Blended yarn of organic silicon nitrogen system flame-retardant fiber and organophosphorus system flame-retardant fiber

A technology of flame-retardant fiber and silicon-nitrogen flame retardant, which is applied in textiles, textiles, papermaking, and artificial filaments made of viscose. It can solve the problems of low strength, large amounts of harmful smoke, and low smoke emission. , to meet the requirements of perspiration, good moisture absorption and comfort, and high tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

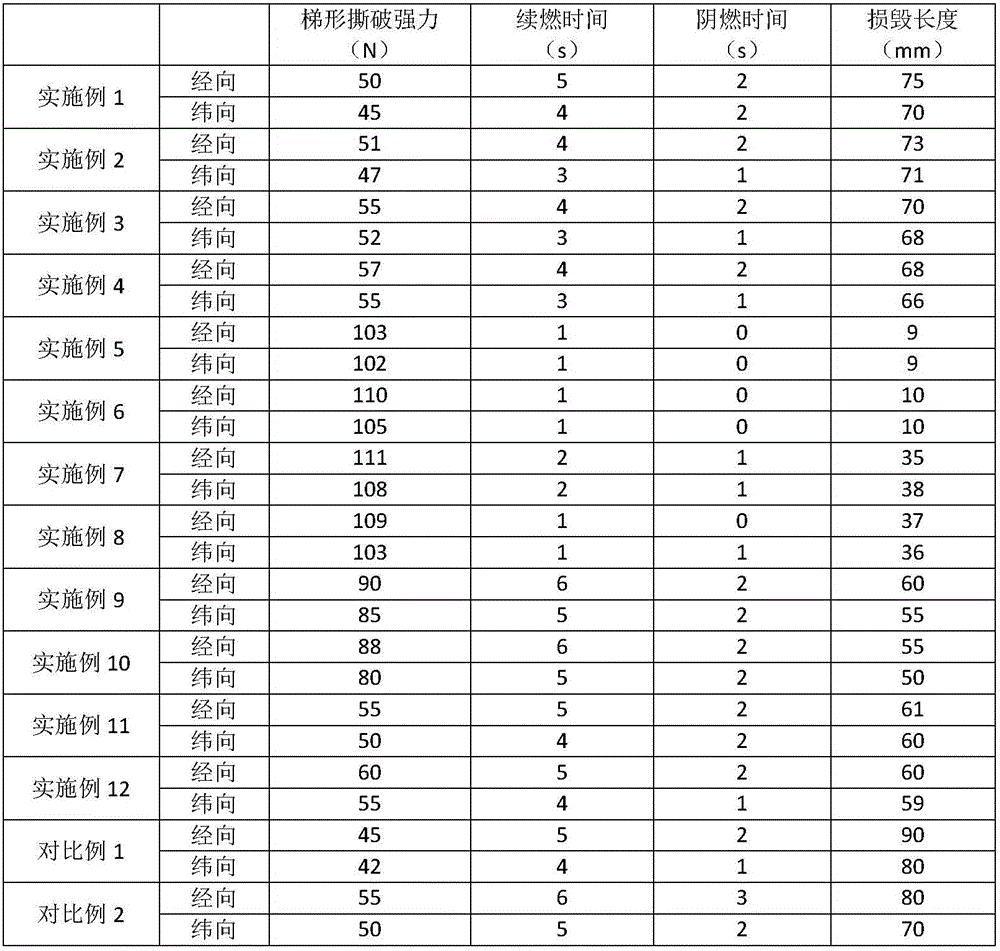

Examples

Embodiment 1

[0023] (1) Provide SOL FR and Lenzing FR short fibers of the same size of 2D×51mm at a weight ratio of 30:70, and mix the two fibers.

[0024] (2) Spinning process: picking cotton → mixing and opening → carding and beating hand opening → vibrating cotton box feeding → single beating hand forming coils → carding → primary drawing → secondary drawing → third drawing → roving → spun yarn → Winding → Packing.

[0025] (3) Weaving process: yarn steaming → warping → sizing → drawing in heald → weaving → inspection → grading → repairing → finished product; the warp and weft yarns are JC 9.7tex (twist 1950 twist / m) strong twisted yarn, and press 2S:2Z arrangement.

[0026] (4) Dyeing and finishing process: singeing → overflow scouring → mercerizing → overflow dyeing → loose drying → softening → pre-shrinking.

[0027] Using the above method, make 10 yarns, twill fabric, weight 200g / m 2 flame retardant fabric.

Embodiment 2

[0029] (1) Provide SOL FR and Lenzing FR staple fibers of the same size of 2D×51mm at a weight ratio of 40:60, and mix the two fibers.

[0030] Other steps are the same as in Example 1.

Embodiment 3

[0032] (1) Provide SOL FR and Lenzing FR short fibers and flame-retardant acrylic fibers of the same size of 2D×51mm in a weight ratio of 50:30:20, and mix the three fibers.

[0033] Other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com