Coating machine having rotary atomizing head

一种旋转雾化、涂装机的技术,应用在喷射装置、静电喷射装置、具有活动出口的喷洒装置等方向,能够解决镀层剥离、无法使用精密零件清洗有效的等问题,达到容易清洗的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

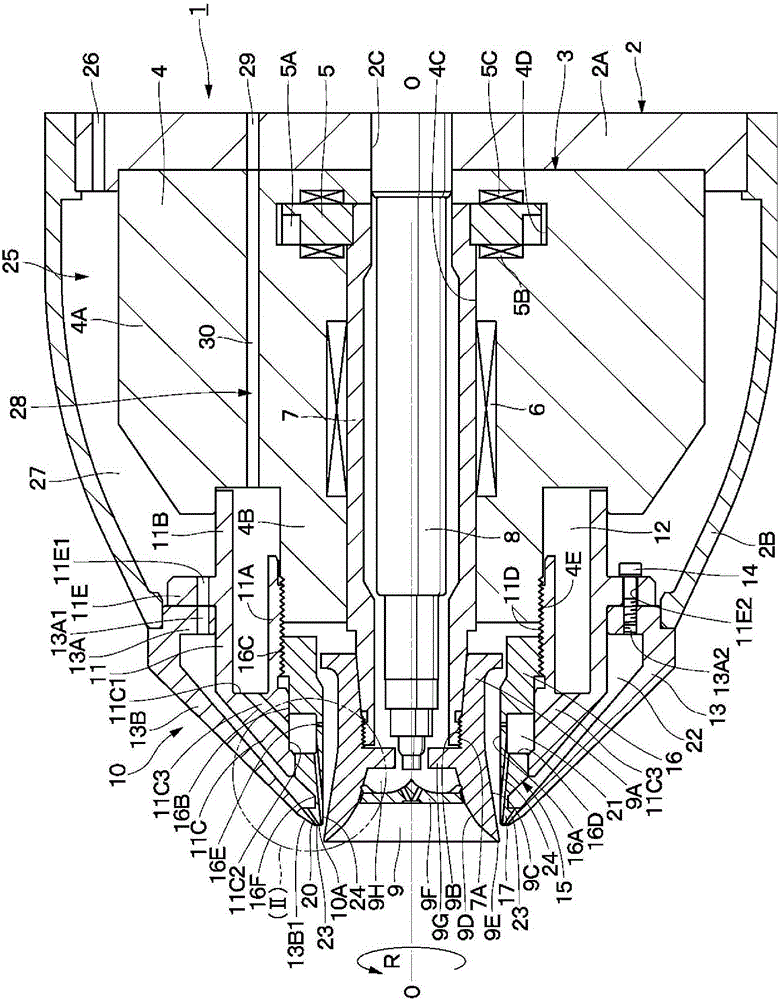

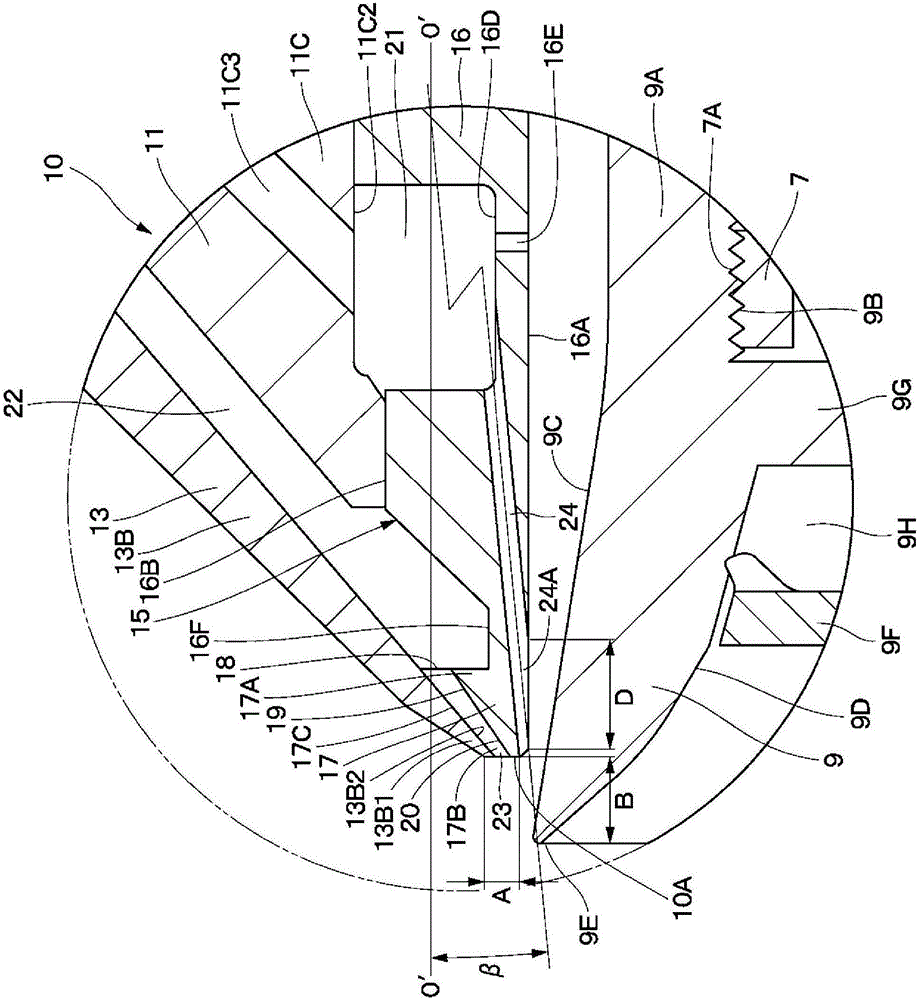

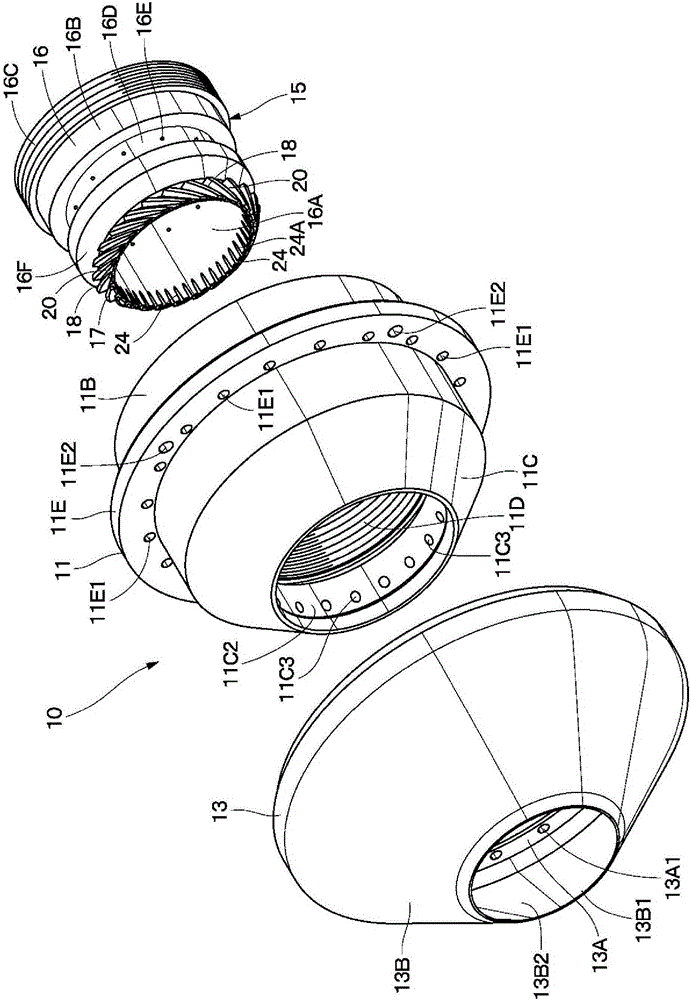

[0044] Refer to the following Figure 1 to Figure 9 A rotary atomizing head type coating machine according to an embodiment of the present invention will be described in detail. Here, the rotary atomizing head type coater includes an electrostatic coater which applies a high voltage to sprayed paint and a non-electrostatic coater which does not apply a high voltage to the paint. In the embodiments described above, a rotary atomizing head type coating machine configured as a direct charging type electrostatic coating machine that directly applies a high voltage to the paint will be described as an example.

[0045] exist figure 1 In , the code|symbol 1 shows the rotary atomizing head type coating machine of this embodiment. This rotary atomizing head type coating machine 1 is configured as a direct charging type electrostatic coating machine that directly applies a high voltage to the paint by a high voltage generator (not shown). The rotary atomizing head type coating machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com