Patents

Literature

83results about How to "Reduce air consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

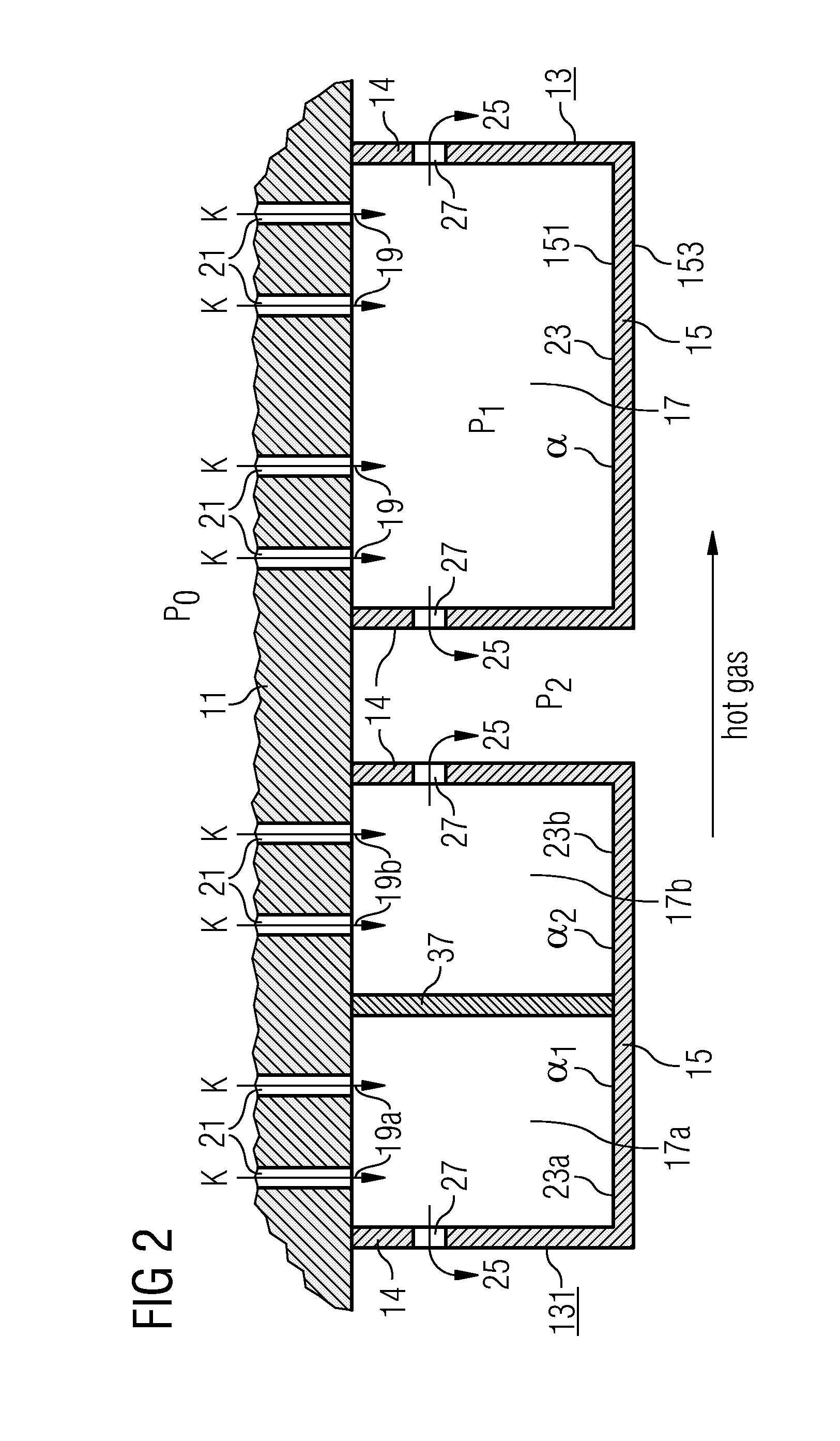

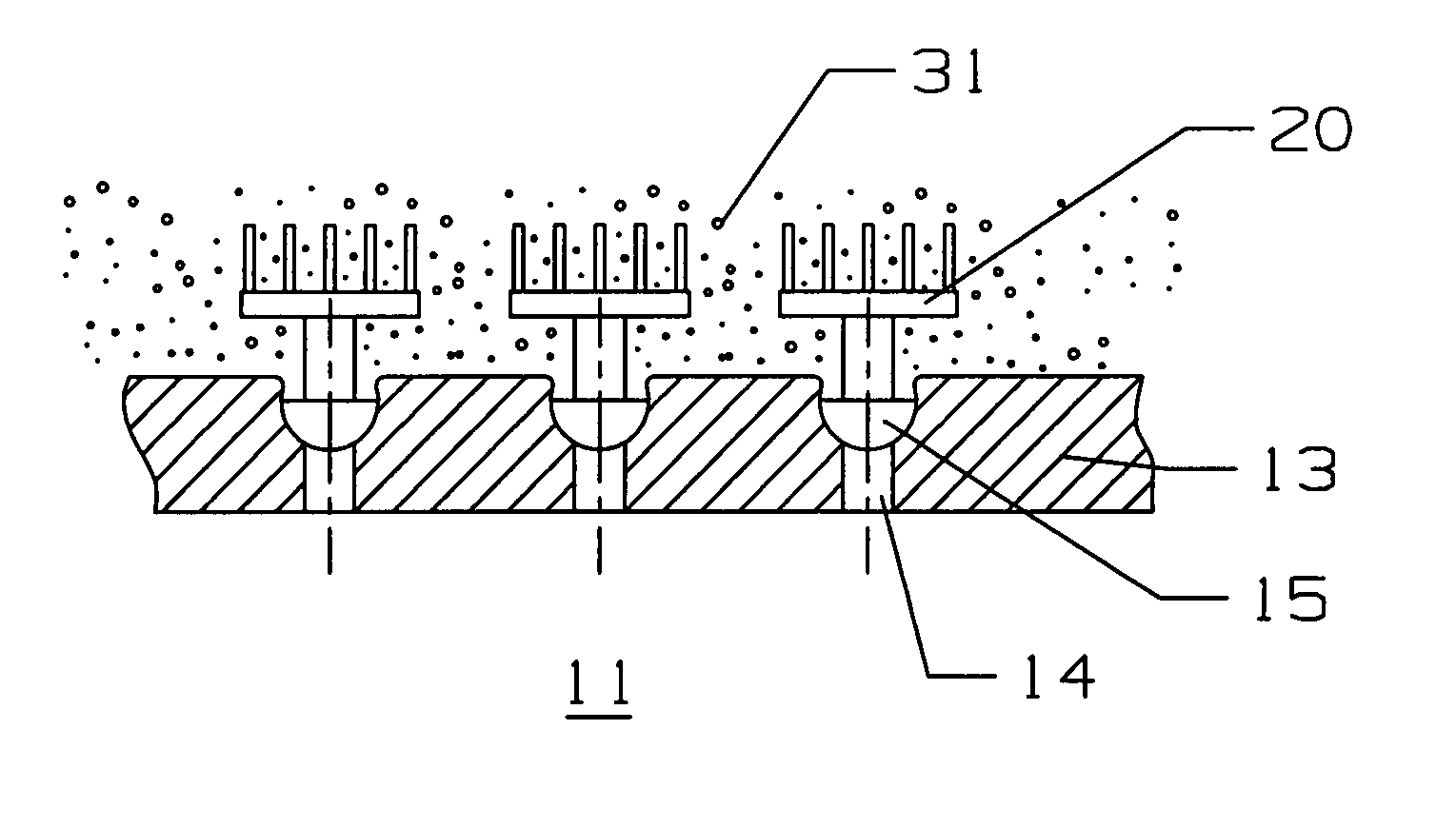

Method of Optimum Controlled Outlet, Impingement Cooling and Sealing of a Heat Shield and a Heat Shield Element

InactiveUS20070245742A1Increase powerImprove efficiencyContinuous combustion chamberEngine fuctionsCombustion chamberCoolant flow

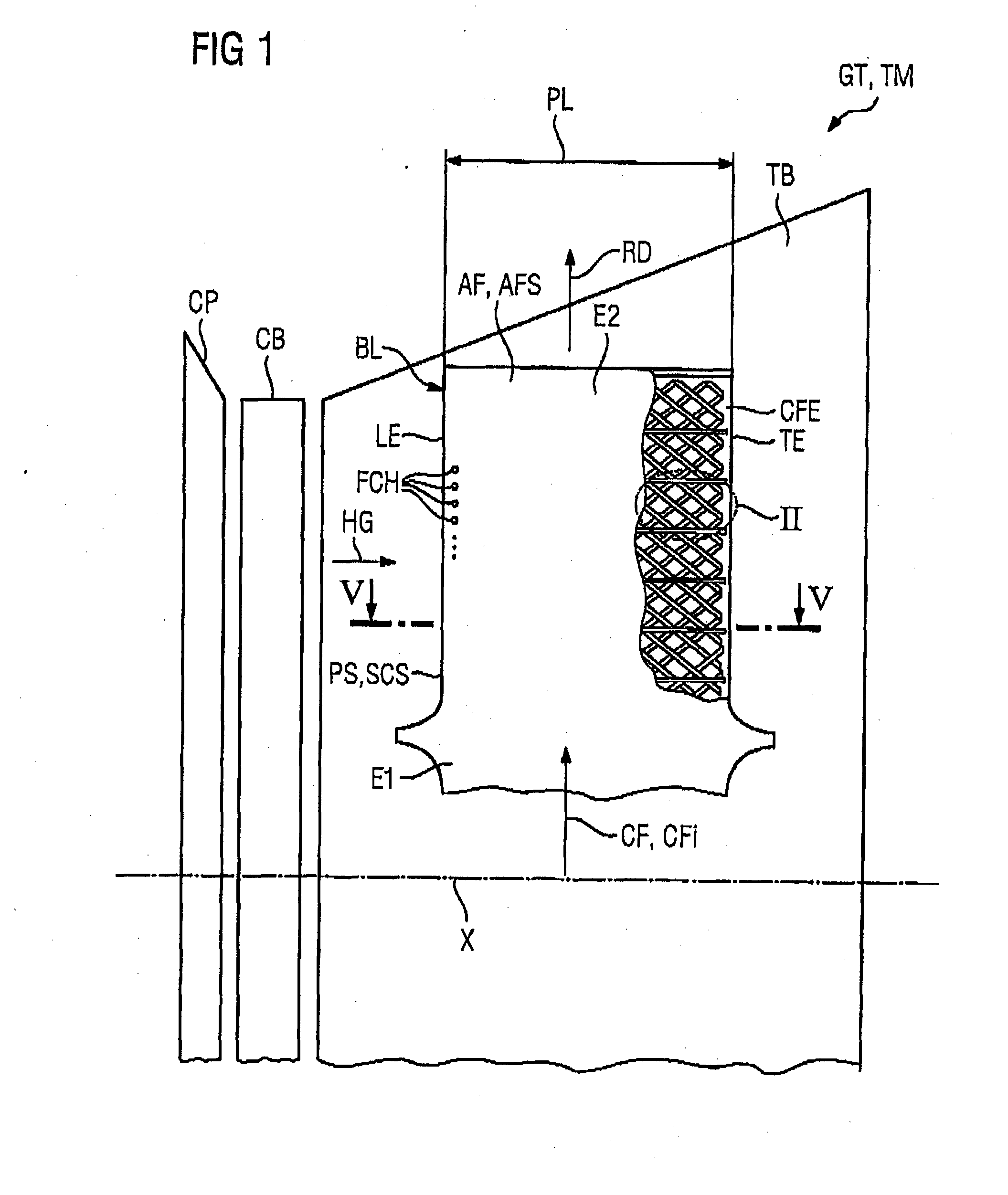

There is described a method for cooling and sealing of a heat shield element, comprising a main wall with an inner side, which is restricted by side walls or rims, and an outer side, which can be exposed to a hot fluid, and wherein a coolant is introduced into an impingement region of that heat shield element and an impingement flow of said coolant is directed on a surface area of that inner side through a plurality of impingement holes, effecting an impingement pressure drop. In the method discharge flow is metered through a number of discharge holes through said side wall or rims from the inner side to the outer side of the main wall, generating a discharge pressure drop in series with the impingement pressure drop. The impingement pressure drop and the discharge pressure drop are matched to one another so that a required coolant flow is generated which yields a required predetermined heat-transfer coefficient of the main wall. Discharging coolant into the gaps between side opposing walls of neighbouring heat shield elements only allows for an effective sealing against hot gas pingestion. Furthermore, the invention relates to a heat shield element, preferably to a single chamber or double chamber metallic heat shield element, which can be exposed to hot gases. In particular the heat shield element is suitable for being used in a combustion chamber of a gas turbine installation.

Owner:SIEMENS AG

Multi-metering and diffusion transpiration cooled airfoil

InactiveUS7717677B1High-temperature resistant coatingIncreased durabilityPump componentsEngine fuctionsDiffusionCoated surface

A turbine airfoil, or a substrate exposed to a high temperature environment, having a plurality of individual cooling circuits in the airfoil wall, each individual cooling circuit having a first metering hole connecting the cooling circuit to a cooling air supply, a first diffusion cavity, a second metering hole, and a plurality of fine film cooling holes connected between the second diffusion cavity and the surface of a high temperature resistant coating. The coating is a refractory coating to provide higher heat resistance than a ceramic based thermal barrier coating. A process of forming the individual cooling circuits is also disclosed, where a ceramic core representing the above described cooling passages is secured in a “fish bowl” shaped cavity in the substrate wall, the refractory coating is applied to just under the core fingers, and the ceramic core is leached out to leave behind the cooling circuit. The cooling circuit thus formed includes a first metering hole, a first diffusion cavity, a second metering hole, a second diffusion cavity, and a plurality of micro film cooling holes to provide transpiration cooling to the coating surface.

Owner:FLORIDA TURBINE TECH

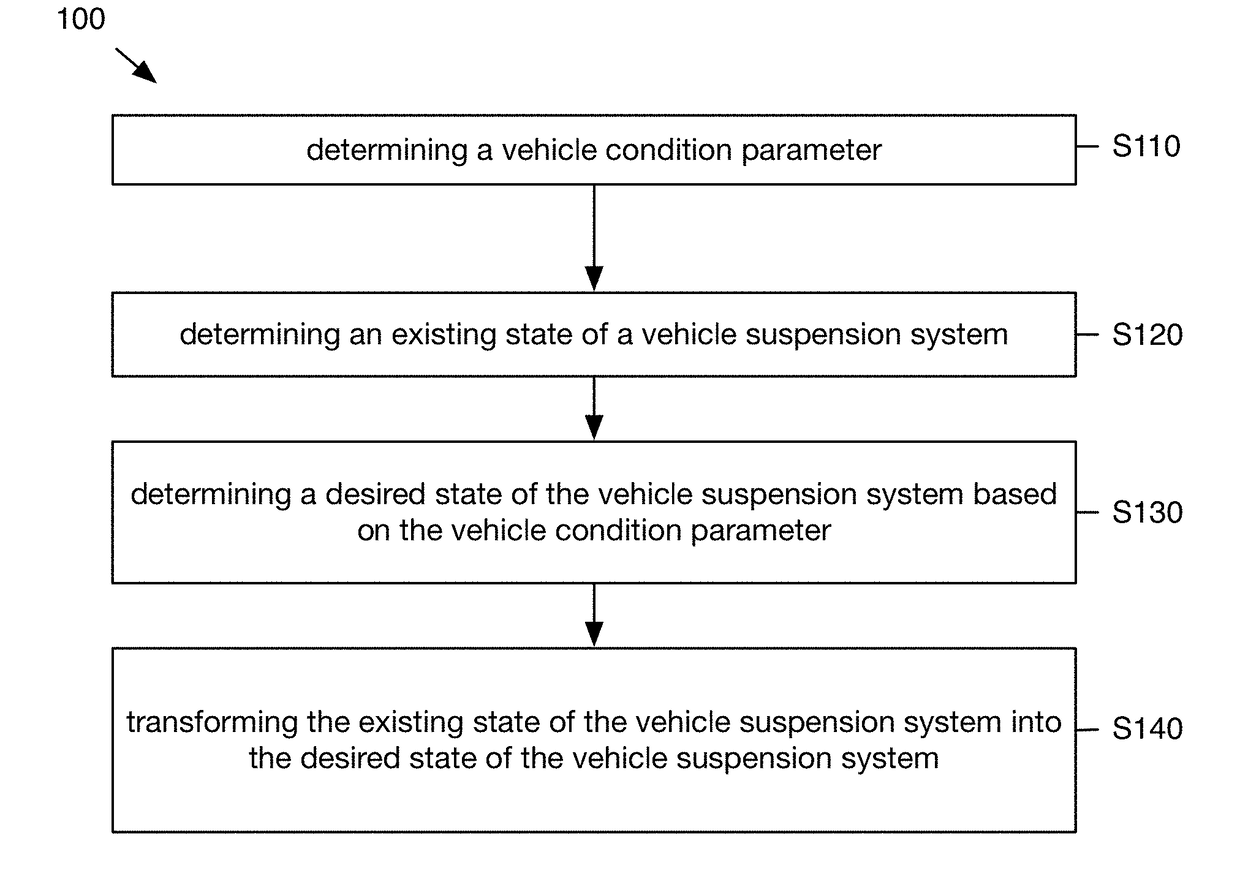

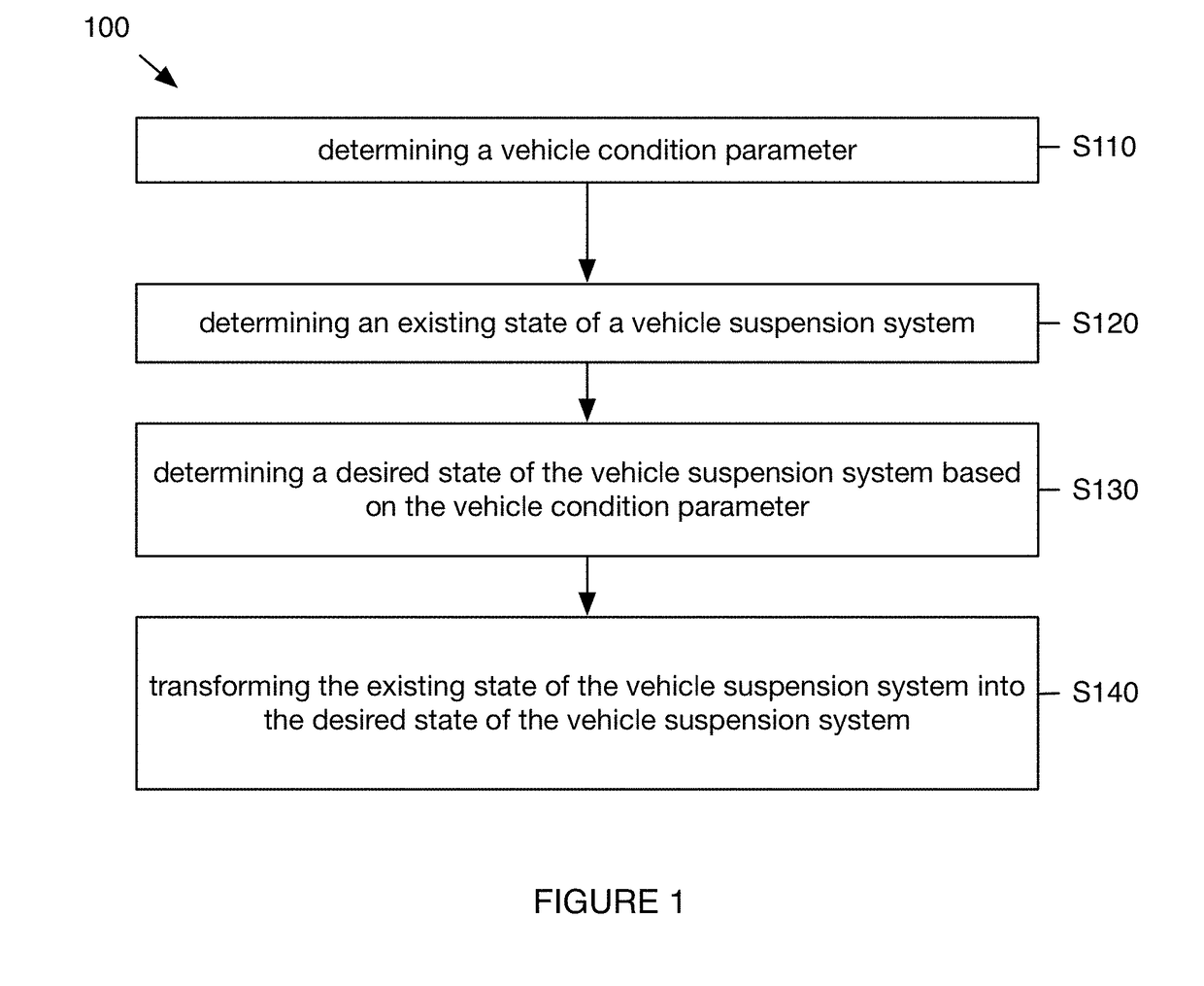

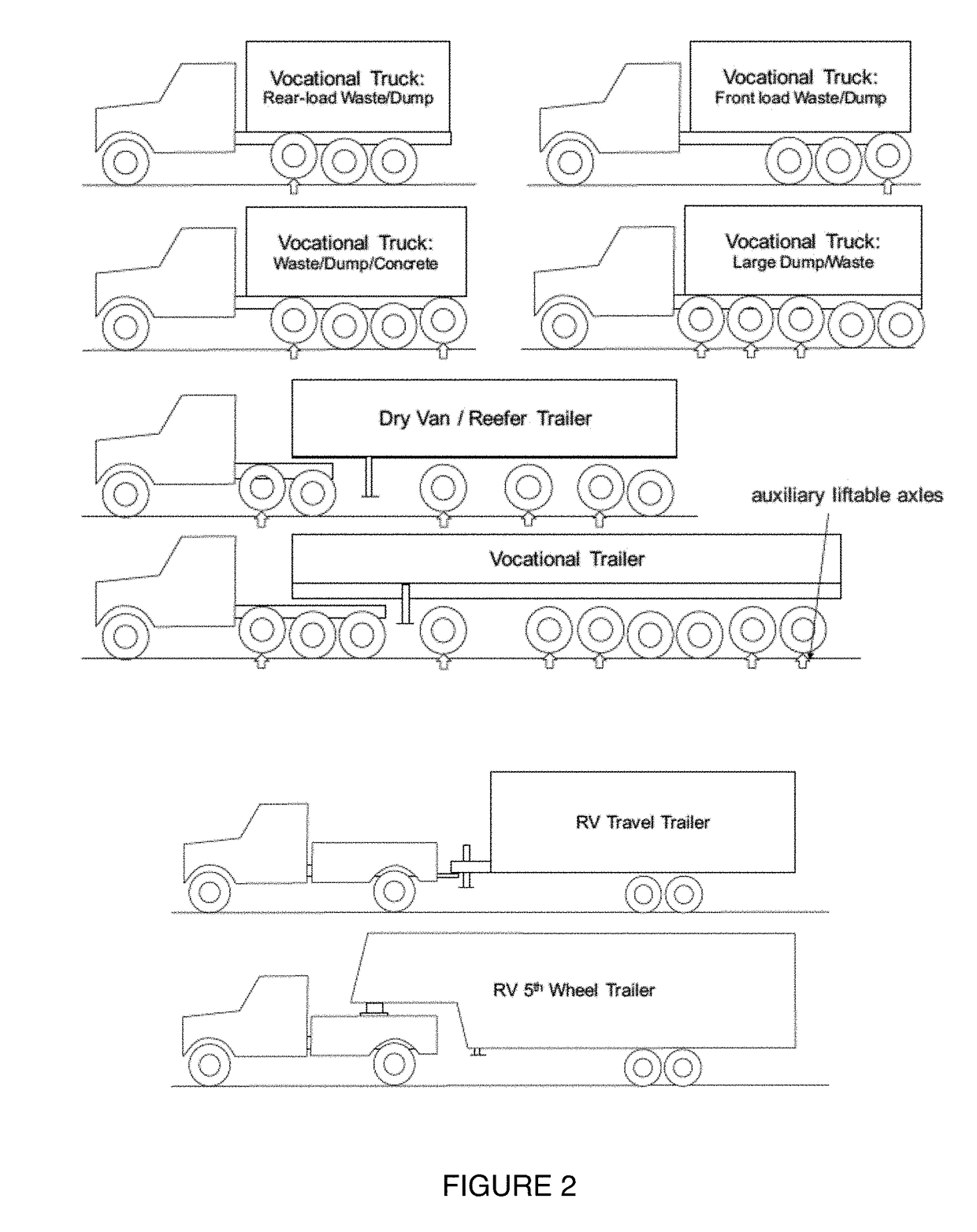

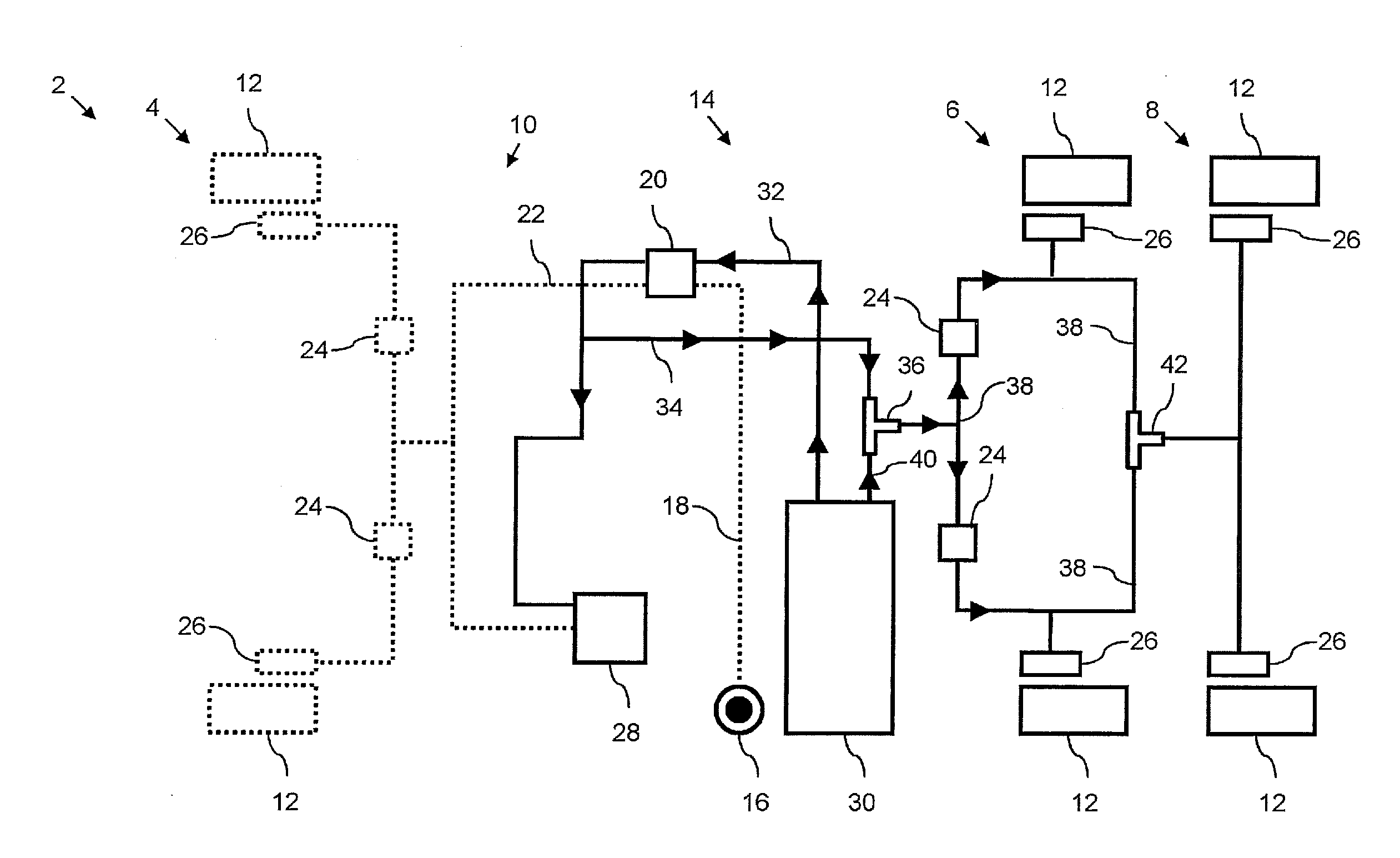

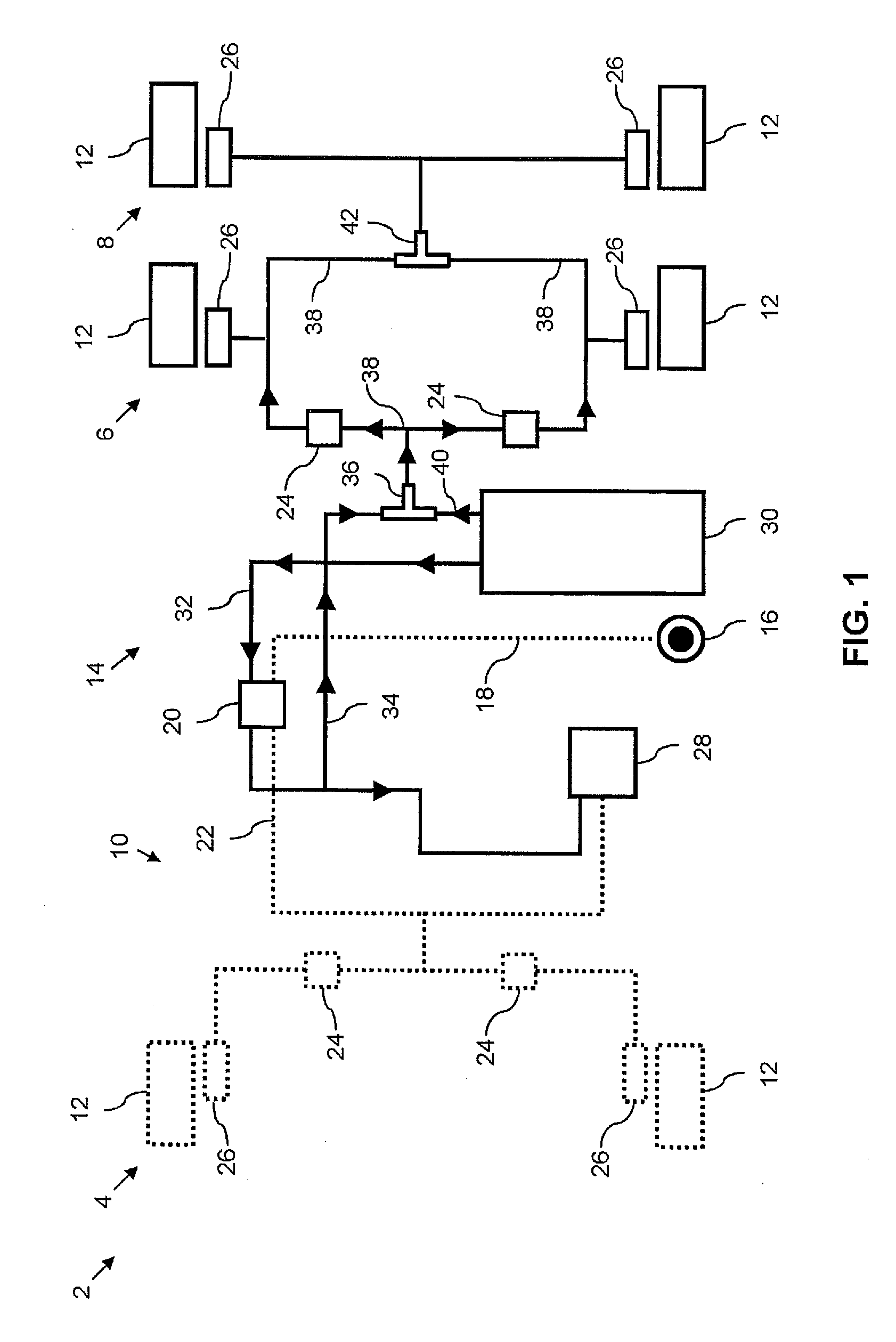

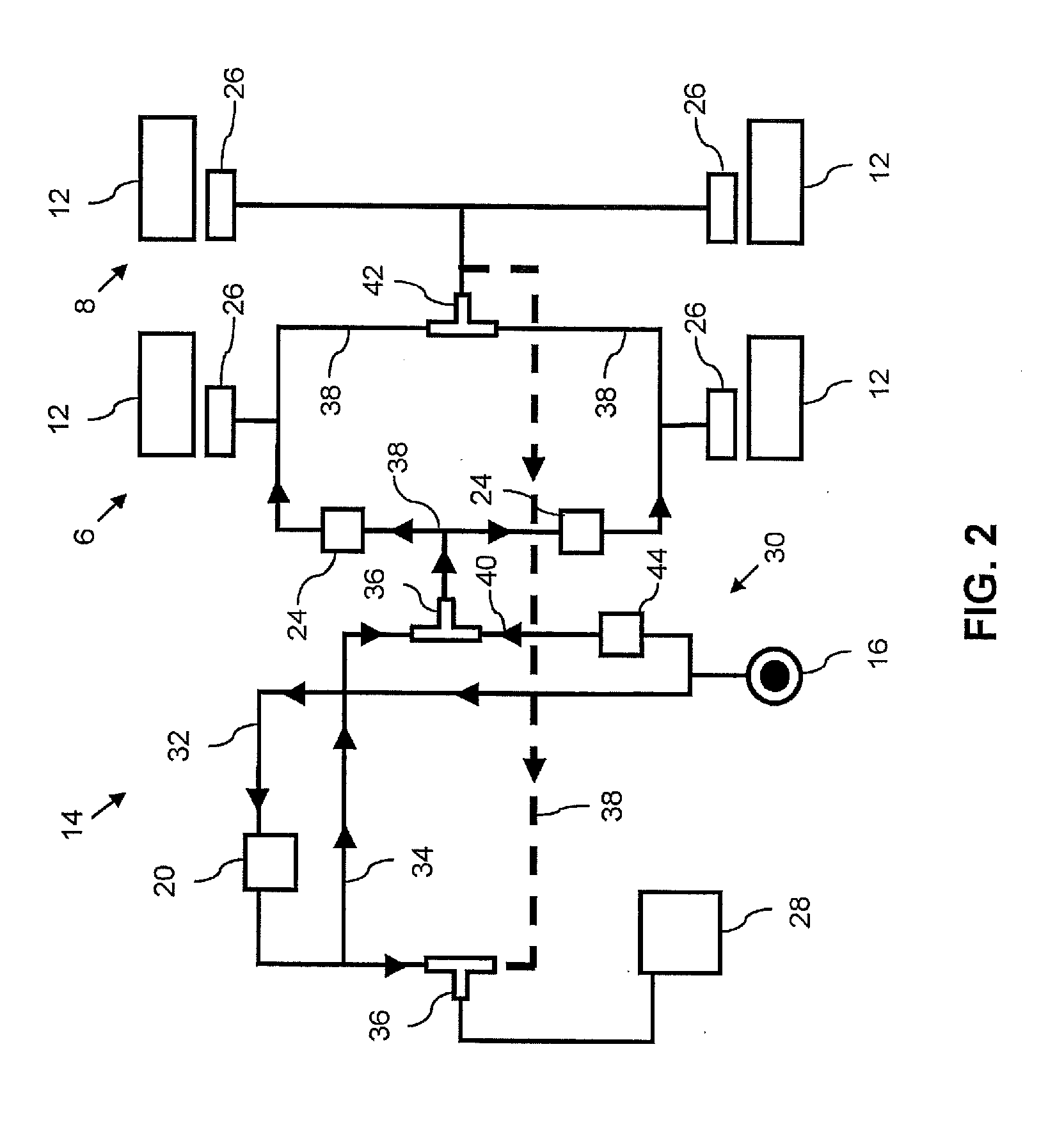

System and method for vehicle load management

InactiveUS20180186208A1Reduce air consumptionImprove fuel economy—thisSignalling/lighting devicesResilient suspensionsContext dataContext based

A method for analyzing and managing a vehicle load carried by a vehicle, the vehicle having a fluid suspension system, the method including sampling, at a manifold of the fluid suspension system, a set of fluid pressures corresponding to a set of fluid springs of the fluid suspension system, wherein the set of fluid springs supports the vehicle load; determining an existing stiffness distribution, the existing stiffness distribution including a stiffness value associated with each of the set of fluid springs; determining a contextual dataset during vehicle operation; determining a desired stiffness distribution based on the contextual dataset; automatically controlling the set of fluid springs at the plurality of actuation points based on the desired stiffness distribution, wherein controlling the set of fluid springs includes setting the stiffness value of the fluid spring associated with each of the plurality of actuation points.

Owner:AKTV8

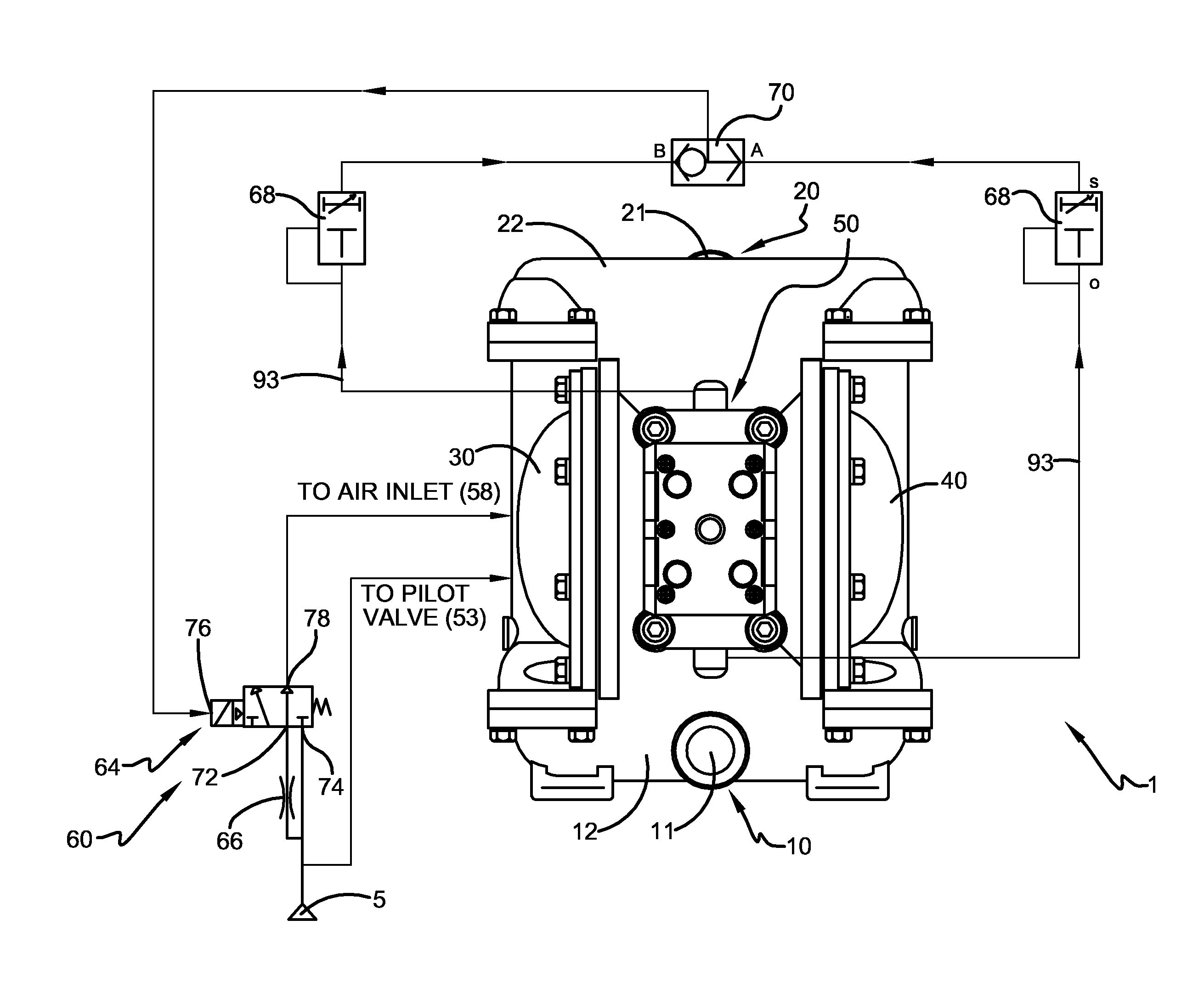

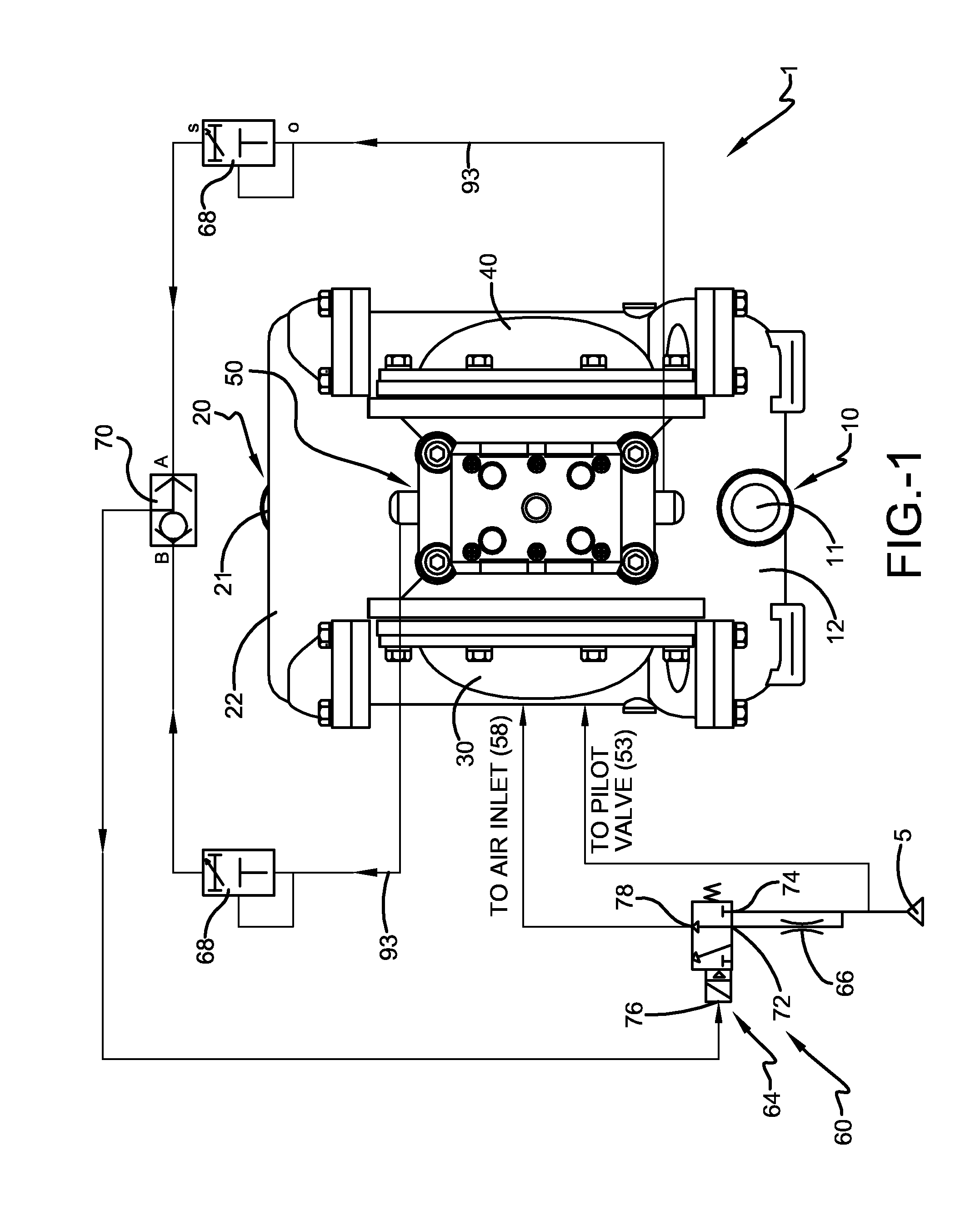

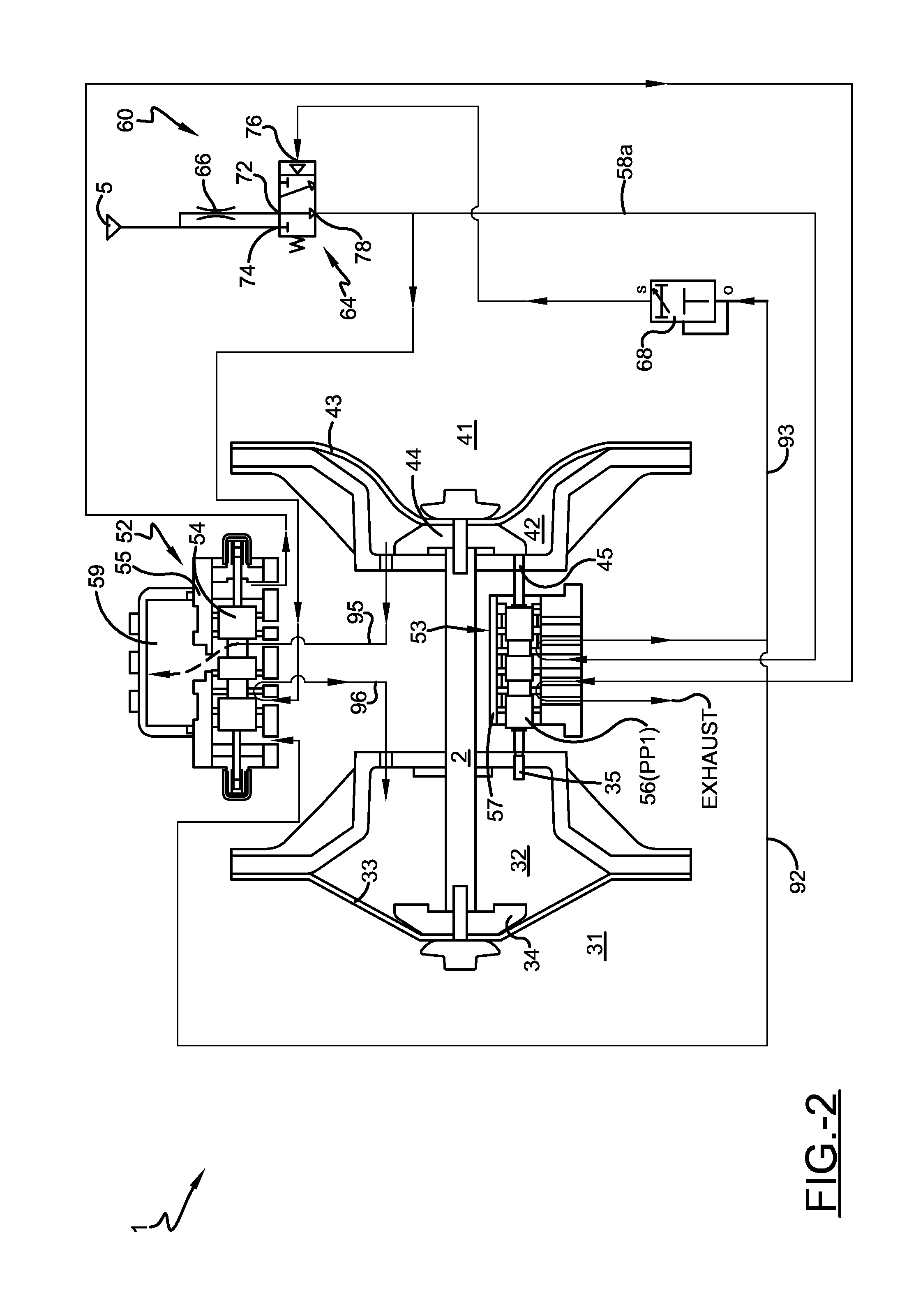

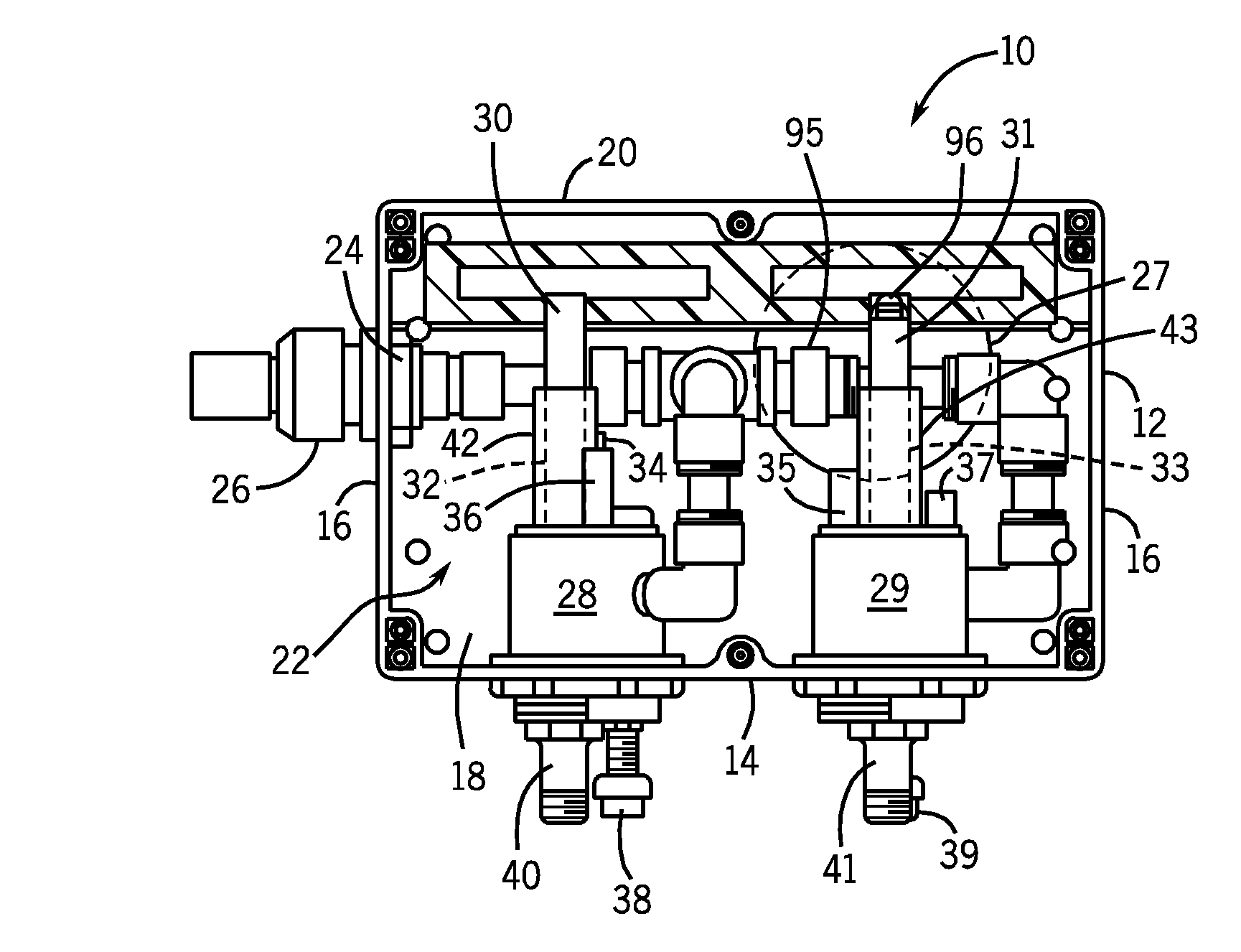

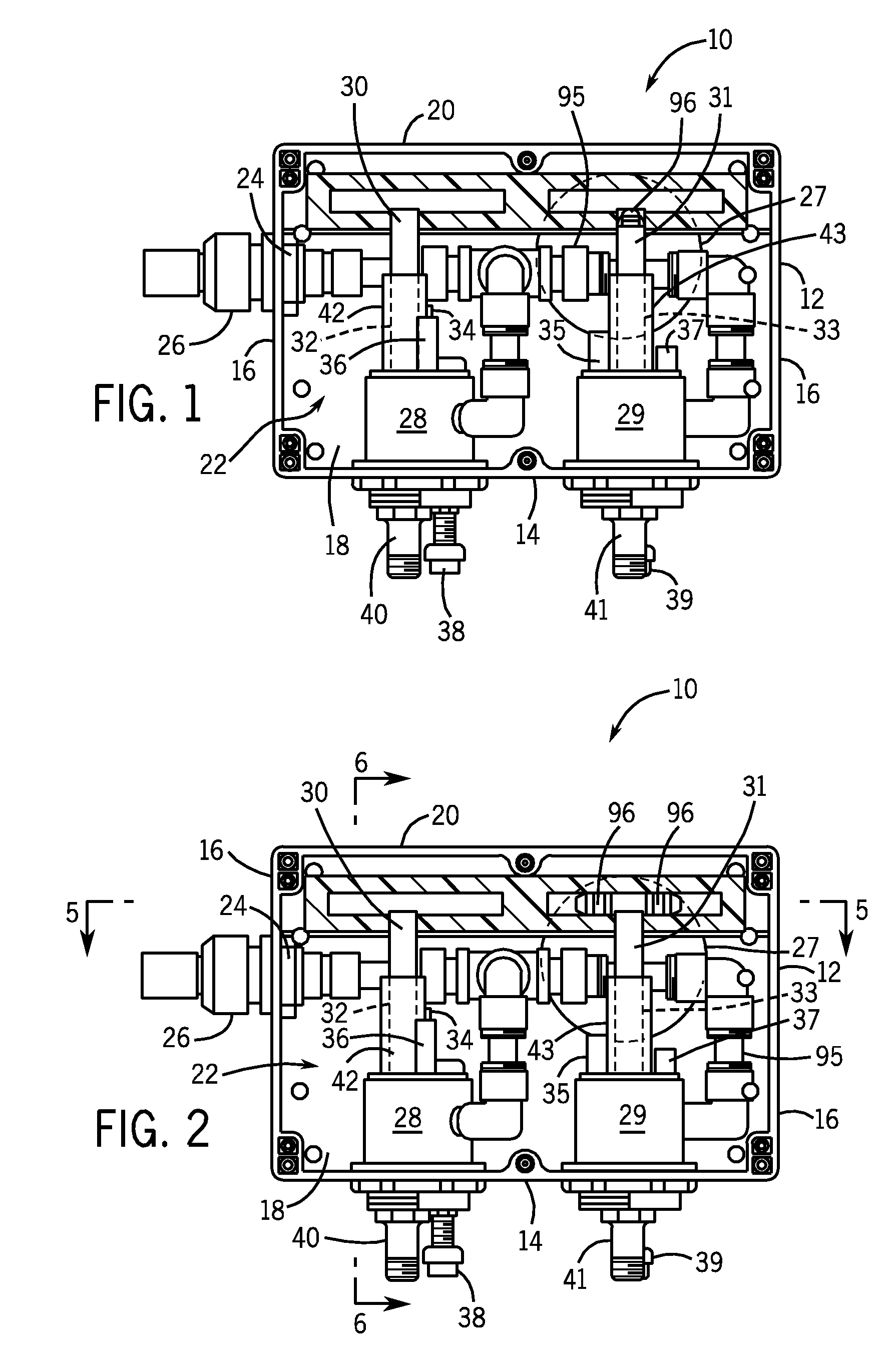

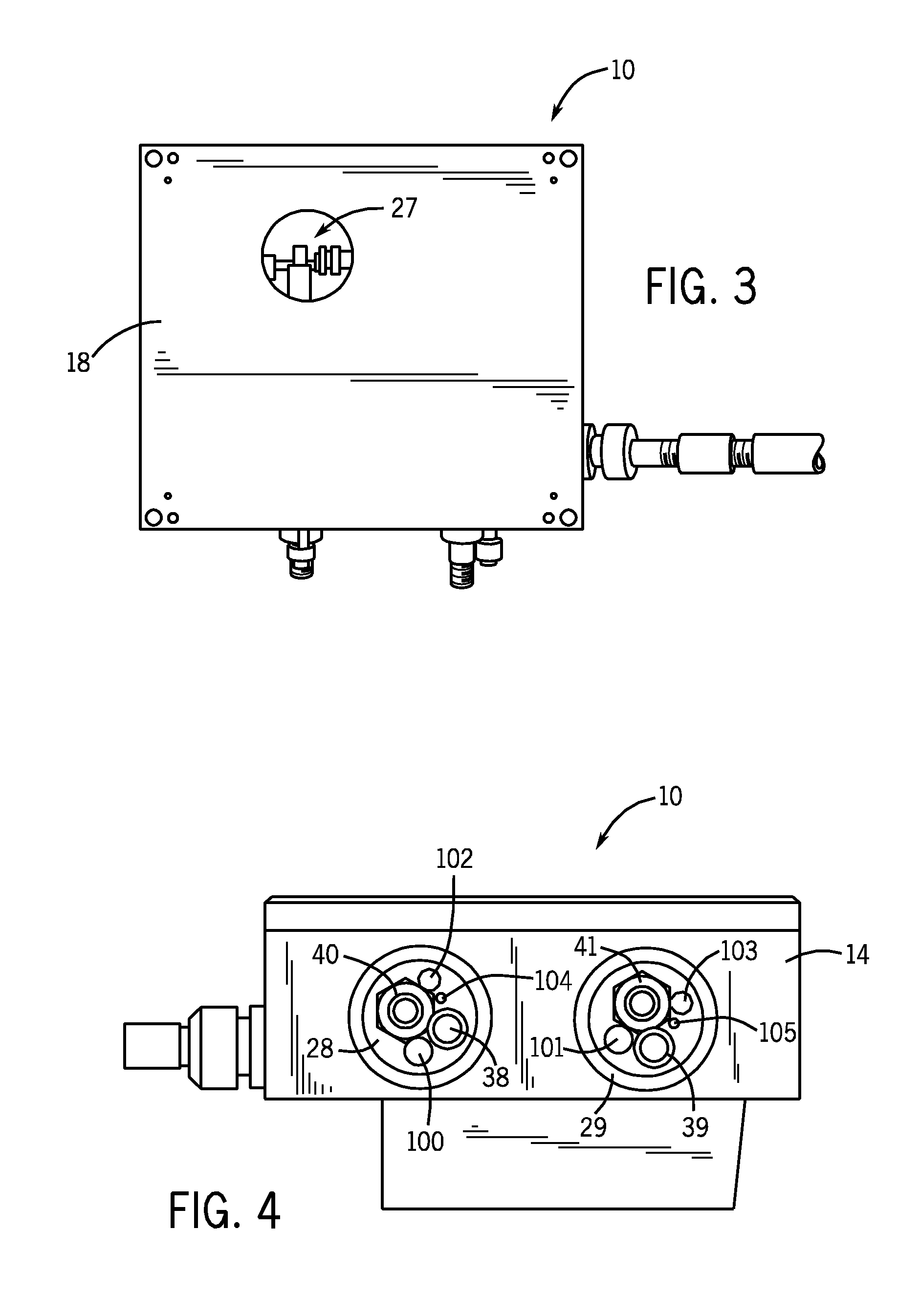

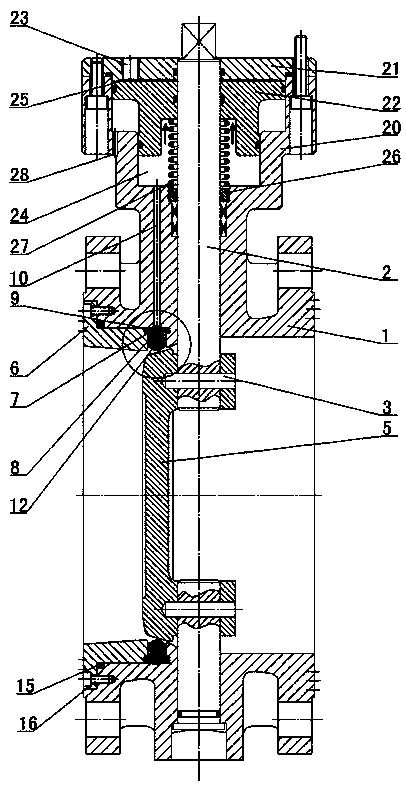

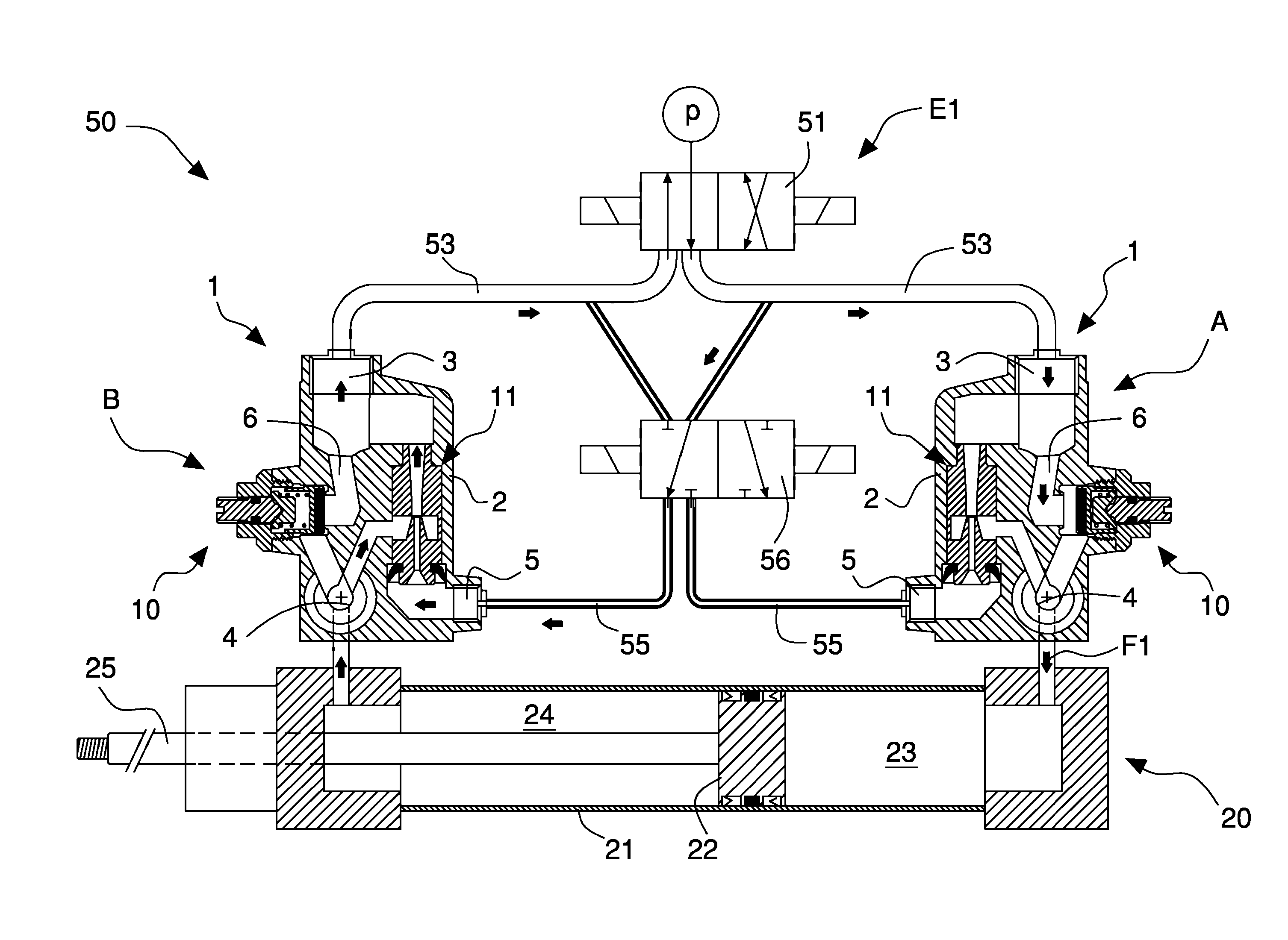

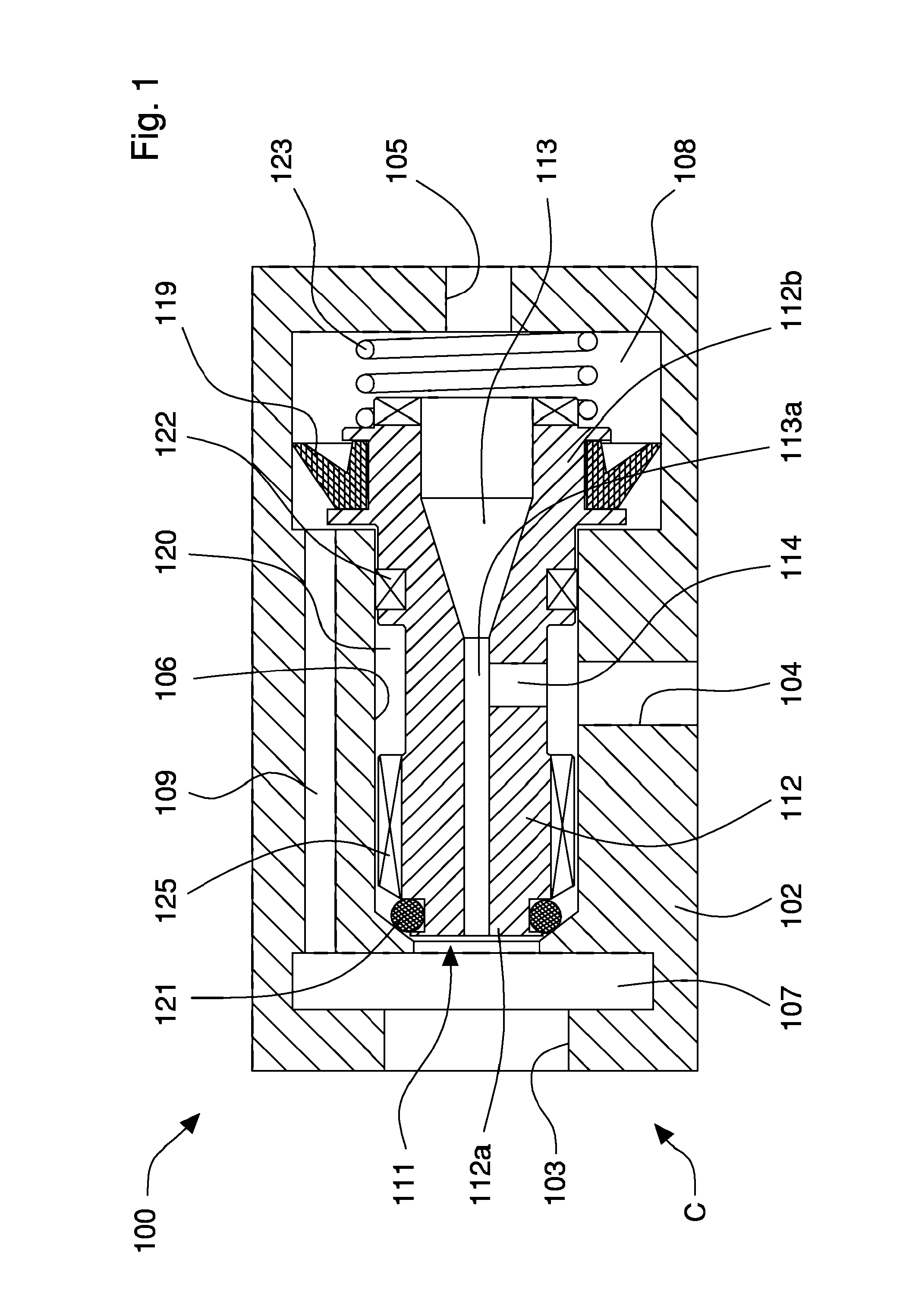

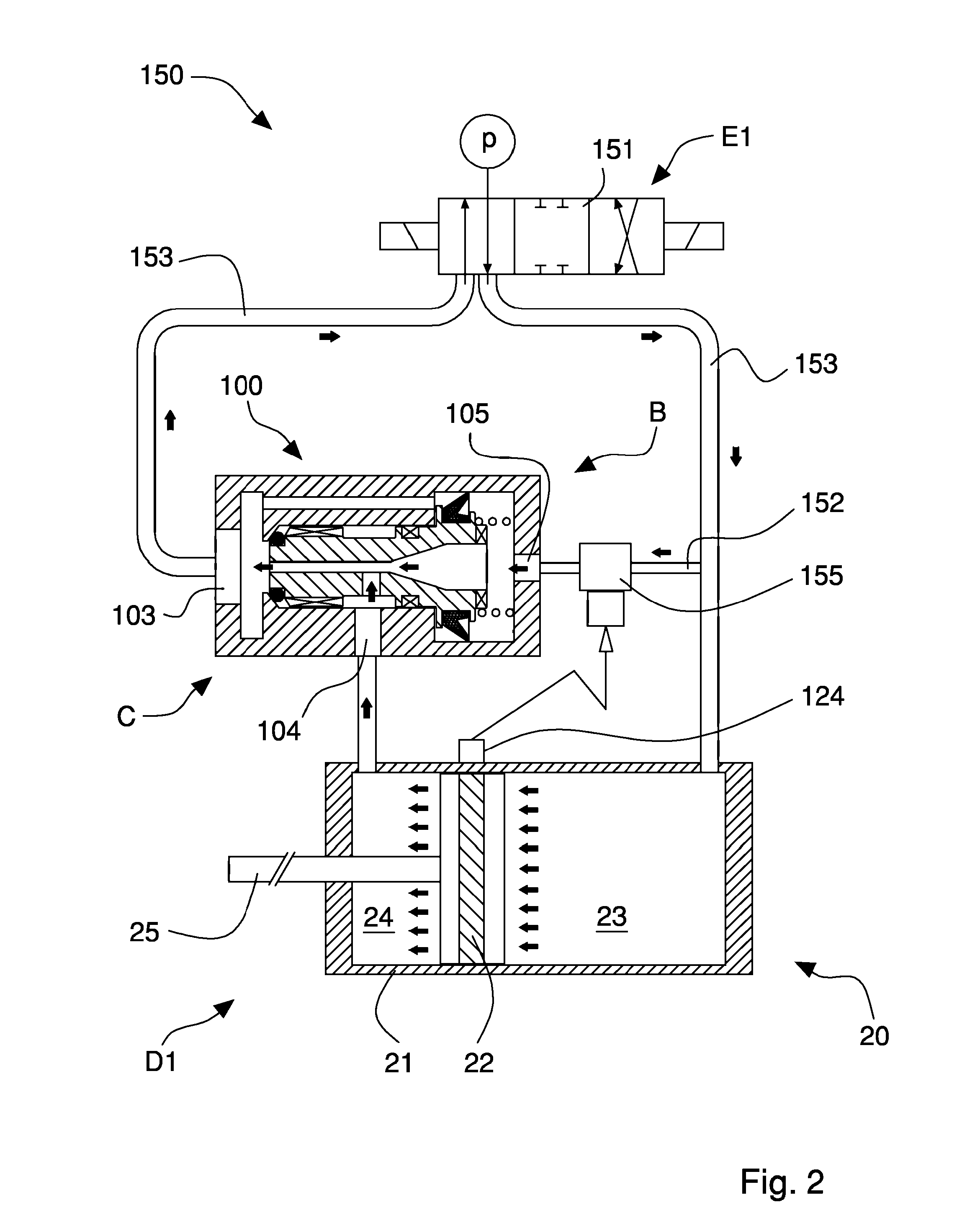

Air logic controller

ActiveUS8382445B2Reduce air consumptionOperating means/releasing devices for valvesFlexible member pumpsDiaphragm pumpTime delays

An air logic controller for increasing the efficiency of an air operated double diaphragm pump. The air logic controller may increase the efficiency of the pump by controlling the supply of compressed fluid to the pump. In one embodiment, the air logic controller may control the supply of compressed fluid to the pump by replacing the continuous, large volume supply of compressed fluid supplied to conventional air operated pumps during a single pumping stroke with a varied supply of compressed fluid. The varied supply of compressed fluid may comprise a supply of compressed fluid that alternates between a large volume supply and a small volume supply of compressed fluid. The air logic controller may vary the supply of compressed fluid to the pump based at least partially on the position of a main air valve spool and the setting on an adjustable pneumatic time delay relay.

Owner:WARREN RUPP INC

Airfoil with cooling passages

InactiveUS20140328669A1Improve gas efficiencyReducing secondary air consumptionEngine manufacturePump componentsLeading edgeSuction stress

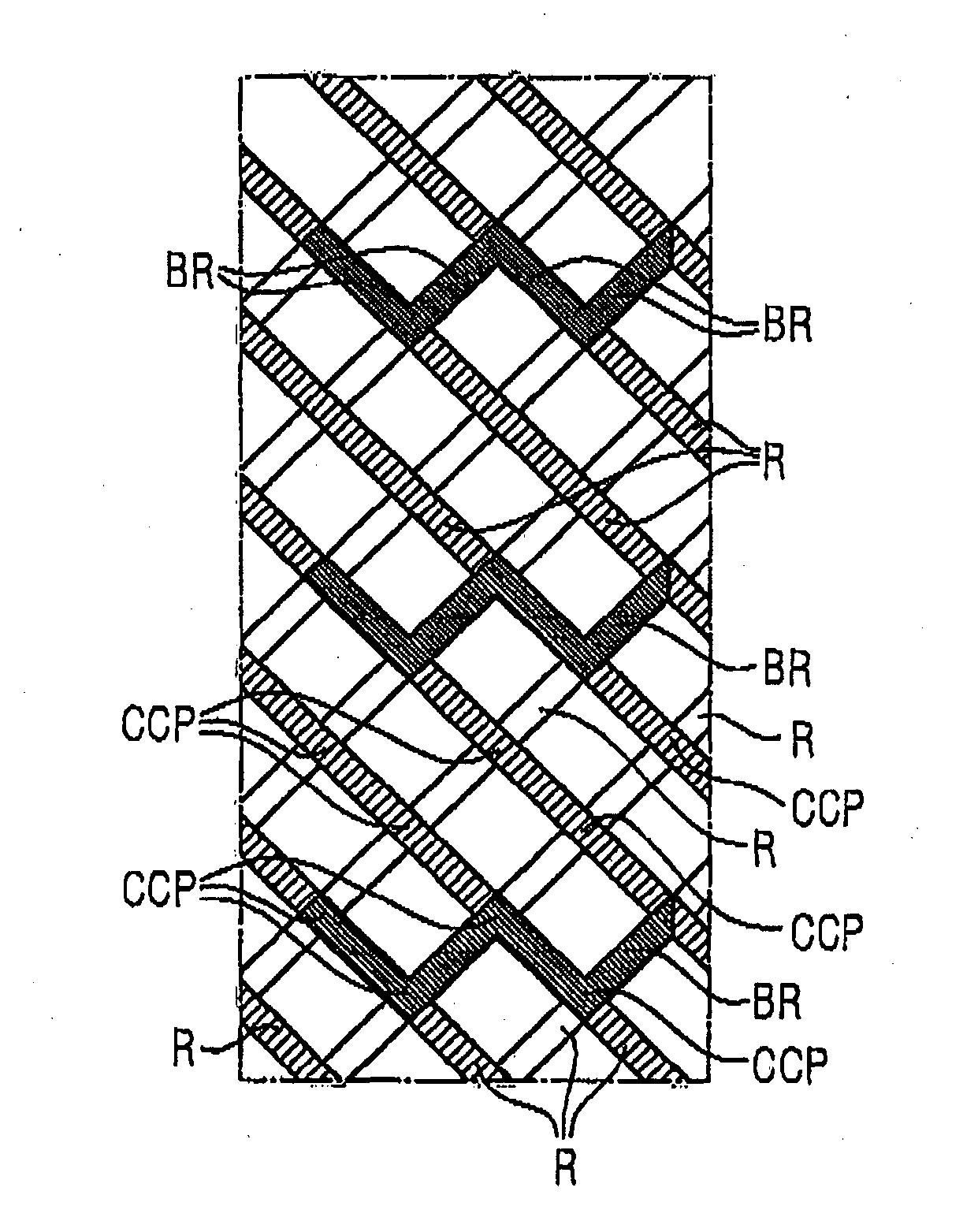

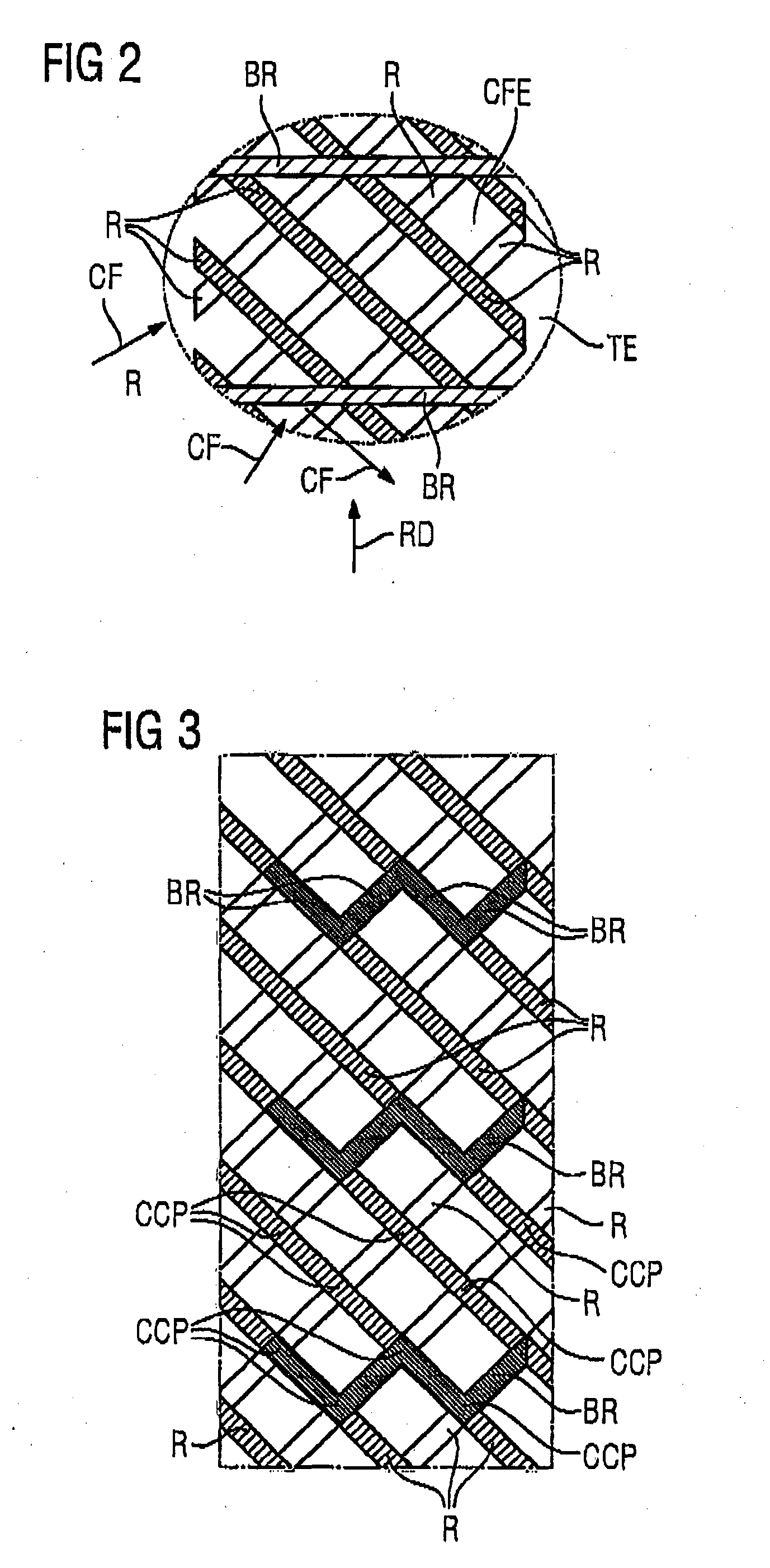

An airfoil having cooling passages inside is provided, wherein each radial cross section of the airfoil has a shape of specific profile, wherein hot gas flows along the airfoil's surface from a leading edge to trailing edge, the airfoil's surface comprises a pressure-side and suction-side defined by the trailing edge and leading edge, wherein the trailing edge has cooling fluid discharge exits, the pressure-side and suction-side are respectively defined by a wall comprising an inner surface and an outer surface, which inner surface has ribs extending in a rib-direction inclined to the radial direction, wherein along a portion of at least 10% of the profile's lengths the inclined ribs contact each other at respective cross-contact-points, forming a 2-dimensional matrix. At least one additional blocking-rib extends from the pressure-side to the suction-side and extends from one cross-contact-point to another to cause additional turbulence of said cooling fluid flow to be discharged.

Owner:SIEMENS AG

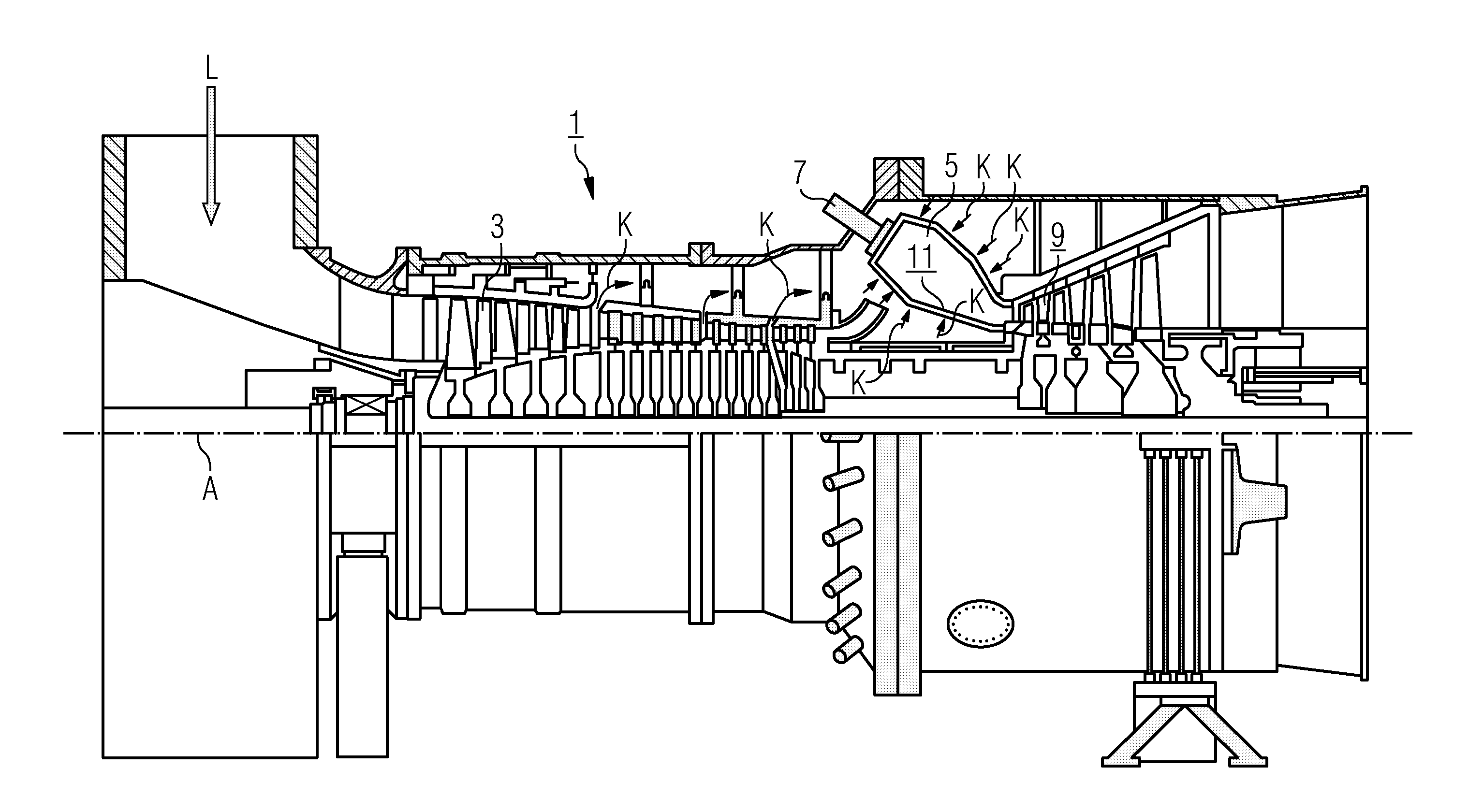

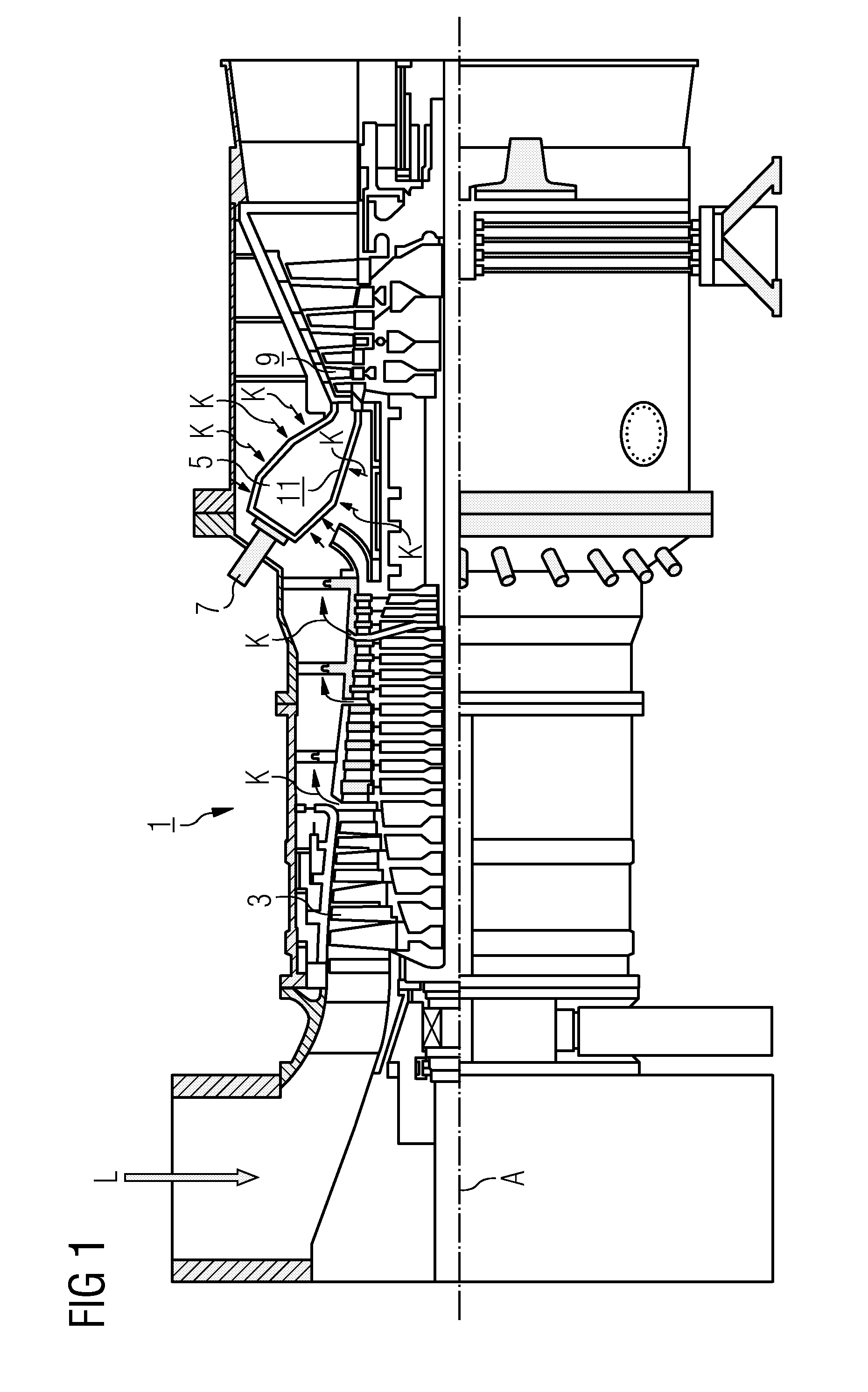

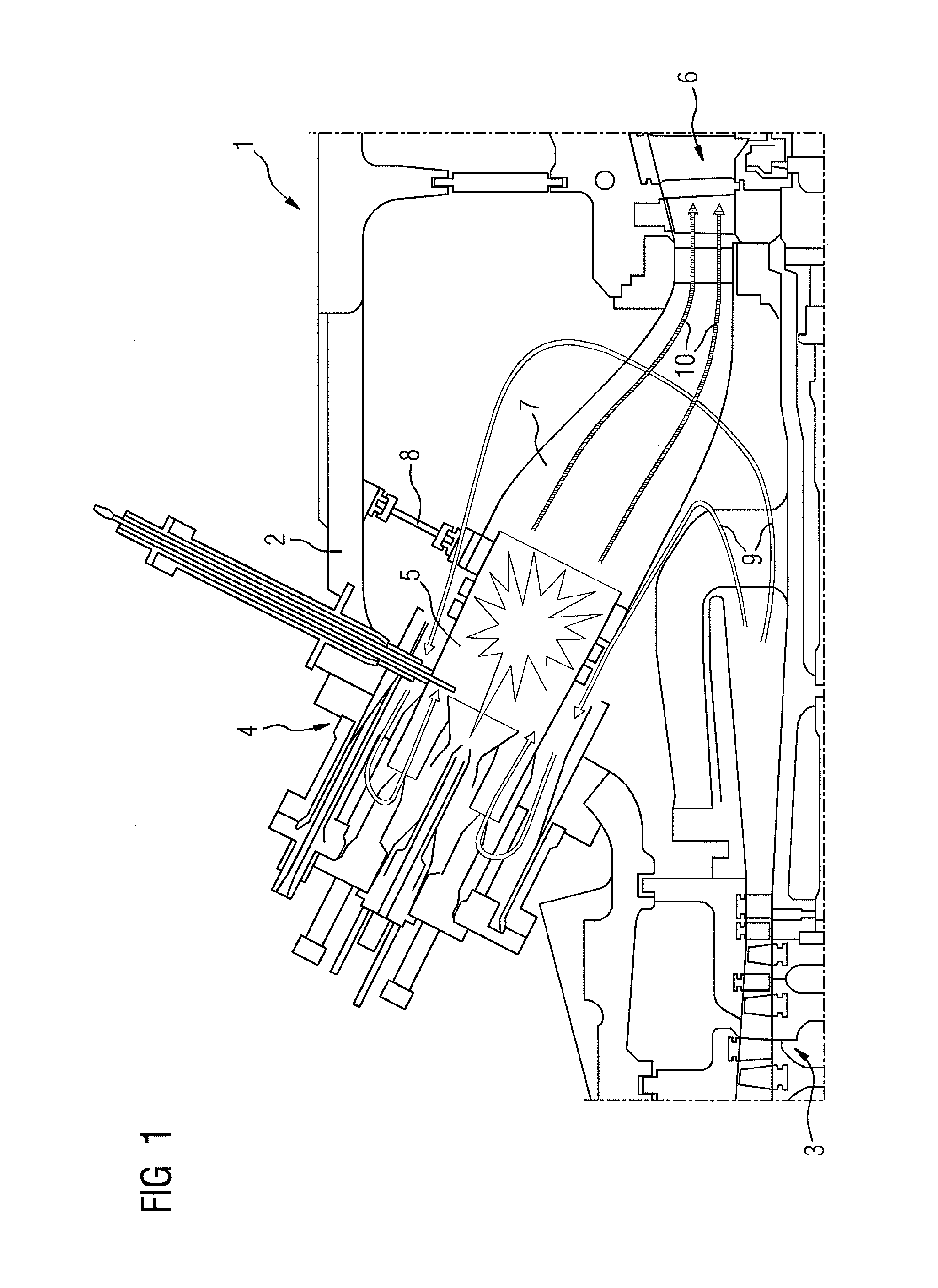

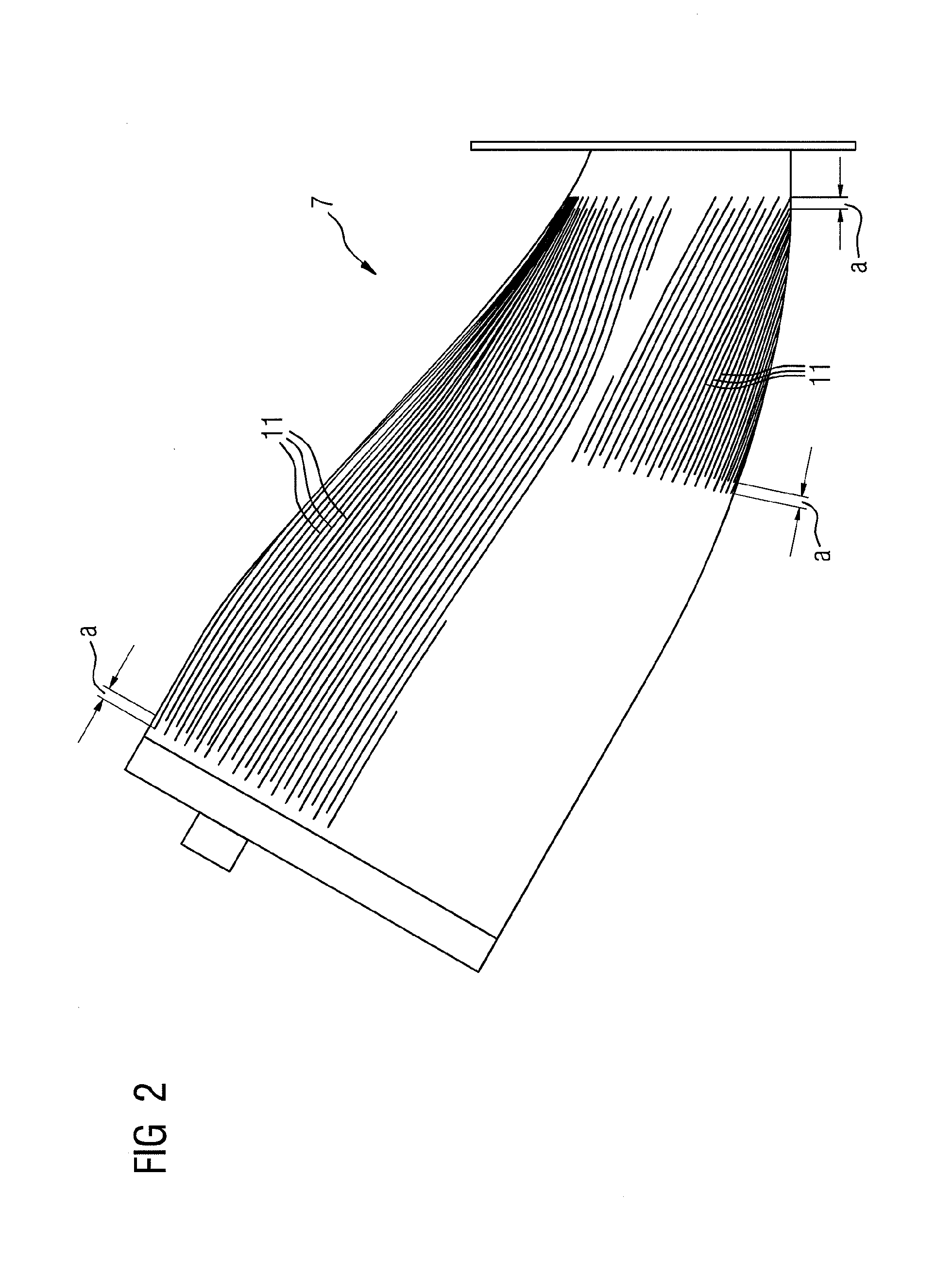

Gas turbine system

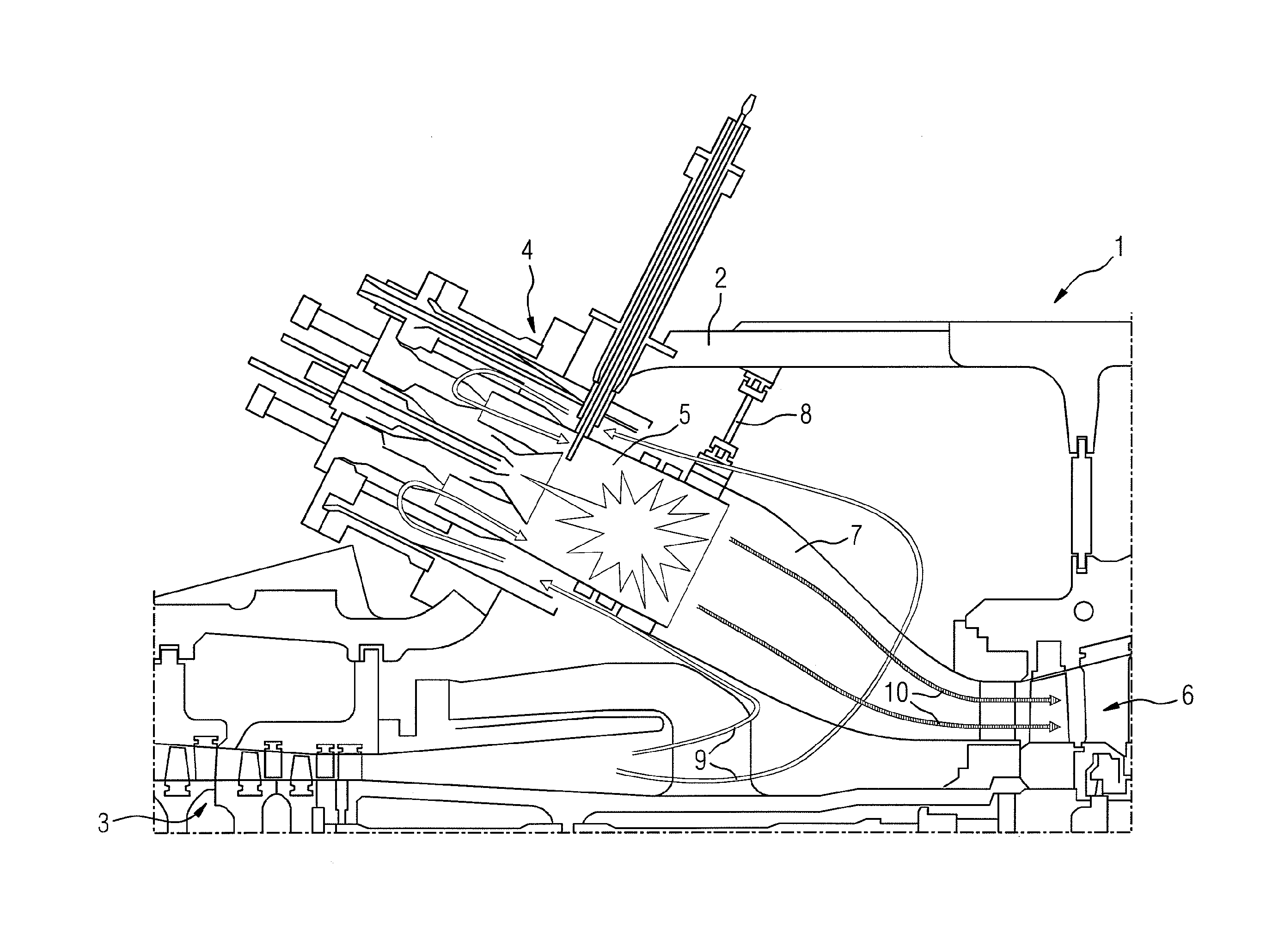

ActiveUS20160047312A1Adjust cooling efficiencyAdjust mechanical robustnessContinuous combustion chamberEngine fuctionsCombustorCombustion chamber

A gas turbine system (1) including a burner arrangement having a tubular combustion chamber (5), a turbine (6) and a transition duct (7) connecting the combustion chamber (5) and the turbine (6), wherein the transition duct (7) is provided with an axially extending cooling air channel (11). The transition duct (7) includes a plurality of axially extending cooling air channels, and wherein each cooling air channel (11) is provided with one single inlet (12) opened to the outside of the transition duct (7) and with one single outlet (12) opened to the inside of the transition duct (7).

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

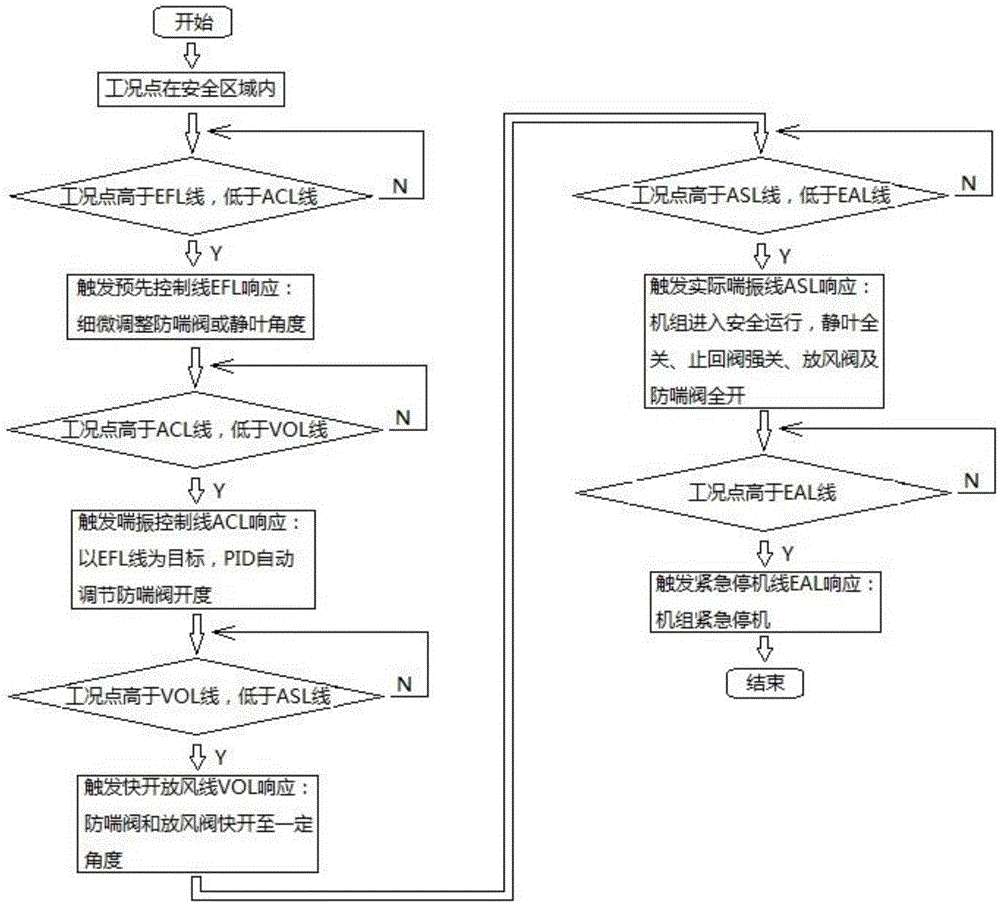

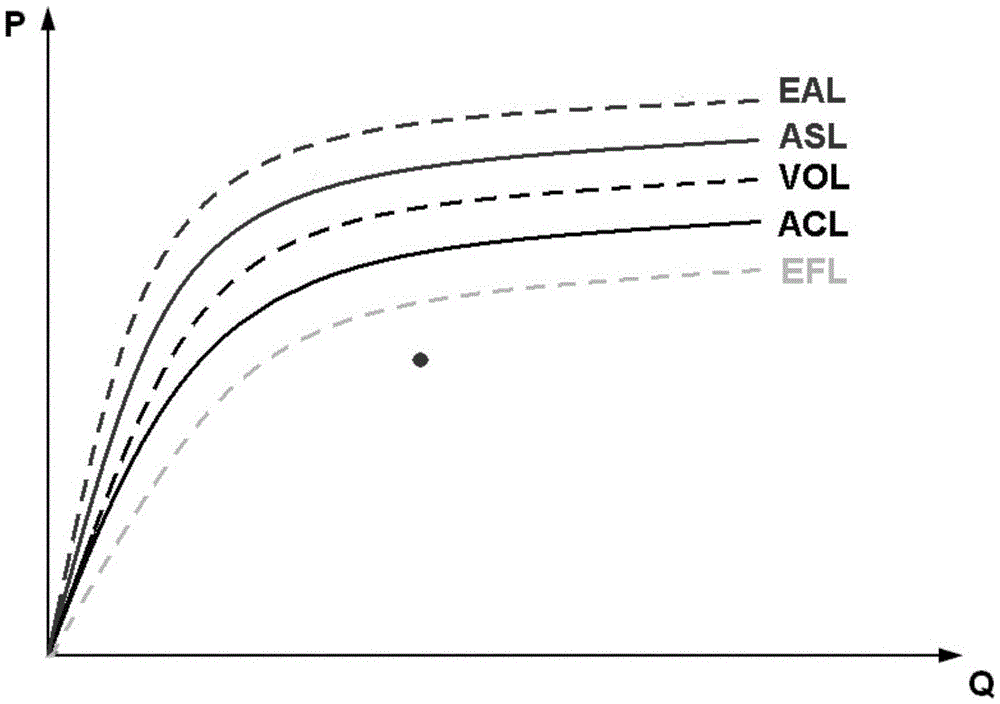

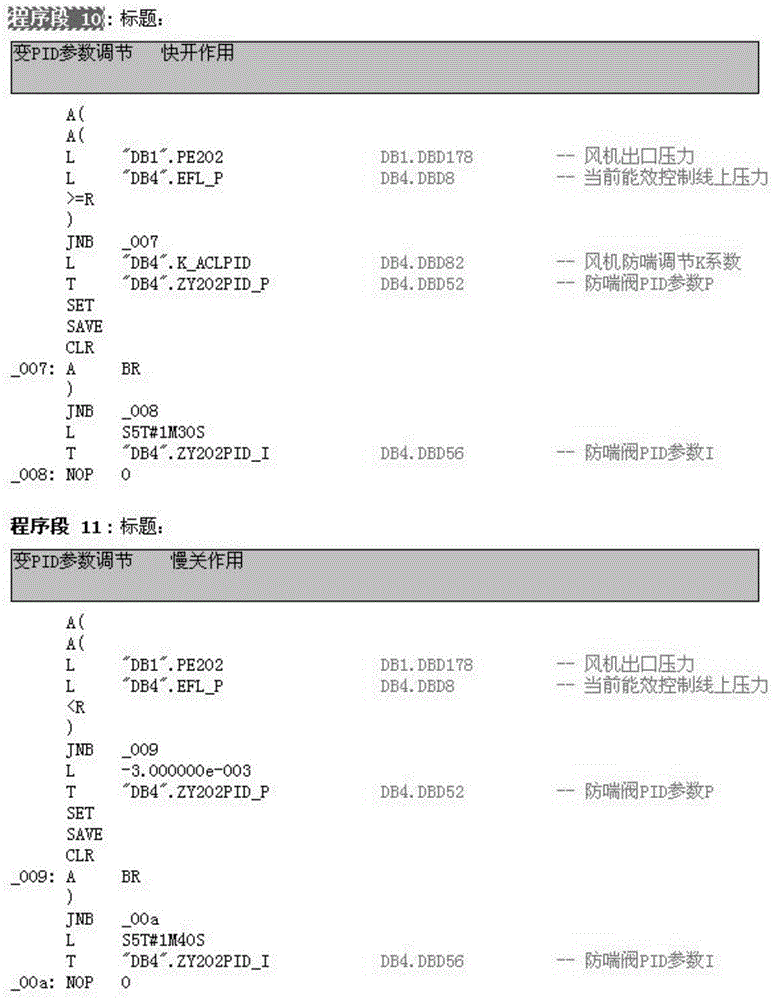

Whole-line anti-surge control method for axial flow compressor

ActiveCN105604973AAccurate guidanceGuaranteed requirements for continuous productionPump controlNon-positive displacement fluid enginesHuman–machine interfaceAutomatic control

The invention relates to an anti-surge control technology for a blast furnace blasting axial flow compressor, in particular to a whole-line anti-surge control method for an axial flow compressor. A pre-control line EFL, a surge control line ACL, a quick-opening blowdown line VOL, an actual surge line ASL and an emergency shutdown line EAL are drawn on a human-computer interface of an automatic control system, wherein the actual surge line ASL is drawn according to the standard throat pressure difference and the standard exhaust pressure formed when the axial flow compressor generates surges, and the throat pressure difference and the exhaust pressure according to which the pre-control line EFL is drawn are 90-92% of the standard throat pressure difference and the standard exhaust pressure respectively. By means of the method, the true performance of the axial flow compressor in all seasons can be reflected, user operation can be accurately guided, and use is safer and more reliable; the anti-surge control strategy is more elaborate and more steady, the influence of wide-range fluctuation of the blast capacity and air pressure of a blast furnace is avoided in the adjusting process, the air supply stability and continuity of the compressor are higher, and the requirement for continuous production of the blast furnace is met.

Owner:CHENGDU CHENGFA SCI & TECH POWER ENG

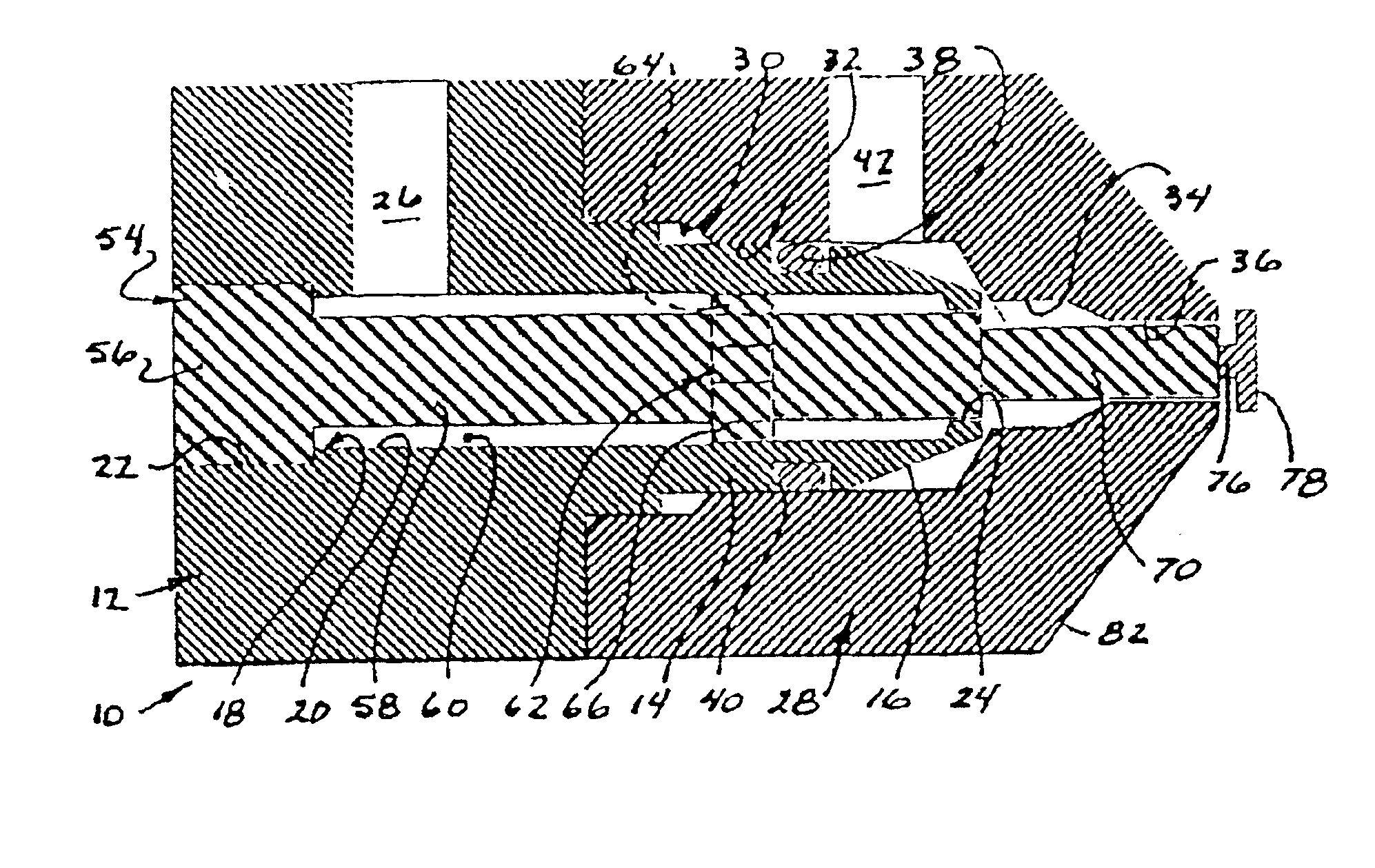

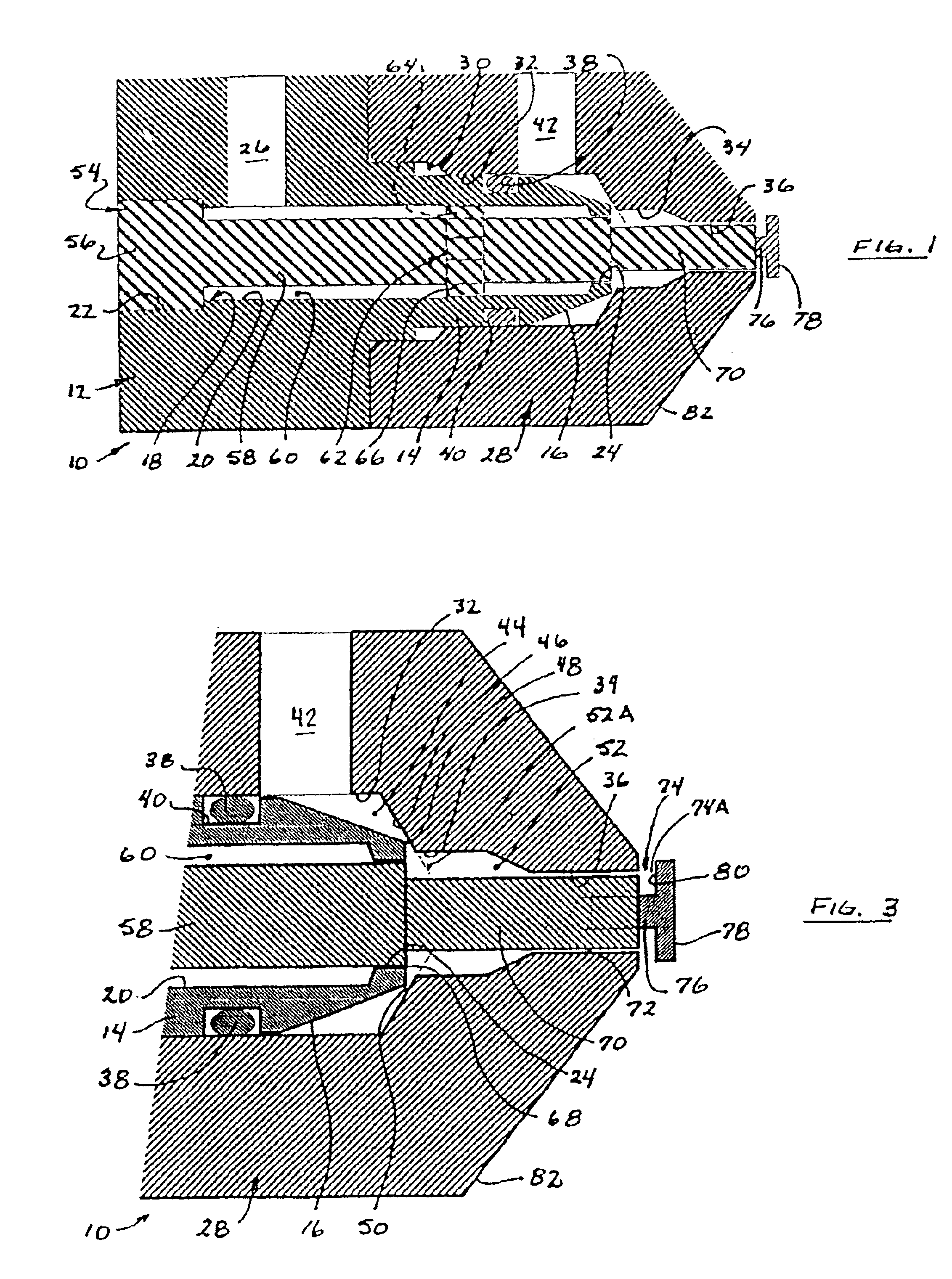

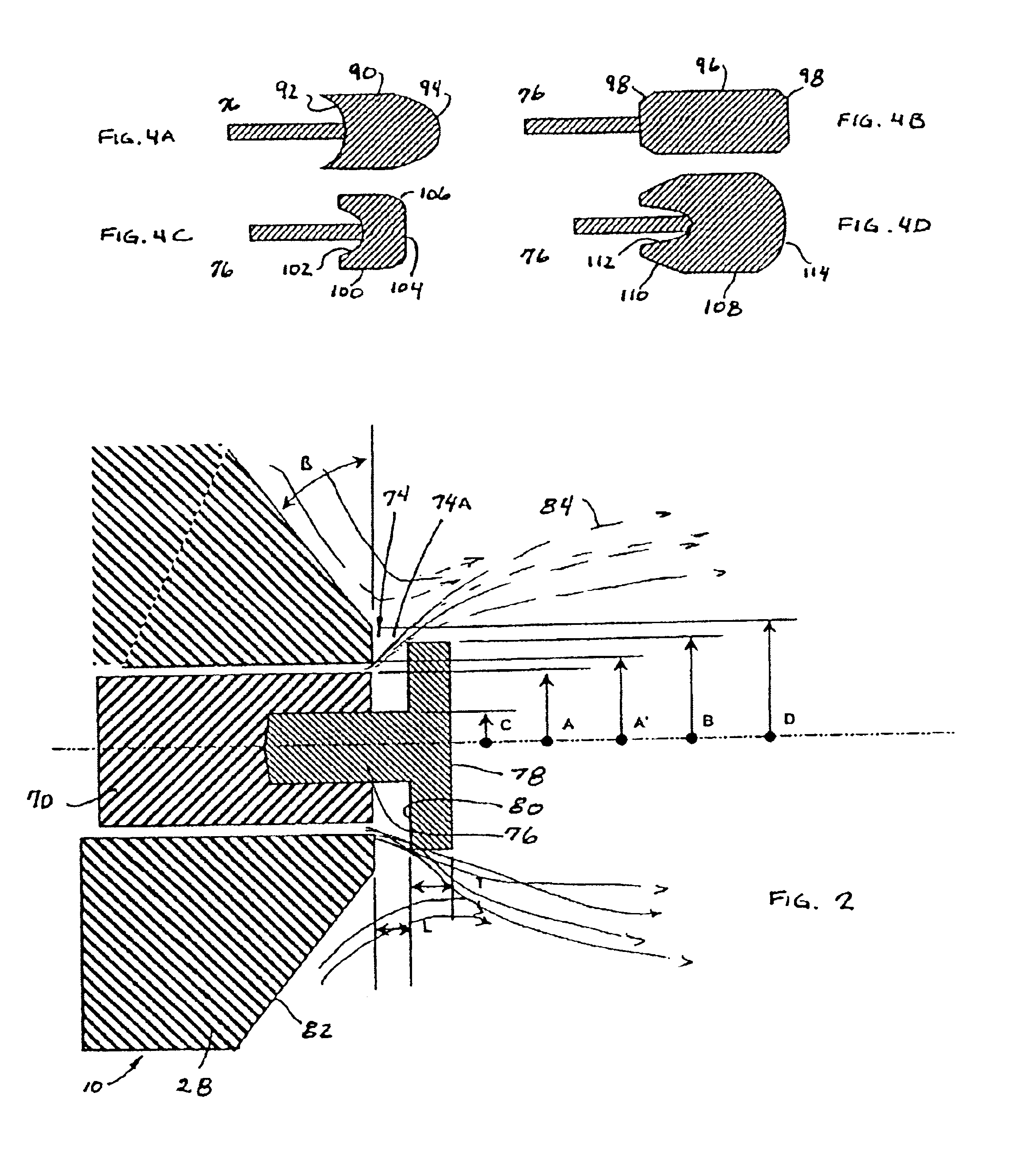

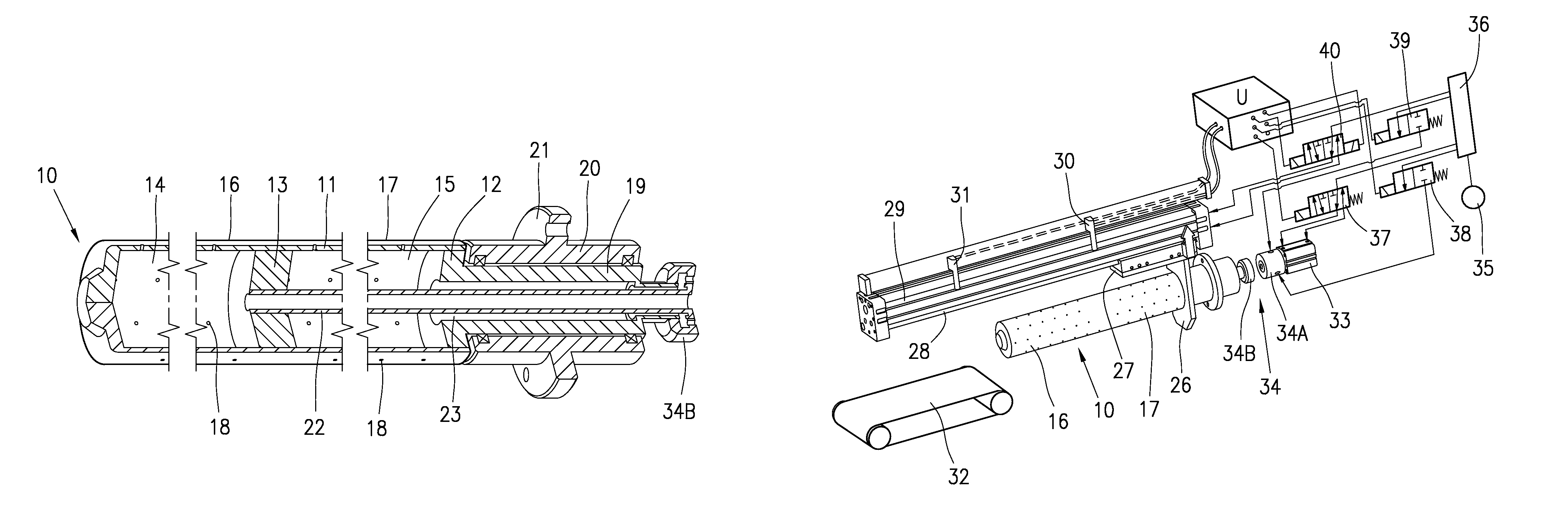

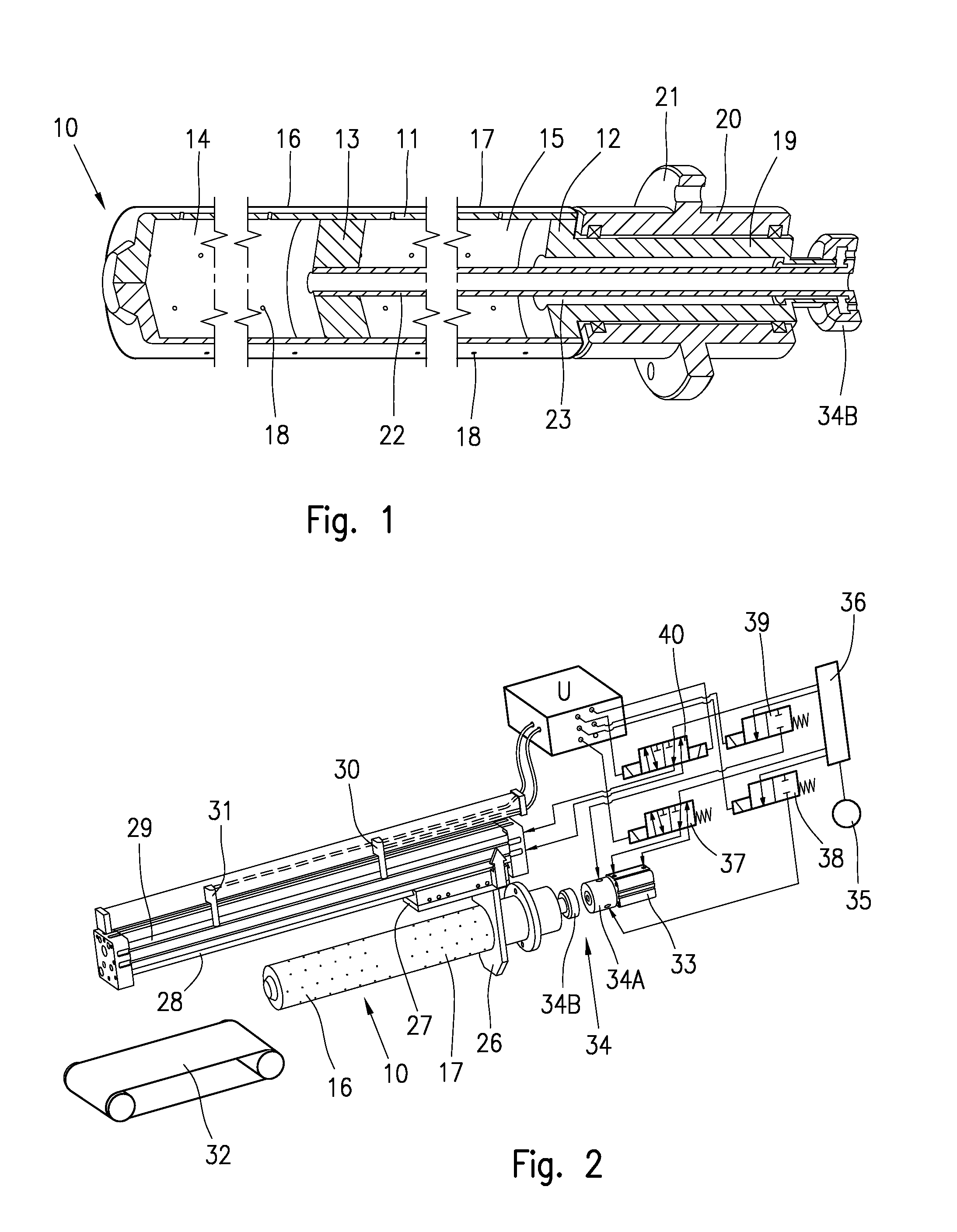

Atomizing nozzle for fine spray and misting applications

InactiveUS6899289B2Low air consumptionPromote atomizationLighting and heating apparatusSpray nozzlesEngineeringNozzle

The invention relates to a nozzle (10) for mixing a gaseous fluid such as air and a liquid such as water and for ejecting an atomized mist of liquid droplets. The nozzle includes a nozzle body defining first (60), second (44) and third (52) annular passages along the length thereof. Pressurized fluid is introduced into the first annular passage (60) and a first restricted annular orifice (68) leads from the first annular passage (60) to the third annular passage (52). Liquid is introduced into the second annular passage (44) and a second restricted annular orifice (48) leads from the second annular passage (44) to the third annular passage (52). Liquid and gaseous fluid are aggressively mixed in the third annular passage (52). A third restricted annular orifice (72) leads from the third annular passage (52) to atmosphere such that mixed liquid and gaseous fluid are forcibly ejected from the nozzle through the third restricted annular orifice (72), the liquid being atomized in small controlled droplets in the ejected gaseous fluid.

Owner:NAT RES COUNCIL OF CANADA

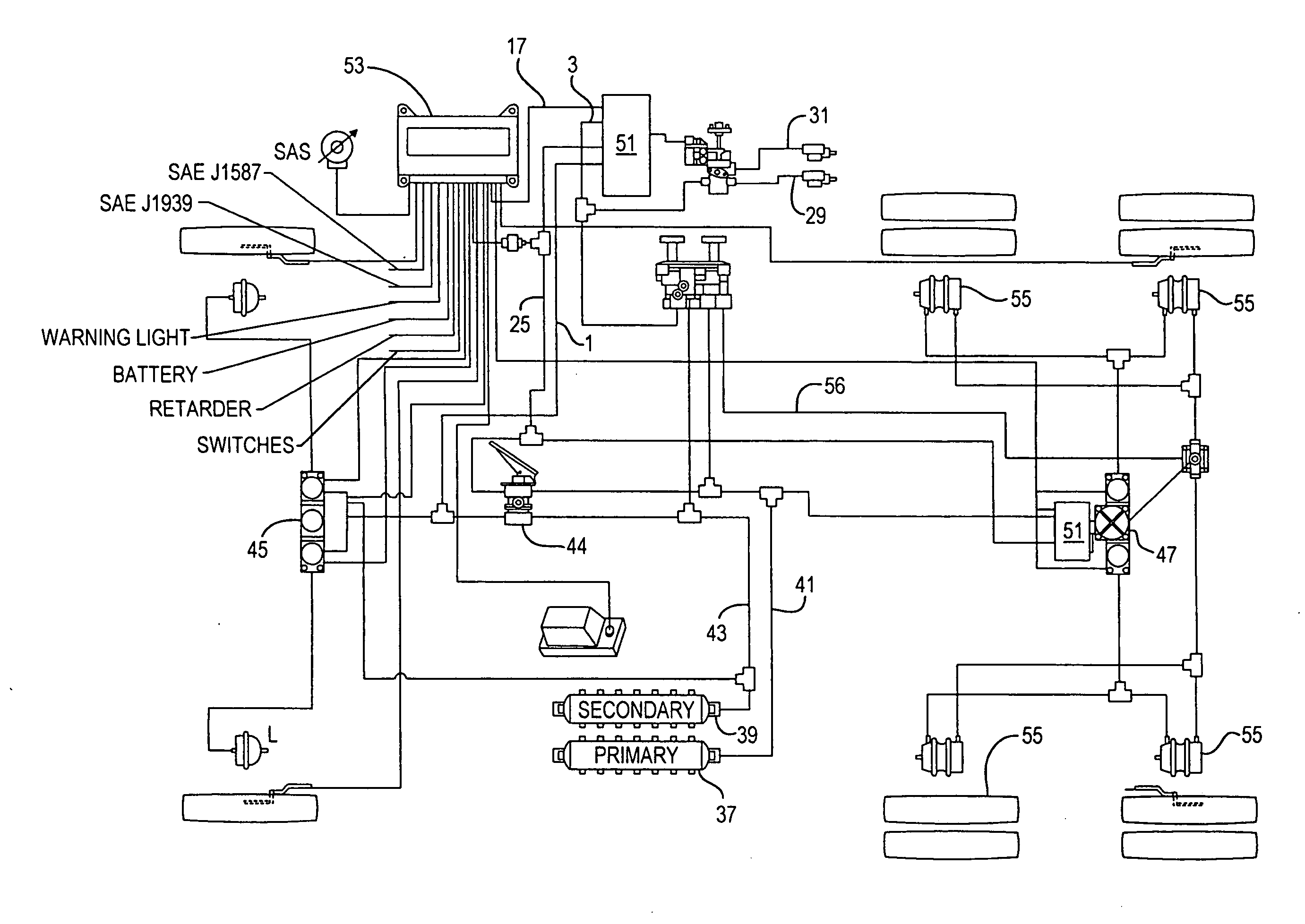

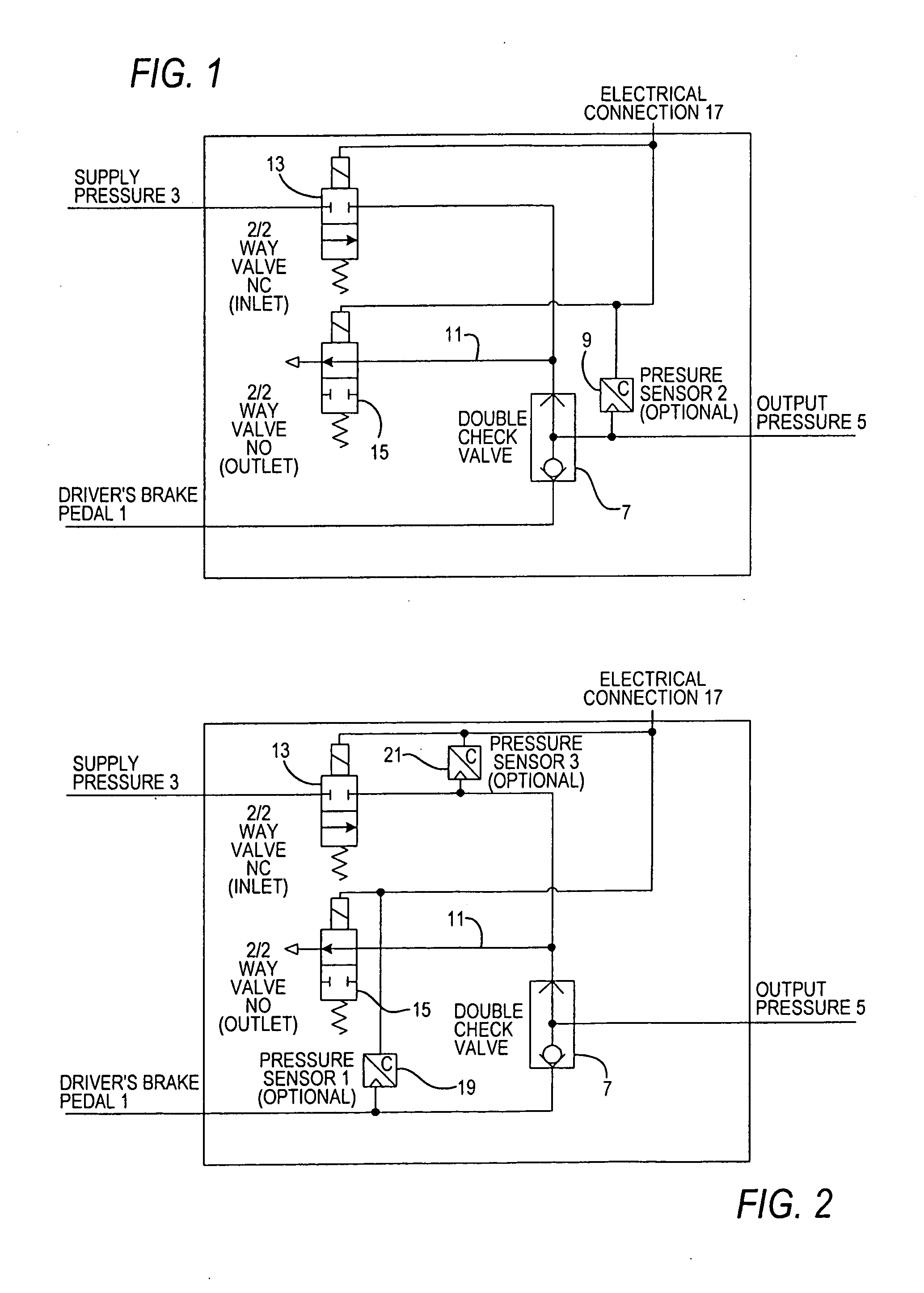

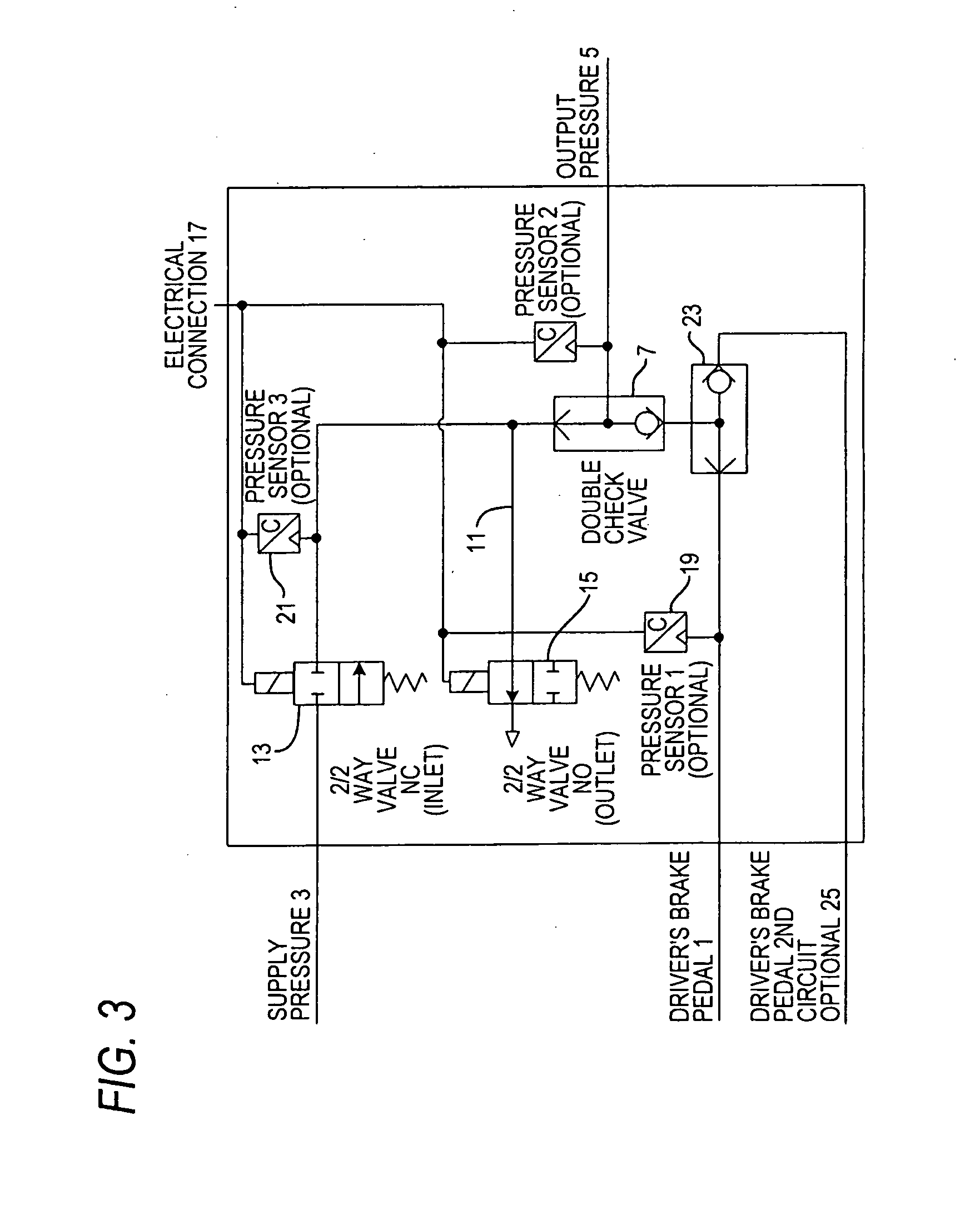

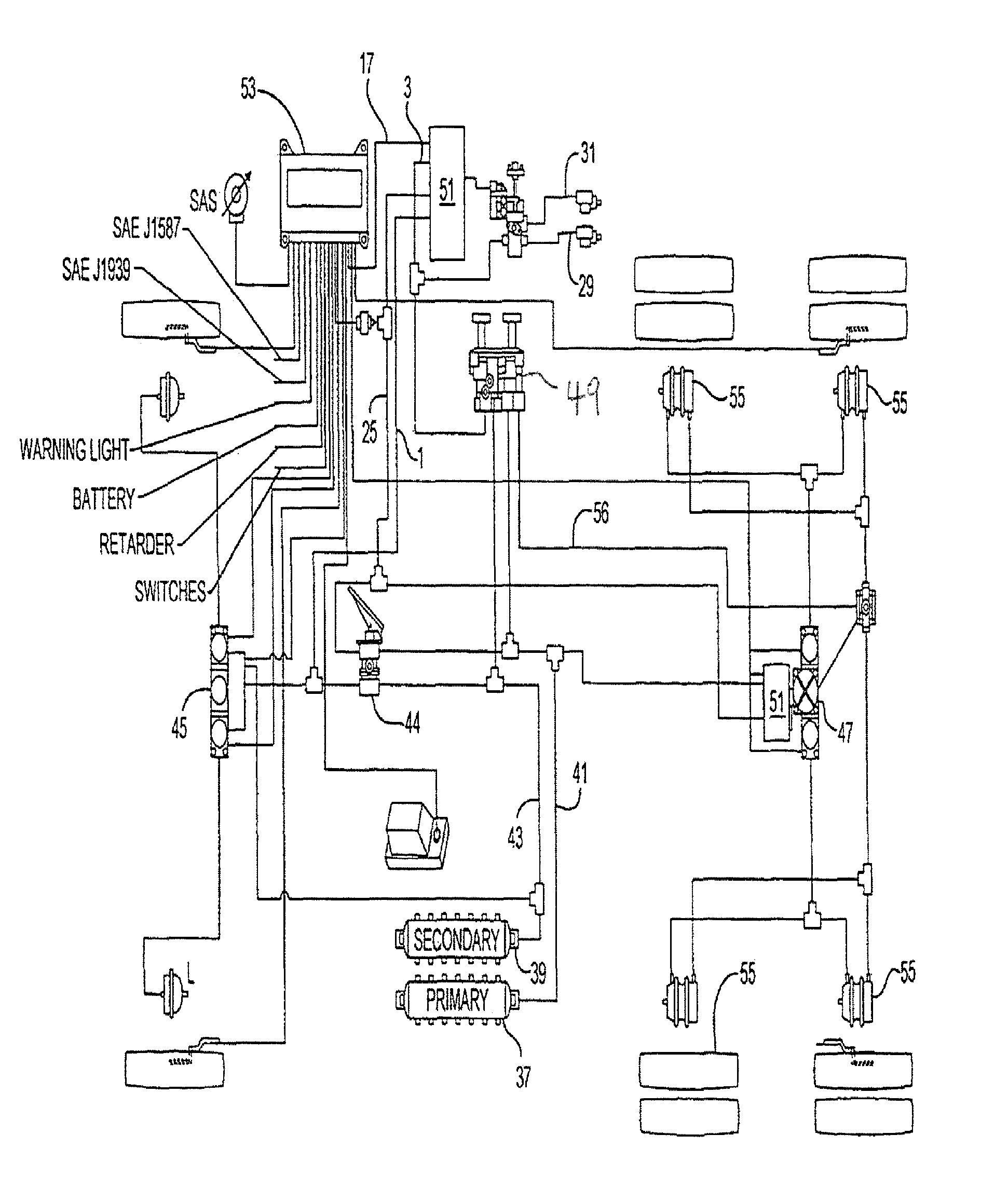

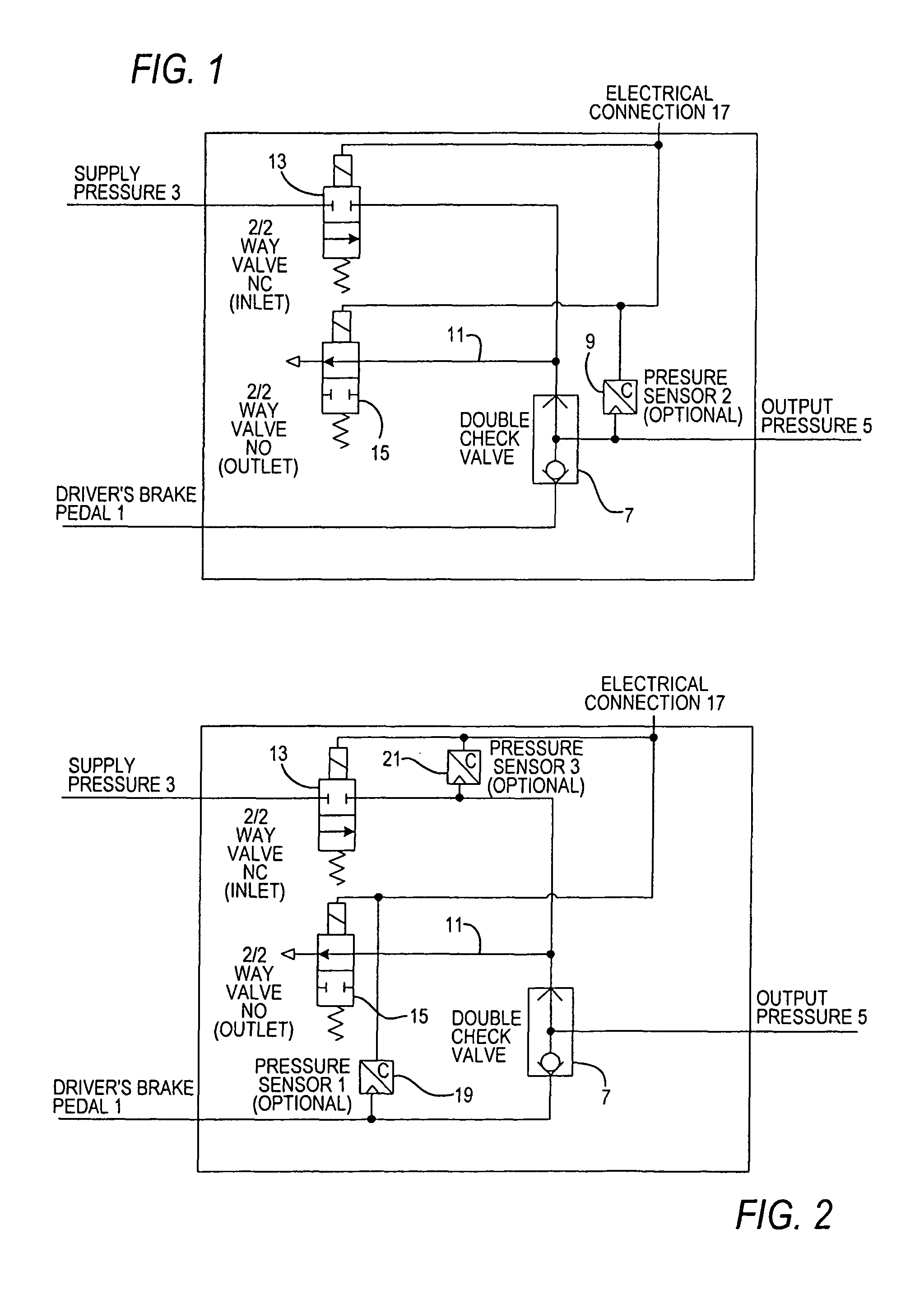

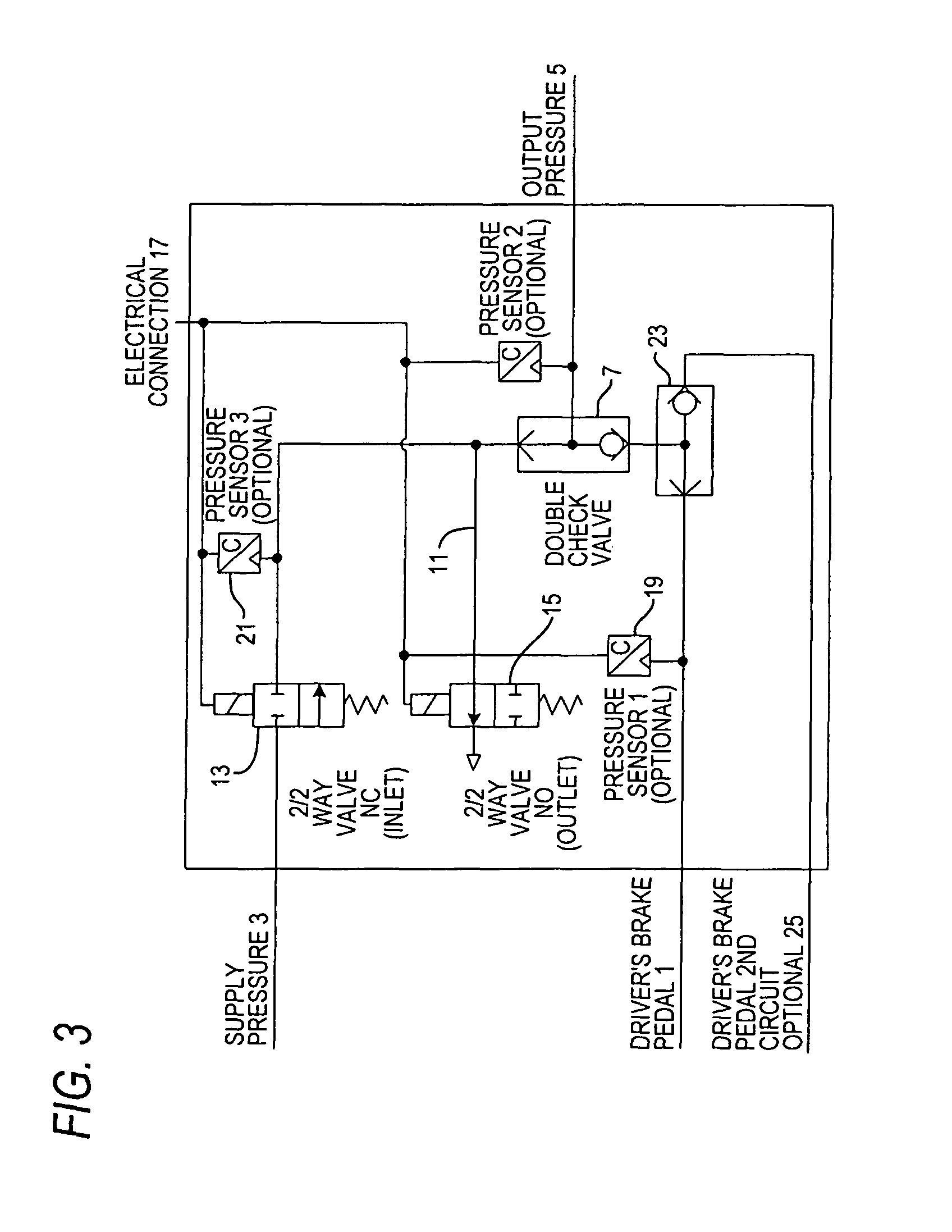

Vehicle braking system

ActiveUS20110193407A1Improve controlEnhance controlAutomatic initiationsFluid braking transmissionDriver/operatorTruck

An improved braking system and brake control method for a vehicle, in particular a truck, utilizes at least one pressure line for carrying a medium from at least one pressurized medium source to a brake device, and a brake pedal for receiving brake commands from a vehicle driver and for operating a brake line, which can be connected to the brake device. A pilot control valve with accompanying measuring capability quantitatively determines the brake pressure demanded by the vehicle driver.

Owner:ZF CV SYST EURO BV

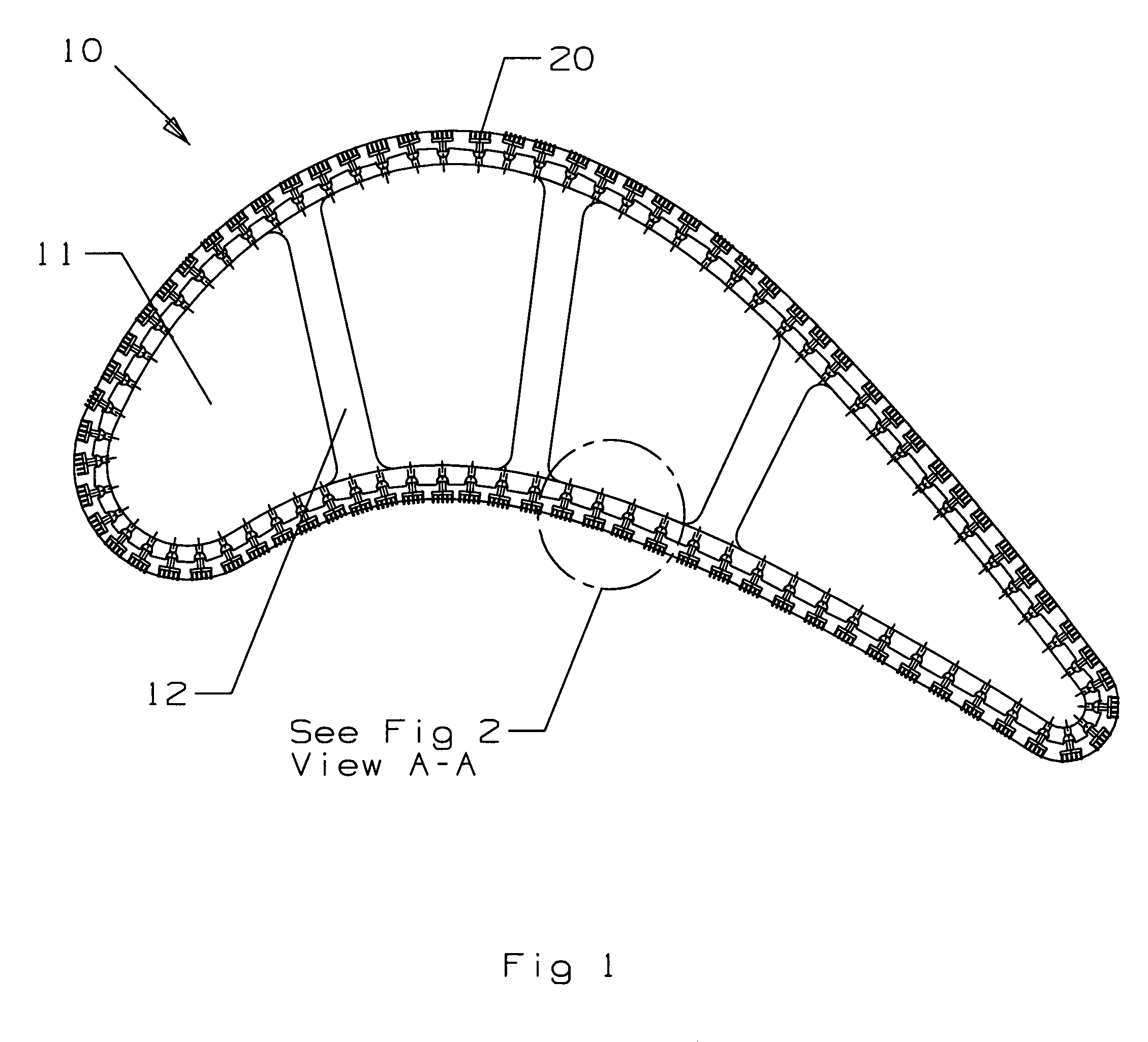

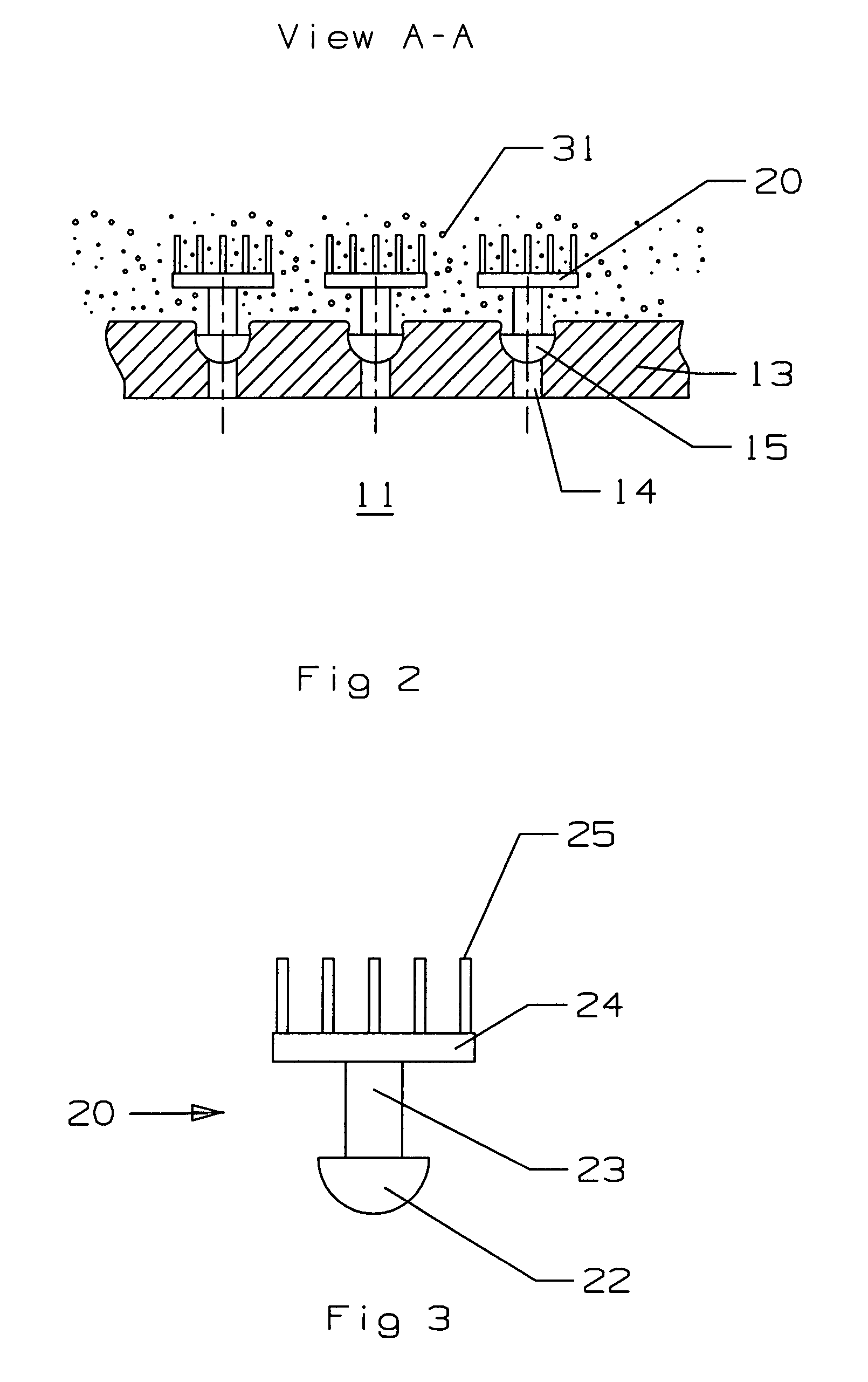

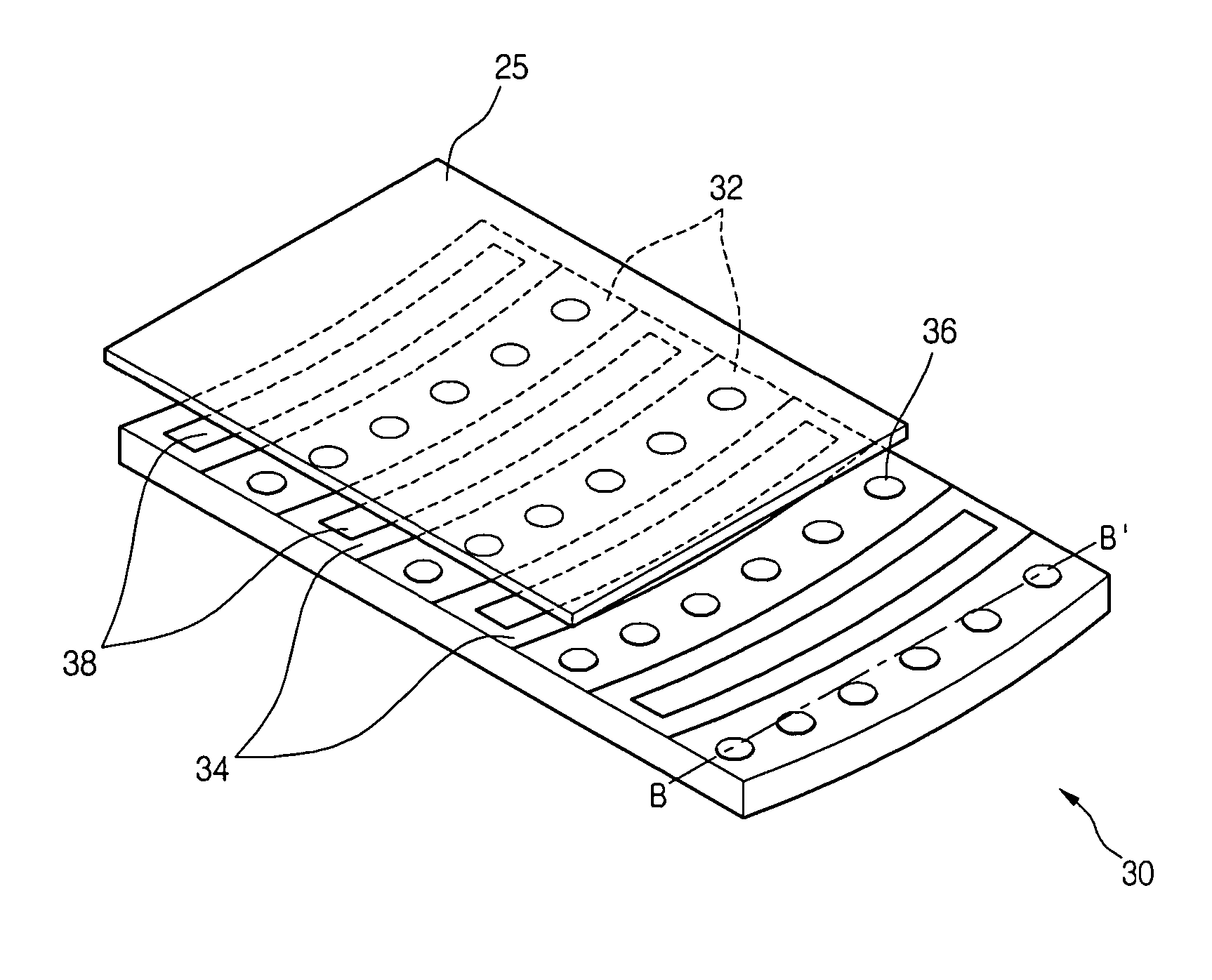

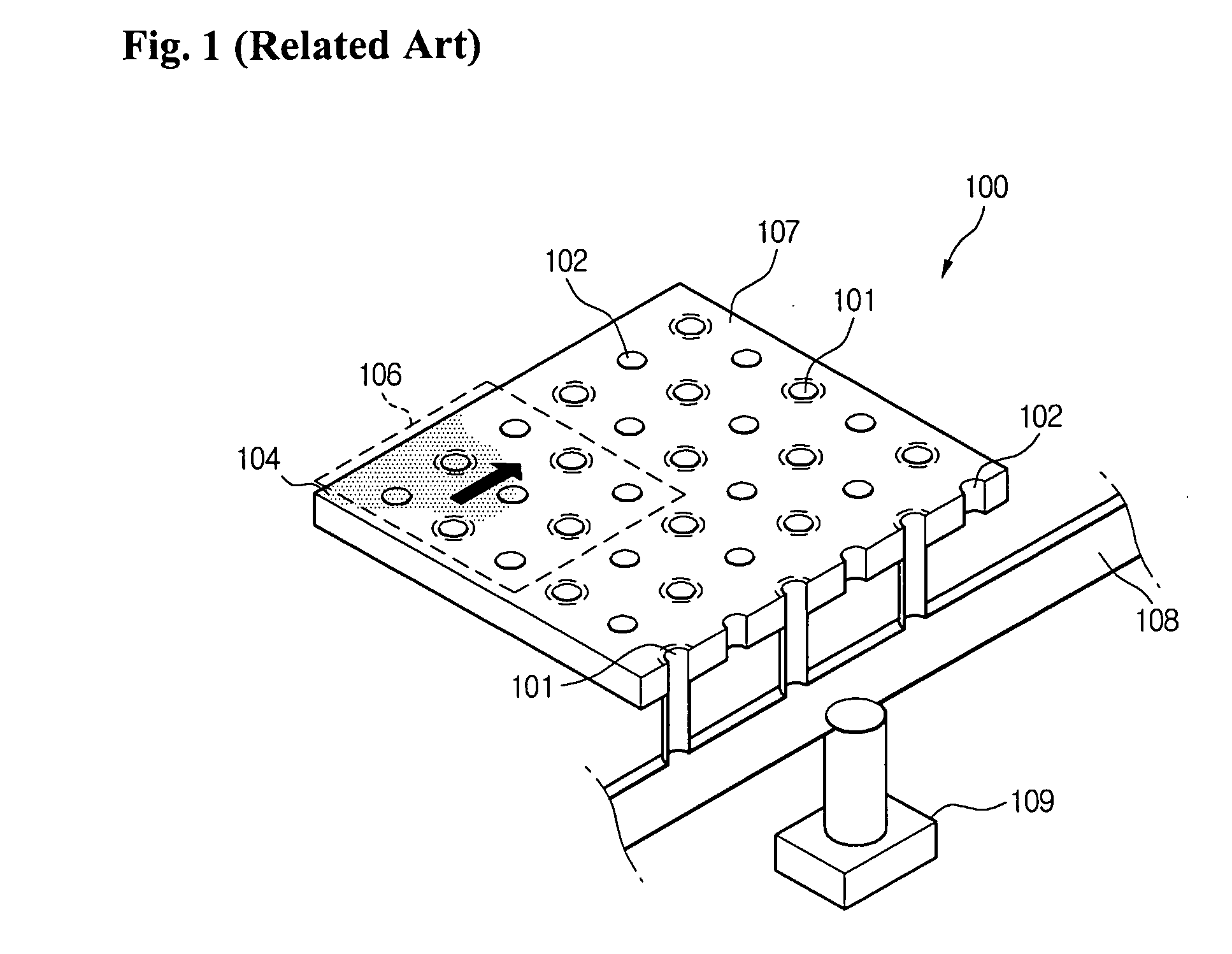

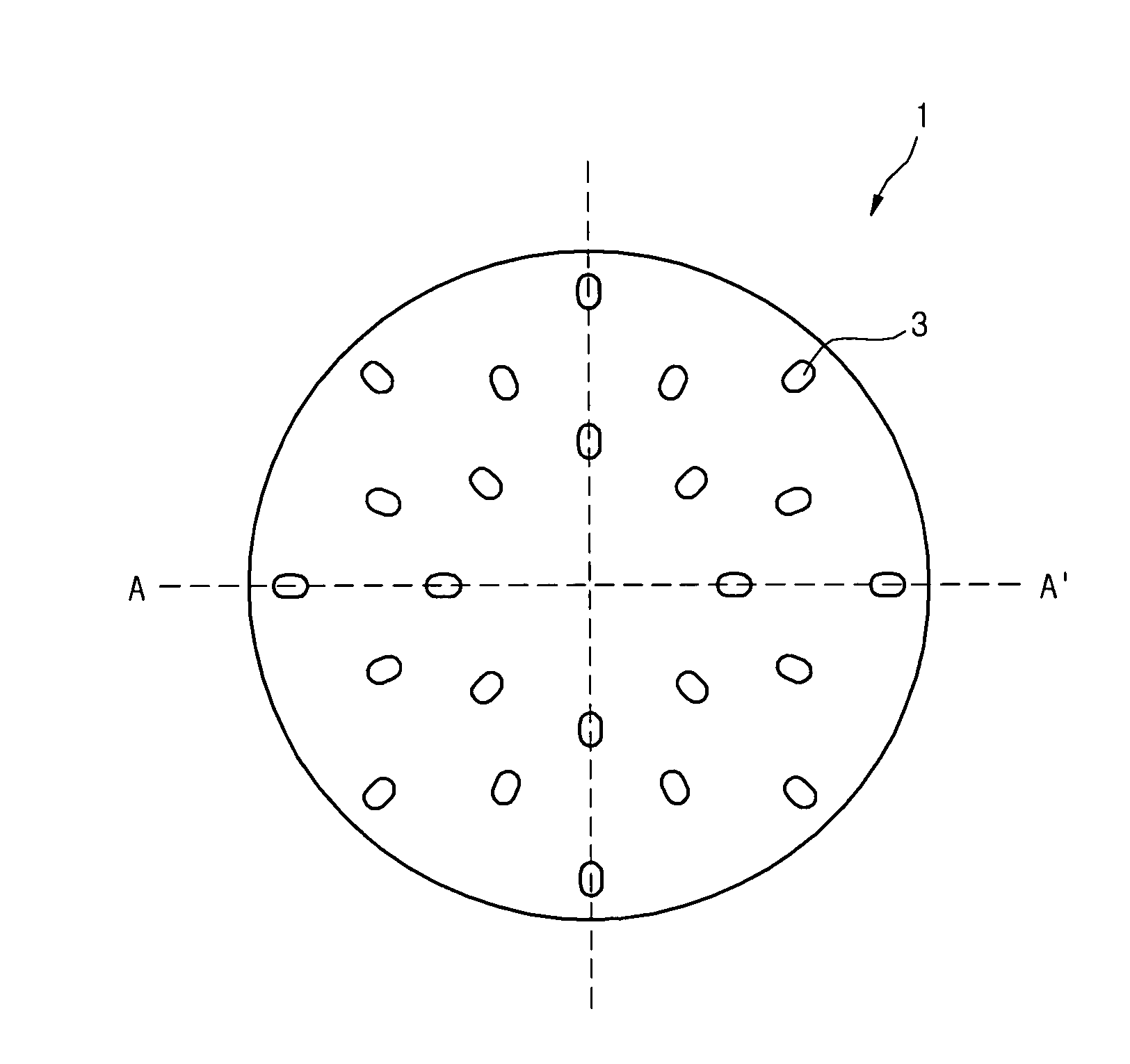

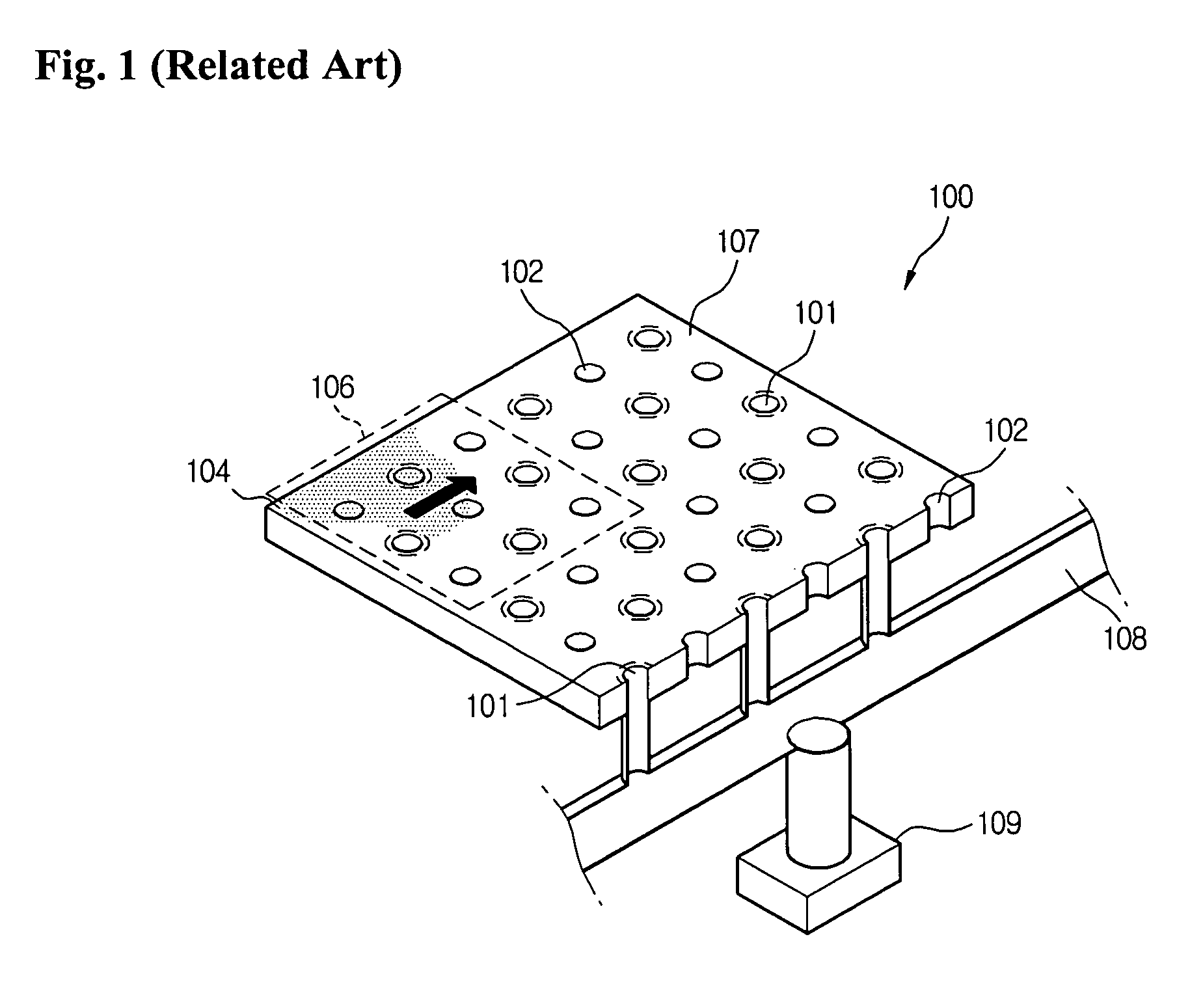

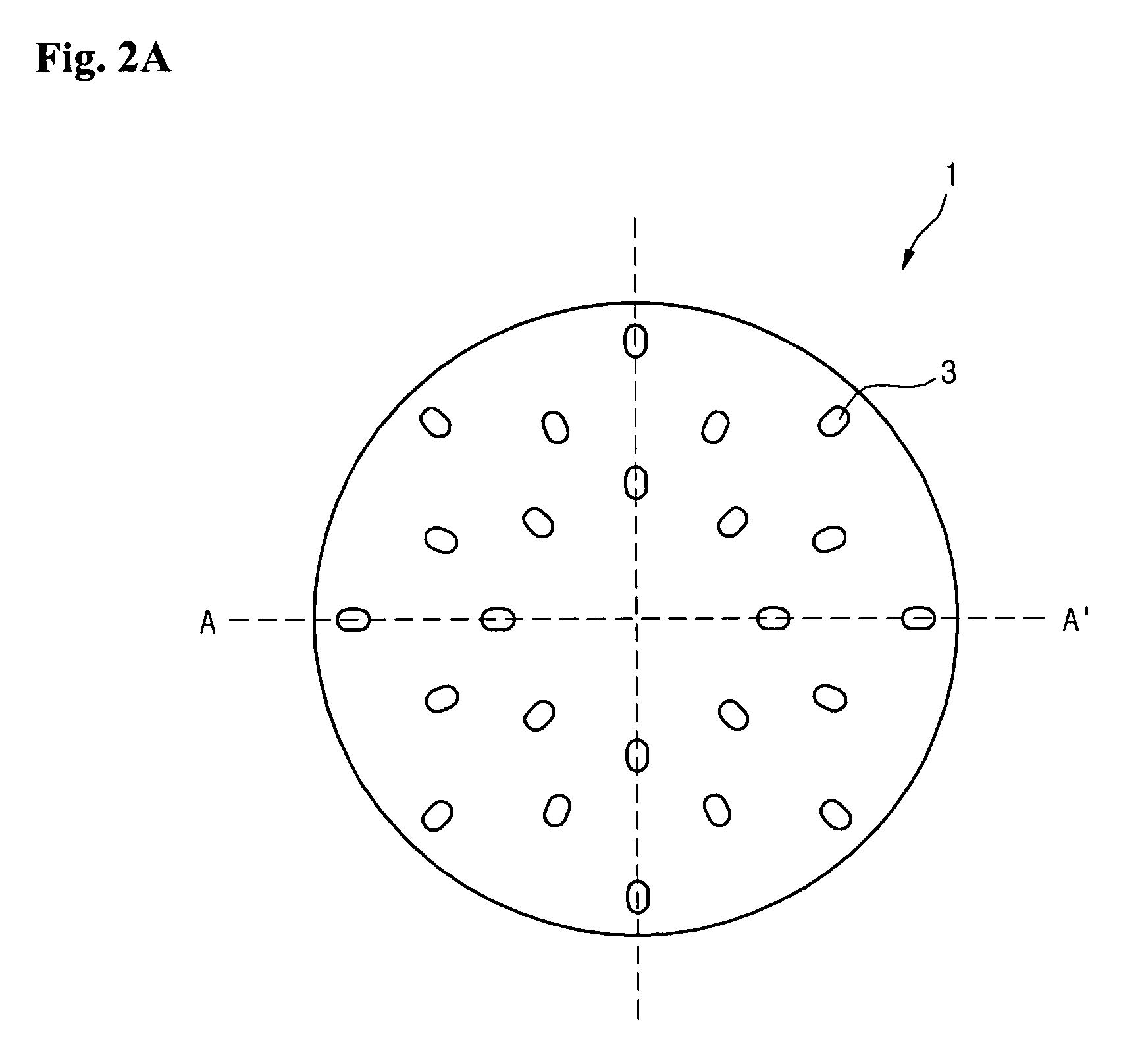

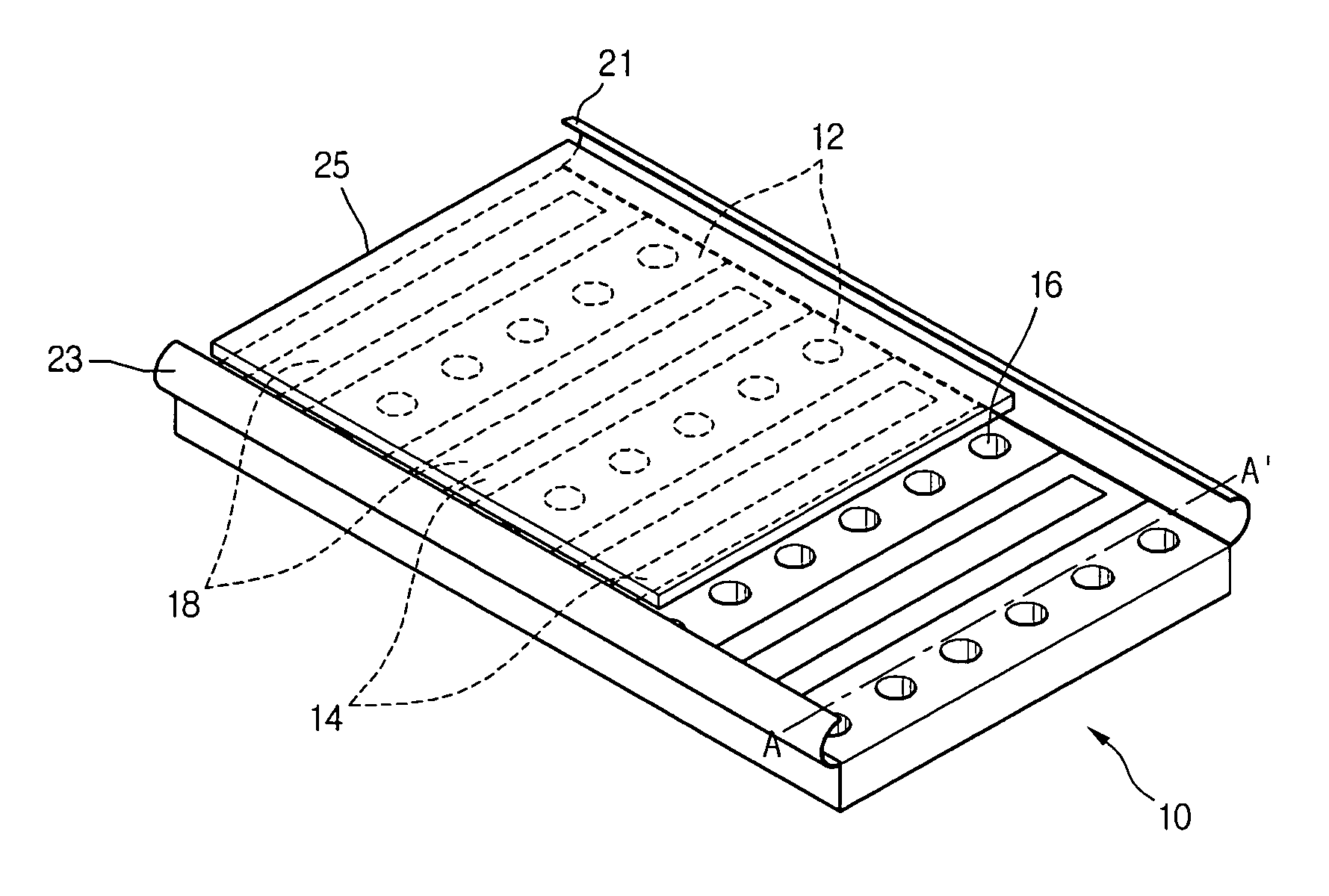

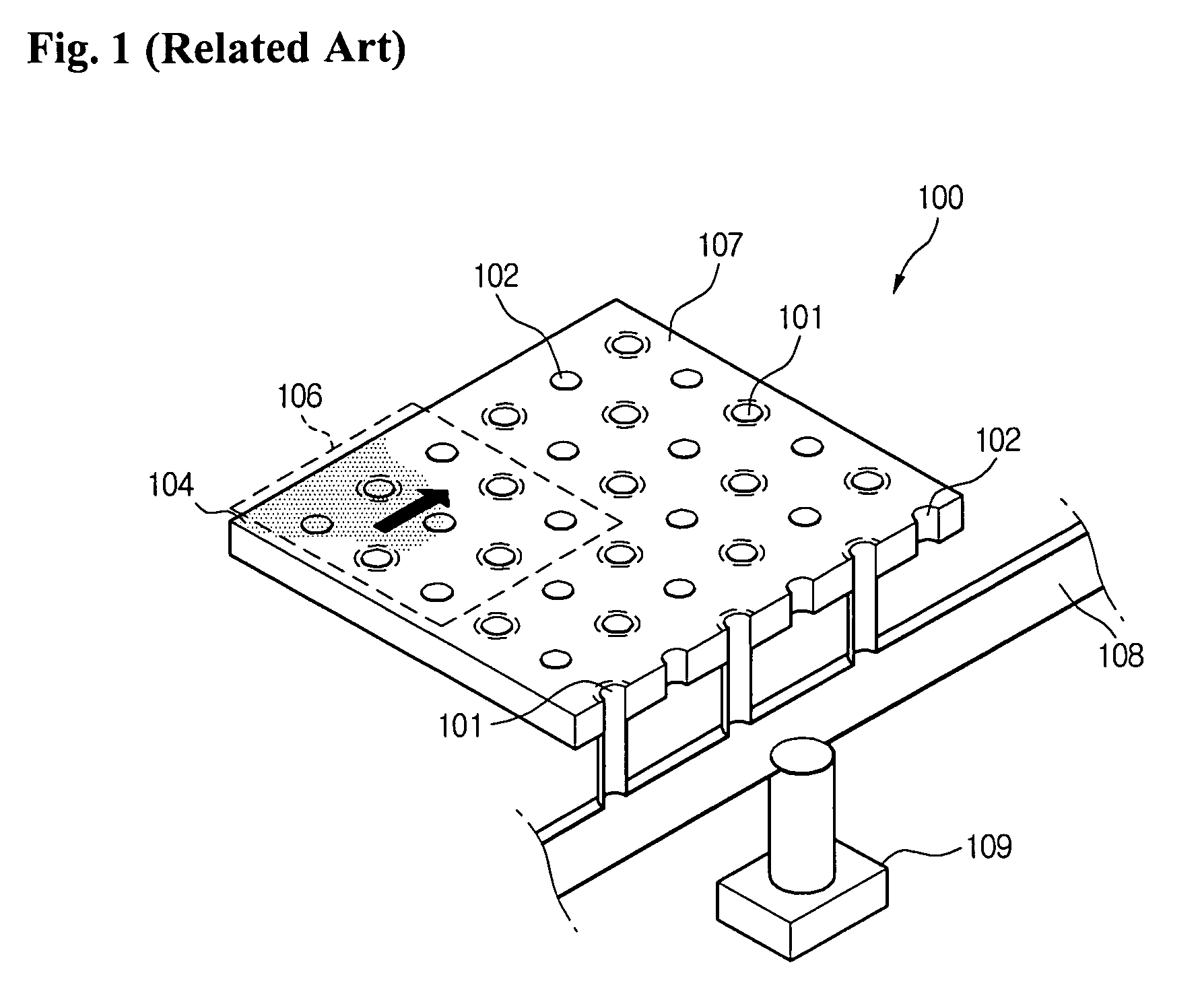

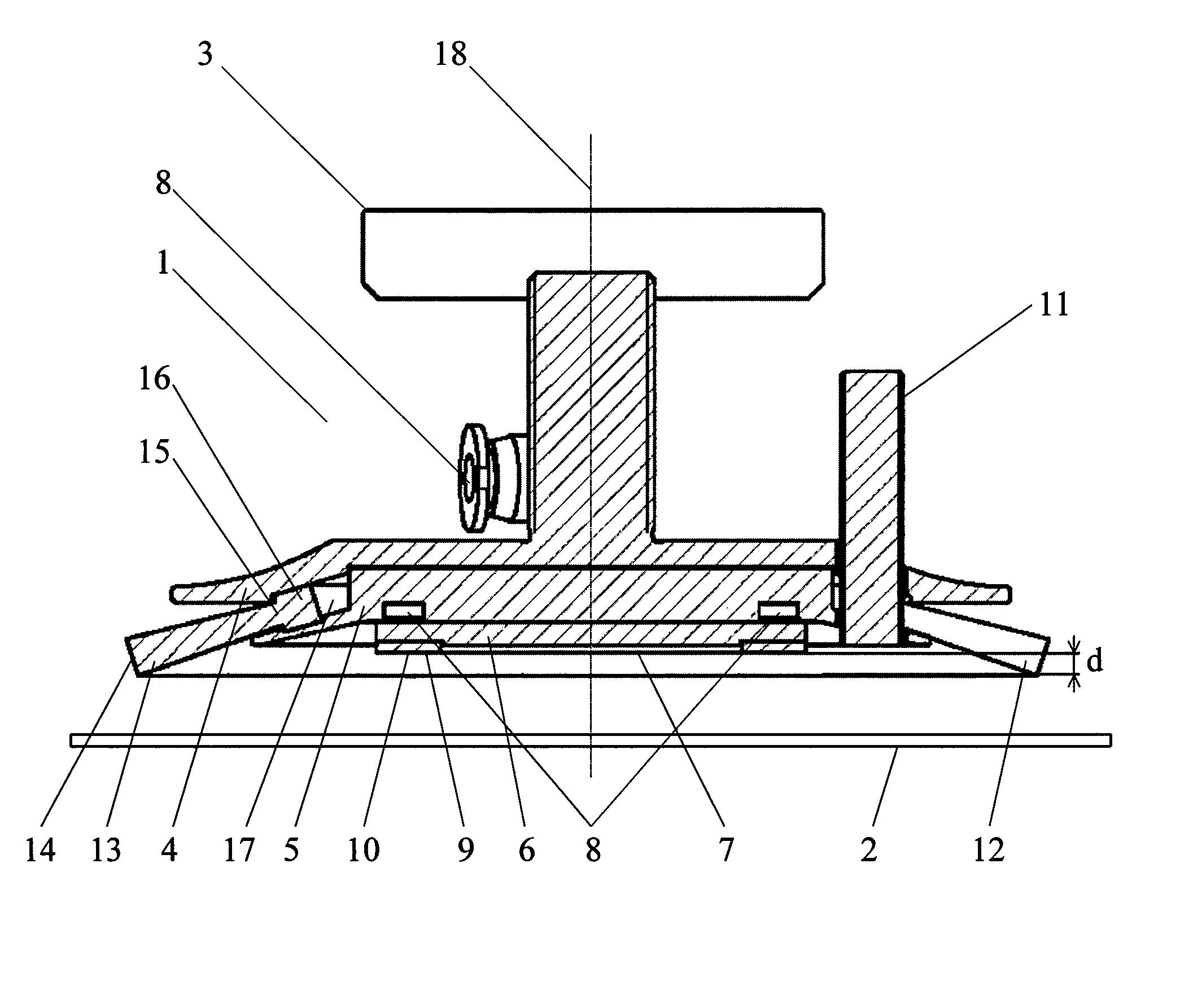

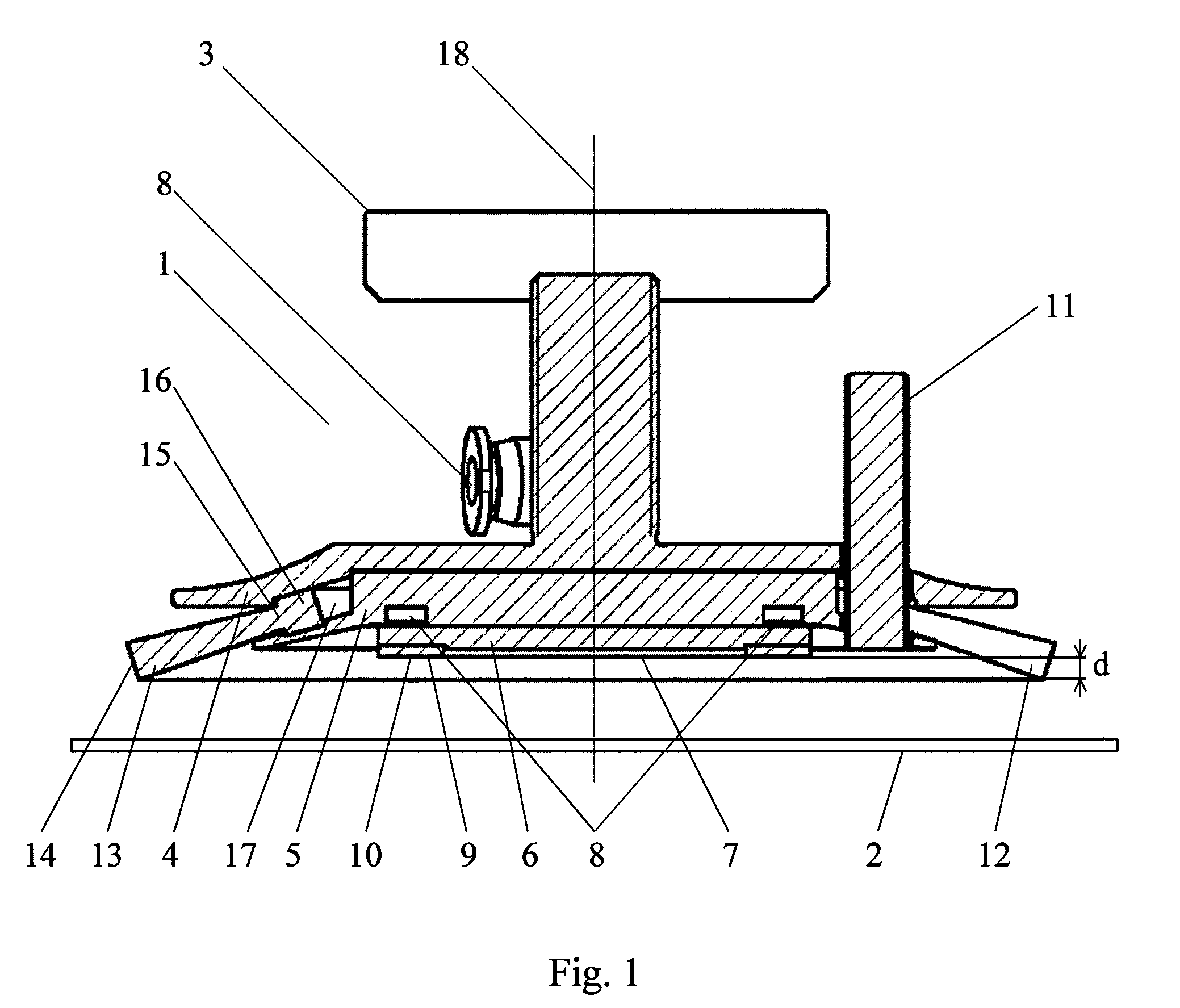

Support platform of non-contact transfer apparatus

ActiveUS20070045499A1Reduce air consumptionSmooth transferSemiconductor/solid-state device manufacturingStands/trestlesEngineeringMechanical engineering

Provided is a support platform of a non-contact transfer apparatus. The support platform is arranged horizontally and includes first and second members adding a lift force to a first force for lifting peripheral portions of a transferred object, wherein the first force is lower than a second force lifting a central portion of the transferred object.

Owner:LG DISPLAY CO LTD +2

Two-stage cooling system

ActiveUS20090235672A1Reduce air consumptionPrevent backflowDomestic cooling apparatusCompression machinesThermostatPhysics

A two-stage cooling system configured to cool an interior of an enclosure includes a cabinet, a first vortex tube secured within the cabinet, and a second vortex tube secured within the cabinet. The cabinet defines a venting chamber. The first and second vortex tubes each include a hot pipe within the venting chamber and a cool gas delivery pipe extending outwardly from the cabinet. The first and second cool gas delivery pipes are configured to deliver cold gas to the interior of the enclosure. A separate thermostat may be operatively attached to each vortex tube and extend outwardly from the cabinet to be positioned within the interior of the enclosure. Additionally, first and second dampening sleeves may be secured around at least a portion of the first and second hot pipes, respectively, such that the dampening sleeves dampen noise produced by the vortex tubes.

Owner:ILLINOIS TOOL WORKS INC

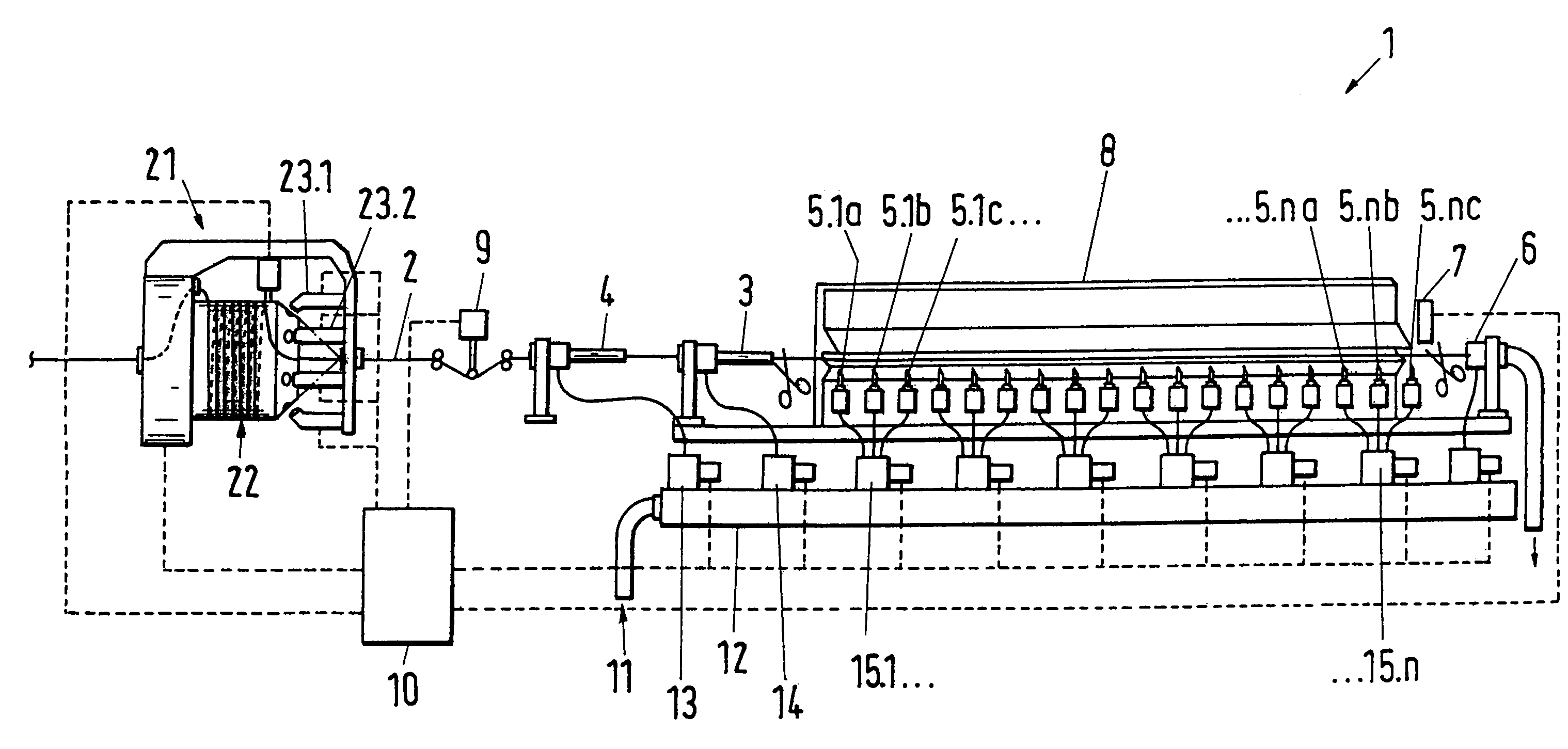

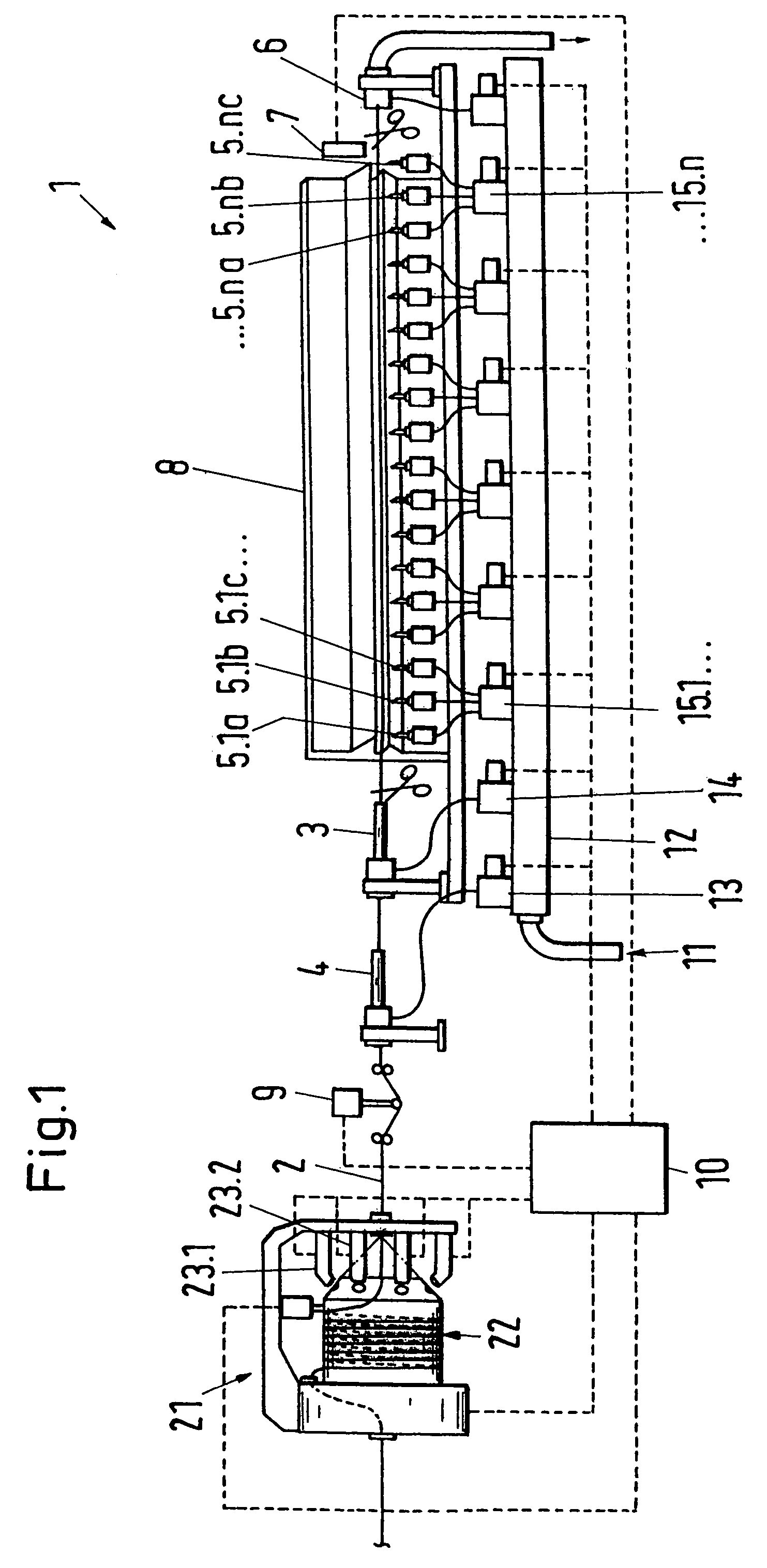

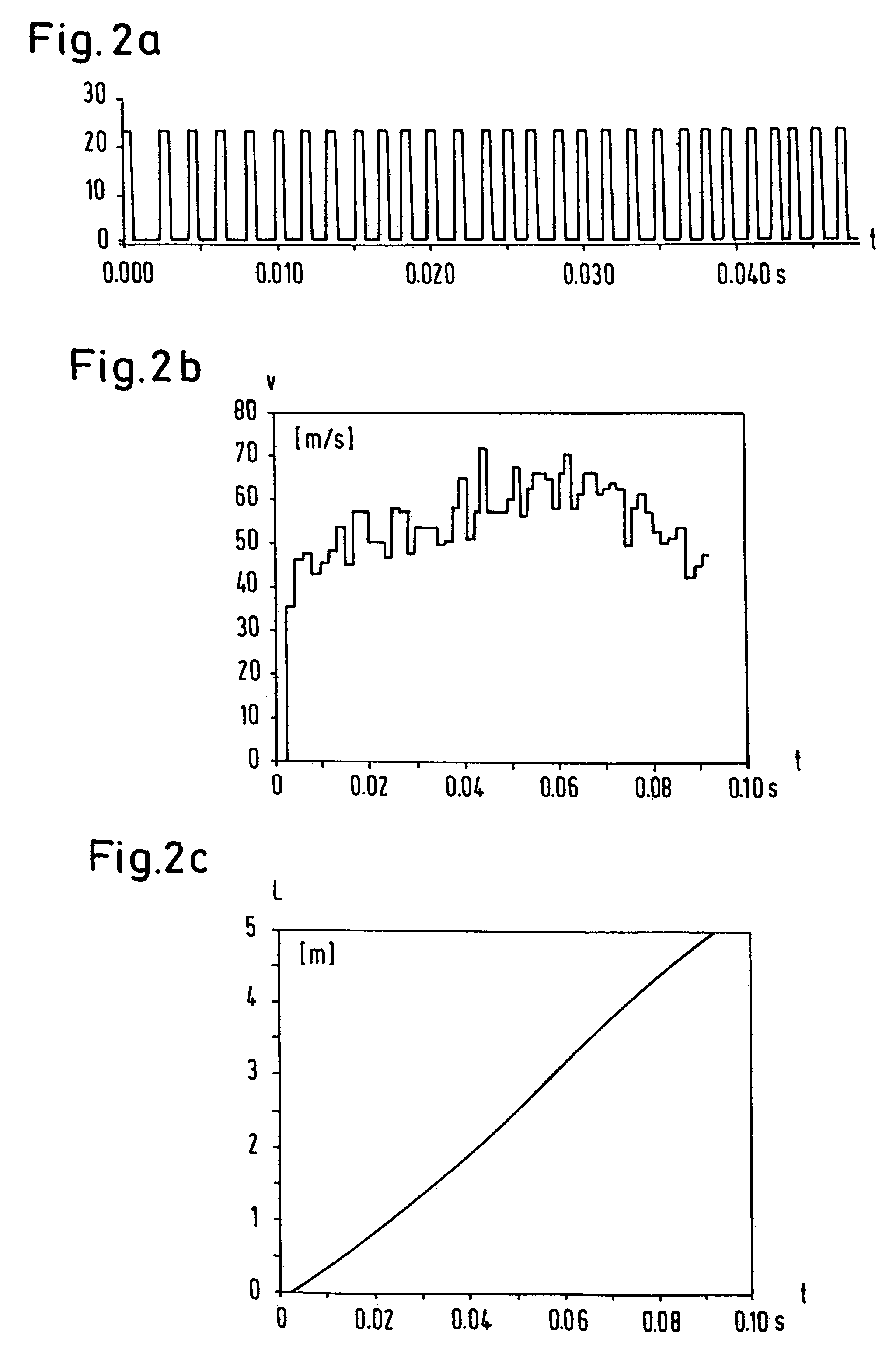

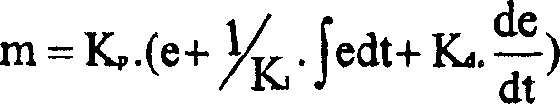

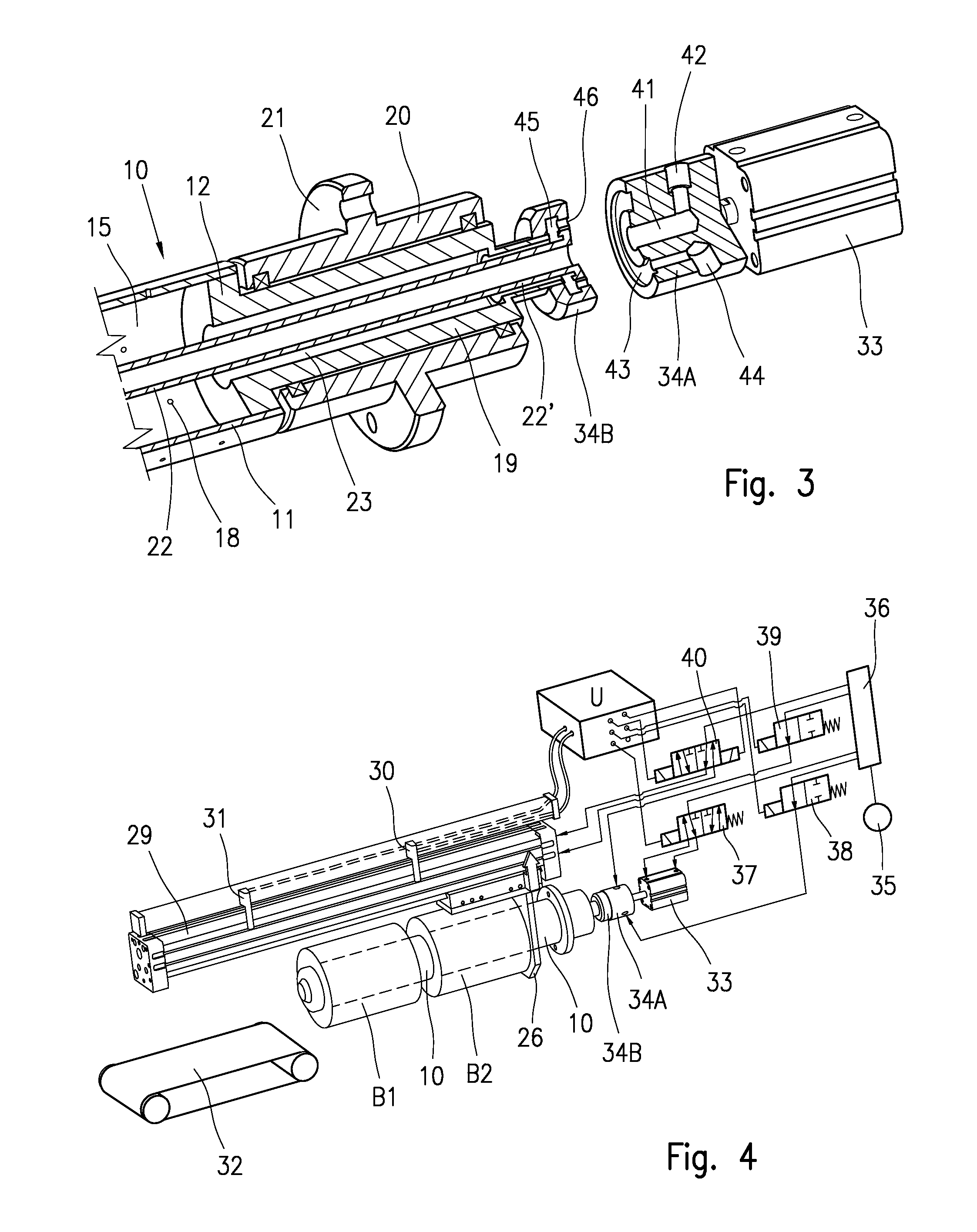

System and method for inserting a weft thread

A system for inserting a weft thread into a shed of an air jet weaving machine includes a thread store with a measuring apparatus, a plurality of air nozzles for the insertion of the weft thread and a control system which is connected to the measuring apparatus in order to be able to control the compressed air supply of the air nozzles in dependence on measurement values of the measuring apparatus. Switch-on points are associated with the air nozzles, with the control system charging one or more of the air nozzles with compressed air as soon as a predictor value for the position of the weft thread tip, which is formed with the help of the measurement values, reaches the switch-on point of the relevant air nozzle or air nozzles respectively.

Owner:SULTEX AG

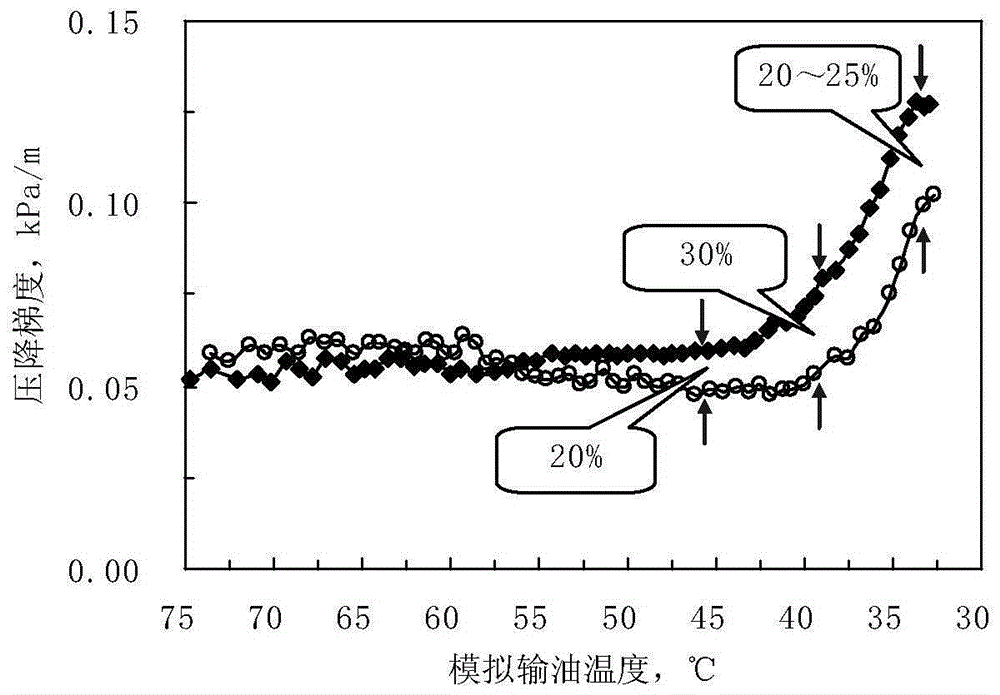

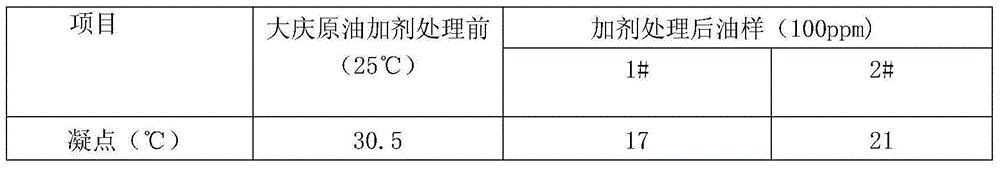

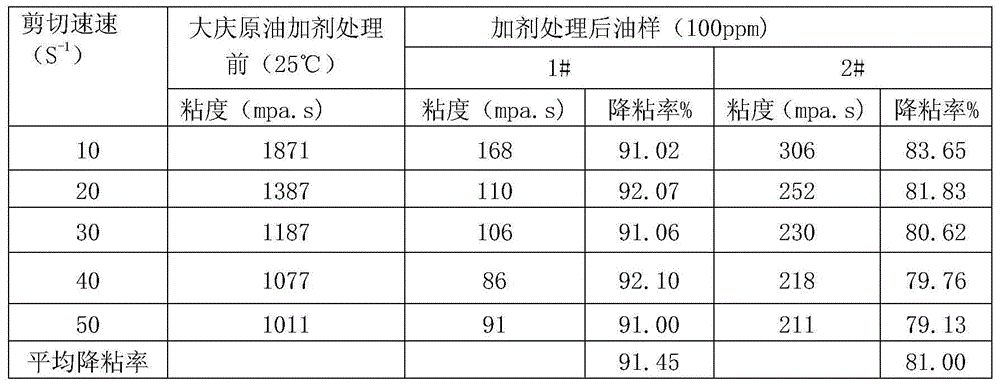

Emulsion type crude oil viscosity-reduction drag reduction agent applied to high-wax-content pure oil pipe transportation

The invention relates to an emulsion type crude oil viscosity-reduction drag reduction agent applied to high-wax-content pure oil pipe transportation. The emulsion type crude oil viscosity-reduction drag reduction agent mainly solves the problems that in the prior art, wax crystallization of a pipe network exists and wax asphaltene deposition of a pipe wall are serious in winter, and consequently the pipe transportation capability is greatly lowered, and safety transportation of crude oil is affected by return pressure rising. The emulsion type crude oil viscosity reduction and drag reduction agent is prepared from, by weight, 20-30% of macromolecule terpolymer, 20-35% of polyolefin drag reduction agent, 20-40% of higher alcohol, 5-10% of compound emulsifier and 1-5% of emulsion stabilizer. The emulsion type crude oil viscosity-reduction drag reduction agent can be rapidly dissolved into crude oil, so that the viscosity of the crude oil is reduced, the friction resistance of the crude oil is reduced, return pressure is reduced, and the pipe transportation capability is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

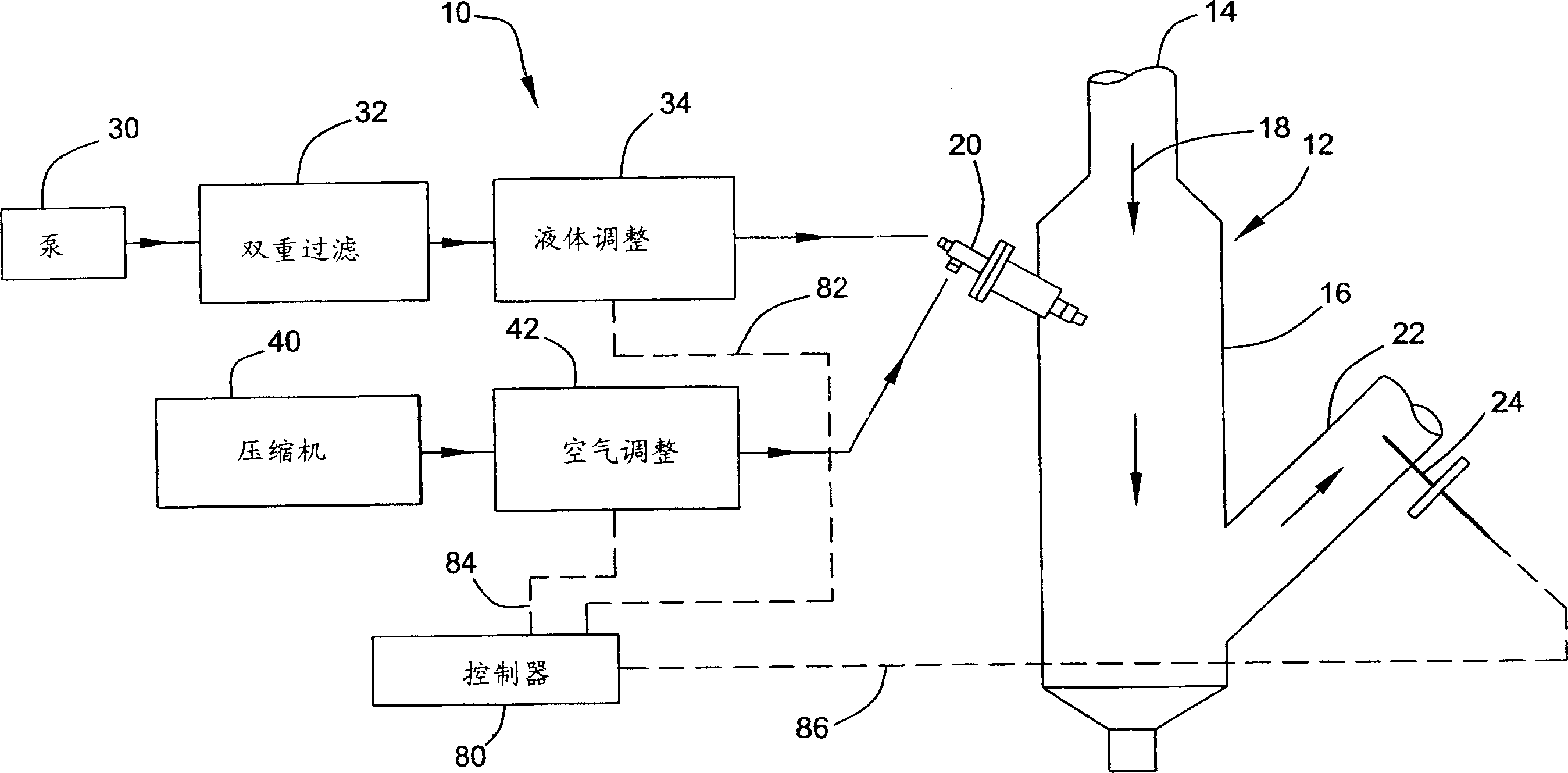

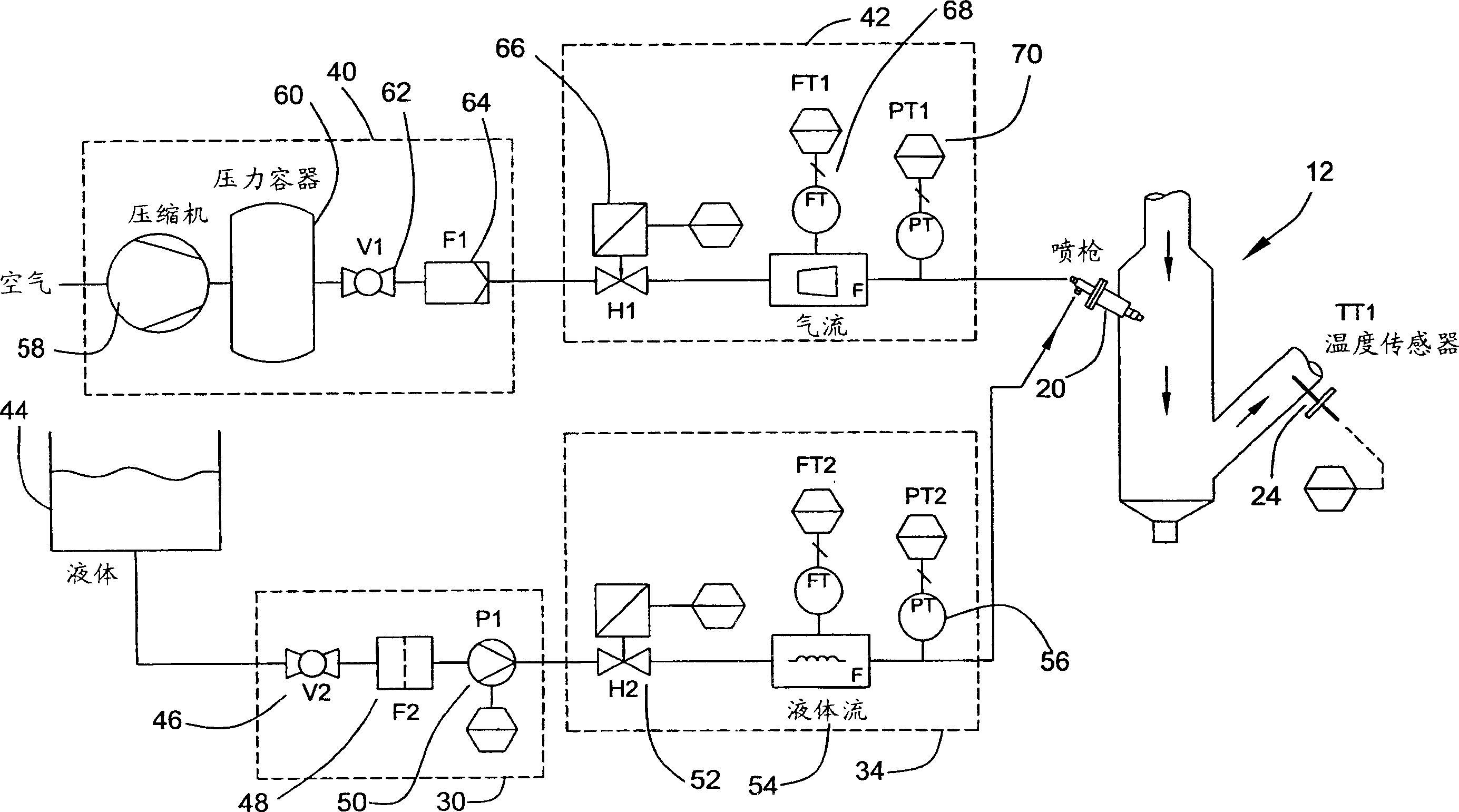

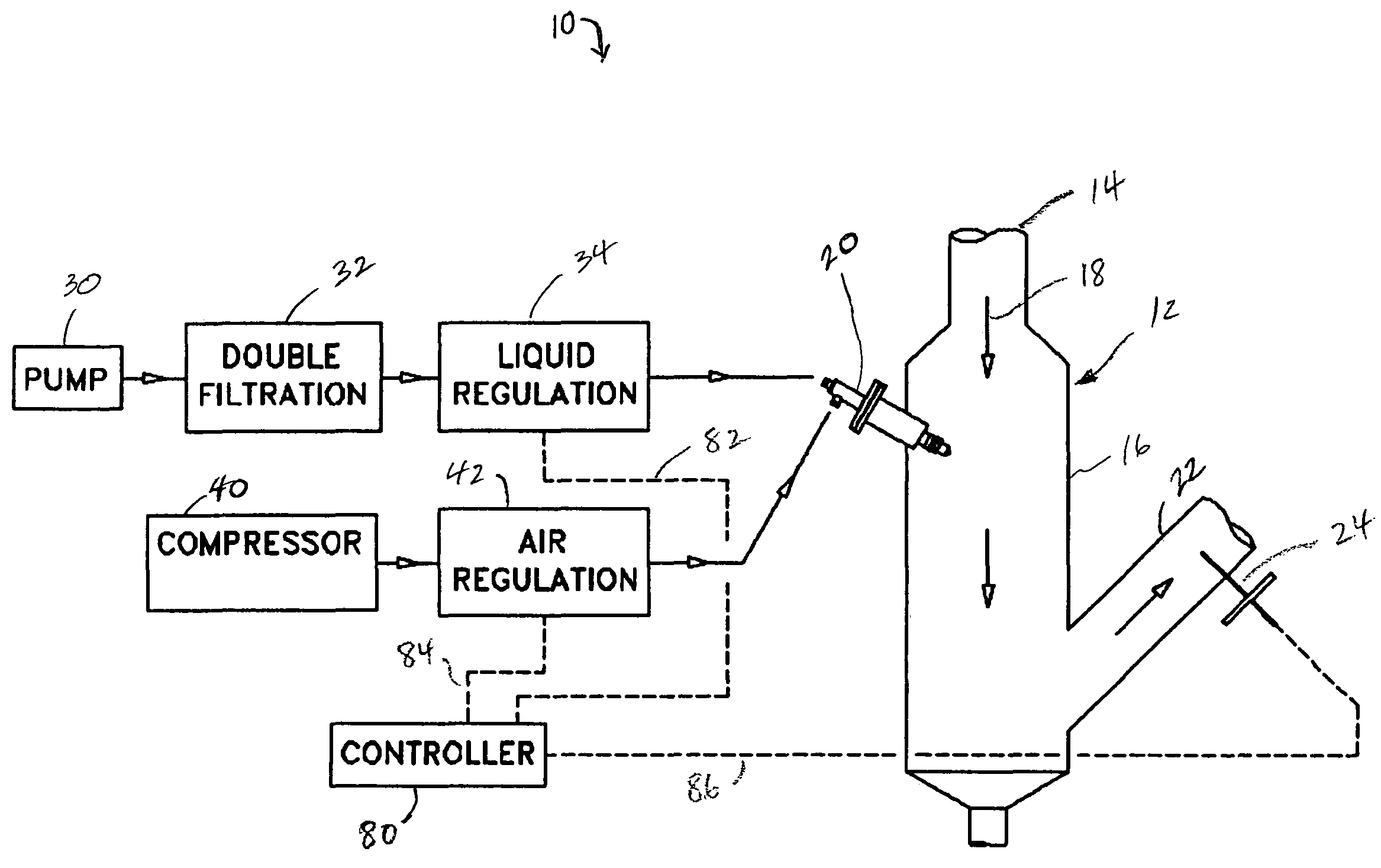

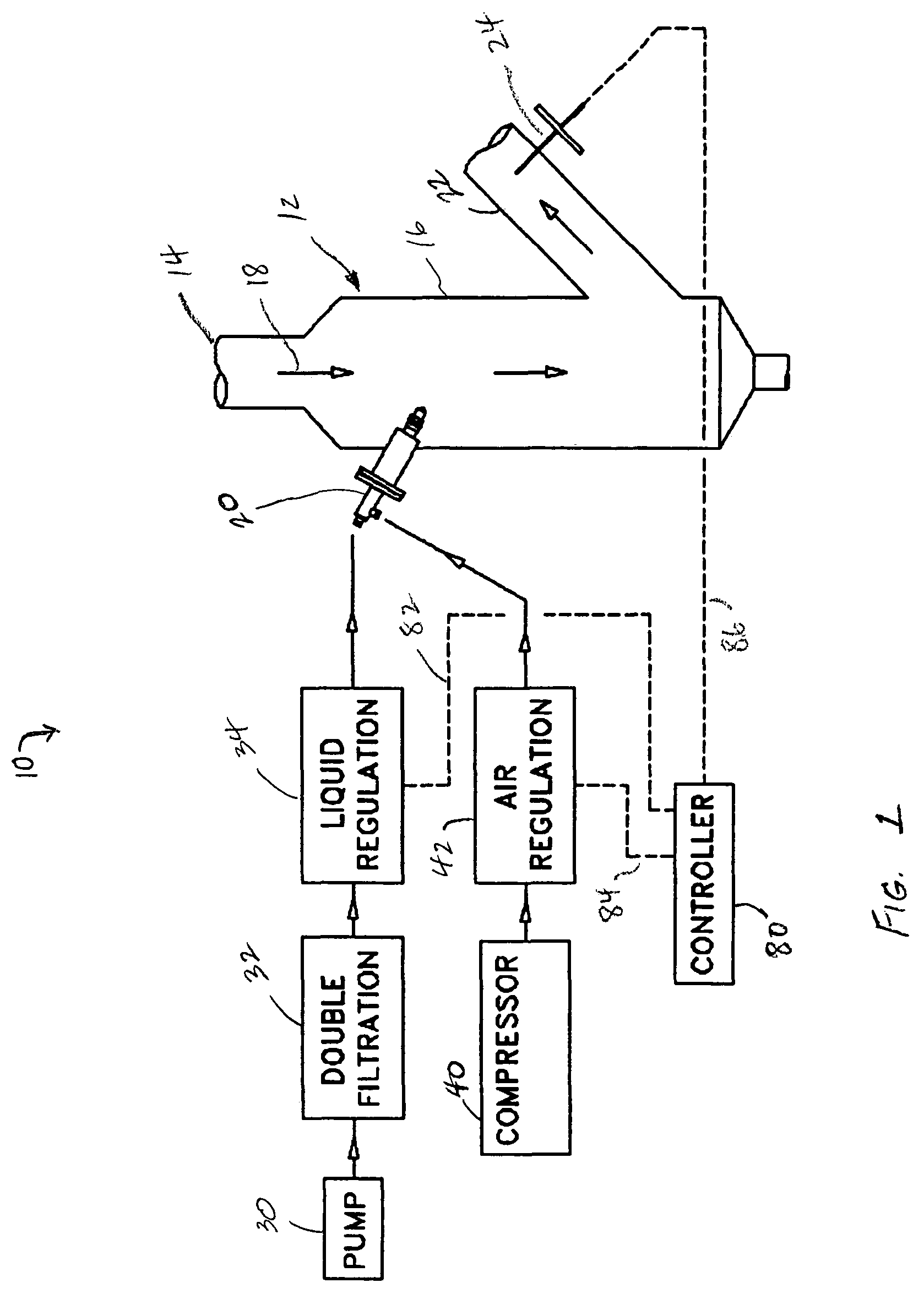

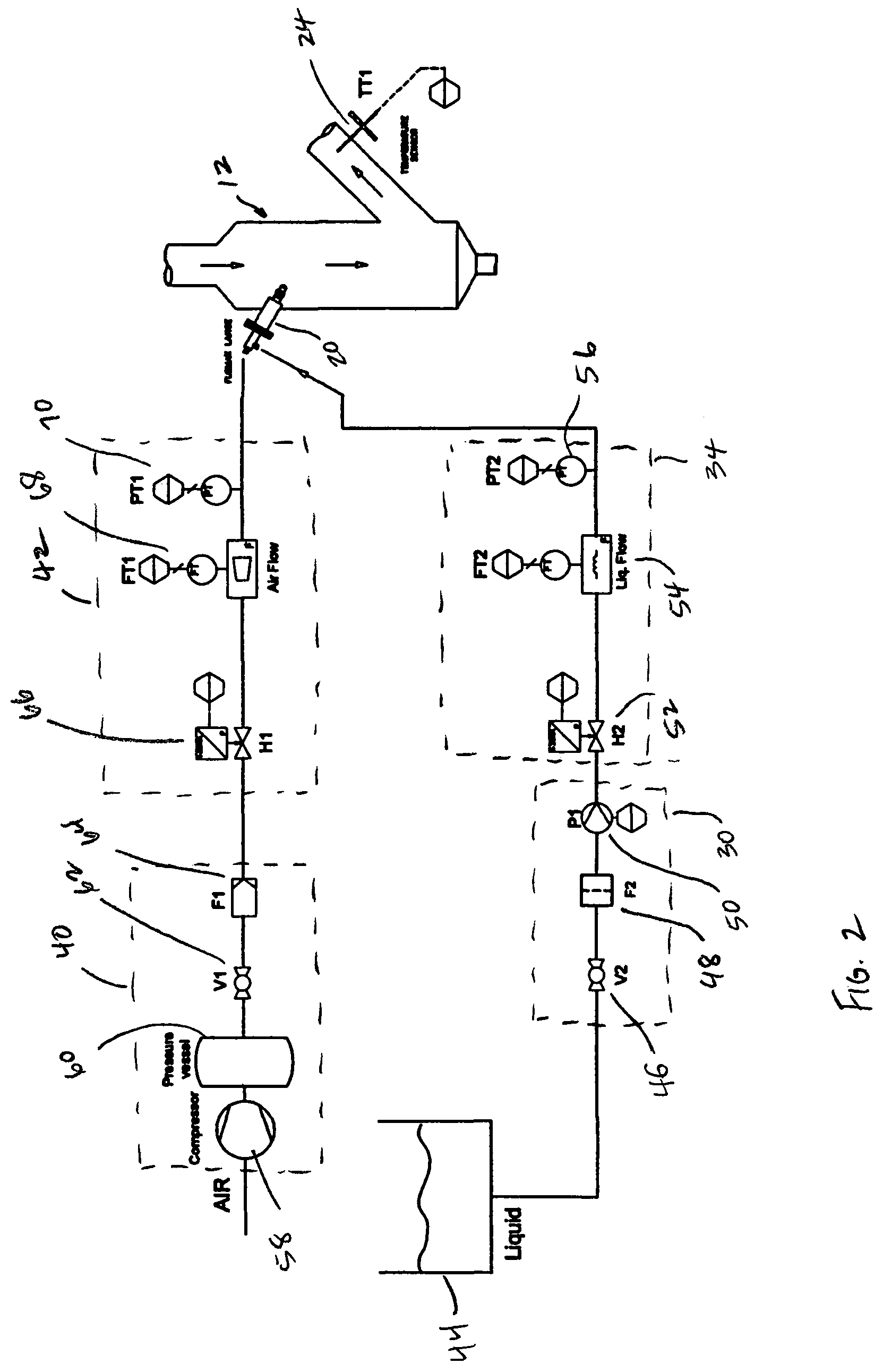

Method and apparatus for reducing air consumption in gas conditioning applications

InactiveCN1607038AReduce air consumptionLiquid spraying apparatusWaste heat treatmentControl systemSpray nozzle

Owner:SPRAYING SYST

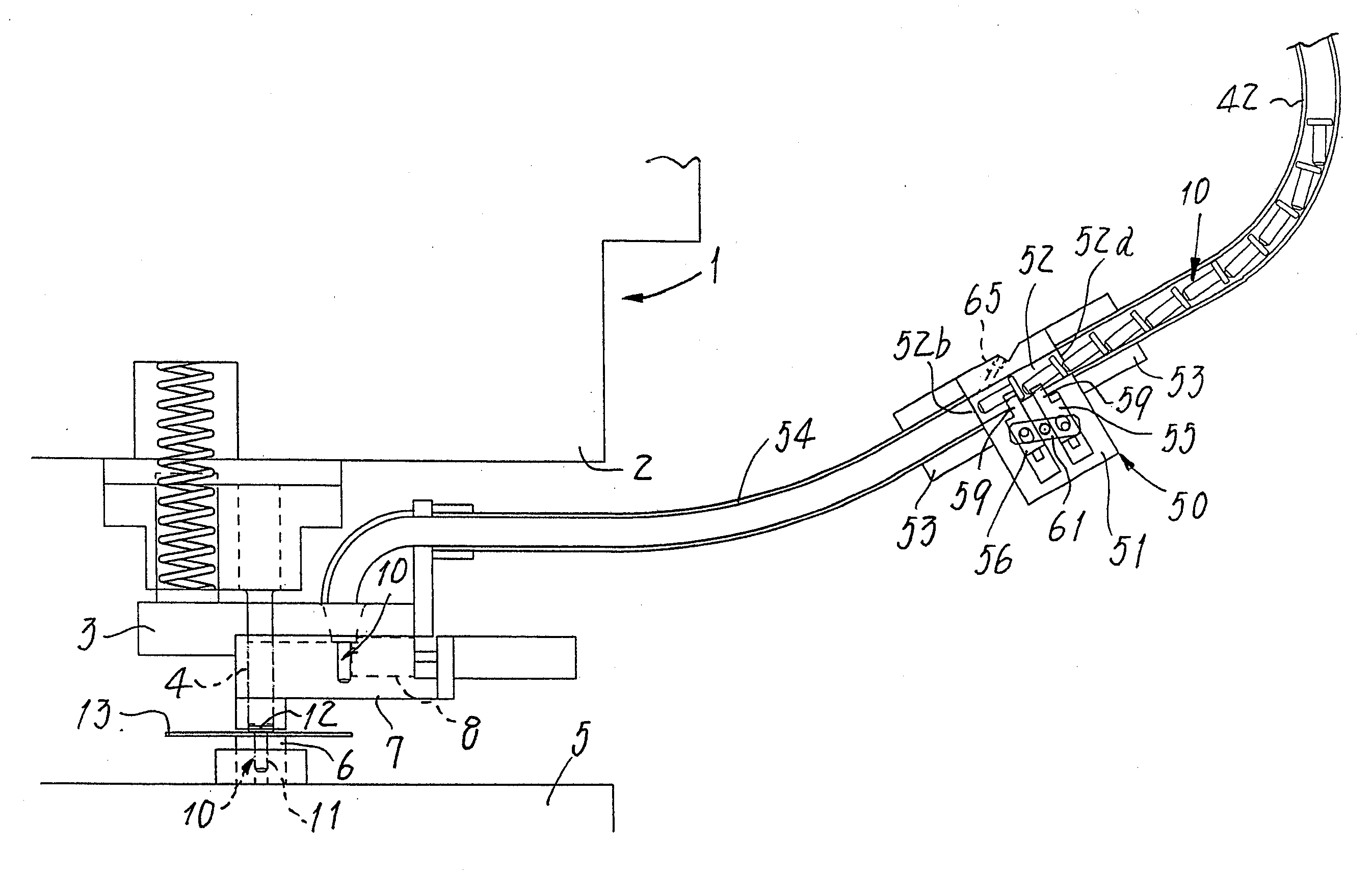

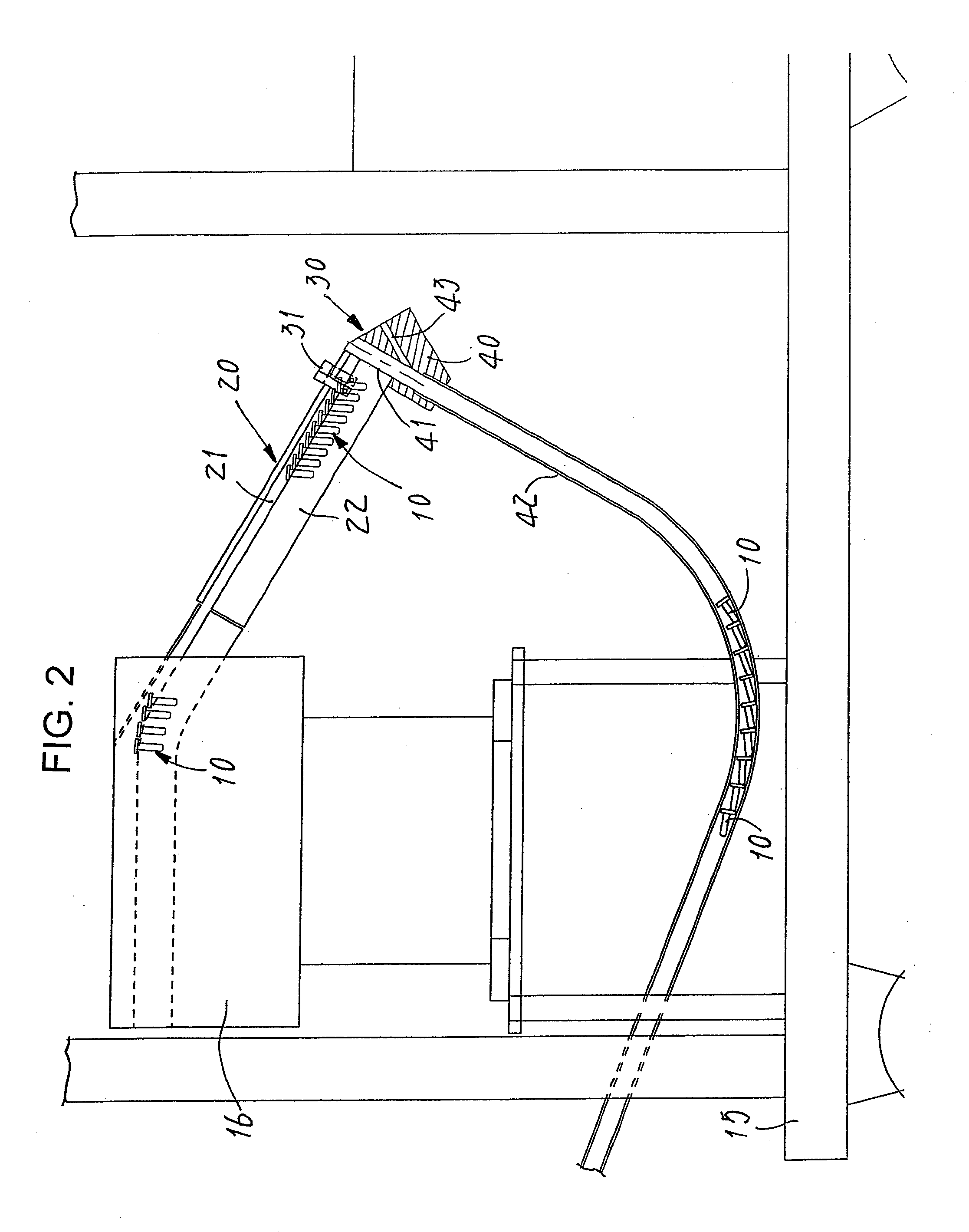

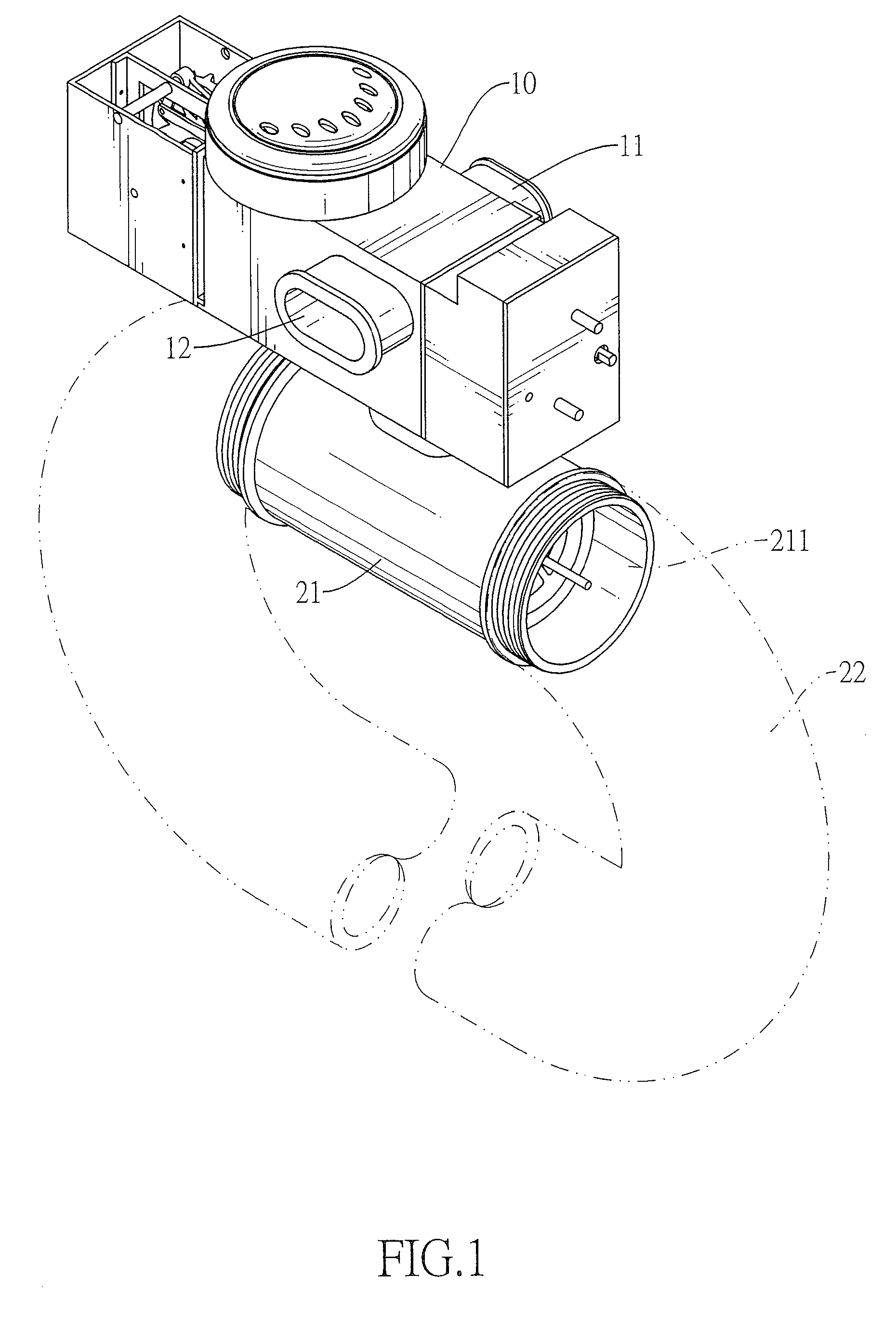

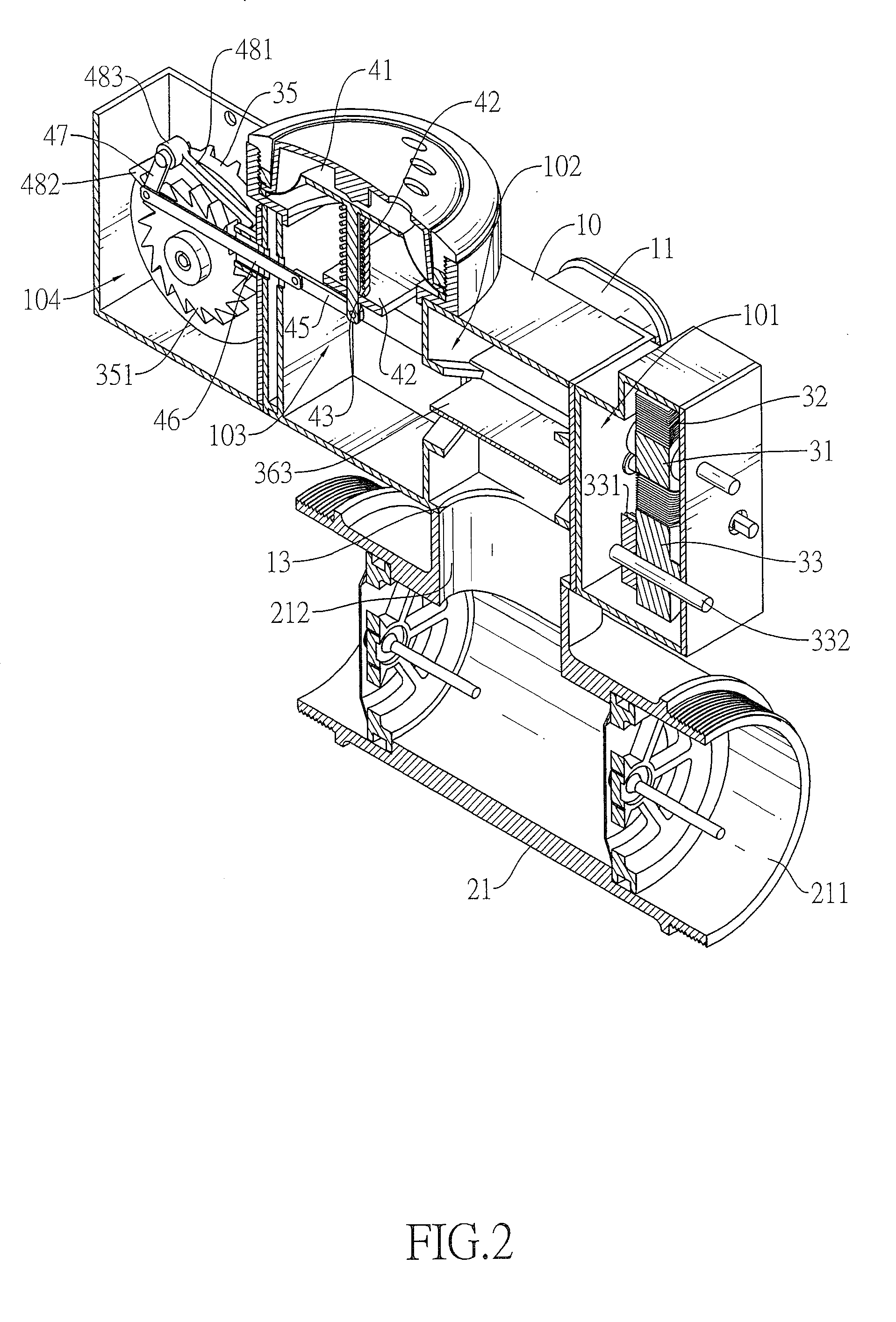

Head type male screw sending and separating feeding apparatus

InactiveUS20110170961A1Increase feed rateReduce air consumptionSpannersWrenchesEngineeringMechanical engineering

It provides a head type male screw sending and separating feeding apparatus which sends a plurality of head type male screws together close to a machine used and separates them one by one in the vicinity of the machine used, and thereby, even in case the distance from the arranging device to the machine used is very long, there is no loss of feeding time and the feeding speed is greatly enhanced, enabling the reduction of air consumption.The device comprises arranging device 20 for delivering head type male screws 10 such as screws and bolts, arranging them in a line, sending device 30 for sending head type male screws 10 delivered from the arranging device 20 to first feed hose 42 with screw shaft 11 positioned at front and head 12 positioned at rear, arranging them in an axial direction, and separating feeding device 50 connected to the front end of first feed hose 42 and installed near the machine used 1 for separating one by one a plurality of male screws 11 fed together through the first feed hose 42 and feeding them to the assembling section of the machine used 1 through short second feed hose 54.

Owner:PIAS SALES

Vehicle braking system

ActiveUS8366209B2Overcome disadvantagesEasy to controlBraking action transmissionAutomatic initiationsDriver/operatorVehicle driving

Owner:ZF CV SYST EURO BV

Method and apparatus for reducing air consumption in gas conditioning applications

InactiveUS7125007B2Great efficiencyReduce consumption of airDispersed particle filtrationUsing liquid separation agentSpray nozzleGas conditioning

A control system for adjusting the desired air pressure provided to one or more spray nozzles disposed to receive liquid and compressed air adjusts the amount of compressed air supplied to the spray nozzle based on various sensed operating parameters of the system.

Owner:SPRAYING SYST

Air recycling device for auxiliary respiration apparatus

InactiveUS20100126509A1Extended durationAvoid communicationRespiratorsBreathing filtersAir cycleEngineering

An air recycling device for auxiliary respiration apparatus has a casing, an air gather assembly, a valve assembly and a pressure switch unit. The casing has a regulator connector and an air feeder. The air gather assembly communicates with the casing. The valve assembly selectively blocks the communication either between the air feeder and the air gather assembly or between the regulator connector and the air feeder. In the moment between inhaling and exhaling, the pressure switch unit drives the valve assembly to block the communication between the air feeder and the regulator connector to gather the air expired from the user into the air gather assembly. When the user inhales again, the user inhales the air in the air gather assembly. The subsequently expired air flows through the regulator connector to a diving regulator. The air expired by the diver is recycled.

Owner:CHANG TA HSIANG

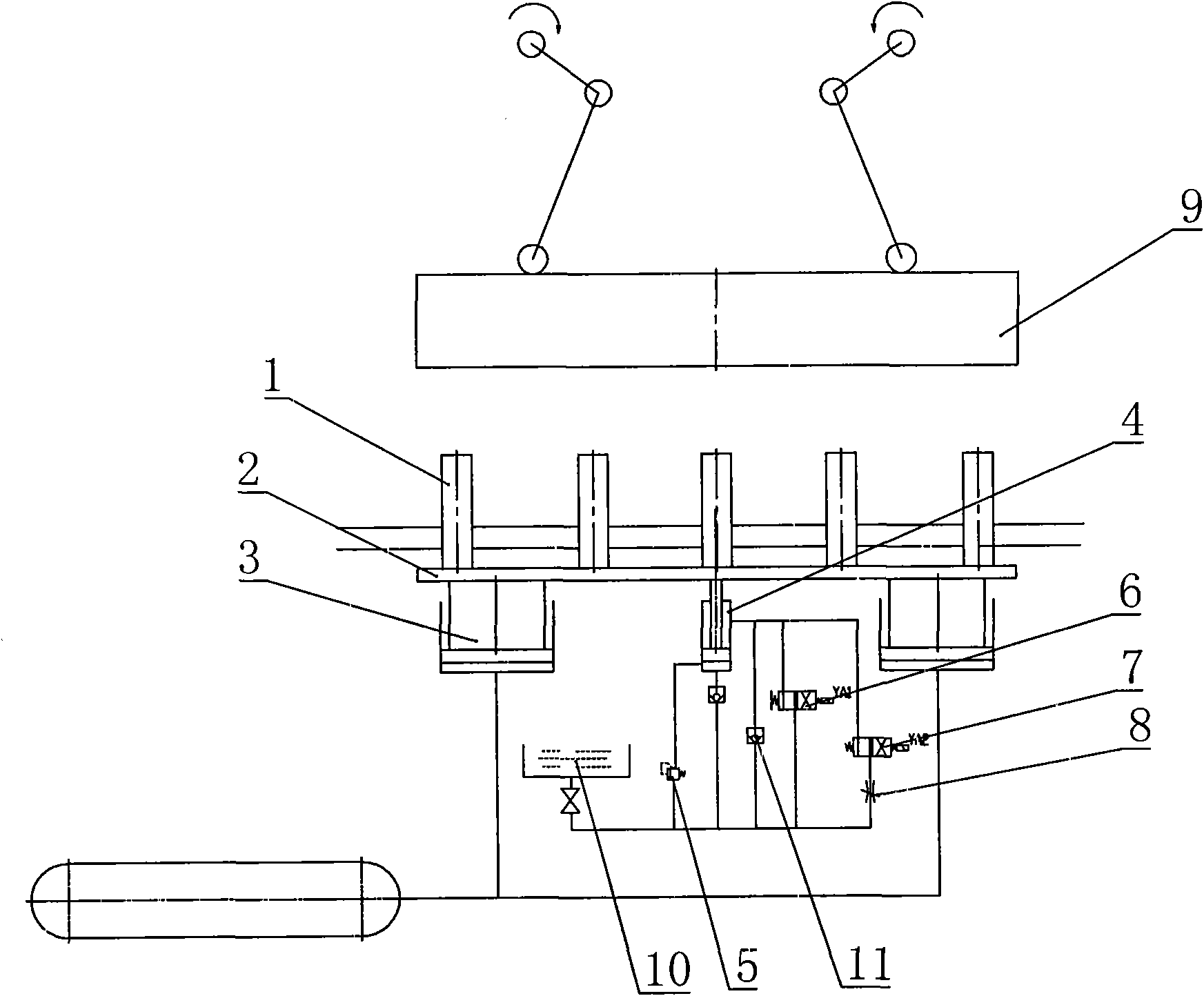

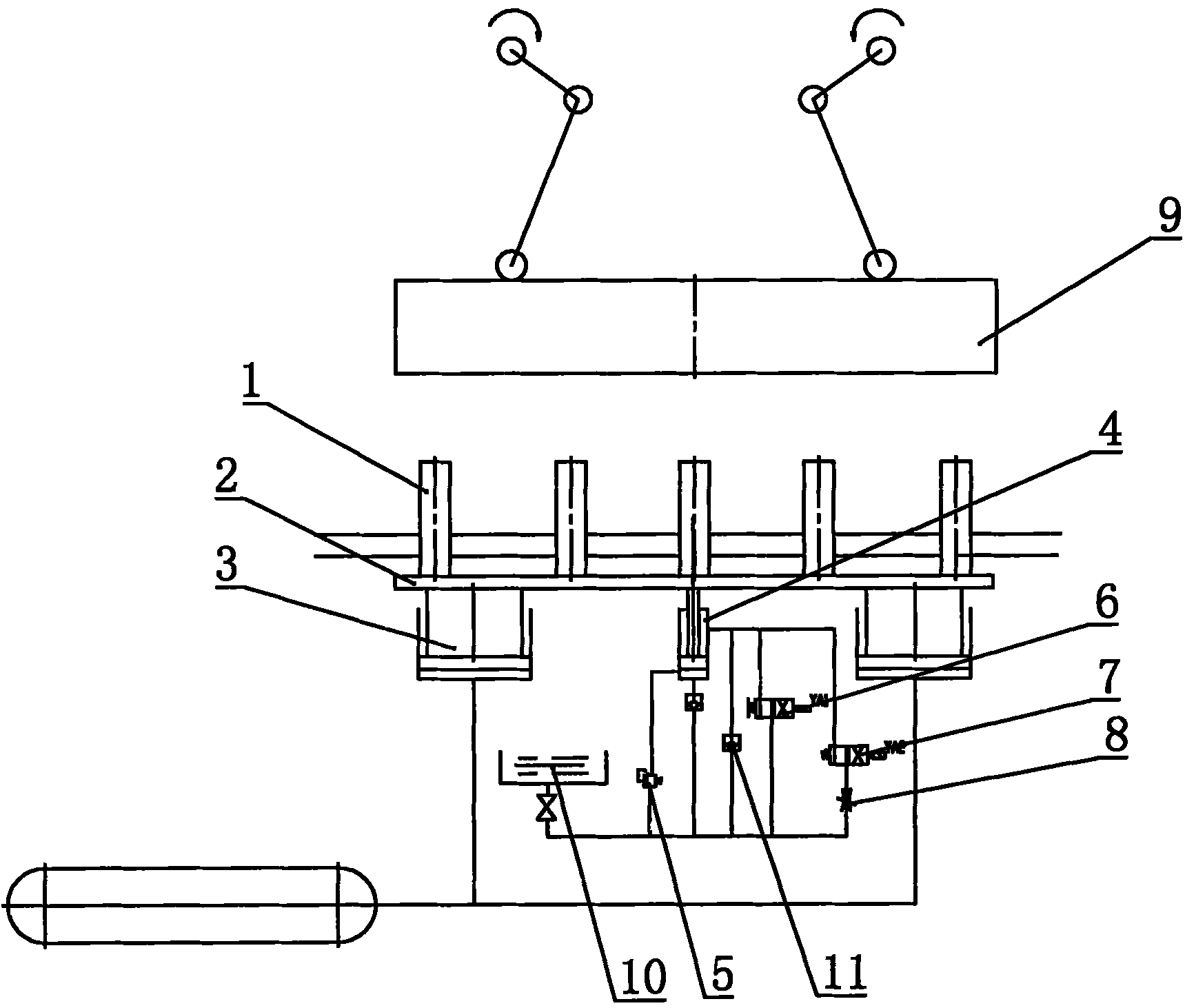

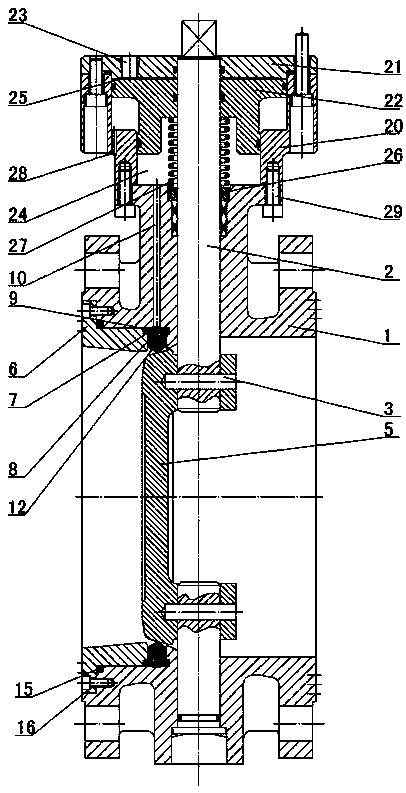

Pressure pad device of mechanical press

The invention relates to a pressure pad device of a mechanical press. The pressure pad device comprises an ejector rod supporting plate on which an ejector rod is arranged; the pressure pad device also comprises a cylinder with a power source and a hydraulic cylinder without a power source, wherein both the cylinder and the hydraulic cylinder are fixedly connected with the ejector rod supporting plate, a rod-holding cavity and a rod-free cavity of the hydraulic cylinder are connected with an oil tank through oil pipes respectively, and a charging valve is connected in series to the oil pipes; and the rod-free cavity of the hydraulic cylinder is connected with a booster oil passage, and the rod-holding cavity of the hydraulic cylinder is connected with an unloading oil passage. The hydraulic cylinder is boosted by the booster oil passage after a sliding block descends to press the ejector rod, and is matched with the cylinder to achieve the rated pressure requirement, so that the cylinder does not need to be designed into a multistage cylinder with huge volume, meanwhile, the consumption of a gas source is reduced, and the use cost of a user is reduced; after the sliding block ascends, the unloading loop of the hydraulic cylinder is respectively locked, quickly unloaded and slowly unloaded according to the process requirements, and the ejector rod is fist static, then quickly ascends and slowly ascends when approaching an upper dead point, so that high impact and noise are reduced.

Owner:NANTONG FORGING EQUIP

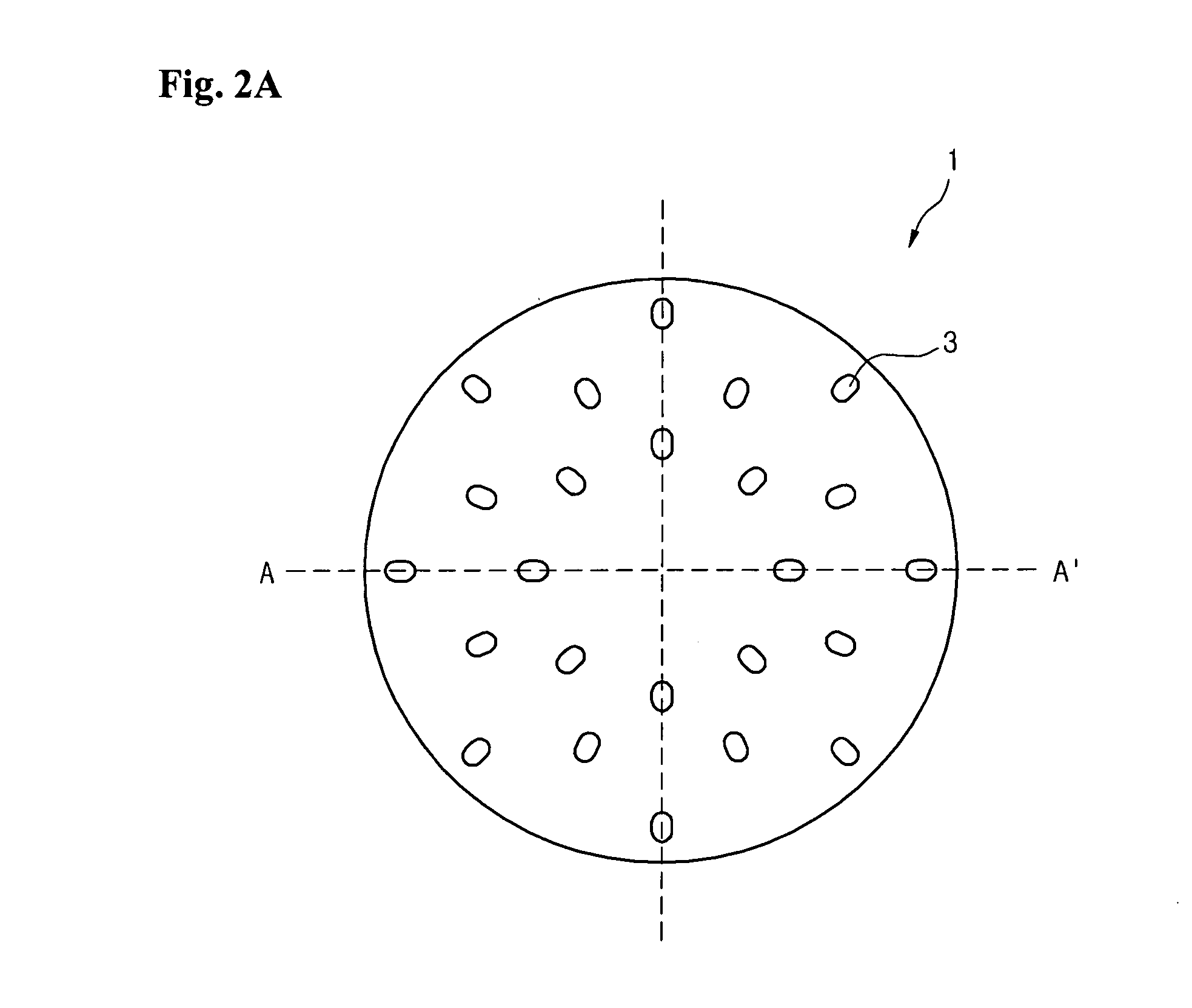

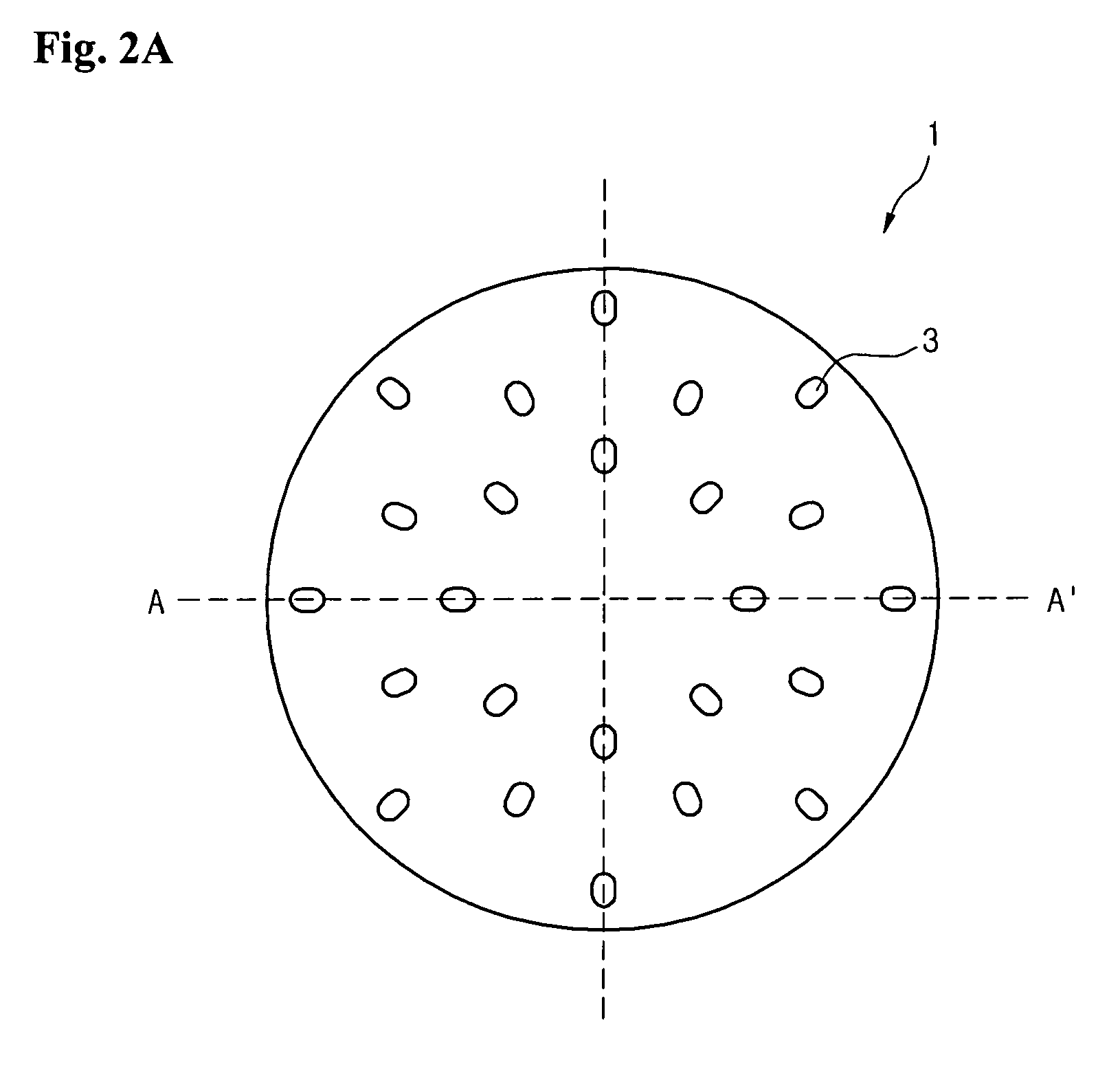

Support platform of non-contact transfer apparatus

ActiveUS8113761B2Reduce air consumptionSmooth transferDrying solid materials with heatSemiconductor/solid-state device manufacturingMechanical engineeringEngineering

There is provided a support platform of a non-contact transfer apparatus. The support platform of a non-contact transfer apparatus includes a plurality of first holes each having a plurality of sub-holes arranged in a radial direction and a plurality of second holes arranged in a line proximate the first holes.

Owner:AVACO +2

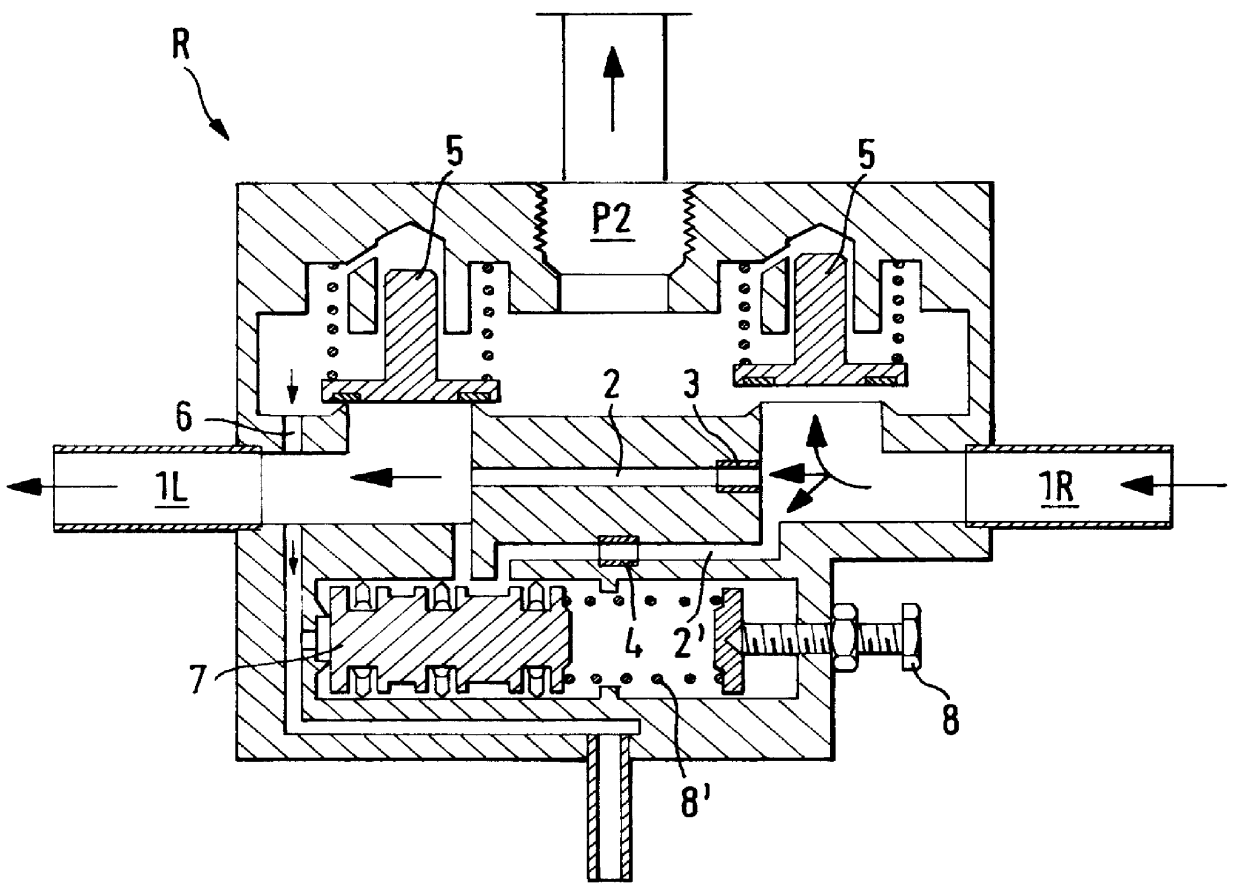

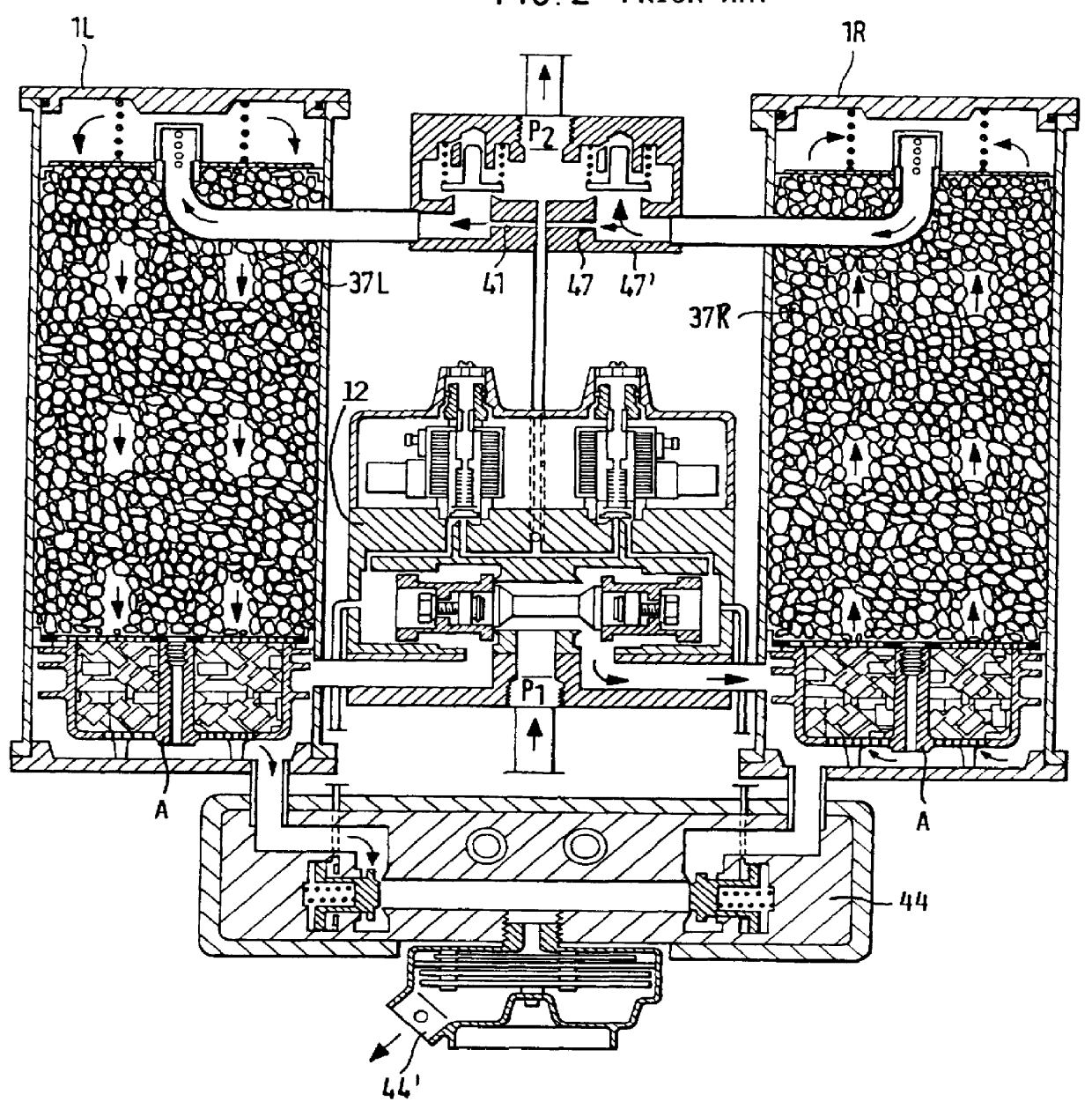

Air-drying system, in particular for rail vehicles

InactiveUS6042197AReduce air consumptionConsiderable energy savingApplication and release valvesAir treatment devicesEngineeringBraking system

PCT No. PCT / DE97 / 00487 Sec. 371 Date May 11, 1998 Sec. 102(e) Date May 11, 1998 PCT Filed Mar. 11, 1997 PCT Pub. No. WO97 / 42068 PCT Pub. Date Nov. 13, 1997An air-drying system, in particular for the pneumatic braking systems of rail vehicles, including at least two air-drying chambers (1L, 1R) interconnected with one another via first and second regeneration lines (2 and 2'). In a reversibly switchable manner one of the chambers is used for air drying and the respective other chamber is used for regeneration of the air-drying agent (adsorbate) contained in the chambers. The second regeneration line (2') can be switched on and off as necessary to provide two different flow rates of regeneration air.

Owner:KNORR BREMSE SYST FUR SCHIENENFAHRZEUGE GMBH

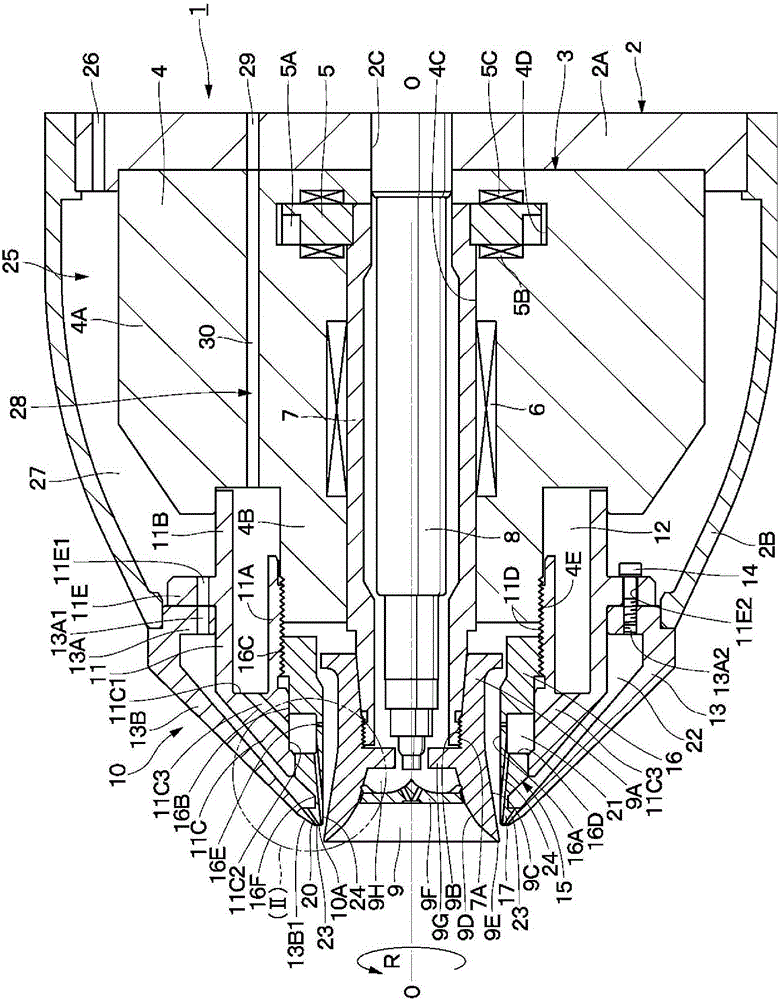

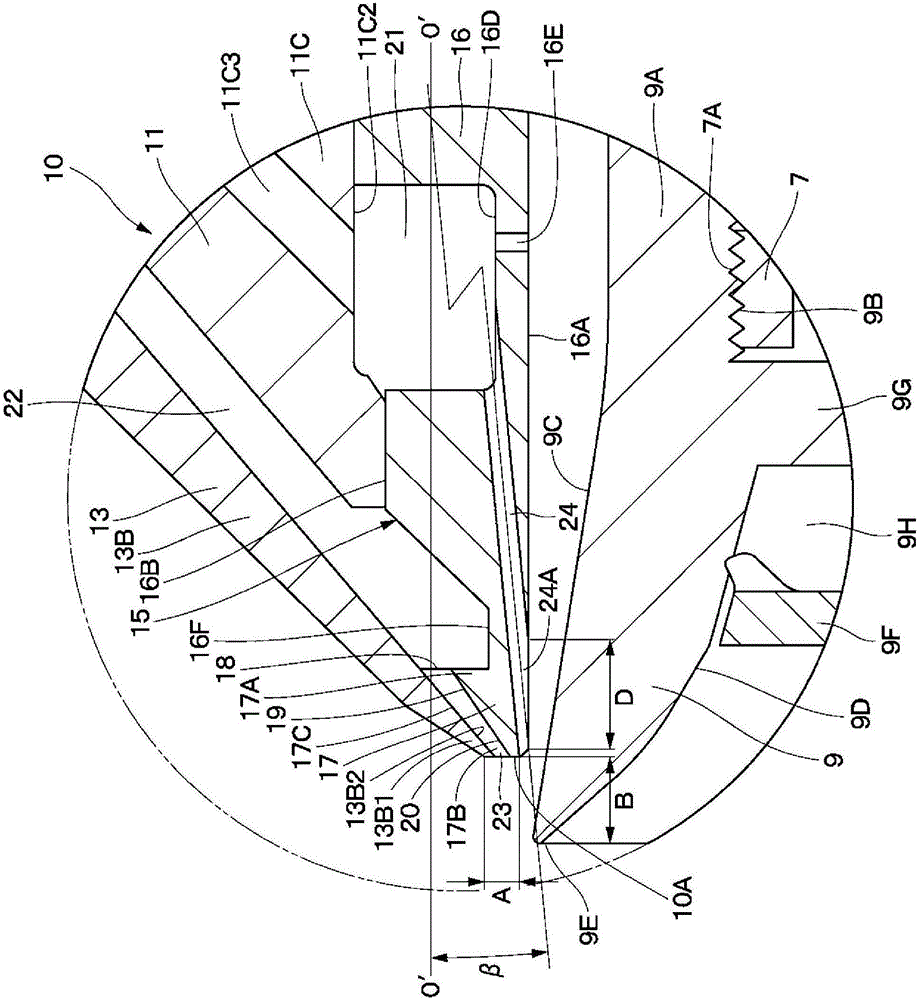

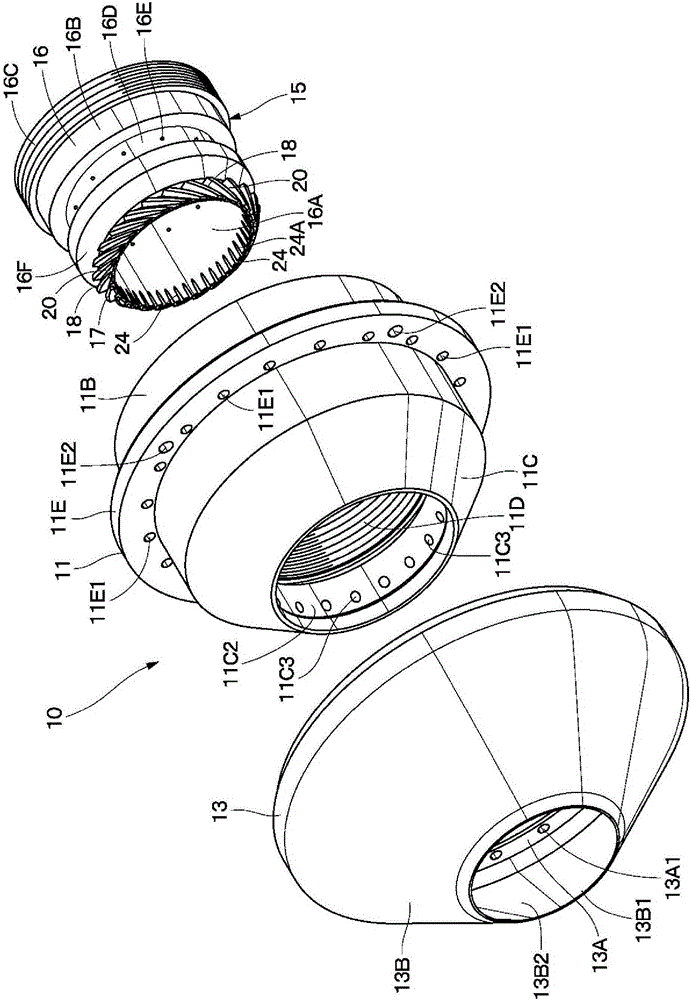

Coating machine having rotary atomizing head

InactiveCN105188950APromote micronizationImprove controllabilityMovable spraying apparatusInduction-charging sprayingEngineeringInjection air

In the present invention, a shaping air ring (10) is configured from a body (11), a cover (13), and a nozzle (15). The tip of the nozzle (15) is provided with a tapered conical protrusion (17) that is abutted against the cover (13) in a gapless contacted state. A plurality of inclination grooves (20) are provided along the entire circumference of a tapered taper surface (17C) of the conical protrusion (17). Furthermore, first shaping-air injection holes (23), which inject shaping air towards a discharge edge (9E) of a rotary atomizing head (9), are provided between each inclination groove (20) and the inner circumferential surface (13B2) of the cover (13). A second shaping-air injection hole (24), which injects shaping air along the outer circumferential surface (9C) of the rotary atomizing head (9), is provided to an inner circumferential surface (16A) of the nozzle (15).

Owner:ABB (SCHWEIZ) AG

Brake control system for a utility vehicle having a trailer

A brake control device for a utility vehicle having a trailer, including: a pneumatic brake control circuit having a vehicle pressure path to output a brake pressure to a vehicle brake which brakes the utility vehicle, based on a target input of a driver of the utility vehicle, and having a trailer pressure path for outputting the brake pressure to a trailer brake, which brakes the trailer, on the basis of the target input; and a pneumatic start assist circuit to output a further brake pressure to a trailer brake of the trailer based on a speed of the utility vehicle, in which the pneumatic start assist circuit is pneumatically connected to the trailer pressure path of the pneumatic brake control circuit.

Owner:KNORR-BREMSE SYST FUER NUTZFAHRZEUGE GMBH

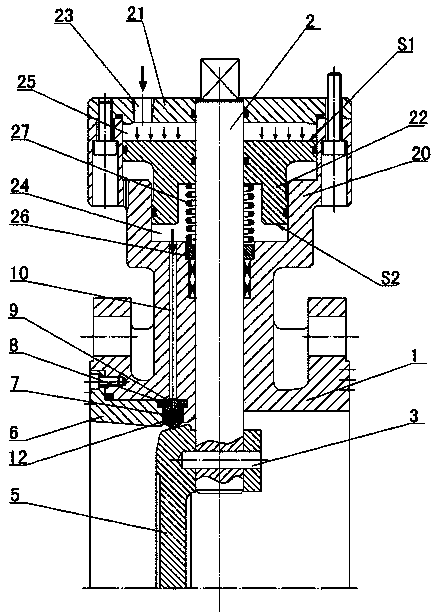

Self-pressurization air inflation sealing butterfly valve

PendingCN108626412AExtended service lifeReduce torqueFluid-pressure convertersLift valveRubber ringEngineering

The invention provides a self-pressurization air inflation sealing butterfly valve. The self-pressurization air inflation sealing butterfly valve comprises a valve body valve plate, wherein a sealingpressing sleeve is arranged on the valve body, a hollow omega-shaped pressure filling rubber ring is arranged on the sealing pressing sleeve, a strip-shaped filling support and a through hole are formed in the omega-shaped filling rubber ring, a pressure filling inner channel is arranged in the wall of the valve body, and the pressure filling inner channel communicates with the through hole to form a sealing cavity in the omega-shaped pressure filling rubber ring, a pressurization cylinder body and a pressurization cylinder cover are arranged on the valve body by taking the valve shaft as thecenter, an air inlet is formed in the pressurization cylinder cover, a pressurizing piston is arranged in the pressurization cylinder body, and the area S1 of the upper end surface of the pressurizingpiston is larger than the area S2 of the lower end surface, a low-pressure cavity is formed between the pressurizing piston and the pressurization cylinder cover, a high-pressure cavity is formed between the pressurization piston and the valve body, hydraulic oil is injected into the high-pressure cavity, the high-pressure cavity communicates with the pressure filling inner channel, a spring seatis arranged on the valve shaft at the side of the high-pressure cavity, a reset spring is arranged on the spring seat, and the reset spring is in contact with the pressurization piston.

Owner:章锡明

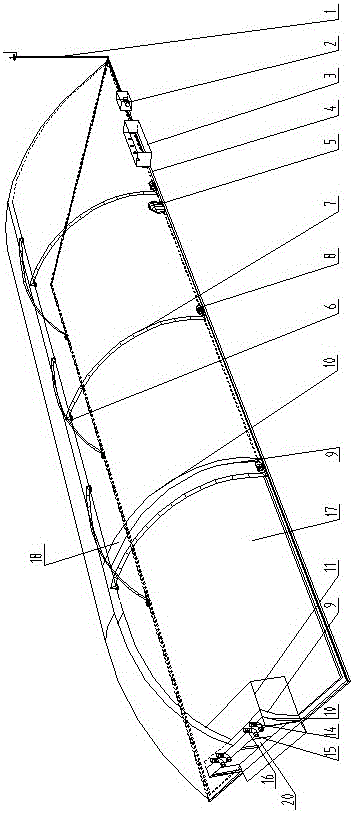

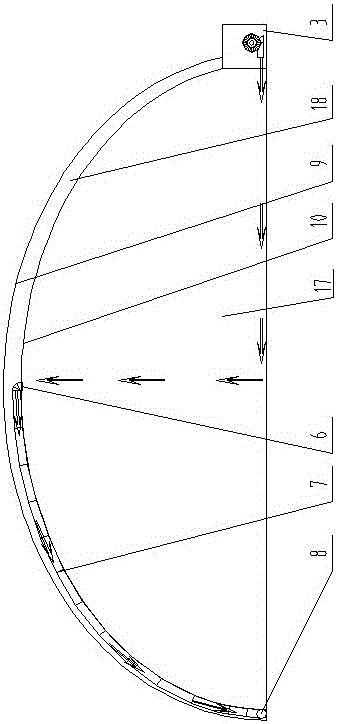

Double-layer differential-pressure air-supported membrane structure

ActiveCN106149884AEnhance structural sealing performanceReduce air consumptionExtraordinary structuresChemistryVentilation tube

The invention discloses a double-layer differential-pressure air-supported membrane structure. The double-layer differential-pressure air-supported membrane structure comprises an inner membrane and an outer membrane which are arranged on a bottom surface in an arched manner. A sealed inner membrane cavity is formed between the inner membrane and the bottom surface. A sealed double-layer membrane sandwich cavity is formed among the outer membrane, the inner membrane and the bottom surface. A communicating device is arranged between the inner membrane cavity and the double-layer membrane sandwich cavity. The communicating device comprises an inner-membrane ventilation hole formed in the top of the inner membrane and a sandwich ventilation pipe arranged in the double-layer sandwich cavity. The air inlet end of the sandwich ventilation pipe is connected with the inner-membrane ventilation hole. The air outlet end of the sandwich ventilation pipe is arranged at the bottom of the double-layer membrane sandwich cavity. A fan arranged outside the outer membrane supplies air for the inner membrane cavity. The pressure intensity of the inner membrane is larger than that of the outer membrane. The pressure intensity of the outer membrane is larger than the intensity of atmospheric pressure outside the outer membrane. The double-layer differential-pressure air-supported membrane structure has the advantages that the stability of the double-layer membrane structure is achieved through pressure intensity difference, and the double-layer differential-pressure air-supported membrane structure is convenient to mount and high in safety.

Owner:河南科琦智能科技有限公司

Economizer Device For Linear Pneumatic Actuator

InactiveUS20140190346A1Performance unchangedReduce air consumptionServomotor componentsServomotorsAtmospheric airWorking pressure

An economizer device associable with a linear pneumatic actuator includes a body having openings and a Venturi vacuum generator slidably housed in a first conduit. The device operates between a first operating configuration, where a first opening is supplied with air at an operating pressure and the vacuum generator moves in the first conduit to permit primary flow of air and to reduce outlet pressure thereof from a second opening so as to supply the chamber of the actuator with air at a reduced pressure lower than the operating pressure, and a second operating configuration, where the first opening is connected to the environment at atmospheric pressure and a third opening is supplied with pressurized air with which it supplies the vacuum generator, which creates a vacuum in the second opening in such a manner as to suck air from and create a vacuum in the chamber.

Owner:LANDI ENZO

Support platform of non-contact transfer apparatus

ActiveUS7927045B2Reduce air consumptionSmooth transferSemiconductor/solid-state device manufacturingBulk conveyorsEngineeringMechanical engineering

Owner:LG DISPLAY CO LTD +2

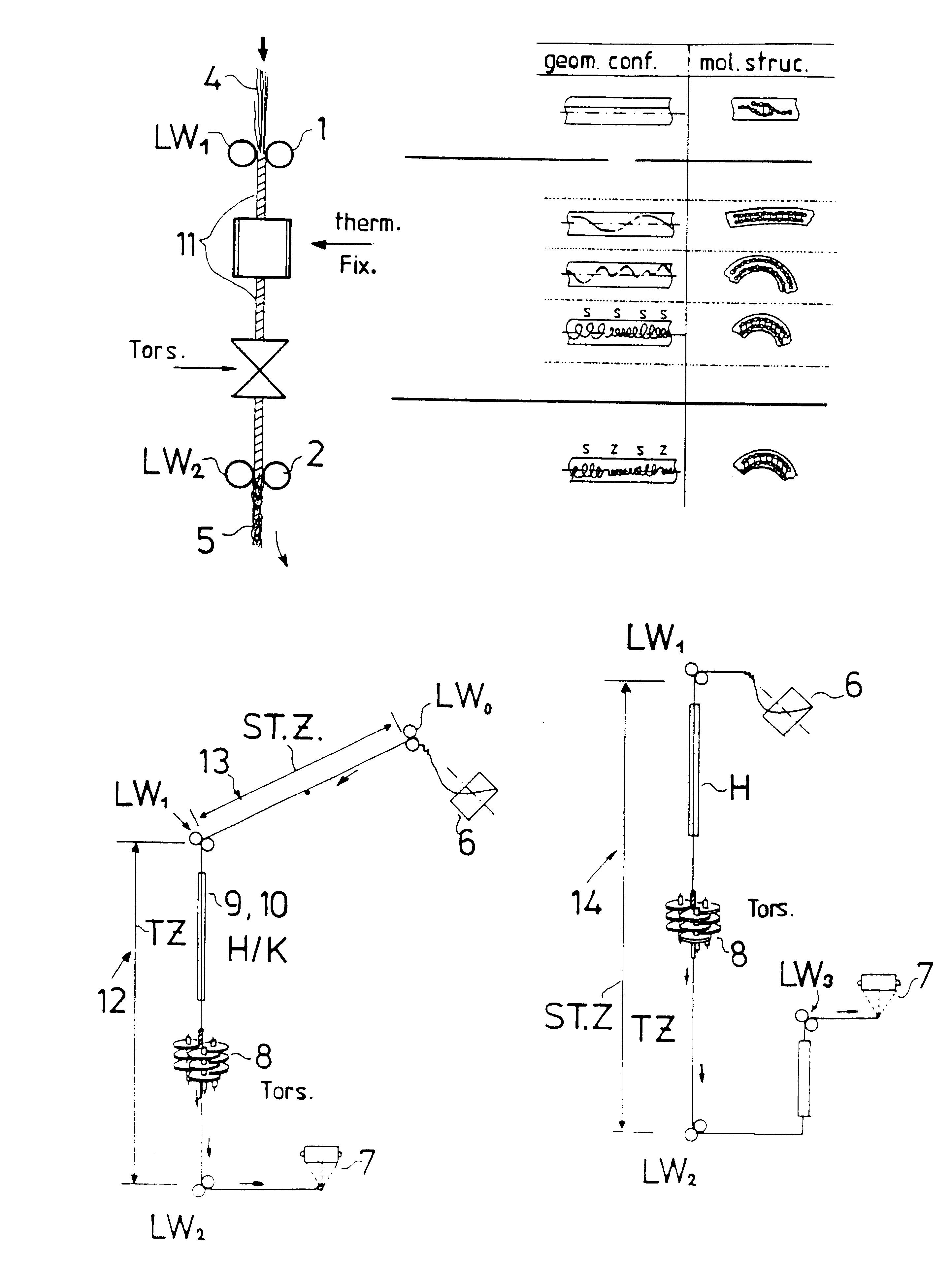

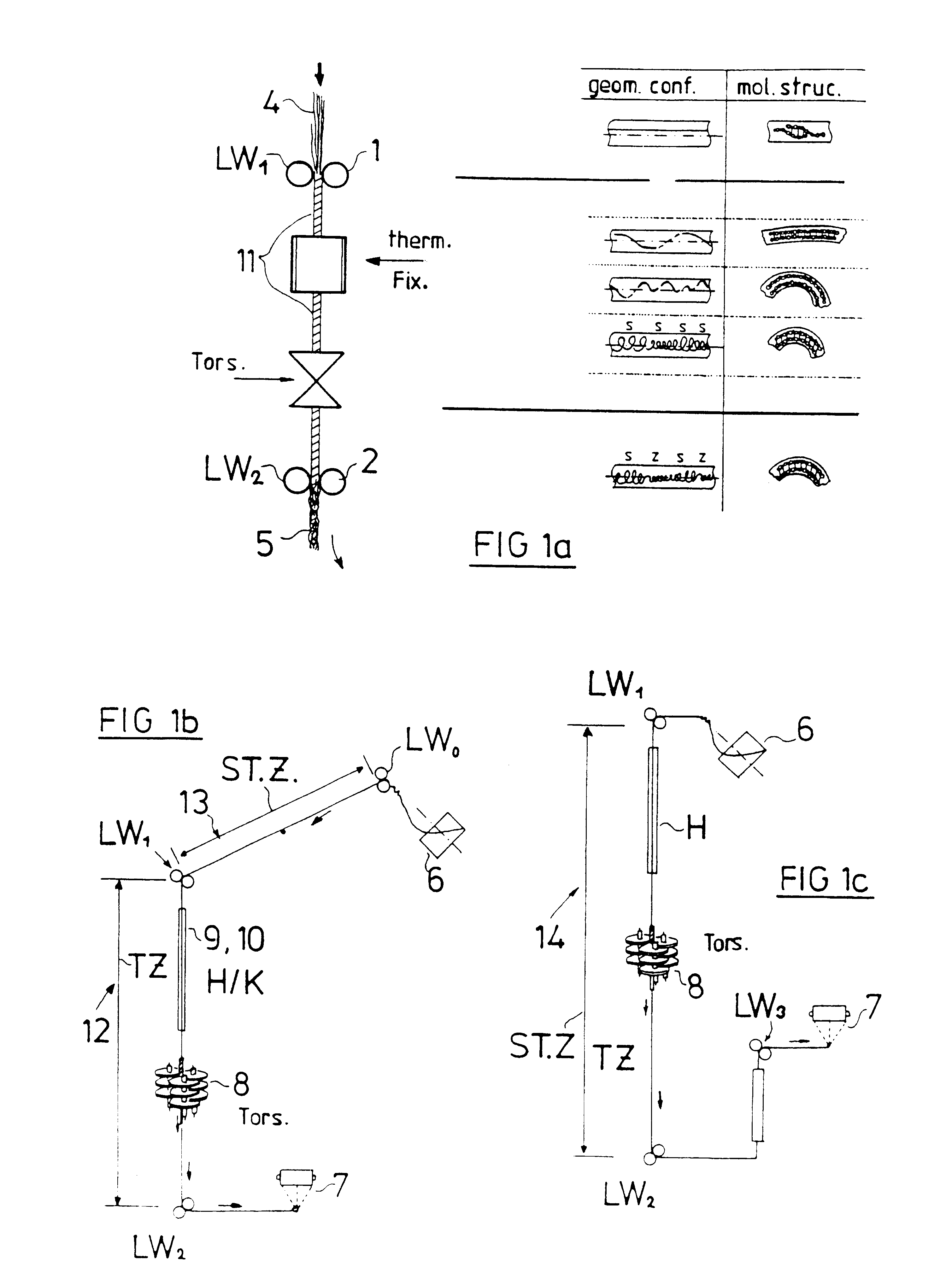

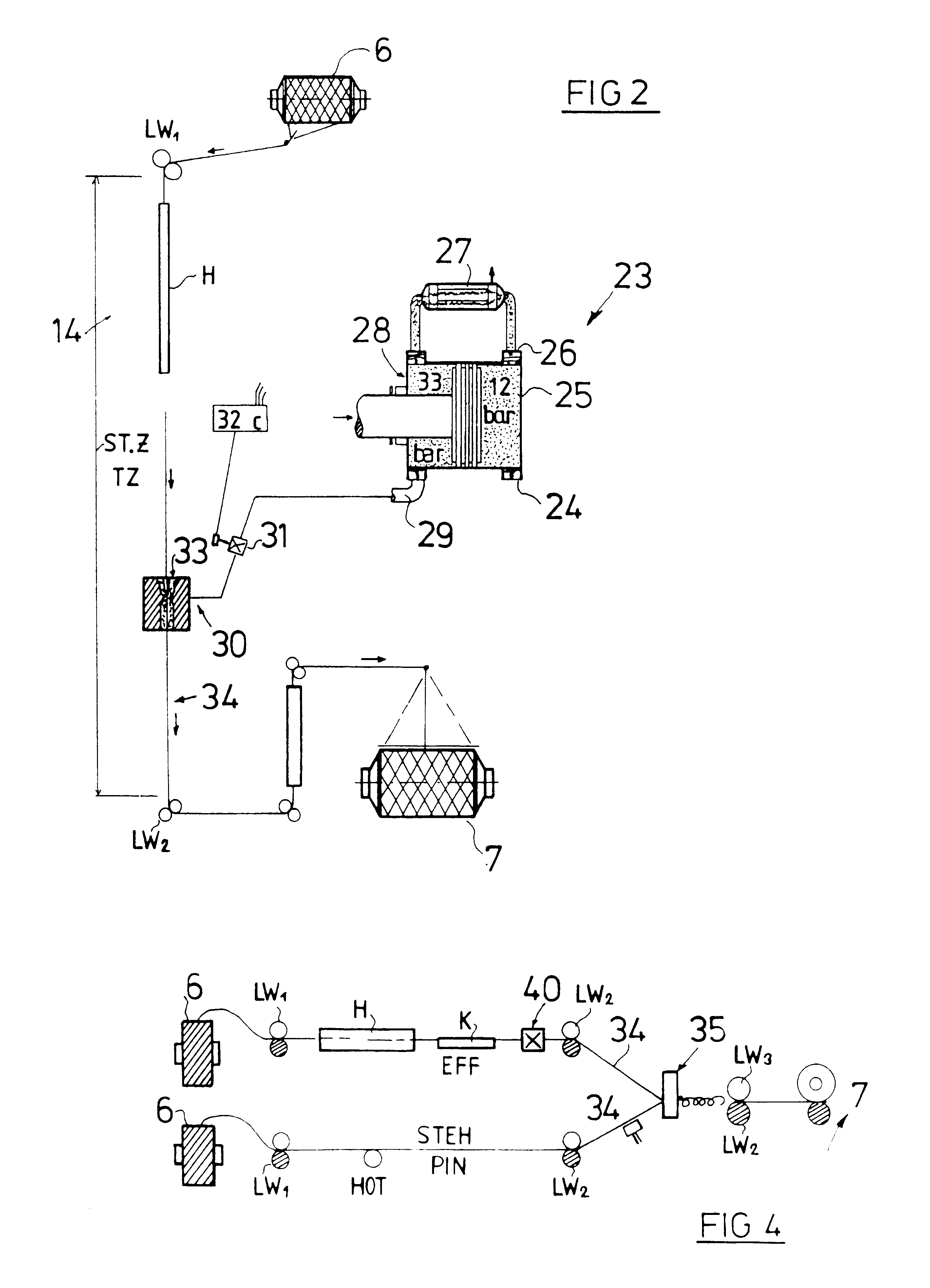

Method and device for treating filament yarn with air

InactiveUS6354069B1High production costEasy to produceFilament handlingBeaming machinesMiniaturizationAir treatment

The new invention proposes that filament yarns, in particular partially stretched yarns known as POY yarns, be subjected to stretch texturing via an air treatment nozzle. The air treatment nozzles are designed in miniaturized form, have a continuous yarn duct in which there open a plurality of transverse bores for the supply of high pressure air in the range over 14 bar, preferably within specific working windows between 20 and 50 bar. With the new invention, it was possible for the first time to process POY yarn via simultaneous stretch texturing using an air twister. The invention allows an individual thread as well as a parallel bundle of threads to be treated and permits for the first time the construction of a false twist stretch texturing bundle device with simultaneous air treatment of 500 to 1000 and more threads.

Owner:HEBERLEIN MASCHFAB +1

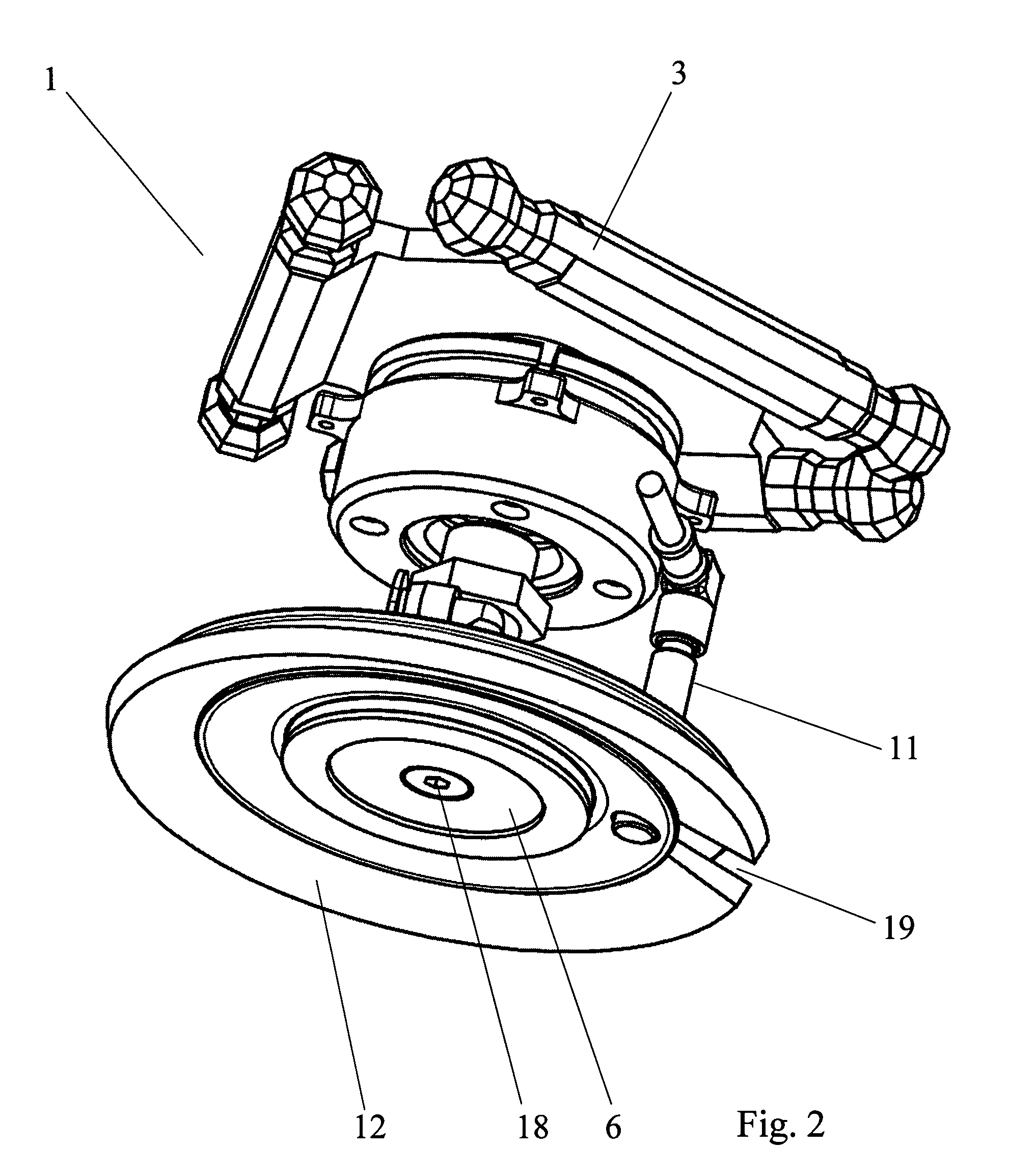

Method, mandrel and apparatus for winding up and removing coreless rolls of stretch film

ActiveUS8286904B2Lower overall pressure dropReduce air consumptionFilament handlingWebs handlingEngineeringPlastic film

One or a plurality of coreless rolls of a stretchable plastic film are wound up on a mandrel (10) having a tubular body; the mandrel (10) comprises at least a fore air chamber (14) and a rear air chamber (15) axially aligned, wherein the peripheral wall (11) of the mandrel (10) comprises a perforated zone (16, 17) in correspondence of each air chamber (14, 15). One or a plurality of coreless rolls (B1, B2) of stretchable plastic film are wound up on the mandrel (10) at said perforated zones (16, 17) and air chambers (14, 15); the roll or rolls (B1, B2) are removed by pushing said roll or rolls along the mandrel (10), by supplying pressurized air initially into all air chambers (14, 15) during a first removal step of the roll or the rolls (B1, B2) and selectively disconnecting each chamber (14, 15) from the pressurized air source, starting from the rear air chamber (15) to the fore air chamber (14) at overcoming of each air chamber (14, 15) by said roll or rolls (B1, B2).

Owner:NOEL

Gripper, in particular a Bernoulli gripper

InactiveUS8172288B2Reduce wasteRapid lateral movementGripping headsSemiconductor/solid-state device manufacturingElectrical resistance and conductanceBearing surface

A gripper for holding two-dimensional components with a low degree of loading, has a clamping ring connected to a controllable robot arm with a baffle plate connected to the clamping ring by a funnel-shaped component and has a gripping face which communicates with a flow system which passes through the funnel-shaped component and the baffle plate. After an excess pressure has been applied to the gripper, a negative pressure is produced on the gripping face in order to attach by suction a wafer to be gripped. A rubberized bearing surface of a bearing ring integrated in the gripping face provides a slip-resistant movement of the wafer. A sensor detects the wafer hat is attached to the gripping face by suction. In order to permit an extremely shock-resistant attachment of the wafer to be gripped on the gripping face of the gripper, a damping device which is circumferentially adapted to the gripper has a contour as viewed in plan that protrudes circumferentially above the contour of the gripper and forms a damping resistance for the wafer.

Owner:JONAS & REDMANN AUTOMATIONSTECHNIK GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com