LED multi color line light source and its producing process

A manufacturing process and light source technology, applied in the field of linear multi-color lighting sources, can solve the problems of not being able to provide lighting light, and achieve the effects of convenient lighting angle, simple and convenient manufacturing process, and uniform light intensity distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

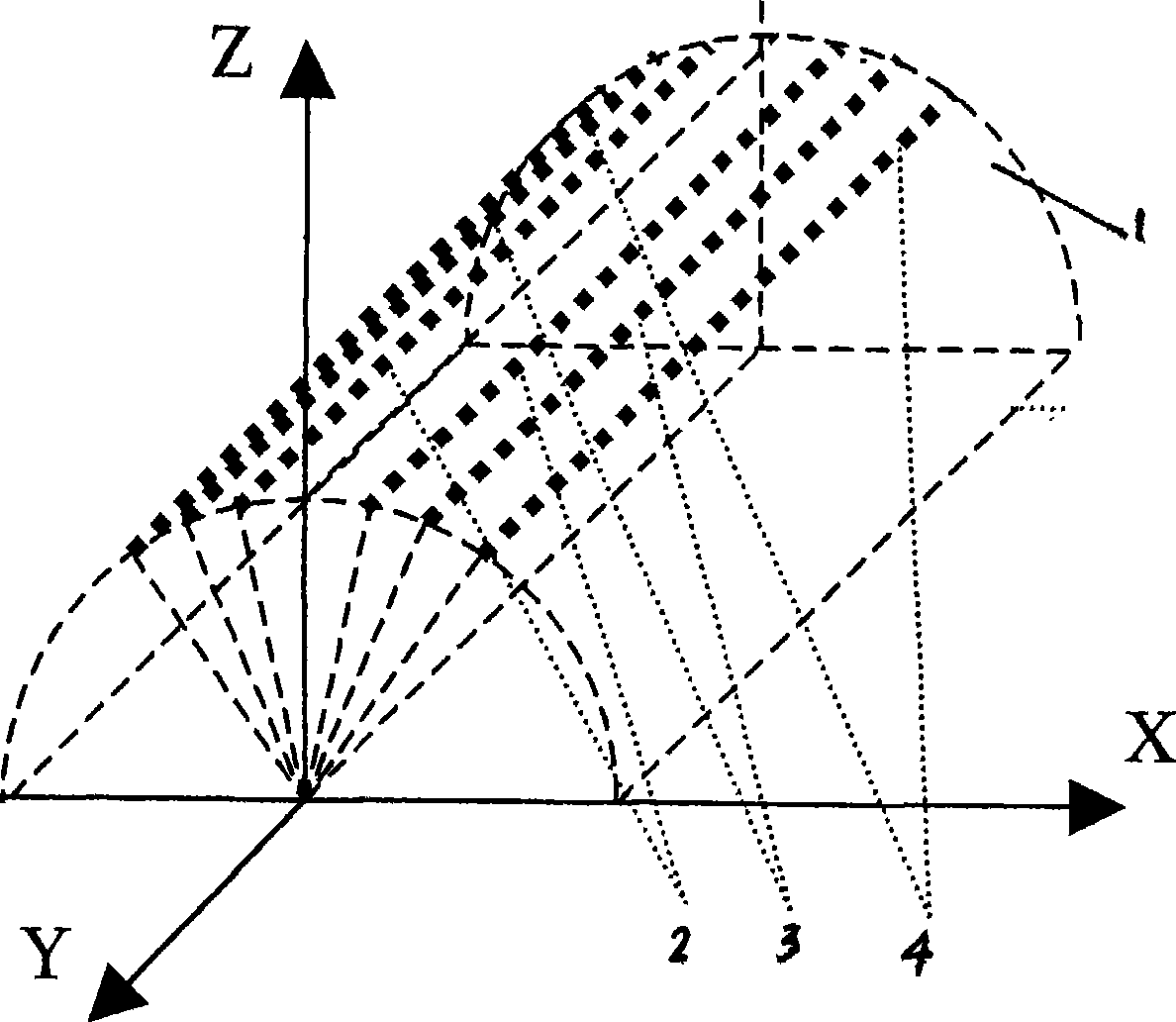

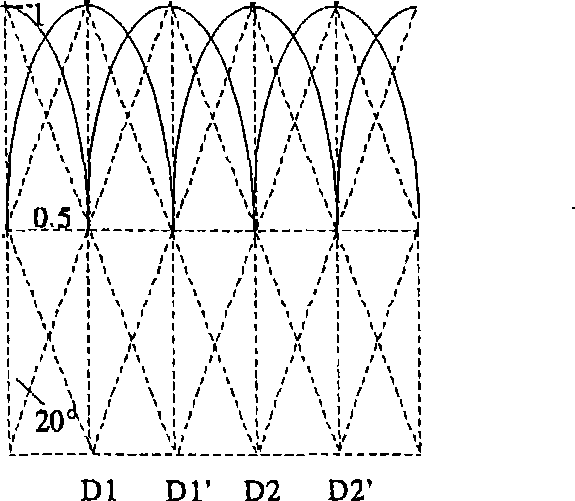

[0034] The structure diagram of LED multi-color line light source of the present invention is as follows figure 1 As shown, there are LEDs of several colors, and the LEDs of the same color are divided into several columns and arranged at equal intervals on the semi-cylindrical surface of the bracket (1). The extension line passes through the center of the semi-cylindrical surface of the support (1) and overlaps with the radial direction of the semi-cylindrical surface of the support (1).

[0035] The above-mentioned LEDs include three colors. The LEDs of the same color are divided into two rows and arranged at equal intervals on the semi-cylindrical surface of the bracket (1). The LEDs of the three colors are arranged in six rows, and the two rows of LEDs of the same color are staggered by half spacing. In this embodiment, the above-mentioned LEDs include three colors: a blue LED row (2), a green LED row (3), and a red LED row (4).

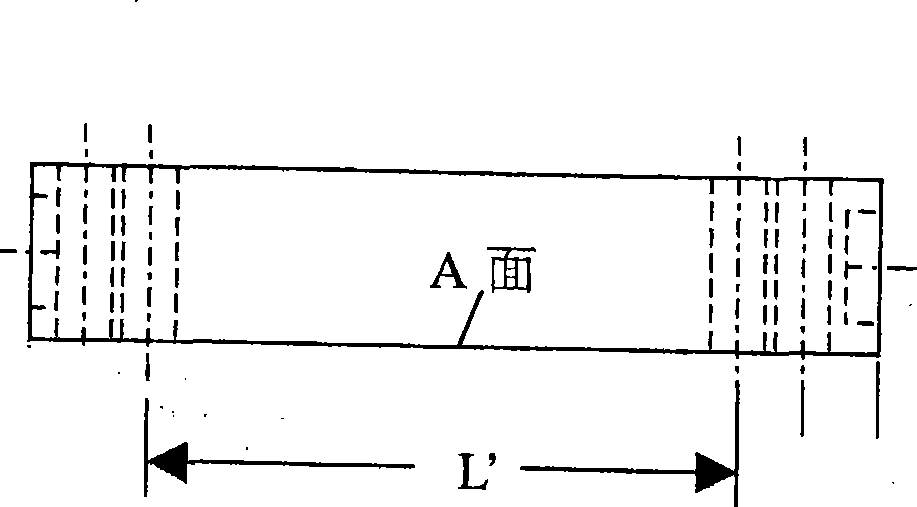

[0036] The manufacturing process of the L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com