Petrol-electric hybrid using working residual heat to generate power

A waste heat and work technology, applied in the field of hybrid electric power, can solve problems affecting human health and life, negative effects of the atmospheric environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

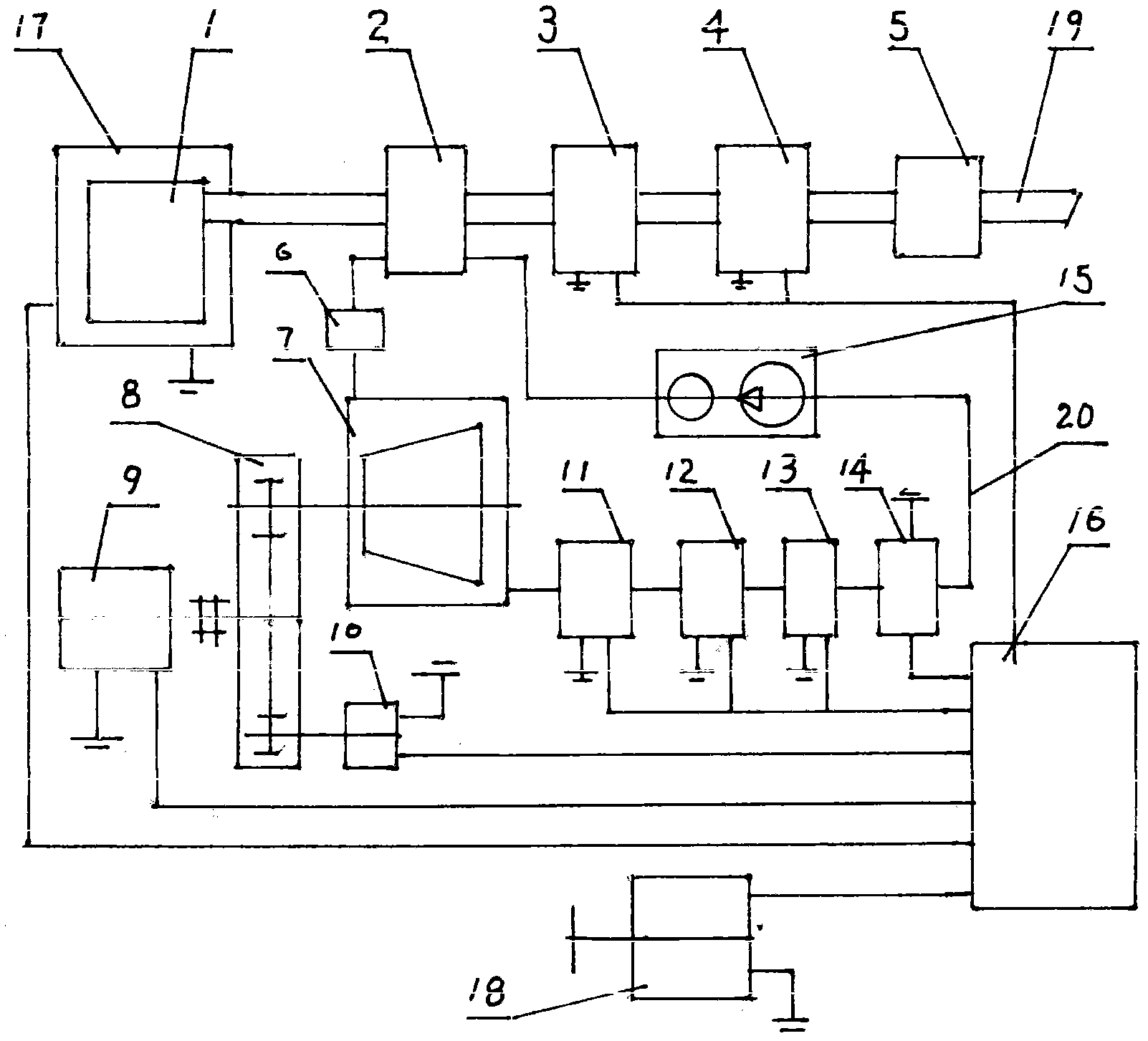

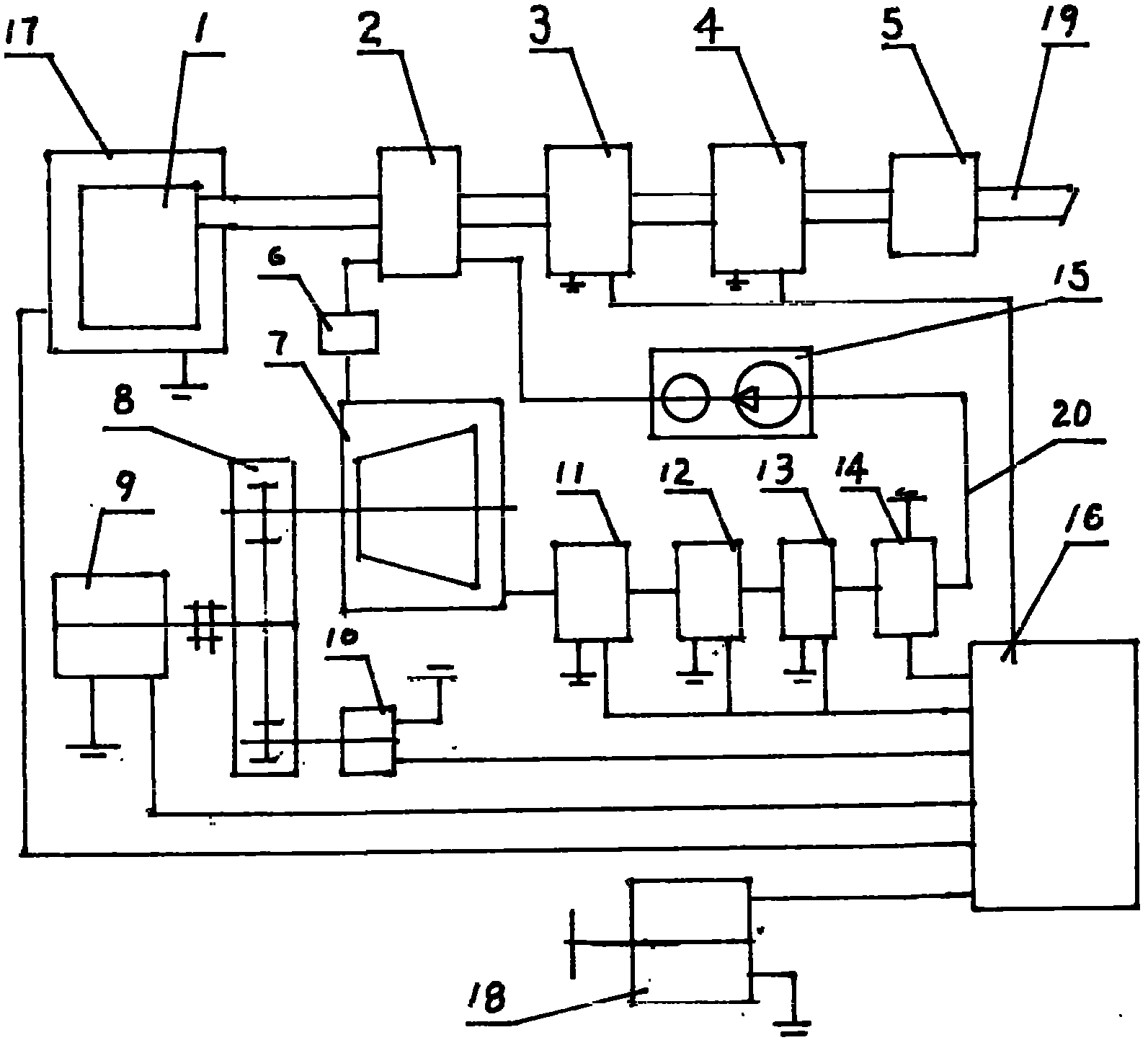

[0011] Below in conjunction with embodiment and accompanying drawing, the present invention is described further, embodiment: with reference to figure 1 , in above-mentioned feature, internal combustion engine 1 machine top surface, body side, radiator position are equipped with the circuit of heat collector generator 17 and battery array 16 link, and the electric power that it sends is charged in the positioning battery in battery array 16.

[0012] Among the above-mentioned features, the exhaust pipe 19 is equipped with a first-stage heat collecting evaporator 2, which generates power through the heat conversion of the turbine 7, and starts from the heat collecting evaporator 2 and connects the flow regulator 6 to the turbine 7 to perform work. The turbine 7 transmits the power energy to the rotor of the generator 9 through the gearbox 8 and converts it into electric energy. The gaseous working medium after the turbine 7 has done work enters the loop pipeline 20, and on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com