Multi-stage monitoring system of stretching and fracture state of carbon fiber structure and monitoring method thereof

A tensile fracture and monitoring system technology, applied in the direction of applying stable tension/pressure to test material strength, measuring devices, and analyzing materials, can solve problems such as unrealized carbon fiber structure monitoring, and achieve distributed measurement and resolution High, guaranteed reliability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

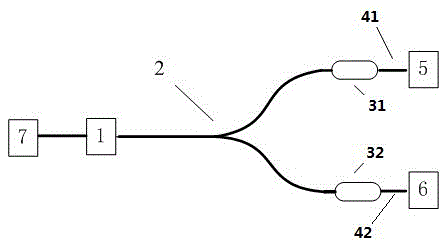

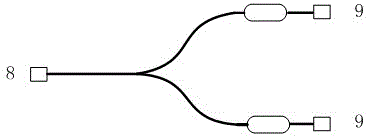

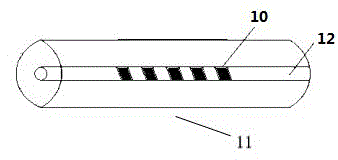

[0033] like Figure 1-5 As shown, the stage-by-stage monitoring system of the tensile fracture state of the carbon fiber structure includes a computer 7, a fiber grating analyzer 1, a Y-type fiber coupler 2, a first coupler joint 31, a second coupler joint 32, a first sensor Optical fiber 41, second sensing optical fiber 42, FBG strain sensing probe 5 and FBG strain wave sensing probe 6; computer 7 is connected to fiber grating analyzer 1, and Y-type fiber coupler 2 includes a Y-type fiber coupler input end 8 and two Y-type fiber coupler output ports 9, the Y-type fiber coupler input port 8 is connected to the fiber grating analyzer 1; two Y-type fiber coupler output ports 9, one of the Y-type fiber coupler output ports 9 It is connected with the first coupler joint 31, the first sensing fiber 41, and the FBG strain sensing probe 5 in turn, and the output end 9 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com