Corrosion resistant magnesium alloy material and preparation method thereof

A magnesium alloy, corrosion-resistant technology, applied in the field of corrosion-resistant magnesium alloy materials and its preparation, can solve the problems of limited application, high cost, difficult mass production, etc., and achieve the effect of wide source and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

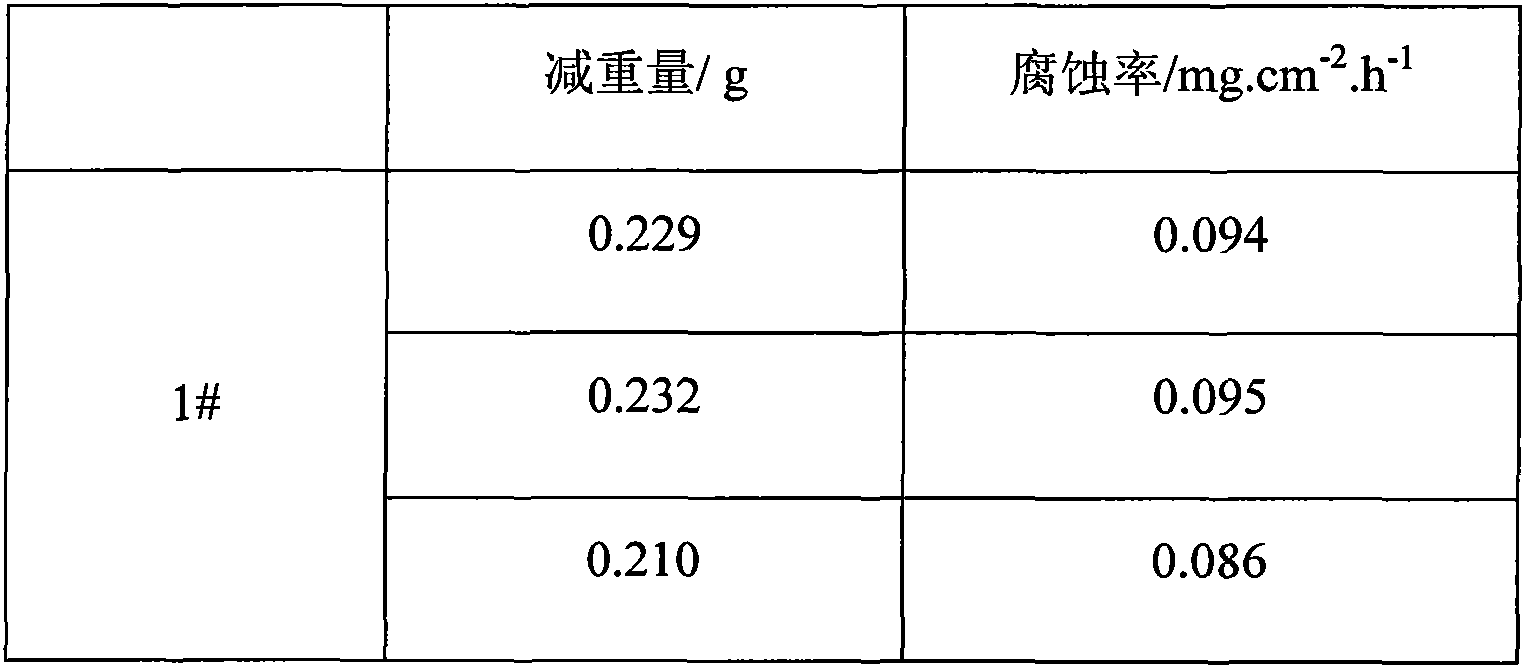

Examples

Embodiment 1

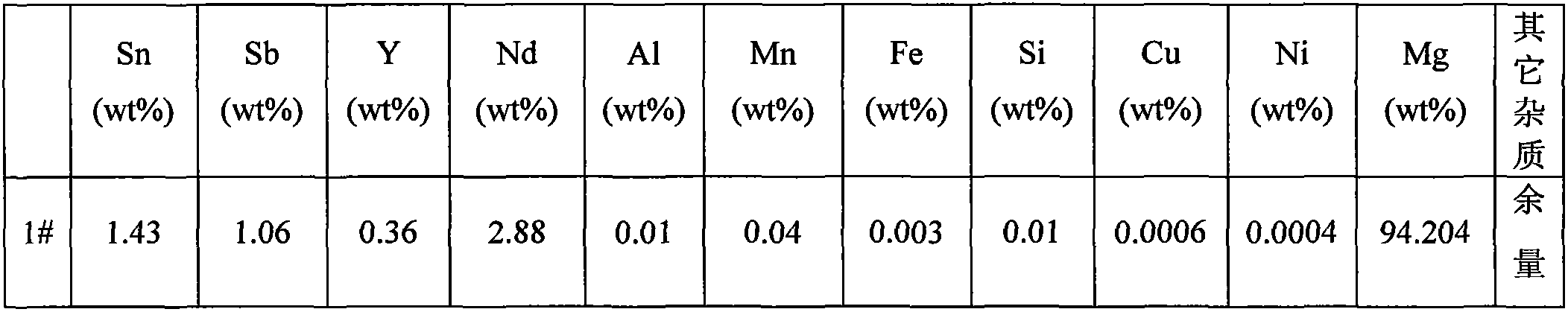

[0026] Purchase pure Mg, pure Sn, pure Sb, MgY10 master alloy, and MgNd10 master alloy with impurity content within the required range, and configure the components according to the content of the master alloy elements, as shown in Table 1.

[0027] Table 1 Ingredients weight and element content

[0028]

Sn / g

Sn / wt%

Sb / g

Sb / wt%

MgY10 / g

Y / wt%

MgNd10 / g

Nd / wt%

Mg / g

Mg / wt%

1#

150

1.5

120

1.2

400

0.4

3000

3

6330

63.3

[0029] The process is to heat pure magnesium, pure Sn, and pure Sb in an industrial power frequency induction melting furnace, and then pass in 1.5L / min argon gas for protection when heated to 402°C, heat to 720°C, and keep warm for 20 minutes Completely melt the material, keep the melt temperature at 720°C for 20 minutes after melting, add Mg-Nd master alloy and Mg-Y master alloy in turn, keep the melt temperature at 720°C after melting, keep ...

Embodiment 2

[0038] Purchase pure Mg, pure Sn, pure Sb, MgY10 master alloy, and MgNd10 master alloy with impurity content within the required range, and configure the components according to the content of the master alloy elements, as shown in Table 3.

[0039] Table 3 Ingredients weight and element content

[0040]

Sn / g

Sn / wt%

Sb / g

Sb / wt%

MgY10 / g

Y / wt%

MgNd10 / g

Nd / wt%

Mg / g

Mg / wt%

2#

200

2.0

300

3.0

800

0.8

2500

2.5

6200

62

[0041] The process is as follows: firstly heat pure magnesium, pure Sn, and pure Sb in an industrial power frequency induction melting furnace, and then pass in 1.6L / min argon gas for protection when heated to 405°C, heat to 715°C, and keep warm for 25 After melting, keep the melt temperature at 715°C for 20 minutes, add Mg-Nd master alloy and Mg-Y master alloy in turn, keep the melt temperature at 715°C after melting, and keep it warm for 13 m...

Embodiment 3

[0051] Purchase pure Mg, pure Sn, pure Sb, MgY10 master alloy, and MgNd10 master alloy with impurity content within the required range, and configure the components according to the content of the master alloy elements, as shown in Table 5.

[0052] Table 5 Ingredients weight and element content

[0053]

Sn / g

Sn / wt%

Sb / g

Sb / wt%

MgY10 / g

Y / wt%

MgNd10 / g

Nd / wt%

Mg / g

Mg / wt%

3#

350

3.5

200

2.0

1200

1.2

800

0.8

7450

74.5

[0054] The process is as follows: firstly heat pure magnesium, pure Sn, and pure Sb in an industrial power frequency induction melting furnace, and then pass in 1.8L / min argon gas for protection when heated to 406°C, heat to 710°C, and keep warm for 22 After melting, keep the melt temperature at 710°C for 20 minutes, add Mg-Nd master alloy and Mg-Y master alloy in turn, keep the melt temperature at 710°C after melting, and keep it for 14 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com