Wire winding machine for annular coil

A technology of toroidal coils and winding machines, which is applied in coil manufacturing and other directions, can solve problems such as troublesome and laborious, and affect coil production efficiency, and achieve the effects of convenient operation, shortened auxiliary man-hours, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

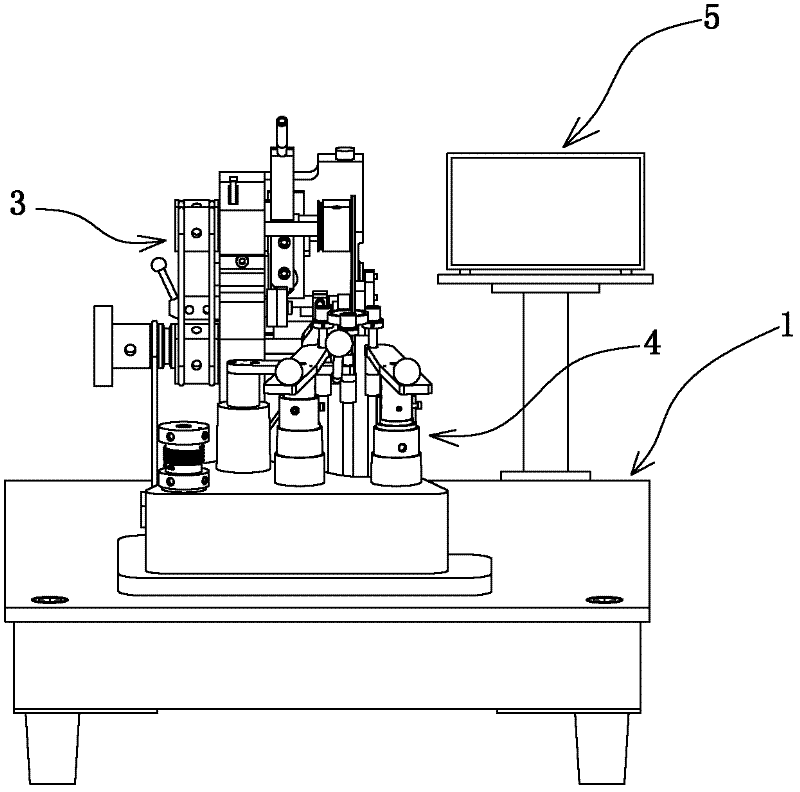

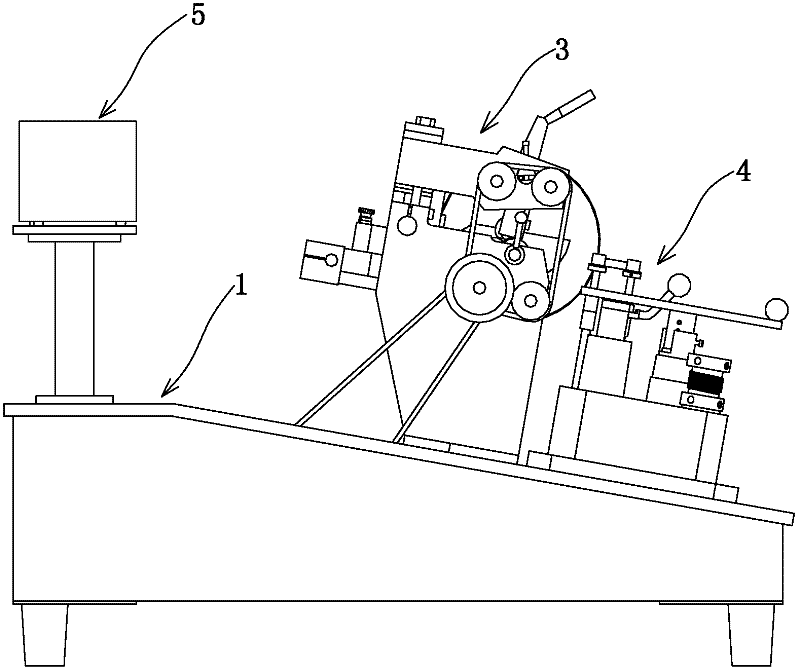

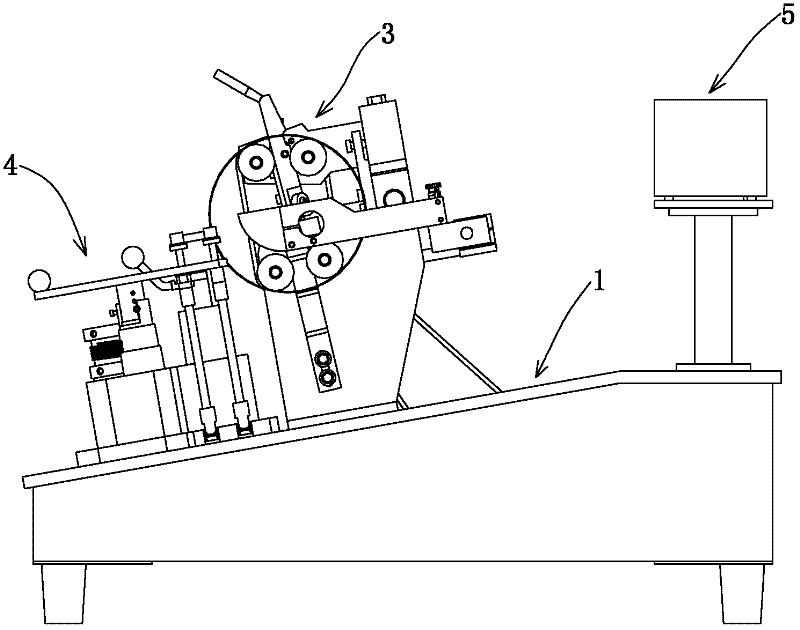

[0032] See Figure 1-13 , A toroidal coil winding machine, consisting of a workbench 1, a motor 2 arranged at the lower end of the workbench, a winding actuator 3, a coil clamping mechanism 4, and an electrical control part 5 arranged on the workbench. The motor transmits the power to the winding execution structure and the coil clamping mechanism through the transmission mechanism, and drives the wire storage ring and the coil core to rotate respectively, and winds the copper wire wound on the wire storage ring on the coil core, and finally makes Loop coil.

[0033] The above-mentioned winding execution structure includes a bracket 3-1 fixedly mounted on the workbench, a wire storage ring 3-2, and a supporting part 3-3 that is mounted on the bracket and includes sev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com