Near-infrared laser surface treatment method of carbon fiber/resin matrix composites

A technology of laser surface treatment and composite materials, which is applied in the field of near-infrared laser surface treatment of carbon fiber/resin-based composite materials, and can solve the problem that processing efficiency has not been further improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

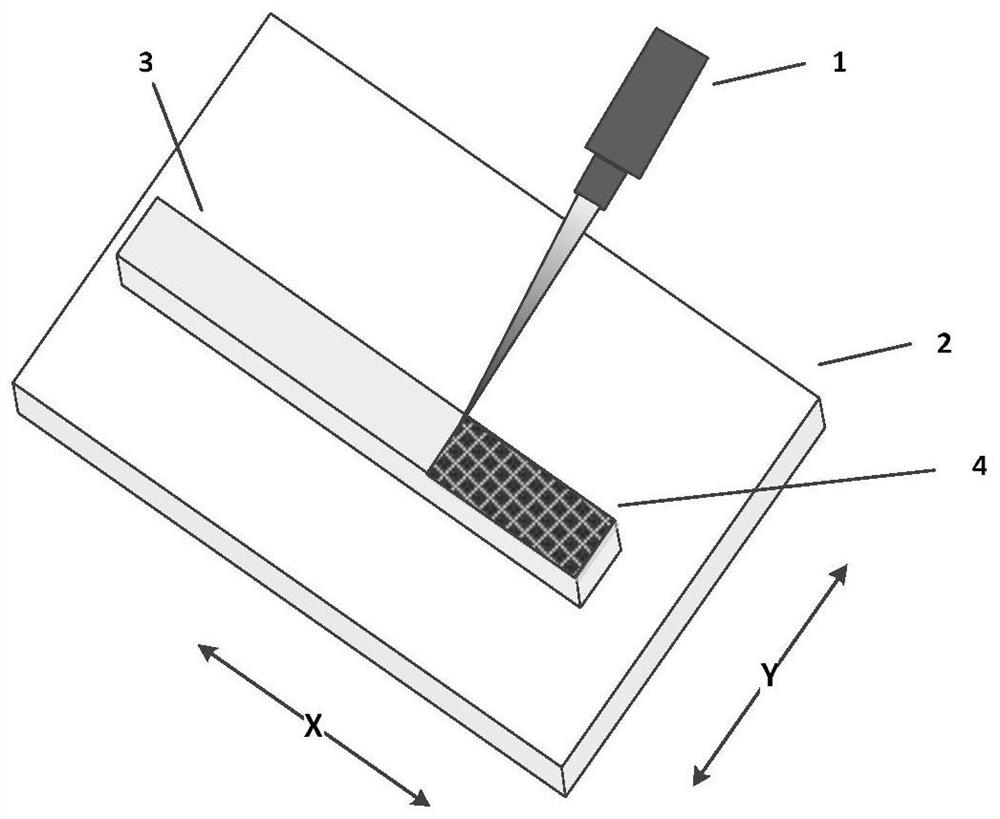

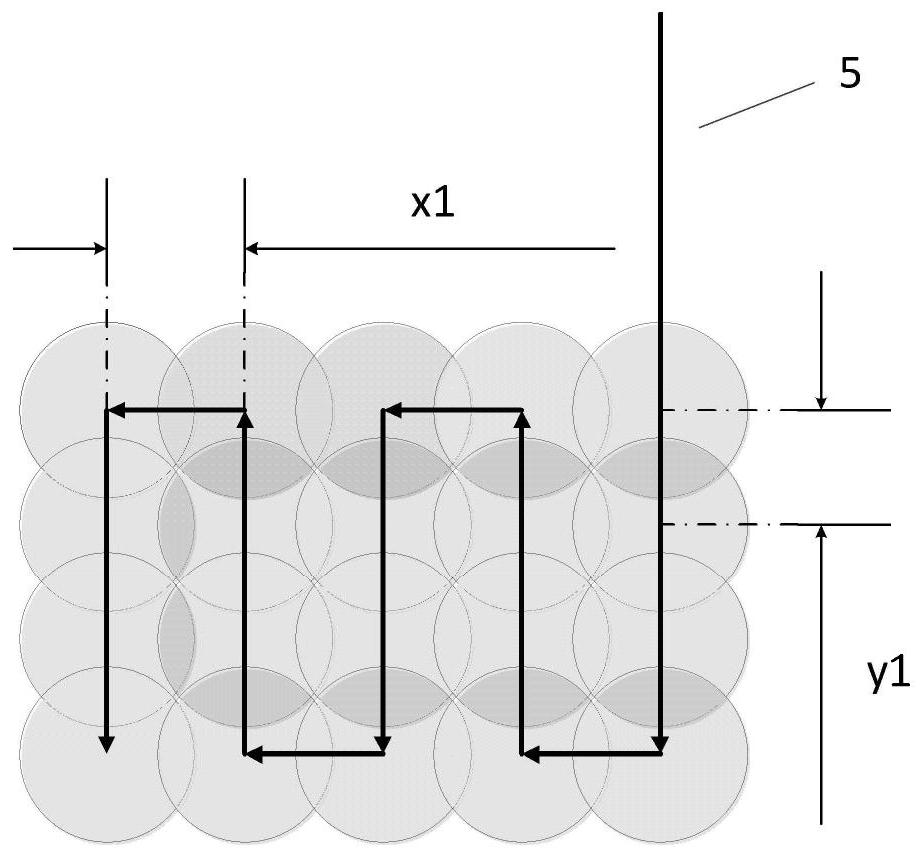

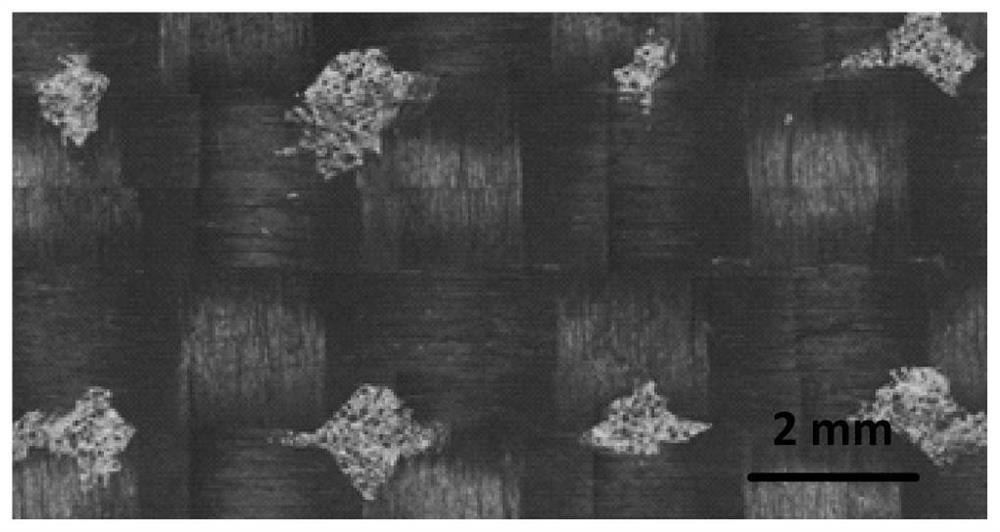

[0040] like figure 1 As shown, the laser source 1 in this embodiment is a YAG laser with a wavelength of 1064 nm, a pulse width of 7 ns, and a single pulse energy ranging from 3 to 200 mJ. A carbon fiber / epoxy resin-based composite plate with a specification of 80mm×10mm×1mm is fixed on the electronically controlled two-dimensional mobile platform 2 . The pulse energy used in this embodiment is 40 mJ, and the pulse frequency is 10 Hz. The laser source remains fixed, the laser beam is always perpendicular to the surface of the plate with a thickness of 1 mm, and the diameter of the spot on the material surface 4 is 3.8 mm. In the laser spot, the energy has a flat-top distribution, so the pulse power density received on the material surface 4 is always 5×10 7 W / cm 2 . The material surface with a specification of 80mm×10mm moves along with the moving platform 2 in a manner of step length x1=2.8mm, y1=3.8mm. Partial micrographs of the treated material surface 4 as image 3 s...

Embodiment 2

[0050] The laser source is the same as in Embodiment 1, which is a pulsed YAG laser with a wavelength of 1064 nm, a pulse width of 7 ns, and a frequency of 10 Hz. The material specification is the same as that of Embodiment 1, which is a carbon fiber / epoxy resin-based composite plate of 80mm×10mm×1mm, which is fixed on the mobile platform 2 in the same manner as in Embodiment 1. The diameter of the light spot on the material surface 4 is the same as that in Embodiment 1, which is 3.8 mm. The pulse energy used in the present invention becomes 34mJ. In the laser spot, the energy has a flat-top distribution, so the pulse power density received on the material surface 4 is always 4.3×10 7 W / cm 2 . The material surface with a specification of 80mm×10mm moves along with the moving platform 2 in a manner of step length x1=3mm, y1=2.5mm. Partial micrographs of the treated material surface 4 as Image 6 shown. Analyzed by image processing software, Image 6 The residual ratio η ...

Embodiment 3

[0053] The laser source is the same as in Embodiment 1, which is a pulsed YAG laser with a wavelength of 1064 nm, a pulse width of 7 ns, and a frequency of 10 Hz. The material specification is the same as that of Embodiment 1, which is a carbon fiber / epoxy resin-based composite plate of 80mm×10mm×1mm, which is fixed on the mobile platform 2 in the same manner as in Embodiment 1. The diameter of the light spot on the material surface 4 is the same as that in Embodiment 1, which is 3.8 mm. The pulse energy used in the present invention is 40mJ. In the laser spot, the energy has a flat-top distribution, so the pulse power density received on the material surface 4 is always 5×10 7 W / cm 2 . The material surface with a specification of 80mm×10mm moves along with the moving platform 2 in a manner of step length x1=3mm, y1=2.5mm. Partial micrographs of the treated material surface 4 as Figure 7 shown. Analyzed by image processing software, Figure 7 The residual rate η of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com