Bicycle gyro transmission structure and bicycle equipped with same

A transmission structure, bicycle technology, applied in wheel transmission, vehicle components, vehicle gearboxes, etc., can solve the problems that cannot meet the needs of new people and aesthetic requirements, and achieve the effect of novel structure, more physical strength, and physical strength saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

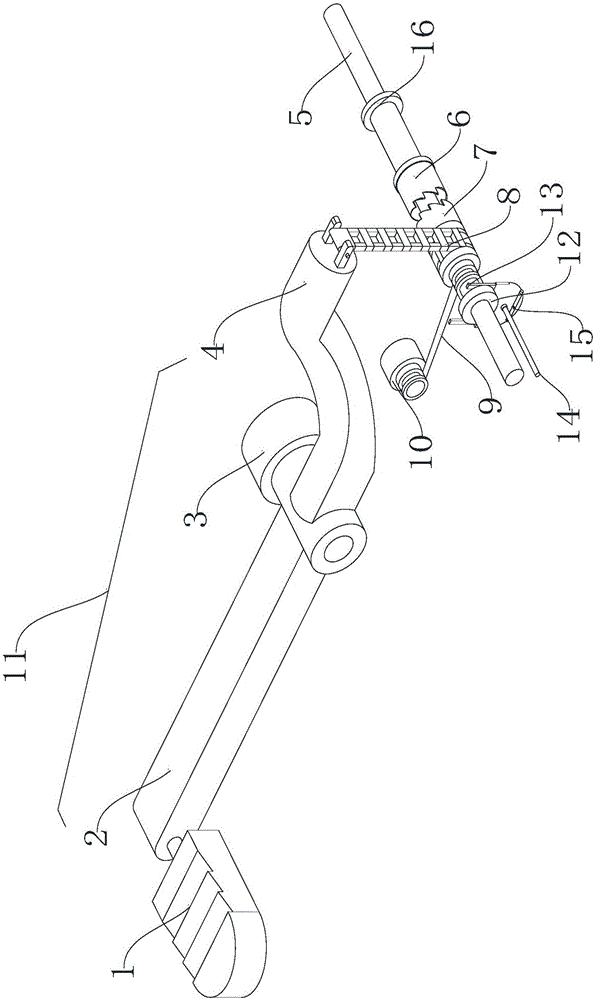

[0023] Embodiment 1: A bicycle gyro transmission structure, including a connecting rod 11, a driven transmission tooth 6, a driving transmission tooth 7, and a transmission belt 8, wherein the connecting rod 11 is connected to the driving transmission tooth 7 through the transmission belt 8, and the driving transmission tooth 7 passes through the recovery The mechanism rotates around the wheel shaft 5 of the bicycle, the driving gear 7 and the driven gear 6 are driven in one direction through the locking teeth and the driven gear 6 is fixed on the hub 16 of the wheel shaft 5 .

Embodiment 2

[0024] Embodiment 2: A bicycle gyro transmission structure, one side of the active transmission tooth 7 is connected with a toggle block 12 with a clearance fit with the wheel shaft 5, one side of the toggle block 12 is provided with a toggle tooth 13, and the toggle tooth 13 The lower part is provided with conversion control line 14, return spring 15. The recovery mechanism includes a steel wire rope 9 and a coil spring 10 , and the coil spring 10 drives the steel wire rope 9 to connect with the driving tooth 7 . The connecting rod 11 includes a front rod body 2 and a rear rod body 4 , both of which are fixedly connected with the hinge 3 . The rest of the structure is the same as that described in Example 1.

Embodiment 3

[0025] Embodiment 3: A kind of bicycle, at least comprises vehicle frame, driving wheel, and driving wheel is installed on the vehicle frame through the axle 5 that has hub 16, and the two sides of described vehicle frame are provided with bicycle gyro transmission structure, and described bicycle gyro The transmission structure includes a connecting rod 11, a driven transmission tooth 6, a driving transmission tooth 7, and a transmission belt 8, wherein the connecting rod 11 is hinged on the vehicle frame, and a pedal 1 is arranged at the head end of the connecting rod 11, and the connecting rod 11 The end is connected with the driving gear 7 through the transmission belt 8, the driving gear 7 rotates around the wheel shaft 5 through the return mechanism, and the driving gear 7 and the driven gear 6 are unidirectionally transmitted through the locking teeth, and the driven gear 6 is fixed on the hub 16 on.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com