Patents

Literature

31results about How to "High performance ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

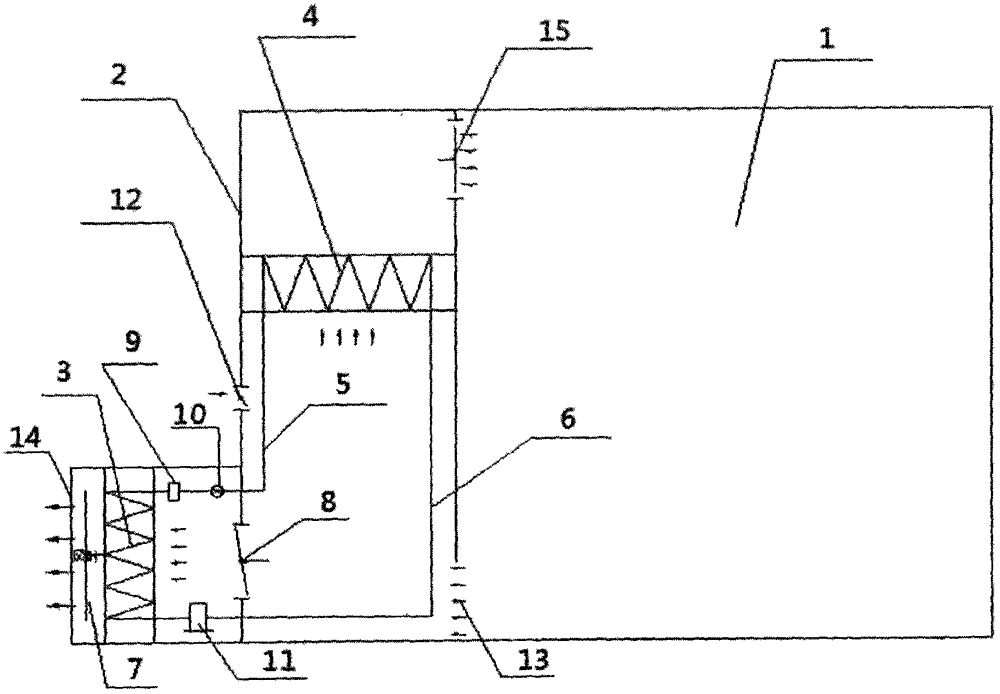

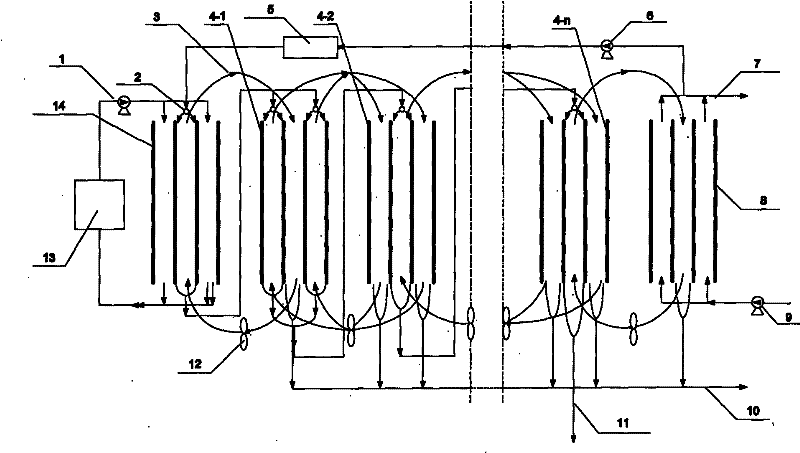

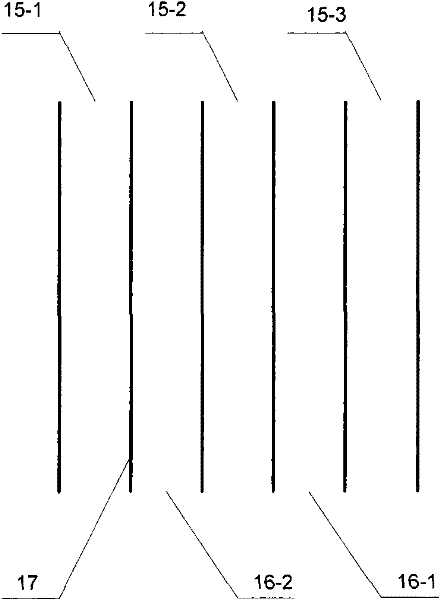

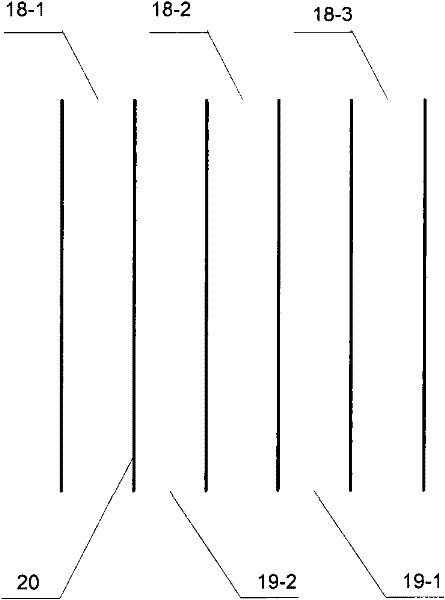

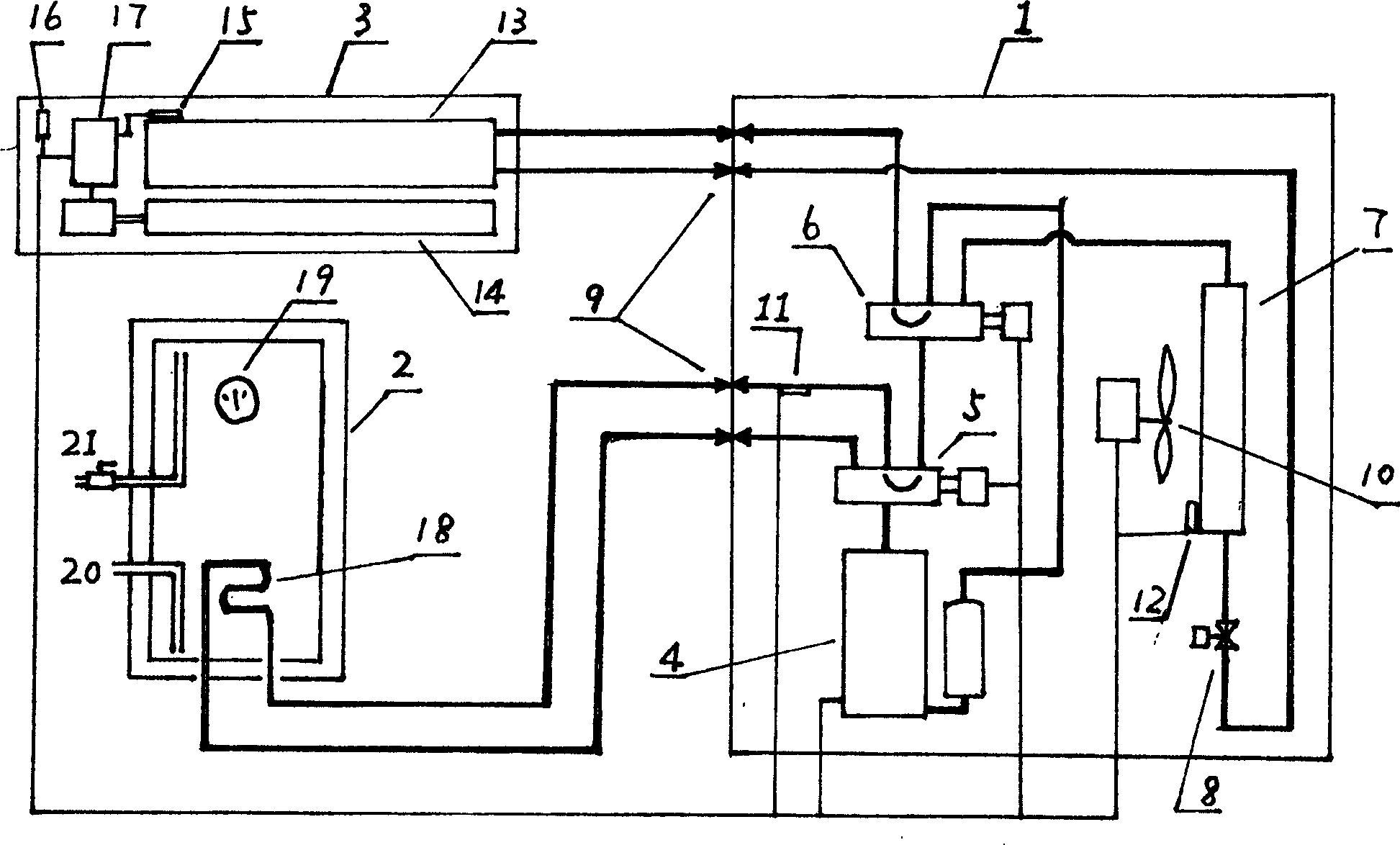

Constant-pressure multiple-effect evaporation condensation sea water desalination device with air medium

InactiveCN101921036AReduce consumptionImprove performanceSeawater treatmentMultistage water/sewage treatmentWater desalinationEnergy recovery

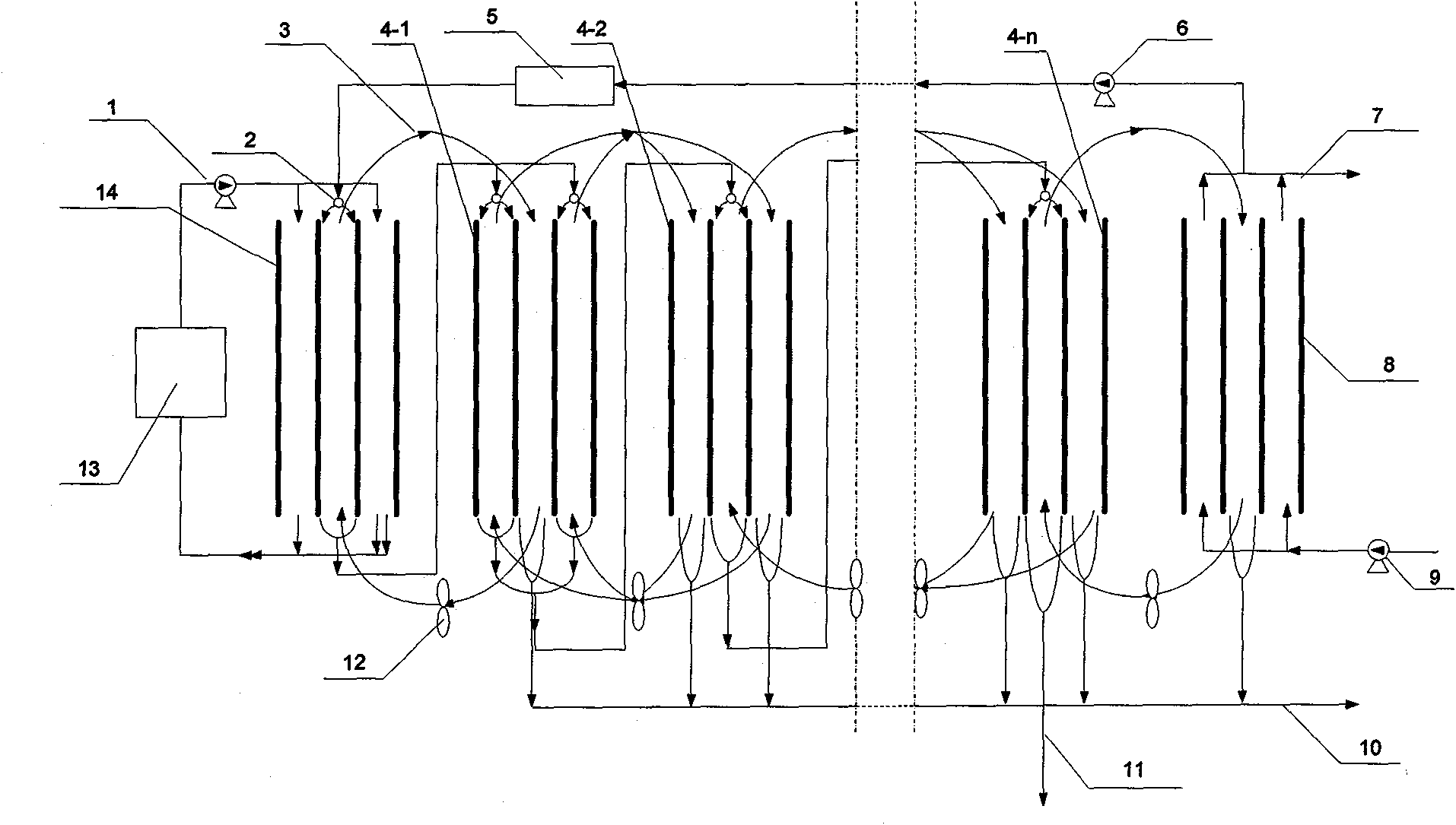

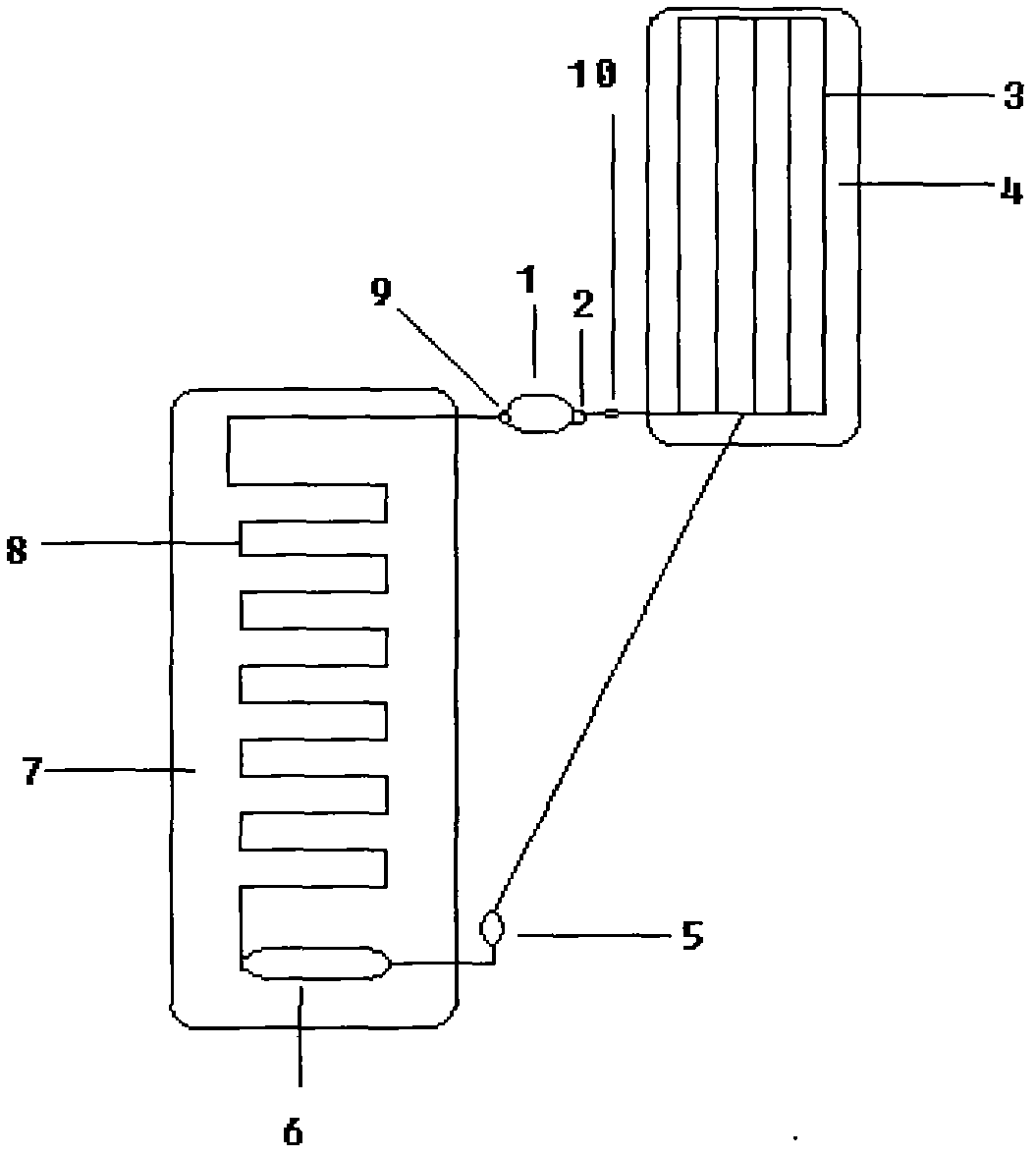

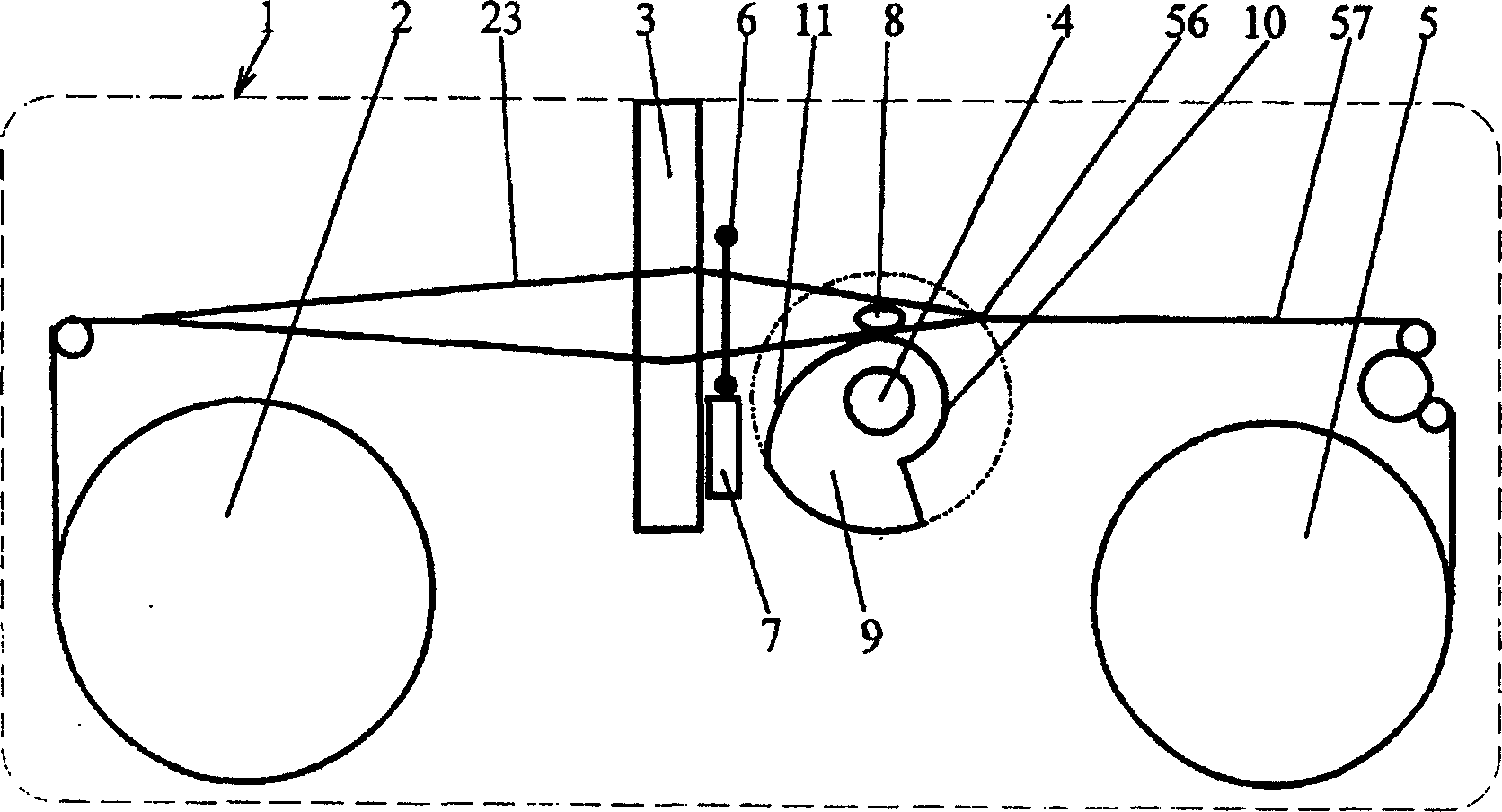

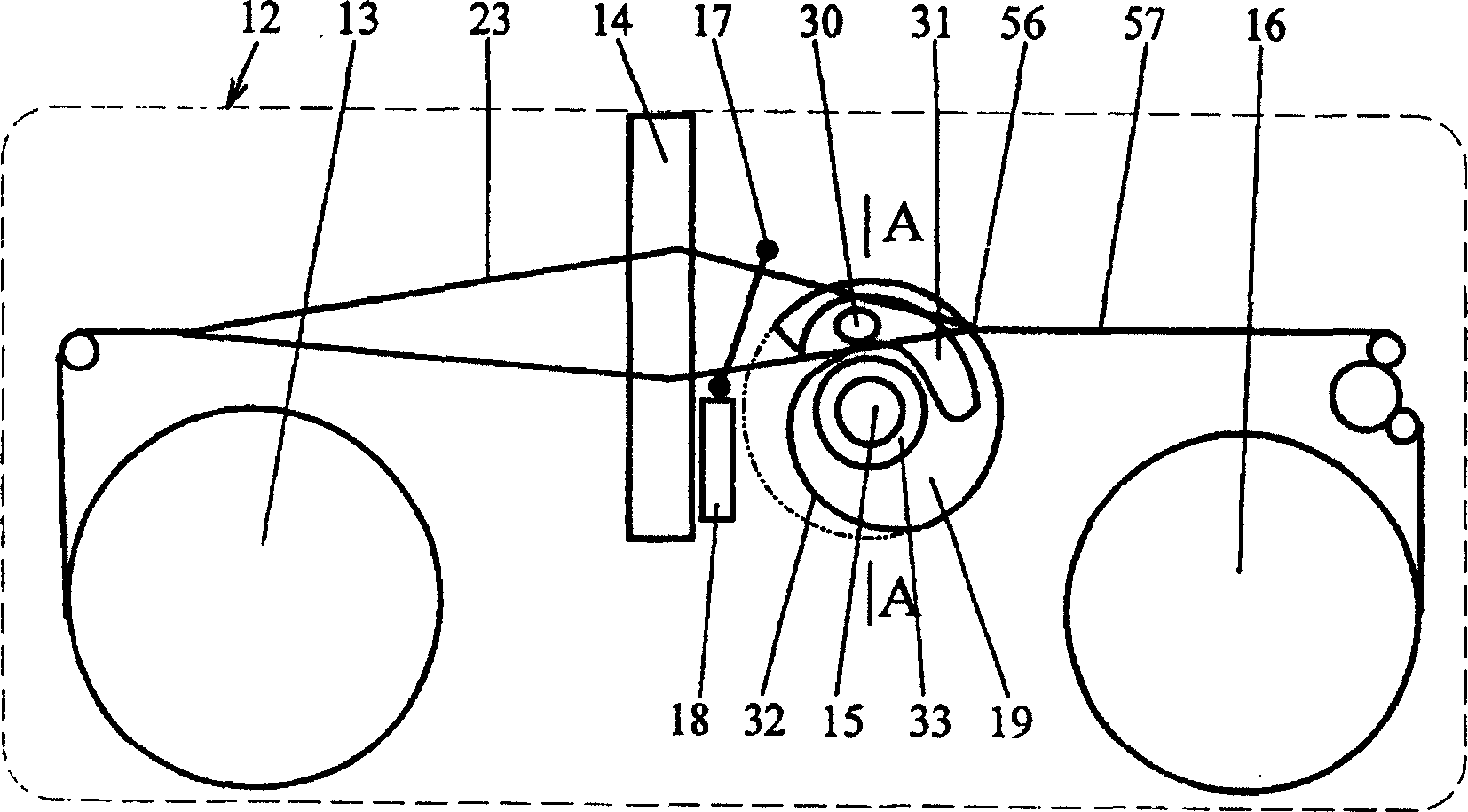

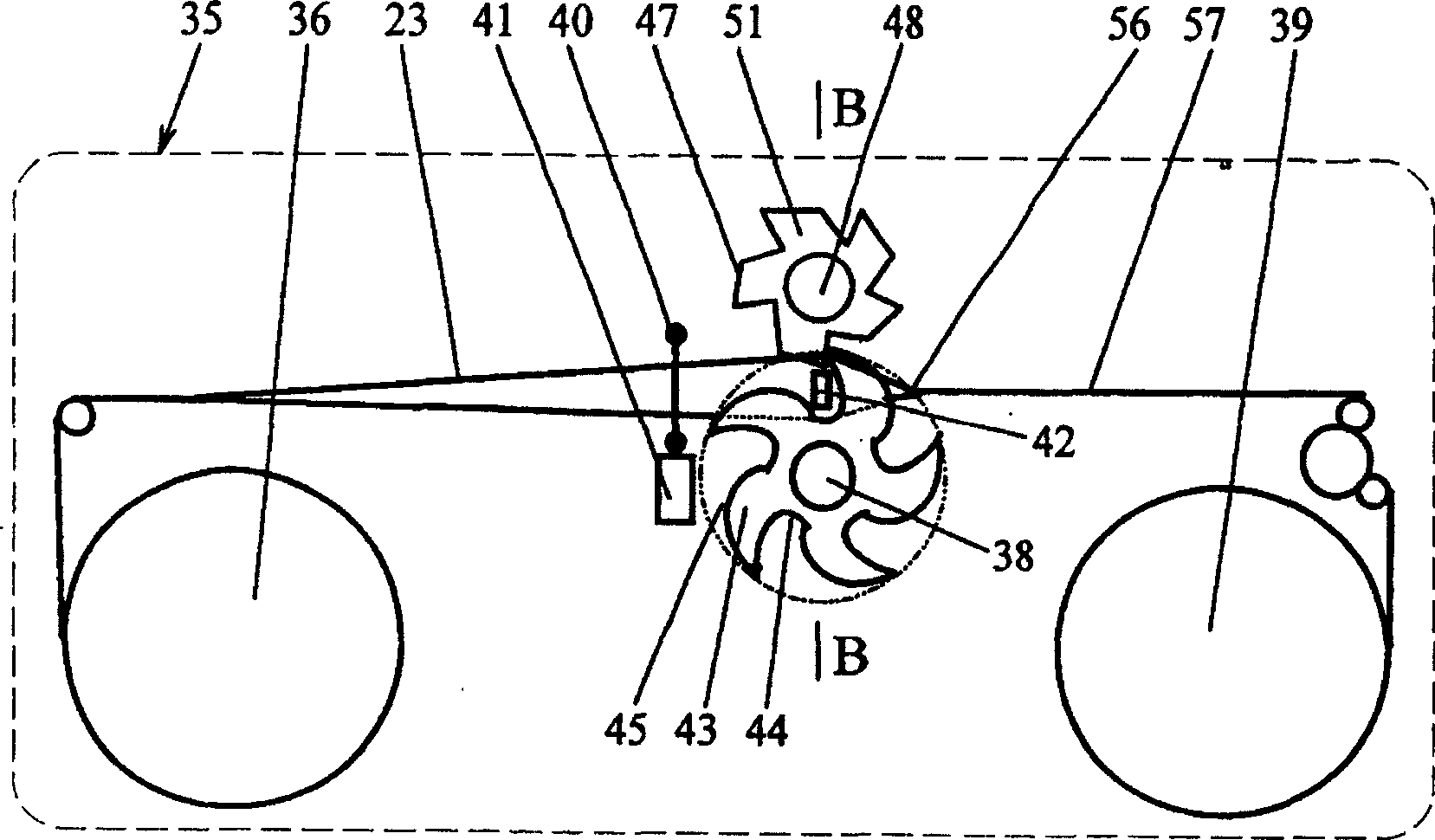

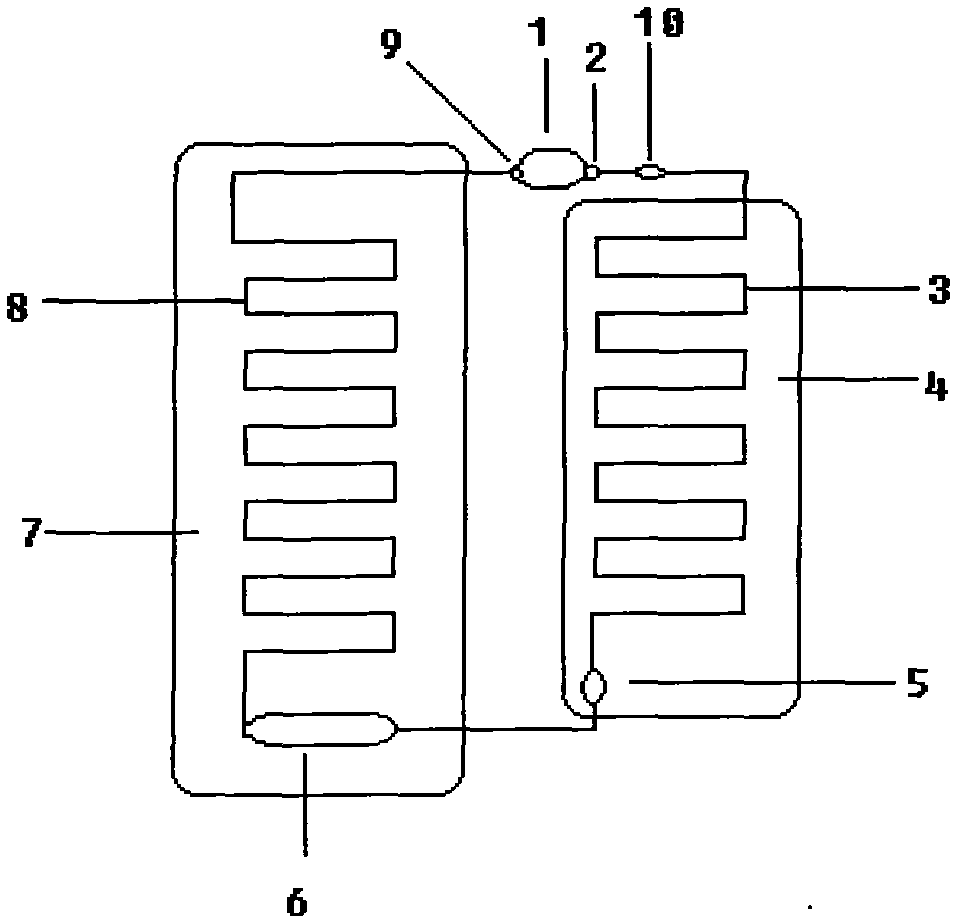

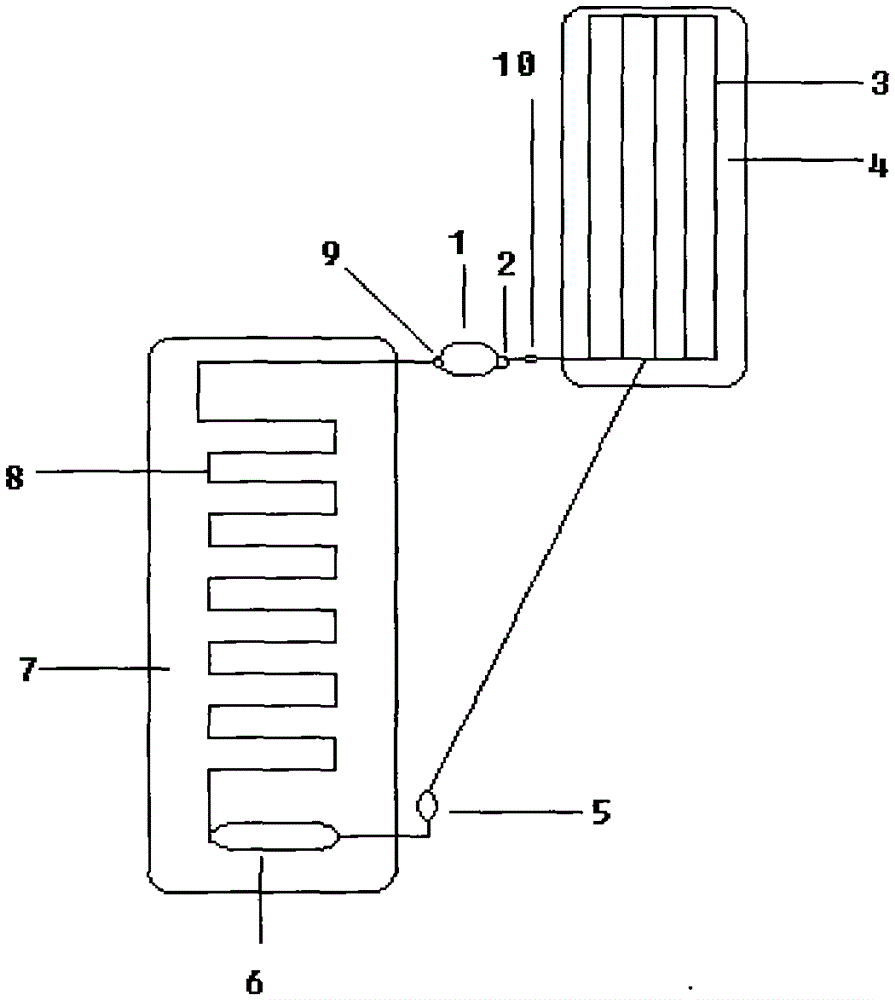

The invention discloses a constant-pressure multiple-effect evaporation condensation sea water desalination device with an air medium, which mainly comprises a low-and-medium temperature heat source (13), a first-stage heating evaporator (14), an evaporation condenser (4) and a last-stage condenser (8). The first-stage heating evaporator (14), the evaporation condenser (4) and the last-stage condenser (8) are installed in sequence closely, and the low-and-medium heat source (13) and the first-stage heating evaporator (14) are connected together. The first-stage heating evaporator (14), the evaporation condenser (4) and the last-stage condenser are all formed by combining a plurality of heat exchange plates which are arranged from left to right in sequence, and a gap is reserved between every two adjacent heat exchanging plates to form a flow channel for heat exchange fluid. By adopting the plate-type heat exchange principle, the sea water desalination device realizes multiple-effect air humidification and dehumidification evaporation and condensation for sea water desalination under constant pressure. Heat and moisture transfer is performed between sprayed sea water and overflowing air, and the condensation latent heat of fore effect heat and moisture air can be absorbed at the same time, and therefore, energy recovery is realized and the fore effect heat and moisture air can be condensed to obtain fresh water.

Owner:GUANGDONG FIVESTAR SOLAR ENERGY

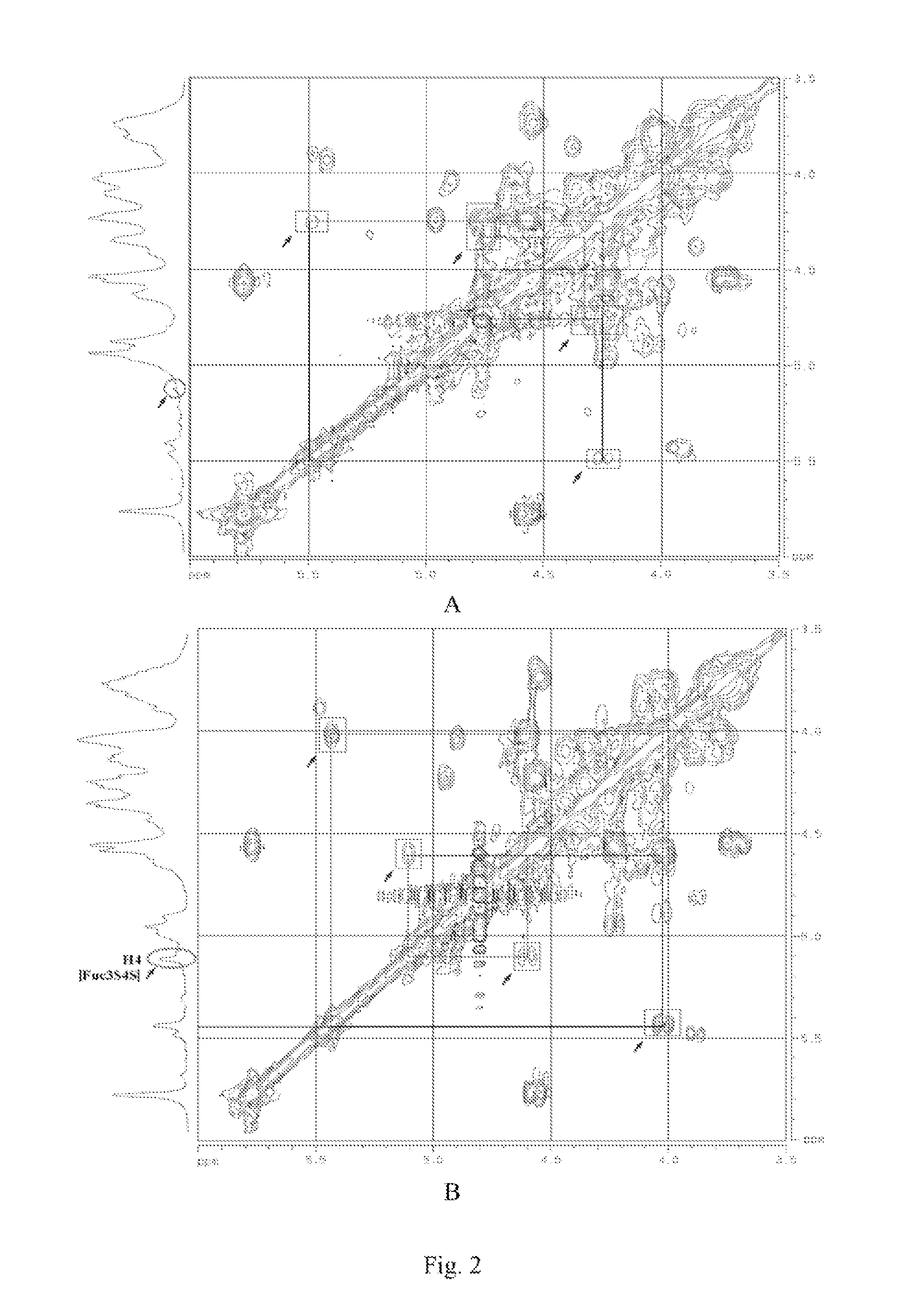

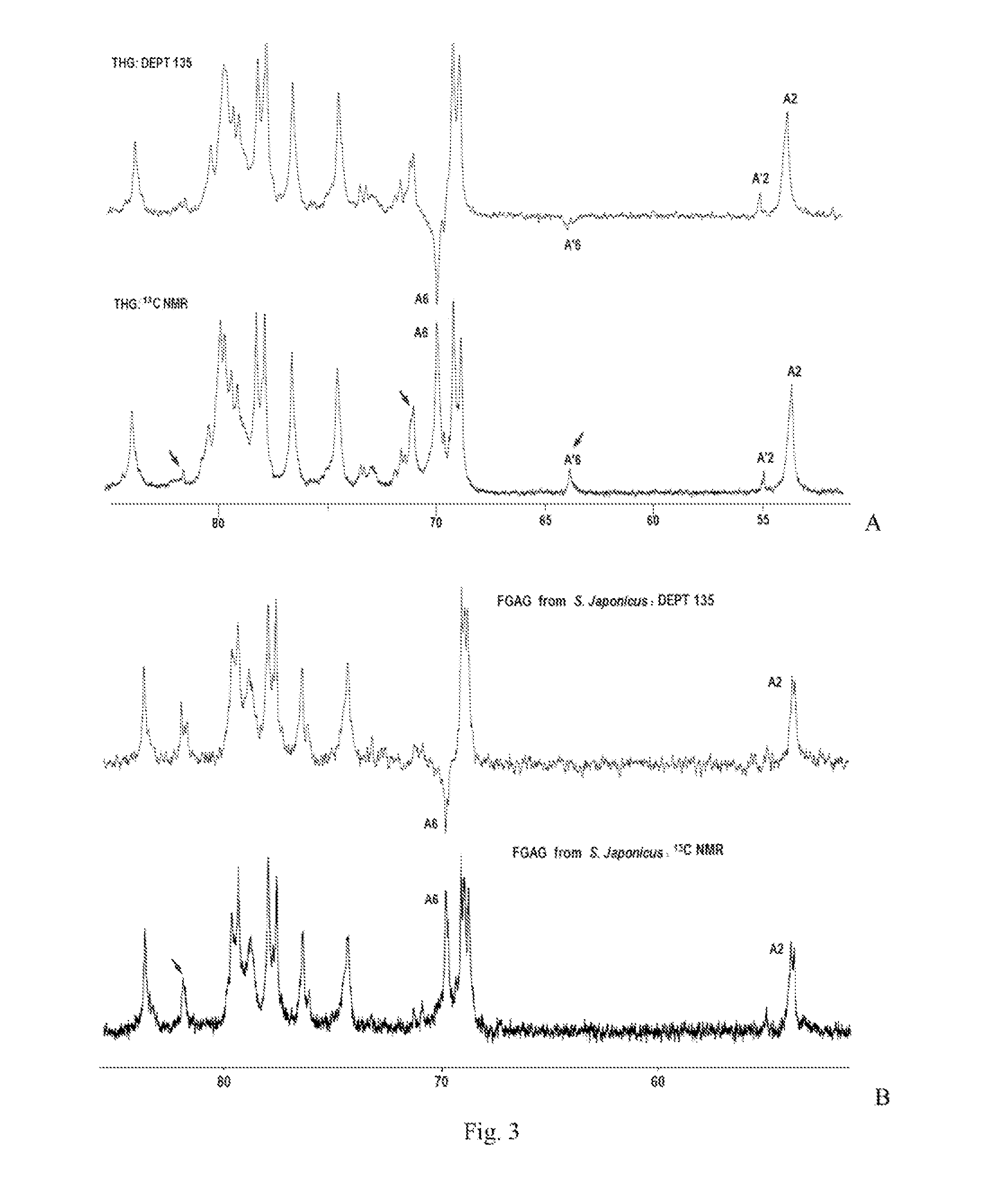

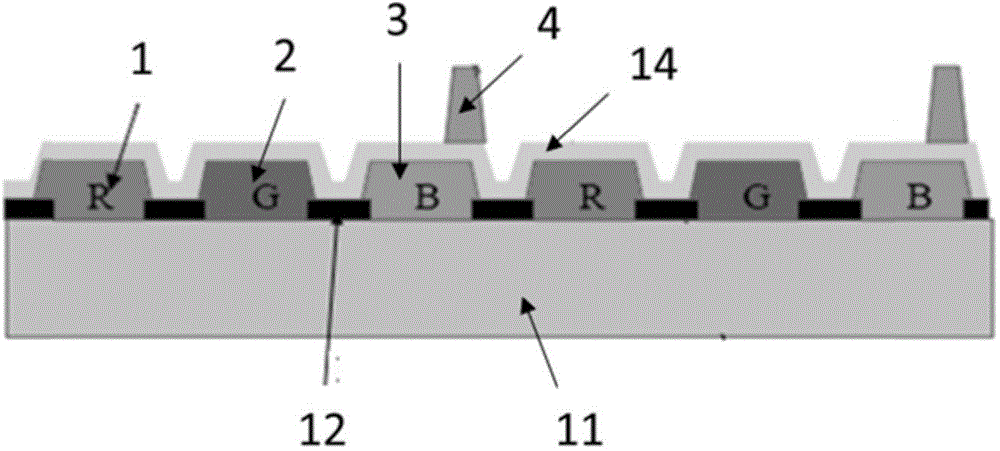

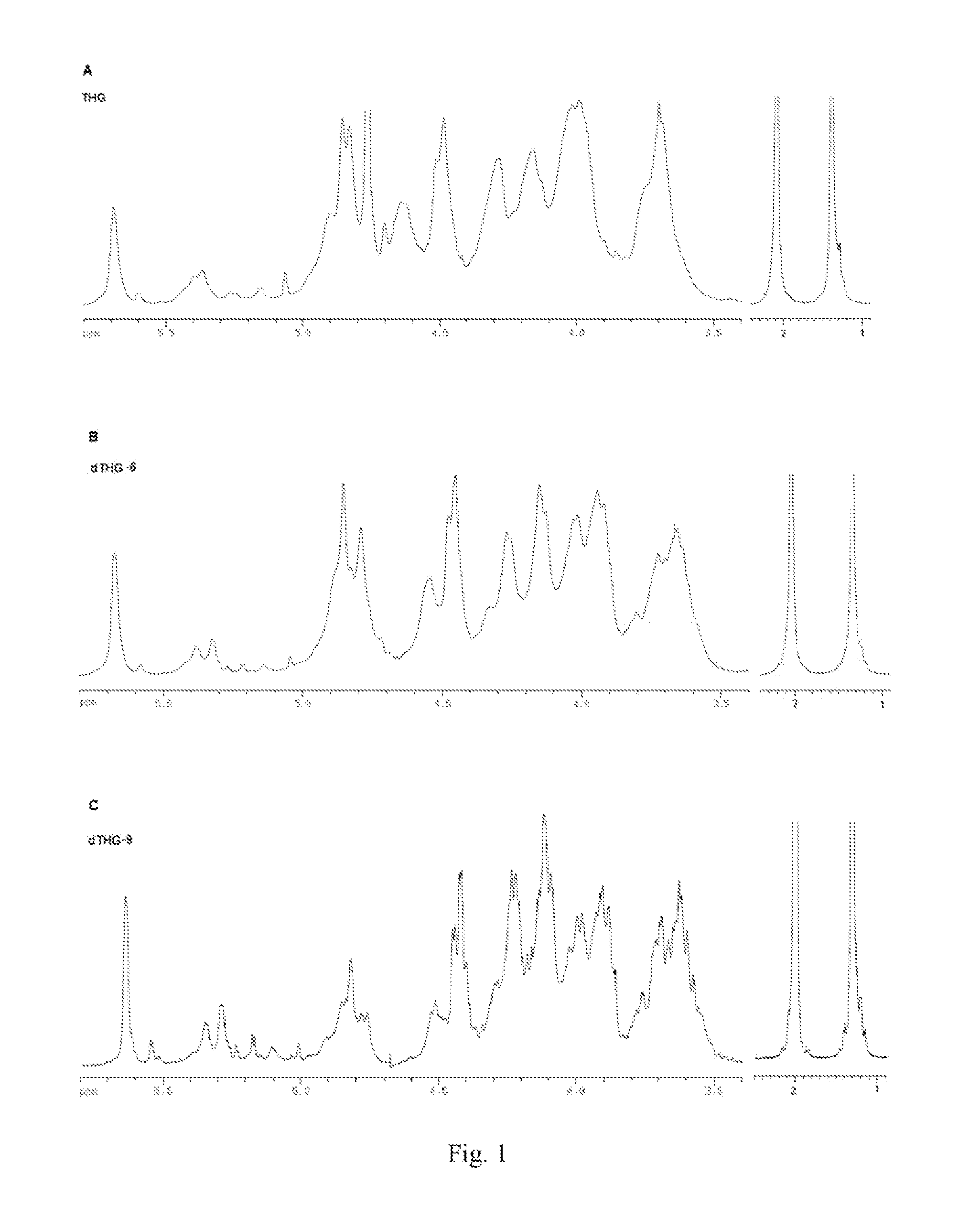

Depolymerized glycosaminoglycan from thelenota ananas and preperation method thereof

ActiveUS20120270834A1Special structureGood anticoagulant potencyOrganic active ingredientsBiocideD-GLUCURONIC ACIDFactor X

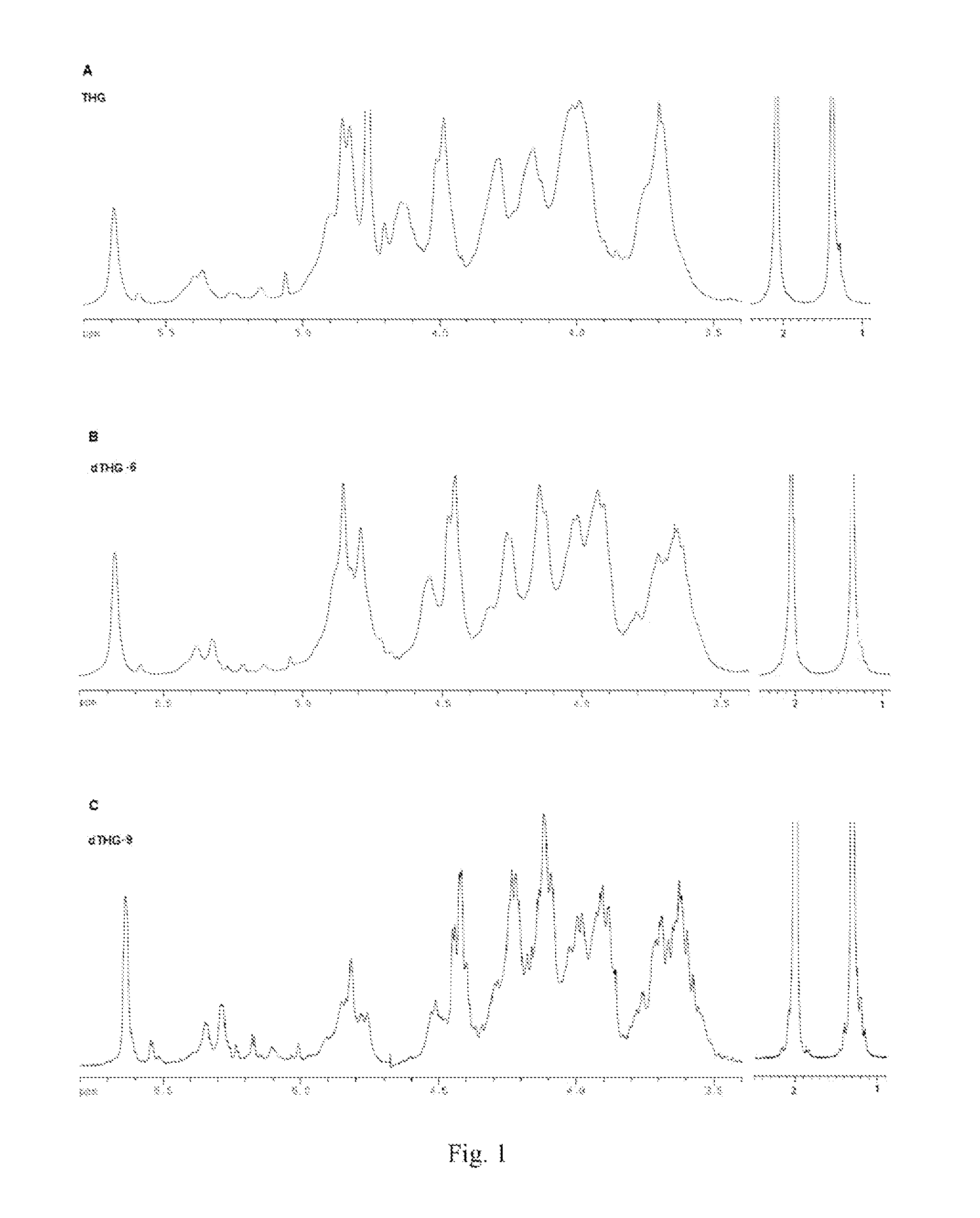

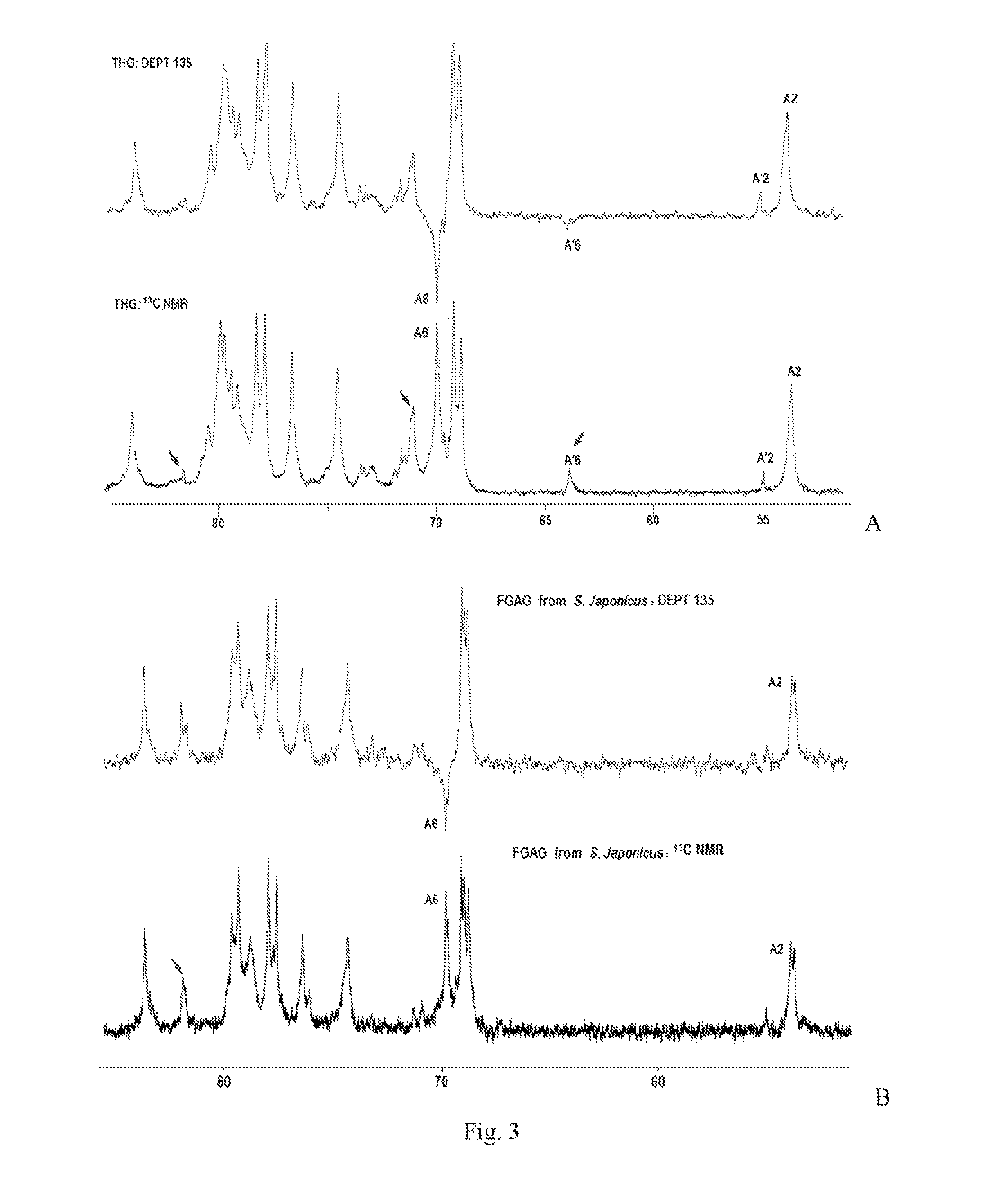

Disclosed is a depolymerized glycosaminoglycan from Thelenota ananas (dTHG), weight average molecular weight of which is about 8000˜20000 Da, and monosaccharide components of which are acetylgalactosamine (GalNAc), glucuronic acid (GlcUA), fucose (Fuc) or their sulfates (expressed as —OSO3−), in which molar ratio of GalNAc:GlcUA:Fuc:—OSO3− is about 1:(1±0.3):(1±0.3):(3.5±0.5). Said dTHG is a potent endogenous inhibitor of factor X, which has good anticoagulant and antithrombotic activity, and can be used for the prevention and / or treatment of thrombotic diseases. Also provided is a method for preparing said dTHG, which comprises steps of 1) extracting and obtaining fucosylated glycosaminoglycan (THG) from the body wall of Thelenota ananas; 2) depolymerizing THG to obtain dTHG by method of peroxide depolymerization or method of peroxide depolymerization catalyzed by catalyst of the fourth period transition metal ions; 3) removing impurities with lower and / or higher molecular weight in dTHG.

Owner:SHENZHEN NEPTUNUS PHARM CO LTD

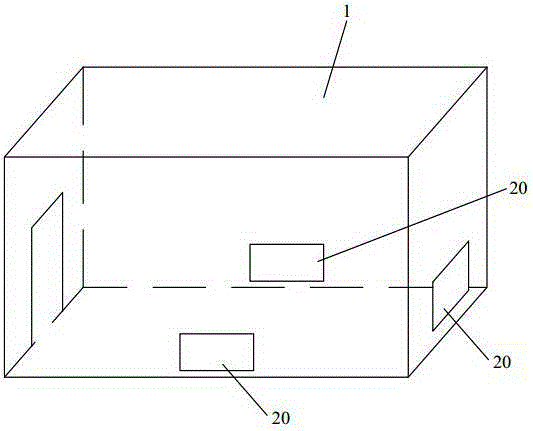

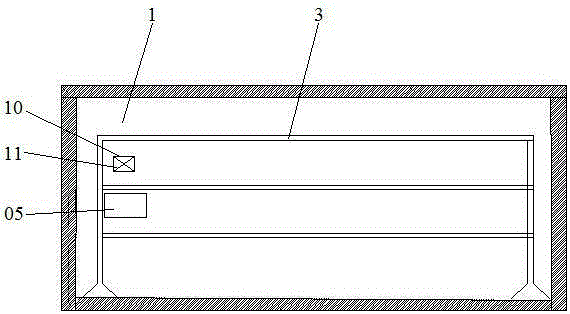

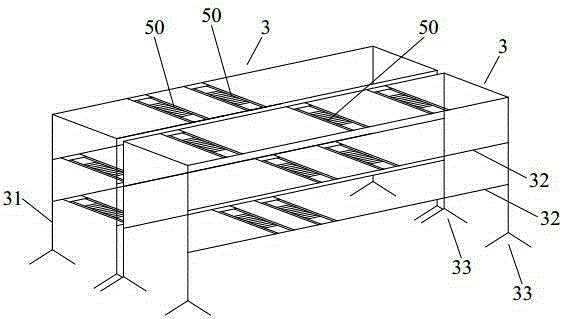

Heating piece tobacco baking chamber for waste heat recycling

InactiveCN105286072AHigh performance ratioIncrease heating capacityTobacco preparationFinal product manufactureCooking & bakingProcess engineering

The invention relates to the technical field of tobacco-baking equipment, in particular to a heating piece tobacco baking chamber for waste heat recycling. The heating piece tobacco baking chamber for waste heat recycling comprises a tobacco baking room provided with two tobacco hanging racks, each tobacco hanging rack comprises vertically arranged vertical rods and transversely arranged transverse rods, and the lower portions of the vertical rods are provided with supporting feet; the transverse rods are provided with tobacco clamps; the two tobacco hanging racks are arranged side by side; the tobacco baking room further comprises heating piece devices arranged on walls. One side of the tobacco baking room is further provided with waste heat recycling equipment. By means of the heating piece tobacco baking chamber, tobacco baking efficiency and quality are remarkably improved; hot air emitted by the heating piece devices is utilized to conduct baking, the heating piece devices are utilized, no additional heating device is needed, and the cost of the additional heating device is omitted; besides, the heating piece devices are small in size, space is saved, and the tobacco leaves can be baked effectively.

Owner:GUANGDONG BRANCH OF CHINA TOBACCO GENERAL +1

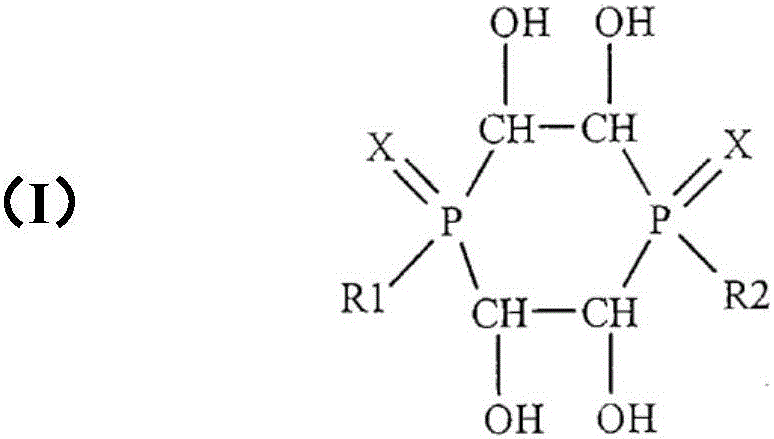

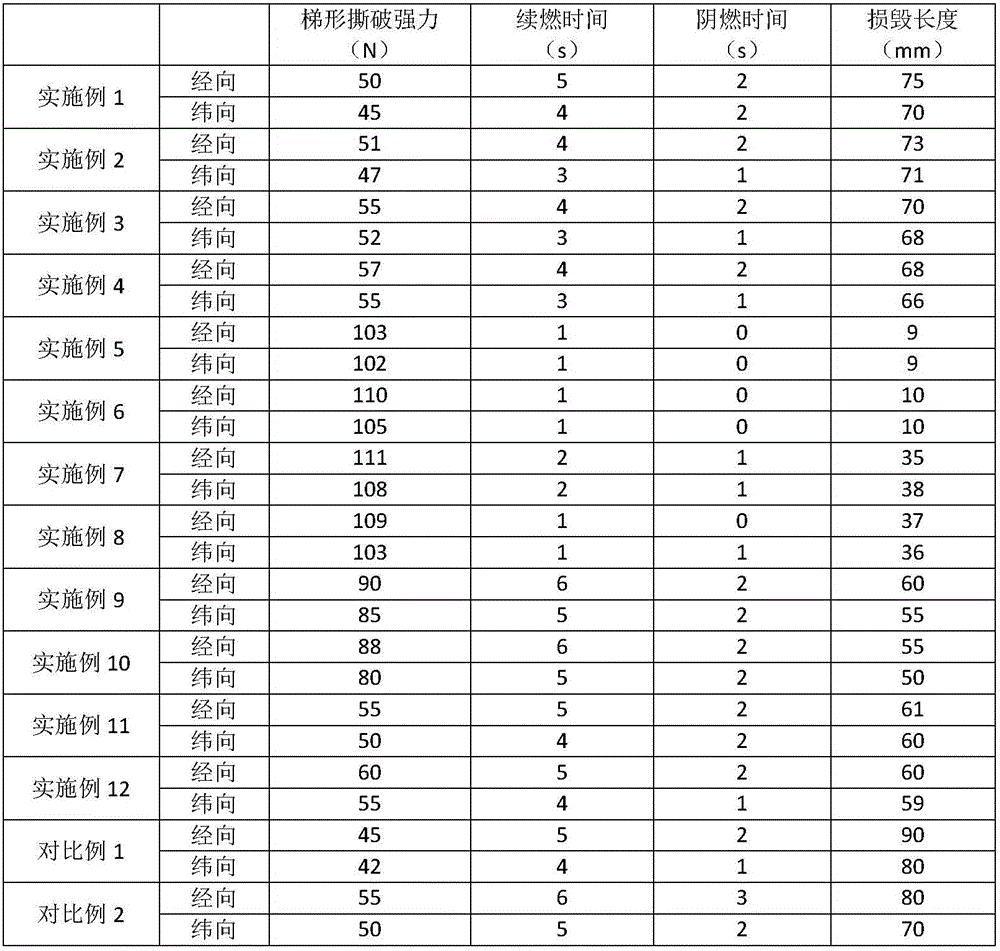

Blended yarn of organic silicon nitrogen system flame-retardant fiber and organophosphorus system flame-retardant fiber

InactiveCN106400235AImprove flame retardant performanceGood hygroscopicityArtificial filaments from viscoseWoven fabricsYarnWater vapor permeability

The invention discloses a yarn and a fabric made of organic silicon nitrogen system flame-retardant fiber and organophosphorus system flame-retardant fiber in a blending manner. As two or three types of flame-retardant fiber are blended, a synergistic flame retardancy function can be brought into play, the flame-retardancy effect is better than that of single fiber, meanwhile relatively good air and water vapor permeability and comfort can be provided for the fabric, the fuming amount of single phosphorus system adhesive fiber and the cost of a flame-retardant fabric can be greatly lowered, and relatively good cost performance can be achieved.

Owner:SOL FLAME RETARDANT FIBER

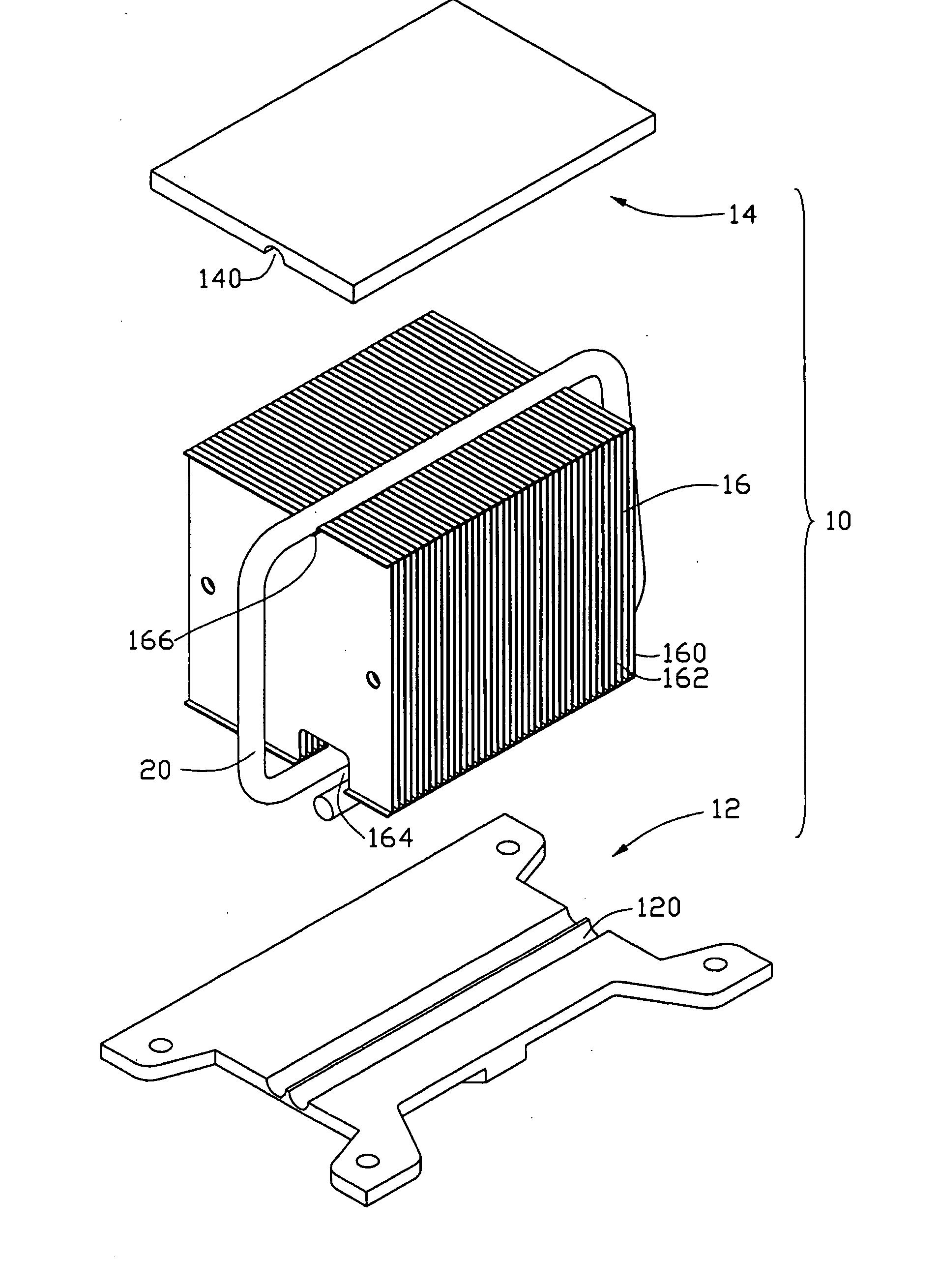

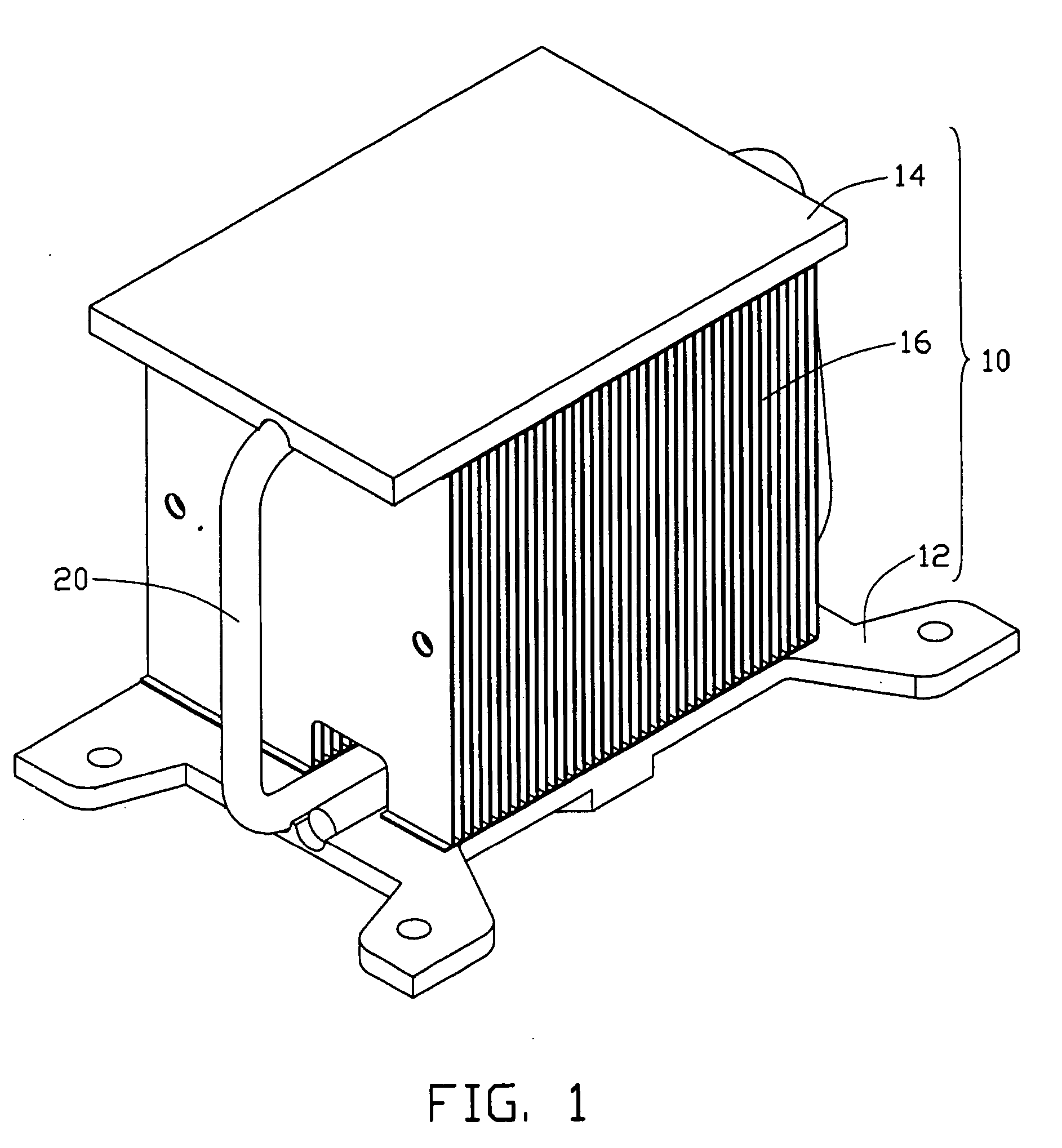

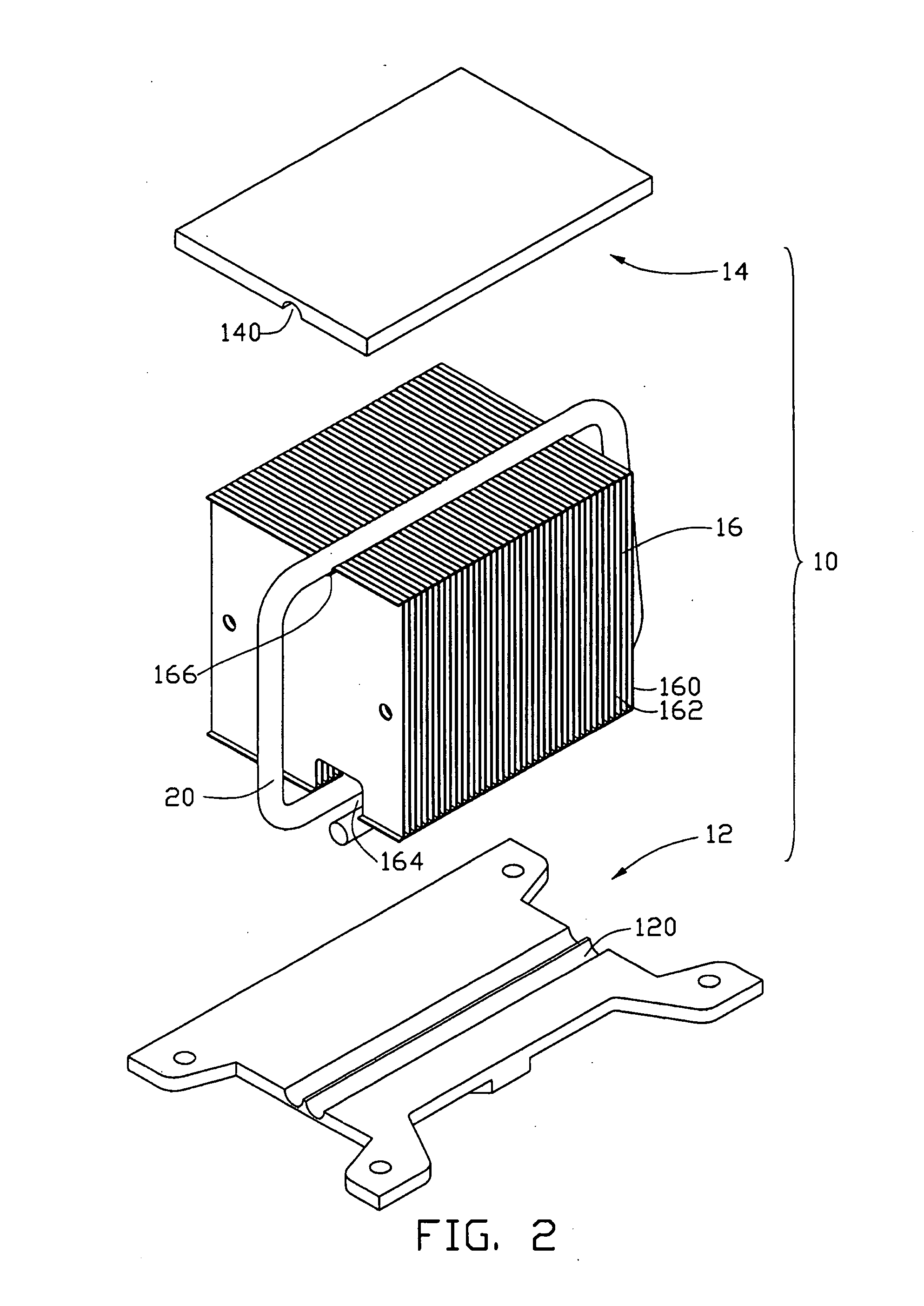

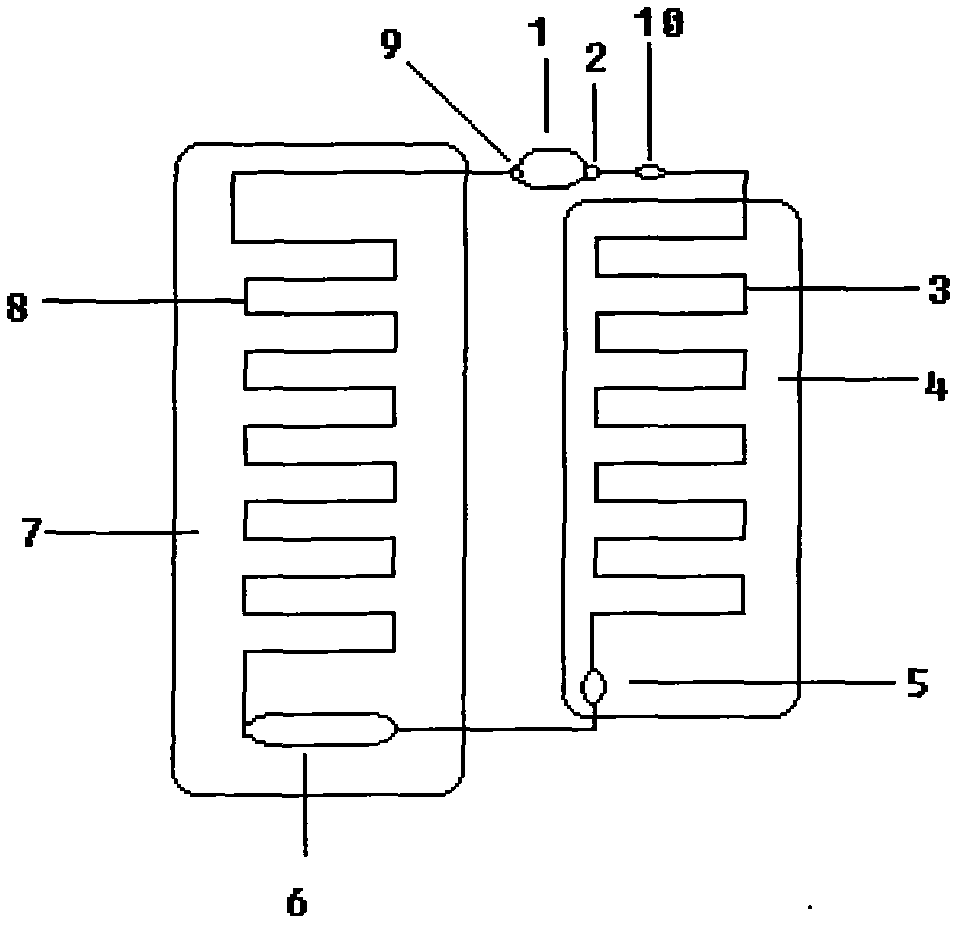

Heat dissipation having a heat pipe

InactiveUS20070095509A1High performance ratioGood value for moneySemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat pipe

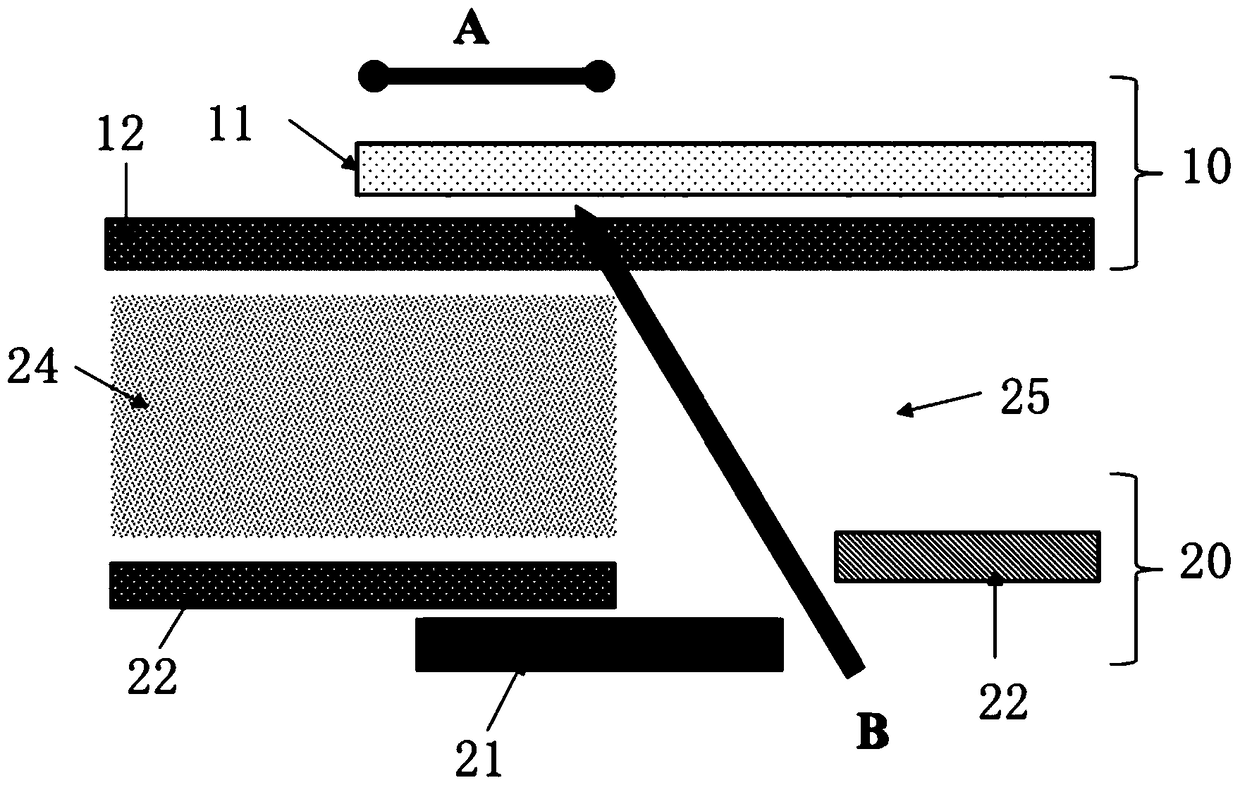

A heat dissipation device includes a heat sink (10) and a heat pipe (20). The heat sink includes a base (12), a fins group (16) extending from the base, and a cover (14) contacting with the fins group. The heat pipe surrounds top and bottom and two opposite sides of the fins group and thermally connects with the base and the cover.

Owner:HON HAI PRECISION IND CO LTD

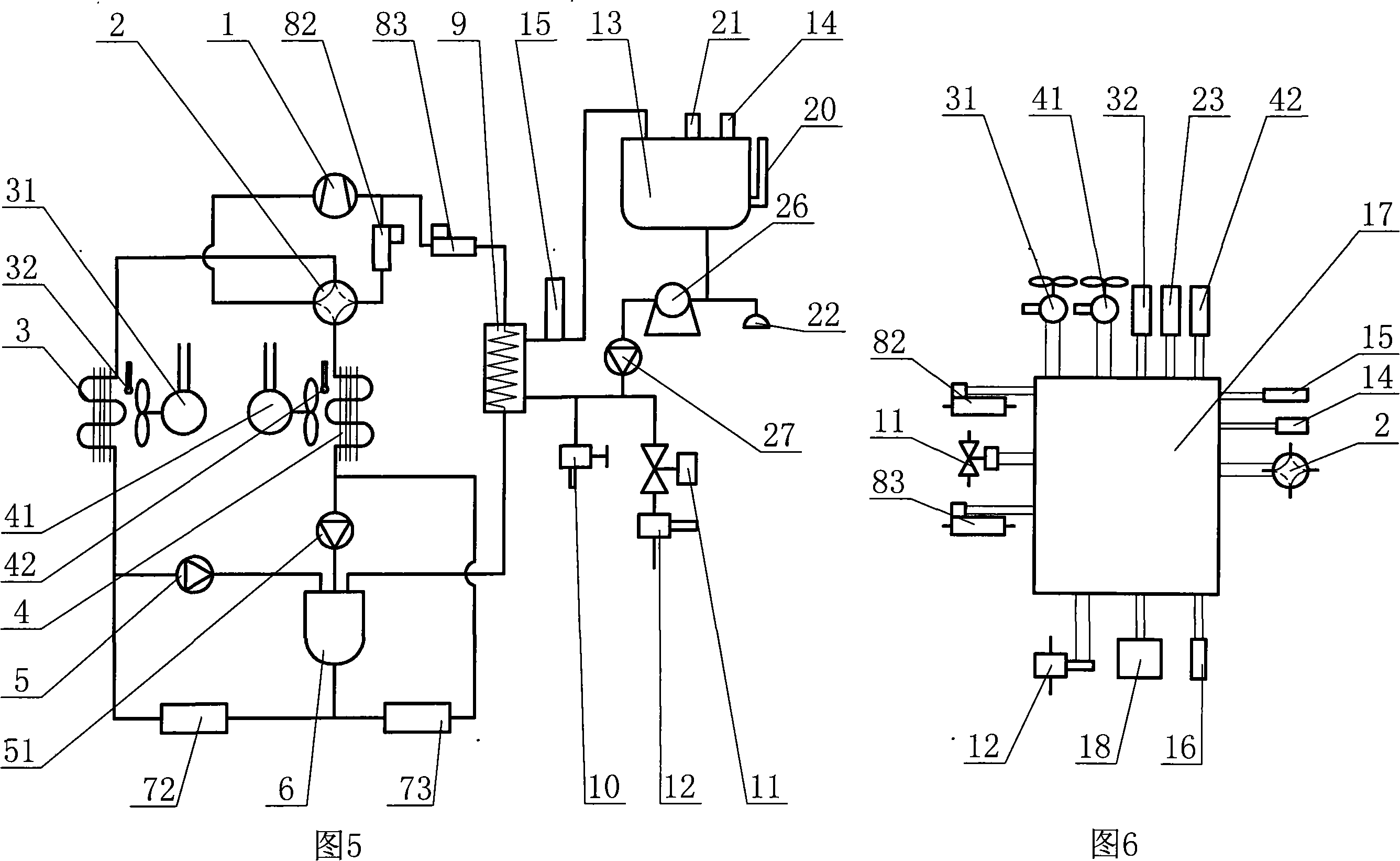

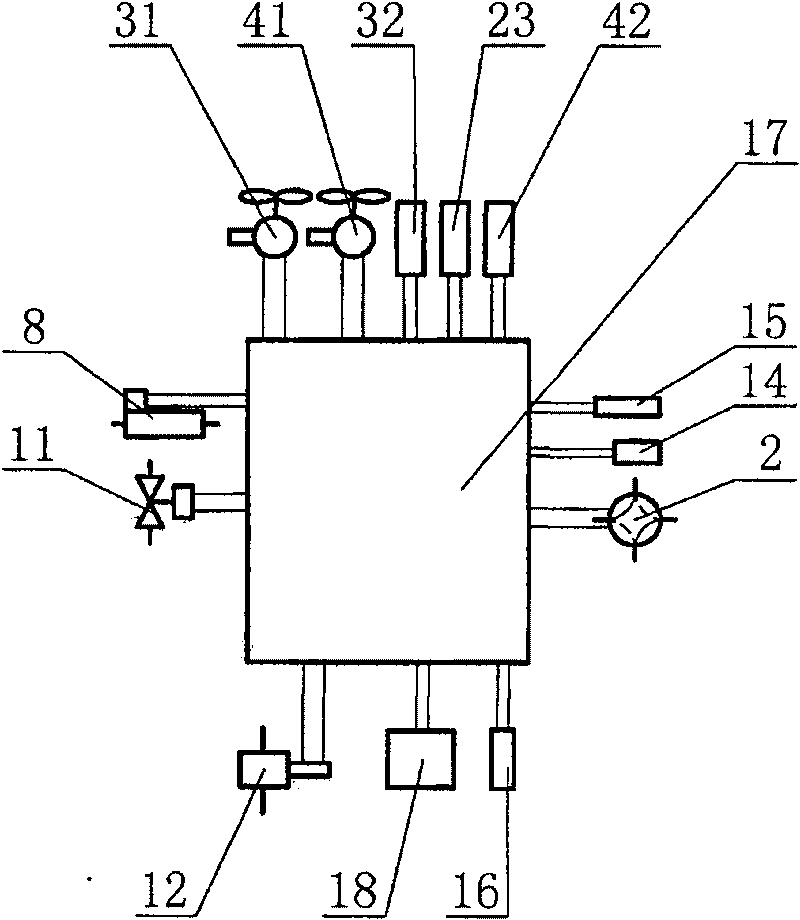

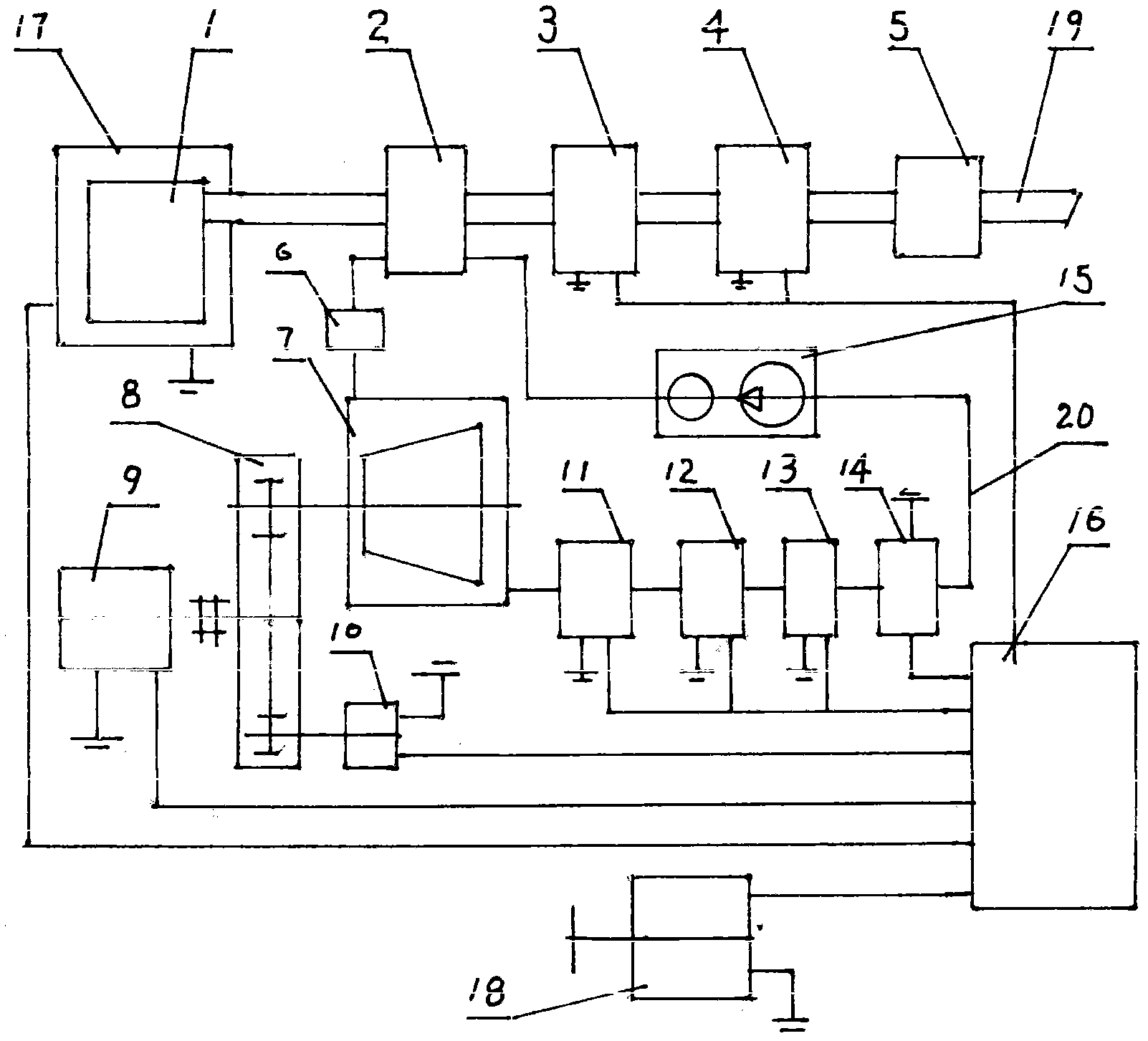

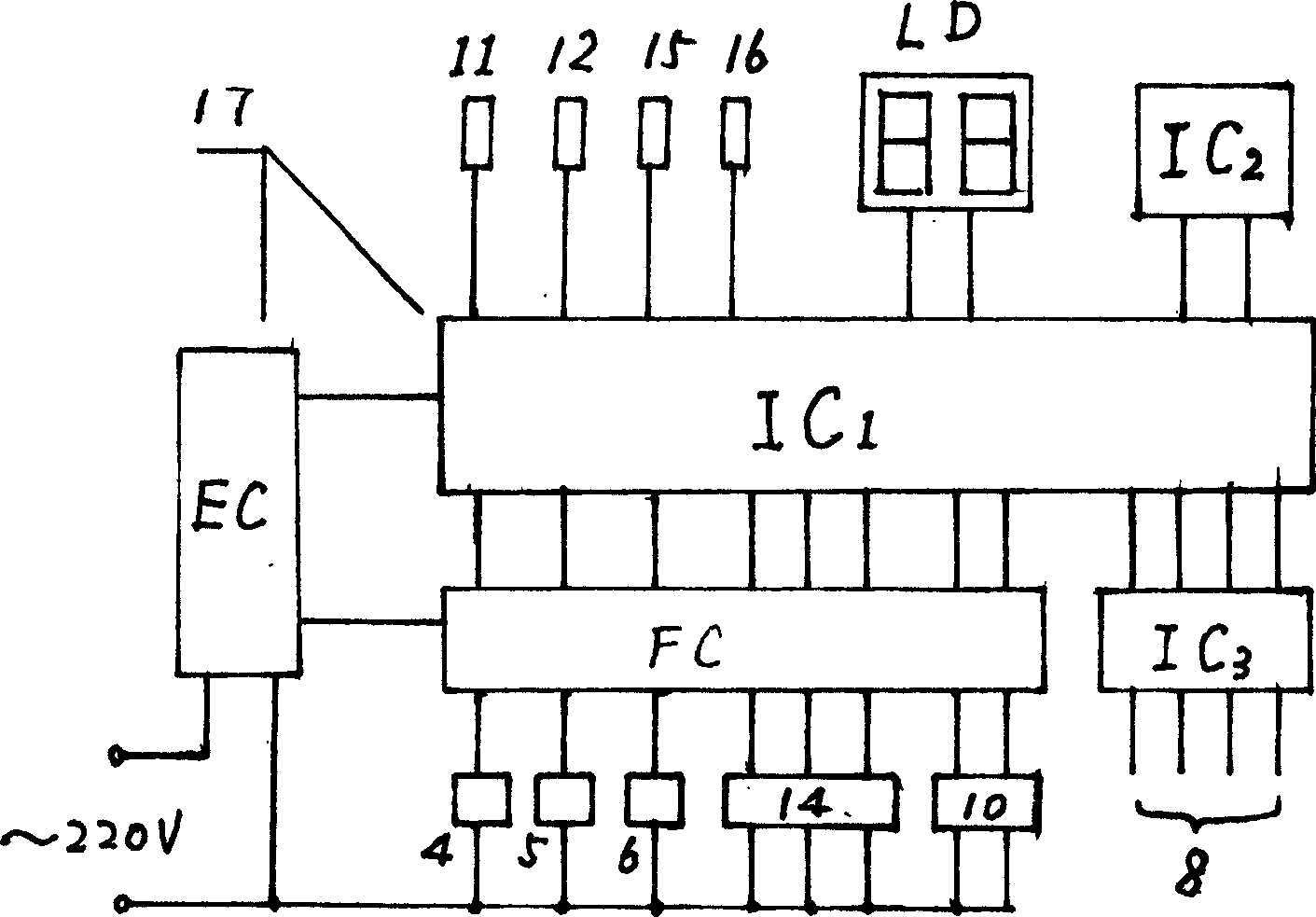

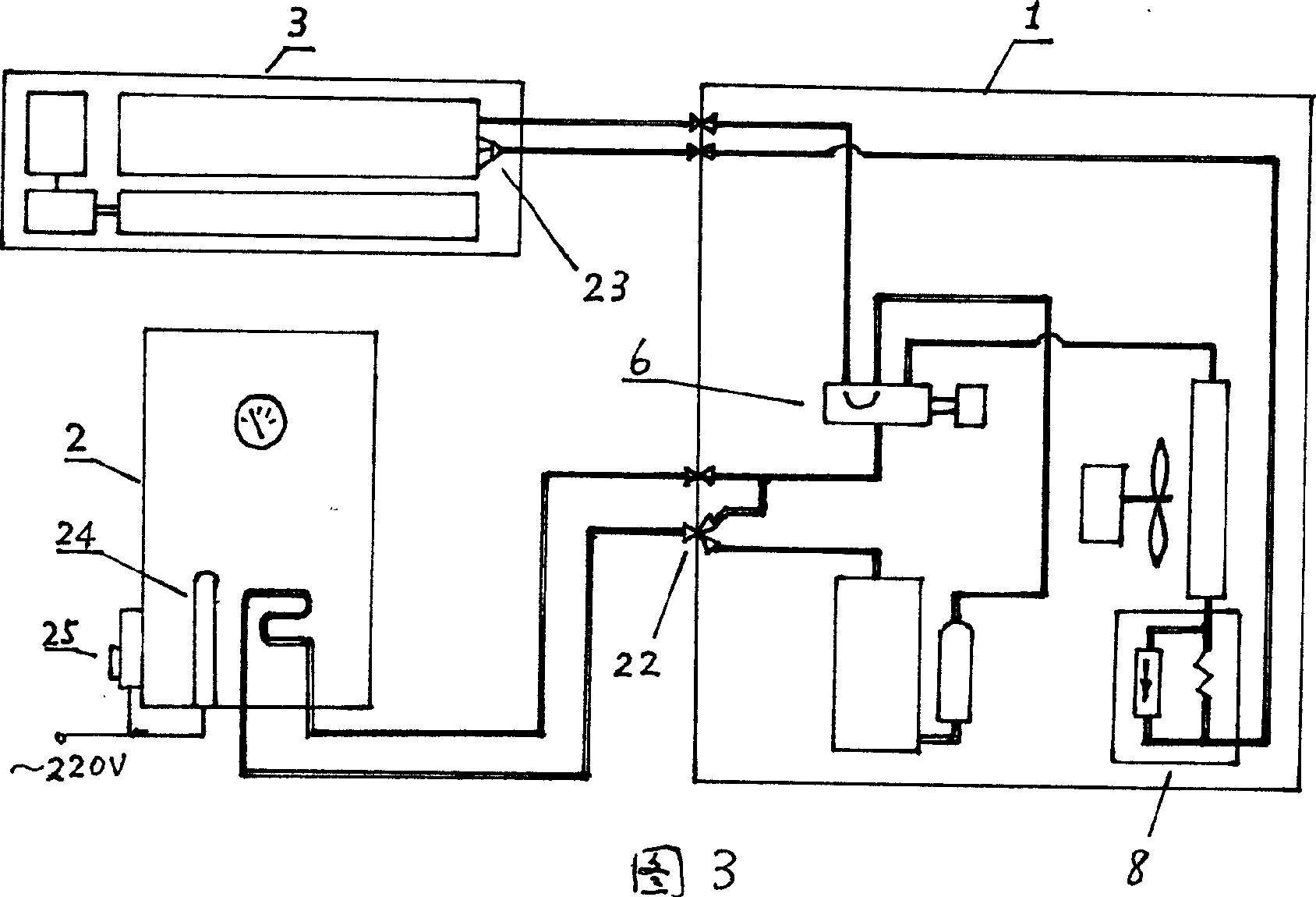

Air-conditioning water heater set

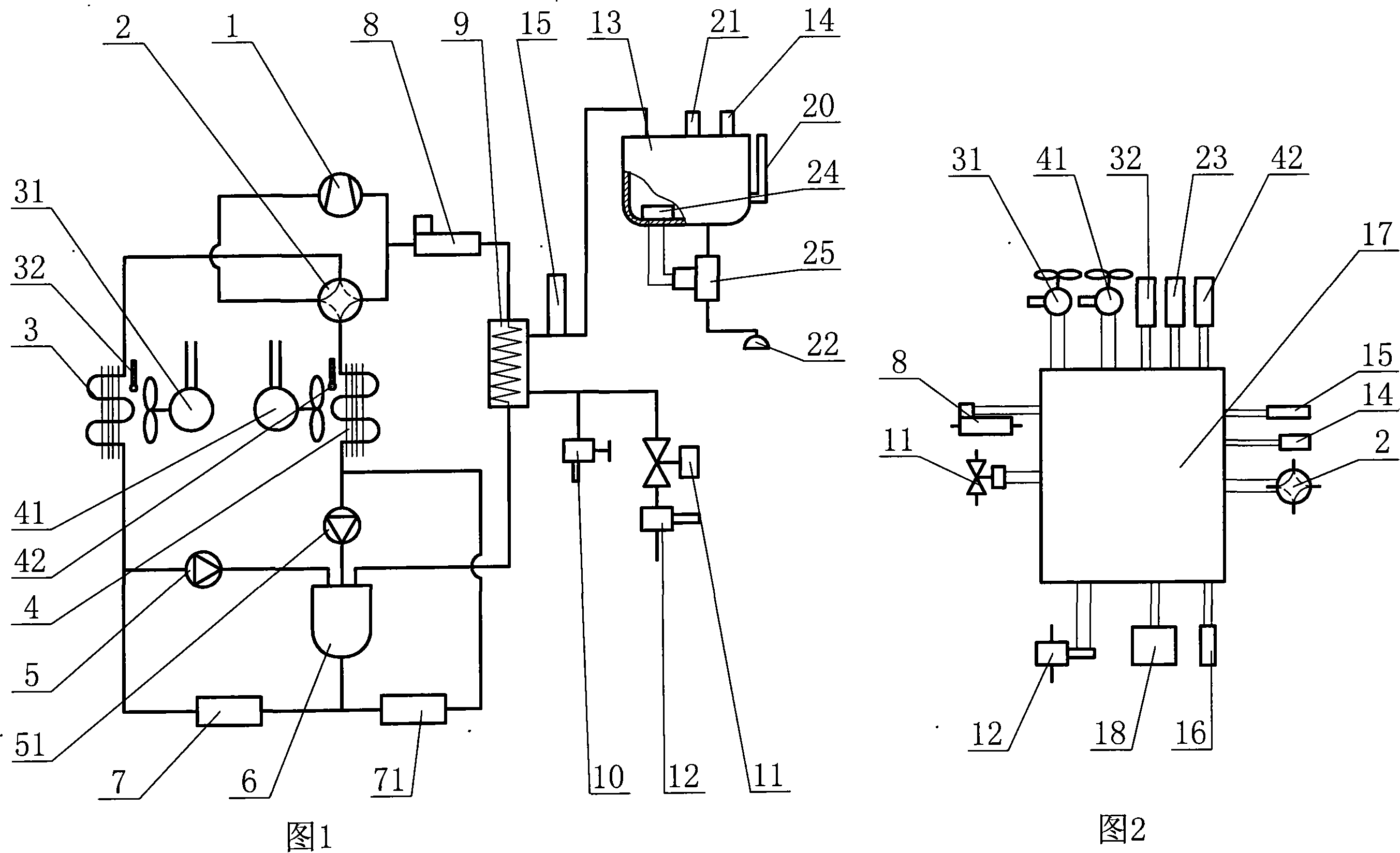

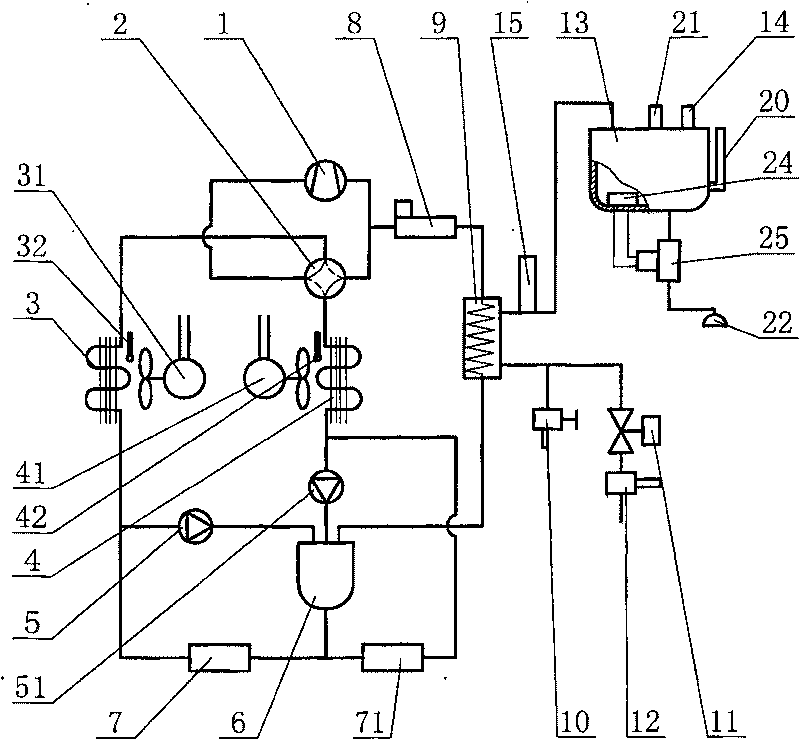

ActiveCN101131249AHigh performance ratioMeet the needs of lifeFluid heatersEnergy efficient heating/coolingWater sourceEngineering

The air conditioning and water heating set includes one compressor, one change-over valve with two ports connected separately to the high pressure exhaust pipe and low pressure inlet pipe of the compressor, one indoor heat exchanger with one indoor fan and one outdoor heat exchanger with one outdoor fan connected separately to two other parts of the change-over valve, one liquid collector communicated with the indoor heat exchanger and the outdoor heat exchanger, one first flow regulator and one second flow regulator with high pressure ends communicated with the liquid outlet of the liquid collector, and one water condensator with water inlet pipe and water outlet pipe communicated separately to one cold water source and one water tank. The present invention has domestic water heated with the afterheat of air conditioner and by means of heat pump, and possesses best utilization of heat, environment friendship, high performance / cost ratio and other advantages.

Owner:邢金良

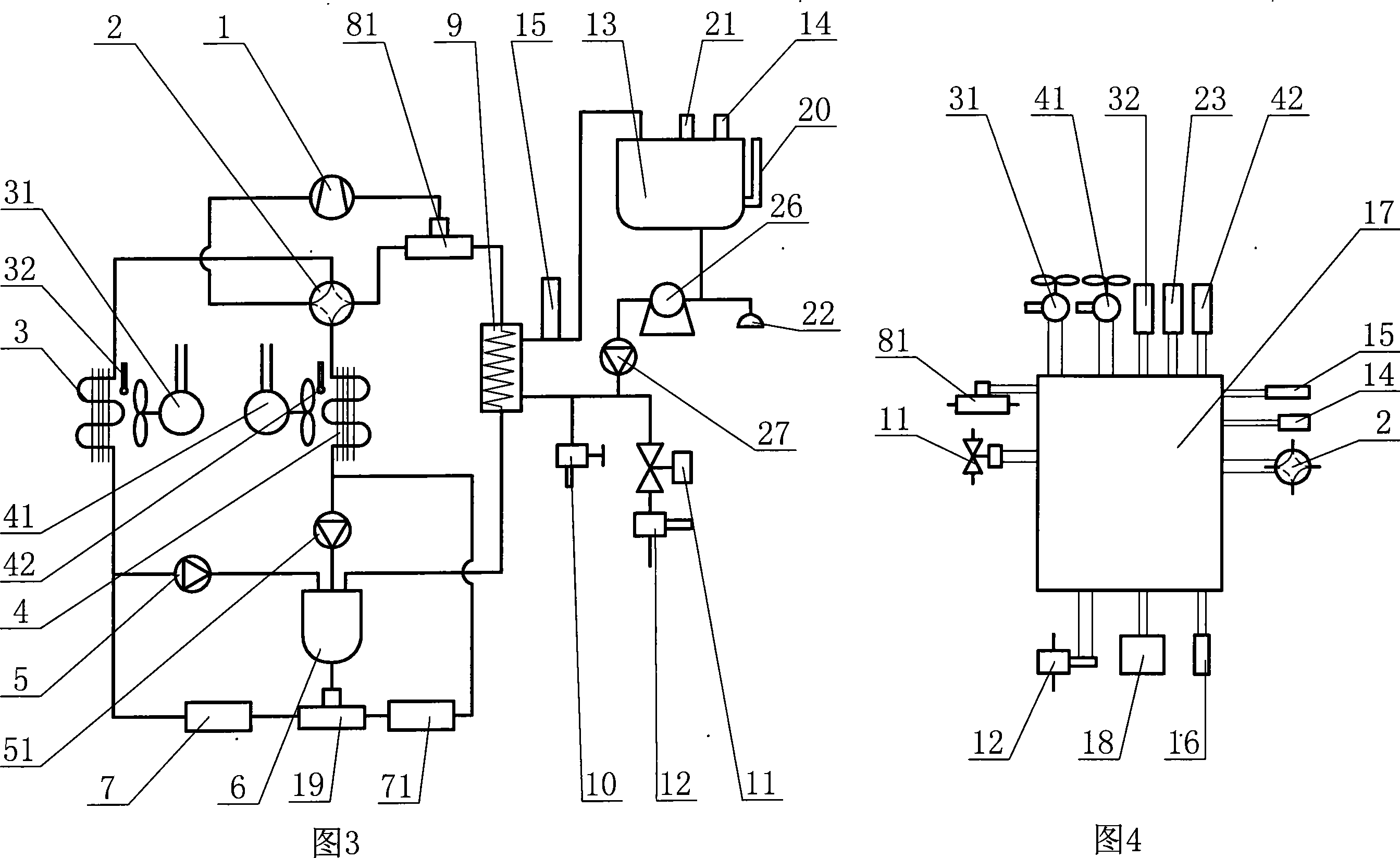

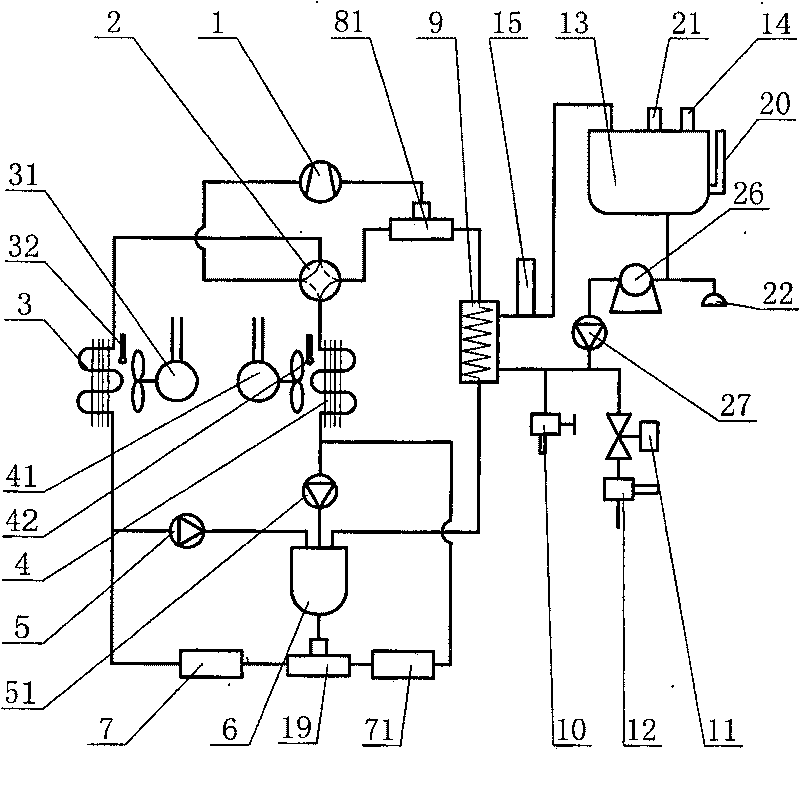

High temperature heat pump-based waste heat recovery curing barn

InactiveCN104664582AIncrease heating capacityReduce power consumptionTobacco preparationHeat pumpsLiquid storage tankEngineering

The invention relates to a high temperature heat pump-based waste heat recovery curing barn comprising a body, a high-temperature heat pump unit disposed on the left of the body, an evaporator, a condenser, a conveying line, a recovery line, fan blades and a waste heat recovery valve hole. The evaporator and the condenser are disposed within the high-temperature heat pump unit; the conveying line and the recovery line connect the evaporator and the condenser; the fan blades are disposed on the left of the evaporator; the right of the evaporator is provided with the waste heat recovery valve hole. The conveying line is provided with a liquid storage tank and a throttle device sequentially from left to right; the recovery line is provided with a compressor. post-curing waste heat generated by the barn is subjected to moisture discharge and recycling, curing heat is provided for the barn, heating power consumption of a main unit is reduced, operational efficiency ratio of the main unit is increased, the waste heat is automatically recycled, moisture is automatically discharged, heat generation of the evaporator is increased, efficiency ratio is increased, energy is thus saved, the fact that direct emission of heat to the atmosphere influences weather balance is avoided, and the barn is environment friendly, simple to use, handy and practical.

Owner:HUBEI KEYANG ENERGY SAVING EQUIP

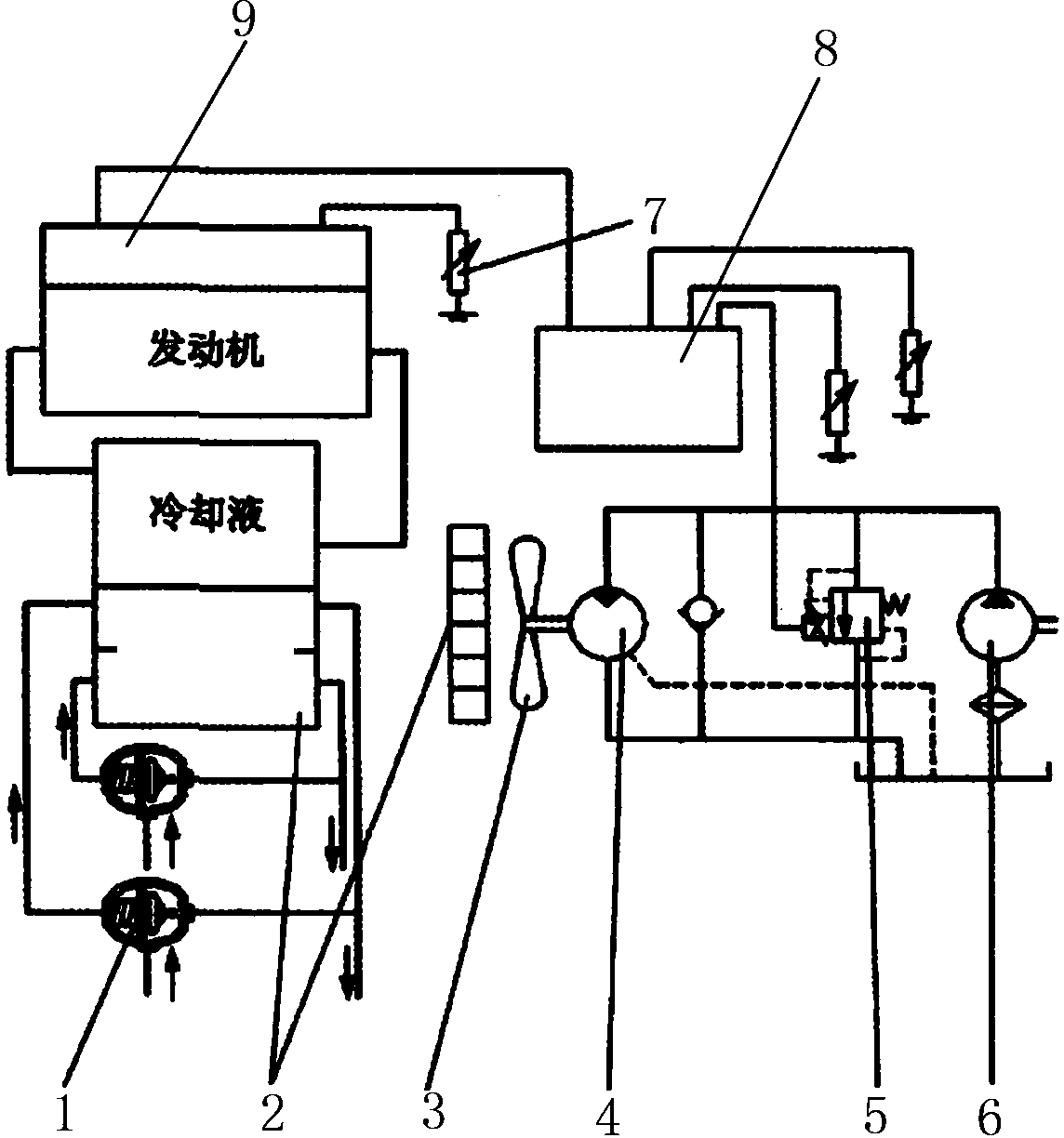

Cooling system

InactiveCN103511054AExtend effective working hoursHigh performance ratioCoolant flow controlSoil-shifting machines/dredgersThermal statePerformance ratio

The invention relates to a cooling system used for a loading machine. The cooling system comprises a fan, wherein the fan is connected with a constant displacement motor, an electric proportional relief valve, a constant displacement pump and an oil tank in sequence, the electric proportional relief valve is further connected with a controller and a temperature sensor, the temperature sensor is connected with an engine ECU through a CAN bus, and a radiator is further arranged at the front end of the fan and connected with hydraulic oil and bending moment oil through a temperature control valve. The independent hydraulic-controlled cooling fan is adopted in the cooling system, the flow of the hydraulic oil flowing through the radiator and the flow of the bending moment oil flowing through the radiator are controlled by the temperature control valve, the hydraulic oil is matched with bending moment oil, operational use time of the fan is greatly increased, and the performance ratio of the fan is improved; meanwhile, the temperature of engine coolant, the temperature of hydraulic oil and the temperature of bending moment oil are controlled to be within the best temperature interval in the shortest time, overheating and supercooling of media are avoided, and stabilization of the thermal state of the whole machine is guaranteed.

Owner:SHAANXI SHENGMAI PETROLEUM

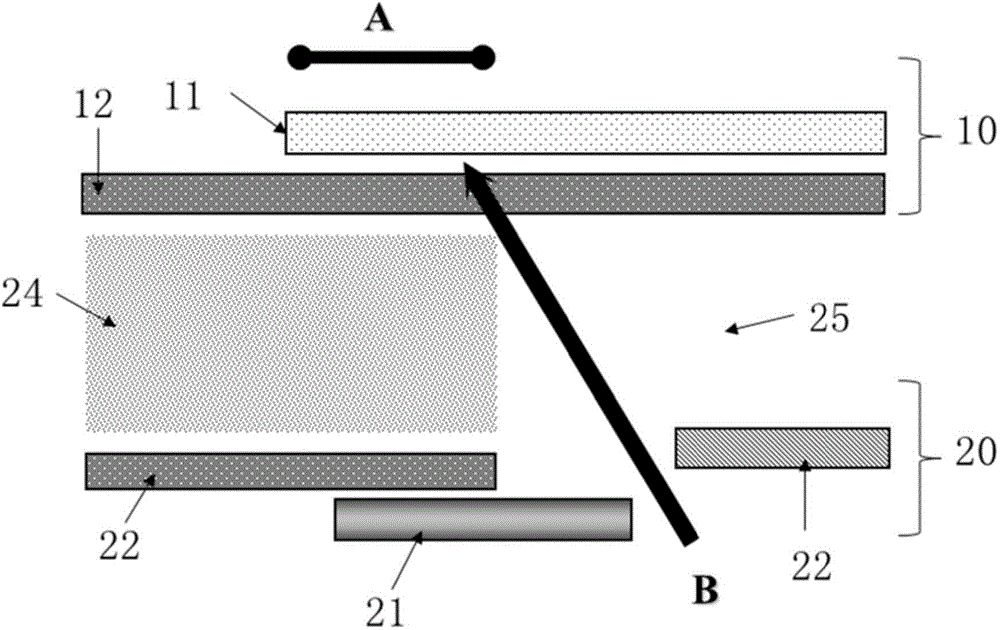

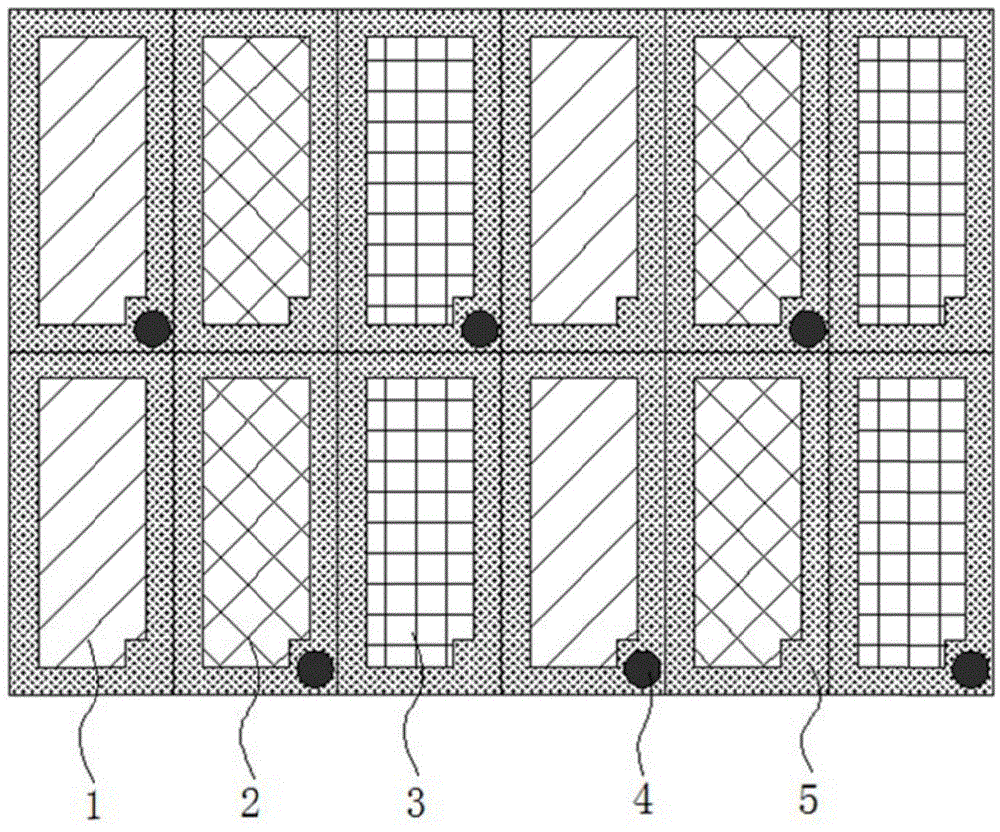

Liquid crystal display

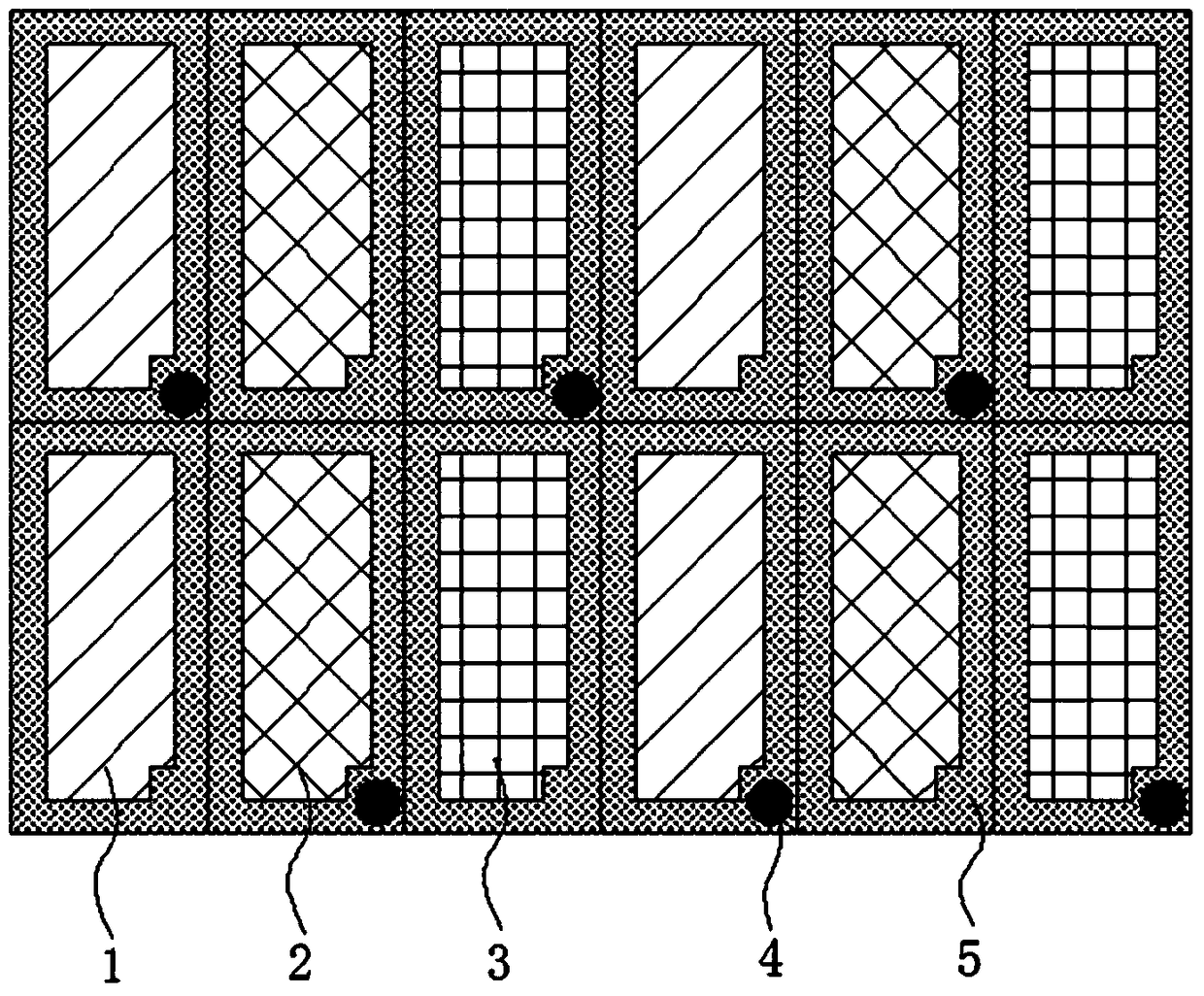

ActiveCN104570456AIncrease brightnessIncrease contrastNon-linear opticsLiquid-crystal displayColor film

The invention provides a liquid crystal display. Support columns are positioned in opposite light-proof regions of a color film substrate and an array substrate; after a part of light of a backlight source penetrates through a gap between a scanning line and a data line, the support columns shield the light deflecting to an opening area. The liquid crystal display provided by the invention aims at realizing the purpose of shielding the light leaking askant through the support columns shaped as water-retaining walls, so that the width of a black matrix on the color film substrate can be appropriately reduced, and thus the light-proof region formed by the black matrix is narrowed, the area of a color-layer light-pervious region on the color film substrate is increased and the opening rate of the color film substrate and the penetration rate of a liquid crystal display panel are increased. The liquid crystal display accords with the development trends of high brightness, high contrast and high efficiency rate of the liquid crystal display.

Owner:NANJING CEC PANDA LCD TECH

Depolymerized glycosaminoglycan from Thelenota ananas and preparation method thereof

ActiveUS8809300B2Special structureGood anticoagulant potencyBiocideOrganic active ingredientsFucosylationDepolymerization

Disclosed is a depolymerized glycosaminoglycan from Thelenota ananas (dTHG), weight average molecular weight of which is about 8000˜20000 Da, and monosaccharide components of which are acetylgalactosamine (GalNAc), glucuronic acid (GlcUA), fucose (Fuc) or their sulfates (expressed as —OSO3−), in which molar ratio of GalNAc:GlcUA:Fuc:—OSO3− is about 1:(1±0.3):(1±0.3):(3.5±0.5). Said dTHG is a potent endogenous inhibitor of factor X, which has good anticoagulant and antithrombotic activity, and can be used for the prevention and / or treatment of thrombotic diseases. Also provided is a method for preparing said dTHG, which comprises steps of 1) extracting and obtaining fucosylated glycosaminoglycan (THG) from the body wall of Thelenota ananas; 2) depolymerizing THG to obtain dTHG by method of peroxide depolymerization or method of peroxide depolymerization catalyzed by catalyst of the fourth period transition metal ions; 3) removing impurities with lower and / or higher molecular weight in dTHG.

Owner:SHENZHEN NEPTUNUS PHARM CO LTD

Optical unit and a projection image display apparatus using the same

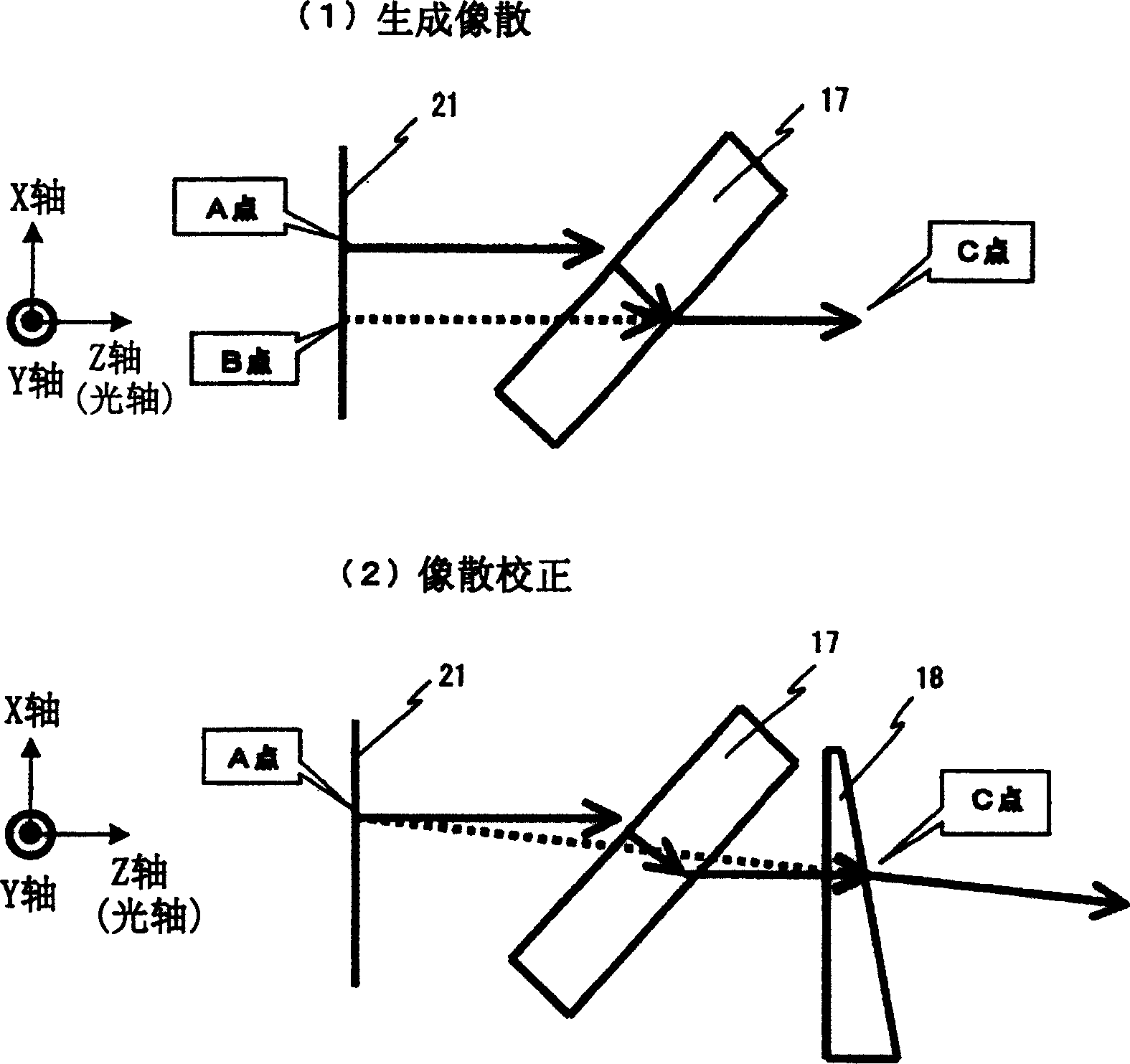

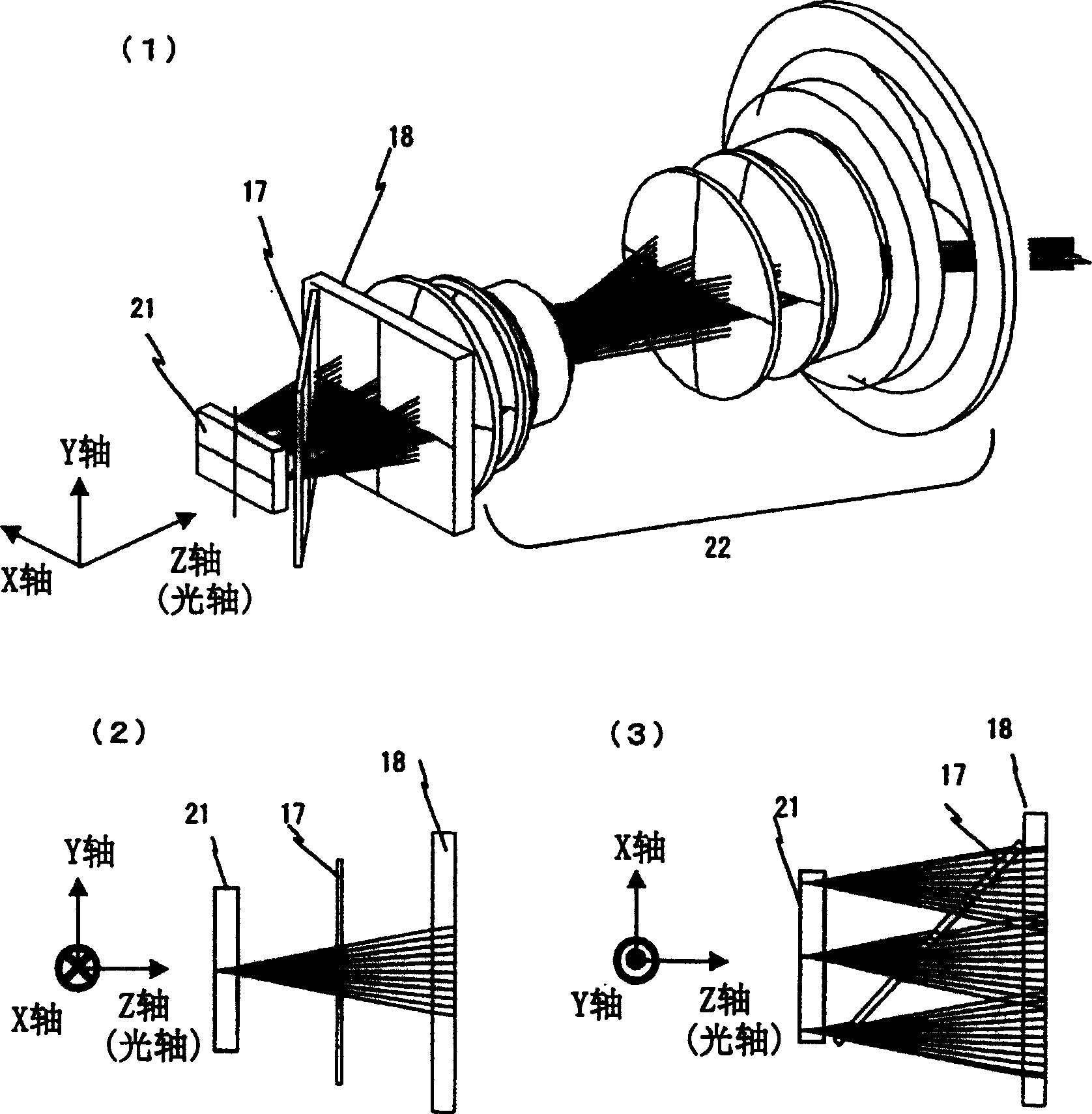

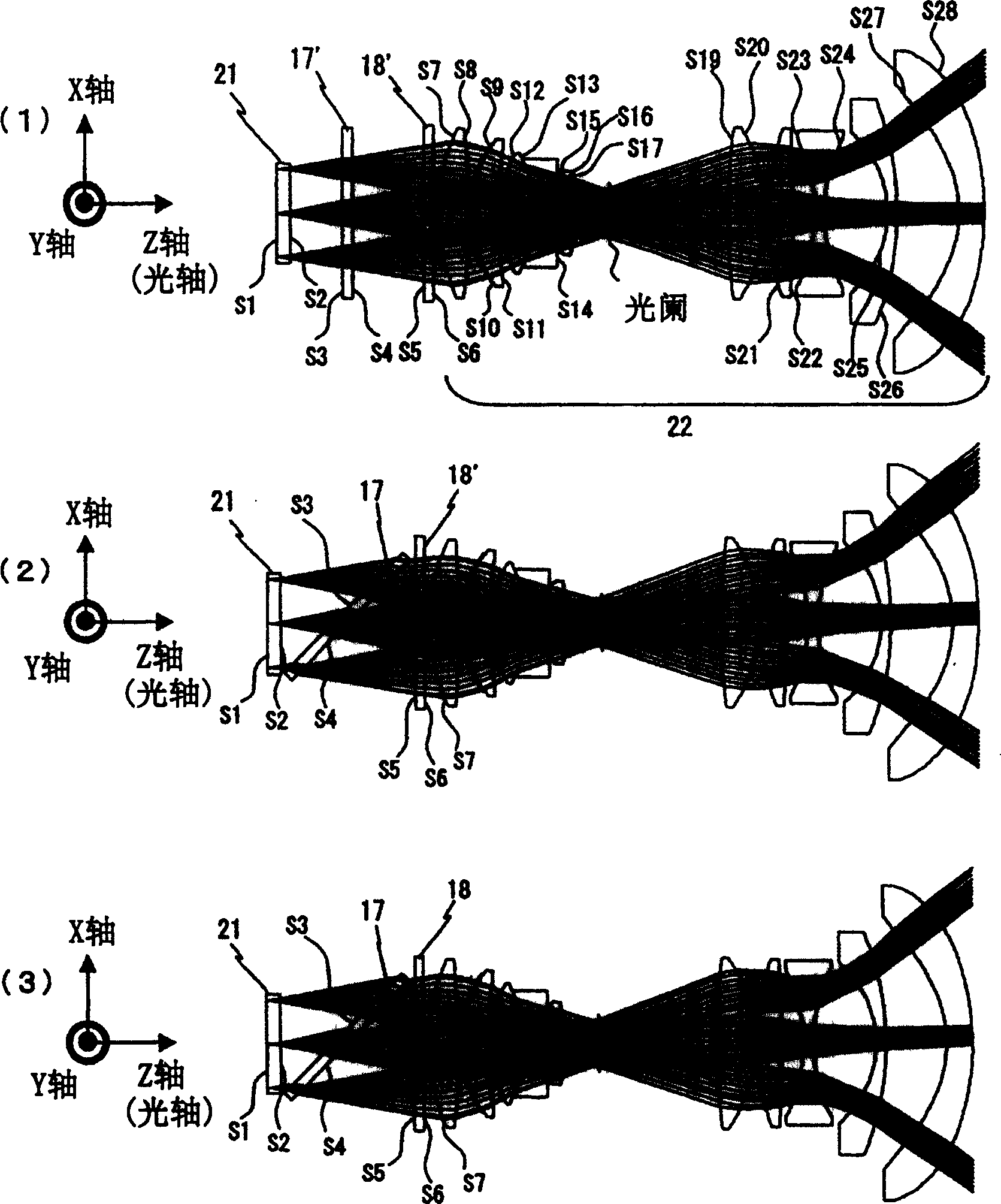

InactiveCN1637461AImprove clarityHigh performance ratioProjectorsPolarising elementsWire gridProjection image

An element with a planar structure such as a wire grid polarization separation element is used as a polarization separation mechanism, and an astigmatism correction mechanism such as a cylindrical lens is provided between the polarization separation mechanism and a projection lens unit, thereby providing a projection-type image display device Among them, the technology that corrects the astigmatism caused by the polarization separation mechanism can ensure the sharpness of the projected image.

Owner:HITACHI LTD

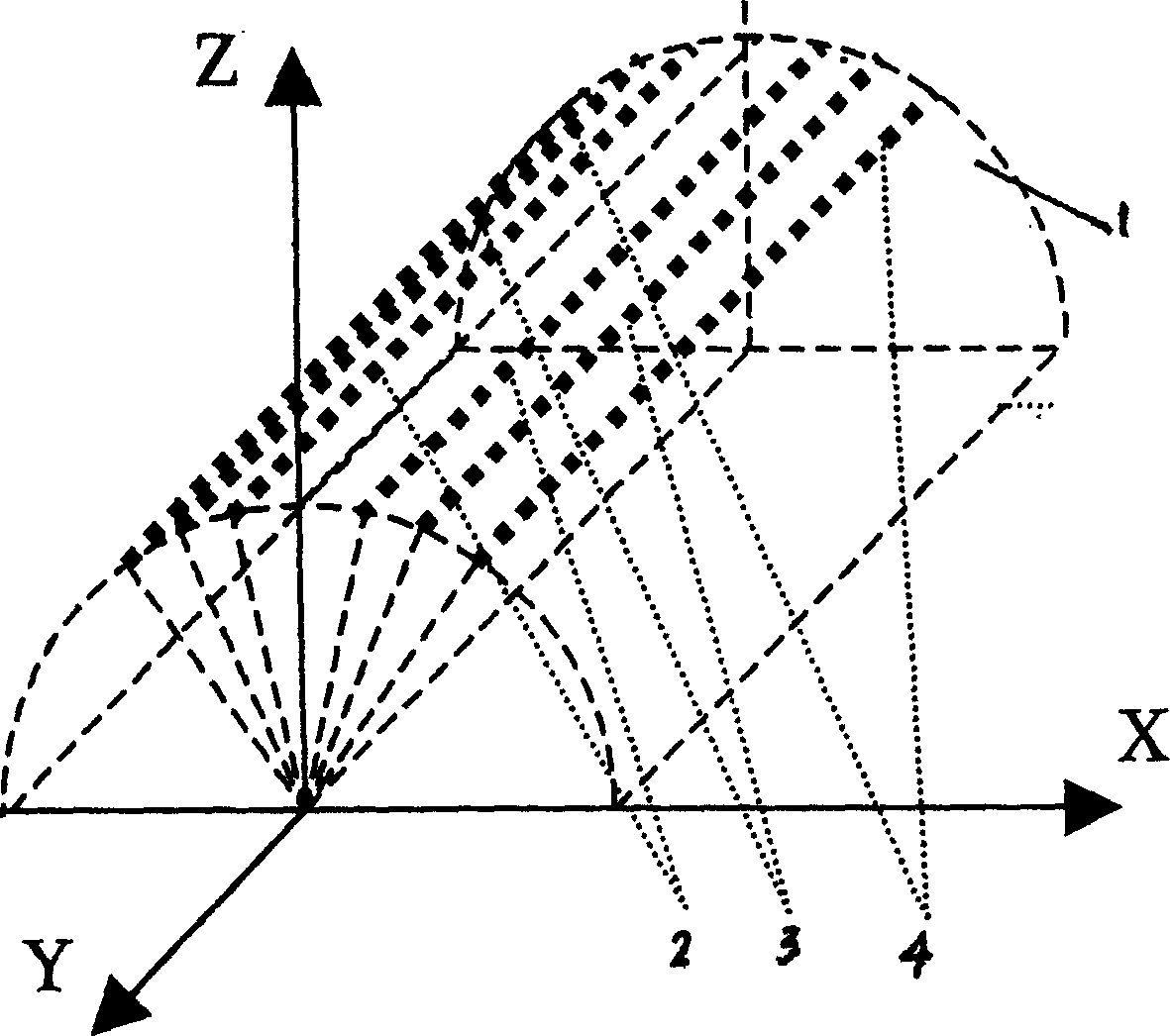

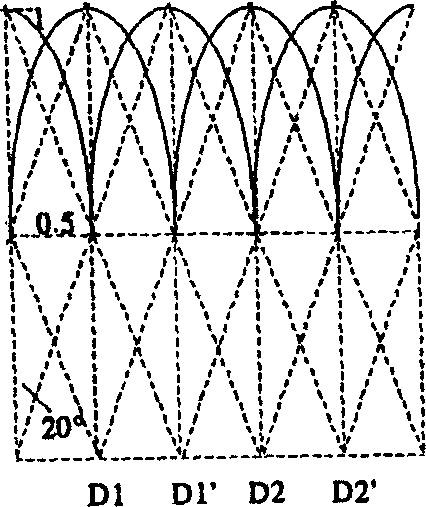

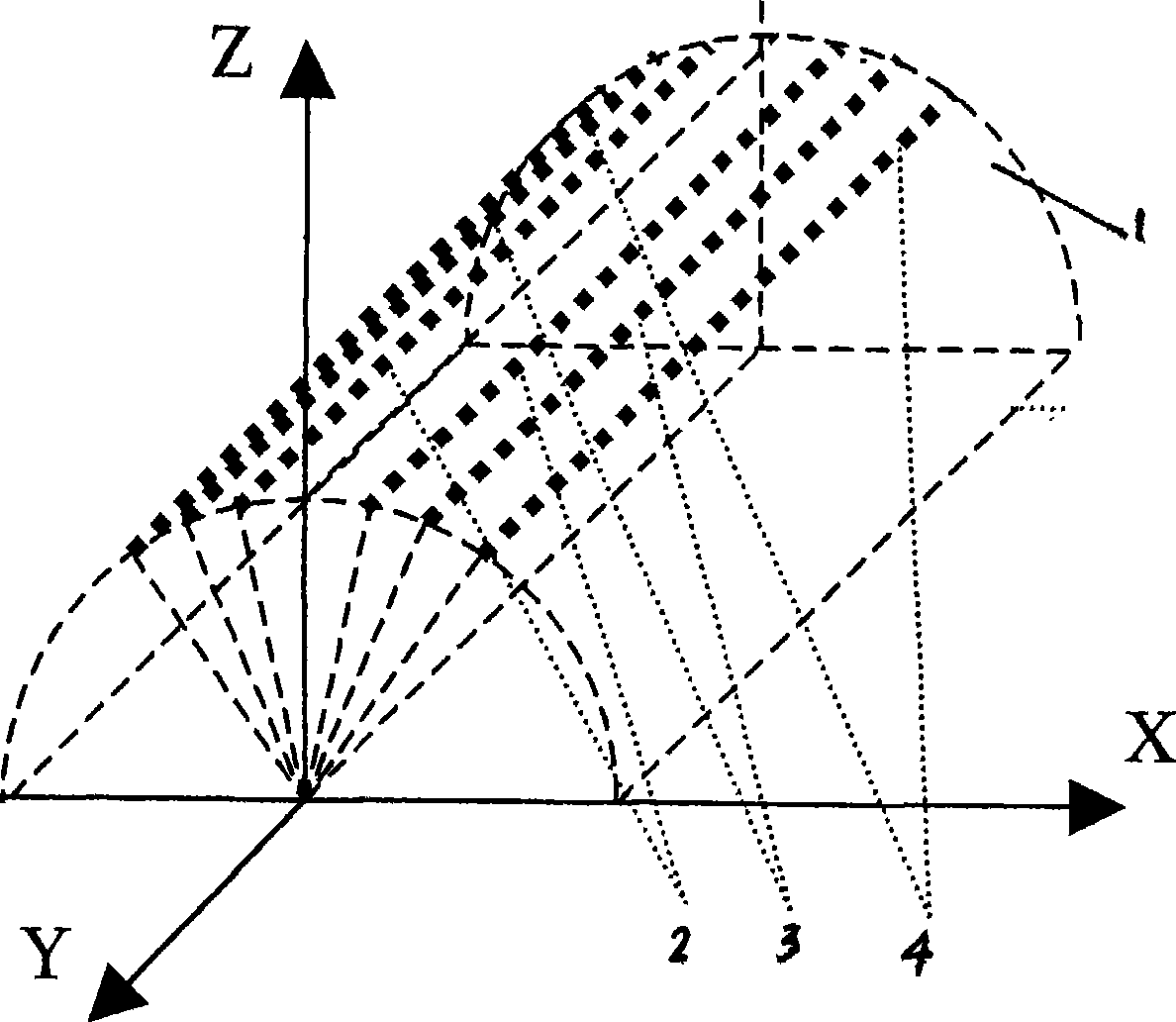

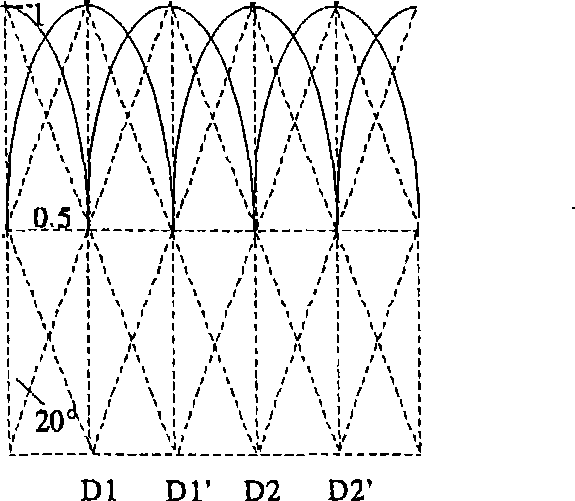

LED multi color line light source and its producing process

InactiveCN1588653AEasy to manufactureUniform distribution of light intensitySolid-state devicesElectric lightingOptical axisEffect light

The invention is linear multicolour lighting source required by obtaining image signal and providing scan image for linear array image sensor and prodn. technology. It consists of LEDs with different colour, they are divided to several rows with equally space according to colour and are arranged on cylinder surface of frame, two rows of LED with same colour are staggered in one-seconds space, extending line of optic axis of LED is coincided with radial direction of cylinder surface of frame through the centre of a circle of it. By the invention, the LED multicolour light source not only has suitable and uniform light intensity in scanning line, but also can provides adjustable lighting source with different wave length and incidence angle.

Owner:GUANGDONG UNIV OF TECH

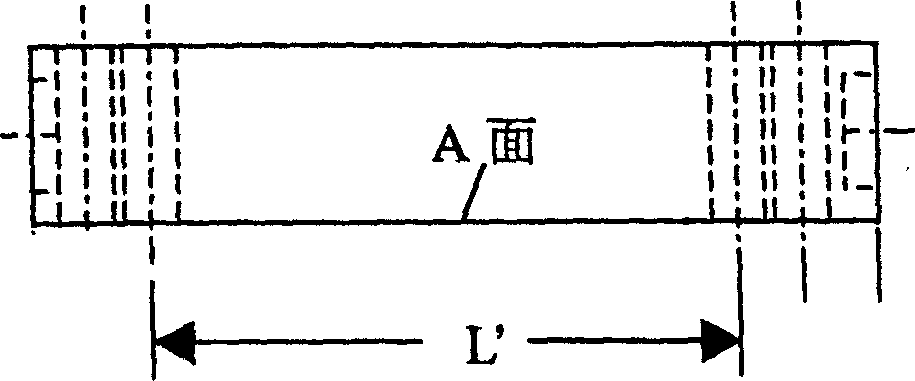

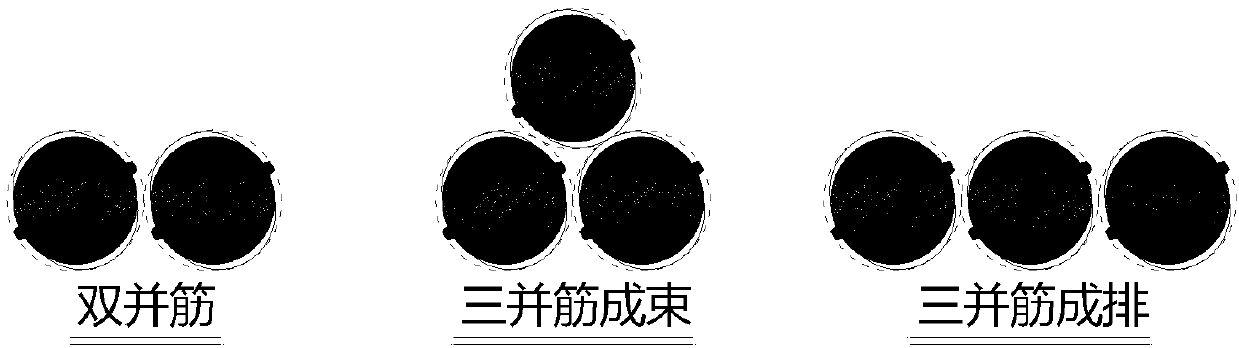

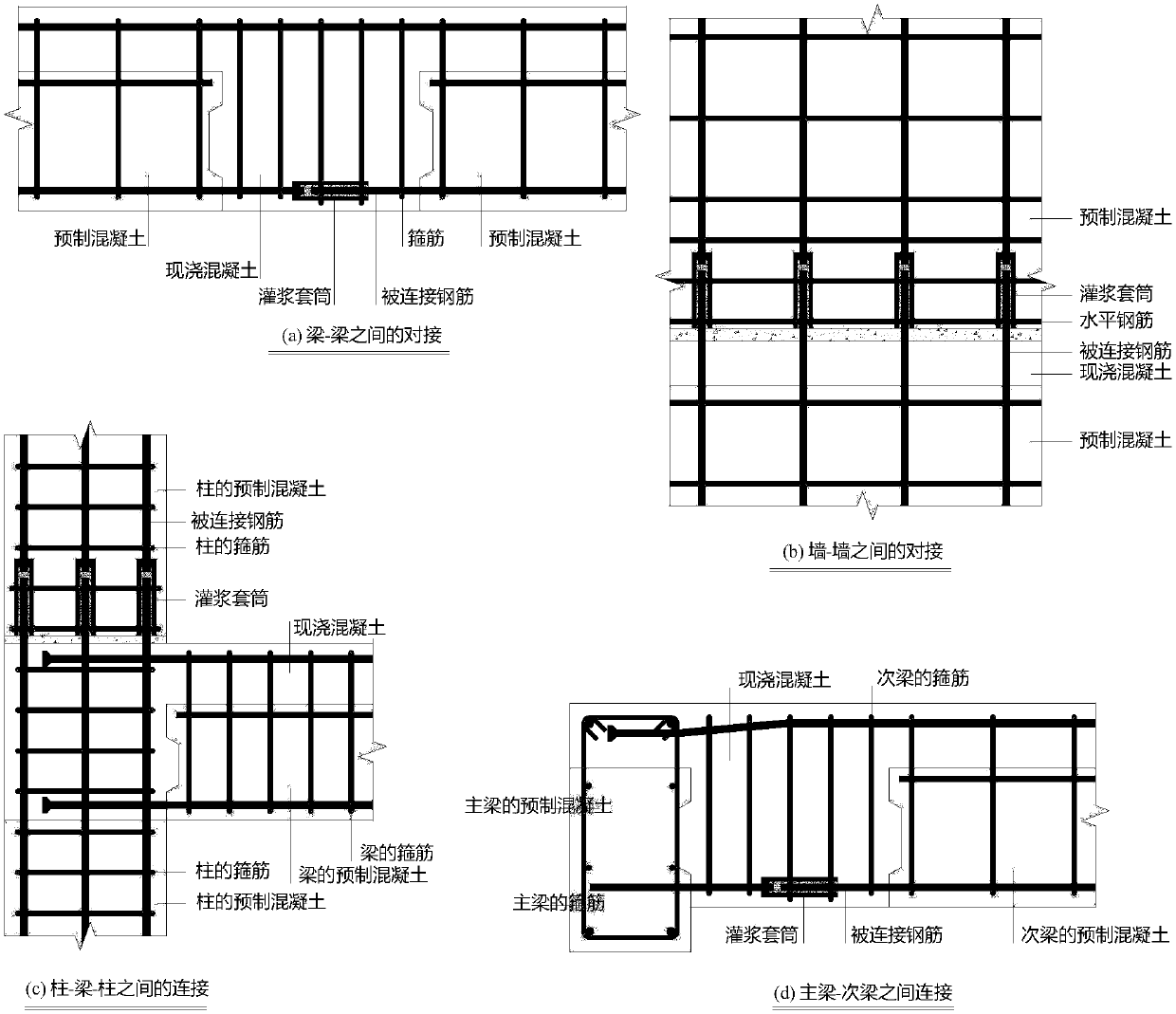

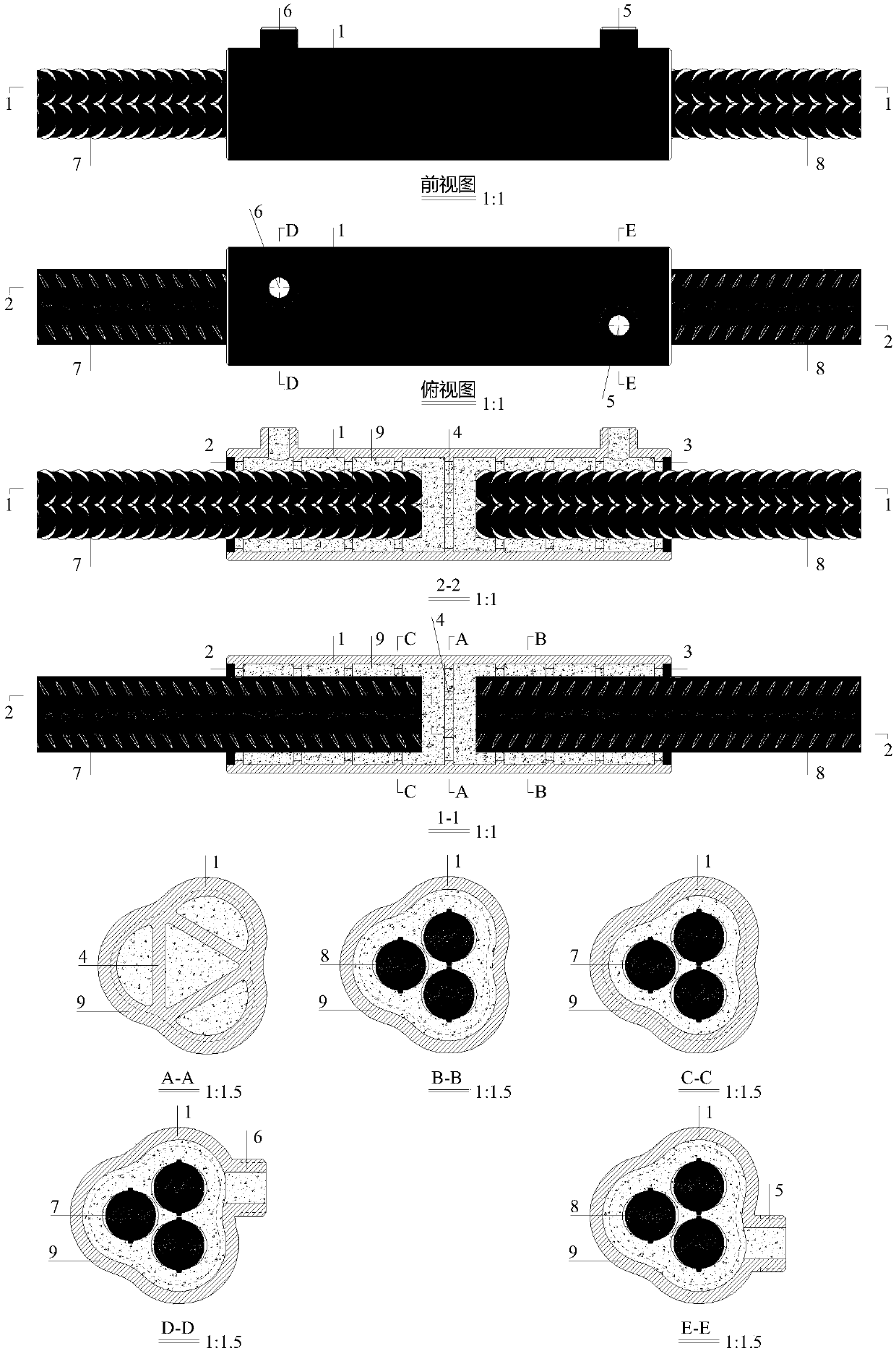

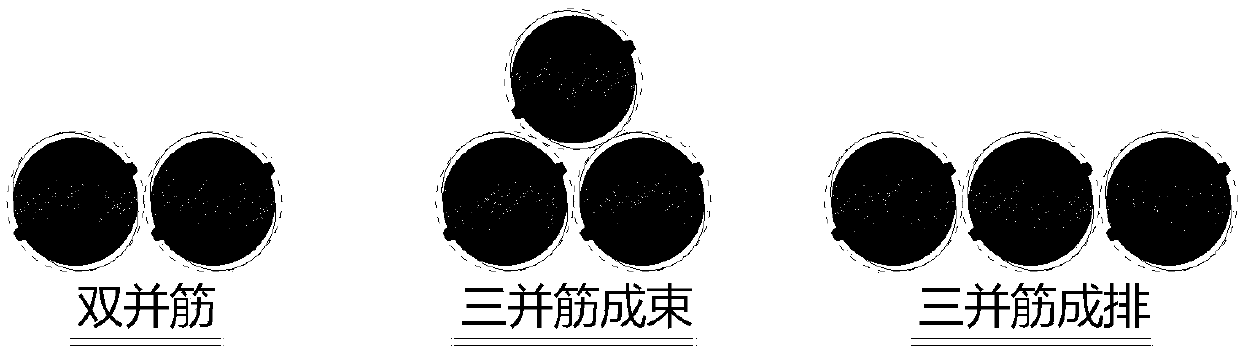

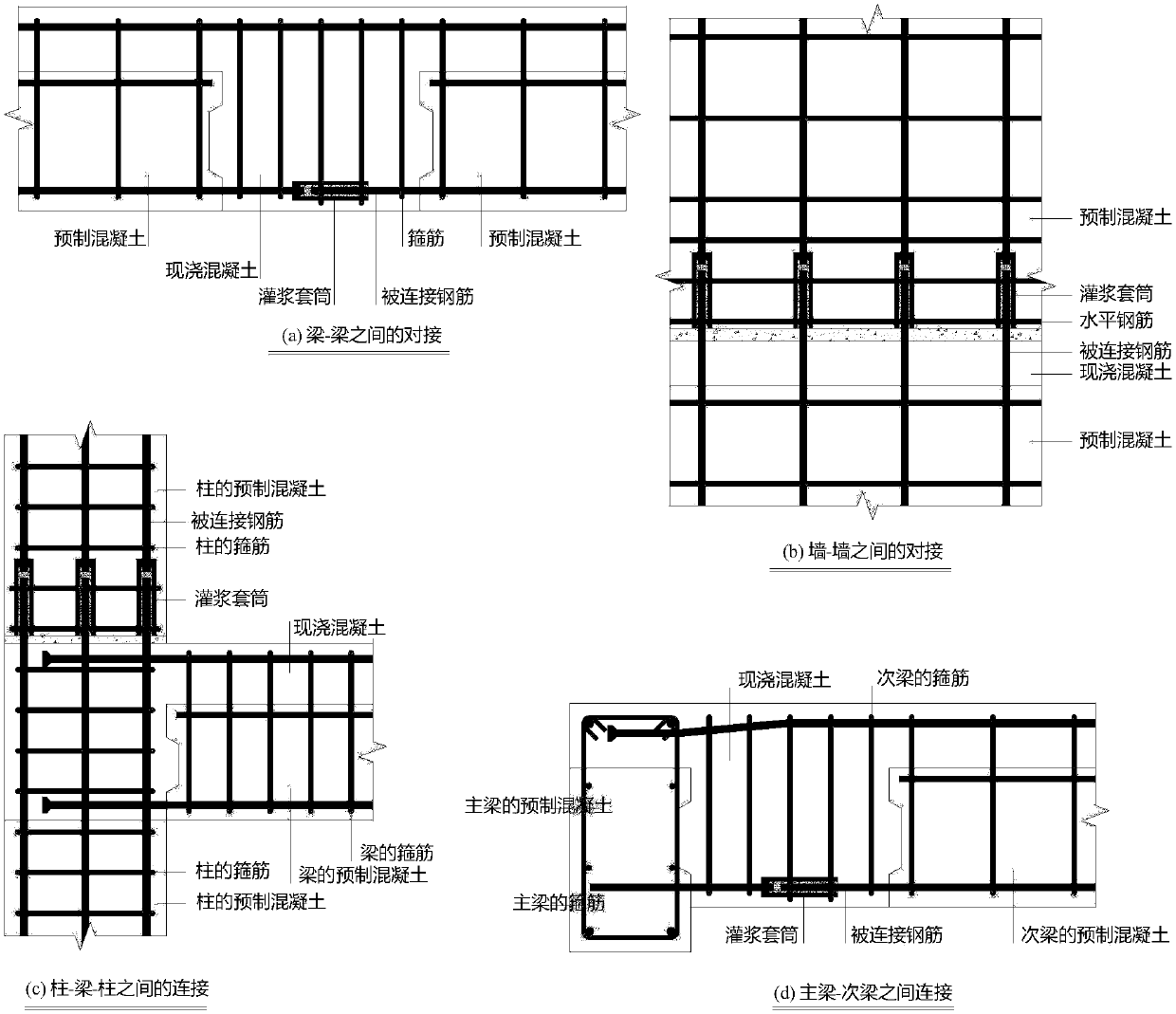

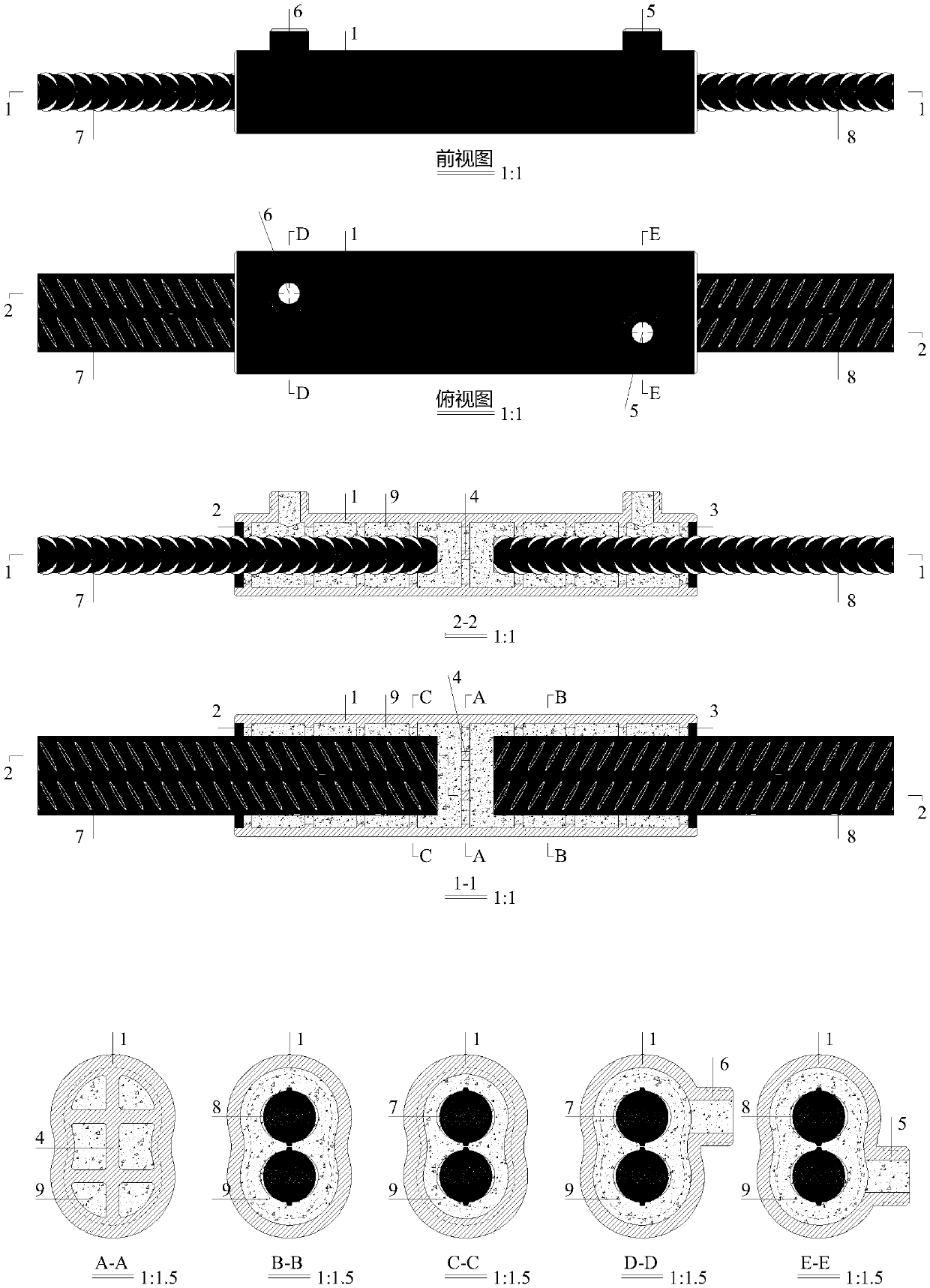

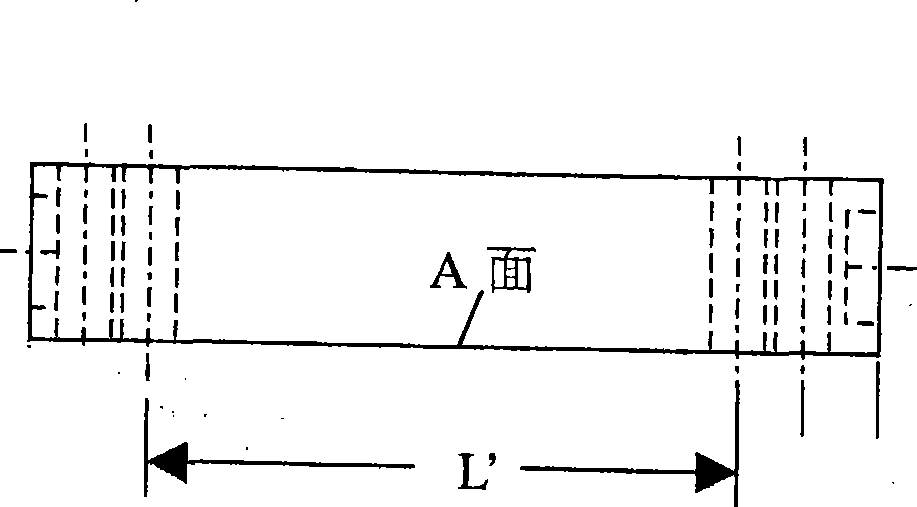

Full grouting sleeve for connecting of three-bundled-bar bundles and connecting method of three-bundled-bar bundles

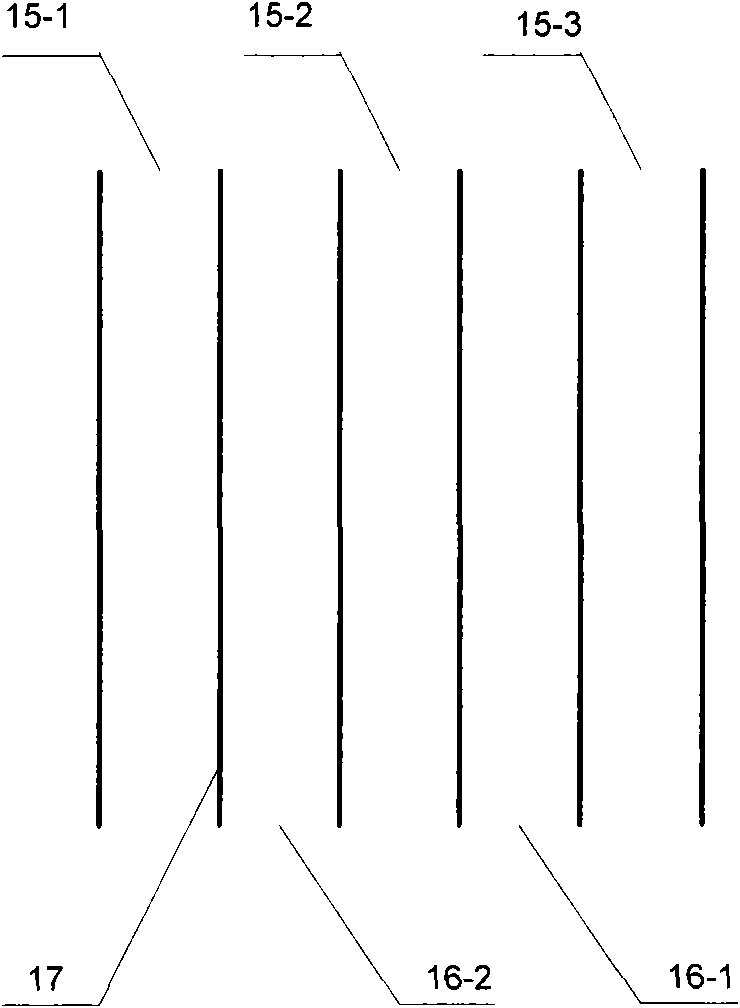

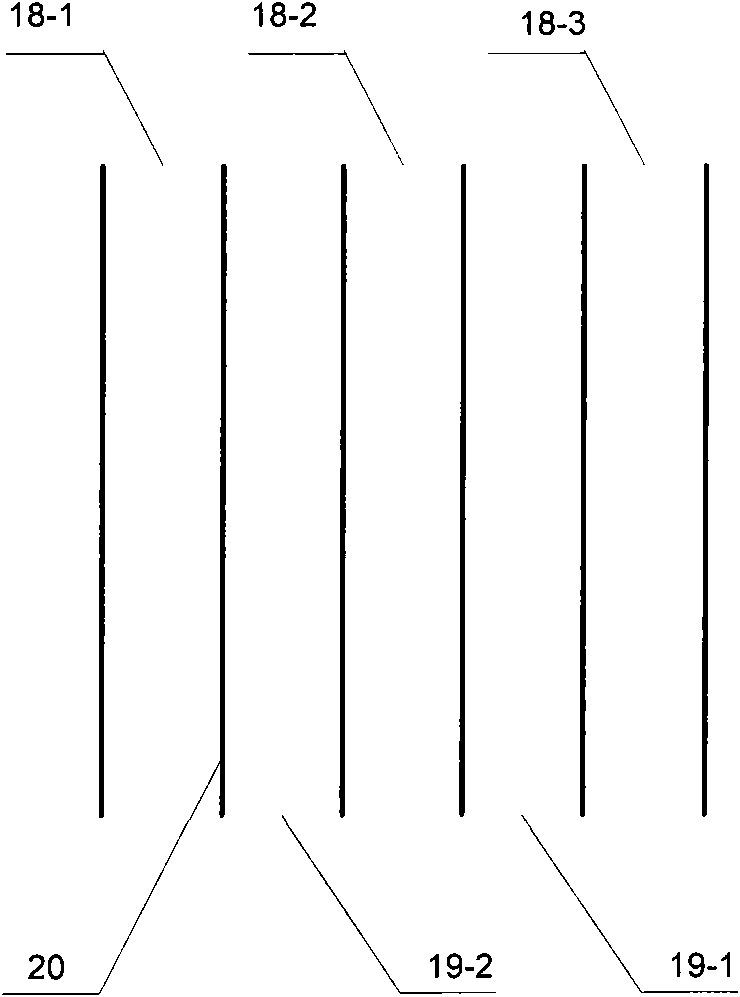

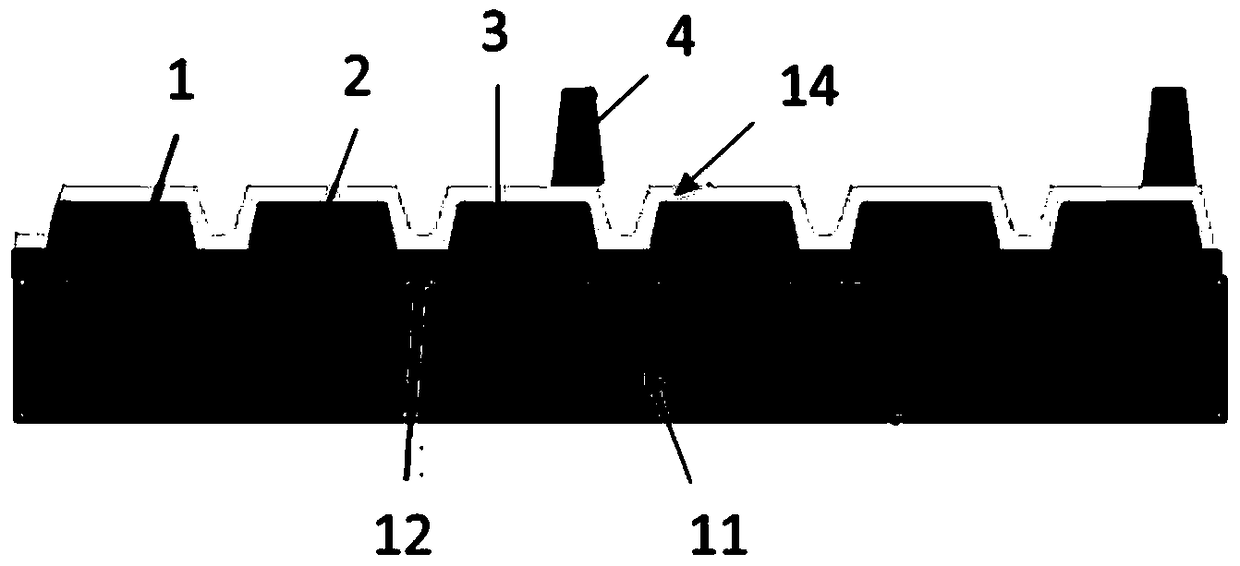

The invention discloses a full grouting sleeve for connecting of three-bundled-bar bundles and a connecting method of the three-bundled-bar bundles. The full grouting sleeve comprises a metal sleeve body (containing limiting stop blocks), two sealing rings and a grouting structure, wherein the metal sleeve body is used for connecting two sections of three-bundled-bar bundles (three-bundled-bar row), the two sealing rings are arranged at the two ends of the metal sleeve body, the grouting structure is formed by grouting materials grouted in a cavity between the metal sleeve body and the two sections of three-bundled-bar bundles, and the metal sleeve body is in a straight line shape or a fish-bellied shape; the two sections of three-bundled-bar bundles, corresponding to rebars, are distributed in the central axis of corresponding holes in the metal sleeve body; and a grout discharging hole and joint and a grout injecting hole and joint are formed in each side wall of the two ends of themetal sleeve body. The connecting method of the three-bundled-bar bundles comprises the following steps that 1, the sealing rings are mounted, the three-bundled-bar bundles are inserted in the metal sleeve body for positioning; 2, a grout discharging extension tube and a grout injecting extension tube are mounted (if necessary); 3, the grouting materials are grouted; and 4, curing is conducted. According to the full grouting sleeve for connecting of the three-bundled-bar bundles and the connecting method of the three-bundled-bar bundles, design is reasonable, construction is convenient, safe and economic, the connecting process of the three-bundled-bar bundles can be completed efficiently, simply and conveniently, and connecting performance is reliable.

Owner:HUNAN UNIV

Full grouting sleeve for connecting of double bundled bars and connecting method of double bundled bars

InactiveCN107740543ASimple structureReasonable designBuilding reinforcementsDouble bundleEngineering

The invention discloses a full grouting sleeve for connecting of double bundled bars and a connecting method of the double bundled bars. The full grouting sleeve comprises a metal sleeve body (containing limiting stop blocks), two sealing rings and a grouting structure, wherein the metal sleeve body is used for connecting two sections of double bundled bars (two bundled bars), the two sealing rings are arranged at the two ends of the metal sleeve body, the grouting structure is formed by grouting materials grouted in a cavity between the metal sleeve body and the two sections of double bundledbars, and the metal sleeve body is in a straight line shape or a fish-bellied shape; the two sections of double bundled bars, corresponding to rebars, are distributed in the central axis of corresponding holes in the metal sleeve body; and a grout discharging hole and joint and a grout injecting hole and joint are formed in each side wall of the two ends of the metal sleeve body. The connecting method of the double bundled bars comprises the following steps that 1, the sealing rings are mounted, the double bundled bars are inserted in the metal sleeve body for positioning; 2, a grout discharging extension tube and a grout injecting extension tube are mounted (if necessary); 3, the grouting materials are grouted; and 4, curing is conducted. According to the full grouting sleeve for connecting of the double bundled bars and the connecting method of the double bundled bars, design is reasonable, construction is convenient, safe and economic, the connecting process of the double bundled bars can be completed efficiently, simply and conveniently, and connecting performance is reliable.

Owner:HUNAN UNIV

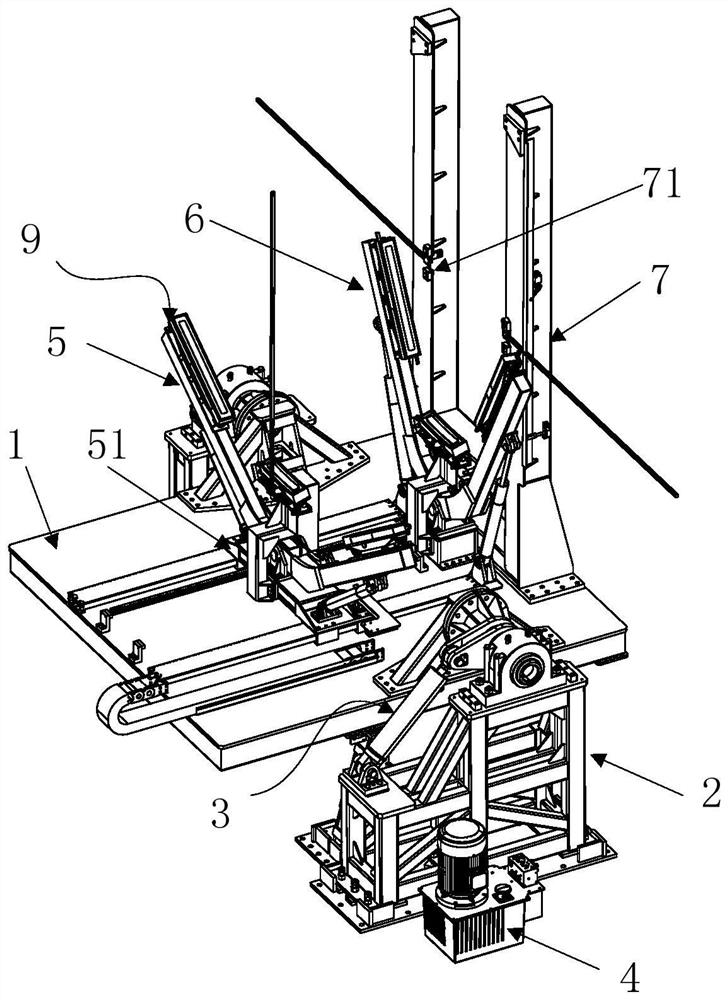

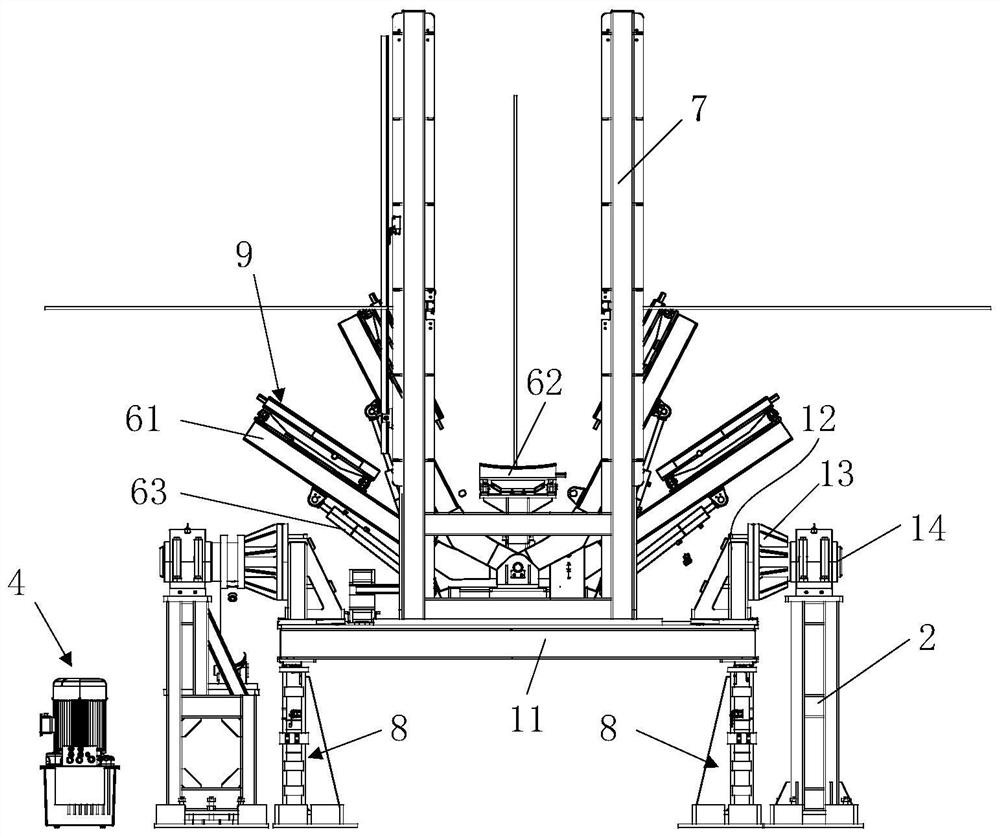

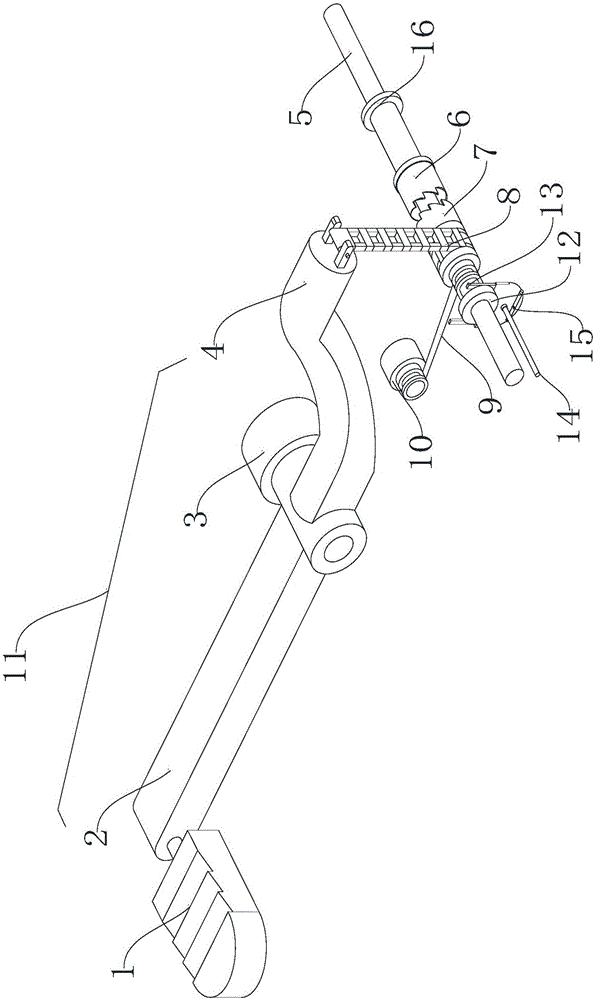

Automatic turnover device for shell rings of various concrete mixers

PendingCN113511589AFacilitate automatic productionHigh performance ratioLifting devicesLoad-engaging elementsClassical mechanicsEngineering

The invention discloses an automatic turnover device for shell rings of various concrete mixers. The automatic turnover device comprises a hydraulic station, a turnover support, a turnover platform, a turnover oil cylinder, a first supporting assembly, a second supporting assembly and a shell end face support, wherein each of the first supporting assembly and the second supporting assembly comprises a V-shaped support and a follow-up bottom support, each V-shaped support comprises a pair of movable supporting arms arranged in a V shape, each movable supporting arm is driven by an angle adjusting oil cylinder to control the angle opening degree of the V-shaped support, the movable supporting arms and the follow-up bottom supports are all provided with electric permanent magnets, the first supporting assembly and the second supporting assembly support the periphery of the shell rings and enable the central axes of the shell rings to be in a roughly horizontal state, the electric permanent magnets magnetically attract the peripheral walls of the shell rings in the shell ring turning-over process, and the shell rings are vertically supported on the shell end face support after being turned over by 90 degrees along with the turnover platform. The device is mainly used for 90-degree automatic turning-over of mixing shell rings of various specifications, and flexible sharing of various shell ring products is achieved.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

Constant-pressure multiple-effect evaporation condensation sea water desalination device with air medium

InactiveCN101921036BReduce energy consumptionReduce power consumptionSeawater treatmentMultistage water/sewage treatmentWater desalinationEngineering

The invention discloses a constant-pressure multiple-effect evaporation condensation sea water desalination device with an air medium, which mainly comprises a low-and-medium temperature heat source (13), a first-stage heating evaporator (14), an evaporation condenser (4) and a last-stage condenser (8). The first-stage heating evaporator (14), the evaporation condenser (4) and the last-stage condenser (8) are installed in sequence closely, and the low-and-medium heat source (13) and the first-stage heating evaporator (14) are connected together. The first-stage heating evaporator (14), the evaporation condenser (4) and the last-stage condenser are all formed by combining a plurality of heat exchange plates which are arranged from left to right in sequence, and a gap is reserved between every two adjacent heat exchanging plates to form a flow channel for heat exchange fluid. By adopting the plate-type heat exchange principle, the sea water desalination device realizes multiple-effect air humidification and dehumidification evaporation and condensation for sea water desalination under constant pressure. Heat and moisture transfer is performed between sprayed sea water and overflowing air, and the condensation latent heat of fore effect heat and moisture air can be absorbed at the same time, and therefore, energy recovery is realized and the fore effect heat and moisture air can be condensed to obtain fresh water.

Owner:GUANGDONG FIVESTAR SOLAR ENERGY

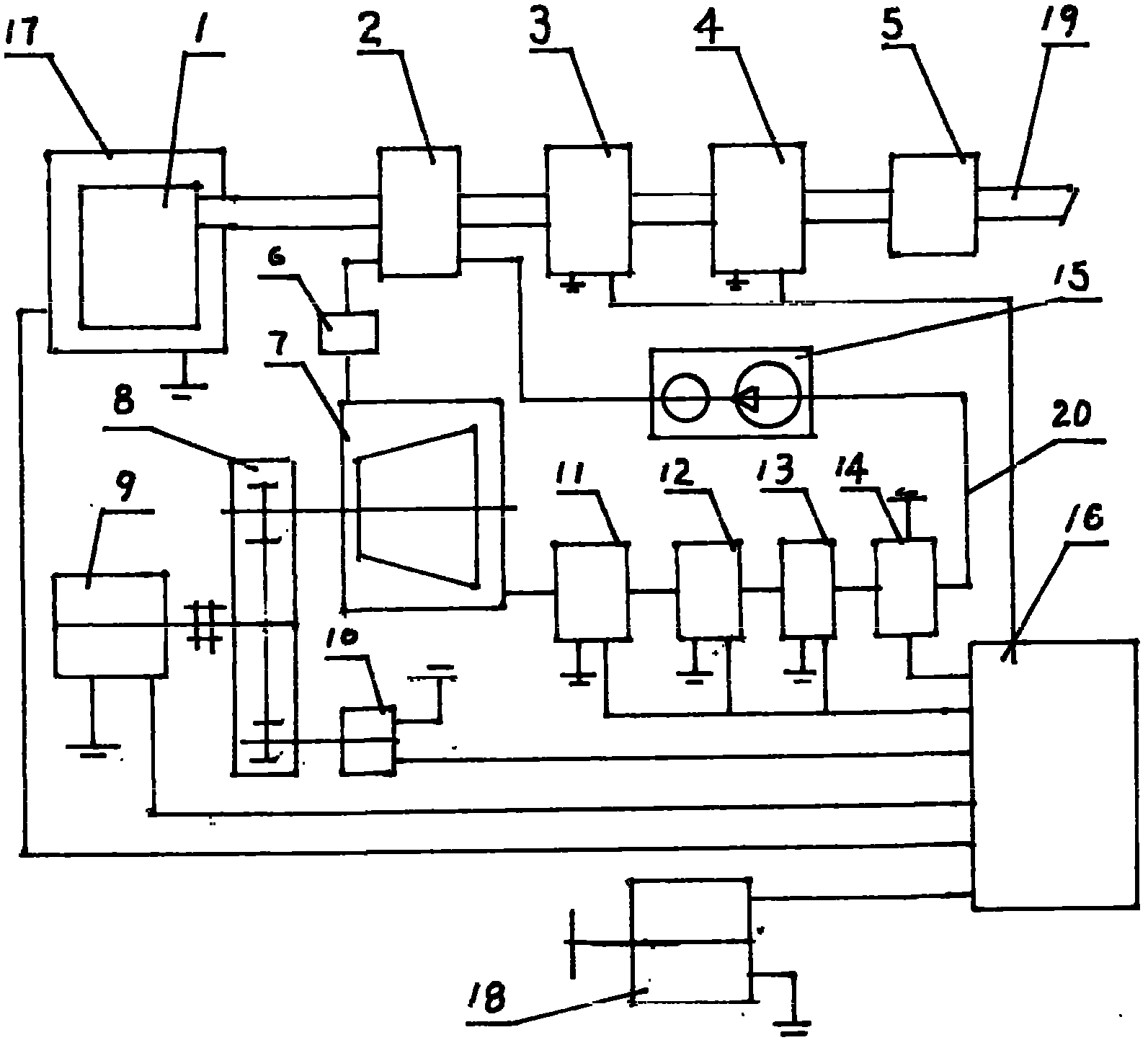

Method for manufacturing high-efficiency air conditioner and heat pump controller

ActiveCN102425894AIncrease the heat exchange areaIncrease the heat transfer coefficient kRefrigeration safety arrangementAutomatic controlEngineering

The invention provides a method for manufacturing a high-efficiency air conditioner and a heat pump controller, belonging to the field of energy saving. The automatic control function of an air conditioner and a heat pump is set for controlling environmental temperature by a controller, however, the control mode cannot control a high-efficiency and energy-saving factor in the prior art. The method comprises the following steps of: setting the temperature of external environment liquid or gas of an evaporator to be t1; setting the temperature of internal environment gas-liquid mixture of the evaporator to be T1; setting the temperature of gas-liquid mixture in a condenser to be T2; setting the temperature of external environment liquid or gas of the condenser to be t2; switching on a power source of a compressor by the controller when the temperature of the t1 is more than the set temperature upper limit or the temperature of the t2 is less than set lower limit and the value of t1-T1 or the value of T2-t2 is less than 15 DEG C or less than 10 DEG C or less than 5 DEG C or less than 2 DEG C; and stopping the compressor otherwise. Therefore, the efficiency ratio is improved by more than 6 and even more than 50 under the specific condition by cooperatively increasing the heat exchange area of a heat exchanger, increasing the heat transfer coefficient k of the heat exchanger, increasing the heat exchange time, reducing the power of the compressor and the like. The energy-saving running of the compressor can be effectively guaranteed by the controller.

Owner:广西天涌节能科技股份有限公司

a liquid crystal display

ActiveCN104570456BIncrease brightnessIncrease contrastNon-linear opticsLiquid-crystal displayColor film

The invention provides a liquid crystal display. Support columns are positioned in opposite light-proof regions of a color film substrate and an array substrate; after a part of light of a backlight source penetrates through a gap between a scanning line and a data line, the support columns shield the light deflecting to an opening area. The liquid crystal display provided by the invention aims at realizing the purpose of shielding the light leaking askant through the support columns shaped as water-retaining walls, so that the width of a black matrix on the color film substrate can be appropriately reduced, and thus the light-proof region formed by the black matrix is narrowed, the area of a color-layer light-pervious region on the color film substrate is increased and the opening rate of the color film substrate and the penetration rate of a liquid crystal display panel are increased. The liquid crystal display accords with the development trends of high brightness, high contrast and high efficiency rate of the liquid crystal display.

Owner:NANJING CEC PANDA LCD TECH

Solar desalination system

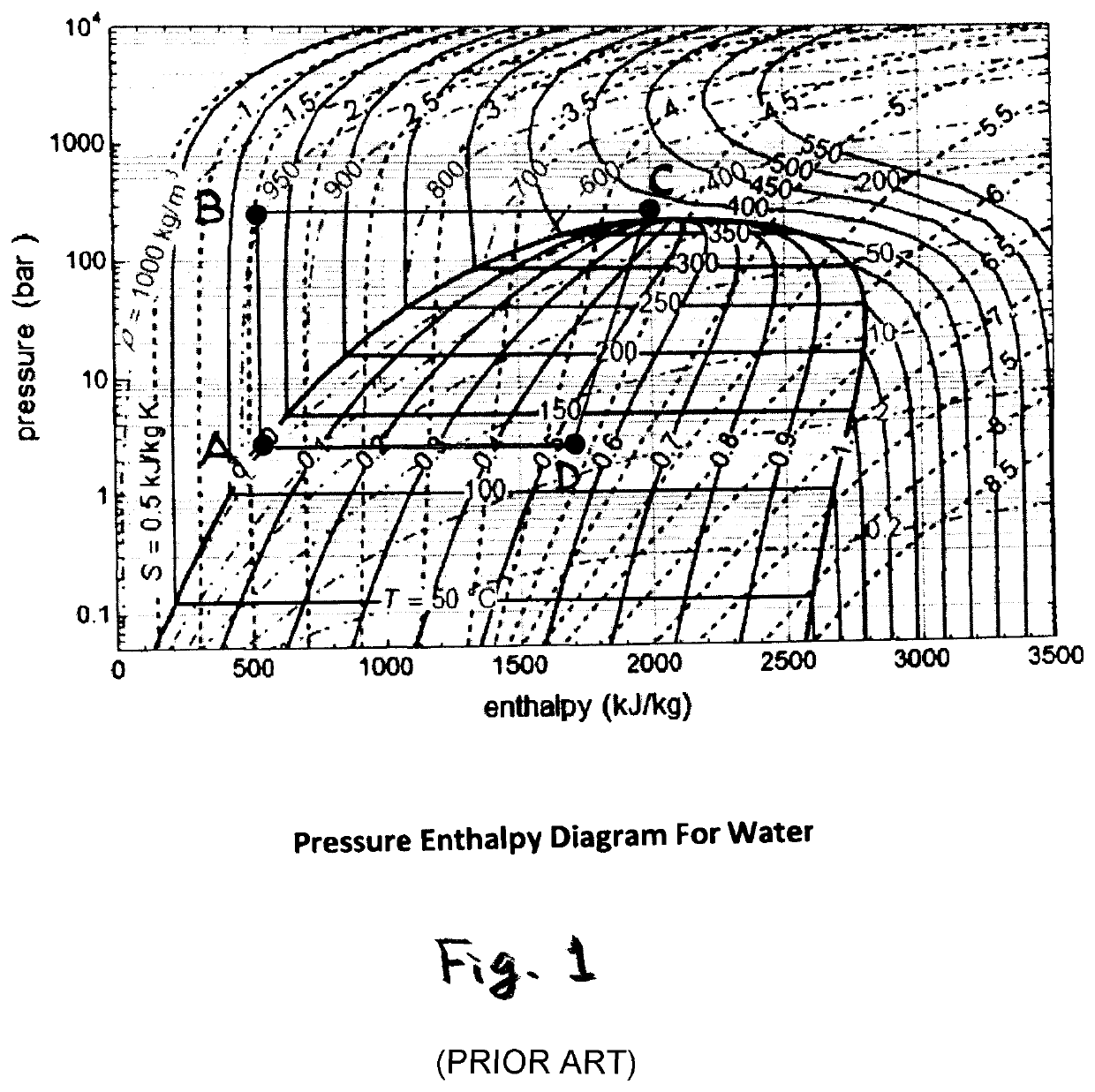

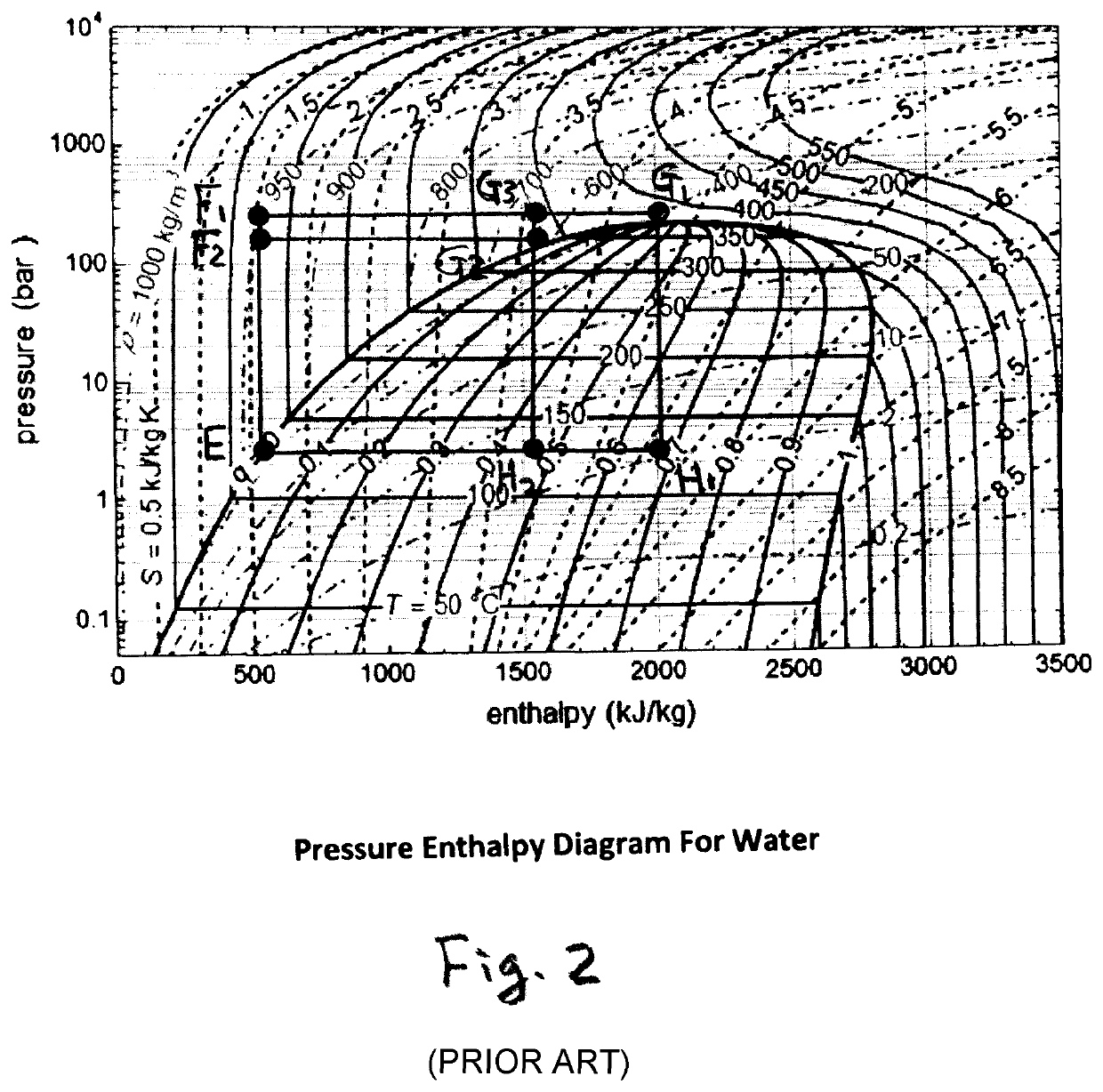

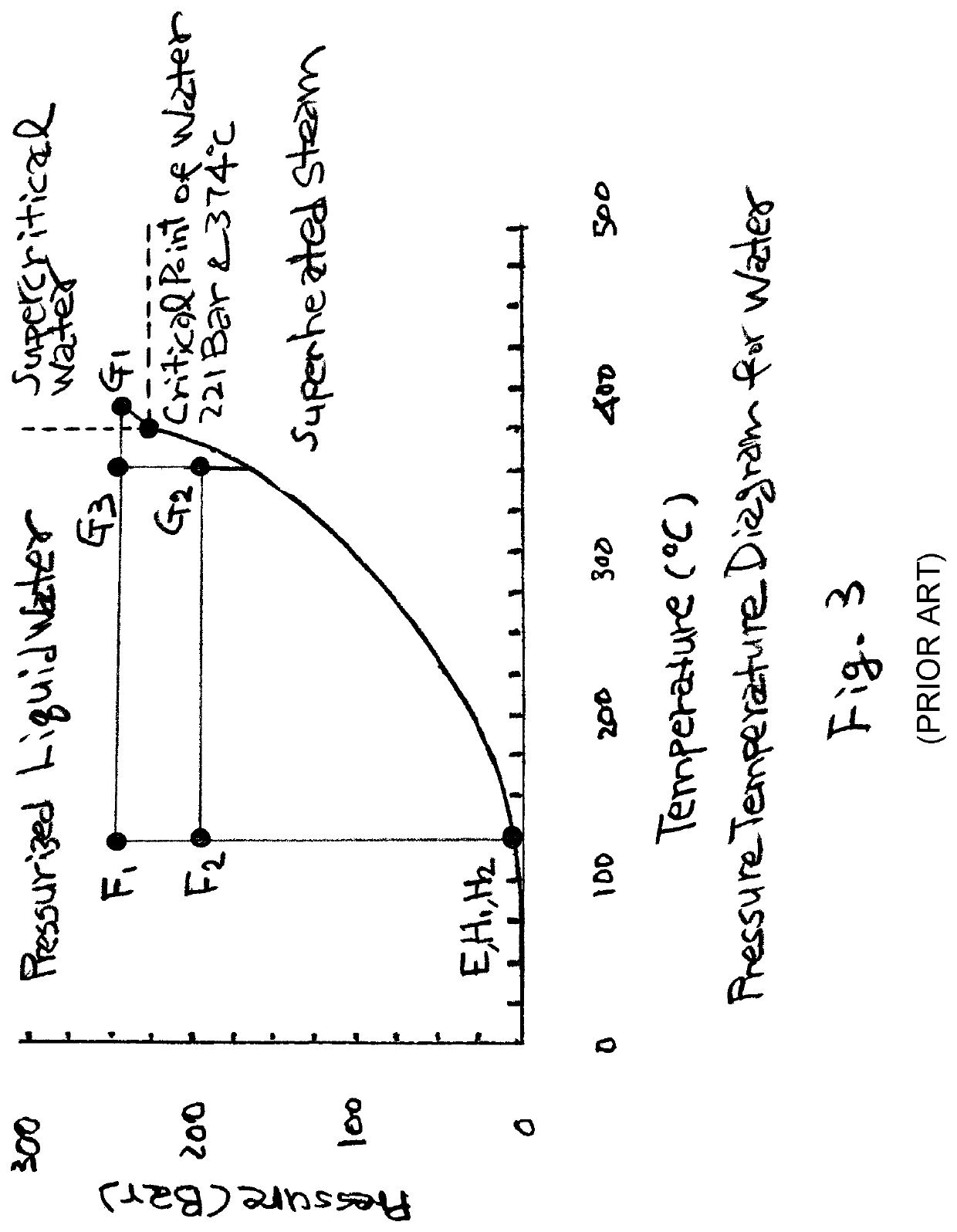

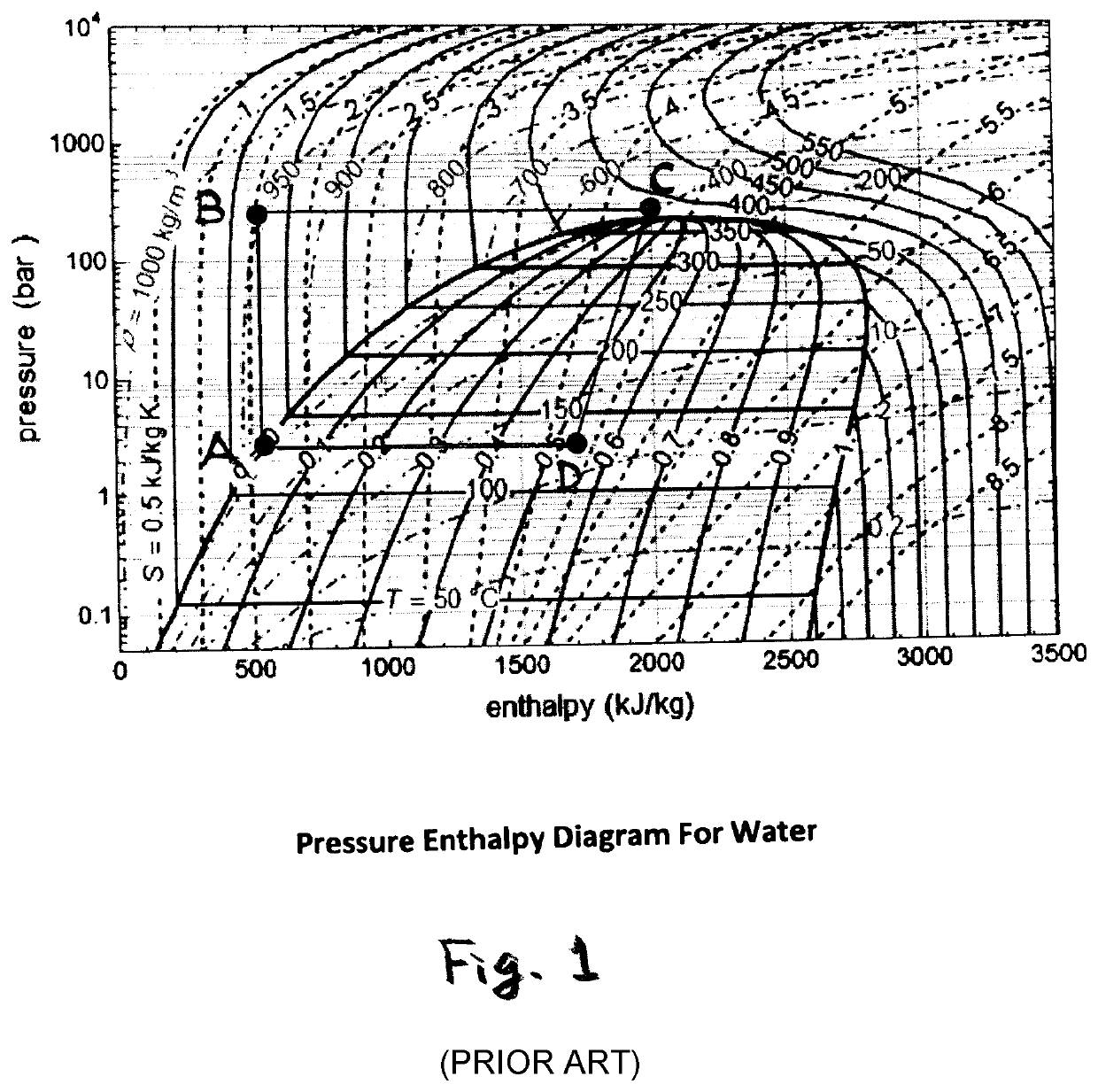

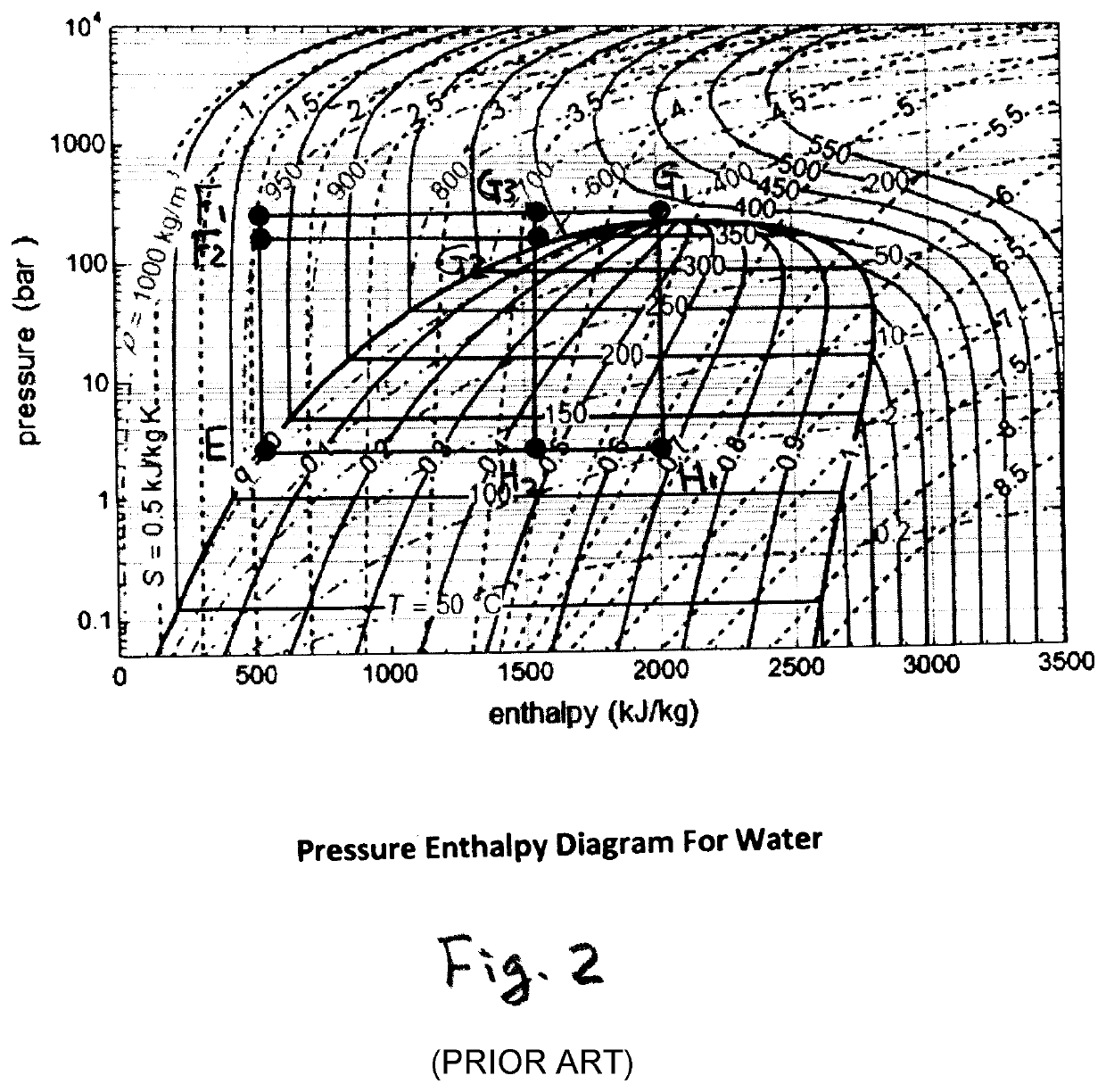

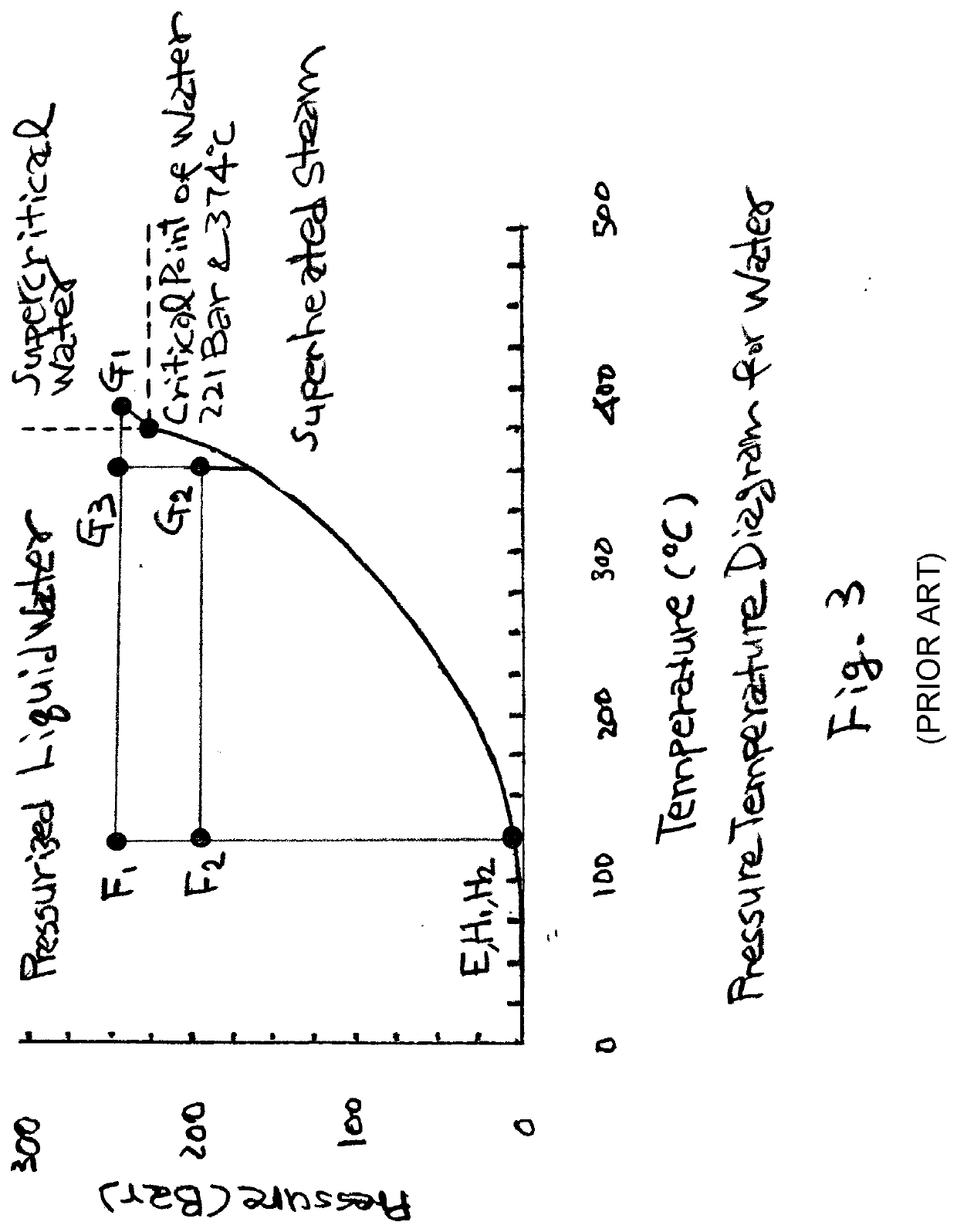

ActiveUS11097959B2Low costHigh performance ratioFrom solar energyGeneral water supply conservationWater desalinationWet steam

A single-phase fluid (SPF) storage is introduced for desalination of high-salt water using thermal energy from a concentrated solar power (CSP) unit. The SPF having a specific volumetric enthalpy higher than that of water at critical point in the operating ranges from 20 to 300 bar in pressure and 190 to 400 C in temperature is used as a new type of thermal energy storage (TES) medium and heat transfer fluid (HTF). It produces wet steam of a quality required by the desalination unit generating both steam for utilization of latent heat and condensate for sensible heat when its pressure is reduced to lower operating pressures. With a MED-TVC unit by using the steam as motive steam, the capacity of the CSP unit and SPF storage can be reduced as much as the energy recycled in the desalination unit.

Owner:CHOI PETER B

Air-conditioning water heater set

ActiveCN101131249BHigh performance ratioMeet the needs of lifeFluid heatersEnergy efficient heating/coolingWater sourceEngineering

The air conditioning and water heating set includes one compressor, one change-over valve with two ports connected separately to the high pressure exhaust pipe and low pressure inlet pipe of the compressor, one indoor heat exchanger with one indoor fan and one outdoor heat exchanger with one outdoor fan connected separately to two other parts of the change-over valve, one liquid collector communicated with the indoor heat exchanger and the outdoor heat exchanger, one first flow regulator and one second flow regulator with high pressure ends communicated with the liquid outlet of the liquid collector, and one water condensator with water inlet pipe and water outlet pipe communicated separately to one cold water source and one water tank. The present invention has domestic water heated withthe afterheat of air conditioner and by means of heat pump, and possesses best utilization of heat, environment friendship, high performance / cost ratio and other advantages.

Owner:邢金良

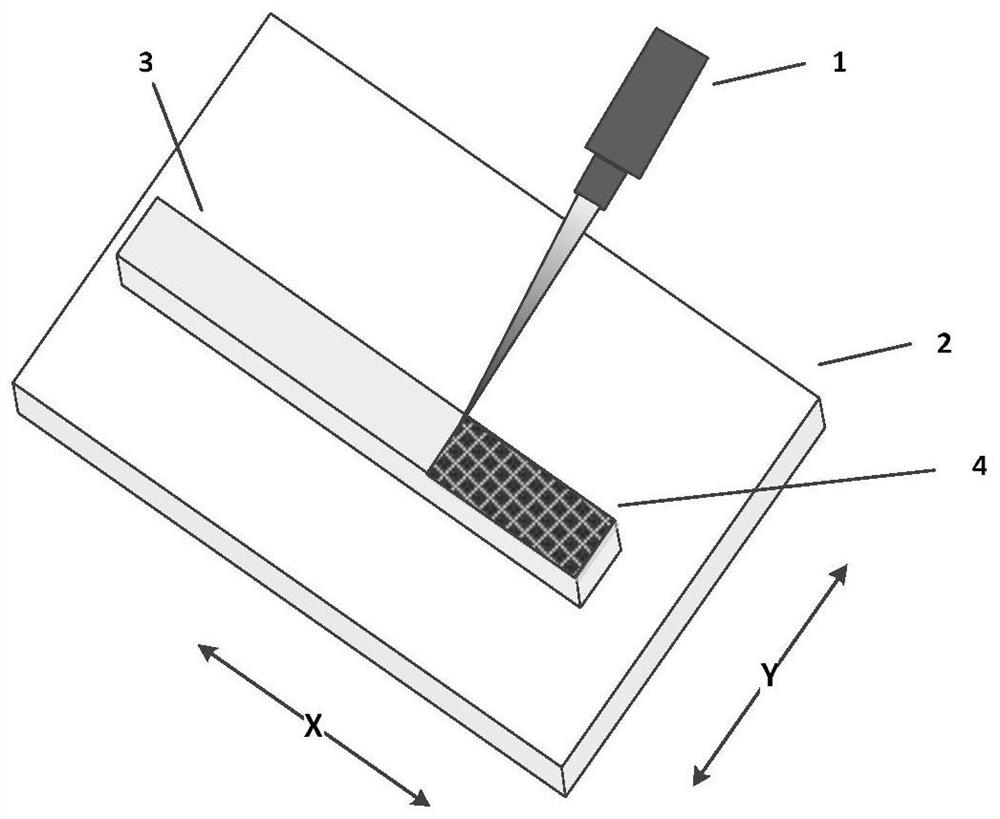

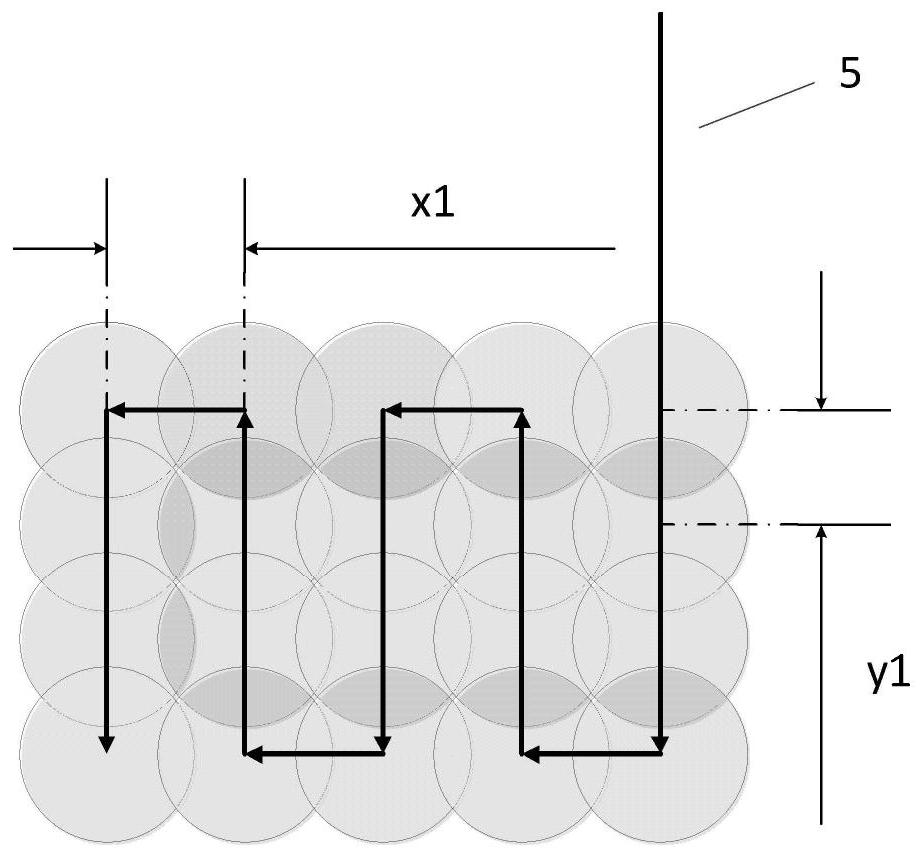

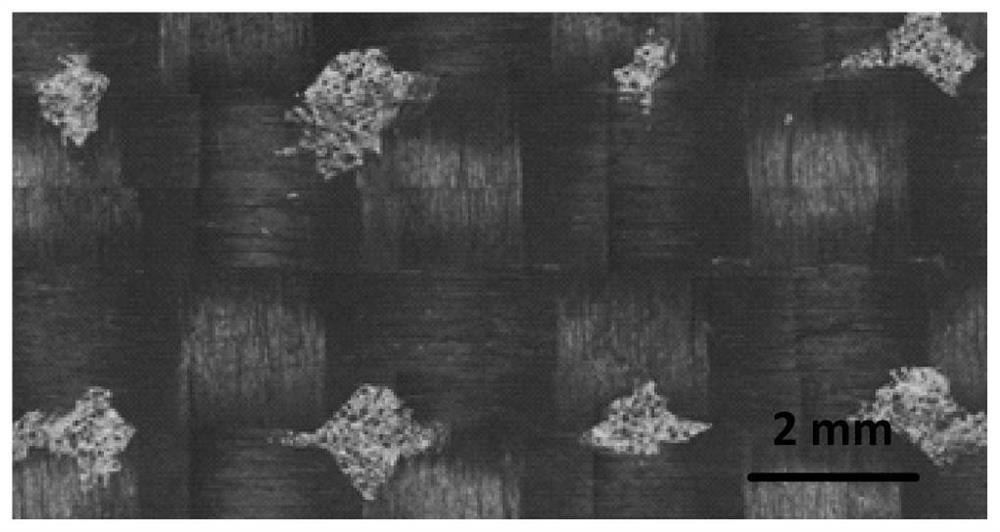

Near-infrared laser surface treatment method of carbon fiber/resin matrix composites

The invention provides a near-infrared laser surface treatment method for carbon fiber / resin-based composite materials. The inner fiber layer of the material and its surrounding resin are heated by near-infrared ns pulse laser, thereby generating high-temperature and high-pressure air mass, and the mechanical energy of the air mass expansion is used to disperse the surface layer of the material. The resin matrix is completely removed. With a specific laser spot size, laser pulse power density and laser scanning method, the resin matrix can be efficiently removed from the treated surface. The invention can be used for surface cleaning, surface modification and pretreatment before bonding of carbon fiber / epoxy resin matrix composite materials.

Owner:无锡锐科光纤激光技术有限责任公司

Aluminium alloy material for manufacturing cylinder block of refrigerator compressor

The invention belongs to the technical field of refrigeration equipment materials and provides an aluminium alloy material for manufacturing a cylinder block of a refrigerator compressor. The aluminium alloy material comprises the following raw materials in parts by weight: 30-40 parts of manganese, 20-33 parts of antimony, 2-9 parts of silicon, 3-8 parts of niobium, 1-5 parts of molybdenum, 5-11 parts of nickel, 7-15 parts of vanadium and the balance of magnesium. Through the scientific formula design of manganese, antimony, silicon, niobium, molybdenum, nickel, vanadium and magnesium, the corrosion resistance of the aluminium alloy material is greatly improved at a relatively low cost. The aluminium alloy material has a high price-to-performance ratio. Through a salt spray test, the aluminium alloy material has the corrosion rate of smaller than 0.1 mg / cm<2> / h<1>.

Owner:HEFEI JINTONGWEI LOW TEMPERATURE TECH CO LTD

Battening reed wheel mechanism and reed wheel loom with phase controlled jetting and magnetic shuttle reed wheels

The present invention relates to reed wheel battening mechanism of flat weft guiding loom which is composed of reed wheel, main shaft and rotary driving system, it not only increases the battening efficiency and speed, but also solves the difficult problem of high speed multi phose weaving technique. The present invention also discloses various non-mechanical high speed multi phase weff guiding technique, weft make-up technology and sheading technology. Advantages include: high efficiency weaving, low weaving cost etc.

Owner:杨凡赤

A method for making high-efficiency air conditioner and heat pump controller

ActiveCN102425894BIncrease the heat exchange areaIncrease the heat transfer coefficient kRefrigeration safety arrangementAutomatic controlControl manner

A method for making high-efficiency air-conditioning and heat pump controllers belongs to the energy-saving field. The automatic control function of the air-conditioning and heat pumps is set by the controller for controlling the ambient temperature, but the current control method does not control the factors of high efficiency and energy saving. And the present invention is: the temperature of the external environment liquid or gas of setting evaporator is t1, the temperature of the internal environment gas-liquid mixture of evaporator is T1, the temperature of gas-liquid mixture in the condenser is T2, the external environment liquid of condenser or The temperature of the gas is t2, then when the temperature of t1 is higher than the set temperature upper limit or the temperature of t2 is lower than the set lower limit and the value of t1-T1 or T2-t2 is less than 15° or less than 10° or less than 5° or When it is less than 2°, turn on the power of the compressor to start working through the controller, otherwise stop the compressor. This method can increase the efficiency ratio to more than 6 by increasing the heat exchange area of the heat exchanger, increasing the heat transfer coefficient k of the heat exchanger, increasing the heat exchange time, and reducing the power of the compressor. The ratio can be increased to more than 50. The controller is an effective guarantee to realize the energy-saving operation of the compressor.

Owner:广西天涌节能科技股份有限公司

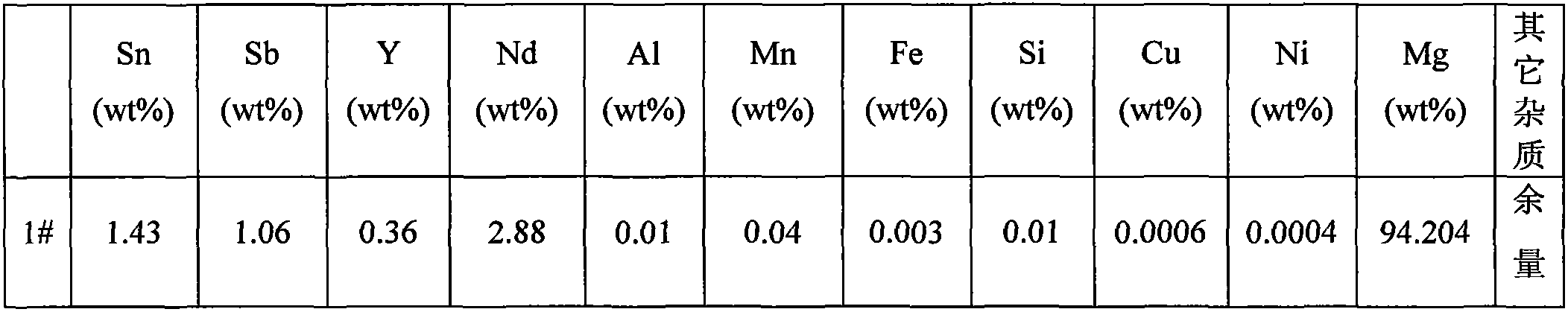

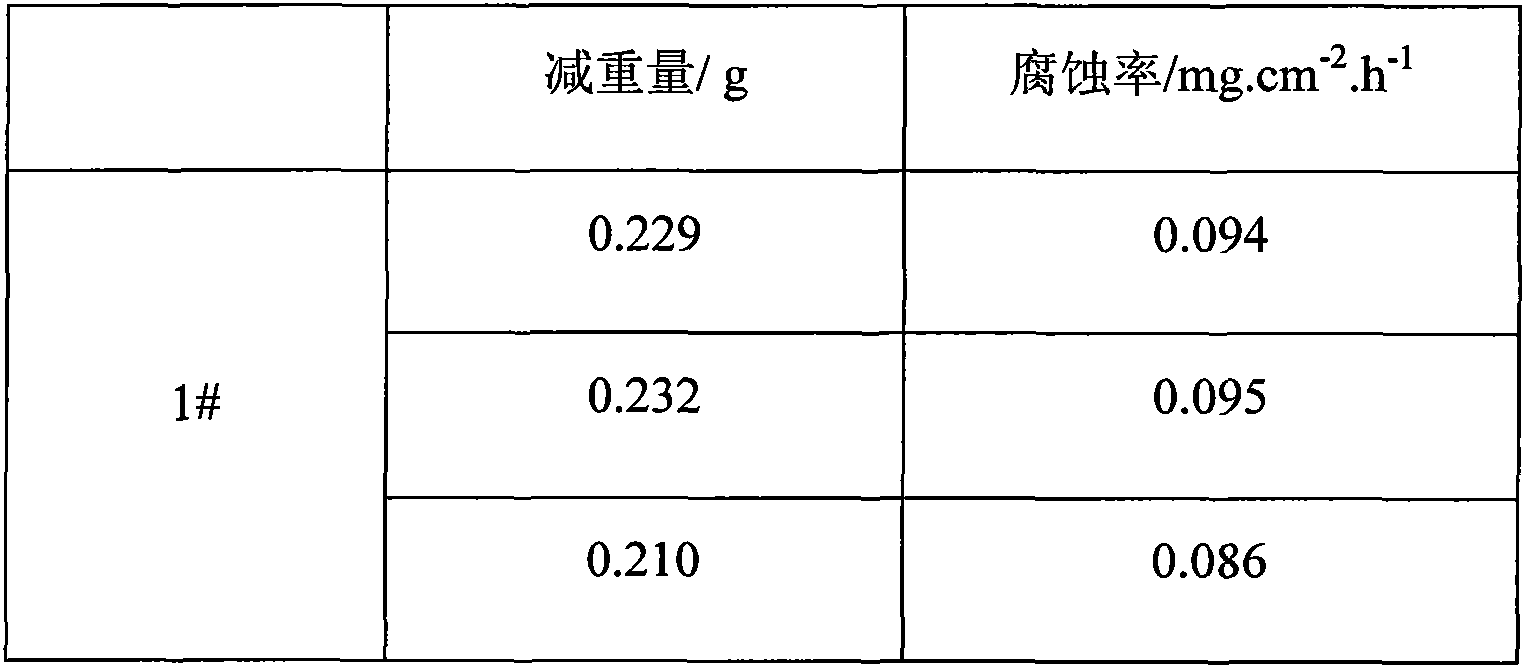

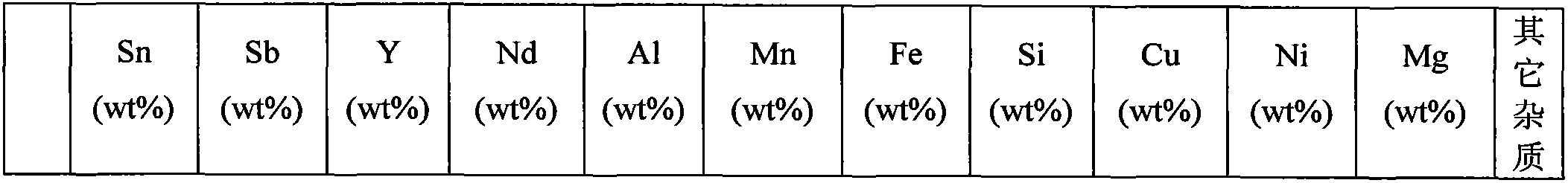

Corrosion resistant magnesium alloy material and preparation method thereof

The invention relates to a corrosion resistant magnesium alloy material and a preparation method thereof. The corrosion resistant magnesium alloy material comprises the following compositions in percentage by mass: 0.5-3.5 wt% of Nd, 0.2-1.2 wt% of Y, 1.5-3.5 wt% of Sn, 1.2-3.0 wt % of Sb, and teh balance of impurity elements, wherein Al in the impurity elements is less than or equal to 0.02 wt%, Mn in the impurity elements is less than or equal to 0.05 wt%, Fe in the impurity elements is less than or equal to 0.005 wt%, Si in the impurity elements is less than or equal to 0.05 wt%, Cu is less than or equal to 0.001 wt%, the mass percent of Ni is less than or equal to 0.001 wt%, and the other impurity element content is less than or equal to 0.05 wt% and the balance of Mg. The preparation method comprises the following steps: pure magnesium, pure Sn and pure Sb are heated in an industrial line frequency induction melting furnace to reach the temperature of 720 DEG C plus minus 10 DEG C until being molten through heat preservation, common industrial argon with the flow rate of 1.0-2.0L / min is introduced to the furnace for protection when the metals in the furnace are heated to reach 400 DEG C, then the molten metals are subjected to heat preservation for 20 min, Mg-Nd intermediate alloy and Mg-Y intermediate alloy are sequentially added to the furnace, the molten metals are subjected to heat preservation for 10-15 min and are then cast, and after metal mold casting, stress relief annealing treatment is carried out at the temperature of 100-150 DEG C for 10-20 min. The invention has the advantages that: the corrosion resistance is high, a salt mist experiment that 5% NaCl is adopted, the corrosion time is 72 hours, and the temperature is 25 plus minus 1 DEG C shows that: the corrosion rate of magnesium alloy is less than 0.1 mg. cm<-2>.h-1.

Owner:狄石磊 +1

Solar Desalination System

ActiveUS20210155504A1Effective in controlling corrosionThinner and stable scaleFrom solar energyGeneral water supply conservationWater desalinationWet steam

A single-phase fluid (SPF) storage is introduced for desalination of high-salt water using thermal energy from a concentrated solar power (CSP) unit. The SPF having a specific volumetric enthalpy higher than that of water at critical point in the operating ranges from 20 to 300 bar in pressure and 190 to 400 C in temperature is used as a new type of thermal energy storage (TES) medium and heat transfer fluid (HTF). It produces wet steam of a quality required by the desalination unit generating both steam for utilization of latent heat and condensate for sensible heat when its pressure is reduced to lower operating pressures. With a MED-TVC unit by using the steam as motive steam, the capacity of the CSP unit and SPF storage can be reduced as much as the energy recycled in the desalination unit.

Owner:CHOI PETER B

LED multi color line light source and its producing process

InactiveCN100502061CEasy to manufactureUniform distribution of light intensityPoint-like light sourceSolid-state devicesOptical axisEffect light

The invention is linear multicolour lighting source required by obtaining image signal and providing scan image for linear array image sensor and prodn. technology. It consists of LEDs with different colour, they are divided to several rows with equally space according to colour and are arranged on cylinder surface of frame, two rows of LED with same colour are staggered in one-seconds space, extending line of optic axis of LED is coincided with radial direction of cylinder surface of frame through the centre of a circle of it. By the invention, the LED multicolour light source not only has suitable and uniform light intensity in scanning line, but also can provides adjustable lighting source with different wave length and incidence angle.

Owner:GUANGDONG UNIV OF TECH

Petrol-electric hybrid using working residual heat to generate power

InactiveCN102545344AIncrease magnetic fluxHigh performance ratioBatteries circuit arrangementsInternal combustion piston enginesElectrical batteryFast charging

The invention relates to a system device using residual heat of an internal-combustion engine to do heat work and thermoelectric conversion to generate power and charge. When fuel oil power works, a battery array is continuously charged to be full by the system device; an electric driving motor is started to work while a fuel oil machine is stopped; when the electric quality of the battery array is not enough, the fuel oil power is restarted to work in a work process and the process is repeated to improve the utilization rate of the energy consumption. According to the invention, on the basis of not changing the structure of the modern internal-combustion engine, the residual heat energy is sufficiently utilized to be converted into electric energy and the battery is rapidly charged; and the total heat work and thermoelectric conversion of the comprehensive internal-combustion engine reaches 64%. According to a generator provided by the invention, on the basis of changing a stator structure, magnetic flux can be increased by one time, the efficiency of the generator with the same type is improved by 0.18%, the volume is reduced by 1 / 3 and the weight is reduced by 1 / 4. For example, the oil consumption of hundred kilometers of 2.0-displacement is 3.3 kilograms together and the oil is saved by more than 3 kilograms in the hundred kilometers; the temperature of an air outlet of an exhaust pipe of an engine is about 26 DEG C and the effects of low carbon, energy saving and emission reduction are obvious.

Owner:张善军

Bicycle gyro transmission structure and bicycle equipped with same

InactiveCN106627956AMove fastSave energyWheel based transmissionRider propulsionDrive wheelVehicle frame

The invention discloses a bicycle gyro transmission structure and a bicycle equipped with the structure, belongs to the field of bicycle, and is used for traveling. The bicycle gyro transmission structure comprises a connecting rod, a wheel axle, a hub, a driven transmission tooth, a driving transmission tooth and a transmission belt, wherein the connecting rod is connected with the driving transmission tooth through the transmission belt; the driving transmission tooth rotates around the wheel axle through a returning mechanism; the driving transmission tooth and the driven transmission tooth perform unidirectional transmission through a clamping tooth; the driven transmission tooth is fixed on the wheel axle. The bicycle provided by the invention is at least equipped with a frame and a driving wheel besides the above structure; the driving wheel is mounted on the frame through the wheel axle and the hub. According to the technical scheme, the bicycle driving wheel can be driven to rotate at high speed by using a novel transmission structure provided by the invention; the bicycle gyro transmission structure can be operated by acting with single foot or both feet at the same time, and is stable and high in transmission efficiency.

Owner:李延芝

Air-conditioning water heater used in four seasons

InactiveCN100470151CReduce cooling power consumptionHigh performance ratioFluid heatersEnergy efficient heating/coolingElectric heatingWater storage tank

The invention relates to a air-condition water heater which is formed by an air condition outdoor machine; a thermal-insulated water storage tank; and the indoor machine last two of which are connected by two pipe copper valve. It can be selected the modes via remote control as: cold wind / warm water, warm wind / warm water, single cooling wind, single warming wind, and sing warming water. It can use the compression air to store left heat. The condensing coil is at the lower part of water storage tank; the fan can emit heat secondary to make the water temperature inside the water storage tank higher than condensing temperature to reach the electric heating effect. In summer, the heat generated by refrigeration can be used to heat water, which can reduce the refrigeration energy-consumption to improve efficiency-energy ratio. In spring, fall and winter, the heat pump can be used to heat water which can save 70% of energy and shorten 2 times of time than directly heating water with electricity. The refrigeration agent can be contained in outdoor heat exchanger. The invention has simple structure, reasonable design and wider application.

Owner:奉政一

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com