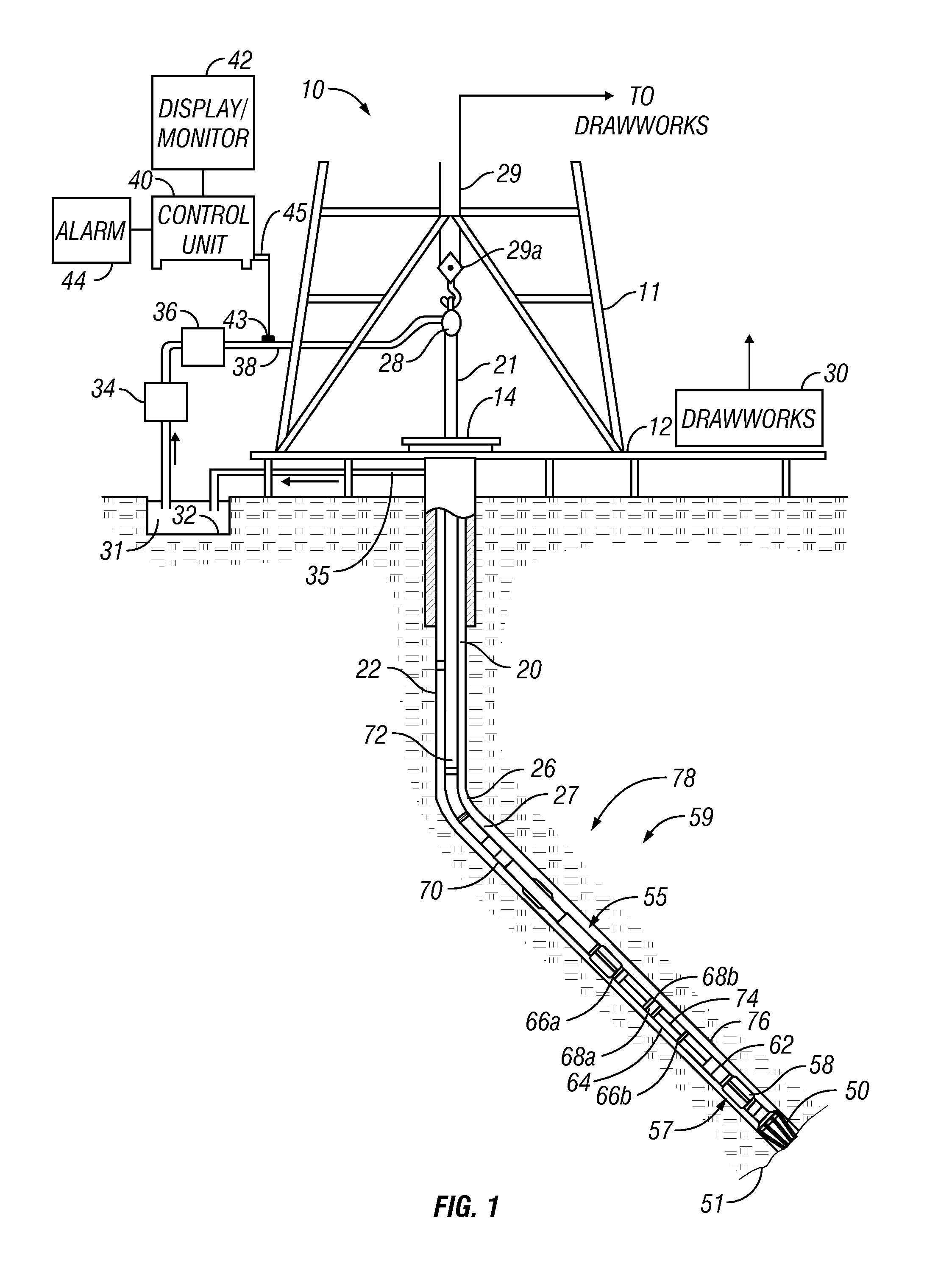

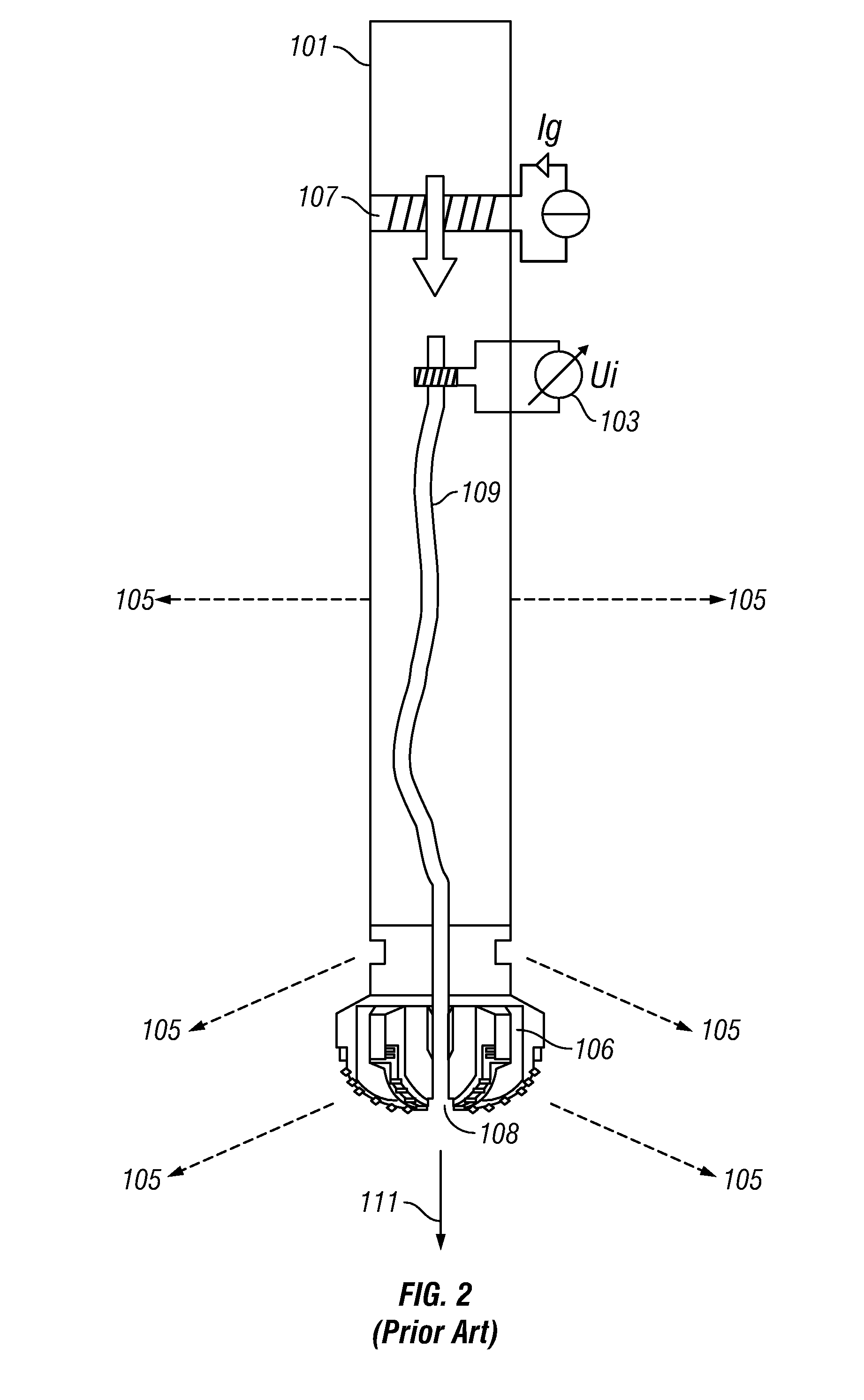

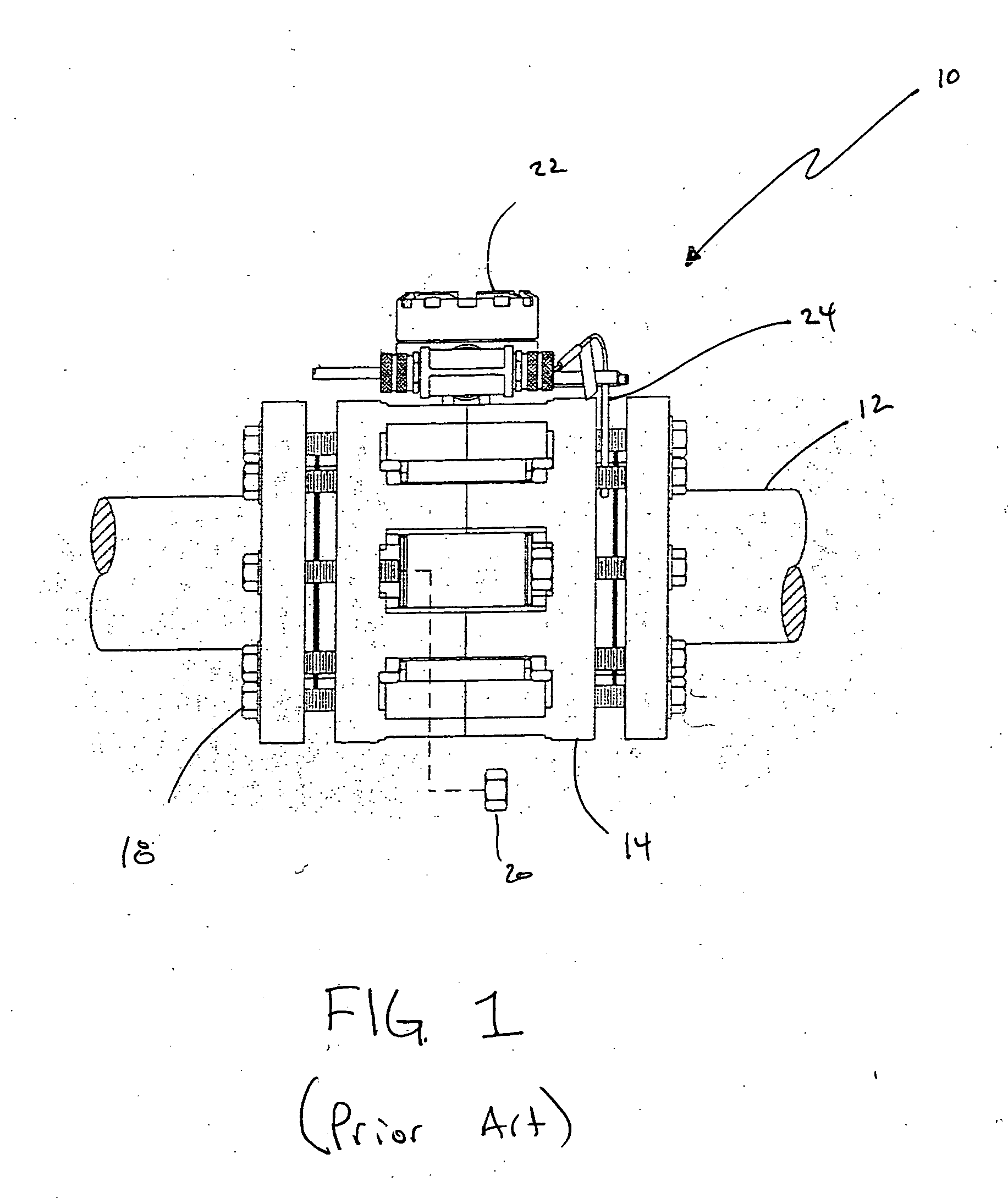

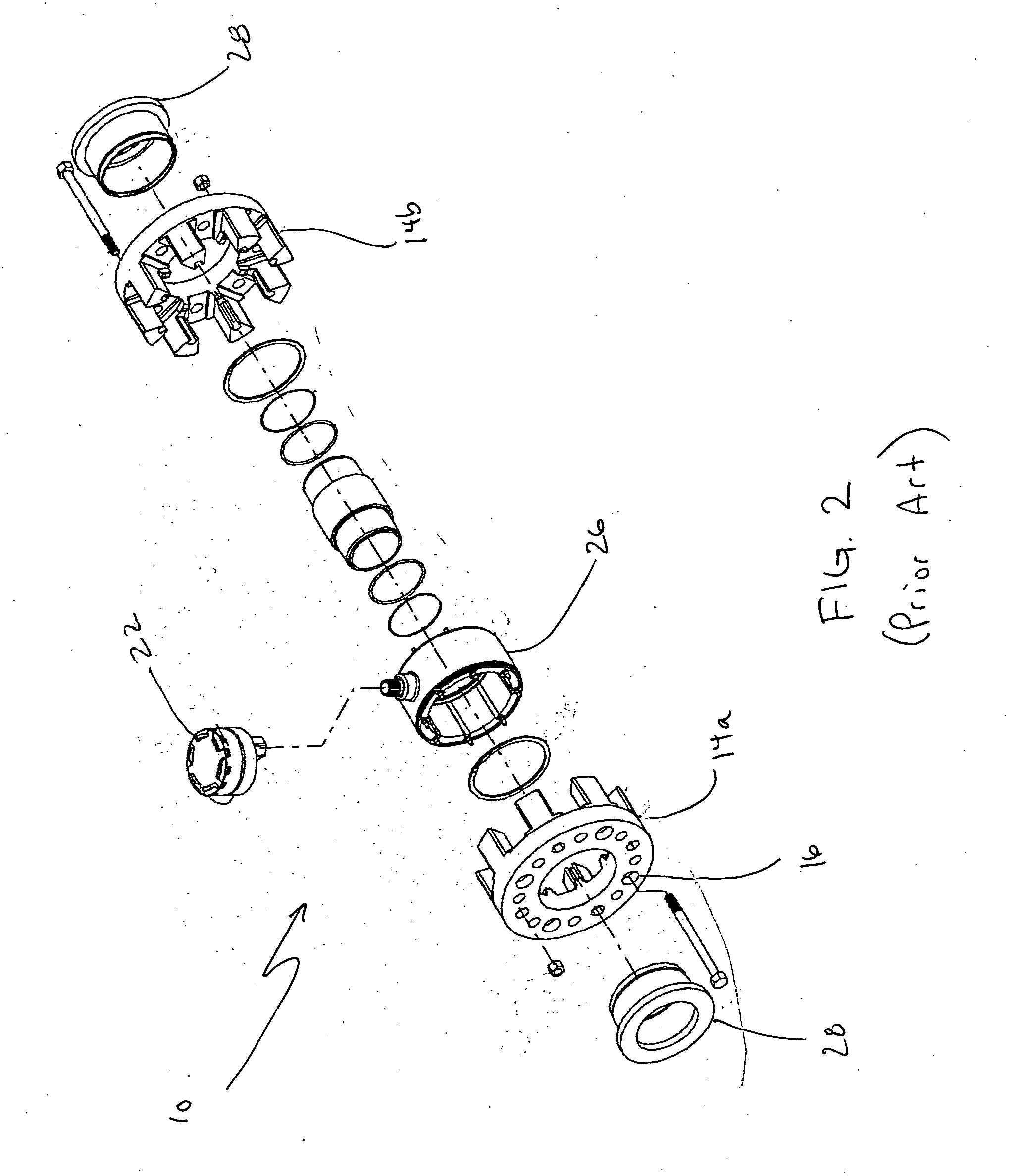

Method and Apparatus for Determining Formation Boundary Near the Bit for Conductive Mud

ActiveUS20080297161A1Electric/magnetic detection for well-loggingAcoustic wave reradiationEngineeringToroidal coil

A method and apparatus for determining a parameter of interest of an earth formation during drilling of a borehole. A first toroidal coil antenna induces a current along a path that includes a bottomhole assembly and the formation. A second toroidal coil antenna disposed at the drillbit and oriented at a non-zero angle to the longitudinal axis of the bottomhole assembly measures an electrical signal resulting from the current, the electrical signal being a parameter of interest of the formations.

Owner:BAKER HUGHES INC

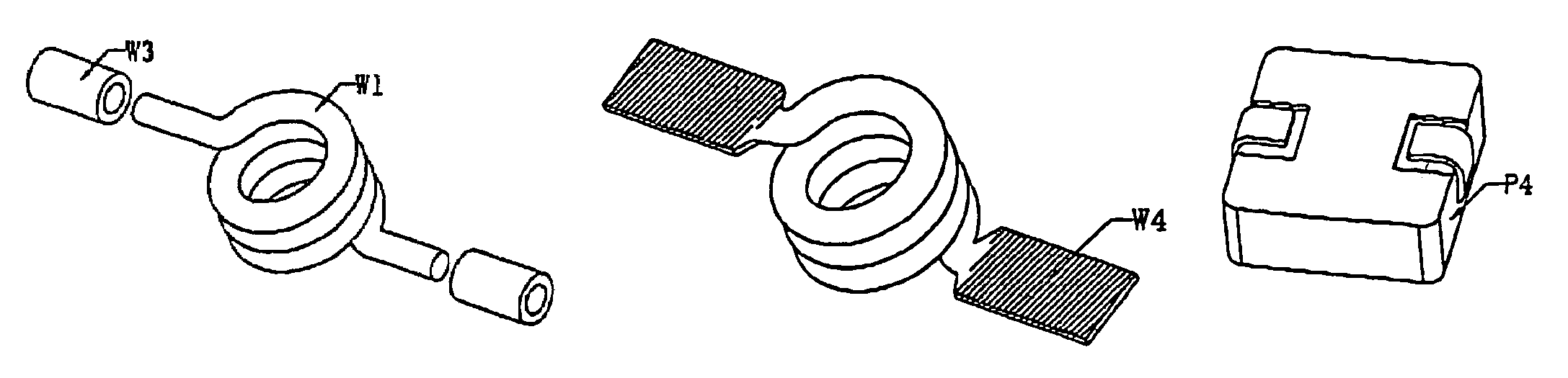

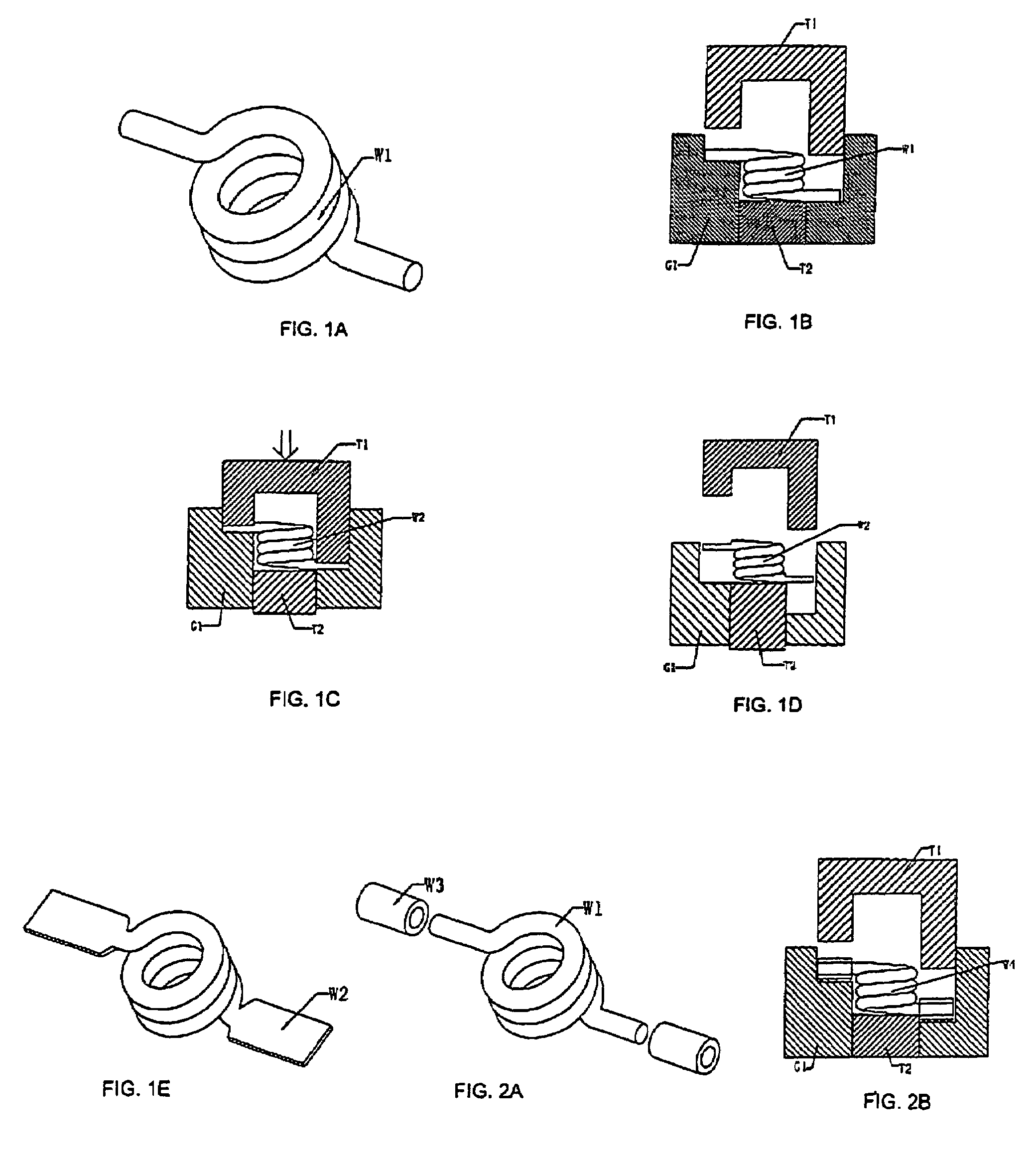

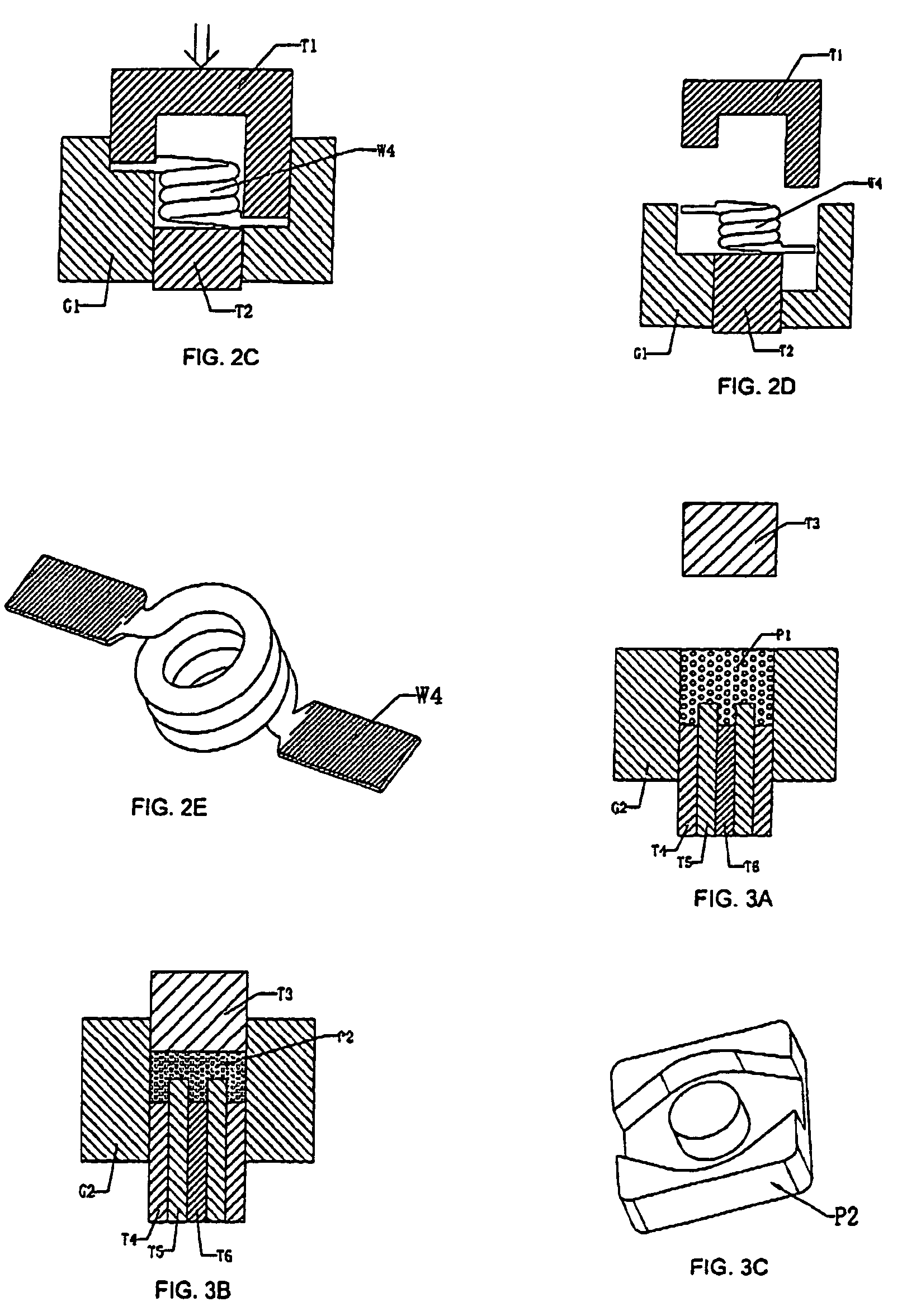

High current inductor and the manufacturing method

InactiveUS20060001517A1Improve featuresCompact structureTransformers/inductances casingsTransformers/inductances coils/windings/connectionsElectrical conductorDie casting

An inductor with the characteristic of resisting high current comprising a conductor coil and a magnet envelope, the magnet envelope tightly wraps the periphery of the conductor coil and forms the main body of the inductor, and the two extending parts of the conductor coil extend to outside of the main body of the inductor, forming terminal electrode. As of the manufacturing method, it includes the part of toroid coil and the extending parts composing the conductor coil. After the toroid coil part is winded into rings, the unwinded wire ends form the extending parts. Through magnet envelope die-casting and wrapping the molded magnet core of the conductor coil to form the main body of the inductor, and the extending parts of the conductor coil extend to outside of the main body to form the terminal electrode.

Owner:CHENG CHANG MAO

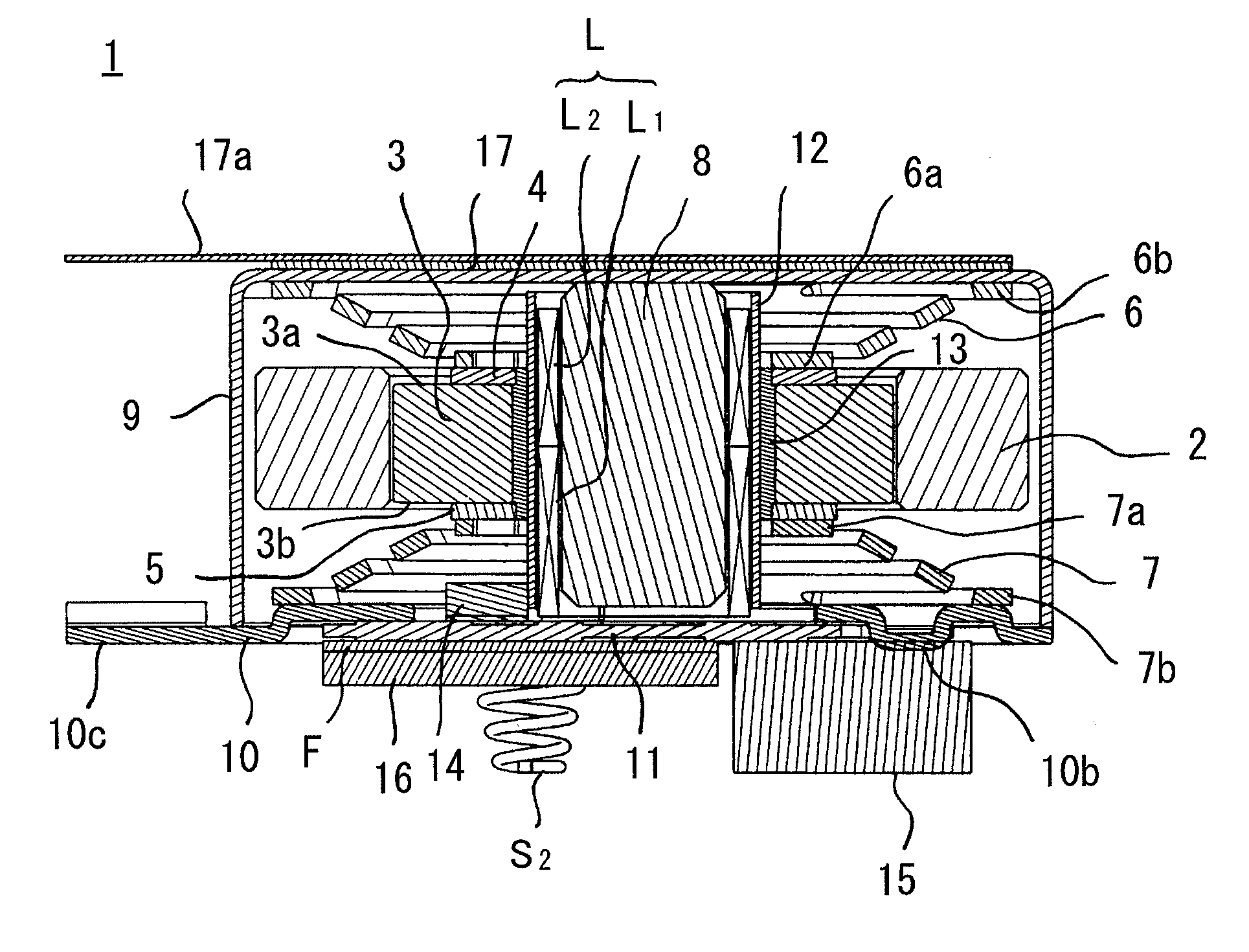

Recirocating vibration generator

InactiveUS20110198948A1Increase vibration intensityReduce power consumptionMechanical vibrations separationSupports/enclosures/casingsReciprocating motionClosed loop

A reciprocating vibration generator making the magnetic circuit of a permanent magnet a closed loop so as to obtain a high vibration force, specifically a vibration linear actuator having a ring-shaped weight, a reciprocating vibrator having a ring-shaped permanent magnet in a center hole of the weight, a first plate spring and a second plate spring supporting this reciprocating vibrator with respect to a recessed case and an end plate to be able to elastically displace in a thickness direction between a first end face and a second end face, a tube-shaped toroidal coil running through a center hole of the ring-shaped permanent magnet and generating a reciprocating vibration magnetic field for driving the ring-shaped permanent magnet to reciprocate in the thickness direction, and a columnar core running through the inside of this toroidal coil, wherein the ring-shaped permanent magnet is magnetized in the thickness direction, and the toroidal coil has a lower stage toroidal coil and an upper stage toroidal coil coaxial with and adjacent to the same, wound in the opposite direction, and connected in series with the same.

Owner:SANYO SEIMITSU

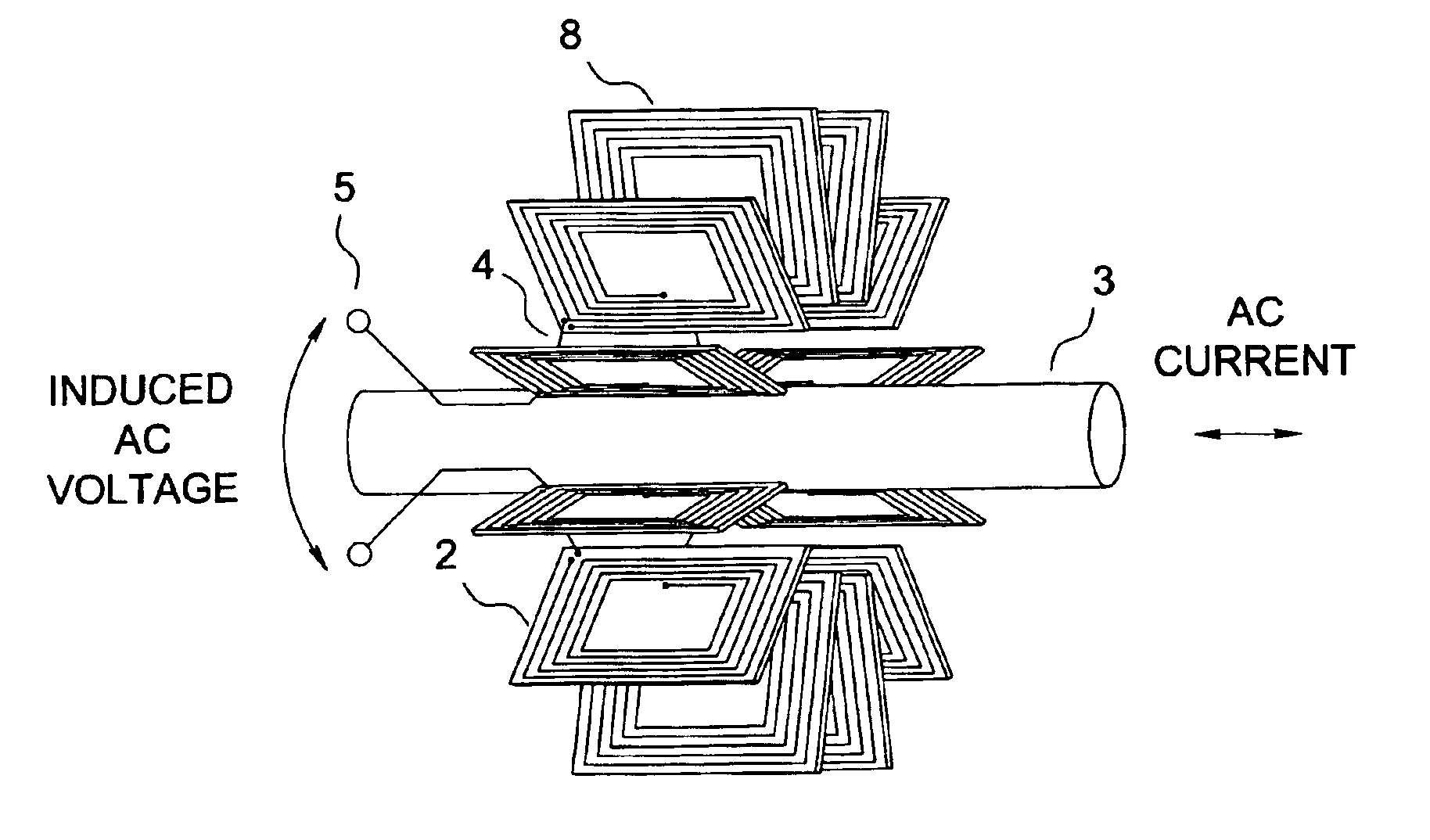

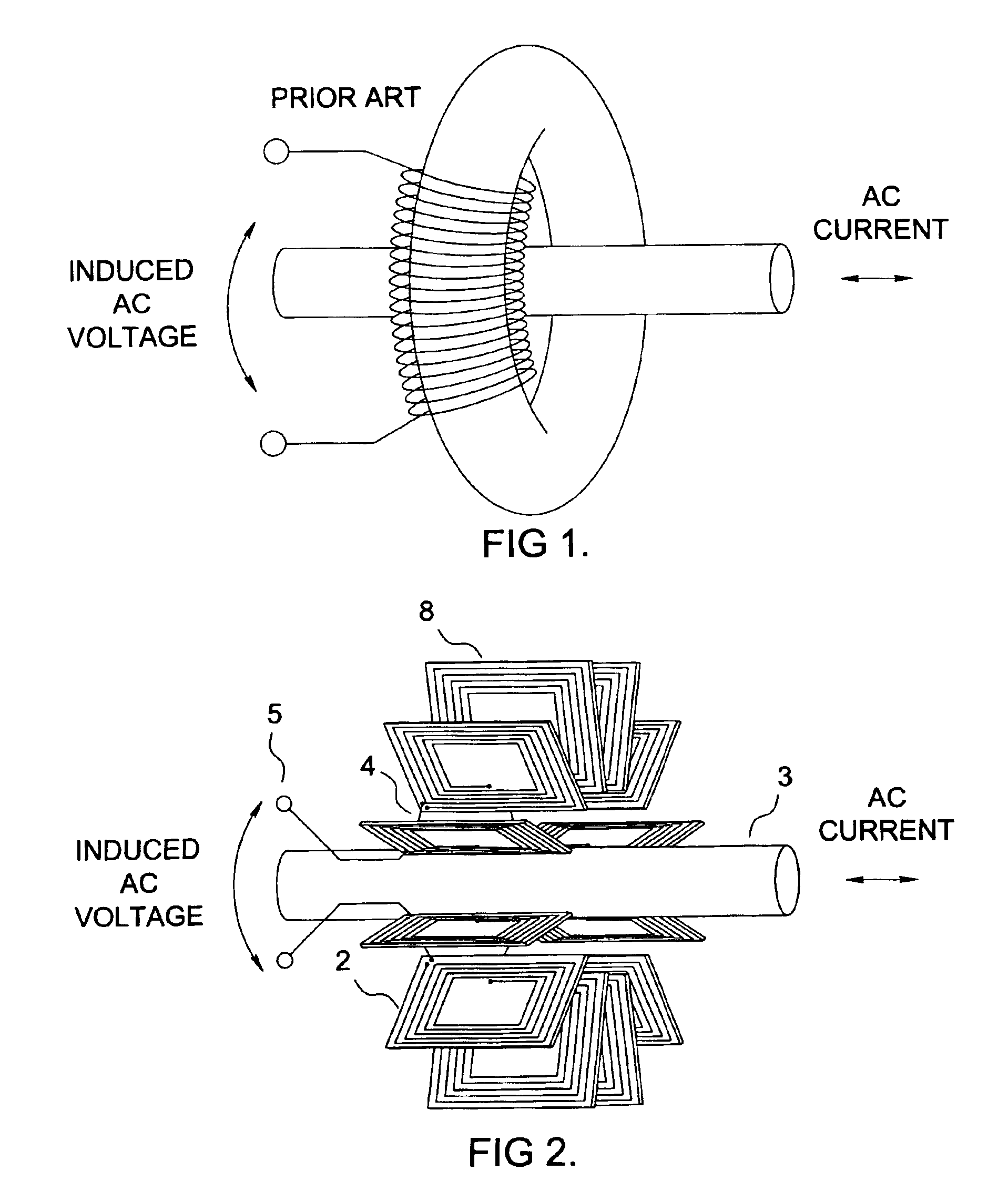

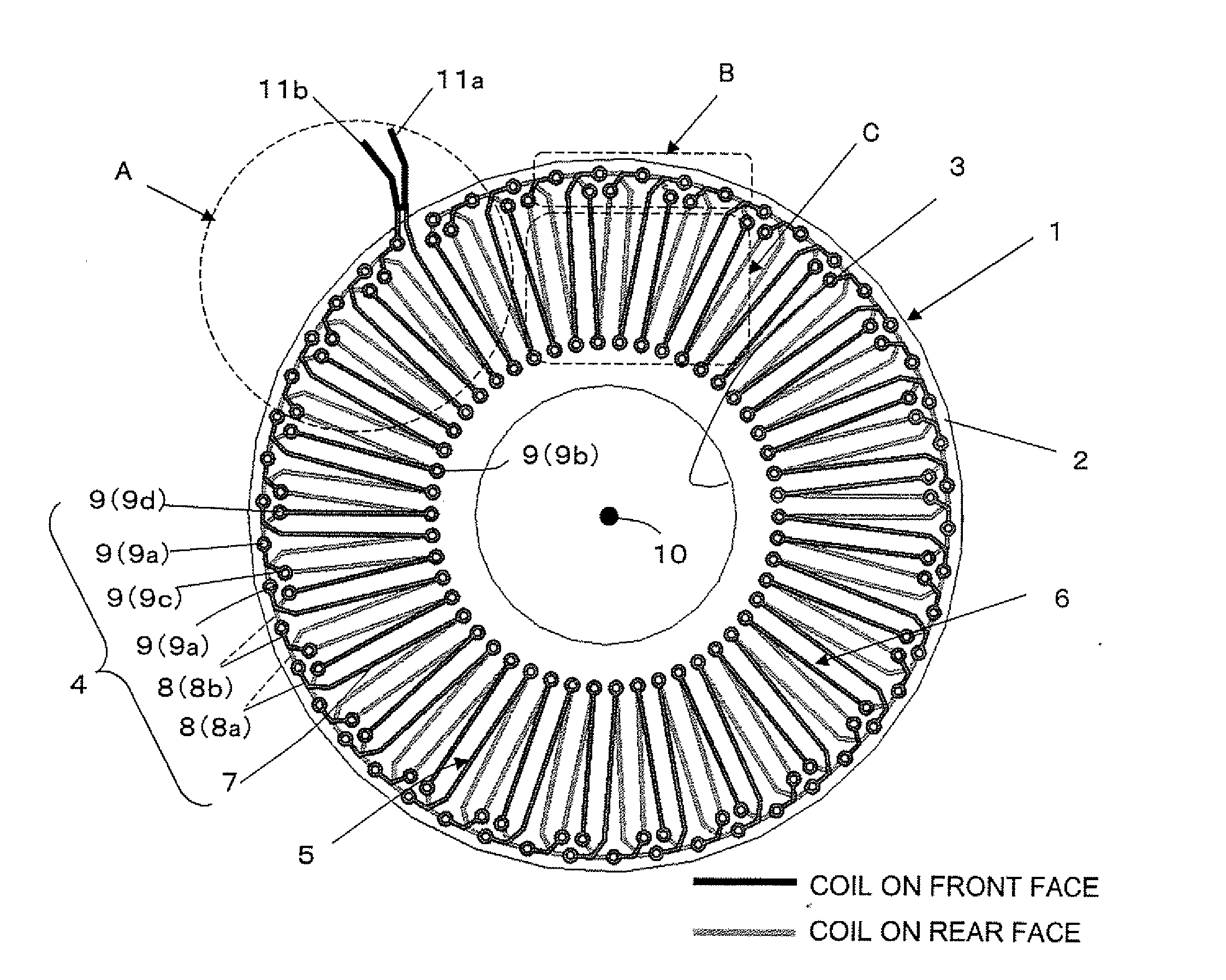

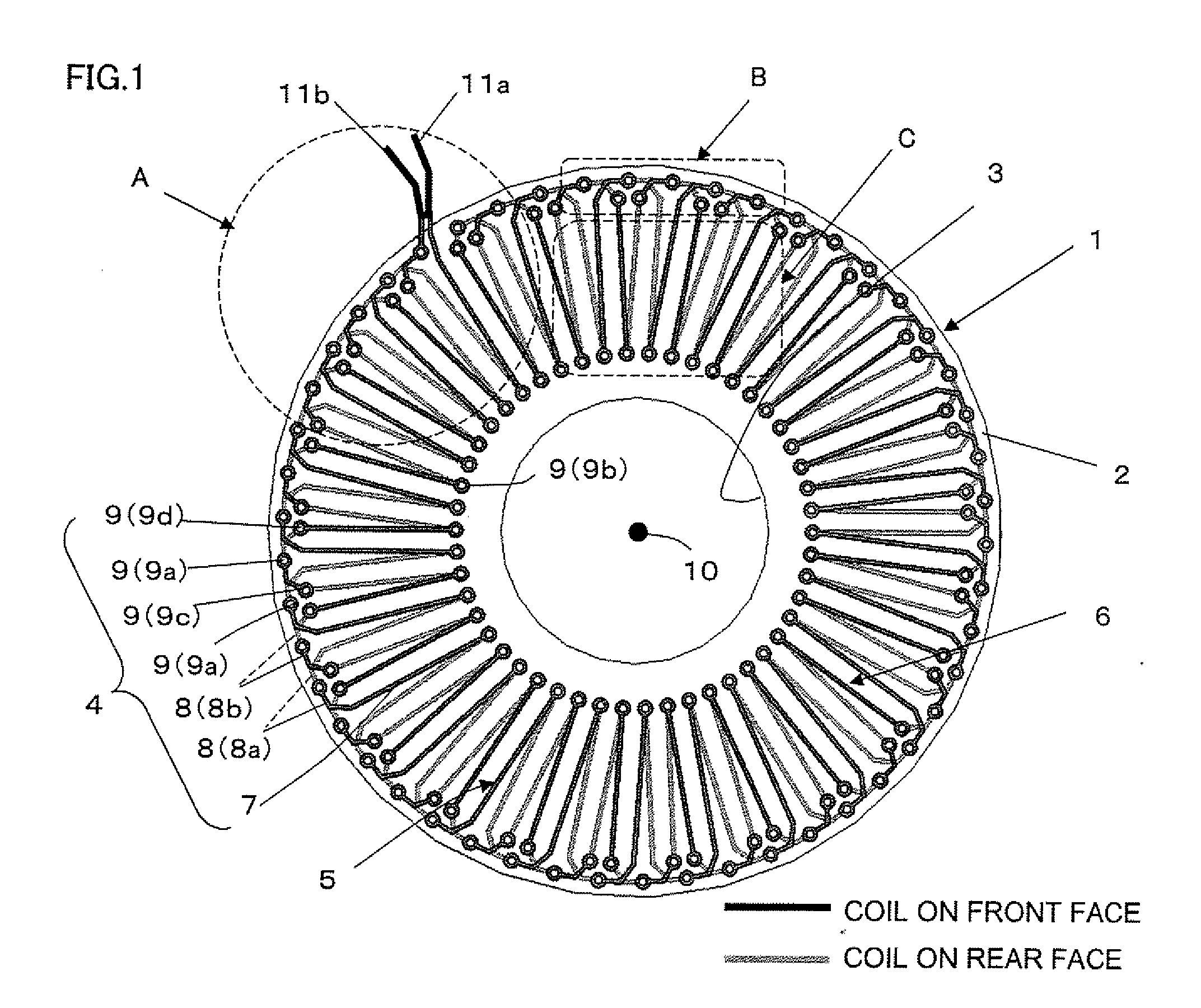

Alternating current detection coil

InactiveUS20070152651A1Improve detection accuracyCanceled outCurrent/voltage measurementTransformers/inductances coils/windings/connectionsElectricityElectrical conductor

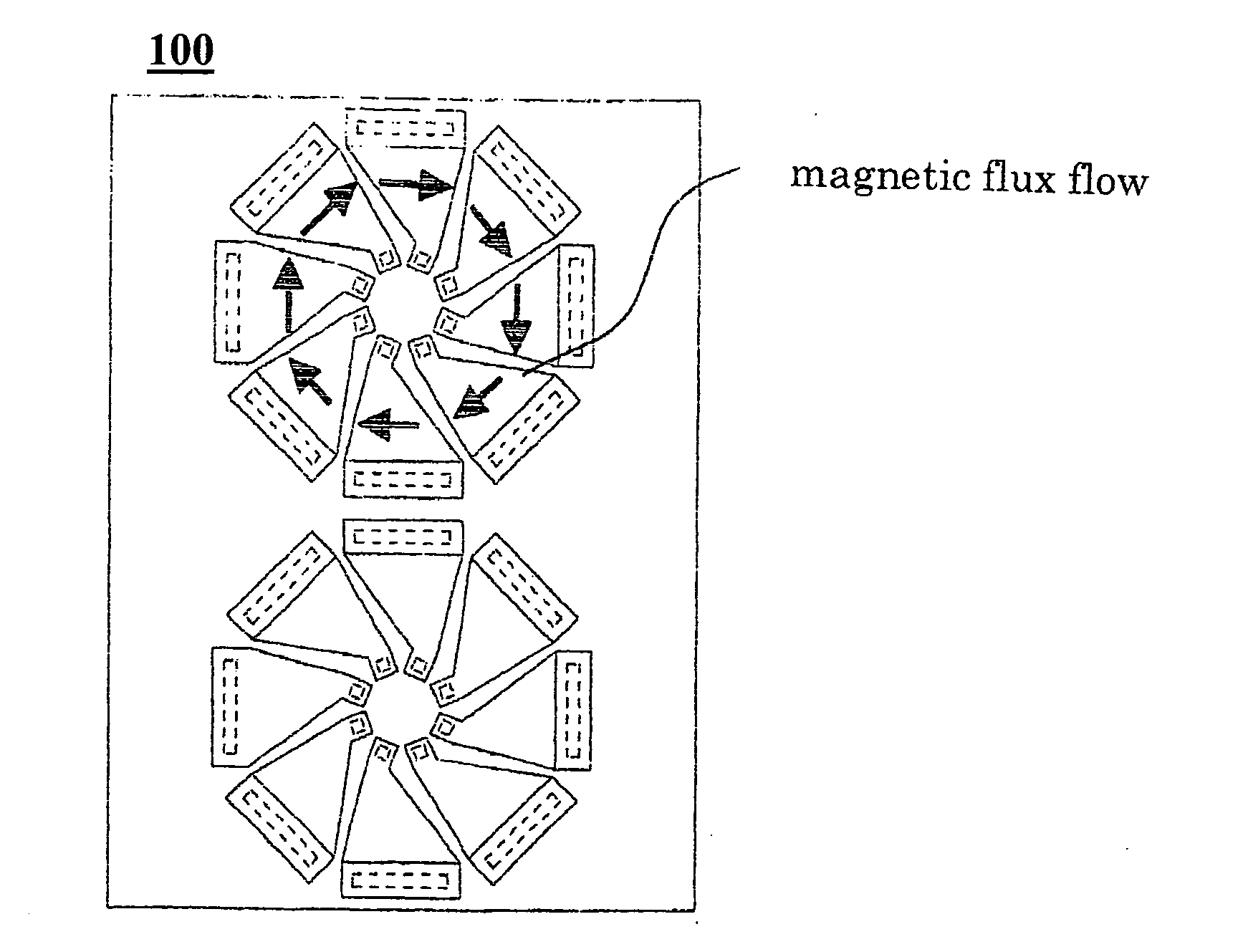

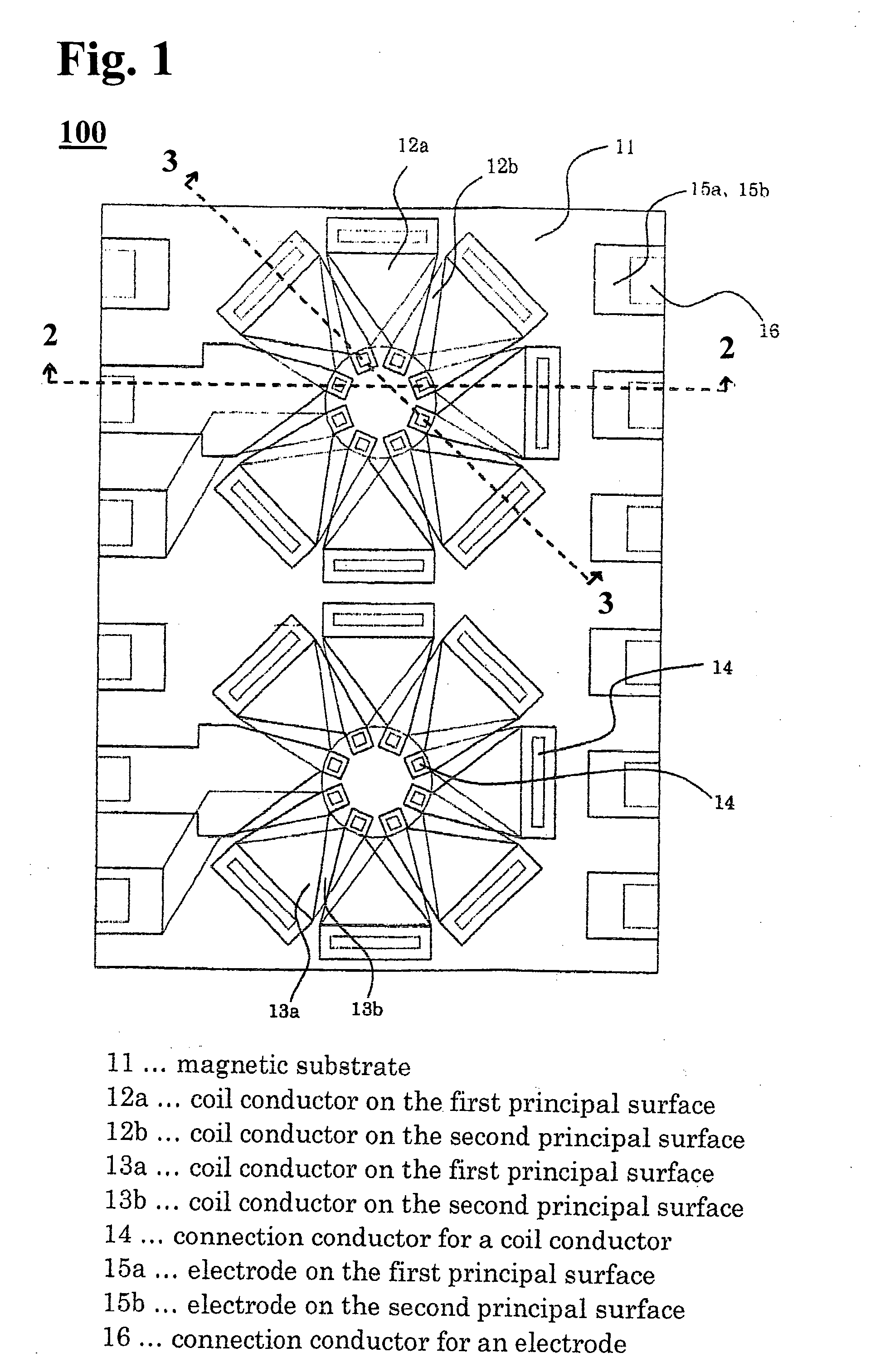

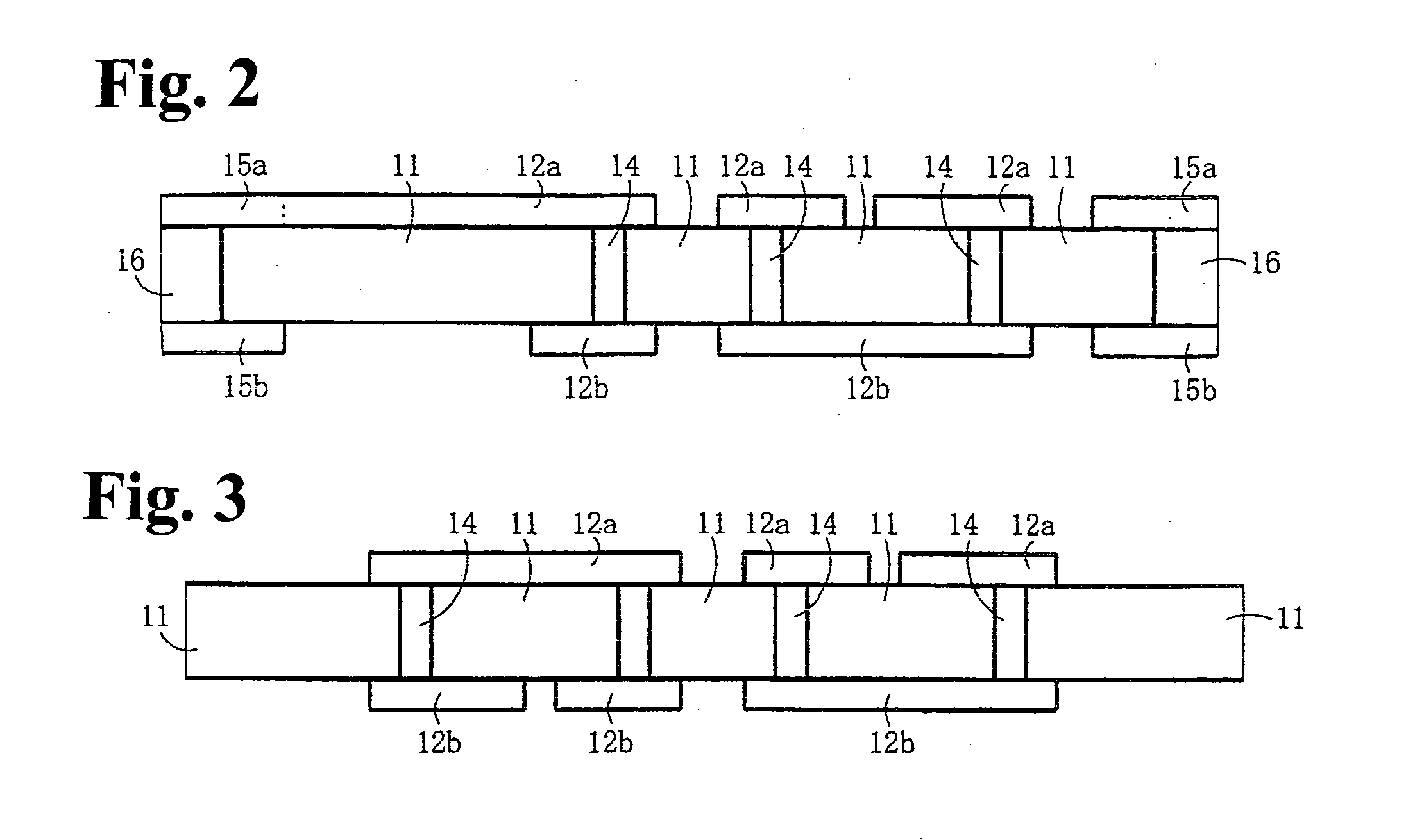

The alternating current detection coil is a toroidal coil, and comprises plural radial-line conductors which are formed on a front face and a rear face of a substrate, conductive connection parts and conductive through-holes which connect electrically each end of radial-line conductors, wherein plural winding turns are consecutively formed by a connection of each radial-line conductor on the front face and the rear face respectively, the winding turns comprise a forward coil and a backward coil, and each shape on the front face and the rear face of the radial-line conductors and the conductive connection parts are identical with each other. Consequently, when seen from a thickness direction of the substrate, areas of the forward coil and the backward coil are equal to each other, and an external magnetic field, which does not need to be detected, can be canceled each other by the forward coil and the backward coil, then a current detection accuracy can be improved.

Owner:MATSUSHITA ELECTRIC WORKS LTD

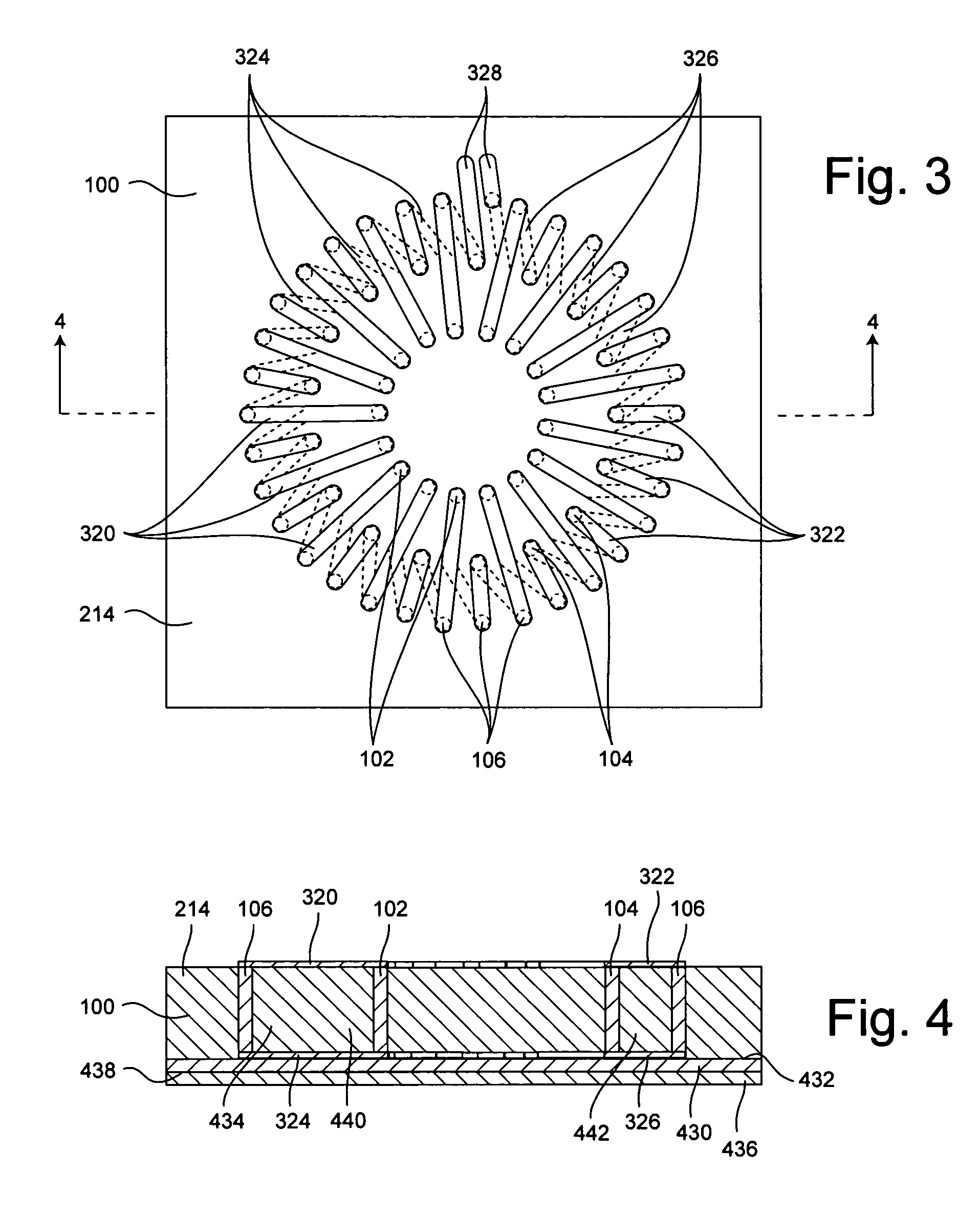

Embedded toroidal inductor

ActiveUS7158005B2Transformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureEngineeringInductor

A toroidal inductor, including a substrate (100), a toroidal core region (434) defined within the substrate, and a toroidal coil including a first plurality of turns formed about the toroidal core region and a second plurality of turns formed about the toroidal core region. The second plurality of turns can define a cross sectional area (440) greater than a cross sectional area (442) defined by the first plurality of turns. The substrate and the toroidal coil can be formed in a co-firing process to form an integral substrate structure with the toroidal coil at least partially embedded therein. The first and second plurality of turns can be disposed in alternating succession. The toroidal core region can be formed of a substrate material having a permeability greater than at least one other portion of the substrate.

Owner:HARRIS CORP

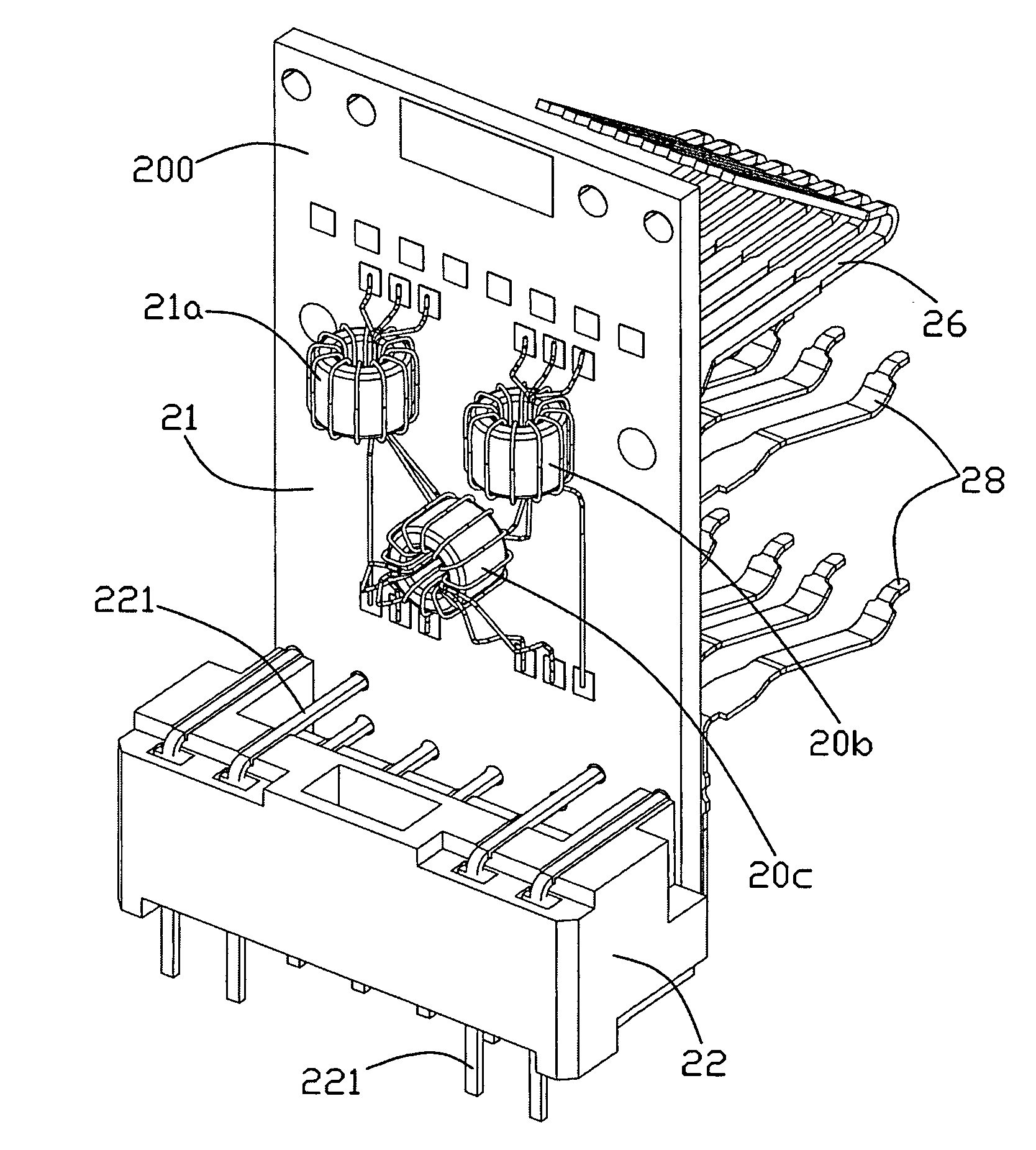

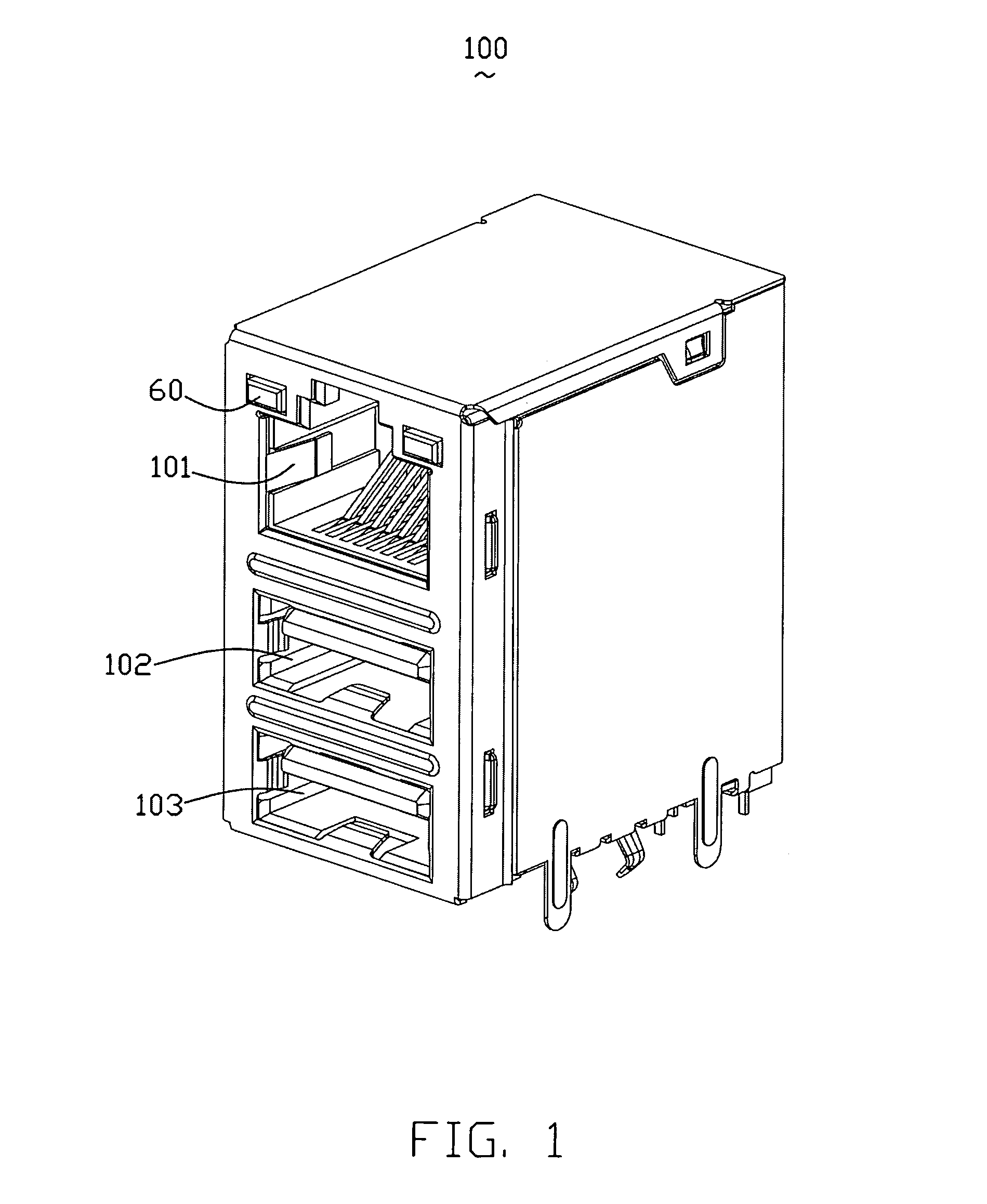

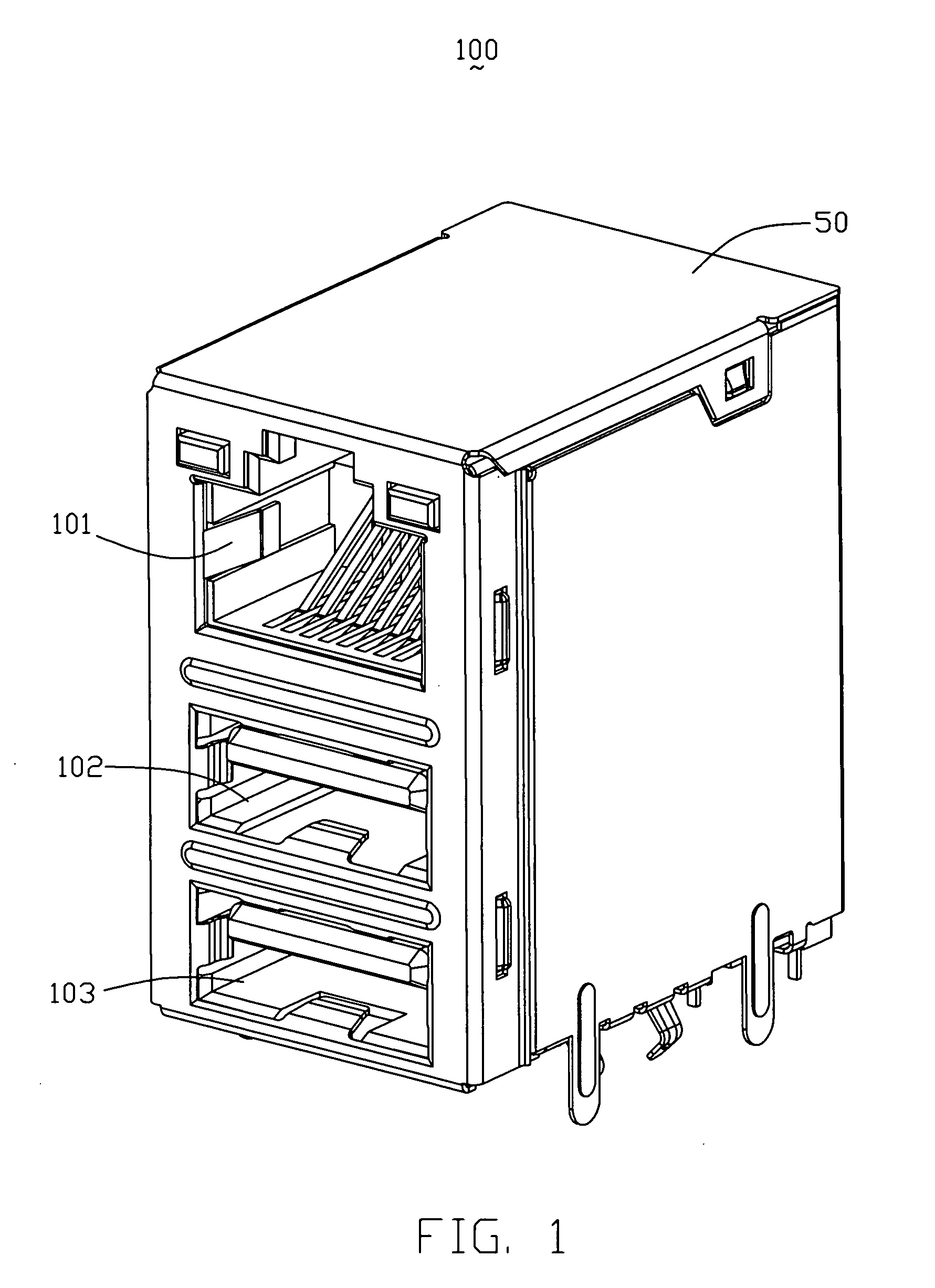

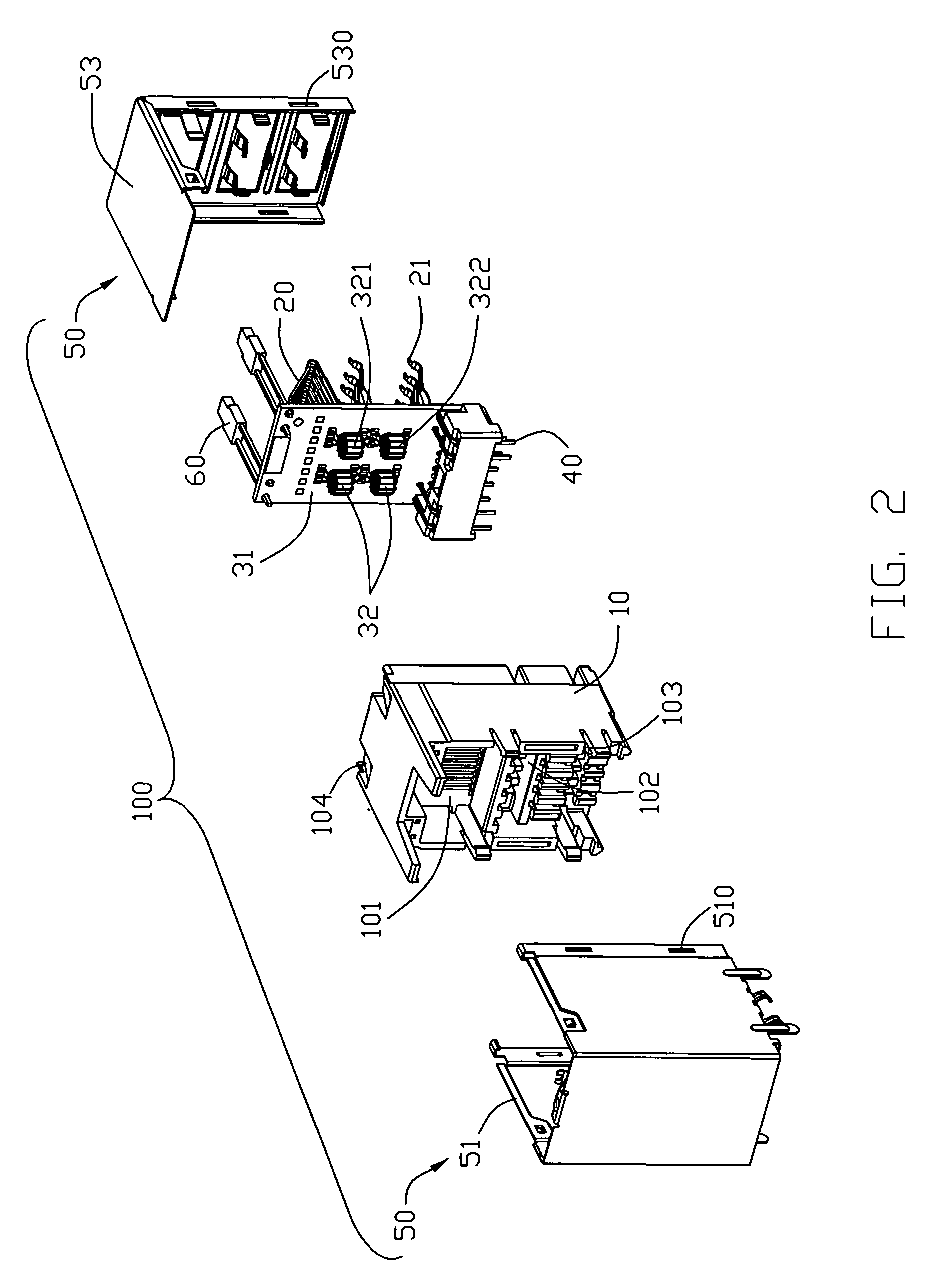

Modular jack having an improved magnetic module

InactiveUS7670183B2Eliminate high frequency noiseLow costCoupling device detailsTwo-part coupling devicesEngineeringToroidal coil

Owner:HON HAI PRECISION IND CO LTD

Inductive conductivity sensor

InactiveUS7965167B2Small axial lengthEasy to processTransformers/inductances coils/windings/connectionsMaterial impedanceElectrical conductorToroidal coil

A conductivity sensor for measuring conductivity of a medium surrounding the conductivity sensor includes a first toroidal coil bounding a medium-receiving passageway and serving for inducing an electrical current in the medium, and a second toroidal coil also bounding the passageway and serving for registering a magnetic field produced by the electrical current. At least one of the toroidal coils has a plurality of first conductor segments, which extend in a plane of a multi-ply circuit board, a plurality of second conductor segments, which extend in a second plane of the circuit board, and a plurality of through-contacts, which connect the first conductor segments with the second conductor segments, wherein the first conductor segments, the second conductor segments and the through-contacts form, together, the windings of a toroidal coil.

Owner:ENDRESS HAUSER CONDUCTA GESELLSCHAFT FUER MESS UND REGELTECHNIK MBH CO KG

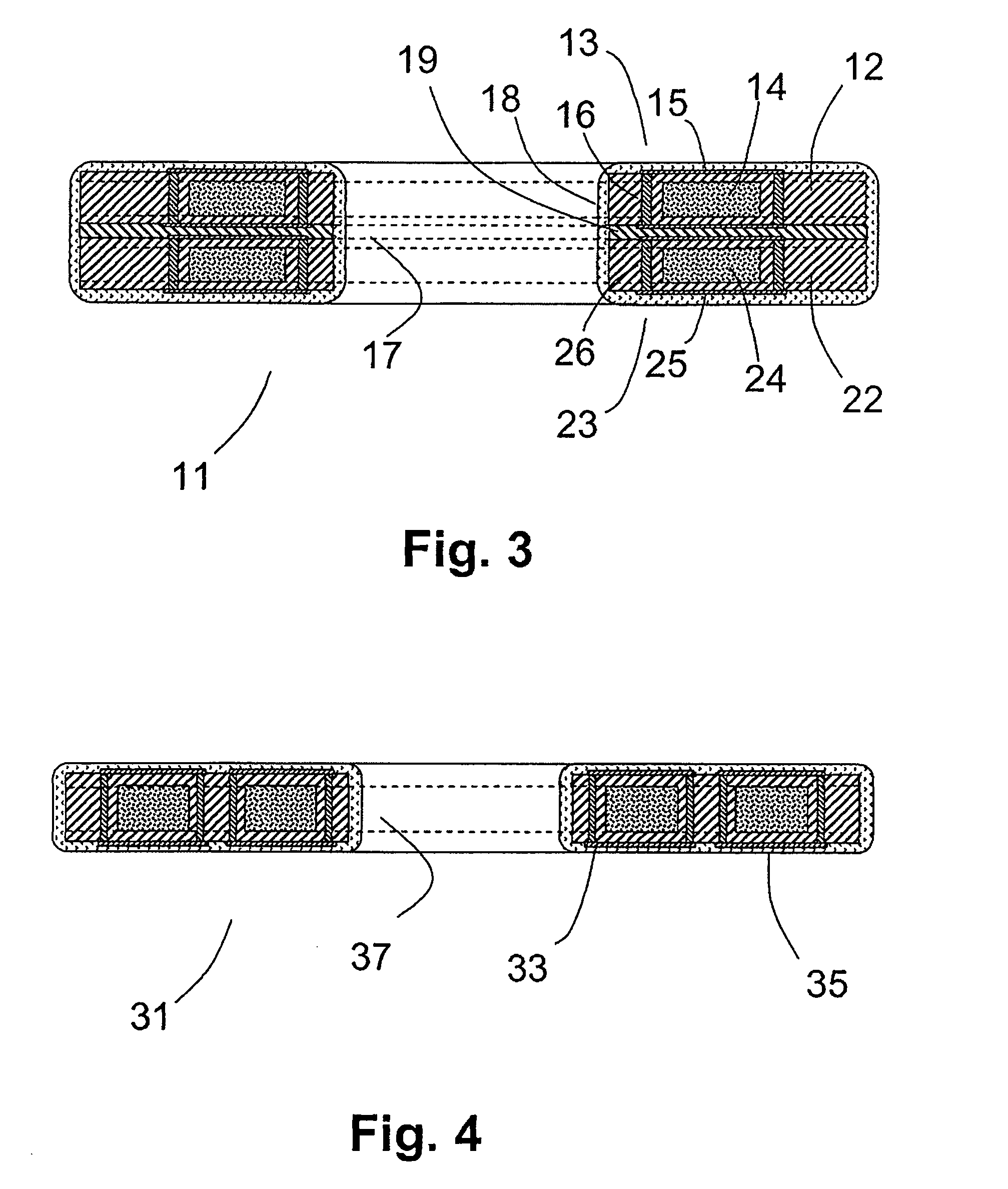

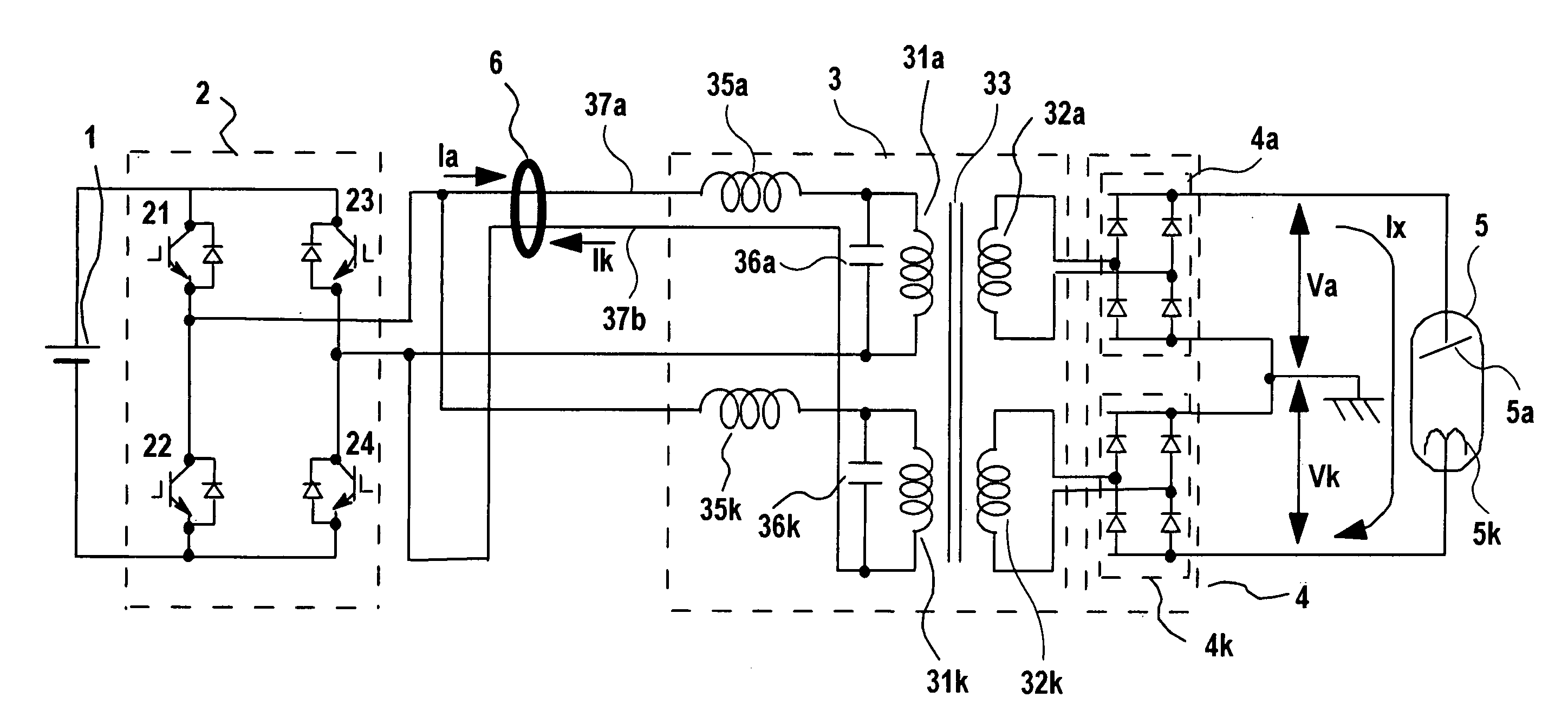

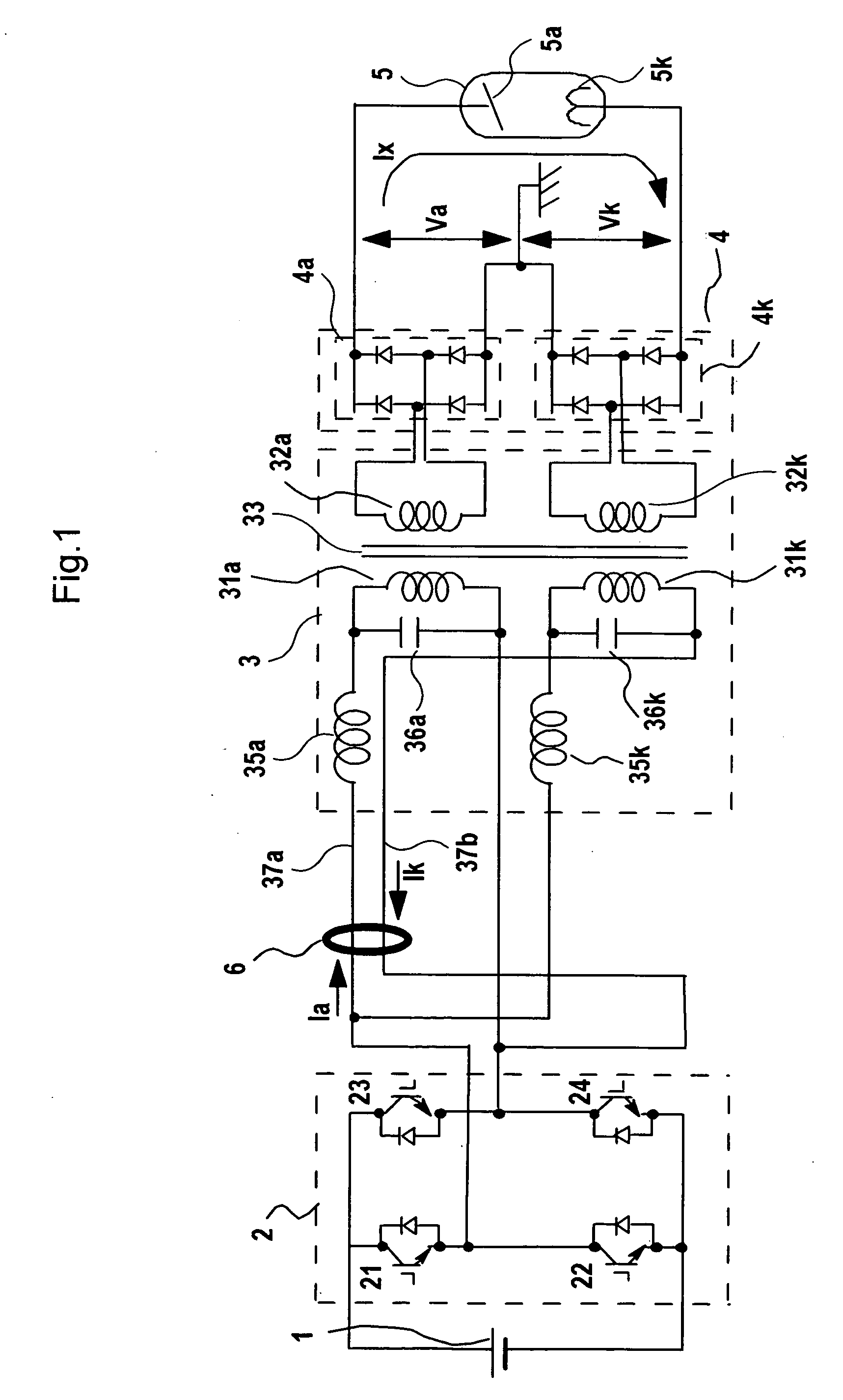

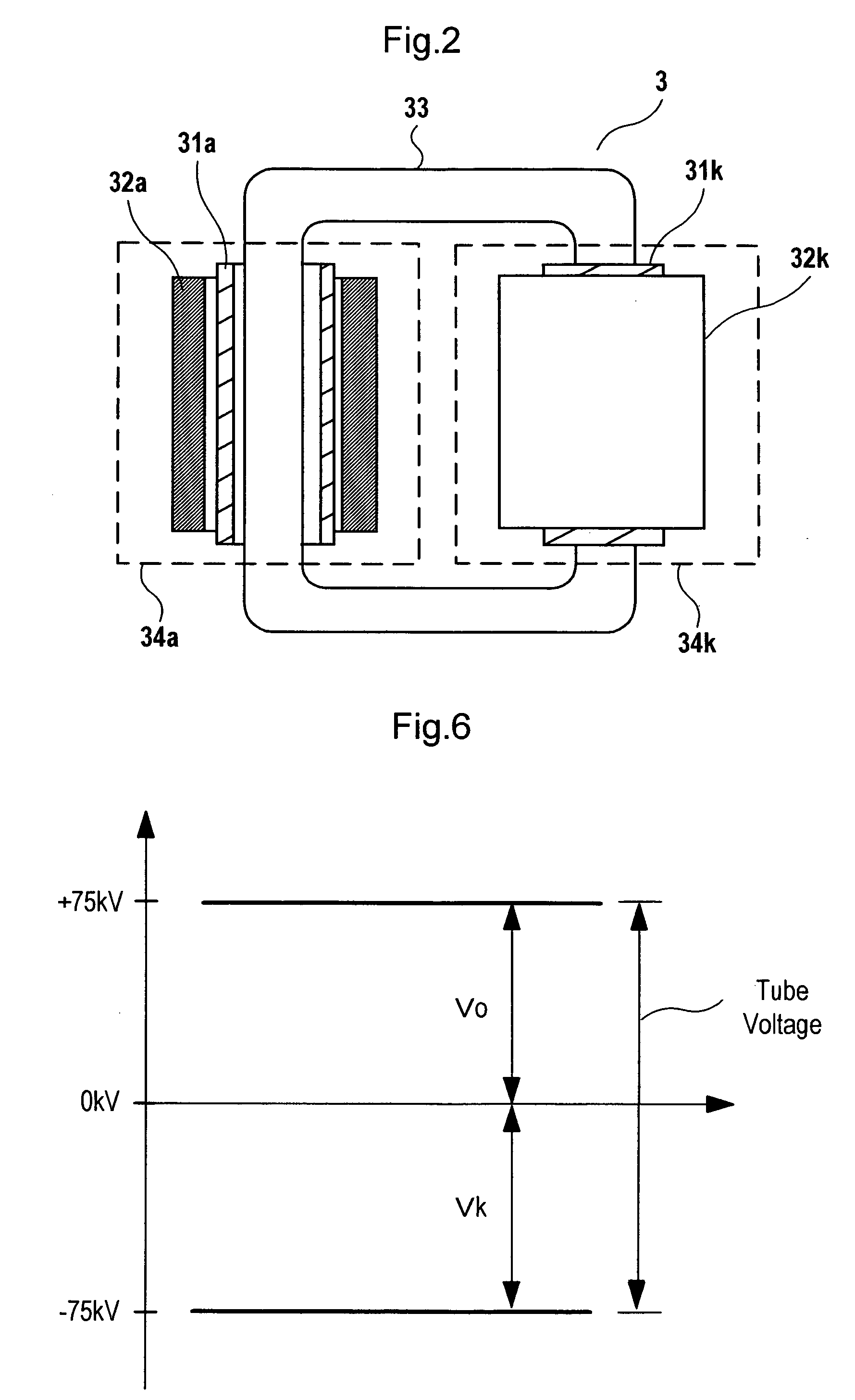

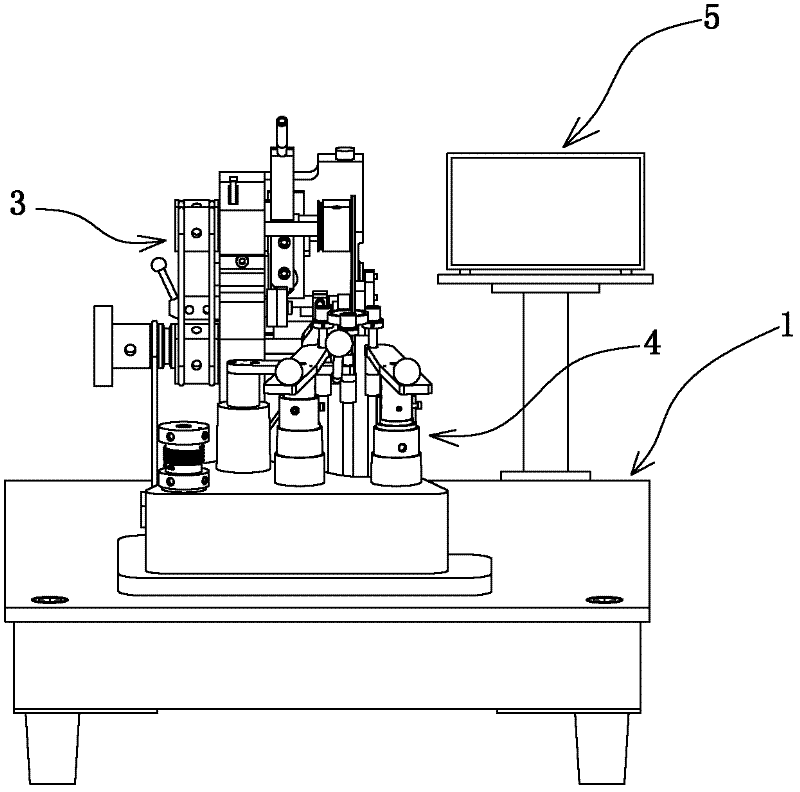

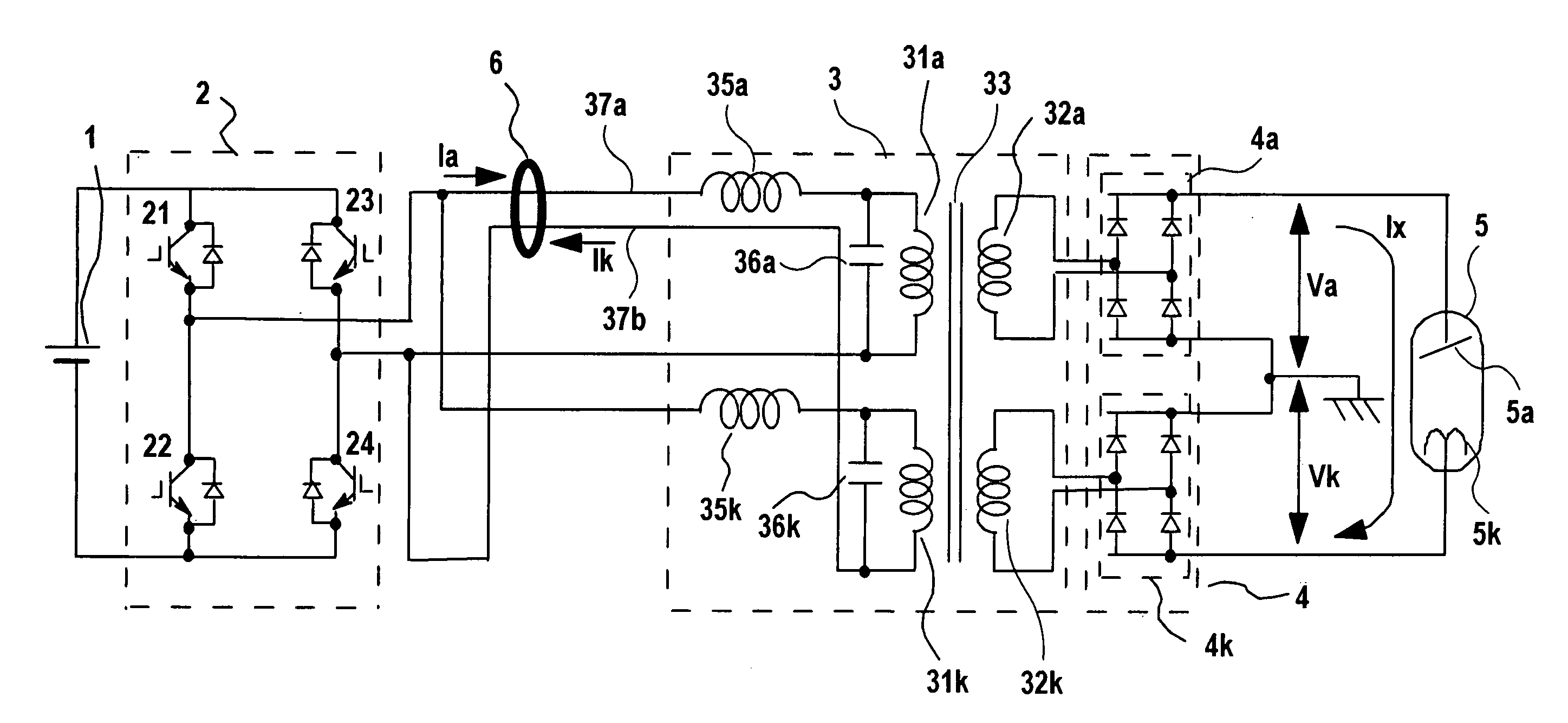

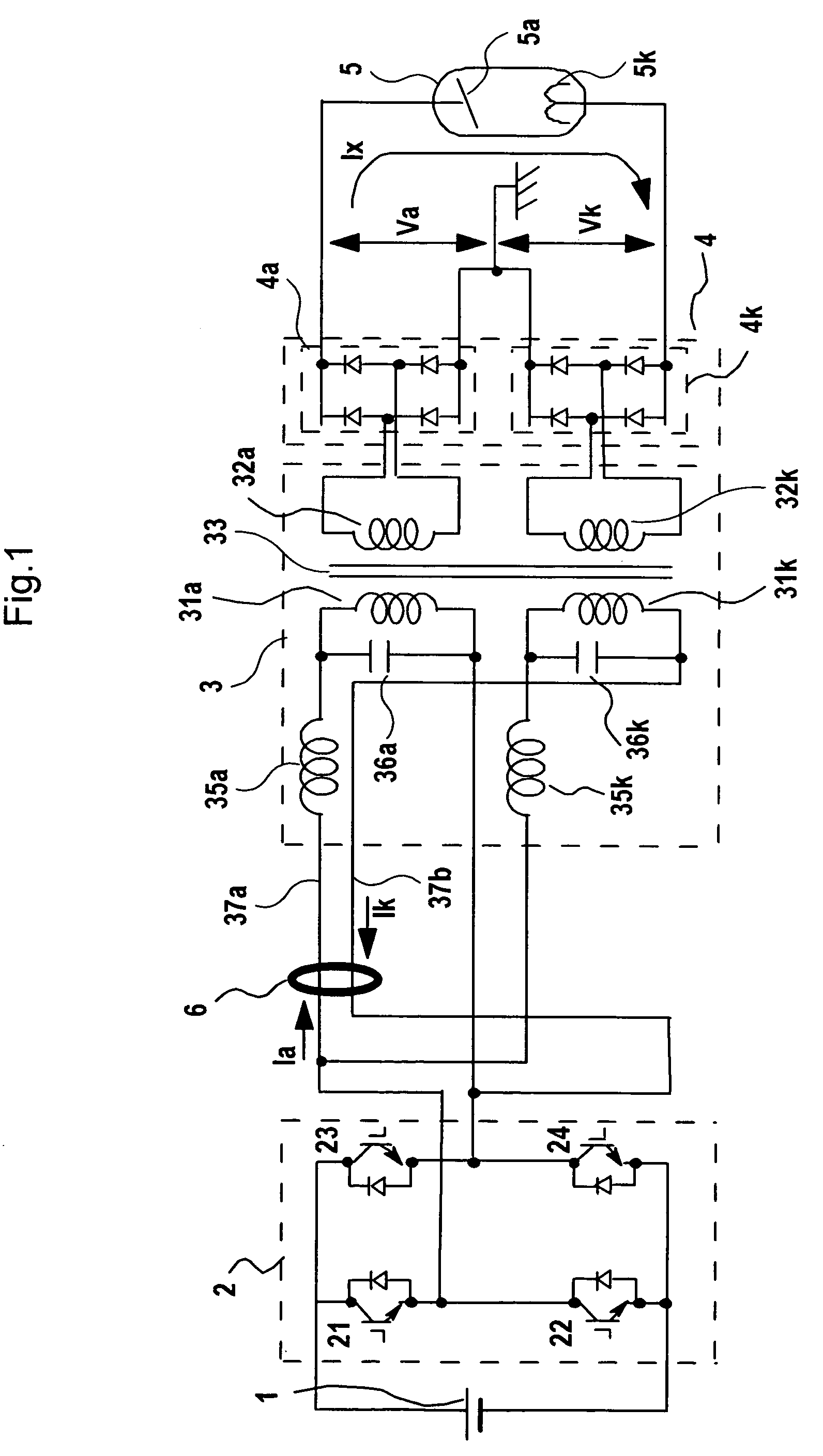

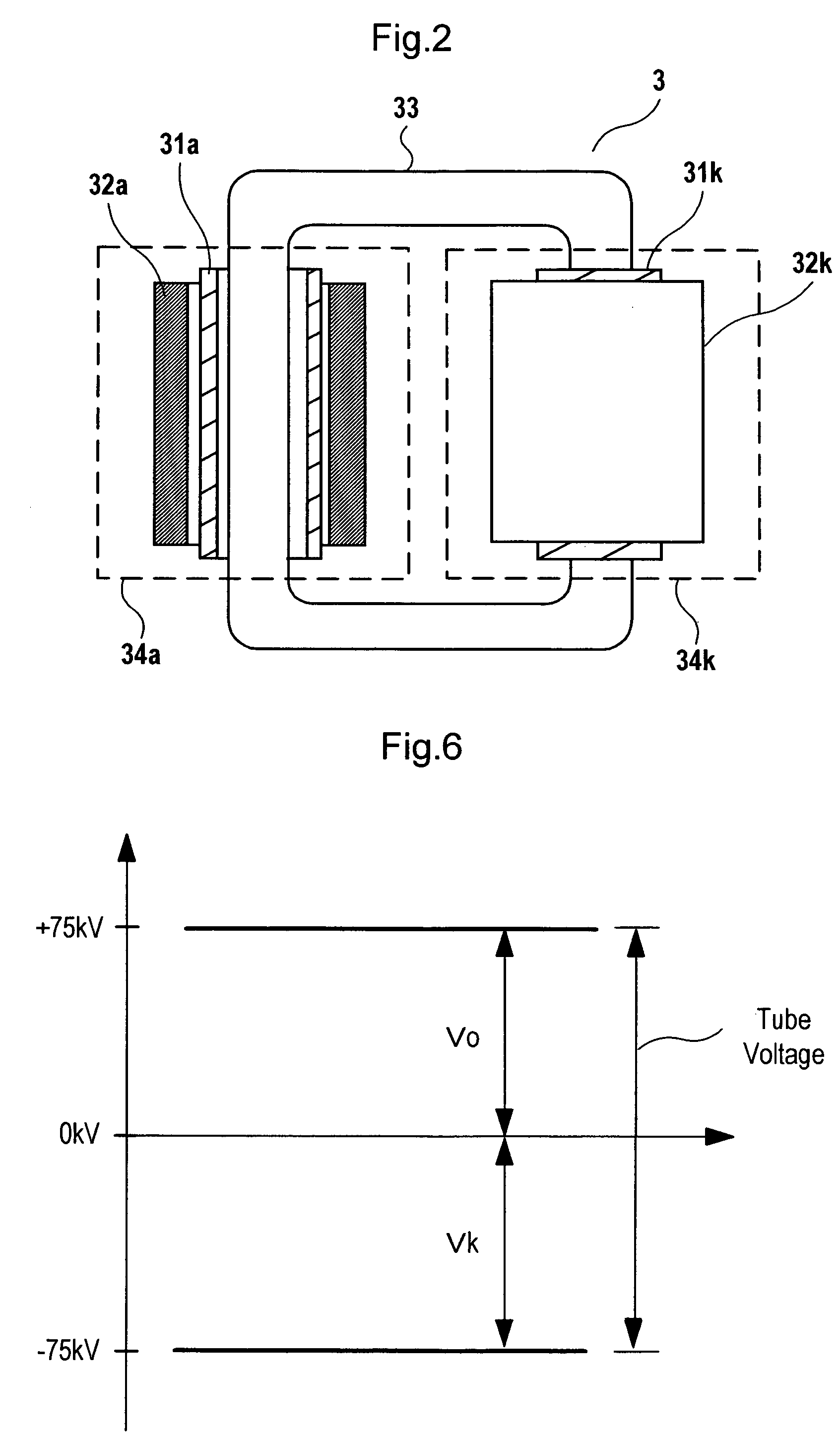

X-ray generator and x-ray ct apparatus comprising same

InactiveUS20060165220A1Reduce unbalance voltageImprove reducibilityX-ray apparatusToroidal coilElectrical impedance

In an X-ray generating device of the neutral grounding system, to remove an unbalance voltage generated due to difference in impedance of parallel transformer coils of the high voltage transformer and particularly an unbalance voltage involved with difference in impedance above and below the neutral points generated in a metal X-ray tube, a plurality of currents flowing in opposite directions through primary windings of the parallel transformer coils in the high voltage transformer are passed through by or wound around a common toroidal coil or wound around an outer circumference of the toroidal coil at a predetermined ratio of winding number, and the unbalance voltage occurring to the secondary side is cancelled by changing primary current with magnetic behavior.

Owner:HITACHI MEDICAL CORP

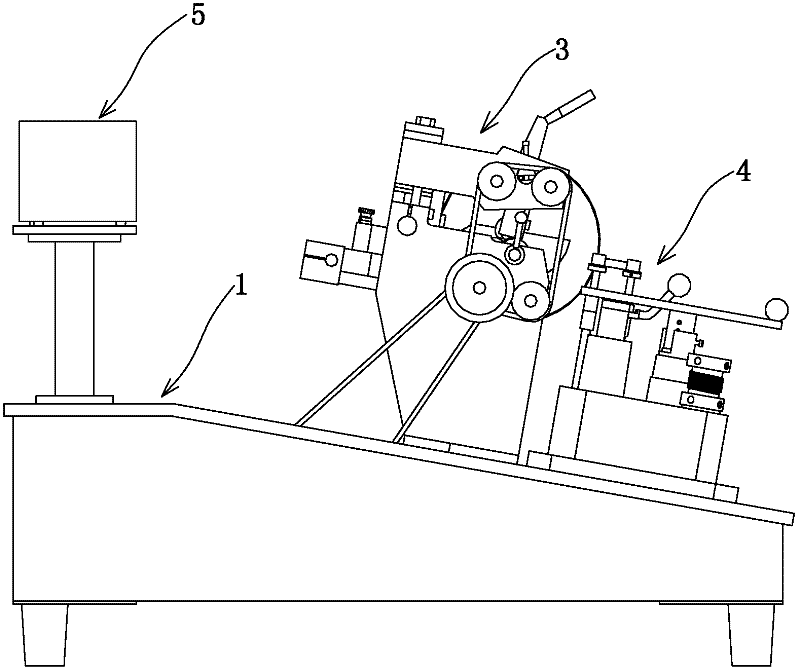

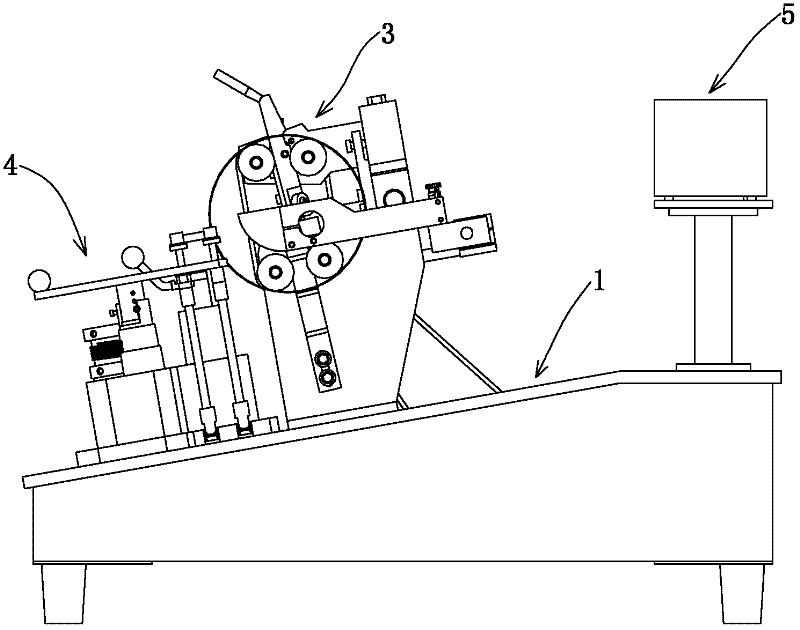

Wire winding machine for annular coil

ActiveCN102360943AImprove effective working timeIncrease productivityCoils manufactureWinding machineDrive shaft

The invention relates to a wire winding machine for an annular coil. The wire winding machine for the annular coil consists of a working platform, a motor, a wire winding actuating mechanism, a coil clamping mechanism and an electric appliance control part, wherein the wire winding actuating mechanism consists of a bracket, a wire storing ring, a supporting part, a slotting adjusting part and a pressing part; and the coil clamping mechanism consists of three clamping shafts which are uniformly distributed along a circumference, a clamping shaft opening and closing mechanism and a clamping sleeve. The wire winding machine for the annular coil is characterized in that the bracket consists of an upper bracket and a lower bracket which are rotationally connected; the slotting adjusting part consists of a first split and a second split which are respectively mounted on the upper bracket and the lower bracket; and the clamping shaft opening and closing mechanism comprises an opening actuating mechanism consisting of a driving shaft and a supporting arm, and a resetting mechanism consisting of a resetting shaft and a torsion spring. Compared with the prior art, the wire winding machine for the annular coil has the advantages that the opening and closing of the wire storing ring are realized by adjusting the second handle of the second split, two-step operation is simplified into one-step operation, the opening of the clamping shafts is realized by tightly holding a handle on the supporting arm, and bidirectional adjustment is simplified into unidirectional adjustment. Thus, the wire winding machine has the characteristics that operation is convenient, time is saved and production efficiency is improved.

Owner:TIANJIN BINHAI ELECTRICAL EQUIP

High current inductor and the manufacturing method

InactiveUS7142084B2Improve featuresCompact structureTransformers/inductances coils/windings/connectionsEncapsulation/impregnationElectrical conductorDie casting

An inductor with the characteristic of resisting high current comprising a conductor coil and a magnet envelope, the magnet envelope tightly wraps the periphery of the conductor coil and forms the main body of the inductor, and the two extending parts of the conductor coil extend to outside of the main body of the inductor, forming terminal electrode. As of the manufacturing method, it includes the part of toroid coil and the extending parts composing the conductor coil. After the toroid coil part is winded into rings, the unwinded wire ends form the extending parts. Through magnet envelope die-casting and wrapping the molded magnet core of the conductor coil to form the main body of the inductor, and the extending parts of the conductor coil extend to outside of the main body to form the terminal electrode.

Owner:CHENG CHANG MAO

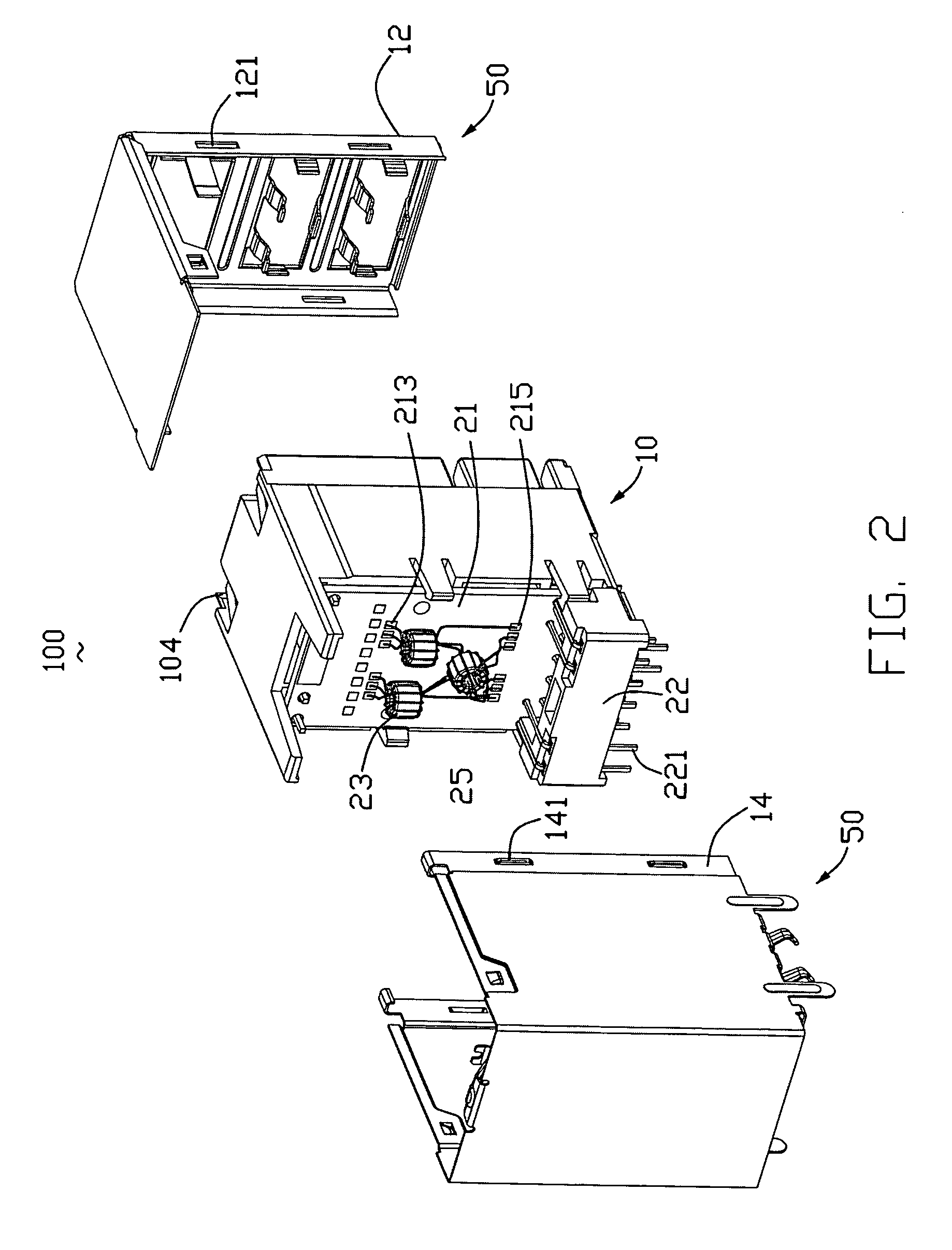

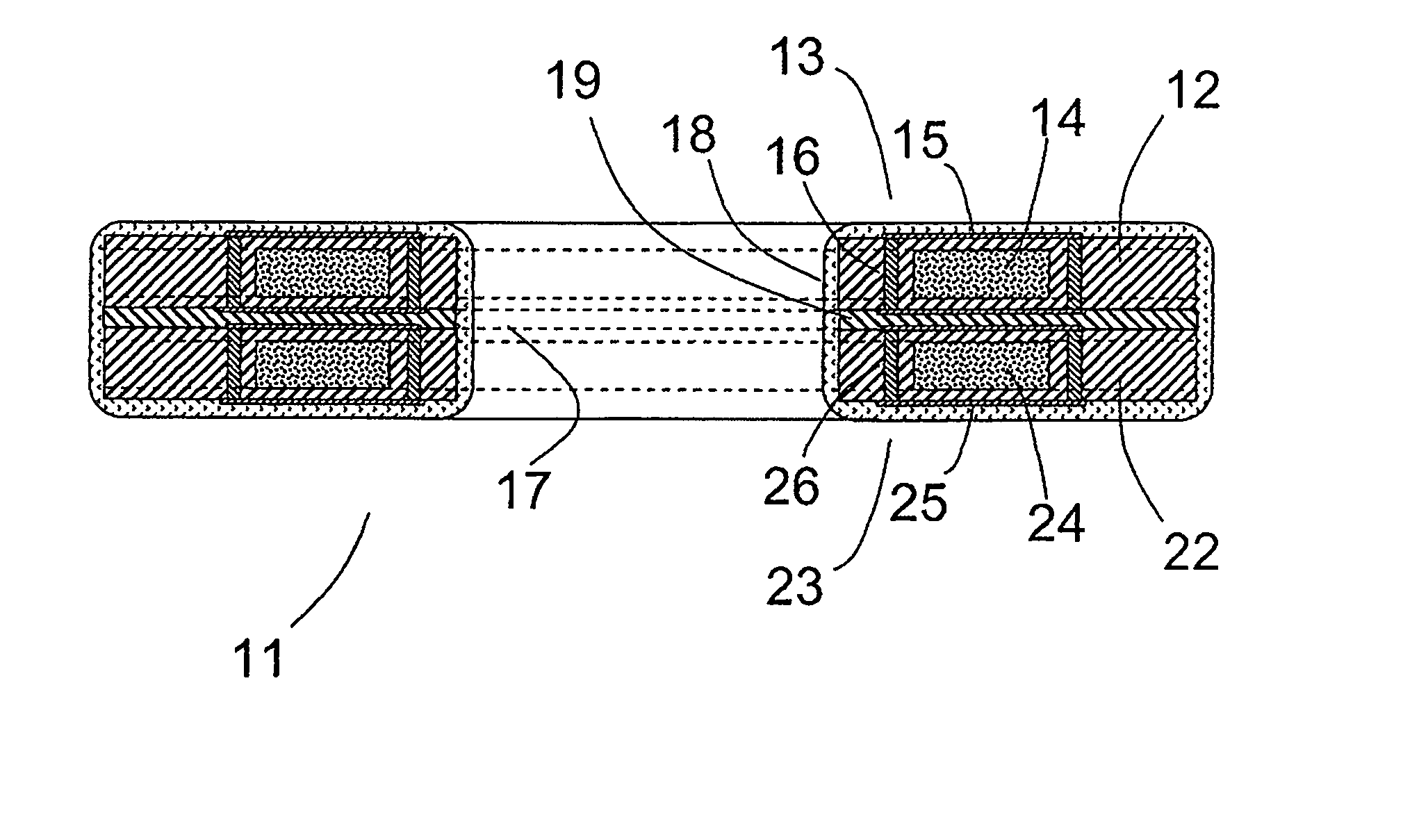

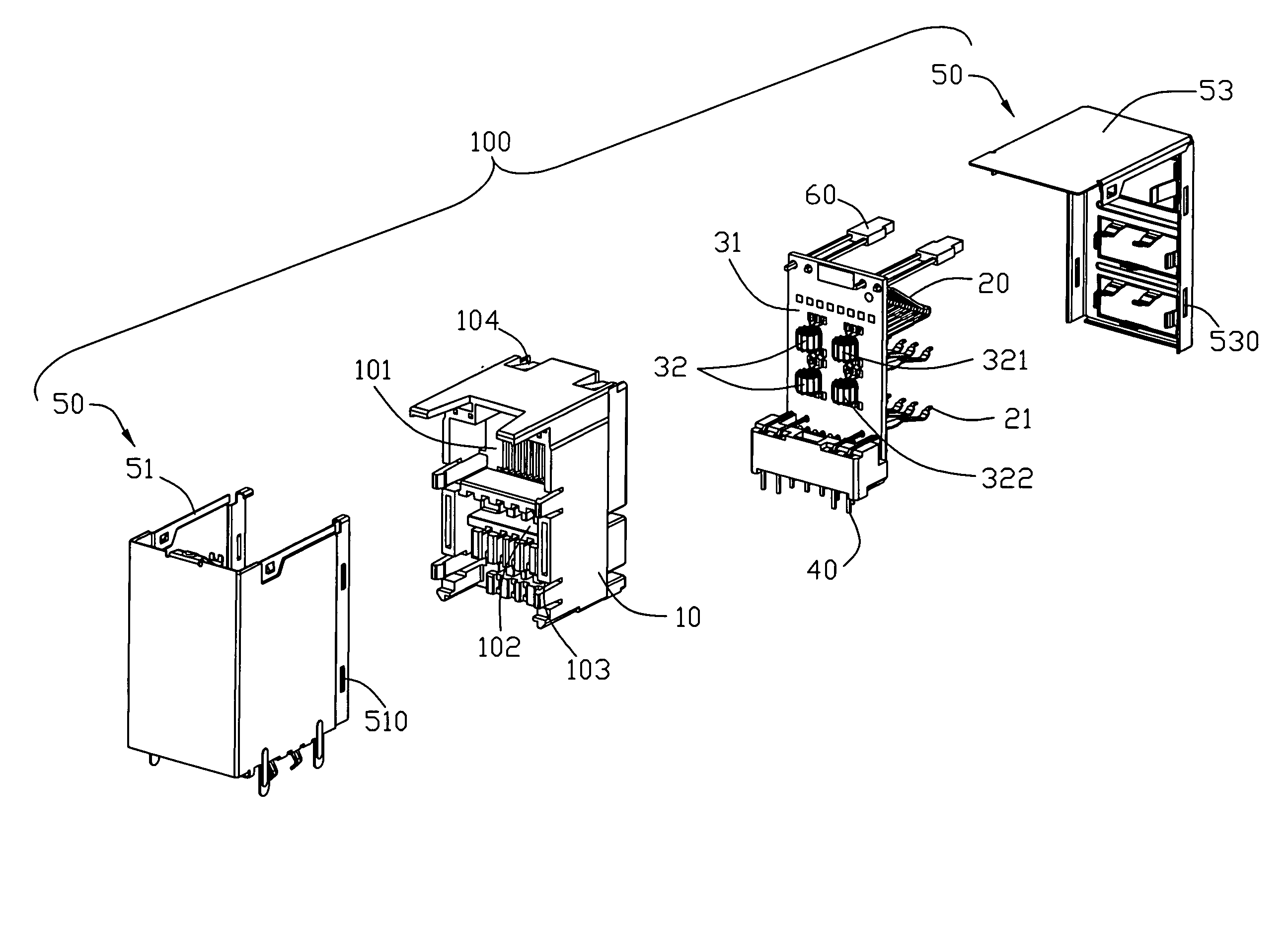

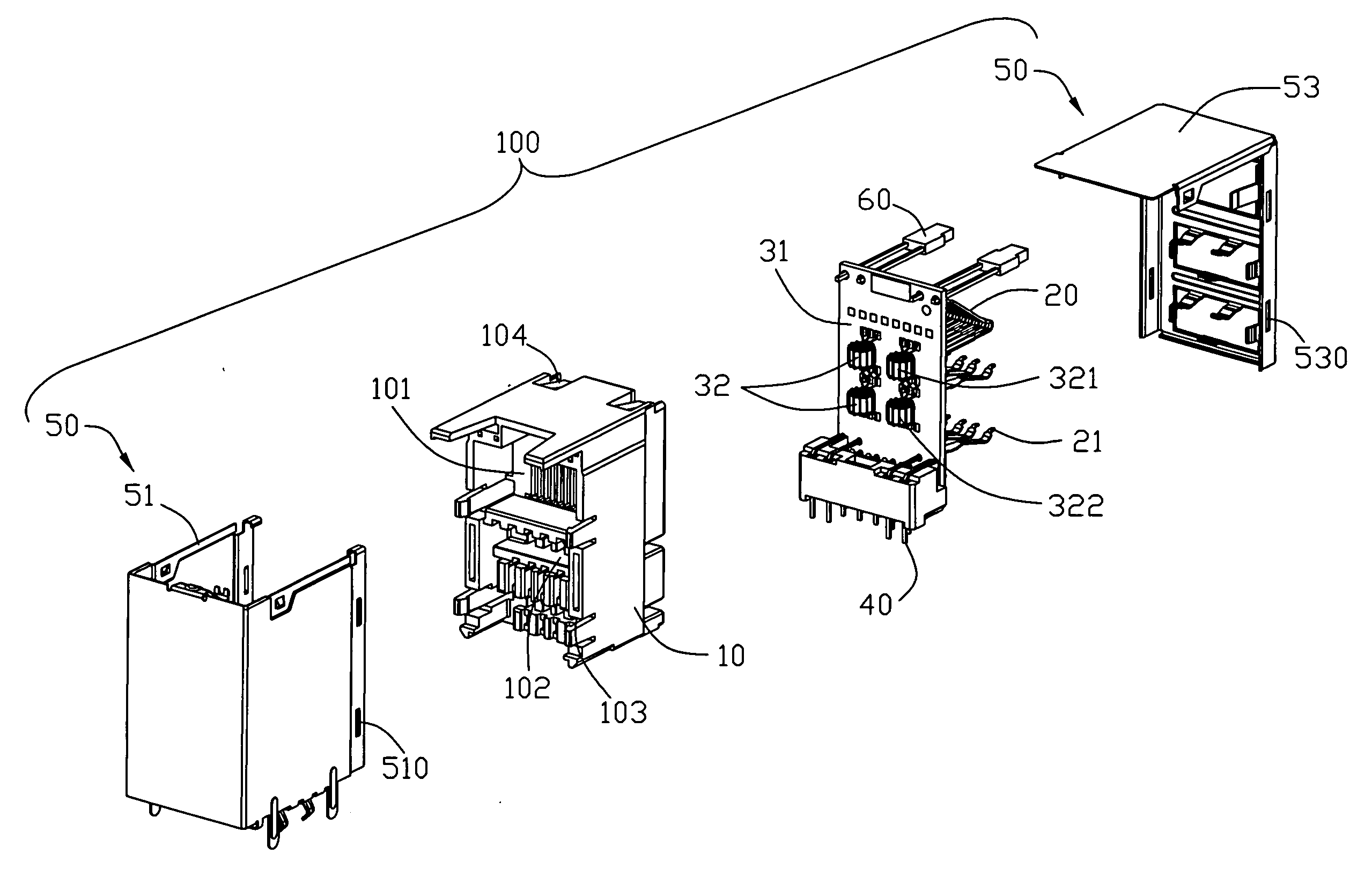

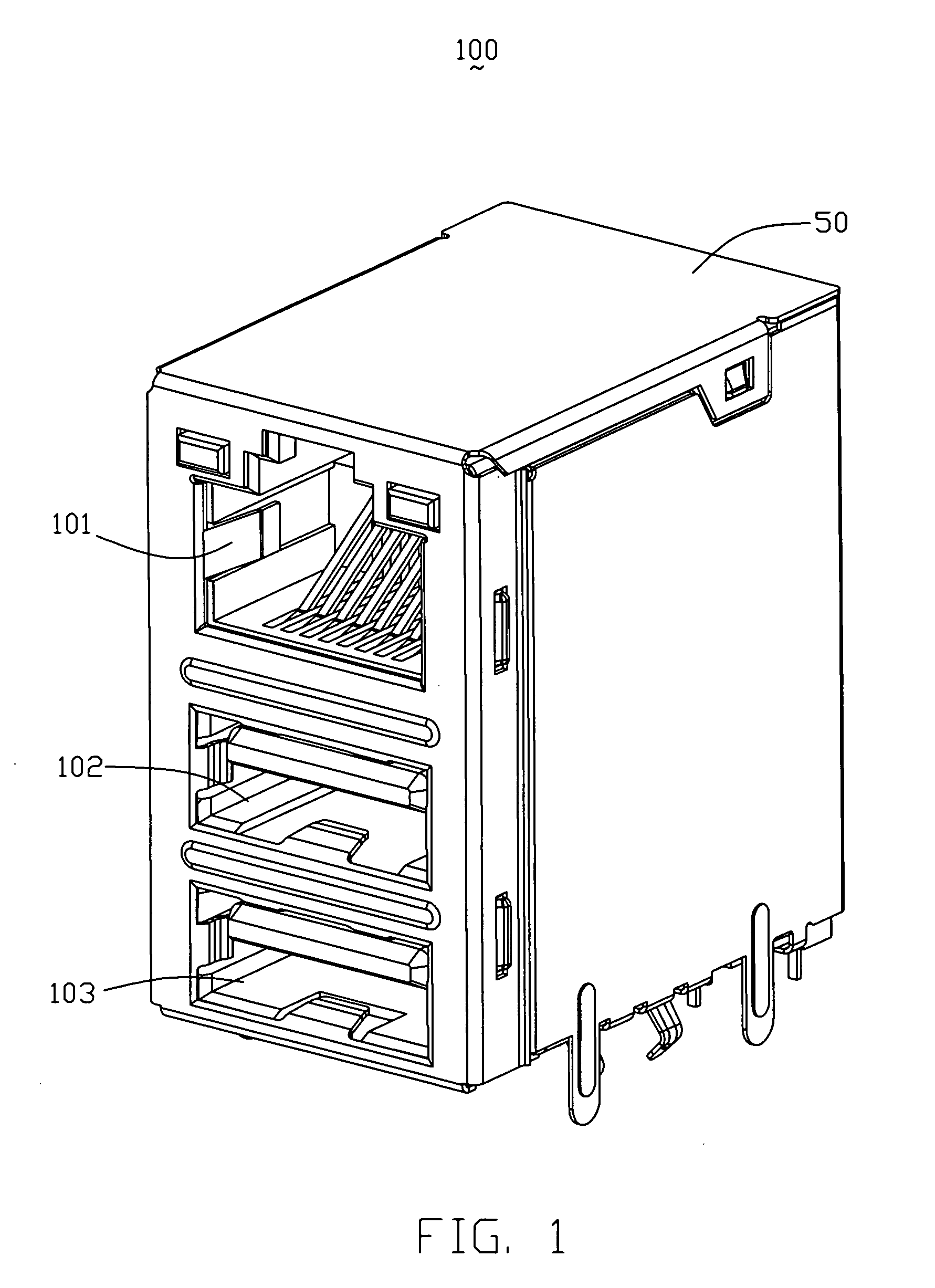

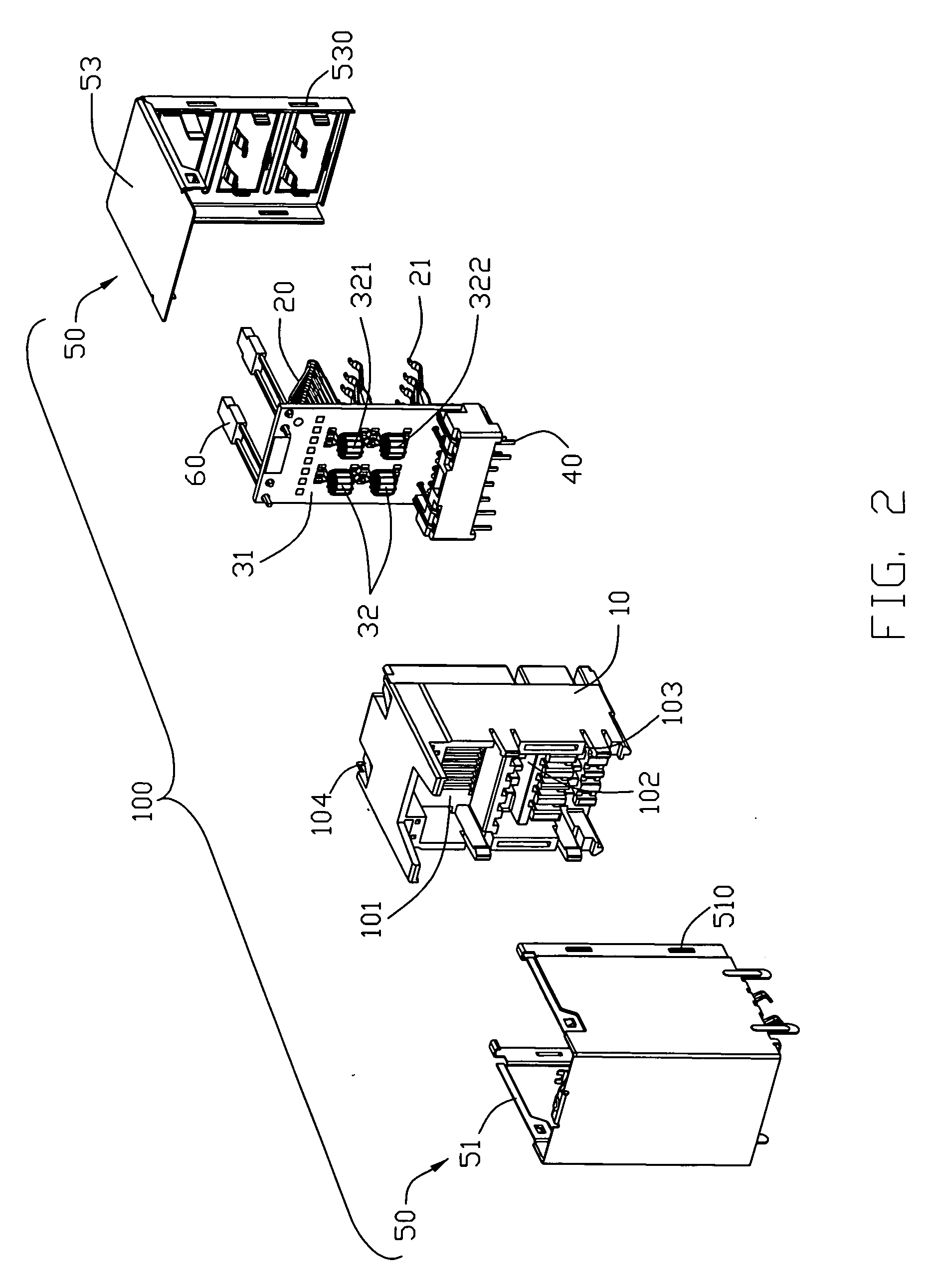

Electrical connector having an improved magnetic module

InactiveUS7785135B2Efficient connectionLow costElectrically conductive connectionsCoupling for high frequencyEngineeringElectrical connector

An electrical connector (100) has a housing (10) defining an opening therein (101), a magnetic module (3) mounted to the housing and a shield (50) surrounding the housing. The magnetic module includes a printed circuit board (31), a first set of terminals (20) mounted to a front face of the printed circuit board and received in the opening, a second set of terminals (21) mounted to a rear side of the printed circuit board, a toroidal coil pair (32) mounted to the printed circuit board and having a first toroidal body and (321), and a second toroidal body (322) electrically connected with each other by a circuit provided on the printed circuit board.

Owner:HON HAI PRECISION IND CO LTD

X-ray generator and X-ray CT apparatus comprising same

In an X-ray generating device of the neutral grounding system, to remove an unbalance voltage generated due to difference in impedance of parallel transformer coils of the high voltage transformer and particularly an unbalance voltage involved with difference in impedance above and below the neutral points generated in a metal X-ray tube, a plurality of currents flowing in opposite directions through primary windings of the parallel transformer coils in the high voltage transformer are passed through by or wound around a common toroidal coil or wound around an outer circumference of the toroidal coil at a predetermined ratio of winding number, and the unbalance voltage occurring to the secondary side is cancelled by changing primary current with magnetic behavior.

Owner:HITACHI MEDICAL CORP

Method and apparatus for determining formation boundary near the bit for conductive mud

ActiveUS8049508B2Electric/magnetic detection for well-loggingAcoustic wave reradiationPower flowEngineering

A method and apparatus for determining a parameter of interest of an earth formation during drilling of a borehole. A first toroidal coil antenna induces a current along a path that includes a bottomhole assembly and the formation. A second toroidal coil antenna disposed at the drillbit and oriented at a non-zero angle to the longitudinal axis of the bottomhole assembly measures an electrical signal resulting from the current, the electrical signal being a parameter of interest of the formations.

Owner:BAKER HUGHES HLDG LLC

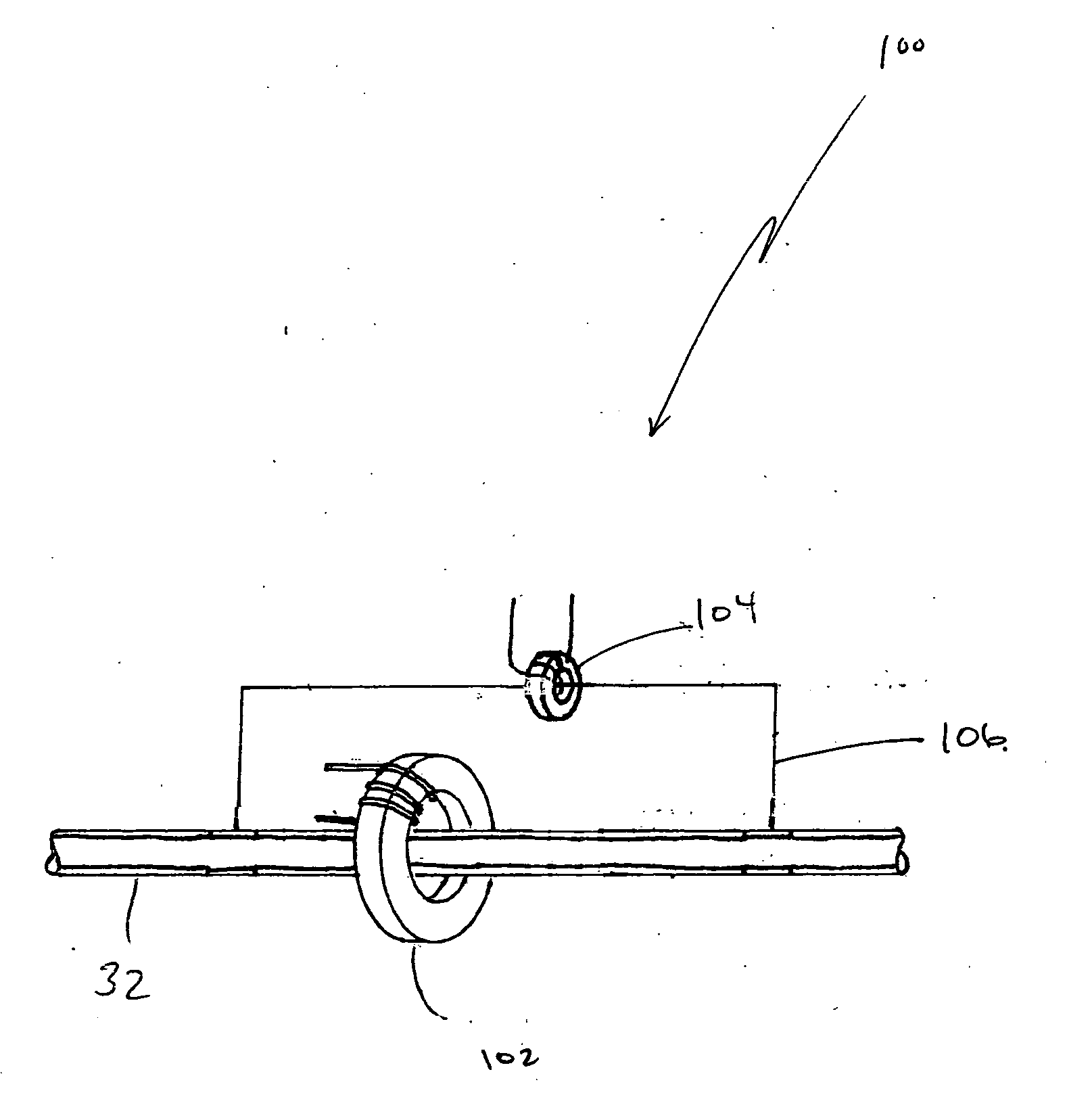

Total Fluid Conductivity Sensor System and Method

InactiveUS20070008060A1Improve fitEasy to packTransformers/inductances coils/windings/connectionsFluid resistance measurementsToroidal coilRadio frequency

The present invention provides an apparatus and method for measuring the conductivity of a fluid employing the differential radio frequency phase detection between two embedded toroidal coils.

Owner:UNIV OF SOUTH FLORIDA

Induction heater and induction heating method

ActiveUS20100163551A1Favorable induction heatingImprove the heating effectFurnaces without endless coreCoil arrangementsInduction heaterToroidal coil

An object of the present invention is to provide an induction heater and an induction heating method capable of heating by induction a work in which a gear portion and a shaft are integrated.An induction heater for a gear portion and a stepped shaft is arranged in such a manner that a first heating coil (annular coil) surrounds the gear portion and that a second heating coil (linear coil) faces the stepped shaft in an axial direction. Alternating currents of different frequencies are supplied to the first heating coil 1 and the second heating coil. Further, a part of the second heating coil is arranged so as to come opposite a boundary between the gear portion and the stepped shaft, thereby connecting a hardened pattern of the gear portion by the first heating coil and a hardened pattern of the stepped shaft by the second heating coil.

Owner:FUJI ELECTRONICS IND

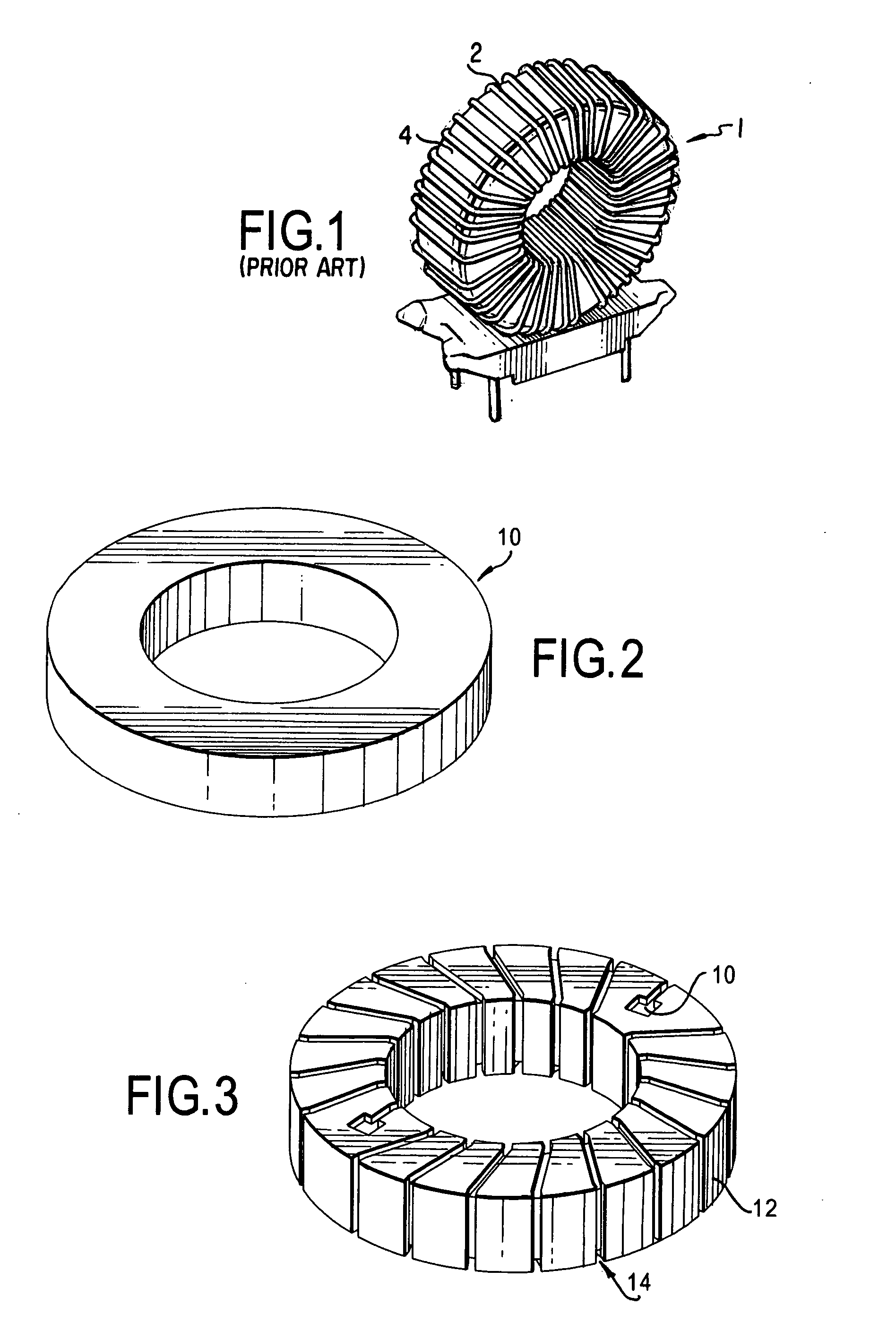

Magnetic toroid connector

InactiveUS20050156703A1Improve automationLow costTransformers/inductances coils/windings/connectionsInductance with magnetic coreTransformerEngineering

The present invention is directed to a toroid used as an inductor or transformer to filter unwanted noise from electrical connectors and devices. The toroid comprises a metal ring surrounded by a platable and non-platable plastic cast, and a conductive layer deposited onto the platable cast. The toroid is manufactured by first molding the non-platable plastic, having helically patterned grooves, around the metal ring. The platable plastic is then molded into the grooves of the non-platable plastic. A conductive plating is then electrodeposited onto the platable plastic to form a helically patterned winding around the metal ring.

Owner:TWAALFHOVEN MARK

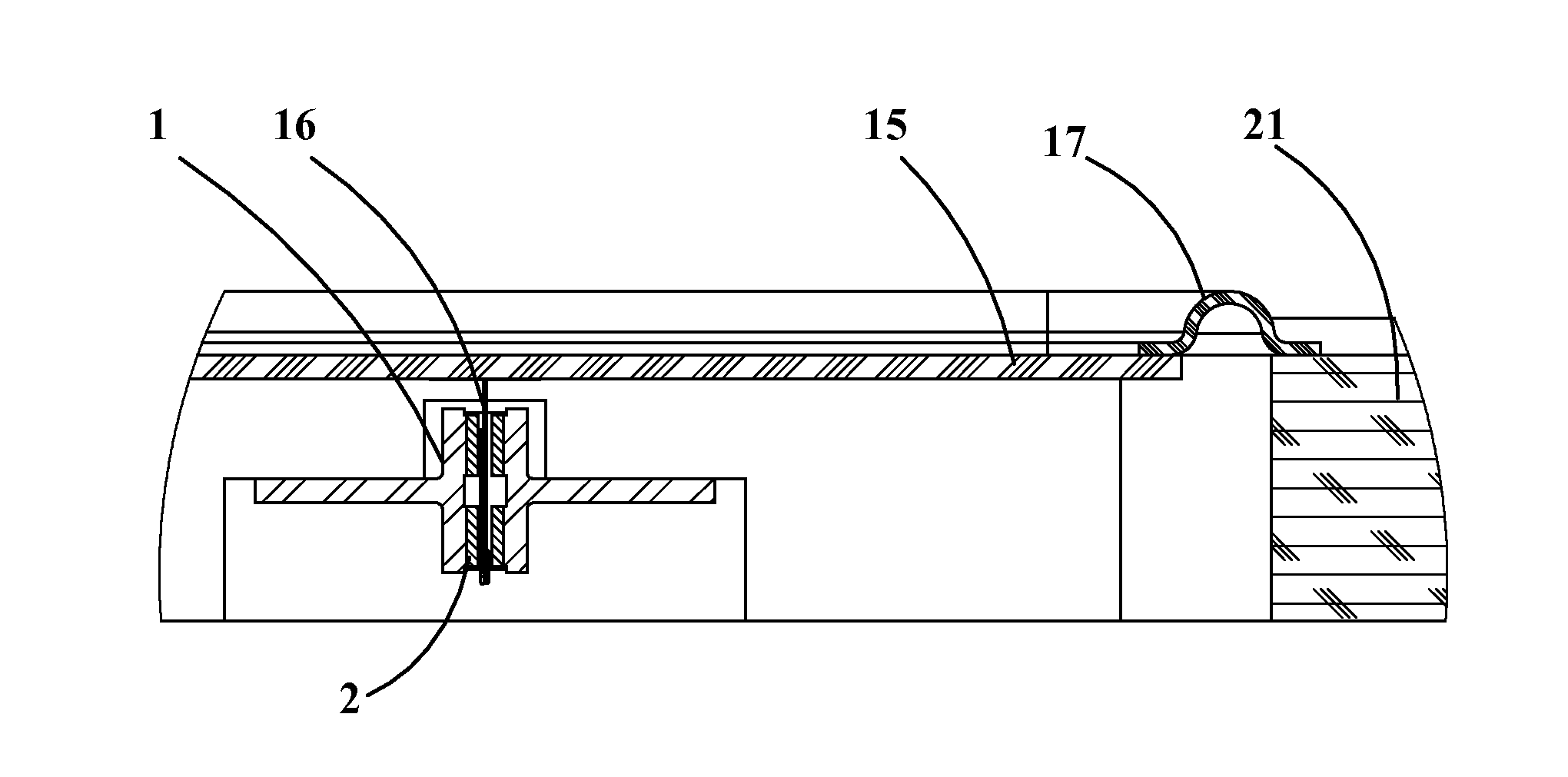

Flow-through conductivity sensor

InactiveUS20050127919A1Fluid resistance measurementsVoltage/current isolationElectrical conductorTransformer

An improved flow-through conductivity sensor is provided. The sensor includes a current return path that has a current return conductor. At least one toroid of the sensor is removed from the flow path and configured to interact with the current return conductor to provide an indication of conductivity. Additional aspects of the invention include disposing a pair of toroids about the current return conductor; disposing a toroid about the current return conductor and configuring the toroid as a transformer.

Owner:ROSEMOUNT ANALYTICAL

Multilayer coreless coil permanent magnet motor

ActiveCN102097906ASave raw materialsReduce volumeMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic polesPermanent magnet motor

The invention provides a multilayer iron core coil-free permanent magnet motor, belonging to the technical field of generating equipment or energy-saving motors. The multilayer iron core coil-free permanent magnet motor is characterized in that an central hole of a rotor is fixed on a spindle; the radial circle area is internally provided with N circular grooves; an inner wall of each circular groove is provided with a permanent magnet which rotates along with the spindle; a stator center is provided with bearings for supporting the spindle; the longitudinal circle area is internally providedwith M coil racks; each coil rack is internally provided with stator windings which are led out by guide lines; each pair of magnetic poles are internally provided with one coil pitch fraction formedby F coils in longitudinal arrangement; 20+F coil pitch fractions are connected in series to form one layer of toroidal coil; three layers of coils are overlaid and pressed to obtain one three-phase stator winding; and a design containing N circular grooves, M coil racks, a pair of conjoined multilayer rotor permanent magnets and the stator windings can be used to improve the output power of a motor with the same diameter by several times. The multilayer iron core coil-free permanent magnet motor can be applied to the technical fields requiring for transmission such as war industry, spaceflight, wind power, electromobiles, generators, electric motors, machinery and the like, and has a wide applied range and development potential.

Owner:肇庆市端州区英菲特电机有限公司

High performance linear moving coil magnetic drive system

ActiveUS20150195655A1Minimal and reduced separationNew level of acousticLoudspeaker screensPlane diaphragmsVoltage amplitudeFiber

A linear moving coil magnetic drive system includes a continuous loop coil of flat, thin, rigid construction which levitates inside a quadrupole permanent magnet assembly with minimum gap. The linear coil may be a flat, racetrack-shaped, continuous loop, which may be constructed with single or multilayers PCB, flex-circuit, or other membrane process. The linear coil may include a coating of permeable magnetic material along the insulated conductor traces. The linear coil may be sandwiched between carbon fiber fabrics and cured to create a long, flat, thin and perfectly straight, extremely stiff, light-weight, load-bearing tee-shaped structure. This structure is levitated inside a quadrupole permanent magnetic assembly with minimum air gap between the high gauss magnets. In additional to the bare conductor traces inside this coil, also integrated into this PCB structure, is simple second-order equalizer electronic circuitry, comprised of surface-mounted resistors, capacitors, and IC chips. Either a close loop or open loop control may be included to tune the voltage amplitude at the resonance frequency of this magnetic drive system.

Owner:WALL AUDIO

Electrical connector having an improved magnetic module

InactiveUS20090176408A1Low costEfficient connectionElectrically conductive connectionsCoupling for high frequencyToroidal coilElectrical connector

An electrical connector (100) has a housing (10) defining an opening therein (101), a magnetic module (3) mounted to the housing and a shield (50) surrounding the housing. The magnetic module includes a printed circuit board (31), a first set of terminals (20) mounted to a front face of the printed circuit board and received in the opening, a second set of terminals (21) mounted to a rear side of the printed circuit board, a toroidal coil pair (32) mounted to the printed circuit board and having a first toroidal body and (321), and a second toroidal body (322) electrically connected with each other by a circuit provided on the printed circuit board.

Owner:HON HAI PRECISION IND CO LTD

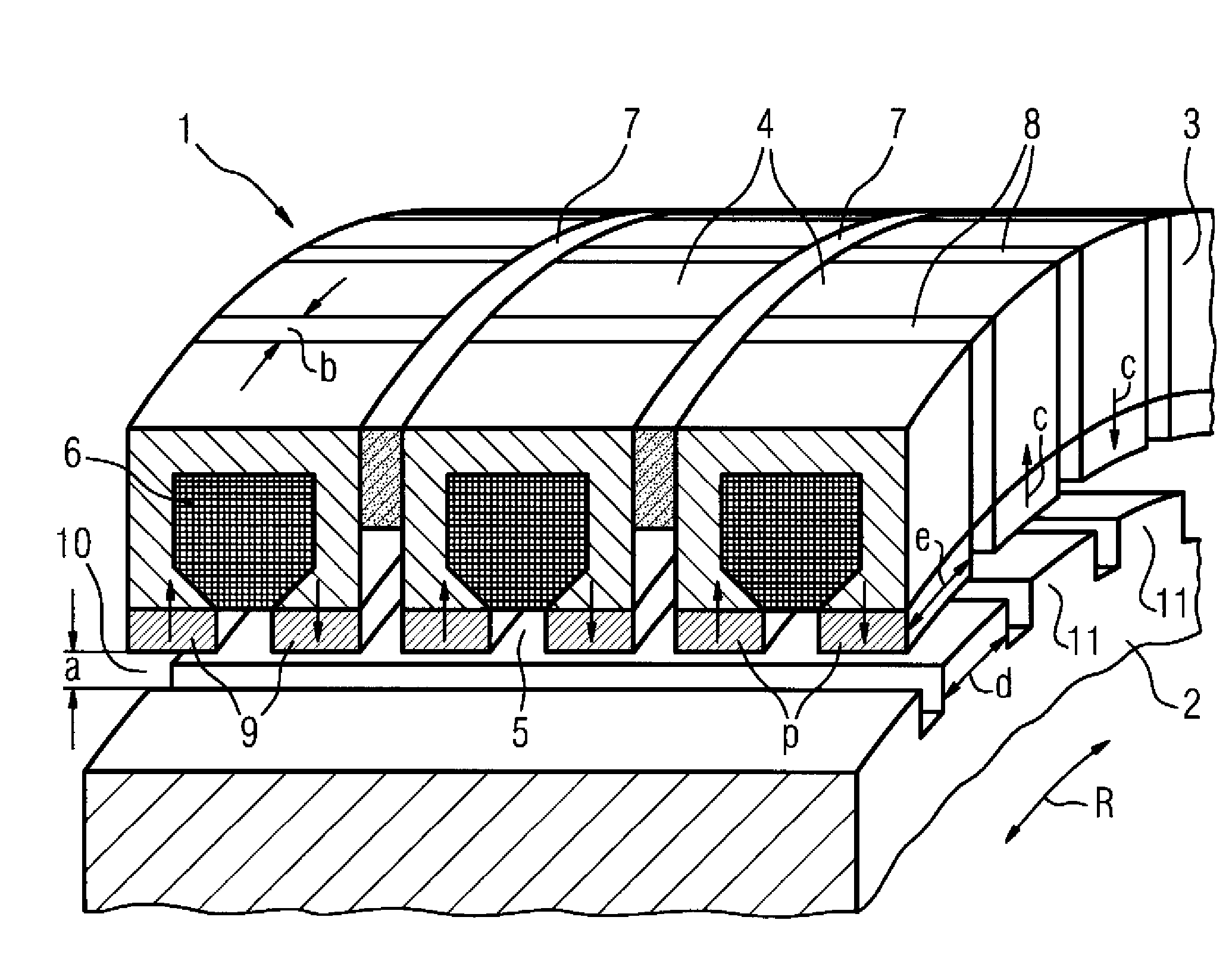

Ring coil motor

InactiveUS7915777B2Simple and cost-effective to manufactureHighly suitableSynchronous generatorsAsynchronous induction motorsElectric machineEngineering

Owner:SIEMENS AG

Method for manufacturing a three-phase transformer

InactiveUS6880228B2High efficiencySmall magnetic coreTransformers/inductances coils/windings/connectionsVariable inductancesEngineeringThree-phase

A three-phase transformer and a method of its manufacture are presented. The transformer comprises a magnetic circuit and three coil blocks. The magnetic circuit comprises two spaced-apart, parallel, plate-like elements; and three spaced-apart, parallel column-like elementary circuits. Each of the column-like elementary circuits carries the corresponding one of the three coil blocks, and serves for the corresponding one of the three phases. The column-like elementary circuits are substantially perpendicular to the plate-like elements, and are enclosed therebetween such as to form a spatial symmetrical structure about a central axis of the transformer. Each of the column-like elementary circuits is substantially a toroid in the form of a multi-layer structure formed by winding a predetermined number N of packages of magnetic strips about a central axis of the toroid, each package being composed of a predetermined number n of layers formed by n strips placed on top of each other.

Owner:A T T ADVANCED TRANSFORMER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com