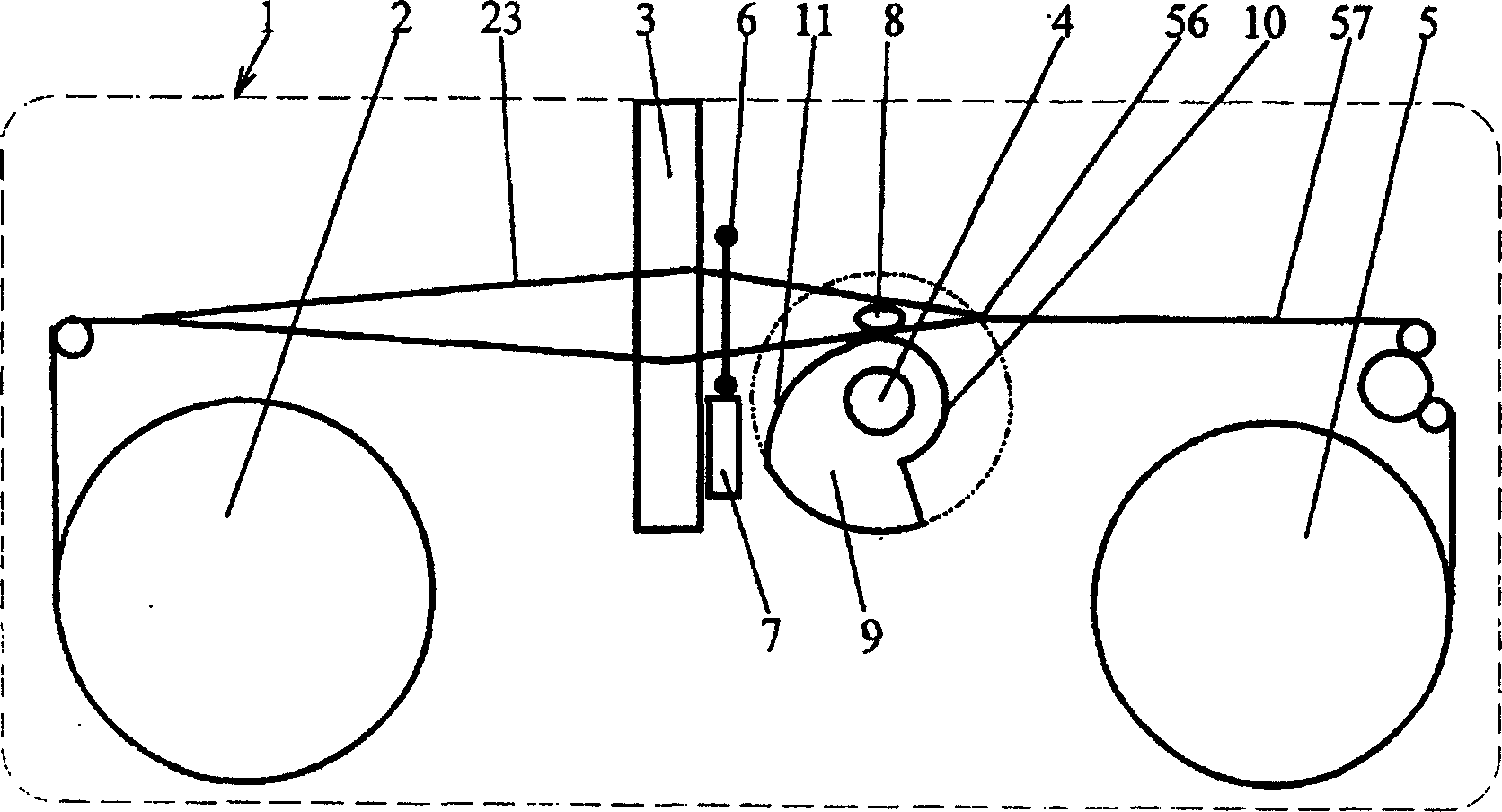

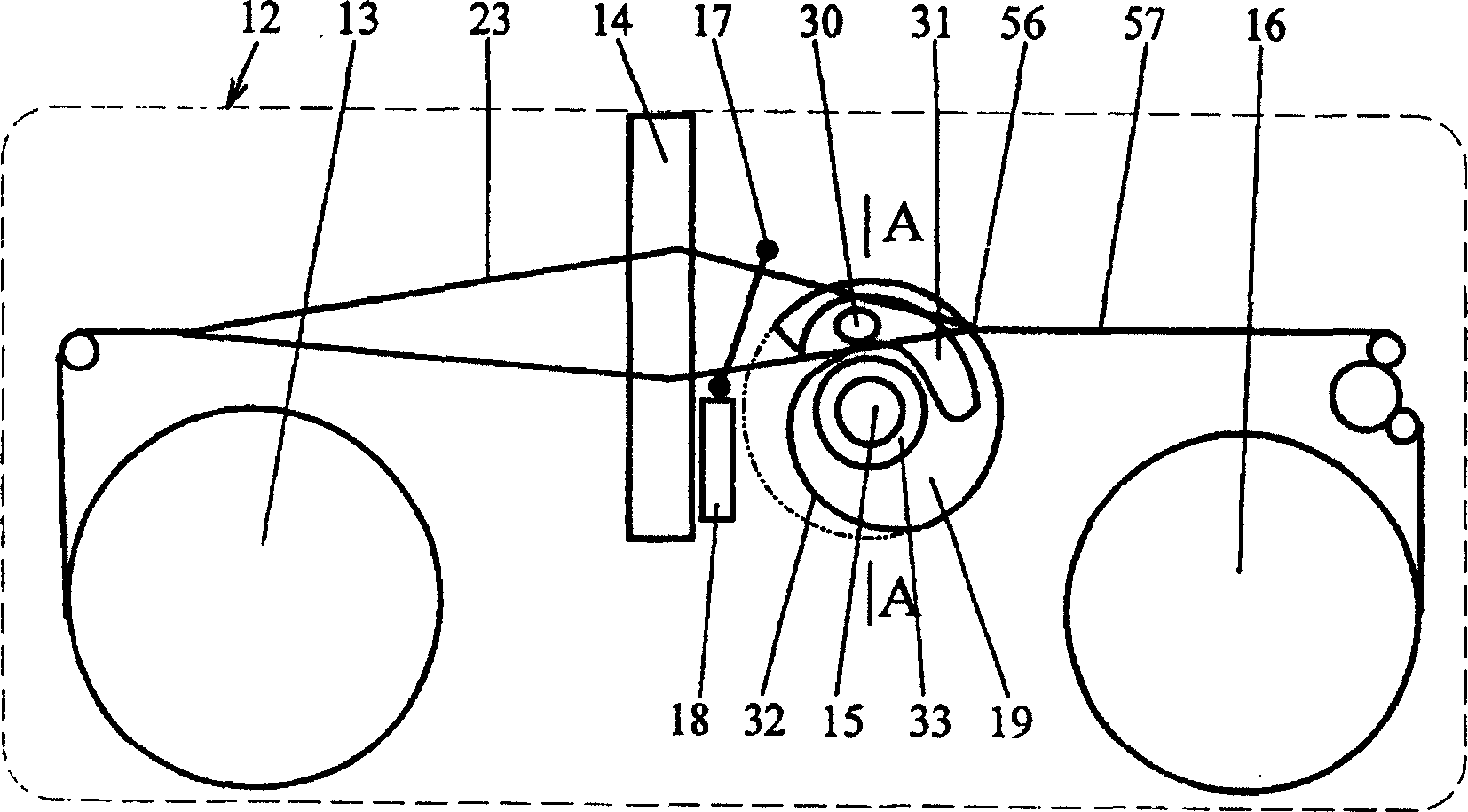

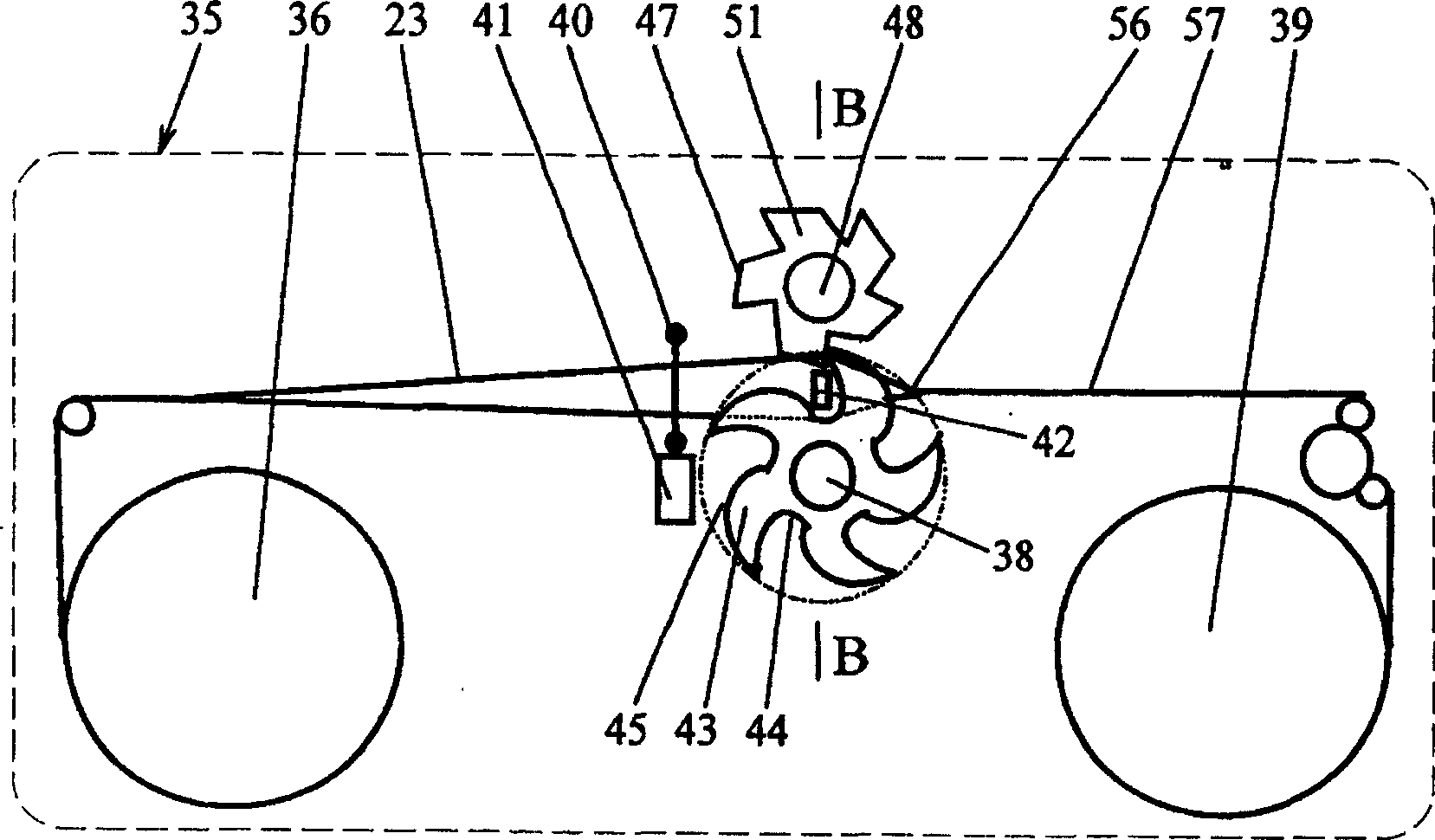

Battening reed wheel mechanism and reed wheel loom with phase controlled jetting and magnetic shuttle reed wheels

A reed wheel and flat type technology, applied in the field of beating-up mechanism, can solve the problems of large air consumption, low air utilization rate, low beating-up speed and efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0110] Since the present invention is a large-scale and systematic invention with many technical features and intertwined and complicated relationships, in order to reduce unnecessary descriptions as much as possible, when a feature can be implemented in multiple ways and appears in multiple embodiments, it will usually be described as Each implementation is distributed in each embodiment, even though this implementation may not necessarily be the best in this embodiment. At this time, in principle, it is considered that various implementation means can be used in common use in various embodiments. In different technical solutions and embodiments of the present invention, there are often some common features. When this feature has been described in detail in one or several embodiments, it is generally not described in detail in other embodiments. Sometimes regardless of this embodiment Whether the example is a previous example. Among the different technical solutions and embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com