High temperature heat pump-based waste heat recovery curing barn

A high-temperature heat pump and waste heat recovery technology, which is applied in the field of flue-cured tobacco rooms, can solve the problems of low working efficiency of drying tobacco, failure to recycle waste heat of flue-cured tobacco rooms, and long drying time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

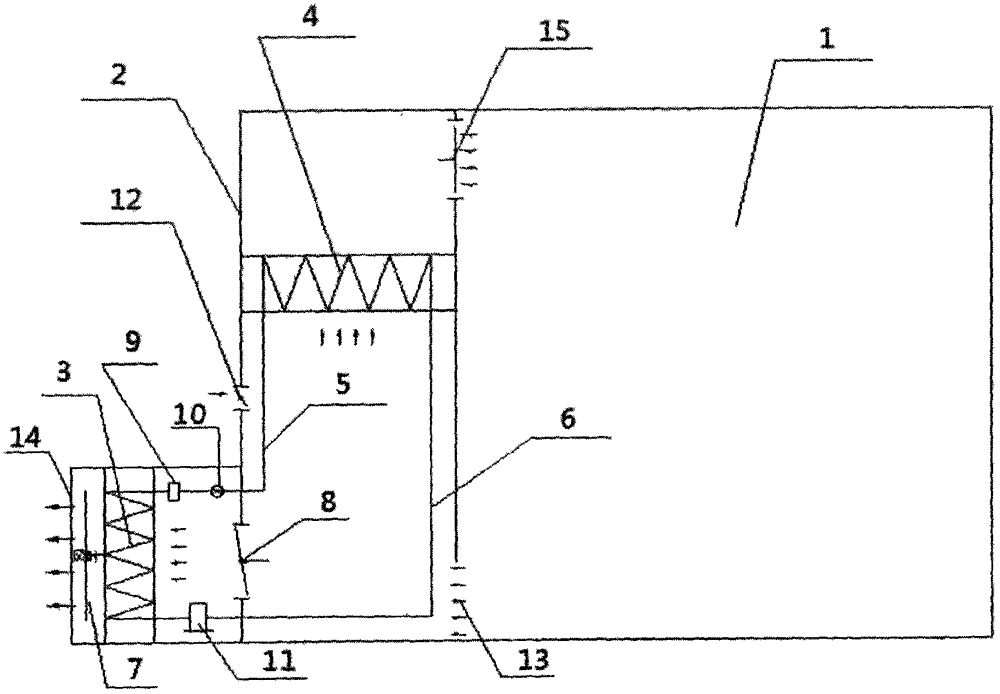

[0013] In this example, refer to figure 1 As shown, a high-temperature heat pump waste heat recovery tobacco flue-cured room includes a barn 1, a high-temperature heat pump device 2 arranged on the left side of the barn 1, an evaporator 3 and a condenser 4 arranged in the high-temperature heat pump device 2, and a connection The delivery pipeline 5 and the recovery pipeline 6 of the evaporator 3 and the condenser 4, and the fan blade 7 arranged on the left side of the evaporator 3, and the waste heat recovery valve port 8 arranged on the right side of the evaporator 3; the delivery pipe A liquid storage tank 9 and a throttling device 10 are sequentially arranged on the road 5 from left to right, and a compressor 11 is arranged on the recovery pipeline 6 .

[0014] Wherein, the middle part of the left side of the high temperature heat pump device 2 is provided with a fresh air valve port 12 .

[0015] Wherein, the upper left corner of the barn 1 is provided with a circulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com